Patents

Literature

37results about How to "Increase the baking temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing normal-temperature storage type roasted goose

InactiveCN103340432AShort timeImprove processing efficiencyFood preservationFood preparationBiotechnologyAgricultural science

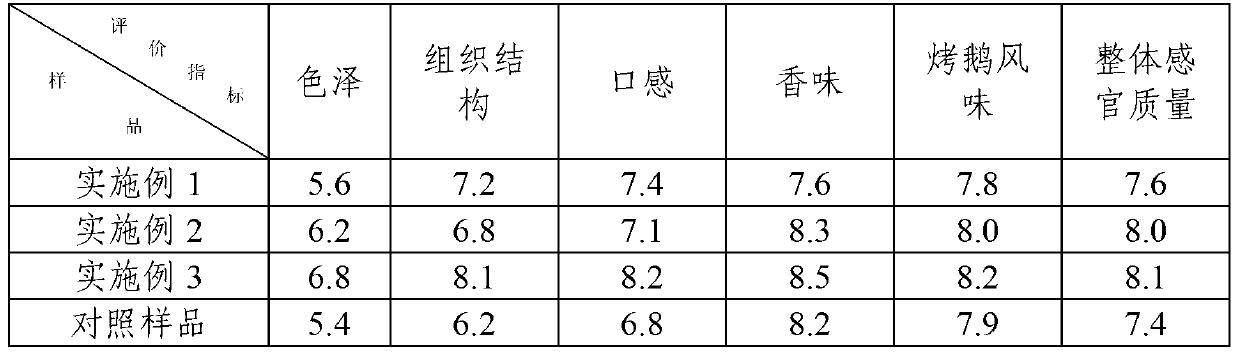

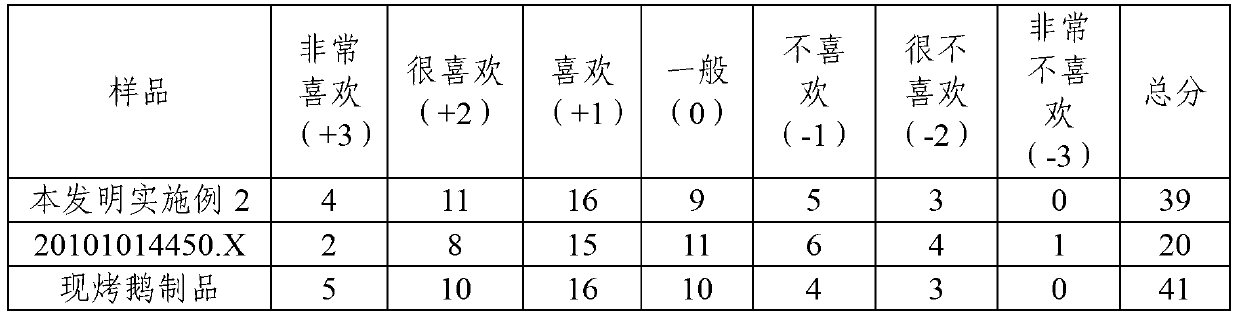

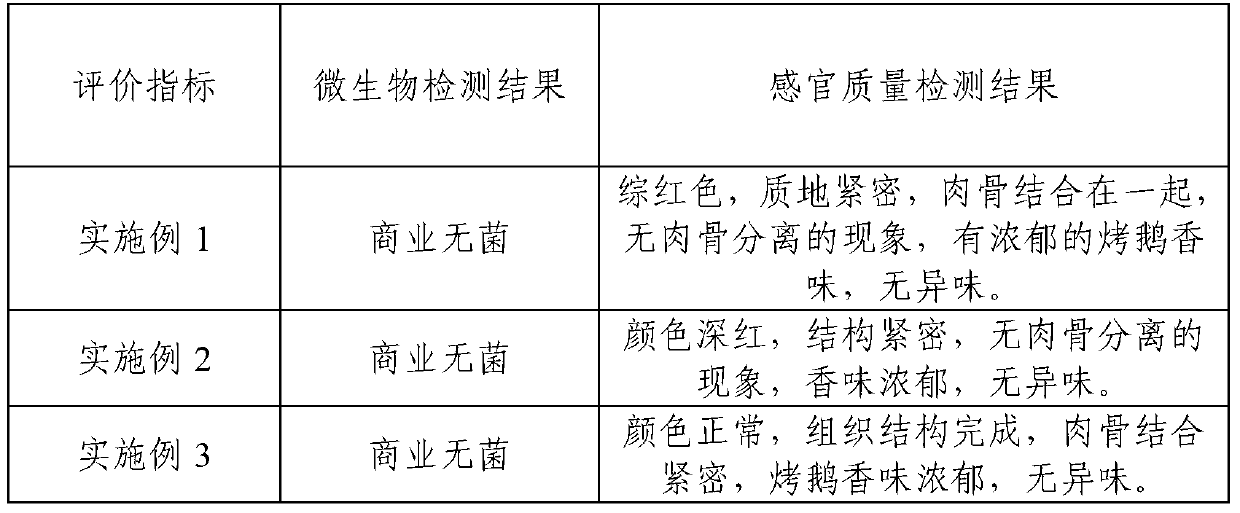

The invention belongs to the field of food processing, and in particular provides a method for processing a normal-temperature storage type roasted goose. The method comprises the following steps of: (1) preparing a spice solution; (2) treating a goose carcass; (3) curing the goose carcass; (4) draining the goose carcass; (5) baking the goose carcass; (6) roasting the goose; (7) sterilizing and cooling a product, wherein in the step (7), the packaged product is put into a high-temperature sterilization pot, is sterilized for 15 to 30min at the temperature of 115 to 121 DEG C, and is cooled by water until the temperature drops to the room temperature. According to a sterilization method provided by the invention, the quality guarantee period of the product at the normal temperature is over 180 days; the water content of the product is about 40 percent during sterilization, so that an organization structure of the product can be kept perfectly in a sterilization process, and the roasted goose has a good taste. According to the method, the processing efficiency of the product is greatly improved, the industrial production of the product is facilitated, and the flavor and the safety of the product are obviously improved.

Owner:HUNAN AGRICULTURAL UNIV +1

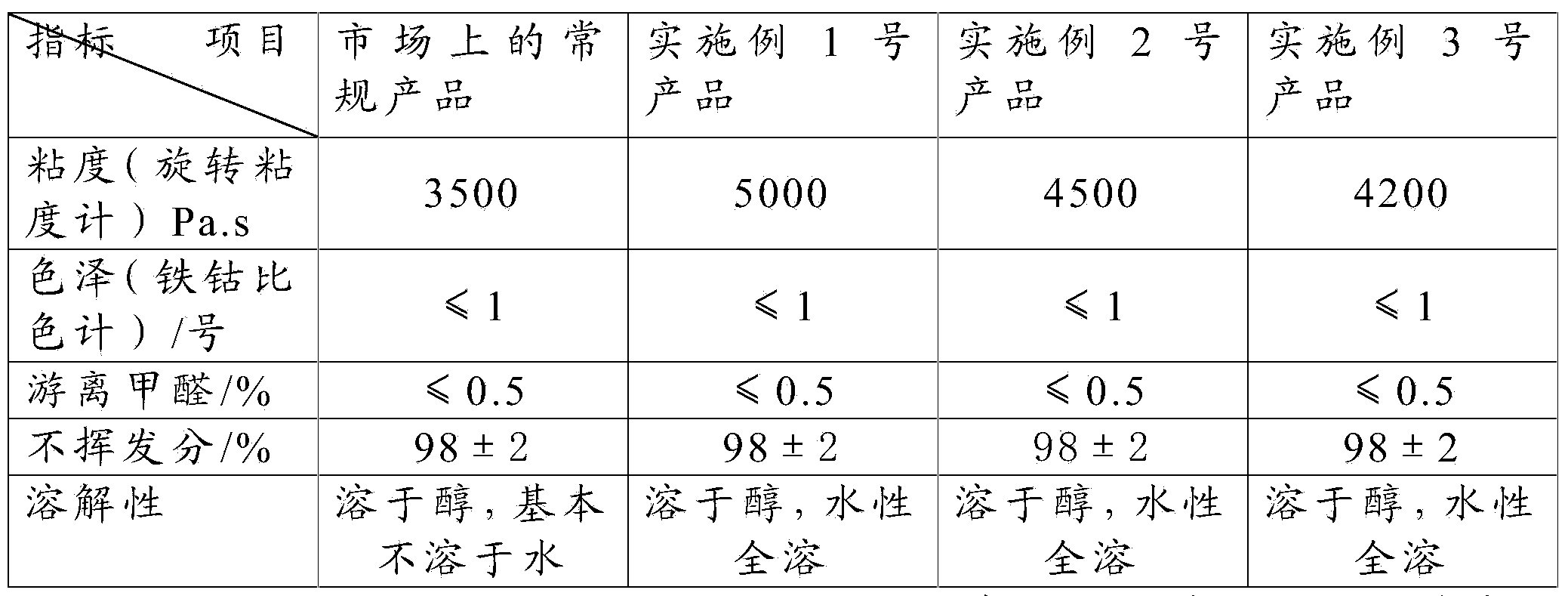

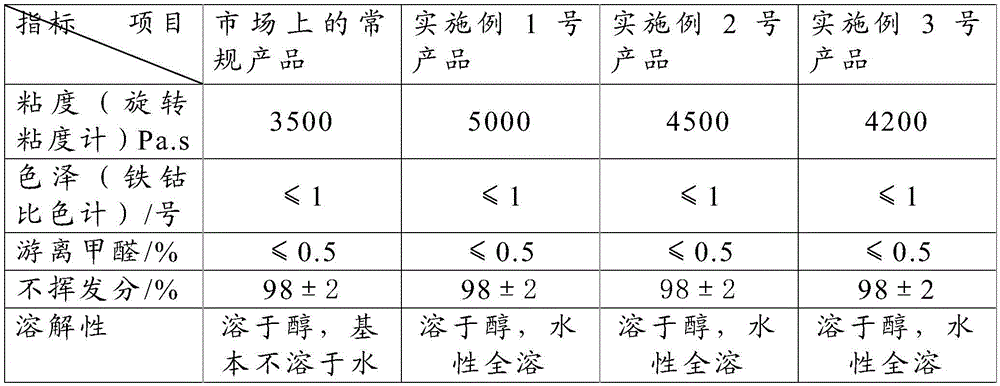

High-hydroxyl methylated melamine resin and preparation method thereof

InactiveCN103709353ALower degree of etherificationLow baking temperatureCoatingsMelamine resinWater soluble

The invention belongs to the technical field of melamine resin and specifically relates to high-hydroxyl methylated melamine resin and a preparation method thereof. The high-hydroxyl methylated melamine resin is prepared from the following materials: melamine, formaldehyde aqueous liquor, methanol and formic acid, wherein a weight ratio of melamine to the formaldehyde aqueous liquor to methanol is (2-3):(8-12):(12-20); the weight ratio of formic acid to melamine is 1:5. The high-hydroxyl methylated melamine resin disclosed by the invention is water-soluble, so that scope of application of the resin is increased, and time and cost of roasting the resin into a film are lowered.

Owner:SHANDONG ZHANHUA OSITER CHEM

Novel production method of mica tape with a few glues by reducing organic solvent dosage

ActiveCN102412037AReduce manufacturing costReduce dosageMicaInsulating bodiesCooking & bakingOrganic solvent

The invention relates to a novel production method of a mica tape with a few glues by reducing an organic solvent dosage. The method comprises the following steps that: (1), a reinforcing material is dipped; (2), composition is carried out; (3), baking is carried out; (4), cooling is carried out to manufacture a blank; and (5), slitting and rolling are carried out. According to the method provided in the invention, a gluing method and a glue scraping method are improved as well as a gluing amount is controlled; a baking temperature is controlled in a segment mode and the production speed is enhanced by 1.3 to 1.5 times. When gluing is carried out, a solid content of an adhesive solution reaches 50% to 60% wt. About 120 Kg of organic solvents can be saved to produce one ton of mica tapes with a few glues as well as production costs of the mica tapes are reduced; and pollution of the organic solvents on the environment can be substantially reduced. Moreover, the production speed is improved and the baking temperature is reduced as well as a third of power consumption can be reduced.

Owner:JIANGSU BINGCHENG HYDROGEN ENERGY TECH CO LTD

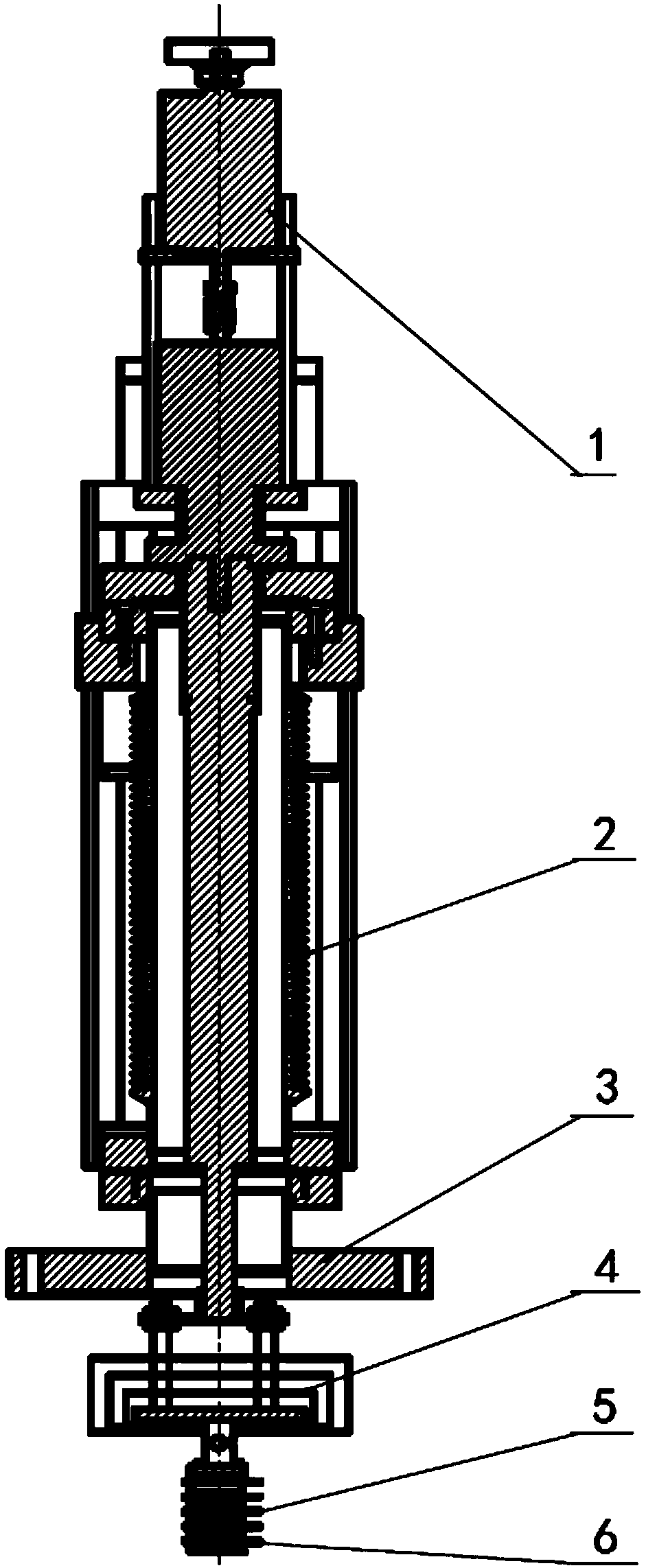

Pretreatment device of sample for measuring secondary electron emission characteristic of material

PendingCN108896594AIncrease the baking temperatureEliminate adsorptionMaterial analysis using wave/particle radiationSecondary electronsProduct gas

The invention discloses a pretreatment device of a sample for measuring the secondary electron emission characteristic of a material, which comprises a vacuum cavity and a vacuum pump, and also comprises a heating device, wherein the heating device comprises a bottom barrel and a gland; a driving part, wherein the driving part is used for driving the gland to move in the direction of the opening end of the bottom barrel; a sample storage platform, wherein the sample storage platform is positioned in the space enclosed by both the bottom barrel and the gland when the gland is buckled on the opening end of the bottom barrel; a grabbing and transferring part and a gate part, wherein the gate part is used as a passage outside the closed space and vacuum cavity; the heating device is used for heating the space enclosed by both the bottom barrel and the gland. The pretreatment device not only can effectively eliminate the influence of the sample surface adsorption gas and volatile organic contaminants on the measurement of the secondary electron emission characteristic of the material, and meanwhile, the structure design can effectively prevent secondary pollution when the sample is transferred from the pretreatment cavity to the measuring cavity.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

Low-temperature shaped dried egg and processing method thereof

InactiveCN110338365AAdd flavorIncrease elasticityFood ingredient as taste affecting agentLipidic food ingredientsYolkCooking & baking

The invention discloses a low-temperature shaped dried egg and a processing method thereof. The dried egg mainly takes fresh egg white and fresh egg yolk, and the main production steps include seasoning, injection molding, molding and baking. The method is characterized in that the injection molding and molding steps are as follows: adding an edible alkali solution to the seasoned egg liquid, uniformly stirring the materials, and then injecting the material into a mold to perform molding, wherein the molding temperature is 30-50 DEG C, and after 24h-48h, fixing the egg liquid in the mold to obtain the formed dried egg. The dried egg has soft and tender taste, and has full taste, smooth mouthfeel, long-lasting taste, and long aftertaste, and has a slightly preserved egg-like flavor withoutastringent mouthfeel.

Owner:HUBEI SHENDAN HEALTHY FOOD

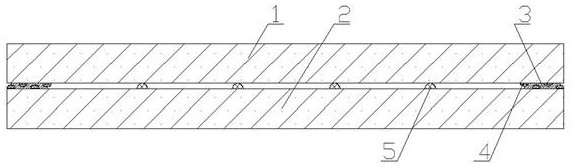

Ladle cover suitable for ejection burner

ActiveCN106513649AReduce weightReasonable structureMelt-holding vesselsAir preheaterInsulation layer

The invention provides a ladle cover suitable for an ejection burner. The ladle cover comprises a cover body, a reinforcing ring plate, refractory cottons, lifting lugs, an air through hole, an insulation layer, inverted F-shaped hanging pieces, air preheaters, a burner reserved port and a separation plate; the separation plate is arranged in a cavity of the cover body for dividing the cavity of the cover body into an upper cavity and a lower cavity; the burner reserved port penetrates through the center of a cover body upper-layer plate an the center of the separation plate; the reinforcing ring plate is arranged on the lower end surface of the cover body; the refractory cottons are arranged on the lower surface of the separation plate and the inner wall of the lower cavity, and are fixed through the inverted F-shaped hanging pieces; the upper ends of the inverted F-shaped hanging pieces are fixed on the lower surface of the separation plate; at least four lifting lugs are provided; all the lifting lugs are annularly and uniformly fixed on the outer wall of the cover body; the air through hole is formed in the cover body upper-layer plate; the insulation layer is fixed on the lower surface of the cover body upper-layer plate; and the air preheaters are annularly and uniformly fixed in the upper cavity with the center of the cover body upper-layer plate as the circle center. The ladle cover has such advantages as light weight, reasonable structure and low manufacturing cost.

