Method for baking horizontal continuous casting tundish and horizontal continuous casting tundish with negative pressure device

A technology of horizontal continuous casting and negative pressure device, which is used in foundry equipment, casting melt containers, metal processing equipment, etc., can solve the problem of low baking temperature of nozzle channel, freezing death of casting, tundish bottom and nozzle baking. Problems such as poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

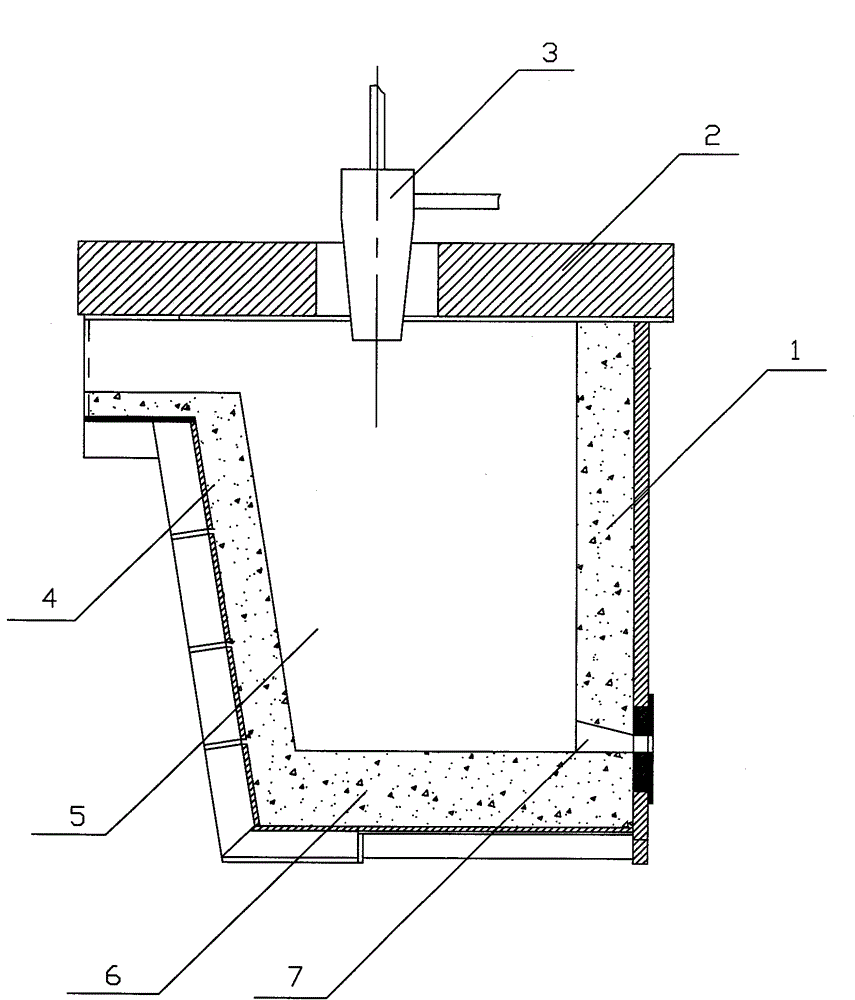

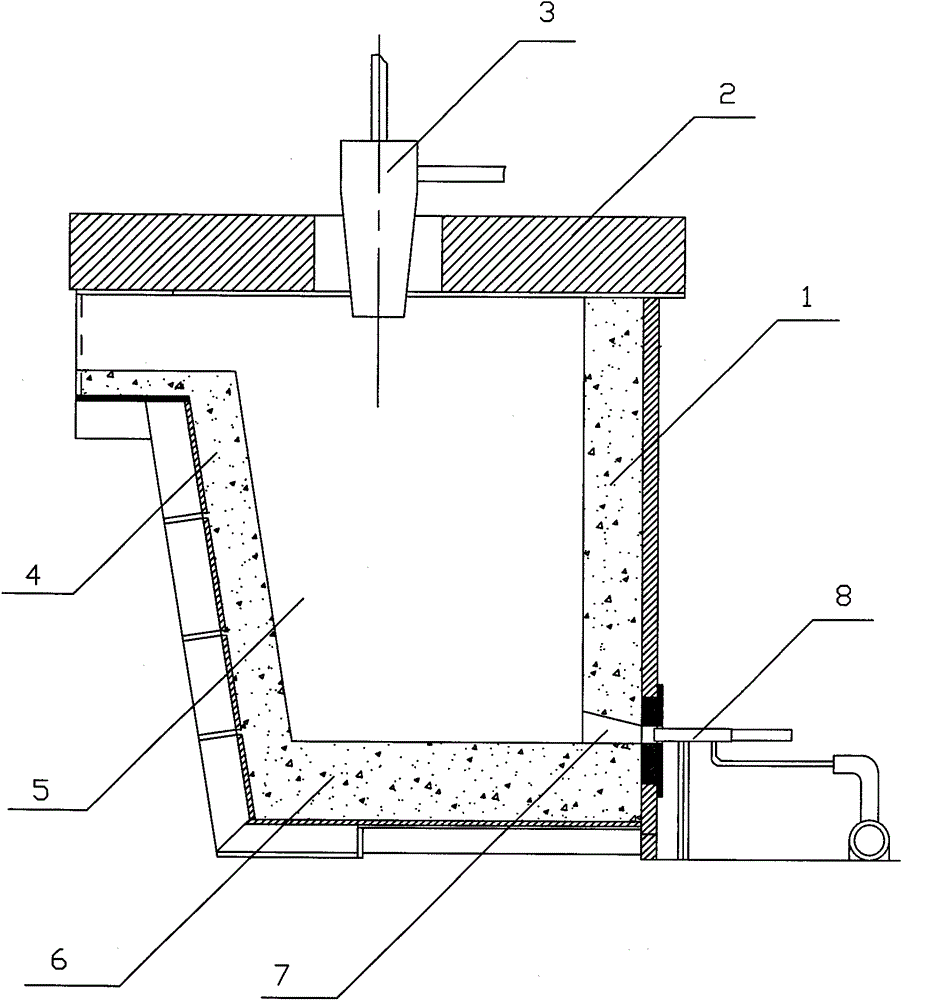

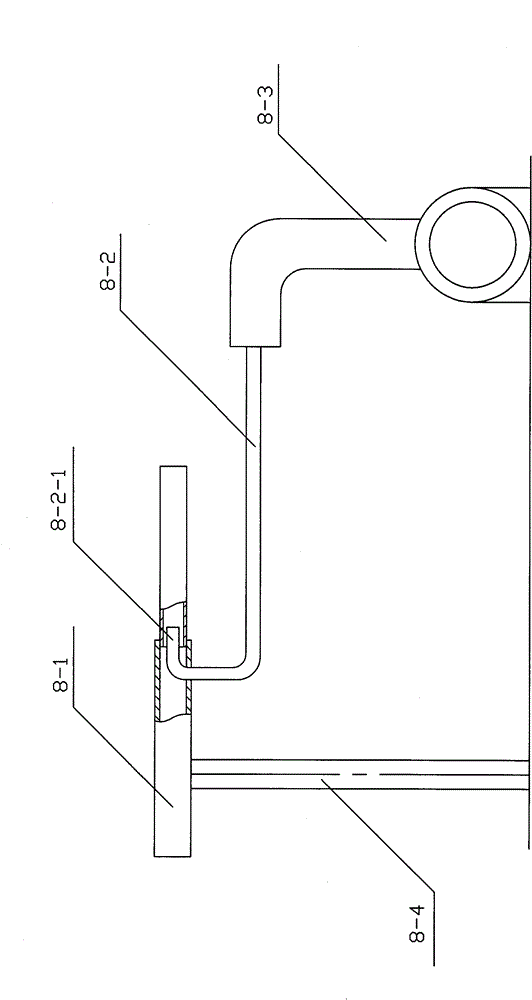

[0016] as attached figure 2 Shown: a method for baking a horizontal continuous casting tundish, which is to install a negative pressure device 8 at the channel of the nozzle 4 of the horizontal continuous casting tundish, so that negative pressure is generated at the channel of the nozzle 4, and the horizontal continuous casting middle The heat flow in the tundish is directed to the nozzle 4 channel, changing the heat flow direction of the original horizontal continuous casting tundish baking, so that the horizontal continuous casting tundish nozzle 4 and the bottom 6 of the horizontal continuous casting tundish are quickly baked. The specific operation process is as follows:

[0017] When baking the horizontal continuous casting tundish, move the horizontal continuous casting tundish to the online baking position and add the tundish cover 2, install the tundish regenerative roaster 3, and then put the tundish in the negative pressure device 8 The large pipe of the exhaust p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com