Method for treating oil field produced water and treatment flow thereof

A treatment method and technology of treatment process, applied in the direction of mining wastewater treatment, water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of serious scaling, unable to solve the problem of produced water purification, and water quality deterioration along the process, to achieve control and enhance the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

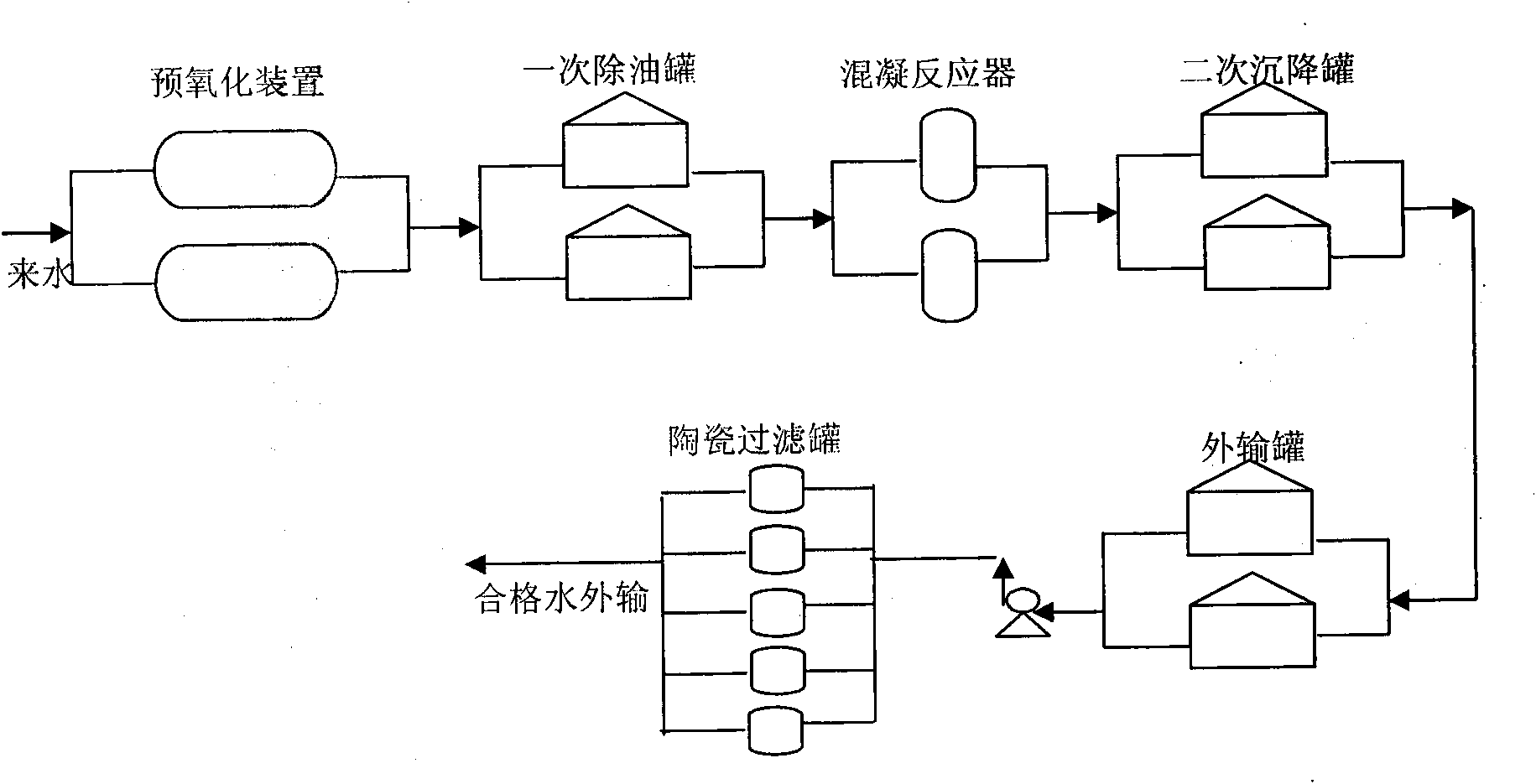

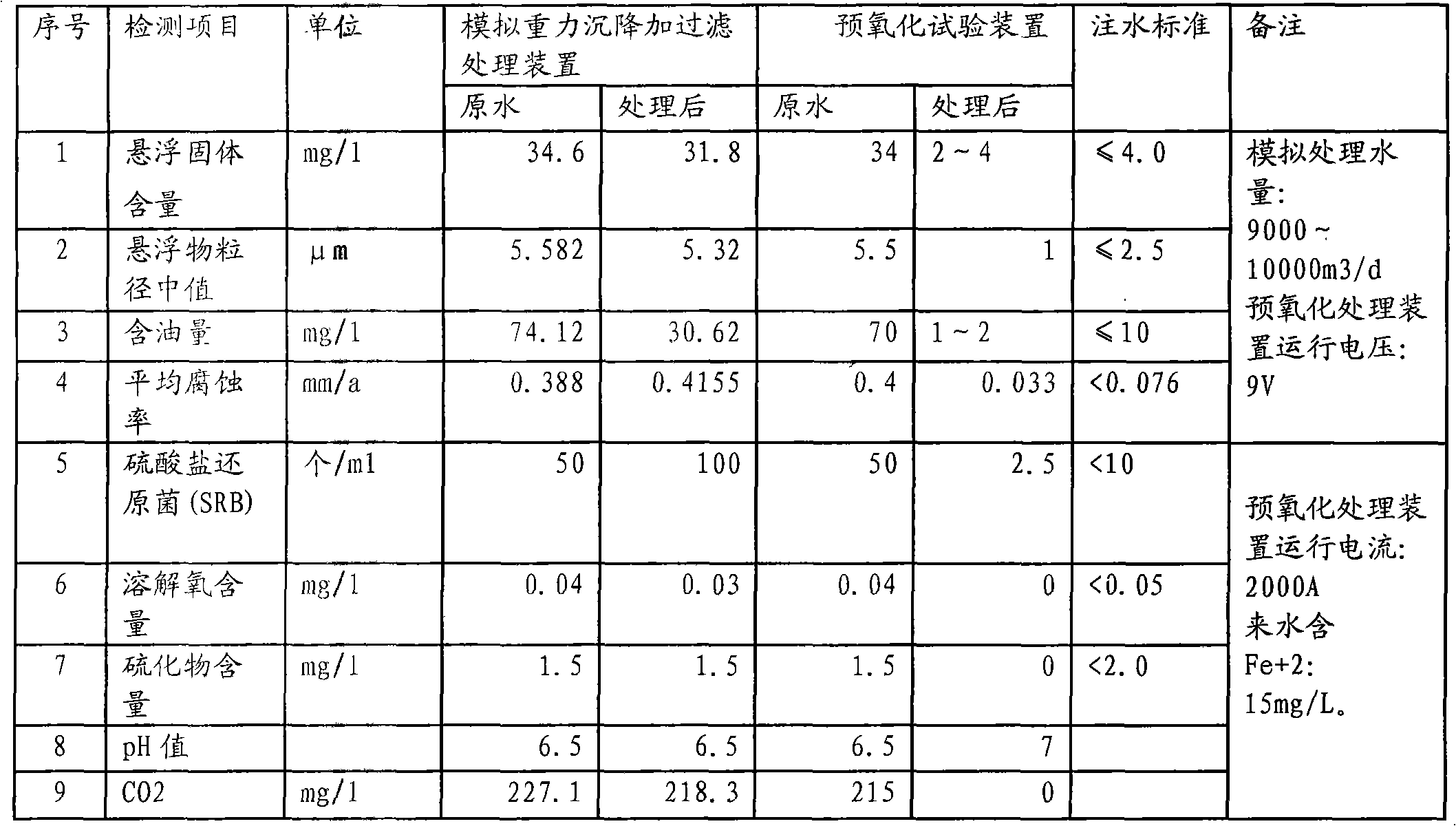

[0026] The present invention will be further described in detail below in conjunction with the examples: a method for treating oilfield produced water, first using a pre-oxidation treatment device to treat oilfield produced water, and placing the medicament between the primary deoiling tank and the secondary settling tank, Finally, it is filtered through the microporous ceramic particle filter material and then exported, and the agent is put into the coagulation reactor and mixed thoroughly. The specific treatment process is as follows: incoming water from the oil station → pre-oxidation treatment device → primary oil removal tank → coagulation reactor → secondary settling tank → external transport tank → external transport pump → ceramic filter → external transport. See attached figure 1 , the treatment process of the present invention includes a primary oil removal tank, a secondary settling tank, an external transport tank and an external transport pump, which are connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inhomogeneity coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com