Patents

Literature

98results about How to "Avoid encapsulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

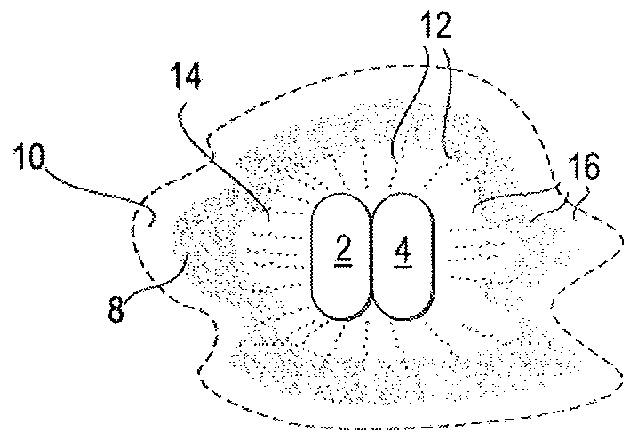

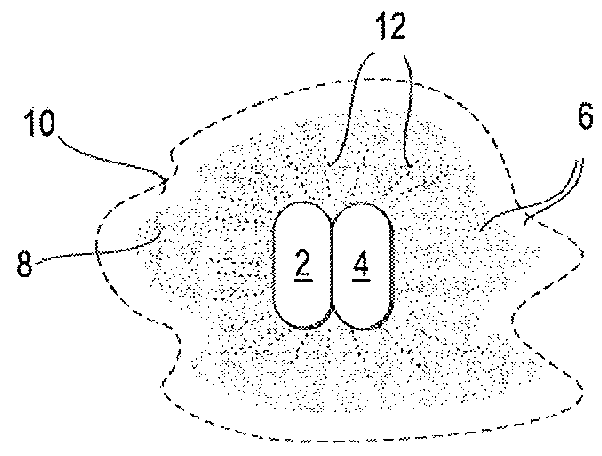

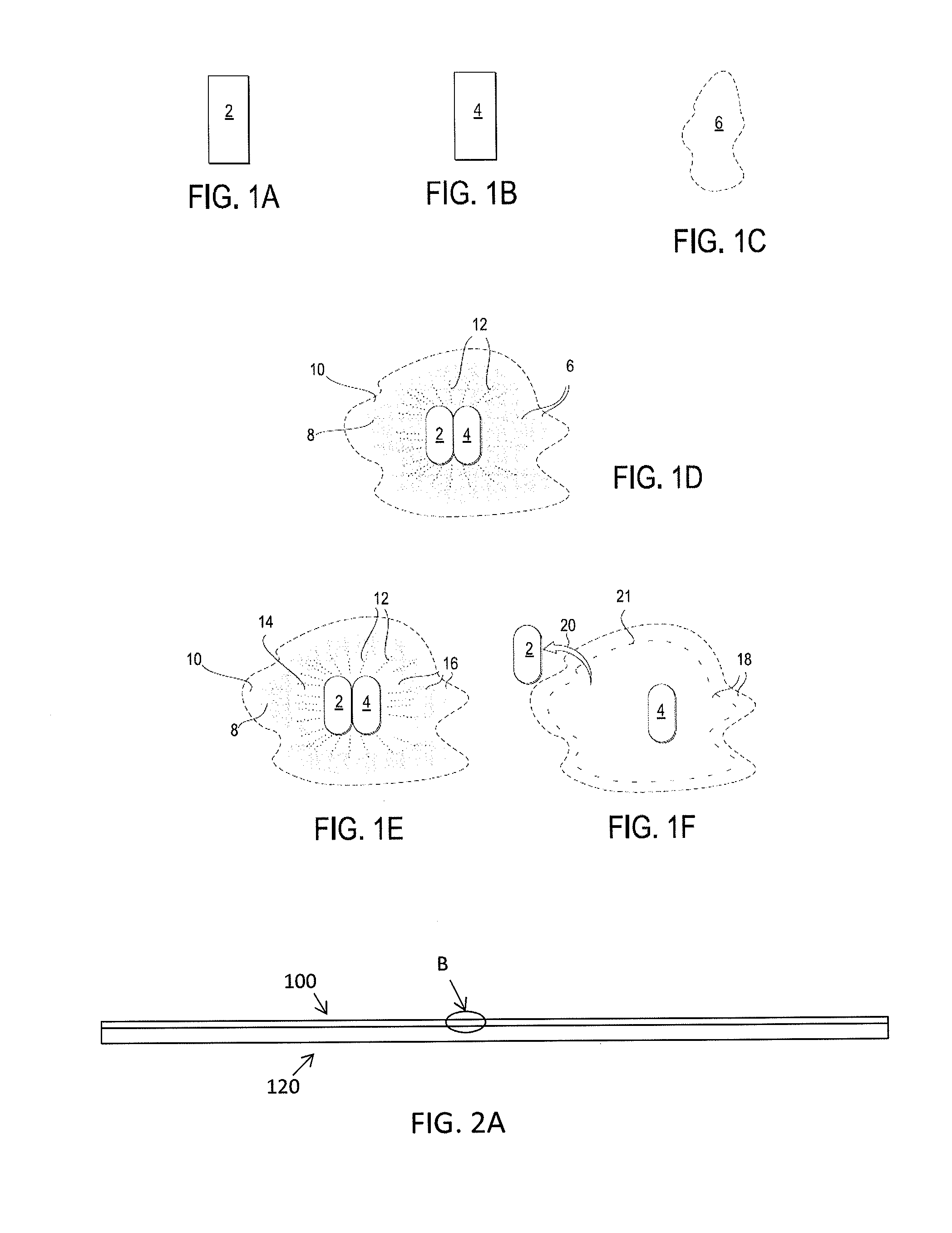

Soft tissue implants and anti-scarring agents

InactiveUS20050142162A1Guaranteed functionImprove clinical outcomesPeptide/protein ingredientsAntipyreticChinBiomedical engineering

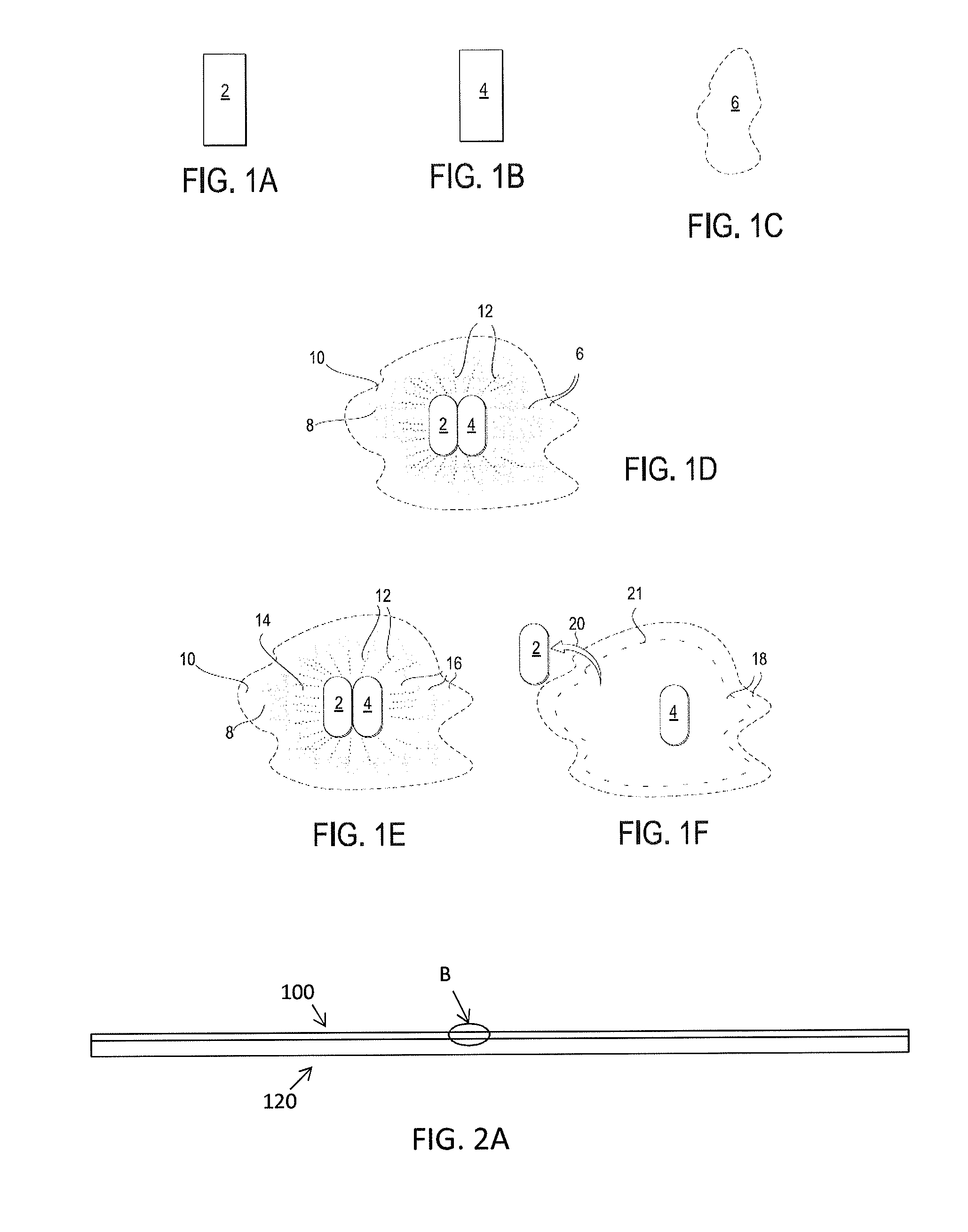

Soft tissue implants (e.g., breast, pectoral, chin, facial, lip, and nasal implants) are used in combination with an anti-scarring agent in order to inhibit scarring that may otherwise occur when the implant is placed within an animal.

Owner:ANGIOTECH INT AG (CH)

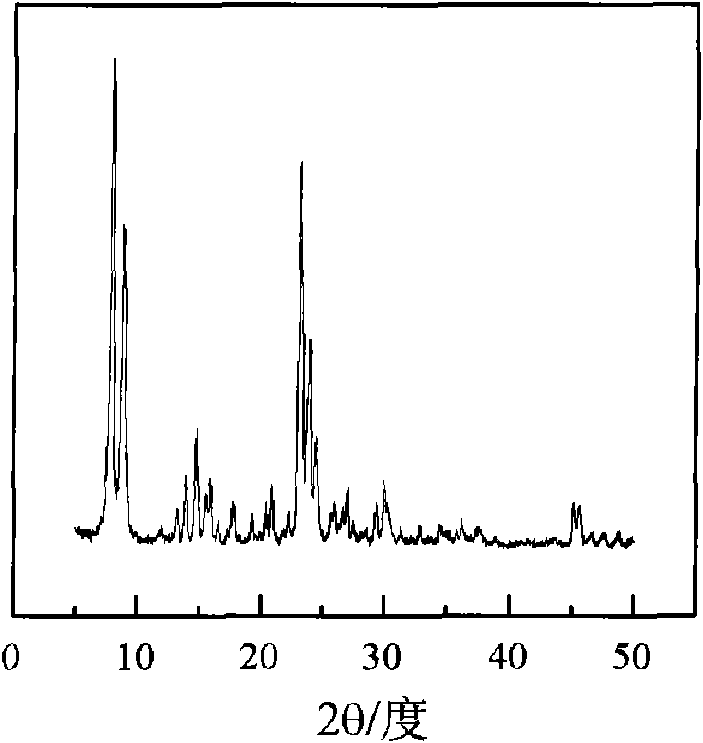

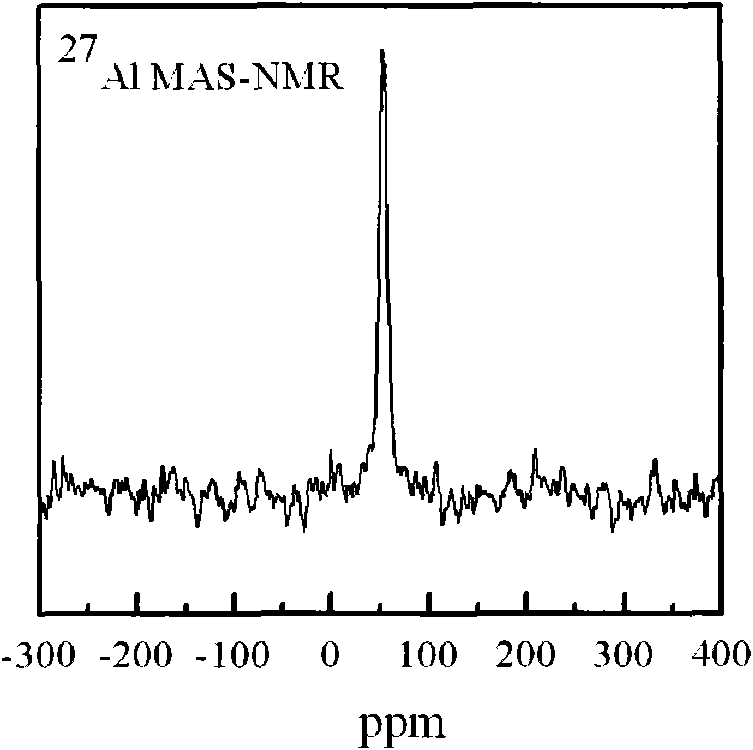

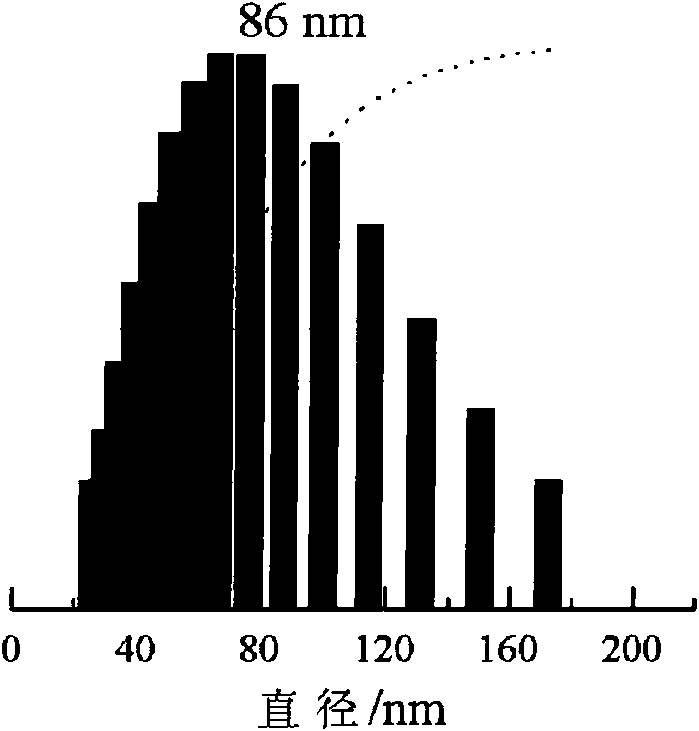

ZSM-5 type molecular sieve for catalyst for reaction for preparing propylene from methanol and/or dimethyl ether

ActiveCN101624192AImprove diffusion abilityHigh P/E ratioMolecular sieve catalystsHydrocarbon from oxygen organic compoundsDispersitySilicon

The invention provides a ZSM-5 type molecular sieve for a catalyst for a reaction for preparing propylene from methanol and / or dimethyl ether, which has a silica alumina ratio of 250-1,150 and a grain diameter of 65-250nm. A preparation method of the molecular sieve comprises the following steps: (1) mixing an aluminum source and an organic directing agent and stirring an obtained mixture at constant temperature of 0-30 DEG C for 2-24 hours; (2) adding a silicon source and an organic addition agent to the mixed solution obtained in the step (1) and continuing stirring the mixed solution to obtain gel; (3) stirring the gel obtained in the step (2) at 35-95 DEG C and then carrying out a crystallization reaction for 24-240 hours at 60-200 DEG C, wherein in the raw materials for synthesizing the molecular sieve, and the molar ratio of OH<-1> to SO2 to AL2O3 to H2O to the organic directing agent to the organic directing agent is (0.1-0.35):1:(0.0005-0.01):(10-25):(0.1-0.6):(0.5-8). The ZSM-5 type catalyst has the characteristics of controllable grain size, adjustable silica alumina ratio, high dispersity, and the like and has higher propylene selectivity and P / E ratio in the reaction for preparing low carbon olefin from the methanol and / or the dimethyl ether.

