Nitromethane synthesis reaction tower

A synthesis reaction, nitromethane technology, applied in the chemical method of liquid-liquid reaction, preparation of organic compounds, chemical instruments and methods, etc., can solve the problem of unsatisfactory nitromethane synthesis reaction, production process interruption, production work Inconvenience and other problems, to reduce the risk of safety and environmental protection, reduce waste, and fully respond

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technology, features, purposes and effects of the present invention easier to understand and understand, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention, but the present invention is not limited thereto.

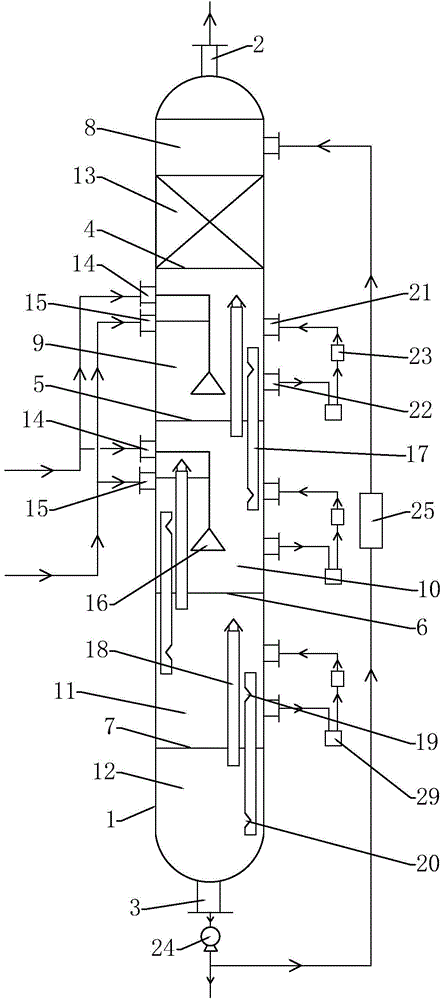

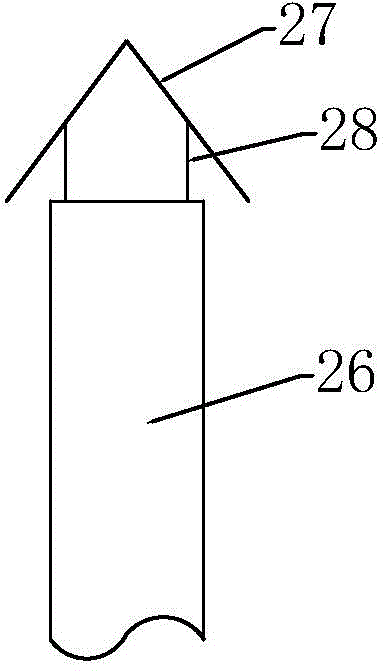

[0014] Such as Figure 1-Figure 2 As shown in , this embodiment includes a tower body 1, the top gas outlet 2 and the material outlet 3 are respectively provided at the top and bottom of the tower body 1, and the first tray 4 arranged in sequence from top to bottom in the tower body 1 , the second tray 5, the third tray 6 and the fourth tray 7 divide the interior of the tower body 1 from top to bottom into the first tower chamber 8, the second tower chamber 9, the third tower chamber 10, the fourth tower chamber The tower chamber 11 and the fifth tower chamber 12, the first tray 4 is a sieve tray, the upper surface of the first tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com