Owner:JIANGSU UNIV

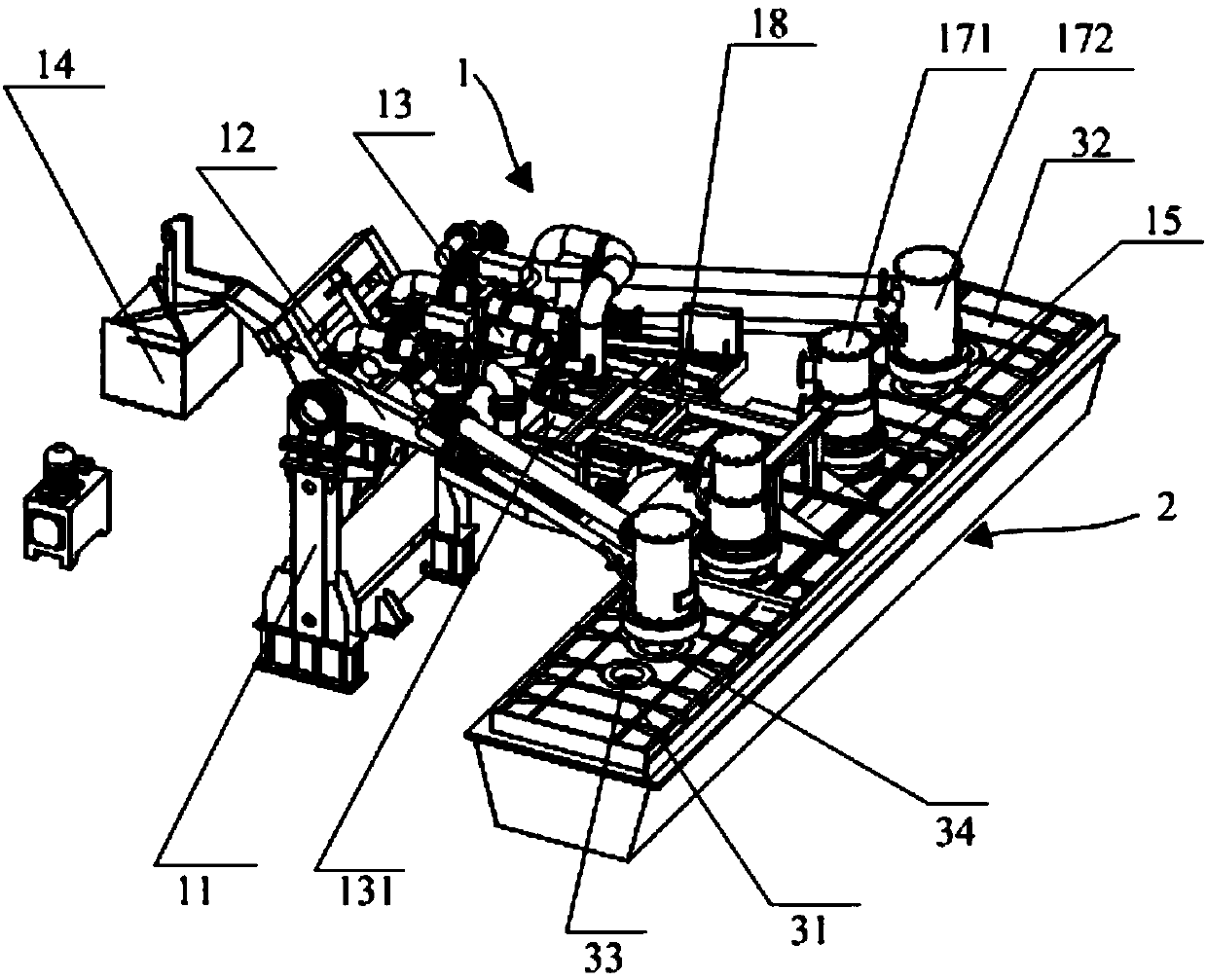

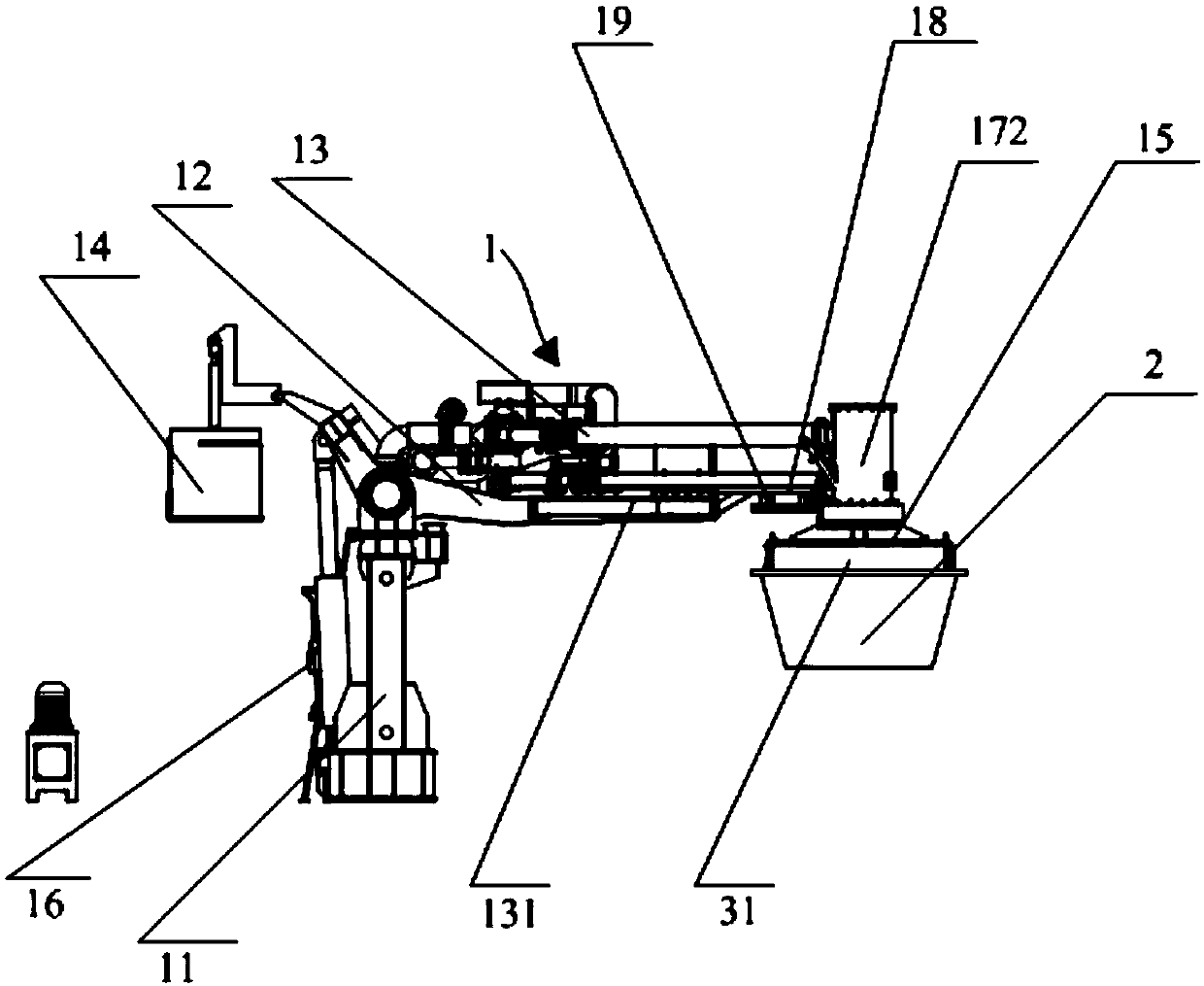

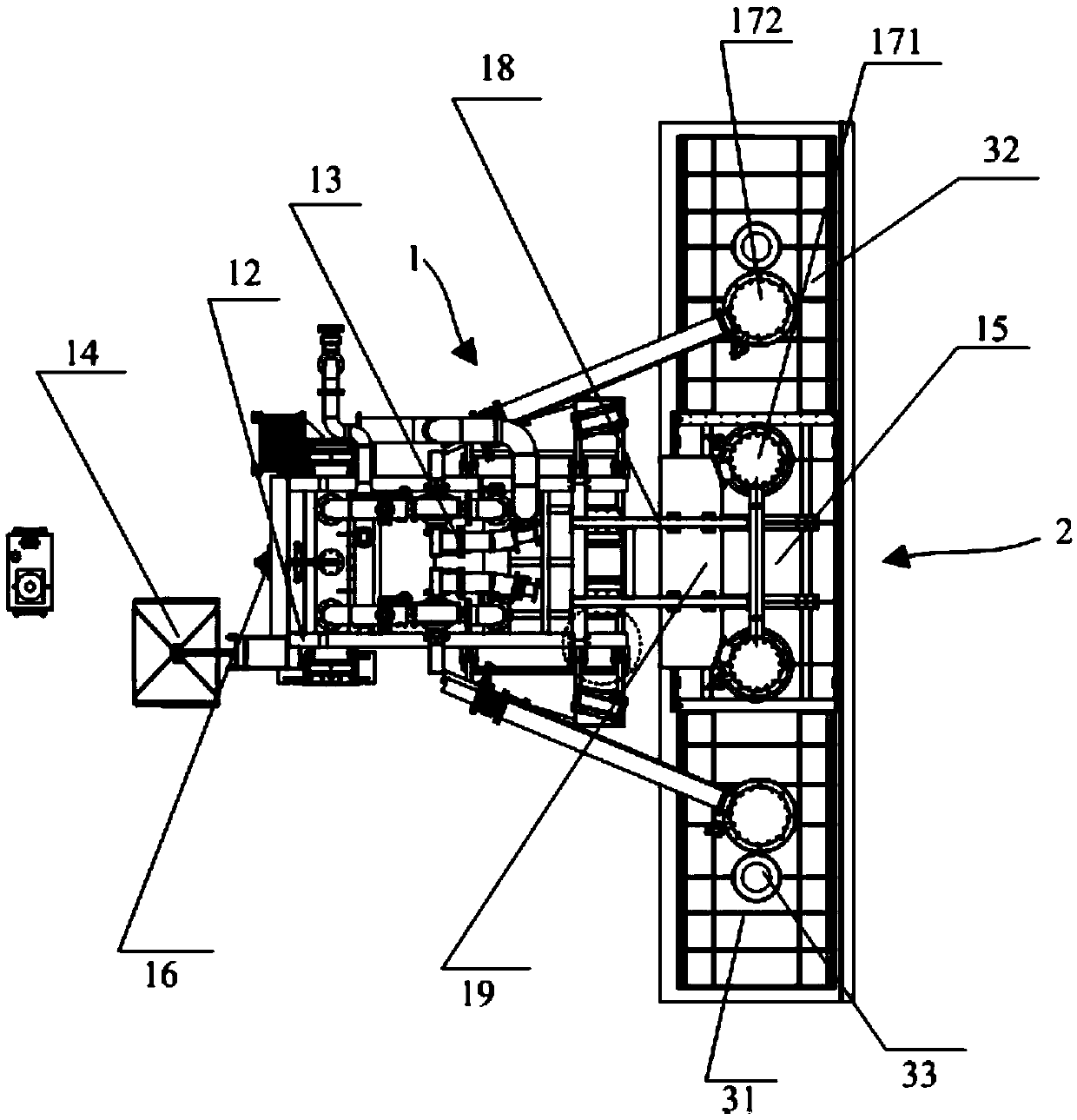

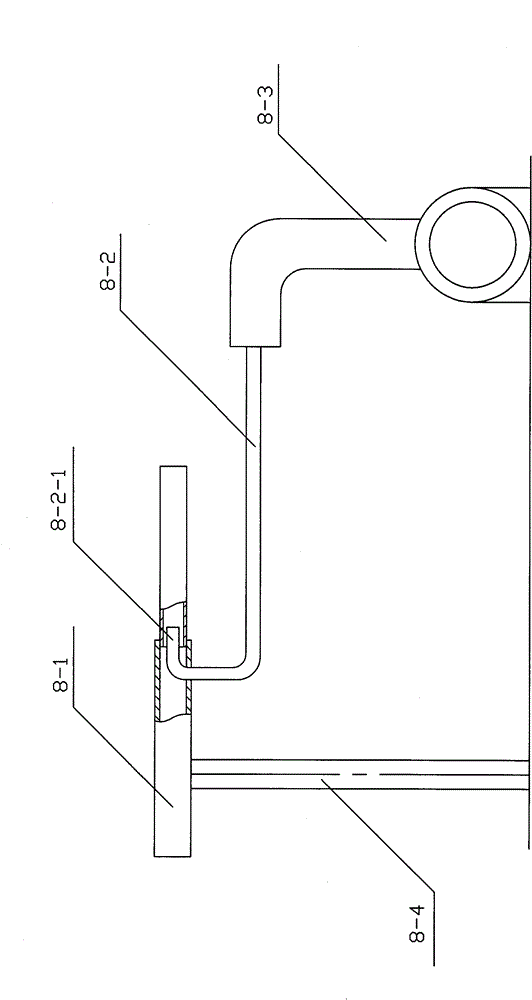

Tundish roaster

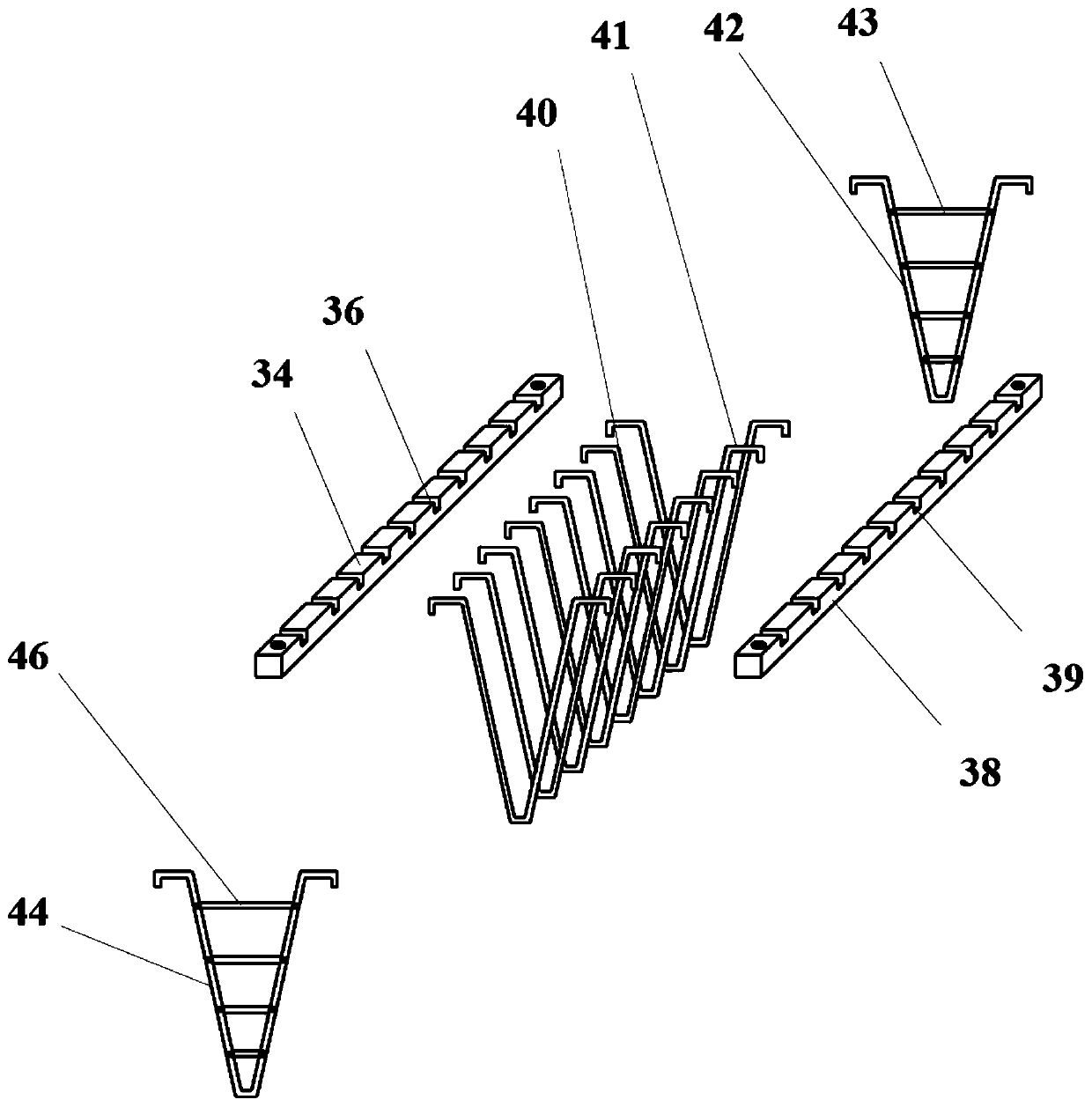

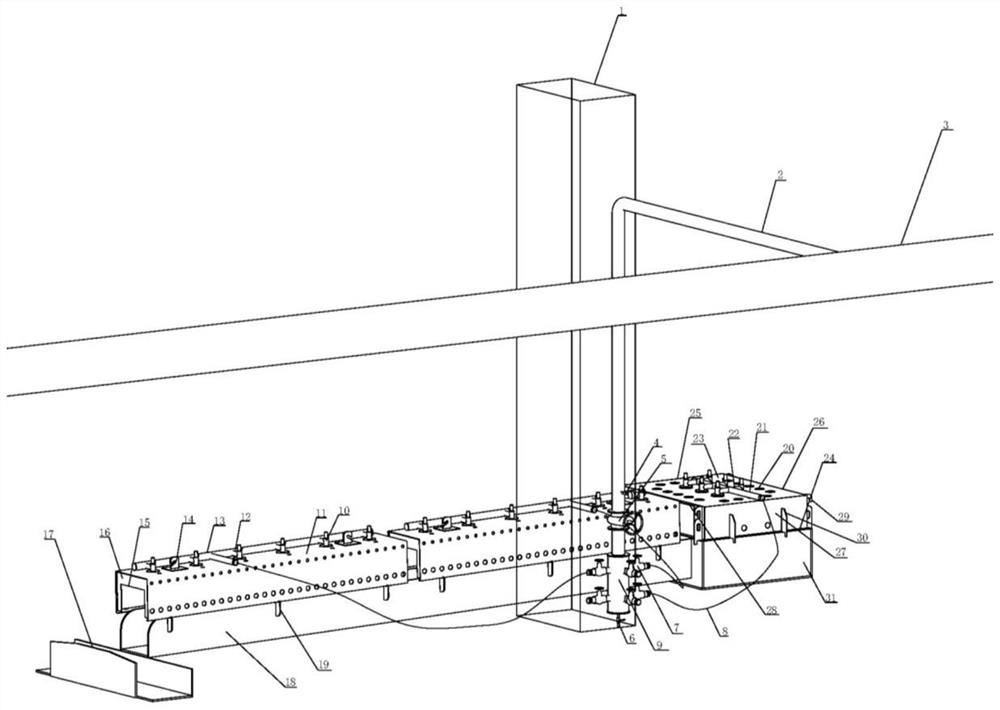

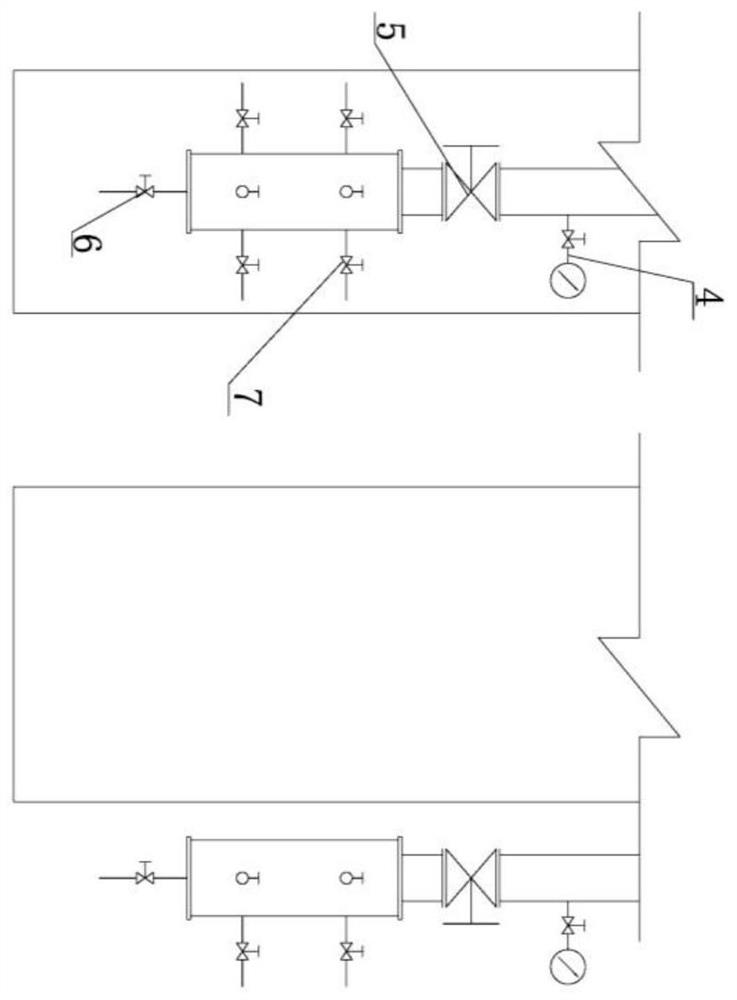

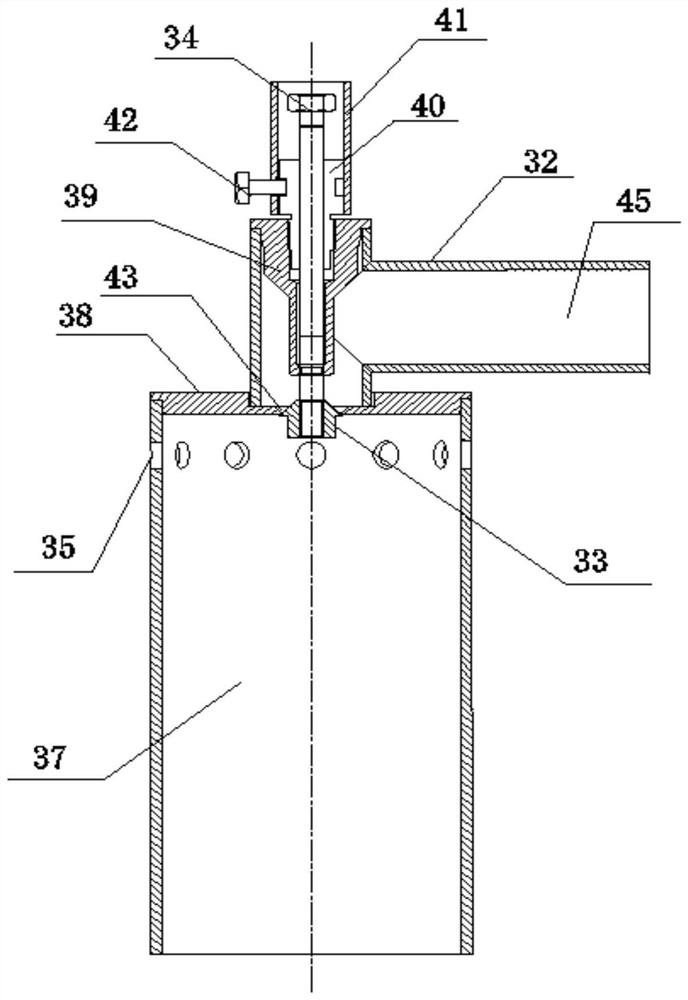

PendingCN111215614AReduce dosageShorten the timeMelt-holding vesselsMechanical engineeringIndustrial engineering

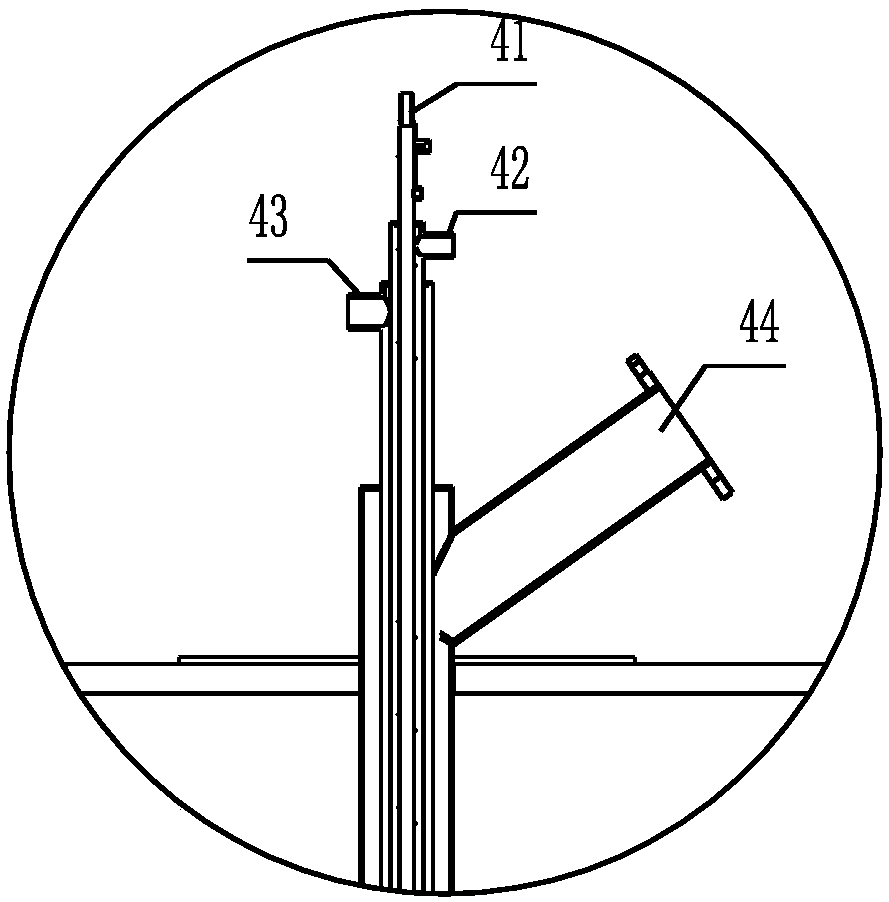

The invention provides a tundish roaster. The tundish roaster comprises a support frame, a lifting arm structure, first burners, a pipeline assembly, and a movable cover plate, wherein the lifting armstructure is movably connected to the top of the support frame through a rotating shaft, the first burners are arranged and fixed on a first end of the lifting arm structure, the pipeline assembly isarranged and fixed on the lifting arm structure, one end of the pipeline assembly is in communication with the first burners, and the other end of the pipeline assembly is in communication with a gassource, the movable cover plate is arranged and fixed at the first end of the lifting arm structure, and the movable cover plate is located on one sides of the first burners, and is provided with burner holes matched with the first burners. According to the tundish roaster, when a tundish is roasted, it is not necessary to manually cover a hole in an existing tundish cover for receiving molten steel with fire blocking cotton and remove the fire blocking cotton after roasting each time so that time, manpower and material resources can be saved, the roasting temperature can be increased, the coal gas consumption is greatly saved, and the production cost is reduced.

