Patents

Literature

77results about How to "Uniform particle shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

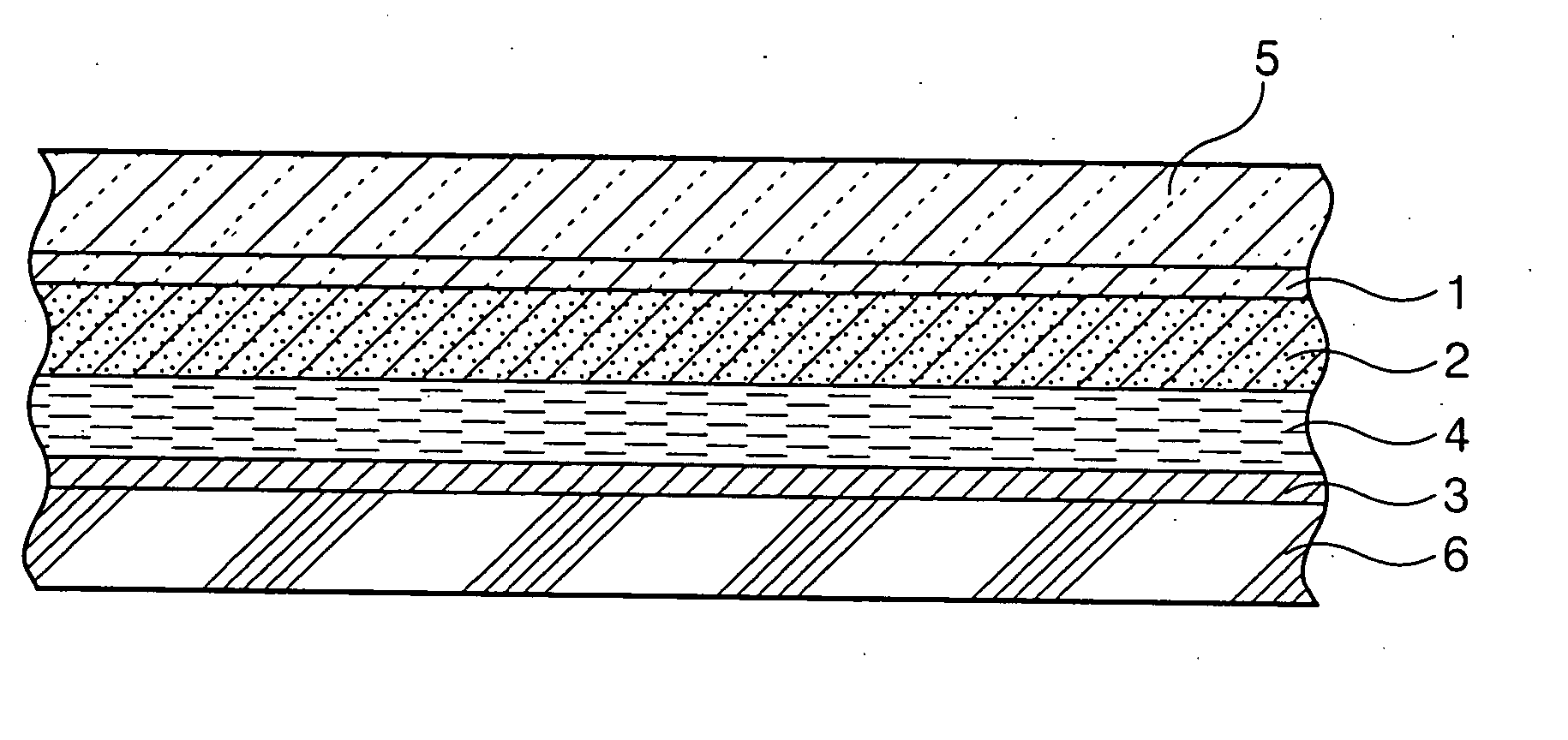

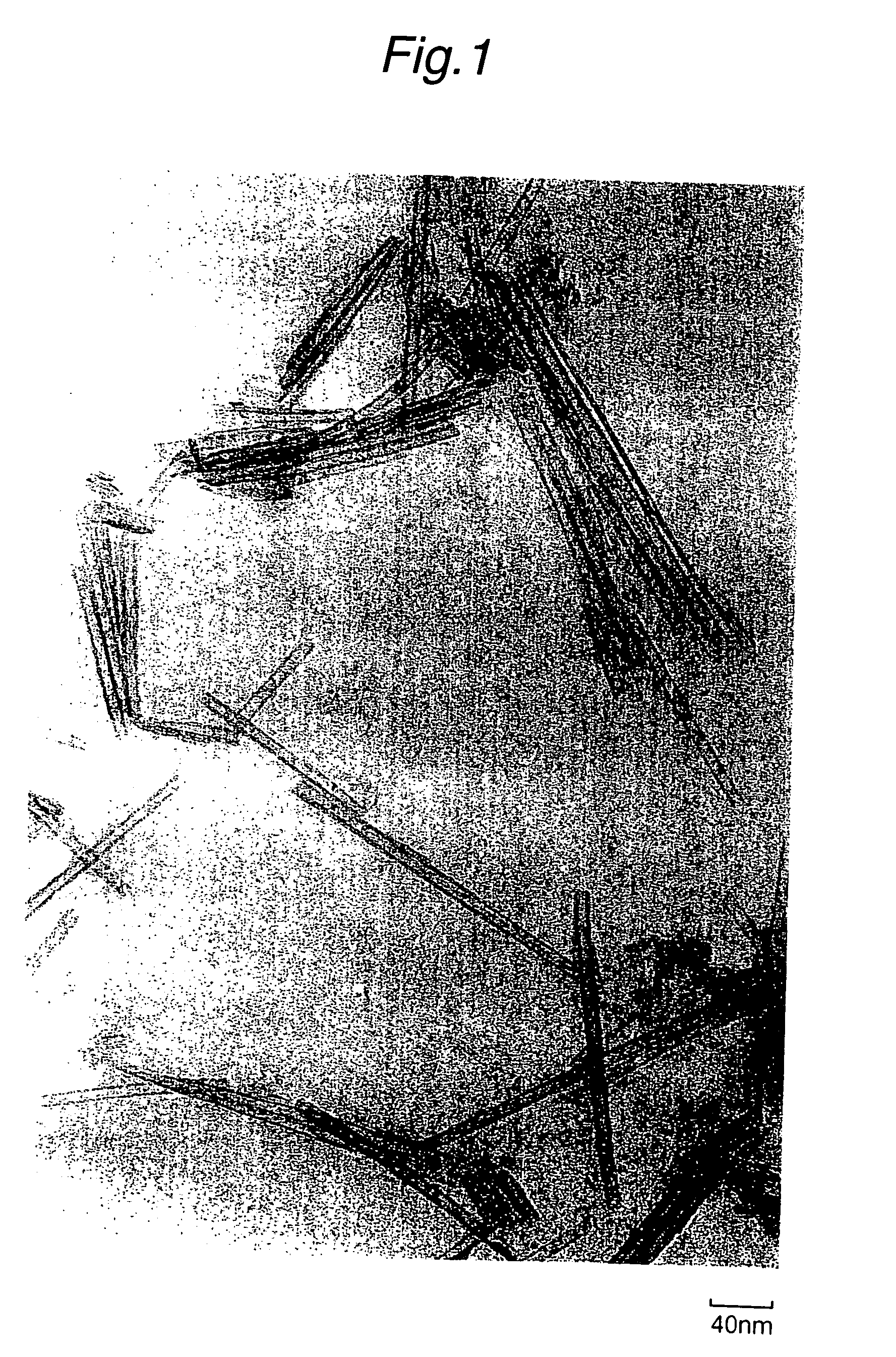

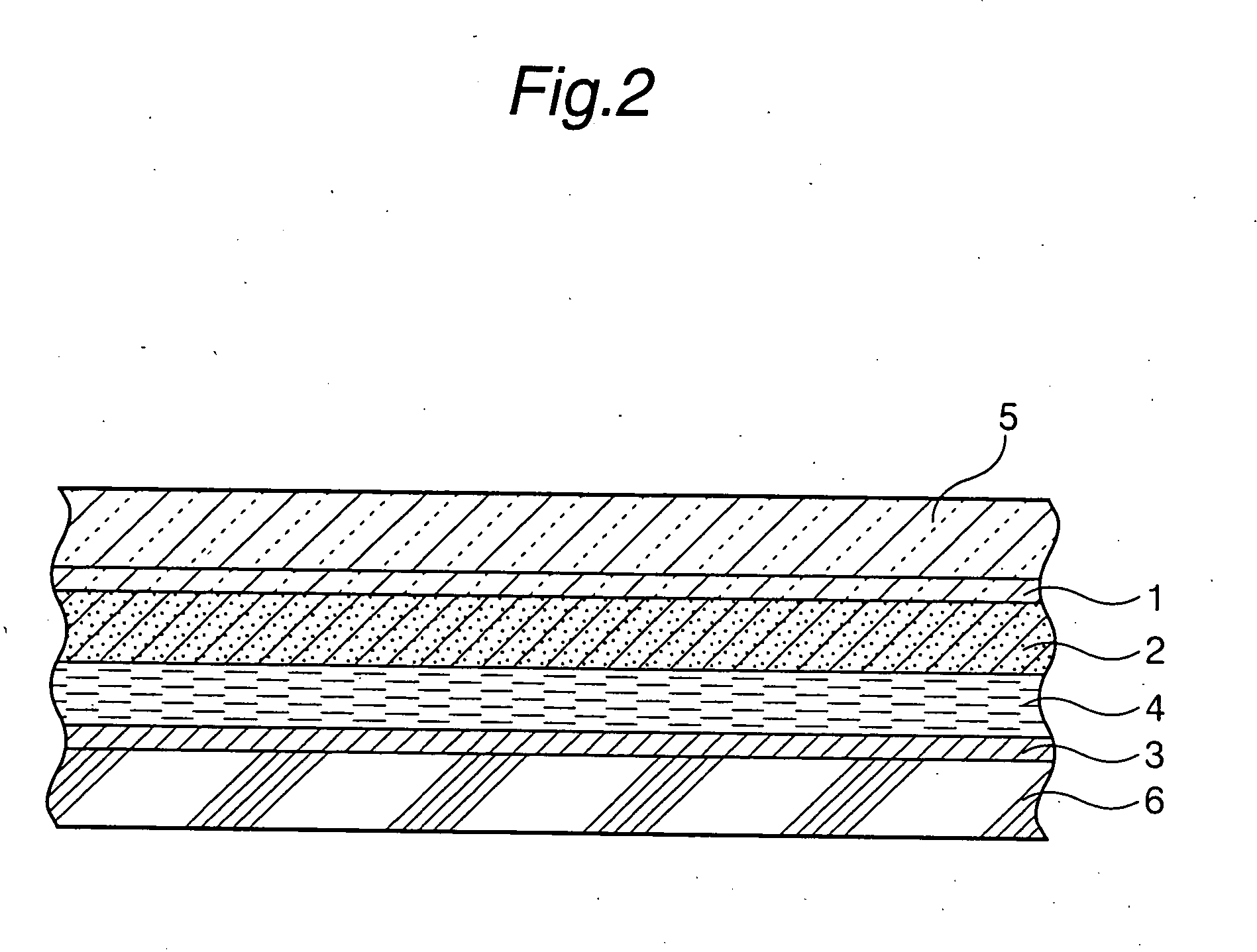

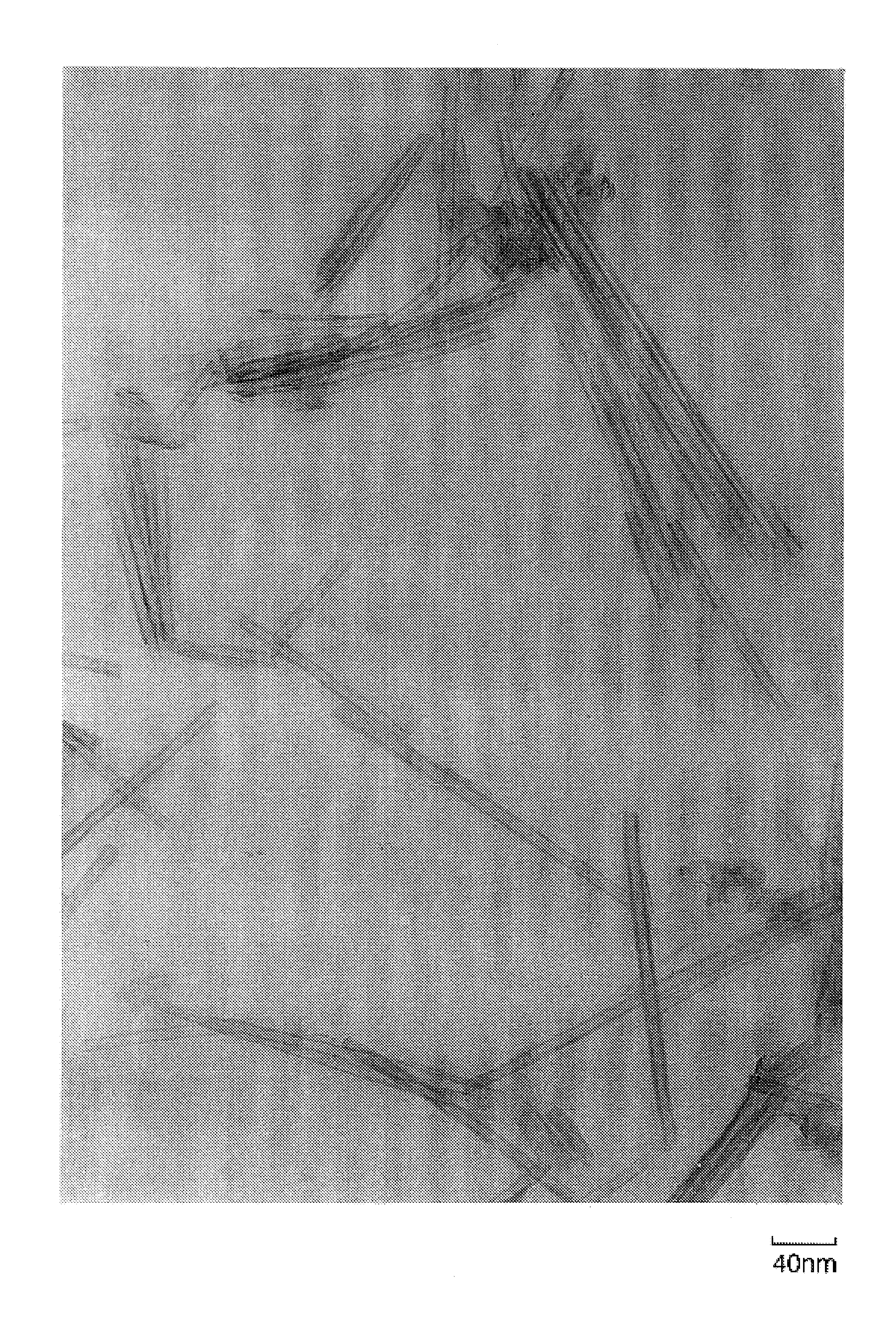

Tubular titanium oxide particles, method for preparing the same, and use of the same

InactiveUS20040265587A1Large specific surface areaImprove detection accuracyMaterial nanotechnologyLight-sensitive devicesReduction treatmentSorbent

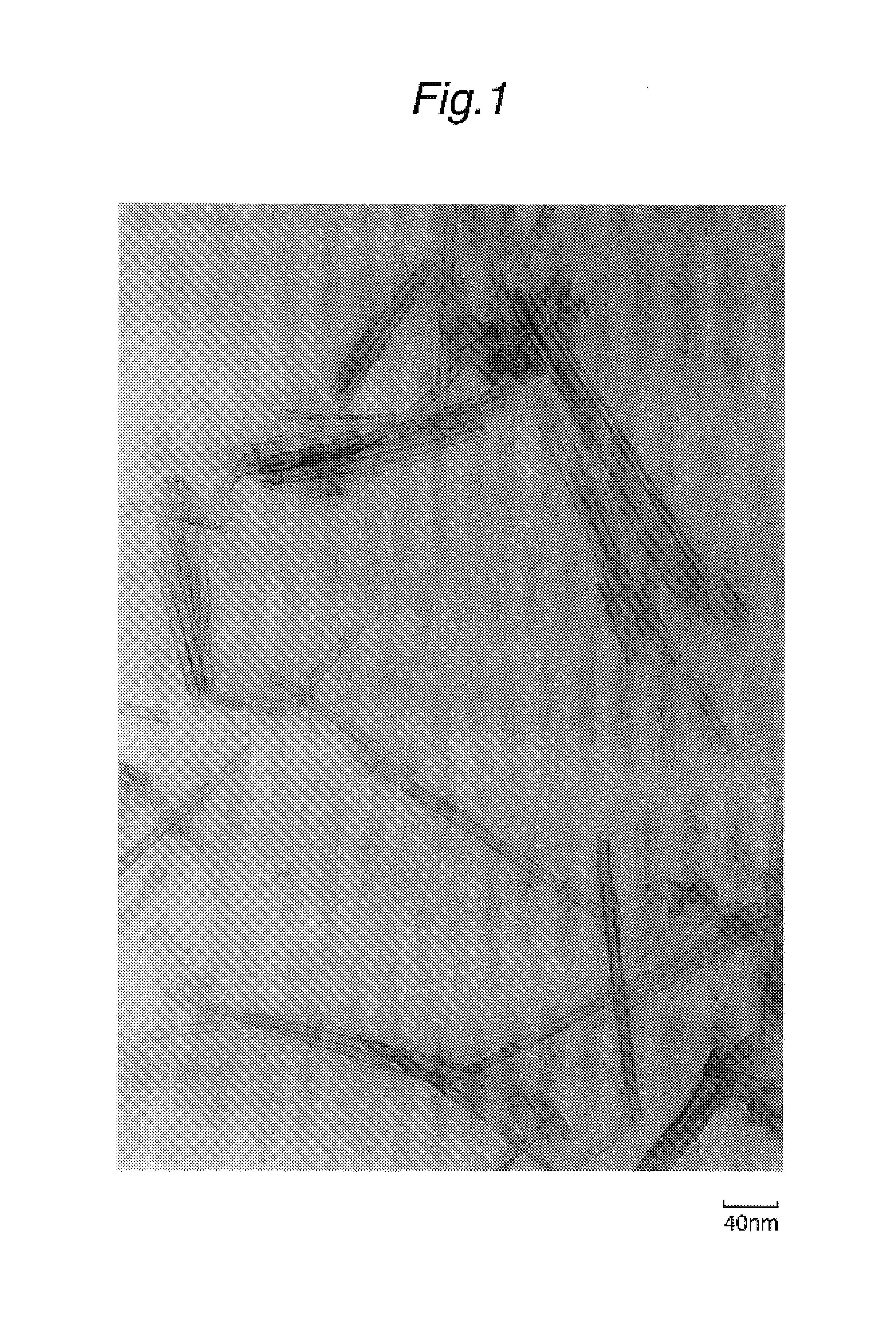

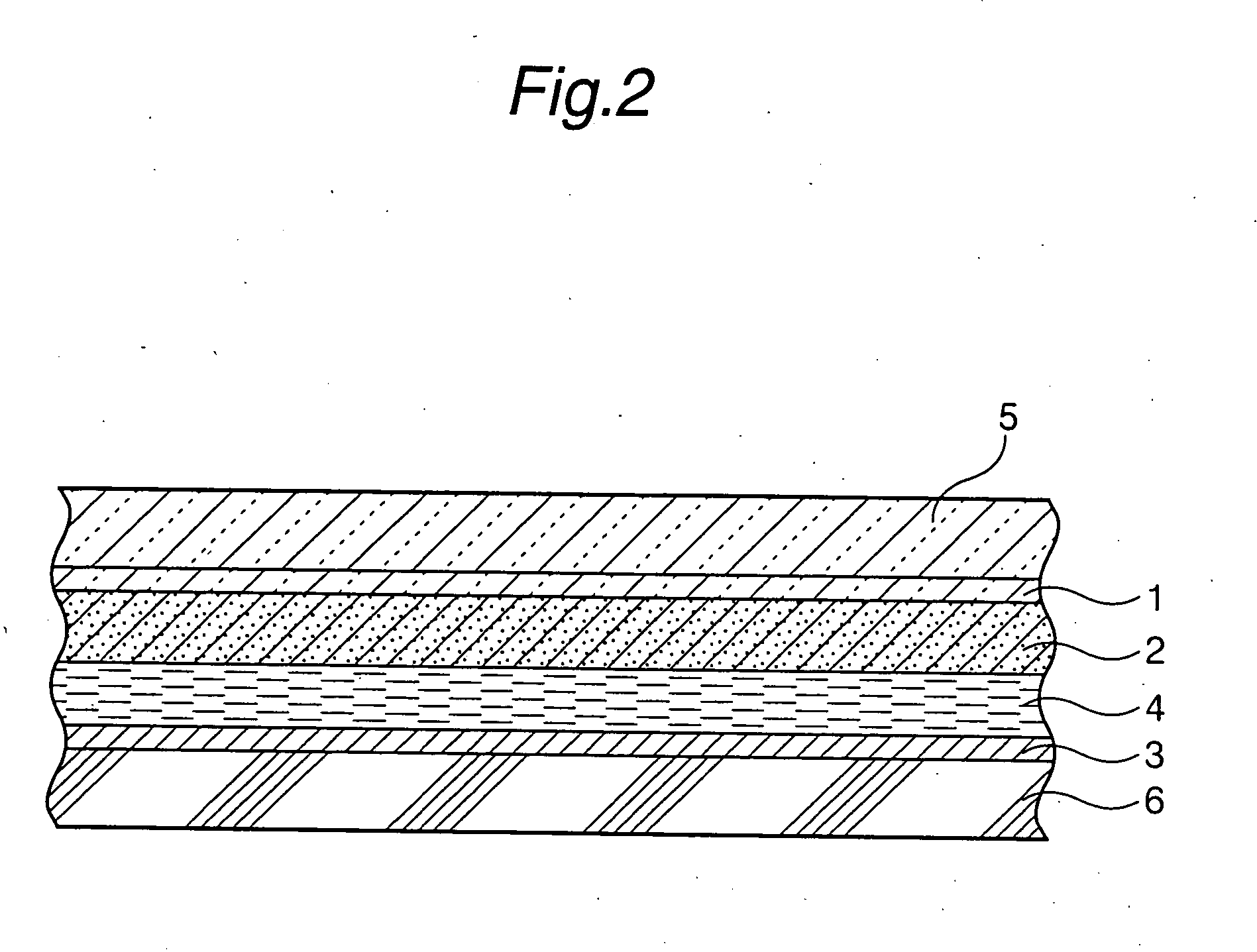

The process for preparing tubular titanium oxide particles comprises subjecting a water dispersion sol, which is obtained by dispersing (i) titanium oxide particles and / or (ii) titanium oxide type composite oxide particles comprising titanium oxide and an oxide other than titanium oxide in water, said particles having an average particle diameter of 2 to 100 nm, to hydrothermal treatment in the presence of an alkali metal hydroxide. After the hydrothermal treatment, reduction treatment (including nitriding treatment) may be carried out. The tubular titanium oxide particles obtained in this process are useful as catalysts, catalyst carriers, adsorbents, photocatalysts, decorative materials, optical materials and photoelectric conversion materials. Especially when the particles are used for semiconductor films for photovoltaic cells or photocatalysts, prominently excellent effects are exhibited.

