A dry method for producing limestone machine-made sand

A limestone machine-made sand and dry process technology, applied in the direction of grain processing, etc., can solve the problems of the influence of water content control of machine-made sand, many large and fine particles, and coarse particle size, etc., to reduce the process of repeated crushing and simplify the process. and equipment, grading stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1

[0028] A dry method for producing limestone machine-made sand, like the prior art, includes the following processes in sequence: gravel stacking, floor feeding, feeding, crushing and sieving, mixing, and obtaining finished products.

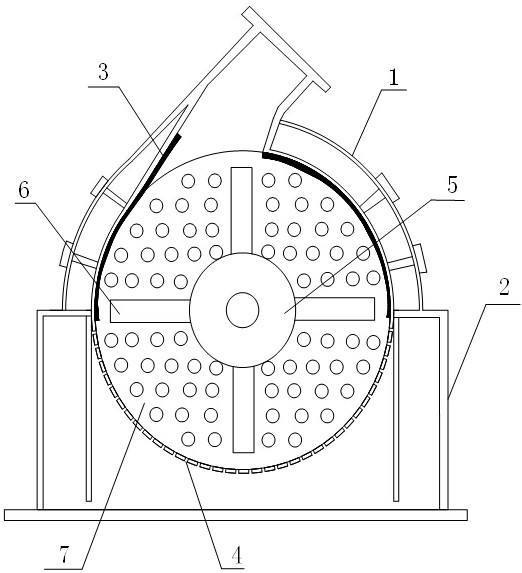

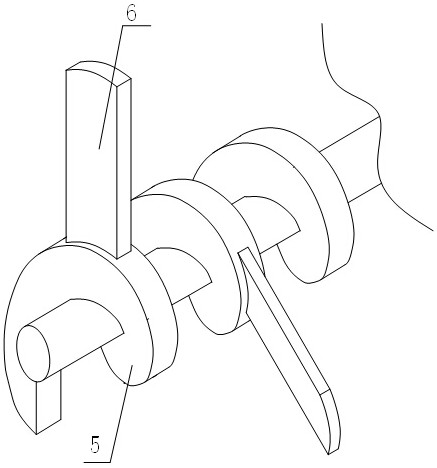

[0029] In order to solve the problems of the prior art, this embodiment also has the following designs based on the above-mentioned traditional technology: first, the structure of the feeding equipment is improved so that the drying operation is carried out simultaneously during the feeding process to ensure that the crushing and sieving The dryness of the crushed stone raw materials is basically uniform, which facilitates the uniformity of the amount of water added during the wet mixing process. Second, improve the structure of the crushing equipment, so that the work of crushing and screening can be realized in the crushing equipment, and through the improvement of the structure, it can be formed in a single machine at one ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com