Patents

Literature

143 results about "Ammonal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonal is an explosive made up of ammonium nitrate and aluminium powder, not to be confused with T-ammonal which contains trinitrotoluene as well to increase properties such as brisance. The ammonium nitrate functions as an oxidizer and the aluminium as fuel. The use of the relatively cheap ammonium nitrate and aluminium makes it a replacement for pure TNT.

Process for producing magnesium hydroxide and calcium carbonate by dolomite conversion method

InactiveCN102225775AReduce consumptionGood environmental benefitsCalcium/strontium/barium carbonatesMagnesium hydroxideEvaporationCarbonization

The invention provides a process for producing magnesium hydroxide and calcium carbonate by the dolomite conversion method. The process comprises the following steps: calcining dolomite, carrying out a digestion reaction on dolomite and water and refining so as to obtain a refined slurry of calcium hydrate and magnesium hydroxide; reacting the slurry with an ammonium chloride solution to enable calcium hydrate to react with ammonium chloride; carrying out ammonia evaporation so as to obtain a fluid suspension of a calcium chloride solution, ammonia gas and magnesium hydroxide; carrying out filtering and washing so as to obtain a magnesium hydroxide product; carrying out a carbonization reaction on the calcium chloride aqueous solution which has absorbed ammonia gas with kiln gas generated by the calcination of dolomite so as to obtain calcium carbonate; carrying out filtering and washing so as to obtain a calcium carbonate product. In the invention, washing water is used for the digestion of dolomite ashes so as to totally separate magnesium from calcium in dolomite and produce magnesium hydroxide and calcium carbonate products, thereby fully utilizing dolomite. The process provided in the invention enables cyclic utilization of the intermediate product ammonium chloride and no discharge of the three wastes, being in accordance with the developmental requirements for green chemicals in modern society.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

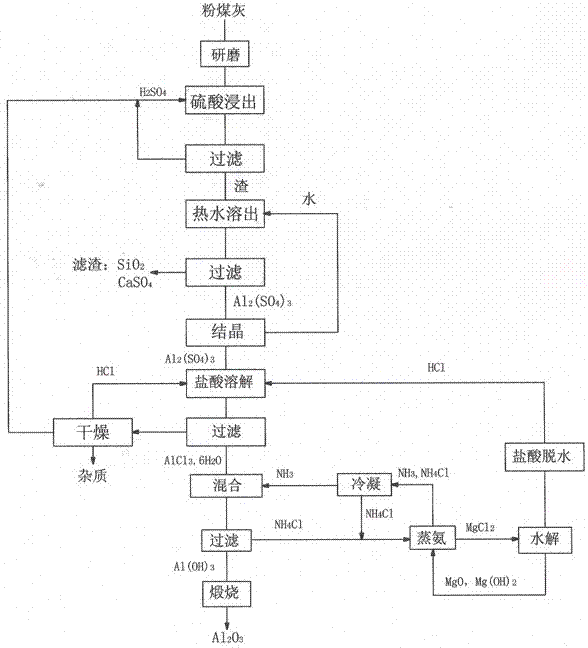

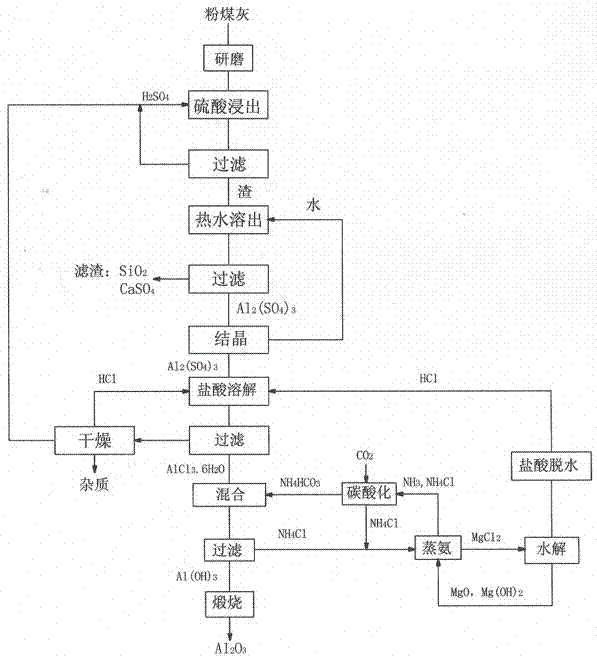

Method for preparing alumina by using power plant fly ash

InactiveCN102849767ASaturated precipitation with high purityThe process steps are simpleAluminium oxide/hydroxide preparationAluminium hydroxideAmmonium chloride mixture

The invention discloses a method for preparing alumina by using power plant fly ash, characterized by: grinding the fly ash, leaching with concentrated sulfuric acid to obtain an aluminum sulfate solution, precipitating aluminum sulfate crystals by concentrating and cooling, dissolving the aluminum sulfate crystals with hydrochloric acid, then letting an HCl gas in the solution to saturate the solution to precipitate AlCl3-6H2O crystals, reacting the AlCl3-6H2O crystals with an ammonium hydroxide solution or liquid ammonia or an ammonium bicarbonate solution or an ammonium carbonate solution to obtain an aluminium hydroxide and ammonium chloride solution, calcining aluminium hydroxide to obtain alumina, displacing ammonium chloride by using magnesium oxide to obtain ammonia gas and magnesium chloride, and hydrolyzing magnesium chloride to obtain magnesium oxide and hydrochloric acid for recycling.

Owner:李景江

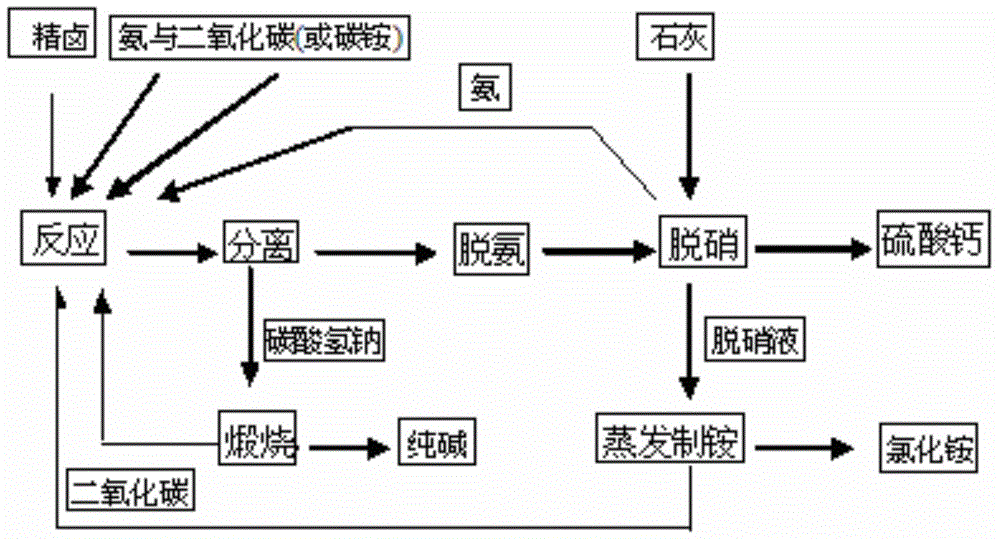

Technology for combined production of sodium carbonate and ammonium chloride through sodium sulfate type brine thermal cycle method

InactiveCN105000579AAdaptableThe main product is of high qualityAmmonium halidesCarbonate preparationSodium bicarbonateSodium sulfate

The invention discloses a technology for combined production of sodium carbonate and ammonium chloride through a sodium sulfate type brine thermal cycle method. The technology comprises the following steps: (1) carrying out a metathesis reaction on sodium sulfate type brine, ammonia and carbon dioxide as raw materials, separating to obtain sodium bicarbonate and an alkali production mother liquor containing ammonium chloride, sodium sulfate, sodium chloride, ammonium bicarbonate and ammonium carbonate, and calcining the obtained sodium bicarbonate to obtain a sodium carbonate product; (2) preheating the alkali production mother liquor to carry out high temperature removal of ammonium bicarbonate and ammonium carbonate in order to obtain a deaminized mother liquor containing ammonium chloride, sodium sulfate and sodium chloride; (3) adding lime with the amount equal to that of sodium sulfate to the deaminized mother liquor, and reacting to remove sodium sulfate in order to obtain calcium sulfate, ammonia and a denitrified mother liquor containing ammonium chloride and sodium chloride; and (4) evaporating the denitrified mother liquor, and separating to obtain ammonium chloride and an ammonium production mother liquor. The technology has the characteristics of high quality of main products, strong adaptability of the raw materials, low cost, low energy consumption, closed loop, and no discharge of three wastes.

Owner:CHINA LIGHT IND INT ENG CO LTD

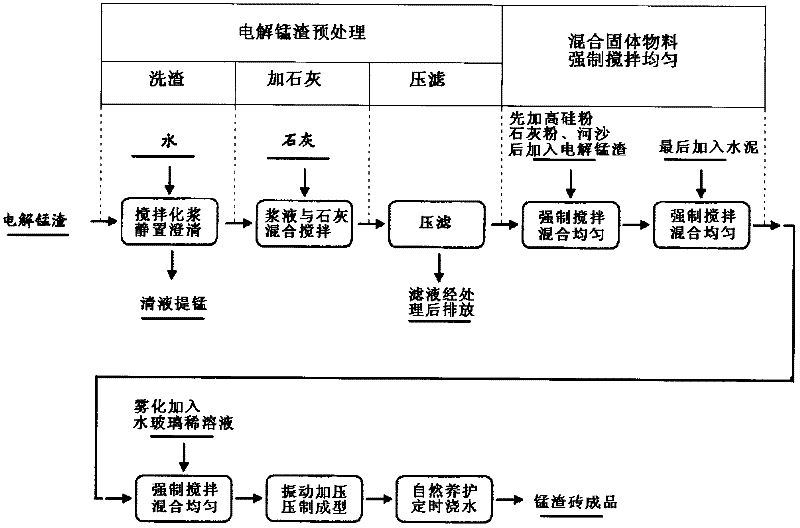

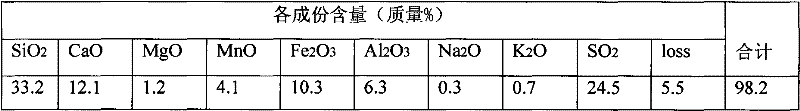

New formula and process method for preparing electrolytic manganese slag brick

The invention provides a new formula and a process method for preparing an electrolytic manganese slag brick, and belongs to the fields of the comprehensive utilization of industrial solid wastes and building materials. At present, the patent technology of preparing the building materials by using manganese slag has the common defect that before alkaline materials such as cement and the like are added, a large quantity of ammonium salts such as ammonium sulfate in the electrolytic manganese slag are not extracted, and the ammonium salts react with the alkaline materials to release a large amount of ammonia during operation, so environmental pollution and the loss of ammonia nitrogen are caused; and before being used, the electrolytic manganese slag is not modified, so the gelatinization activity of the electrolytic manganese slag cannot be well exerted. In order to solve the problem, programs for washing the slag and processing lime slurry and the operations of atomizing and adding a water glass dilute solution are added specially in the process, wherein by the program for washing the slag, the problem of the pollution of the electrolytic manganese slag is solved; and water glass is used as an active initiator for the electrolytic manganese slag serving as gelled materials and a reinforcer for reinforcing the strength of silicate concrete, so that the strength of the electrolytic manganese slag brick serving as a finished product can be reinforced greatly.

Owner:卿富安

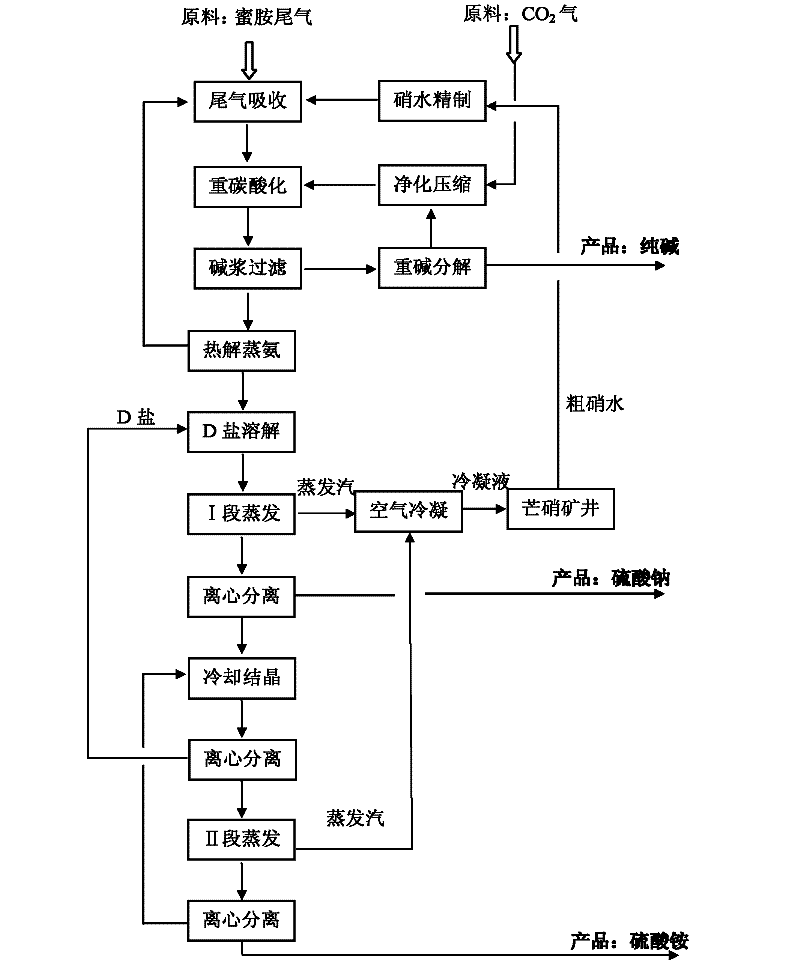

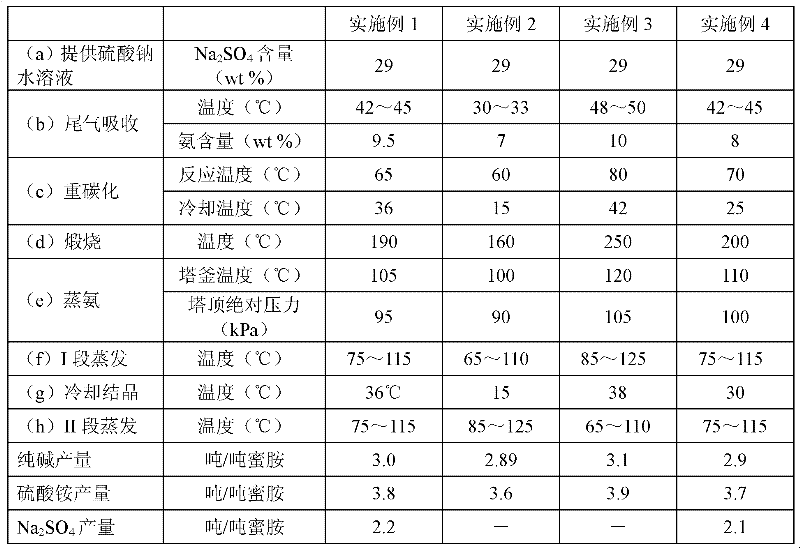

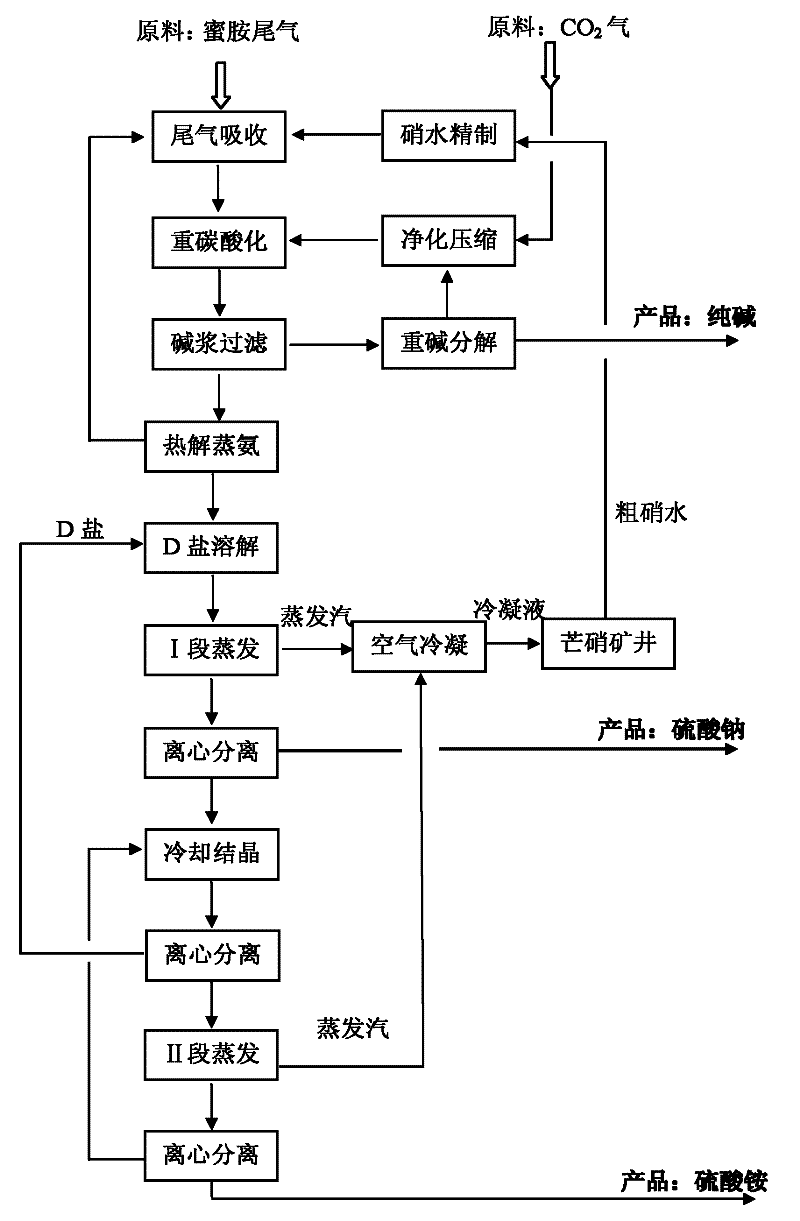

Methods for coproducing sodium carbonate and ammonium sulfate from melamine tail gas and mirabilite