Owner:上海安可科技股份有限公司

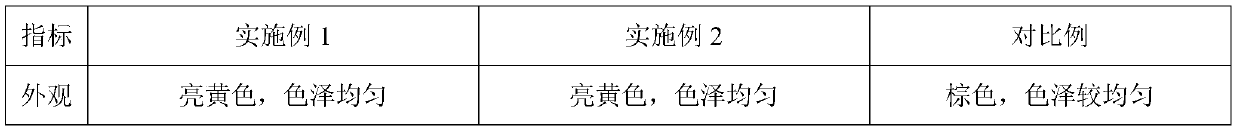

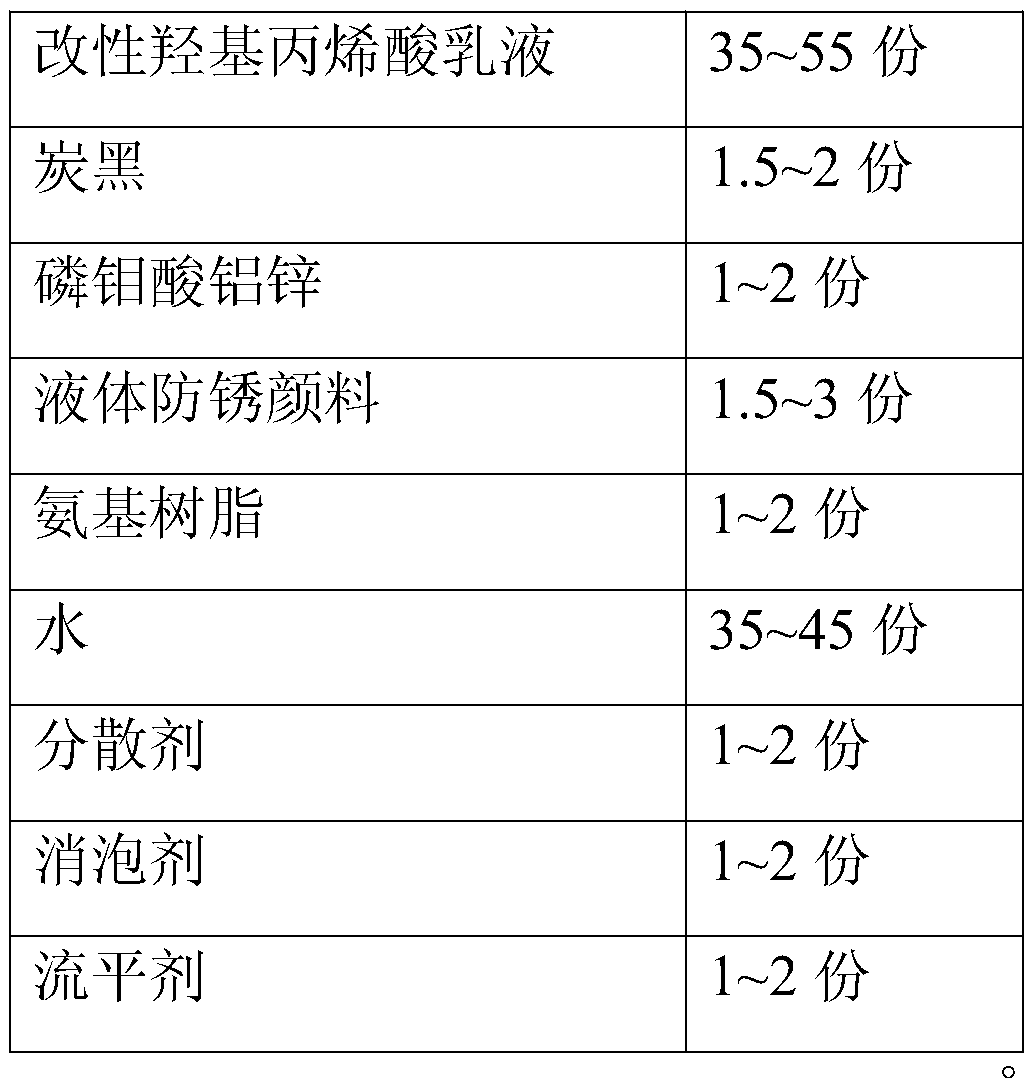

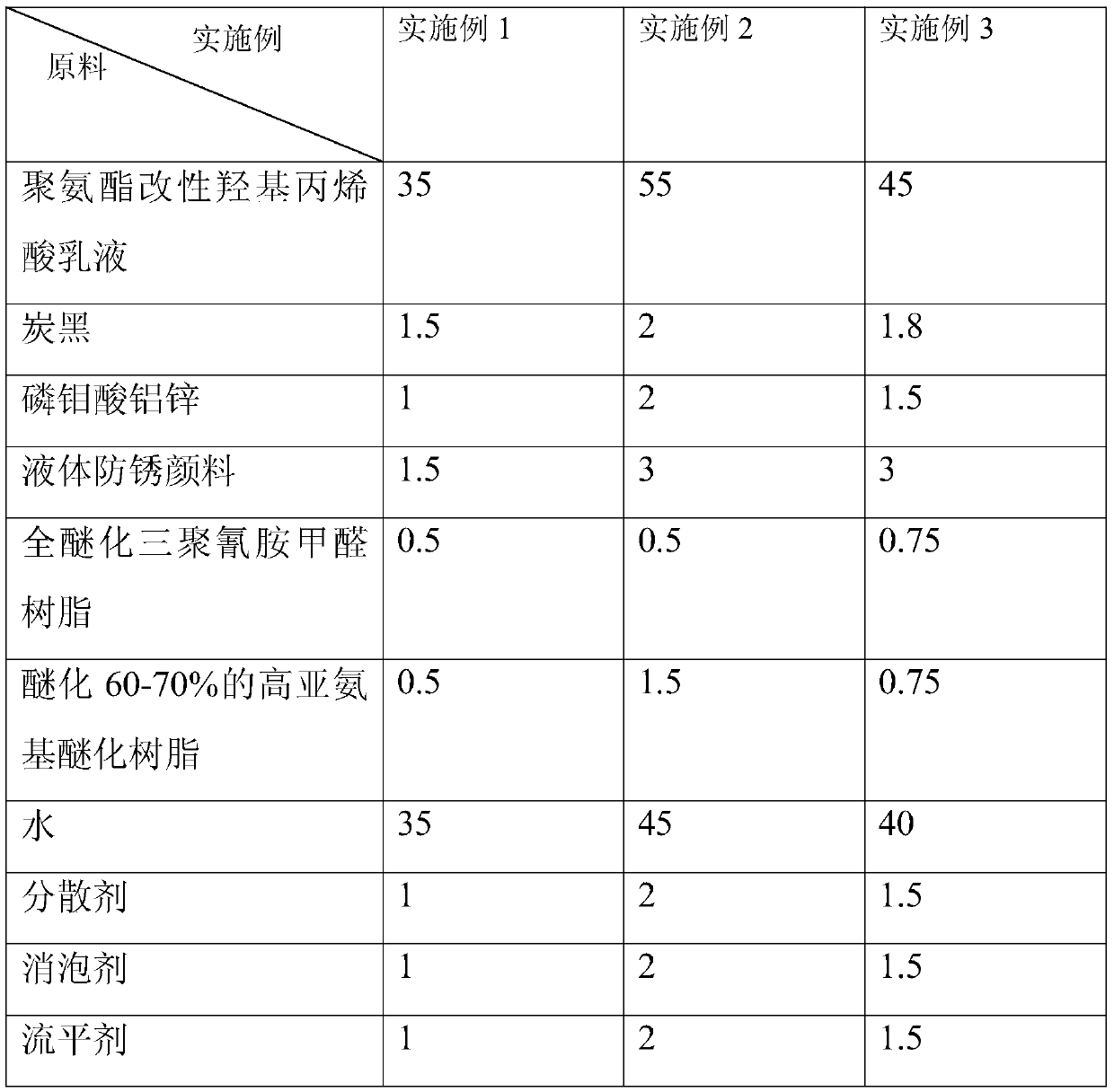

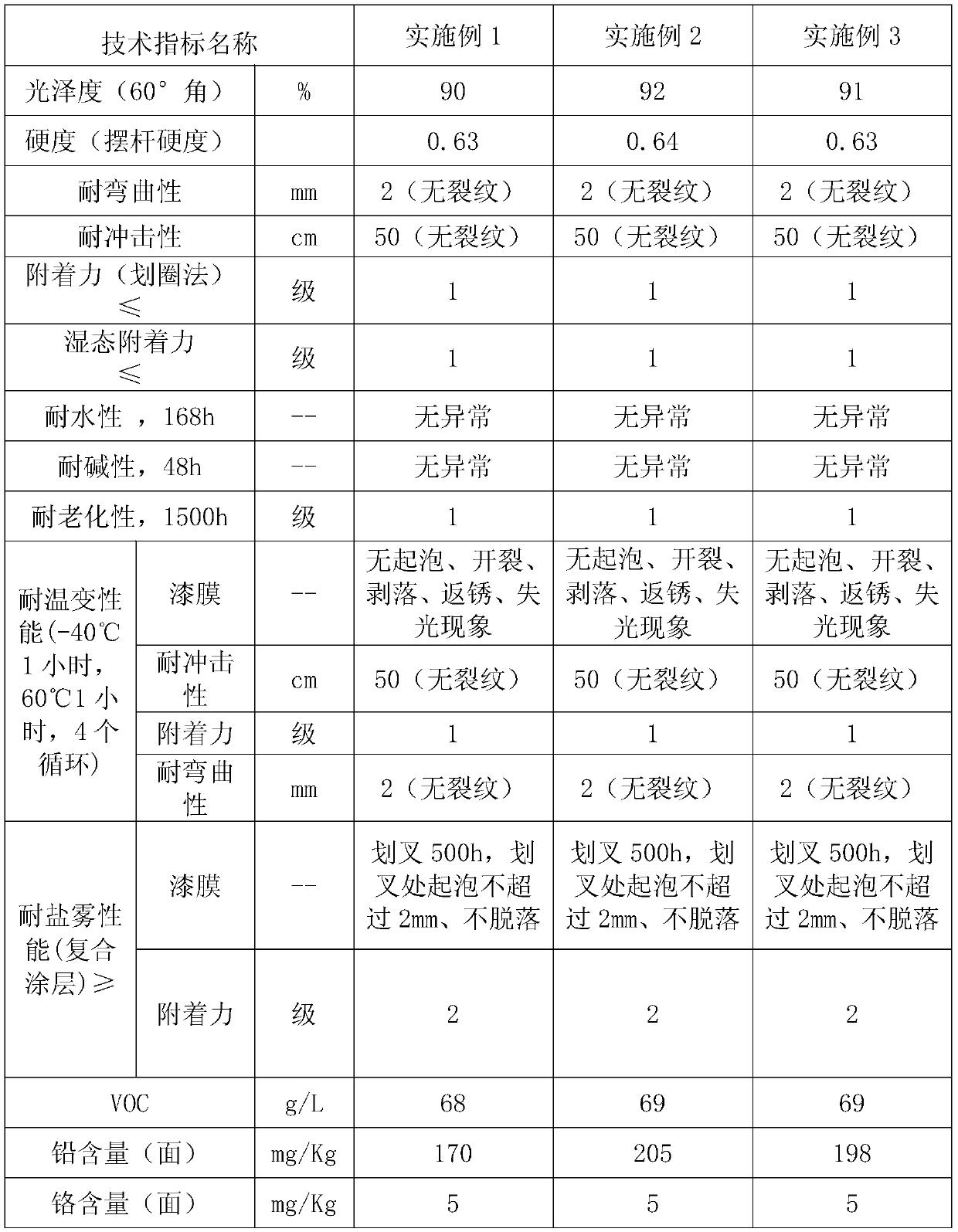

Waterborne amino industrial paint and preparation method thereof

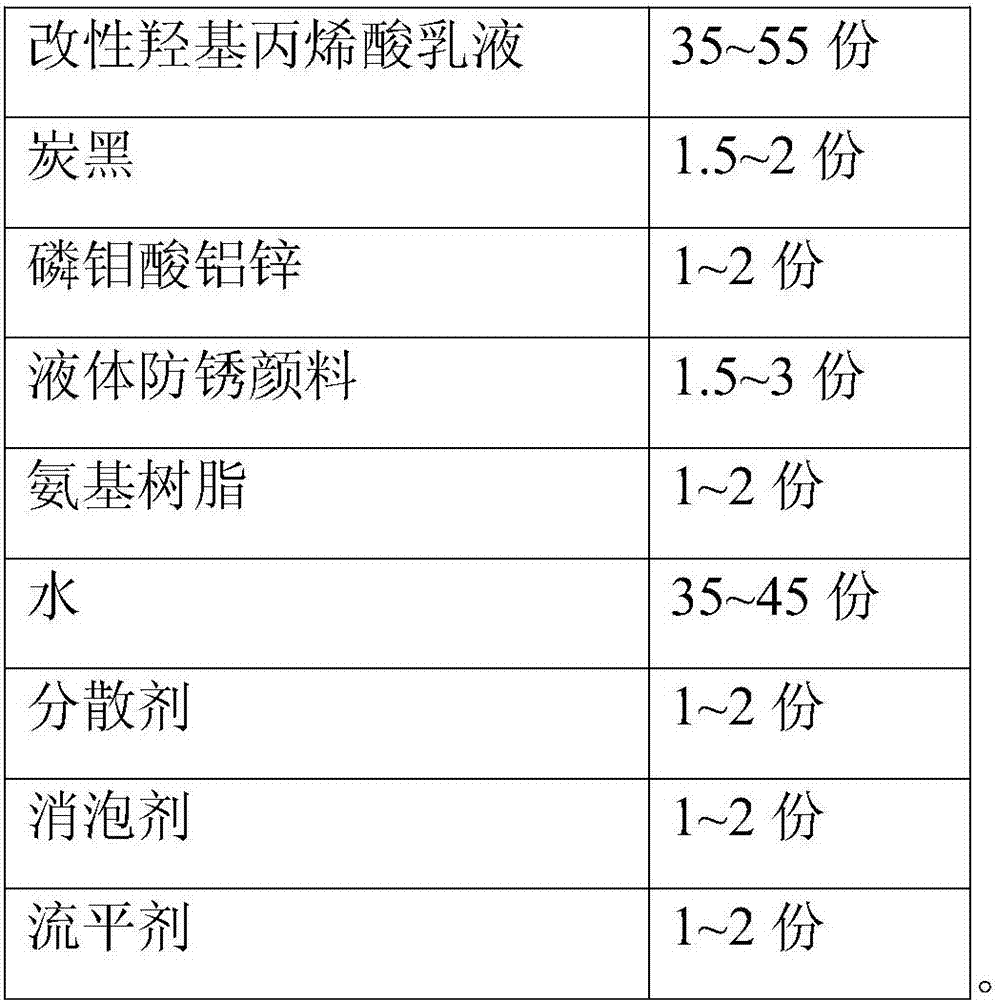

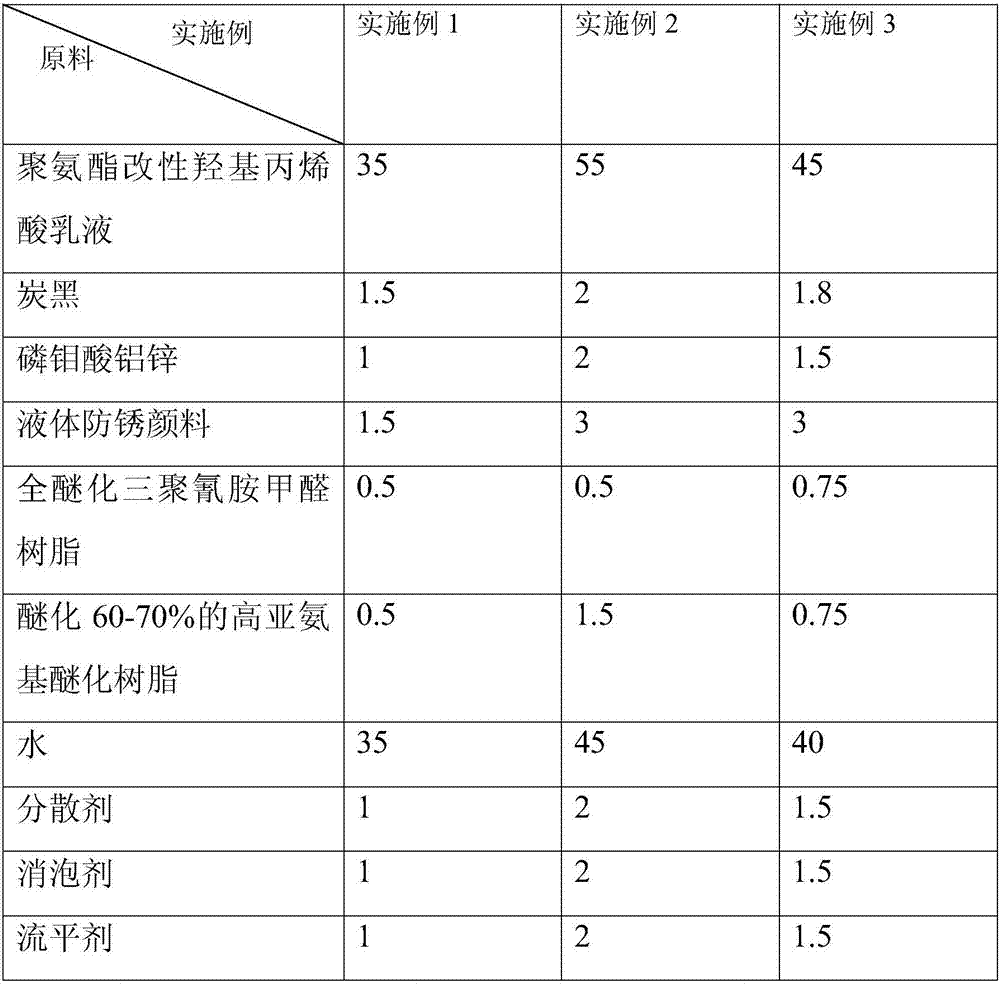

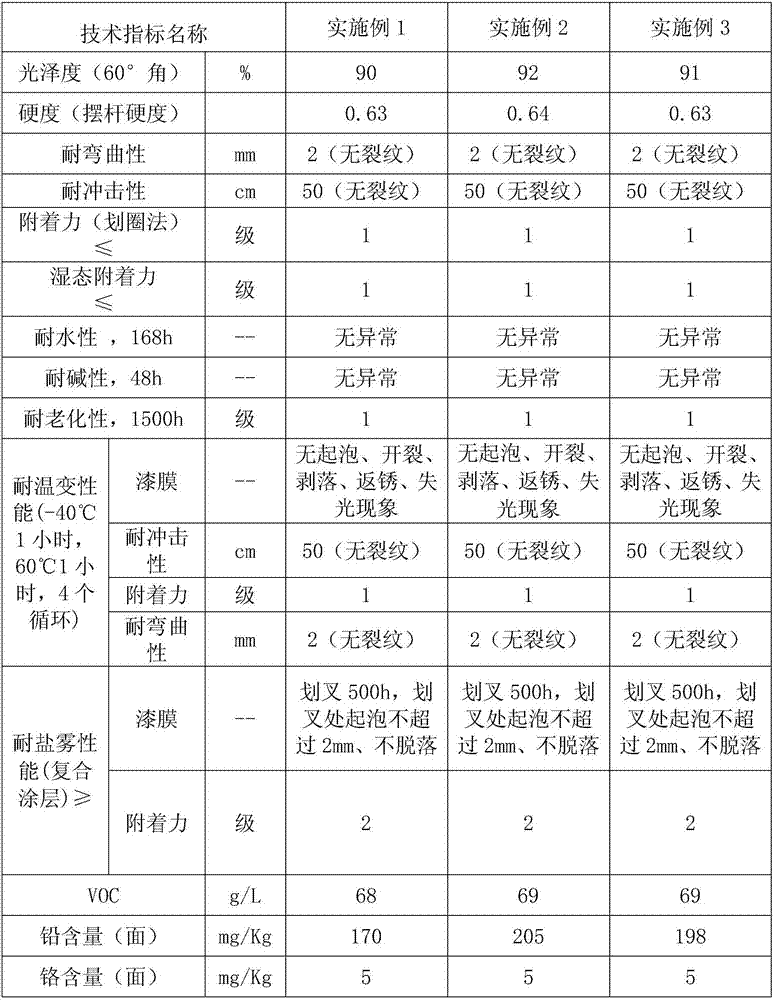

ActiveCN107964340AHigh hardnessGood flexibilityAnti-corrosive paintsPolyurea/polyurethane coatingsEmulsionHardness

The invention discloses a waterborne amino industrial paint. The waterborne amino industrial paint comprises the following raw materials by weight: 35-55 parts of a modified hydroxyl acrylic emulsion,1.5-2 parts of carbon black, 1-2 parts of zinc aluminum phosphomolybdate, 1.5-3 parts of a liquid antirust pigment, 1-2 parts of amino resin, 35-45 parts of water, 1-2 parts of a dispersant, 1-2 parts of a defoamer and 1-2 parts of a leveling agent. The paint prepared by the method provided by the invention has the advantages of high hardness, good flexibility, excellent adhesion to different substrates, excellent interlayer adhesion when matching with a primer, and good decorativeness and chemical resistance.

