Harmless treatment method and device for aluminum ash residues

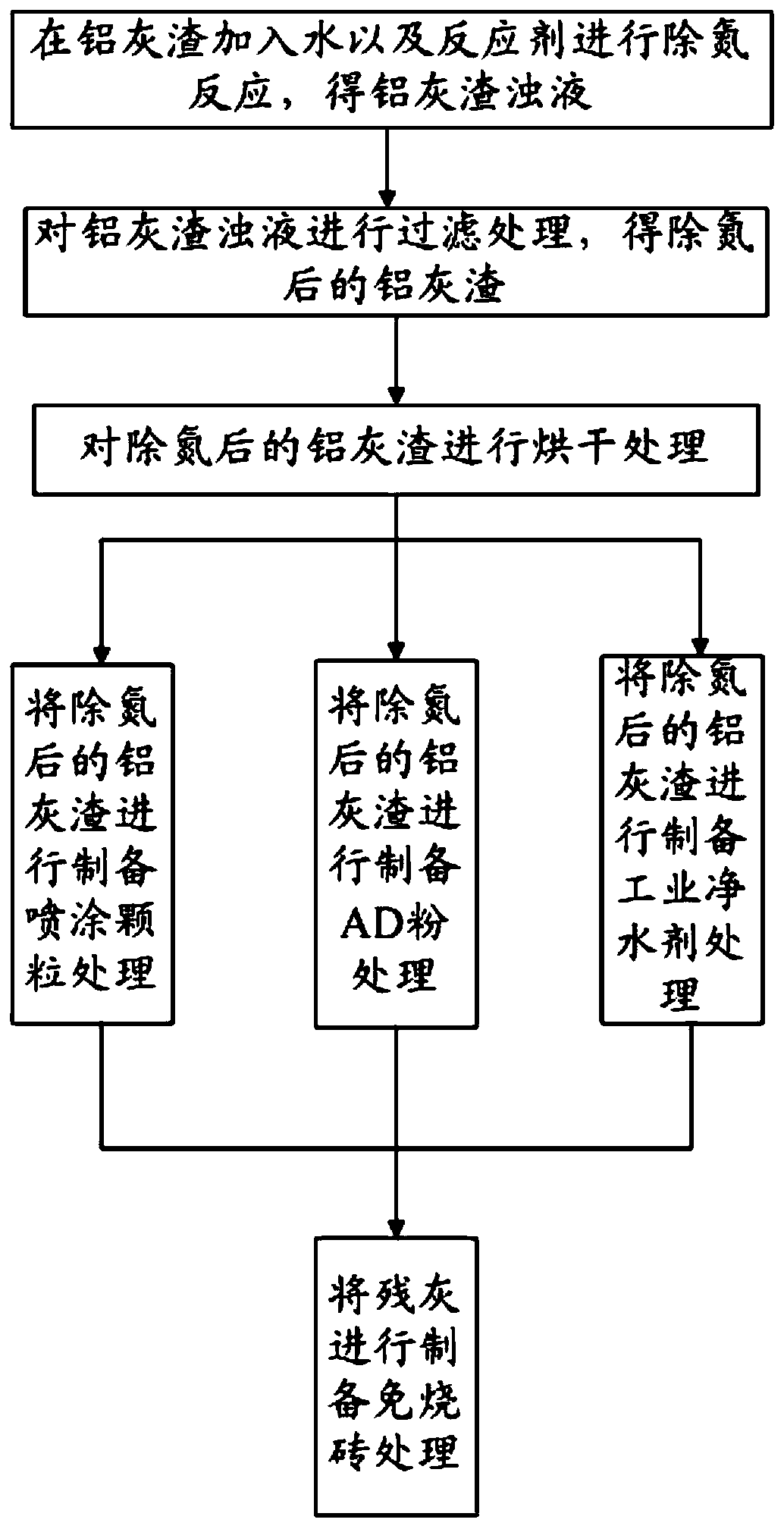

A harmless treatment and aluminum ash slag technology, applied in the field of aluminum ash treatment, can solve the problems of poor nitrogen removal effect, inability to be widely used, environmental and human hazards, etc., and achieve the effect of improving nitrogen removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