InactiveCN102198953AIncrease profitReduce consumptionAmmonium sulfatesCarbonate preparationSodium bicarbonateSlurry

The invention relates to methods for coproducing sodium carbonate and ammonium sulfate from melamine tail gas and mirabilite. The method for producing the sodium carbonate comprises the following steps of: a, providing a sodium sulfate water solution; b, introducing melamine tail gas into the sodium sulfate water solution to form an ammonium carbonate-sodium sulfate water solution; c, introducing carbon dioxide into the ammonium carbonate-sodium sulfate water solution to obtain a suspension serous fluid of sodium bicarbonate crystals; and d, carrying out solid and liquid separation on the suspension serous fluid to obtain sodium bicarbonate and a mother solution I, calcining sodium bicarbonate solid to obtain the sodium carbonate. The method further comprises the following steps of: e, adding the mother solution I into an ammonia stilling tower, heating, forming tower top mixed gas containing ammonia and carbon dioxide, generating a deamination solution in the tower; f, evaporating the deamination solution for dewatering to obtain sodium sulfate crystals and a mother solution II; g, cooling the mother solution II for crystallizing to obtain Na2SO4.(NH4)2SO4.4H2O salt crystals and a mother solution III; and h, evaporating the mother solution III for dewatering, and separating out ammonium sulfate crystals. The methods have the advantages of high utilization rate of raw materials and low energy consumption.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD +1

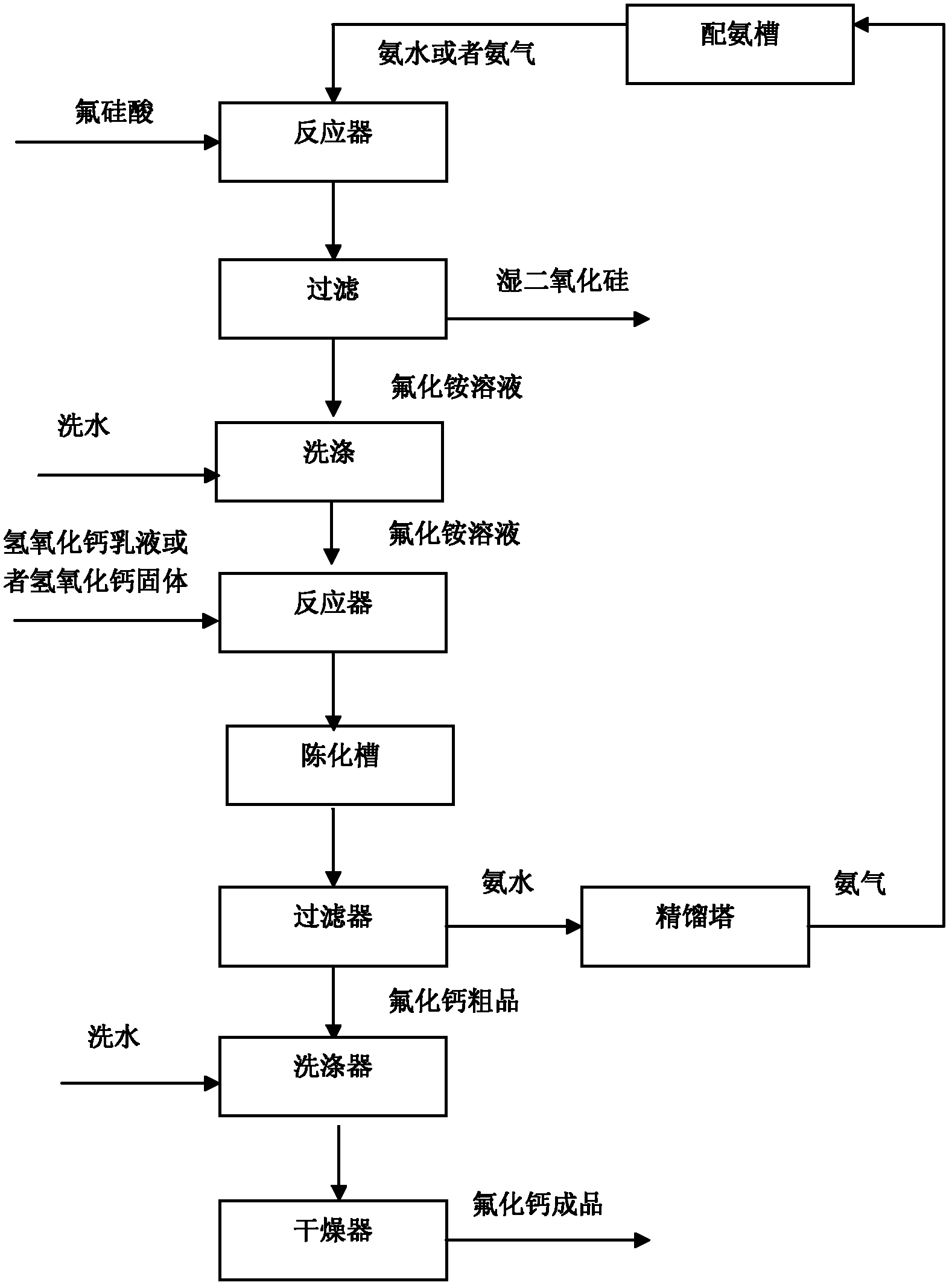

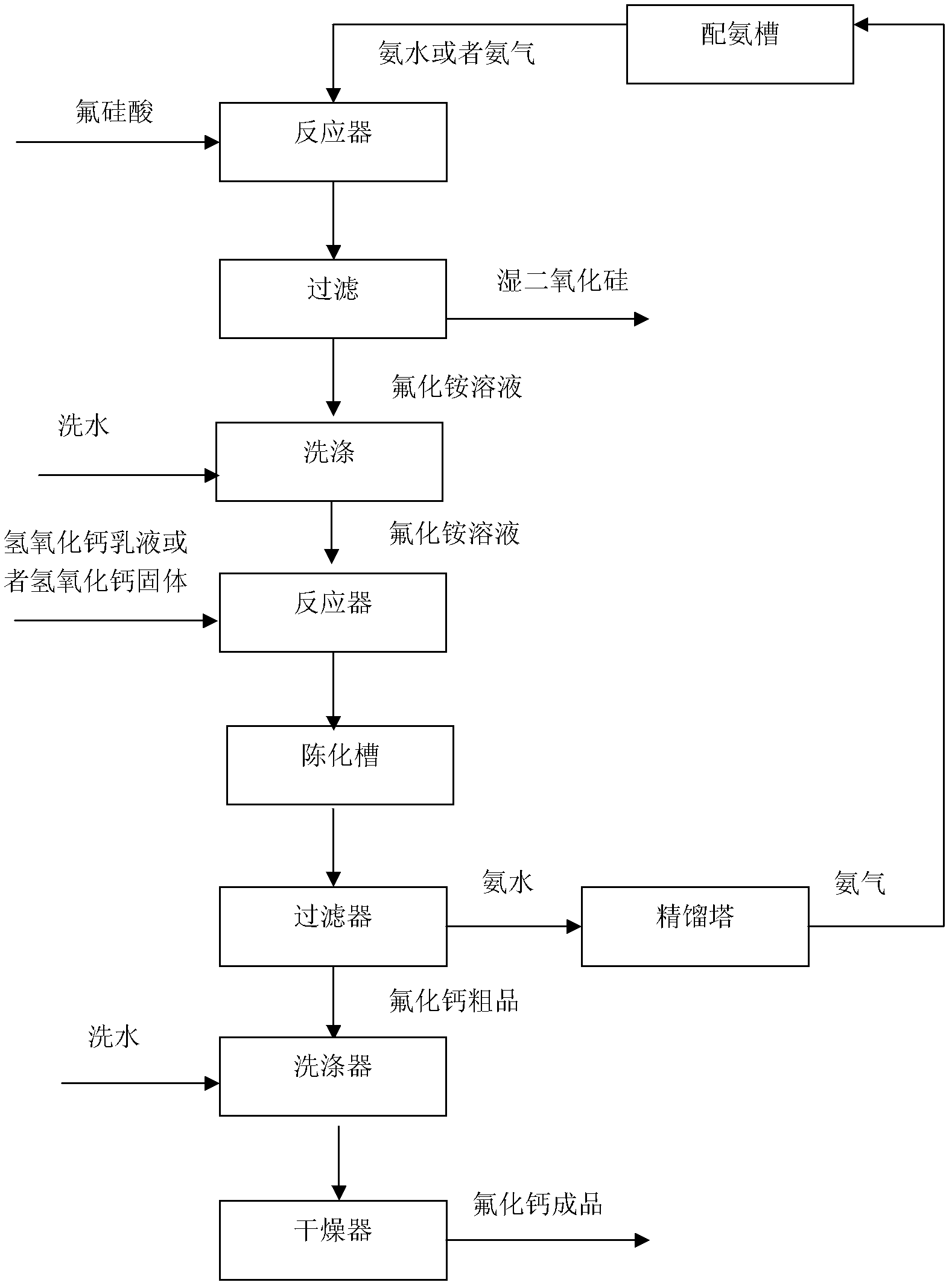

Synthetic method of calcium fluoride

ActiveCN102502753AImprove solubilityAchieve separationCalcium/strontium/barium fluoridesSolubilityTwo step

The invention relates to a synthetic method of calcium fluoride, hydrofluosilicic acid produced during a phosphate fertilizer production process is adopted as raw materials so as to synthesize calcium fluoride through two steps of reaction, the first step of reaction is that ammonium fluoride and silicon dioxide are produced through the reaction of fluosilicic acid and ammonia gas or ammonia water, the solubility of ammonium fluoride is high, and the separation of ammonium fluoride from silicon dioxide is achieved through the method of filtering and washing; the second step of reaction is that calcium fluoride and ammonia water are produced through the reaction of ammonium fluoride solution and calcium hydroxide, the separation of calcium fluoride from ammonia water is achieved through the filtering way, ammonia gas is obtained by rectifying the ammonia water, and calcium fluoride is produced by taking ammonium fluoride as an intermediate product. Therefore, the invention overcomes defects of insufficient reaction during the process of synthesizing calcium fluoride through the reaction of hydrofluosilicic acid and calcium hydroxide, and mass of calcium fluosilicate contained in calcium fluoride products, further solves the problem of difficulty separation of calcium fluoride from silicon dioxide mixture, and achieves efficient utilization of by-product hydrofluosilicic acid ofphosphate fertilizer.

Owner:KUNMING DAOERSEN TECH

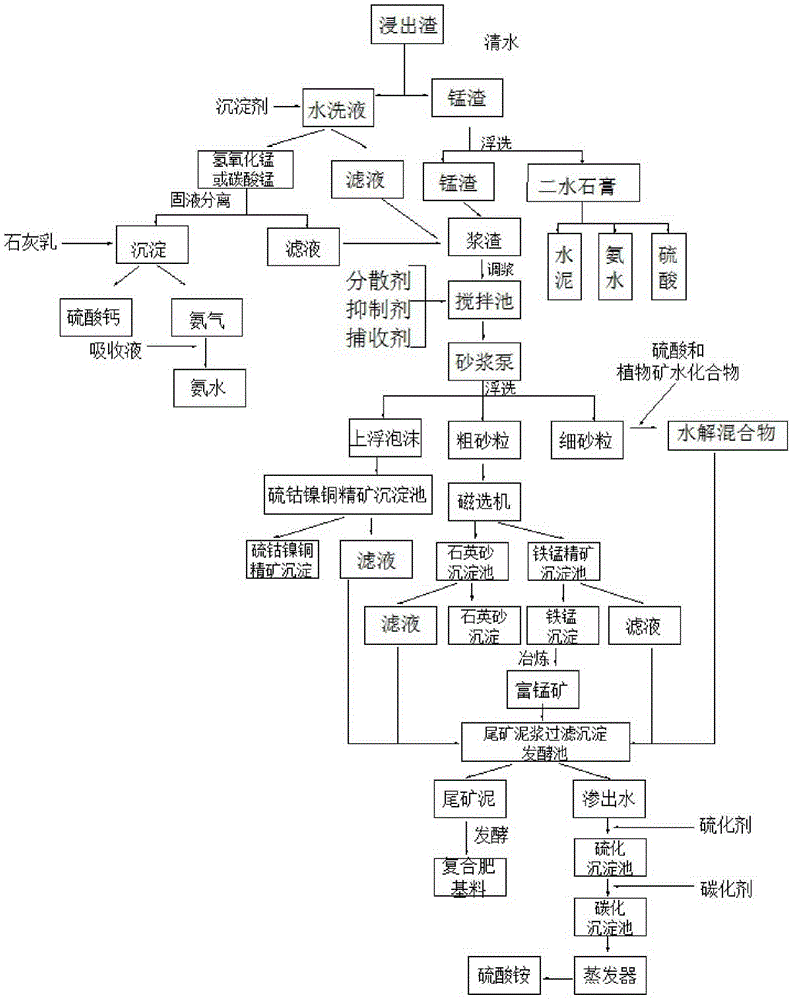

Technology for comprehensively recycling leaching residue in production of electrolytic manganese metal and manganese dioxide

ActiveCN103555959AAchieve comprehensive recyclingComprehensive recycling NoneClimate change adaptationCalcium/strontium/barium sulfatesElectrolysisManganese

The invention discloses a technology for comprehensively recycling a leaching residue in production of electrolytic manganese metal and manganese dioxide. The concrete technology comprises the following parts: recovery of manganese, ammonium sulfate, calcium sulfate and an ammonia gas, recovery of manganese-enriched ore, dihydrate gypsum, ferrum and sulfur cobalt nickel copper concentrate; crystal separation of ammonium sulfate, and preparation of composite fertilizer stock. By adopting the technology, a novel document technique is opened up for comprehensive recycling of the leaching residue produced in the process of producing electrolytic manganese metal and electrolytic manganese dioxide; not only can the ammonium sulfate, the ammonia gas, the ferromanganese ore concentrate, the sulfur cobalt nickel copper concentrate, the dihydrate gypsum, the quartz sand and the calcium sulfate be comprehensively recovered, but also associated products of the ammonia gas, the sulfuric acid, the manganese-enriched ore and the compound fertilizer stock can be prepared. Thus, comprehensive recycling of all components and zero emission are achieved.

