Patents

Literature

33results about How to "Uniform dryness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick roasting method of fresh grosvenor momordica

ActiveCN102100394AGuaranteed circulationExtend the baking timeFood preservationPharmaceutical product form changeTime rangeMicrowave oven

The invention discloses a quick roasting method of a fresh grosvenor momordica, which comprises the following steps: (1) classifying the ripe grosvenor momordica according to large, middle and small specifications and respectively placing into a special roasting tray used for a microwave oven; (2) placing the roasting tray filled with the grosvenor momordica into an intelligent microwave vacuum drying oven; and (3) determining the roasting time according to the weight of the grosvenor momordica and the power of the microwave oven and roasting, wherein the roasting temperature range is 20-40 DEG C, and the roasting time range is 30-150 minutes under the condition of vacuum degree less than -0.08MPa. In the method, the microwave technology for roasting is utilized, the roasting process is carried out at low temperature and constant temperature, the time consumption is short, the cost is low, and the fresh grosvenor momordica well keeps the bright yellow color and nutrition constituents and has good taste.

Owner:桂林普兰德生物科技有限公司

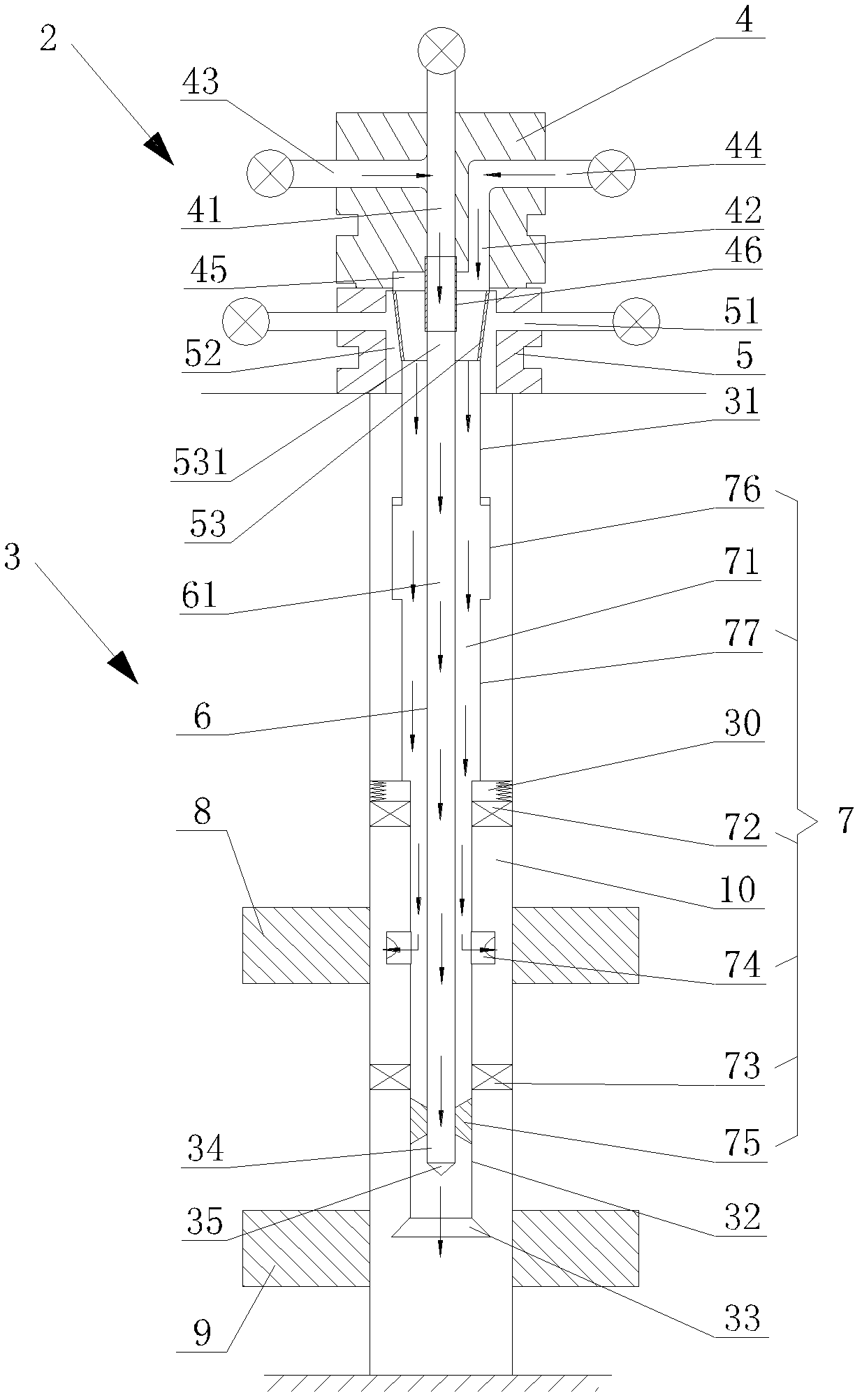

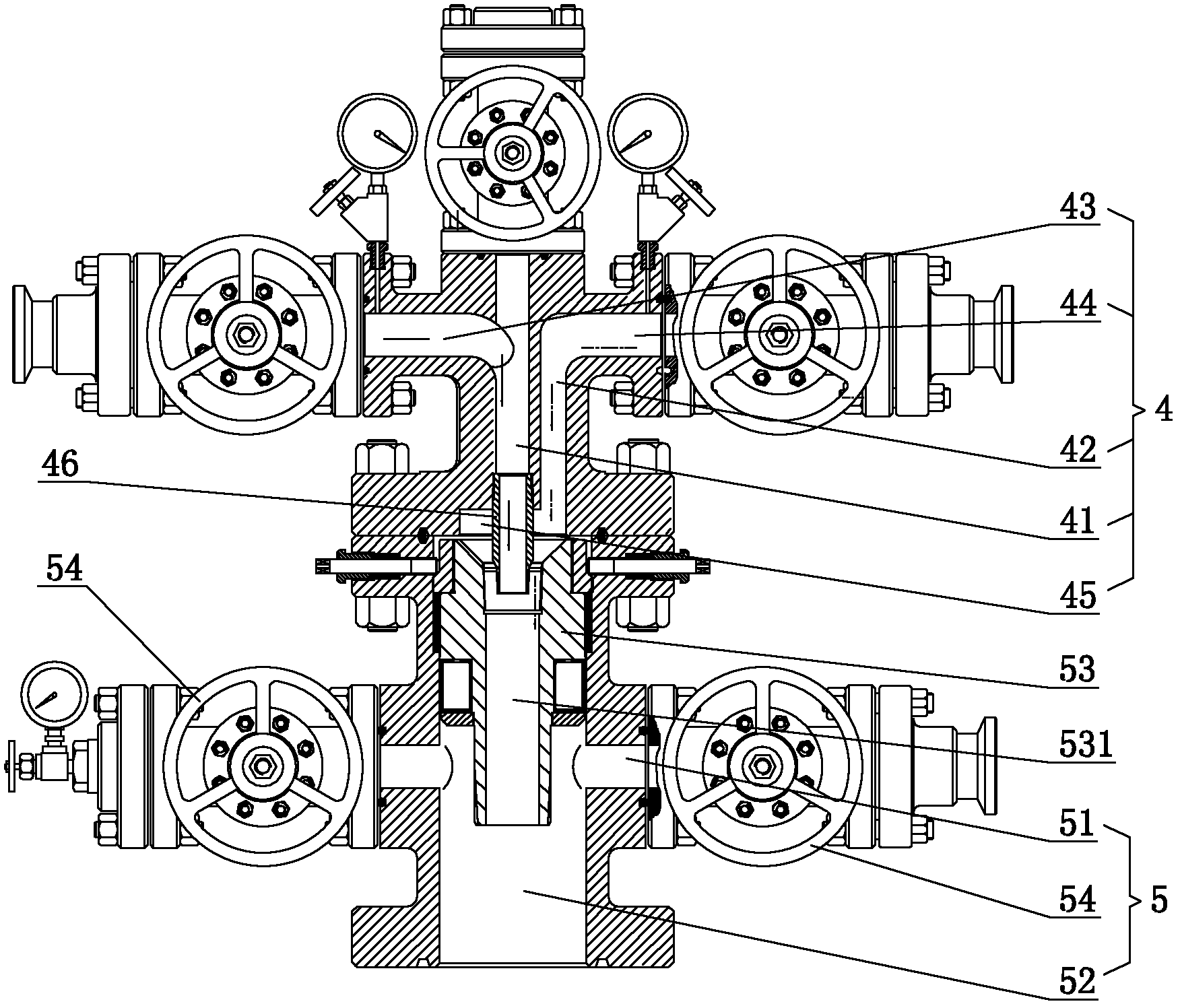

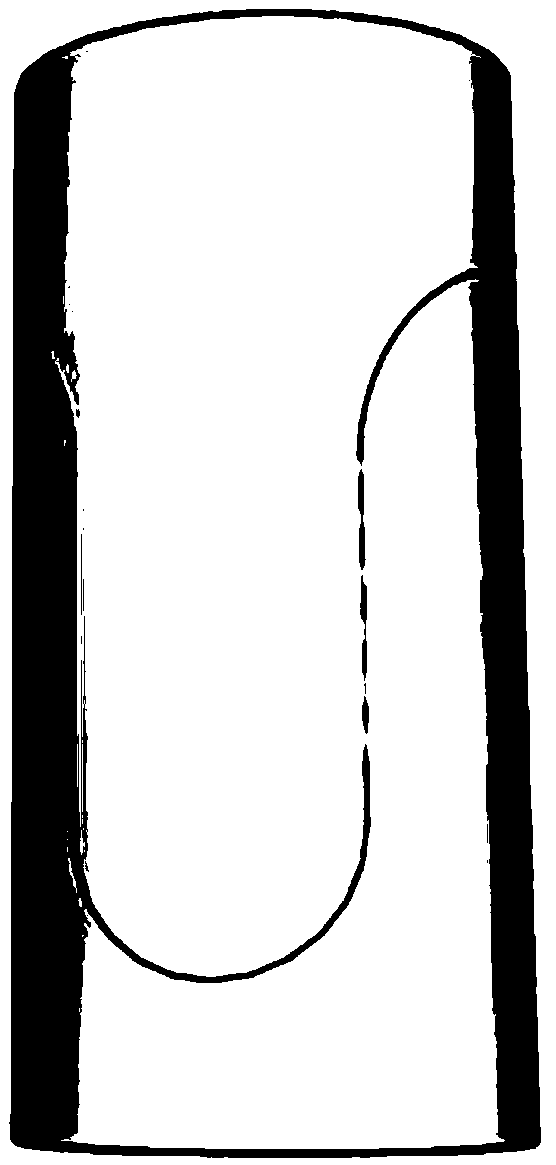

Concentric pipe layered steam injection system and method

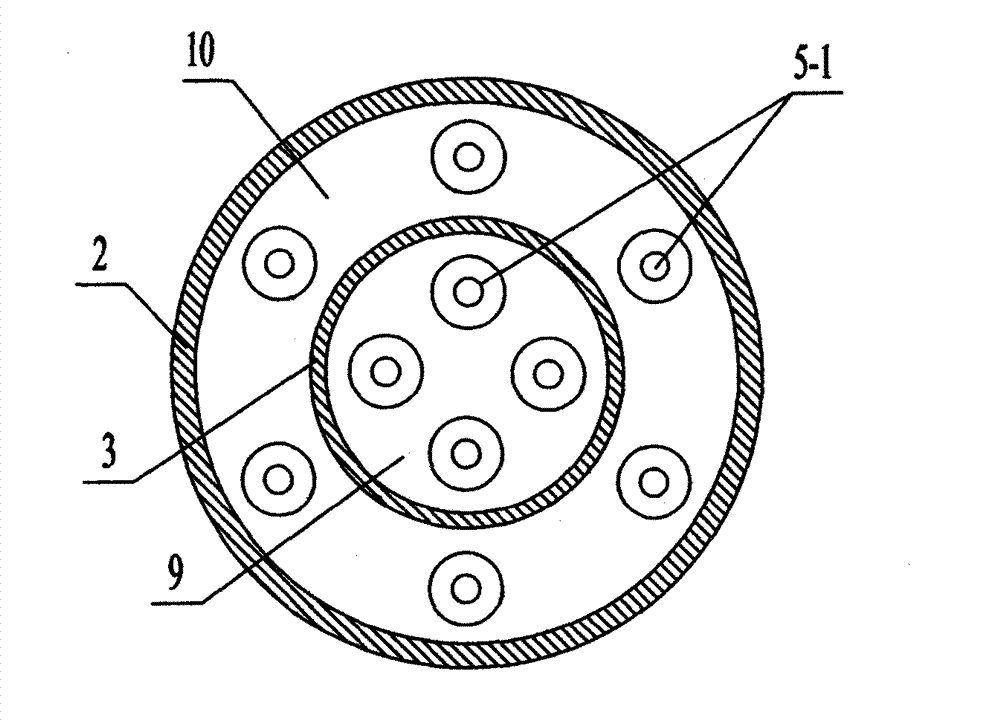

The invention discloses a concentric pipe layered steam injection system and a method. A cyclone and a phase mixing device are arranged in a steam inlet passage of a steam distributor of the concentric pipe layered steam injection system, the outlet end of the steam inlet passage is respectively connected with a first steam outlet passage and a second steam outlet through a dryness distribution chamber, an inner steam injection flow passage and an outer steam injection flow passage of a well opening device are respectively connected with a steam distributor through an inner steam injection opening and an outer steam injection opening, a concentric type layered steam injection pipe post is connected under the well opening device and realizes the steam injection to a first underground oil layer through the concentric steam distributor arranged on an outer steam injection pipe post, and the steam is injected to a second underground oil layer through an inner steam injection pipe post. The steam dryness from a boiler can be regulated, and in addition, the double-flow-passage layered steam injection is realized, so the accuracy of the steam injection quantity is ensured, simultaneously, certain compensation is provided for the thermal stress deformation generated by the pipe posts through high temperature in the well in the steam injection process, the steam injection effect is improved, and simultaneously, the occurrence of the condition of the pipe post damage is avoided.

Owner:PETROCHINA CO LTD

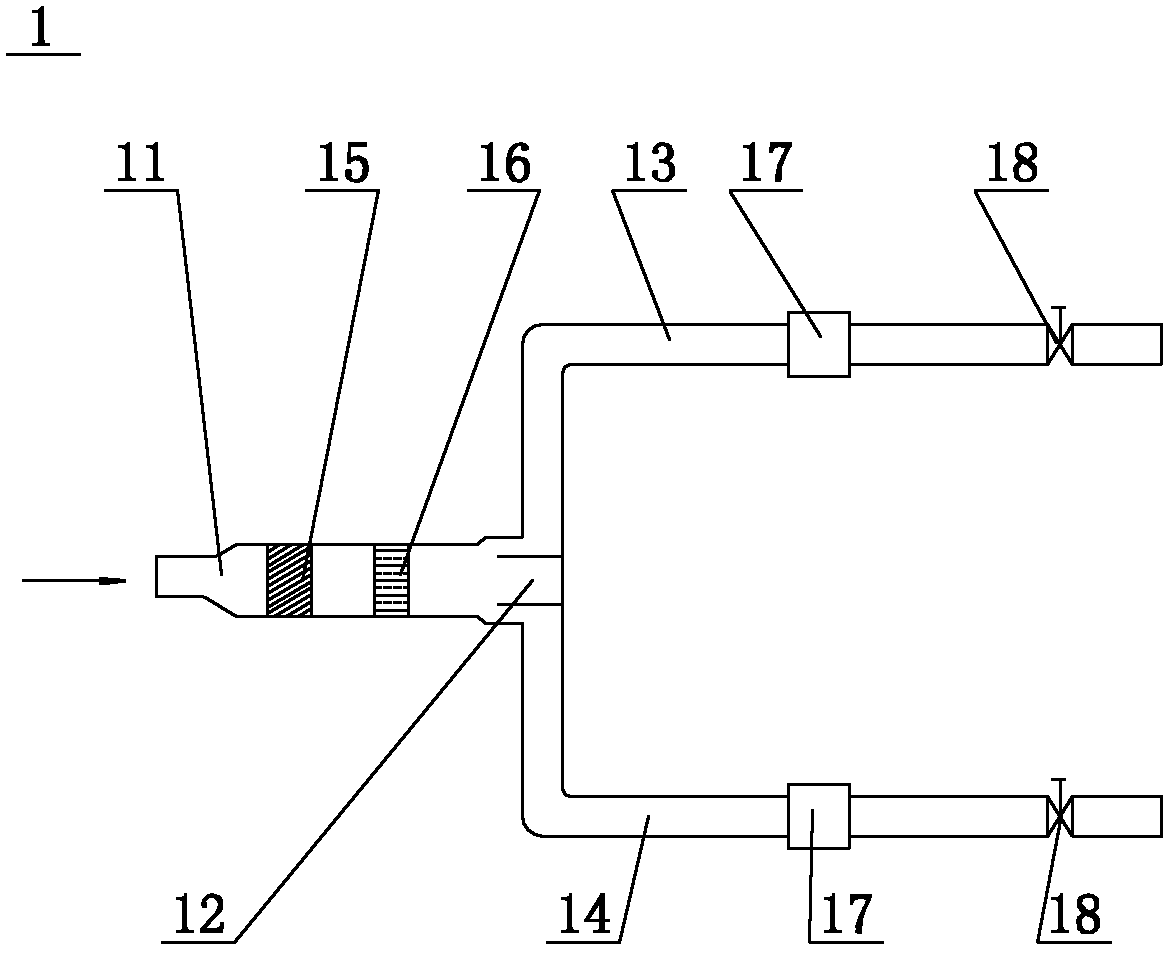

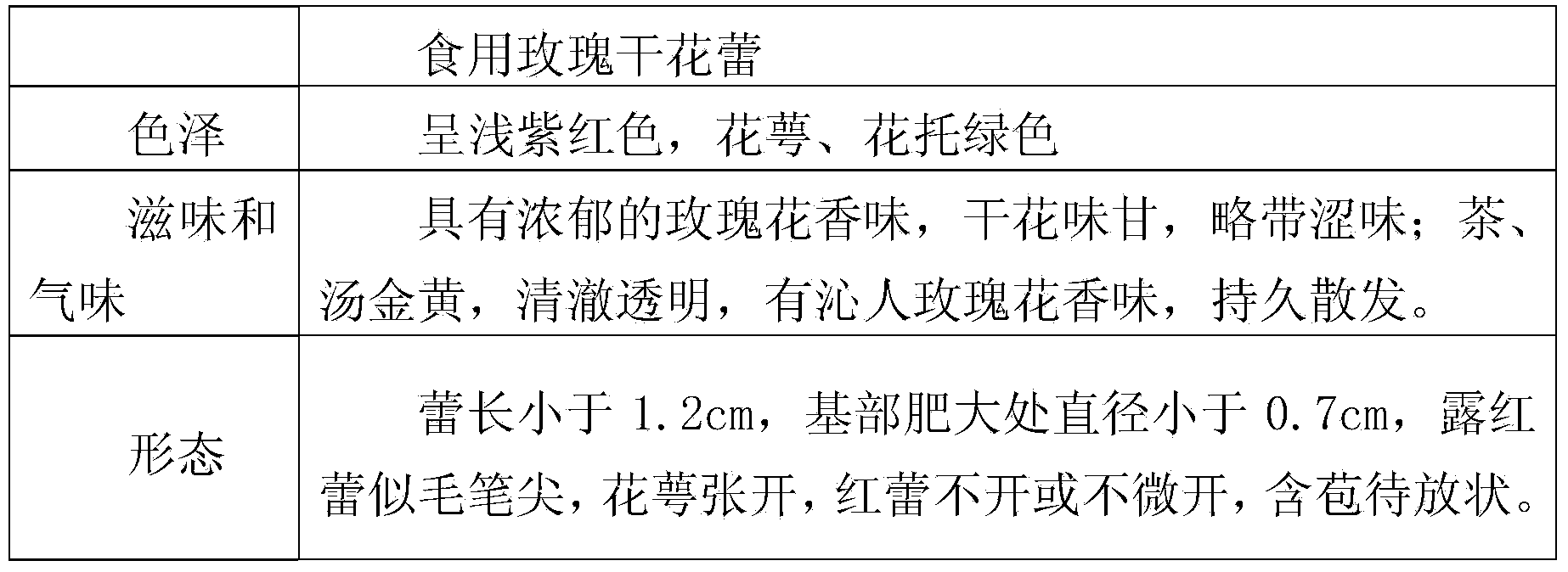

Comprehensive method for drying rosebuds through microwave vacuum and heated air circulation

ActiveCN103504448AEasy to useHumidity removalFood thermal treatmentFloral handlingEngineeringMicrowave

The invention discloses a method for drying rosebuds and belongs to the technical field of rosebud drying through microwave vacuum and heated air circulation. A comprehensive method for drying rosebuds through microwave vacuum and heated air circulation comprises the following steps: (1) feeding the rosebuds to a heated air circulation dryer for drying; (2) feeding the rosebuds obtained in the step (1) to a microwave vacuum drier for drying. According to the comprehensive method, the temperatures are low during the drying processes, the drying time is short, the product quality is high, meanwhile energy consumption is lowered, and the production efficiency is improved. Besides, microwaves can effectively sterilize the rosebuds and kill worms' eggs attached to the rosebuds, and are beneficial for prolonging product shelf lives.

