Patents

Literature

53results about How to "Extend the baking time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick roasting method of fresh grosvenor momordica

ActiveCN102100394AGuaranteed circulationExtend the baking timeFood preservationPharmaceutical product form changeTime rangeMicrowave oven

The invention discloses a quick roasting method of a fresh grosvenor momordica, which comprises the following steps: (1) classifying the ripe grosvenor momordica according to large, middle and small specifications and respectively placing into a special roasting tray used for a microwave oven; (2) placing the roasting tray filled with the grosvenor momordica into an intelligent microwave vacuum drying oven; and (3) determining the roasting time according to the weight of the grosvenor momordica and the power of the microwave oven and roasting, wherein the roasting temperature range is 20-40 DEG C, and the roasting time range is 30-150 minutes under the condition of vacuum degree less than -0.08MPa. In the method, the microwave technology for roasting is utilized, the roasting process is carried out at low temperature and constant temperature, the time consumption is short, the cost is low, and the fresh grosvenor momordica well keeps the bright yellow color and nutrition constituents and has good taste.

Owner:桂林普兰德生物科技有限公司

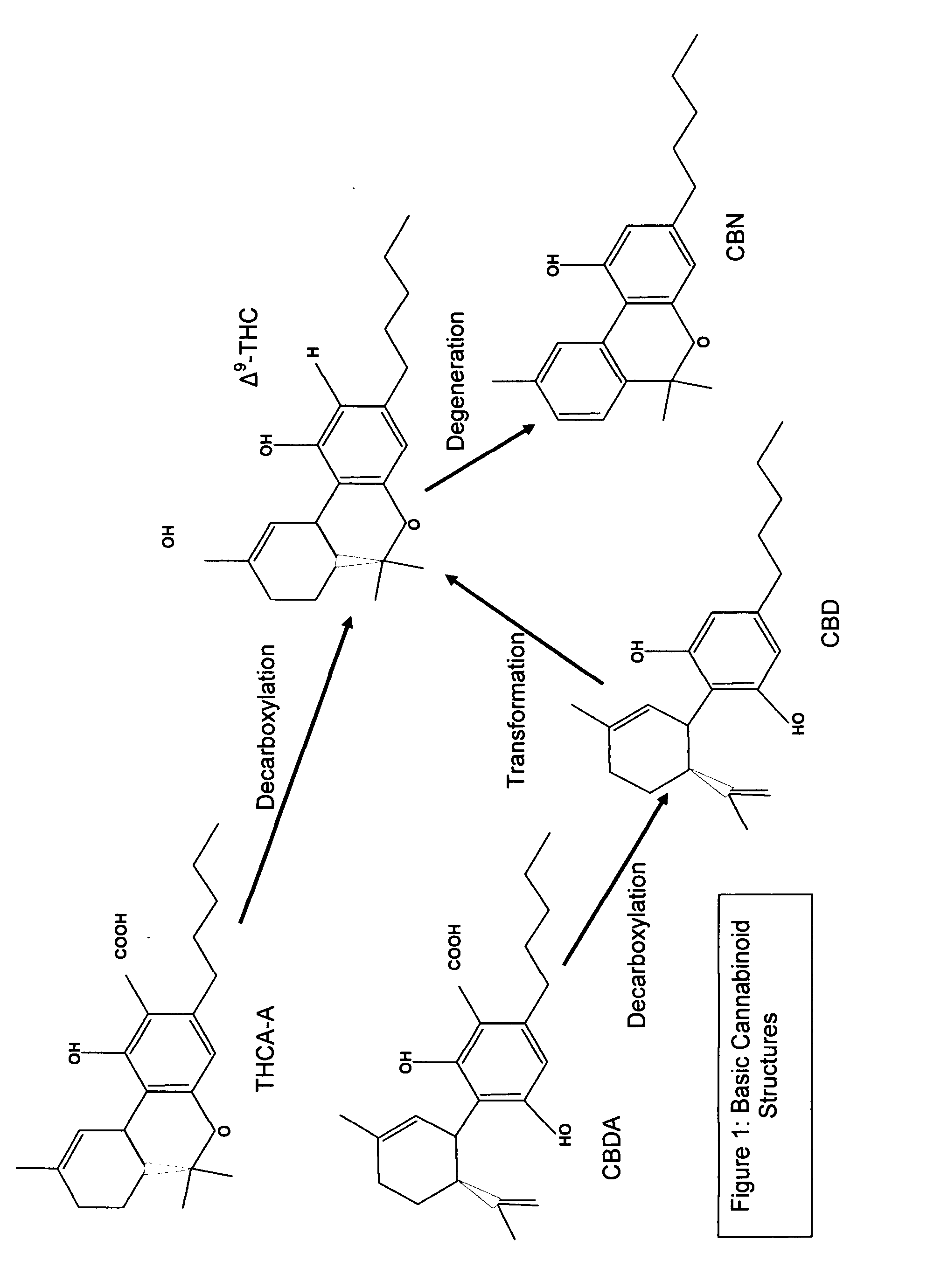

Medicinal cannabis uniform in food

InactiveUS20120095088A1Low baking temperatureExtend the baking timeBiocideNervous disorderCannabinoidMedicine

The invention is a product and a process wherein cannabinoids such as Medicinal Δ9-THC and / or other substances associated with medicinal cannabis, including yet not necessarily limited to cannbidiols, cannabigerol are contained or processed into foodstuffs or medicinal compounds in controlled ways and with specific characteristics. First a medicinal substance with a known about of medicinal cannabis is mixed into a foodstuff such that the medicinal cannabis is distributed uniformly in the foodstuff. Foodstuffs consistent with this invention include baked goods, hard candies, ice cream, bases, ice cream, and yogurt. The product is characterized by a controlled amount of cannabinoids per unit volume of the foodstuff. Another provision of the invention is providing controlled amounts or ratios of Δ9-THC as compared to CBD in a foodstuff.

Owner:HOSPODOR ANDREW DAVID

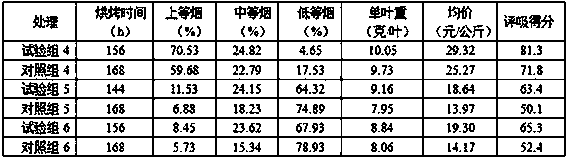

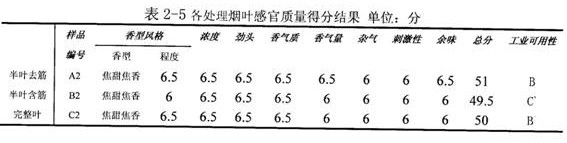

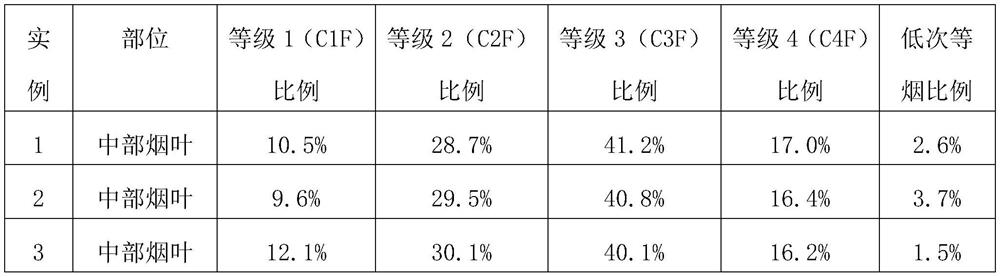

Cured tobacco curing process capable of effectively reducing ash stuck on tobacco leaves

InactiveCN105212255AFully witheredMake sure it's dryTobacco preparationHigh humidityMechanical engineering

The invention relates to a cured tobacco curing process capable of effectively reducing ash stuck on tobacco leaves. The process is divided into three specific stages, namely a yellowing stage, a color fixing stage and a vein drying stage, wherein the yellowing stage comprises the steps of raising the wet bulb temperature to 36-37 DEG C, stabilizing the temperature, and maintaining high humidity curing for 20-30 hours; after the tobacco leaves are yellowed by 60%-70%, starting humidity elimination in advance; the color fixing stage comprises the steps of adopting slow color fixing before the temperature is below 45-46 DEG C, conducting humidity elimination frequently, and promoting the tobacco leaves to sufficiently wither; after the later color fixing stage, prolonging the time of maintaining the temperature of 54 DEG C, and achieving the purposes of improving the quality and enhancing the fragrance; the vein drying stage comprises the steps of raising the temperature for conducting curing, and ensuring all the tobacco leaves and tobacco veins are dry. The advantages of the cured tobacco curing process can be simply concluded that the high temperature is maintained and the humidity is preserved so that the tobacco leaves can be yellowed; humidity elimination is conducted in advance so that the temperature can be stabilized; the humidity is maintained at the low level and the color is fixed so that the appearance can be maintained; the time of maintaining the temperature of 54 DEG C is prolonged, and the fragrance is enhanced.

Owner:GUIZHOU TOBACCO SCI RES INST

A curing method for improving protein degradation rate of tobacco leaves

The invention discloses a curing method for improving the protein degradation rate of tobacco leaves. The curing method comprises the following steps: A. harvesting; B, weaving a rod and charging thatfurnace; C, flue-curing: the flue-cured tobacco leaves are flue-cured after the oven is charged, and the flue-cured tobacco leaves can be obtained through the yellowing period, the color fixing period and the dry rib period. The method of the invention has extremely great significance for ensuring the high-quality raw material supply of the cigarette industry by regulating the curing time, optimizing the curing process, improving the protein degradation rate of the tobacco leaves, regulating the protein content, and improving the quality of the bulk curing tobacco leaves.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Method for improving curing quality of tender mature-delay tobacco leaves

The invention discloses a method for improving the curing quality of tender mature-delay tobacco leaves. According to the method, the tobacco leaf harvesting standards include that tobacco leaves are mature to be yellowing in green and have yellow leaf tips, the smoke filling density in a curing room is 38-40 kg / m<3> and the curing room is filled with smoke accounting for 85-90% of the volume. Through the three-stage baking process, the method specifically includes the yellowing stage, the color fixing stage and the vein drying stage till main veins of tobacco leaves in the whole curing room are cured to be dry. In the later period of the yellowing stage, the wind speed among tobacco leaves in the curing room reaches 0.3-0.4 m / s in the high wind speed layer, reaches 0.25-0.35 m / s in the medium wind speed layer and reaches 0.2-0.3 m / s in the low wind speed layer. The curing method is particularly suitable for lower tobacco leaves formed under the conditions of high water and fertilizer, high densities, inharmonious nutrients and too much nitrogen, leaves are fat, high in water content, high in moisture holding capacity and little in dry substance, nitrogen compounds are mainly contained, and the problems that tobacco leaves have no maturity delay capacity in the field and can get rotted before being mature are solved. The method is easy to operate, the curing quality of tender mature-delay tobacco leaves can be improved, loss can be reduced, and income of tobacco farmers is increased.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

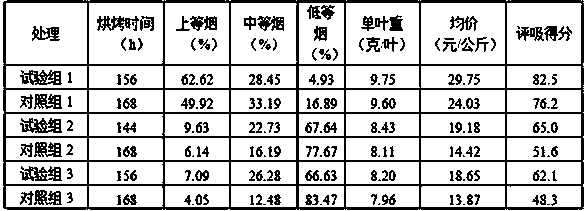

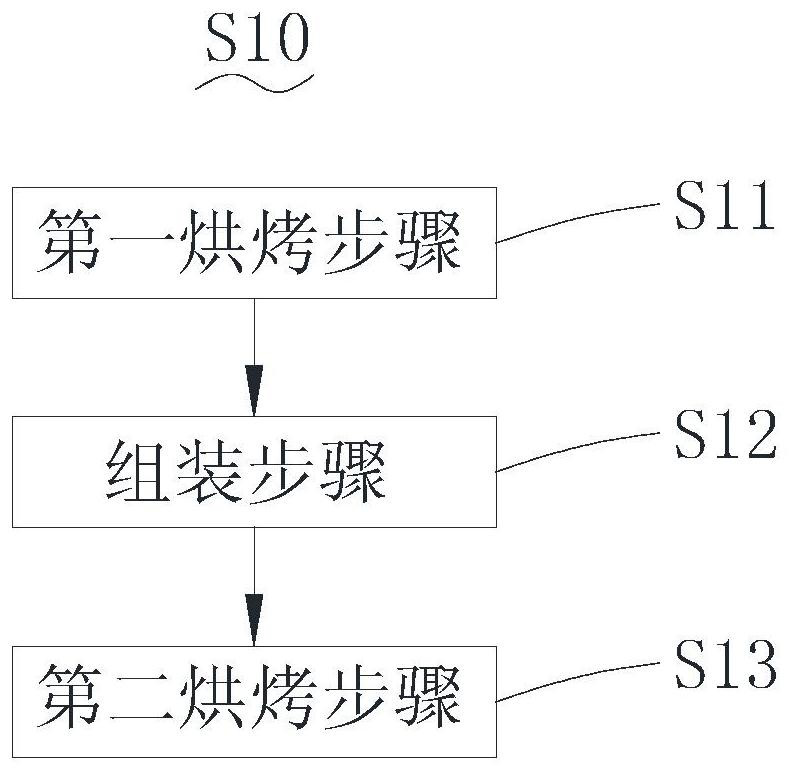

Lithium battery manufacturing process

InactiveCN109687036AImprove performanceImprove wettabilityFinal product manufactureSecondary cellsCooking & bakingWork in process

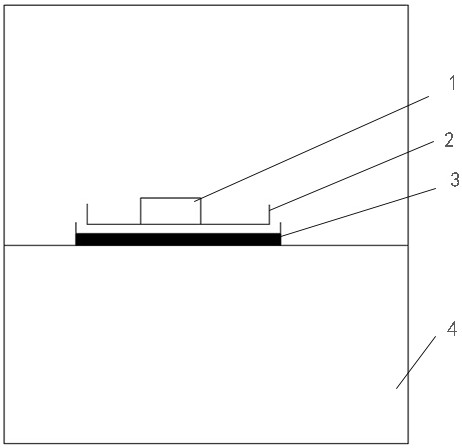

The invention discloses a lithium battery manufacturing process which comprises a preparation process, a first baking process, an assembly process, a second baking process, a liquid injection wettingprocess, a sealing process, a shelving wetting process and a formation process. The lithium battery manufacturing process includes conducting the first baking process on a pole piece or a core to remove some moisture in the pole piece or the core, then conducting the second baking process to bake a semi-finished battery to effectively remove the moisture inside the battery to improve the overall performance of the battery. A user does not need to increase the drying temperature or prolong the baking time significantly during the baking process, no negative impact is generated on the performance of the battery, and no more energy consumption is caused. In addition, the semi-finished battery is first subjected to liquid injection wetting by setting and then subjected to shelving wetting. Theshelving wetting includes first inverted wetting and then upright wetting, so that the core wetting effect is better, and the overall performance of a finished battery is improved.