Owner:GUANGXI GUILIU CHEM CO LTD

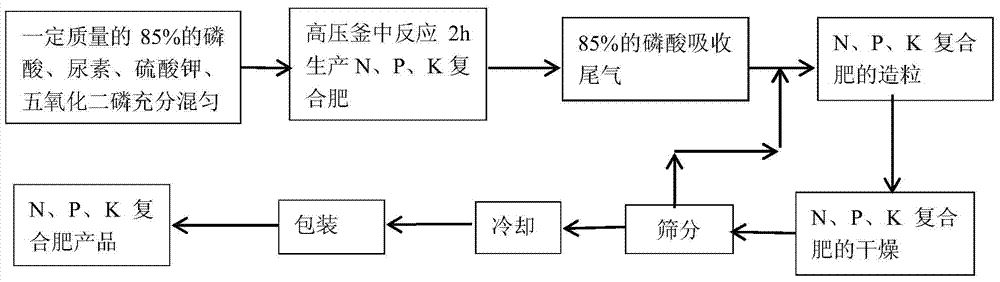

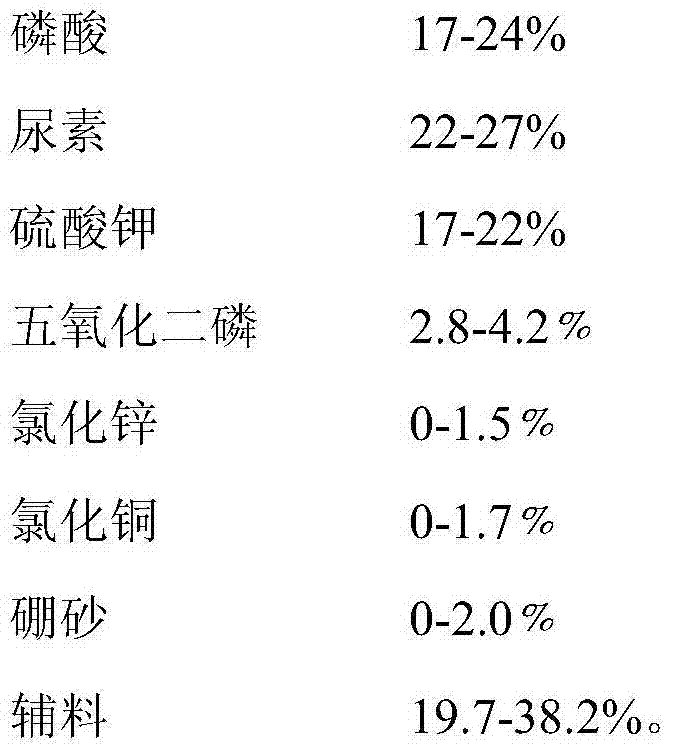

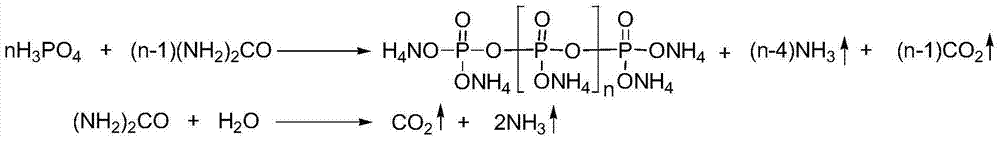

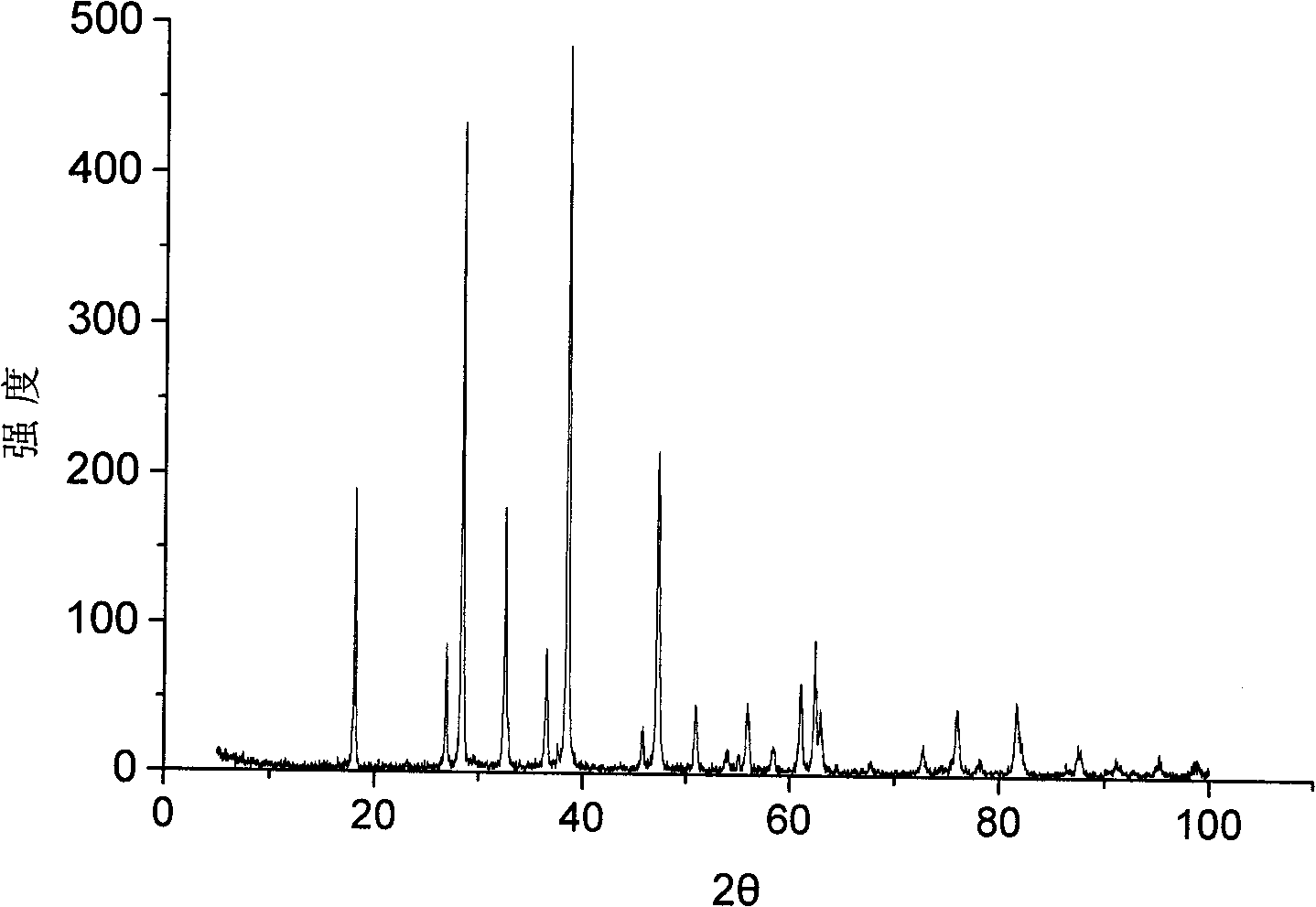

Ammonium polyphosphate water soluble fertilizer and preparation method thereof

ActiveCN103787726AGood water solubilityLow impurity contentPhosphatesFertilizer mixturesSolubilityPhosphoric acid

The invention belongs to the field of fertilizers and particularly relates to an ammonium polyphosphate water soluble fertilizer and a preparation method thereof. The preparation method comprises the following steps: adding phosphoric acid, urea, potassium sulphate, zinc chloride, copper chloride, borax and auxiliaries into a reaction kettle, mixing and dissolving in the kettle, then adding phosphorus pentoxide and uniformly stirring; heating the reaction kettle to 180-185 DEG C while stirring, reacting for 30-45 minutes, and then heating to 200-205 DEG C to react for 1.5-2 hours; and after the reaction is finished, reducing the temperature in the reaction kettle to room temperature, and simultaneously absorbing ammonia gas generated by reaction by using a diluted phosphoric acid solution to obtain the ammonium polyphosphate water soluble fertilizer. The ammonium polyphosphate-potassium sulfate water soluble fertilizer prepared by the preparation method has the characteristics of good water solubility, low impurity content and high effective contents of nitrogen, phosphorus and potassium. The preparation method disclosed by the invention has the advantages of simplicity, practicality, low production cost and the like.

Owner:广西泰宝生物科技有限公司

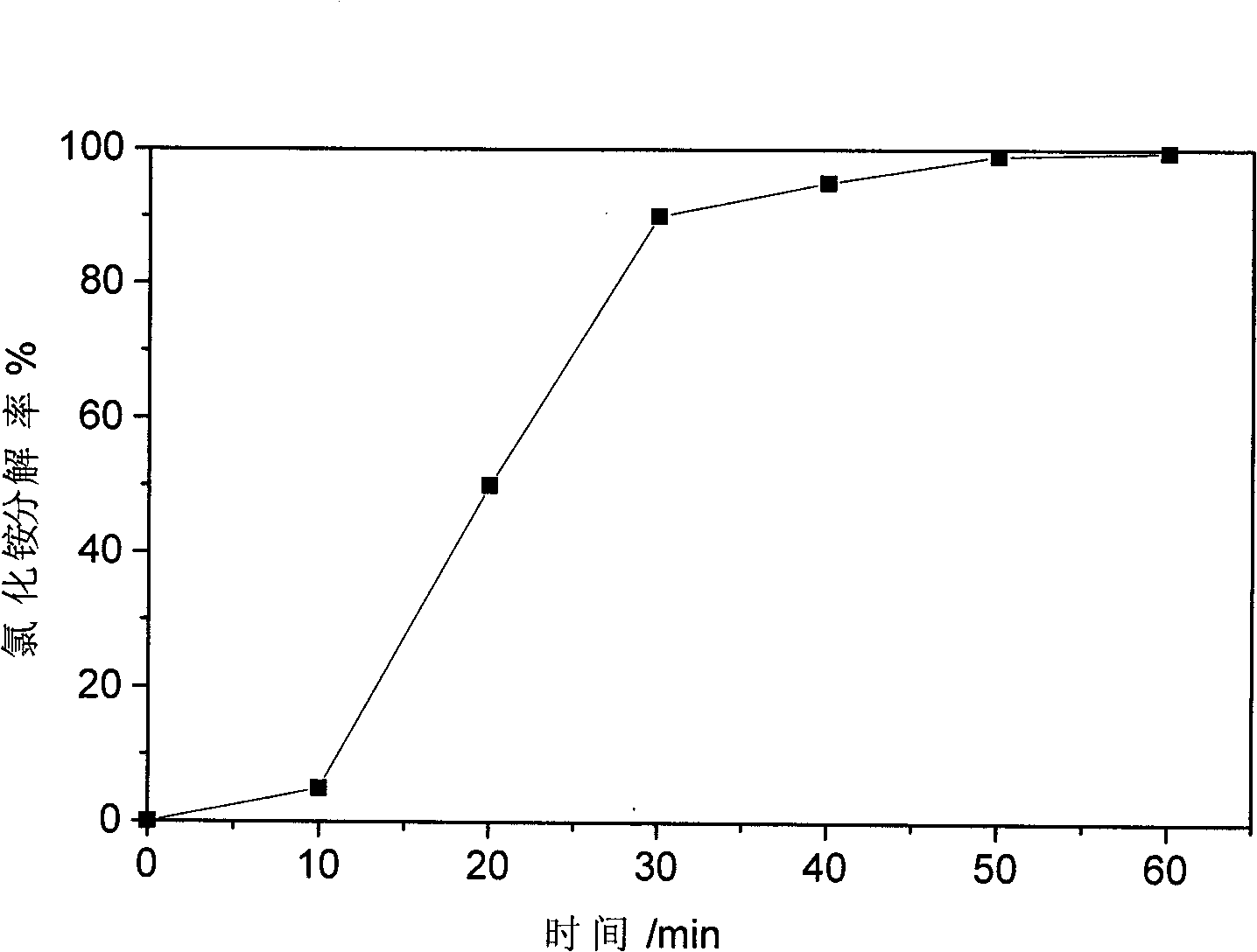

Method for combined production of ammonia and basic calcium chloride by decomposing ammonium chloride

InactiveCN101941719AReduce energy consumptionLess investmentCalcium/strontium/barium chloridesAmmonia preparation/separationChemical reactionSolvay process

The invention provides a method for the combined production of ammonia and basic calcium chloride by decomposing ammonium chloride, which comprises the following steps: grinding or crushing calcareous materials and ammonium chloride according to a mol ratio of 1:0.5-2 in a ball grinder or a crusher at -20-200 DEG C, enabling the calcareous materials and the ammonium chloride to be subject to a chemical reaction to decompose the ammonium chloride so as to release ammonia gas and generate basic calcium chloride. The invention fully uses the large amount of ammonium chloride as the byproducts of the combined soda process and the ammonia soda process, realizes the recycling of ammonia and generates the basic calcium chloride as the byproduct. The invention has the characteristics of simple process, low investment, high conversion rate, no pollution and low energy consumption, is applicable to industrial production and meets the requirements green chemical development in the present society.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Ammonium metavanadate preparation method

ActiveCN103420416AReduce dosageReduce the burden onVanadium compoundsAmmonium metavanadateSodium salt

The present invention discloses an ammonium metavanadate preparation method, which comprises that: a sodium vanadate solution contacts an ammonium salt under an acid condition, and the contacting product is subjected to precipitation and separation to obtain an ammonium polyvanadate solid; and the ammonium polyvanadate solid contacts water and an ammonium vanadate structure reforming agent to convert the ammonium polyvanadate into ammonium metavanadate, and the contacting product is subjected to solid-liquid separation to obtain an ammonium metavanadate solution, wherein the ammonium vanadate structure reforming agent is one or a plurality materials selected from ammonium carbonate, ammonium bicarbonate and ammonia water. According to the ammonium metavanadate preparation method, ammonium ions of the original ammonium polyvanadate can be completely utilized so as to reduce ammonium salt consumption; alkality of the ammonium vanadate structure reforming agent is completely adopted to achieve ammonium polyvanadate dissolving, such that the sodium salt (sodium hydroxide, sodium carbonate, and the like) is not required to be adopted to dissolve the ammonium polyvanadate so as to simplify steps and reduce cost; and no converted ammonia gas escapes so as to reduce burden on the environment .

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Method for preparing ammonia water and calcium chloride solution through decomposition recovery of ammonium chloride waste liquor

InactiveCN104876383ASimple processEmission reductionCalcium/strontium/barium chloridesWater contaminantsHigh concentrationLiquid waste

The invention discloses a method for preparing ammonia water and calcium chloride solution through the decomposition recovery of ammonium chloride waste liquor. The method comprises the following steps: the waste liquor is pretreated, and ammonium chloride and calcium oxide or calcium hydroxide powder is added into the pretreated ammonium chloride waste liquor; ammonia is distilled from the treated ammonium chloride waste liquor and is transferred into an ammonia absorption tower after being condensed, and a reaction liquid flows out from the bottom of a distillation tower; ammonia is absorbed from the condensed ammonia in the absorption tower by using desalted water, and the tail gas is exhausted after residual ammonia is washed by a tail gas washing tower; reaction liquid out of the bottom of the distillation tower is subjected to flash vaporization for recycling the energy and then is transferred into a clarifying barrel, and the clarified calcium chloride supernatant is used as the target product. According to the invention, the method is particularly suitable for the transformation of ammonium chloride wastewater treatment technology of enterprises in the existing rare earth industry, potassium carbonate industry and baking soda industry, and is simple in process; the ammonia is recycled by using desalted water through multi-stage absorption, and the recovery rate is up to 99%; the high-concentration calcium chloride solution can be used for producing calcium chloride products and the products can be recycled so as to have better economic benefits.

Owner:江苏大江干燥设备有限公司

Method for extracting vanadium by leaching vanadium-contained raw material roasting clinkers through ammonium phosphate

ActiveCN105714102AReduce leachingEasy to manufactureProcess efficiency improvementSelective leachingWastewater

The invention provides a method for extracting vanadium by leaching vanadium-contained raw material roasting clinkers through ammonium phosphate. The method includes the steps that a mixture of a vanadium-contained raw material and an additive is roasted, and the vanadium-contained raw material clinkers are obtained; and the vanadium-contained raw material clinkers are leached in an ammonium phosphate solution to extract vanadium, and vanadium extracting tailings and a vanadium-contained leaching agent are obtained after solid-liquid separation is carried out. According to the method, the vanadium selective leaching efficiency is high and can reach more than 90%; meanwhile, leaching of impurity element is less, preparation of products with the high-purity vanadium is facilitated, and brine waste is avoided; the leaching agent-ammonium phosphate solution used in the method does not volatilize, and the problem of ammonia gas volatilization is avoided; and in addition, the leaching technological process of the method is simple, the operation environment is friendly, and the production cost is low.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

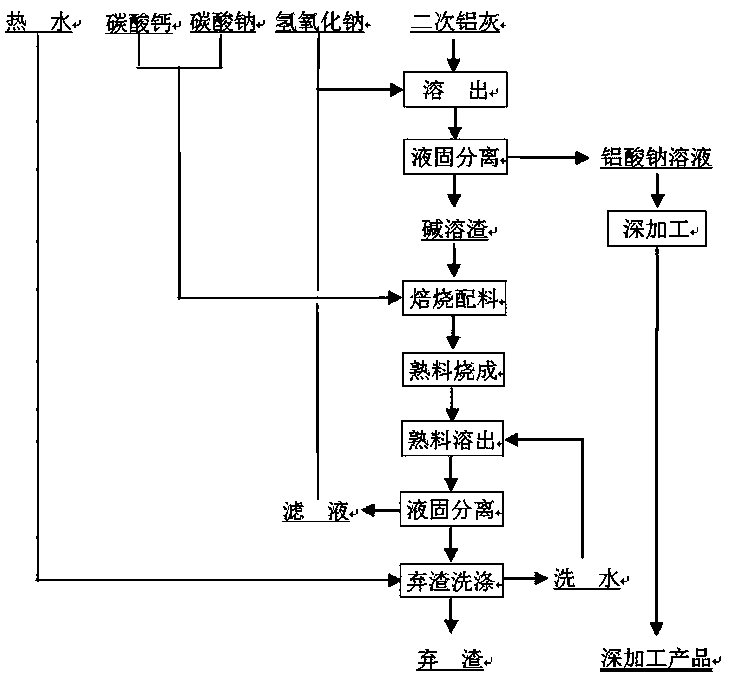

Comprehensive treatment technology of waste aluminum ash

The invention relates to a comprehensive treatment technology of waste aluminum ash, and concretely relates to processes for producing aluminum hydroxide from the waste aluminum ash, producing refractory materials through utilizing waste residues, and producing ammonium chloride through utilizing wastewater and an exhaust gas. The technology is characterized in that a sodium aluminate solution and a plaster are generated through dissolving out the aluminum ash by a cycle alkaline solution having a high concentration Na2Ok 220g / l at a temperature of above 260DEG C under a pressure of above 60kg / cm<3>; the aluminum ash is washed with water to remove most chlorides before the dissolving-out of the aluminum ash by the cycle alkali solution, and the obtained washing solution is used for absorbing ammonia generated in the dissolving-out process; and the plaster generated by the aluminum ash is used for producing refractory bricks or castable materials. A large amount of ammonia is contained in the waste aluminum ash, and ammonium chloride is prepared through recovering the ammonia with a salt washing solution in a cycle mode, so the ammonia pollution is eliminated, and products are prepared from the ammonia. The sodium aluminate solution undergoes crystal seed decomposition to generate an aluminum hydroxide fire retardant and a decomposition mother solution, and the aluminum ash is dissolved after the decomposition mother solution evaporates.

Owner:于斌

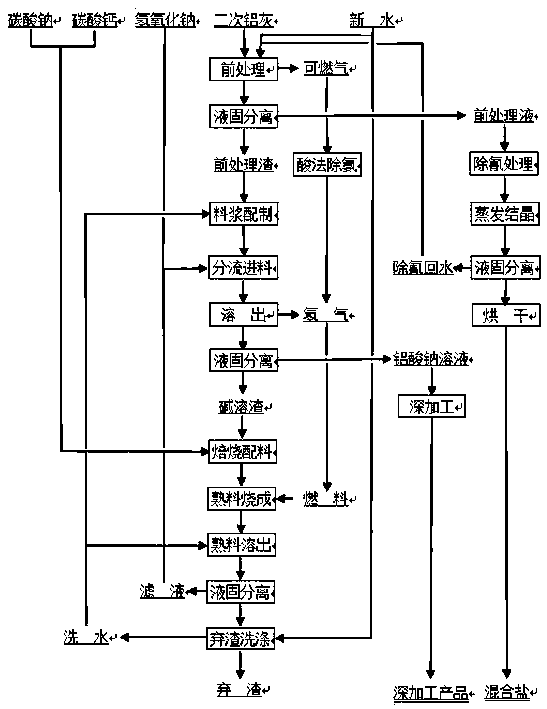

Harmless treatment and utilization method for aluminum ash

InactiveCN107697884ASlightly affectedTake advantage ofSolid waste disposalAluminium oxide/hydroxide preparationSolid phasesChemistry

The invention discloses a harmless treatment and utilization method for aluminum ash. On the basis of a conventional process, the method comprises the following steps: additionally pretreating an aluminum ash raw material, namely performing primary disliquid washing treatment on the aluminum ash with a diluted alkali liquid or water, performing gas-water separation on a gas with ammonia gases, hydrogen and acetylene in the disliquid washing process, collecting the gas, recycling the ammonia gases with a diluted acid liquid for preparing an ammonium salt, and utilizing a combustible gas after ammonia removal as fuel of later procedures; dissolving cyanide, dissoluble fluoride and chloride in the aluminum ash into a liquid phase in disliquid washing to form an alkali pretreatment liquid, thereby separating the dissoluble substances from insoluble solid phases in the aluminum ash. Due to addition of a specific procedure of harmless treatment on environment danger sources, main danger sources, namely cyanide and dissoluble fluoride in the aluminum ash are separated from the aluminum ash, convenience is brought to later harmless treatment, meanwhile the chloride in the aluminum ash is dissolved, and the situation that later disliquid process is affected by the chloride is avoided; and therefore, the purpose that potential danger is eliminated while the aluminum ash is recycled is achieved.