Owner:石家庄市油漆厂

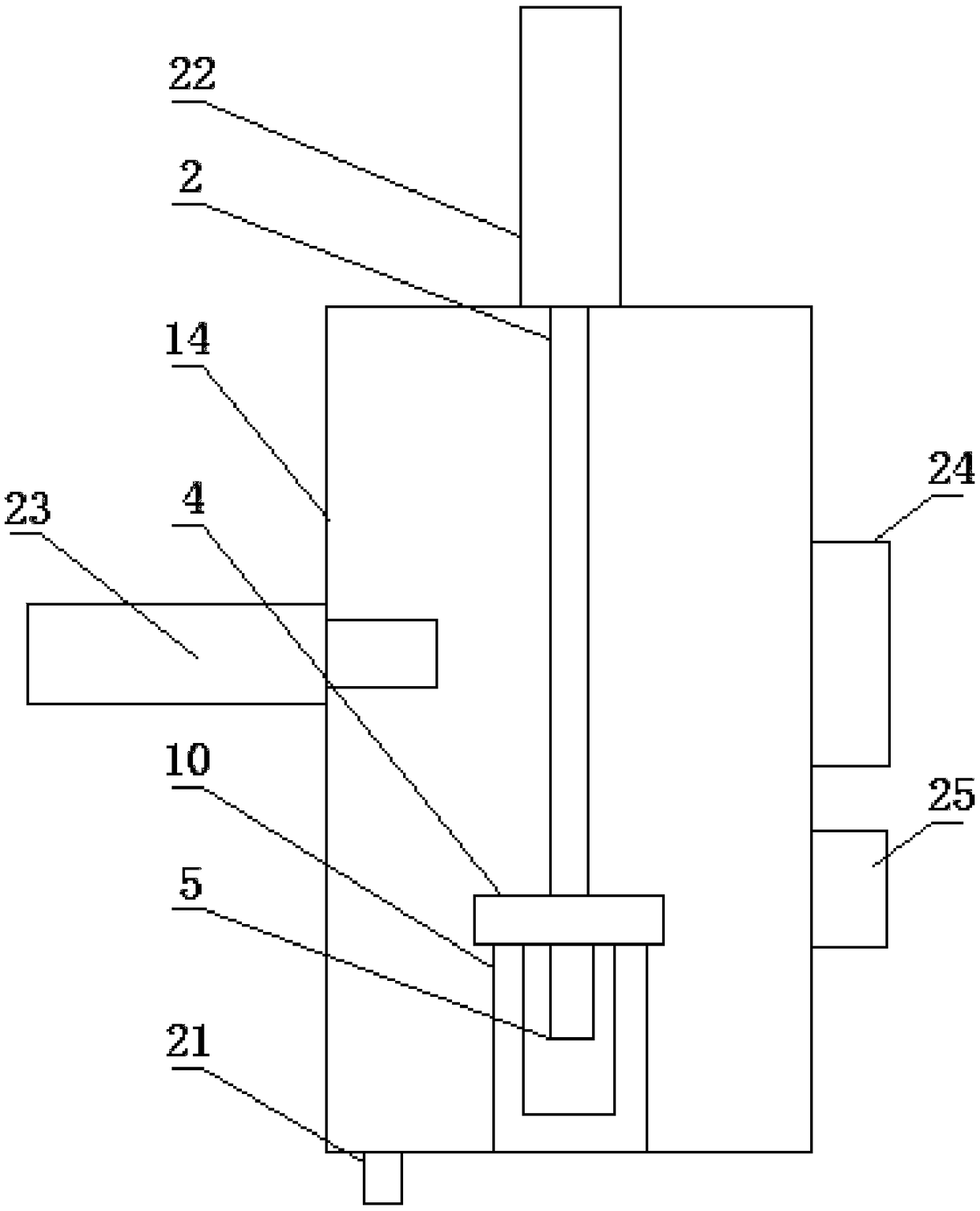

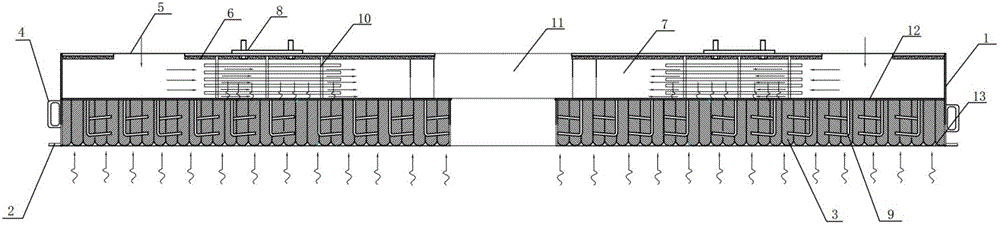

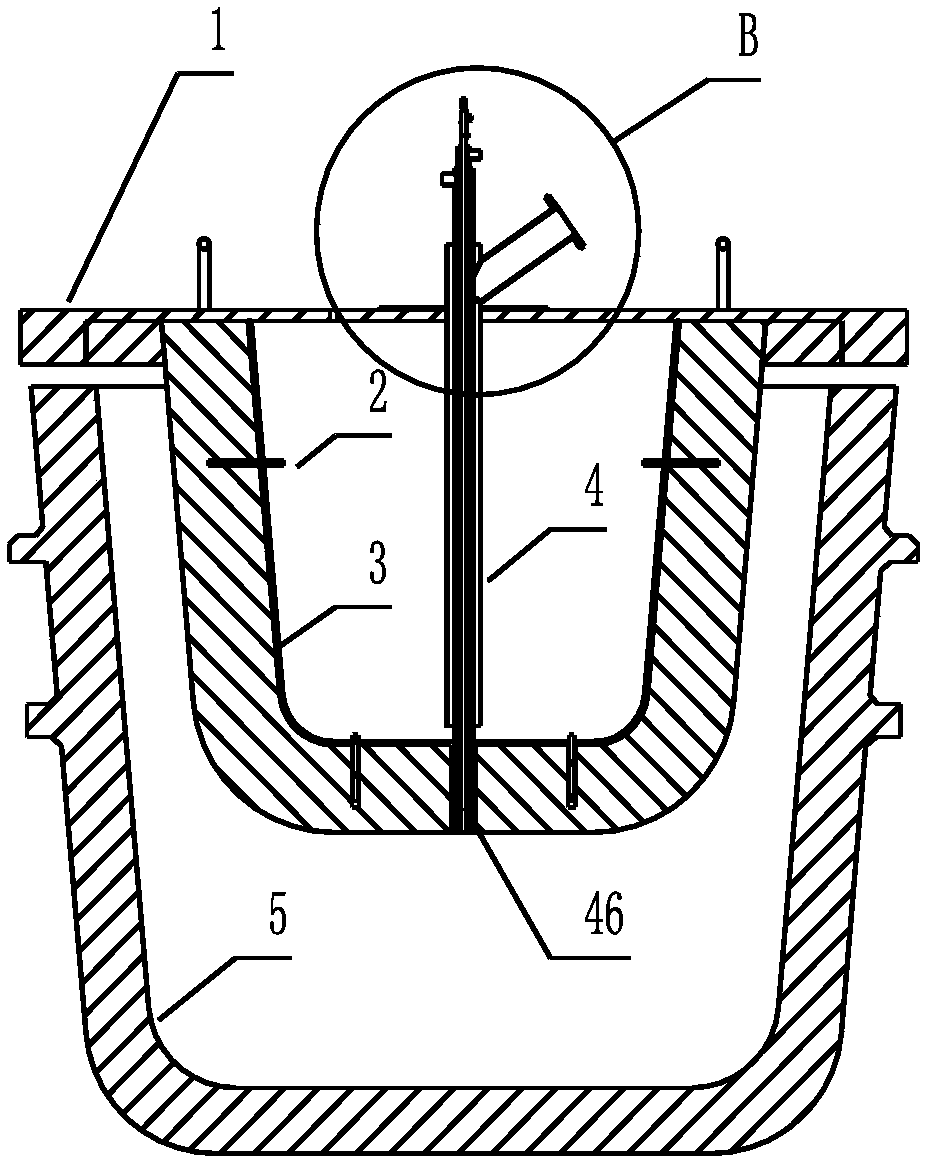

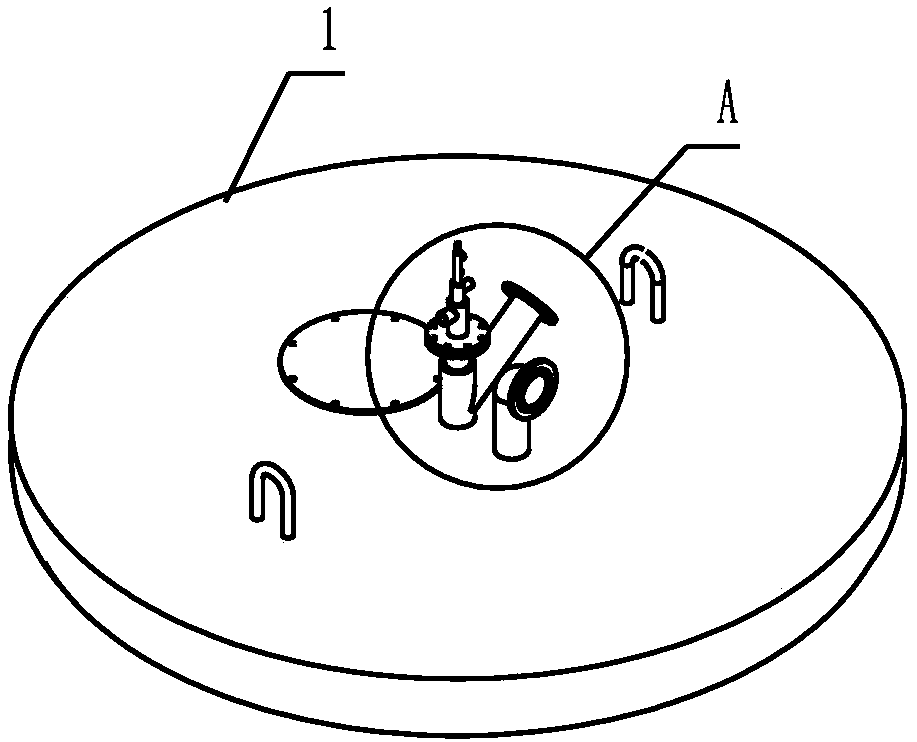

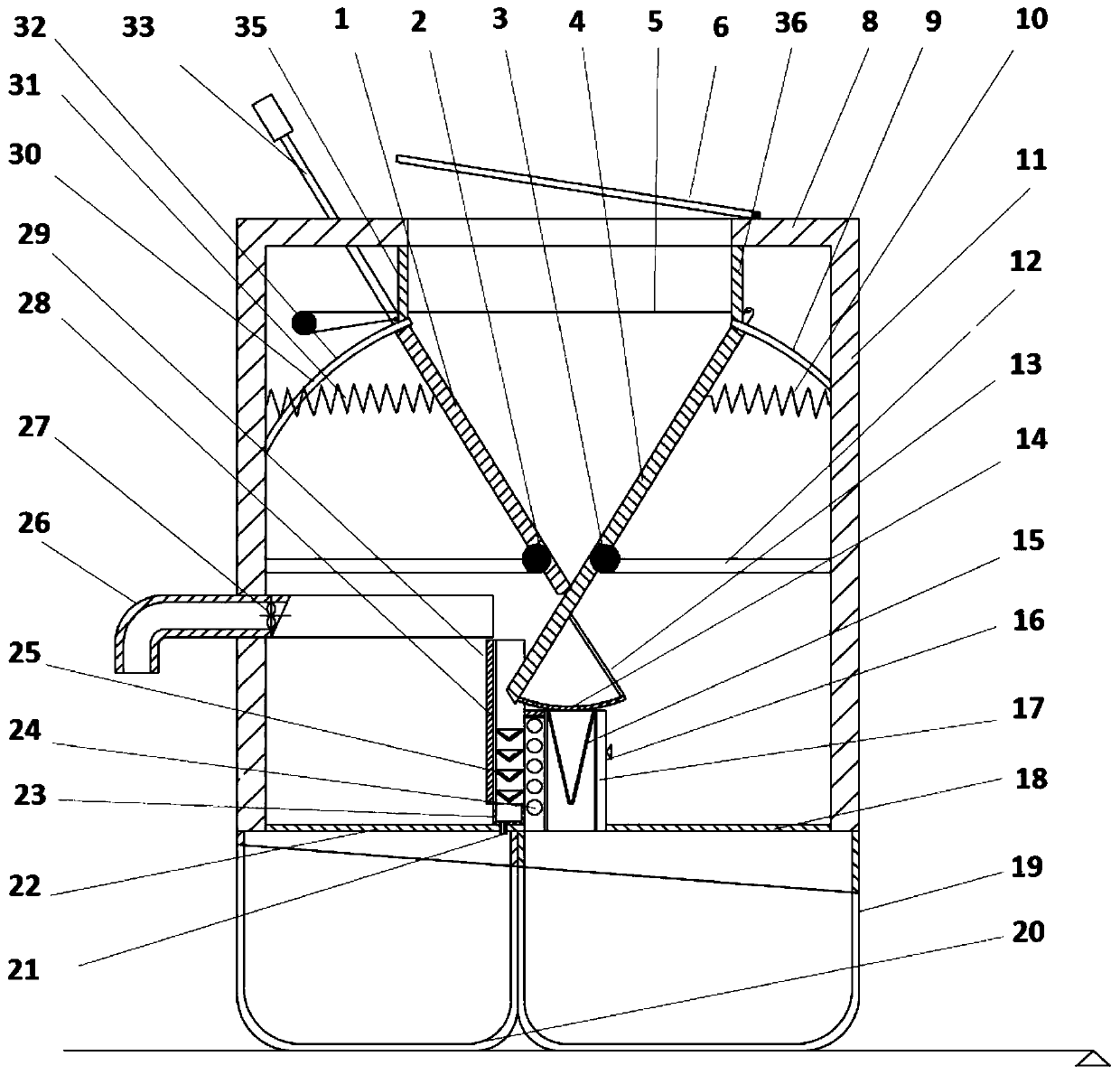

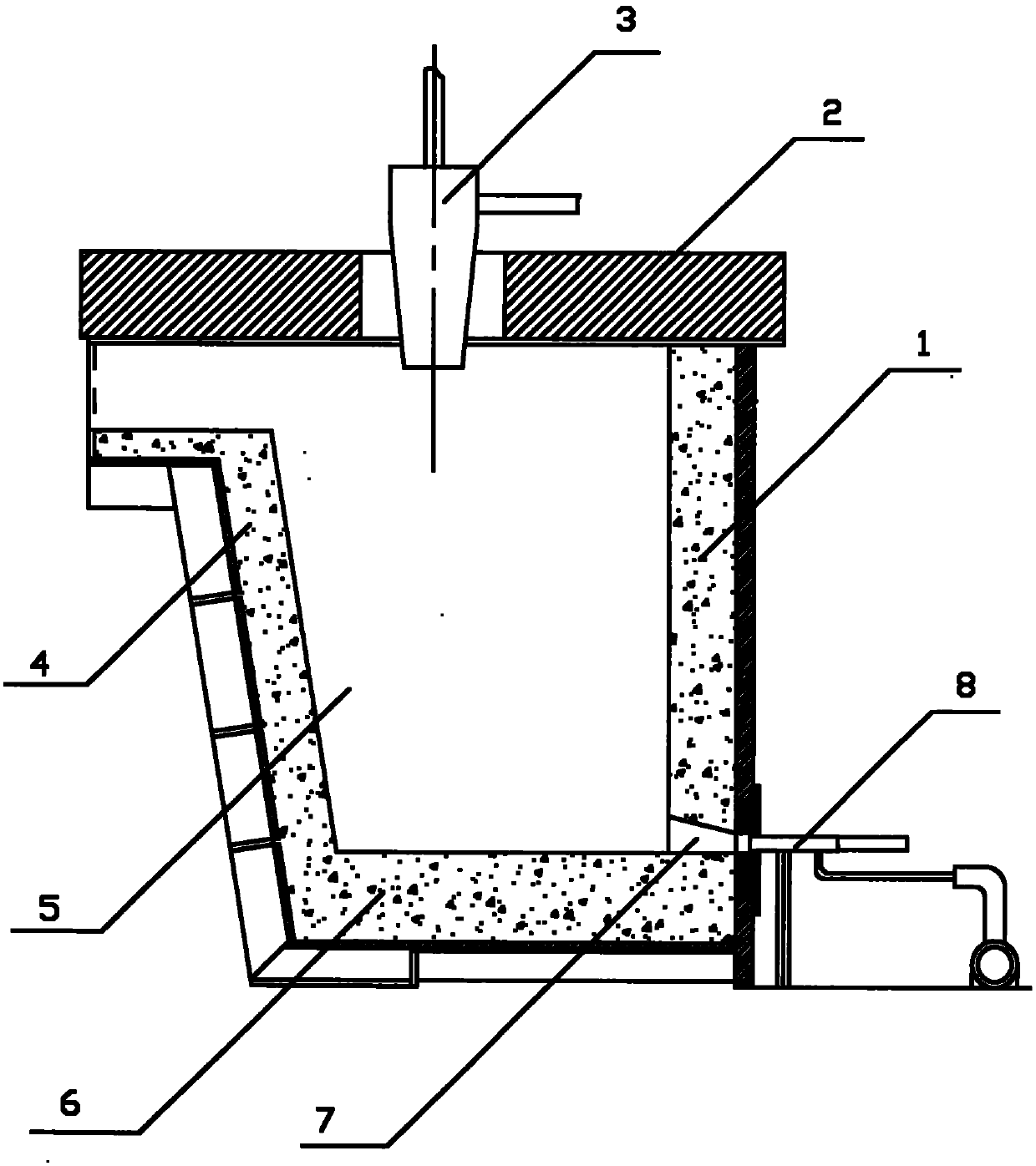

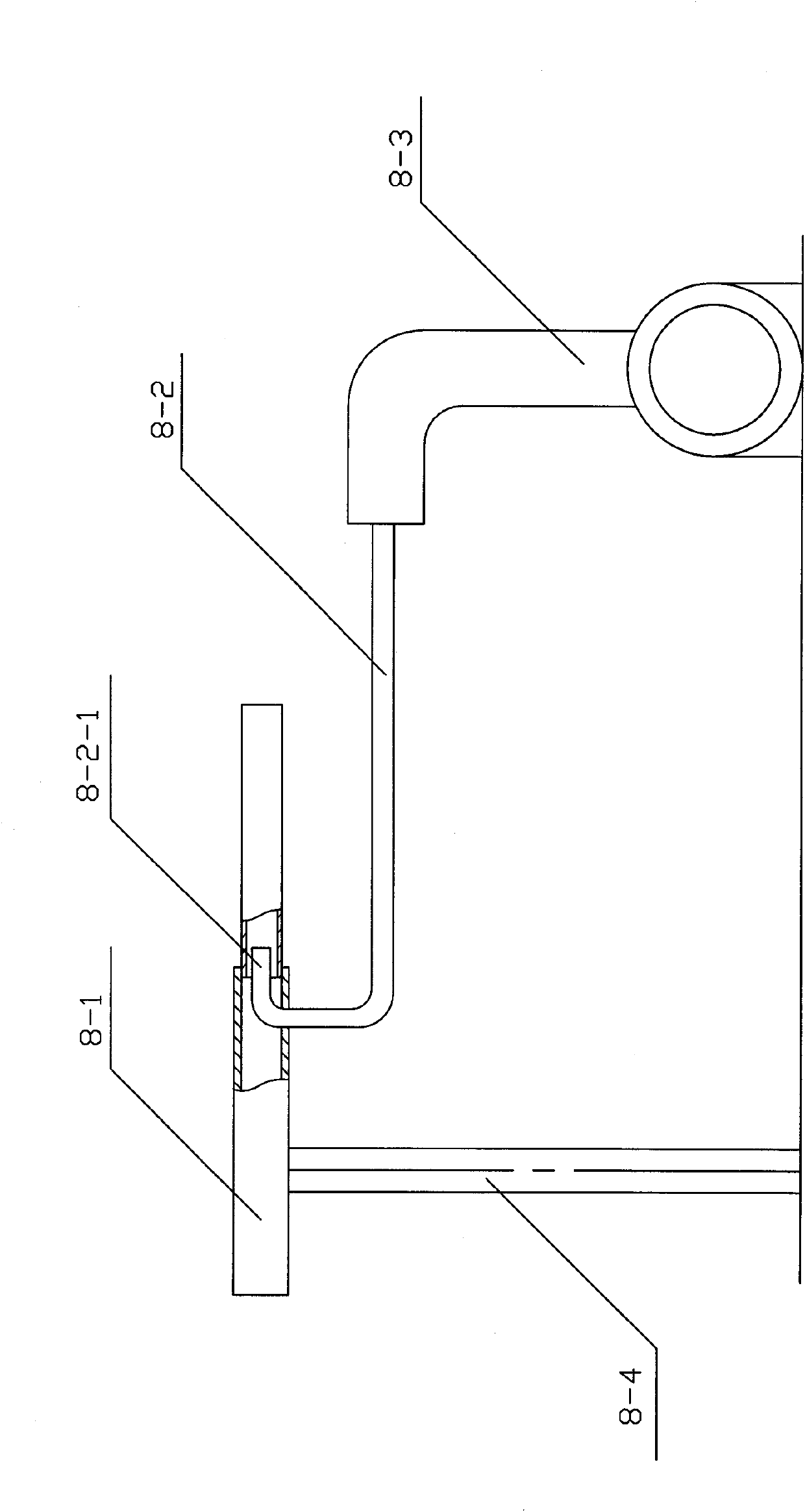

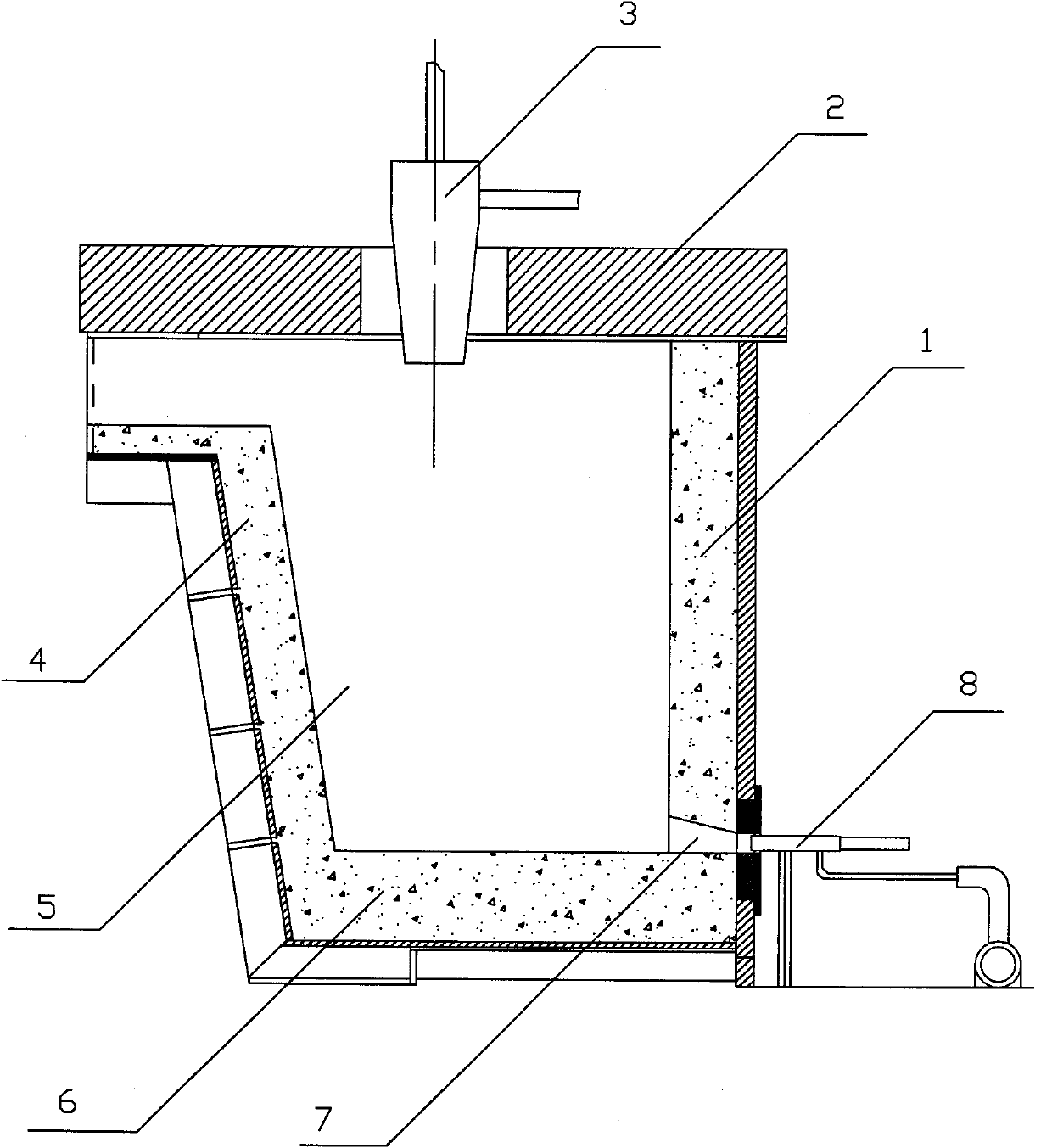

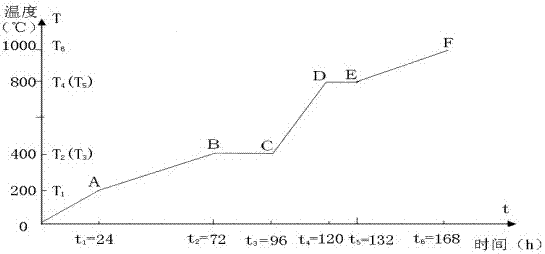

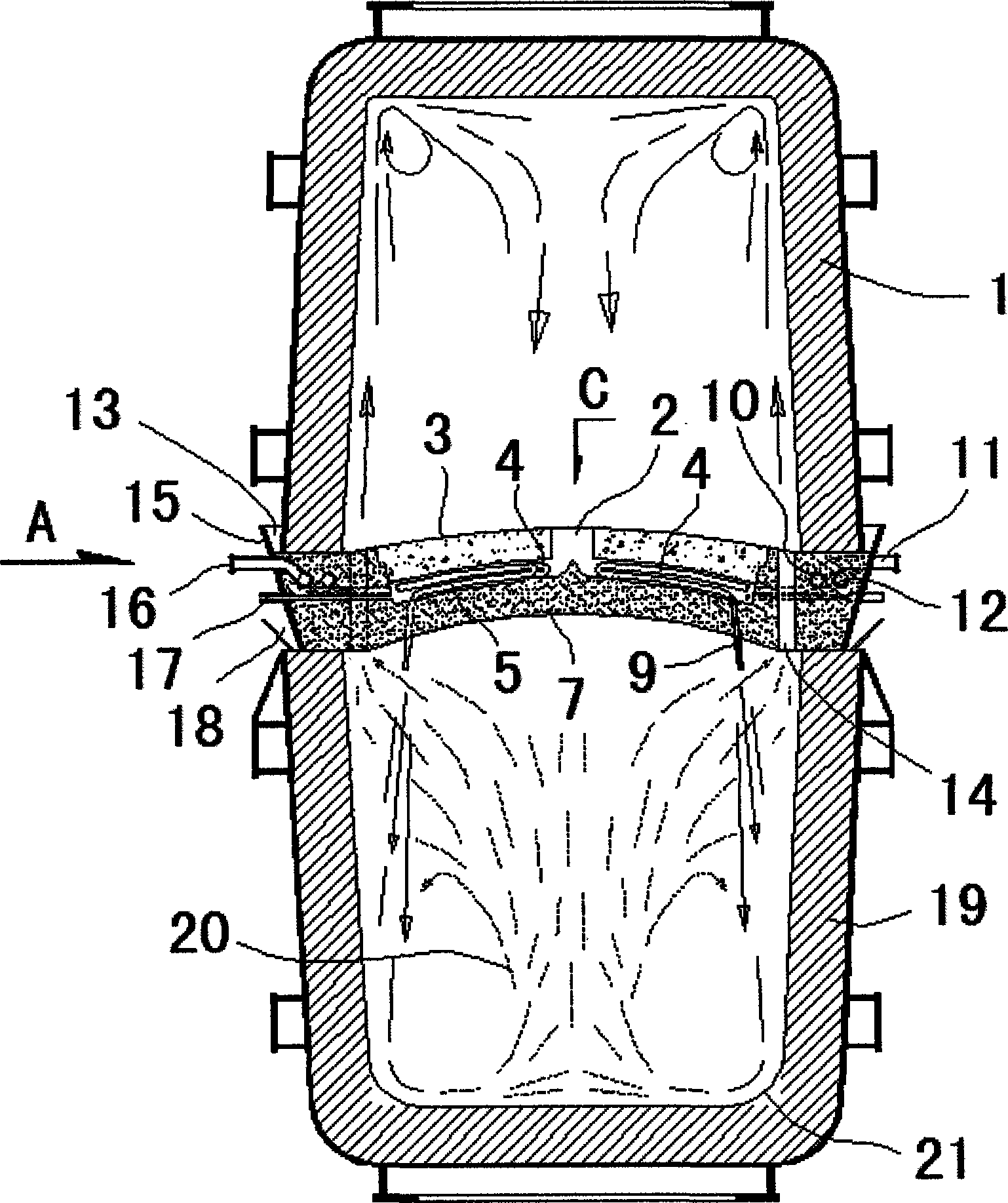

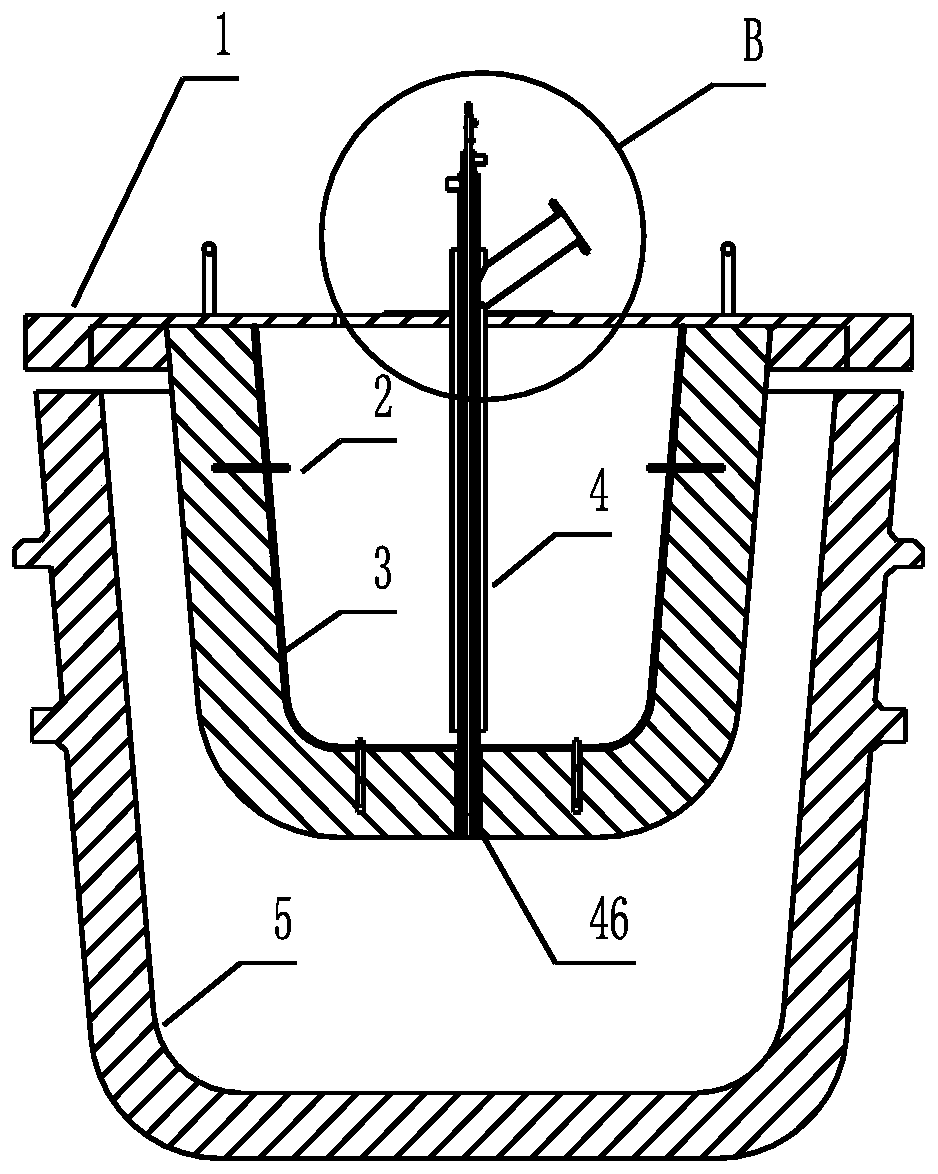

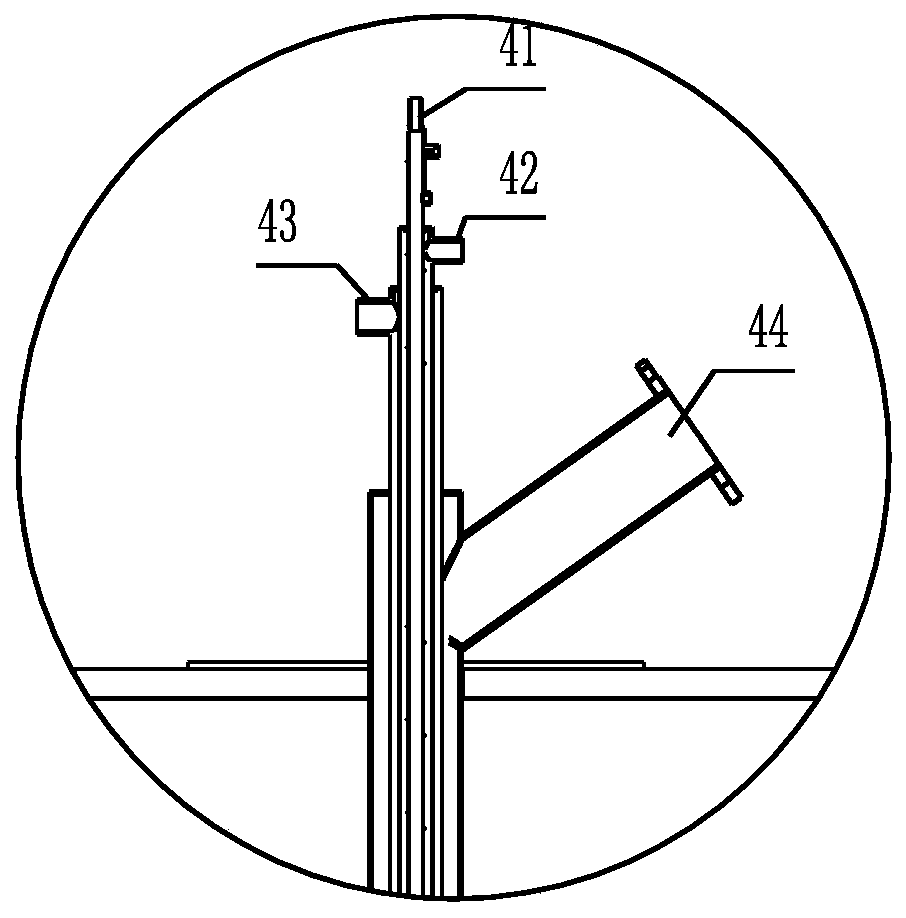

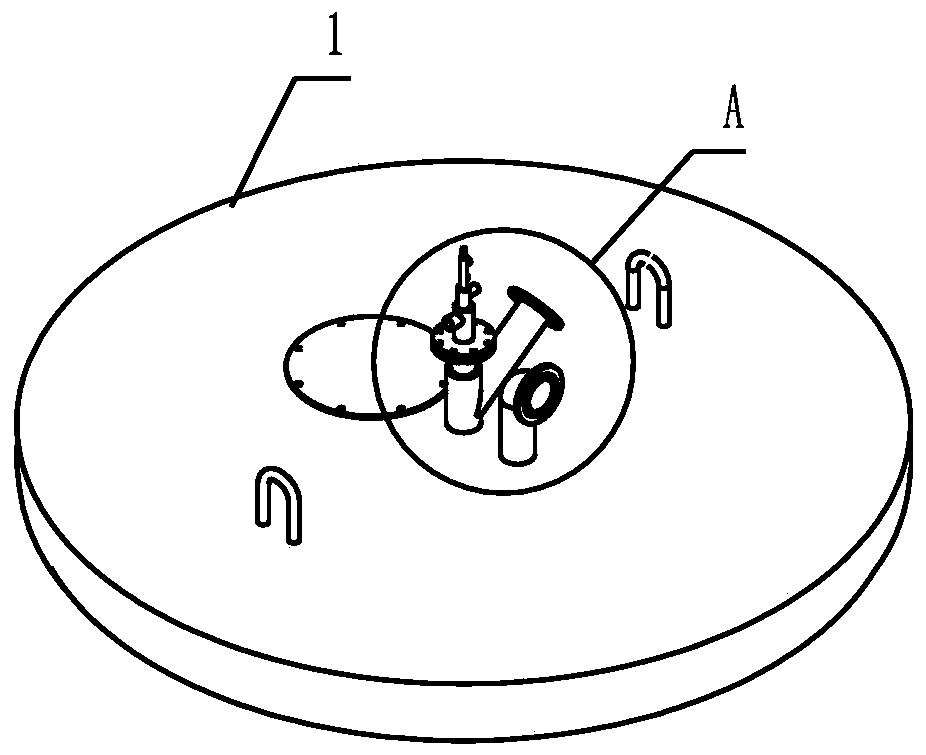

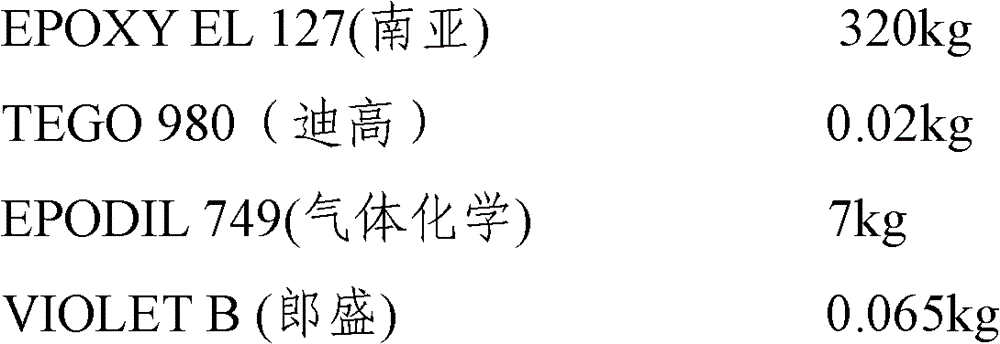

Oxygen-rich intelligent temperature-control ladle baking device and using method thereof