Owner:JGC CATALYSTS & CHEM LTD

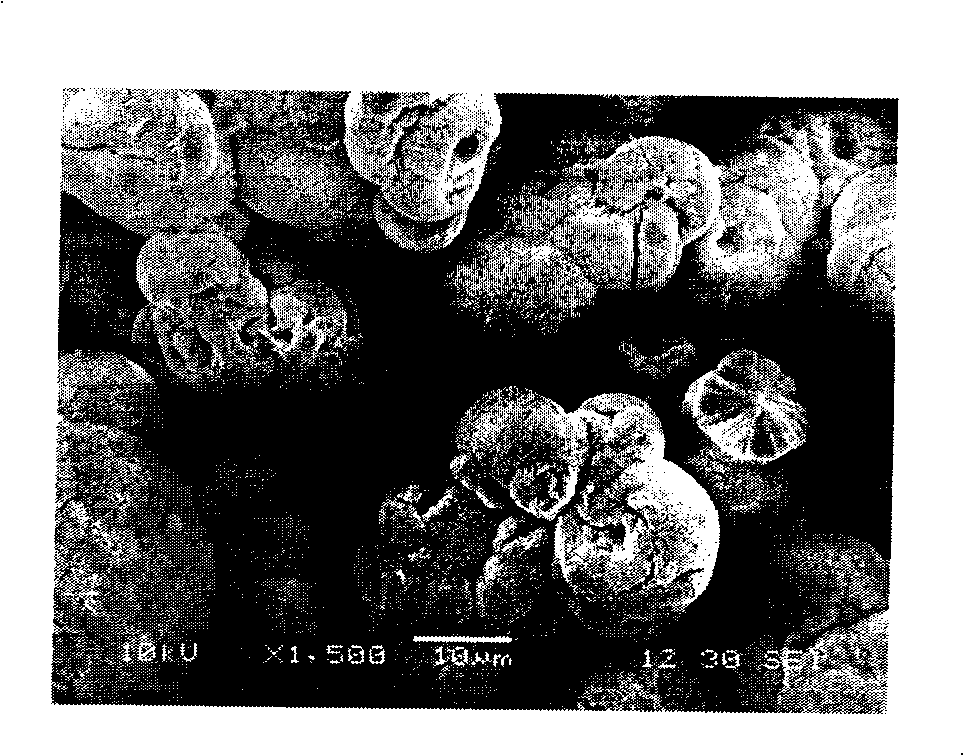

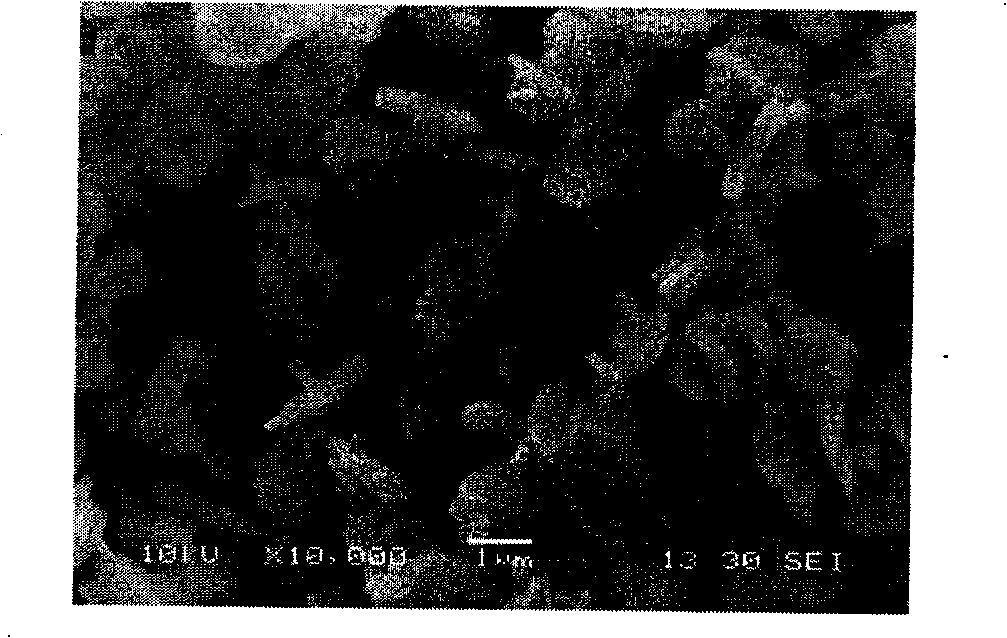

Tubular titanium oxide particles and process for preparing same

InactiveUS7431903B2Uniform particle shapeReduce contentMaterial nanotechnologyLight-sensitive devicesReduction treatmentSorbent

The process for preparing tubular titanium oxide particles comprises subjecting a water dispersion sol, which is obtained by dispersing (i) titanium oxide particles and / or (ii) titanium oxide type composite oxide particles comprising titanium oxide and an oxide other than titanium oxide in water, said particles having an average particle diameter of 2 to 100 nm, to hydrothermal treatment in the presence of an alkali metal hydroxide. After the hydrothermal treatment, reduction treatment (including nitriding treatment) may be carried out. The tubular titanium oxide particles obtained in this process are useful as catalysts, catalyst carriers, adsorbents, photocatalysts, decorative materials, optical materials and photoelectric conversion materials. Especially when the particles are used for semiconductor films for photovoltaic cells or photocatalysts, prominently excellent effects are exhibited.

Owner:JGC CATALYSTS & CHEM LTD

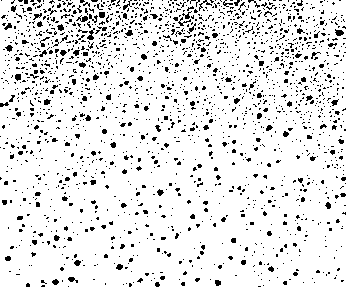

Preparation method of silver/carbon quantum dot composite nanometer materials

The invention provides a preparation method of silver / carbon quantum dot composite nanometer materials. The specific preparation processes comprise the steps of adding a certain amount of silver nitrate solution to polyvinylpyrrolidone solution, adding a certain amount of carbon quantum dot solution to the polyvinylpyrrolidone solution, mixing for some time, transferring the solution into a reaction kettle, conducting a hydrothermal reaction at a certain temperature for some time, conducting centrifugal separation on a product, washing the product several times by using deionized water and ethanol, and obtaining the silver / carbon quantum dot composite nanometer materials after vacuum desiccation. The preparation method of the silver / carbon quantum dot composite nanometer materials is environment-friendly, high-efficient and easy to operate. Besides, the prepared silver / carbon quantum dot composite nanometer materials have good application prospects in the field of sensing, catalysis and the like.

Owner:苏州市洁优卫生材料科技有限公司

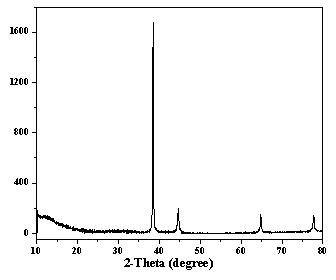

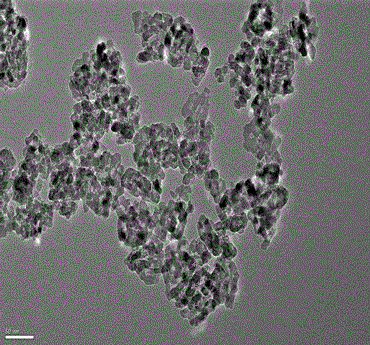

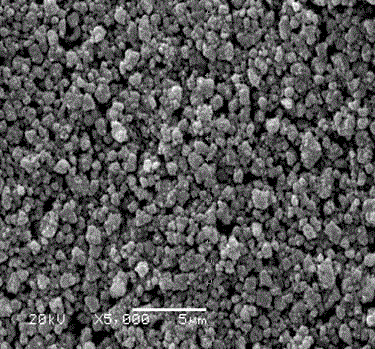

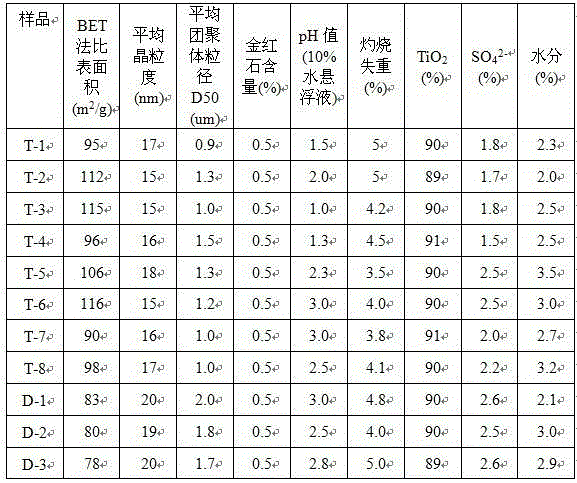

Preparation method for denitration catalyst carrier nano titanium dioxide

InactiveCN104667901AReduce manufacturing costSimple processCatalyst carriersDispersed particle separationCatalyst supportTitanium dioxide

The invention discloses a preparation method for a denitration catalyst carrier nano titanium dioxide. According to the method, an intermediate metatitanic acid for preparing titanium dioxide with a sulfuric acid method is used as a raw material; an ammonium salt is added to adjust the pH value; and the steps of washing, filtering, drying and roasting are carried out to obtain the denitration catalyst carrier nano titanium dioxide product. Compared with the prior art, the method disclosed by the invention has low manufacturing cost and a simple process; and the prepared product has the advantages of large specific surface area, high dispersion degree, uniform particle morphology, narrow grain diameter distribution, small grain diameters of aggregates and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

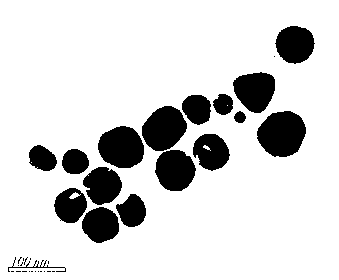

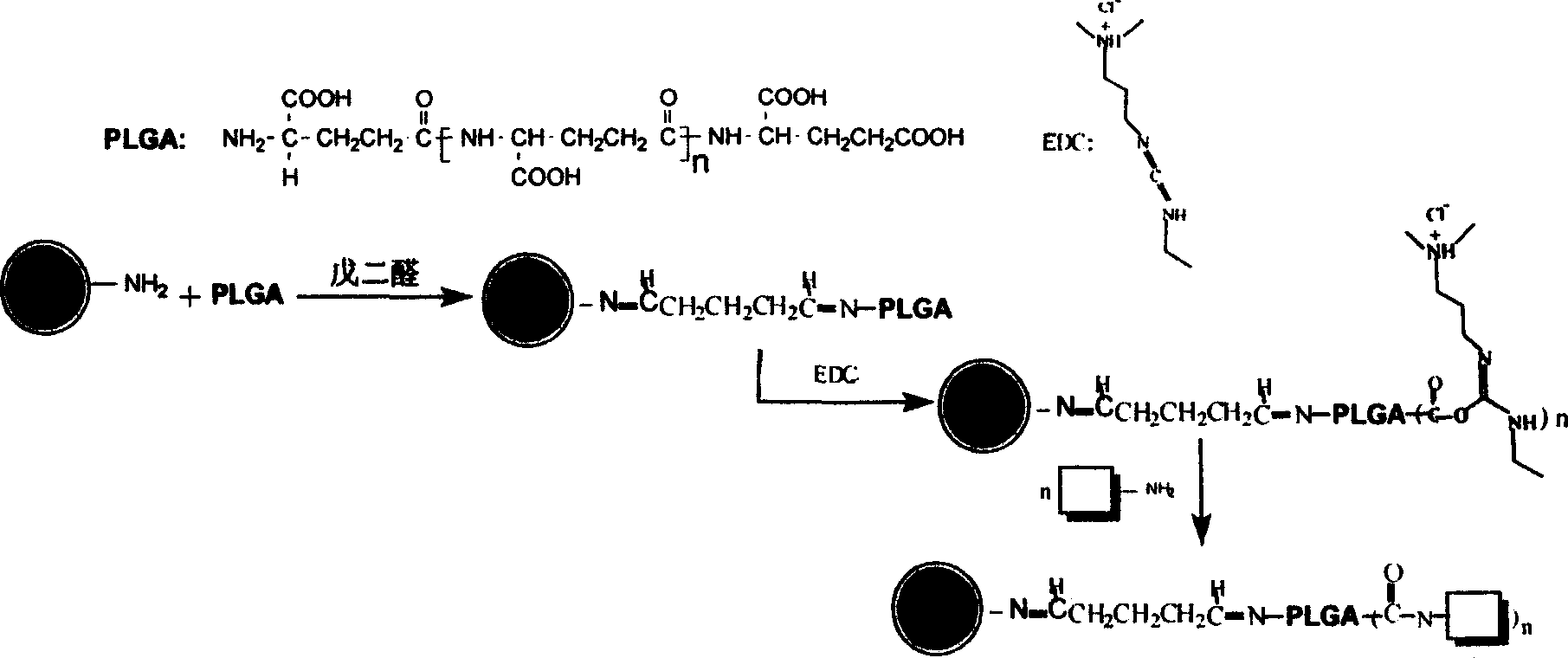

Biomagnetism nano target anti-cancer drug and its preparation

ActiveCN1927400AGood biocompatibilitySmall side effectsInorganic material magnetismRadioactive preparation carriersChemical reactionSide effect

The invention relates to a biological nanometer magnetic target anti-cancer drug, which is formed by coupled biological nanometer magnetic smalls and anti-cancer chemical drug. Wherein, the biological nanometer magnetic small is nanometer magnetic particle formed in magnetic bacterial cell, at 35-120nm diameter, while its main component is Fe3O4 or Fe3S4; single magnetic particle is packed by film; and the coupled anti-cancer chemical drug comprises chemotherapy drug, nucleic acid drug, radioactive nuclide or antibody drug. The invention also provides relative production that using physical adsorption couple or based on the active function group contained by smalls and anti-cancer drug, to select right coupler via chemical reaction to couple them. And the smalls has better bioavailability, less side effect, therefore, the anti-cancer drug can be accurately transmitted to ill part via external magnetic field, to reduce the contact between drug and normal organism., to realize target positioning treatment.