Owner:银谷芳香科技有限公司

Plastic particle drying device and drying method thereof

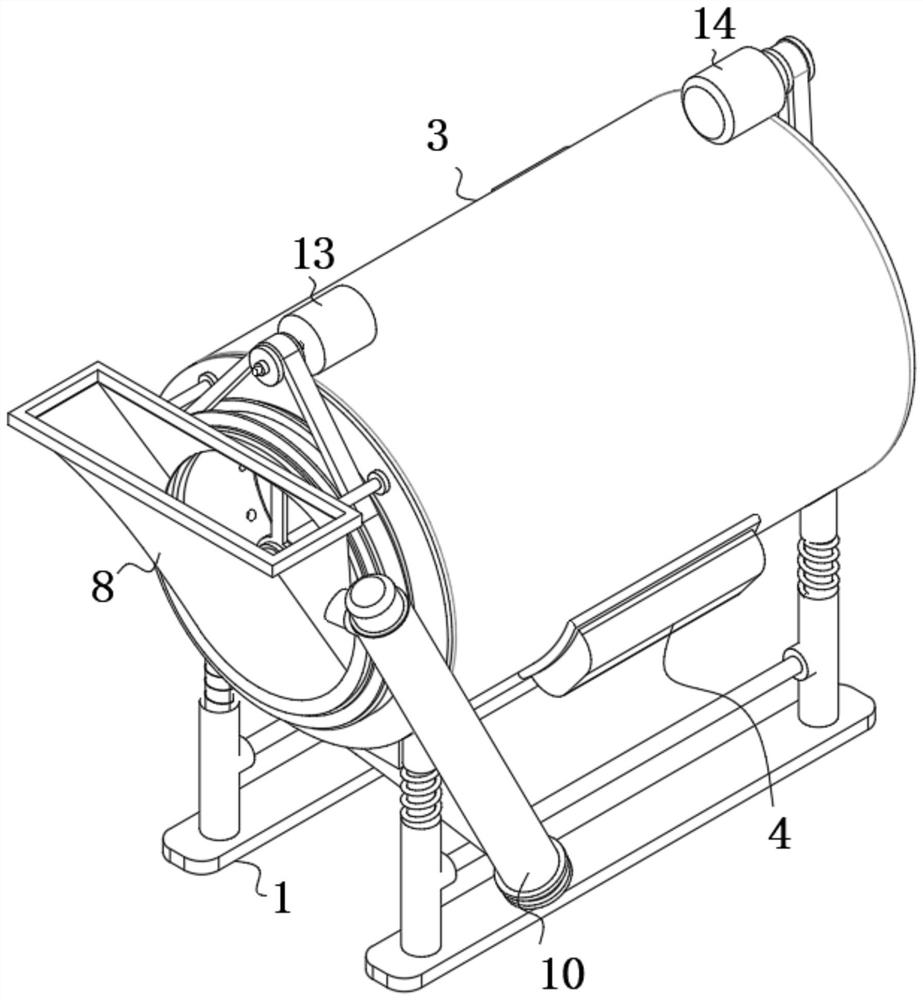

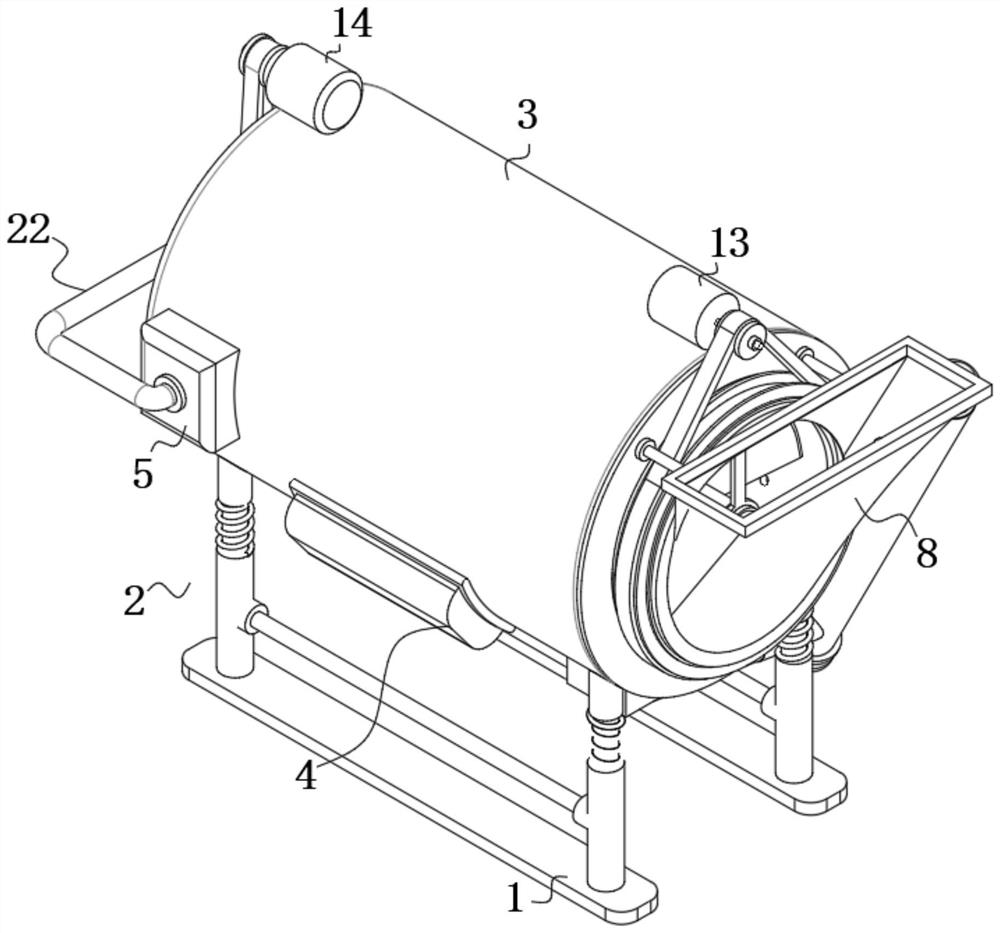

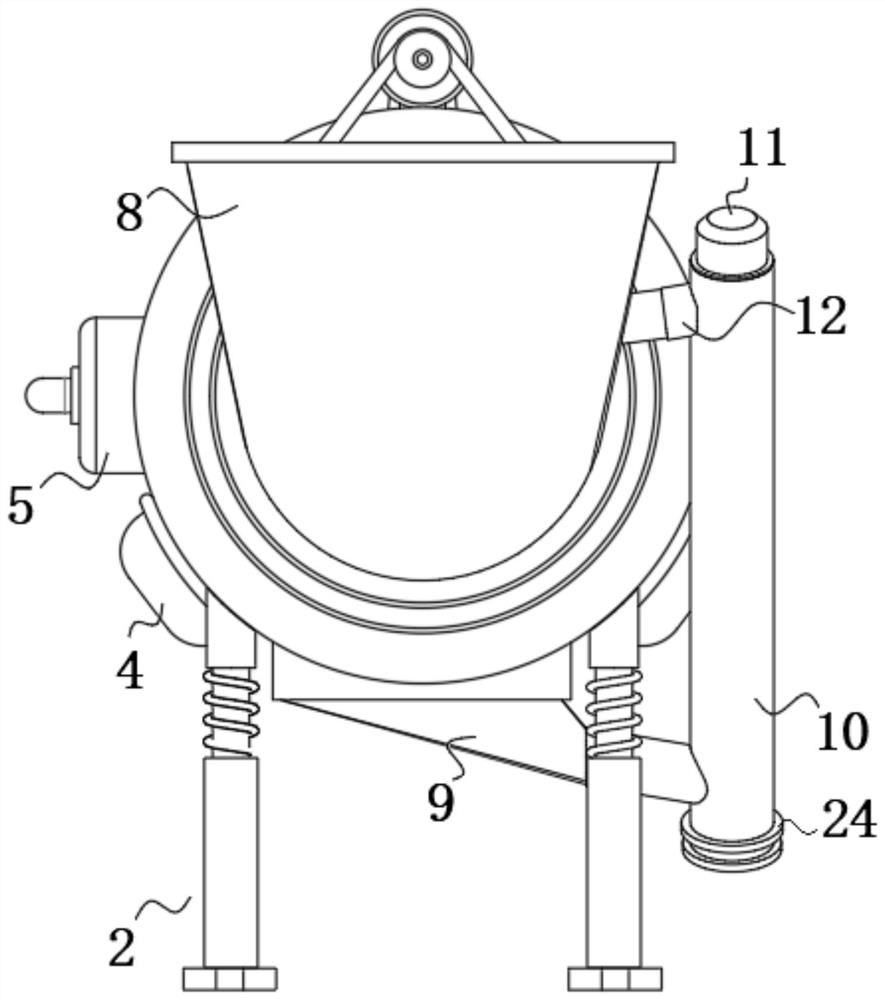

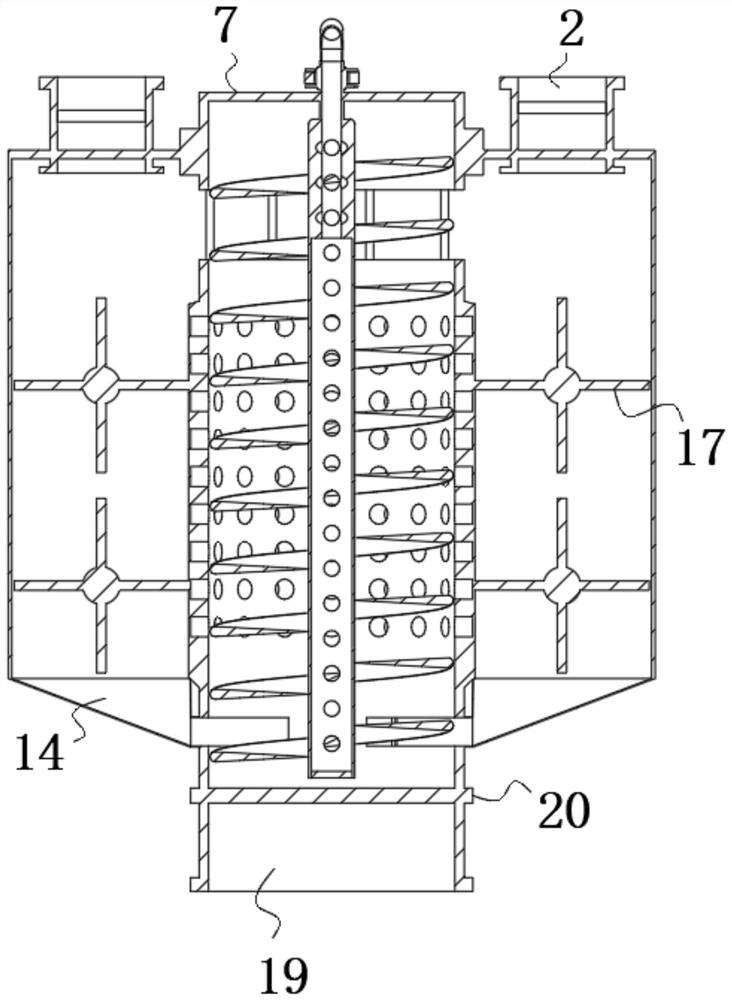

InactiveCN111998662AUniform drynessRealize all-round windDrying gas arrangementsDrying chambers/containersElectric machineryStructural engineering

The invention discloses a plastic particle drying device and a drying method thereof, and relates to the technical field of plastic processing. The device comprises two symmetrically-arranged bases, wherein the bottom faces of the two bases are each fixedly connected with a damping buffer piece, and the top ends of the two damping buffer pieces are fixedly connected with a shell; the peripheral side face of the shell is fixedly connected with two symmetrically-arranged vibration motors and a hot air generating mechanism; two connecting rings are fixedly connected into the shell; the inner walls of the two connecting rings are rotationally connected with a drying mechanism through bearings; and one end of an air outlet of the hot air generating mechanism rotationally communicates with the drying mechanism through a pipeline. Through the design of spiral material conveying outer pieces and spiral material conveying inner pieces, static single-time drying of a traditional drying device ischanged into flowable circulating repeated drying, and during work, under the action of the spiral material conveying outer pieces and the spiral material conveying inner pieces, on one hand, materials can flow circularly, and on the other hand, the materials can be turned over in a reciprocating mode.

Owner:马鞍山金瓦格机械科技有限公司

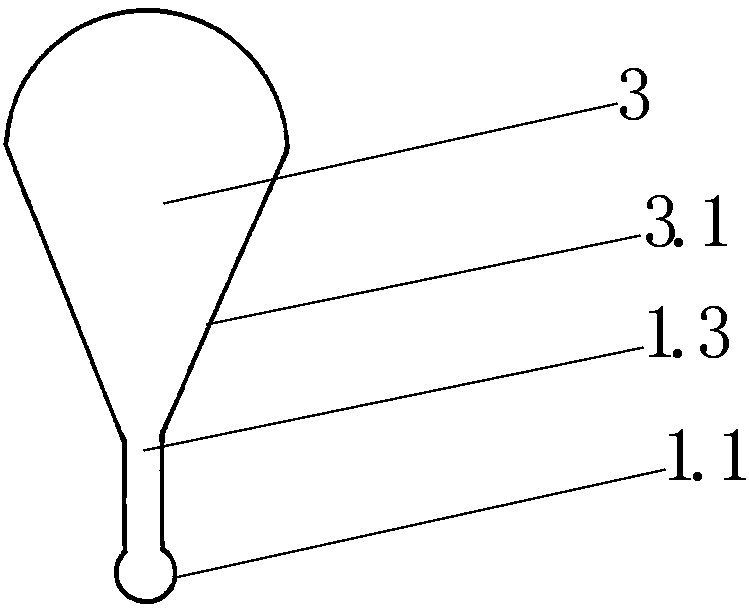

Disposable moisture-absorbing product

InactiveCN105496653ASolve AbsorbencyFix the leakSanitary towelsBaby linensSuper absorbentEngineering

The invention relates to the technical field of personal sanitary products, in particular to a disposable moisture-absorbing product for absorbing liquid excrement. The disposable moisture-absorbing product comprises a liquid-permeable top player, a liquid-tight bottom layer and an absorptive layer, wherein the absorptive layer is arranged between the liquid-permeable top layer and the light-tight bottom layer, and can be used for absorbing and accommodating liquid; at least one absorptive layer comprises multiple absorbing hole layers; the absorbing hole layers are provided with a plurality of absorbing holes; the absorbing holes in adjacent absorbing hole layers are formed in a staggered way. According to the disposable moisture-absorbing product, the absorbing hole layers provided with the absorbing holes are provided, and the plurality of hole layers can be better laminated, so that the glue dosage is reduced, and the softness of the product is increased. Super absorbent polymers are uniformly distributed in the plurality of hole layers, so that the dryness of the product is more uniform. The liquid excrement flows into the absorbing holes, and is temporarily stored in the absorbing holes and absorbed by the absorbing hole layers, so that the problem that a part of excessive liquid excrement is not absorbed and leaks is solved.

Owner:GUANGDONG YINYIN CO LTD

Rapid baking method for sweet osmanthus

InactiveCN103006787AOvercomingEvenly heatedDigestive systemRespiratory disorderTime rangeAdditive ingredient

The invention discloses a rapid baking method for sweet osmanthus. The rapid baking method comprises the steps as follows: firstly fresh sweet osmanthus is cleaned, impurities are removed, the sweet osmanthus is dried in the air and placed in a microwave machine, the temperature is controlled in a range from 110 DEG C to 115 DEG C, and water removing is performed for 2-3minutes; the sweet osmanthus subjected to water removing is placed into a vacuum microwave baking chamber to be baked, under the condition that the vacuum degree is smaller than 0.08 Mpa below zero, the baking temperature ranges from 45 DEG C to 50 DEG C, the baking time ranges from 60 minutes to 90 minutes, and then the dried sweet osmanthus is weighed, bag-dispensed and packaged. According to the rapid baking method for the sweet osmanthus, the fresh sweet osmanthus is rapidly baked under the conditions of the low and constant temperature, so that the energy and time are saved, further, the original colors, fragrances, shapes, taste and nutritional ingredients of the sweet osmanthus can be maintained, the operation is simple, and the cost is low.

