Strip tidying machine

A technology of a strip machine and a motor, applied in the field of strip machines, can solve the problems of uneven dryness, uneven dryness of tea leaves, fragile tea leaves, etc., and achieve the effect of uniform dryness of tea leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

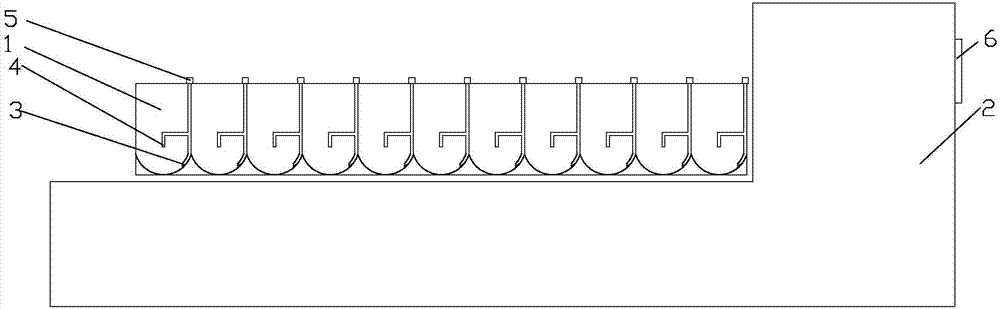

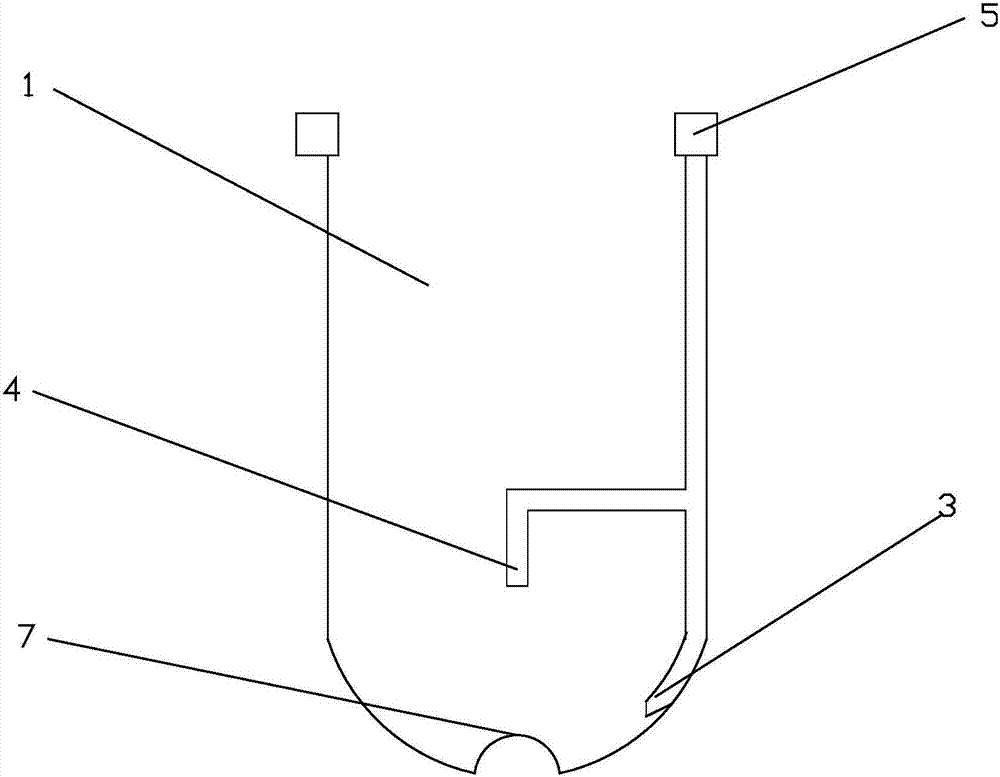

[0014] Such as Figure 1-3 As shown, the present invention includes several groove units 1, and several groove units 1 are welded to each other, and the bottom of the groove unit 1 is provided with an electric heating device, and also includes a motor and a transmission mechanism, and the motor and the transmission mechanism are connected, and the transmission mechanism is connected to the groove unit Connected, the transmission mechanism drives the groove unit 1 to reciprocate, the lower part of each groove unit 1 is provided with a temperature sensor 3, the temperature sensor is 5-10mm away from the bottom of the groove unit 1, and the middle of each groove unit 1 is equipped with a humidity sensor 4. The temperature sensor 3 and the humidity sensor 4 are respectively connected to the controller; the groove unit 1 is also provided with several indicator lights 5, and the indicator lights 5 are connected to the controller.

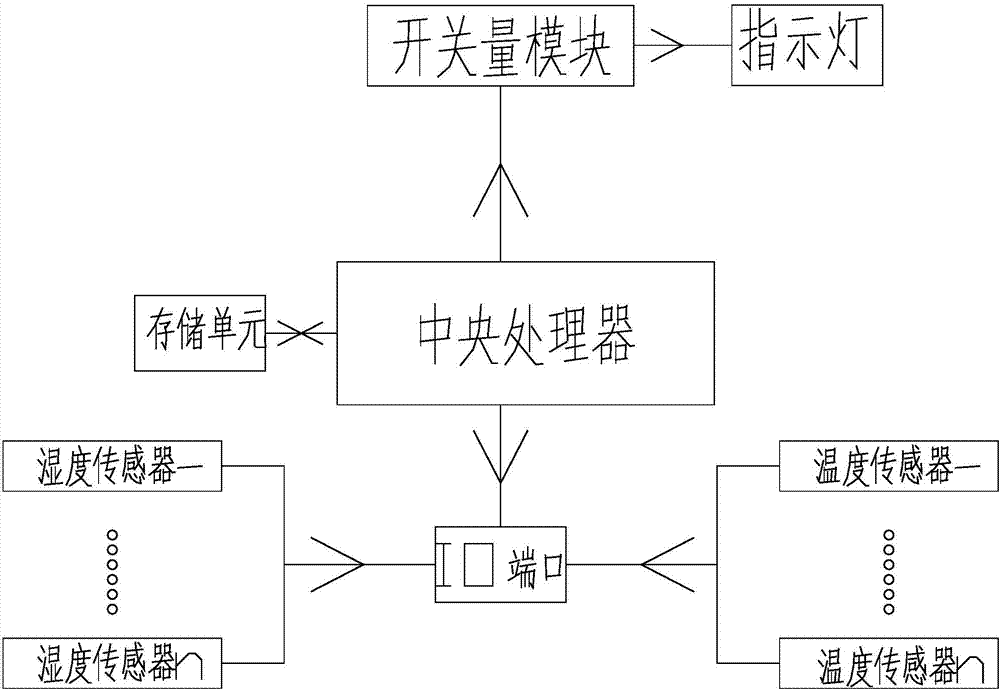

[0015] The controller includes a central processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com