Method of controlling a rotatable tumble dryer and a rotatable tumble dryer implementing the method

A dryer and drum-type technology, which is applied in the field of rotatable drum-type clothes dryers, can solve problems such as waste of electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

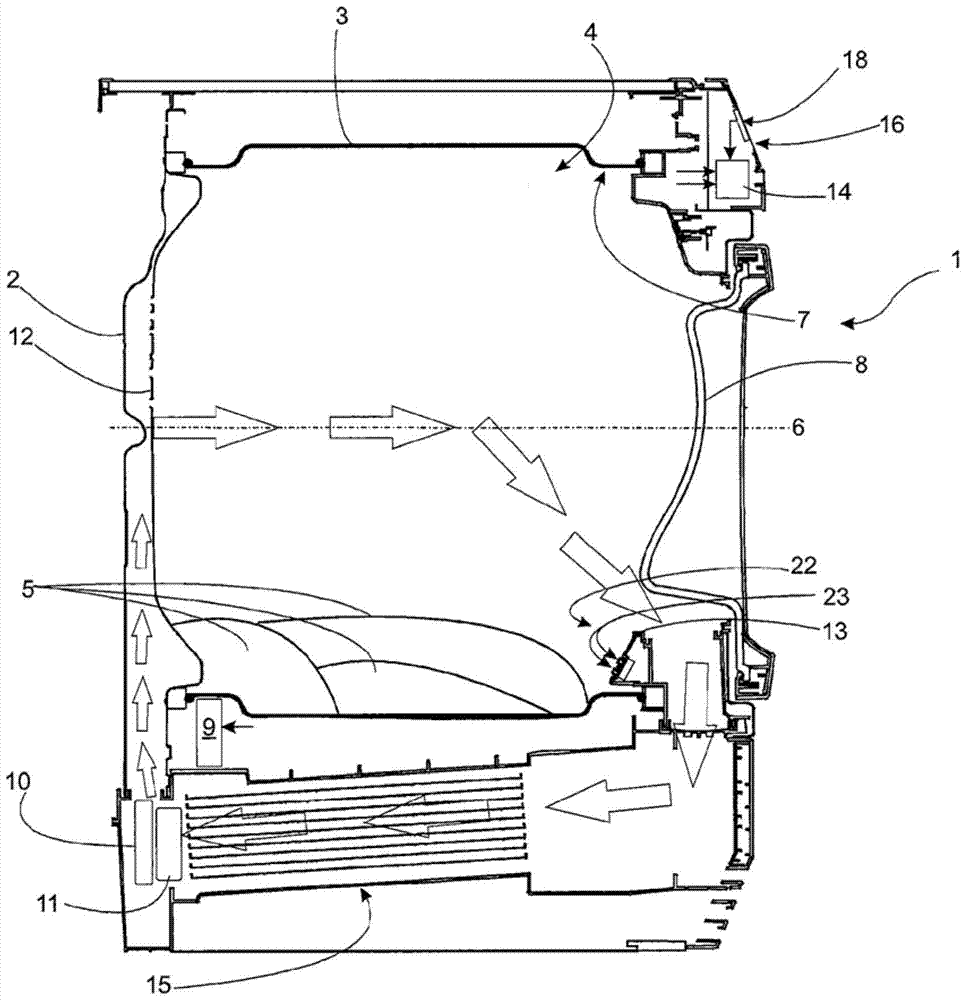

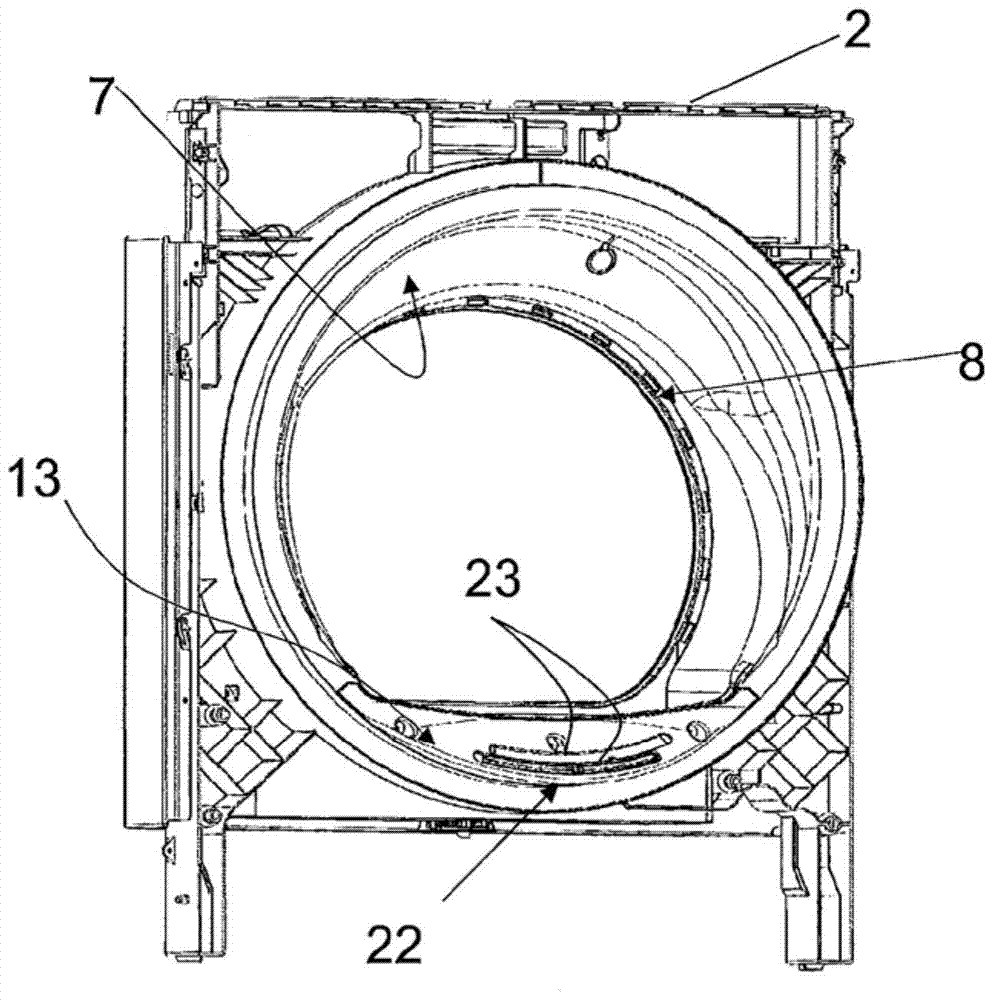

[0029] figure 1 The reference numeral 1 in , generally designates a rotatable tumble clothes dryer comprising an outer housing 2 resting on the floor, preferably by a plurality of feet.

[0030] The housing 2 supports a rotatable laundry drum 3 , which defines a drying chamber 4 for laundry 5 and preferably, but not necessarily, rotates about a horizontal axis of rotation 6 . In alternative embodiments not shown, the axis of rotation 6 may be vertical or inclined.

[0031] The drying chamber 4 preferably has a front access opening 7 which can be closed by a door 8 which is preferably hinged to the housing 2 .

[0032] The drum 3 can be rotated about the axis of rotation 6 by means of an electric motor which figure 1 Schematically shown in and denoted by reference number 9, the drum 3 is supplied with hot air heated by heating means, which in the figure 1 is schematically shown in and denoted by reference numeral 10, and the hot air is preferably fed into the drum 3 by a fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com