Owner:上海添瑞环保科技有限公司

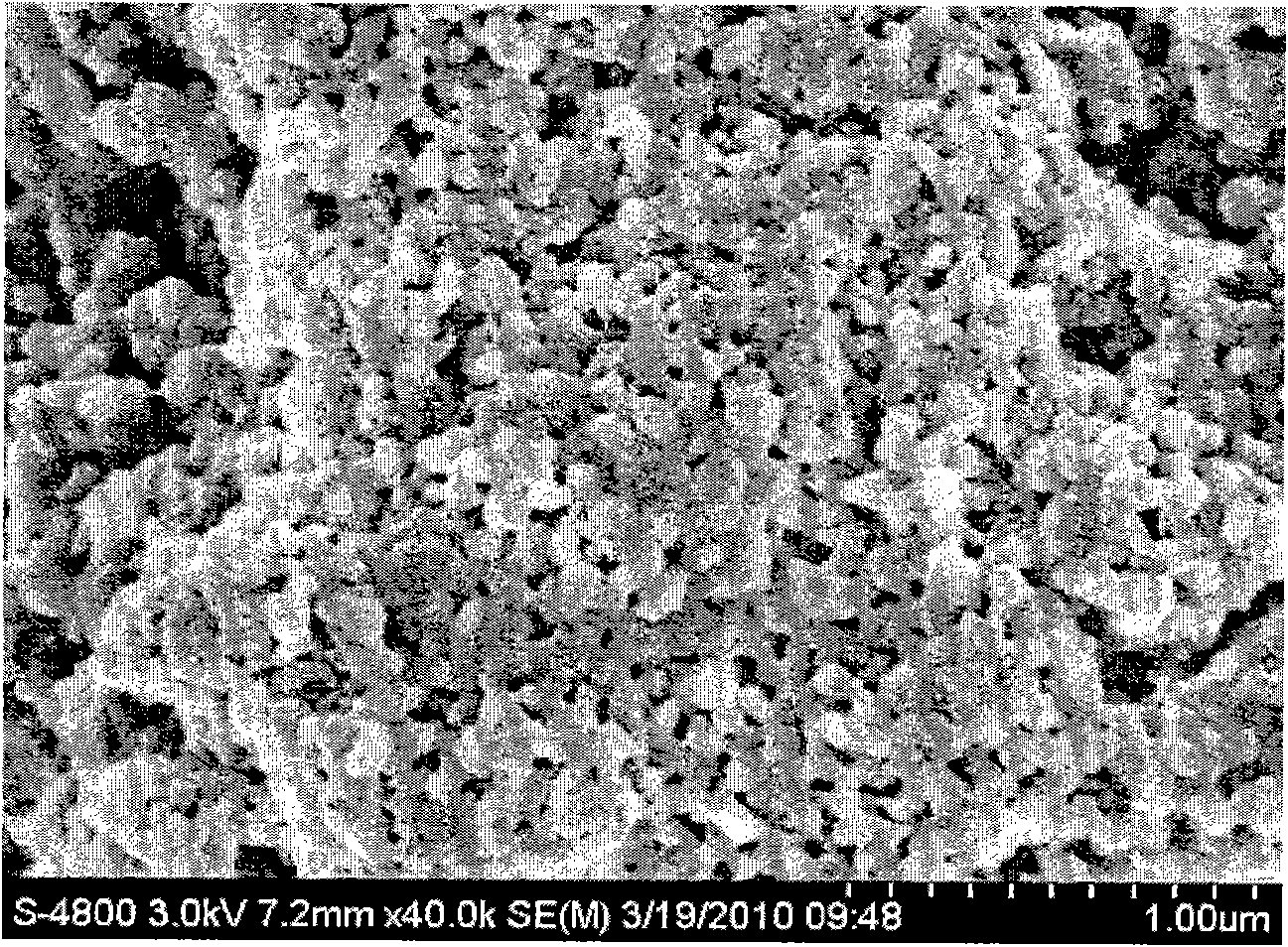

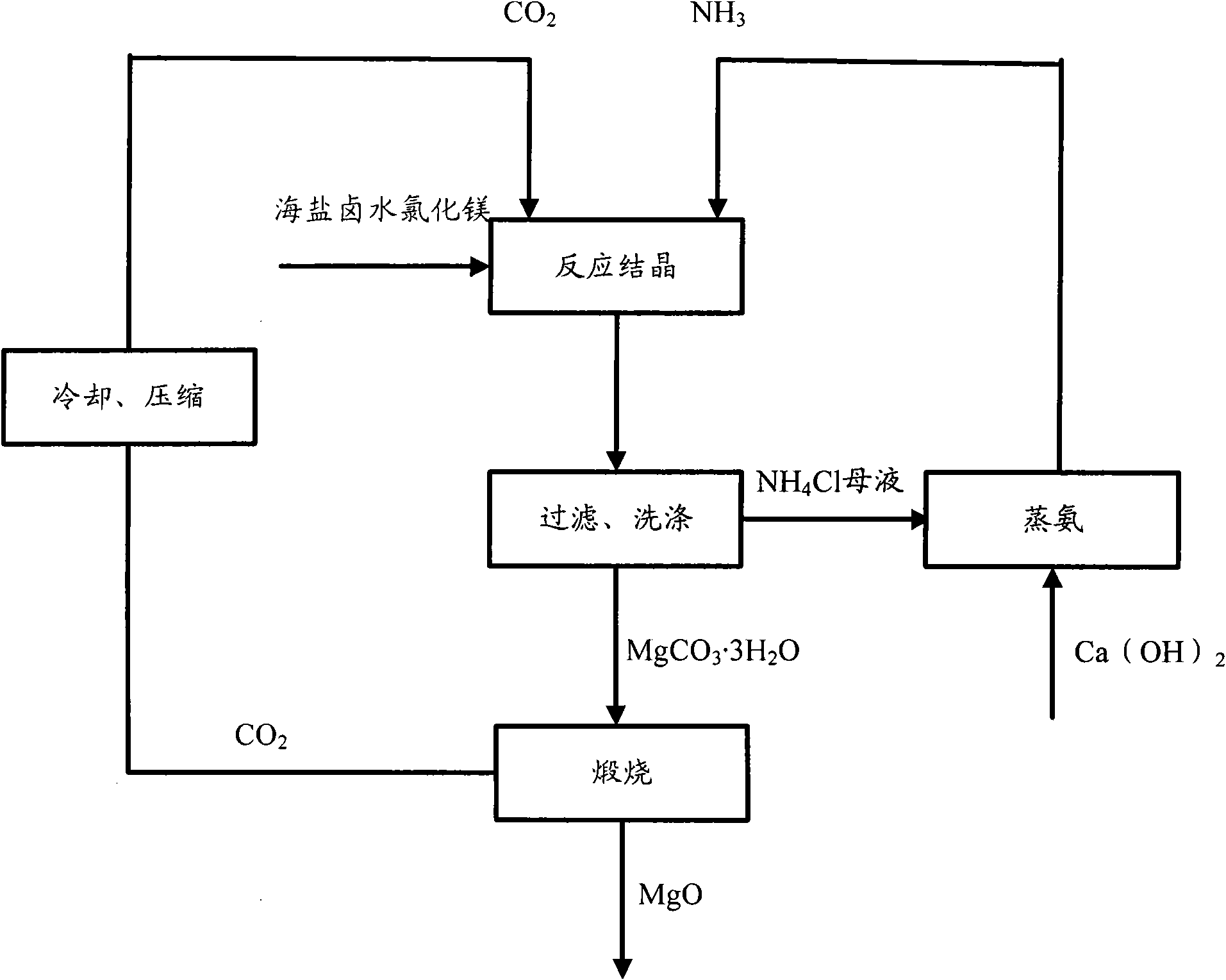

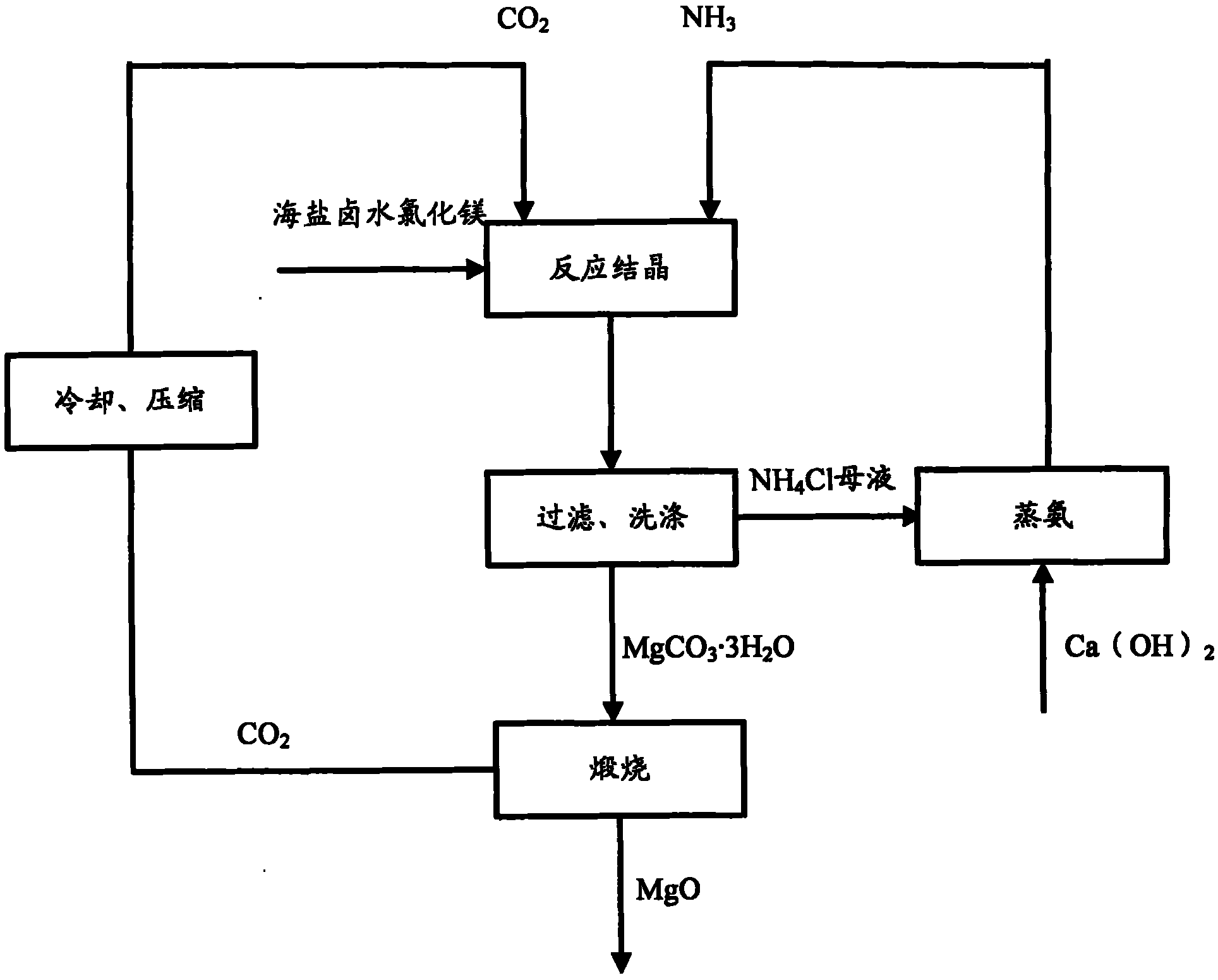

Method for preparing high-purity magnesium oxide from nesquehonite by carbon-ammonia recycle method

InactiveCN101993098ANo pollution in the processSimple processing methodMagnesiaInorganic saltsOperability

The invention discloses a method for preparing high-purity magnesium oxide from nesquehonite by a carbon-ammonia recycle method, belonging to the field of chemical production of inorganic salts. The method comprises the following steps of: with brine magnesium chloride as a raw material, preparing a nesquehonite intermediate which has good crystalline form and is easy to filter by using the carbon-ammonia recycle method; further calcining to produce high-purity magnesium oxide and simultaneously realize the recycle of carbon dioxide and ammonia, wherein the carbon dioxide is generated in the process of calcining the nesquehonite, and the ammonia is obtained by evaporating the ammonium chloride mother liquid and used for depositing magnesium. The method has the advantages of fully solving the problem of greenhouse effect and environmental pollution caused by ammonium chloride emission in the process of producing magnesium oxide and realizing high-value utilization of sea salt magnesium chloride resources. The method disclosed in the invention has high operability and is easy for industrialized production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

