Tea dryer

A tea dryer and tea technology, applied in the directions of tea processing, transportation and packaging, loading/unloading, etc. before extraction, can solve the problems of limited number of tea leaves, limited number of conveyor belt layers, limited internal space of the oven, etc., and achieve a reasonable design , Improve drying efficiency, extend the stroke and the effect of baking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

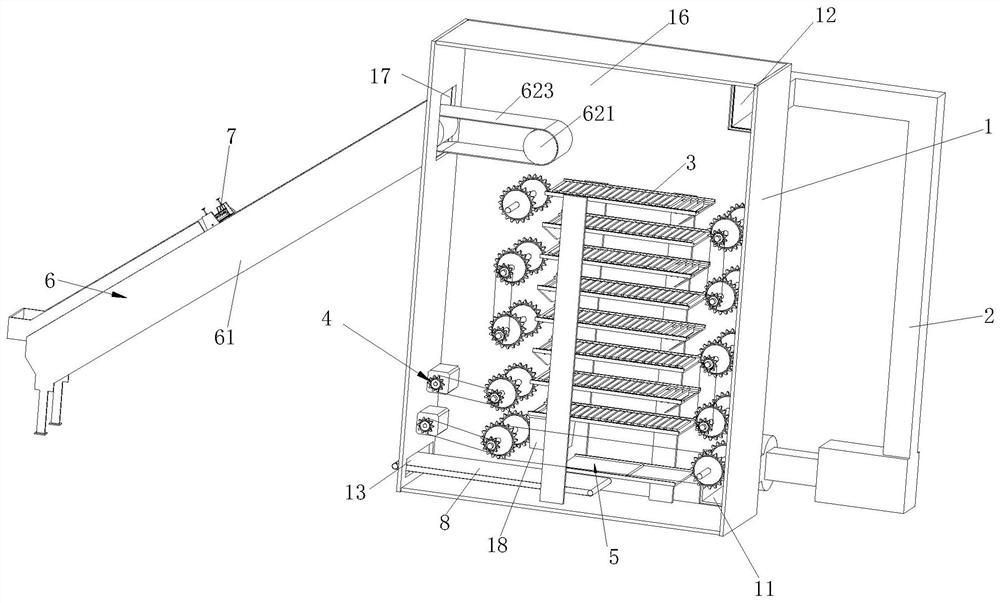

[0042] The present invention is described in detail below in conjunction with accompanying drawing description:

