Cable air-drying device

An air-drying device and cable technology, used in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of occupying a large space, air-cooled lines cannot guarantee the drying effect of cable products, and dripping on the bottom, etc., to shorten the drying time. time, prolonging the stroke and residence time, and reducing the effect of water attachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the technical solution of the present invention will be described in detail through specific examples.

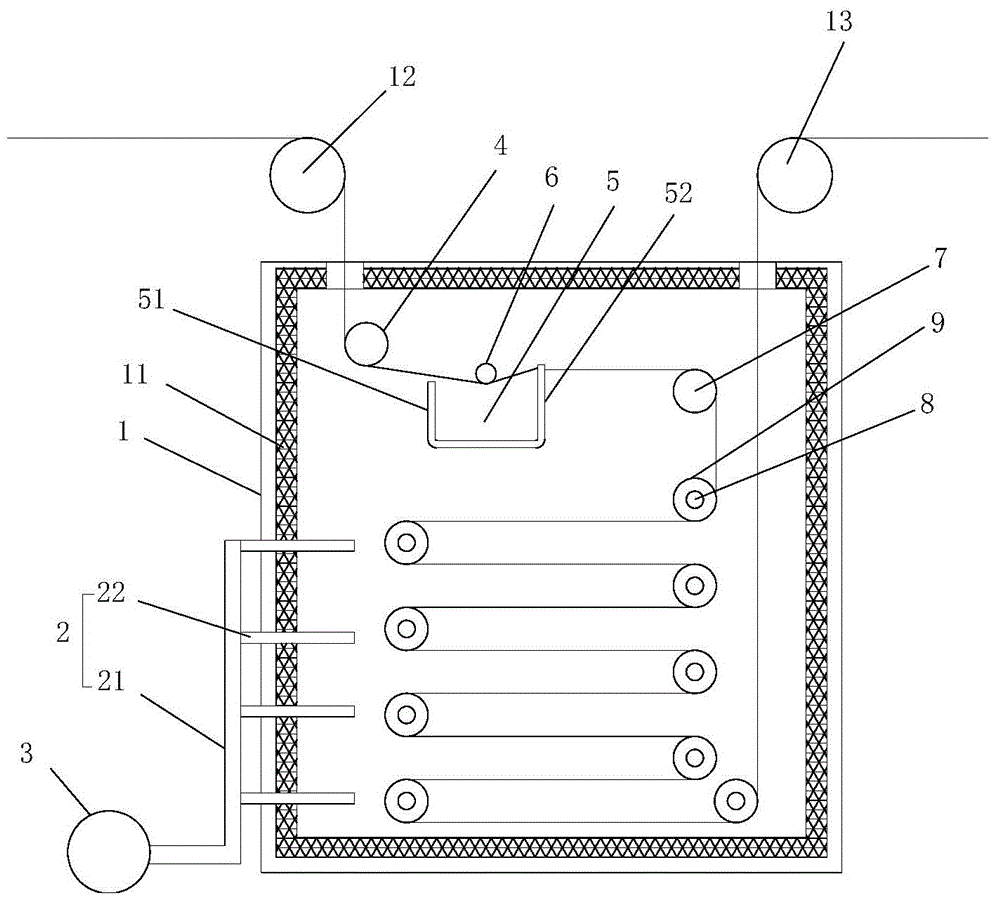

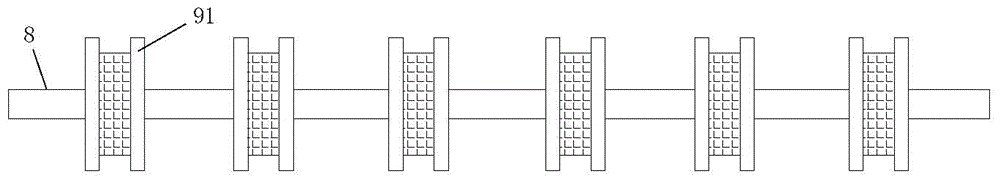

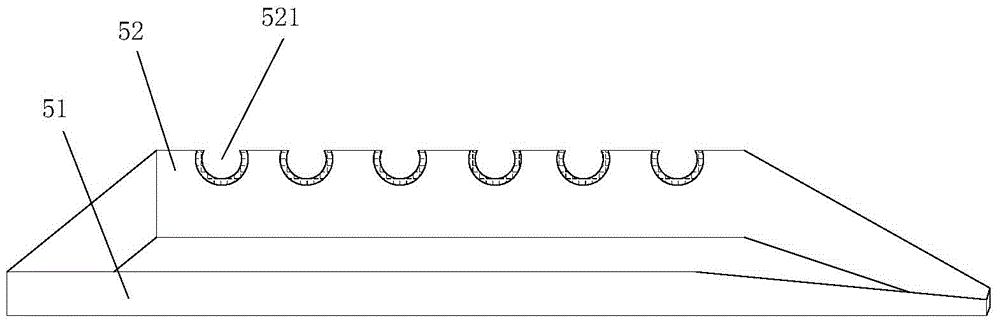

[0021] like Figure 1-4 as shown, figure 1 It is a structural schematic diagram of a cable air-drying device proposed by the present invention; figure 2 It is a schematic diagram of the assembly structure of the horizontal column and the guide wheel in a cable air-drying device proposed by the present invention; image 3 It is a structural schematic diagram of the water control tank in a cable air-drying device proposed by the present invention; Figure 4 It is the structural intention of the limit pressing bar in a cable air-drying device proposed by the present invention.

[0022] refer to Figure 1-4 , a kind of cable air-drying device that the embodiment of the present invention proposes, comprises: box body 1, air inlet pipe 2 and blowing device 3, wherein, the top of box body 1 feed inlet is provided with first guide wheel 12, box body 1 exits The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com