Owner:SHENZHEN ZHUONENG NEW ENERGY TECH

High-healthcare-value highland barley bread and preparing method thereof

InactiveCN105961515AImprove processingIncrease nutritionModified nutritive productsBeta-glucanMaterials processing

The invention discloses high-healthcare-value highland barley bread and a preparing method thereof. Common highland barley with the content of beta-glucan higher than 5% and a high-quality glutinous highland barley raw material with the content of beta-glucan higher than 8% are selected for processing the bread. The bread has the advantages that the glutinous highland barley material is used for preparing high-value whole-wheat bread which is high in nutrition content and good in mouthfeel and has thick highland barley fragrance, a consumption market and territory of highland barley is broadened, structural adjustment and optimized upgrade of the highland barley industry is promoted, and the positive role of highland barley in the Tibetan region is brought into play better.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S +1

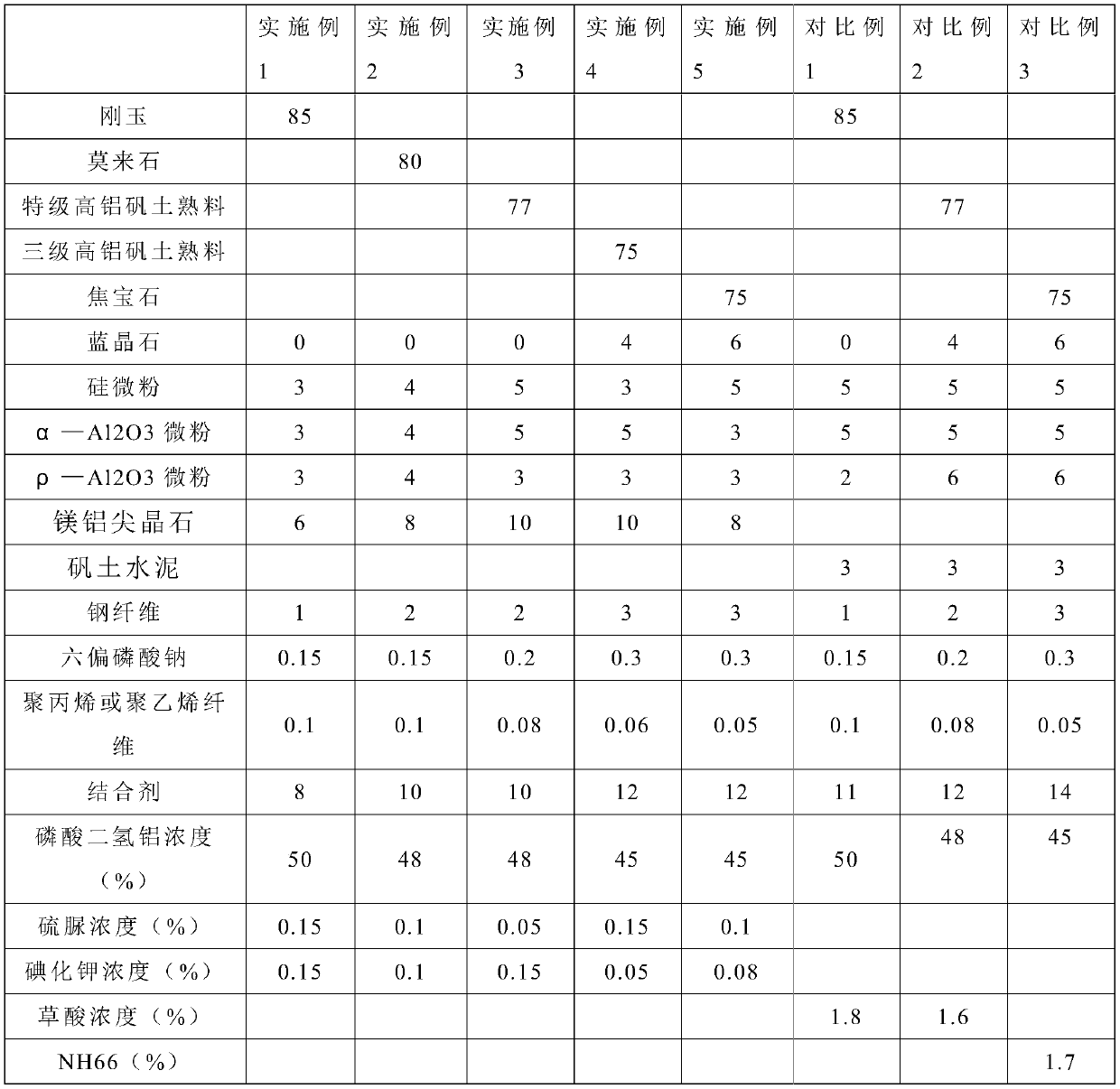

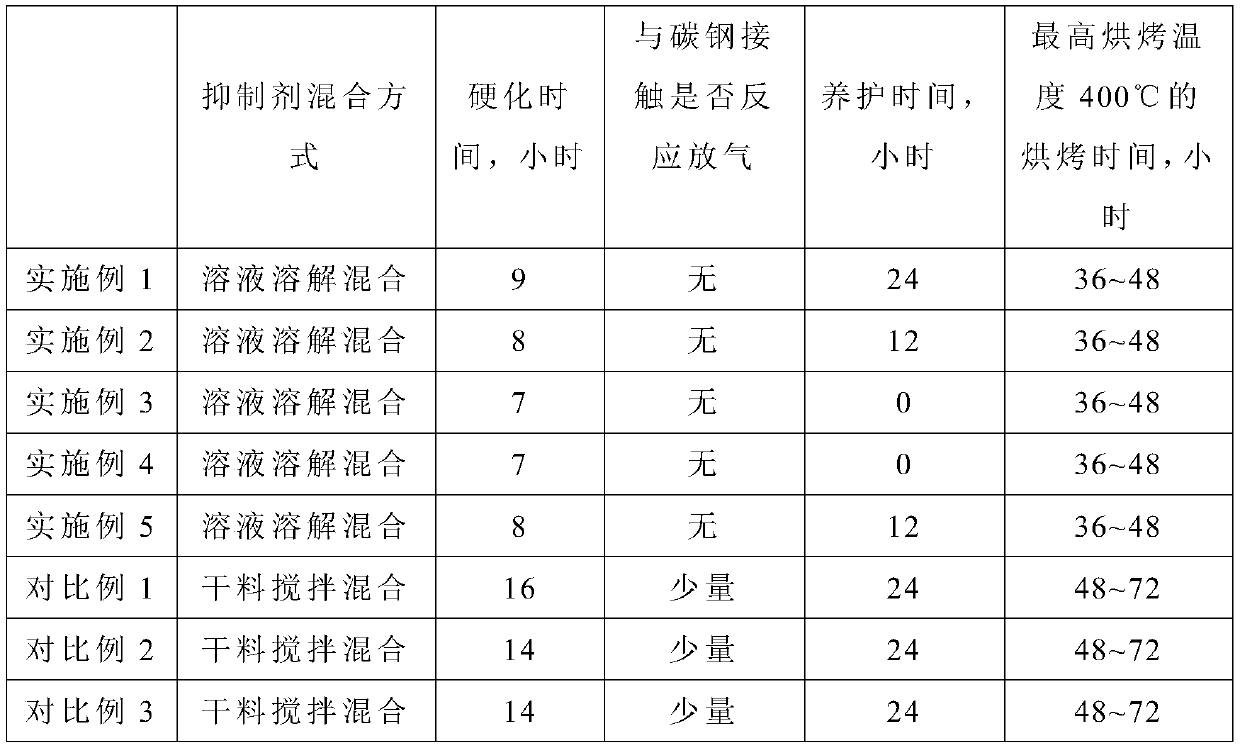

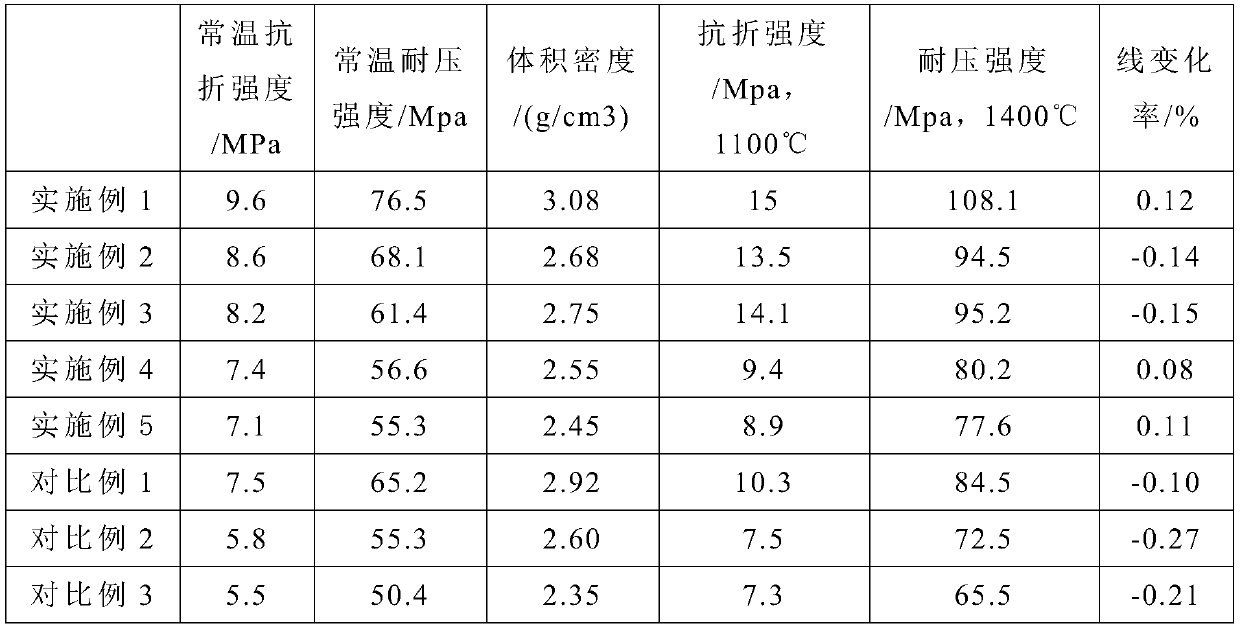

Aluminum dihydrogen phosphate and steel fiber reinforced refractory castable and preparation method

The invention discloses an aluminum dihydrogen phosphate and steel fiber reinforced refractory castable and a preparation method. The aluminum dihydrogen phosphate and steel fiber reinforced refractory castable comprises a main refractory material, an additive and a binding agent; the raw material of the binding agent comprises an aluminum dihydrogen phosphate aqueous solution in mass concentration of 45-50%; thiourea and potassium iodide are dissolved in the aluminum dihydrogen phosphate aqueous solution in mass concentration of 45-50%; the weight of the aluminum dihydrogen phosphate aqueoussolution in mass concentration of 45-50% is 8-12% of total weight of the main refractory material. The aluminum dihydrogen phosphate and steel fiber reinforced refractory castable is adopted for preparing the products, such as a molten iron slagging plate with a carbon steel metal core wrapped with a refractory material; the generation of reaction gas of aluminum dihydrogen phosphate is avoided during the processes of castable preparation and casting molding; water resistance and strength under normal temperature of the casting body are promoted; excellent effects of greatly reducing the timeof casting molding and baking preparation, reducing baking energy consumption and prolonging service life are achieved.

