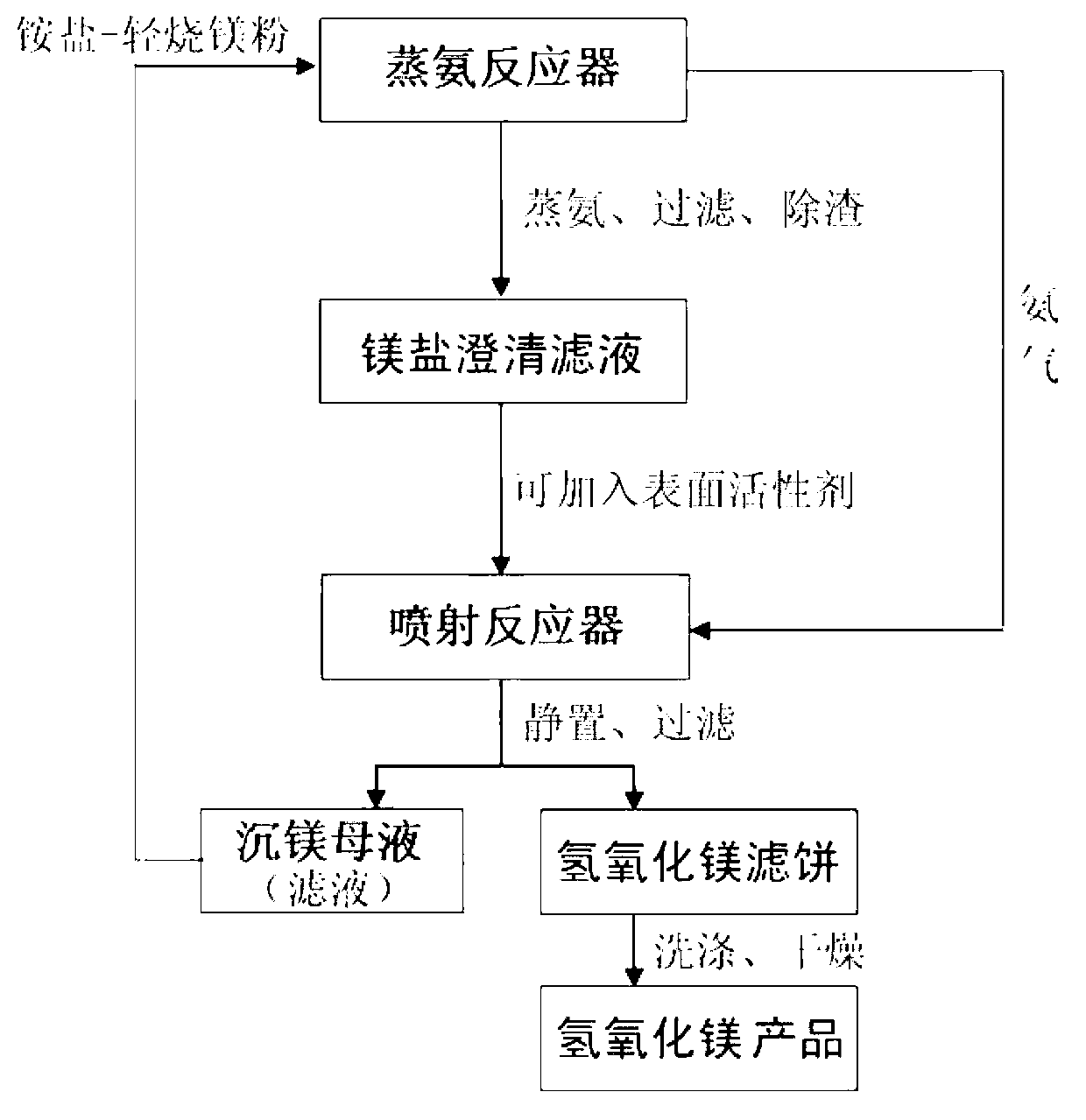

Method for preparing magnesium hydrate through ammonia spray method

A technology of magnesium hydroxide and injection method, applied in the direction of magnesium hydroxide, etc., can solve the problems of not getting rid of the three-step process of normal temperature synthesis, hydrothermal treatment surface modification, poor particle consistency of magnesium hydroxide products, high temperature and pressure, etc. Achieve the effect of saving raw material transportation costs, optimizing macro and micro mixing effects, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