ActiveCN108393475AUniform heating temperatureIncrease the baking temperatureMelt-holding vesselsTemperature controlCombustor

The invention relates to an oxygen-rich intelligent temperature-control ladle baking device and a using method thereof. The ladle baking device is provided with a ladle cover, a ladle liner and a burner assembly, a space is reserved between the outer periphery of the ladle liner and the inner wall of a steel ladle, and a gap is further reserved between the periphery of the ladle cover and the edgeof the upper opening of the steel ladle; a plurality of temperature sensors capable of testing the temperature of the outer wall of the ladle liner are arranged on the wall of the ladle liner; the burner assembly is provided with an igniter, a fuel gas pipe, a combustion-supporting gas pipe and a combustion head, the combustion head extends out of the bottom of the ladle liner, the upper end of the burner assembly extends out of the ladle cover, the burner assembly is fixed in the middle of the ladler cover, and a self-control switch of the igniter, a gas inlet of the fuel gas pipe and a gasinlet of the combustion-supporting gas pipe are arranged at the upper end of the burner assembly; and the ladle baking device is further provided with a PLC, and the PLC is in signal and control connection with the temperature sensors and the self-control switch. The ladle baking device has the advantages that the structural design is reasonable, running is safe and reliable, the automation degreeis high, the operation and the use are convenient, the steel ladle is uniformly baked, the baking time is effectively shortened, the baking efficiency is improved, and the pollution to the environment is relatively low.

Owner:王研

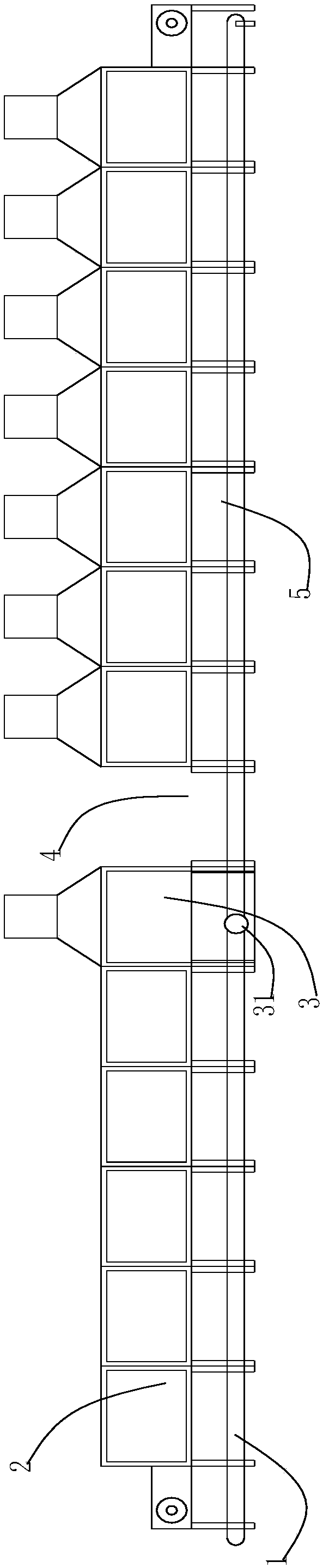

Barbecue machine and using method thereof

InactiveCN109588424AQuickly increase the baking temperatureIncrease the baking temperatureBaking ovenHigh-frequency/infra-red heating bakingCooking & bakingProcess engineering

The invention discloses a barbecue machine and a using method thereof. The barbecue machine comprises a conveyor belt and an oven, a heat dissipation zone, a detection zone and a cooling zone arrangedin sequence along the conveying path of the conveyor belt; a screen is arranged on the conveyor belt; the oven is an infrared electric heating oven; a fan is arranged in the heat dissipation zone; the temperature in the cooling zone is 5-10 DEG C; and the conveyor belt is connected end to end. The using method comprises the following steps: a baking step: spreading raw meat slices on the screen,and conveying the meat slices to the oven through the conveyor belt for baking; a heat dissipation step: conveying the baked meat slices to the heat dissipating zone by the conveyor belt, and extracting the heat of the meat slices through the fan; a detection step: conveying the meat slices after heat dissipation to the detection zone to remove poor baked meat slices; and a cooling step: conveyingthe detected meat slices to the cooling zone for cooling to obtain a barbecue. The barbecue machine uses the infrared electric oven to achieve a rapid increase in the baking temperature, and the braking efficiency is high.

Owner:广东真美食品股份有限公司

Solid-liquid separation integrated toilet tool capable of remarkably reducing residues, and applications thereof

PendingCN110981149AIngenious structural designSimple structureSludge treatment by de-watering/drying/thickeningClimate change adaptationLiquid wasteProcess engineering

The invention relates to a solid-liquid separation integrated toilet tool capable of remarkably reducing residues, and applications thereof. The toilet tool comprises a storage processor, an ash storage device and a standby liquid storage device, wherein the storage processor is connected with the standby liquid storage device and the ash storage device, the storage processor comprises a shell, astorage extrusion device and baking treatment equipment, the storage extrusion device and the baking treatment equipment are arranged in the shell, and the baking treatment equipment comprises a baking device, a liquid treatment device and a solid treatment device. According to the toilet tool, solid-liquid separation in excrement is facilitated, the liquid waste in excrement is evaporated to dryness so as not cause residue, the ash-like organic solid fertilizer is produced regularly, the size is reduced by one order of magnitude, and the integrated design of toilet function is achieved; by using the aerodynamic heat principle, no peculiar smell is generated, so that the toilet user experience is good; and the solid-liquid separation integrated toilet tool is simple in structure, low in cost, high in efficiency, low in construction or transformation cost and convenient to clean and maintain, and can achieve the absolute water-free toilet tool by only requiring a small amount of water for regular cleaning.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

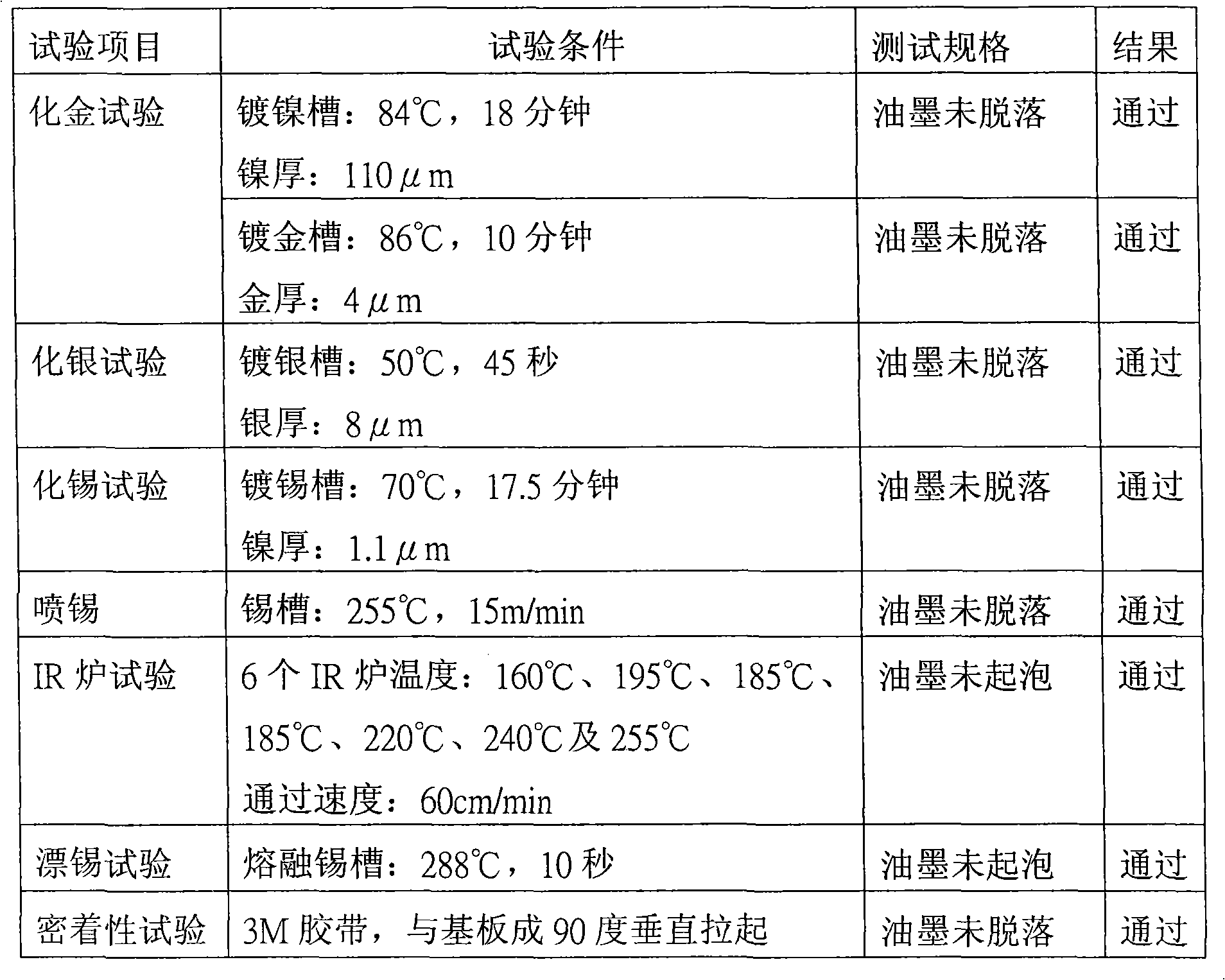

Method for manufacturing printed circuit board

InactiveCN101841978ALow costReduce usageConductive material chemical/electrolytical removalChemical treatmentMetallurgy

The invention provides a method for manufacturing a printed circuit board, which comprises the steps of: grinding a copper foil substrate to be processed and chemically processing the copper foil substrate to be processed; coating anticorrosive printing ink on the copper foil in the thickness of between 13 and 18 mu m; pre-baking the coated copper foil at the temperature of between 65 and 85 DEG C for 5 and 10 minutes; exposing the baked copper foil by using a photomask and then developing the exposed copper foil; and baking the obtained product at the temperature of 150 and 155 DEG C for 30 minutes. According to the method for manufacturing the printed circuit board, the printed circuit board can be obtained by coating thinner anticorrosive printing ink, so the use amount of the anticorrosive printing ink can be reduced; besides, the coated film is thinner, so the drying process can be complemented at a low temperature in a short time period, the cost is saved, and the effects of energy conservation and carbon reduction are achieved.

Owner:FULL TREASURE INT ENTERPRISE

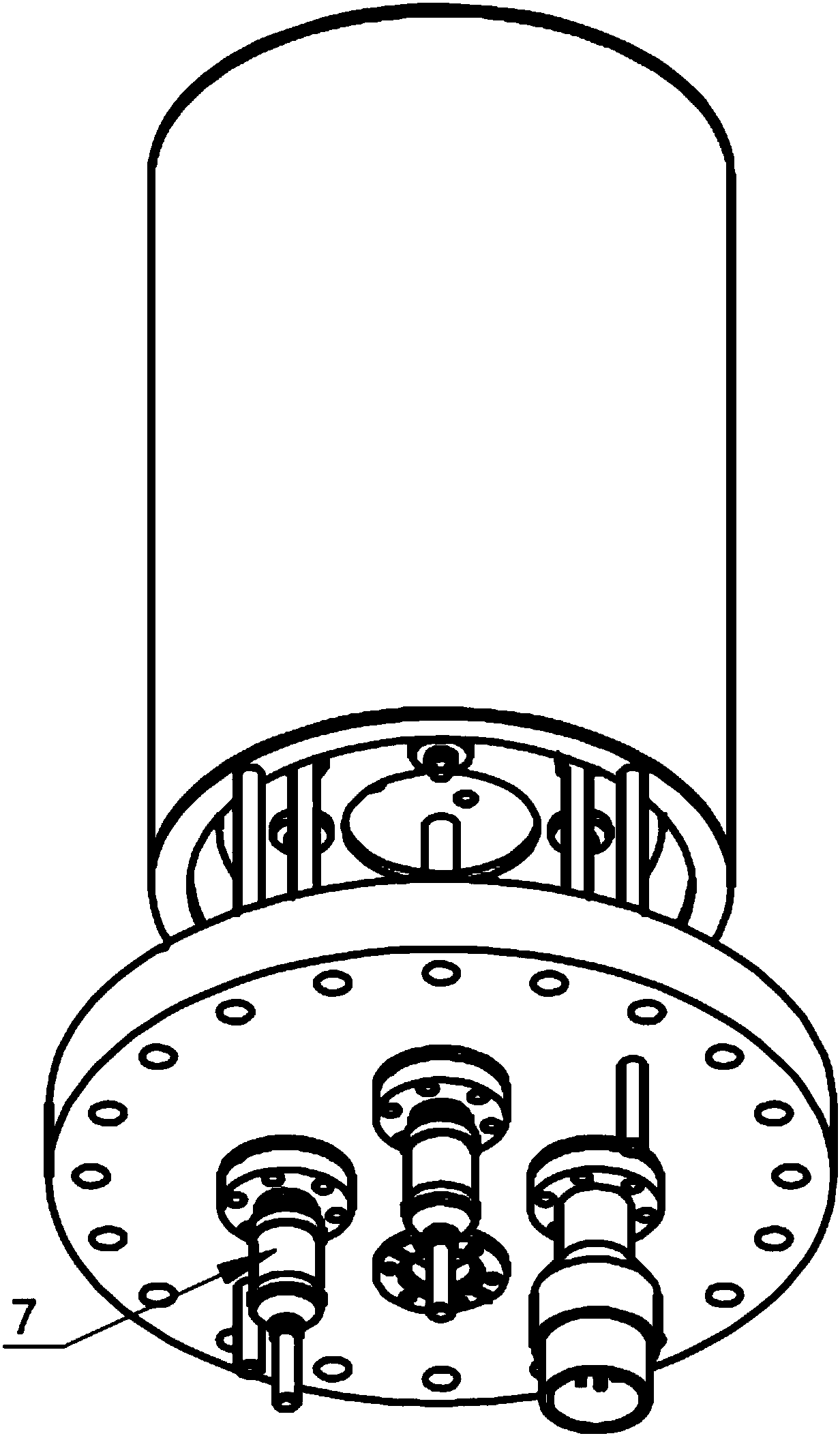

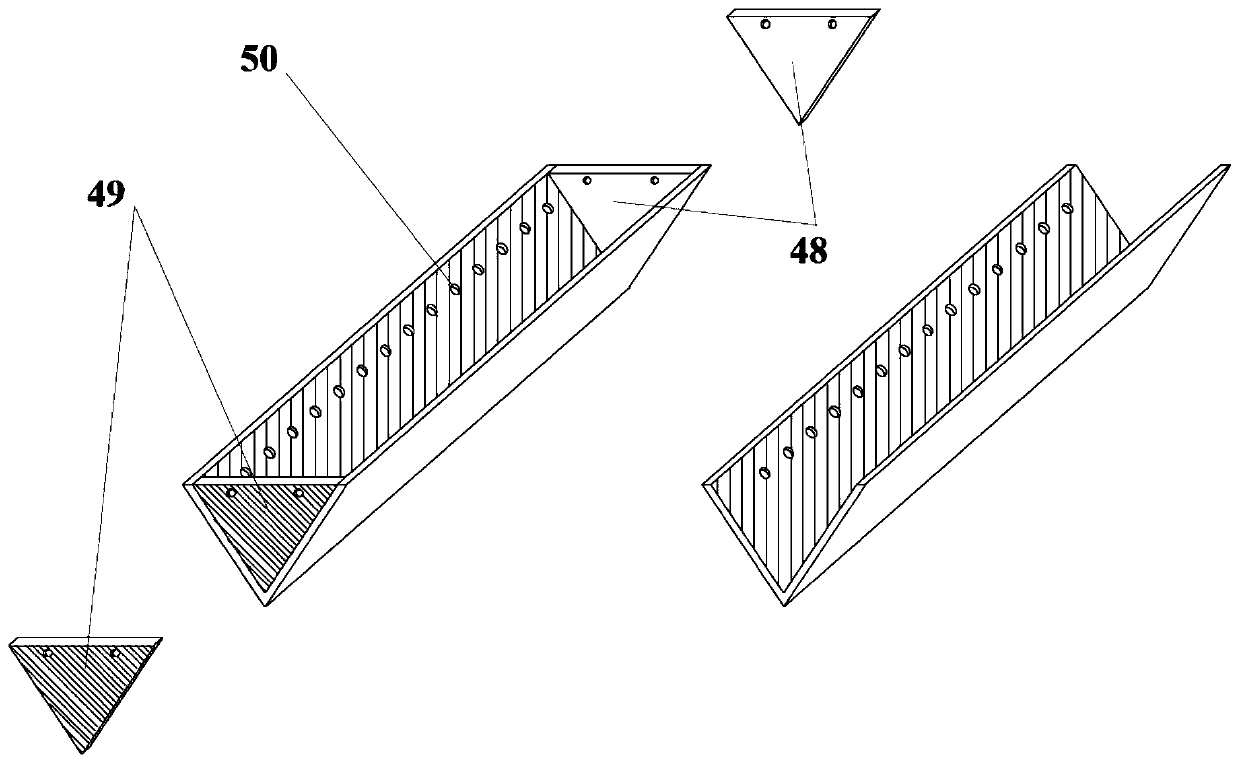

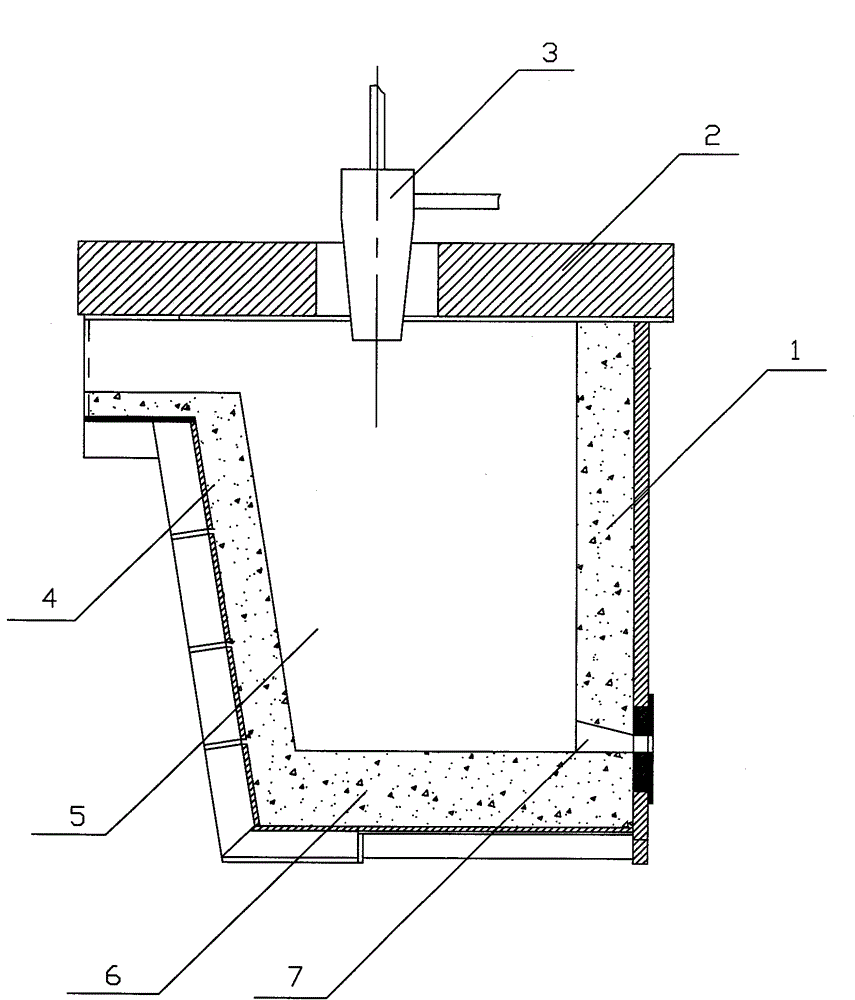

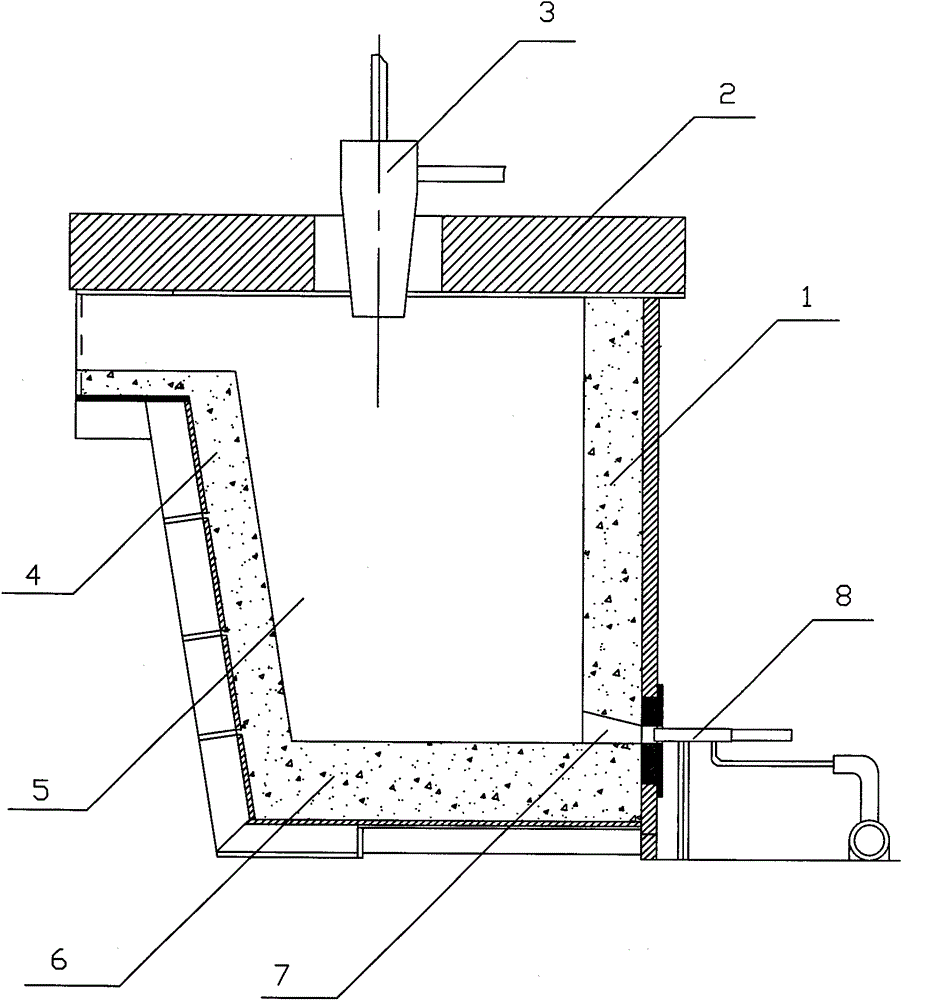

Method for baking horizontal continuous casting tundish and horizontal continuous casting tundish with negative pressure device

ActiveCN101905314AIncrease the baking temperatureEasy to operateMelt-holding vesselsHeat flowAir blower

The invention discloses a method for baking a horizontal continuous casting tundish. In the method, a negative pressure device is arranged at the position of a water port channel to generate a negative pressure at the position of a water port channel for inducing a heat flow in the horizontal continuous casting tundish to the water port channel in a way different from the heat flow for baking theconventional horizontal continuous casting tundish, and thus, the water port and the tundish bottom of the horizontal continuous casting tundish can be baked quickly. The invention also provides the horizontal continuous casting tundish with the negative pressure device. The horizontal continuous casting tundish is a rectangular and conical container with an opening on the upper end, and consistsof the tundish bottom, a front wall, a rear wall and two side faces, wherein a tundish cover is arranged above the tundish; a storage type baking device is arranged on the tundish cover; the tundish water port is arranged below the front wall of the tundish; the negative pressure device is arranged at the position of the water port channel of the tundish; and the negative device consists of an exhaust pipe, a compressed air pipe, an air blower and a bracket.