Owner:武汉钢铁有限公司

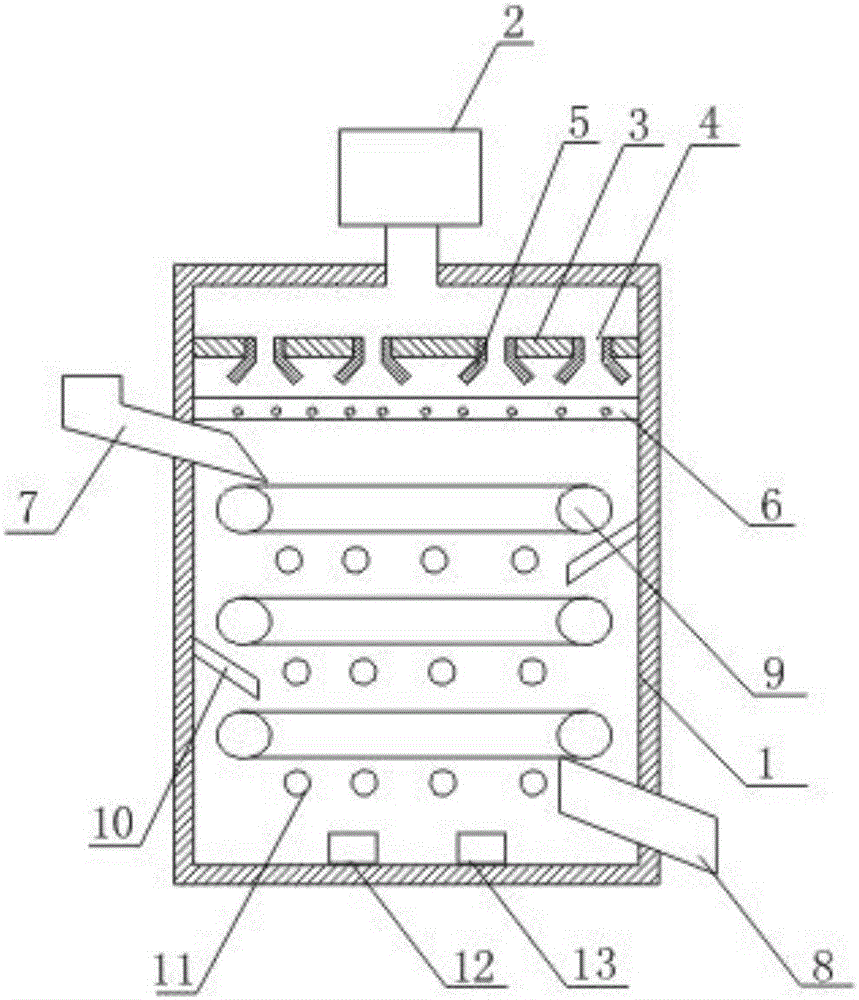

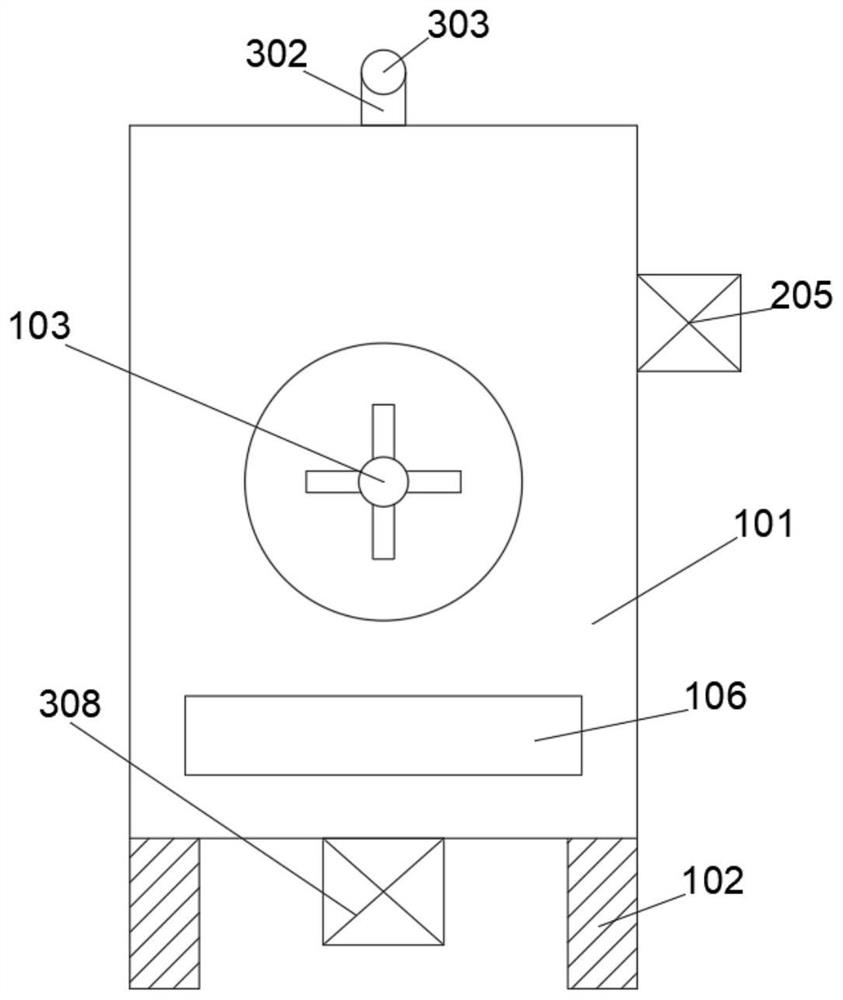

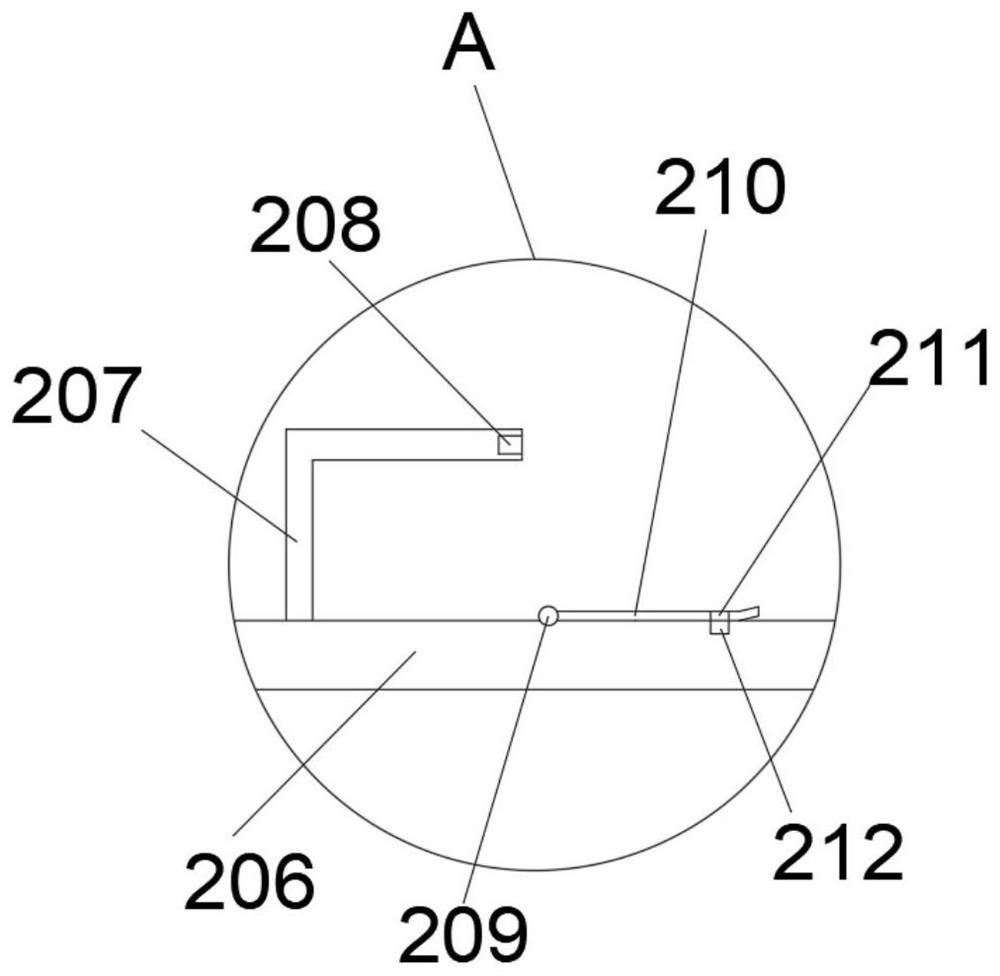

Device for evenly drying objects

InactiveCN106174646APlay the role of evenly distributed diversionPlay a buffer roleFood treatmentFruits/vegetable preservation by dehydrationEngineeringDried fruits

The invention discloses a device for evenly drying objects. The device comprises a drying box, the upper end of the drying box is connected with an air heater, a baffle A is arranged on the upper portion of an inner cavity of the drying box, ventilation openings are evenly distributed in the baffle A, and flow guide sheets are arranged on the two sides of the ventilation openings respectively. A porous separation plate is arranged below the baffle A, and a hot air buffer area is formed between the porous separation plate and the upper surface of the drying box. A feeding channel is formed in the top of one side face of the drying box, a discharging channel is arranged at the bottom of the other side face of the drying box, a conveying device is further arranged in the drying box and located below the porous separation plate, the feeding channel extends to the upper surface of the feeding end of the conveying device, and the discharging channel is in contact with the discharging end of the conveying device. The arranged hot air buffer area achieves a buffer function on hot air, the hot air can slowly dry fruits and vegetables after passing through the porous separation plate, and the situation that hot air suddenly enters the upper surfaces of the fruits and vegetables for strong drying, and the lower surfaces of the fruits and vegetables are not heated is avoided.

Owner:成都元始信息科技有限公司

Flue-curing method of increasing aroma amount of novel heat-not-burn tobacco and application thereof

The invention discloses a flue-curing method of increasing the aroma amount of novel heat-not-burn tobacco and application thereof. The flue-curing method is applicable to flue-cured tobacco varietiessuch as K326, Honghuadajinyuan and Yunyan 87, by targetedly prolonging the flue-curing time of tobacco leaves, aromatic substances in the tobacco leaves are effectively accumulated, the dryness and crispness of the tobacco leaves are improved, accordingly, during use of the novel heat-not-burn tobacco, the tobacco leaves can volatilize smoke with the high aroma amount at the temperature of 300 DEG C, and the mouthfeel of the tobacco leaves is improved; the flue-curing method is suitable for increasing the aroma amount of the novel heat-not-burn tobacco.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

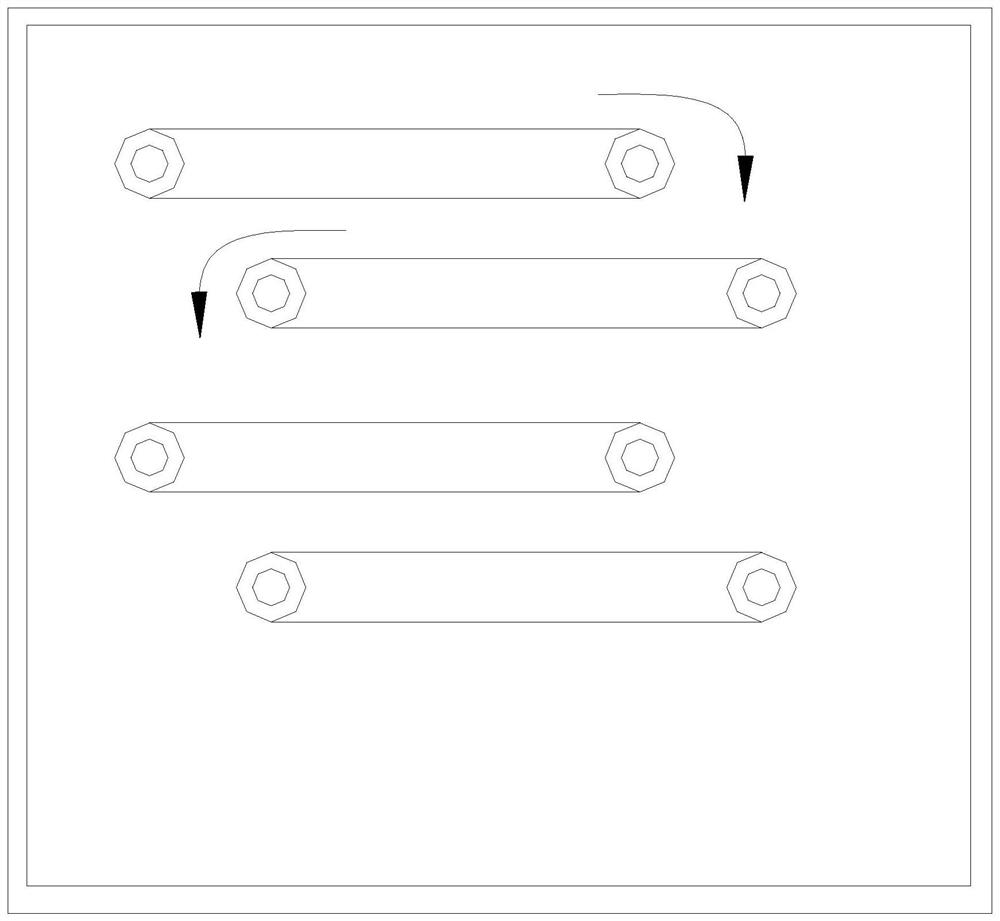

Half-leaf curing method for reducing starch content of flue-cured tobacco

ActiveCN112998303AShorten the total baking timeSmoke bad smokeTobacco preparationHarvestersCuring of tobaccoEnvironmental geology

The invention relates to a half-leaf curing method for reducing starch content of flue-cured tobacco. According to the method, a half-leaf harvesting mode is adopted, two half tobacco leaves without tobacco stems are put on rods, the rods are put into heating beds for curing; and the curing process only comprises the three stages, namely, a leaf yellowing stage, a leaf withering and branch vein yellowing stage and a leaf delayed color fixing stage. By means of the tobacco leaf curing method provided by the invention, the starch content of the cured tobacco leaves can be obviously reduced, the irritation of the cured tobacco leaves during smoking can be reduced, and the comfort of the aftertaste of the tobacco leaves during smoking can be improved; a stem drying stage is omitted, the total time of single-heating bed curing can be shortened under the condition that the yellowing stage and the color fixing stage are fully prolonged, and precious curing season resources are saved; the curing time is obviously shortened, a large amount of curing fuel consumption is saved, and air pollution of fuel to the environment is reduced; only the leaves are cured in a curing barn, the occupied space of the curing barn is small, and the tobacco loading capacity of a single heating bed is greatly improved; half-leaf curing does not contain tobacco stems, and the cured tobacco leaves do not need to be threshed.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