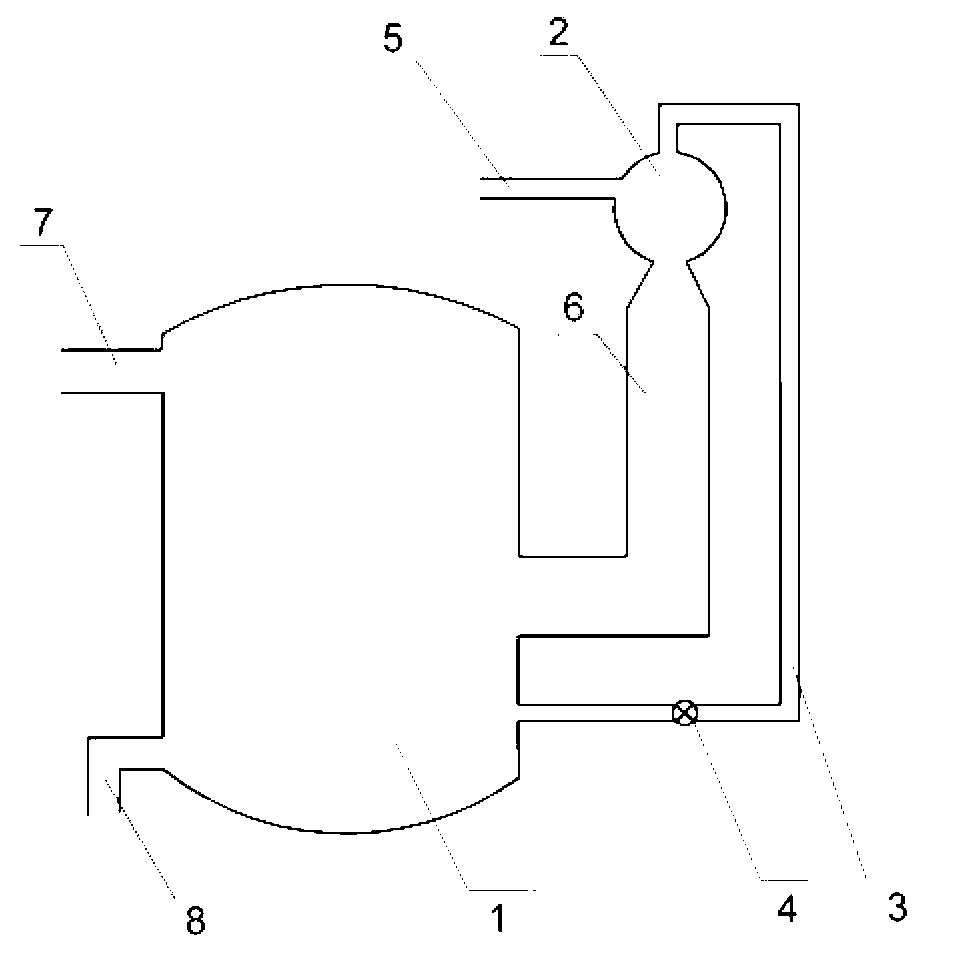

Method used

Image

Examples

Embodiment 1

[0041] Take 7kg of ammonium sulfate to prepare 30L of aqueous solution, adjust it to 19% (mass percentage concentration) ammonium sulfate aqueous solution, then slowly add light-burned magnesium powder (1 ton / hour), stop adding when the pH value of the solution is 9, and then Ammonia distillation reaction (in the ammonia distillation reactor), the ammonia distillation reaction temperature is 136°C. The reaction solution of the ammonia distillation reaction is filtered to remove Fe 3+ and Al 3+ After the precipitate formed, a clear filtrate of the magnesium salt (magnesium sulfate solution) was obtained.

[0042] The ammonia gas produced by the ammonia distillation reaction is sucked into the absorption tube of the jet reactor through the jet tube of the jet reactor (the flow rate of ammonia gas is 0.09m 3 / h), the magnesium sulfate solution obtained after the above filtration is added to the cylindrical container of the jet reactor, and the temperature in the jet reactor is ...