Owner:衡阳华菱连轧管有限公司

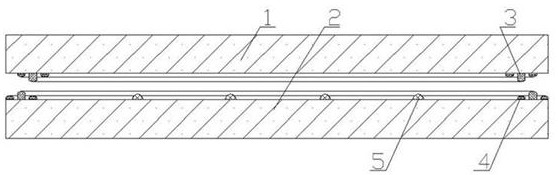

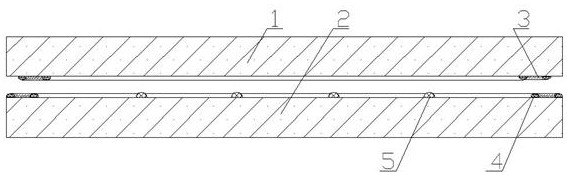

Manufacturing method and production line of tempered vacuum glass

InactiveCN112777953AReduce edge temperatureSolve the problem of foamingGlass tempering apparatusAir tightnessGlass manufacture

The invention discloses a manufacturing method and a production line of tempered vacuum glass, and belongs to the technical field of vacuum glass manufacturing. The manufacturing method disclosed by the invention specifically comprises the following steps of: preparing a glass substrate, coating a glass solder and an isolating bar, respectively drying the glass substrate coated with the glass solder and the isolating bar, directly carrying out high-temperature and quenching toughening treatment on the glass substrate without cooling, and then carrying out sheet combination and vacuum edge sealing. According to the manufacturing method and the production line disclosed by the invention, the defects in the prior art can be overcome, low-cost, large-batch and mechanical production of the tempered vacuum glass can be realized, the air tightness and the service life of the tempered vacuum glass can be effectively ensured, the mechanical strength, the heat insulation performance and the sound insulation performance of the vacuum glass can be improved, and the manufacturing method and the production line are suitable for market popularization and application.

Owner:戴海玥

Preparation method of silver solder paste and silver solder paste product

ActiveCN101837526BImprove utilization efficiencyWell mixedWelding/cutting media/materialsSoldering mediaPotassium fluorideRetention time

The invention provides a preparation method of silver solder paste, which comprises the following steps: 1, preparing raw materials and pretreating the raw material; 2, stirring the raw materials; 3, roasting the raw materials; and 4 grinding the raw materials. The invention also provides silver solder paste prepared by the method. The silver solder paste is prepared from the following raw materials in percentage by weight: boric acid 33-38, potassium fluoborate 28-32, potassium fluoride 20-25, monomer boron 2.0-2.5 and distilled water 10-20. Compared with the prior art, the method has the advantages of stable product quality and high material utilization rate. The product has the characteristics of long soldering high-temperature life, long activity retention time, high solder wettability and high soldered joint quality.

Owner:HUIZHOU WUFU IND TECH

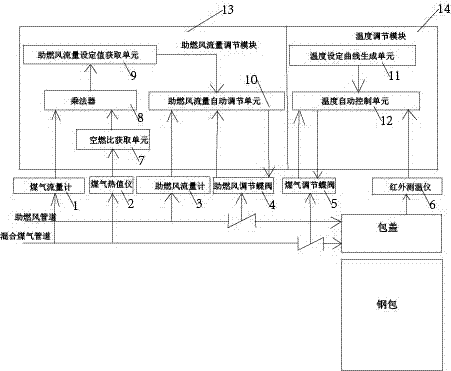

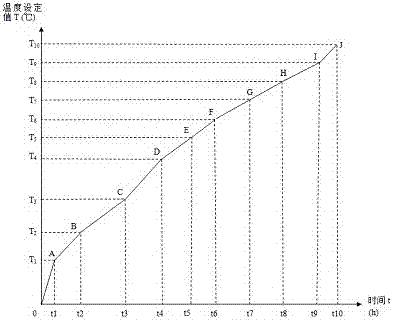

Temperature control device and temperature control method

PendingCN107092187AAccurate measurementEasy to controlMelt-holding vesselsControlling ratio of multiple fluid flowsSteelmakingButterfly valve

The invention discloses a temperature control device and a temperature control method, which relate to the technical field of steel making. The temperature control device comprises a combustion-supporting air flow regulating module and a temperature regulating module, wherein the combustion-supporting air flow regulating module is connected with a mixed gas pipeline through a gas flow meter; the combustion-supporting air flow regulating module is connected with the mixed gas pipeline through a gas calorimeter; the combustion-supporting air flow regulating module is connected with a combustion-supporting air pipeline through a combustion-supporting air flow meter; the combustion-supporting air flow regulating module is connected with the combustion-supporting air pipeline through a combustion-supporting air regulating butterfly valve; the temperature regulating module acquires the temperature of a clad through an infrared thermometer; and the temperature regulating module is connected with the mixed gas pipeline through a gas regulating butterfly valve, electric signals are acquired, and according to the electric signals, the gas regulating valve is controlled to regulate the flow of the gas in the mixed gas pipeline. Thus, the operation is simple and convenient; accurate measurement and accurate control on the temperature are realized; energy is saved; the product quality is ensured; the service life of a ladle heater is prolonged; and the cost is saved.

Owner:HEBEI IRON AND STEEL

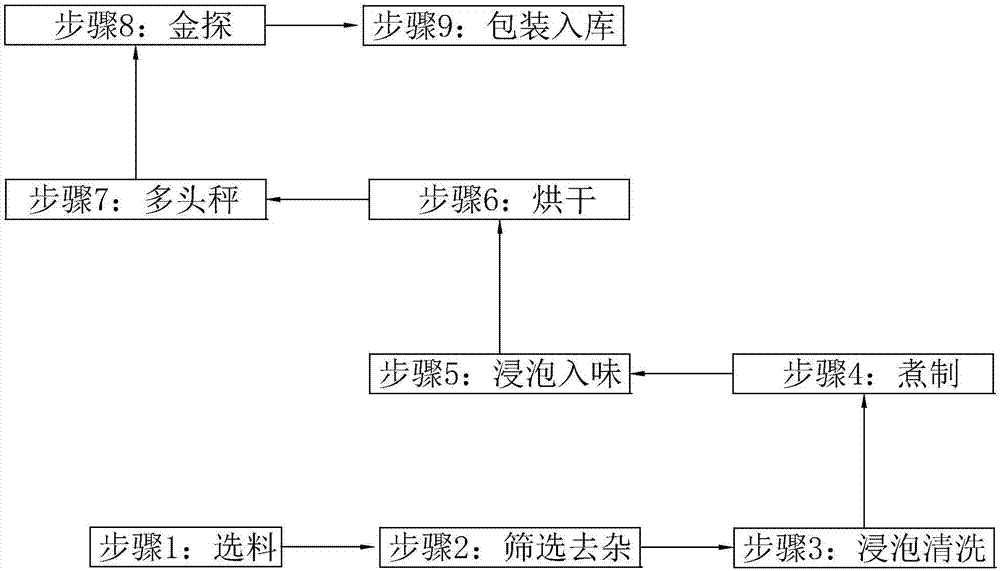

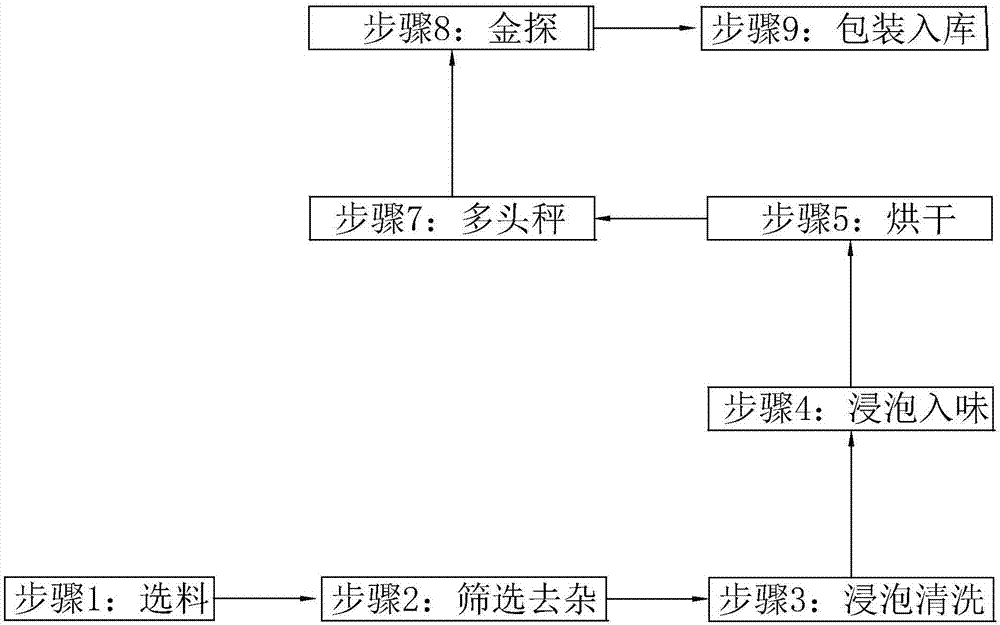

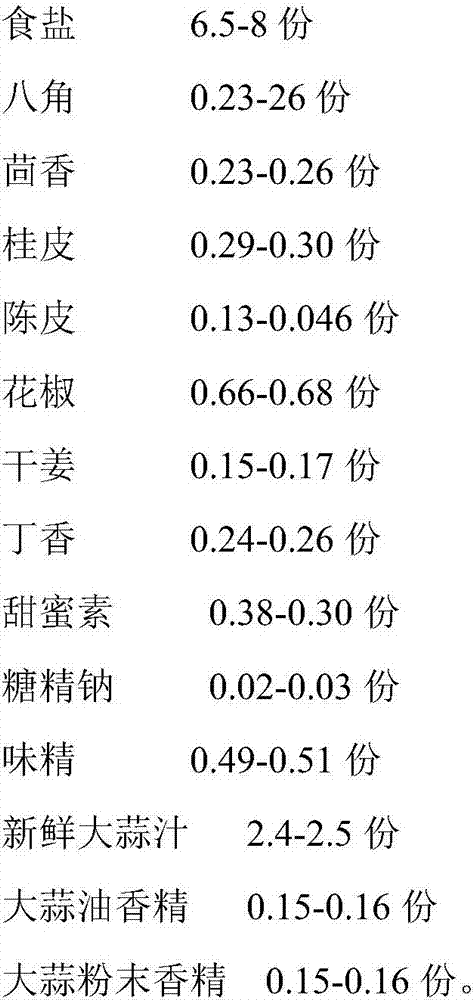

Production technology of peanuts

The invention relates to a production technology of peanuts. The production technology comprises the following steps of step 1, selecting materials; step 2, performing sieving and impurity removing; step 3, performing soaking and washing; step 4, performing boiling; step 5, performing soaking to enable the boiled peanuts to be tasteful; step 6, performing drying; step 7, performing weighting by amulti-head weigher; step 8, performing metal detection; and step 9, performing packing and warehousing. In the braising process, seed coats of the peanuts are soaked in braising juice, so that moisture in the seed coats is sufficiently maintained, and the phenomenon that the seed coats come off cannot be easily generated; then the peanuts are put in seasonings, so that through the moisture on thesurface of the seed coats, the situation that the seasonings are adhered onto the surfaces of the peanuts is facilitated; and then in the roasting process, the seasonings packed outside the peanuts are heated in advance and dehydrated to form a housing packing the outer part of the corresponding peanut; and when heat quantity is conducted to the inner parts of the peanuts by the housings, under the block of the housings, the moisture in the seed coats of the peanuts is difficult to disperse outwards, and flexibility is still kept to a certain extent, so that the phenomenon that the seed coatscome off cannot be easily generated.

Owner:青岛胶平食品有限公司

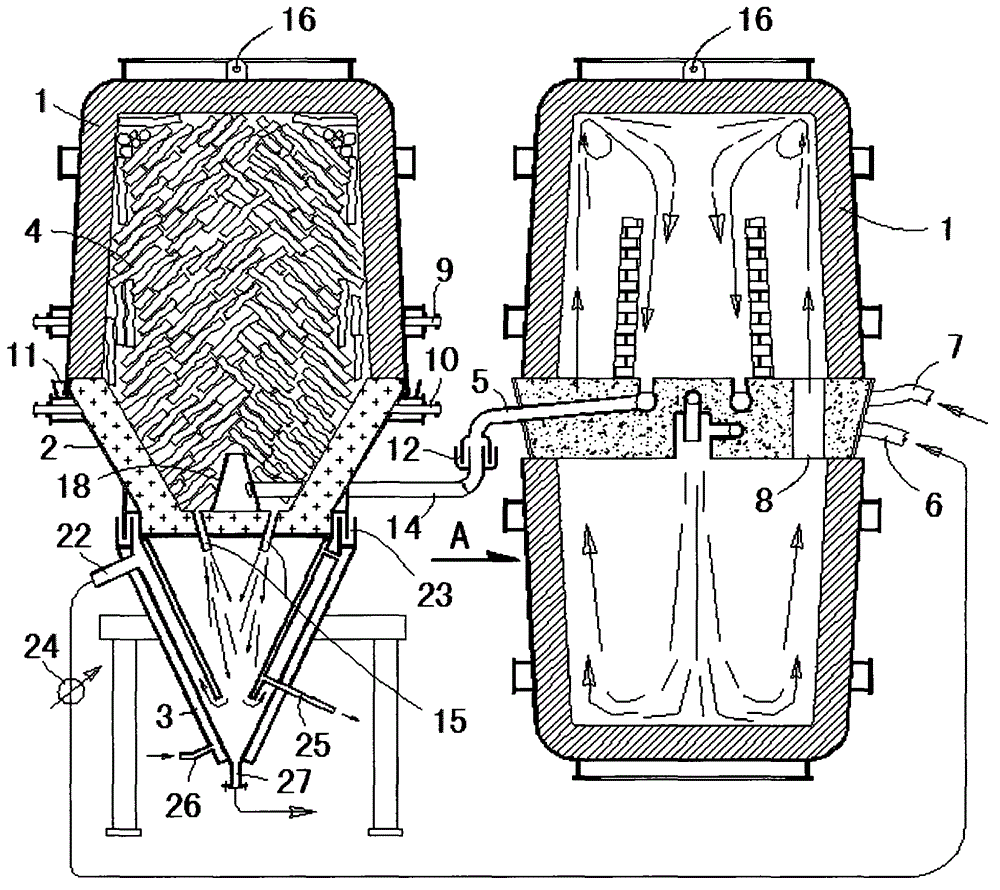

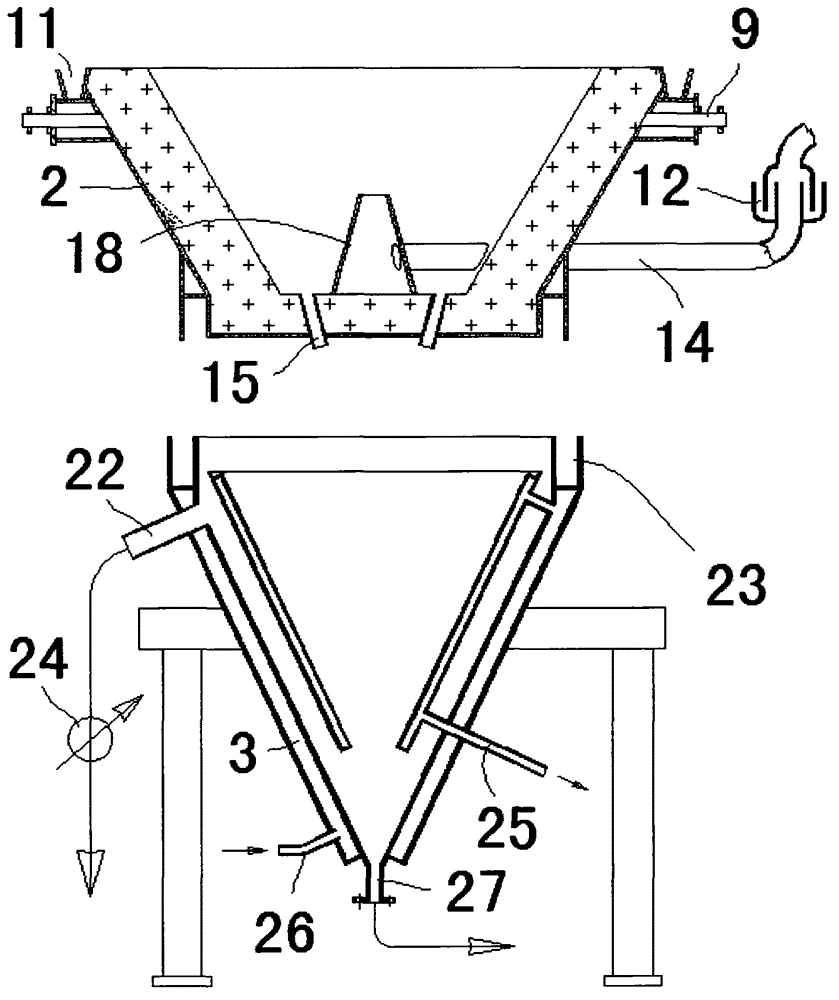

Charcoal-burning tank roasting device

The invention discloses a charcoal-burning tank roasting device. The device comprises a tank (1), a cone base (2) and a water cooling cone (3), wherein the tank (1) is filled with coal and firewood (4) and buckled on a tank sand seal (11) of the cone base (2), the cone base (2) is arranged on a bottom sand seal (23) of the water cooling cone (3), multiple bottom pipes (15) are arranged on the bottom of the cone base (2) in an annular mode, a smoke port (18) is arranged between the bottom pipes (15) and communicated with a smoke receiving pipe (14), the smoke receiving pipe (14) is communicated with a tank roasting cover smoke vent (5) through a smoke pipe sand seal (12), hot smoke generated by tank roasting passes through the smoke vent (5), the smoke pipe sand seal (12) and the smoke receiving pipe (14) to heat the coal and firewood (4) upwards through the smoke port (18), then destructive distillation is conducted on the coal and firewood (4) to form carbon, coal gas and tar for destructive distillation of the coal and firewood (4) flow downwards and enter the water cooling cone (3) to be cooled through the bottom pipes (15), tar is discharged through a tar port (27), and coal gas is discharged through a coal gas port (22).

Owner:边仁杰

A kind of water-based coating containing high hydroxyl methyl etherified melamine resin and preparation method thereof

ActiveCN103694846BImprove water separation tendencyPrevent spoilage and demulsificationCoatingsWater basedAluminum silicate

The invention belongs to the technical field of paint, and particularly relates to a water-based paint containing high-hydroxyl methylated melamine resin and a preparation method thereof. The paint containing high-hydroxyl methylated melamine resin comprises the following raw materials: water, ethylene glycol, ultrafine aluminum silicate, titanium dioxide, kaolin and high-hydroxyl methylated melamine resin. By adding the high-hydroxyl methylated melamine resin into the paint, the medium and shear viscosity is greatly improved, the water distribution trend of the paint is improved, and the storage period of the paint is prolonged.

Owner:SHANDONG ZHANHUA OSITER CHEM

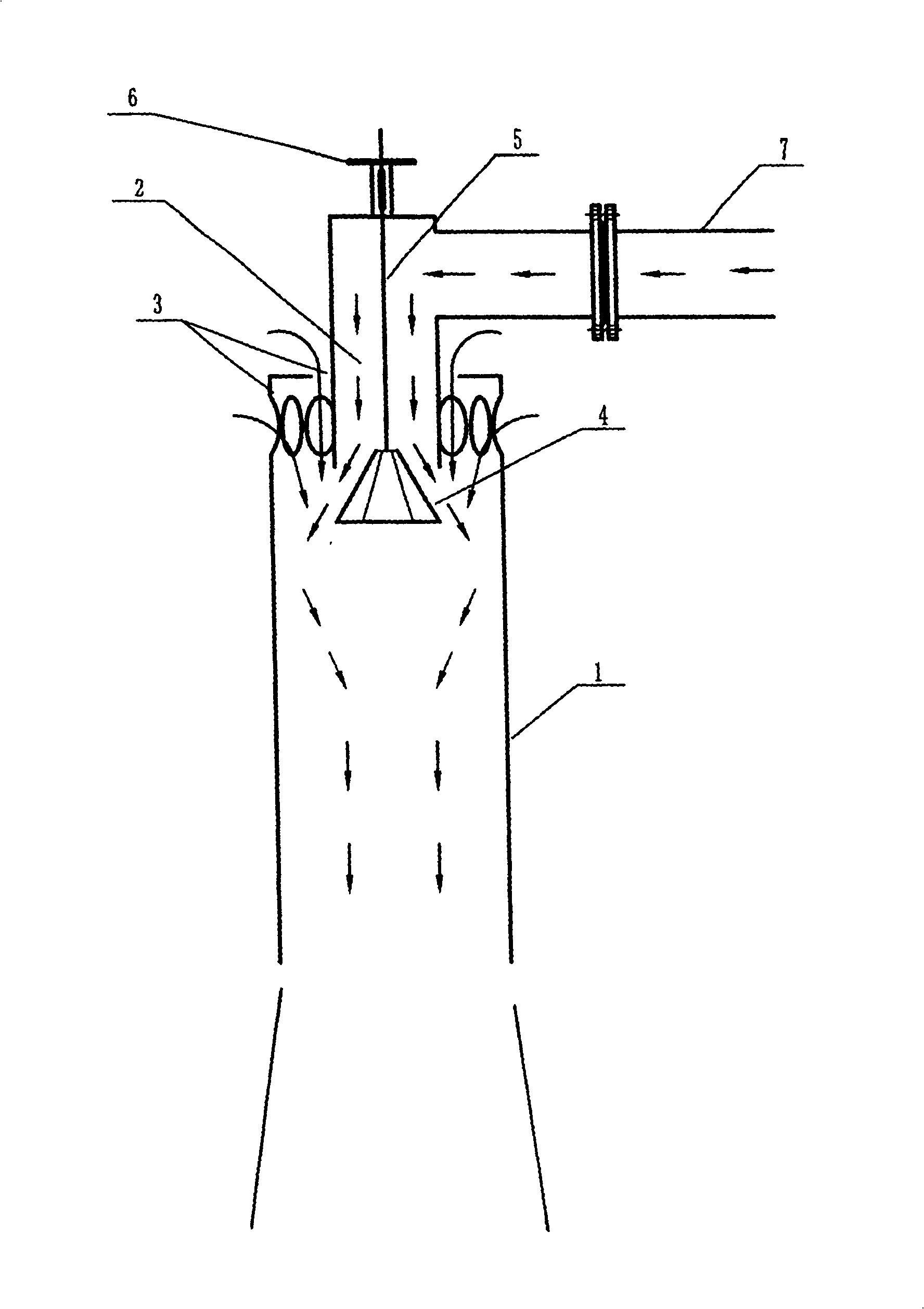

Internal combustion blast furnace gas special nozzle with pyramid trustum jet device

InactiveCN100427827CFacilitate chemical reactionsSolve the problem of flameoutGaseous fuel burnerCombustionBlast furnace gas

The invention discloses internal fire type blast furnace gas special burner nozzle with prismatic table body fluidizing device. It has the advantages of reasonable structure, convenient using, and normal firing. Its structure is as follows: it has nozzle set at one end of burner tube, and in which is set matching prismatic table body fluidizing device; and the burner tube is set at least one air hole at corresponding place.

Owner:王志祥

A casting machine slag ditch baking device and baking method

The invention discloses a cast iron machine slag ditch baking device and a baking method, comprising a hollow baking oven arranged above the molten iron along the flowing direction of the molten iron, the baking oven is a long box preheating box with a concave cross section and / or Or a square box with a square structure, the upper end surface and / or side of the oven is provided with a plurality of air inlets, the middle of the oven is provided with a burner, and the burner penetrates to the bottom surface of the oven. The roasting device of the present invention uses molten iron radiant heat to heat the air, which can increase the roasting temperature, shorten the roasting time, reduce heat pollution and improve the roasting effect. Meet the pouring temperature of the existing cast iron machine.