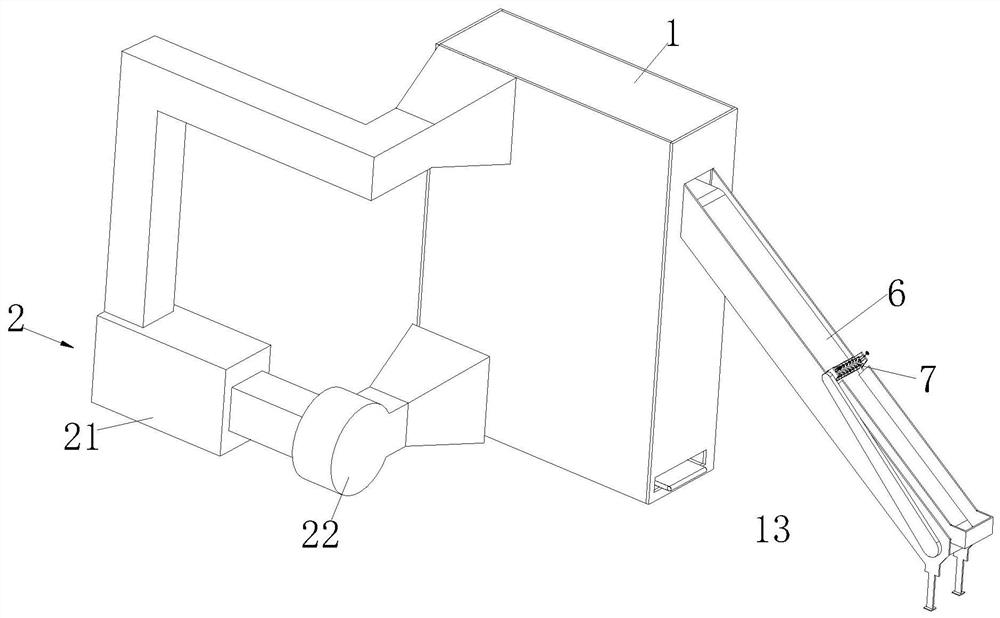

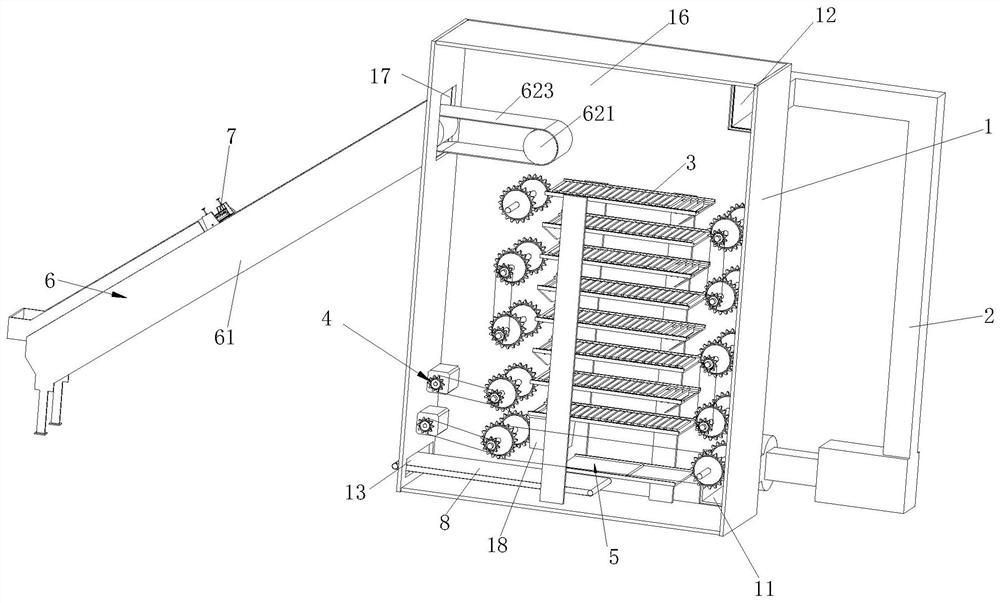

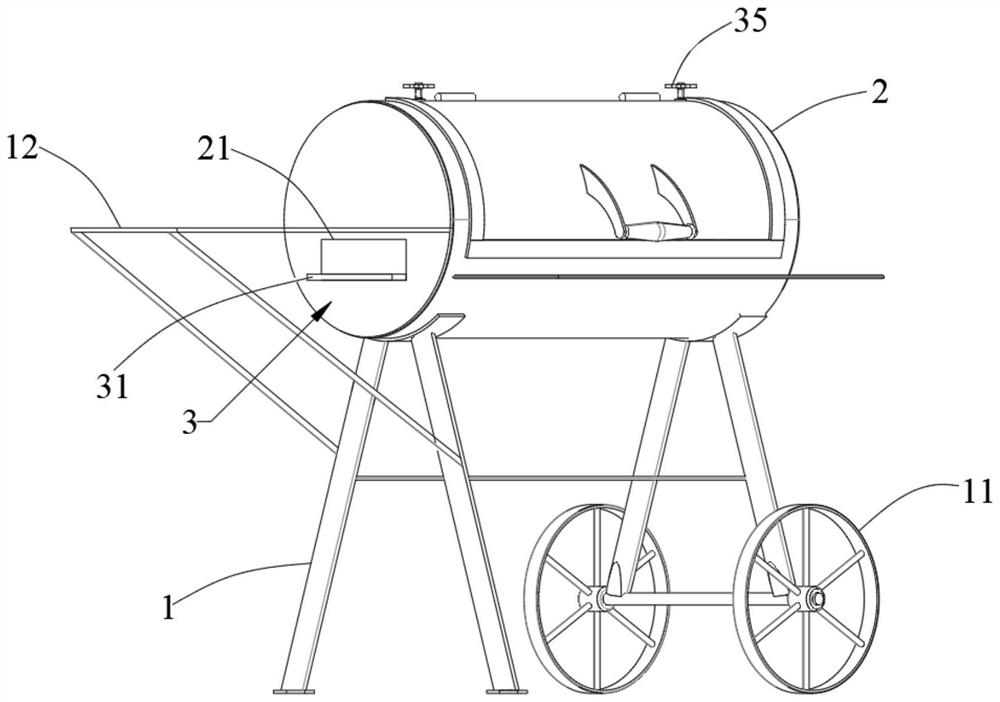

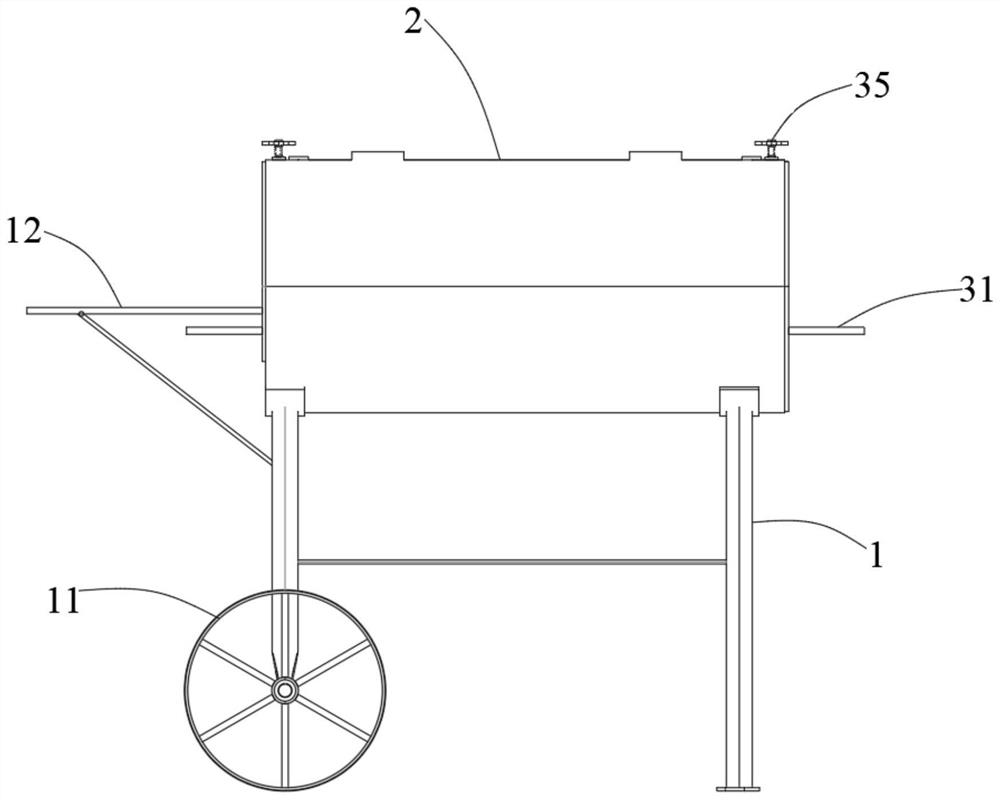

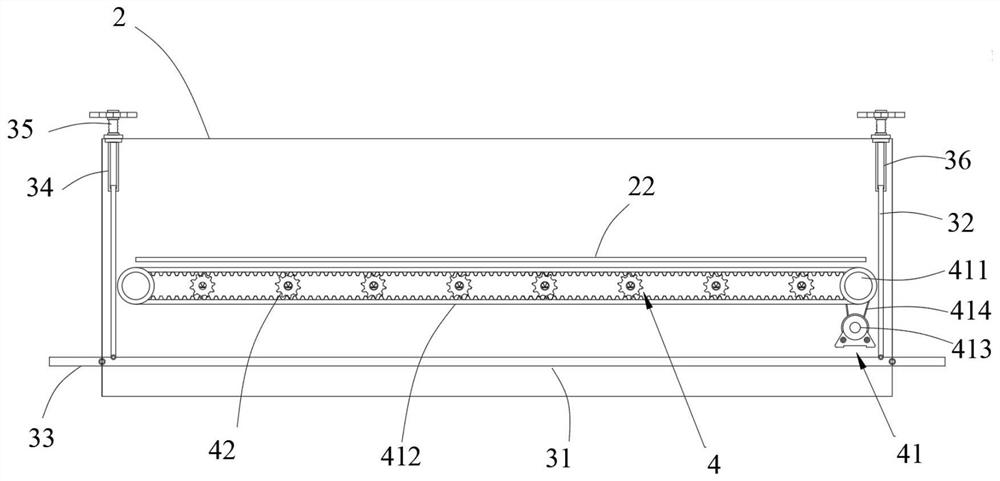

Tea dryer

PendingCN111758800AExtend travel timeExtend the baking timePre-extraction tea treatmentLoading/unloadingAgricultural engineeringSprocket

The invention relates to a tea dryer. The tea dryer comprises a drying box, a hot air conveying device, a conveying device and a conveying driving assembly; an air inlet and an air outlet are formed in the wall of the drying box; the conveying device comprises two or more layers of conveying assemblies; each layer of conveying assembly comprises two sets of chain wheel assemblies, and each set ofchain wheel assembly comprises a first chain wheel, a second chain wheel, a conveying chain and a conveying plate; each chain wheel assembly is provided with an upper supporting plate and a lower supporting plate in a matched mode, and the upper supporting plate is provided with an upper notch; and the lower supporting plate is provided with a lower notch. The upper-layer chain and the lower-layerchain of each chain wheel assembly can be fully utilized to drive tea leaves to be conveyed forwards and reversely in the conveying direction once, so that the stroke and the baking time of the tea leaves in the drying box are prolonged, the space utilization rate and the tea leaf baking amount in the drying box are increased, and the drying efficiency of the tea leaves is greatly improved.

Owner:武夷山香江茶业有限公司

Substrate surface treatment process enabling surface to be provided with wrinkle grains

InactiveCN103706543AExtend the baking timeGuaranteed firmnessPretreated surfacesCoatingsSurface finishingLacquer

The invention belongs to the technical field of substrate surface treatment, and particularly relates to a substrate surface treatment process enabling a surface to be provided with wrinkle grains. According to the technical scheme, electrostatic precipitation is carried out on the substrate surface after the substrate surface is cleaned; wrinkle paint is sprayed, and the thickness of the wrinkle paint coating is 30-200 microns; then the substrate surface is baked through infrared rays for 2-3 hours, and the temperature is 120-150 DEG C; the substrate surface is cooled at room temperature for 2-4 hours, then vacuum evaporation coating is carried out, and the thickness of the coating layer is 50-500nm; ultraviolet light polymerization finish paint is sprayed, and the thickness of a finish paint coating is 10-30 microns; then ultraviolet irradiation is carried out, the finish paint is cured, the irradiation time is 5-10 seconds, and the surface is made to be provided with the natural wrinkle grains. The defects in the prior art are overcome, the heat curing type wrinkle paint is combined with the vacuum coating, and the substrate surface is made to be provided with the wrinkle grains with metallic luster.