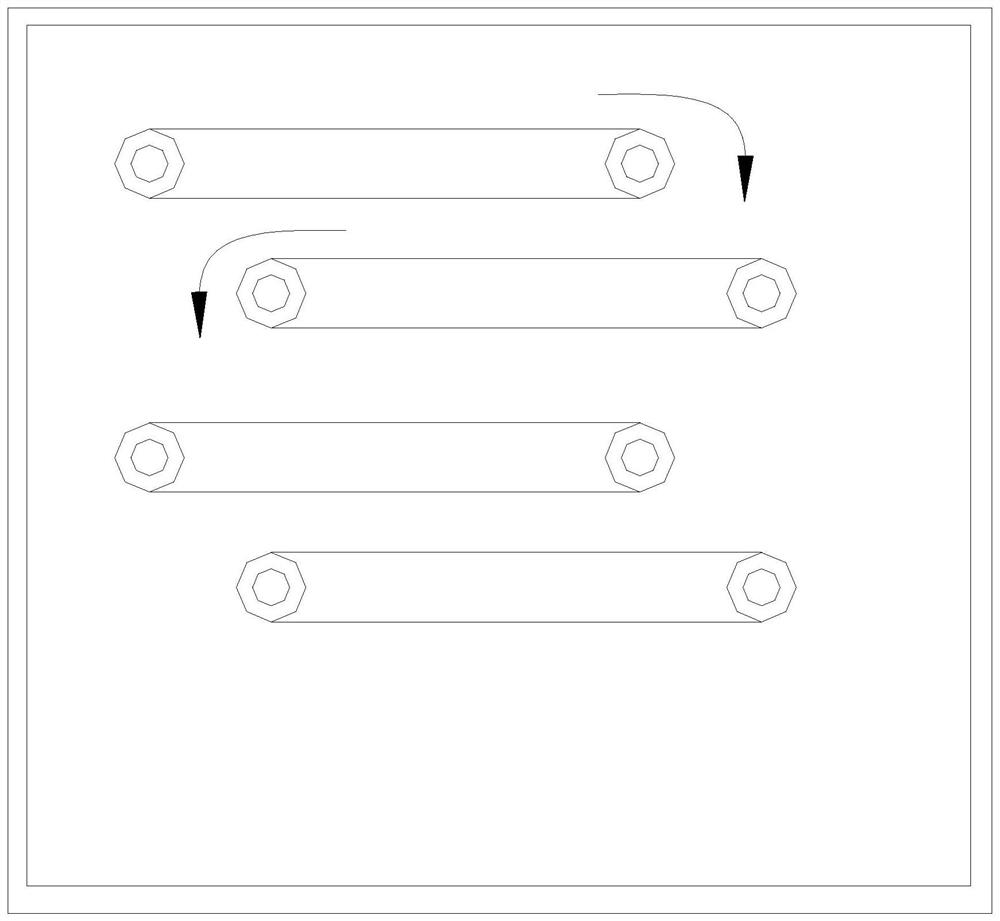

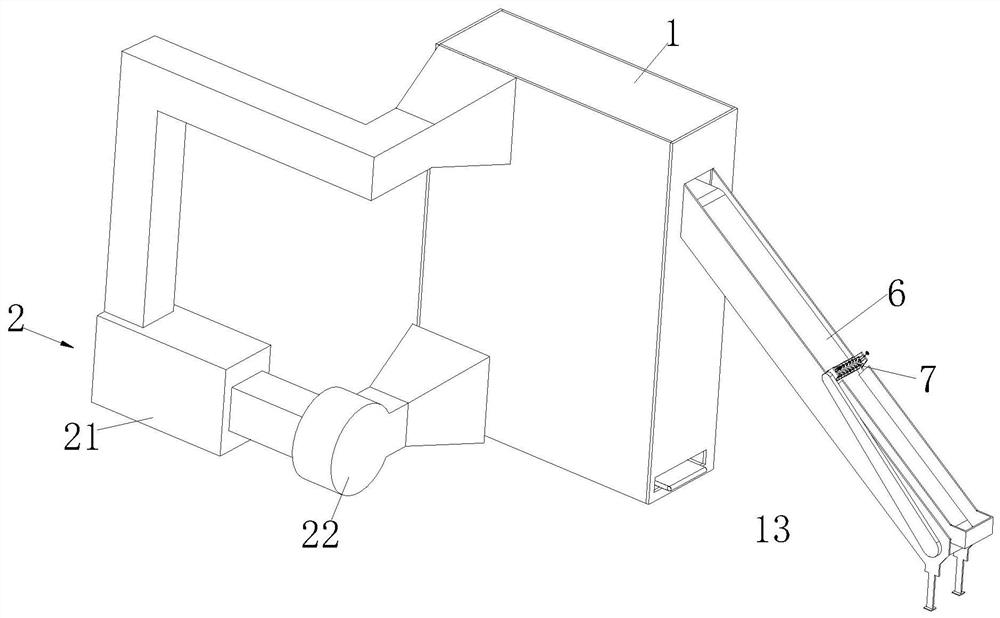

[0043] Such as Figure 2-12 As shown, a tea drying machine of the present invention is characterized in that it includes a drying box 1 with a drying cavity 16 inside, a hot air conveying device 2 located outside the drying box 1, and a drying box installed in the drying cavity 16. The conveying device used to place the tea leaves and drive the tea leaves to move and convey in the drying cavity 16, and the conveying drive assembly 4 connected with the conveying device to drive the conveying device to work;

[0044] The lower side of the box wall of the drying box 1 is provided with an air inlet 11 for communicating with the hot air conveying device 2 and the drying cavity 16 to deliver hot air to the drying cavity 16, and on the upper side of the box wall of the drying box 1 There is also an air outlet 12 that communicates the drying cavity 16 with the outside;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com