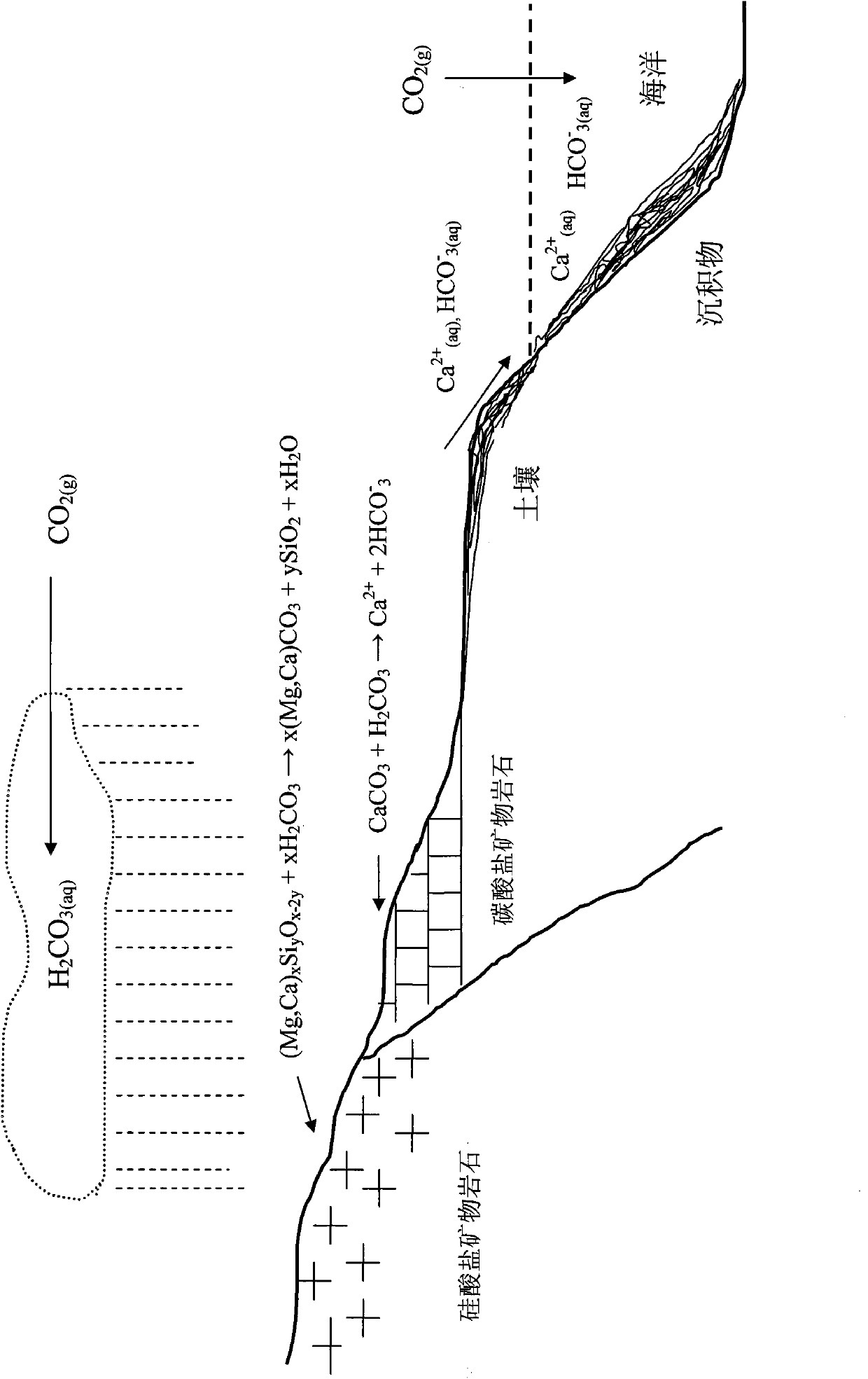

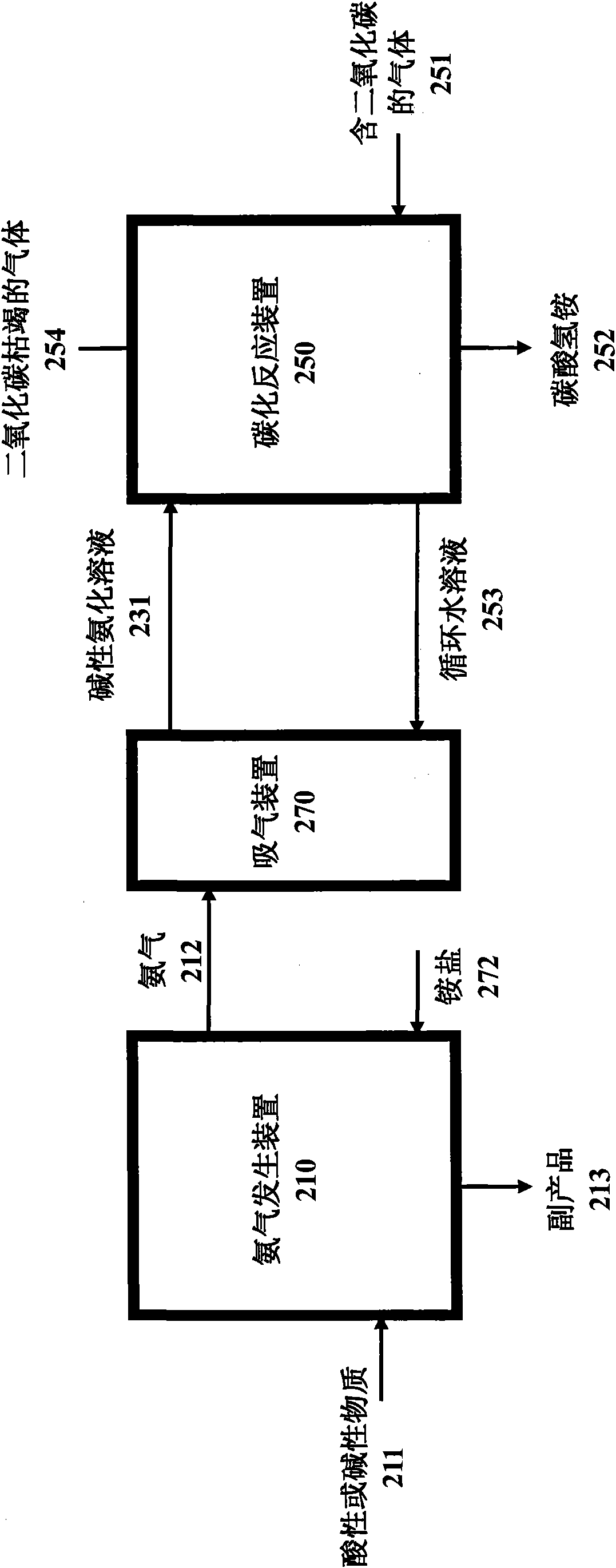

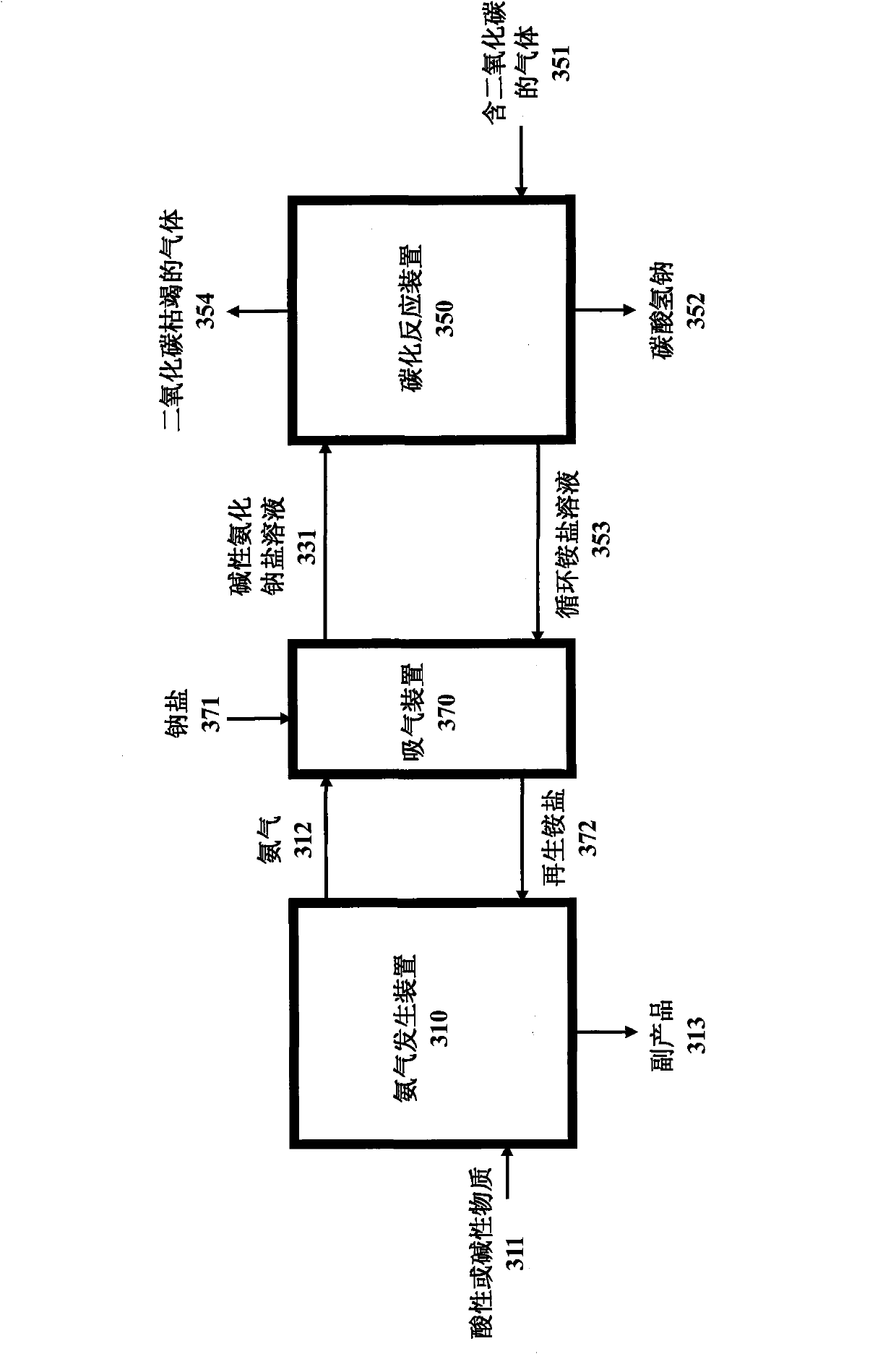

Method for sequestering carbon dioxide

InactiveCN101992015AEase acidificationPromote absorptionCalcium/strontium/barium carbonatesProductsSodium bicarbonateSlag

The present invention discloses a method for sequestering carbon dioxide (CO2) that includes generating ammonia from an ammonium salt to make a basic ammoniated aqueous solution and using the solution to remove at least a portion of CO2 from a CO2-bearing gas and precipitate the removed CO2 as bicarbonate. The aqueous solution is recycled. Various valuable byproducts, including sodium bicarbonate, sodium carbonate, ammonium bicarbonate, and hydrochloric acid, are produced. Ammonia is generated by reacting an ammonium salt with either acidic or basic materials. Non-limiting examples of suitable ammonium salt include ammonium chloride, ammonium sulfate, ammonium bisulfate, and ammonia nitrate, those of the acidic material include ammonium bisulfate and sulfuric acid, and those of the basic material include calcium oxide, limestone, dolomite, cement kiln dust, calcium-rich fly ash, steel and iron slag, and silicate rocks or mining wastes that are rich in serpentine, olivine or wollastonite.

Owner:钟少军

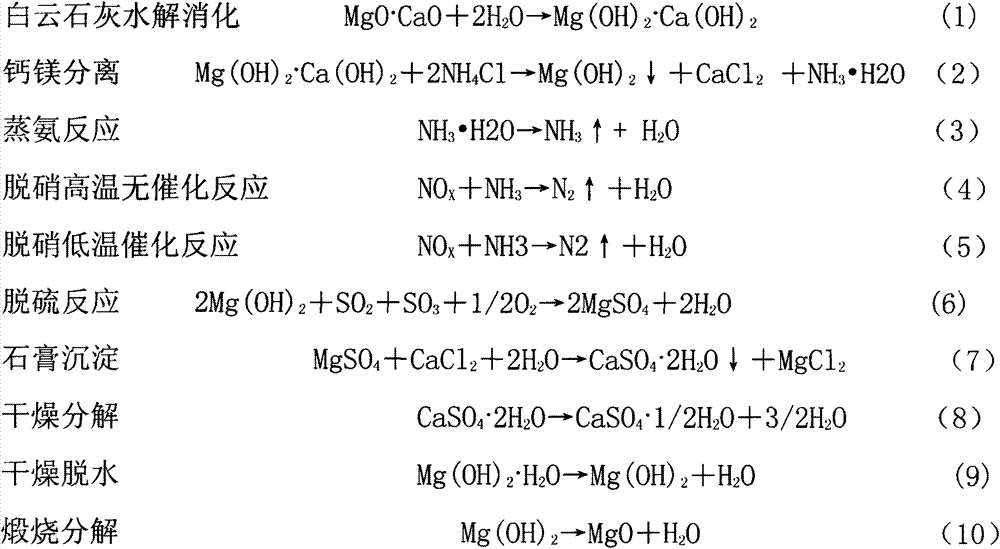

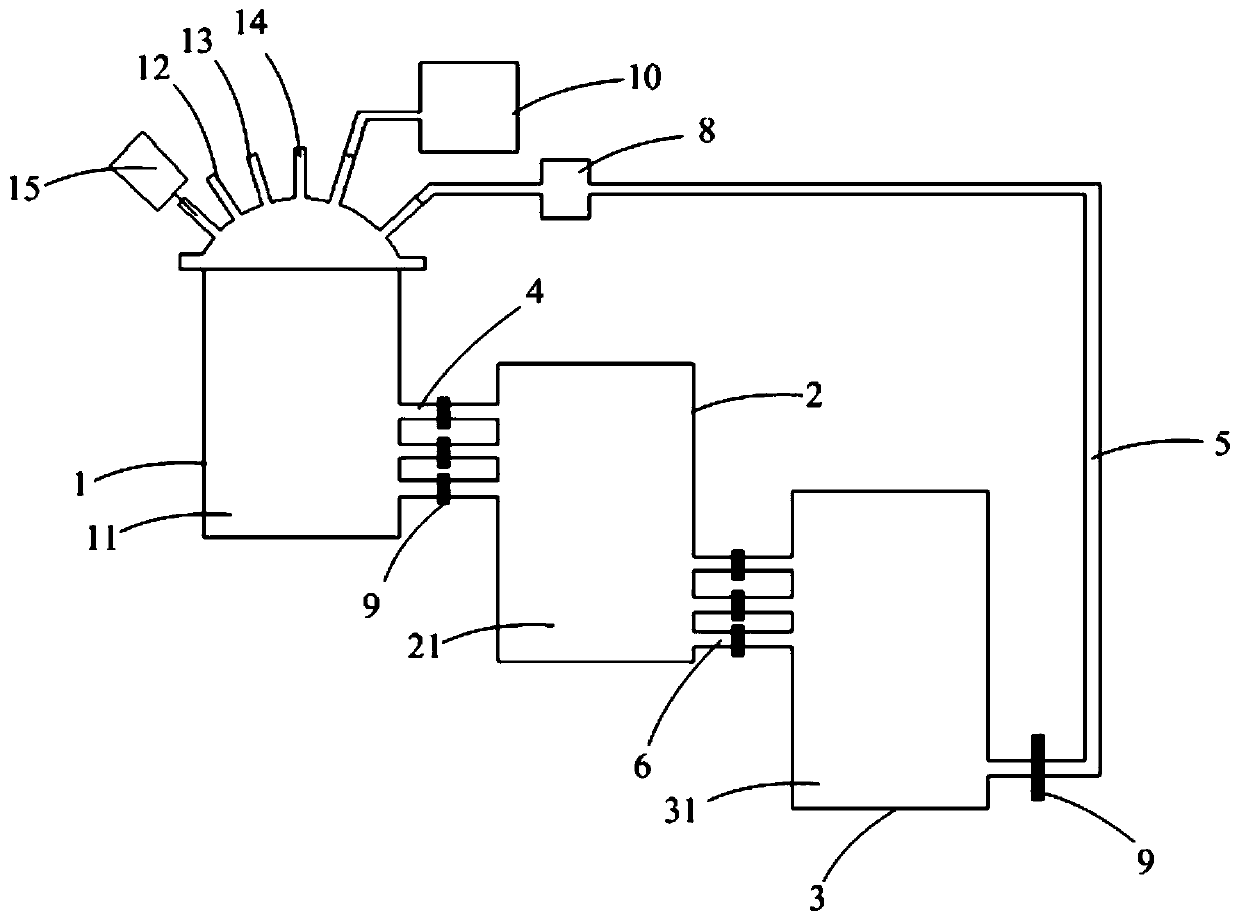

Method for preparing magnesium hydroxide, magnesium oxide and gypsum from dolomite lime denitration and desulfurization of flue gas

ActiveCN103566726ASolve the separation problemRealize comprehensive utilizationCalcium/strontium/barium sulfatesDispersed particle separationDistillationDolomite

The invention relates to a method for simultaneously preparing magnesium hydroxide, magnesium oxide and gypsum from dolomite lime denitration and desulfurization of flue gas, and belongs to the technical field of flue gas pollution control. The problems of separation of dolomite lime calcium-magnesium separation are ingeniously solved by a low-cost solution of NH4Cl. Ammonia gas (NH3) obtained by ammonia distillation in a calcium-magnesium separation process is heated for denitration. Mg(OH)2 precipitates formed in the calcium-magnesium separation process are used for the desulfurization of the flue gas. A solution of CaCl2 subjected to solid-liquid separation after calcium-magnesium separation is used for precipitating a solution of MgSO4 generated by desulfurization to produce byproducts CaSO4.1 / 2H2O building gypsum and a solution of MgCl2. Residual Mg(OH)2 is dried or calcinated to form a finished product Mg(OH)2 or MgO. According to the method, the denitration and desulfurization cost is greatly lowered; in addition, a novel production process for magnesium hydroxide and magnesium oxide products are created, and waste is comprehensively utilized.

Owner:彭振超 +1

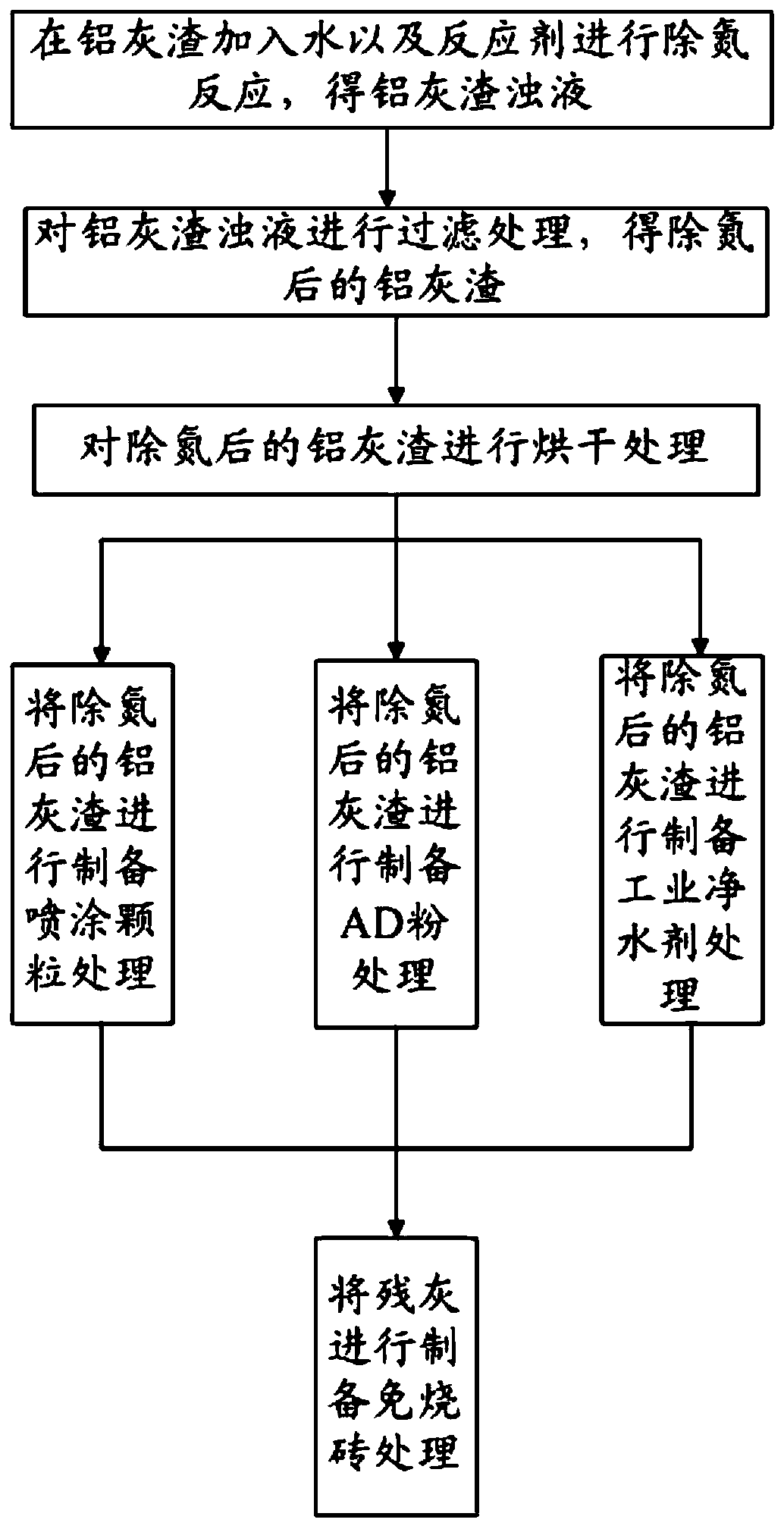

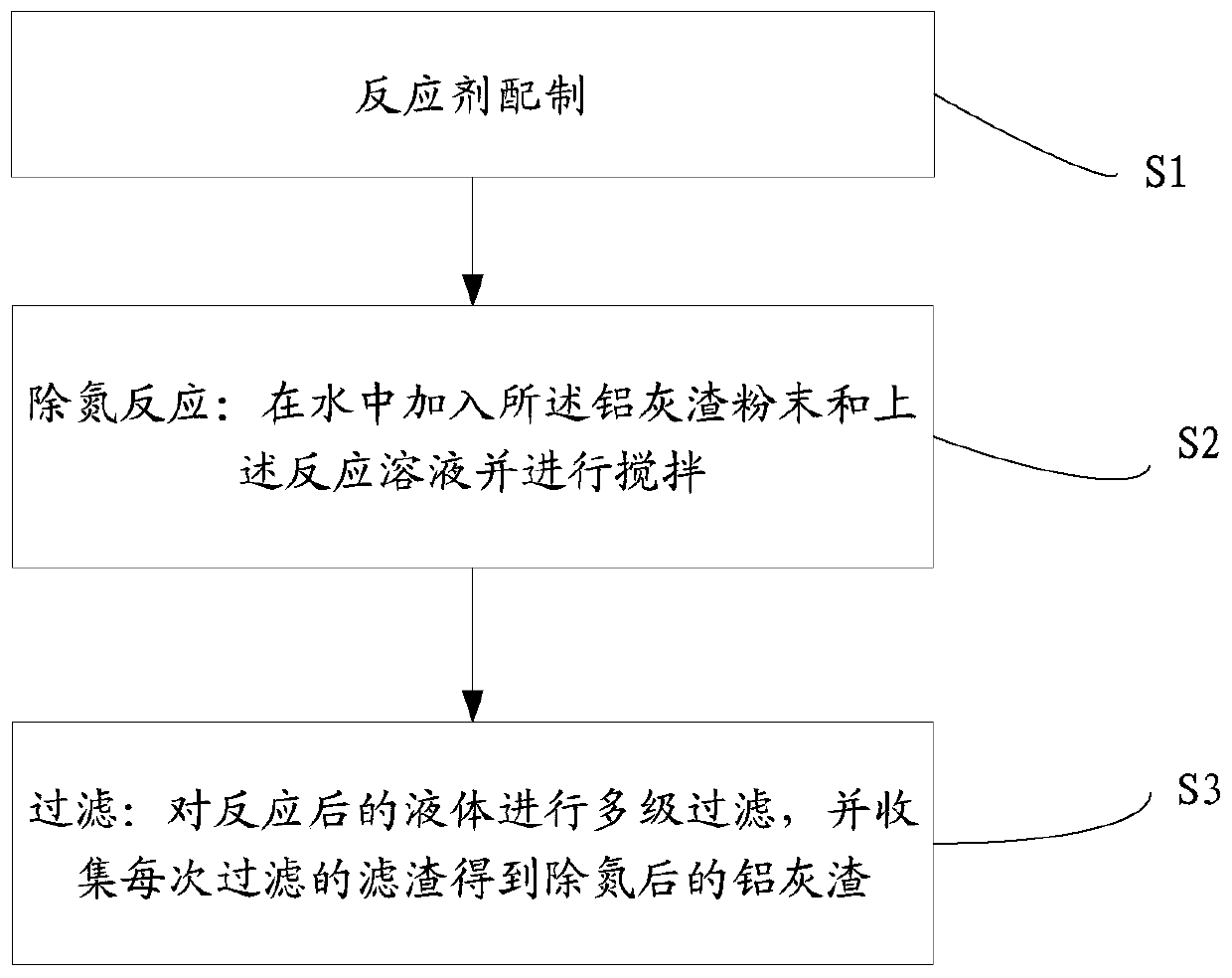

Harmless treatment method and device for aluminum ash residues

InactiveCN110025920AHarmless removalAvoid encapsulationChemical protectionAcetic acidNitrogen removal