Owner:桂林普兰德生物科技有限公司 +1

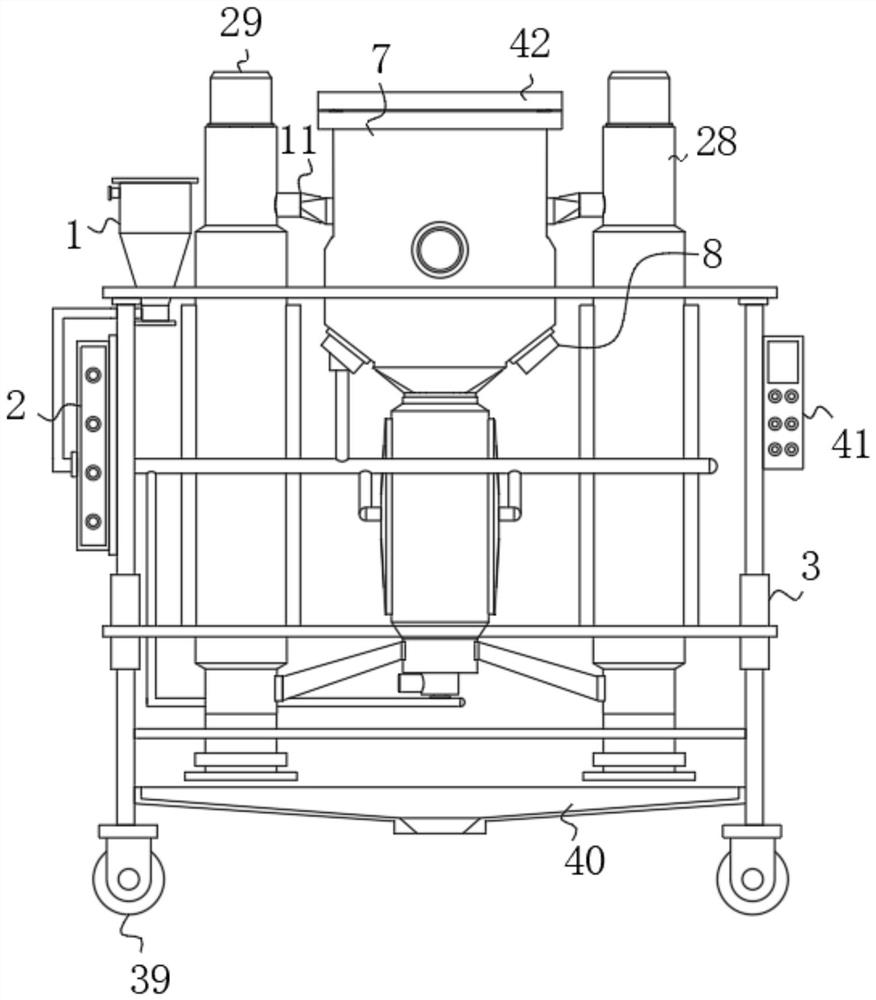

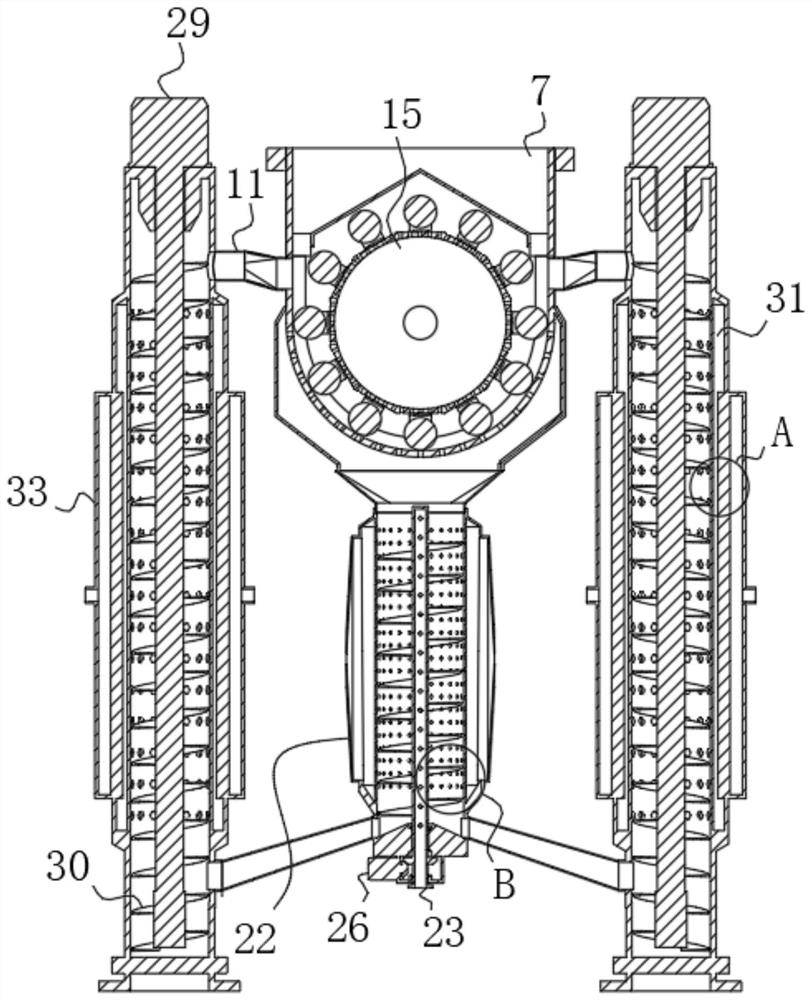

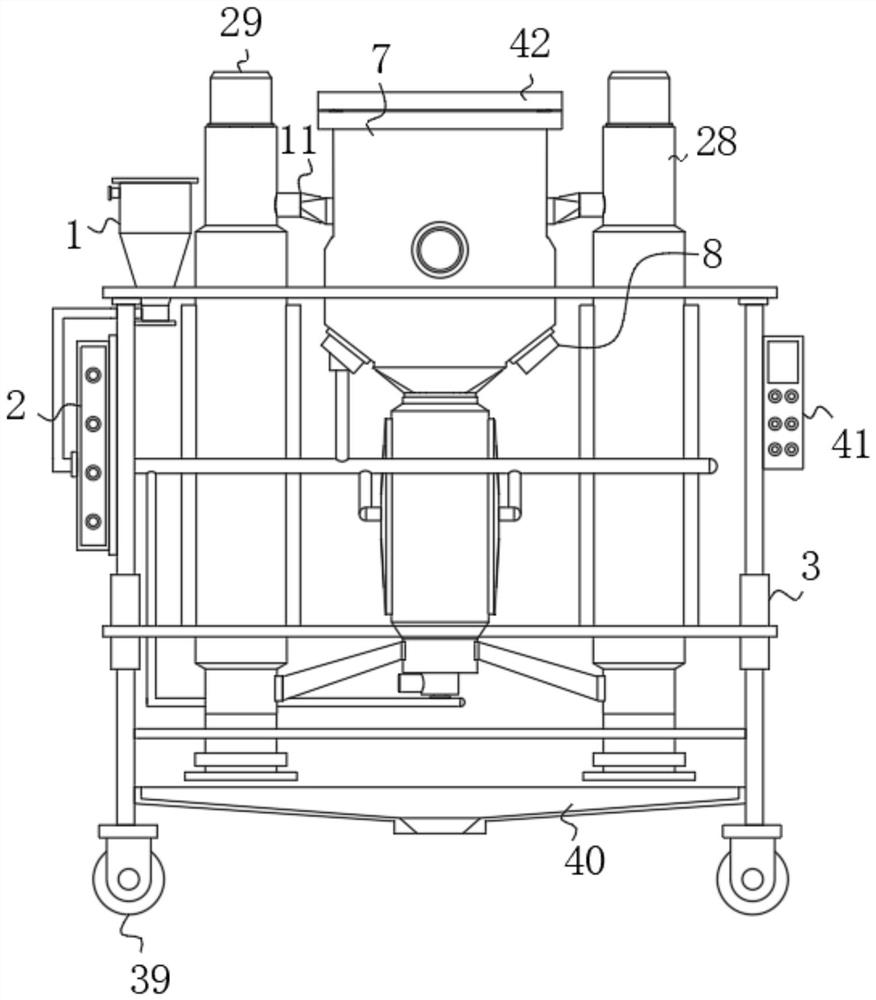

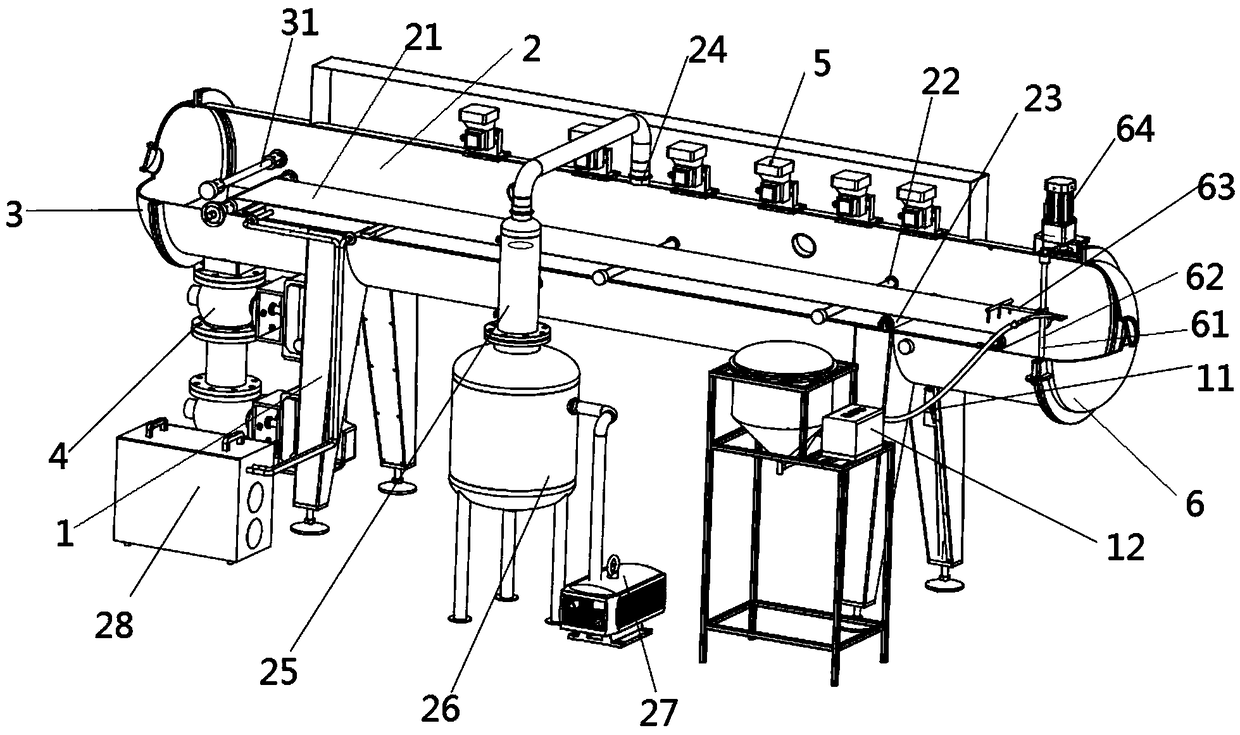

Drying equipment for production of hydroxypropyl methylcellulose

The invention discloses drying equipment for production of hydroxypropyl methylcellulose, and relates to the technical field of production of the hydroxypropyl methylcellulose. The drying equipment comprises a cyclone dust remover, a hot air supplying module and a support framework, wherein the circumferential sides of the cyclone dust remover and the hot air supplying module are fixedly connectedwith the support framework; and one end of an air inlet of the hot air supplying module fixedly communicates with the cyclone dust remover. The drying equipment also comprises a thinning mechanism, adrying main machine and two symmetrically-arranged drying auxiliary machine, wherein the circumferential sides of the thinning mechanism, the drying main machine and the two drying auxiliary machineare fixedly connected with the support framework; and one end of a discharging hole of each of the two drying auxiliary machines fixedly communicates with the thinning mechanism. According to the drying equipment for production of the hydroxypropyl methylcellulose disclosed by the invention, through design of the hot air supply module, the thinning mechanism, the drying auxiliary machines and thedrying main machine, the device can quickly and completely perform drying operations of the hydroxypropyl methylcellulose in an automatic manner, and when the device performs drying, a static type drying structure of a conventional drying device can be changed into a circulating type multi-time drying mechanism.

Owner:安徽森淼实业有限公司

Quick baking method of osmanthus fragrans

InactiveCN103636823AEvenly heatedImprove finishing effectPre-extraction tea treatmentPlant ingredientsMicrowave ovenAdditive ingredient

The invention discloses a quick baking method of osmanthus fragrans, which comprises the following steps: putting the selected fresh osmanthus fragrans into a microwave machine, and performing enzyme deactivation at 110 DEG C for 3 minutes; baking the osmanthus fragrans after the enzyme deactivation in a vacuum microwave oven; baking for 80 minutes at a vacuum degree lower than -0.08MPa and a baking temperature of 45 DEG C. The method disclosed by the invention is used for quickly baking fresh osmanthus fragrans in a low-temperature constant-temperature condition, thereby saving time and maintaining the original color, aroma, shape, taste and nutritional ingredients of osmanthus fragrans; the operation is simple, and the cost is low.

Owner:桂林普兰德生物科技有限公司 +1

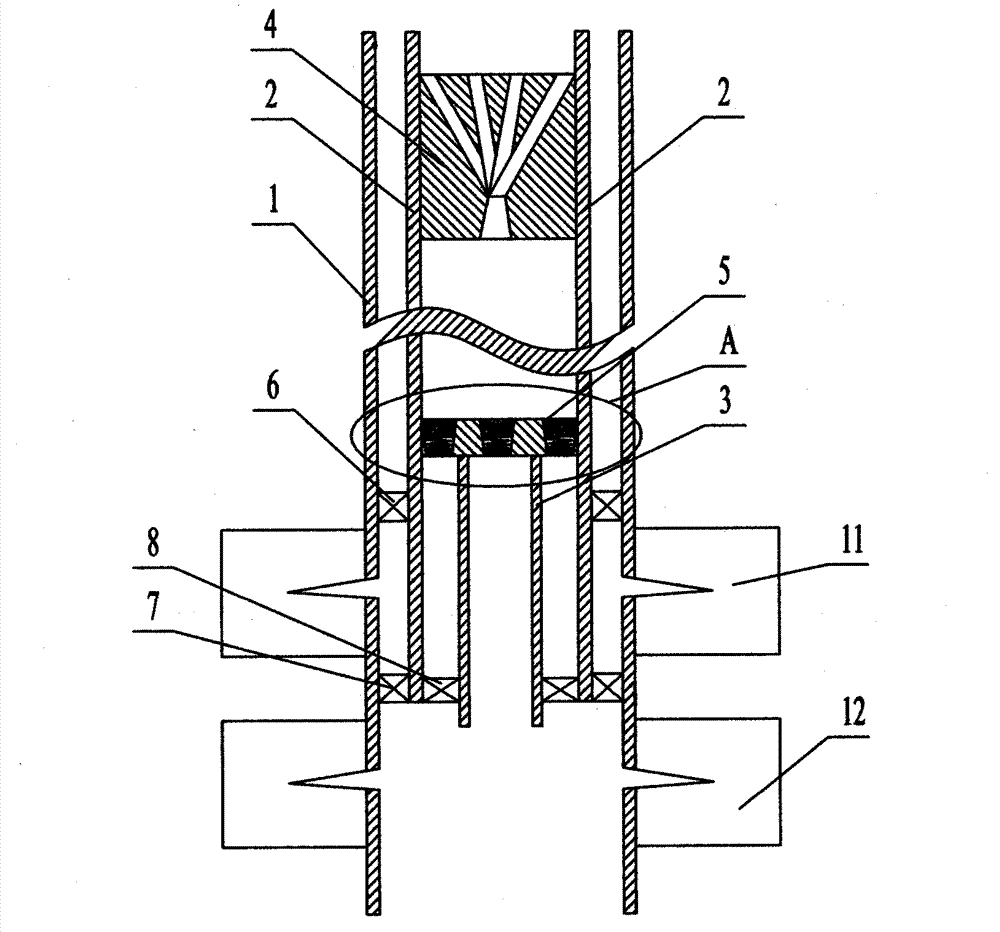

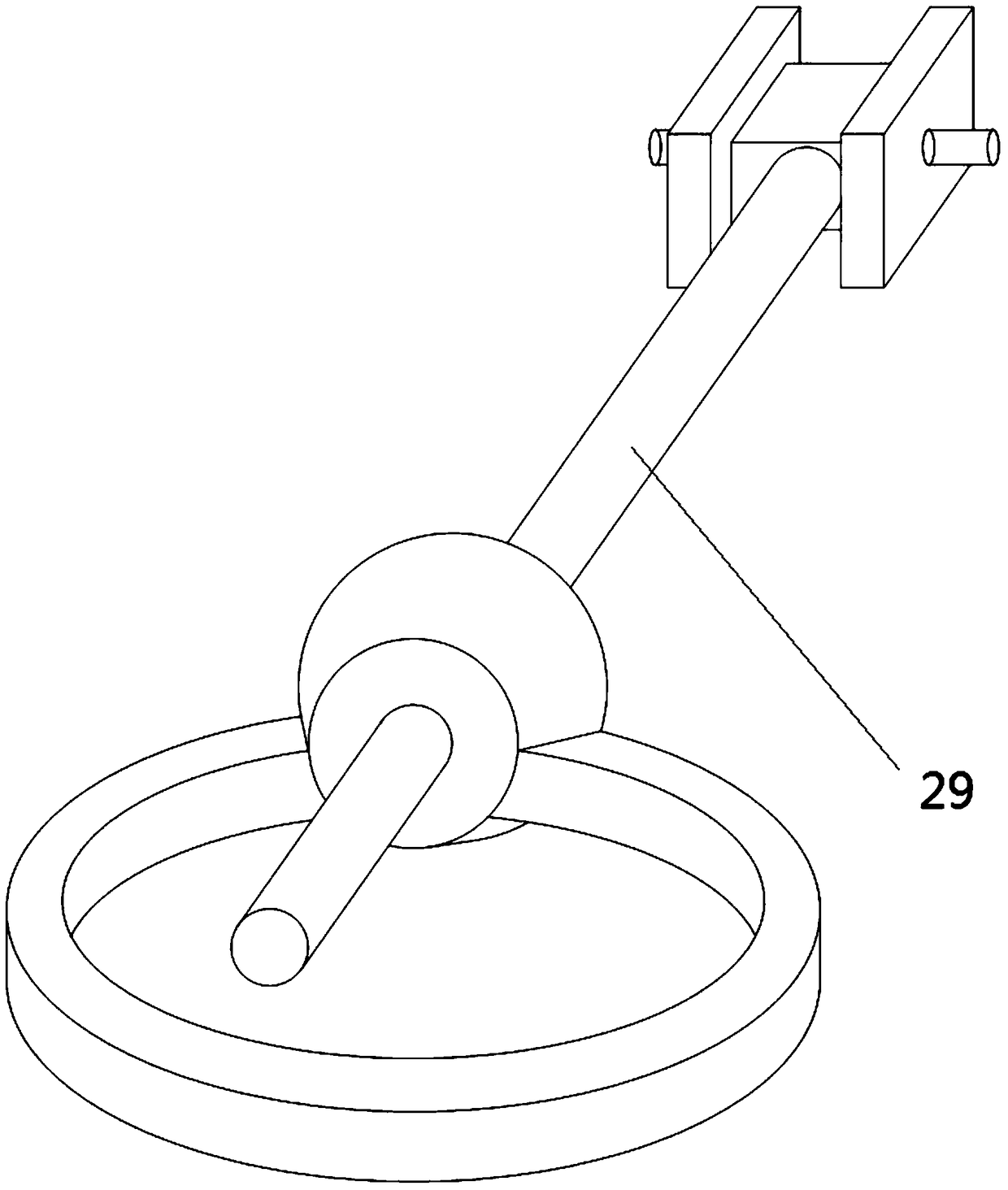

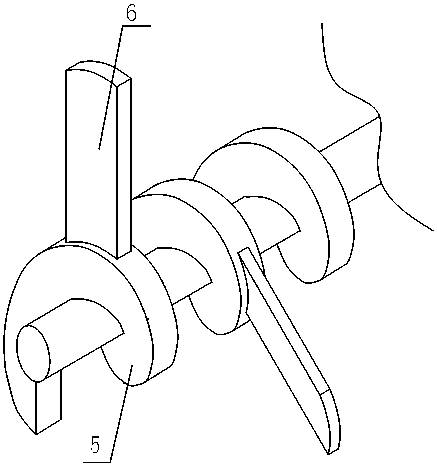

Pressure-adjustable uniform-dryness layered steam distributing tool

The invention discloses a pressure-adjustable uniform-dryness layered steam distributing tool, and relates to pressure adjusting steam distributing tool. The tool solves the problems that during the steam injection process, under change of the pressure, the steam dryness is not distributed uniformly; the pressure cannot be adjusted to allow the designed steam amount to go into the target oil layer, the steam injection effect is bad, and the oil-steam ratio is low. A swirler is mounted at the upper part inner wall of an outer pipe; a distributer comprises a distributer disk, a plurality of pistons and a plurality of springs, wherein the distributor disk is welded on the inner wall of the outer pipe; the upper end of the inner pipe is welded on the distributer disk; the part on the distributor disk corresponding to the inner pipe is defined to be a round area; the part except the round area on the distributer disk is defined to be an annular area; a plurality of reversed circular cone steam distribution holes are uniformly formed in the round area and the annular area; pistons and springs are arranged from top to bottom inside each reversed circular cone steam distribution hole; the upper ends of the springs are welded on the pistons; and the lower ends of the springs are welded on the walls of the reversed circular cone steam distribution holes. The tool can be used for steam injection oil recovery.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