Owner:南京英睿杰生化科技有限公司

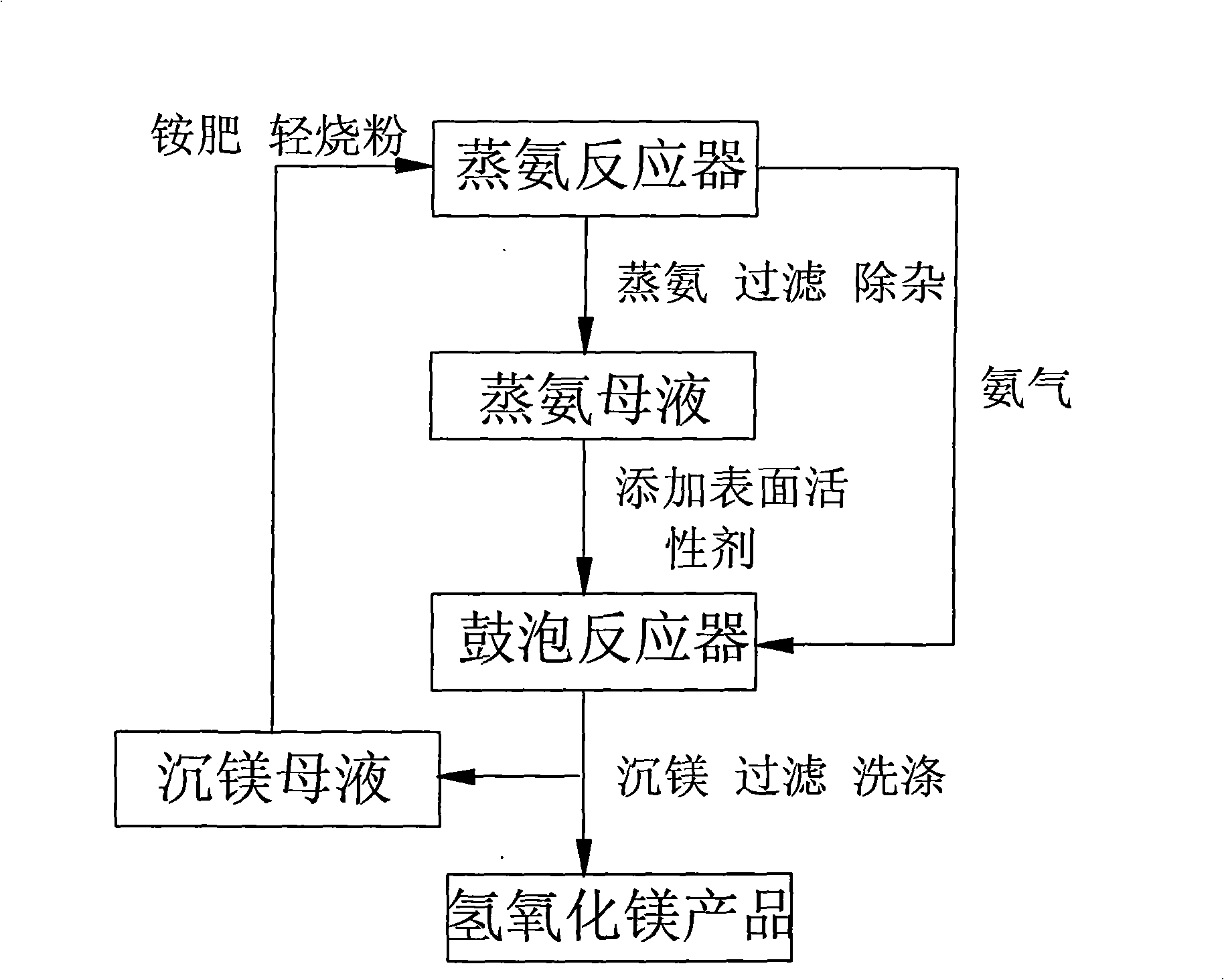

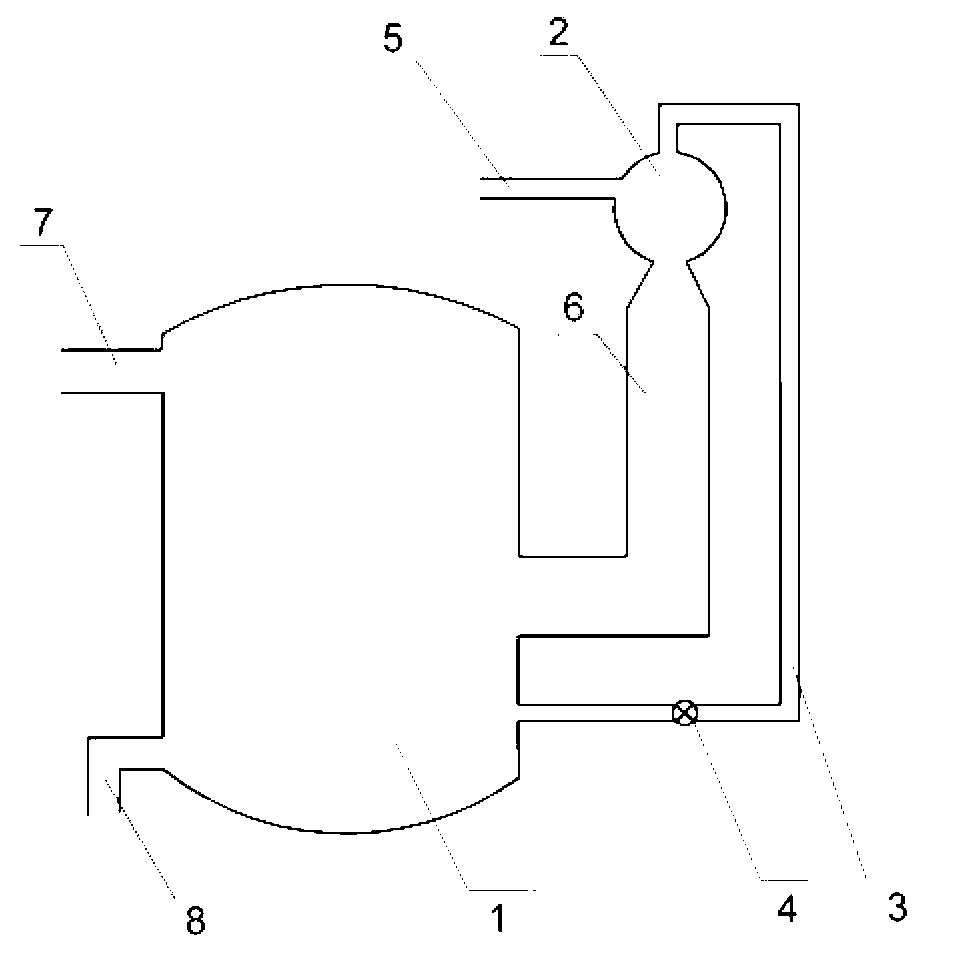

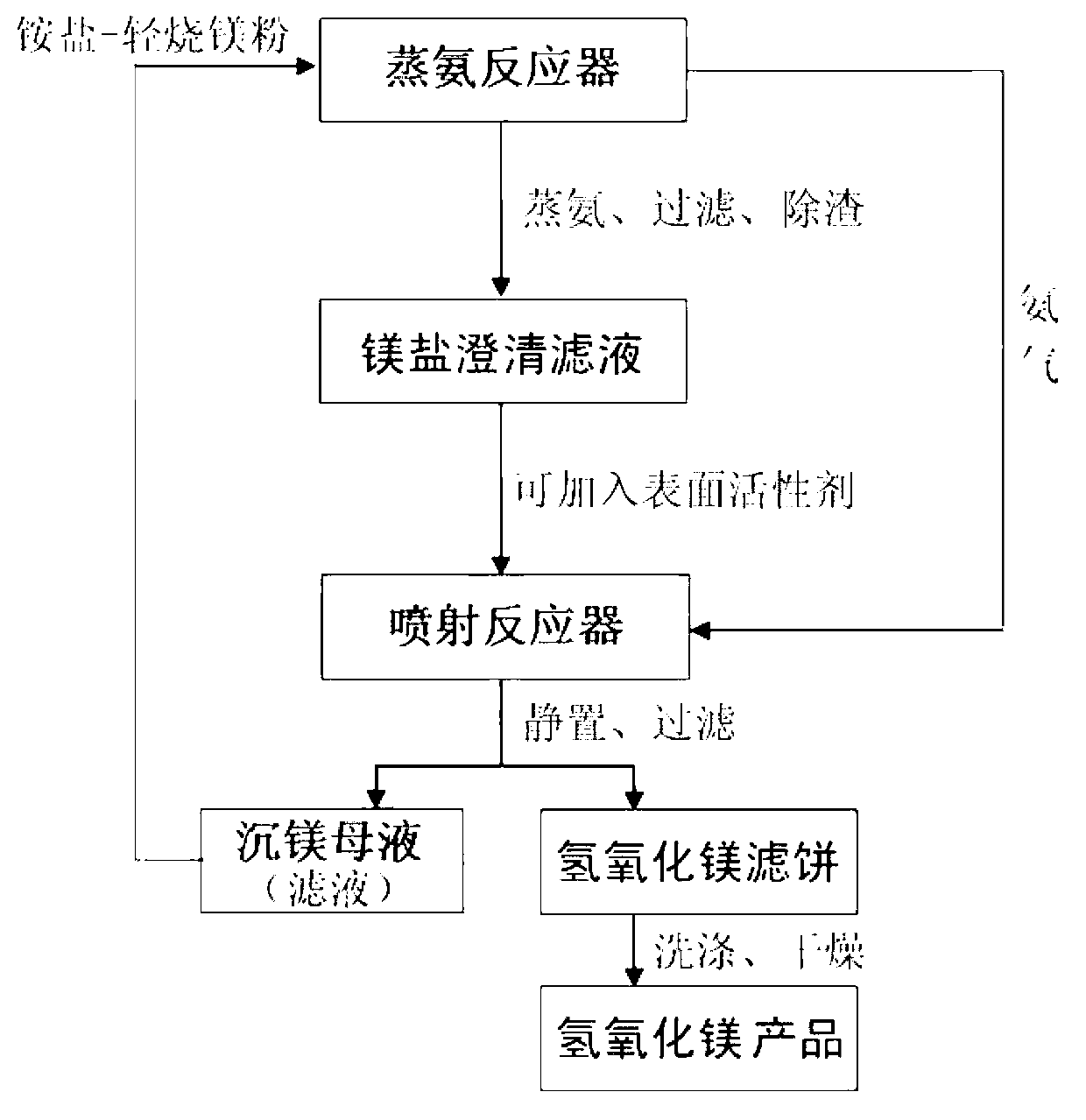

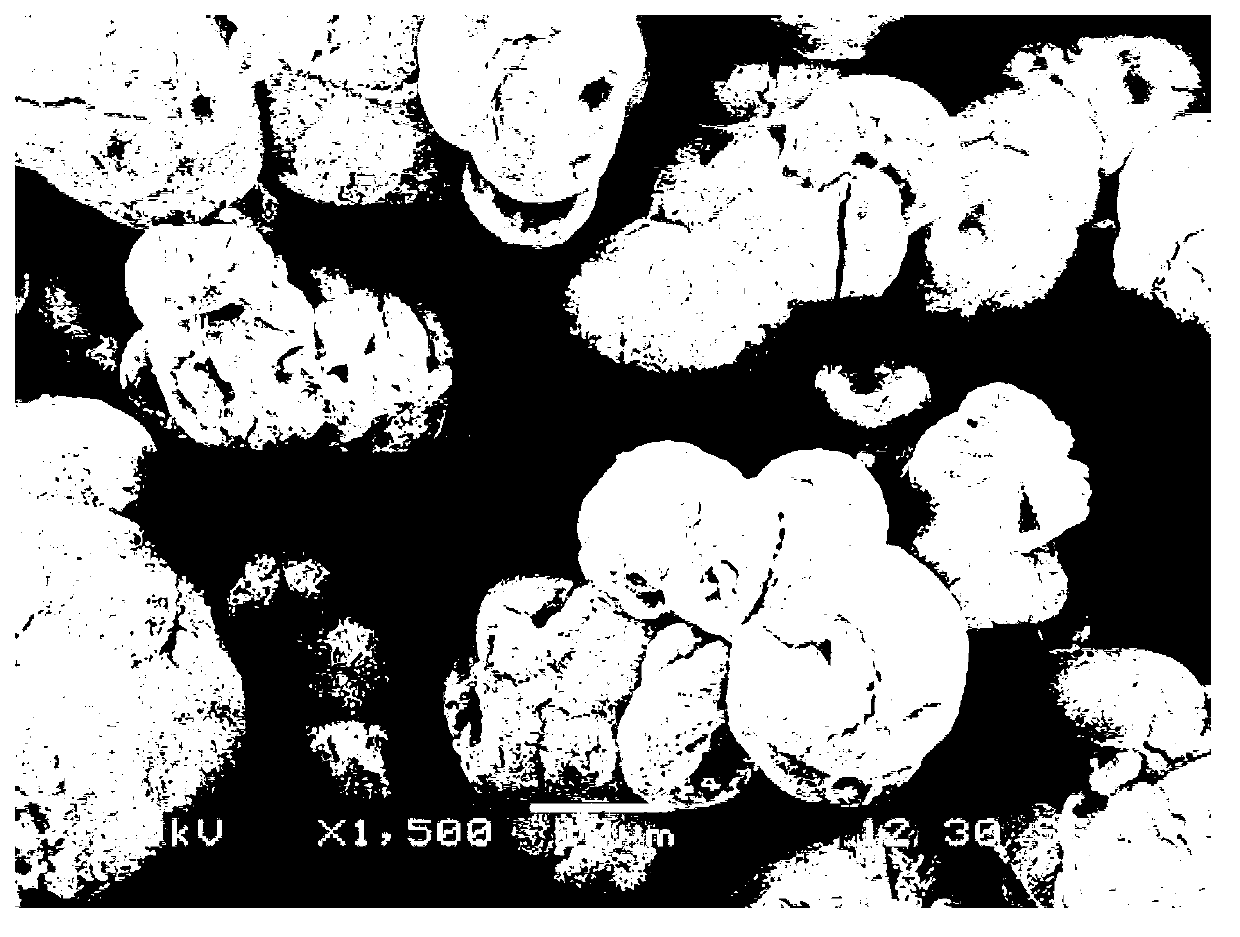

Method for preparing uniform granular magnesium hydrate by one-step reaction with ammonia bubbling method

InactiveCN101525144AReduce shipping costsDoes not affect concentrationMagnesium hydroxideMagnesium saltDistillation

The invention relates to a method for preparing uniform granular magnesium hydrate by a one-step reaction with ammonia bubbling method. The method uses light fire powder (magnesia) as a raw material, uses ammonia sulfate, ammonium chloride or ammonium nitrate as an intermediate material and obtains ammonia gas and a magnesium salt solution by an ammonia distillation reaction; the ammonia gas and the magnesium salt solution contact in a bubbling reactor and generate a magnesium hydrate precipitation reaction under the action of an added surface active agent; product mother liquor is filtered after being aged for a suitable period of time, filtrate containing the ammonia sulfate, the ammonium chloride or the ammonium nitrate returns to an ammonia distillation system, and a filter cake is washed and dried to obtain a magnesium hydrate product in uniform granular shape and good dispersion state. The process prepares the magnesium hydrate by the one-step reaction with simple operation steps under mild reaction conditions, the product has uniform granular shape and can adjust and control the granular shape by changing the reaction conditions; and ammonium salt and ammonia gas circulate in the process. The invention has low production cost and little pollution, is suitable for mass production, and the product can be used as a raw material for producing high-purity magnesia or a flame-retardant additive of a polymer material.

Owner:LIAONING TAXACEAE TECH DEV

Diamond grinding wheel for metal binding agent

The invention discloses a diamond grinding wheel for metal binding agent. The diamond grinding wheel for metal binding agent is characterized bu being made up of metal powder, copper-cerium alloys, pore-forming agents, TS-1 titanium silicalite molecular sieves and diamond composite abrasive grains; the metal powder is iron powder, copper powder, nickel powder and tin powder; the pore-forming agents can be PE / CeO2 / Cu compound; and the diamond composite abrasive grains are diamond / cerium oxide nuclear shell composite abrasive grains. According to the invention, the defects of poor self-sharpening property and low efficiency of the diamond grinding wheel for the metal binding agent are overcome; and the diamond grinding wheel for the metal binding agent has good mechanical property and self-sharpening property, and is high in holding force of diamond, good in molding property and long in service life.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method for preparing fluorine-containing polymer by using mixed fluorine-containing surfactant

The invention relates to a method for preparing a fluorine-containing polymer by using a mixed fluorine-containing surfactant. The method comprises the following steps of: performing homopolymerization or copolymerization by using a fluorine-containing olefin monomer or performing copolymerization on the fluorine-containing olefin monomer and the fluorine-fee olefin monomer under the effect of an initiator; adding 0.01-1% of mixed fluorine-containing surfactant to the reaction system, wherein the fluorine-containing surfactant is combined by a molecular weight fluorine-containing surfactant [Rf-(O)m-Rf'-COO]nAn+ and high molecular fluorine-containing surfactant [CF2=CF-(O)p-Rf1-(O)q-Rf2-COO]nAn+ containing unsaturated bonds. Without perfluoro caprylic acid as a dispersant, the method is high in safety and easy to control polymerization conditions, so that the environmental pollution by perfluoro caprylic acid is avoided, and the product system is good in stability and uniform in grain shape.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Method of making barium titanate

InactiveUS7001585B2High yieldImprove volumetric efficiencyAlkaline earth titanatesTitanium organic compoundsOxalateBarium titanate

Owner:FERRO CORP

Instant macroelement water-soluble fertilizer capable of increasing soil organic matter content

InactiveCN105646083AImprove physical and chemical conditionsImprove biological characteristicsAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDipotassium phosphateDrip irrigation

The invention relates to fertilizer, in particular to instant macroelement water-soluble fertilizer capable of increasing the soil organic matter content. The instant macroelement water-soluble fertilizer capable of increasing the soil organic matter content is prepared form components in parts by weight as follows: 100-200 parts of concentrated molasses yeast powder, 8-15 parts of poly potassium aspartate, 50-80 parts of citric acid, 3-10 parts of chitin, 30-50 parts of potassium carbonate, 10-30 parts of boric acid, 150-300 parts of urea, 200-400 parts of anhydrous dipotassium phosphate and 180-280 parts of ammonium polyphosphate. The fertilizer can be quickly dissolved, is fully water-soluble, can be applied to facility agriculture such as sprinkling and drip irrigation and the like and realizes integration of water and fertilizer and the efficiency of saving water, fertilizer and labor. The fertilizer can provide organic matters and various macroelement nutrients for soil and crops after usage.