Owner:襄阳鑫锐机械科技有限公司

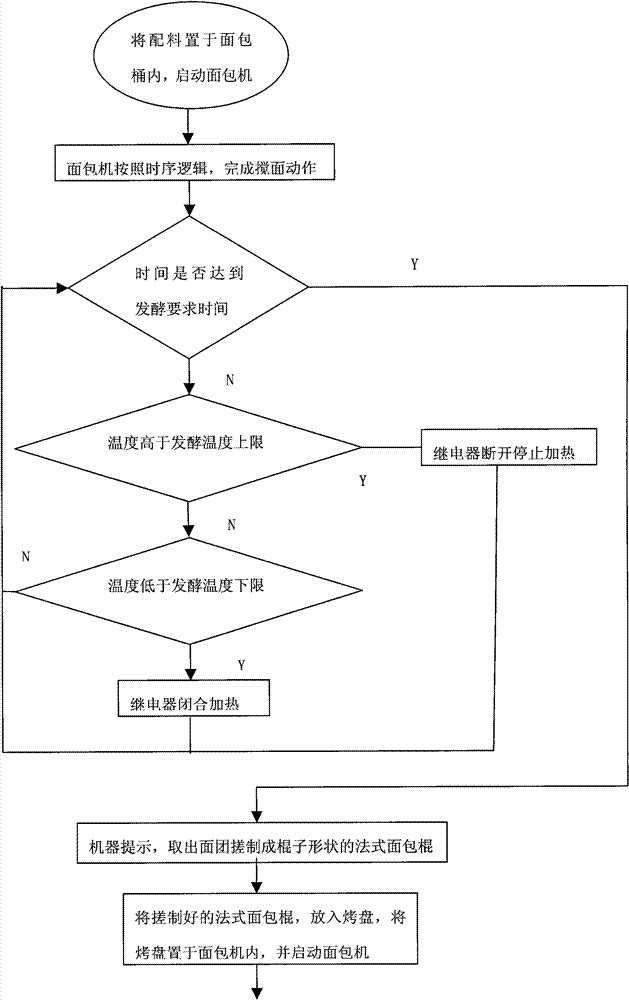

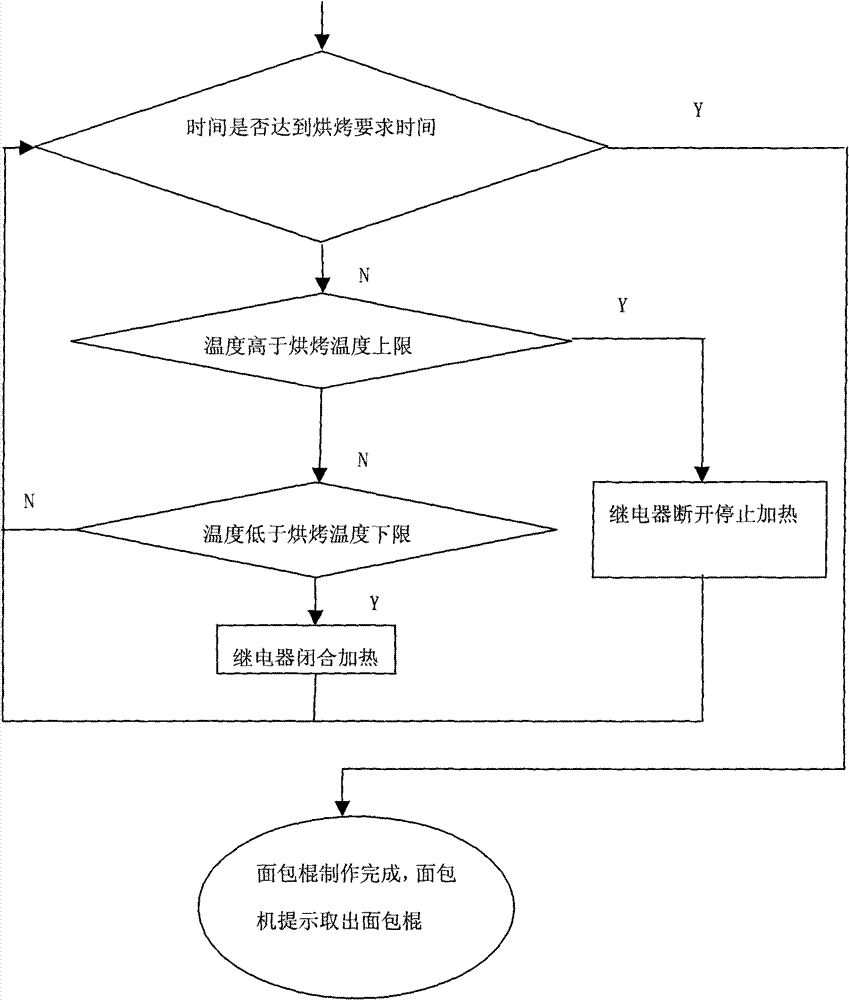

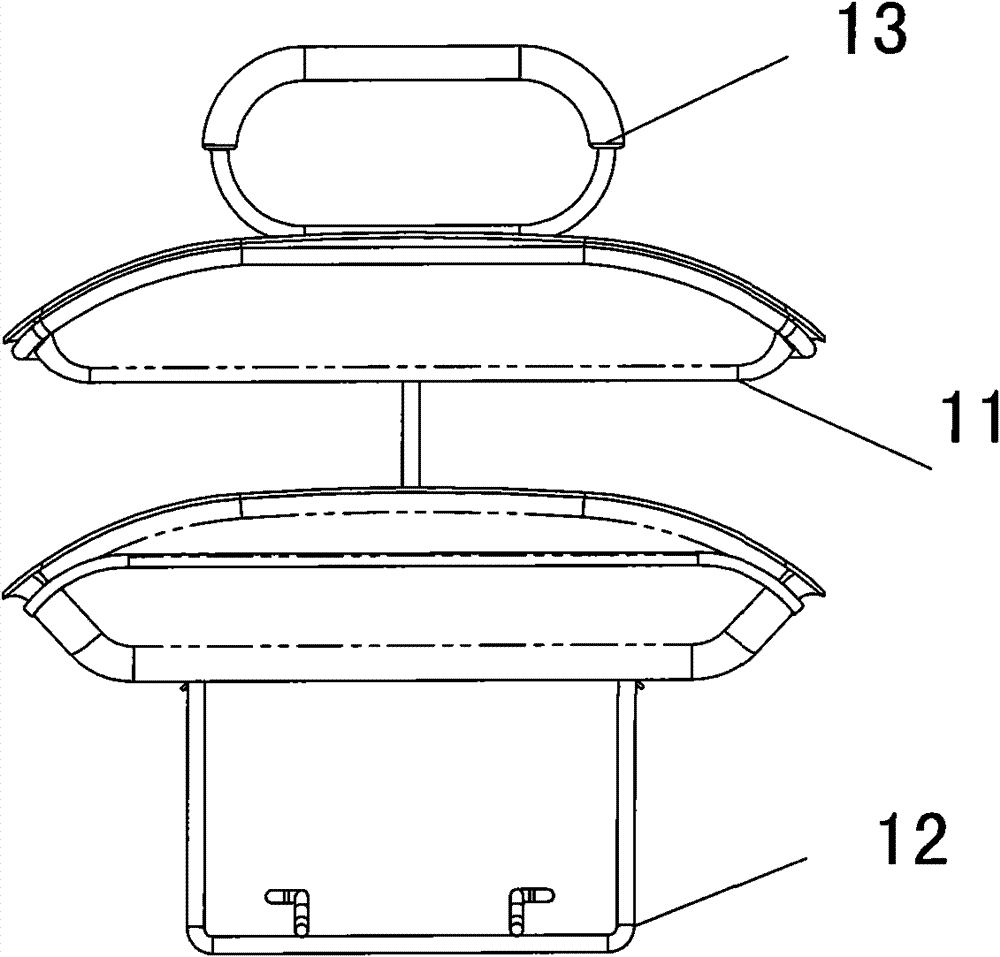

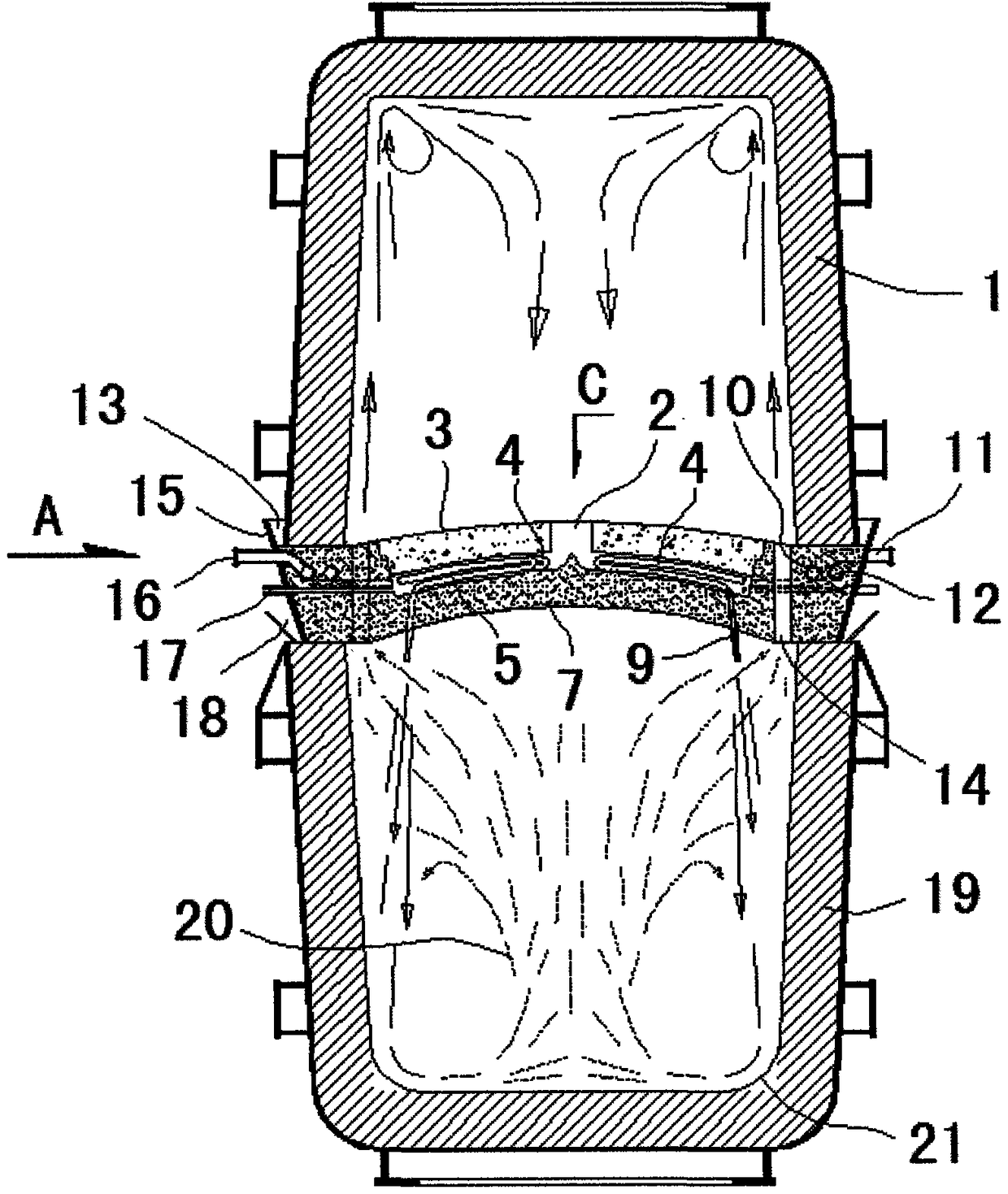

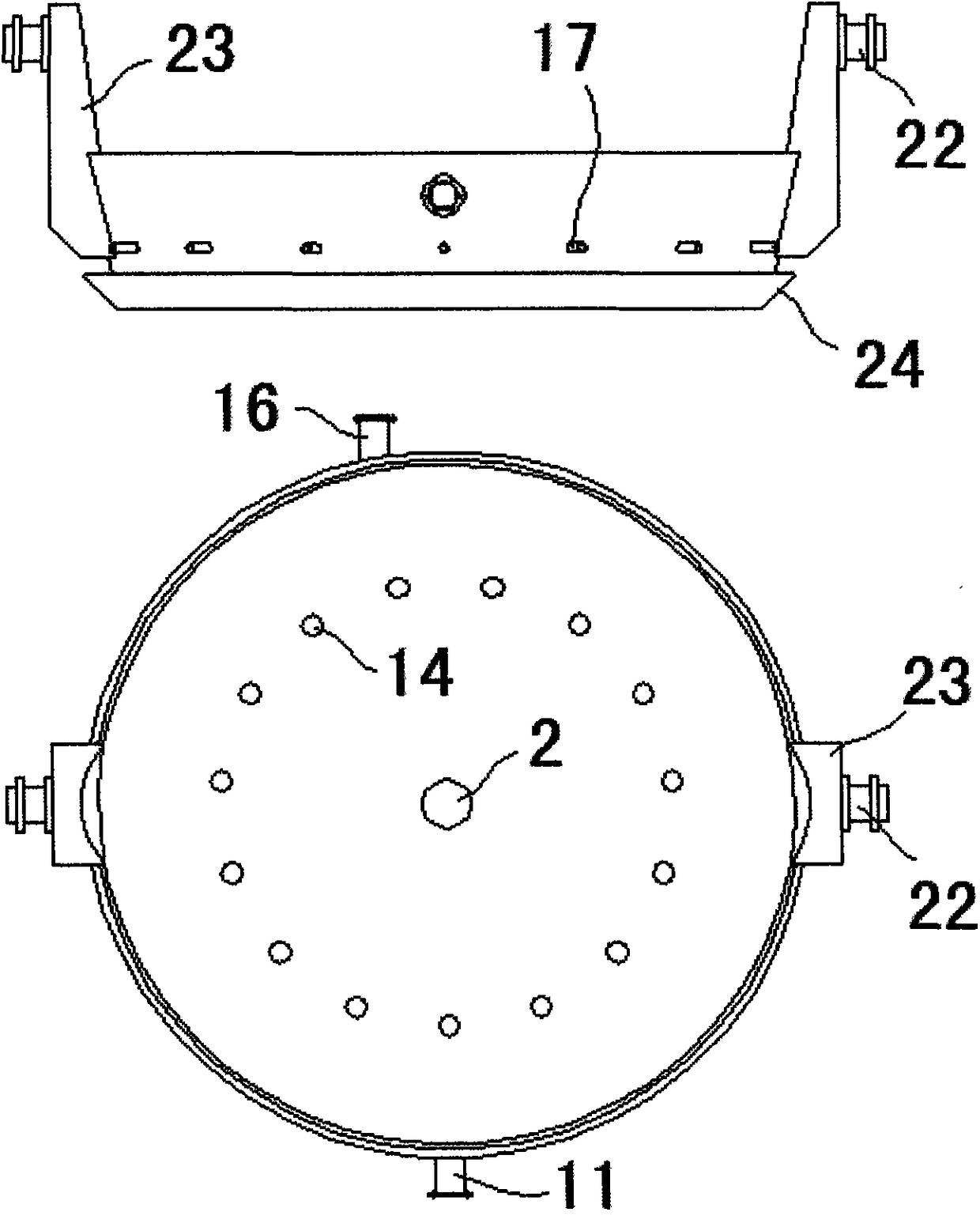

Bread machine capable of manufacturing baguette and manufacturing method of baguette

ActiveCN101933768BHigh degree of automationEnsure consistencyBakery productsRoasters/grillsHeating elementSurface plate

The invention provides a bread machine capable of manufacturing baguette and a manufacturing method of baguette, which can realize the step of twisting and shaping the baguette, can provide high enough baking temperature and increases the manufacturing flavour of bread specimens. The invention is realized by the following technical scheme: the bread machine capable of manufacturing baguette comprises an outer shell, an oven arranged in the outer shell and an upper cover installed on the top of the outer shell, wherein the outer shell is provided with a control panel; the upper cover, the ovenand the outer shell surround to form a sealed manufacturing cavity; the manufacturing cavity in the bread machine is internally provided with a heating element and is also provided with a baking trayassembly capable of baking the baguette; the baking tray assembly comprises more than one baking trays and a bracket for fixing the braking trays, wherein the bracket is fixed on the oven, and the baking trays are placed on the bracket; and the control panel is provided with a control device for manufacturing the baguette.

