Carrying and locating device of LED lamp filament column

An LED filament and positioning device technology is applied in the field of handling devices, which can solve the problems of difficult handling, unqualified welding products, and difficult adsorption, and achieve good handling effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

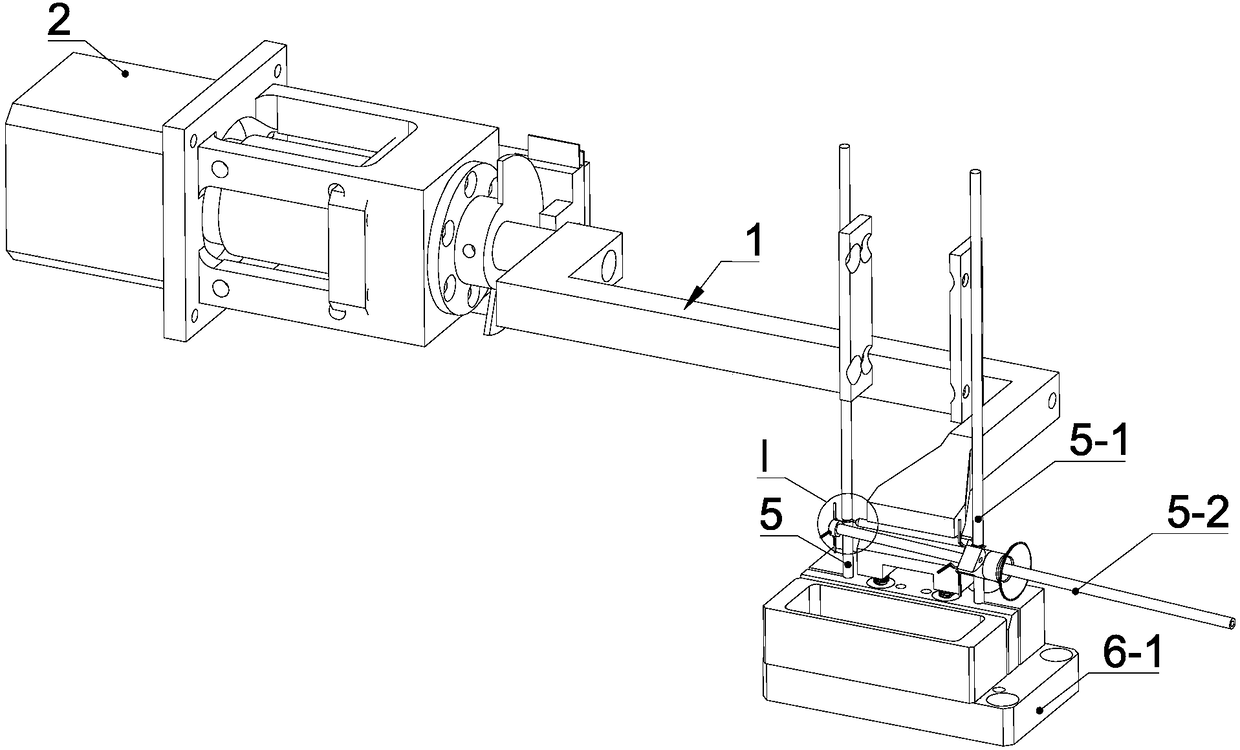

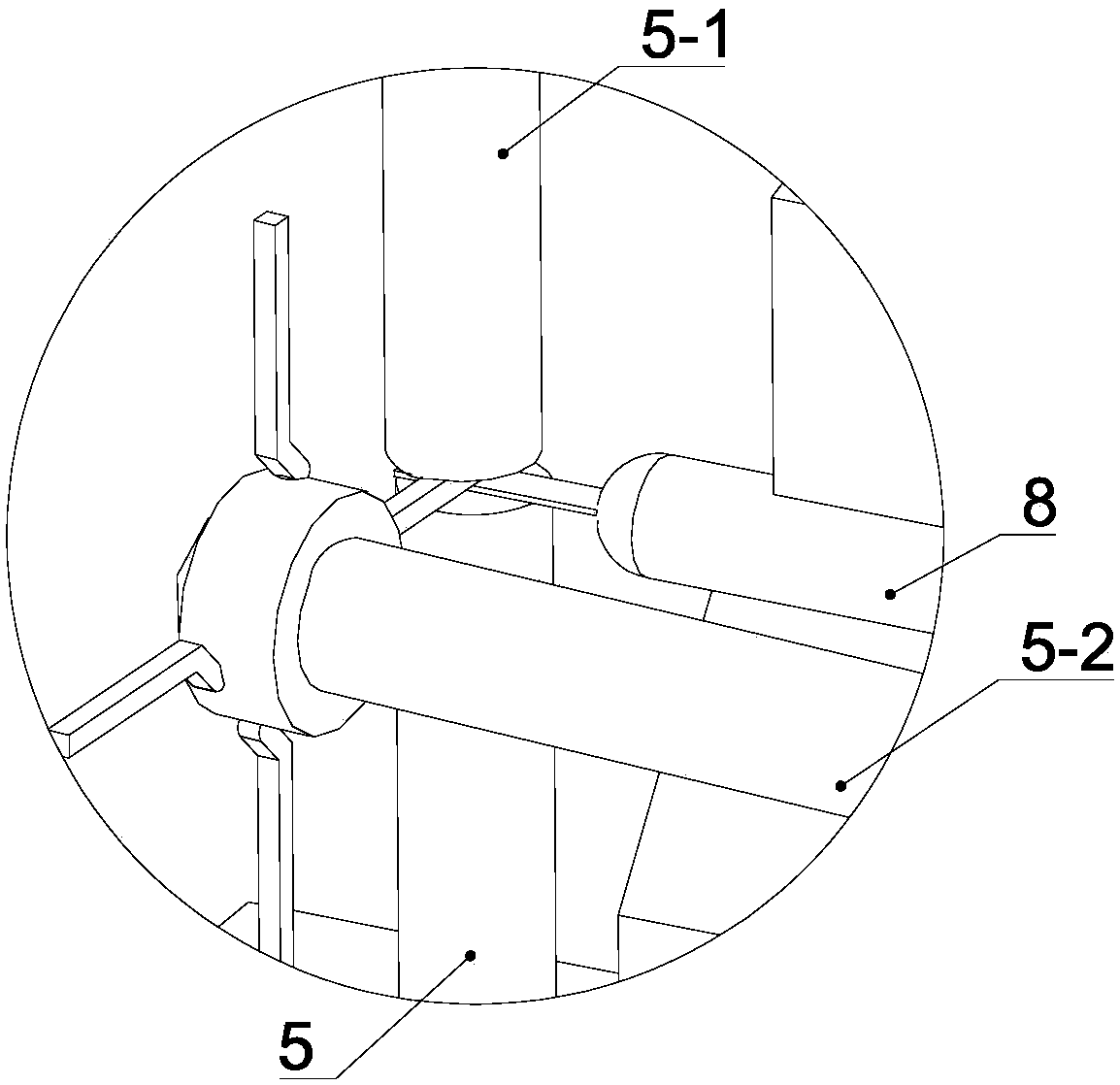

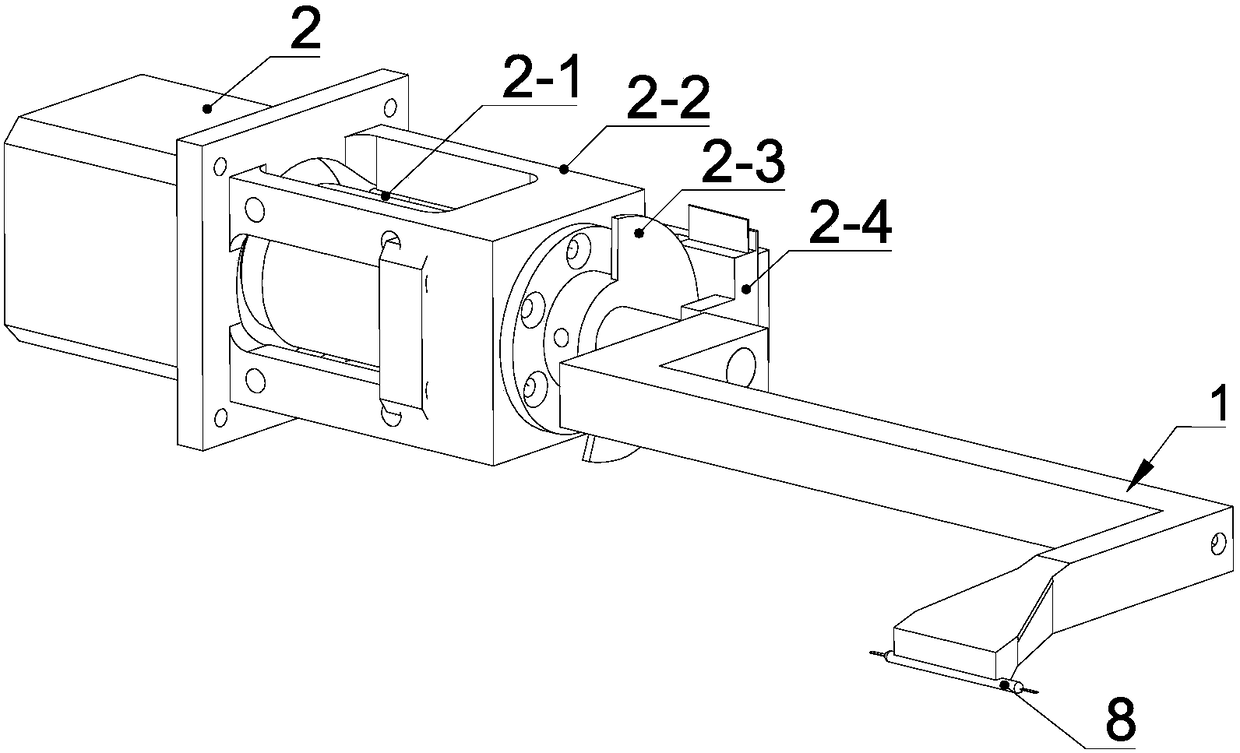

[0042] see figure 1 and image 3 , an LED filament column carrying and positioning device of the present invention includes a carrying mechanism and a welding positioning mechanism; the carrying mechanism includes a carrying arm 1 and a motor 2 that drives the carrying arm 1 to rotate; see Figure 4 , wherein, the carrying arm 1 includes a connecting piece 3 and a carrying head 4, one end of the connecting piece 3 is connected with the motor 2, and the other end is connected with the carrying head 4; the carrying head 4 is provided with a notch 4-1 , the groove wall of the slot 4-1 has a cylindrical surface with the same diameter as the LED filament column 8, and the cylindrical surface is provided with a negative pressure through hole 4-2, see Image 6 , the negative pressure through hole 4-2 communicates with the inner cavity of the carrying head 4 to form a negative pressure cavity, and the negative pressure cavity is connected with a negative pressure device.

[0043] se...

Embodiment 2

[0056] see Figure 13 The difference between this embodiment and Embodiment 1 is that the negative pressure through hole 4-2 in this embodiment is a long groove with a rectangular cross-section, and the long groove is arranged along the axial direction of the cylindrical surface. The purpose of this arrangement is that, since the long groove has a larger working area and a longer span, the adsorption force applied to the LED filament column 8 is more uniform, so that the adsorption effect is better.

[0057] For other implementations other than the above in this example, refer to Example 1 for implementation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com