Owner:王越

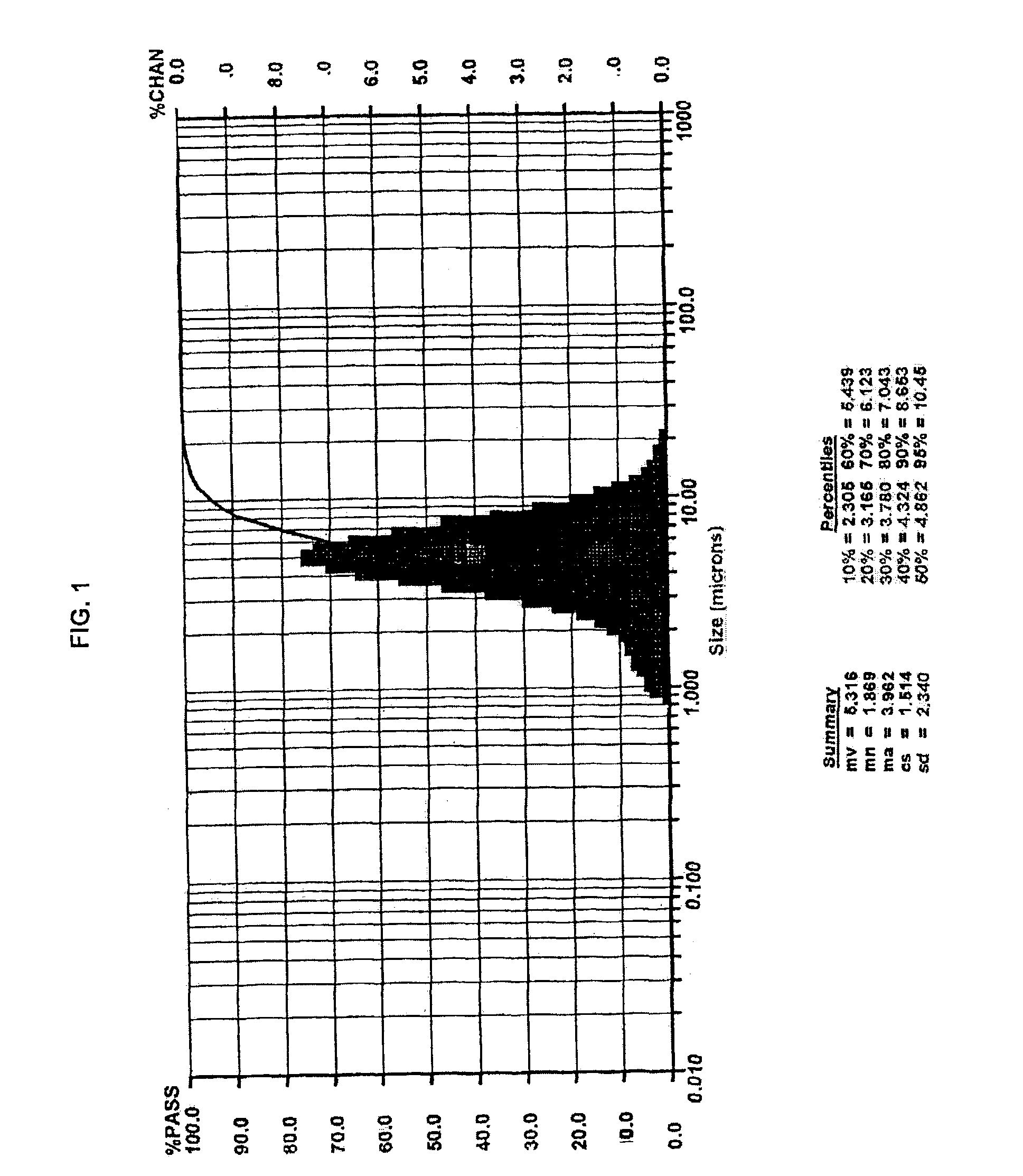

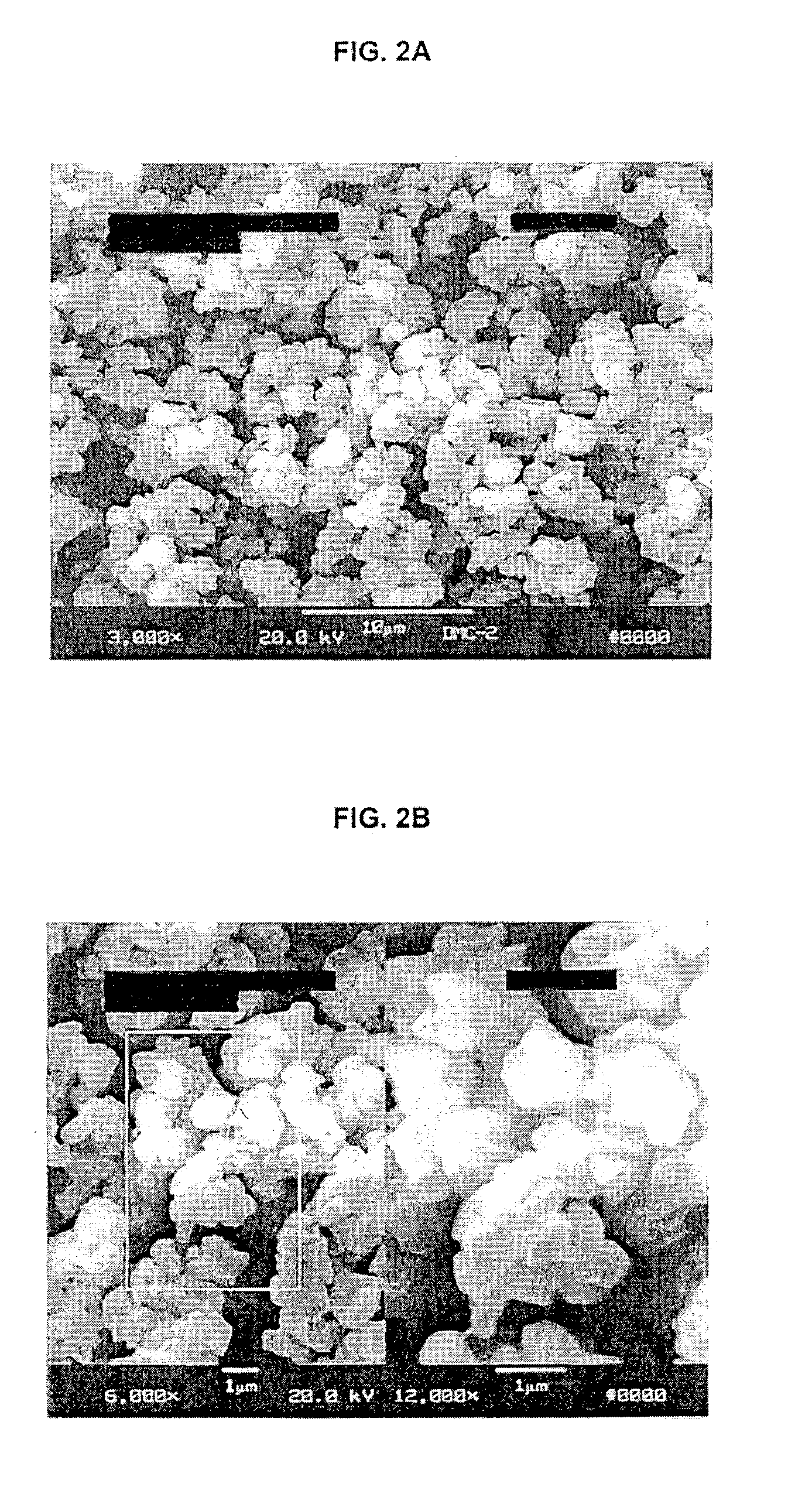

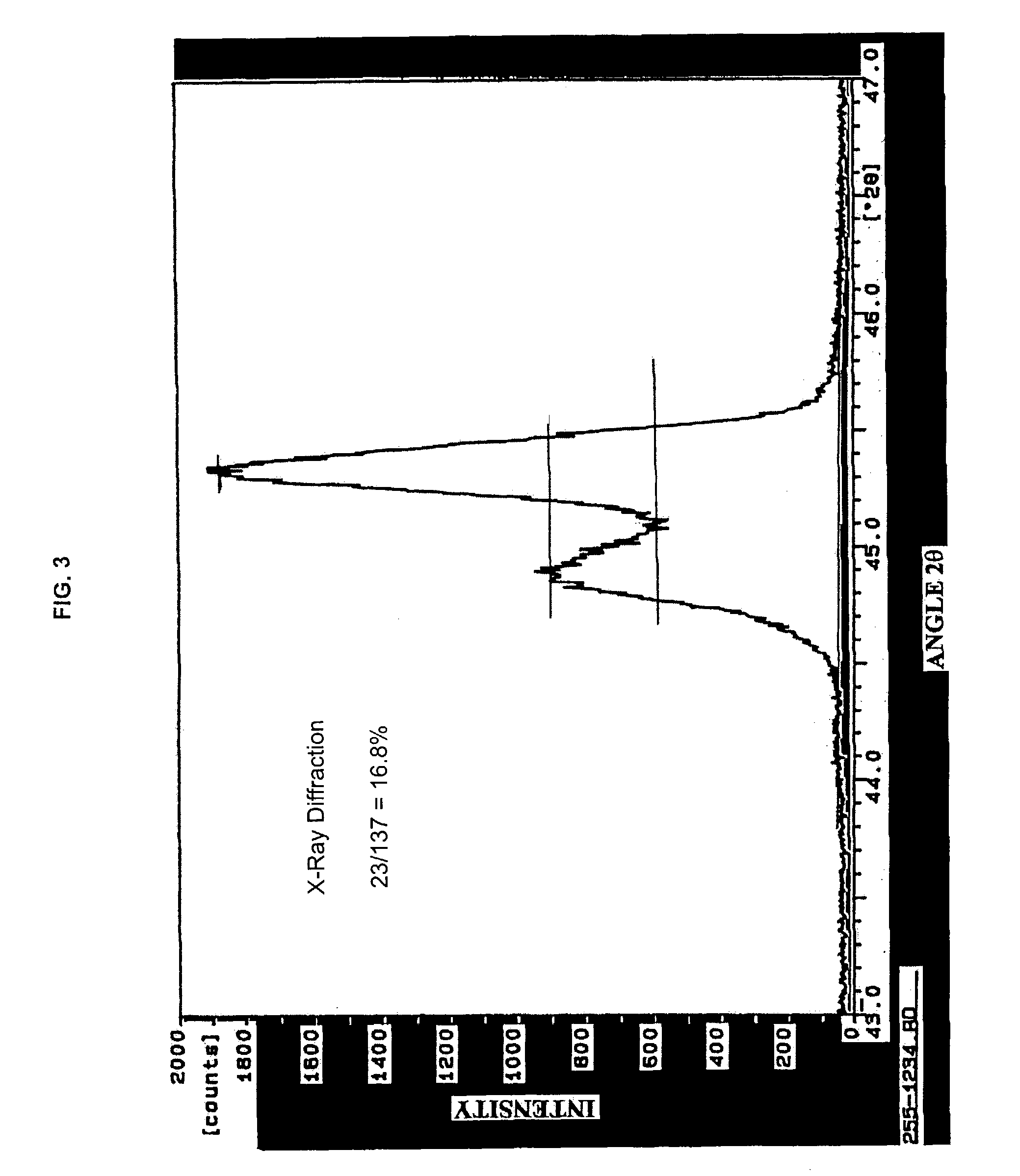

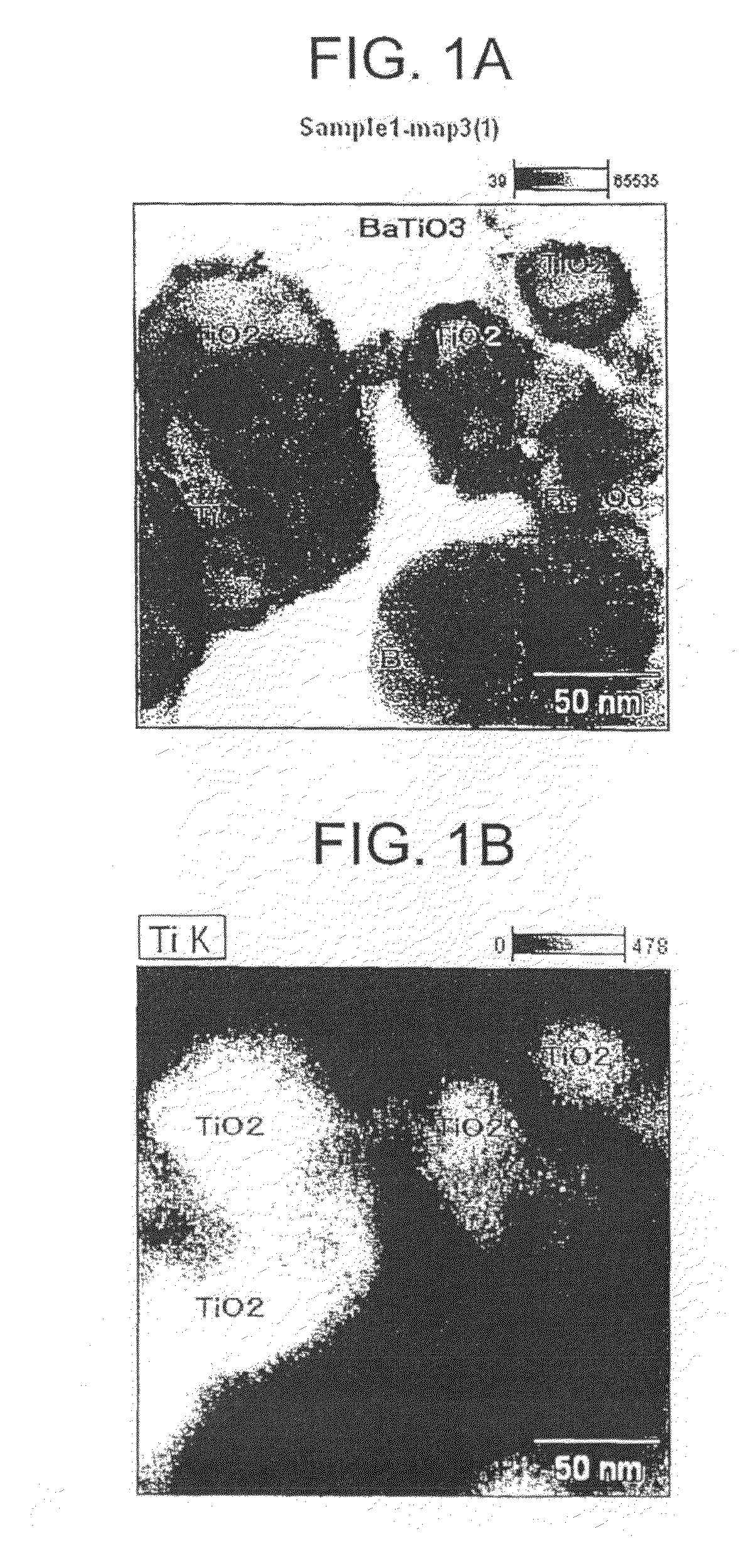

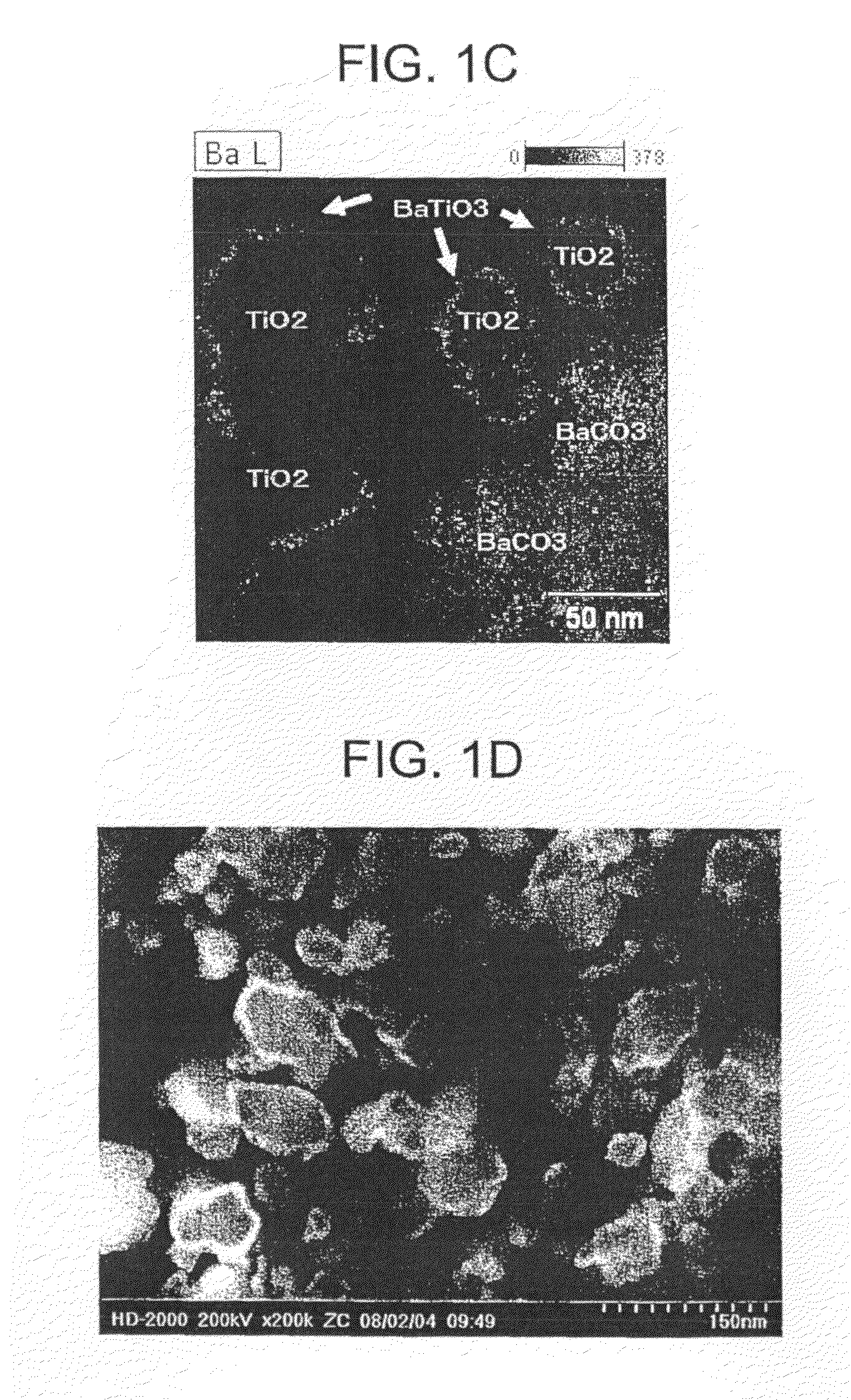

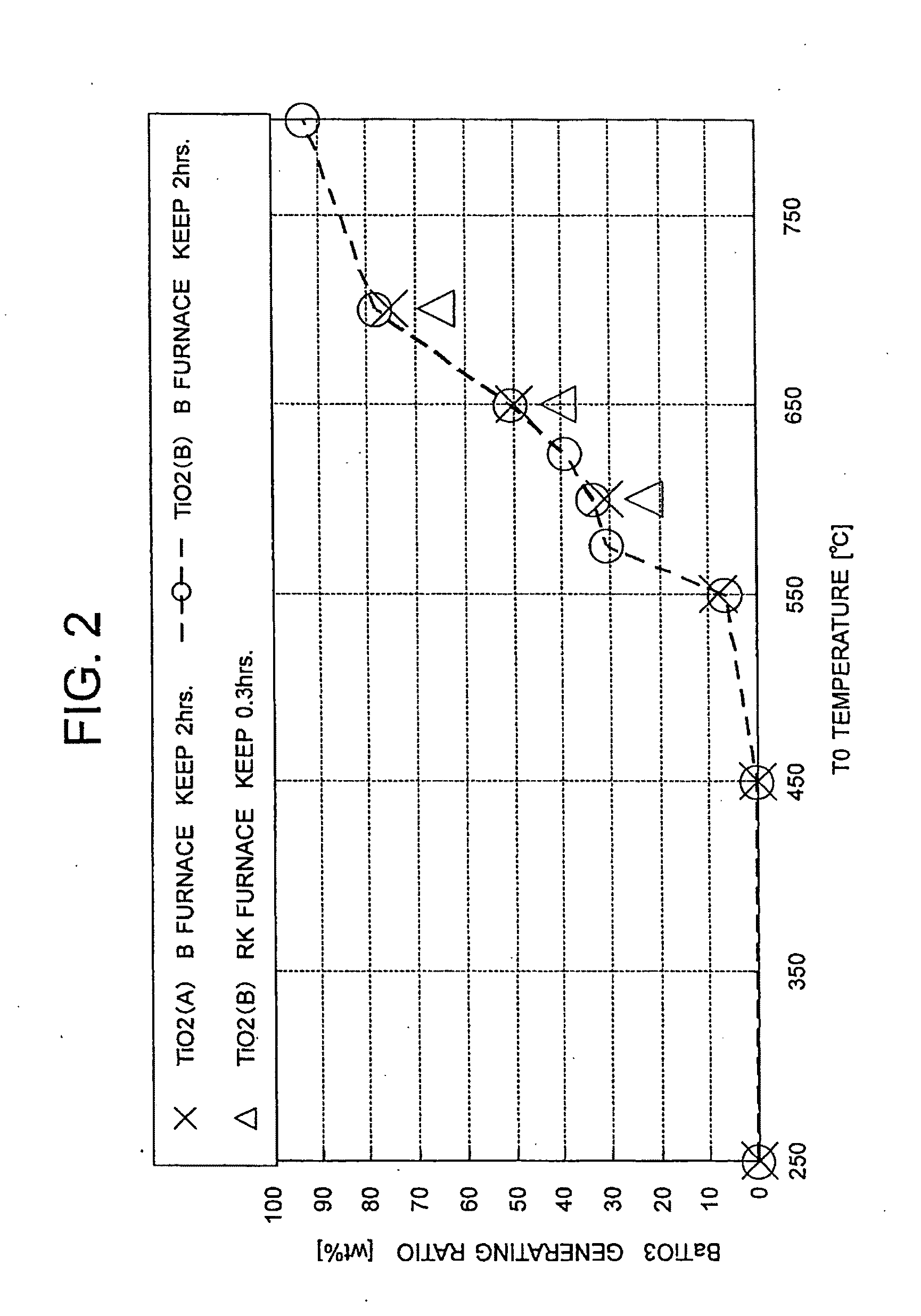

Production method of dielectric particles

InactiveUS20090264276A1Uniform particle sizeLow rutile ratioMaterial nanotechnologyAlkaline earth titanatesBarium titanateCrystallinity

A method of producing fine and uniform barium titanate particles having high crystallinity by performing a heat treatment on titanium dioxide and barium carbonate having a specific surface area of at least 20 m2 / g and low rutile ratio; comprising the steps of preparing mixed powder by mixing titanium dioxide particles having a rutile ratio of 30% or lower and a specific surface area of 20 m2 / g or more and barium carbonate particles, a first heat treatment step for performing a heat treatment on the mixed powder to generate a barium titanate phase having an average thickness of at least 3 nm continuously on surfaces of titanium dioxide particles by an amount of 15 wt % or more, and a second heat treatment step for performing a heat treatment at 800° C. to 1000° C.