Owner:ELEC TECH ZHUHAI CO LTD

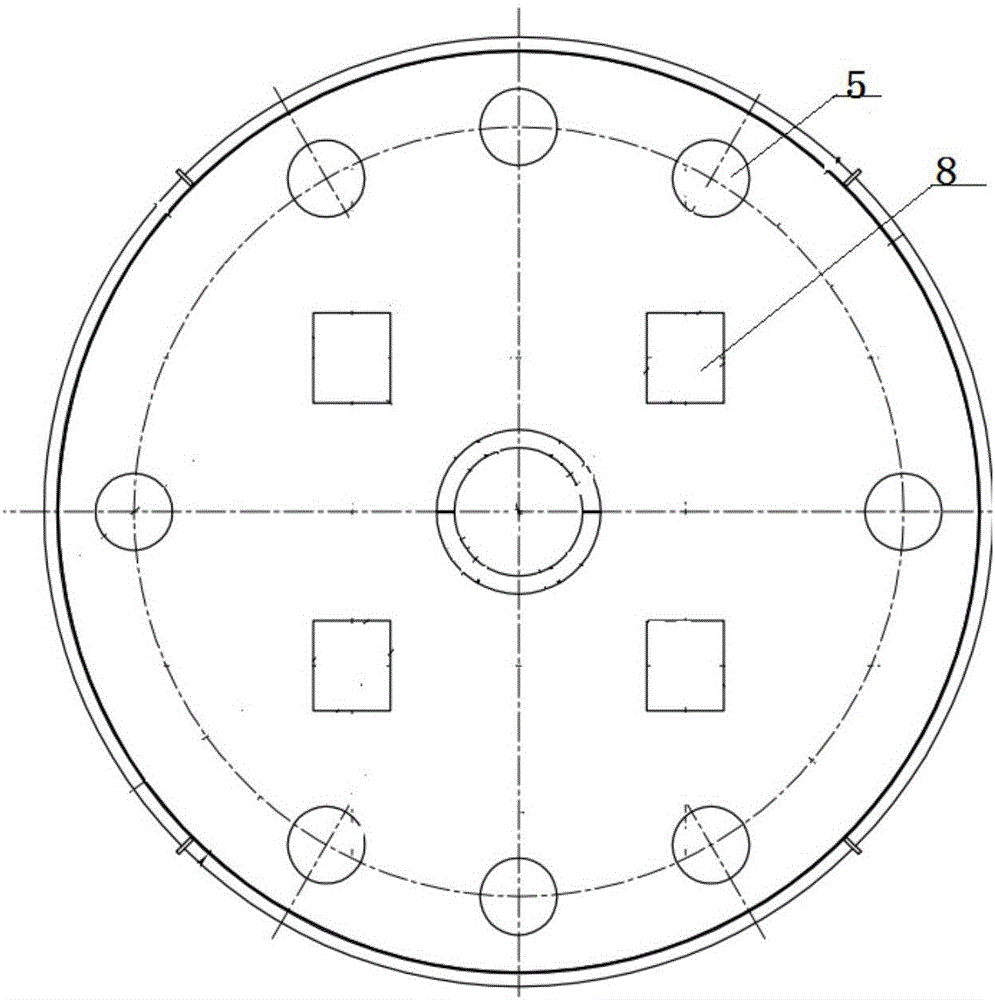

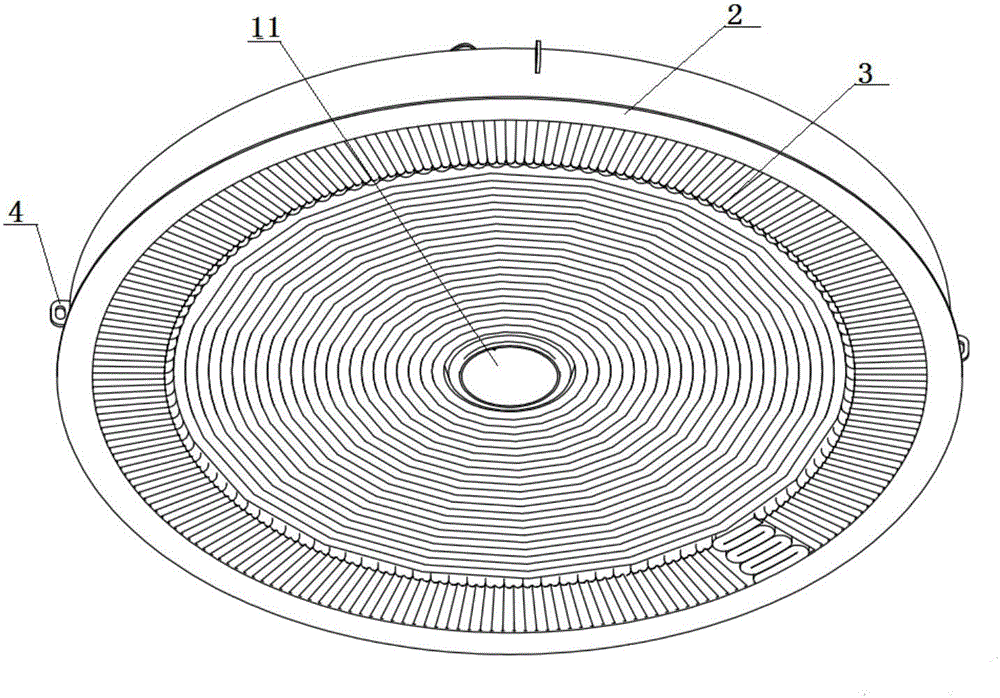

A barrel lid for baking

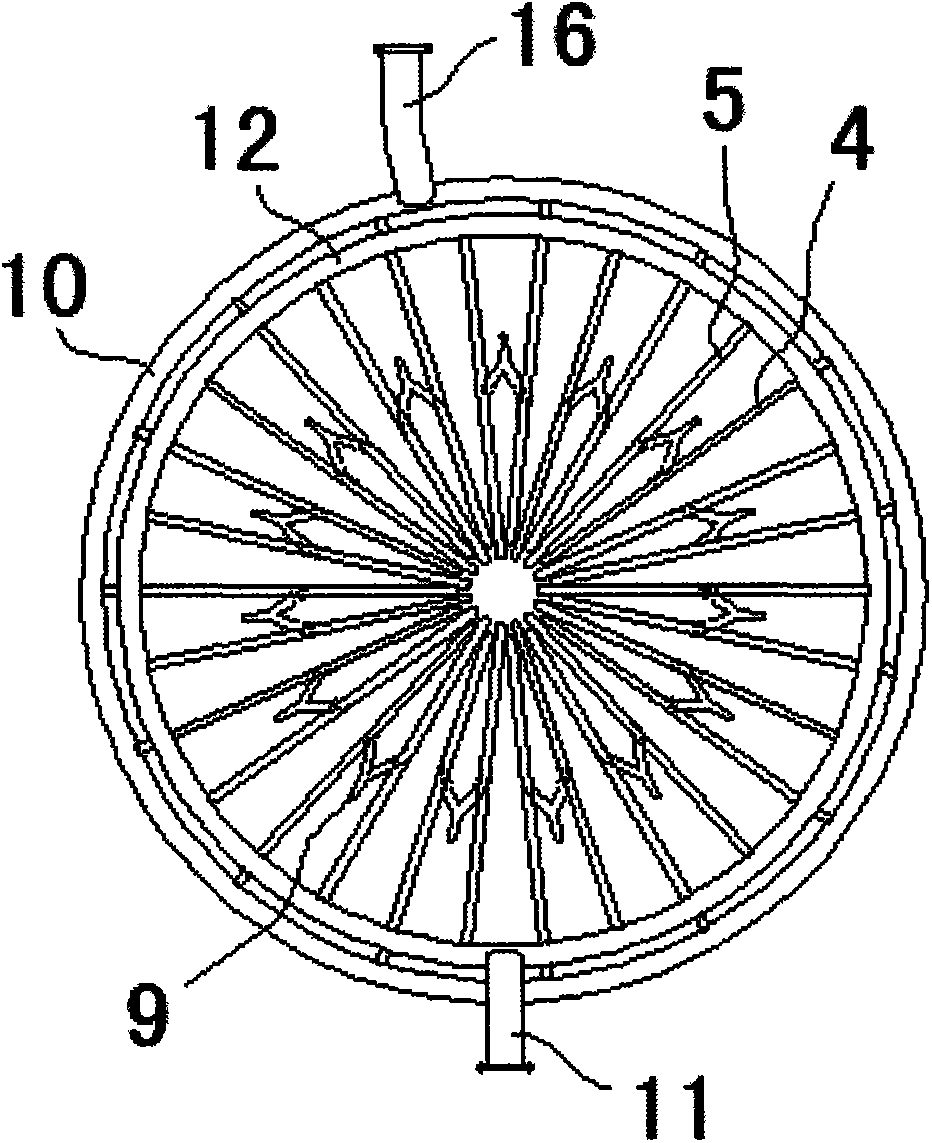

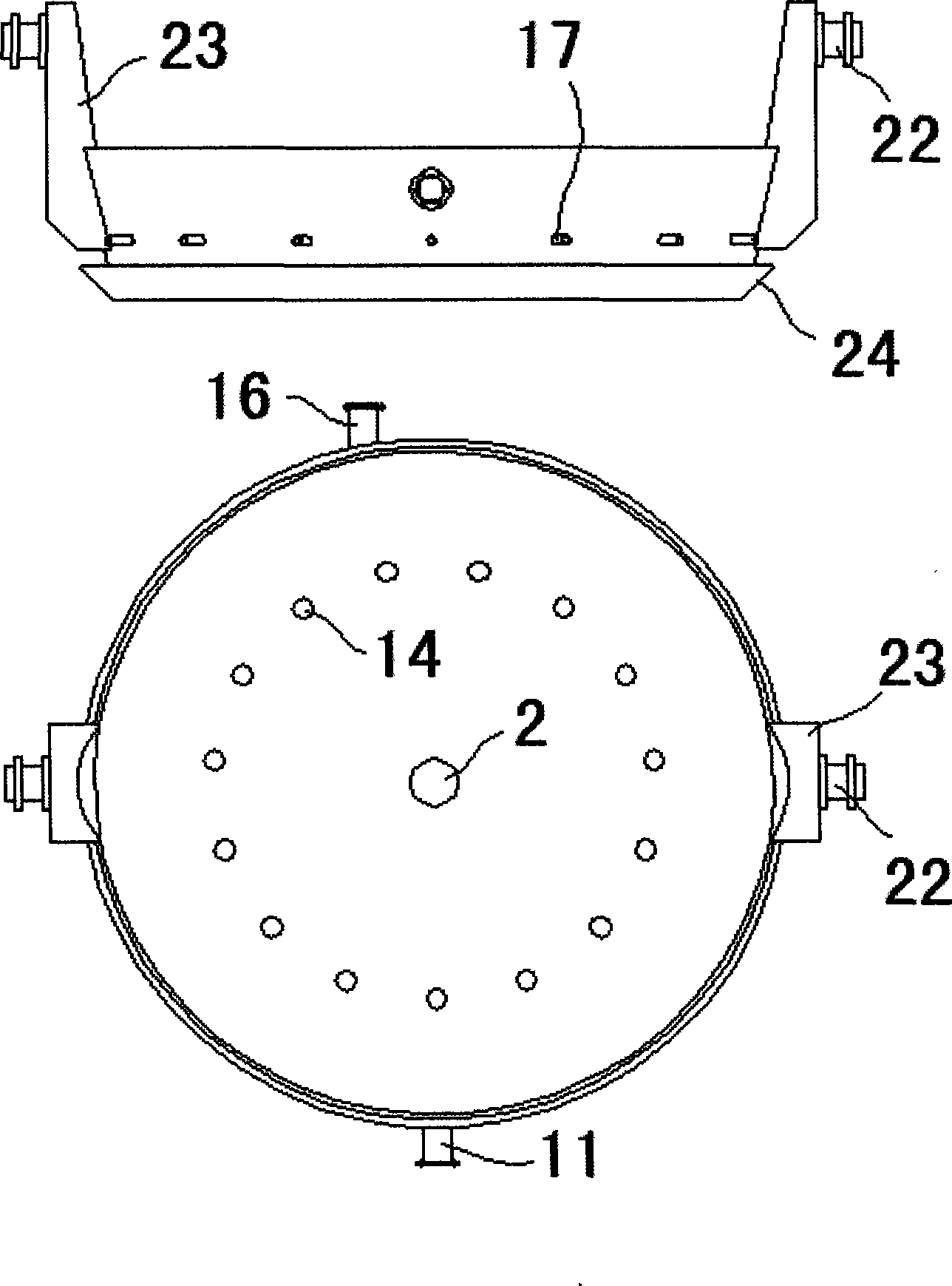

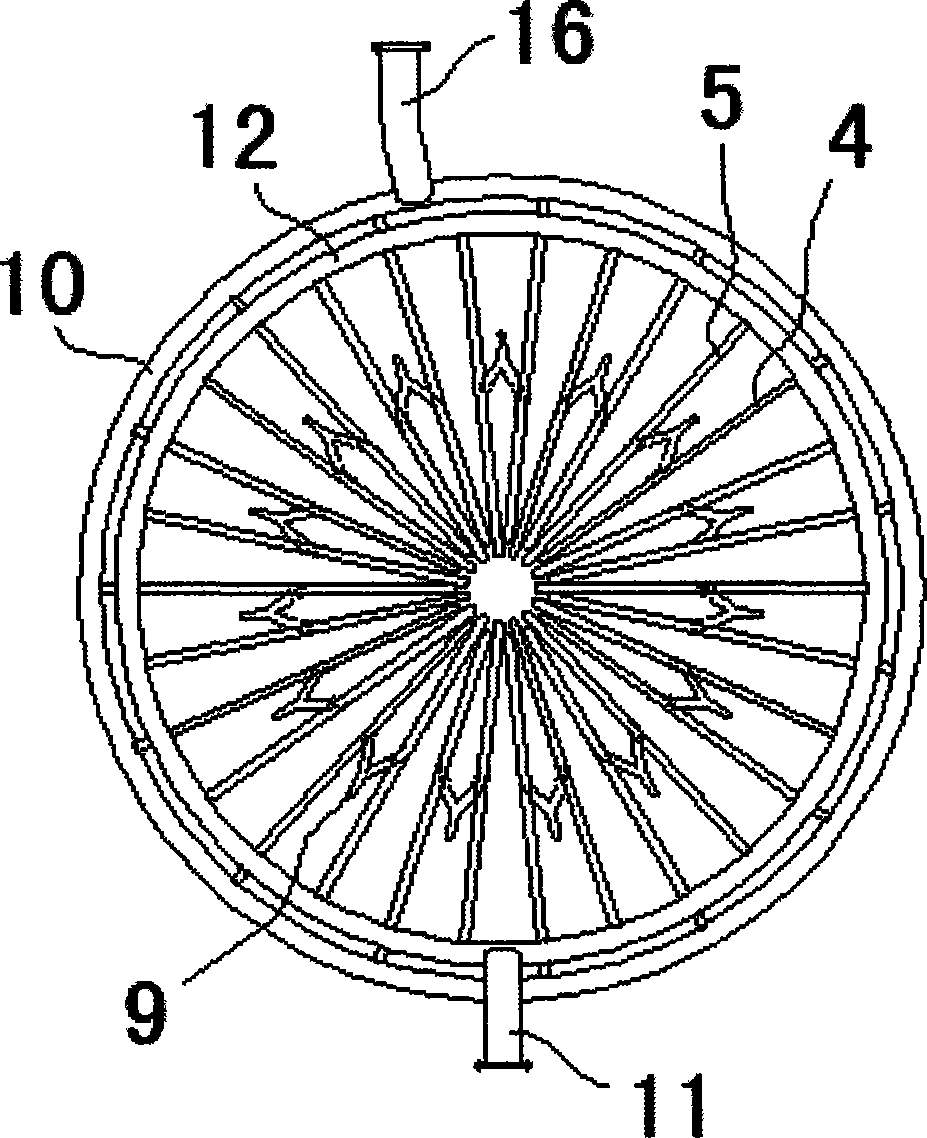

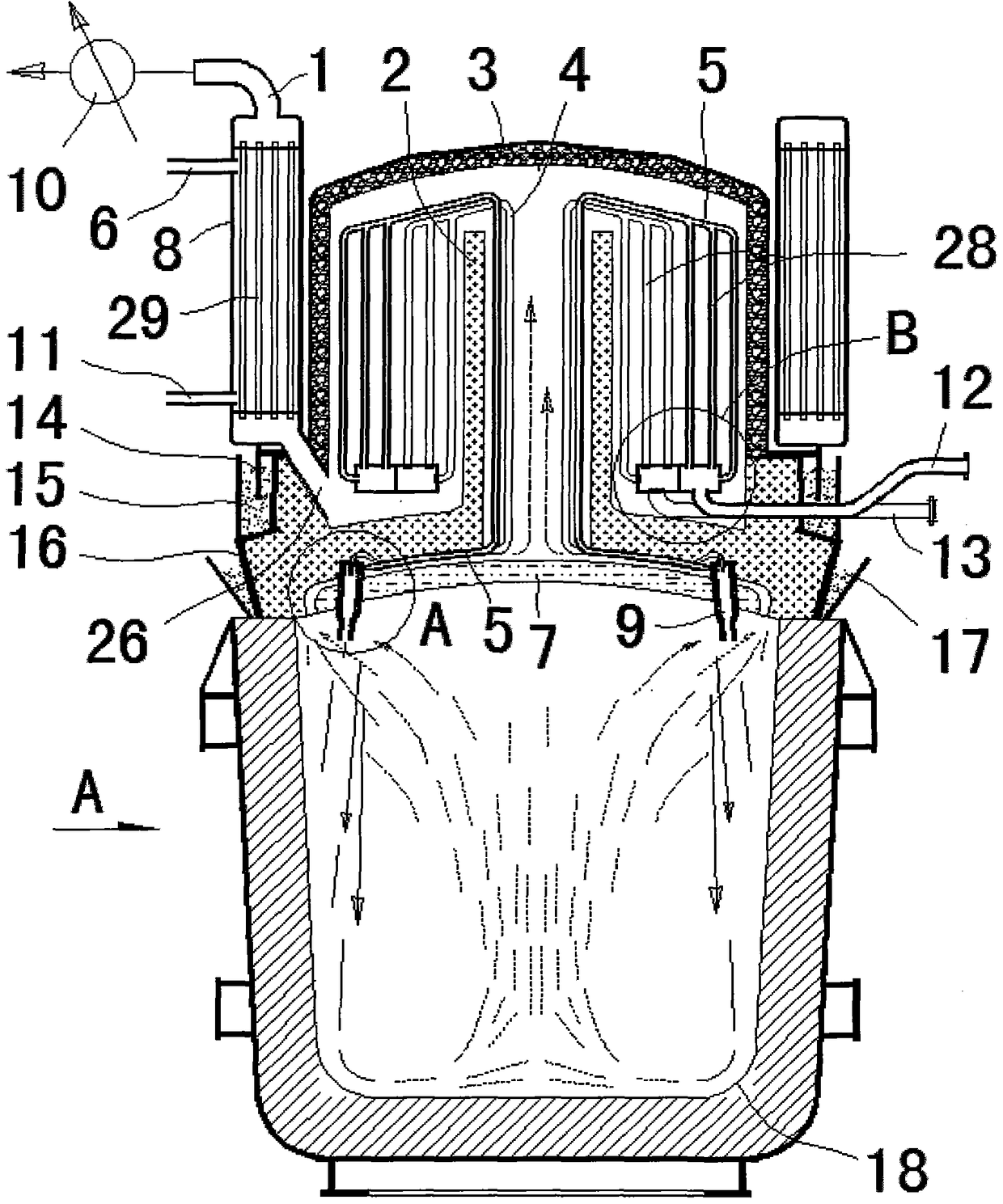

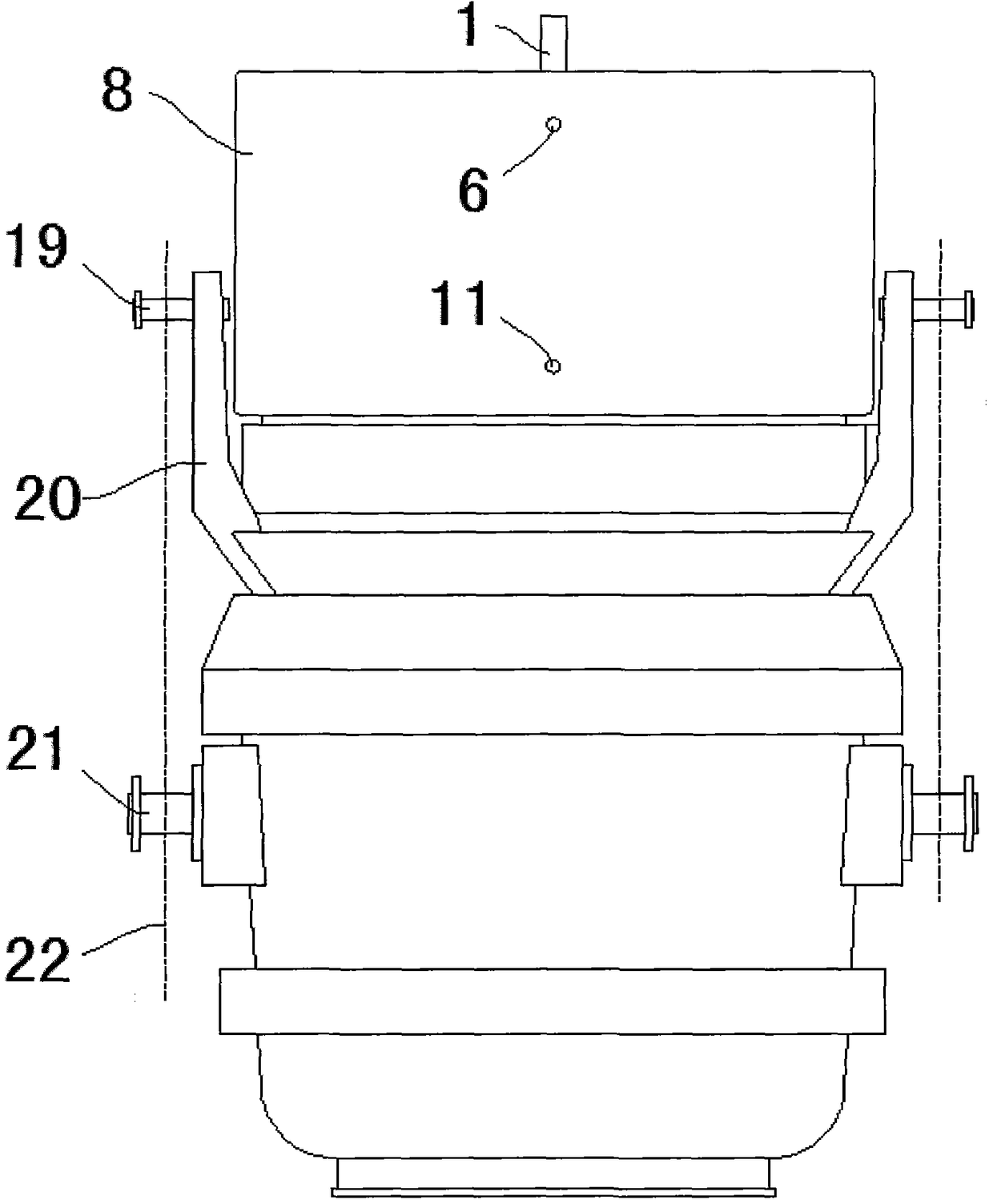

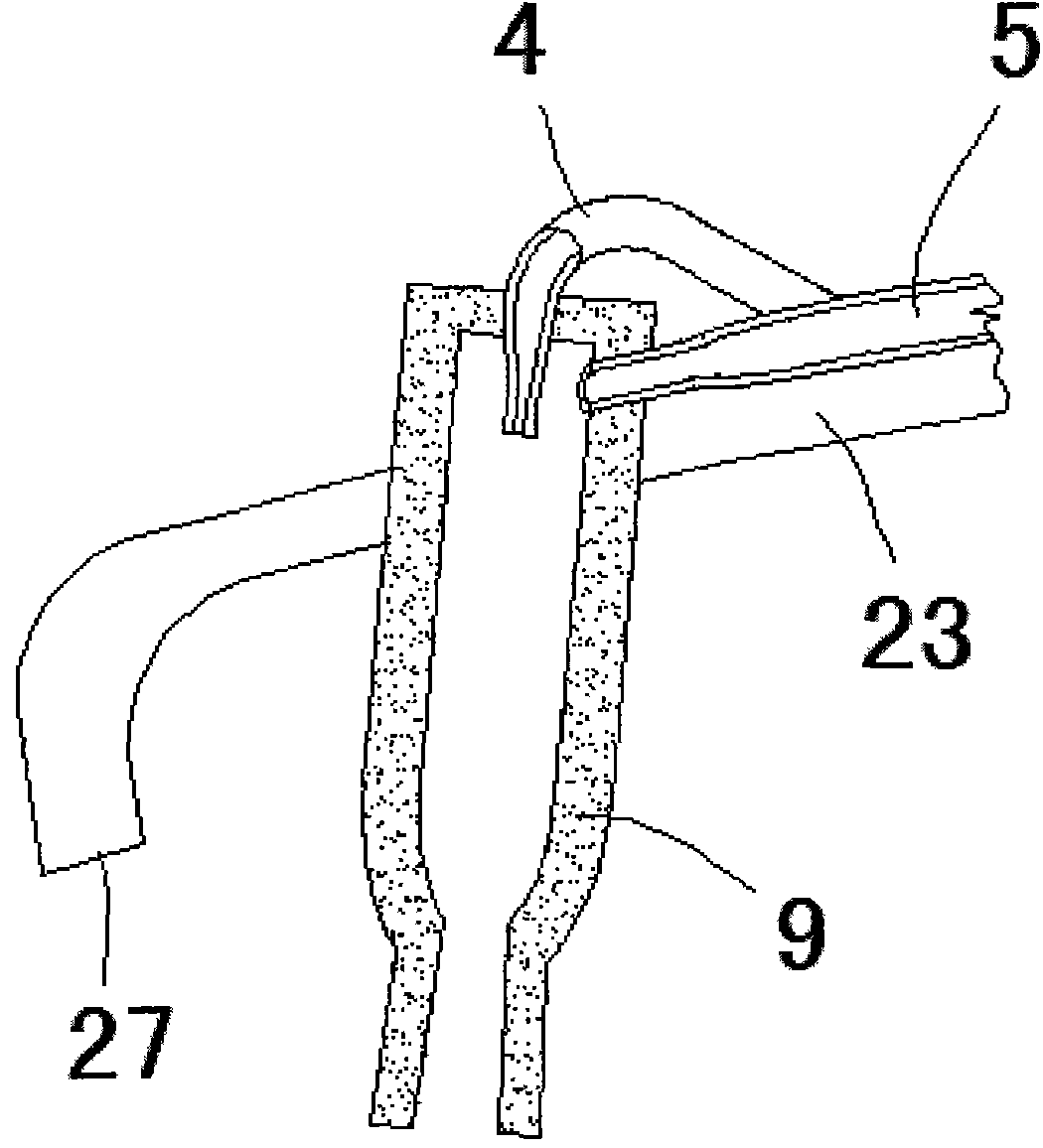

ActiveCN104057074BAvoid relatively fluid defectsIncrease the heat exchange areaMelt-holding vesselsEngineeringNozzle

The invention discloses a cover for barrel roasting. The cover comprises an arch hoop (15), an arch (7) arranged in the arch hoop (15) in a bearing mode and an arch cover (3) arranged on the arch (7). An interlayer cavity is formed between the arch (7) and the arch cover (3), a roasting burning device is disposed in the interlayer cavity, a fire inlet (2) is formed in the center of the arch cover (3), the fire inlet (2) guides flames to heat a roasting device, the roasting device is provided with multiple gas pipes (4) and air pipes (5) of the same number, the gas pipes (4) and the air pipes (5) are distributed in a radial mode with the axis as the center, each gas pipe (4) and front section fluid of the corresponding air pipe (5) are communicated with the same double-pipe nozzle (9), the double-pipe nozzles (9) are distributed circumferentially to eject the flames, the flames roast two barrel liners made of fire-resistant materials, and all the directions of the ejected flames are towards the upper portion of an intersection corner portion (21) of a barrel body and a barrel bottom.

Owner:武安市飞翔金属制品有限公司

A production process for continuous casting of ultra-high manganese steel

The invention belongs to the technical field of metallurgy continuous casting and particularly relates to an extra-high manganese steel continuous casting production technology. The extra-high manganese steel continuous casting production technology is characterized by comprising cooling a reduced casting-time first-tank steel liquid in a tundish, cooling the reduced casting-time first-tank steel liquid in a crystallizer and preventing a shell inside the crystallizer from being broken, wherein for the cooling of the reduced casting-time first-tank steel liquid in the tundish, in the tundish baking stage, coal gas, air and combustion-supporting oxygen are used for improving the coal gas combustion efficiency; for the cooling of the reduced casting-time first-tank steel liquid in the crystallizer, the flow of cooling water in the crystallizer is controlled to be within 200-260m<3> / h in the casting starting stage; and for the prevention of the shell inside the crystallizer from being broken, the thickness of the shell in the casting starting stage is increased, and the pulling rate variation amplitude in the casting starting stage is reduced. Compared with the prior art, the technology has the advantages that the smooth casting starting of the high-alloy steel grade comprising about 0.60% of the carbon content and about 20% of the manganese content is achieved.

Owner:ANGANG STEEL CO LTD

Cover for barrel roasting

ActiveCN104057074AAvoid relatively fluid defectsIncrease the heat exchange areaMelt-holding vesselsEngineeringNozzle

The invention discloses a cover for barrel roasting. The cover comprises an arch hoop (15), an arch (7) arranged in the arch hoop (15) in a bearing mode and an arch cover (3) arranged on the arch (7). An interlayer cavity is formed between the arch (7) and the arch cover (3), a roasting burning device is disposed in the interlayer cavity, a fire inlet (2) is formed in the center of the arch cover (3), the fire inlet (2) guides flames to heat a roasting device, the roasting device is provided with multiple gas pipes (4) and air pipes (5) of the same number, the gas pipes (4) and the air pipes (5) are distributed in a radial mode with the axis as the center, each gas pipe (4) and front section fluid of the corresponding air pipe (5) are communicated with the same double-pipe nozzle (9), the double-pipe nozzles (9) are distributed circumferentially to eject the flames, the flames roast two barrel liners made of fire-resistant materials, and all the directions of the ejected flames are towards the upper portion of an intersection corner portion (21) of a barrel body and a barrel bottom.

Owner:武安市飞翔金属制品有限公司

A multi-oxygen intelligent temperature-controlled baking device and its use method

ActiveCN108393475BUniform heating temperatureIncrease the baking temperatureMelt-holding vesselsTemperature controlCombustor

The invention relates to an oxygen-rich intelligent temperature-control ladle baking device and a using method thereof. The ladle baking device is provided with a ladle cover, a ladle liner and a burner assembly, a space is reserved between the outer periphery of the ladle liner and the inner wall of a steel ladle, and a gap is further reserved between the periphery of the ladle cover and the edgeof the upper opening of the steel ladle; a plurality of temperature sensors capable of testing the temperature of the outer wall of the ladle liner are arranged on the wall of the ladle liner; the burner assembly is provided with an igniter, a fuel gas pipe, a combustion-supporting gas pipe and a combustion head, the combustion head extends out of the bottom of the ladle liner, the upper end of the burner assembly extends out of the ladle cover, the burner assembly is fixed in the middle of the ladler cover, and a self-control switch of the igniter, a gas inlet of the fuel gas pipe and a gasinlet of the combustion-supporting gas pipe are arranged at the upper end of the burner assembly; and the ladle baking device is further provided with a PLC, and the PLC is in signal and control connection with the temperature sensors and the self-control switch. The ladle baking device has the advantages that the structural design is reasonable, running is safe and reliable, the automation degreeis high, the operation and the use are convenient, the steel ladle is uniformly baked, the baking time is effectively shortened, the baking efficiency is improved, and the pollution to the environment is relatively low.

Owner:王研

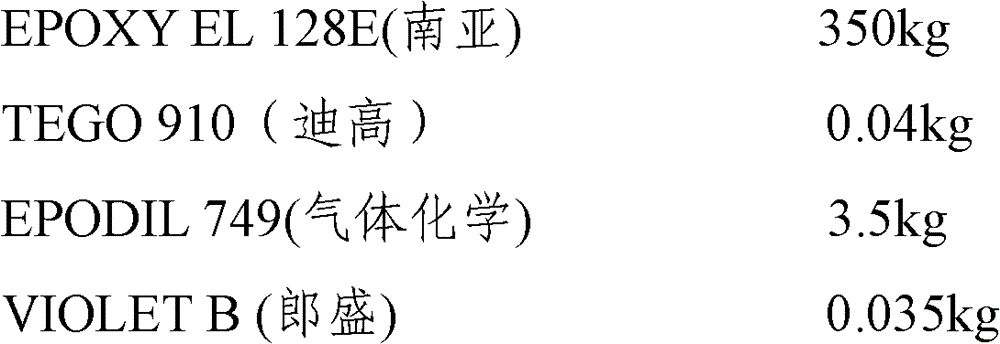

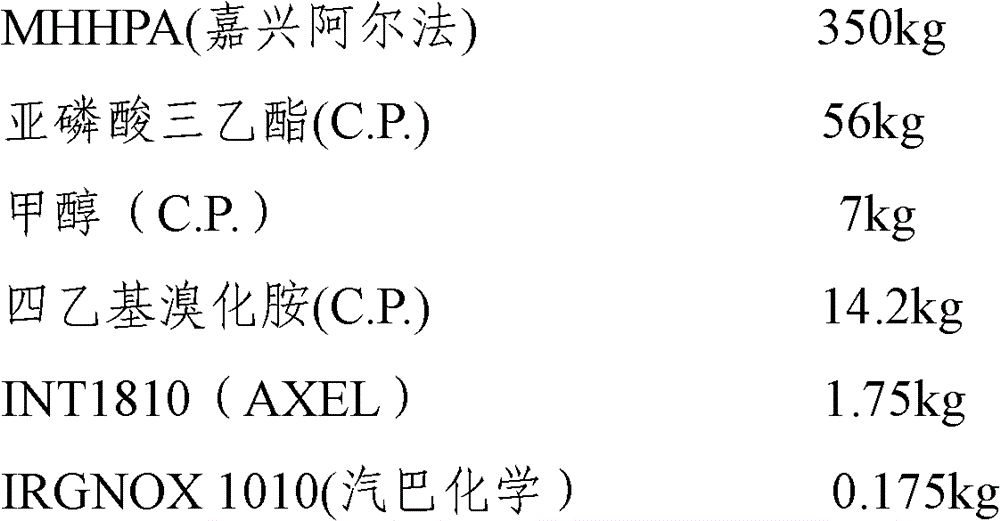

Light emitting diode (LED) epoxy encapsulation adhesive

InactiveCN102181253BImprove performanceIncrease brightnessNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyWeather resistance

The invention relates to light emitting diode (LED) epoxy encapsulation adhesive and a preparation method thereof. Aiming at the defects that the epoxy resin has poor weather resistance and is aged and yellowed under the irradiation of ultraviolet, an ultraviolet absorbent is added into the conventional LED epoxy encapsulation adhesive. The ultraviolet absorbent can absorb the light with wavelength of about 290 to 400 nanometers; and by chemical redox reaction, color molecules are finally decomposed and faded, and ultraviolet resistant effect is achieved. The LED encapsulation adhesive prepared by the method overcomes the defect that the common epoxy encapsulation adhesive cannot be used for long time under the environment of ultraviolet or high temperature; and in addition, because the yellowing resistance of the adhesive is promoted, the baking temperature and the baking time in the product encapsulation process can be improved when the adhesive is used, and the mechanical property of a product is greatly improved.

Owner:SUZHOU BANGCEN TECH

Method for baking horizontal continuous casting tundish and horizontal continuous casting tundish with negative pressure device

ActiveCN101905314BIncrease the baking temperatureEasy to operateMelt-holding vesselsHeat flowAir blower

Owner:衡阳华菱连轧管有限公司

Water-based amino industrial coating and preparation method thereof

ActiveCN107964340BHigh hardnessGood flexibilityAnti-corrosive paintsPolyurea/polyurethane coatingsPhosphomolybdic acidPolymer chemistry

The invention discloses a waterborne amino industrial paint. The waterborne amino industrial paint comprises the following raw materials by weight: 35-55 parts of a modified hydroxyl acrylic emulsion,1.5-2 parts of carbon black, 1-2 parts of zinc aluminum phosphomolybdate, 1.5-3 parts of a liquid antirust pigment, 1-2 parts of amino resin, 35-45 parts of water, 1-2 parts of a dispersant, 1-2 parts of a defoamer and 1-2 parts of a leveling agent. The paint prepared by the method provided by the invention has the advantages of high hardness, good flexibility, excellent adhesion to different substrates, excellent interlayer adhesion when matching with a primer, and good decorativeness and chemical resistance.

Owner:石家庄市油漆厂

Barrel and tank baking heat exchange cover

ActiveCN104070155BIncrease temperatureImprove energy efficiencyMelt-holding vesselsCooking & bakingCombustion chamber

Owner:武安市飞翔金属制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com