Owner:DATANG INT CHEM TECH RESINST

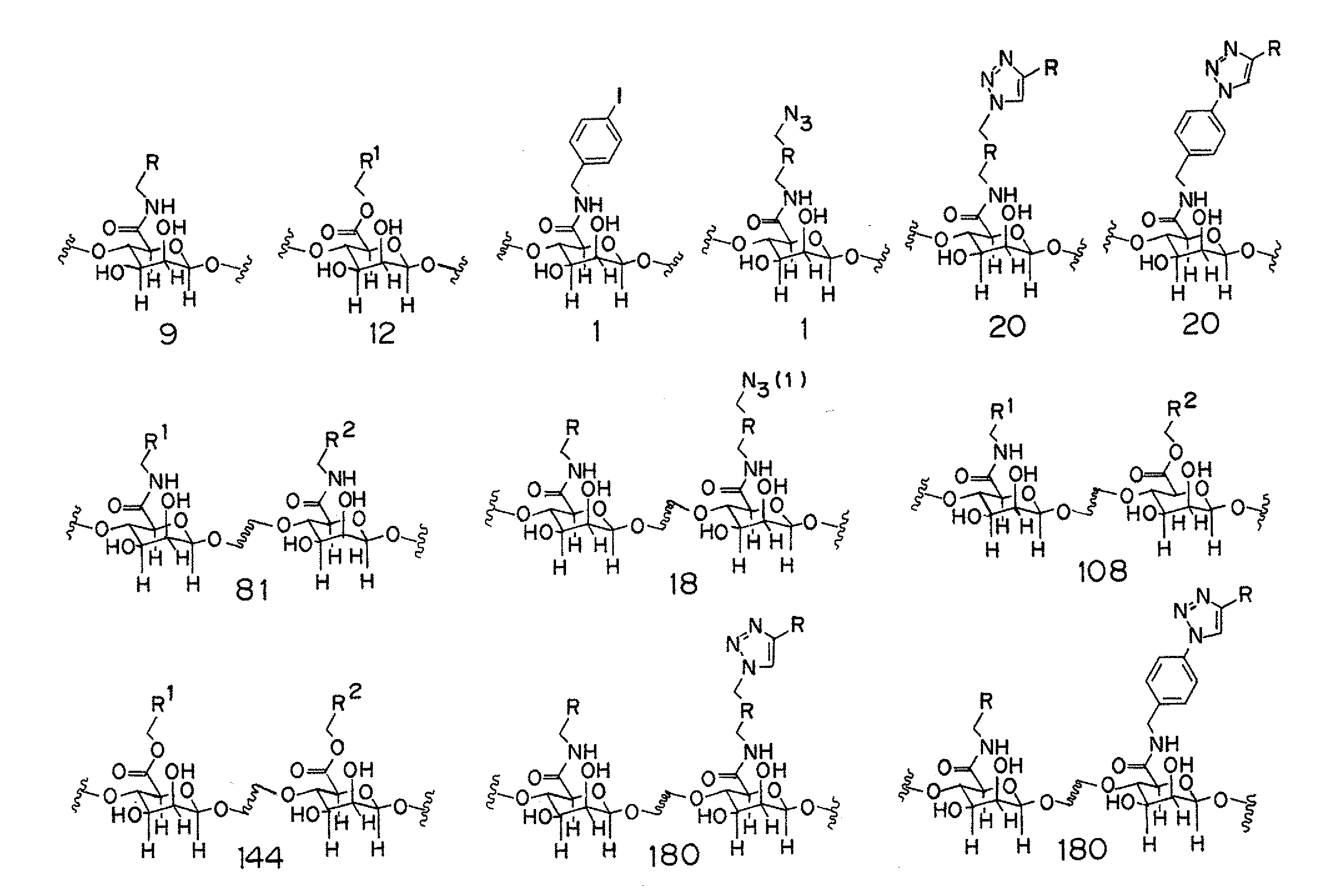

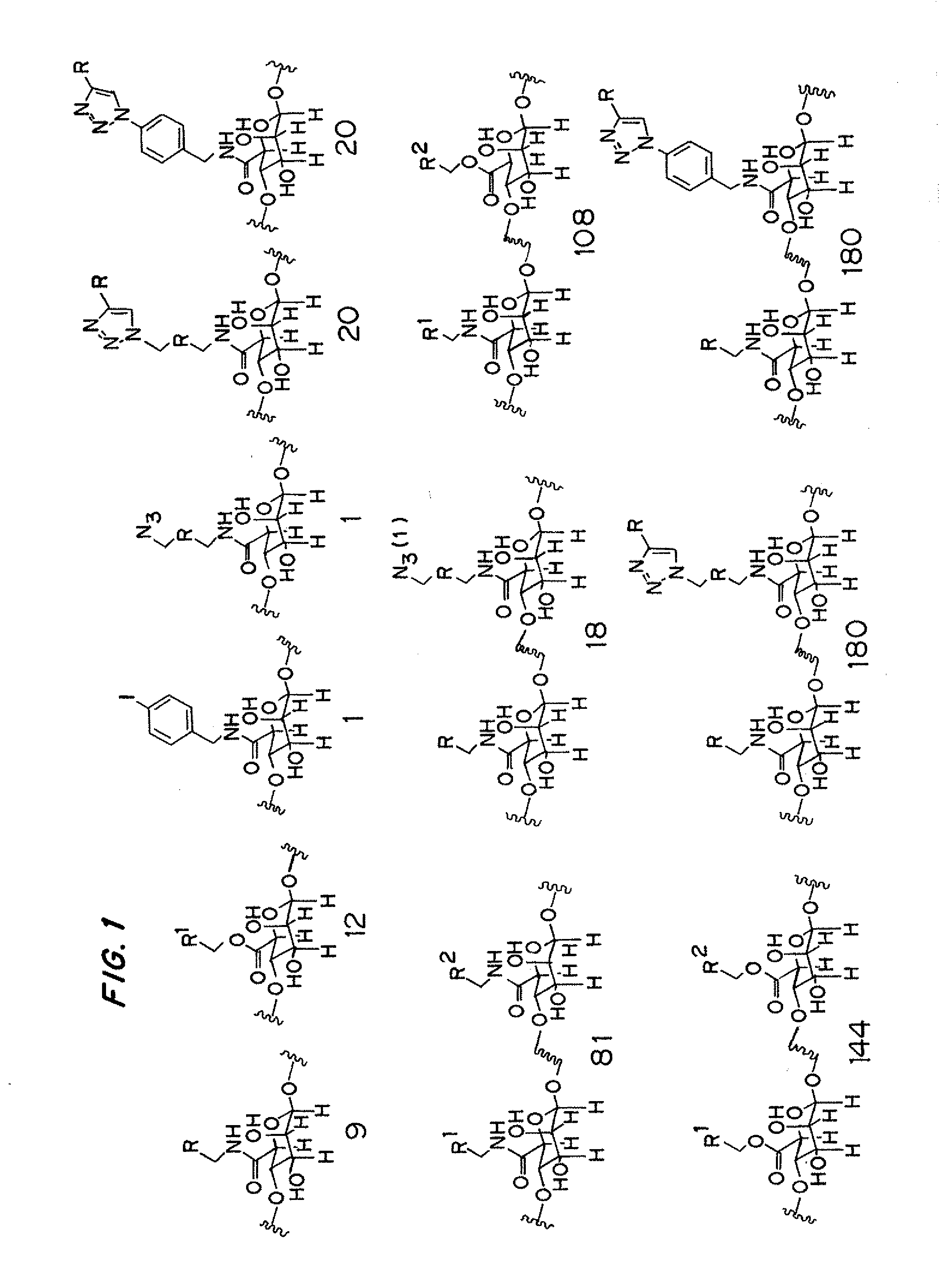

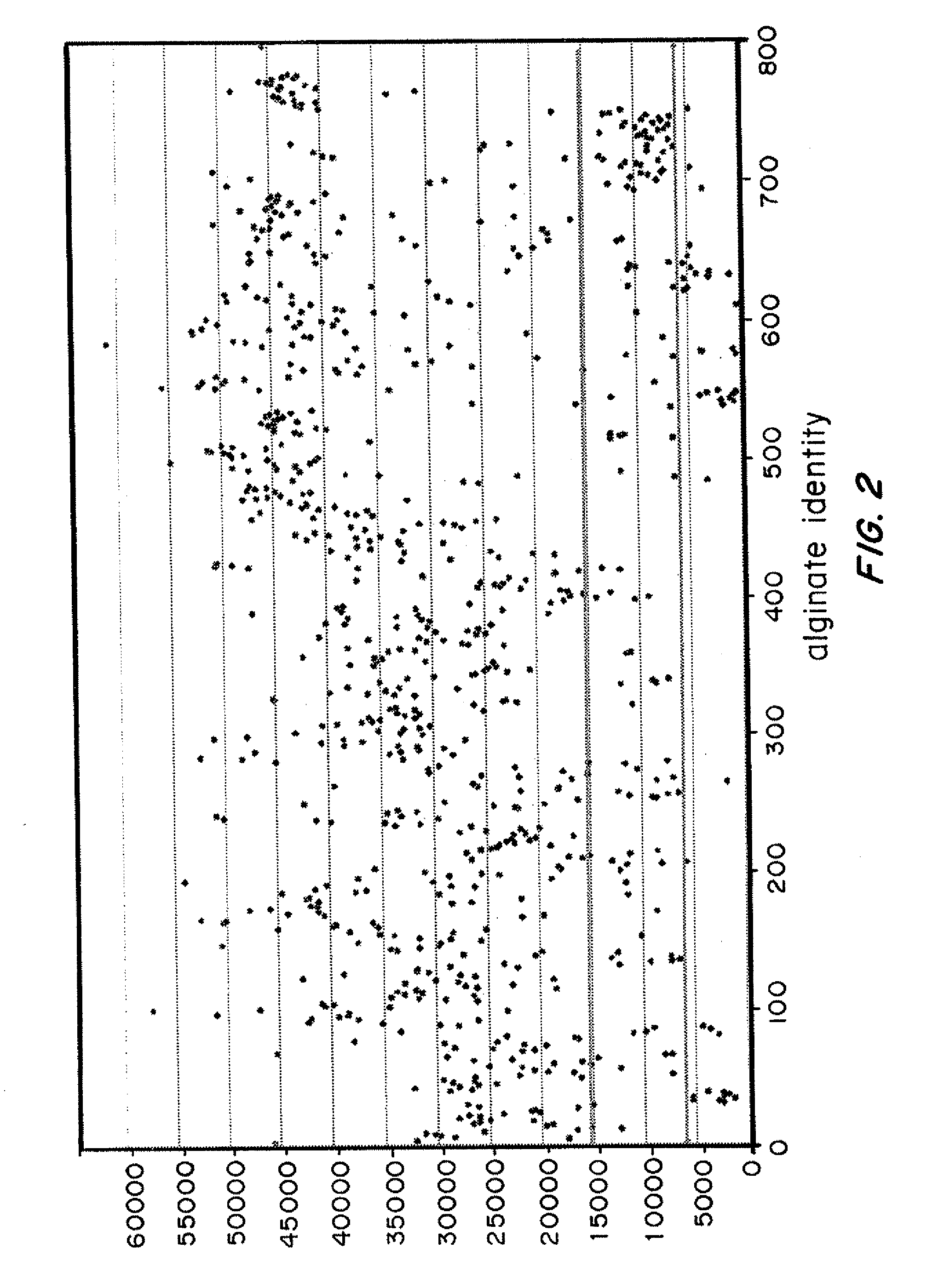

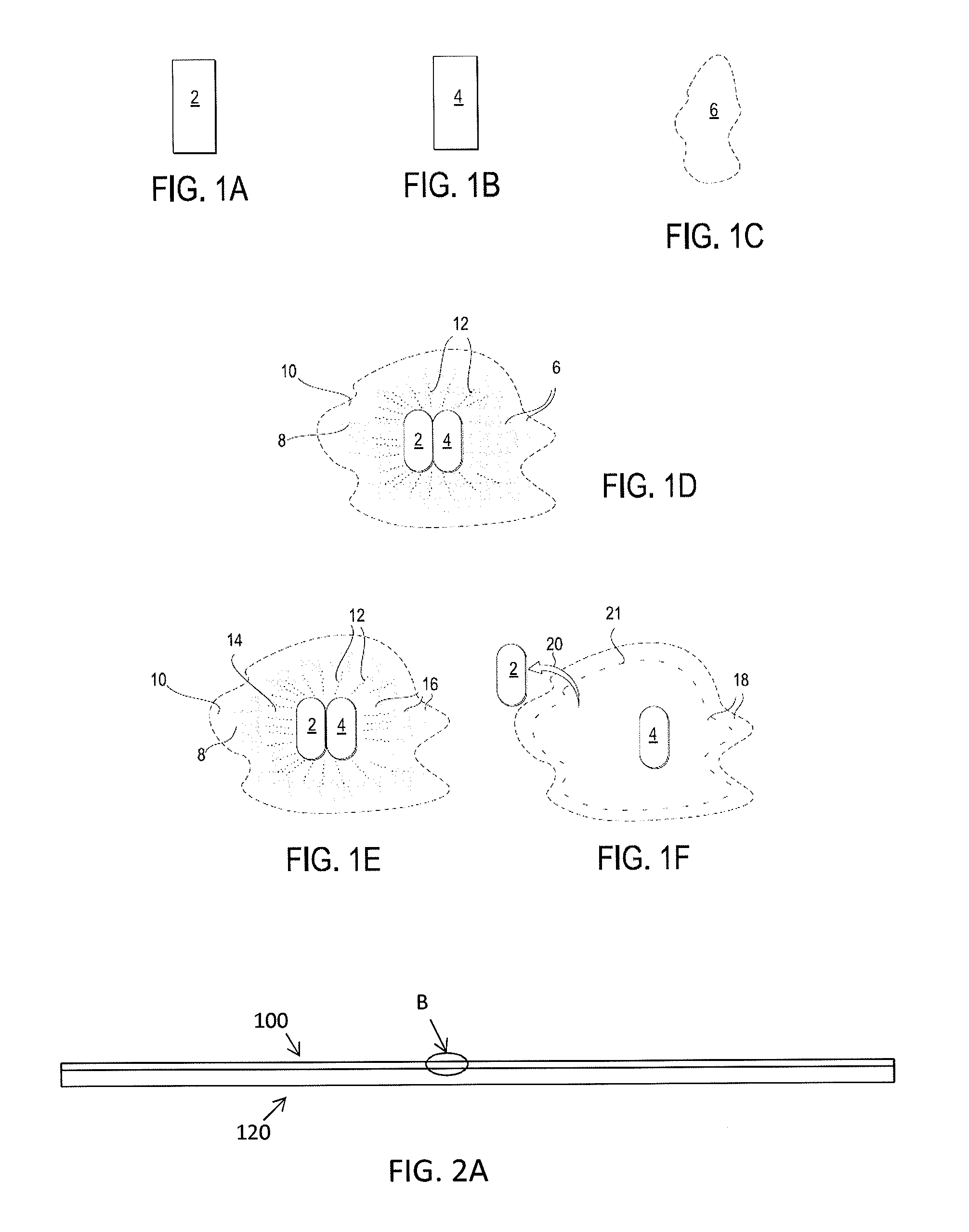

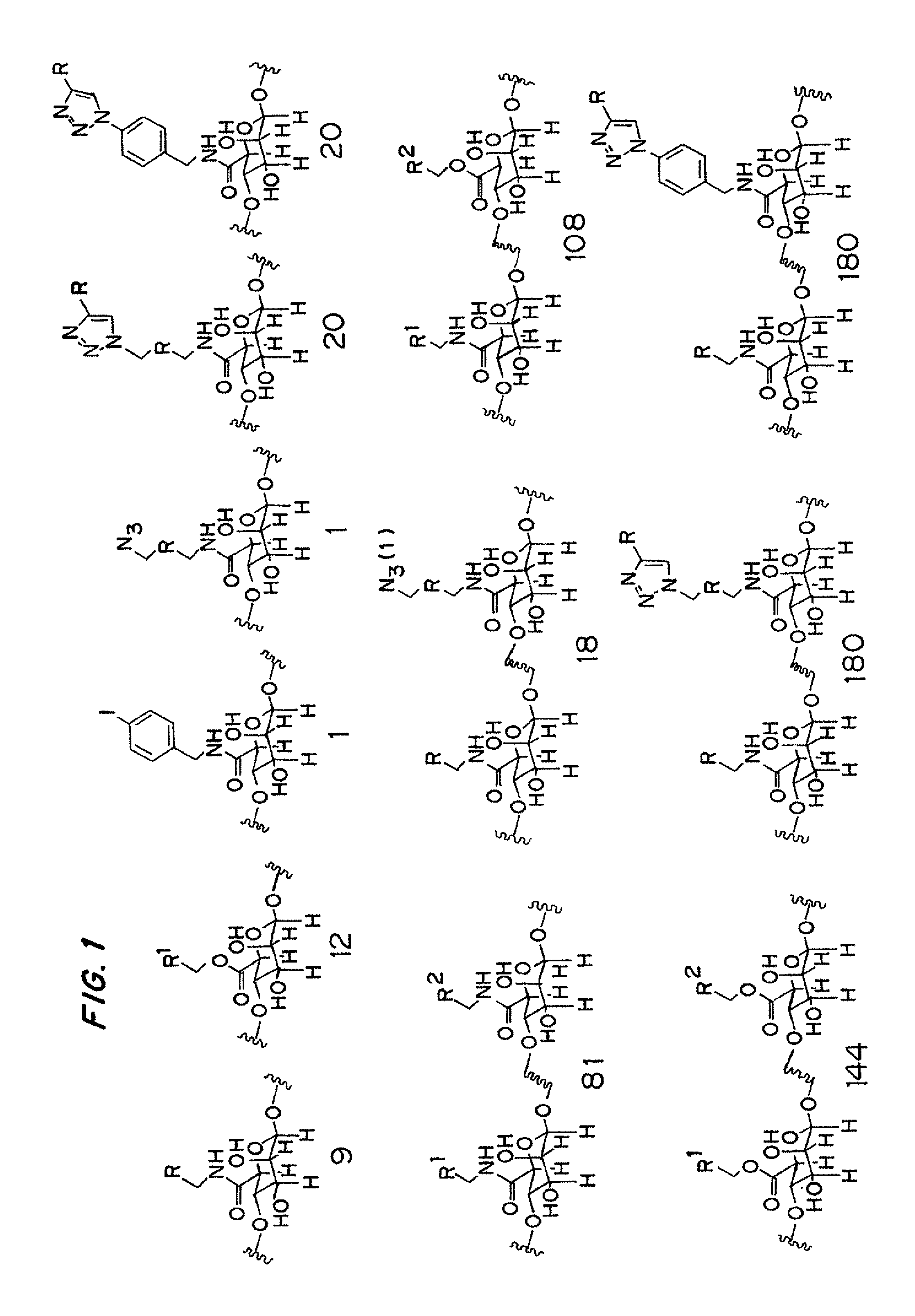

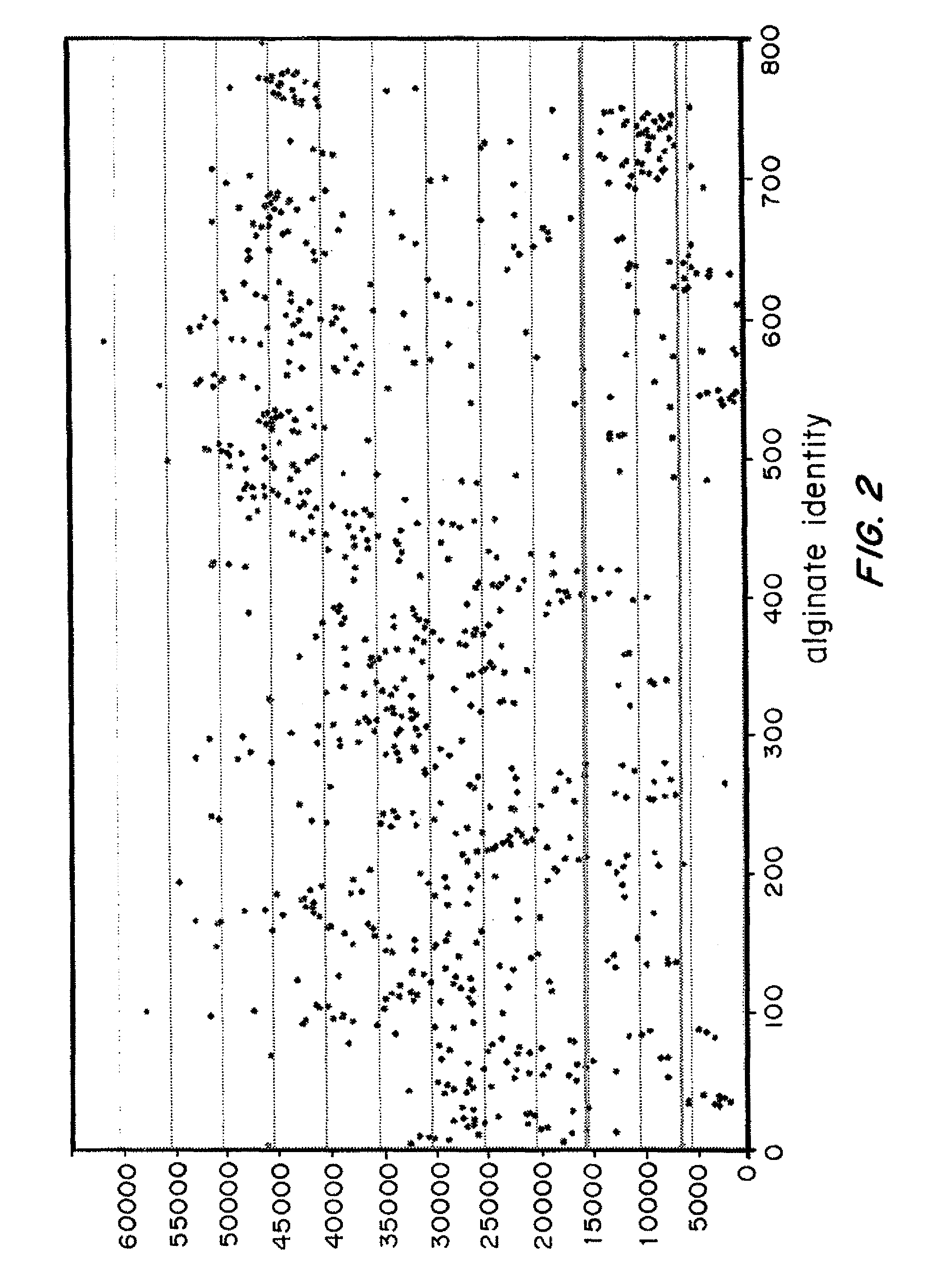

