A blast furnace oven method

A furnace method and blast furnace technology, applied in the field of blast furnace metallurgy, can solve the problems affecting the life of the blast furnace and the poor effect of the blast furnace, and achieve the effects of promoting the longevity of the blast furnace, meeting the requirements for equipment use, and increasing the baking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

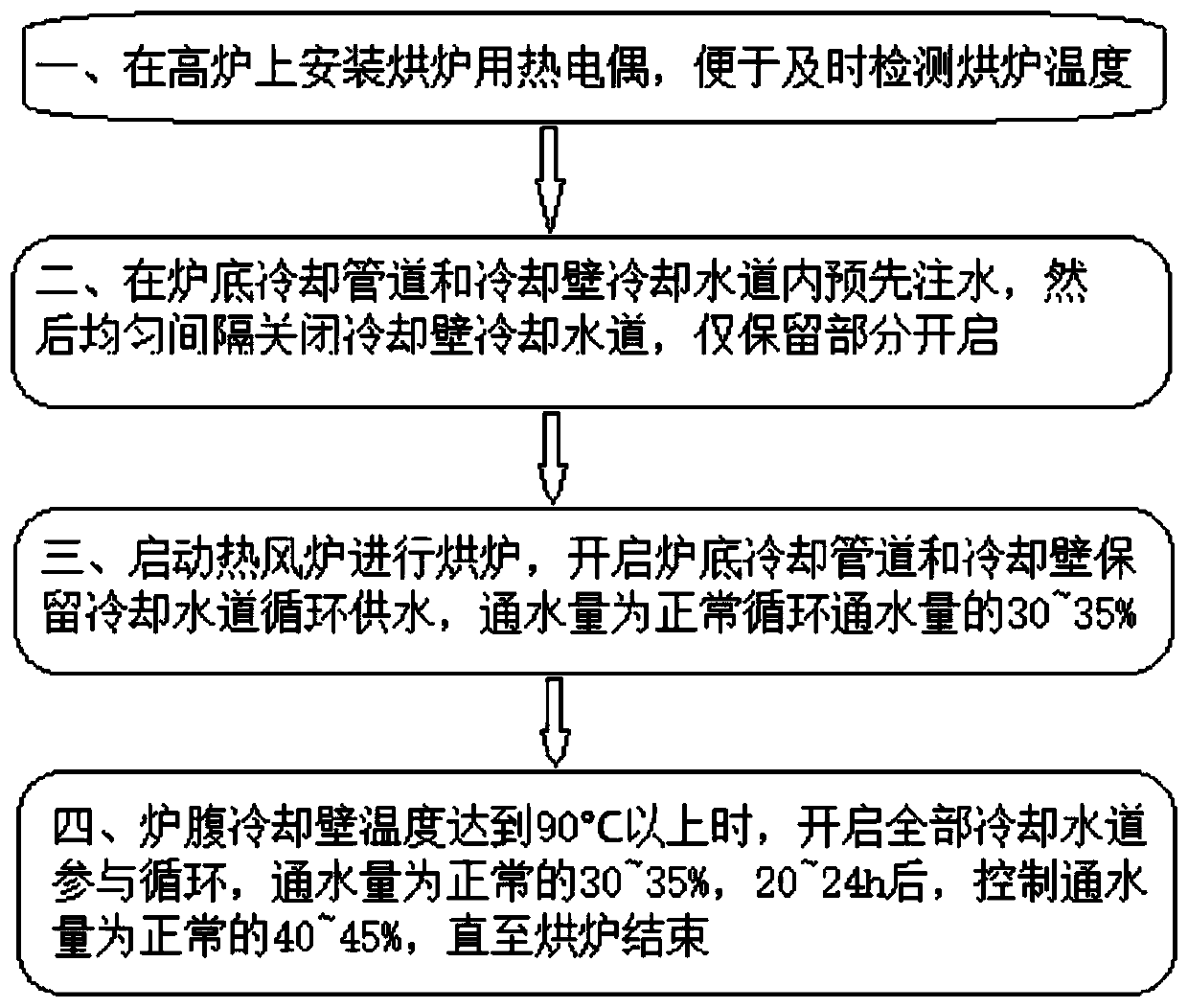

[0035] Such as figure 1 As shown, a kind of blast furnace oven method of the present embodiment is carried out according to the following steps:

[0036] Step 1. Install thermocouples for ovens at the center of the blast furnace bottom, above the blast furnace tuyere, and on both sides of the front end of the blast furnace, to monitor the temperature of the blast furnace oven in time, and adjust the subsequent oven process according to the real-time temperature; in production practice According to the detection requirements, thermocouple detection can be installed in multiple different positions of the blast furnace, which will not be detailed here;

[0037] Step 2: Pre-fill cooling water in the cooling channels of the furnace bottom of the blast furnace and the cooling channels of the cooling stave of the blast furnace respectively, and then close a plurality of cooling channels in the cooling wall at even intervals, and keep some cooling channels open; in this embodiment, ea...

Embodiment 2

[0043] A kind of blast furnace baking method of the present embodiment is basically the same as that of Embodiment 1, the difference is that in the step 3 in the present embodiment, the water flow rate in the cooling water channel that is kept open in the cooling wall is 35% of the normal circulation water flow rate, and the furnace The water flow in the bottom cooling pipe is 35% of the normal circulating water flow, and the water flow in the blast furnace tuyere small sleeve is 20% of the normal circulating water flow; in step 4, when the thermocouple detects that the temperature of the bosh cooling wall of the blast furnace reaches above 90°C , open all the cooling water channels in the cooling wall of the blast furnace to participate in the circulation, the water flow of each cooling water channel is 35% of the normal circulation water flow; after 24 hours, control the water flow of each cooling water channel to 45% of the normal circulation water flow, until the end of the...

Embodiment 3

[0046] A kind of blast furnace baking method of the present embodiment is basically the same as that of the embodiment 1, the difference is that in the step 3 in the present embodiment, the water flow rate in the cooling water channel opened in the cooling wall is 32% of the normal circulation water flow rate. The water flow in the bottom cooling pipe is 32% of the normal circulating water flow, and the water flow in the blast furnace tuyere small casing is 16% of the normal circulating water flow; in step 4, when the thermocouple detects that the temperature of the bosh cooling wall of the blast furnace reaches above 90°C , open all the cooling water channels in the cooling wall of the blast furnace to participate in the circulation, and the water flow of each cooling water channel is 32% of the normal circulating water flow; after 22 hours, the water flow of each cooling water channel is controlled to be 42% of the normal circulating water flow, until the end of the oven;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com