Owner:HANGZHOU SANJING ART CRAFT PLASTIC

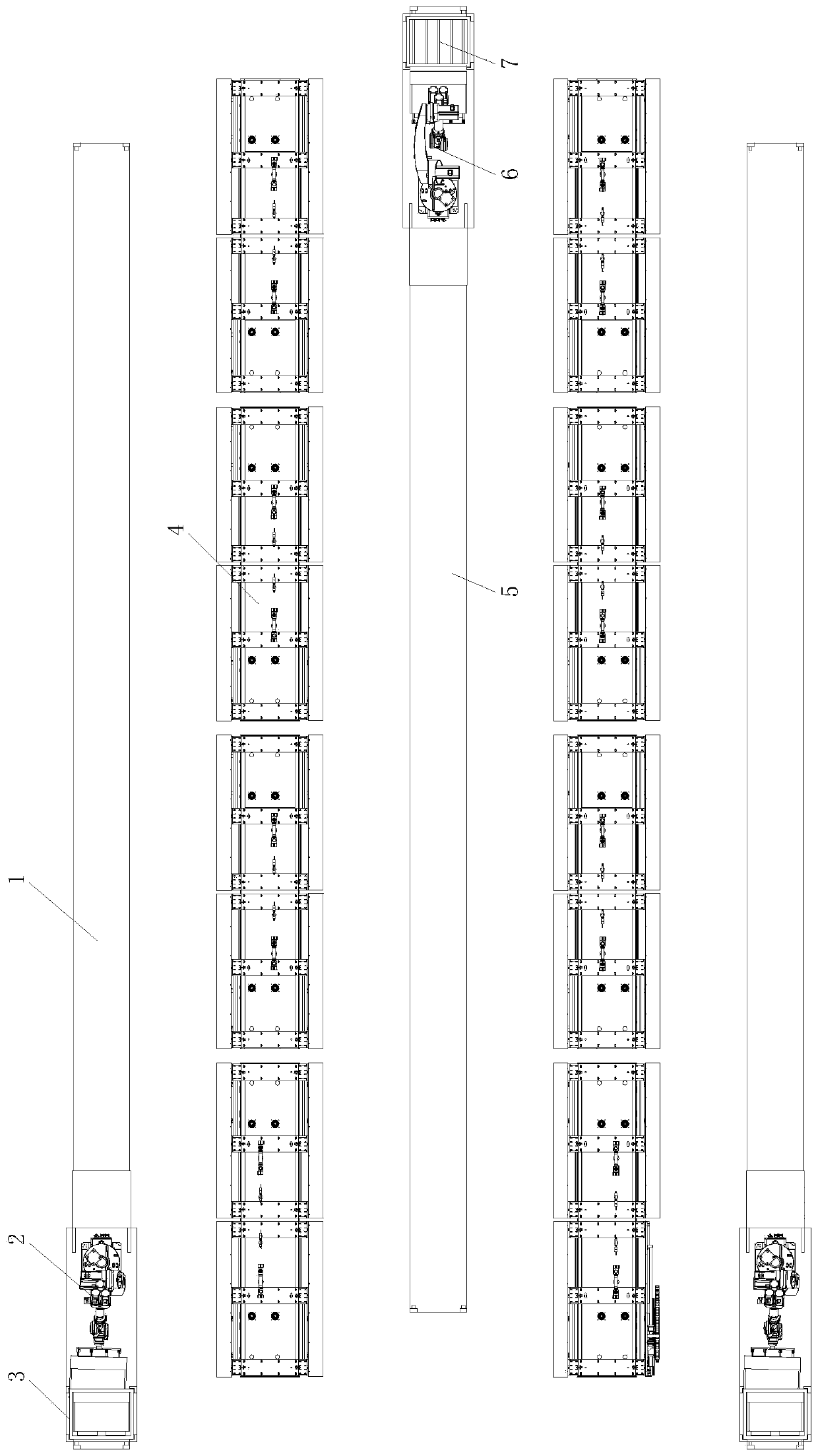

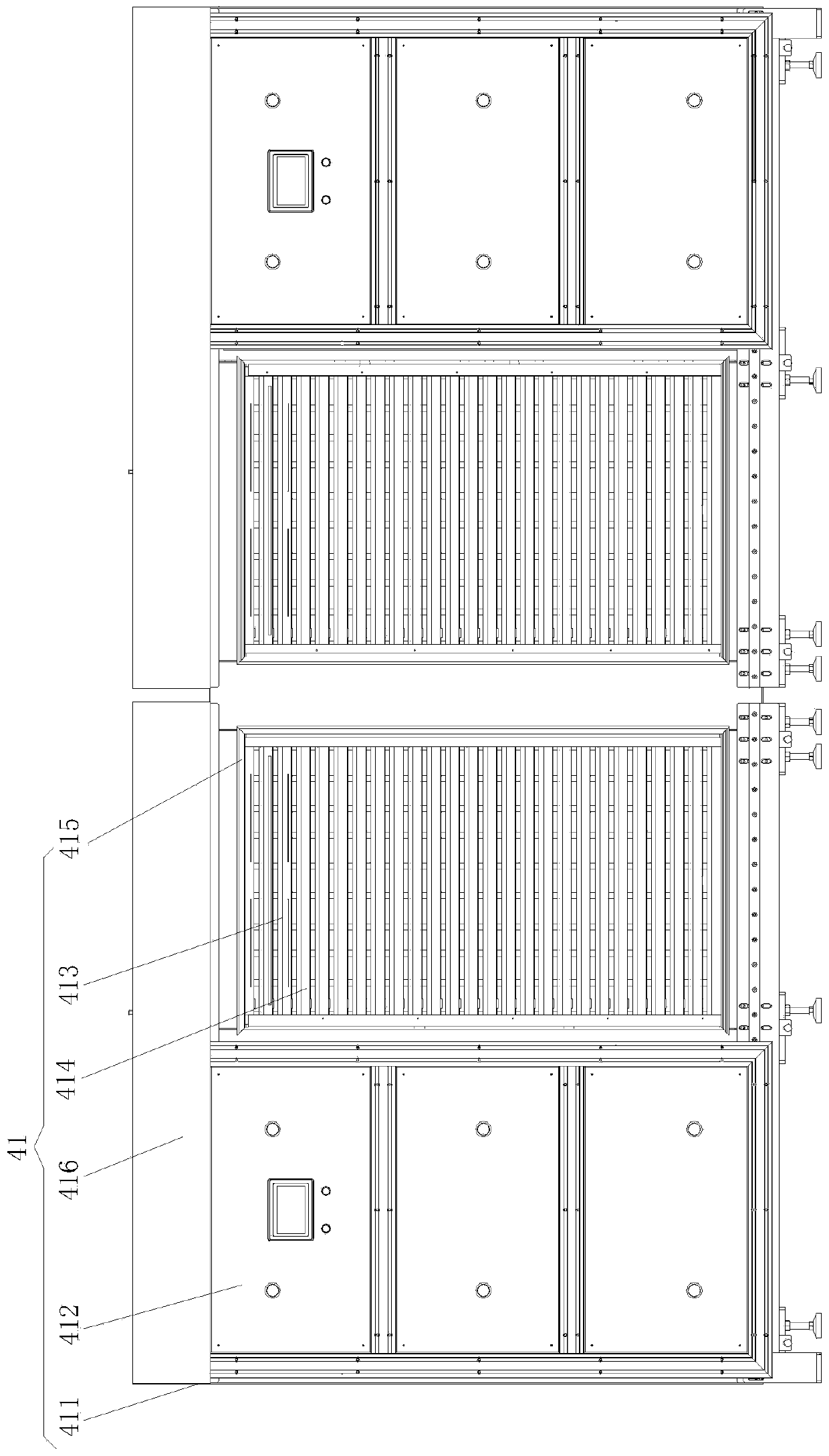

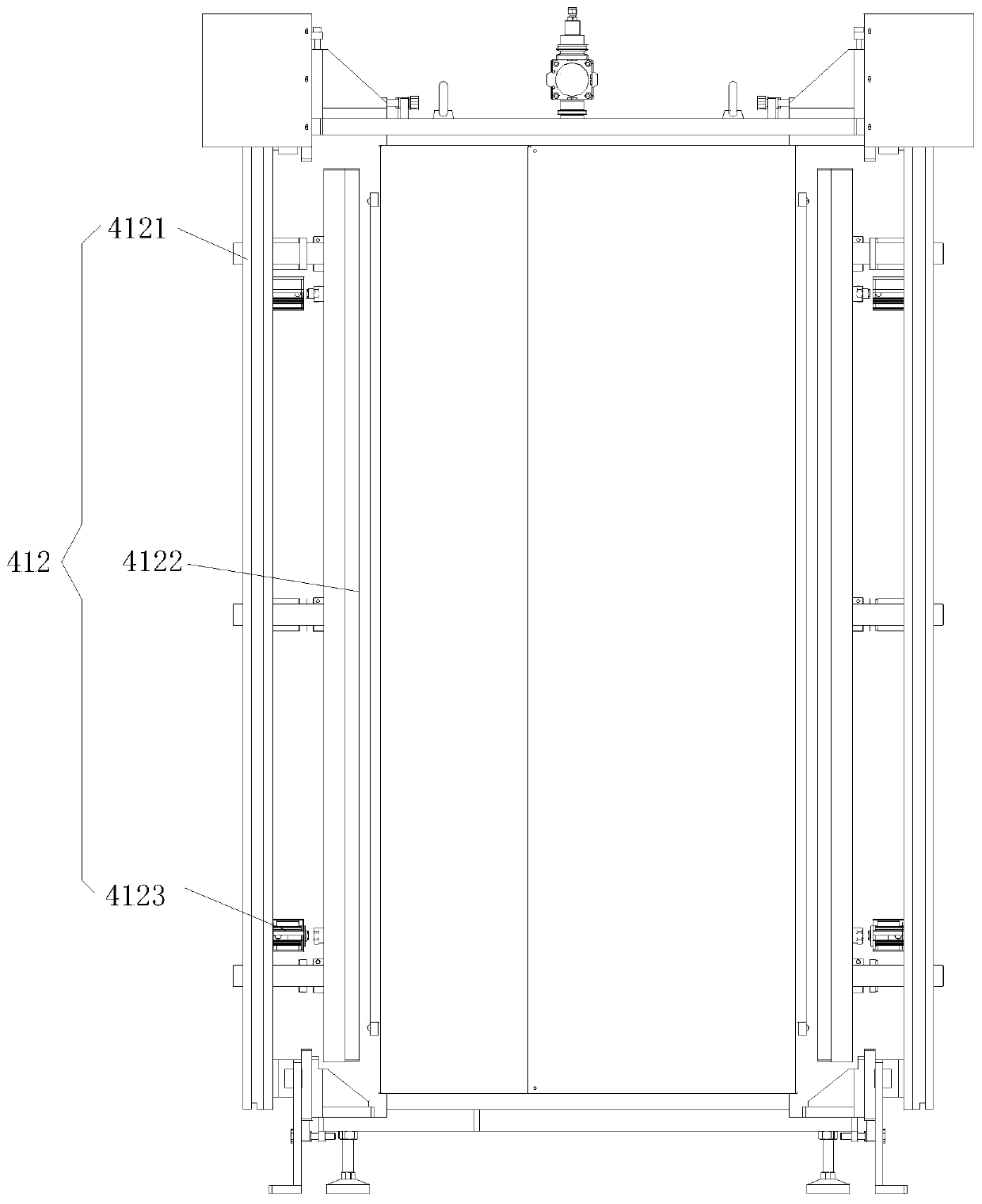

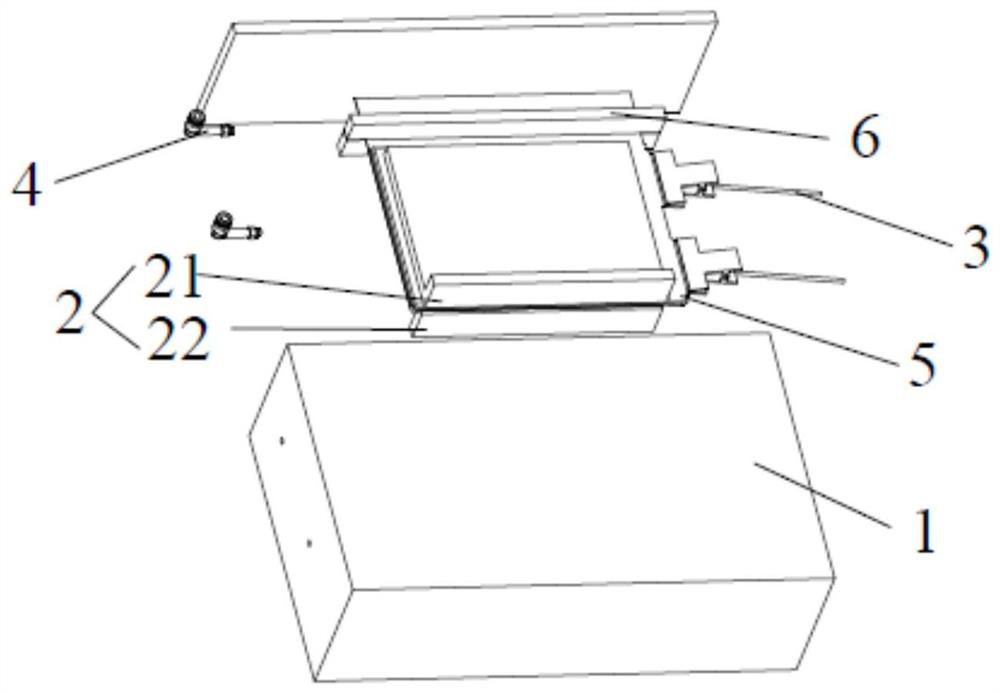

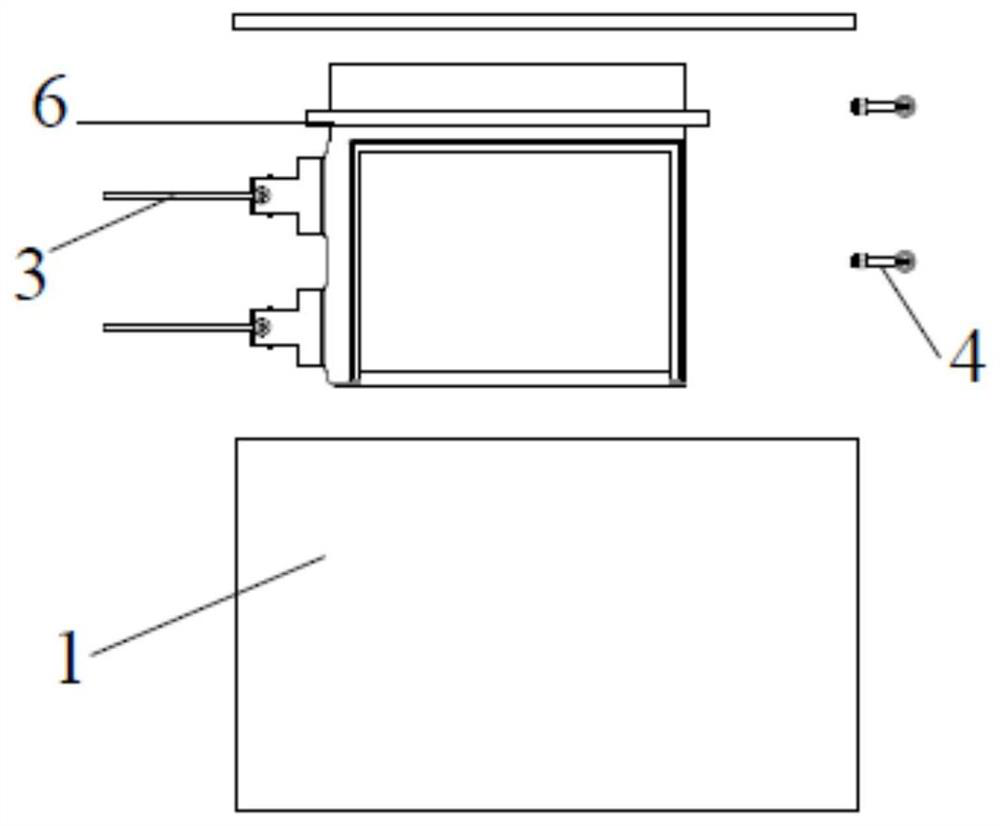

High vacuum baking line for new energy power battery intelligent robot

InactiveCN110081669AImprove qualityEasy to put inFinal product manufactureDrying solid materials without heatPower batteryNew energy

The invention relates to the technical field of new energy, in particular to a high vacuum baking line for a new energy power battery intelligent robot. The high vacuum baking line for the new energypower battery intelligent robot comprises feeding ground rail lines, contact baking oven groups and a receiving ground rail line; two groups of the feeding ground rail lines and the contact baking oven groups are respectively arranged on the two sides of the receiving ground rail line; and the tops of the two groups of the feeding ground rail lines are respectively and fixedly connected with a feeding rack and a feeding six-axis manipulator from left to right. The high vacuum baking line for the new energy power battery intelligent robot is short in baking time, uniform in temperature, high incontrollability and high in continuous production speed, and can be randomly assembled and synchronously produced with other machine sets; heat does not lose; manual operation is not required; completely automatic unmanned feeding and receiving is realized; the baking time can be greatly shortened; the equipment utilization rate is improved; and streamline operation can also be realized with former and later processes, so that the labour intensity of operating personnel is lightened, and the production efficiency and the production progress of the baking of cells are improved.

Owner:HUIZHOU XIN NENG AUTOMATION EQUIP

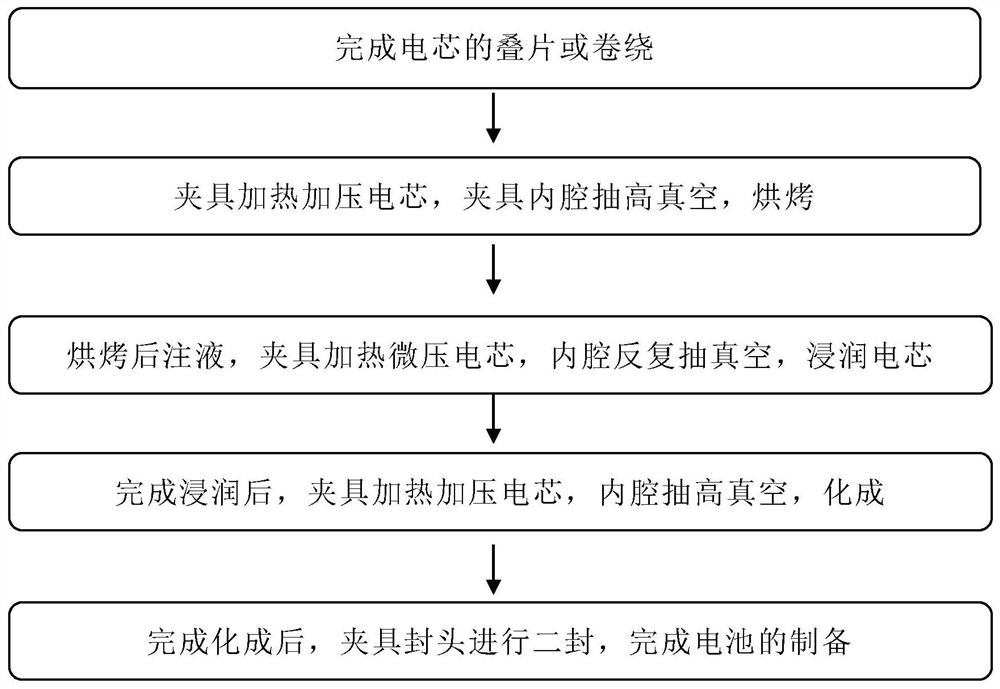

Preparation method of soft package battery

PendingCN111628223AShort preparation timeFast heat conductionAssembling battery machinesFinal product manufactureEngineeringElectrical and Electronics engineering

The invention provides a preparation method of a soft package battery. The method comprises the following steps that a laminated or wound battery cell is placed in an inner cavity of a clamp, the clamp clamps and heats the battery cell, and the inner cavity of the clamp is vacuumized at the same time; after baking is completed, the clamp is opened to inject liquid into the battery cell, after liquid injection is completed, the clamp clamps the battery cell slightly and heats the battery cell, and meanwhile, the inner cavity of the clamp is vacuumized repeatedly to infiltrate the battery cell;after infiltration is completed, the clamp clamps the battery cell and heats the battery cell, meanwhile, the inner cavity of the clamp is vacuumized to a high degree, and formation is started; and after the formation is finished, the battery cell is packaged secondarily to finish preparation of the soft package battery. Compared with the prior art, baking, liquid injection and formation are carried out in the same clamp in a centralized manner, progressing and simplifying are carried out layer by layer, the time from baking to formation in battery cell preparation is shortened step by step, and the production efficiency of the battery is greatly improved.

Owner:东莞汇洋动力科技有限公司

Picking and baking method for reviving tobacco in high-altitude tobacco area

The invention provides a picking and baking method for reviving tobacco in a high-altitude tobacco area, and solves the technical problems that in the prior art, when the reviving tobacco in the high-altitude tobacco area is baked by using an existing baking method, yellowing and dehydration are difficult, dry leaves are prone to browning during color fixing, and the baked tobacco leaves are poorin grade. The method comprises the following steps: (1) harvesting; (2) carrying out tobacco loading; (3) carrying out yellowing temperature stabilizing; (4) carrying out color fixing; and (5) after the tobacco leaves are dried to 2 / 3 of the leaf drying degree, continuously heating to achieve the dry bulb temperature of 48-50 DEG C, keeping at 48-50 DEG C, stabilizing the wet bulb temperature at 38-40 DEG C until the main veins of the tobacco leaves in the whole heatable brick bed are completely dried, and finishing tobacco leaf baking. According to the picking and baking method for the reviving tobacco in the high-altitude tobacco area, tobacco leaves become yellow and dehydrated easily, browning during color fixing of the dry leaves can be avoided, slice steaming or vinasse slices are avoided, and the grade of the baked tobacco leaves can be improved.