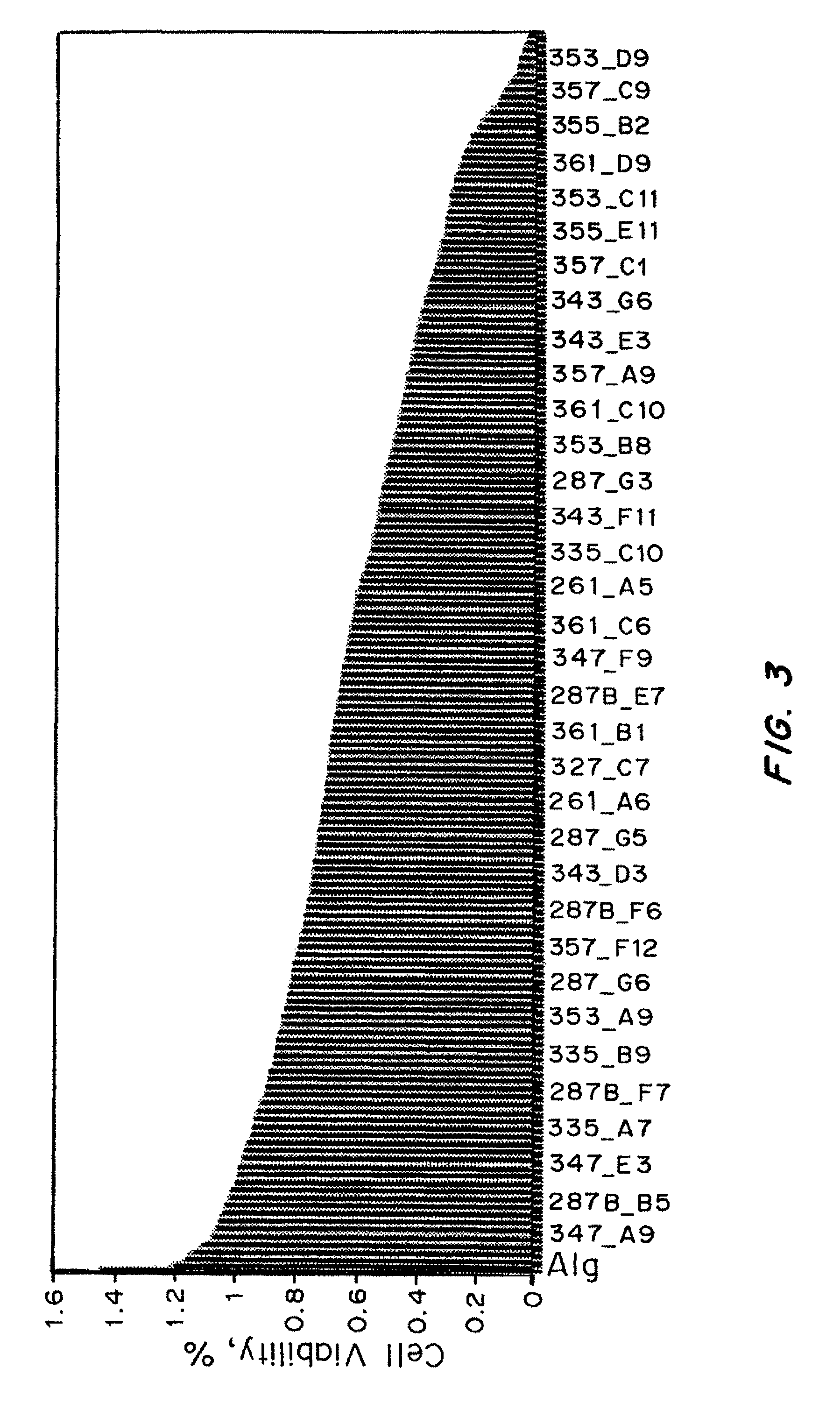

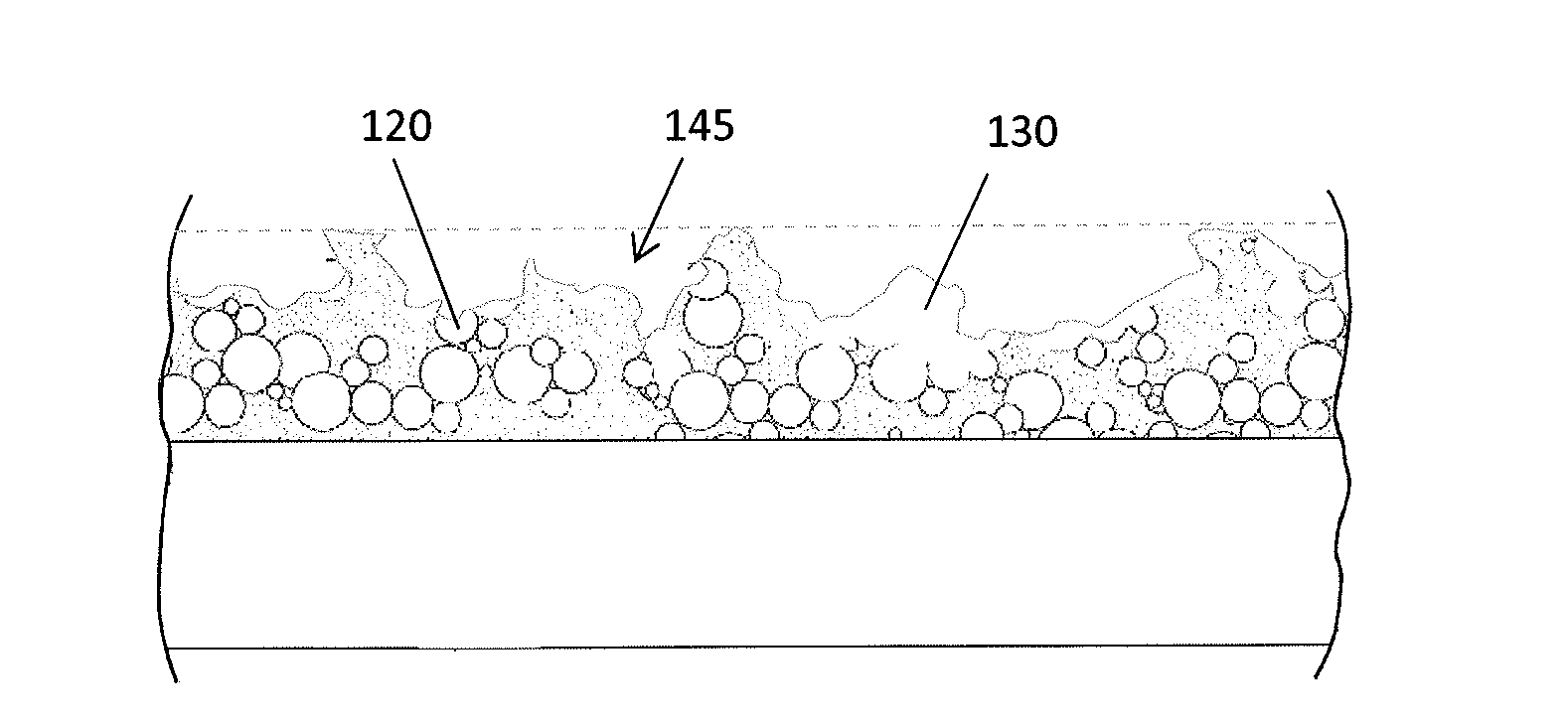

Modified alginates for cell encapsulation and cell therapy

ActiveUS20120308650A1Avoid encapsulationImprove propertiesPowder deliveryBiocideBiocompatibility TestingBiochemistry