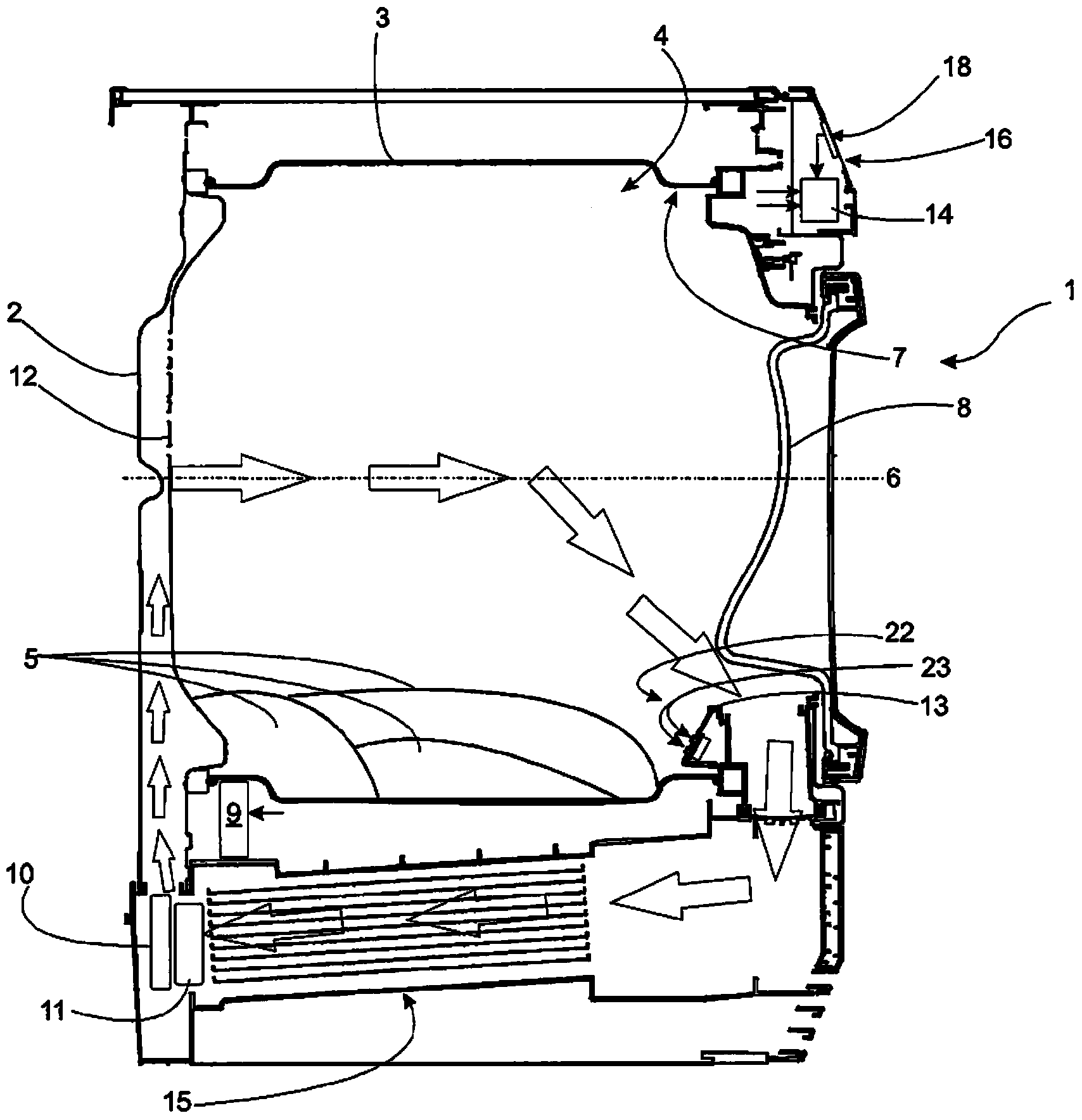

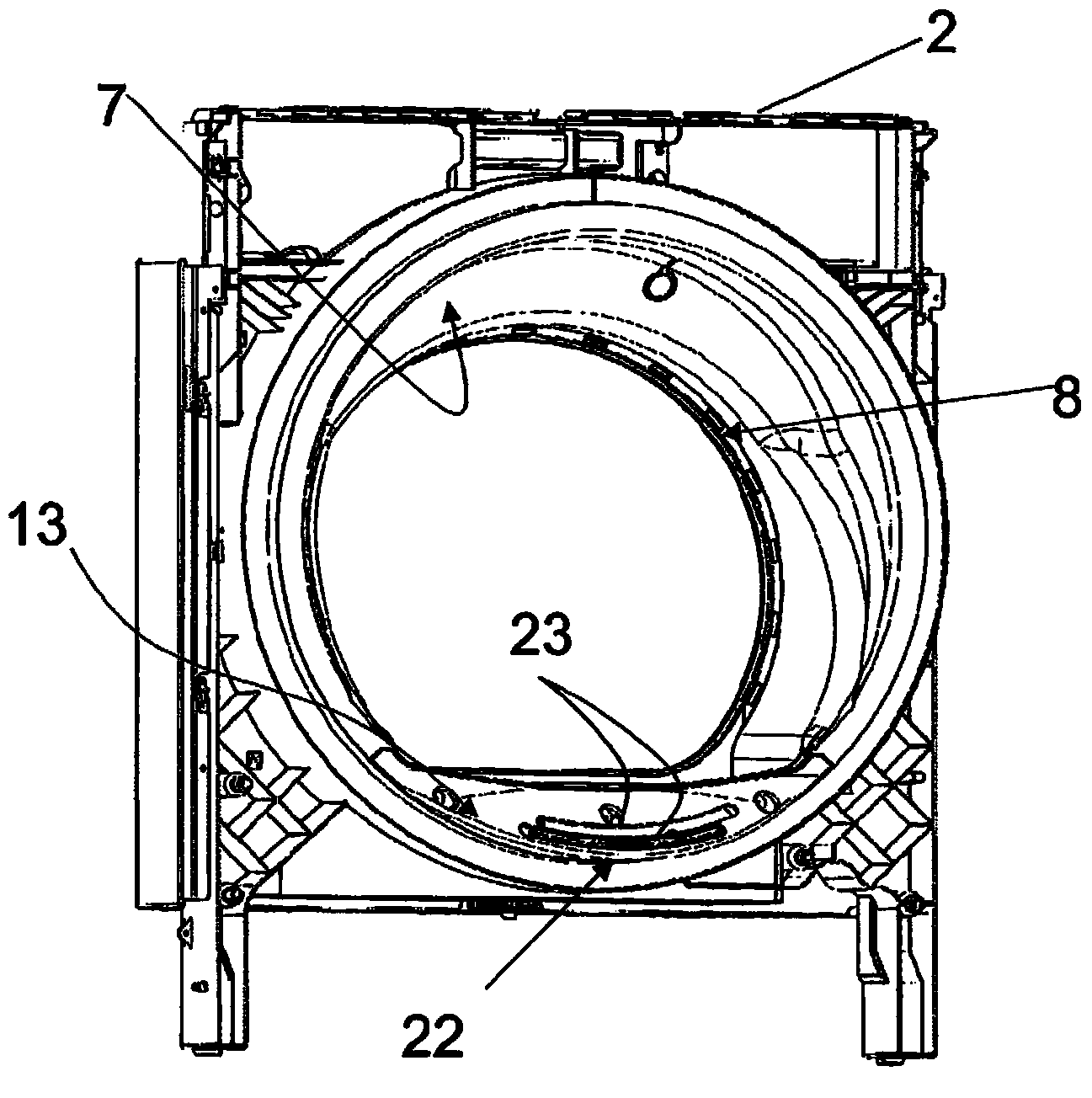

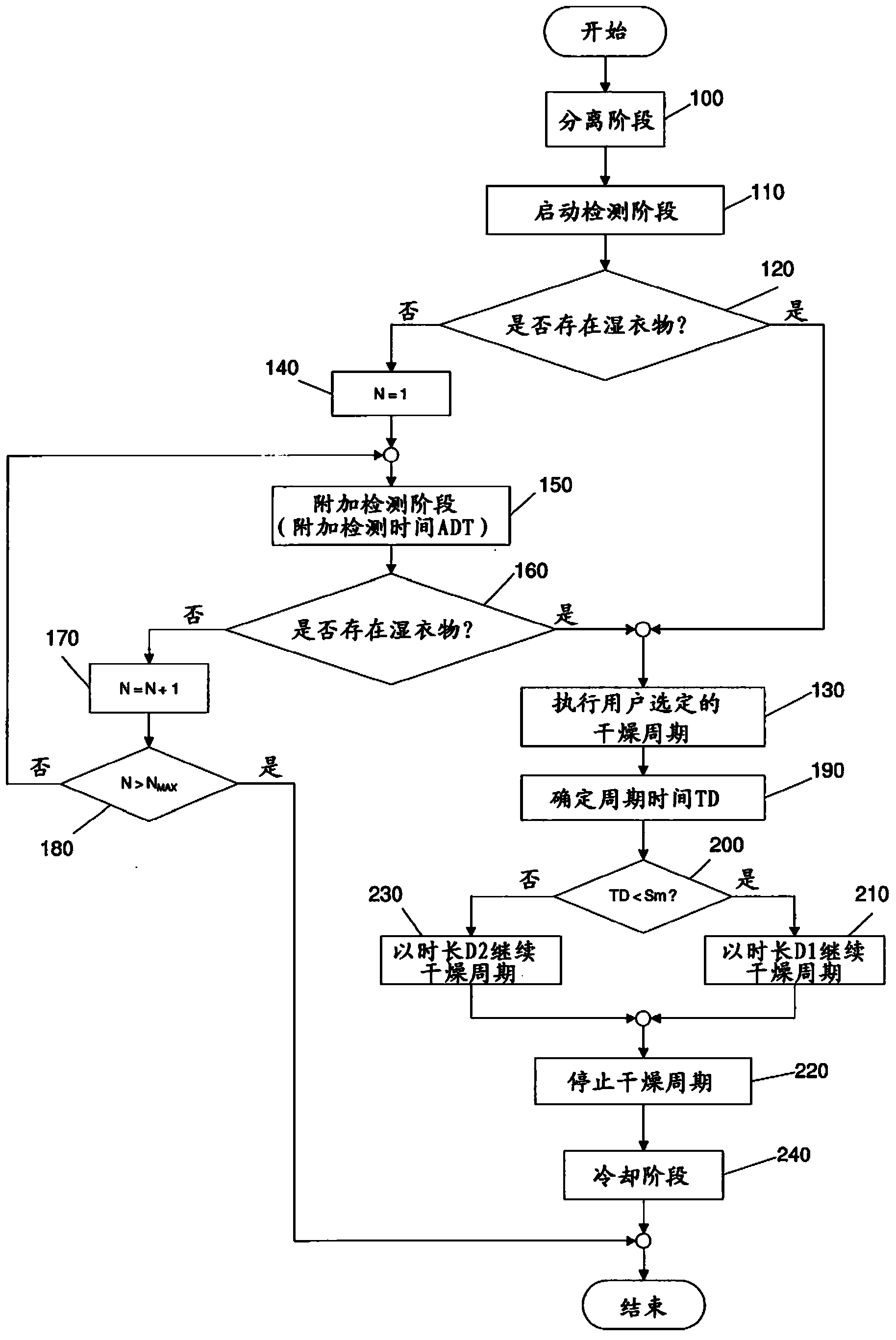

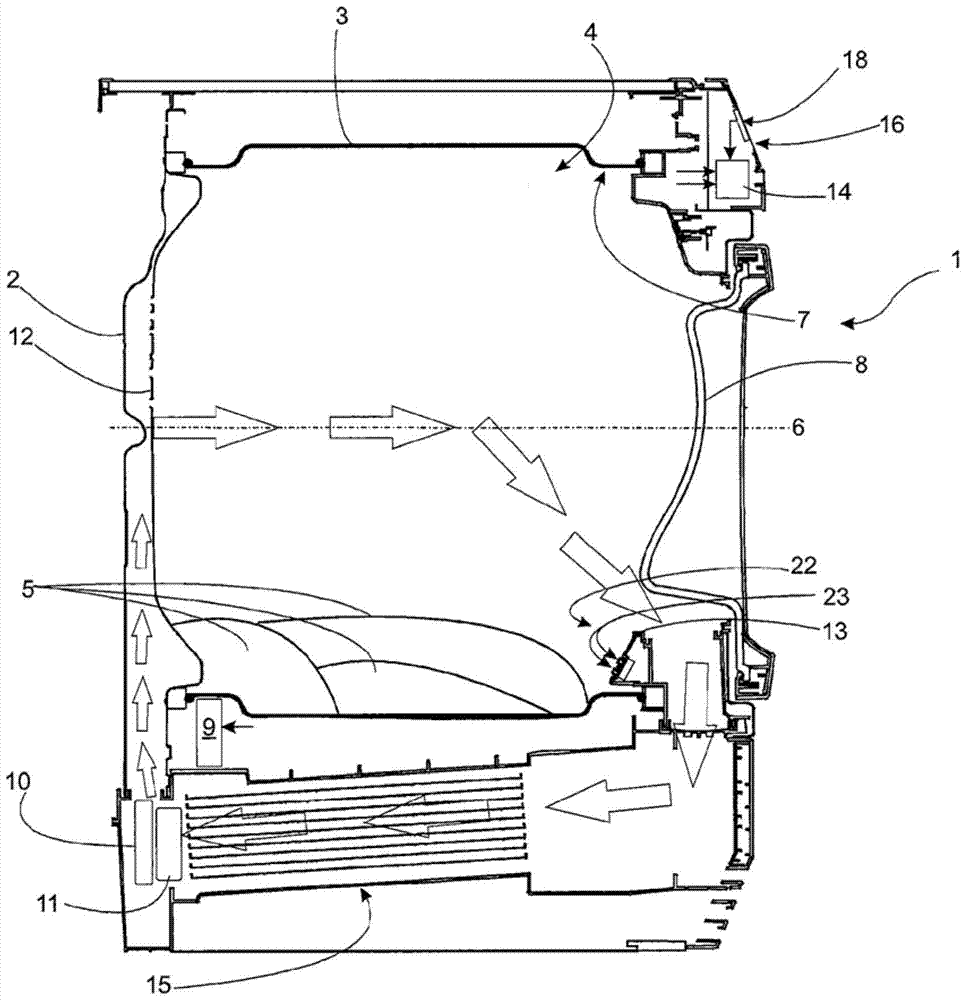

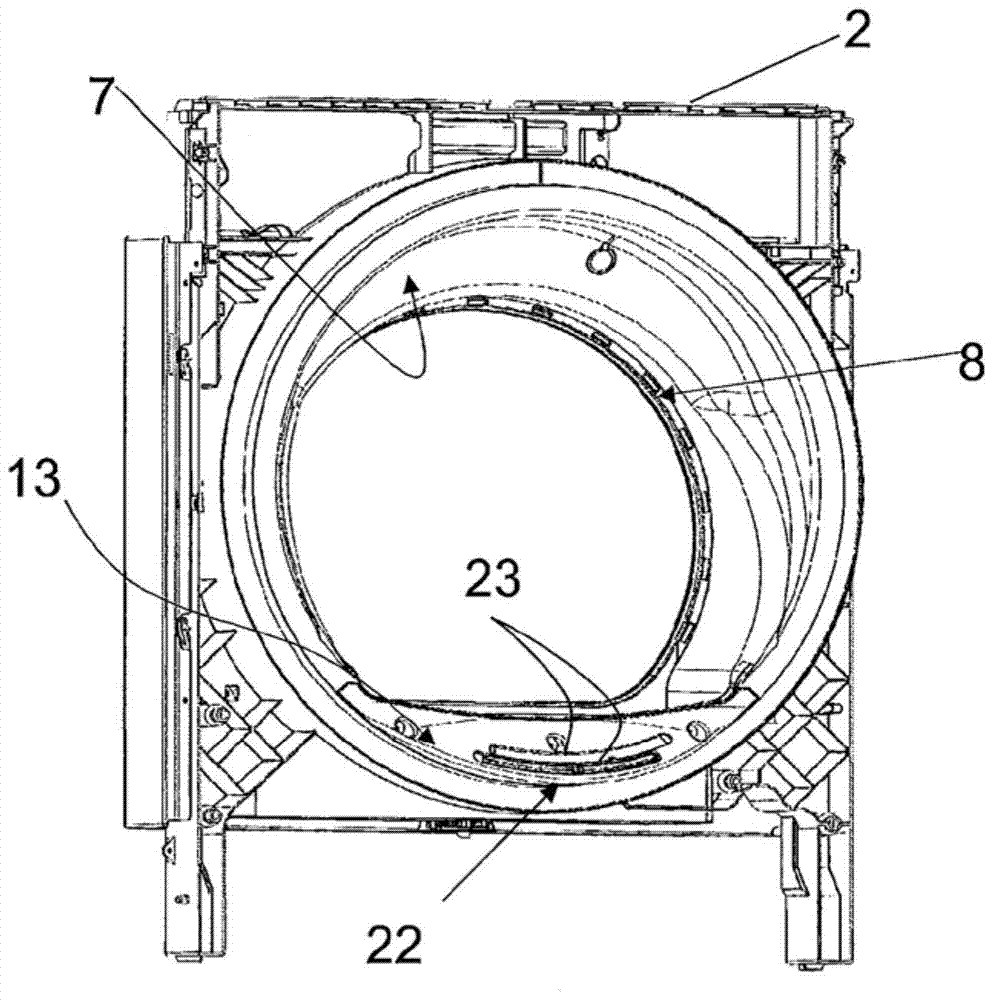

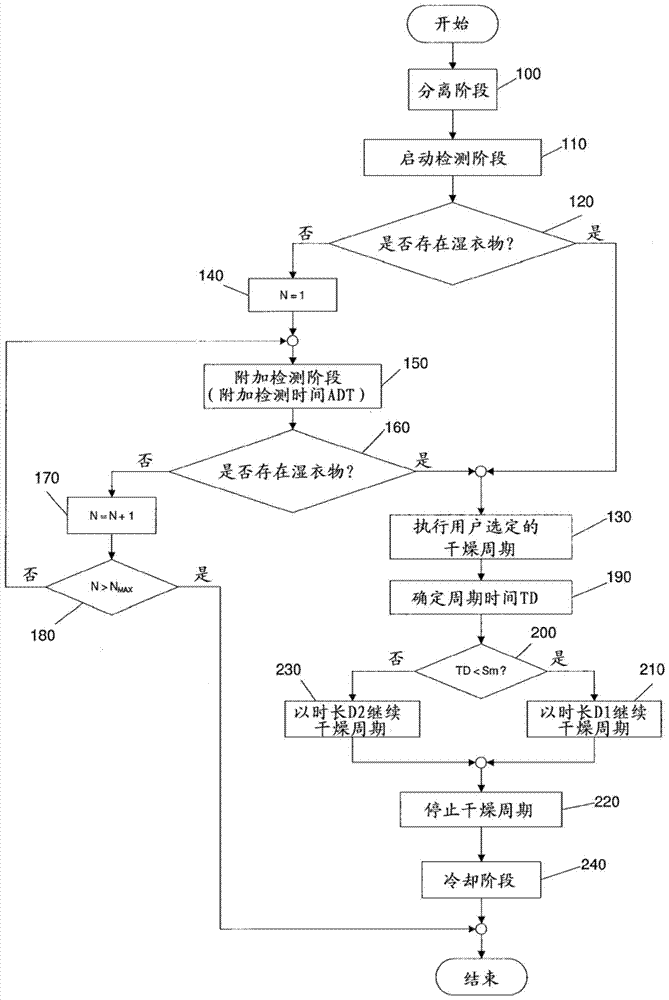

A method of controlling a rotatable-drum laundry dryer and a rotatable-drum laundry dryer implementing the method

ActiveCN103764897AUniform drynessReduce wasteTextiles and paperLaundry driersProcess engineeringEngineering

A method of controlling a drying operation of a rotatable-drum laundry dryer (1) is provided. The rotatable-drum laundry dryer (1) comprises a rotatable drum (3) for loading laundry (5) and at least an electrode sensor (22) for sensing dryness of the laundry (5). The method comprises the steps of: detecting the presence / absence of moist laundry (5) inside the rotatable drum (3) by the electrode sensor (22); if presence of moist laundry inside the rotatable drum (3) is detected, starting a drying cycle; sensing dryness of the laundry (5) during the drying cycle; measuring a cycle time (TD) at which the sensed dryness reaches a preset dryness threshold; and if the cycle time (TD) is lower than a preset dryness threshold time (Sm), continuing the drying cycle for a first additional time (D1), and stopping the drying cycle at the end of the first additional time (D1).

Owner:ELECTROLUX HOME PROD CORP NV

Herbarium making method

The invention discloses a herbarium making method. The method includes the steps of separating parts of a plant to be made into a herbarium; pressing branches, leaves and flowers on a bottom plate with a pressing piece, fixing with a physical method easy to remove, waiting for air drying, fixing the fruit in the middle with two ventilated metal plates and then drying in an oven; combining the branches, the leaves, the flowers and / or the fruit which are separated and air dried, bonding with a viscous material, then fixing on a bottom layer of a pearl cotton material, bonding a frame of the pearl cotton material to the bottom layer with the size of the frame and the bottom layer determined according to the size of the herbarium, and then bonding a polyphthalate plastic cover plate on the frame. According to the method, the EPE pearl cotton is adopted as the bottom layer and the frame, and the EPE pearl cotton has better flexibility, adjustable thickness and low price compared with the traditional herbarium paper, and has no risk of mildew. The plastic cover plate can be adopted to seal the herbarium, and the effects of preventing dust and preventing the herbarium from being scatteredcan be achieved.