Owner:YUNNAN AGRICULTURAL UNIVERSITY +1

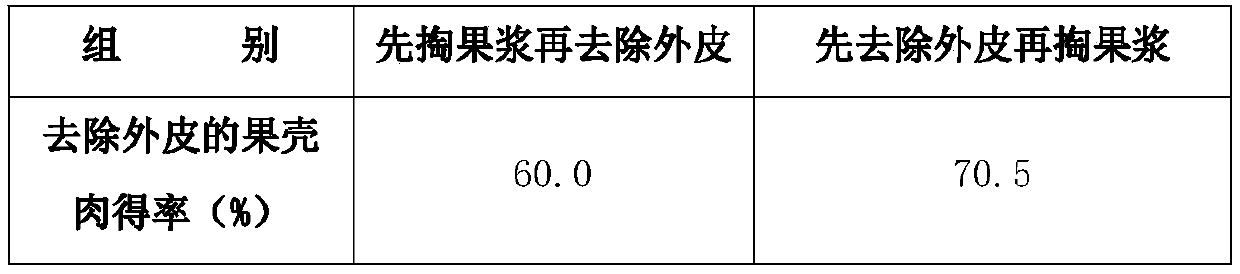

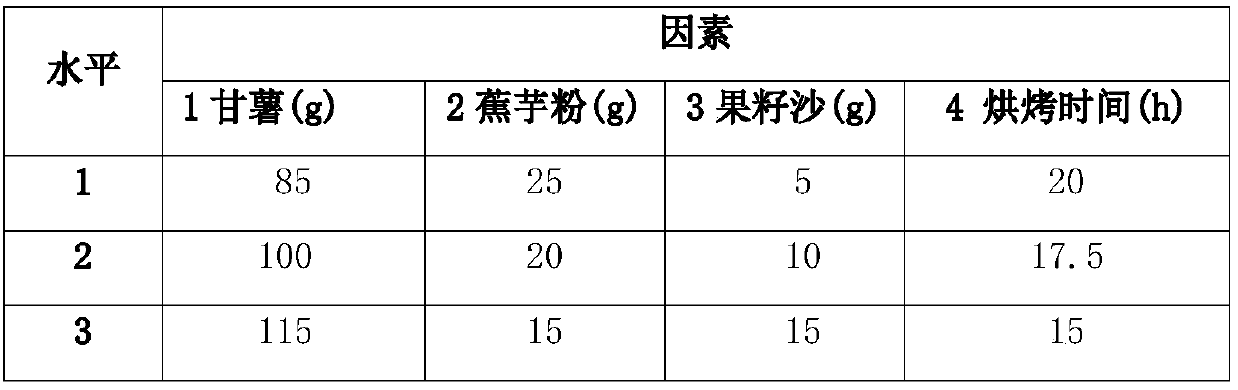

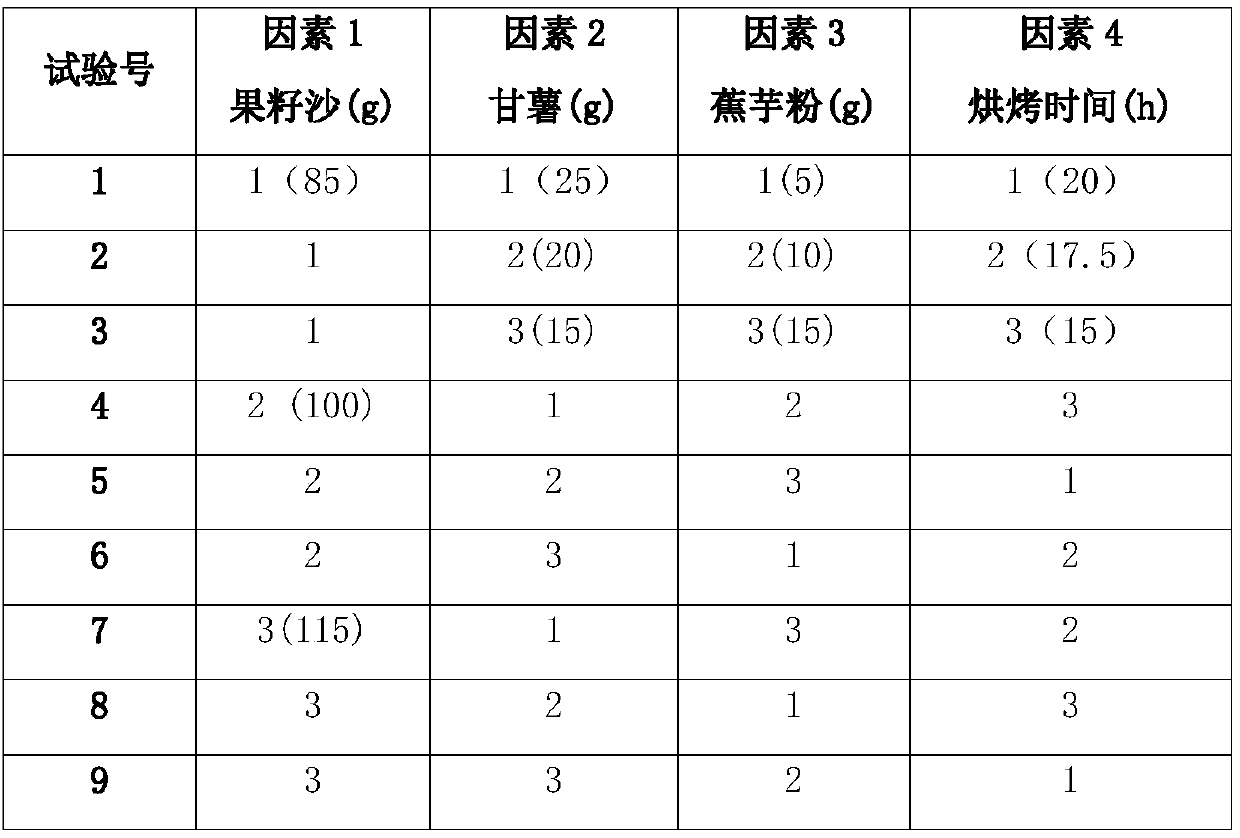

Processing method of sweet potato and passion fruit cakes

ActiveCN109527473ATo achieve the purpose of removing astringencyIncrease production costNatural extract food ingredientsFruit cakeFlavor

The invention discloses a processing method of sweet potato and passion fruit cakes. The method comprises the following steps: pretreatment of raw materials which are sweet potato and all parts of whole passion fruit, blending of the raw materials and auxiliary materials, and processing of the fruit cakes, wherein the pretreatment of all parts of whole passion fruit includes extraction of a fruitshell juice, separation of a fruit juice, and preparation of powdered fruit seeds; and the pretreatment of the sweet potato is preparation of mashed sweet potato. The processing of the fruit cakes iscompleted by the following steps: taking the passion fruit juice, the fruit shell juice, the mashed sweet potato and white granulated sugar, mixing and boiling the taken materials, adding Canna edulisstarch and the powdered fruit seeds, pouring the obtained mixture into a mold, molding the mixture, baking the mixture, demolding the baked mixture and packaging the demolded baked mixture. The method has the advantages of natural and simple raw and auxiliary materials, and realization of the comprehensive utilization of the whole passion fruit, and the product has the advantages of crystal clearappearance, natural, bright and rich color, richness in the passion fruit flavor and the sweet potato flavor, elastic texture, unique crispness, non-sticking to teeth, and sour and refreshing mouthfeel.

Owner:福建紫老虎食品有限公司

Method for controlling circulating fan of bulk curing barn for improving tobacco smoking quality

InactiveCN109820230ADehydration step by stepYellowing step by stepTobacco preparationDrying gas arrangementsElectric energySmoke tobacco

The invention discloses a method for controlling a circulating fan of a bulk curing barn for improving tobacco smoking quality, which comprises the following steps of: setting time and frequency by sections for a frequency converter of the fan of the curing barn, using 5Hz as an adjusting unit, wherein before the tobacco is cured to 38 DEG C, the frequency of the frequency converter is not more than 35Hz, the rotating speed of the circulating fan is not more than 1050r / min, and when the tobacco is cured to 42 DEG C-54 DEG C, the frequency of the frequency converter is 50Hz, the rotating speedof the circulating fan is kept at 1480r / min, after the tobacco is cured to 54 DEG C, the frequency of the frequency converter is 30-45Hz, the rotating speed of the circulating fan is 900-1200r / min,the power consumption is obviously reduced after the frequency converter of the bulk curing barn is reformed, the electric energy is saved by about 30%, the wind speed is soft, the tobacco is dehydrated, becomes yellow and is dried step by step, a large amount of aroma substances are deposited and accumulated, the chemical components are coordinated, and the industrial use value of the tobacco isimproved.

Owner:云南省烟草公司大理州公司 +2

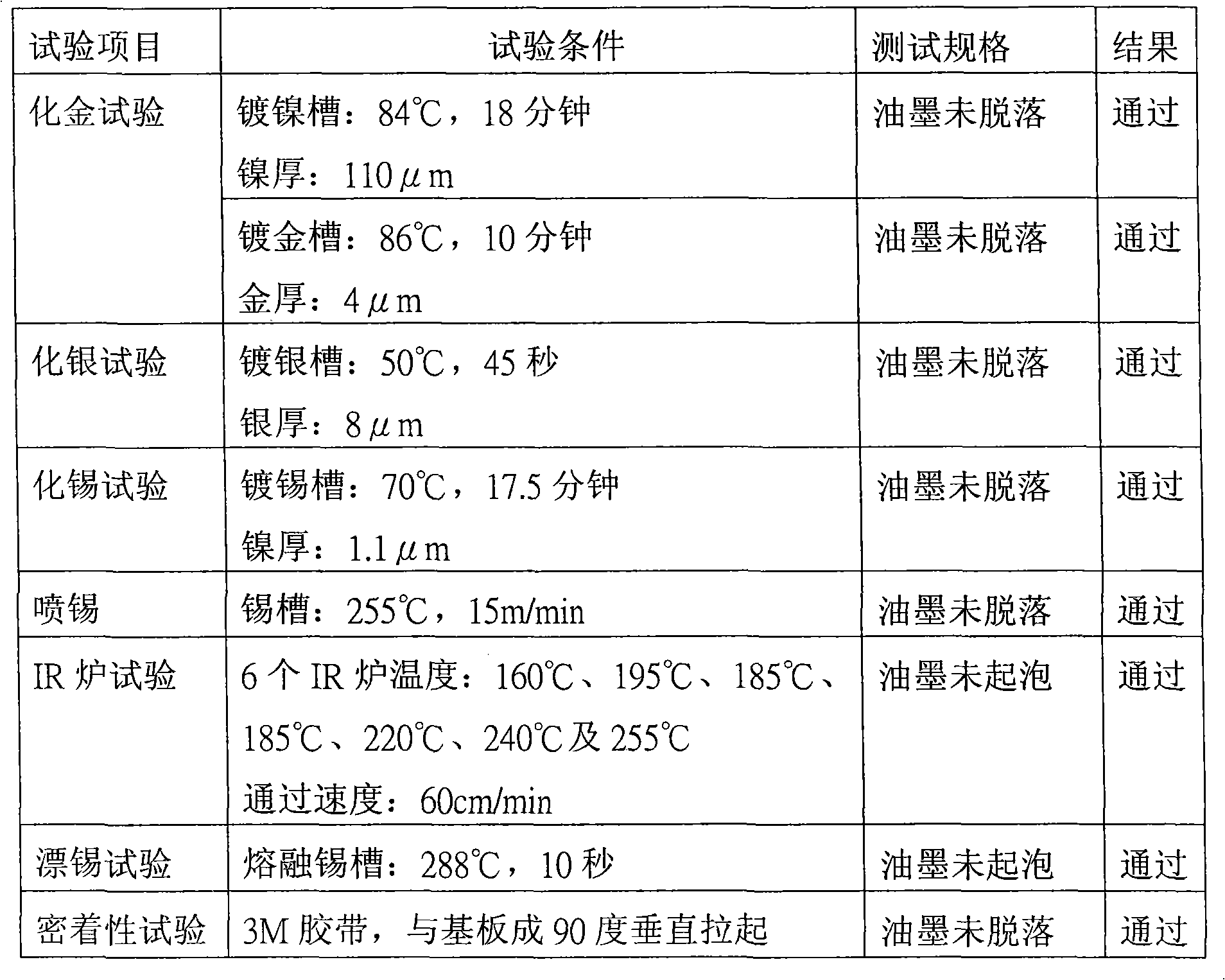

Method for manufacturing printed circuit board

InactiveCN101841978ALow costReduce usageConductive material chemical/electrolytical removalChemical treatmentMetallurgy

The invention provides a method for manufacturing a printed circuit board, which comprises the steps of: grinding a copper foil substrate to be processed and chemically processing the copper foil substrate to be processed; coating anticorrosive printing ink on the copper foil in the thickness of between 13 and 18 mu m; pre-baking the coated copper foil at the temperature of between 65 and 85 DEG C for 5 and 10 minutes; exposing the baked copper foil by using a photomask and then developing the exposed copper foil; and baking the obtained product at the temperature of 150 and 155 DEG C for 30 minutes. According to the method for manufacturing the printed circuit board, the printed circuit board can be obtained by coating thinner anticorrosive printing ink, so the use amount of the anticorrosive printing ink can be reduced; besides, the coated film is thinner, so the drying process can be complemented at a low temperature in a short time period, the cost is saved, and the effects of energy conservation and carbon reduction are achieved.