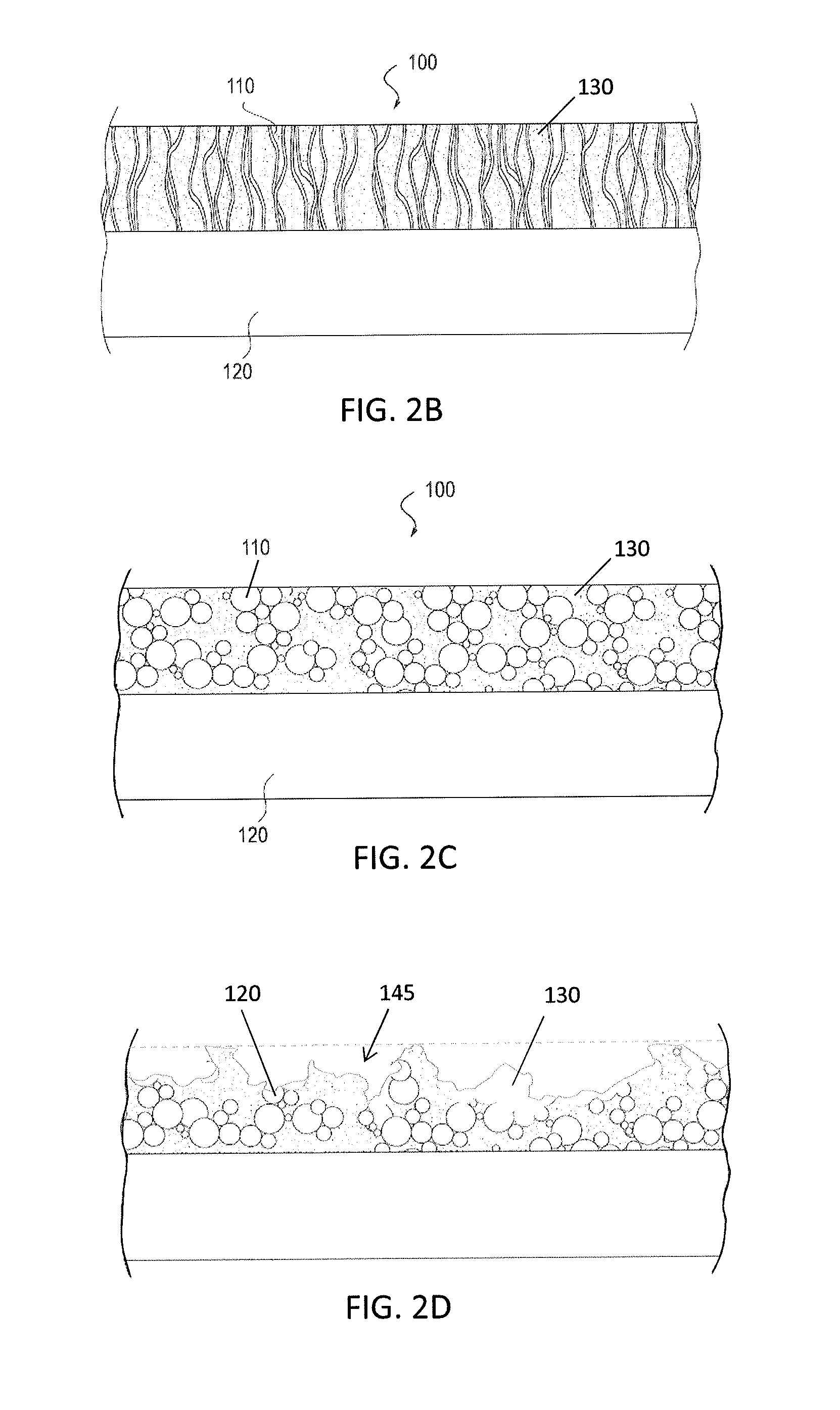

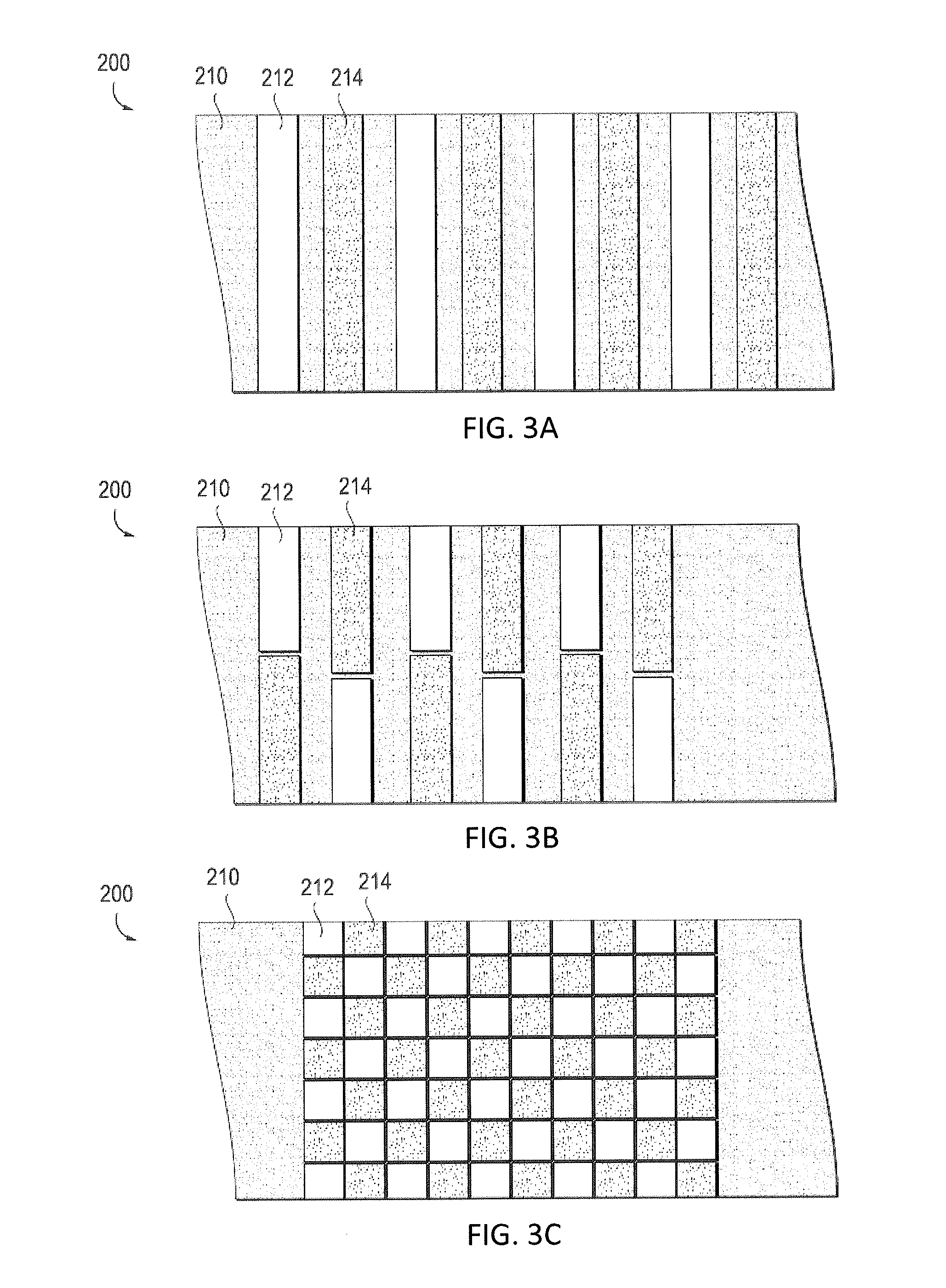

Covalently modified alginate polymers, possessing enhanced biocompatibility and tailored physiochemical properties, as well as methods of making and use thereof, are disclosed herein. The covalently modified alginates are useful as a matrix for the encapsulation and transplantation of cells. Also disclosed are high throughput methods for the characterizing the biocompatibility and physiochemical properties of modified alginate polymers.

Owner:MASSACHUSETTS INST OF TECH +1

Modified alginates for Anti-fibrotic materials and applications

ActiveUS20160030360A1Avoid encapsulationImprove propertiesBiocideMetabolism disorderBiocompatibility TestingAnti fibrotic

Covalently modified alginate polymers, possessing enhanced biocompatibility and tailored physiochemical properties, as well as methods of making and use thereof, are disclosed herein. The covalently modified alginates are useful as a matrix for coating of any material where reduced fibrosis is desired, such as encapsulated cells for transplantation and medical devices implanted or used in the body.