Owner:CHUZHOU UNIV

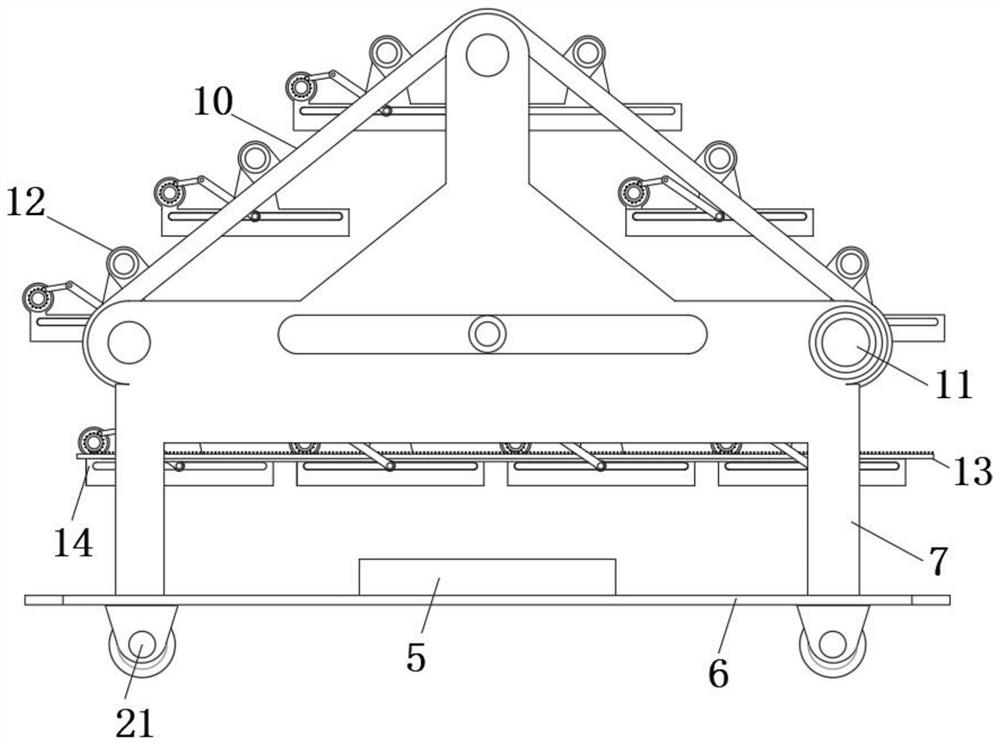

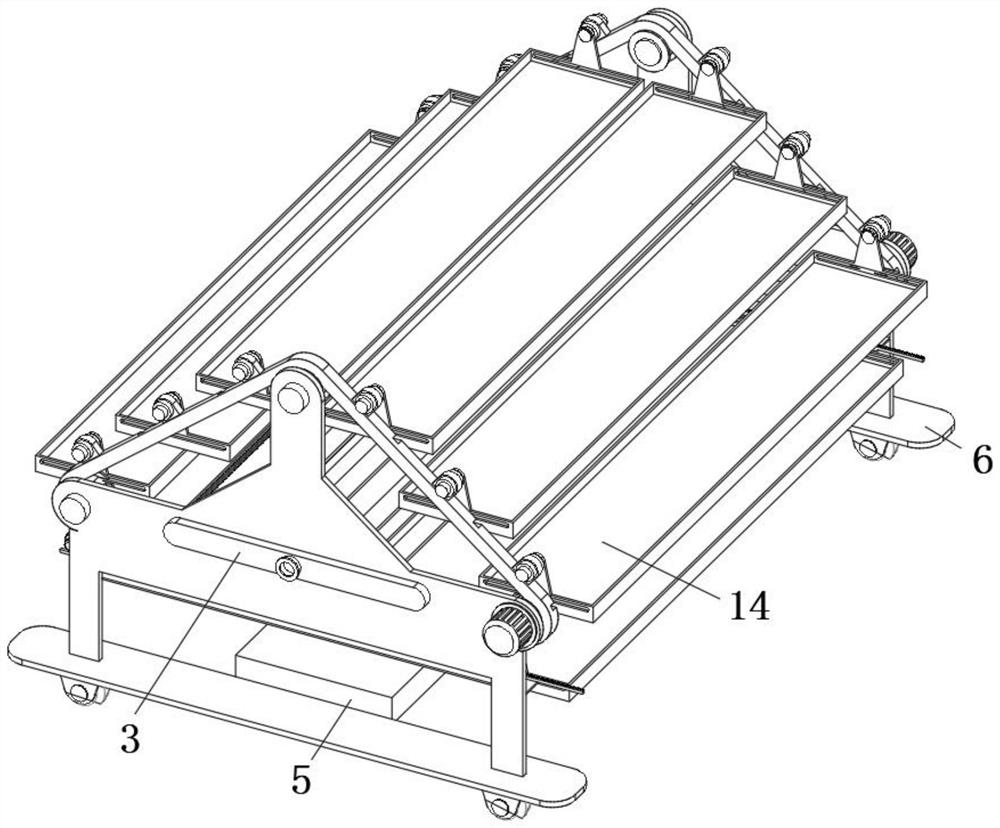

Agricultural grain airing device based on airing and raking assemblies

InactiveCN111707073AIncrease light receiving areaRealize layered dryingDrying gas arrangementsDrying chambers/containersAgricultural scienceDrive wheel

The invention discloses an agricultural grain airing device based on airing and raking assemblies, and relates to the technical field of agricultural instruments. The device comprises two symmetrically disposed support assemblies; a set of equally distributed grain airing assemblies are hinged between the inner surfaces of the two support assemblies; a set of hot air drying pipes which are distributed at equal intervals and communicate with one another through air distribution pipes are fixedly connected between the inner surfaces of the two support assemblies; a hot air supply mechanism is fixedly connected between the inner surfaces of the two support assemblies; and one end of an output shaft of the hot air supply mechanism communicates with the air distribution pipes through a pipeline. The two support assemblies comprise a base, a limiting framework is fixedly connected with the top surface of the base, and one surface of the limiting framework is rotationally connected with two driven wheel discs and a driving wheel disc. Due to the design of the support assemblies and the grain airing assemblies, on one hand, layered grain airing is achieved, so that the light-receiving areaof grains is improved; and on the other hand, the device changes conventional static airing into dynamic airing.

Owner:安徽鳌鸟信息科技有限公司

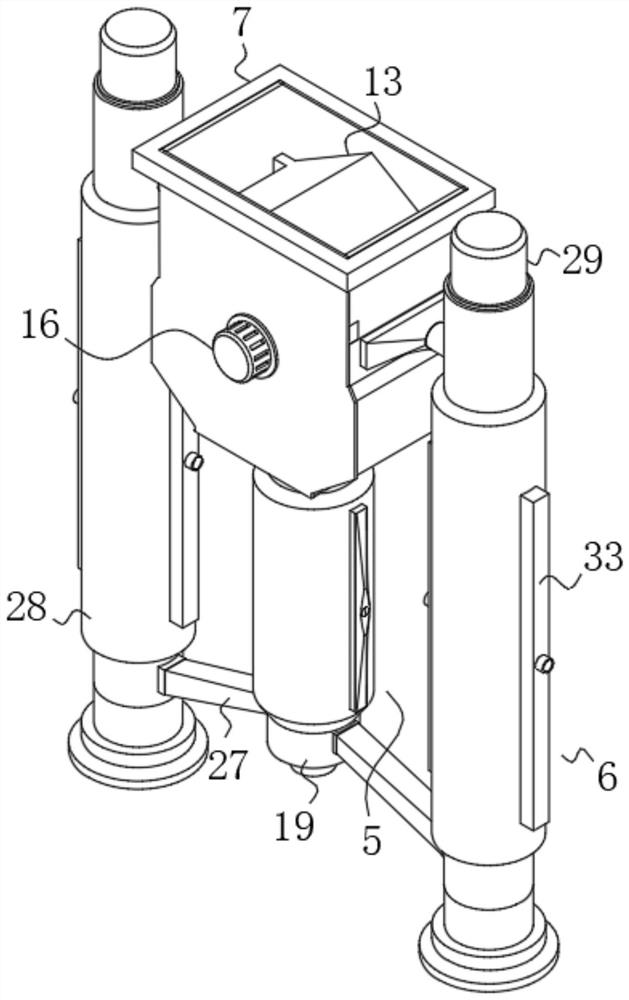

Seed material drying device with circulating mechanism

InactiveCN111829326AFull drying effectKeep dryDrying gas arrangementsDrying solid materialsHuskElectric machinery

The invention discloses a seed material drying device with a circulating mechanism and relates to the technical field of agriculture machines. The seed material drying device with the circulating mechanism comprises an outer shell. The top face of the outer shell fixedly communicates with two hot ventilating assemblies. The side face of the outer shell is fixedly provided with a hot air supplyingassembly. The inner wall of the outer shell is fixedly connected with a drying mechanism. Two scattering mechanisms are rotationally connected to the inner surface of the outer shell through bearings.The surface of the outer shell is fixedly connected with drive motors both at the positions corresponding to the two scattering mechanisms. One end of an output shaft of each of the two drive motorsis fixedly connected with the scattering mechanism at the corresponding position. The drying mechanism comprises an inner pipe body. According to the seed material drying device with the circulating mechanism, by means of design of the drying mechanism and a spiral conveying blade, static-state type one-time drying of a traditional seed material drying device is changed into a circulating repeateddrying, by means of the dynamic circulating drying, materials can sufficiently flow, then the wind bearing face of the materials is circularly changed, and therefore the drying efficiency is improved.

Owner:南连成

Quick baking method of peach blossoms

InactiveCN103006438AEvenly heatedImprove finishing effectPharmaceutical product form changeMicrowave ovenEngineering

The invention discloses a quick baking method of peach blossoms, which comprises the following steps that fresh peach blossoms are selected and cleaned, impurities are removed, then the peach blossoms are dried in the air and then put in a microwave machine, the temperature is controlled to 110 to 115 DEG C, and killing is performed for 2 to 3 minutes; then the peach blossoms are put in a vacuum microwave oven to be baked, in the condition that the vacuum degree is less than -0.08 Mpa, the baking temperature is 45 to 50 DEG C, and the baking time is 60 to 90 minutes; and then the baked peach blossoms are weighed and packaged in bags. According to the quick baking method, the fresh peach blossoms are quickly baked at low temperature and constant temperature, the energy and time are saved, and the original color, aroma, shape, taste and nutritional ingredients are kept basically unchanged. The quick baking method has the advantages of simplicity in operation and low cost.

Owner:桂林普兰德生物科技有限公司 +1

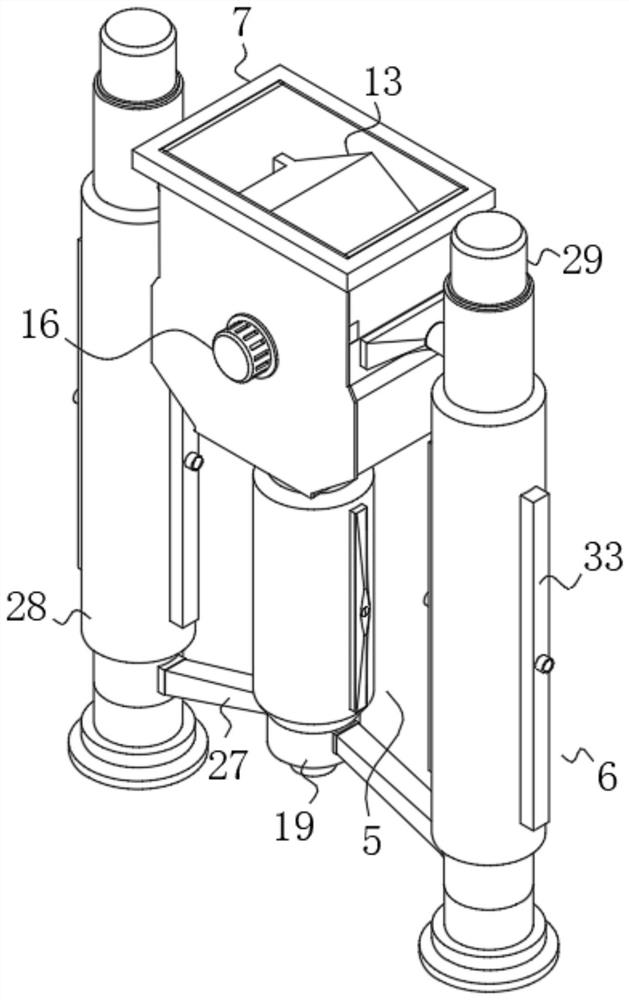

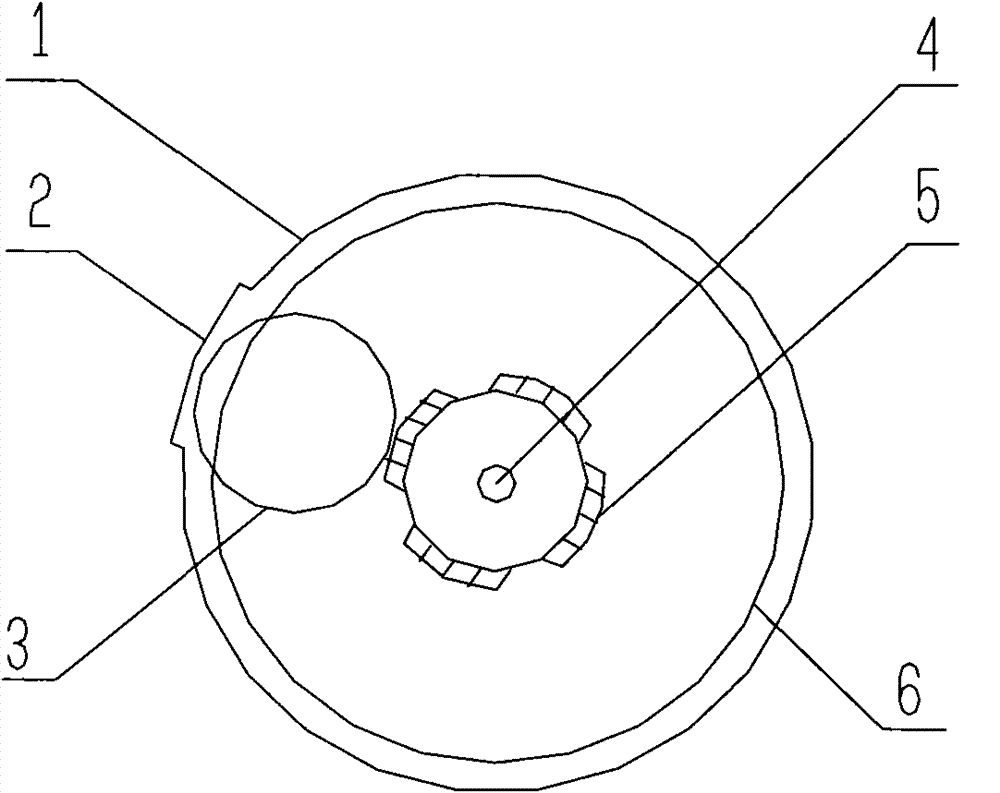

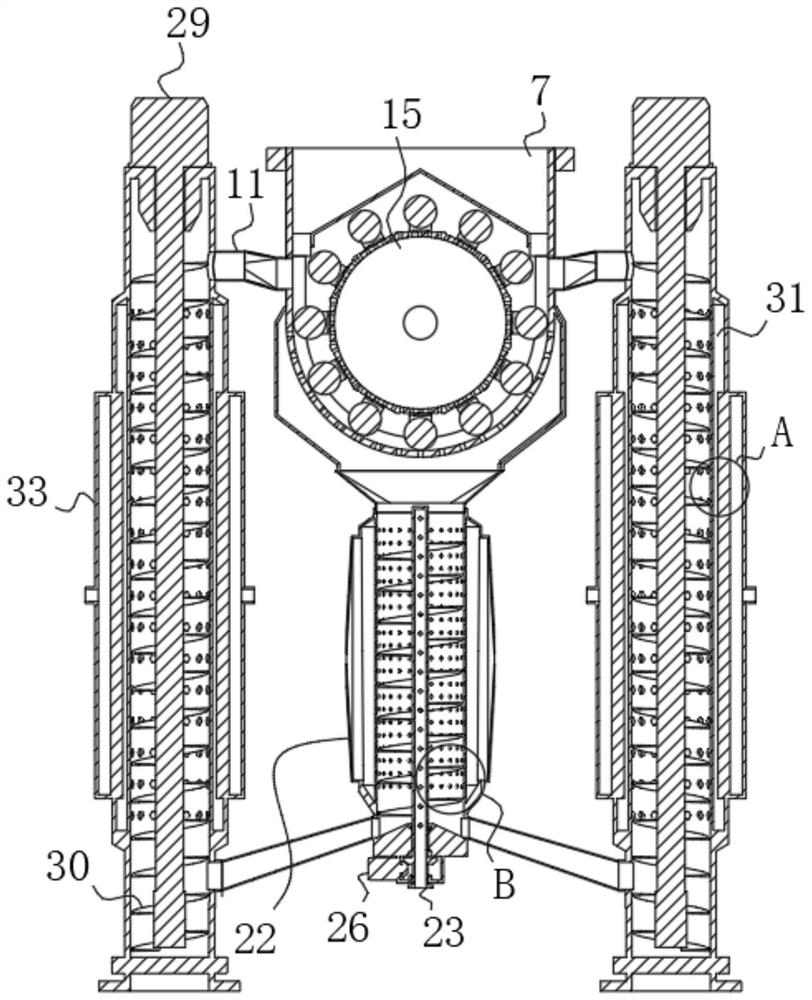

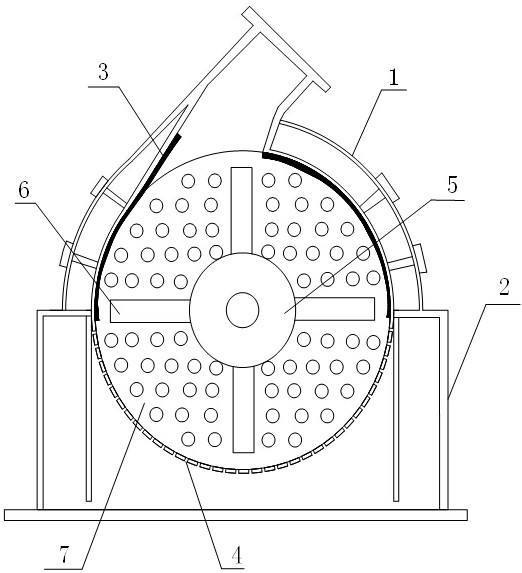

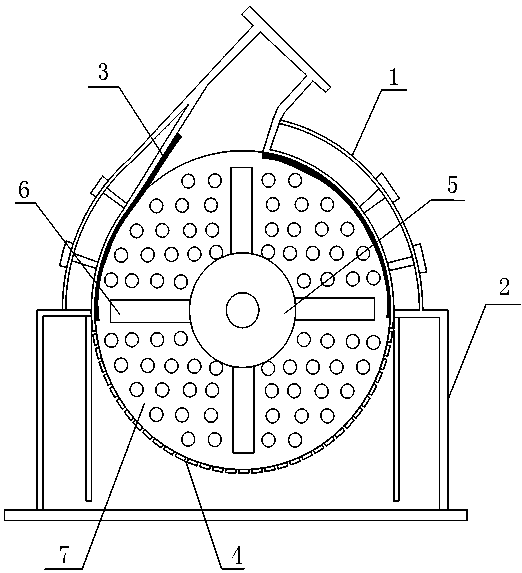

Centrally-mounted friction driving type curing machine

The invention discloses a centrally-mounted friction driving type curing machine. The curing machine comprises a circular cabinet and a circular disc, wherein the circular cabinet is provided with a disc outlet and a disc inlet. The centrally-mounted friction drive type curing machine is characterized in that the internal center of the circular cabinet is provided with a central shaft, and an elastic friction drum is sleeved outside the central shaft; and the circular disc is arranged at a predetermined orbit outside the elastic friction drum, and one end of the circular disc is close to the inner wall of the circular cabinet, while the other end is tightly adhered to the elastic friction drum. The centrally-mounted friction drive type curing machine of the invention has a simple structure, is easy to maintain and an unique design of revolution and auto-rotation, can make the processed materials carry out upward and downward, and leftward and rightward operation and revolution and auto-rotation motions, so that the whole body is heated uniformly and the dryness is absolutely uniform, the working efficiency is greatly improved and the drying time is shortened.

Owner:KUANG BASKETRY DEV NINGGUO COUNTY ANHUI PROV

A kind of drying equipment for the production of hydroxypropyl methylcellulose

The invention discloses a drying device used for the production of hydroxypropyl methyl cellulose, and relates to the technical field of hydroxypropyl methyl cellulose production. The invention includes a cyclone dust collector, a hot air supply module and a support frame, the peripheral sides of the cyclone dust collector and the hot air supply module are fixedly connected with the support frame, and one end of the air inlet of the hot air supply module is fixedly connected with the cyclone dust collector; The refining mechanism, the drying main machine and the two symmetrically arranged drying auxiliary machines, the refining mechanism, the drying main machine and the peripheral sides of the two drying auxiliary machines are all fixedly connected with the supporting frame, and one end of the discharge port of the two drying auxiliary machines is fixedly connected with the refining mechanism. . Through the design of the hot air supply module, the refinement mechanism, the drying auxiliary machine and the drying main machine, the present invention enables the device to quickly complete the drying operation of hydroxypropyl methylcellulose in an automated manner, and the device becomes traditional when drying. The static drying structure of the drying device is a cyclic multiple drying mechanism.