Owner:TDK CORPARATION

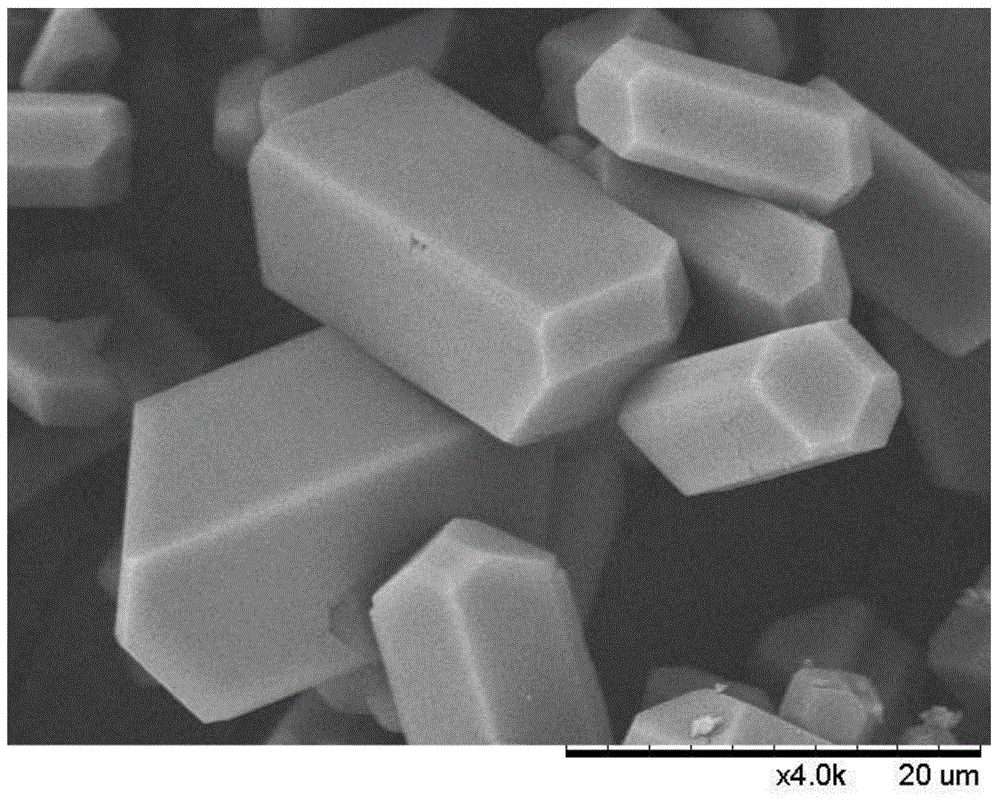

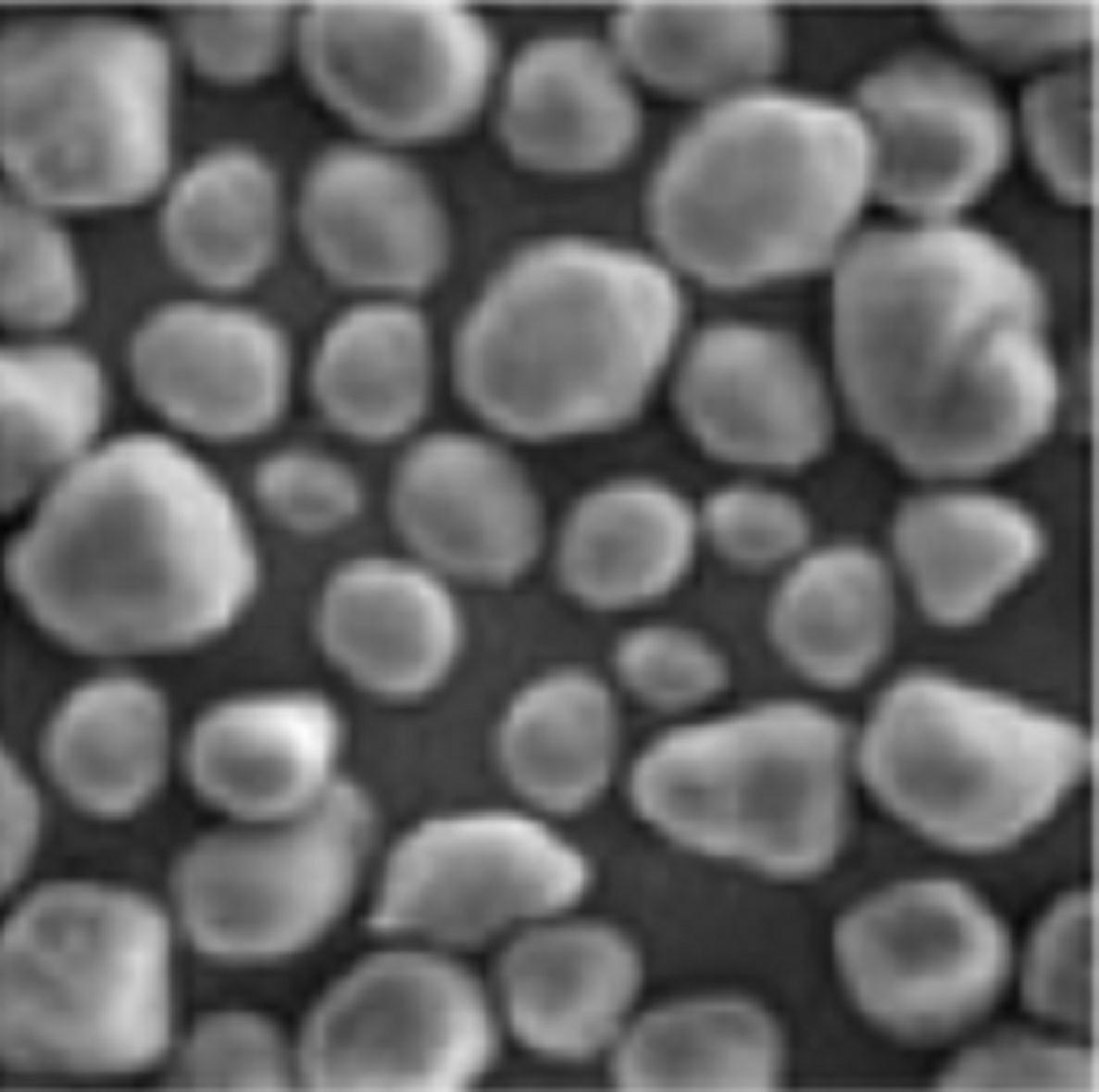

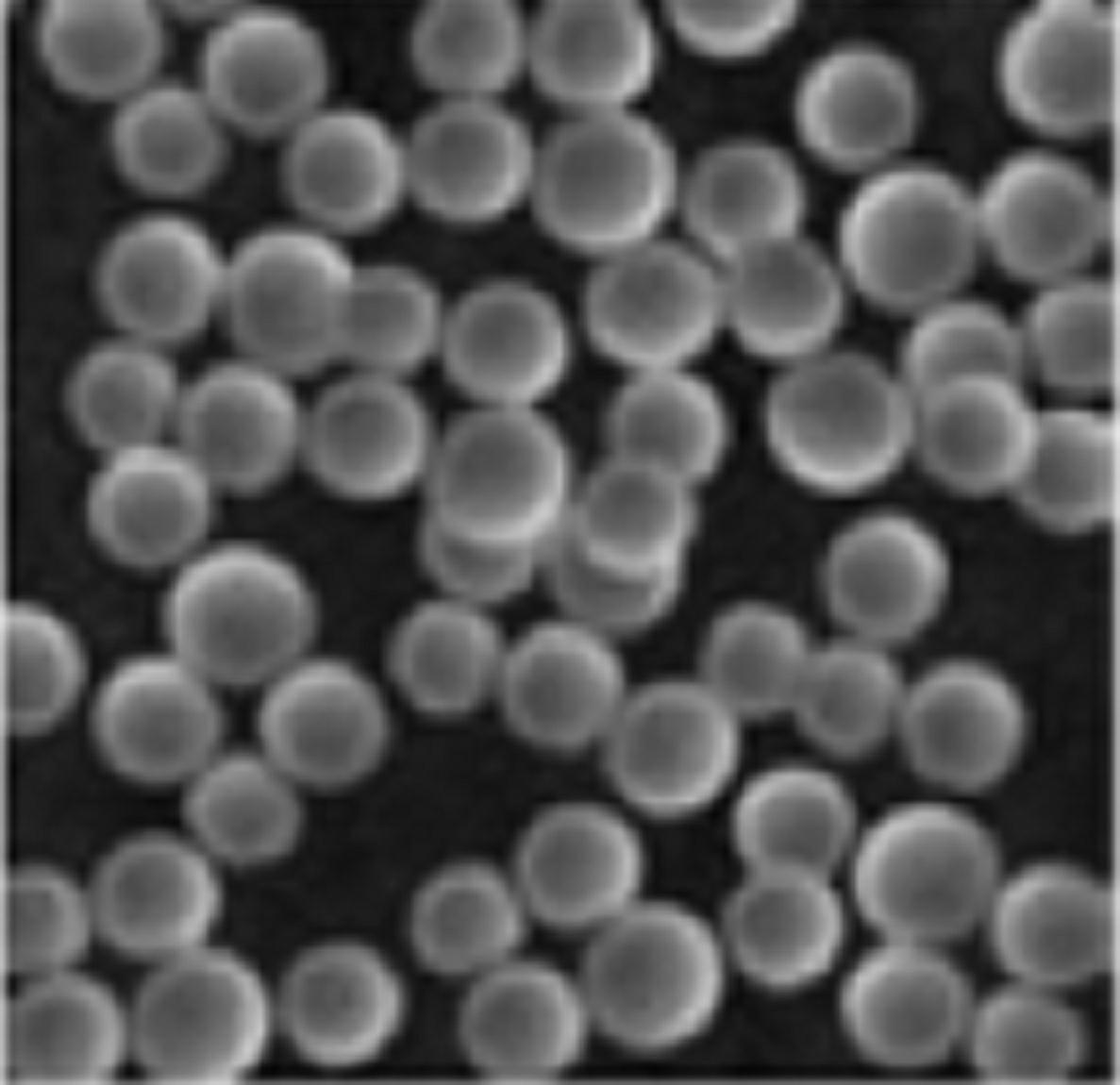

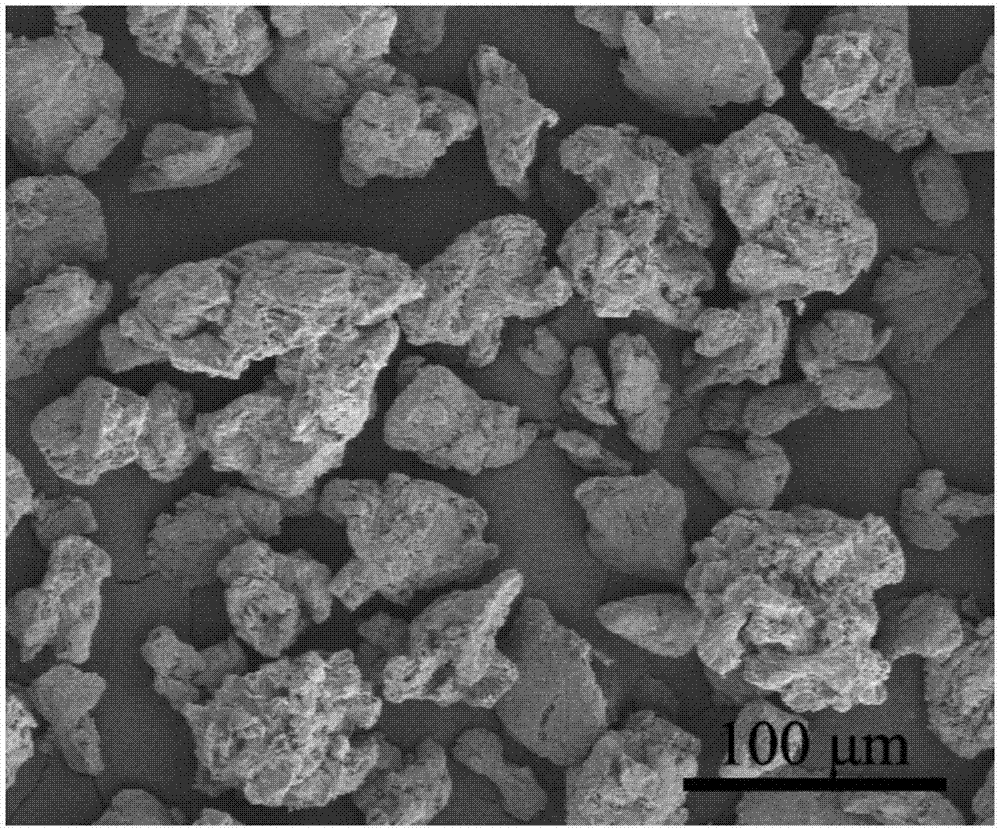

High-quality explosive crystals prepared by self-assembling and preparation method thereof

ActiveCN105753613AReduce internal defectsNarrow particle size distributionNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsParticle densitySolvent

The invention discloses high-quality explosive crystals prepared by self-assembling and a preparation method thereof. The preparation method comprises the following steps: dissolving the explosive crystals and preparing fine-particle crystals by adopting spray crystallization; and subjecting fine-particle explosives to self-assembling reaction of fine particles in a mixed solvent through programmed heating, thereby obtaining the high-quality explosive crystals. The preparation method can be used for preparing various high-quality explosive crystals. The high-quality explosive crystals prepared by the preparation method are uniform in particle morphology, are smooth in crystal surface, are less in inner defects, are narrow in particle diameter distribution, are high in particle density, have crystal purity which is 99 percent or higher, and have sensitivity which is obviously reduced in comparison with that of common explosives. The method for preparing the high-quality explosive crystals is simple in process flow, is short in preparation period, is easy to magnify, and has a yield which is 95 percent or higher.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

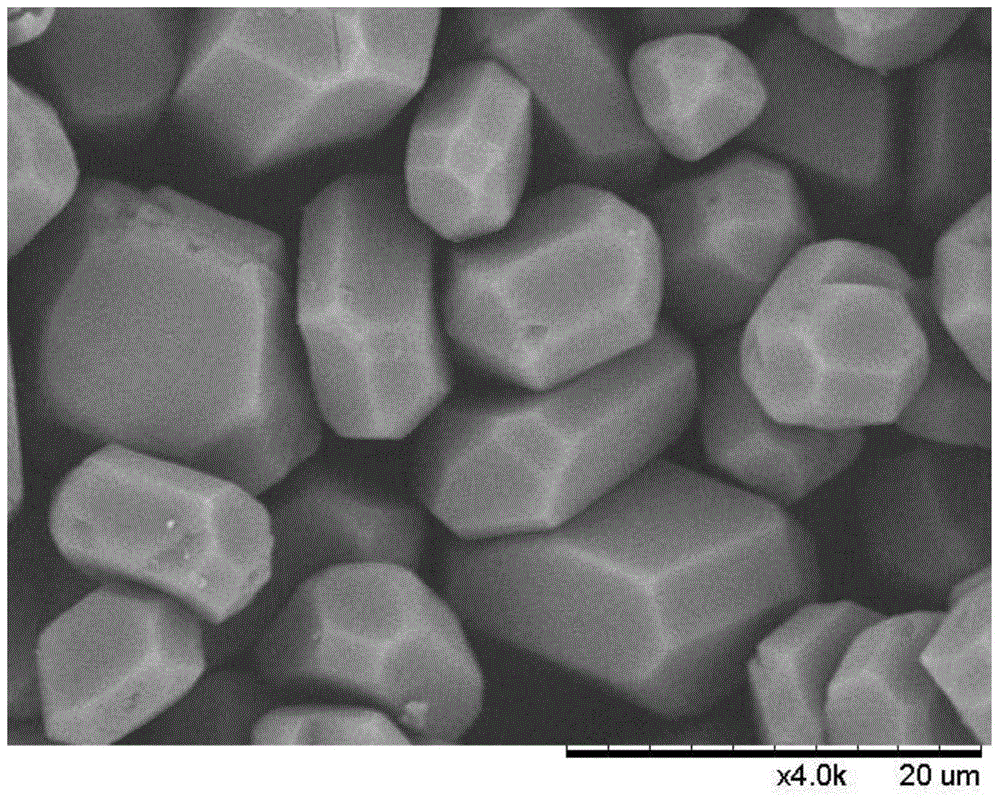

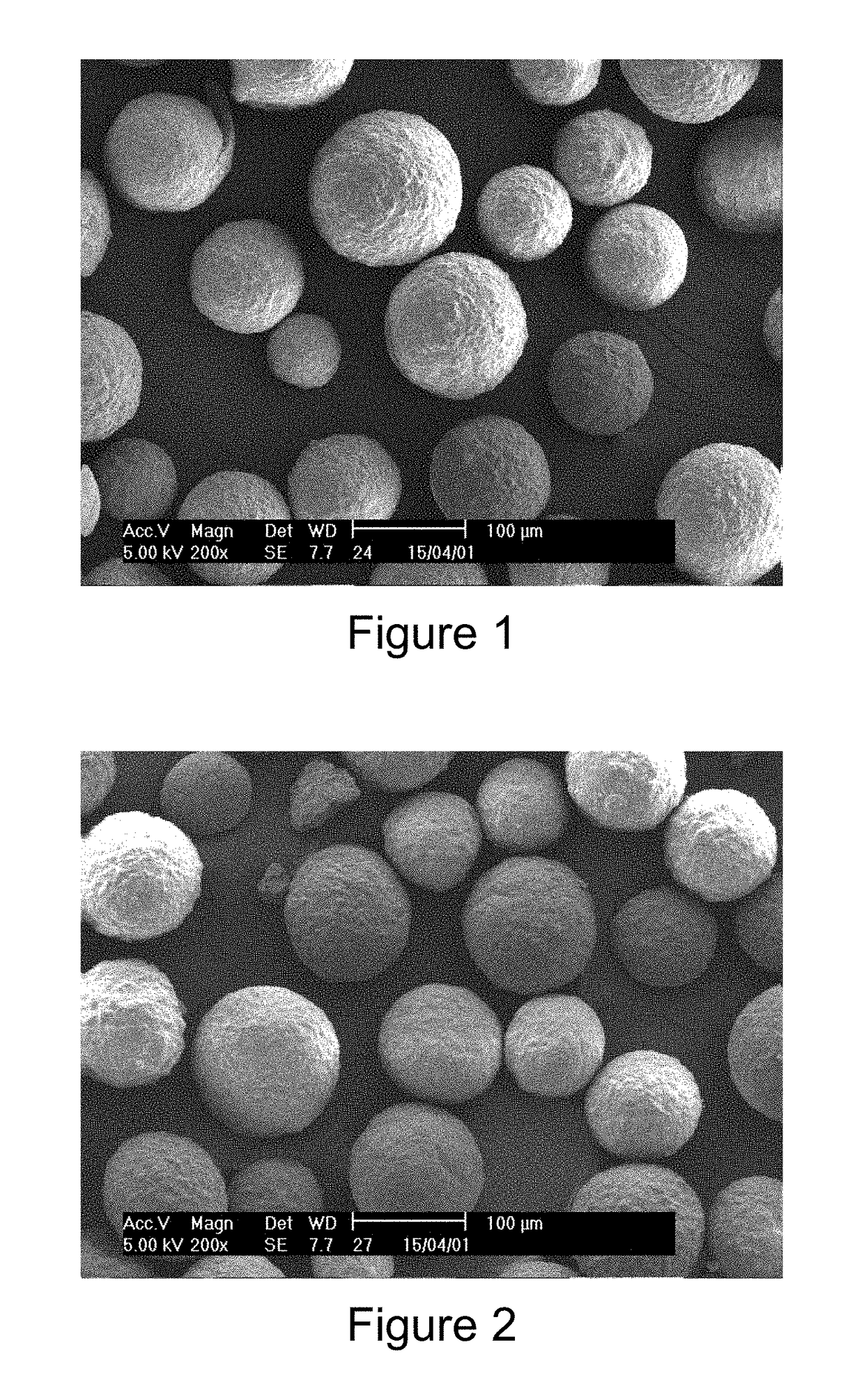

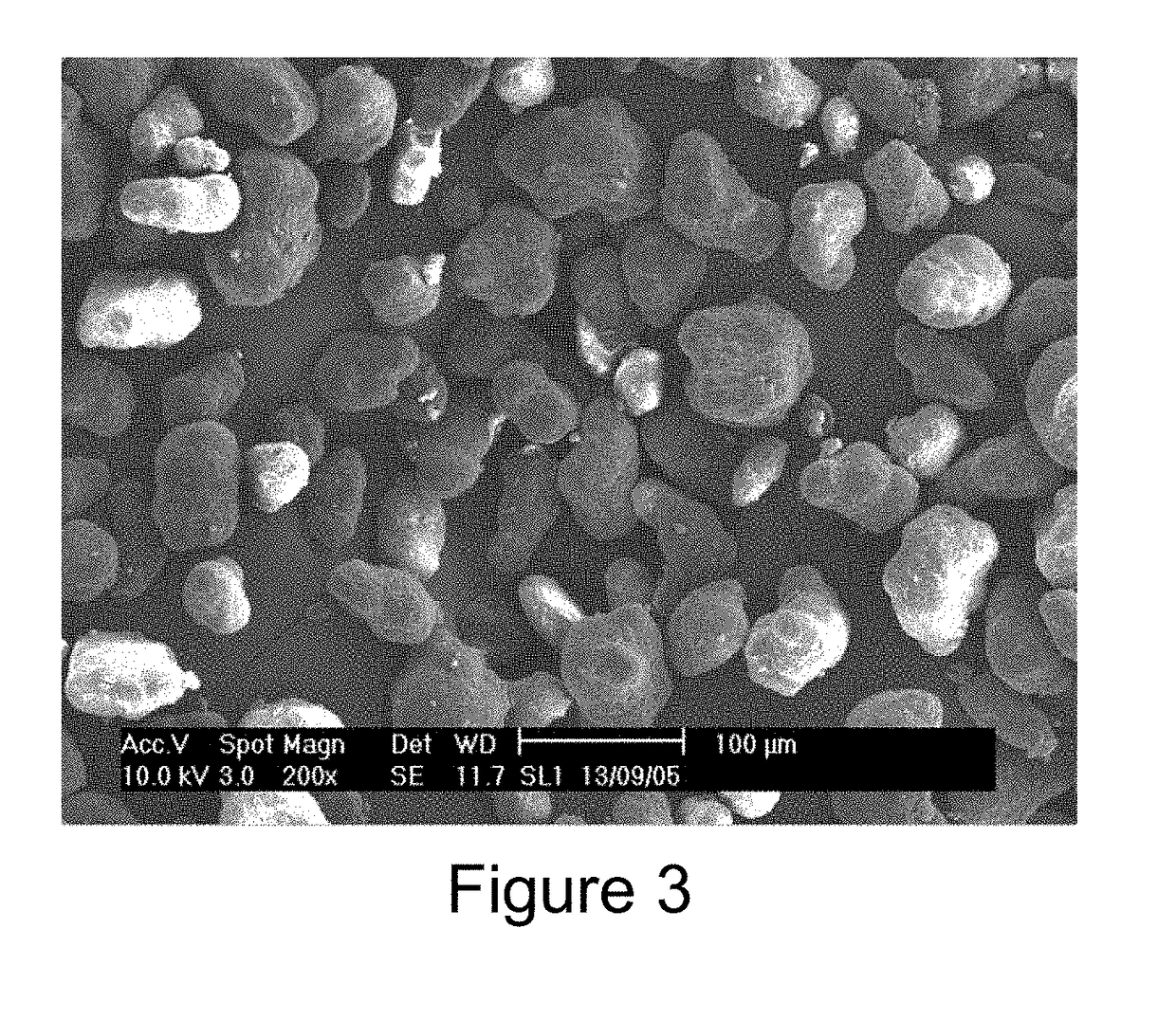

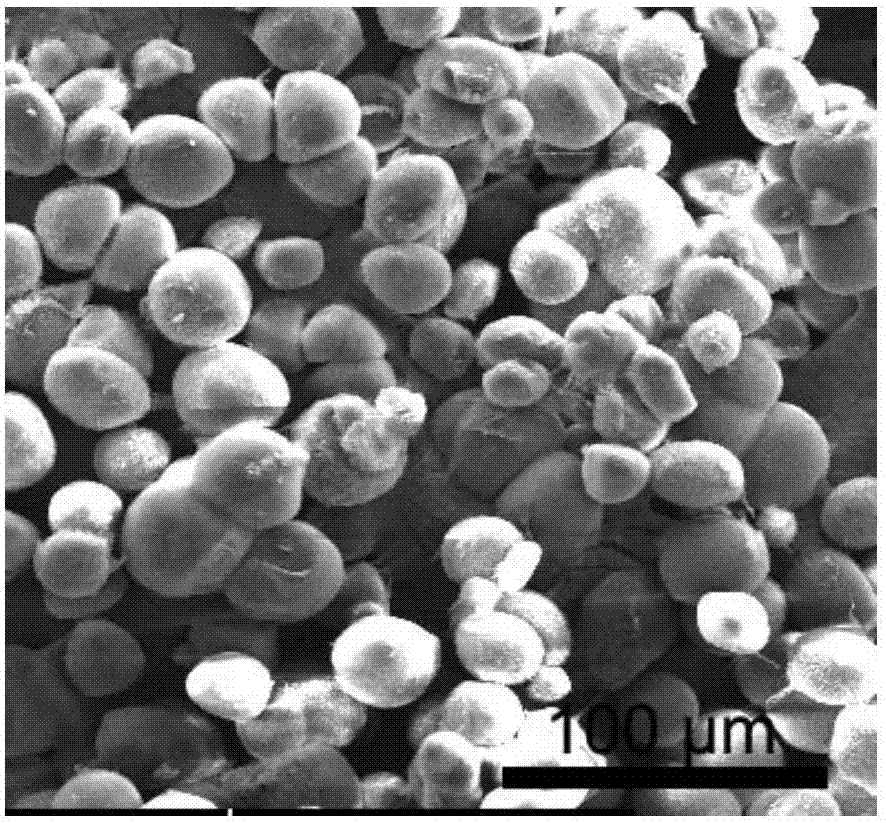

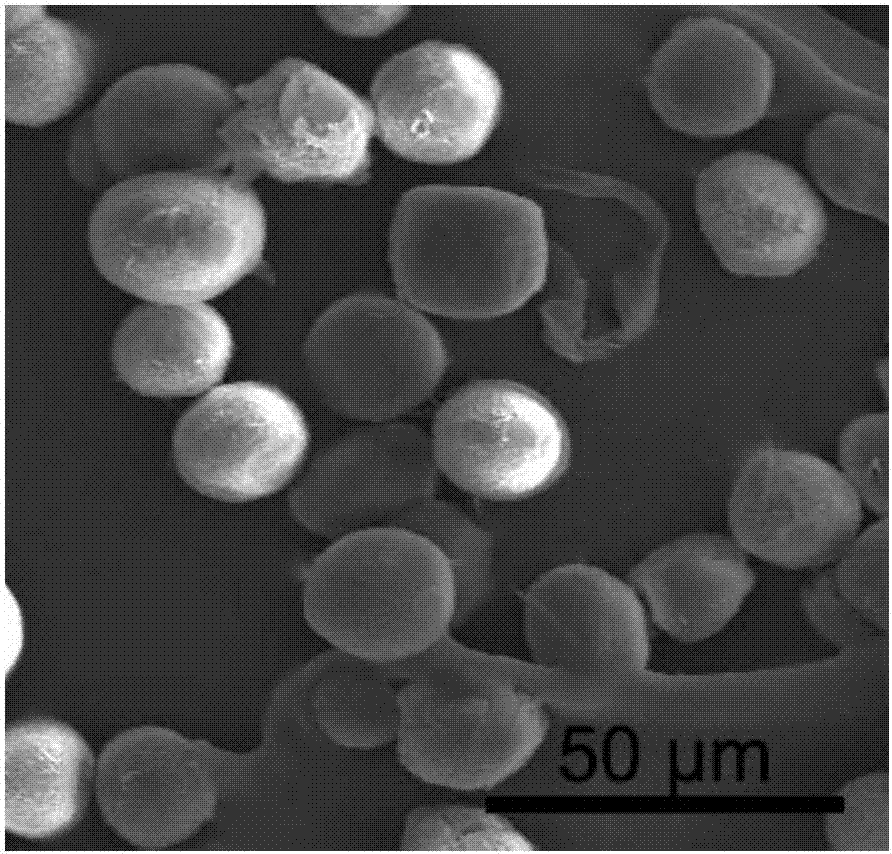

Polyolefin resin powder suitable for selective laser sintering and its preparation method

ActiveUS20180355122A1Improve the immunityReduce sizeAdditive manufacturing apparatusTransportation and packagingSolubilitySelective laser sintering

A method for preparing a polyolefin resin powder has the steps ofa) heat dissolving a polyolefin resin in an organic solvent having a solubility parameter less than or equal to the solubility parameter of the polyolefin resin to obtain a polyolefin resin solution;b) cooling the polyolefin resin solution to precipitate a solid, thereby obtaining a solid-liquid mixture;c) optionally adding an adjuvant to the solid-liquid mixture and mixing; andd) conducting solid-liquid separation and drying to obtain a polyolefin resin powder suitable for selective laser sintering.The difference between the solubility parameters of the organic solvent and of the polyolefin resin is within 0-20% of the solubility parameter of the polyolefin resin. The polyolefin resin powder obtained according to this method has good antioxidant property, good powder flowability, moderate size, smooth surface, suitable bulk density, and suitable dispersibility and particle size distribution.