Owner:MASSACHUSETTS INST OF TECH +1

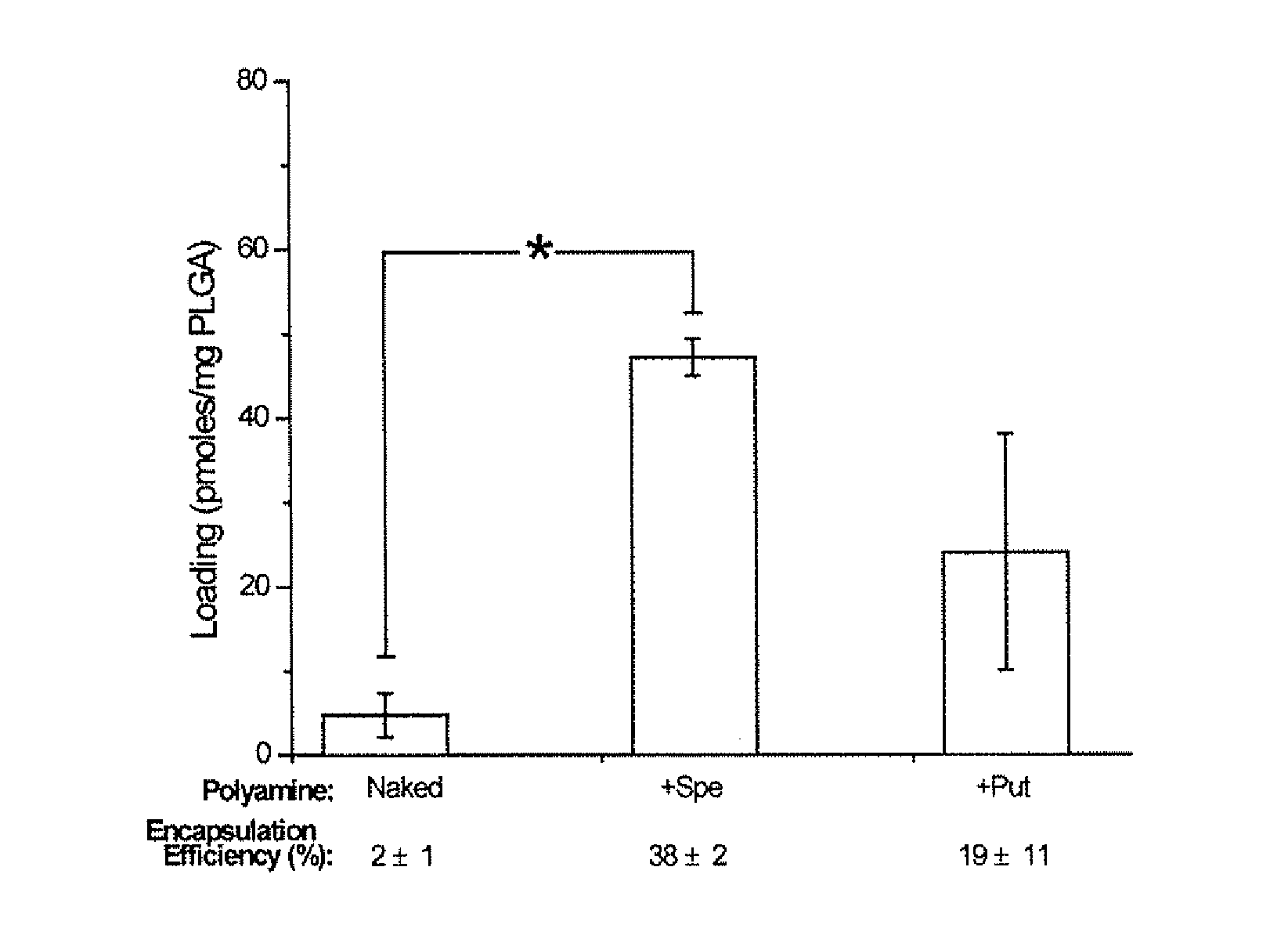

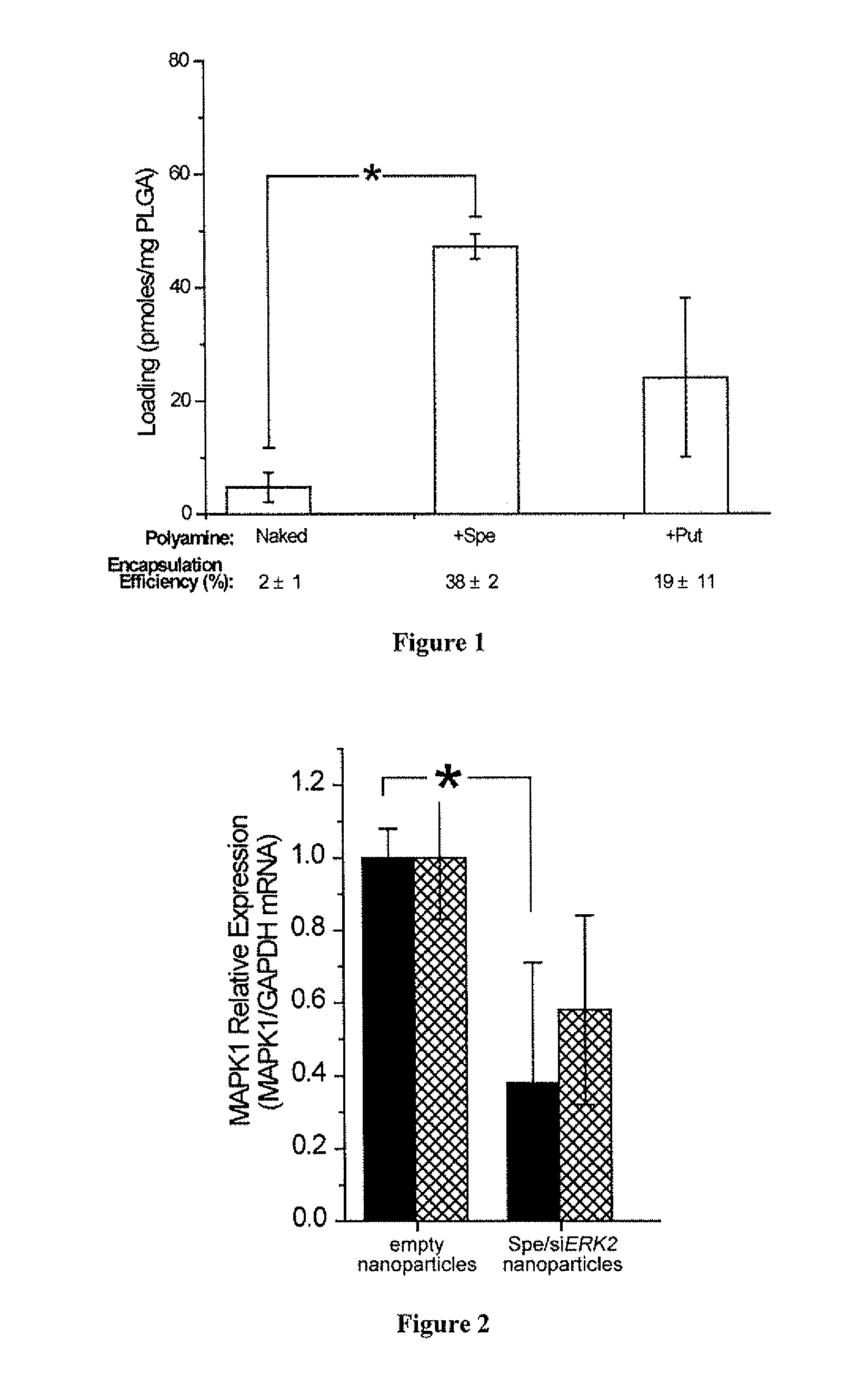

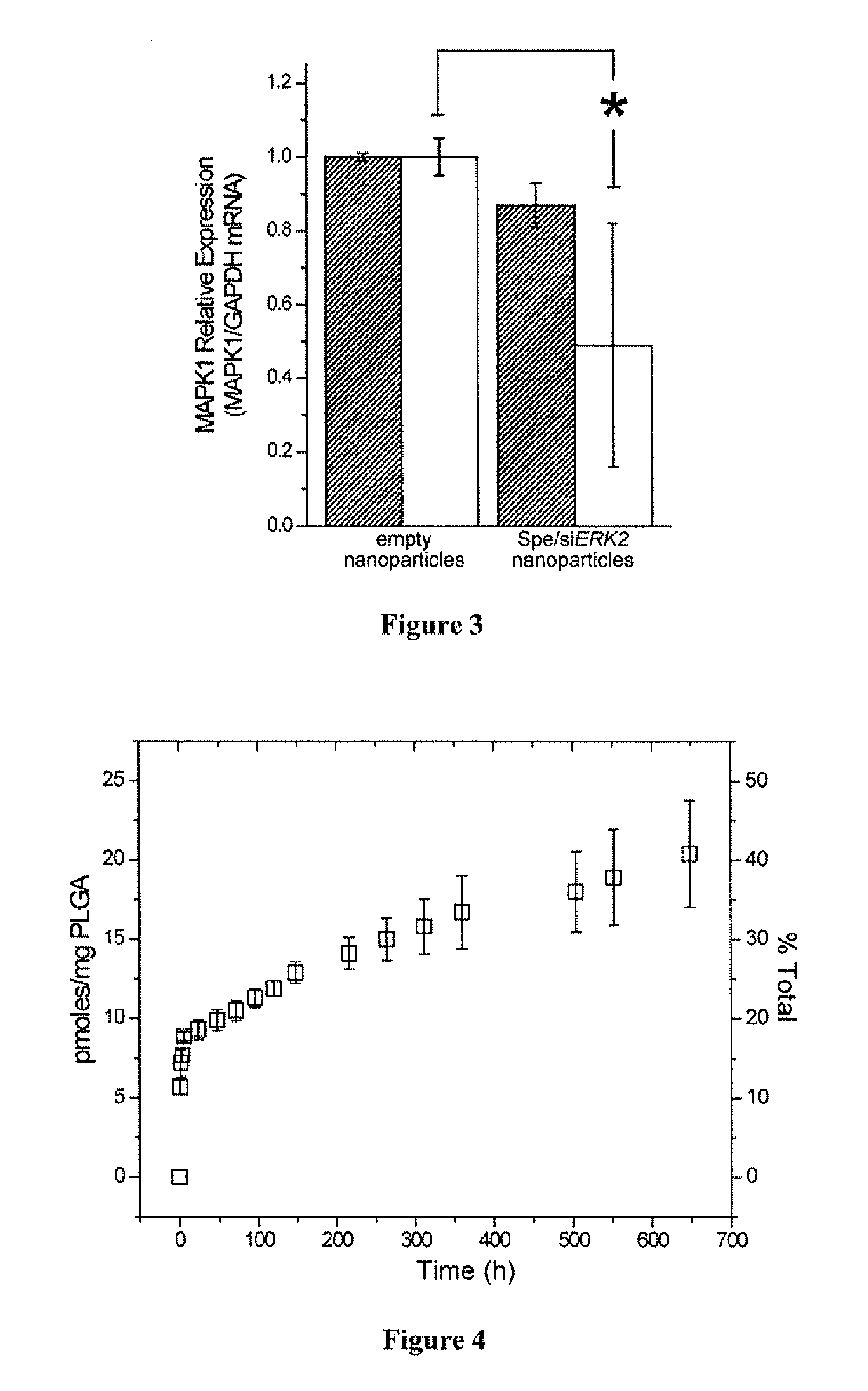

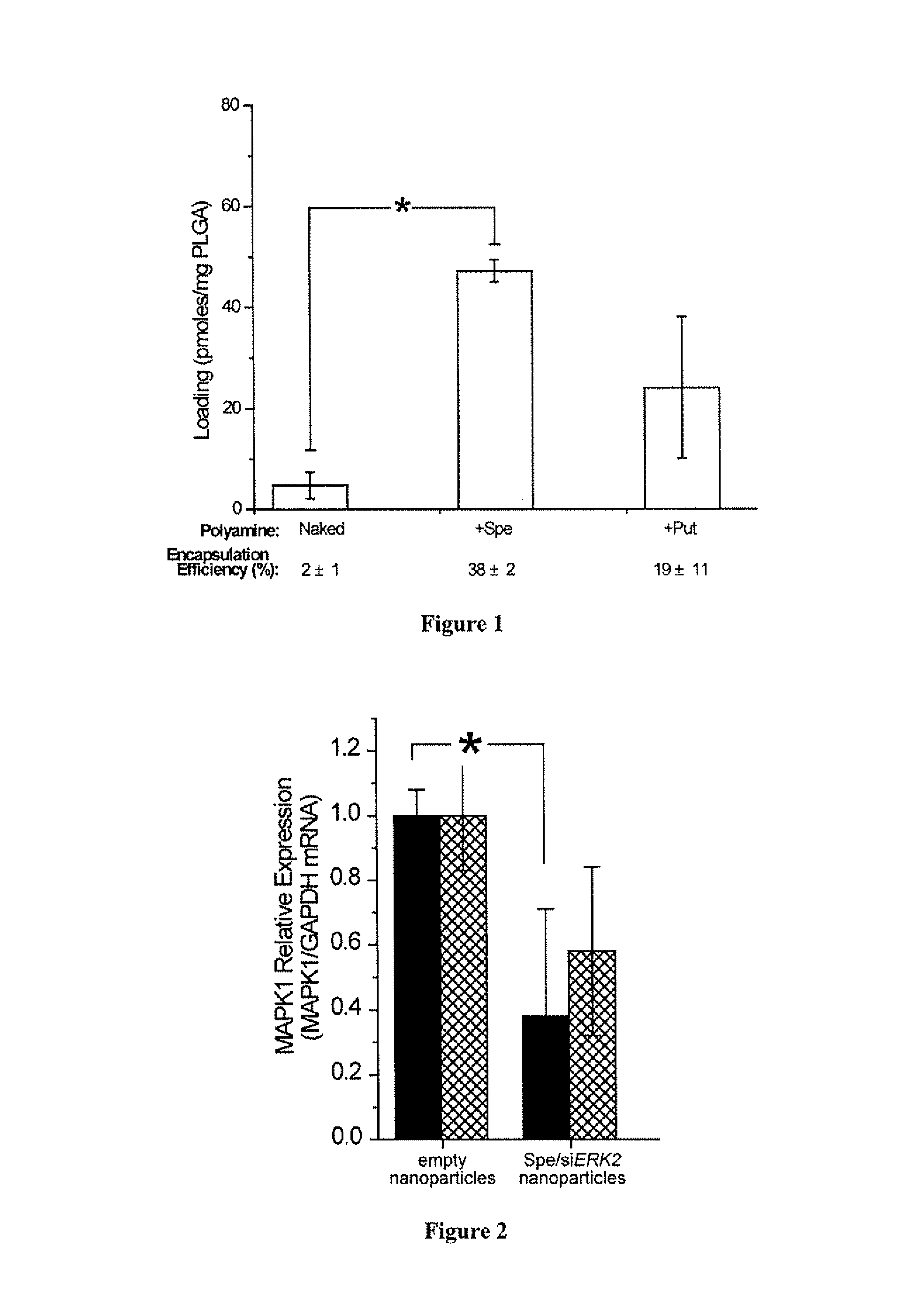

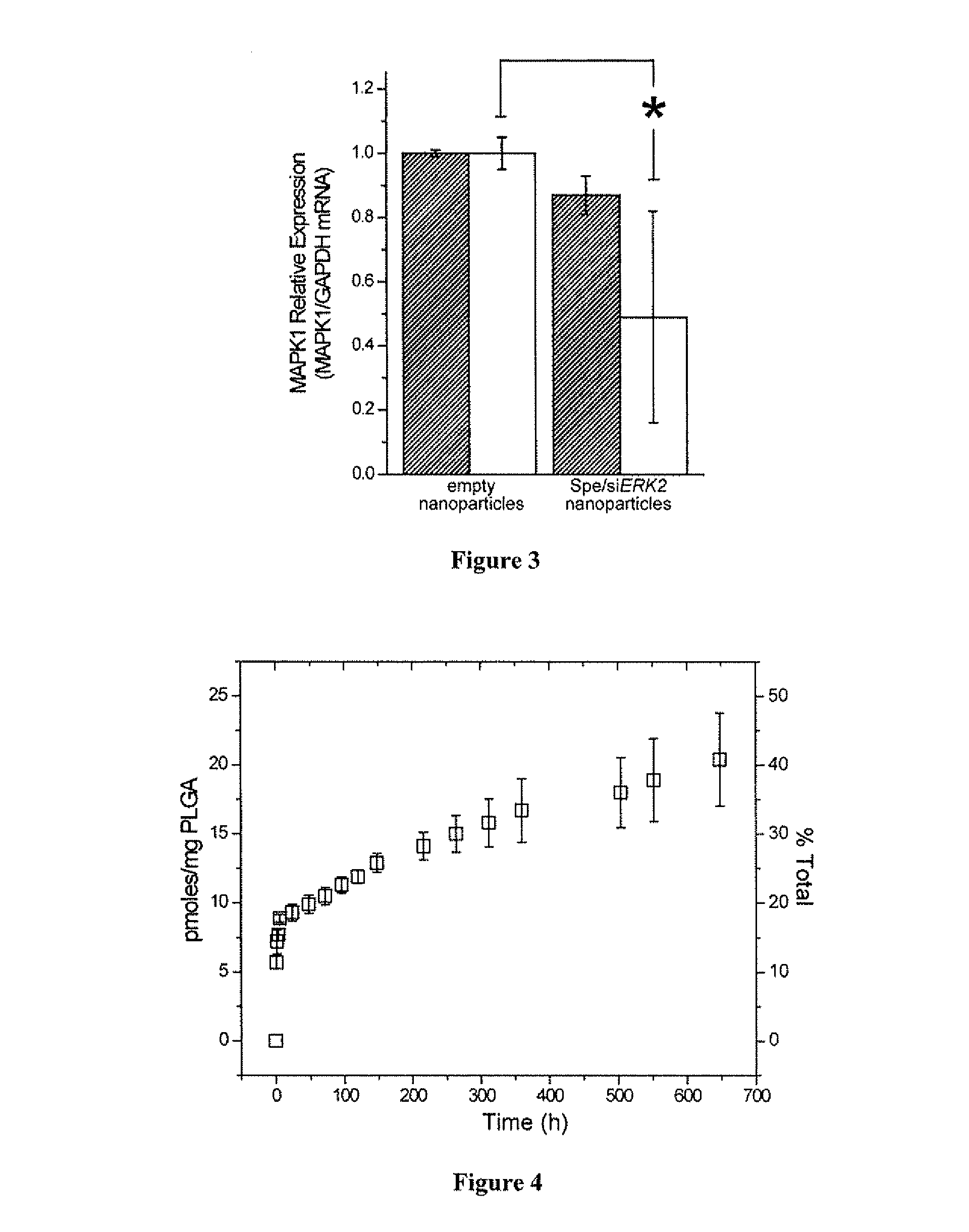

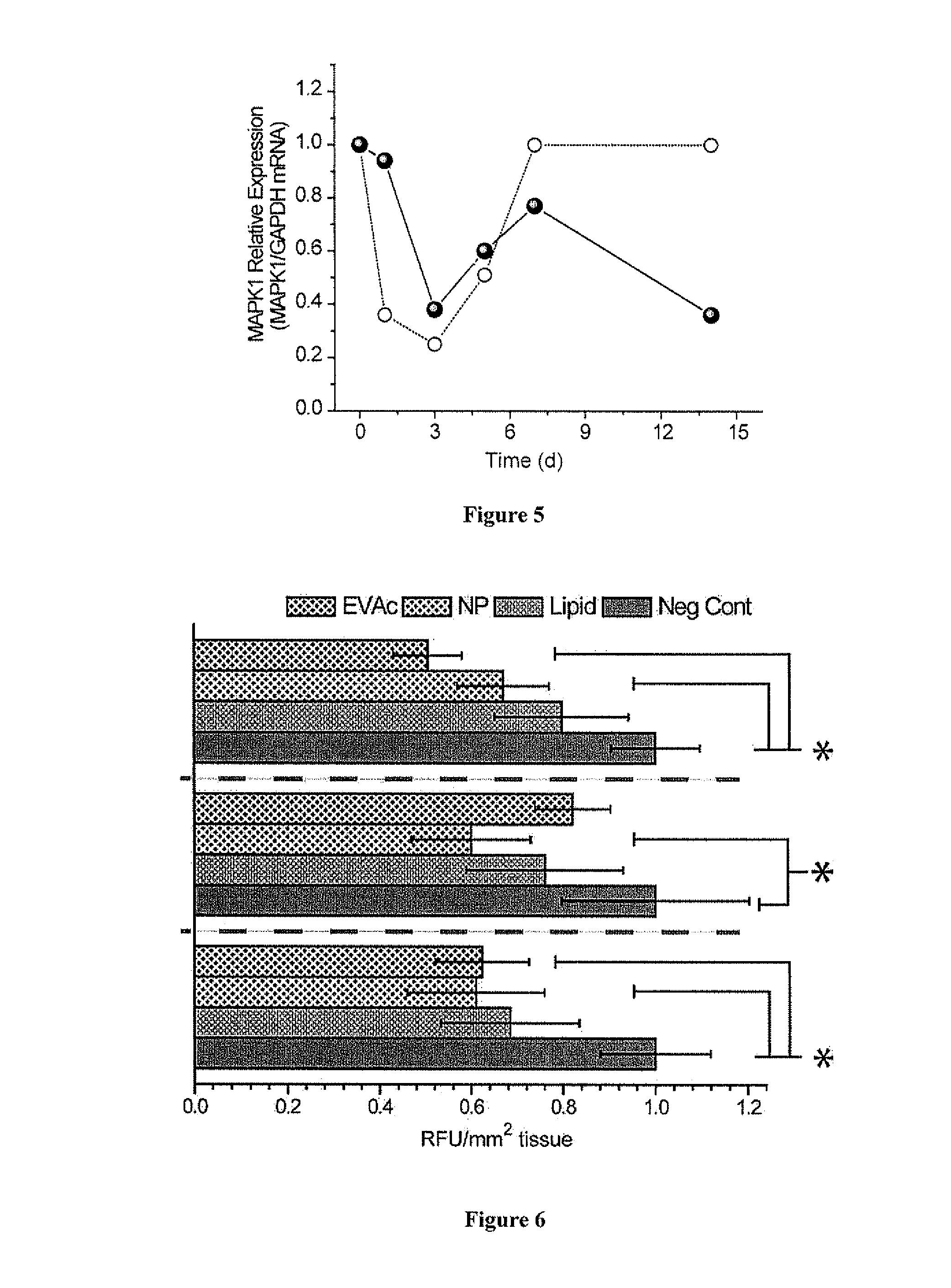

Compositions and methods for controlled delivery of inhibitory ribonucleic acids

ActiveUS20110008451A1Easy modular assemblyAvoid encapsulationPowder deliveryOrganic active ingredientsDiseaseInternalization

Polymeric nanoparticles encapsulating inhibitory ribonucleic acids (RNAs) and methods of their manufacture and use are provided. Advantageous properties of the nanoparticles include: 1) high encapsulation efficiency of inhibitory RNAs into the nanoparticles, 2) small size of the nanoparticles that increases cell internalization, and 3) sustained release of encapsulated inhibitory RNAs by the nanoparticles that allows for administration of an effective amount of inhibitory RNAs to cells or tissues over extended periods of time. Encapsulation efficiency of inhibitory RNAs into the nanoparticles is greatly increased by complexing the inhibitory RNAs to polycations prior to encapsulation. Methods of using the polymeric nanoparticles for treating or inhibiting diseases or disorders are provided.