Owner:安徽森淼实业有限公司

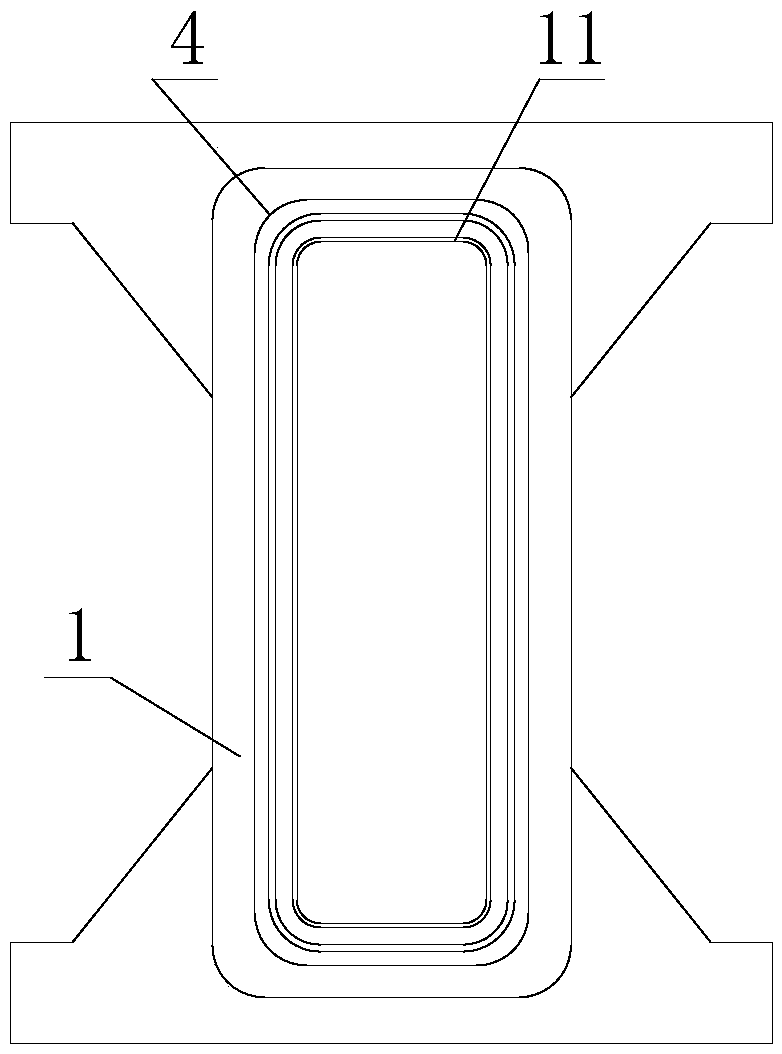

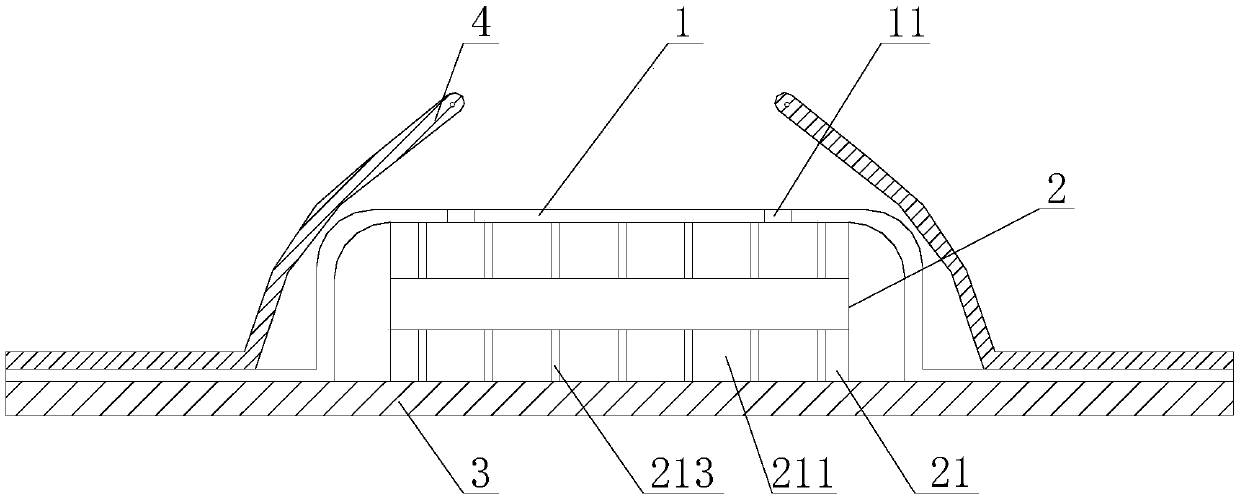

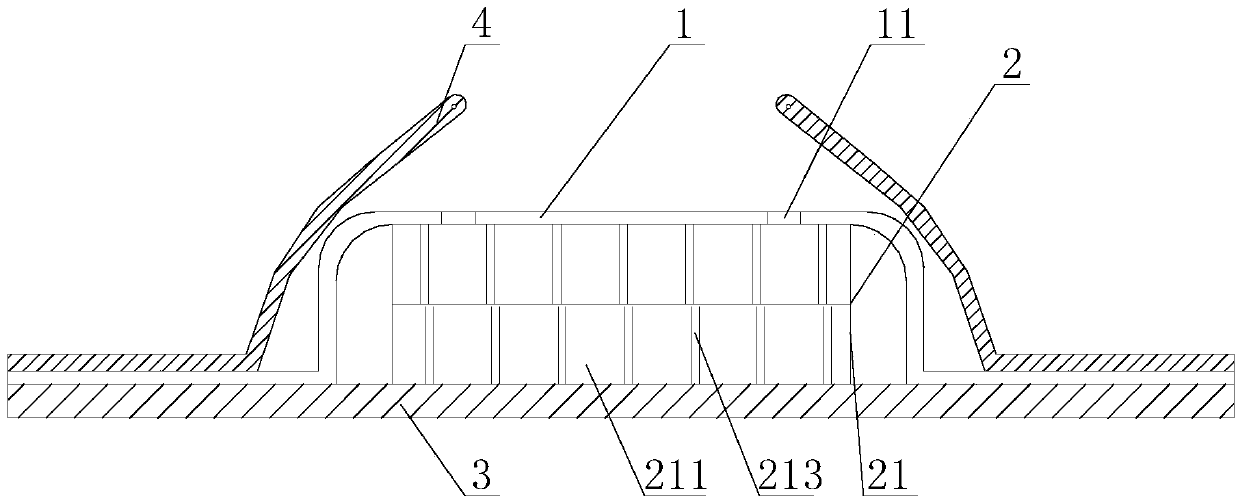

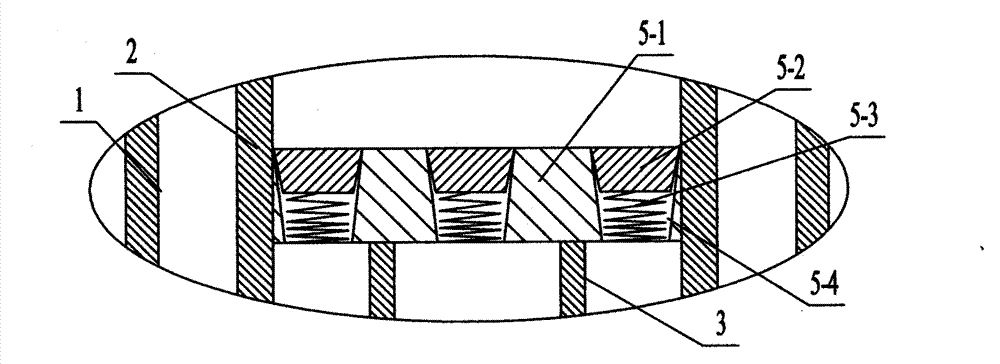

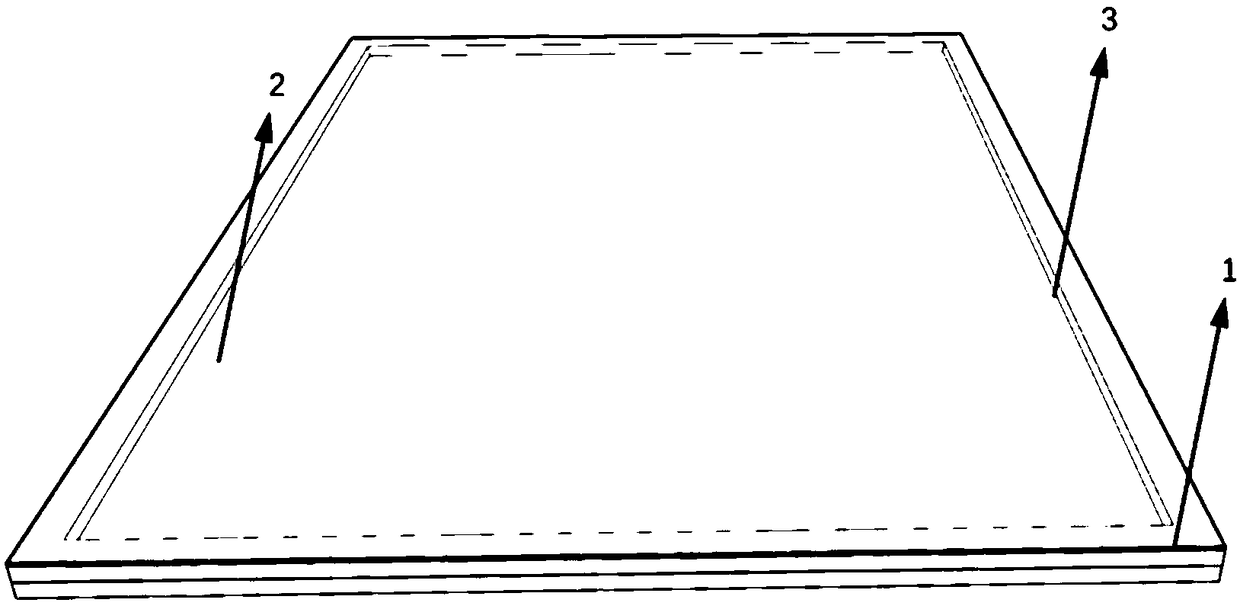

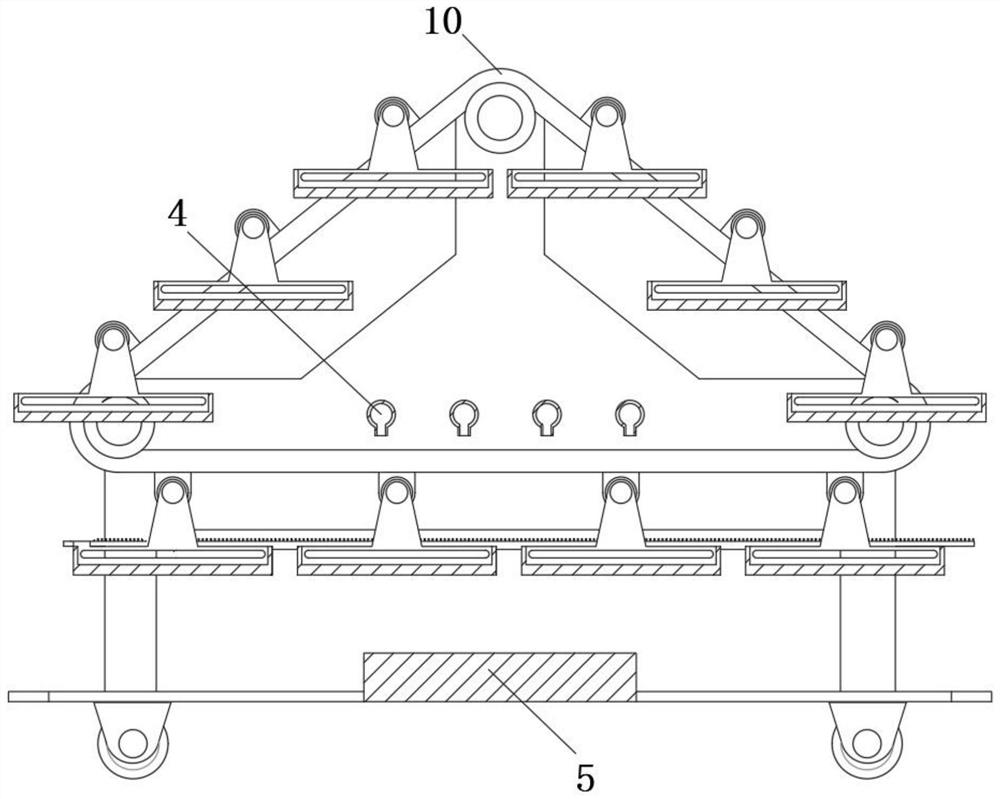

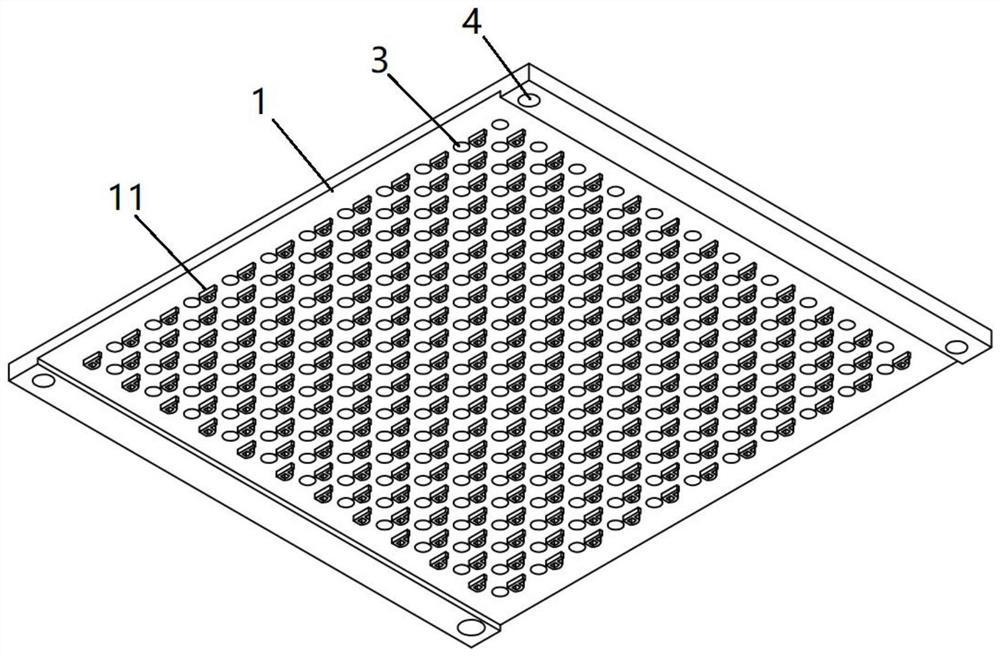

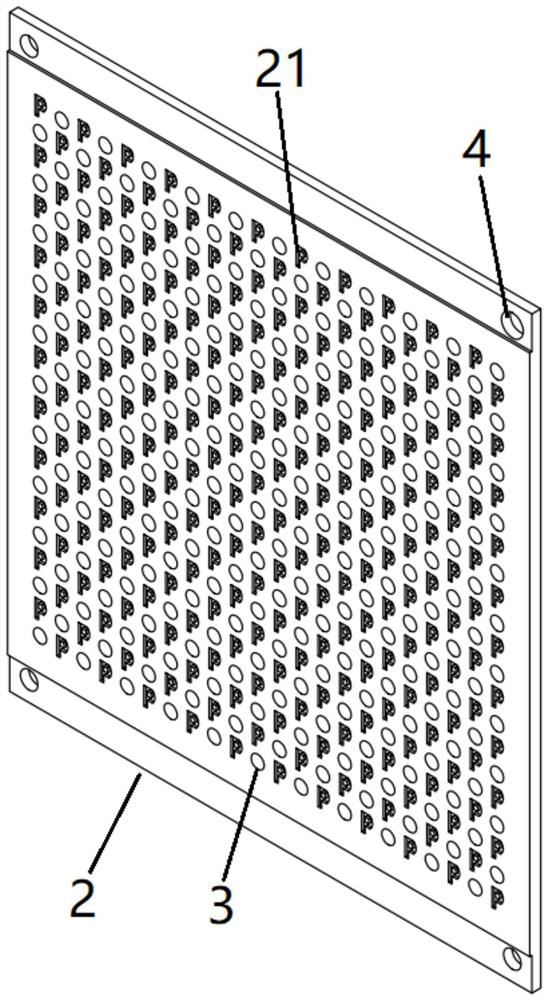

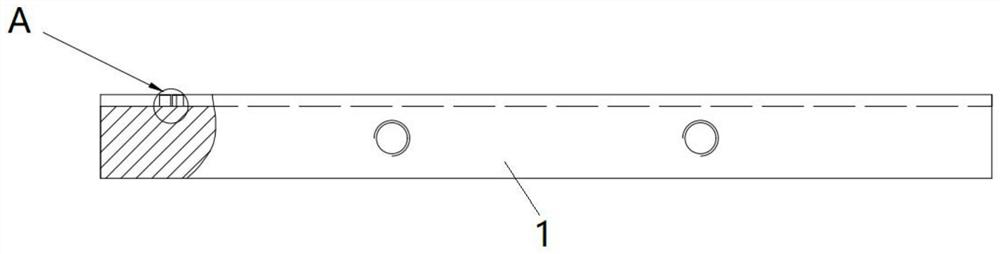

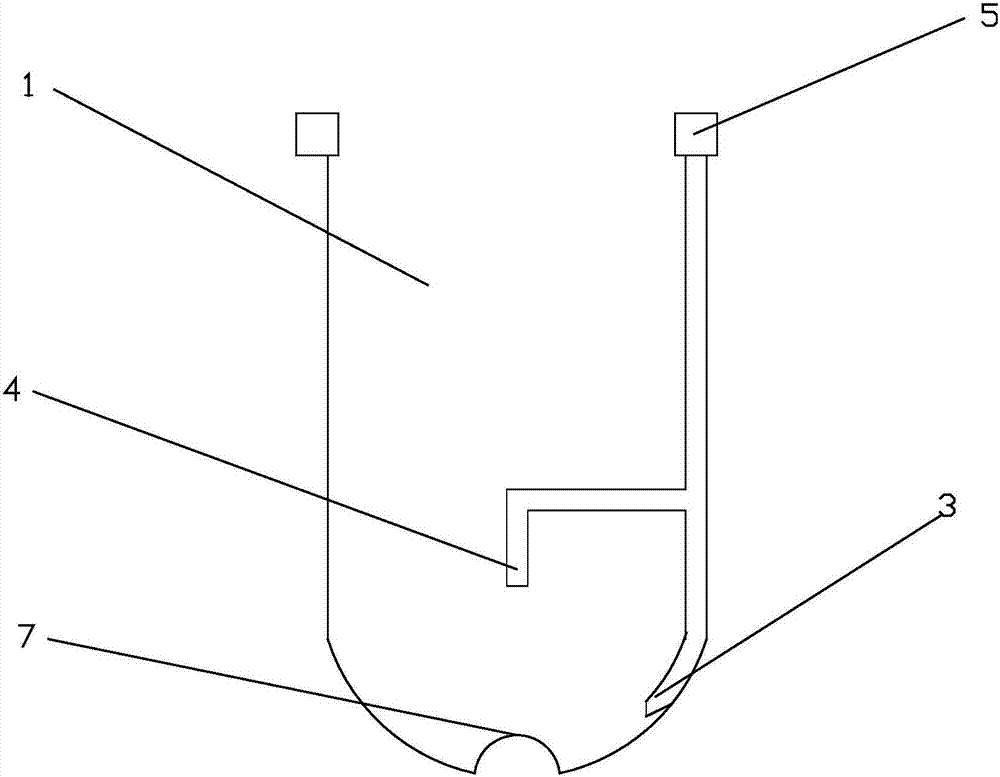

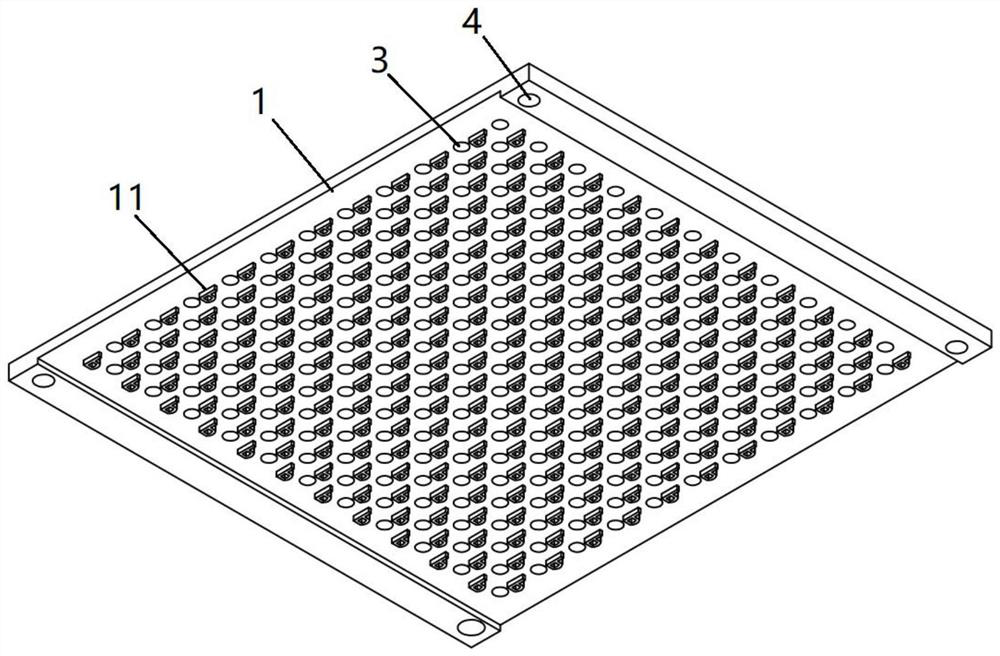

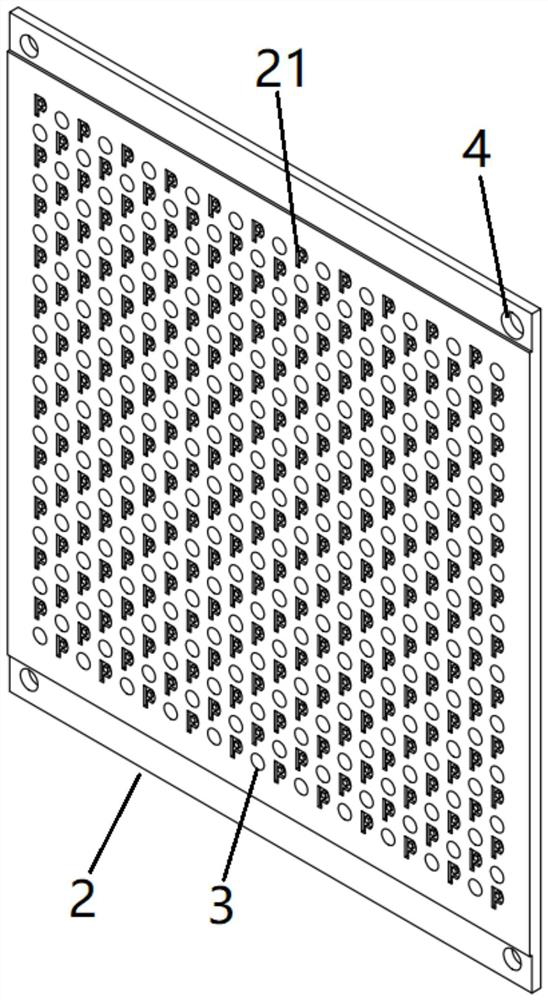

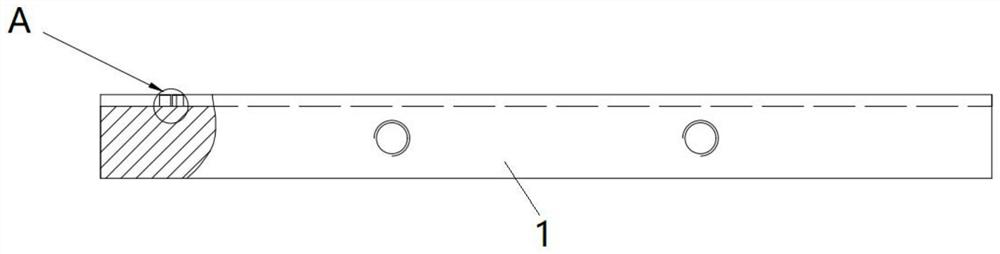

Drying equipment and drying method for biological materials

ActiveCN113566556AActivity is not affectedEven by forceDrying chambers/containersBiotechnologyBiochemical engineering

The invention relates to the technical field of drying equipment, in particular to drying equipment and a drying method for biological materials. The drying equipment comprising a bearing structure and a pressure applying structure which are clamped and matched with each other to fix the biological materials; the bearing structure is provided with a plurality of first bearing parts protruding out of the bearing surface; the pressure applying structure is provided with a plurality of grooves which are concavely arranged away from a pressure applying surface, the grooves and the first bearing parts are arranged in a one-to-one correspondence mode, the depth of the grooves is smaller than the length of the first bearing parts protruding out of the bearing surface, and when the first bearing parts and the grooves are clamped under the action of external force, airflow gaps can be formed between the bearing surface and the pressure applying surface, so that airflow can pass through conveniently, the drying degree of the biological materials is more uniform, meanwhile, the situation that the activity of the biological materials is not affected is ensured, and in addition, the biological materials are evenly stressed, deformation or tearing caused by shrinkage in the drying process is avoided, and the integrity of the dried biological materials is guaranteed.