Owner:FULL TREASURE INT ENTERPRISE

Lithium battery drying process

ActiveCN109883143BPerformance impactEfficient removalFinal product manufactureDrying solid materials without heatThermodynamicsProcess engineering

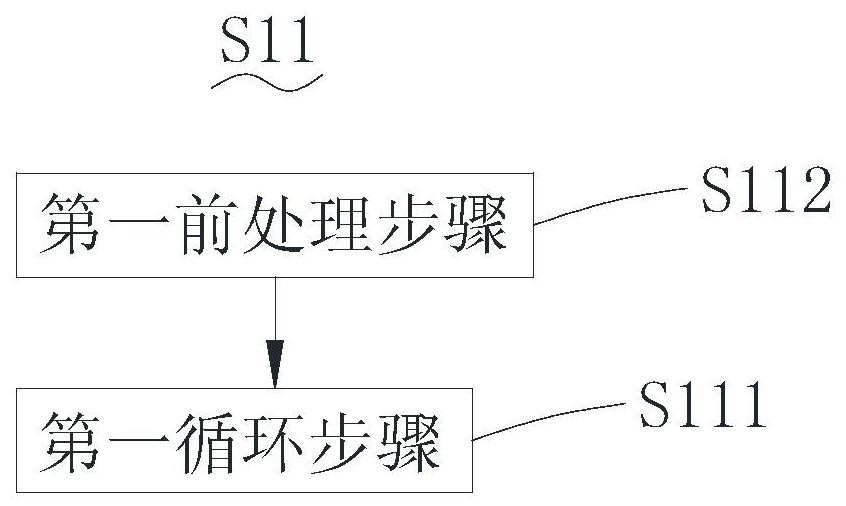

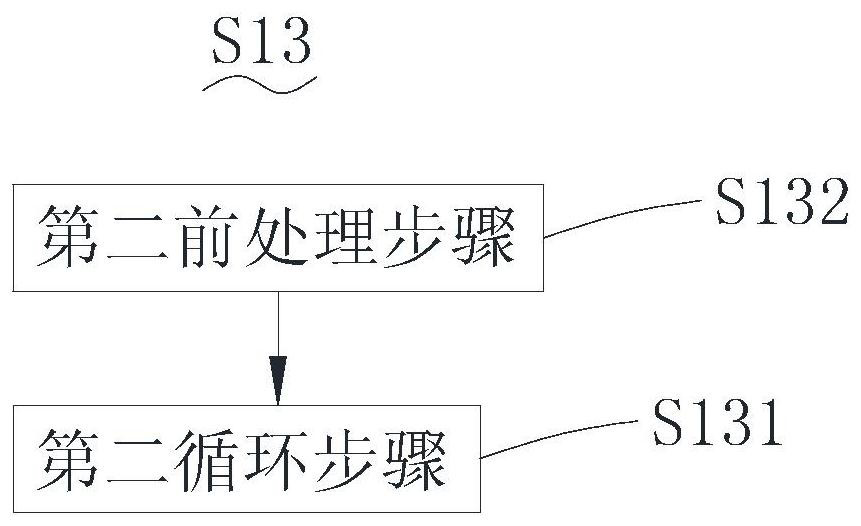

The invention discloses a lithium battery drying process, which comprises a first baking step of putting a pole piece or a pole piece core into an oven for baking; an assembly step of winding the pole piece after the first baking step into a pole piece core, and install the pole piece core inside a battery case with an open end to make a semi-finished battery, or install the pole piece core after the first baking step into a battery with an open end The inside of the casing is used to make a semi-finished battery; in the second baking step, the semi-finished battery is put into an oven for baking. The lithium battery drying process disclosed in the present invention can efficiently remove the moisture inside the battery through the two-stage drying process, and does not need to greatly increase the drying temperature and prolong the baking time during the baking process, and will not damage the battery. Performance is negatively impacted without greater energy consumption.

Owner:广西燚能新能源有限公司

Normal-temperature long-shelf-life cake baking device and preparation method thereof

InactiveCN112602736AHeat reliefExtend the baking timeBakery productsBaking sheets/boardsMaillard reactionEngineering

The invention provides a normal-temperature long-shelf-life cake baking device which comprises a tunnel furnace, a lower baking tray used for containing water is arranged in the tunnel furnace, and an upper baking tray used for containing cakes is arranged on the upper portion of the lower baking tray. Cakes can be baked through the double-layer baking tray by means of the device. Double layers of baking trays are used together, water is added into the lower baking tray to reduce the temperature rising speed of the upper baking tray, heating is more moderate, water loss is less, the baking time of cakes is prolonged, and the surfaces of the made cakes have the specific baking color and luster and are not affected by prolonging of the baking time; and the bottom of the cake bottom cannot reach the Maillard reaction temperature, colors cannot be formed, the color difference is obvious, and the taste is more moist.

Owner:淮南六花庭食品有限公司

Wet nori for preparing sea sedge and preparation method of wet nori

ActiveCN104187879ASolve the problem of slow salesCrispy tasteFood preparationTemperature controlSalt content

The invention provides wet nori for preparing sea sedge and a preparation method of the wet nori, and relates to the field of foods processing. The preparation method of the wet nori comprises the following technical steps of cutting, softening, mixing pulp, pouring, re-drying, discharging cake, bagging and storing to obtain the wet nori for preparing the sea sedge, which contains 20% to 25% of water content. According to the preparation method of the wet nori, raw nori algae of which the stretching degree, freshness and toughness meet requirements is selected and cut into special dimension and then is softened with water, and therefore, the prepared wet nori has loose tissue, contains few pores and is wrinkled and contracted after being braked; the finished sea sedge is thin and tastes soft, fragrant, crispy, free of slag, and just melted in the mouth, and thus the mouth feel of the product can be improved; the drying is performed by steps under temperature control, so that the water content of the wet nori product can be controlled to be 20 to 25%; because the wet nori contains high water content, the baking time can be properly prolonged to improve the sterilizing effect; in addition, the wet nori can not be burned in baking, and therefore, the problem of abnormal quality caused by the factor that the total number of bacterial colony exceeds standard can be solved.

Owner:HEBEI STRONG FOOD

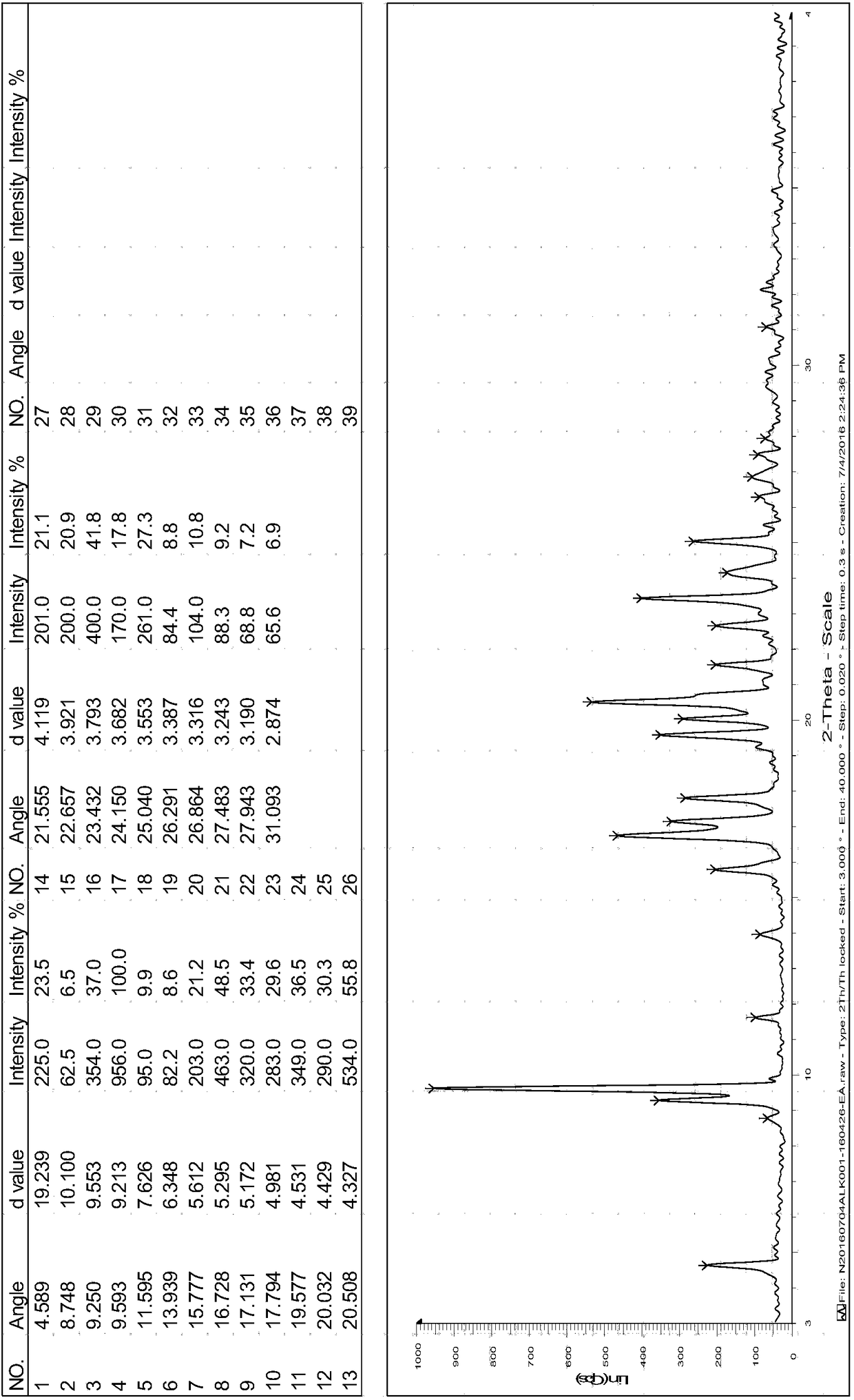

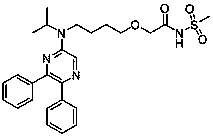

Preparation method of selexipag crystal form

The invention mainly aims at providing a preparation method of a selexipag crystal form. A diffraction pattern of X-ray powder of crystals prepared by utilizing the method has characteristic peaks at(2theta+ / -0.2 degrees) 9.3 degrees, 9.7 degrees, 16.8 degrees, 20.6 degrees and 23.5 degrees. The method has the advantages of simplicity in operation, less solvent residue, stable product quality andsuitability of industrialized mass production.

Owner:JIANGSU ALICORN PHARMATECH CO LTD

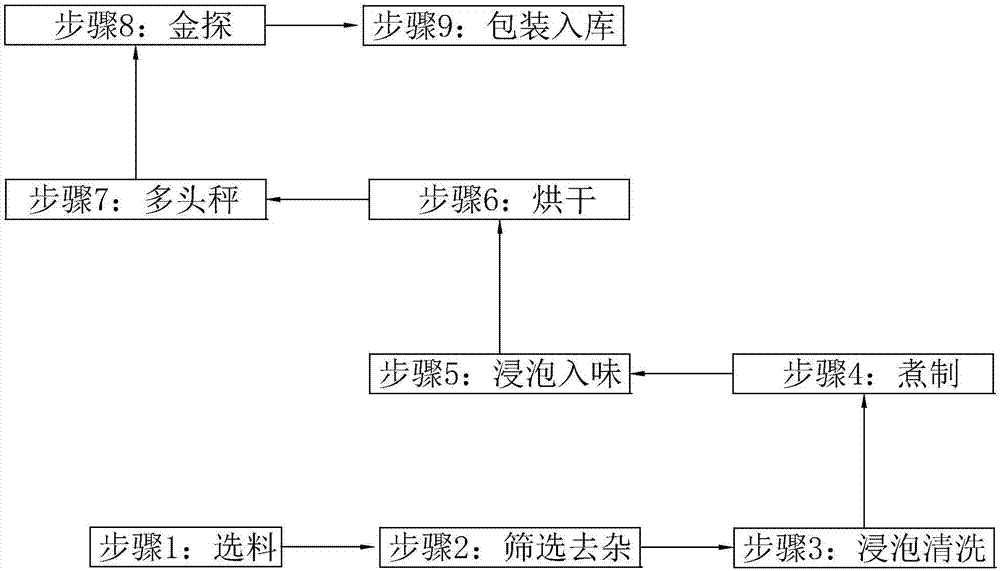

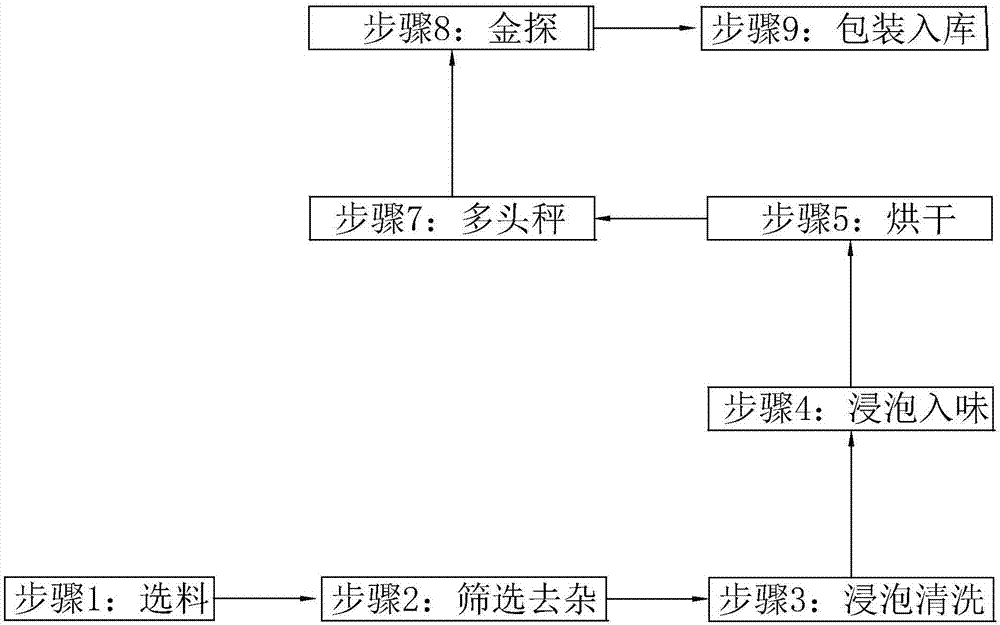

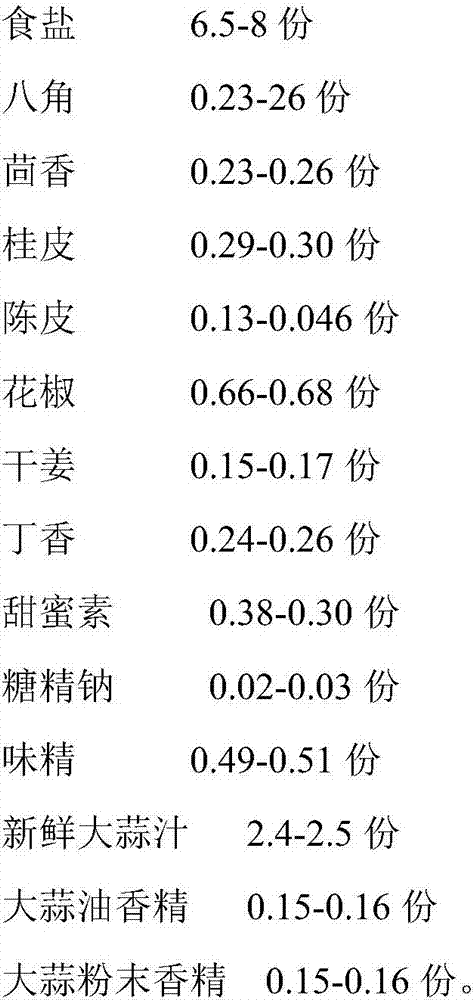

Production technology of peanuts

The invention relates to a production technology of peanuts. The production technology comprises the following steps of step 1, selecting materials; step 2, performing sieving and impurity removing; step 3, performing soaking and washing; step 4, performing boiling; step 5, performing soaking to enable the boiled peanuts to be tasteful; step 6, performing drying; step 7, performing weighting by amulti-head weigher; step 8, performing metal detection; and step 9, performing packing and warehousing. In the braising process, seed coats of the peanuts are soaked in braising juice, so that moisture in the seed coats is sufficiently maintained, and the phenomenon that the seed coats come off cannot be easily generated; then the peanuts are put in seasonings, so that through the moisture on thesurface of the seed coats, the situation that the seasonings are adhered onto the surfaces of the peanuts is facilitated; and then in the roasting process, the seasonings packed outside the peanuts are heated in advance and dehydrated to form a housing packing the outer part of the corresponding peanut; and when heat quantity is conducted to the inner parts of the peanuts by the housings, under the block of the housings, the moisture in the seed coats of the peanuts is difficult to disperse outwards, and flexibility is still kept to a certain extent, so that the phenomenon that the seed coatscome off cannot be easily generated.