Owner:YALE UNIV

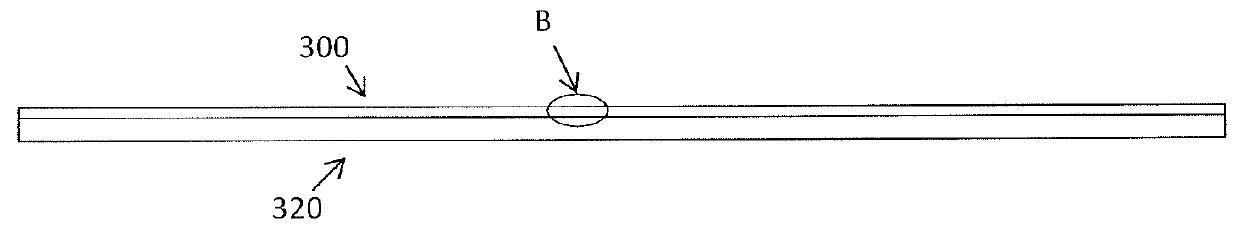

Bioabsorbable substrates and systems that controllably release antimicrobial metal ions

InactiveUS8927004B1Facilitated releaseStay flexibleBiocideInorganic active ingredientsIridiumRhenium

Bioabsorbable substrates having antimicrobial metal ion coatings that are well suited for implantation in to a subject's body to treat and / or prevent infection. In particular, described herein are flexible bioabsorbable filaments that are coated with an anodic metal (e.g., silver and / or zinc and / or copper) that is co-deposited with a cathodic metal (e.g., palladium, platinum, gold, molybdenum, titanium, iridium, osmium, niobium or rhenium) on the filament so that the anodic metal is galvanically released as antimicrobial ions when the apparatus is inserted into a subject's body. The anodic metal may be at least about 30 percent by volume of the coating.