Owner:CHINA PETROCHEMICAL CORP +1

Method for preparing magnesium hydrate through ammonia spray method

ActiveCN103101936AReduce manufacturing costReduce shipping costsMagnesium hydroxideMagnesium saltMagnesite

The invention discloses a method for preparing magnesium hydrate through ammonia spray method. The method comprises the following steps: by using caustic calcined magnesite and ammonium salt as raw materials, carrying out ammonia stilling reaction to obtain an ammonium and magnesium salt solution, wherein the ammonium and magnesium salt are contacted in a spray type reactor and magnesium hydrate precipitation reaction is performed, aging product mother liquor for a proper time, filtering, returning filtrate containing ammonium salt to an ammonia stilling system, washing and drying filter cake to obtain magnesium hydrate product with uniform particle shape and good dispersion state. The process disclosed by the invention is used for preparing magnesium hydrate through one-step reaction, is simple in operation step, mild in reaction condition, uniform in product particle shape, and the particle shape can be regulated by changing the reaction condition. The ammonium slat is circulated with the ammonia in the reaction process, the production cost is low, the pollution is less, and the scale production is realized, the product can be used as production raw material of high-pure magnesium oxide and inflaming retarding additive of polymer material.

Owner:YINGKOU YINGXIN CHEM TECH CO LTD

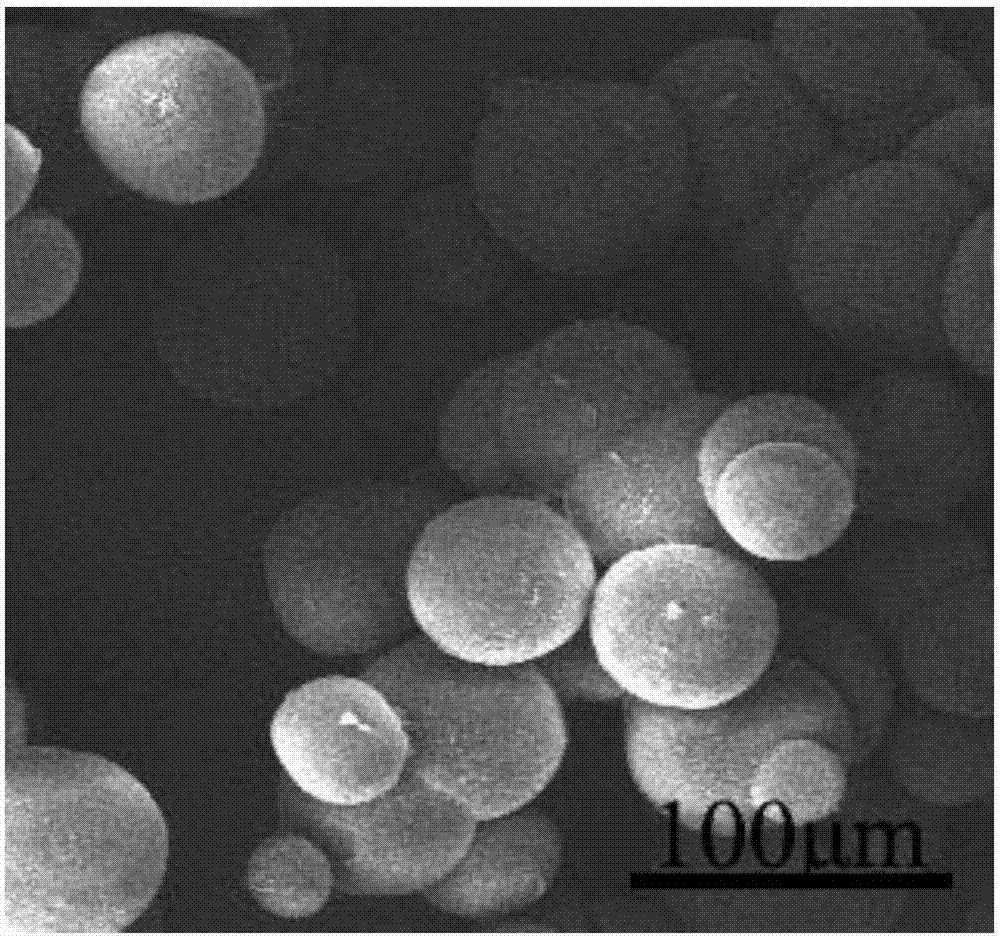

Polypropylene powder for selective laser sintering and preparation thereof

InactiveCN107304251AFlat surfaceUniform shapeAdditive manufacturing apparatusSelective laser sinteringOrganic solvent

The invention provides polypropylene for selective laser sintering, which is spherical and / or sphere-like granules having a degree of sphericity of 0.6-1.0, sizes of 10-100mu m and grain distribution D10 of 10-25mu m, D50 being 30-60mu m and D90 being 70-95mu m. The invention further provides a method for preparing the polypropylene powder, which comprises the following steps: mixing a polypropylene material with an organic solvent for dissolving the polypropylene material, heating under a stirring state to a target heating temperature, and continuing stirring at constant temperature to form a polypropylene solution; (2) quenching the polypropylene solution to the target quenching temperature, standing at a constant temperature until precipitate is generated in the solution; and (3) separating the precipitate, washing and drying to obtain the polypropylene powder.

Owner:CHINA PETROLEUM & CHEM CORP +1

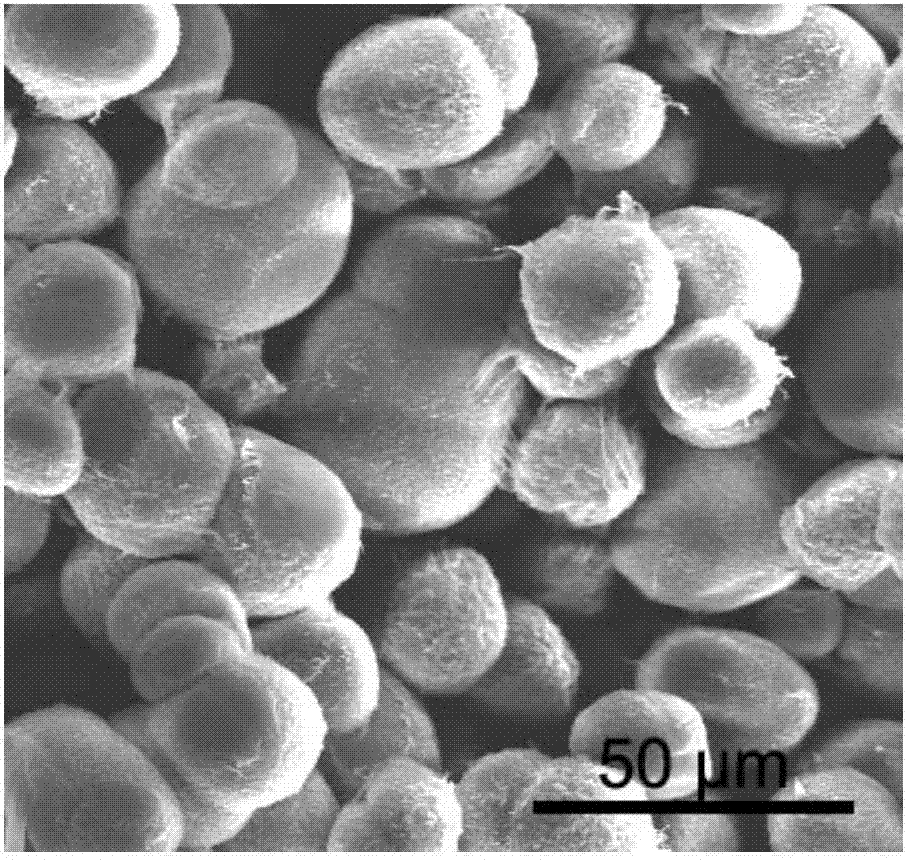

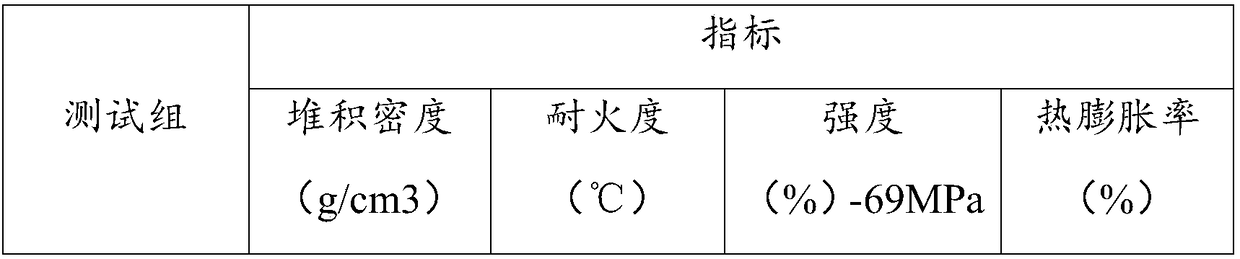

Casting ceramsite and preparation method and application thereof

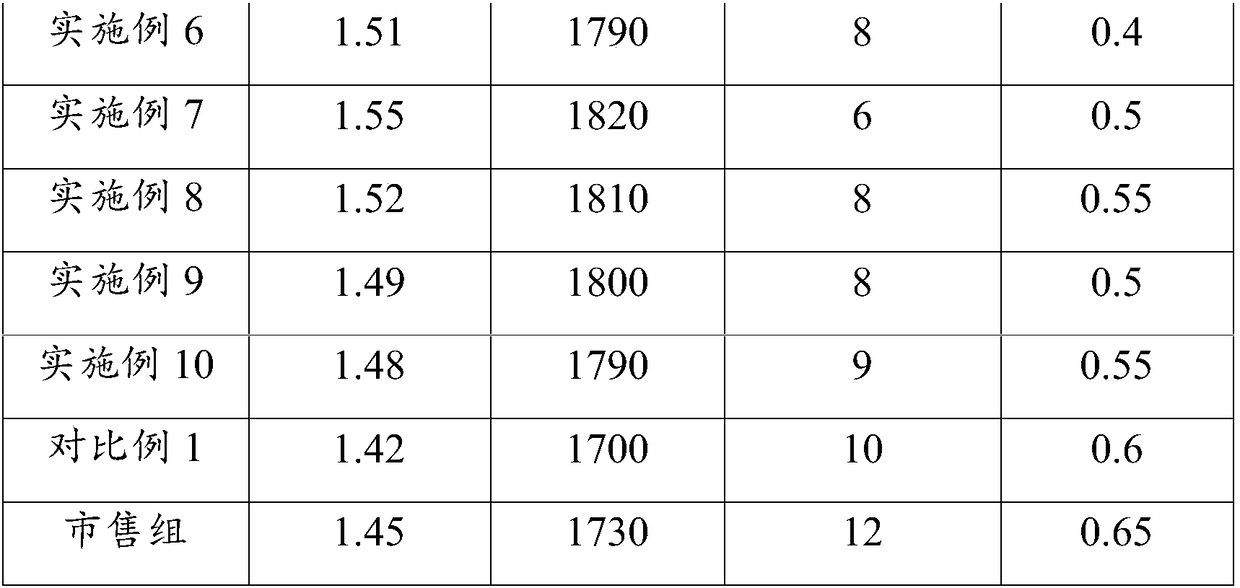

PendingCN108455991ASmall particle sizeUniform particle shapeFoundry mouldsFoundry coresTemperature resistanceAluminium

The invention provides casting ceramsite and a preparation method and application thereof, and relates to the technical field of casting. The casting ceramsite is mainly prepared from bauxite, bauxiteclinker, kaolin and composite additives, the particle size distribution range of the casting ceramsite is 0.106-0.4 mm, and the refractoriness is 1,790-1,900 DEG C. The casting ceramsite has the advantages of high temperature resistance, small particle size, uniform particle shape, high strength, low thermal expansion rate, strong recyclability and the like; not only can ceramic foundry sand be replaced by the casting ceramsite for application in the field of metallurgical casting to meet the casting needs, but also the casting cost can be effectively reduced.

Owner:HANDAN SHENGHUO CERAMIC PROPPANT CO LTD

Method for producing lithium manganate and lithium cell using said lithium manganate

InactiveCN1413171AHigh crystallinityHigh bulk densityCell electrodesManganese oxides/hydroxidesHigh energyManganate

According to the process of this invention, first a manganese oxide seed is prepared, which is then grown to obtain manganese oxide having large particle diameters. The manganese oxide thus obtained is reacted with a lithium compound, whereby lithium manganate having large particle diameters can be obtained. Since the lithium manganate has large particle diameters and gives a high packing density, lithium batteries with a high energy density can be provided by using the lithium manganate.

Owner:ISHIHARA SANGYO KAISHA LTD

Universal powdered ink

The invention provides universal powdered ink, which comprises the following components in percentage by weight: 50-60 percent of Fe3O4 powder, 20-30 percent of polyacrylate-styrol copolymer, 10-20 percent of charge control agent, 4-6 percent of styrene-acrylic resin and 4-6 percent of ferric oxide. The universal powdered ink is obtained by the following steps that: the Fe3O4 powder is processed by supercritical CO2, and then is mixed with other raw materials, then the mixture is subjected to electric treatment of direct current, and finally, spray, drying, cyclone separation and mixing are carried out in sequence. The development imaging of the universal powdered ink is clear, bottom ash does not exist, and the quality and the stability of printed products are increased. The melting point is low, and the electric energy loss of a copier is greatly reduced. The particle of universal powdered ink is neat and uniform in shape, and therefore the universal powdered ink is suitably used for various machine types. The energy is saved and the environment is protected.

Owner:甘肃宏德嘉信息科技有限公司

Instant microelement water-soluble fertilizer capable of increasing soil organic matter content

InactiveCN105646084AImprove physical and chemical conditionsImprove biological characteristicsBioloigcal waste fertilisersAmmonium salt fertilisersSodium bicarbonateDrip irrigation

The invention relates to fertilizer, in particular to instant microelement water-soluble fertilizer capable of increasing the soil organic matter content. The instant microelement water-soluble fertilizer capable of increasing the soil organic matter content is prepared form components in parts by weight as follows: 450-550 parts of concentrated molasses yeast powder, 8-15 parts of poly potassium aspartate, 50-80 parts of citric acid, 20-40 parts of sodium bicarbonate, 20-40 parts of disodium octaborate tetrahydrate, 150-300 parts of zinc sulphate monohydrate, 100-200 parts of manganese sulfate, 5-15 parts of iron EDTA (ethylene diamine tetraacetic acid), 5-15 parts of copper EDTA and 0.5-1.5 parts of ammonium molybdate. The fertilizer can be quickly dissolved, is fully water-soluble, can be applied to facility agriculture such as sprinkling and drip irrigation and the like and realizes integration of water and fertilizer and the efficiency of saving water, fertilizer and labor. The fertilizer can provide organic matters and various microelement nutrients for soil and crops after usage.