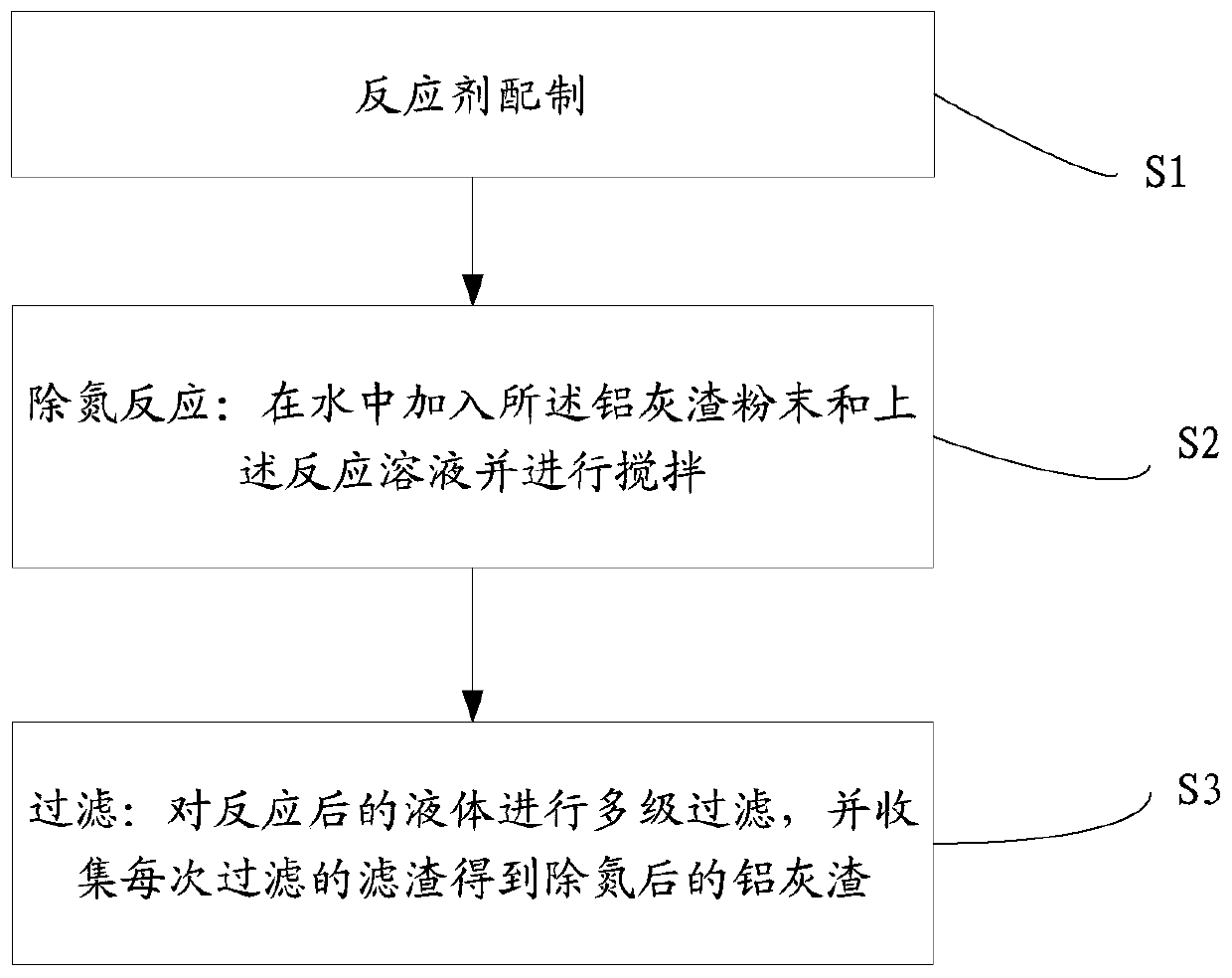

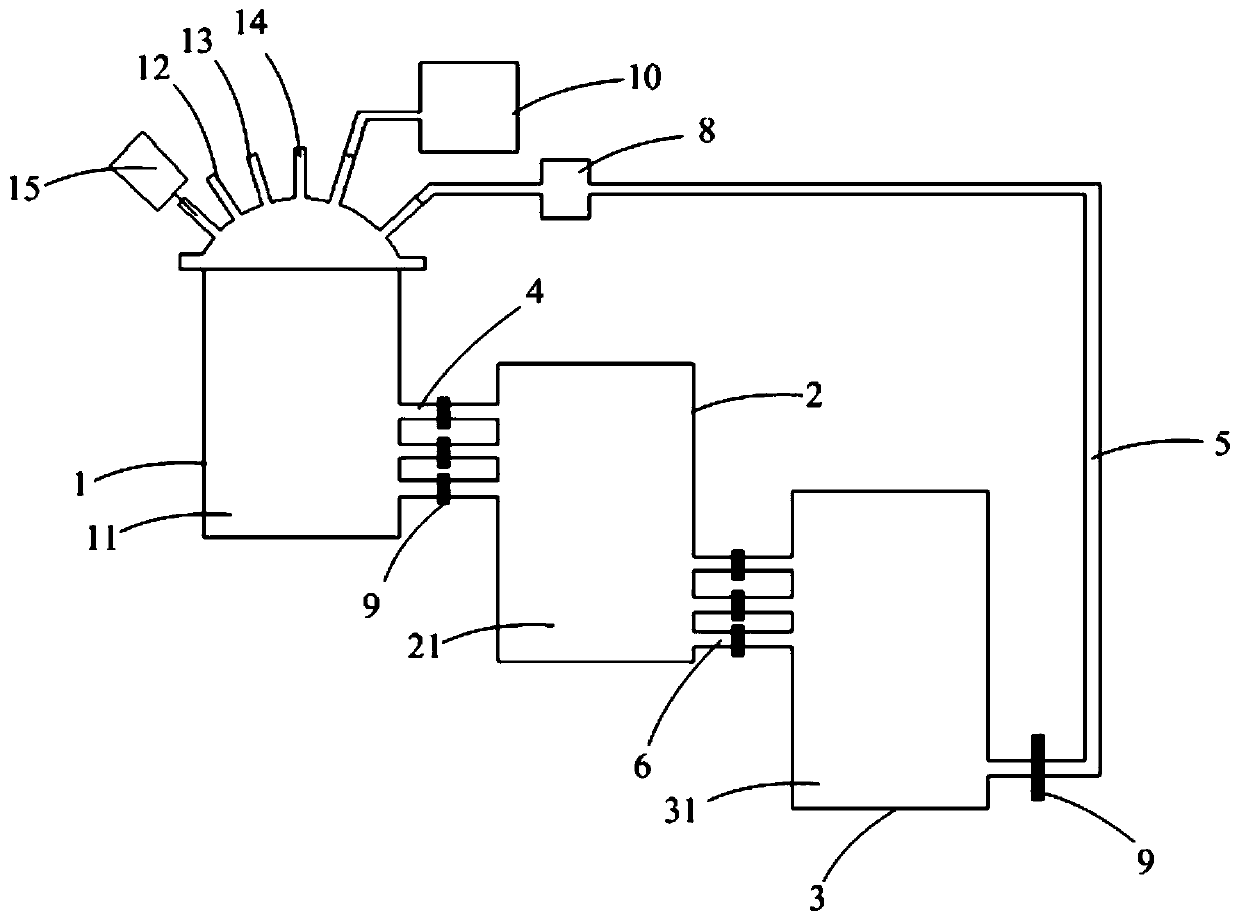

Method used

Image

Examples

Embodiment 1

[0091] 100 parts by mass of aluminum ash slag are processed, and the main chemical components of the aluminum ash slag are: elemental aluminum 3±2%, aluminum oxide 19±2%, aluminum nitride 9±2%.

[0092] (1) Mechanical ball milling of aluminum ash to 80-200 mesh;

[0093] (2) Take 2 parts by mass of calcium oxide and 0.5 part of sodium carbonate and mix them evenly with aluminum ash. Weigh 2 parts of 30% concentration of hydrogen peroxide, 5 parts of 18% concentration of peracetic acid, 2 parts of acetic acid, 1 part of 30% concentration of dilute sulfuric acid, and mix to obtain solution A;

[0094] (3) Heat 500L of water to 60°C, pour in aluminum ash, add solution A immediately, carry out mechanical stirring, and react for 1.5h;

[0095] (4) Filter the mixed solution after the reaction is completed, select a 300-mesh filter screen for the first filtration, the filtration speed is fast, the aqueous solution is turbid, and a large amount of precipitation is left to stand, and ...

Embodiment 2

[0098] 100 parts by mass of the aluminum ash slag are processed, and the main chemical components of the aluminum ash slag are: elemental aluminum 21±3%, aluminum oxide 5±2%, aluminum nitride 44±3%.

[0099] (1) Mechanical ball milling of aluminum ash to 80-200 mesh;

[0100] (2) 1 part by mass of calcium oxide and 1 part of sodium carbonate are uniformly mixed with aluminum ash. Weigh 3 parts of hydrogen peroxide with a concentration of 30%, 8 parts of peracetic acid with a concentration of 18%, 5 parts of acetic acid, and 1.5 parts of dilute sulfuric acid with a concentration of 30%, and mix them to obtain solution A;