Embodiment 2

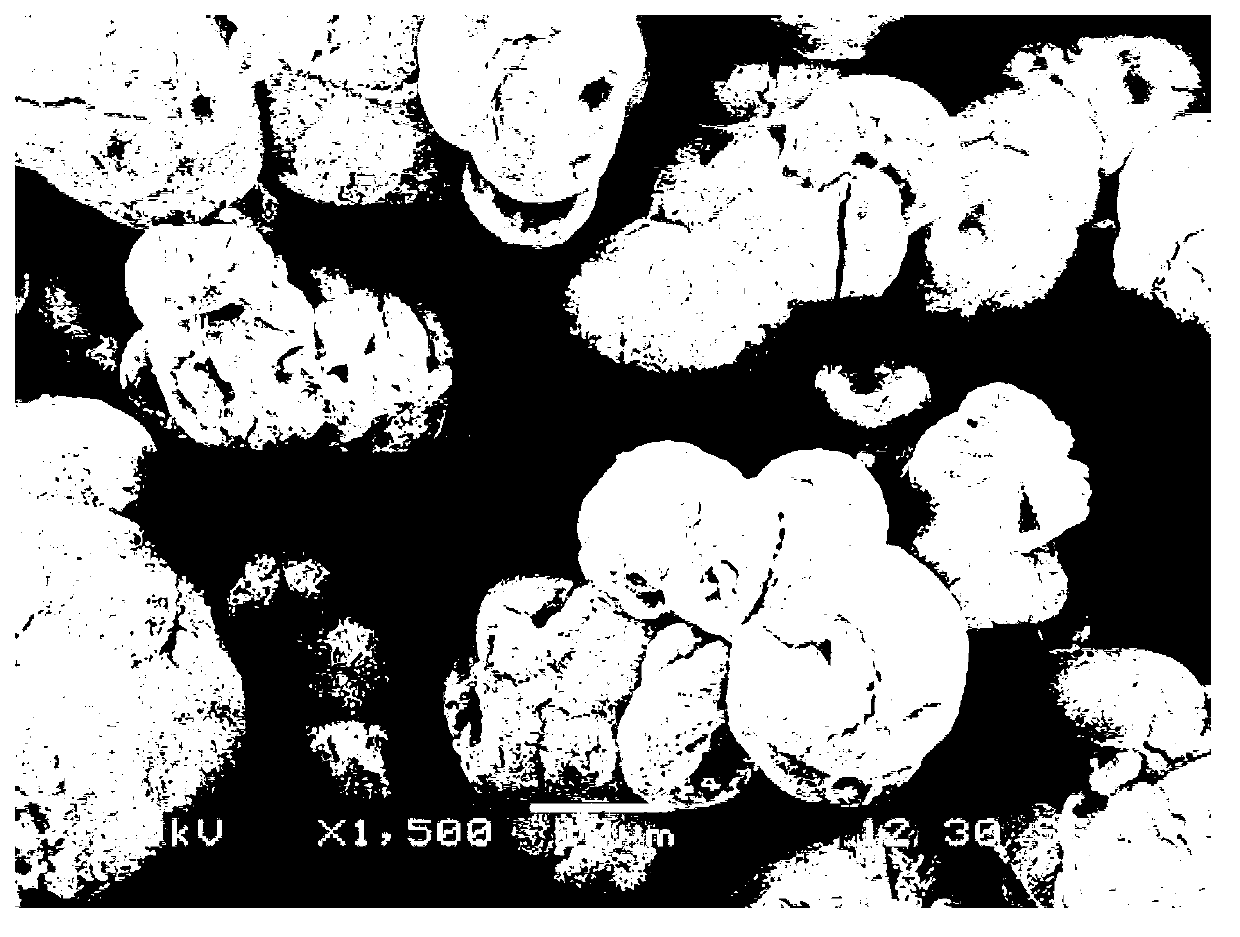

[0044] The difference from Example 1 is: when the ammonia produced by the ammonia distillation reaction is sucked into the injector absorption pipe, its ammonia flow rate is 2m 3 / h, when the magnesium sulfate solution obtained after ammonia distillation reaction, filtration and impurity removal is sprayed to the injector absorption pipe, its flow rate is 300m 3 / h. The magnesium hydroxide product obtained in this process has a purity of 98.8%, good dispersibility and uniform particle shape, and its appearance is hexagonal flakes. The particle size of the obtained magnesium hydroxide product is D 50 2μm, the particle size distribution range is small (concentrated distribution range 0.8-5μm), such as Figure 4 shown.

Embodiment 3

[0046] Ammonia distillation reaction and impurity removal process are the same as embodiment one. The ammonia gas produced by the ammonia distillation reaction is sucked into the absorption pipe of the ejector through the injection pipe of the jet reactor (the flow rate of ammonia gas is 2.5m 3 / h), adjust the magnesium sulfate solution obtained after the above filtration to a temperature of 25°C and add it to the cylindrical container of the jet reactor, and at the same time add a fatty salt surfactant (sodium dodecylbenzenesulfonate, add The amount is 0.5% of the mass of magnesium sulfate solution), the magnesium sulfate solution in the cylindrical container is sprayed into the absorption pipe of the injector through the injection pipe (the flow rate is 300m 3 / h), react with the ammonia gas sucked into the absorption tube of the injector, and stop the reaction when the pH value of the reaction solution is 13, and obtain a milky white suspension mixed with magnesium hydroxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com