The invention discloses a harmless treatment method and device for aluminum ash residues, wherein the aluminum ash residues comprise aluminum nitride. The harmless treatment method comprises the stepsthat water and a reactant are added into the aluminum ash residues for a nitrogen removal reaction to obtain aluminum ash residue turbid liquid, wherein the aluminum ash residue turbid liquid comprises ammonium salts and aluminum ash residues subjected to nitrogen removal, and the reactant comprises one or more of hydrogen peroxide, peracetic acid, calcium oxide, sodium carbonate, acetic acid anddilute sulfuric acid. According to the harmless treatment method and device for the aluminum ash residues, ammonia gas is avoided, the phenomenon that aluminum nitride is coated with aluminum hydroxide is avoided, the nitrogen removal rate is increased, and then the aluminum nitride in the aluminum ash residues is efficiently removed in a low-cost and harmless mode.

Owner:NANTONG UNIVERSITY

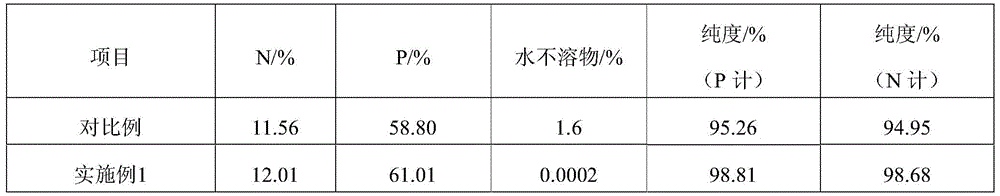

Mono-ammonium phosphate produced by using wet process phosphoric acid and production method of mono-ammonium phosphate

The invention relates to the technical field of mono-ammonium phosphate prepared by using wet process phosphoric acid, and in particular to mono-ammonium phosphate produced by using wet process phosphoric acid and a production method of the mono-ammonium phosphate. When an ammonia gas is introduced or liquid ammonia is added into impurities in phosphoric acid prepared by using the wet process phosphoric acid, the neutralization in mixed liquor is adjusted to 0.5-0.8 to generate a large amount of precipitates from the impurities in the phosphoric acid, separation treatment is carried out by using a separator, after phosphoric acid with higher purity is obtained, the ammonia gas or the liquid ammonia is introduced in the phosphoric acid, and the pH value of the phosphoric acid is controlled to obtain mono-ammonium phosphate slurry with higher purity, so that the purity of a mono-ammonium phosphate product is improved and the total nutrient in the mono-ammonium phosphate is 60.15-60.36%, wherein counted by phosphorus pentoxide, the phosphorus content is 49.0-51.0%, the content of water soluble phosphorus is 47.62-48.15%, the nitrogen content is 9.0-11.0%, the fluorine content is 0.48-0.68%, the quality of the ammonium phosphate is improved, and the environmental pollution of the ammonium phosphate resulting from a fertilization effect is avoided.

Owner:GUIZHOU KAILIN GRP CO LTD

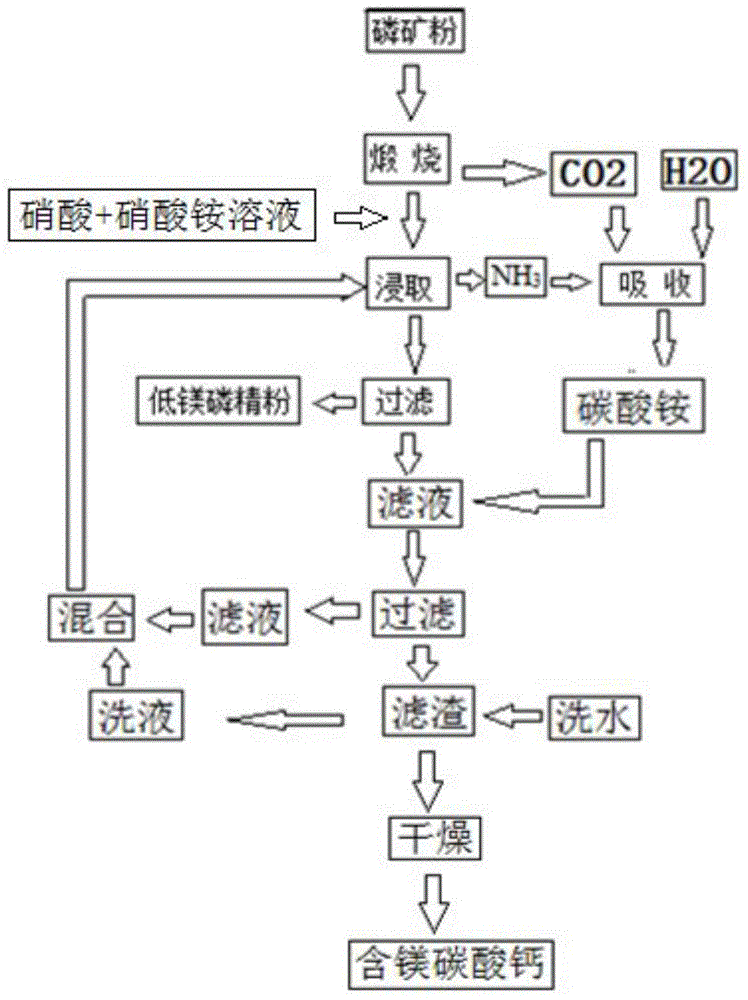

Medium and low grade phosphorus ore magnesium removal treatment method

ActiveCN104860277AAvoid emissionsIncrease added valueRaw phosphate material treatmentPhosphoriteLower grade

The invention relates to the technical field of medium and low grade phosphorus ore pretreatment, particularly to a medium and low grade phosphorus ore magnesium removal treatment method. A magnesium element in a phosphorus ore is converted into an oxide from carbonate after steps of calcining digestion, leaching, absorption, separation and ammonium carbonate treatment, the ionic state is presented in a solution to enable the magnesium element to be separated out, and the treatment is performed on obtained filtrate to enable nitrate in the filtrate to be recycled; absorption and utilization are performed on the waste gas produced in the calcining process and the ammonia gas produced in the leaching process to obtain ammonium carbonate; the ammonium carbonate is reacted in the filtrate to obtain an ammonium nitrate solution and magnesium contained calcium carbonate, the ammonium nitrate solution is returned to the leaching step, and accordingly the discharge of the waste liquid is avoided, the magnesium contained calcium carbonate additional product is obtained, and the additional process value is increased.

Owner:贵州盛源新材料股份有限公司

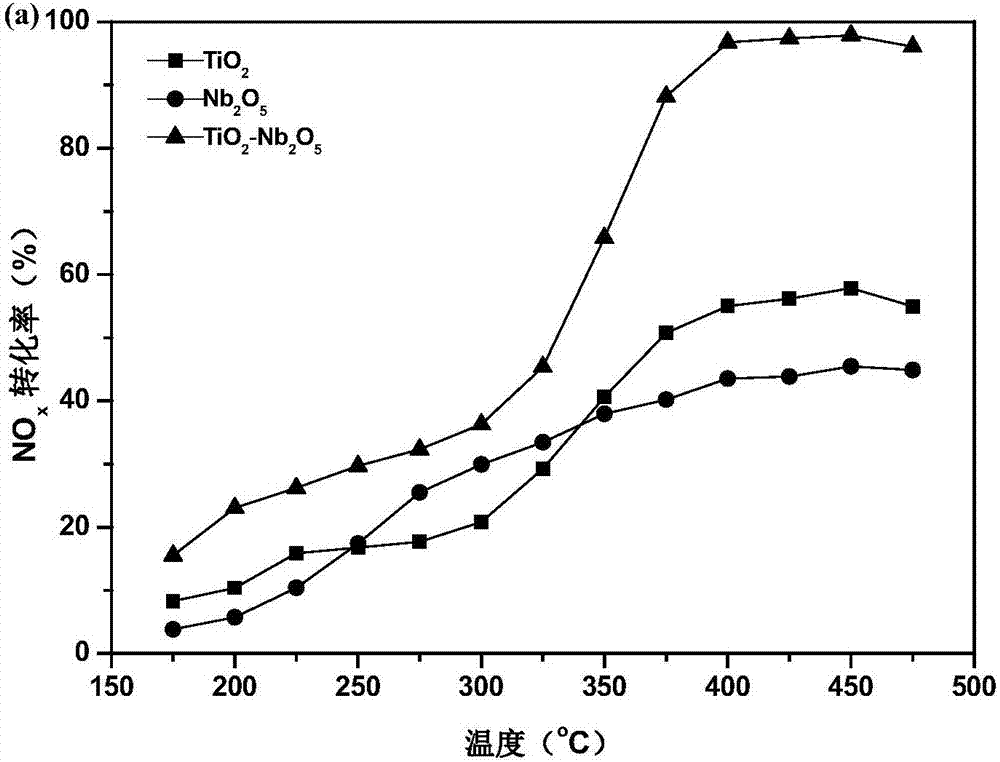

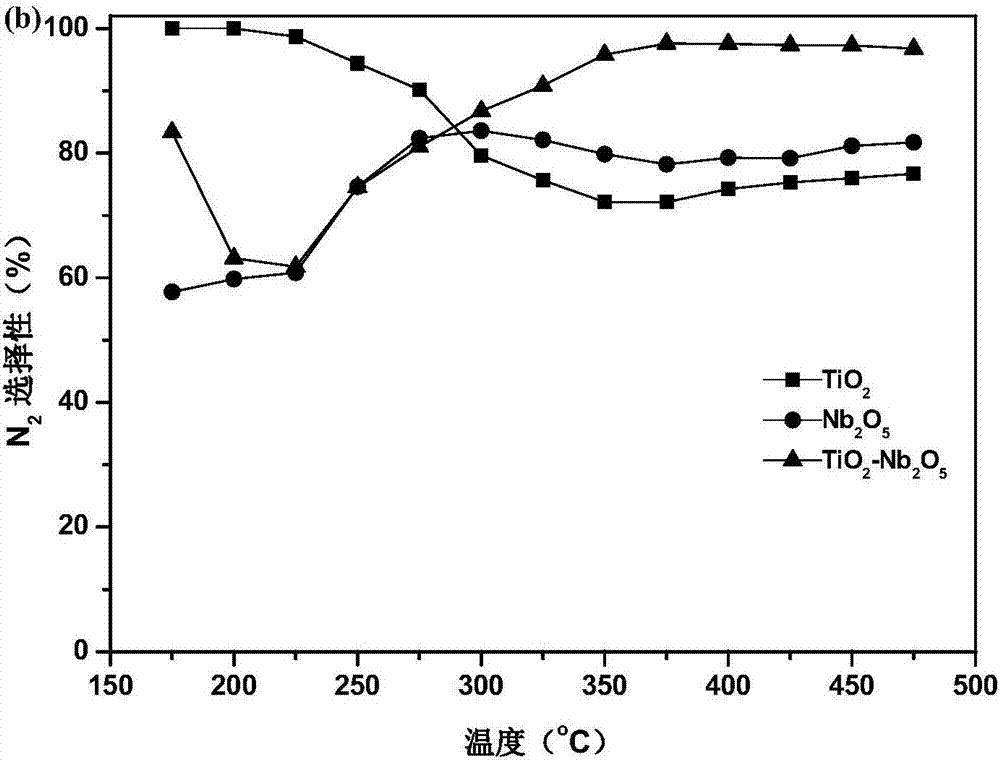

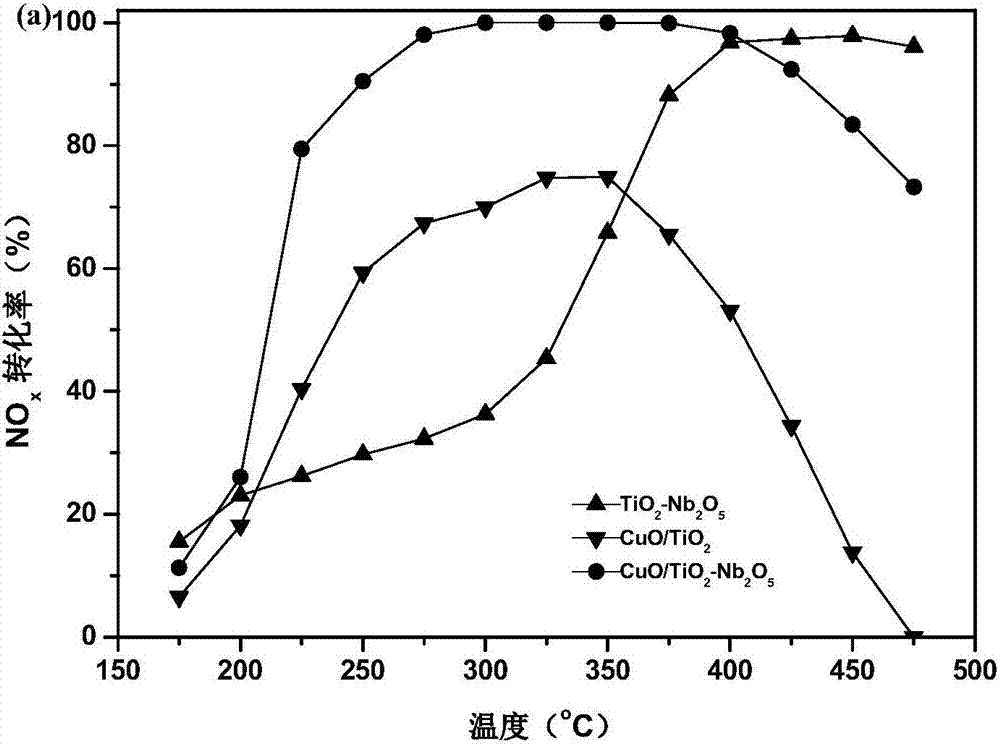

Titanium dioxide-based catalyst, and preparation method and application thereof

ActiveCN107308944ALarge specific surface areaEnhanced Surface AcidityGas treatmentHeterogenous catalyst chemical elementsNiobiumCopper nitrate

The invention discloses a titanium dioxide-based catalyst, and a preparation method and application thereof. The preparation method comprises the following steps: mixing titanyl sulfate, niobium pentachloride, urea, sodium dodecyl benzene sulfonate and water, then carrying out a reaction, carrying out cooling after the reaction, and subjecting a precipitate to centrifugation, washing, drying and calcinations so as to obtain a titanium niobium binary oxide carrier; and mixing the titanium niobium binary oxide carrier with an aqueous copper nitrate solution and then carrying out ultrasonic treatment, stirring, drying and calcining successively so as to obtain the titanium dioxide-based catalyst. The preparation method provided by the invention is simple in process and easy to operate and implement. The titanium dioxide-based catalyst prepared in the invention can be used for selective catalytic reduction of nitrogen oxides in virtue of ammonia, has high nitrogen oxide reduction ability and nitrogen selectivity, a wide reaction window, high anti-sulfur dioxide poisoning performance and high hydrothermal stability, and also has the advantages of economic performance, environment friendliness, easiness in industrialization, etc.