Owner:SILVER BULLET THERAPEUTICS

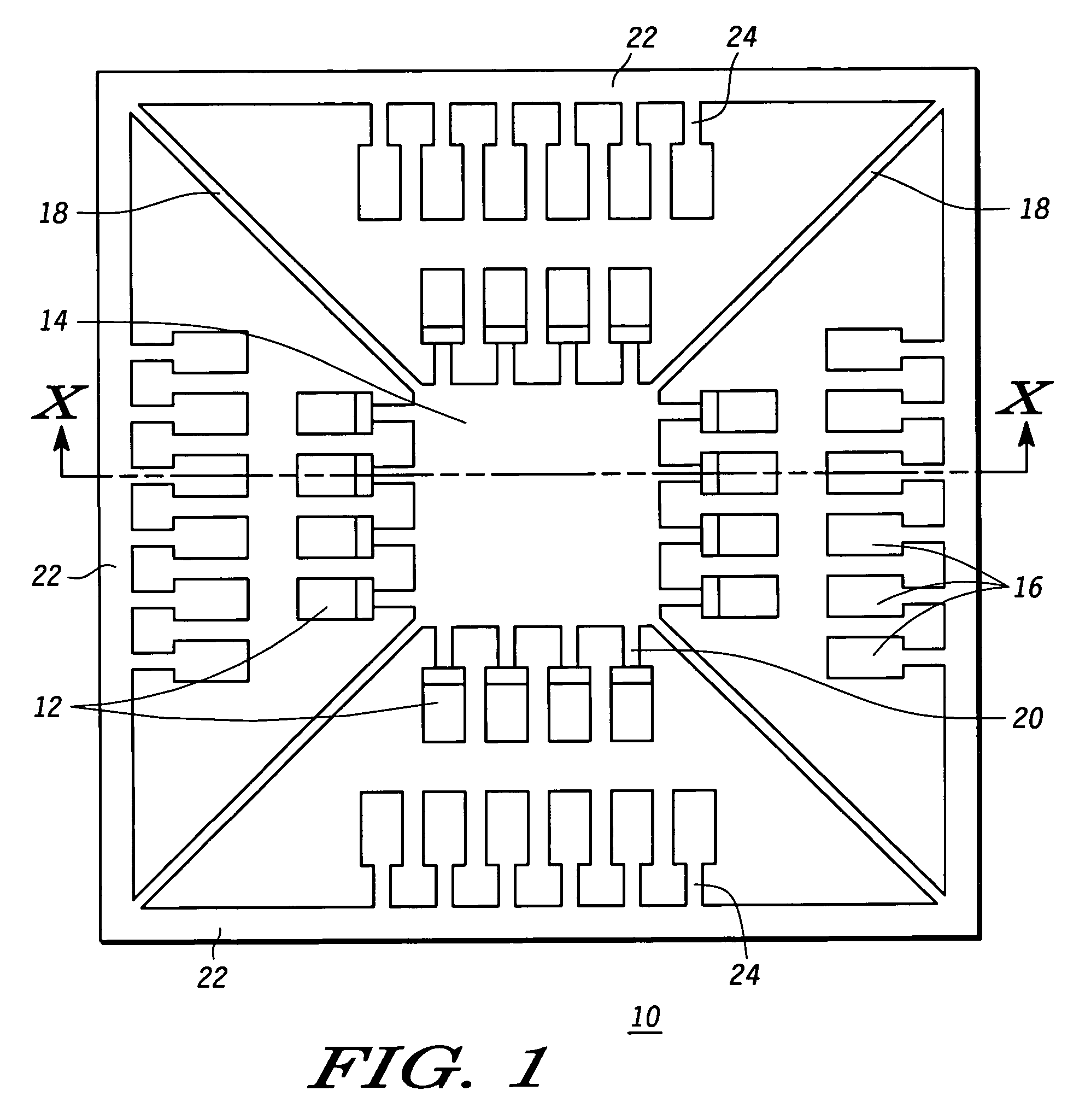

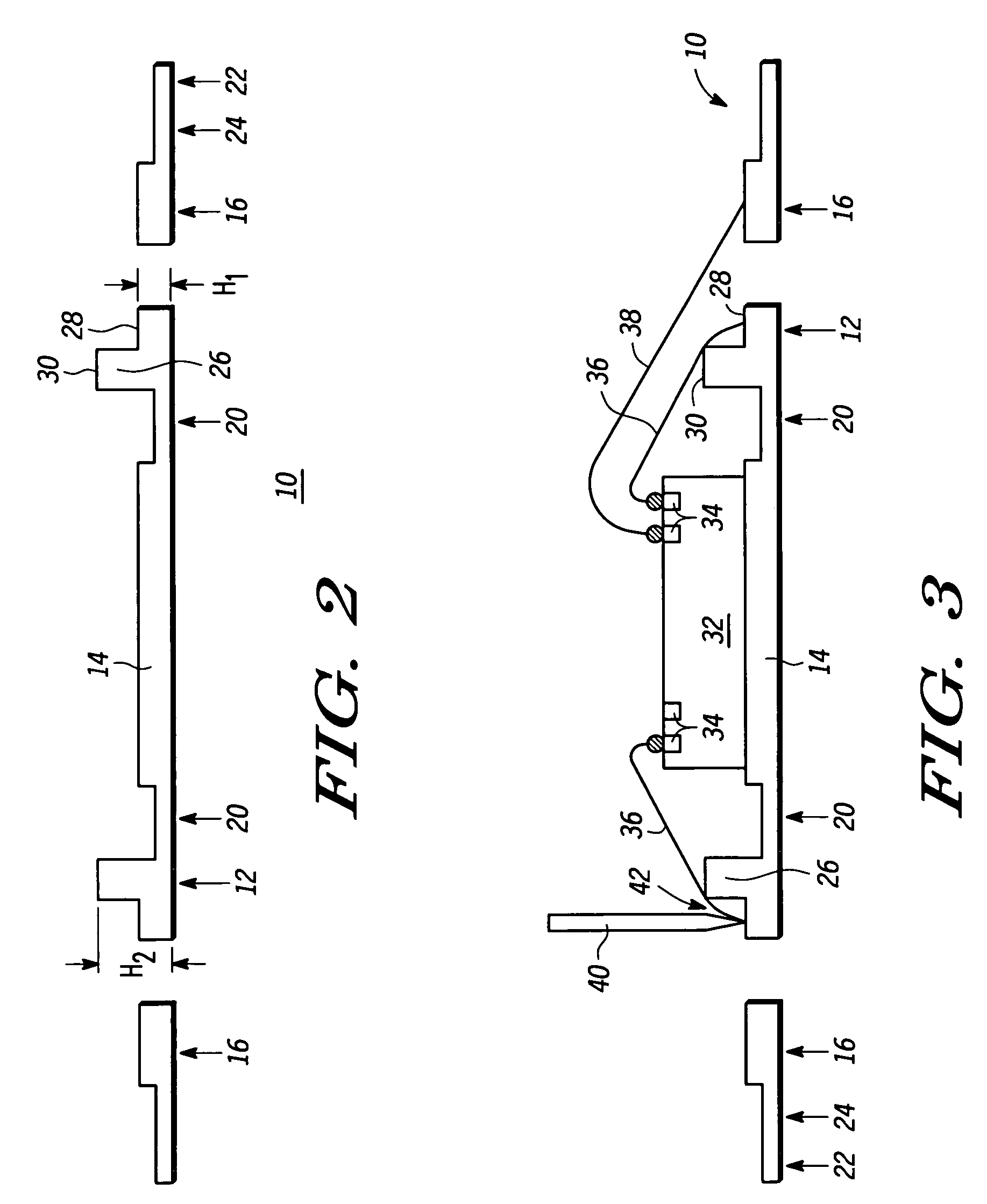

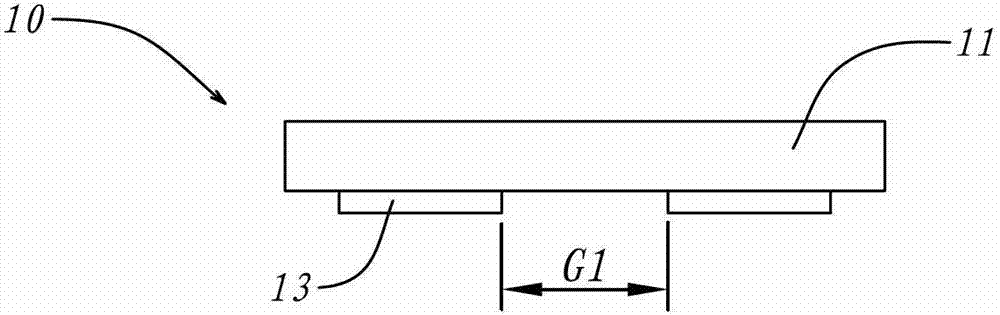

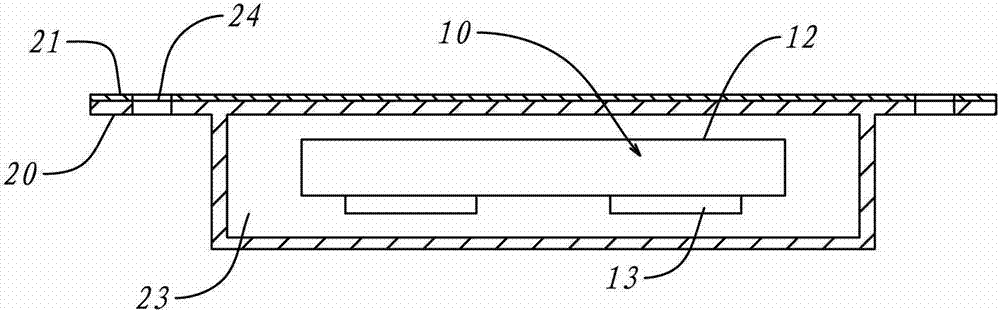

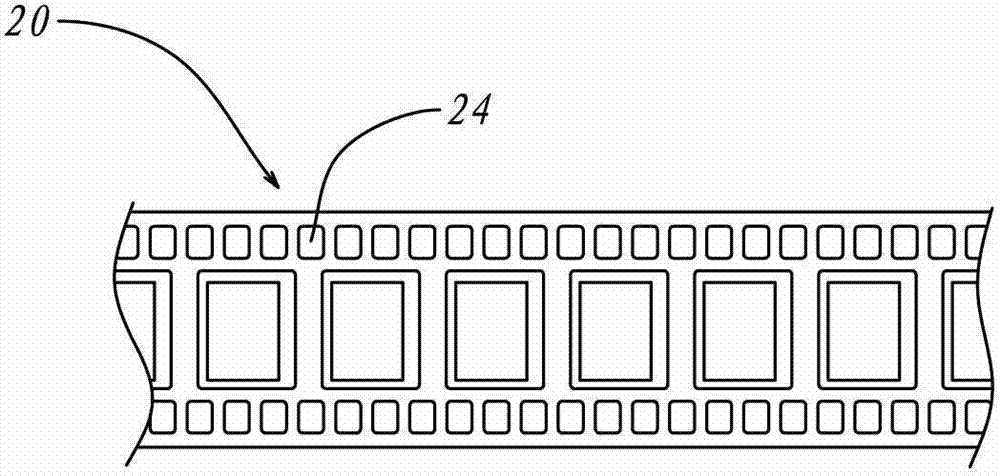

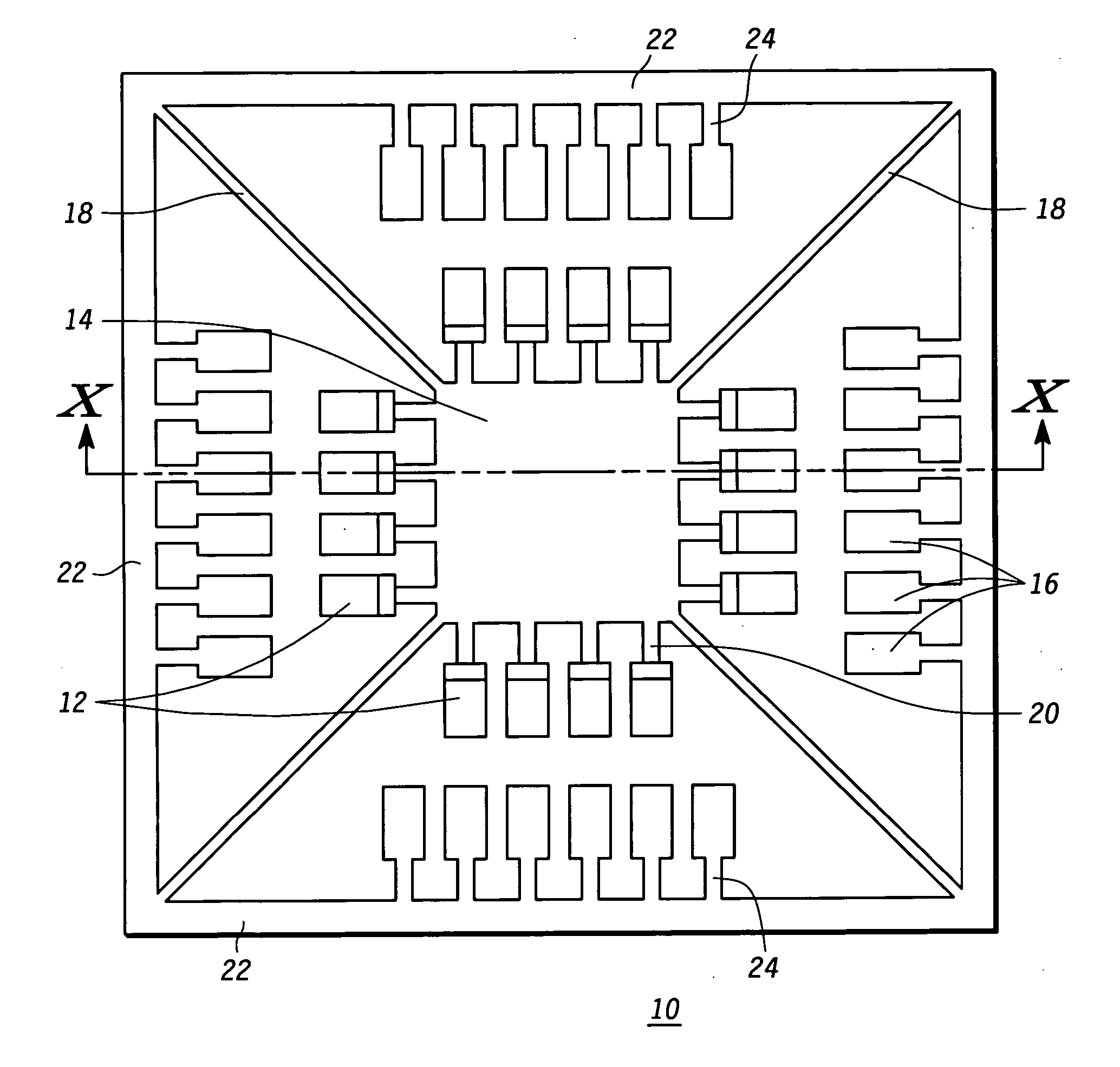

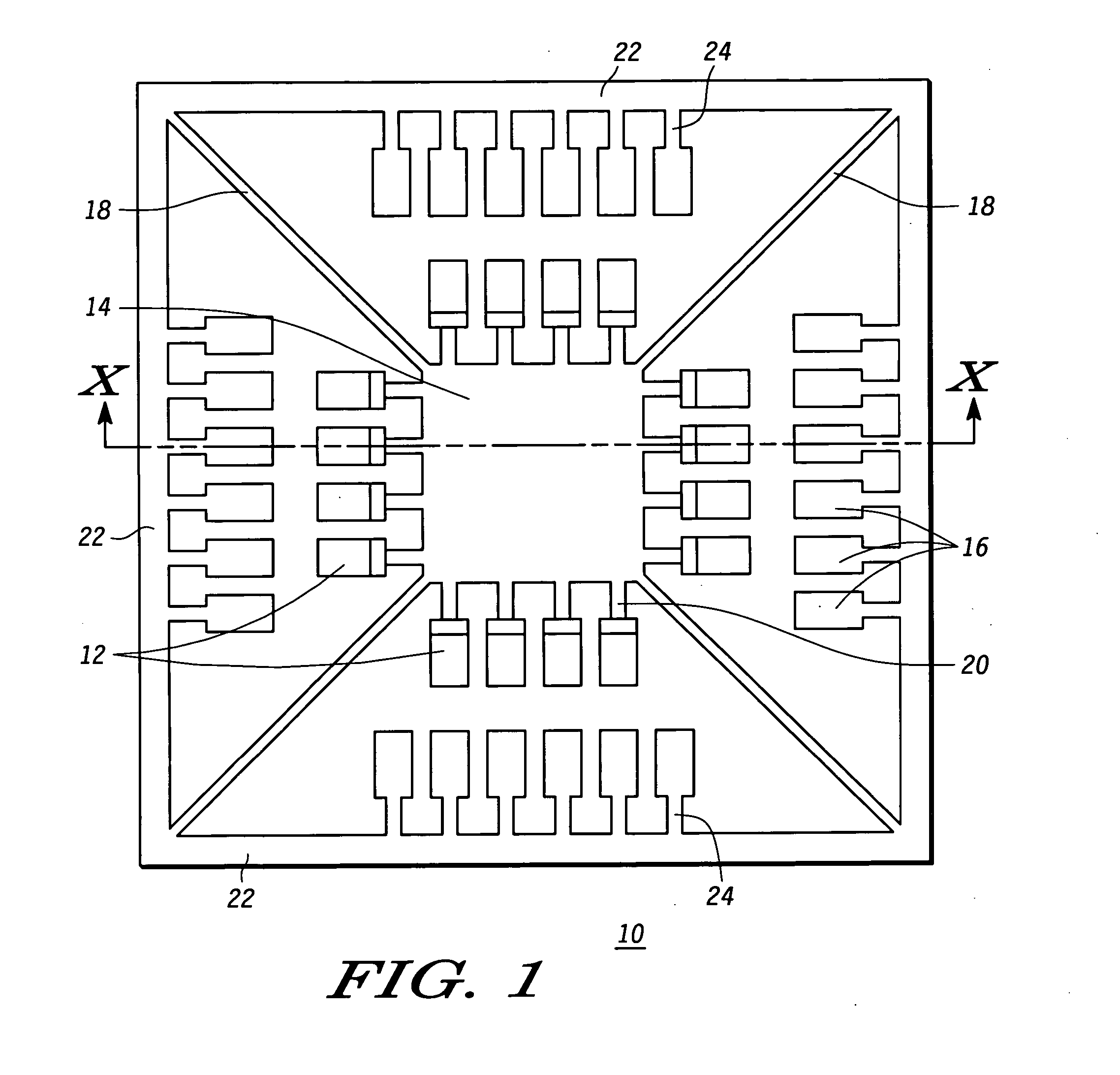

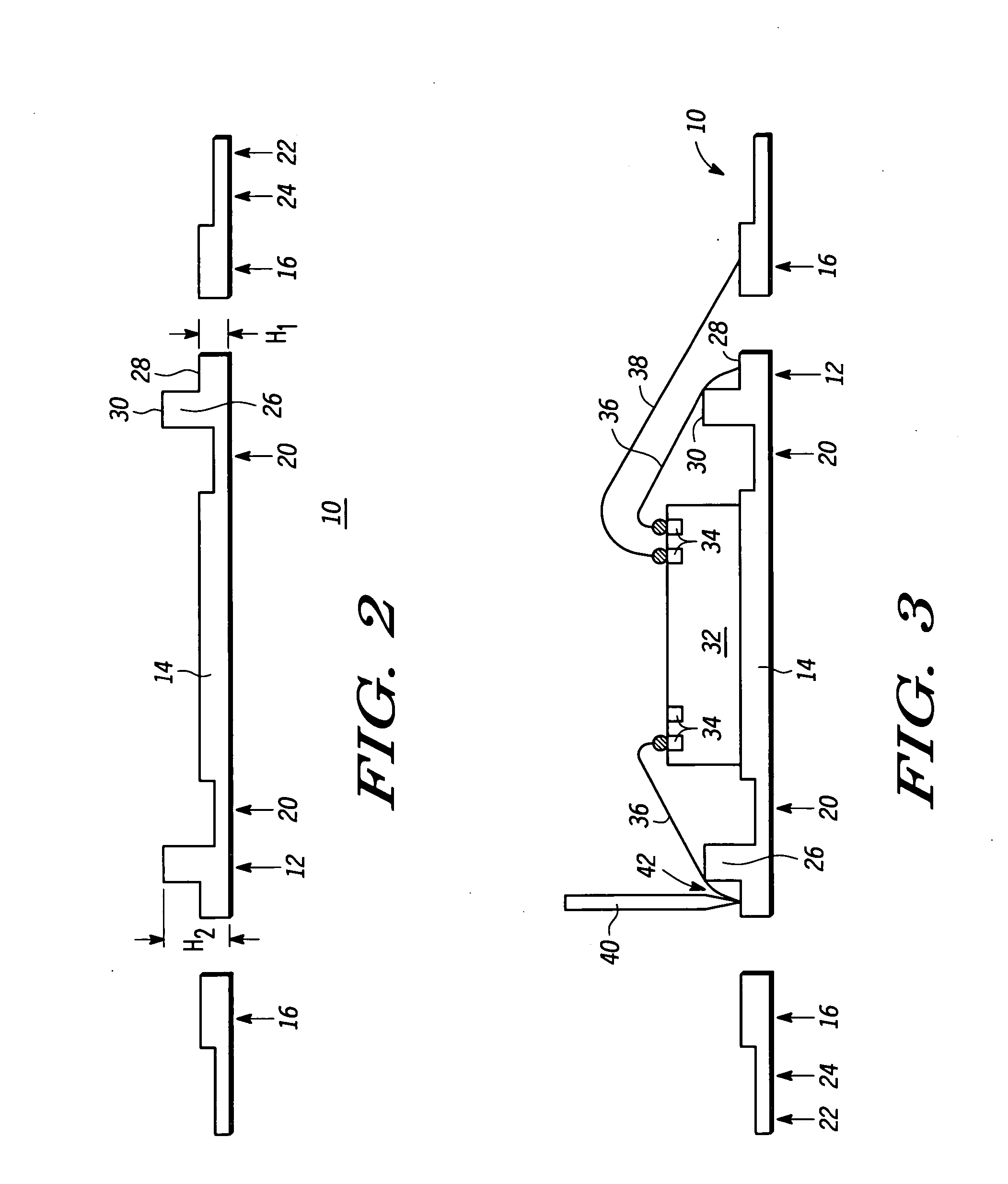

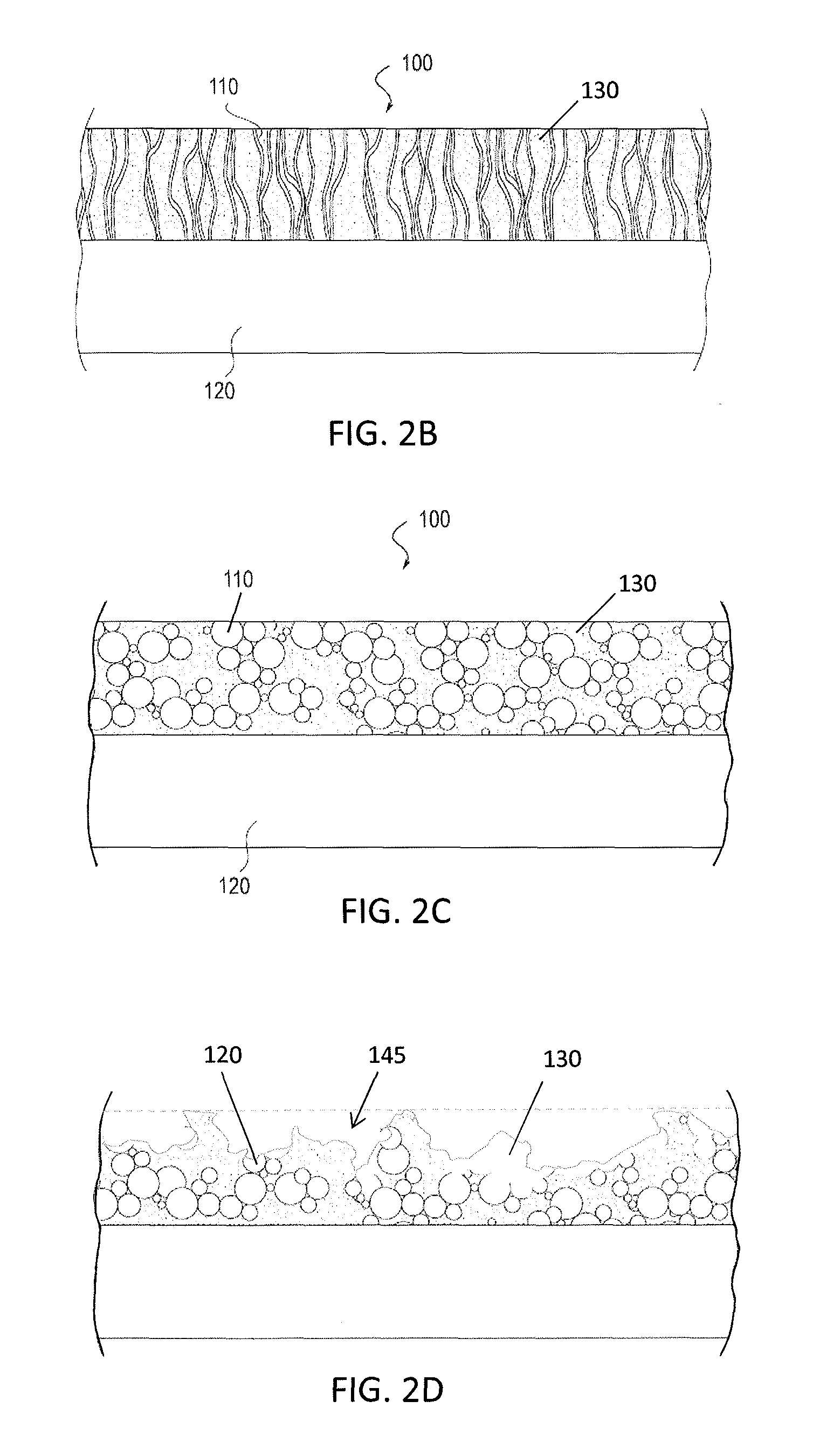

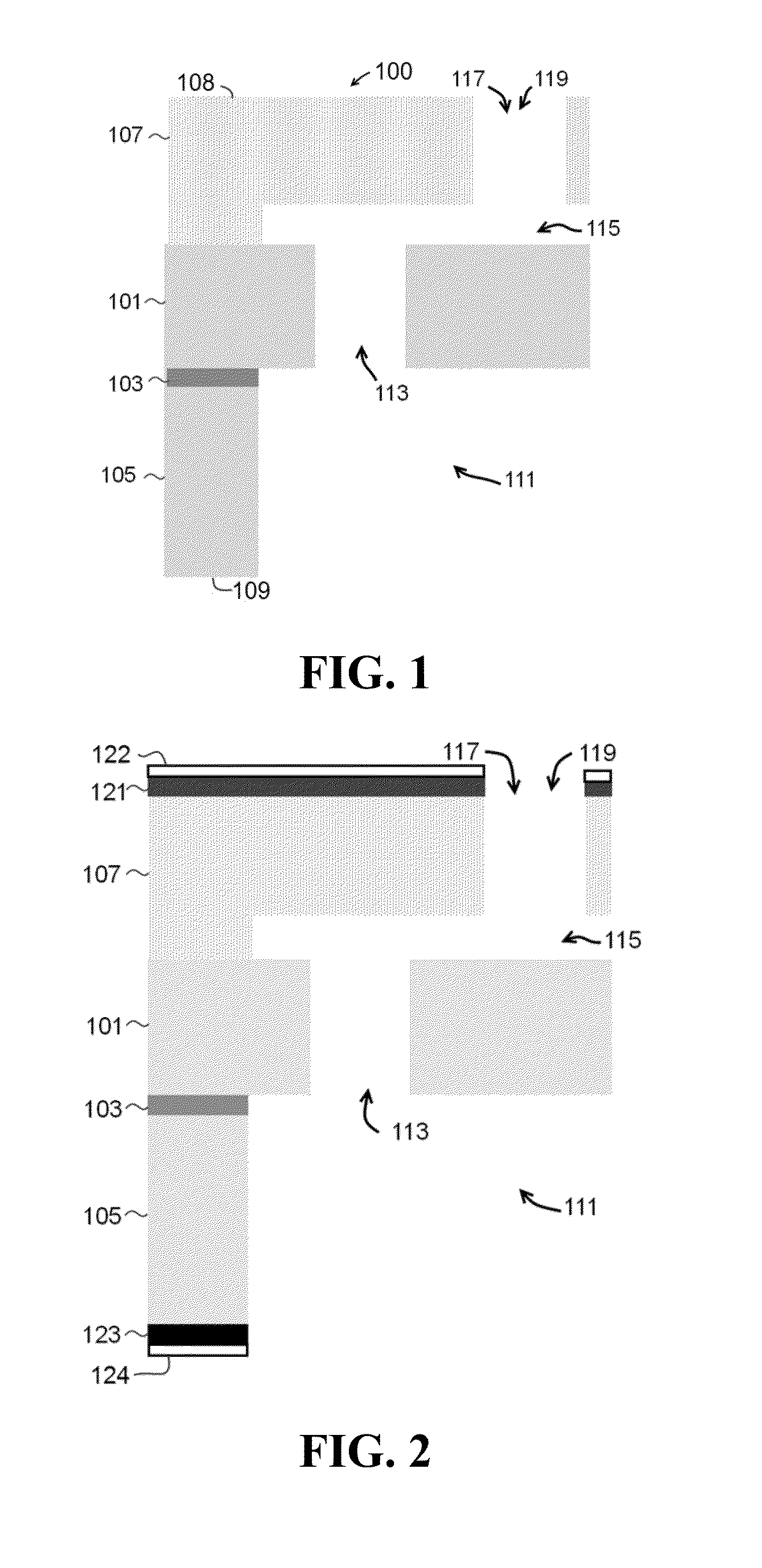

Multi-row lead frame

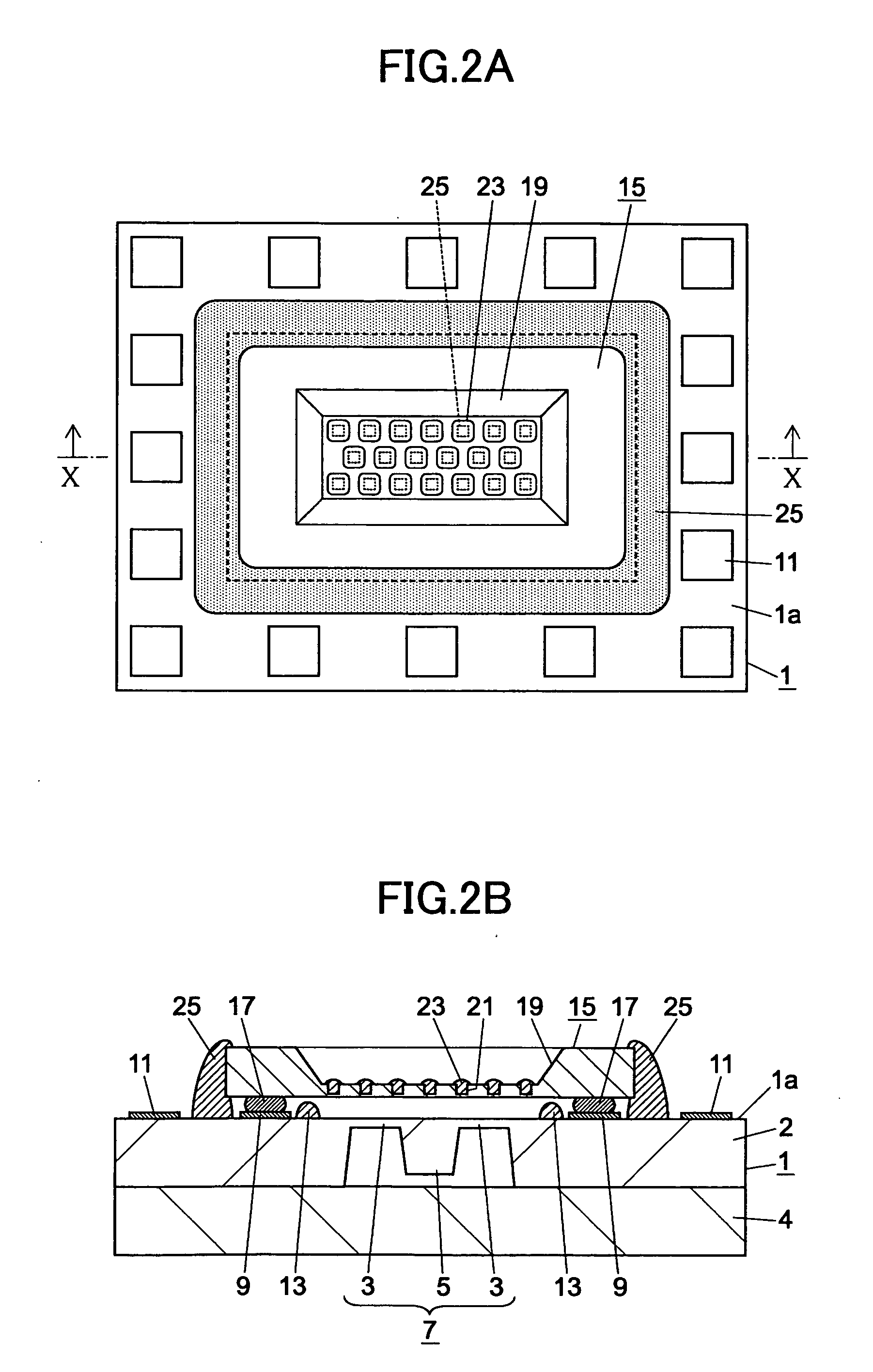

InactiveUS7301225B2Avoid wire damageAvoid encapsulationSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringLead frame

Owner:NORTH STAR INNOVATIONS

