Casting ceramsite and preparation method and application thereof

A technology of ceramsite and particle size distribution, applied in casting molding equipment, casting molds, manufacturing tools, etc., can solve the problems of increasing casting costs, high production costs of pearl sand, and difficulty in controlling pollution, reducing casting costs and thermal expansion. Low rate and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

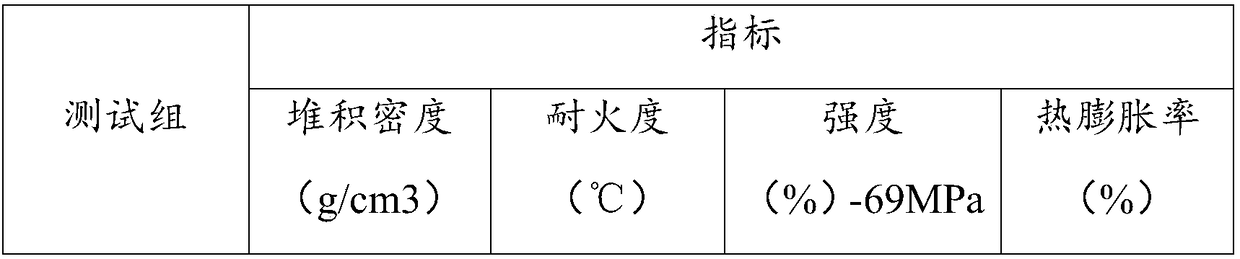

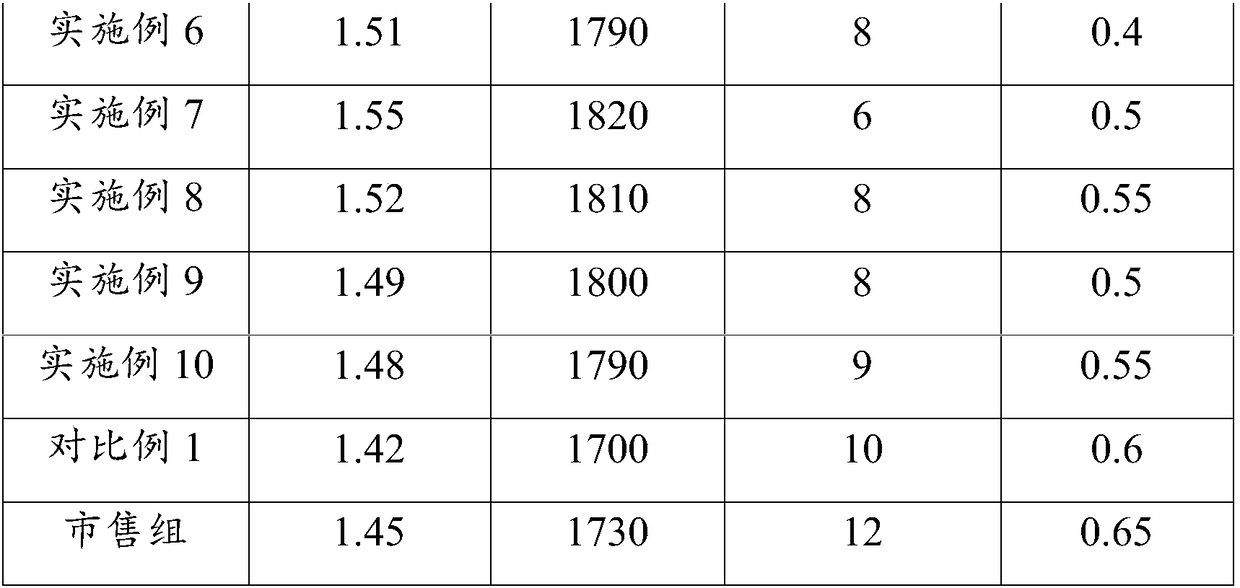

Examples

preparation example Construction

[0036] According to one aspect of the present invention, a kind of preparation method according to above-mentioned casting ceramsite, described preparation method comprises the following steps:

[0037] (a) pulverizing bauxite, bauxite clinker, kaolin and composite additives respectively and mixing uniformly to obtain mixed raw materials;

[0038] (b) Homogenize the mixed raw materials and then granulate to obtain the primary product of cast ceramsite with a particle size distribution range of 0.106-0.4mm, and then perform combined screening and high-temperature calcination on the primary product of cast ceramsite to obtain cast ceramsite .

[0039] In the present invention, the preparation method of the above-mentioned cast ceramsite is as follows: firstly, bauxite, bauxite clinker, kaolin and composite additives are pulverized and mixed evenly to obtain mixed raw materials; then the mixed raw materials are stale and homogenized and then granulated to obtain The primary prod...

Embodiment 1

[0050] A composite additive, in parts by mass, comprising: 12 parts of aluminum oxide, 70 parts of silicon dioxide, 0.6 part of ferric oxide, and 2.5 parts of titanium dioxide.

Embodiment 2

[0052] A composite additive, in parts by mass, comprising: 8 parts of aluminum oxide, 60 parts of silicon dioxide, 0.8 parts of ferric oxide, and 1.5 parts of titanium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size distribution range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com