Owner:SAIKE SAISI BIOTECH CO LTD

Method of controlling a rotatable tumble dryer and a rotatable tumble dryer implementing the method

A method of controlling the drying operation of a rotatable tumble dryer (1) comprising a rotatable drum (3) for loading laundry (5) and a At least one electrode sensor (22) for sensing the dryness of the laundry (5). The method includes the following steps: detecting whether there is wet laundry (5) in the rotatable drum (3) through the electrode sensor (22); if it is detected that there is wet laundry in the rotatable drum (3), then Start a drying cycle; during the drying cycle, sense the dryness of the laundry (5); measure the cycle time (TD) until the sensed dryness reaches a predetermined dryness threshold; if the cycle time (TD) is less than Predetermining a dryness threshold time (Sm), the drying cycle is continued with a first additional time (D1) and stopped at the end of said first additional time (D1).

Owner:ELECTROLUX HOME PROD CORP NV

A dry method for producing limestone machine-made sand

ActiveCN110124800BUniform drynessUniform water additionGrain treatmentsThermodynamicsElectric machine

The invention discloses a method for producing limestone machine-made sand through a dry method. The method comprises the following steps of conducting broken stone stacking, terrace feeding, conveying, crushing and sieving and wet stirring to obtain a finished product, wherein high-temperature drying treatment is conducted in the conveying process. Conveying equipment is provided with an electricheating assembly. A screw conveyor serves as the conveying equipment. The conveying equipment comprises a conveyor shell and a screw rod driven to rotate in the conveyor shell by a motor. One end ofthe conveyor shell is provided with a feed port, and the other end of the conveyor shell is provided with a discharge port. An electric heating wire is embedded in the inner wall of the conveyor shell.

Owner:荣县业远科技有限公司

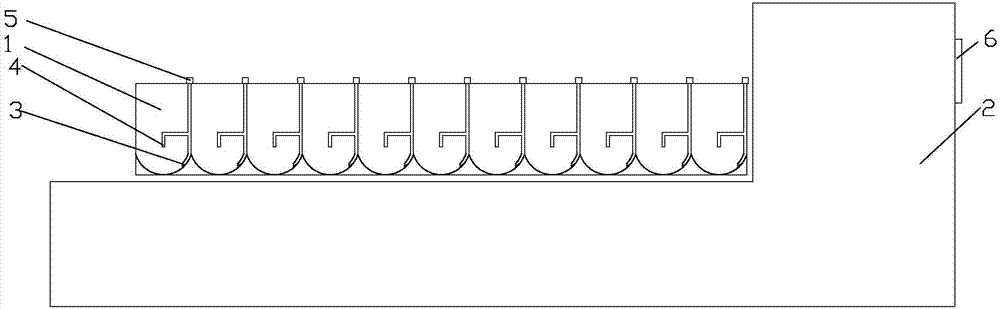

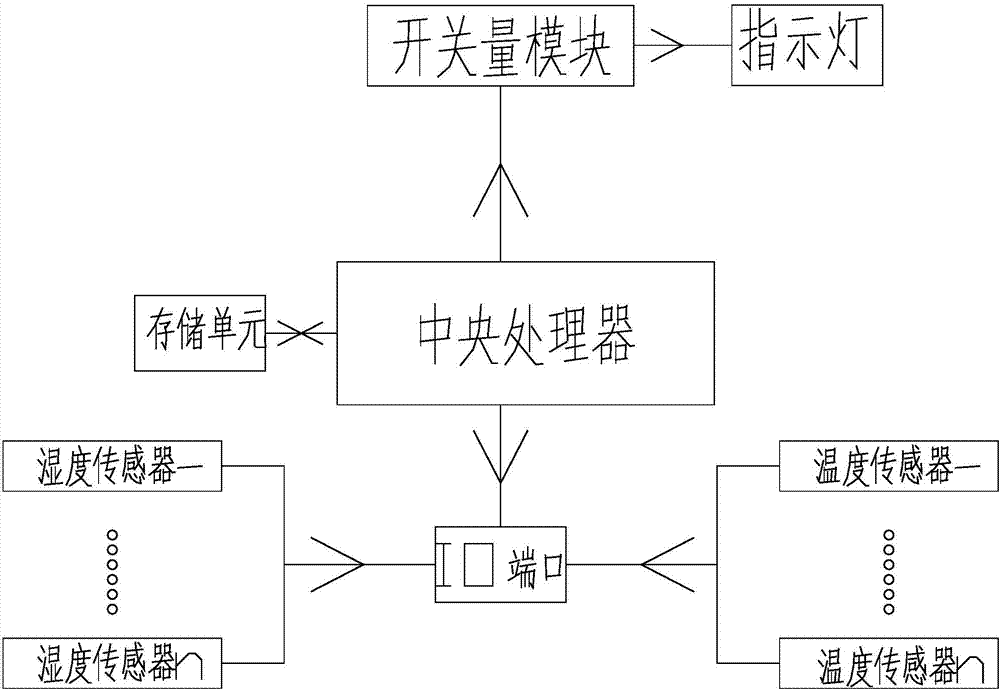

Strip tidying machine

InactiveCN107197961ATemperature measuredUniform drynessPre-extraction tea treatmentComputer moduleEngineering

A sorting machine relates to a tea manufacturing machine, and the technical problem to be solved is to provide a stripping machine capable of achieving uniform dryness of tea leaves. The technical proposal includes several groove units, the groove units are welded and connected, and the bottom of the groove units is An electric heating device is provided, which also includes a motor and a transmission mechanism. The transmission mechanism drives the groove unit to reciprocate. A temperature sensor is installed at the bottom of each groove unit. The temperature sensor is 5-10mm away from the bottom of the groove unit. The humidity sensor, the temperature sensor and the humidity sensor are respectively connected to the controller; an indicator light is also arranged on the groove unit, and the indicator light is connected to the controller. The controller includes a central processing unit, a switch module, a memory and an IO port, a switch module, The memory and the IO port are respectively connected to the central processing unit, the indicator light is connected to the switch module, and the temperature sensor and the humidity sensor are respectively connected to the IO port. According to the actual water content of the tea leaves, the heating temperature and the time of stripping can be controlled to make the tea leaves dry evenly.

Owner:刘义

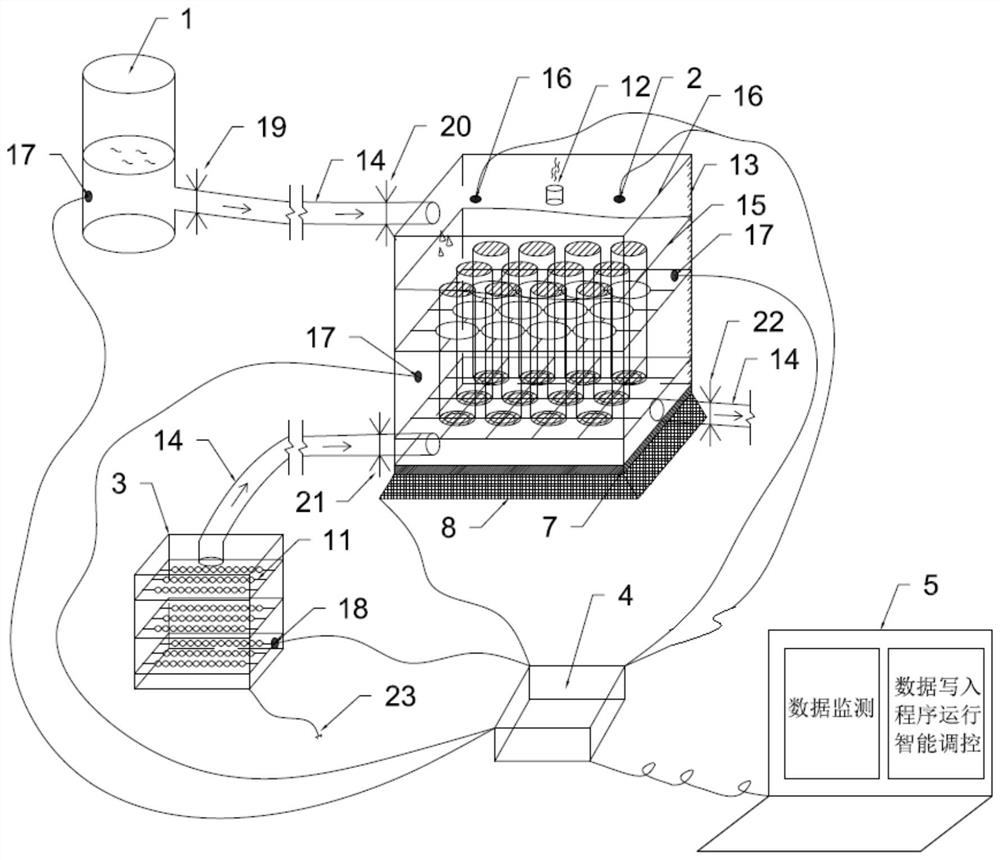

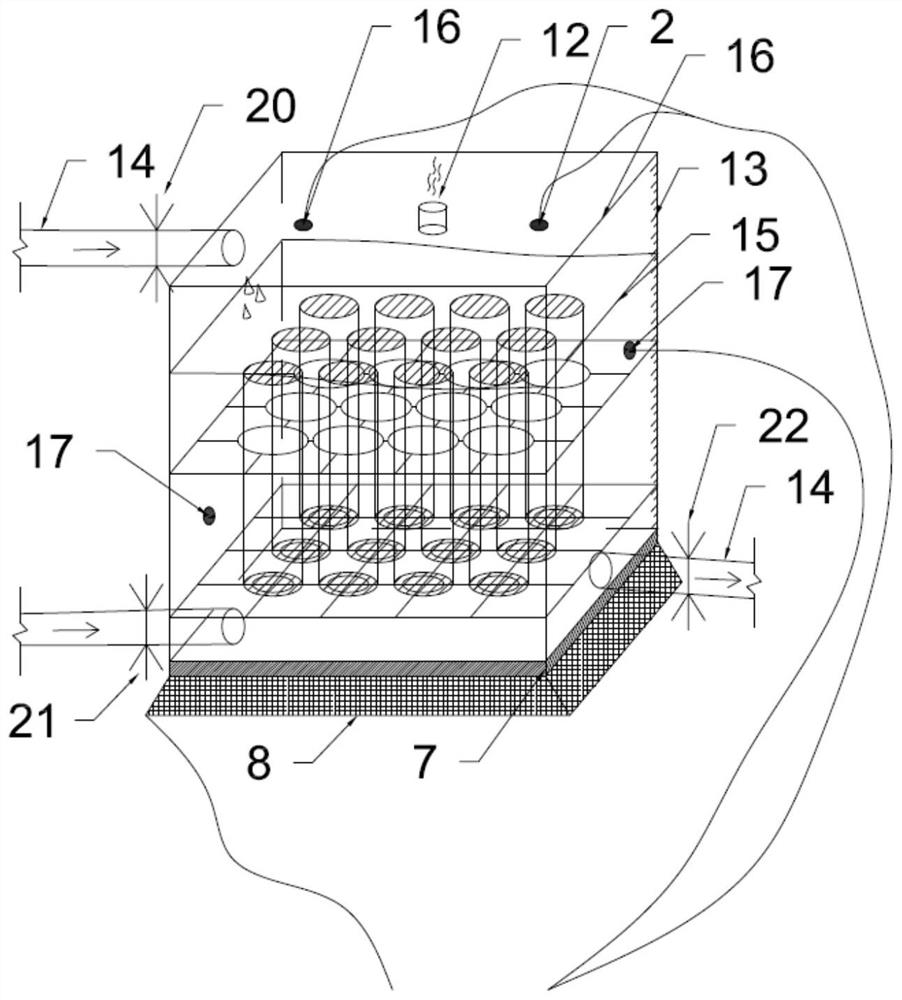

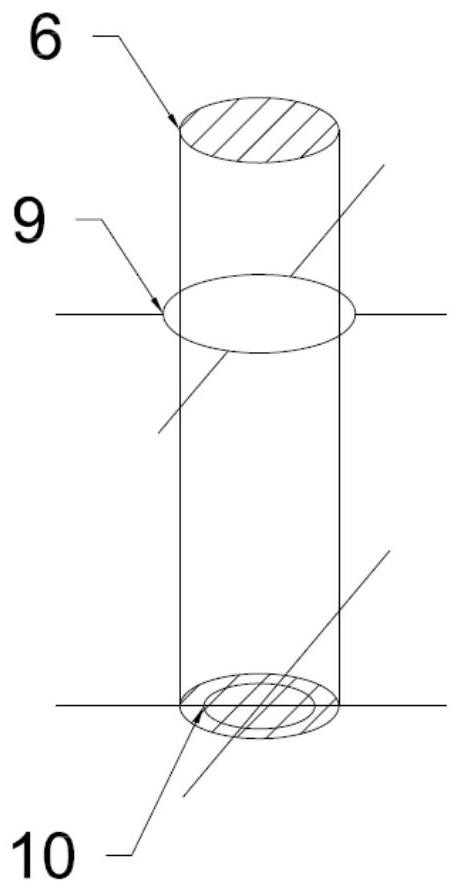

Rock mass dry-wet cycle damage monitoring system and method in chemical corrosion environment

PendingCN114034629AImprove accuracyMotion damageWeather/light/corrosion resistancePermeability/surface area analysisPorosityChemical solution

The invention relates to a rock mass dry-wet cycle damage monitoring system and method in a chemical corrosion environment. The system comprises a dry-wet cycle test box which is placed on a weighing platform; the system further comprises a chemical solution preparation container and a drying heat source supply box; the system further comprises an upper computer configured with a damage degree calculation program, and the damage degree calculation program is used for calculating the porosity according to the dry weight and the wet weight of the rock sample and then calculating the damage degree according to the porosity; the dry weight refers to the weight of the rock sample during drying, the wet weight refers to the weight of the rock sample after soaking, and the dry weight and the wet weight of the rock sample are both calculated according to the reading of the weighing table. The technical problem of how to monitor the damage of the rock mass in the dry-wet cycle process is solved, the monitoring efficiency is improved, and the accuracy of the monitoring result is also improved.

Owner:CHONGQING JIAOTONG UNIVERSITY

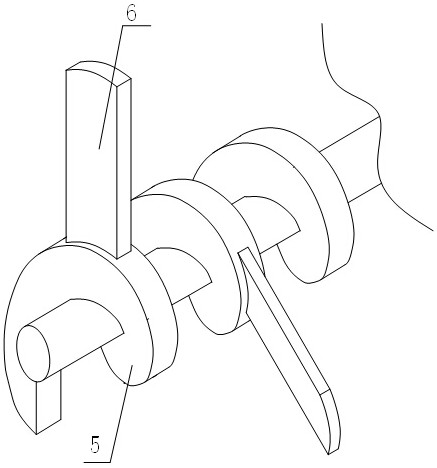

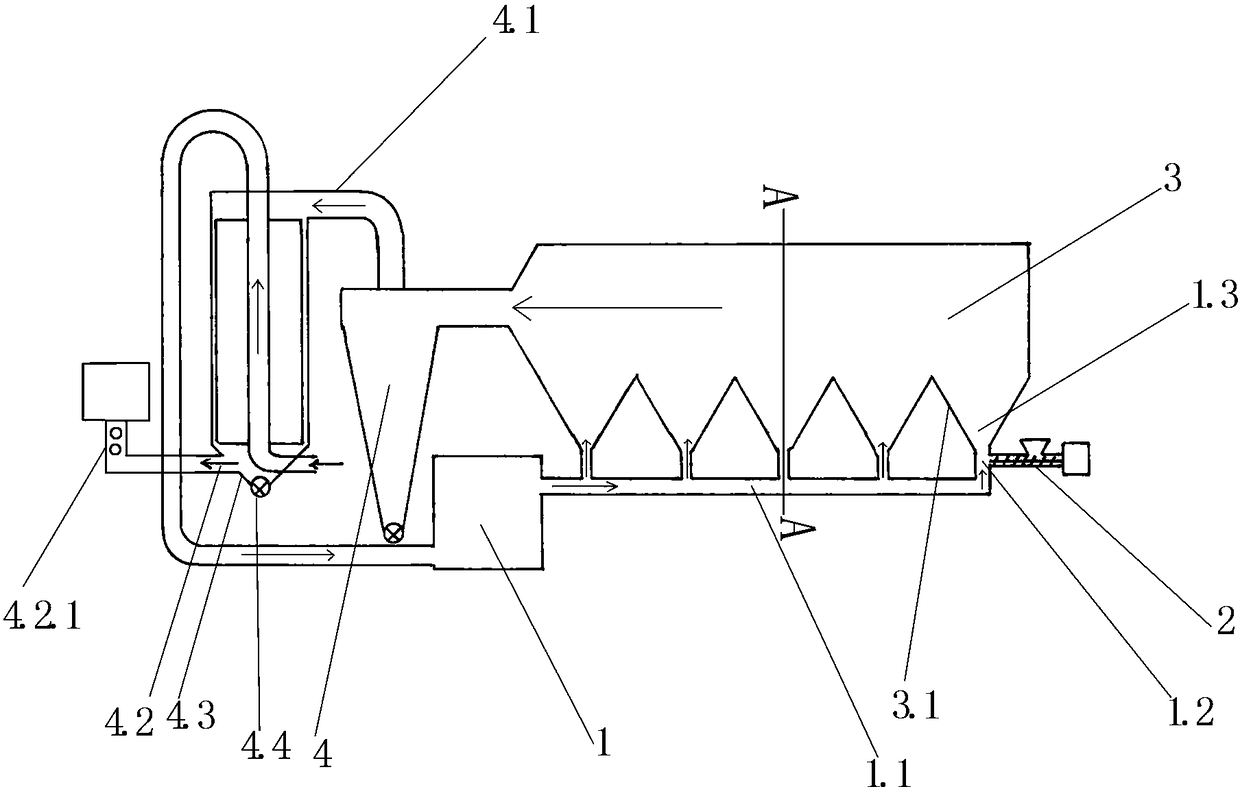

Distilled grain airflow dryer

InactiveCN108731457AProduce energy saving effectUniform drynessDrying gas arrangementsDrying solid materialsCyclonePulp and paper industry

The invention discloses a distilled grain airflow dryer. A drying chamber of the distilled grain airflow dryer is an oblique long container, the cross section of the drying chamber is in a sector shape, the high end of the drying chamber is sealed, and the upper portion of the low end of the drying chamber communicates with an air inlet pipe of a cyclone discharger. Multiple funnels are arranged on the lower portion of the drying chamber and are connected with multiple air blowing openings of an air heater. The air blowing opening of the first air heater on the lower portion of the high end ofthe drying chamber is larger and is connected with a t-branch pipe, and a spiral conveyor is arranged in a transverse pipe of the t-branch pipe. A finned air heater air inlet pipe is wrapped in a gasoutlet pipe of the cyclone discharger, a liquid collection hopper is arranged on the lower portion of the gas outlet pipe of the cyclone discharger, and a liquid discharging valve is arranged below the liquid collection hopper. A gas outlet is formed on the lower portion of the gas outlet pipe of the cyclone discharger, and an advertising gas pipe is arranged on the gas outlet and supplies discharged waste gas to the two sides of a highway to be used as white wine smell advertising. According to the dryer, the drying time of distilled grain in the drying chamber is long, the dryer is an airflow dryer capable of evenly drying large particle containing distilled grain, and the waste gas can be recycled.

