Light emitting diode (LED) epoxy encapsulation adhesive

An epoxy encapsulation and encapsulation technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of poor weather resistance of epoxy resin, large LED light decay, and reduced light output efficiency, etc. Vacuum defoaming, anti-yellowing performance improvement, fast hardening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The LED epoxy encapsulation adhesive of this embodiment consists of a main agent and a hardener.

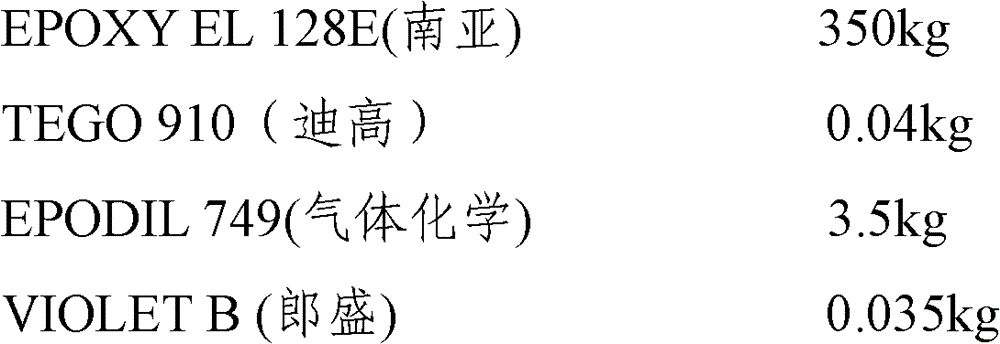

[0063] The composition of the main agent is:

[0064]

[0065] hardener:

[0066]

[0067] Preparation of main ingredients: Add 350 kg of Nanya EPOXYEL 128E resin, 0.04 kg of defoamer (TEGO 910), 3.5 kg of reactive diluent (EPODIL749) into a 500L reactor, and then add 0.035 kg of bluing agent (VIOLET B) and heat to Stir at 100°C for 1 hour, filter and pack.

[0068] Hardener preparation: The 500L reactor is anhydrous and oxygen-free, first add 175 kg of MHHPA, 56 kg of triethyl phosphite, 14.2 kg of tetraethylammonium bromide, 0.175 kg of ultraviolet absorber (irgnox 1010), 7 kg of methanol 1 kg was heated to 80°C and kept stirring for 1 hour, then 175 kg of MHHPA and 1.75 kg of release agent (INT1810) were added and kept stirring for 1 hour, then filtered and packed.

[0069] When using, preheat 1000g of main agent at 60°C for 1 hour, then add 1000g of hardener a...

Embodiment 2

[0074] The LED epoxy encapsulation adhesive of this embodiment consists of a main agent and a hardener.

[0075] The composition of the main agent is:

[0076]

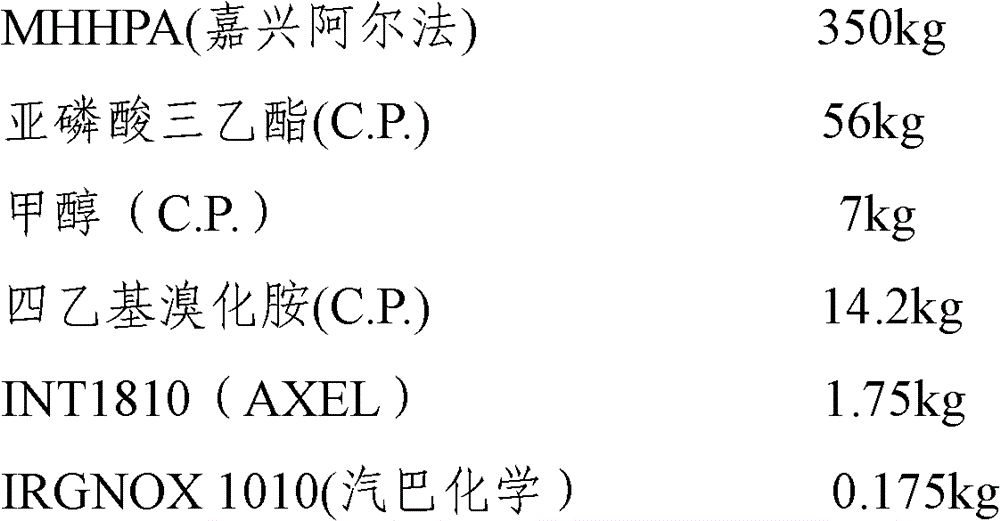

[0077] hardener:

[0078]

[0079] Preparation of main ingredients: Add Nanya EPOXY EL 127 resin, defoamer (TEGO 910) and blueting agent (VIOLET B) into a 500L reactor, heat to 110°C and stir for 0.5 hours, filter and pack.

[0080] Preparation of hardener: first add 50% MHHPA triethyl phosphite, tetrabutylammonium bromide, ultraviolet absorber (irgnox 1010), and 7 kg of methanol to 80 ° C for heat preservation and stirring in a 500 L reaction kettle without water and oxygen After 0.8 hours, add the remaining 50% of MHHPA and release agent (INT1810), keep stirring for 1.2 hours, filter and pack.

[0081] When using, preheat 1000g of main ingredient at 80°C for 0.5 hour, then add 1000g of hardener and stir for 8 minutes. Vacuumize for 6 minutes under the condition of 6mm Hg vacuum degree and temperature of 50°...

Embodiment 3

[0086] The LED epoxy encapsulation adhesive of this embodiment consists of a main agent and a hardener.

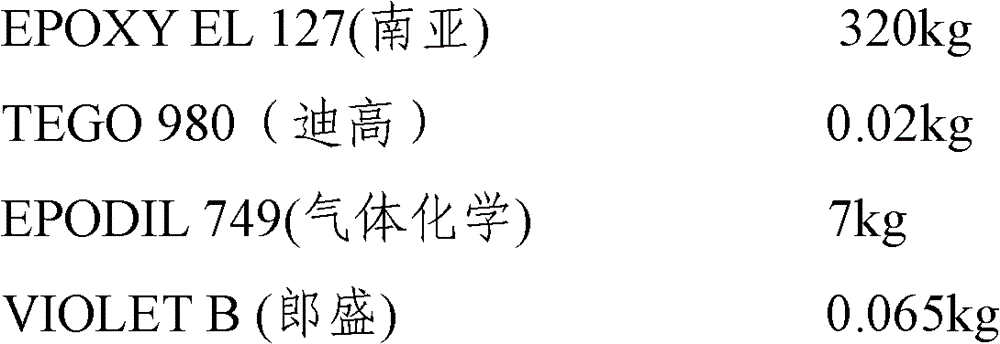

[0087] The composition of the main agent is:

[0088]

[0089] hardener:

[0090]

[0091] Main ingredient preparation: Add Nanya EPOXY EL 128E resin, defoamer (TEGO 910), reactive diluent (EPODIL749) into a 500L reactor, then add blueting agent (VIOLET B), heat to 90°C and stir for 1.2 hours, filter Subpackage.

[0092] Hardener preparation: 500L reaction kettle is anhydrous and oxygen-free, first add 50% MHHPA triethyl phosphite, tetraethylammonium chloride, ultraviolet absorber (irgnox 1010), methanol 7 kg and heat to 75 ° C Stir for 1.2 hours, then add the remaining MHHPA, remover (INT1810) and keep stirring for 0.8 hours, then filter and pack.

[0093] When using, preheat 1000g of main agent at 70°C for 50 minutes, then add 1000g of hardener and stir for 10 minutes. Under the conditions of 10mm Hg vacuum degree and temperature of 50°C, vacuumize for 6 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com