Owner:张学杰

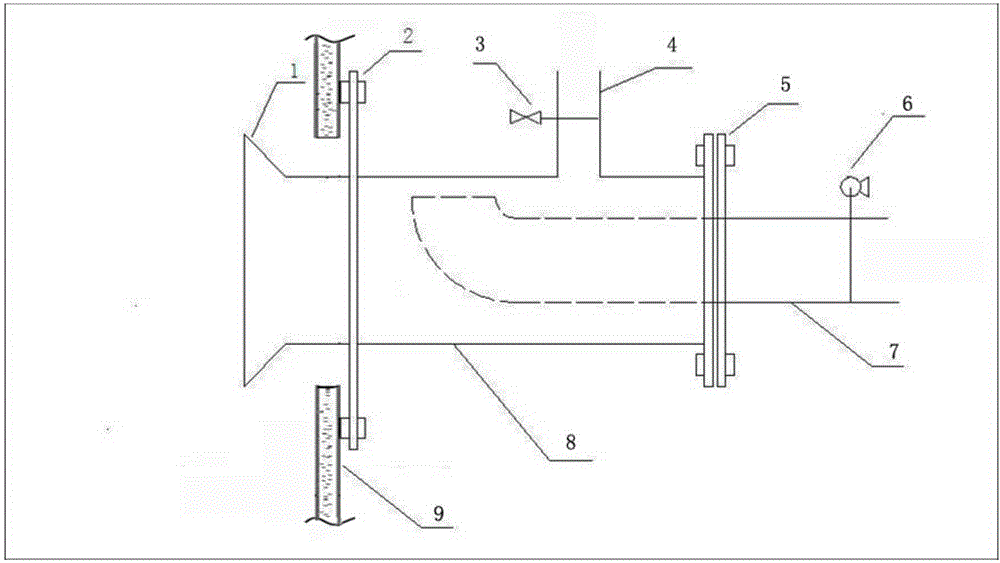

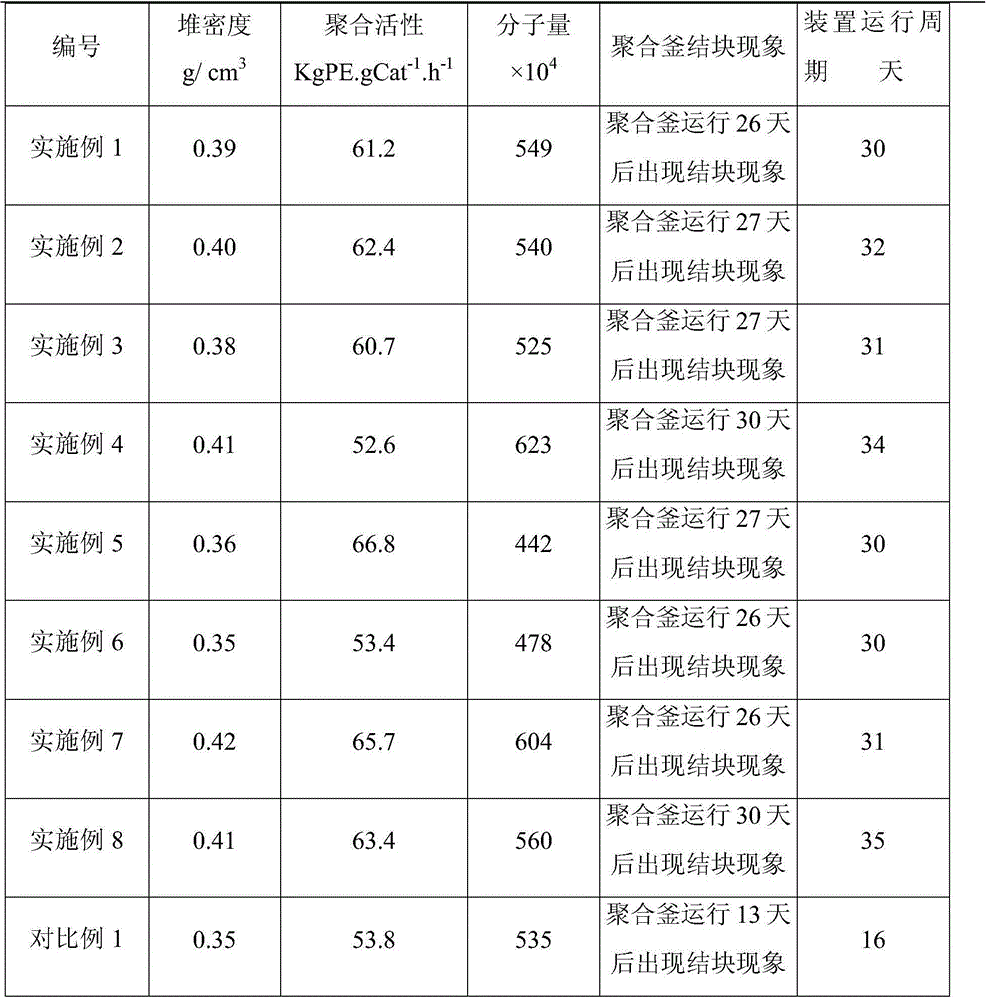

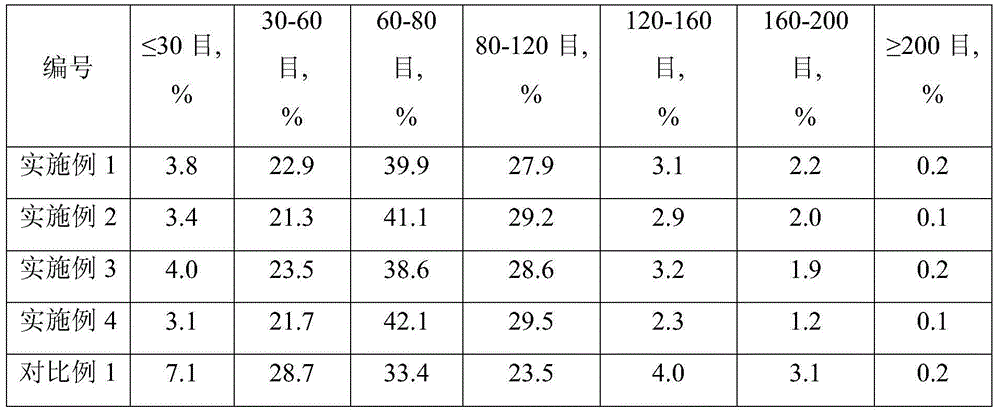

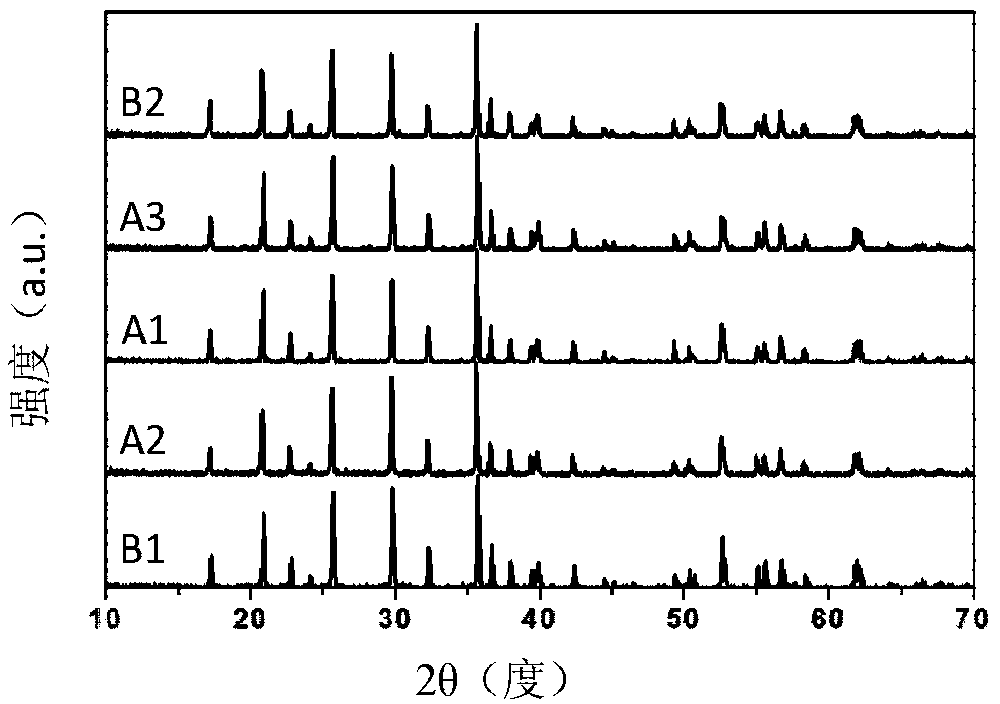

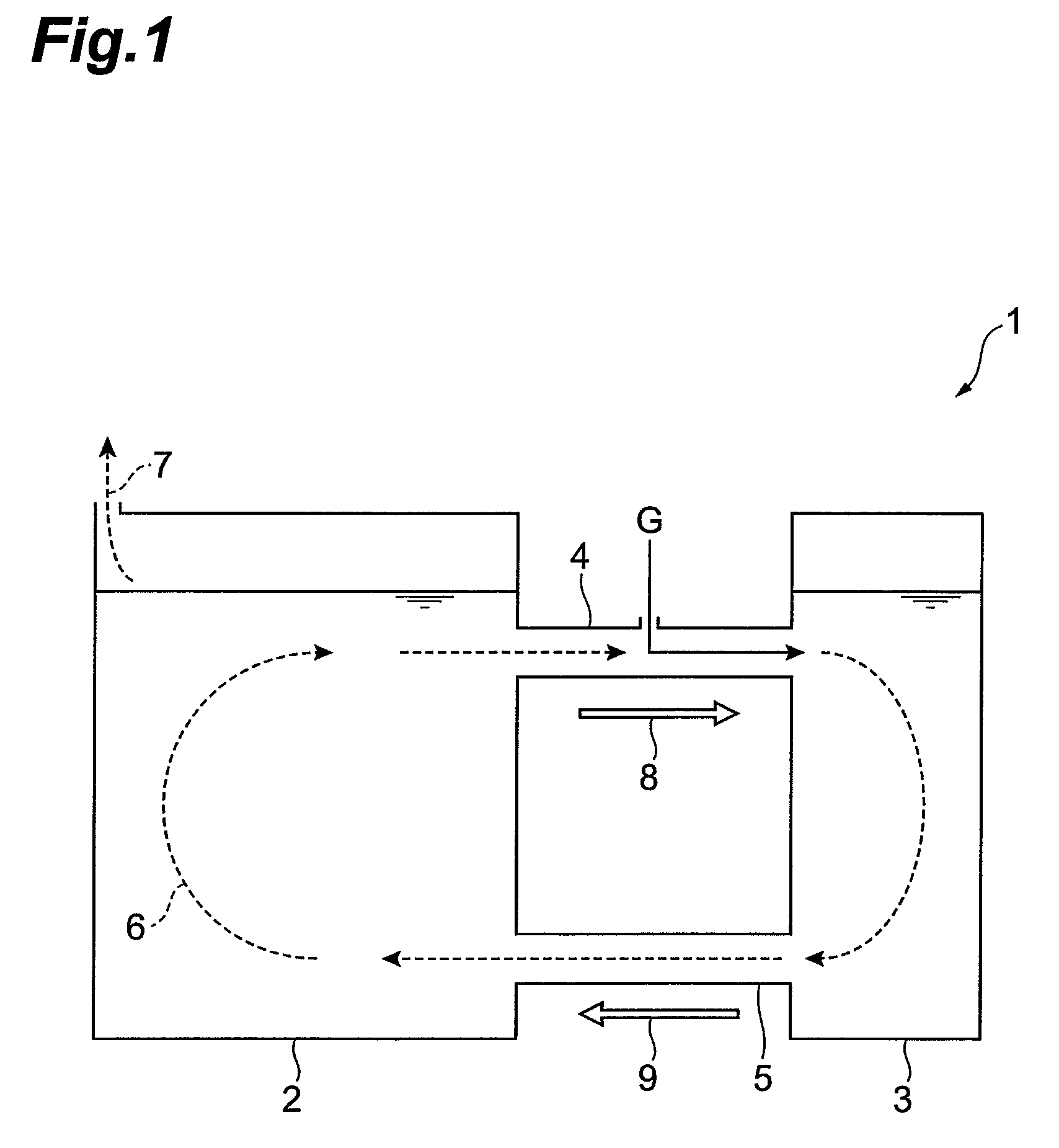

Catalyst feeding device for polymerization process of ultra-high molecular weight polyethylene and application

The invention belongs to the field of macromolecules, in particular to a catalyst feeding device for a polymerization process of ultra-high molecular weight polyethylene and application. The catalyst feeding device comprises a catalyst feeding pipe, wherein a metering pump is arranged on the catalyst feeding pipe, and a catalyst premixing pipe is arranged at an outer shaft of the catalyst feeding pipe; the catalyst feeding pipe is connected with the catalyst premixing pipe through a first flange, and a solvent feeding pipe is arranged on the catalyst premixing pipe; an electromagnetic flow regulating valve is arranged on the solvent feeding pipe, and the catalyst premixing pipe is connected with a polymerizing vessel through a second flange. The online mixing at a catalyst feeding stage is realized due to the unique sleeve type feeding way of the device, a spray structure promotes dispersion of a catalyst after entering the polymerizing vessel, the catalyst agglomeration phenomenon is reduced, the agglomeration phenomenon in the polymerizing process is improved, and the blockage of the catalyst feeding pipe is avoided at the same time. The invention further provides the application of the catalyst feeding device, the prepared ultra-high molecular weight polyethylene polymerisate is uniform in granule shape, the bulk density is increased, and the proportion of large particles is obviously reduced.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of cathode material, cathode material, and battery

InactiveCN105514423AUniform particle shapeReduce manufacturing costCell electrodesSecondary cellsCarbon sourceAmount of substance

The invention discloses a preparation method of a cathode material. The preparation method comprises the following steps: mixing a lithium source, a manganese source, an iron source, and a phosphor source according to a weight ratio of Li:Mn:Fe:P of 1:x:(1-x):1, wherein 0<=x<1, the iron source comprises a first iron source and a second iron source, and the ratio of amount of substance of the first iron source to the second iron source is in a range of 2:8 to 8:2; after mixing, pre-burning the mixture in an inert atmosphere to obtain a product of pre-burning, mixing the product of pre-burning with a carbon source, and sintering the mixture in an inert atmosphere. The provided preparation method can reduce the cost and obtain a uniform cathode material. The invention also discloses a cathode material and a battery.

Owner:苏州艾美得新能源材料有限公司 +1

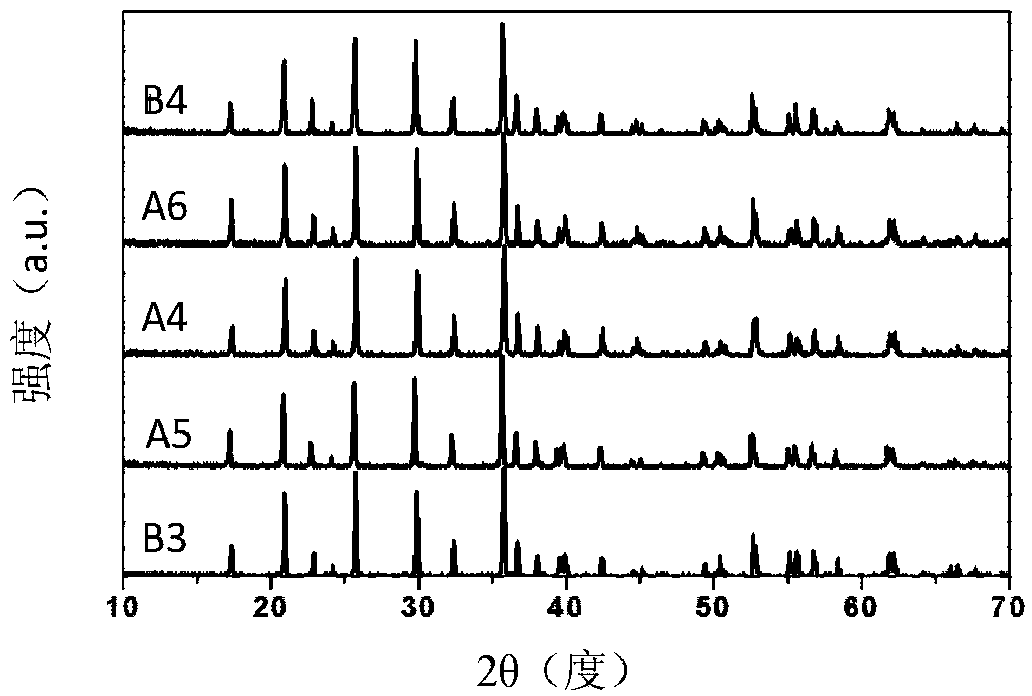

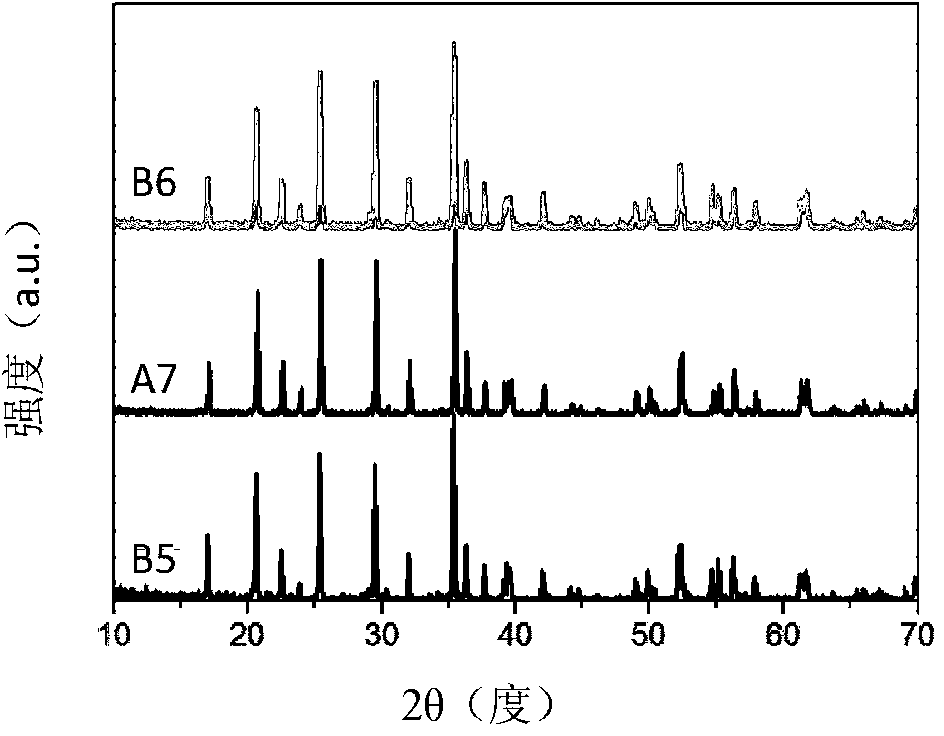

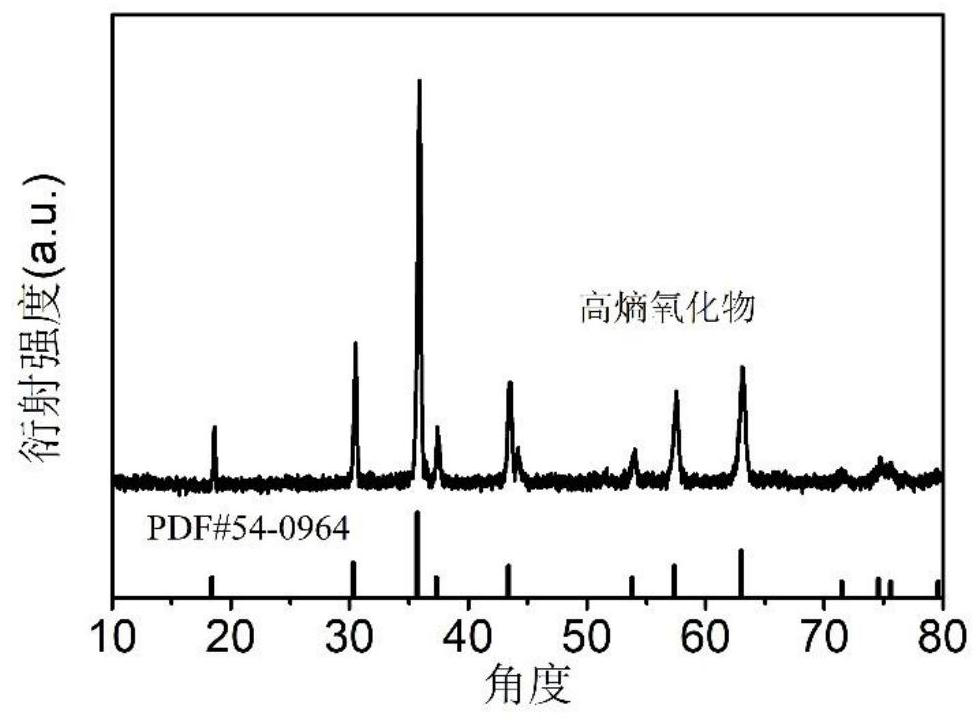

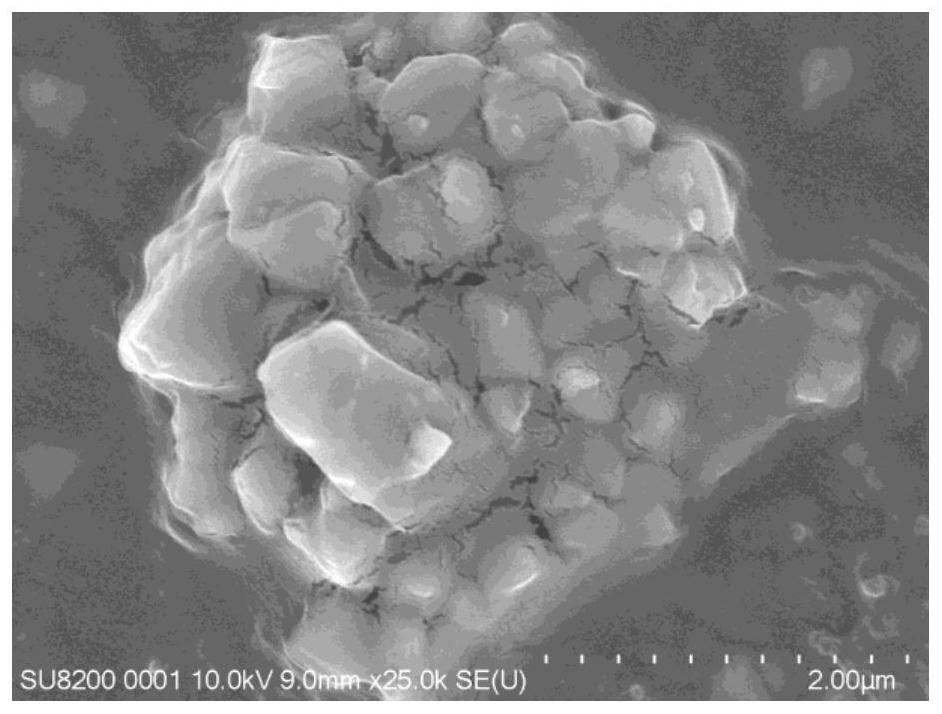

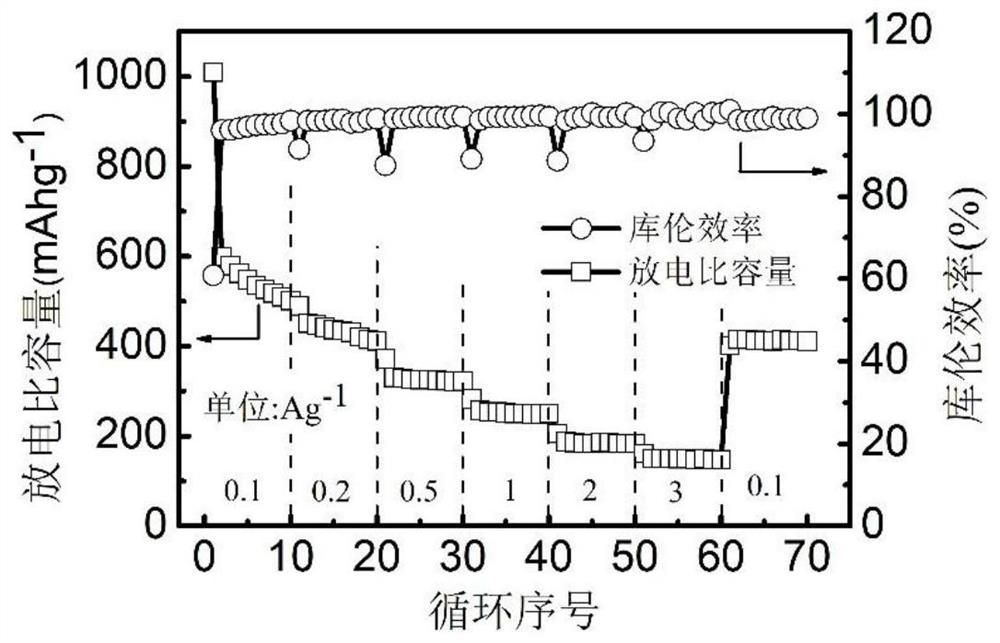

Preparation method of lithium ion battery negative electrode material high-entropy oxide

ActiveCN112875764AImprove performanceUniform particle shapeNegative electrodesSecondary cellsPhysical chemistryLithium-ion battery

The invention discloses a preparation method of a lithium ion battery negative electrode material high-entropy oxide. The preparation method comprises the following steps: S1, carrying out oil removal, polishing and rust removal, distilled water washing, alcohol solution secondary washing and vacuum drying on a high-entropy alloy Cr<0.2>Fe<0.2>Mn<0.2>Ni<0.2>Co<0.2> solid; S2, conducting melting, carrying out gas atomization granulation, and conducting cooling and sieving; and S3, taking the high-entropy alloy powder, and conducting oxidation treatment under flowing oxygen, so as to obtain the required (Cr<0.2>Fe<0.2>Mn<0.2>Ni<0.2>Co<0.2>)<3>O<4> high-entropy oxide lithium ion electrode material. The lithium battery negative electrode material (Cr<0.2>Fe<0.2>Mn<0.2>Ni<0.2>Co<0.2>)<3>O<4> high-entropy oxide obtained through the method is a pure phase, the particle morphology is uniform, the particle size is 0.1-2 microns, namely, the material performance is more stable, a battery assembled by the lithium battery negative electrode material high-entropy oxide has very high specific capacity and very good cycle stability and has remarkable economic value, and the method is short in process, easy to operate, low in cost and suitable for industrial production. The method is high in controllability, good in repeatability, wide in applicability and suitable for industrial production.

Owner:CHINA UNIV OF MINING & TECH

Process for production of iron oxyhydroxide particles

InactiveUS7910085B2Small size changeUniform particle shapeMaterial nanotechnologyPigmenting treatmentIron oxyhydroxidePhotochemistry

The process for production of iron oxyhydroxide particles according to the invention is characterized by comprising a step (A) in which a suspension containing iron(II) is prepared, and a step (B) in which fine bubbles with diameters of 0.05-500 μm are generated in the suspension to form a reaction mixture, and the iron(II) in the reaction mixture is oxidized by the bubbles to produce iron oxyhydroxide particles.