Owner:ZHEJIANG UNIV

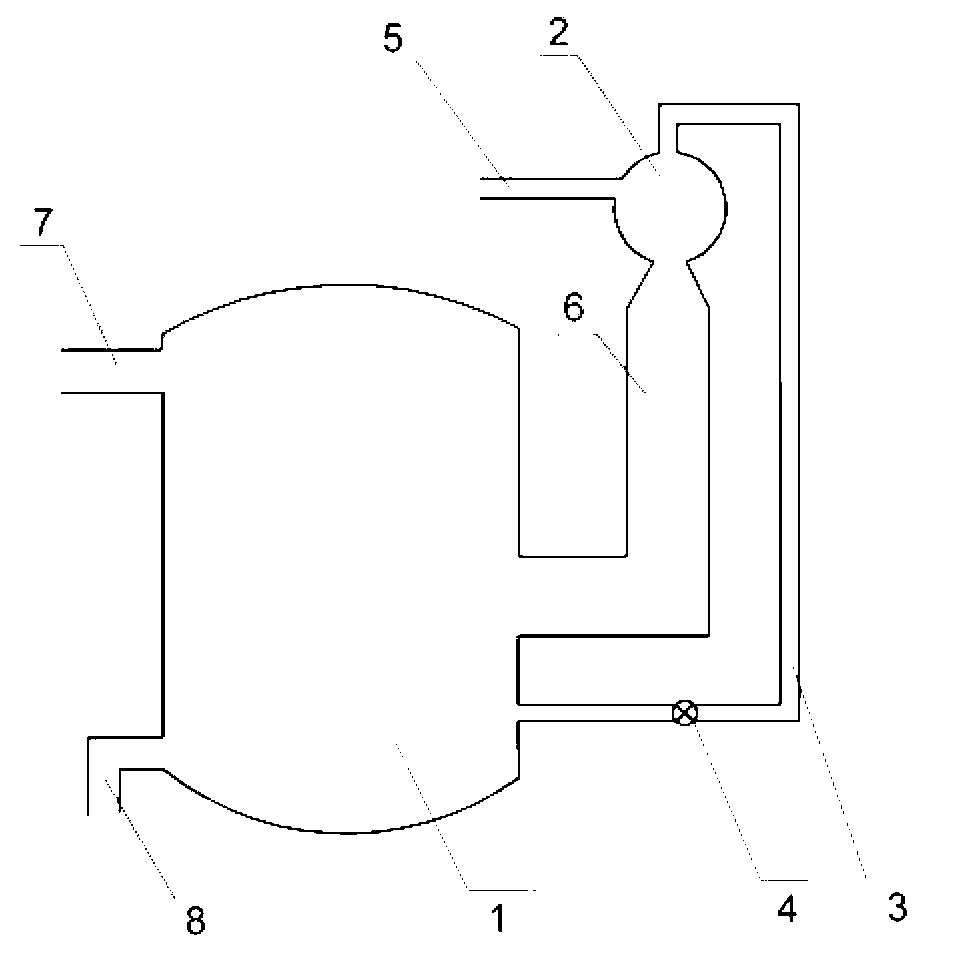

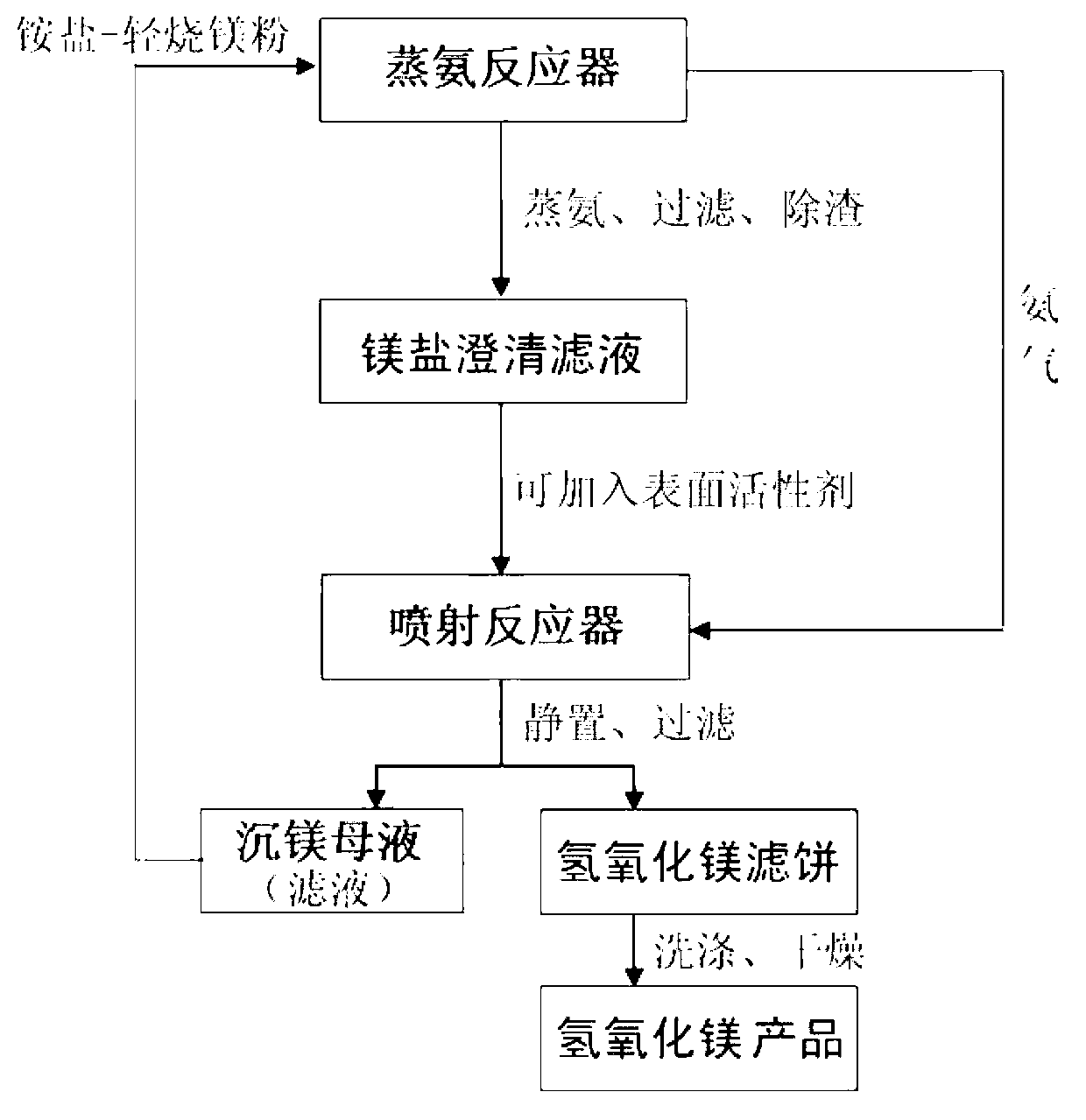

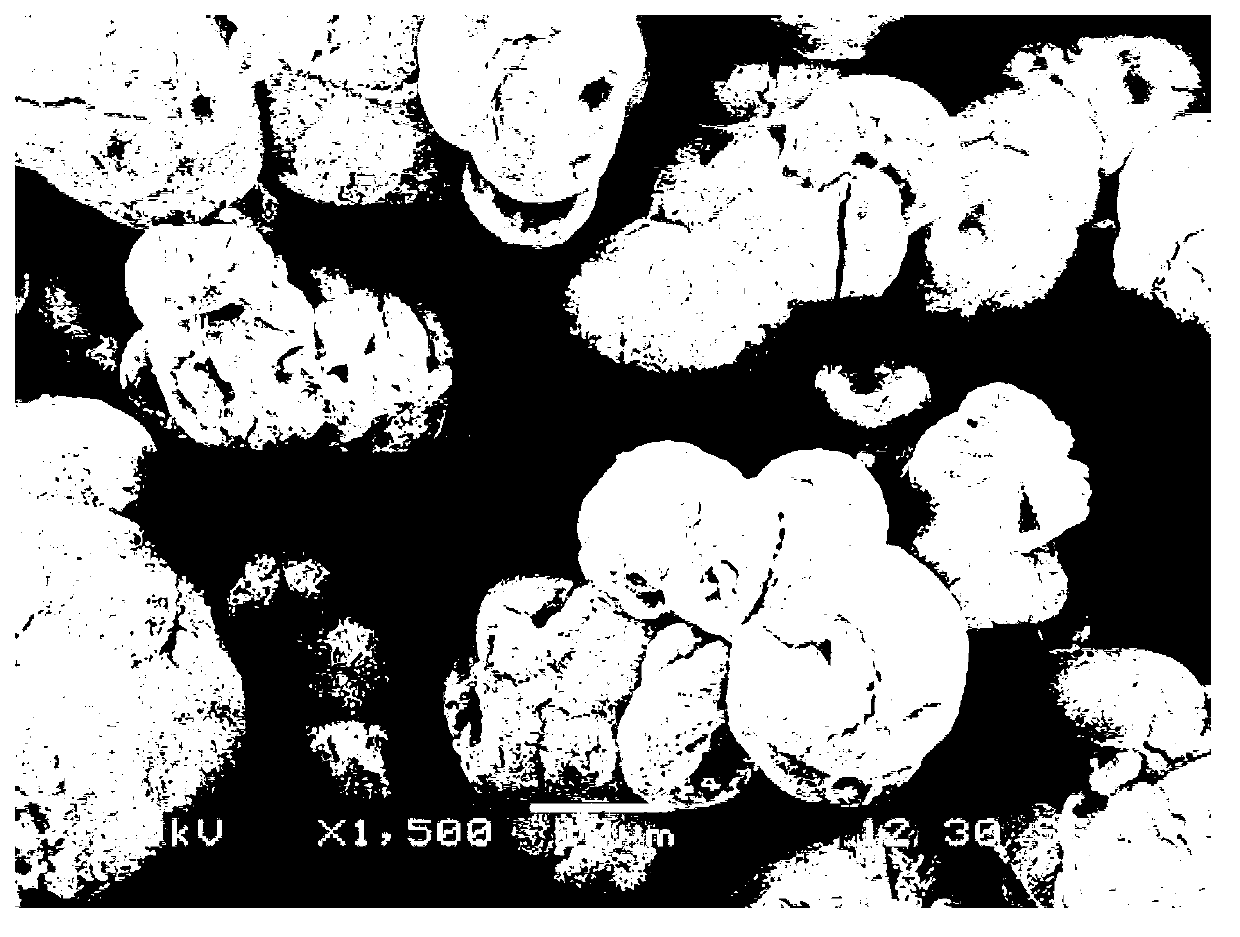

Method for preparing magnesium hydrate through ammonia spray method

ActiveCN103101936AReduce manufacturing costReduce shipping costsMagnesium hydroxideMagnesium saltMagnesite

The invention discloses a method for preparing magnesium hydrate through ammonia spray method. The method comprises the following steps: by using caustic calcined magnesite and ammonium salt as raw materials, carrying out ammonia stilling reaction to obtain an ammonium and magnesium salt solution, wherein the ammonium and magnesium salt are contacted in a spray type reactor and magnesium hydrate precipitation reaction is performed, aging product mother liquor for a proper time, filtering, returning filtrate containing ammonium salt to an ammonia stilling system, washing and drying filter cake to obtain magnesium hydrate product with uniform particle shape and good dispersion state. The process disclosed by the invention is used for preparing magnesium hydrate through one-step reaction, is simple in operation step, mild in reaction condition, uniform in product particle shape, and the particle shape can be regulated by changing the reaction condition. The ammonium slat is circulated with the ammonia in the reaction process, the production cost is low, the pollution is less, and the scale production is realized, the product can be used as production raw material of high-pure magnesium oxide and inflaming retarding additive of polymer material.

Owner:YINGKOU YINGXIN CHEM TECH CO LTD

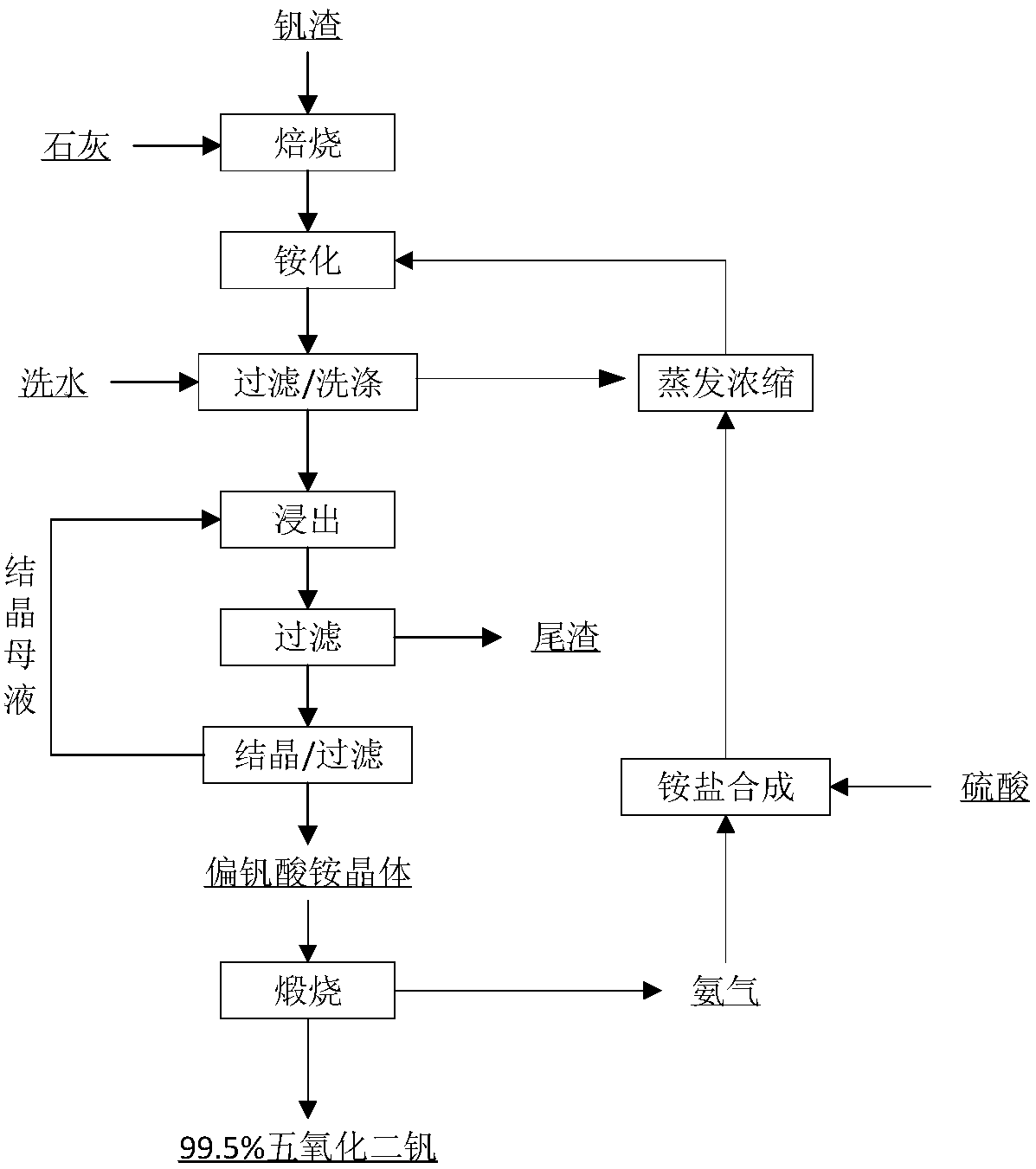

Clean method for extracting vanadium during roasting vanadium slag

InactiveCN110408772AHigh recovery rateImprove conversion rateProcess efficiency improvementSolubilityHigh concentration

The invention relates to a clean method for extracting vanadium during roasting vanadium slag. The method comprises the following steps that vanadium in the vanadium slag is converted into calcium vanadate which is stable at high temperature by adopting a calcification roasting method, high-concentration ammonium sulfate and / or ammonium bisulfate solution are utilized for leaching roasted clinkerto enable most of ammonium metavanadate to be crystallized and then to be mixed with tailings to form crystal-containing slag, then the crystal-containing slag is dissolved in a hot liquid to obtain avanadium-containing solution, and efficient extraction of the vanadium can be realized. According to the method, the problem of high-temperature vanadium volatilization does not exist, the comprehensive recovery rate of the vanadium is higher, ammonia gas is not generated in the leaching process, and compared with other easily-decomposed ammonium salts, the conversion rate of the vanadium is higher under the same concentration and the same leaching temperature; and meanwhile, the problems of small solubility of ammonium metavanadate in the ammonium salt solution and low vanadium extraction rate can be effectively solved. In the subsequent processes, ammonia gas generated by calcining ammonium metavanadate is adsorbed by using a sulfuric acid solution, the ammonium sulfate can be resynthesized, the ammonia recycling can be realized, the whole process is clean, the production cost is greatly reduced, and the method has good economic benefit and application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for vanadium extracting through low liquid-solid-ratio ammonification

ActiveCN106676273AReduce usageReduce ammonia volatilizationProcess efficiency improvementChemical industrySlag

The invention relates to the field of vanadium slag wet process metallurgy and vanadium chemical industry, in particular to a method for vanadium extracting through low liquid-solid-ratio ammonification. According to the method, after raw materials containing vanadium is roasted, clinkers, water and ammonium salt are mixed according to a certain proportion; materials with a low liquid-solid ratio are formed and subjected to the low-temperature ammonification reaction, the vanadium in the clinkers reacts with the ammonium salt to form ammonium metavanadate, and the ammonium metavanadate formed at the low temperature exists in mixed slurry in a crystalline mode; after the mixed slurry is subjected to hydrotherm dissolution, a solution rich in the ammonium metavanadate is obtained; and after slurry filtering, filtrate cooling and crystallizing and separating and ammonium vanadate roasting, vanadium pentoxide products are obtained. Compared with a conventional vanadium extracting through ammonification, according to the method for vanadium extracting through low liquid-solid-ratio ammonification, the using quantity of the water and the ammonium salt are greatly reduced in the ammonification process, and volatilization of ammonia gas is obviously inhibited; and the slurry can be directly subjected to hydrotherm leaching to obtain the ammonium metavanadate solution after ammonification, the process of vanadium extracting through ammonification is greatly simplified, the process is easy to operate and control, efficient and clean extracting of the vanadium can be achieved, and the extracting rate of the vanadium reaches 90% or more.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