Owner:朱增伟

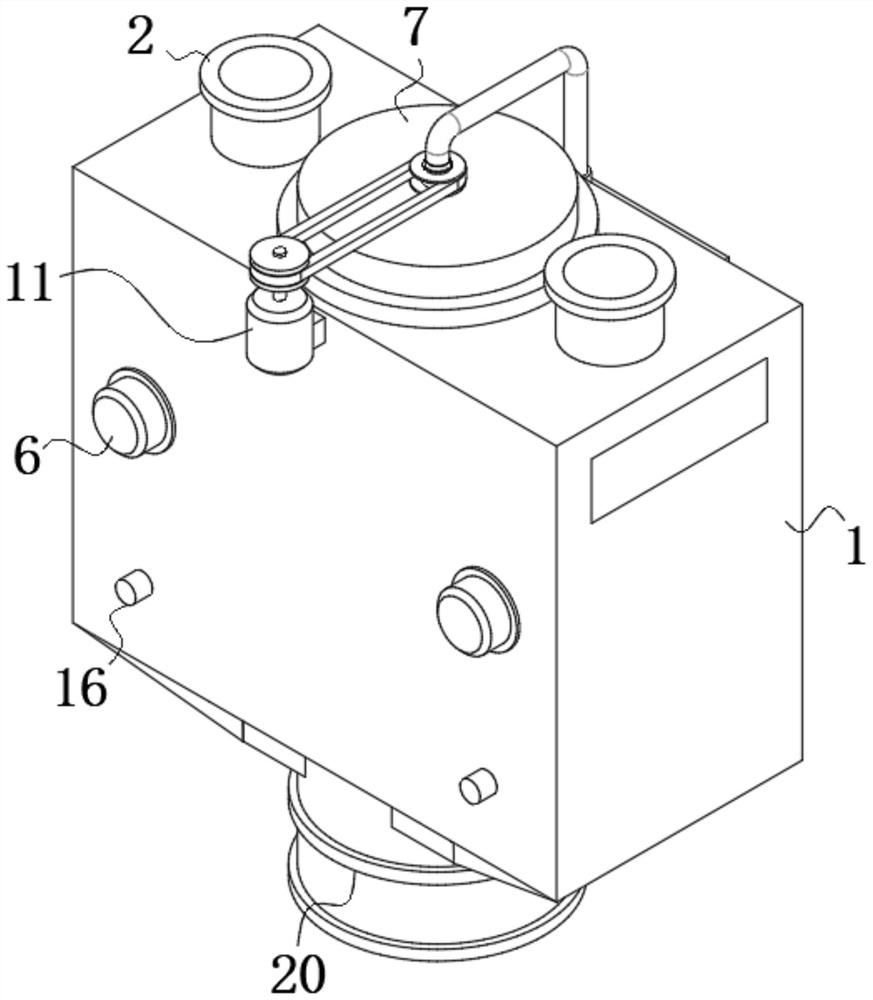

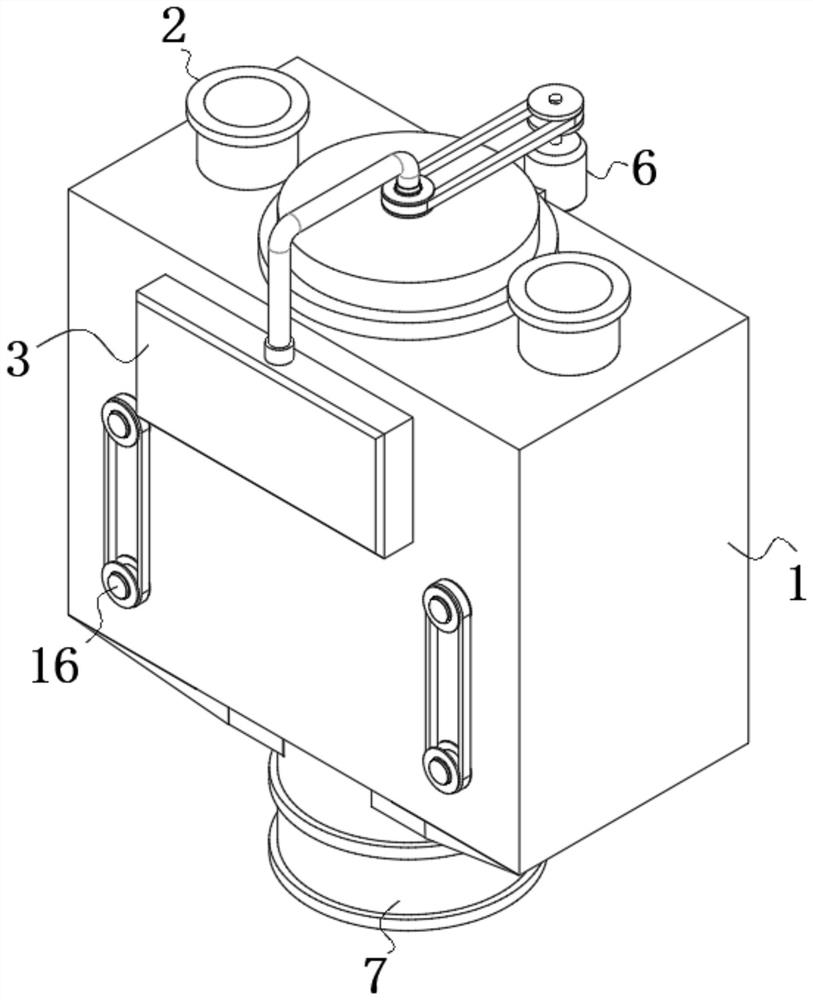

Vacuum environment-friendly drying device

PendingCN109282622AKeep Natural Active IngredientsAvoid contactDrying solid materials without heatHeating arrangementPeristaltic pumpHigh energy

The invention discloses a vacuum environment-friendly drying device. The drying device comprises a supporting frame and a drying main body; a symmetric type support is adopted in the supporting frame,supporting feet spirally subjected to height adjusting are arranged at the bottom of the support, a peristaltic pump is adopted for power drive, precise control is achieved, through the pump, the vacuum state is formed, and sensibility, high-thermal conductivity and the isothermal condition of the liquid phase variable temperature under the state are used for achieving water containing medium surface and inner water vaporization phase change transferring to achieve drying. The vacuum water removal drying equipment and process are continuously achieved under the vacuum state, the higher evaporation drying speed and efficiency can be obtained with small heat energy consumption, a low-water-rate drying medium with the uniform drying effect is obtained, and the device has the very high energy-saving and environment-friendly value.

Owner:浙江绿舟科技有限公司

Method for producing limestone machine-made sand through dry method

ActiveCN110124800ASimple structureReduce repeated crushing processGrain treatmentsScrew conveyorElectric heating

The invention discloses a method for producing limestone machine-made sand through a dry method. The method comprises the following steps of conducting broken stone stacking, terrace feeding, conveying, crushing and sieving and wet stirring to obtain a finished product, wherein high-temperature drying treatment is conducted in the conveying process. Conveying equipment is provided with an electricheating assembly. A screw conveyor serves as the conveying equipment. The conveying equipment comprises a conveyor shell and a screw rod driven to rotate in the conveyor shell by a motor. One end ofthe conveyor shell is provided with a feed port, and the other end of the conveyor shell is provided with a discharge port. An electric heating wire is embedded in the inner wall of the conveyor shell.

Owner:荣县业远科技有限公司

Rapid baking method for peach blossoms

InactiveCN103637910AEvenly heatedImprove finishing effectCosmetic preparationsToilet preparationsProcess engineeringNutrient content

The invention discloses a rapid baking method for peach blossoms. Selected fresh peach blossoms are put into a microwave machine, the temperature is controlled to be 115 DEG C, and deactivation of enzymes is conducted for two minutes; the peach blossoms are then put into a vacuum microwave baking chamber for baking, the vacuum degree is smaller than -0.08 Mpa, and baking is conducted for 90 minutes at the temperature of 45 DEG C. According to the rapid baking method for the peach blossoms, the fresh peach blossoms are baked at the low and constant temperature, time and energy are saved, the original color, fragrance, shape, taste and the nutrient ingredients of the peach blossoms are kept basically unchanged, operation is easy, and cost is low.

Owner:桂林普兰德生物科技有限公司 +1

A kind of drying equipment and drying method of biological material

ActiveCN113566556BActivity is not affectedEven by forceDrying chambers/containersStructural engineeringMechanical engineering

Owner:SAIKE SAISI BIOTECH CO LTD

A method for drying and cooling pellet feed

ActiveCN108592525BReduce pulverization rateImprove qualityDrying solid materials with heatFeeding-stuffNutritionEnvironmental engineering

The invention relates to a method for drying and cooling granular feed, which belongs to the technical field of feed processing. The processing method comprises the following operation steps: first-stage vacuum microwave drying, second-stage vacuum microwave drying, cold air drying and sieving packaging of pellet feed. The present invention has the following advantages: (1) adopting the combined method of vacuum microwave drying and cold air drying, the drying speed is accelerated, the pulverization rate of the feed is reduced, the durability of the pellets is improved, and the quality of the feed is improved; (2) Vacuum microwave drying promotes the further gelatinization of starch in pellet feed, effectively improves the digestion and absorption rate of feed, and improves the nutritional value of feed; (3) It can further kill harmful bacteria and anti-nutritional factors in feed, and improve the hygiene of pellet feed condition.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

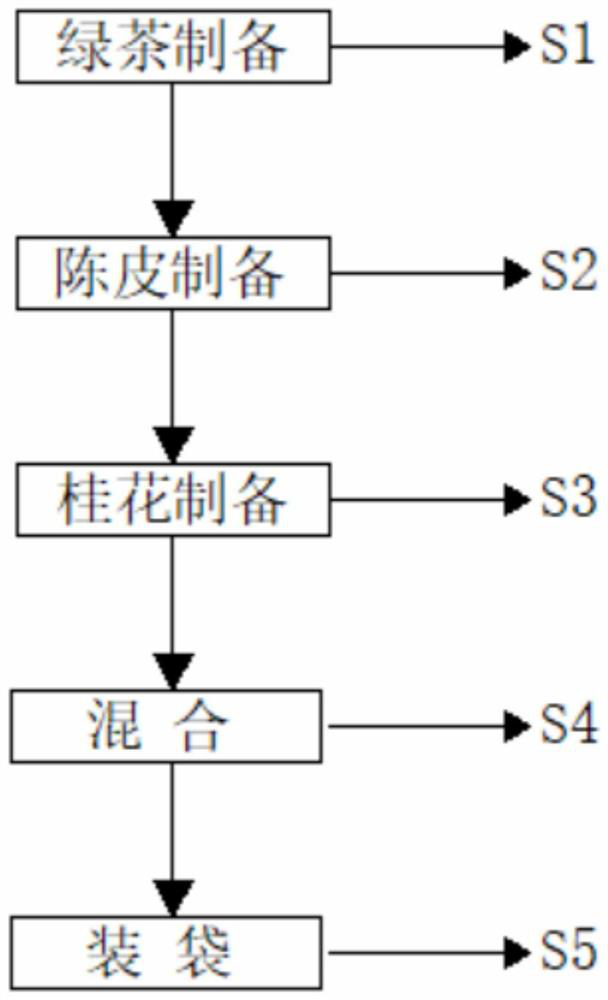

Preparation method of sweet-scented osmanthus and dried orange peel green tea

PendingCN113875848AEnhance the body's anti-inflammatoryMedicinal and calmPre-extraction tea treatmentHorticultureOsmanthus

The invention relates to the technical field of sweet-scented osmanthus and pericarpium citri reticulatae green tea, and discloses a preparation method of sweet-scented osmanthus and pericarpium citri reticulatae green tea. The preparation method of the sweet-scented osmanthus and pericarpium citri reticulatae green tea comprises the following steps: S1, green tea preparation: (1) picking; (2) spreading and airing; (3) performing fixation on the tea leaves; (4) rolling; (5) drying; S2, pericarpium citri reticulatae preparation: (1) fruit picking and washing; (2) peeling; (3) drying in the shade and turning over; (4) drying in the sun; (5) warehousing; (6) tedding; (7), pulp sweeping; S3, sweet osmanthus preparation: (1) picking; (2) removing impurities; (3) airing; (4) performing fixation on the scented tea; S4, mixing; S5, bagging is carried out; according to the invention, the added dried orange peel and green tea are cold in nature and have the effects of clearing heat and promoting salivation, the dried orange peel is warm in nature and can effectively consider the disadvantages of clearing heat and cold in nature of green tea, the dried orange peel has the effects of regulating qi-flowing for strengthening spleen, eliminating dampness and reducing phlegm and facilitating discharge of mucus and pollutants in the lung, and the dried orange peel is combined for use, mild in medicine property, better in taste, more suitable for drinking groups and also has a sterilization function.

Owner:惠州市正圆健康食品有限公司

Quick roasting method of fresh grosvenor momordica

ActiveCN102100394BGuaranteed circulationExtend the baking timeFood preservationPharmaceutical product form changeTime rangeMicrowave oven

The invention discloses a quick roasting method of a fresh grosvenor momordica, which comprises the following steps: (1) classifying the ripe grosvenor momordica according to large, middle and small specifications and respectively placing into a special roasting tray used for a microwave oven; (2) placing the roasting tray filled with the grosvenor momordica into an intelligent microwave vacuum drying oven; and (3) determining the roasting time according to the weight of the grosvenor momordica and the power of the microwave oven and roasting, wherein the roasting temperature range is 20-40 DEG C, and the roasting time range is 30-150 minutes under the condition of vacuum degree less than -0.08MPa. In the method, the microwave technology for roasting is utilized, the roasting process is carried out at low temperature and constant temperature, the time consumption is short, the cost is low, and the fresh grosvenor momordica well keeps the bright yellow color and nutrition constituents and has good taste.

Owner:桂林普兰德生物科技有限公司

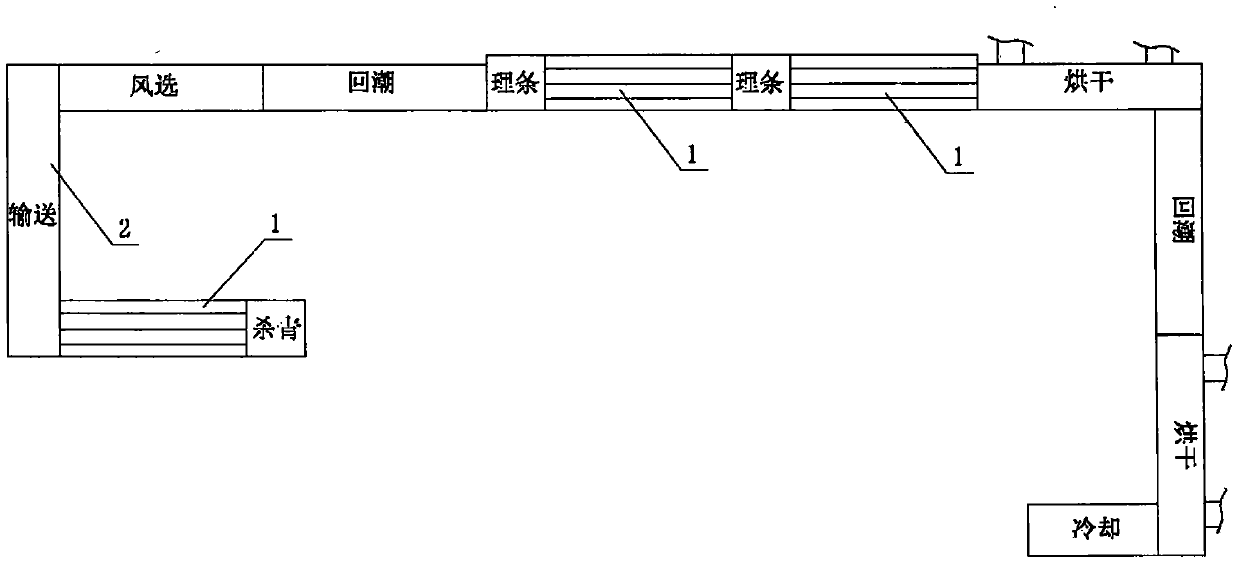

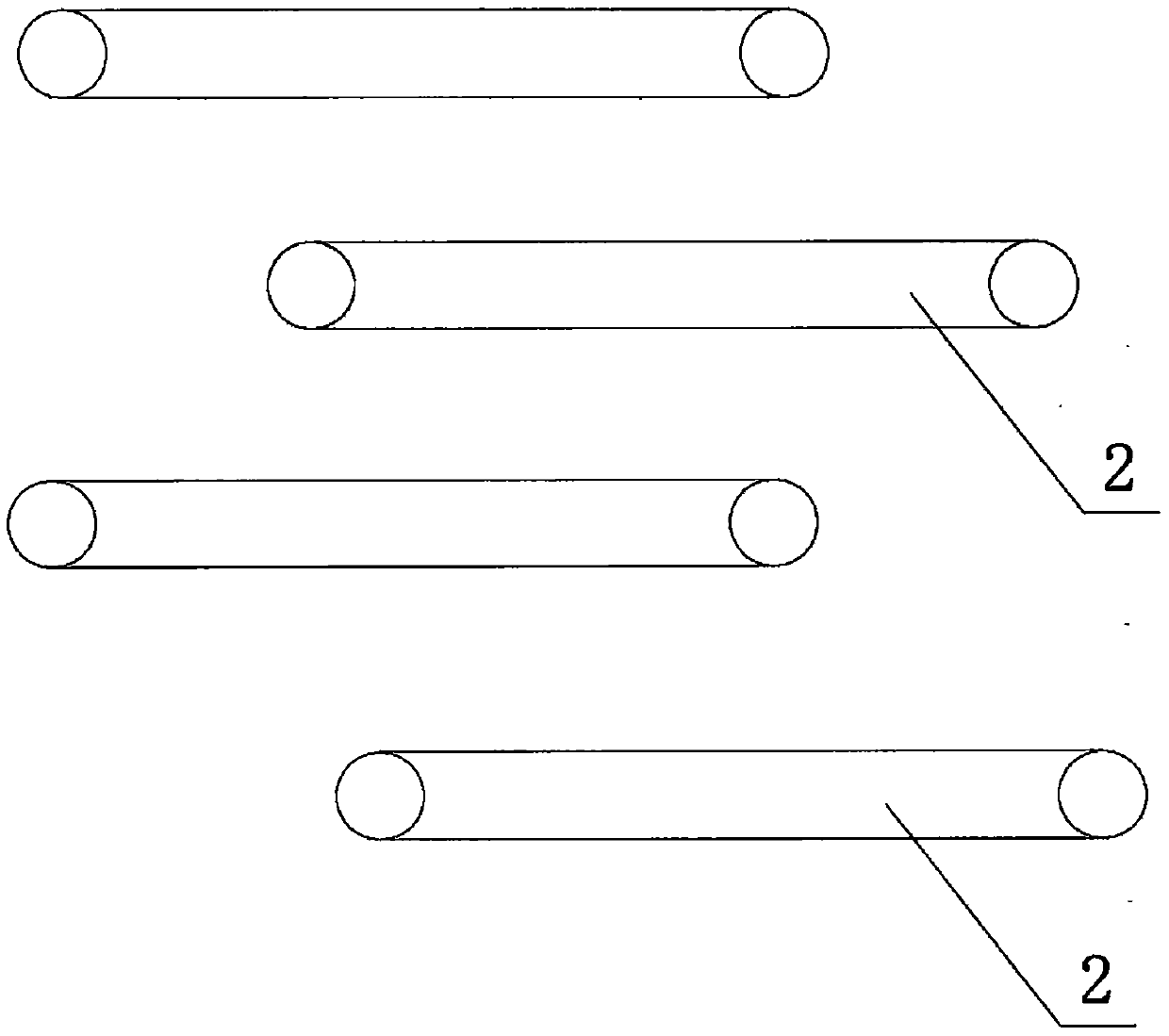

Automatic preparation technique of phoenix-shaped white tea

InactiveCN107771970AFully automatedDoes not destroy and change the nutritional contentPre-extraction tea treatmentEngineeringMoisture regain

The invention relates to the technical field of tea preparation, and particularly relates to an automatic preparation technique of phoenix-shaped white tea. The method includes the first step of fixation; the second step of air selection of tea leaves; the third step of moisture regain; the fourth step of tea strip tidying for the first time; the fifth step of tea strip tidying for the second time; the sixth step of drying; the seventh step of moisture regain; moisture regain for two hours; the eight step of drying; the ninth step of cooling and package. The invention has the advantages of realizing the automation of the whole tea production and reducing labor cost through the steps.

Owner:安吉柏茗茶场

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com