Owner:TDK CORPARATION

Polypropylene compound powder for selective laser sintering and preparation thereof

The invention provides polypropylene compound powder for selective laser sintering, which is prepared from the following components in parts by weight: 100 parts of polypropylene-maleic anhydride grafted polypropylene, 0.1-1.0 part of carbon nano-tube, 0.3-1.0 part of flow additive and 0.1-1.0 part of antioxidant. The invention further provides a method for preparing the compound powder, which comprises the following steps: (1) dissolving the polypropylene powder and maleic anhydride grafted polypropylene powder in an organic solvent, heating under a stirring state to a target heating temperature, and continuously stirring at a constant temperature to form a polypropylene solution; (2) quenching the polypropylene solution to a target quenching temperature, standing at a constant temperature until precipitate is generated in the solution; (3) separating the precipitate, washing and drying to obtain the polypropylene-maleic anhydride grafted polypropylene powder; and (4) uniformly mixing and stirring the polypropylene-maleic anhydride grafted polypropylene powder with the carbon nano-tube, the flow additive and the antioxidant.

Owner:CHINA PETROLEUM & CHEM CORP +1

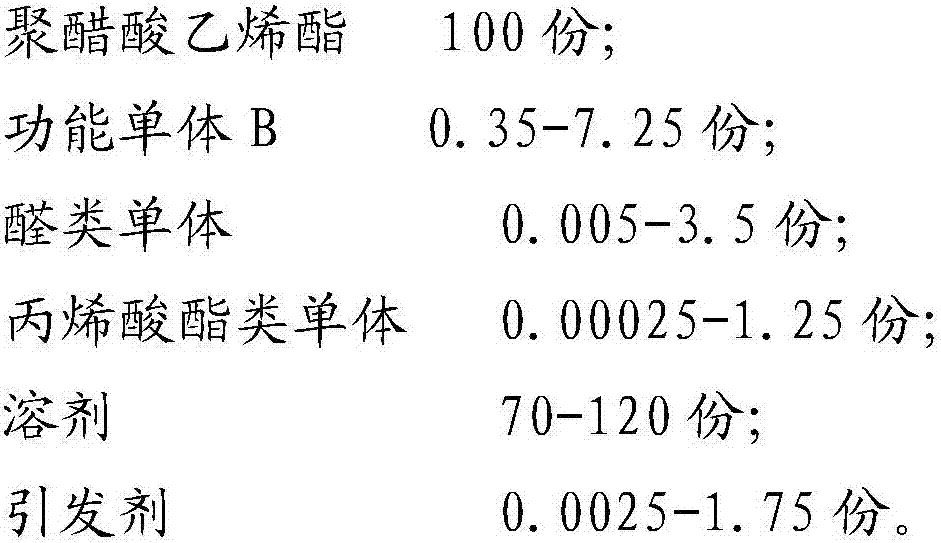

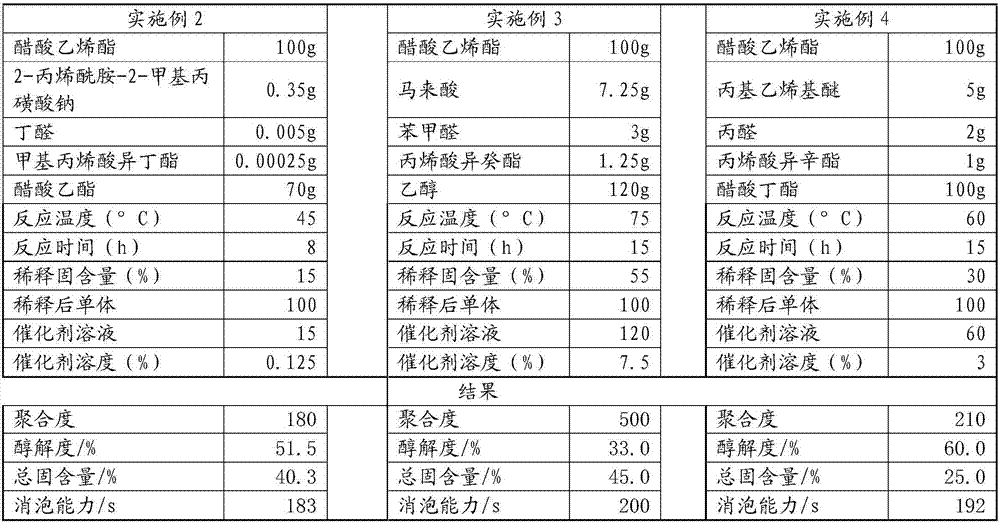

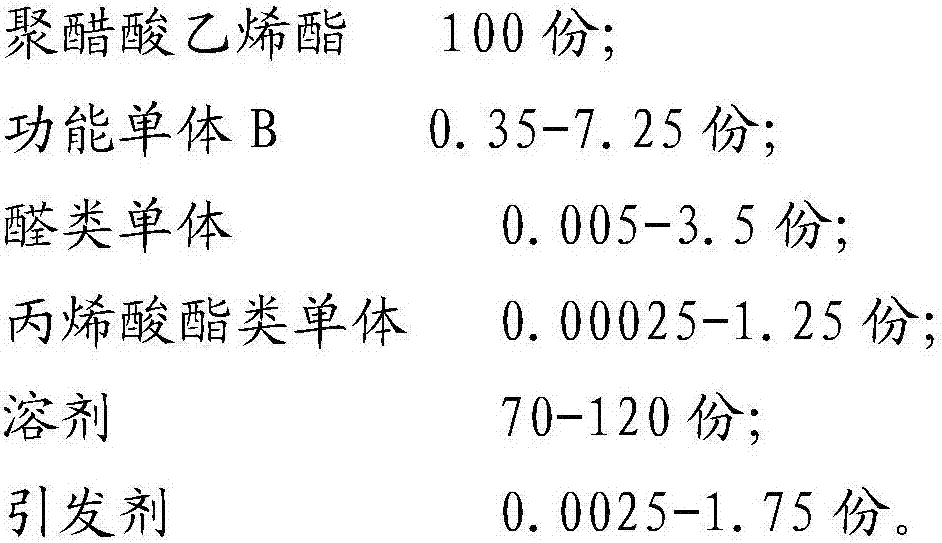

Polyvinyl alcohol with advantages of defoaming function and low alcoholysis degree, and preparation method thereof

ActiveCN107189003ASolve the problem of insoluble in waterSolve the problem of fragmentationPolyvinyl acetateAlcohol

The present invention belongs to the field of preparation of polyvinyl alcohol, and particularly relates to polyvinyl alcohol with advantages of defoaming function and low alcoholysis degree, and a preparation method thereof. The preparation method comprises: a) polyvinyl acetate polynary monomer copolymerization, and b) catalytic alcoholysis, wherein the copolymerization monomer used in the step a) comprise, by weight, 100 parts of polyvinyl acetate, 0.35-7.25 parts of a functional momomer B, 0.005-3.5 parts of an aldehyde monomer, 0.00025-1.25 parts of an acrylate monomer, 70-120 parts of a solvent, and 0.0025-1.75 parts of an initiator. According to the present invention, the problem that the polyvinyl alcohol with the alcoholysis degree of less than 56 mol% is insoluble in water is solved so as to make the auxiliary dispersant become the environmentally friendly product, the problem of the water phase dispersing during vinyl chloride suspension polymerization is solved, and the auxiliary dispersant has the defoaming function.

Owner:TIANJIN SUNNYMER +1

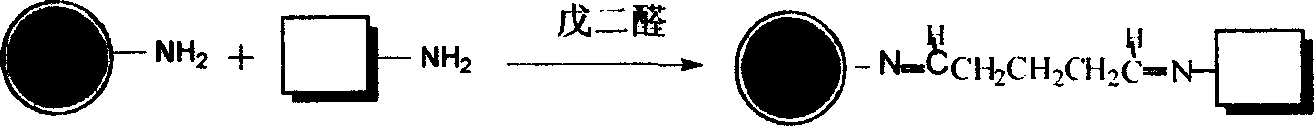

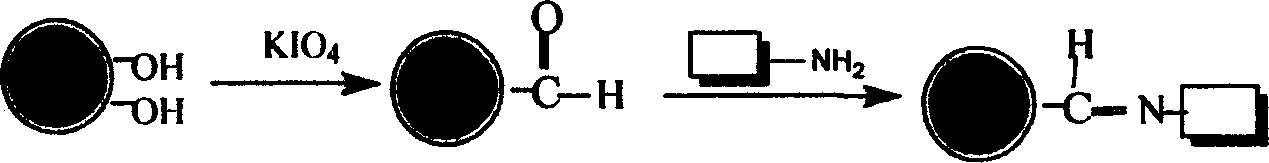

Novel fructosyltransferase immobilization method

InactiveCN101538565AUniform particle shapeGood mechanical strengthOn/in organic carrierChemistrySOLUTION/DROPS

The invention relates to a novel fructosyltransferase immobilization method, comprising the following steps: (1) adding 0.01 percent-0.05 percent adhesive polyvinyl pyrrolidone into chitosan acetic acid solution; (2) dripping the chitosan acetic acid solution to NaOH solution regulated by ethanol for preparing chitosan spherical particles and washing the chitosan spherical particles to be neutral by using distilled water; (3) placing the neutral chitosan spherical particles in phosphate buffer solution with pH of 7, adding glutaraldehyde cross-linker to lead the glutaraldehyde cross-linker to be bonded on the chitosan spherical particles and fully washing to remove the glutaraldehyde which is not bonded; (4) placing the chitosan spherical particles which are bonded with the glutaraldehyde in the phosphate buffer solution with pH of 7 and then adding fructosyltransferase therein for immobilization. The novel fructosyltransferase immobilization method immobilizes the fructosyltransferase, improves the mechanical strength of chitosan as an immobilized enzyme carrier and improves the enzyme loading capacity; and the immobilized enzyme prepared by the method can be used repeatedly for a plurality of times.

Owner:云南健生生物科技有限公司 +1

Preparation method of cigarette filter tip radix puerariae particles, particles and cigarette filter tip

ActiveCN107156904AImprove yieldUniform particle shapeCigarette manufactureTobacco smoke filtersAdhesiveCigarette filter

The invention relates to a preparation method of cigarette filter tip radix puerariae particles, the particles and a cigarette filter tip, and belongs to the field of filter tip materials. The method comprises the following steps: (1) dividing radix puerariae powder into two parts, wherein one part is gelatinized with the addition of water and the gelatinized radix puerariae powder is 8-20% of the total mass of the radix puerariae powder, while the other part serves as dry powder of granulation; (2) adding water to the to-be-gelatinized radix puerariae powder, and implementing heating and gelatinizing, so that a gelatinized radix puerariae powder colloidal solution is obtained, wherein the amount of the added water is 5-10 times as much as the mass of the to-be-gelatinized radix puerariae powder; and (3) implementing granulation by virtue of a conventional fluidized bed granulator, and sieving prepared particles, so that the particles of 20-80 meshes are obtained. With the application of the method, a product yield is improved, and in addition, interference of an external adhesive to sensory quality of radix puerariae is avoided, so that a utilization rate of the material (the radix puerariae) is improved and product cost is reduced, and subsequently, product quality can be further improved.

Owner:CHINA TOBACCO YUNNAN IND

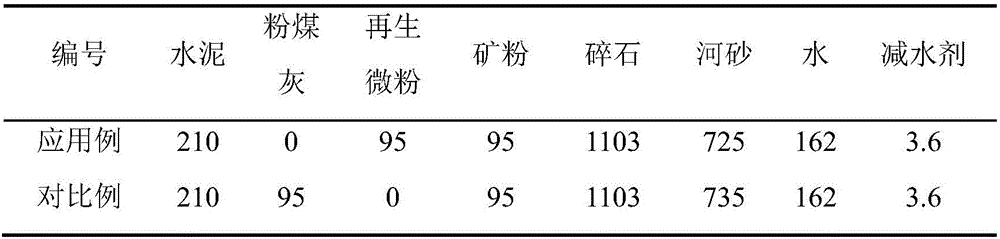

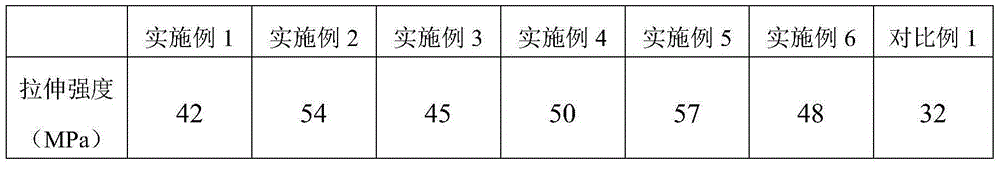

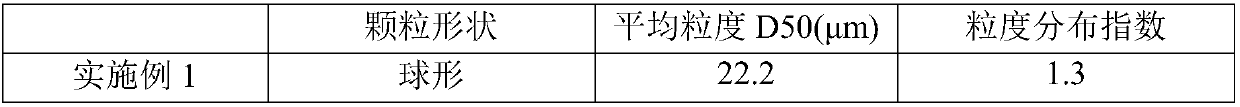

Waste concrete low-temperature heat treatment regenerated active micropowder and preparation method thereof

The invention provides a waste concrete low-temperature heat treatment regenerated active micropowder. The waste concrete low-temperature heat treatment regenerated active micropowder is prepared by grinding raw materials including waste concrete cement stone powder, stone powder, a sintering additive, desulfurizing gypsum and an activator. The waste concrete low-temperature heat treatment regenerated active micropowder has the characteristics that the activity is high, the particle size distribution is uniform, and the like; the activity index of the building waste regenerated active micropowder is effectively improved, the initial flowing property of concrete and mortar is improved, the loss amount in flowing duration is reduced, the early mechanic property of concrete is improved, and the obvious economic and environment-protection benefits are realized.

Owner:HUBEI UNIV

Glass fiber reinforced polypropylene resin powder for selective laser sintering and preparation thereof

InactiveCN106589419ASmall sizeImprove mechanical propertiesAdditive manufacturing apparatusSelective laser sinteringOrganic solvent

The invention provides a preparation method of a glass fiber reinforced polypropylene resin powder for selective laser sintering. The method includes the steps of: a) at a heating temperature, dissolving polypropylene resin in an alkane organic solvent to obtain a polypropylene resin solution; b) cooling the polypropylene resin solution obtained by step a) to make solid precipitate out; c) adding assistants into the solid-liquid mixture obtained by step b), mixing the substances evenly, and performing drying so as to obtain the powder, wherein the assistants include ultra-short glass fiber, an antioxidant and a powder separant. The method has the characteristics of simple operation and easy operation, not only provides the sintering raw material with excellent processing properties for selective laser sintering, but also provides a new direction for processing and application of functional polypropylene resin. The invention further provides the glass fiber reinforced polypropylene resin powder prepared according to the method and a selective laser sintering method adopting the glass fiber reinforced polypropylene resin powder as the sintering powder raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

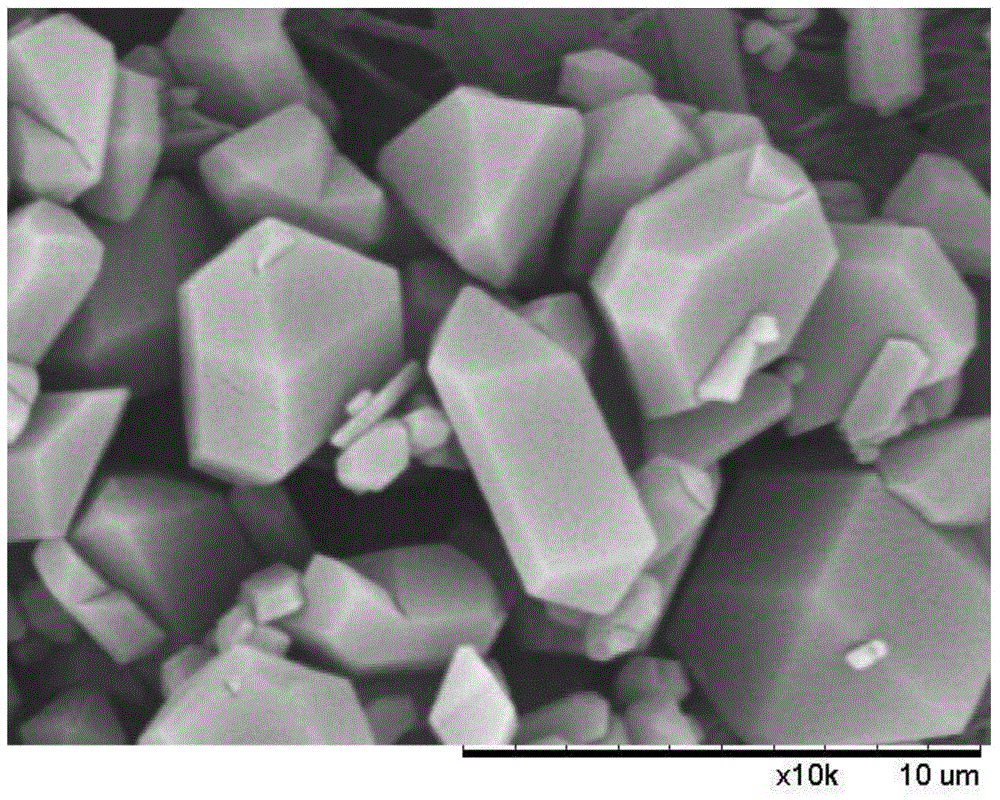

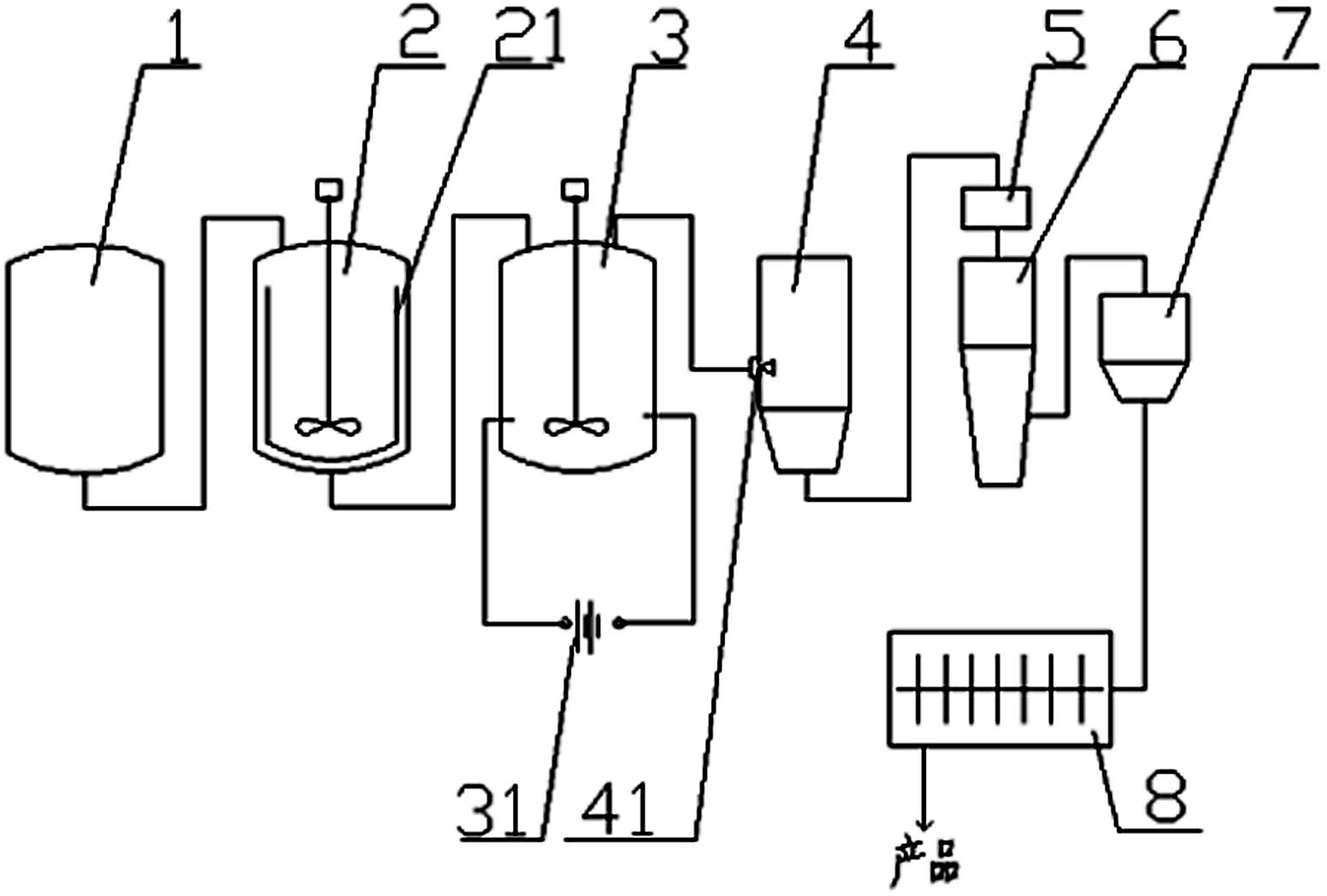

Alkoxy magnesium catalyst carrier as well as preparation method and application thereof

The invention provides an alkoxy magnesium catalyst carrier as well as a preparation method and application thereof. The preparation method of the alkoxy magnesium catalyst carrier comprises the following steps: at 0-90 DEG C, in the presence of an inert gas atmosphere, mixing a magnesium metal, monohydric alcohol, a halogenating agent and a surfactant, and washing with an inert solvent, thereby obtaining the alkoxy magnesium catalyst carrier. The invention further provides the alkoxy magnesium catalyst carrier prepared by using the method, and the alkoxy magnesium catalyst carrier can be applied to olefin polymerization catalysis. The alkoxy magnesium catalyst carrier prepared by using the method is excellent in granular morphology, controllable in size and applicable to preparation of apolyolefin catalyst.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com