[0101] (3) Heat 800L of water to 70°C, pour in aluminum ash, add solution A immediately, carry out mechanical stirring, and react for 1 hour;

[0102] (4) Filter the mixed solution after the reaction is completed, select a 500 mesh filter screen for the first filtration, the filtration speed is fast, the aqueous solution is turbid, and a large amount of prec...

Embodiment 3

[0105] 100 parts by mass of aluminum ash slag are processed, and the main chemical components of the aluminum ash slag are: elemental aluminum 16±2%, aluminum oxide 18±2%, aluminum nitride 21±2%.

[0106] (1) Manually crush aluminum ash to 80-200 mesh;

[0107] (2) 2 parts by mass of calcium oxide and 1 part of sodium carbonate are mixed evenly with aluminum ash. Weigh 1 part of 30% concentration of hydrogen peroxide, 3 parts of 18% concentration of peracetic acid, 5 parts of acetic acid, 2 parts of 30% concentration of dilute sulfuric acid, and mix to obtain solution A;

[0108] (3) Heat 600L of water to 50°C, pour in aluminum ash and immediately add solution A, carry out mechanical stirring, and react for 2.5 hours;

[0109] (4) Filter the mixed solution after the reaction is completed. For the first filtration, select a 500-mesh filter screen. The filtration speed is fast, but the aqueous solution is turbid. There will be a large amount of precipitation when left standing....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com