Owner:青岛胶平食品有限公司

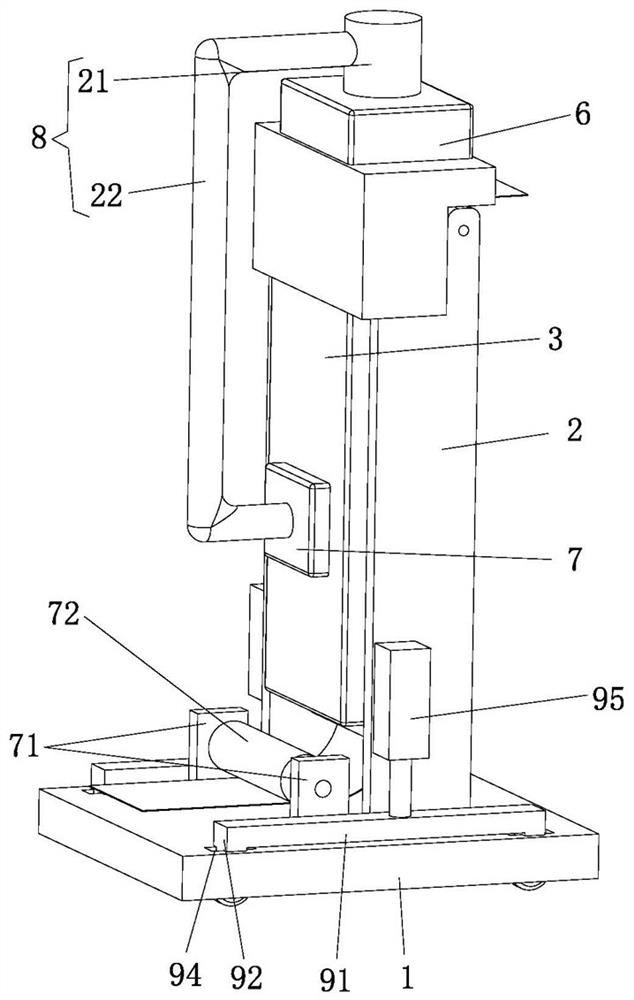

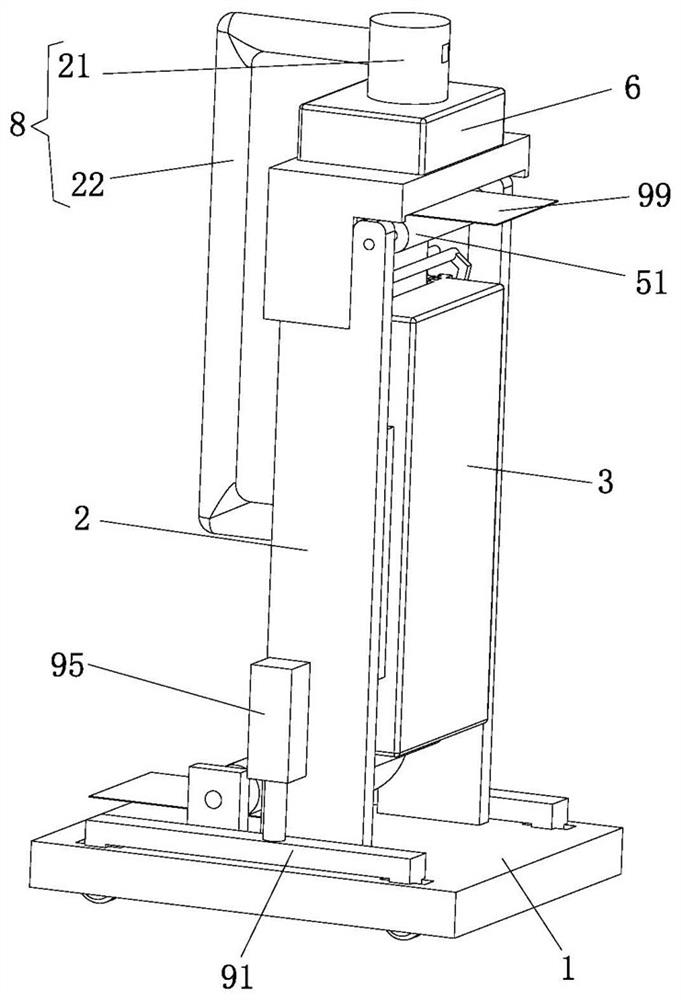

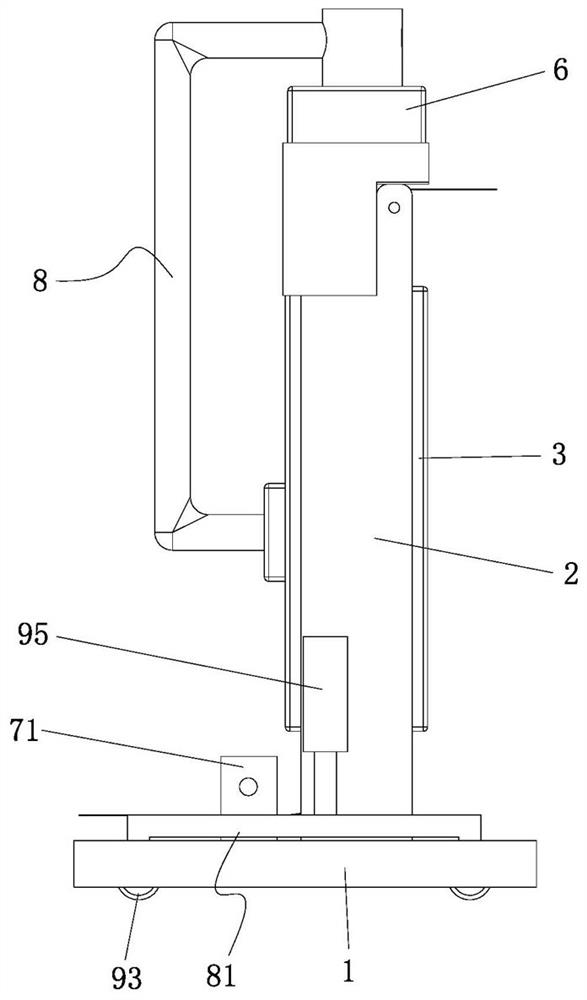

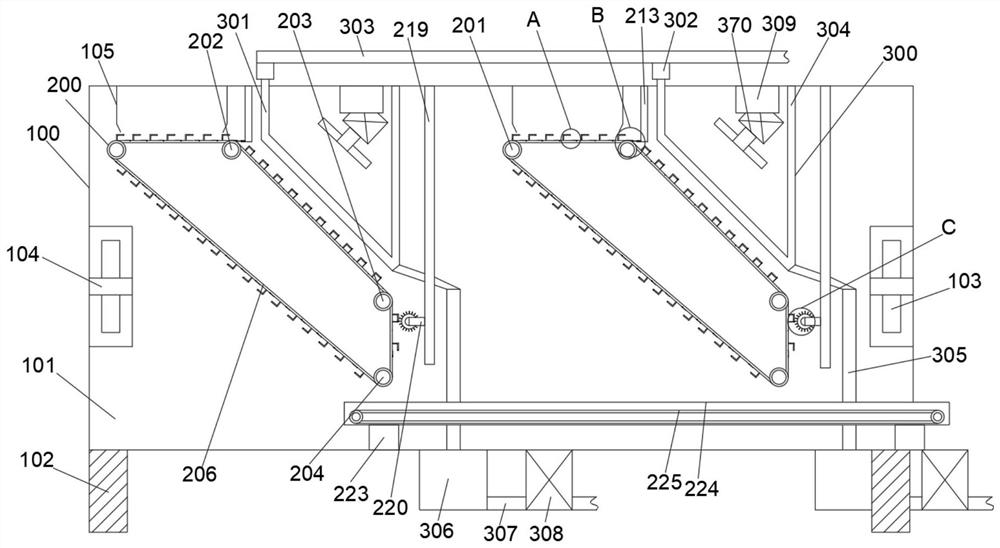

Vertical oven for aluminum foil corrosion production

PendingCN113418366AExtend the baking timeStable qualityDrying gas arrangementsDrying machines with progressive movementsAluminium foilProcess engineering

The invention discloses a vertical oven for aluminum foil corrosion production. A heating channel is formed in an oven body in an up-down penetrating mode, a heat transfer box body is arranged at the upper end of a first supporting frame and located above the heating channel, and an air outlet box body which communicates with the heating channel is arranged on the rear side of the oven body. A connecting pipeline communicates between the heat transfer box body and the air outlet box body, and an air suction device and a steam heat exchanger are arranged in the connecting pipeline. A piece of aluminum-foil paper enters the heating channel from the upper end of the oven body and comes out from the lower end of the oven body, and therefore the hot air in the oven body moves upwards, the quality of the aluminum-foil paper cannot be affected, the baking time of the aluminum-foil paper is longer, and the quality is more stable. In addition, the hot air exhausted from the heating channel can be collected and then is utilized, the hot air is blown out from the air outlet box body to dry the aluminum-foil paper, the waste heat of the oven is subjected to secondary utilization, cyclic utilization of heat energy is achieved, the heat energy utilization rate is increased, and the production cost is reduced.

Owner:恒扬(韶关)工业有限公司

A kind of osmanthus fruit drying device

ActiveCN112923708BPrevent stackingPrevent falling outDrying gas arrangementsDrying machines with progressive movementsMechanical engineeringHorticulture

The invention discloses an osmanthus fruit drying device, which comprises a box body mechanism, an operating mechanism and a drying mechanism; the operating mechanism is fixedly installed inside the box body mechanism, and the drying mechanism is separately connected with the box body mechanism, and The drying mechanism part is located inside the box body mechanism; the present invention can effectively prevent the osmanthus fruit from piling up during drying by setting the placement frame, cover plate and shift lever; and the motor can be adjusted in speed to prevent the osmanthus fruit from It cannot be completely dried; by setting the return pipe and the condensation pipe, the water can be reused to achieve the effect of saving energy; by setting the exhaust fan and the exhaust fan, the water mist or water vapor generated by the drying of the osmanthus fruit can be discharged out of the box , so as to ensure the continuous drying of the box.

Owner:XINYANG AGRI & FORESTRY UNIV

Instant bolete soup base and preparation method thereof

PendingCN113383931AMellow tasteFull of nutritionFood preservationLipidic food ingredientsBiotechnologyNutrition

The invention belongs to the technical field of food, and particularly discloses an instant bolete soup base. The instant bolete soup base comprises the following raw materials in parts by weight of 10-15 parts of yellow bolete, 5-10 parts of boletus edulis, 2-6 parts of dried mushroom, 1-4 parts of chicken paste, 1-4 parts of chicken juice, 5-10 parts of salad oil, 5-10 parts of chicken oil and 1-4 parts of lard oil. The invention further discloses a preparation method of the instant bolete soup base. The preparation method comprises the steps of preparing powder and preparing seasoning. The instant bolete soup base is brewed with boiled water, so that the bolete soup which is mellow in taste, rich in nutrition and rich in fragrance can be eaten.

Owner:CHONGQING DEZHUANG AGRI PROD DEV CO LTD

Unburned carbon-free brick for generating MgAlON/beta-Sialon complex phase in situ under smelting condition

The invention discloses an unburned carbon-free brick for generating an MgAlON / beta-Sialon complex phase in situ under a smelting condition. According to the adopted technical scheme, the MgAlON / beta-Sialon complex phase consists of the following raw materials in parts by weight: 60-70 parts of fused magnesite, 5-10 parts of MaO.Al2O3 spinel with a fiber netlike structure, 3-12 parts of metal aluminum powder and 0-5 parts of metal silicon powder, 2-6 parts of aluminum oxide micro powder and 4-6 parts of a magnesium aluminate cementing agent; and the unburned carbon-free brick is prepared by mixing the raw materials above according to a certain weight proportion, molding and drying at 100-200 DEG C for 24-30 hours. Environmental protection is facilitated, the production period is shortened greatly, and production cost is reduced. An MgAlON / beta-Sialon complex phase refractory material is generated in situ under a smelting condition, and has the advantages of small linear expansion, low apparent porosity, high volume density, high thermal shock resistance, high erosion resistance, high scouring resistance, high oxidation resistance, self-repairing capacity and the like.

Owner:辽宁青花耐火材料股份有限公司

Safe and efficient oven and using method

PendingCN114732293AImprove efficiencyQuality improvementFood processingRoasting apparatusEngineeringMechanical engineering

The invention relates to a safe and efficient oven and a using method. The safe and efficient oven comprises a frame body. The oven is mounted at the top of the frame body, and barbecue is placed in the oven to be baked; the supporting part is mounted at the bottom of the oven and is used for heating the roasted meat; the turnover part comprises a driving mechanism and a plurality of gears, the driving mechanism is mounted at the top of the supporting part, and the gears are mounted in the driving mechanism and used for clamping the ends of the kebabs. The oven capable of being closed is arranged, the baking time is shortened, skewers needing charcoal grilling can be turned over by means of the arranged turning part, during grilling, the ends of the skewers are placed on the side walls of the gears, when the driving mechanism drives the gears to rotate, the skewers can rotate along with the gears, turning charcoal grilling is conducted, and the barbecue efficiency is improved. The skewering efficiency can be improved, the surface of barbecued meat is evenly charcoal-grilled, and the barbecuing quality is improved.

Owner:江苏德格莱斯科技股份有限公司

Method for solving skip plating of fixed position of PCB (Printed Circuit Board) caused by battery effect

PendingCN114828436AFast heatingSolve skip plating problemPrinted circuit manufactureComposite materialPrinted circuit board

The invention discloses a method for solving skip plating of a fixed position of a PCB (Printed Circuit Board) caused by a battery effect, which comprises the following steps of: providing a production board, arranging a solder resist windowing position to be subjected to nickel-gold immersion treatment and antioxidant treatment on the production board so as to expose a PAD, and arranging a non-plated-through hole and a plated-through hole on the production board; the PAD comprises a first PAD connected with the non-plated-through hole, a second PAD connected with the plated-through hole and / or a third PAD not connected with the hole; wherein the first PAD is subjected to nickel-gold deposition treatment, the second PAD connected with the plated-through hole and the plated-through hole are subjected to nickel-gold deposition treatment or anti-oxidation treatment at the same time, and the third PAD with the distance smaller than 20 mil s from the plated-through hole and the plated-through hole are subjected to nickel-gold deposition treatment at the same time; after a film is pasted on the production board, windowing is conducted on the positions corresponding to the non-plated-through holes and the positions to be subjected to nickel and gold immersion treatment; carrying out chemical nickel and gold immersion treatment on the production board; and after the film is removed, the production board is subjected to anti-oxidation treatment. The method effectively solves the problem of skip plating of the PAD in the prior art.

Owner:江西景旺精密电路有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com