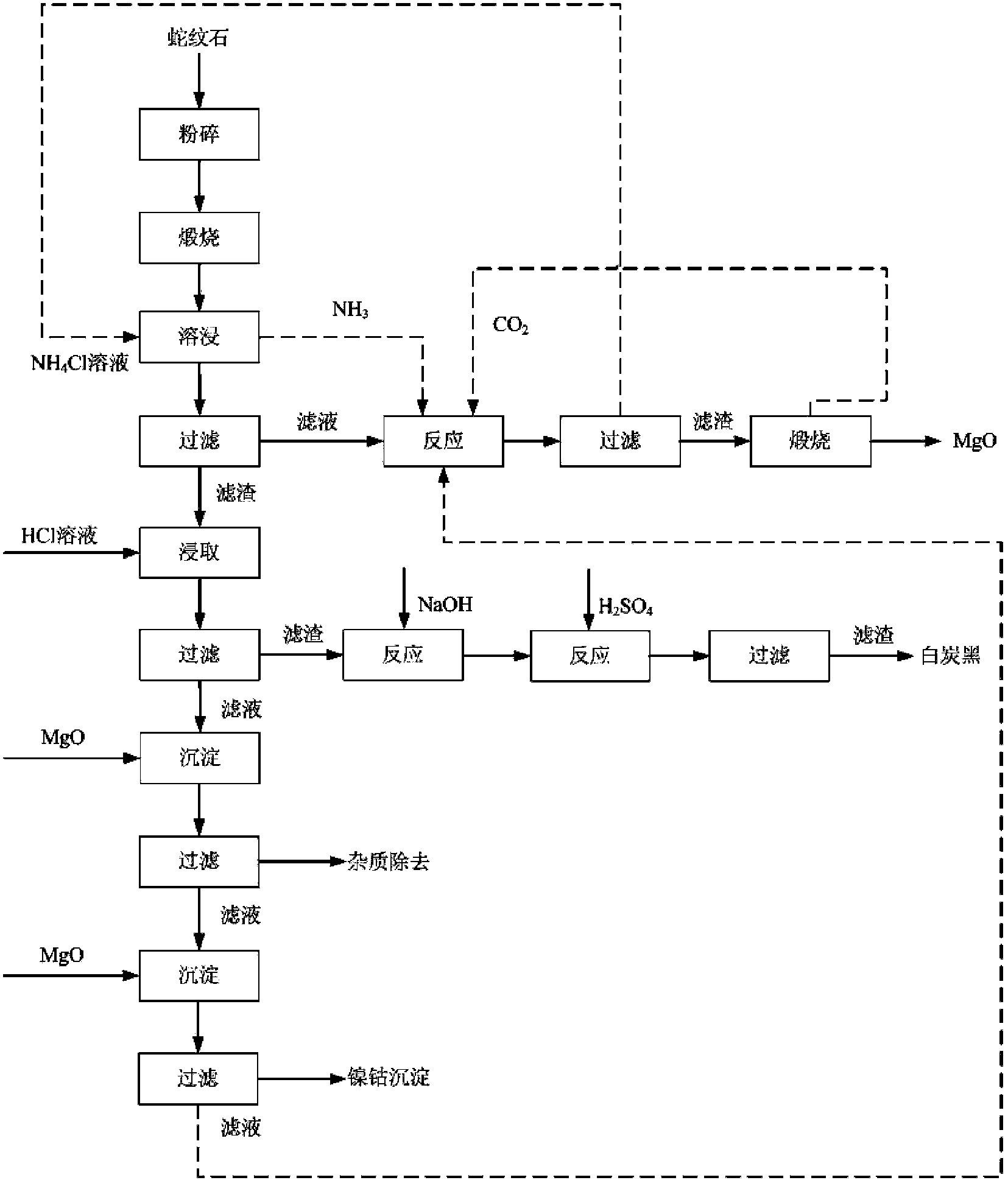

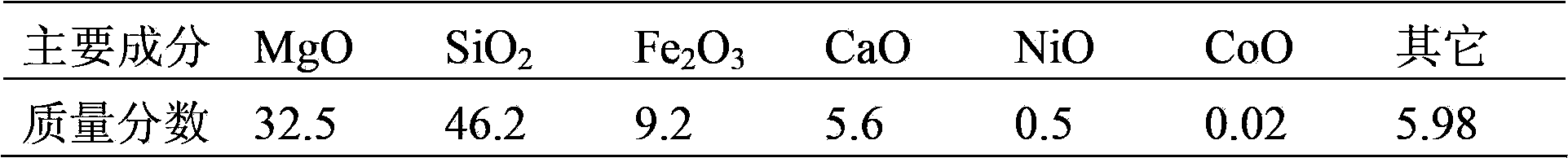

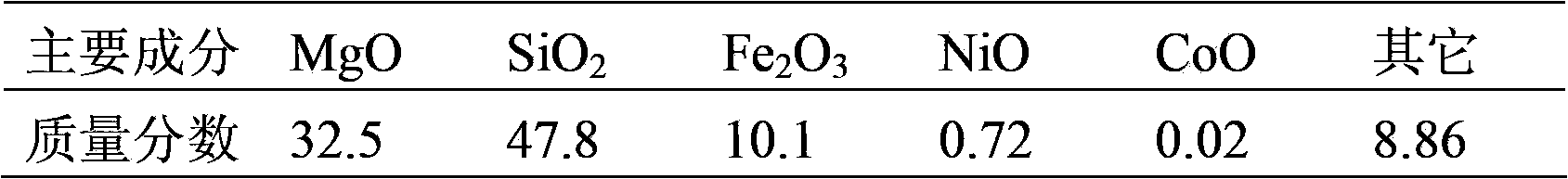

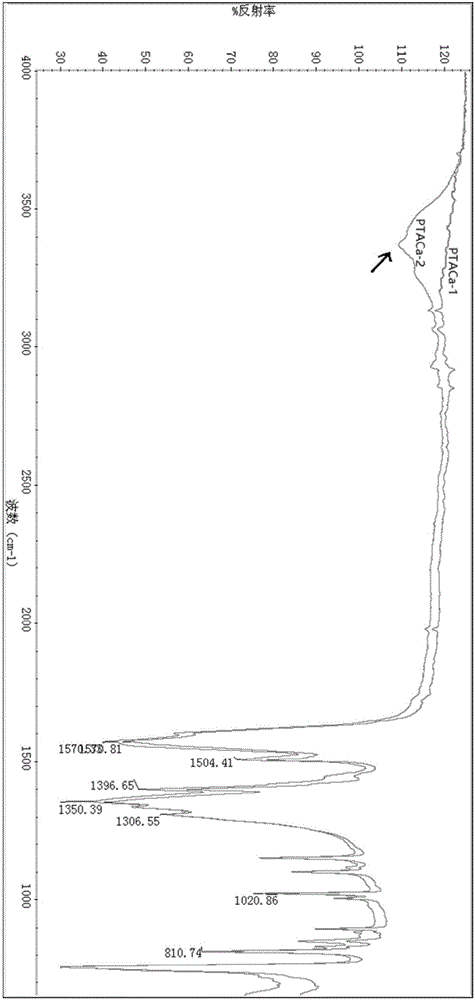

Method for preparing magnesium oxide, nickel, cobalt and white carbon black through utilizing serpentine

InactiveCN103449482ATake advantage ofPromote resource utilizationSilicaCobalt compoundsSolventCobalt

The invention relates to method for preparing magnesium oxide, nickel and cobalt or white carbon black through utilizing serpentine, or for simultaneously preparing magnesium oxide, nickel, cobalt and white carbon black through utilizing serpentine. The method comprises the following steps: roasting a raw material serpentine, milling, leaching by an ammonium salt containing NH4<+> to obtain a magnesium ion solution, preparing a magnesium carbonate hydrate intermediate which has a good crystal form and is easy to filter through an ammonium carbonate cycle process, calcining to produce highly pure magnesium oxide; leaching above filter residues by hydrochloric acid, filtering, adding magnesium oxide to an obtained filtrate to adjust the pH value to obtain precipitated nickel and cobalt; dissolving an obtained filtrate residue through a concentrated alkali, and neutralizing by sulfuric acid to prepare a white carbon black product. The method has the following advantages: magnesium, nickel, cobalt and silicon in the serpentine are comprehensive utilized, and the cycle use of carbon dioxide, ammonia gas and a mother liquor containing NH4<+> is realized; an aqueous solution containing the NH4<+> is adopted as a leaching solvent, so there is no extract Ca, Al and Fe impurity removal operation of an obtained magnesium ion solution; and magnesium oxide is adopted to adjust the pH value, so other impurities are not introduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

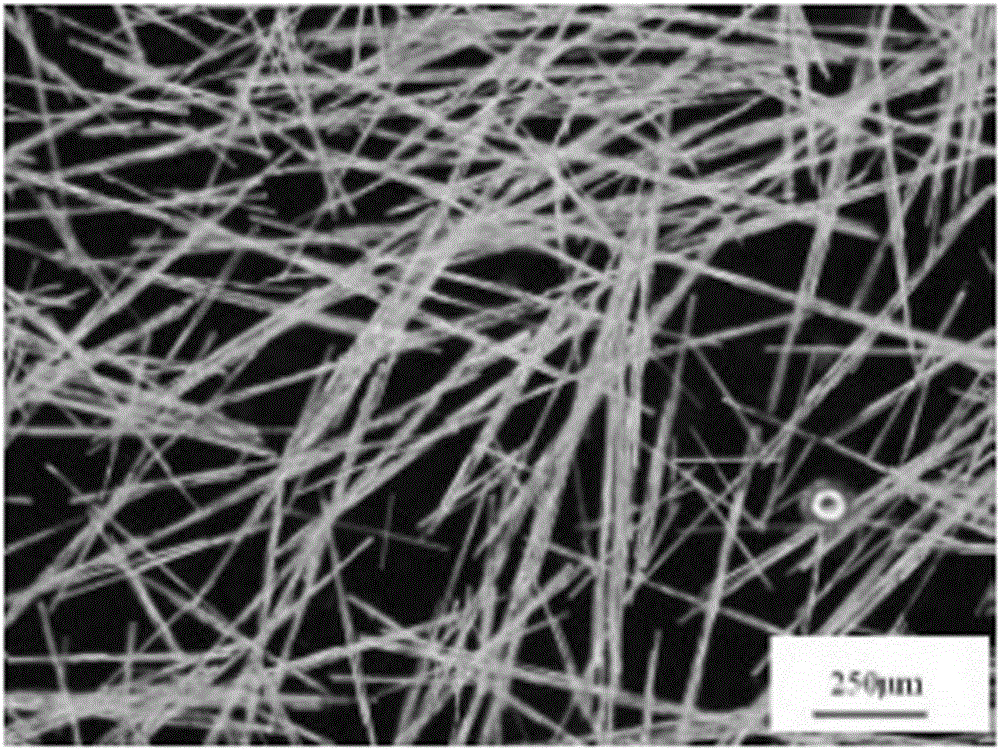

Preparation method and application of anhydrous calcium terephthalate whiskers

ActiveCN106119970AHigh crystal strengthLarge aspect ratioPolycrystalline material growthFrom normal temperature solutionsSlurryHigh pressure

The invention discloses a preparation method and application of anhydrous calcium terephthalate whiskers. The preparation method of anhydrous calcium terephthalate whiskers includes the steps of subjecting ammonium terephthalate solution and calcium hydroxide slurry to reaction to obtain a precursor, and continuing the reaction at 120-150 DEG C in a high-pressure kettle for 1-6 h to obtain the anhydrous calcium terephthalate whiskers. The preparation method is green, low in cost and high in cleanliness level. The production process is free of three wastes, and the obtained anhydrous calcium terephthalate whiskers have large length-diameter ratio, high crystal strength and significant reinforcement effect. During the preparation of the calcium terephthalate whiskers from ammonium terephthalate and calcium hydroxide, isolated ammonia water may continue to dissolve terephthalic acid for next cycle or remaining water is also suitable for reuse after ammonia gas is recycled by means of ammonia steaming, and the whole process is free of three wastes and belongs to clean production.

Owner:JIANGSU ATE DONGTAI NEW MATERIALS TECH

Method for extracting vanadium from vanadium-contained raw material clinker via ammonium oxalate leaching

ActiveCN105779758AHigh selective leaching rateHigh recovery rateProcess efficiency improvementLeaching rateAmmonal

The invention provides a method for extracting vanadium from vanadium-contained raw material clinker via ammonium oxalate leaching. The method comprises the following steps: conducting blank roasting on a vanadium-contained raw material, so as to obtain the vanadium-contained raw material clinker; leaching the vanadium-contained raw material clinker in an ammonium oxalate solution for vanadium extraction; carrying out solid-liquid separation, so as to obtain leaching residue and vanadium-contained liquid. The method has the advantages that the selective vanadium leaching rate can reach up to 90% or higher; the impurity element content of the obtained vanadium-contained liquid is low; the PH value of the obtained vanadium-contained liquid is proper; the purification and impurity removing process can be simplified or eliminated, so as to facilitate the nest step of vanadium precipitation and preparation of a high-purity vanadium product; no salinity-contained wastewater is generated; the ammonium oxalate solution, which serves as a leaching agent, cannot volatilize, so as to avoid the volatilization problem of ammonia gas; and moreover, the method is simple in leaching technological process, environmentally friendly in operation, and low in production cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for producing industrial monoammonium phosphate through fluoride salt purification method

ActiveCN105600763AGood effect of removing impuritiesMake full use of fluorine resourcesSilicaPhosphatesPurification methodsPhosphate

The invention relates to a method for producing industrial monoammonium phosphate through a fluoride salt purification method. Wet process phosphoric acid is used as a raw material, powdered rock phosphate is added for desulfuration, sodium carbonate is added for defluorination, sodium fluosilicate prepared in the defluorination process is added into ammonia water to react, a fluoride salt purifying agent is prepared, after desulfurized and defluorinated phosphoric acid is neutralized with ammonia gas, the prepared fluoride salt purifying agent is added to adjust the pH value, the reaction continues to be conducted after a period of time, filtering is carried out while the mixture is hot to obtain a monoammonium solution, a complexing agent is added to complex microelements, and after complete dissolution, water-soluble monoammonium phosphate is prepared through concentration, crystallization, separation and drying. The fluoride salt purifying agent produced from fluorine in wet process phosphoric acid is used for removing most impurities in monoammonium phosphate slurry, the impurity removal effect is remarkable, and industrial monoammonium phosphate has the advantages of being high in purity, simple in process, low in cost and suitable for industrial large-scale production and has few impurities.

Owner:KINGENTA NORSTERRA CHEM CO LTD +1

Method for preparing high purity ammonium poly-vanadate

InactiveCN107117653ASimple processLow costVanadium compoundsPregnant leach solutionChemical industry

A method for preparing high-purity ammonium polyvanadate belongs to the technical field of hydrometallurgy and vanadium chemical industry. The method comprises the following steps: feeding ammonia gas into the vanadium-containing purified leaching solution, adjusting the pH value to 4.0-7.0, stirring, Sodium ammonium vanadate is obtained after filtration; the sodium ammonium vanadate is heated and dissolved after adding water, ammonium salt is added and the pH value is adjusted to 2.0-3.0 to obtain high-purity ammonium polyvanadate. The method has the advantages of simple process, low cost, and easy operation. The content of the prepared high-purity ammonium polyvanadate is greater than 90%, and the vanadium yield is greater than 90%. It has good social and economic benefits and is convenient for industrial promotion.

Owner:HEBEI IRON AND STEEL

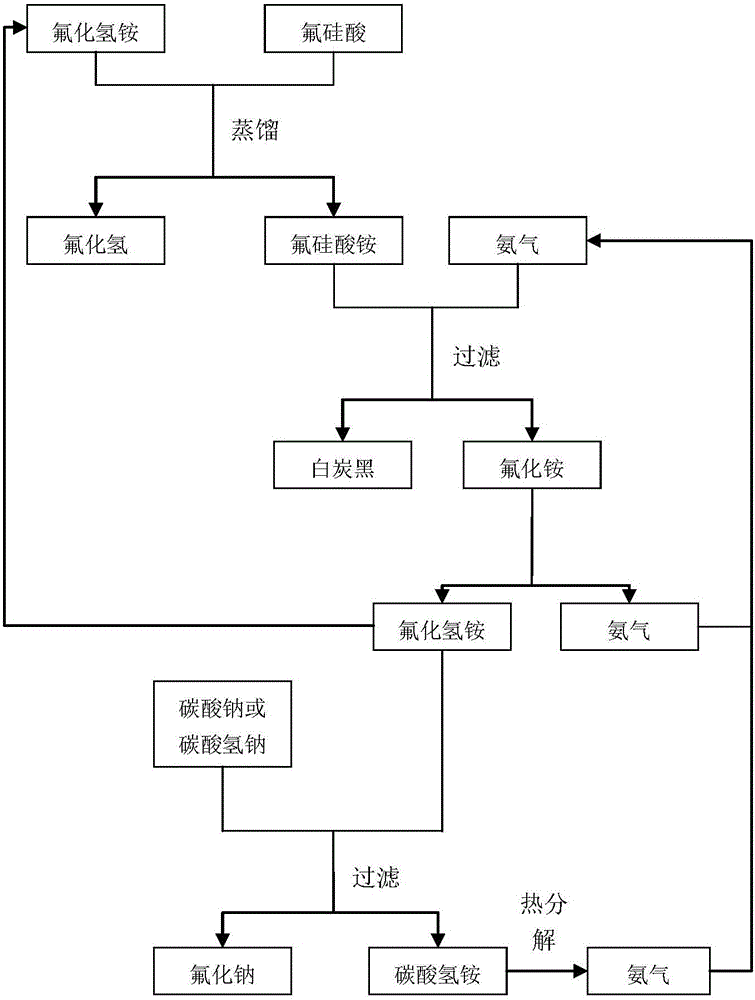

Method for preparing hydrogen fluoride and sodium fluoride by use of fluosilicic acid

ActiveCN106348248AWide variety of sourcesLow costSilicaHydrogen fluorideSodium bicarbonateFiltration

The invention discloses a method for preparing hydrogen fluoride and sodium fluoride by use of fluosilicic acid. The method comprises the following steps of: adding ammonium bifluoride into fluosilicic acid for reaction, and performing distillation, thereby obtaining a hydrogen fluoride gas and an ammonium fluosilicate solid; 2) adding aqueous ammonia into ammonium fluosilicate for reaction, performing filtration to obtain white carbon black, heating and distilling a filtrate to obtain an ammonia gas and an ammonium bifluoride solid; and 3) reacting the ammonium bifluoride obtained in the step 2) with sodium carbonate or sodium bicarbonate, filtering the filtrate after reaction is over, thereby obtaining a sodium fluoride precipitate, distilling the filtrate, and collecting the ammonia gas. The method is wide in raw material source, low in cost, low in equipment requirement, less in pollution and low in energy consumption, is capable of repeatedly using ammonium bifluoride and aqueous ammonia and converting ammonium bifluoride and sodium carbonate or sodium bicarbonate into sodium fluoride and hydrogen fluoride which are relatively high in application value and wide in application range, and has favorable economic benefits and environmental benefits.

Owner:张旭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com