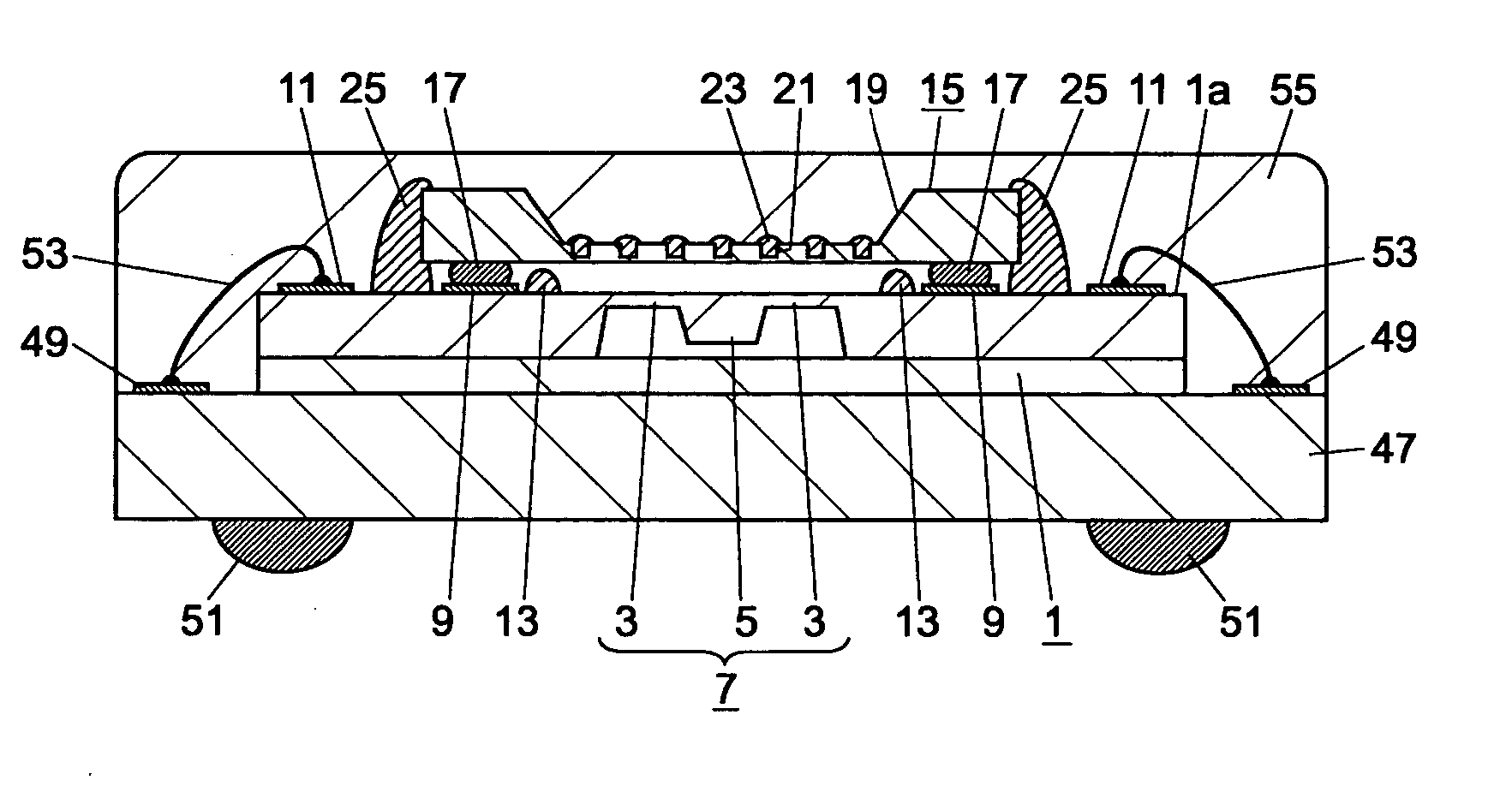

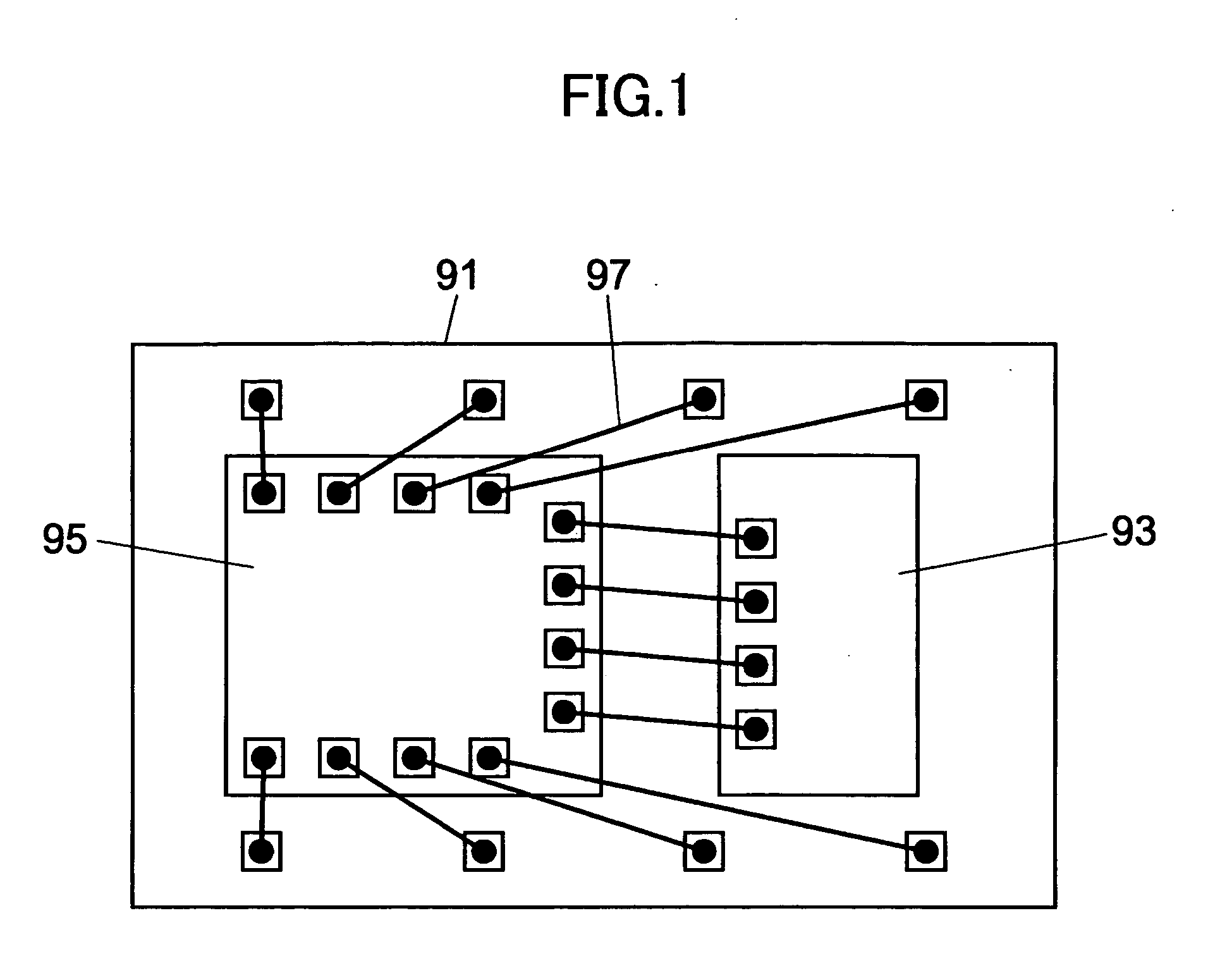

Semiconductor sensor device and method of producing the same

InactiveUS20050146004A1Adjusting output characteristicAvoid encapsulationAcceleration measurement using interia forcesSemiconductor/solid-state device detailsSemiconductor sensorSignal processing

A semiconductor sensor device is provided with a semiconductor sensor chip having a plurality of electrodes formed on a substrate surface and a semiconductor sensor, and a signal processing IC chip mounted on the semiconductor sensor chip by flip-chip bonding.

Owner:RICOH KK

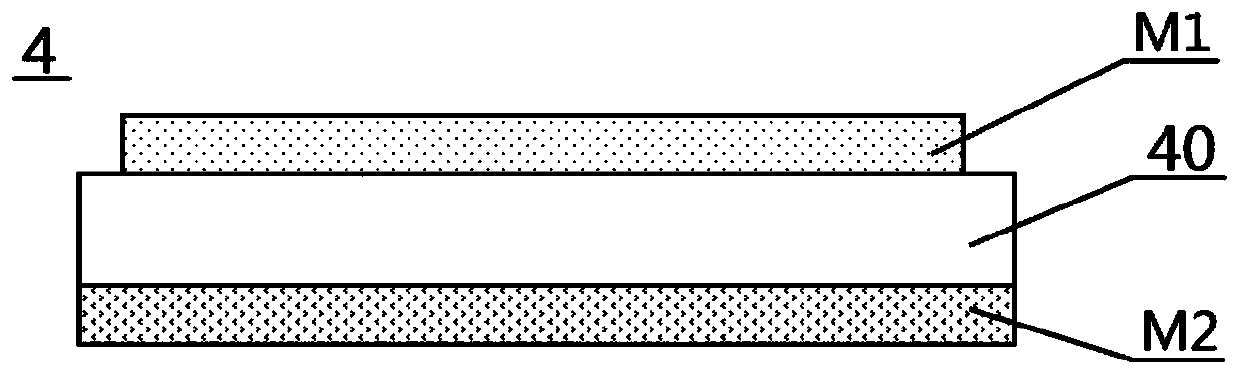

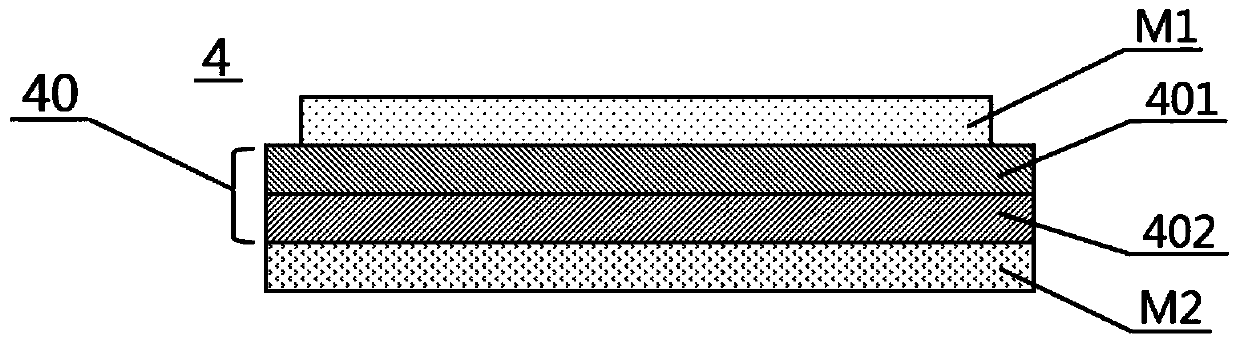

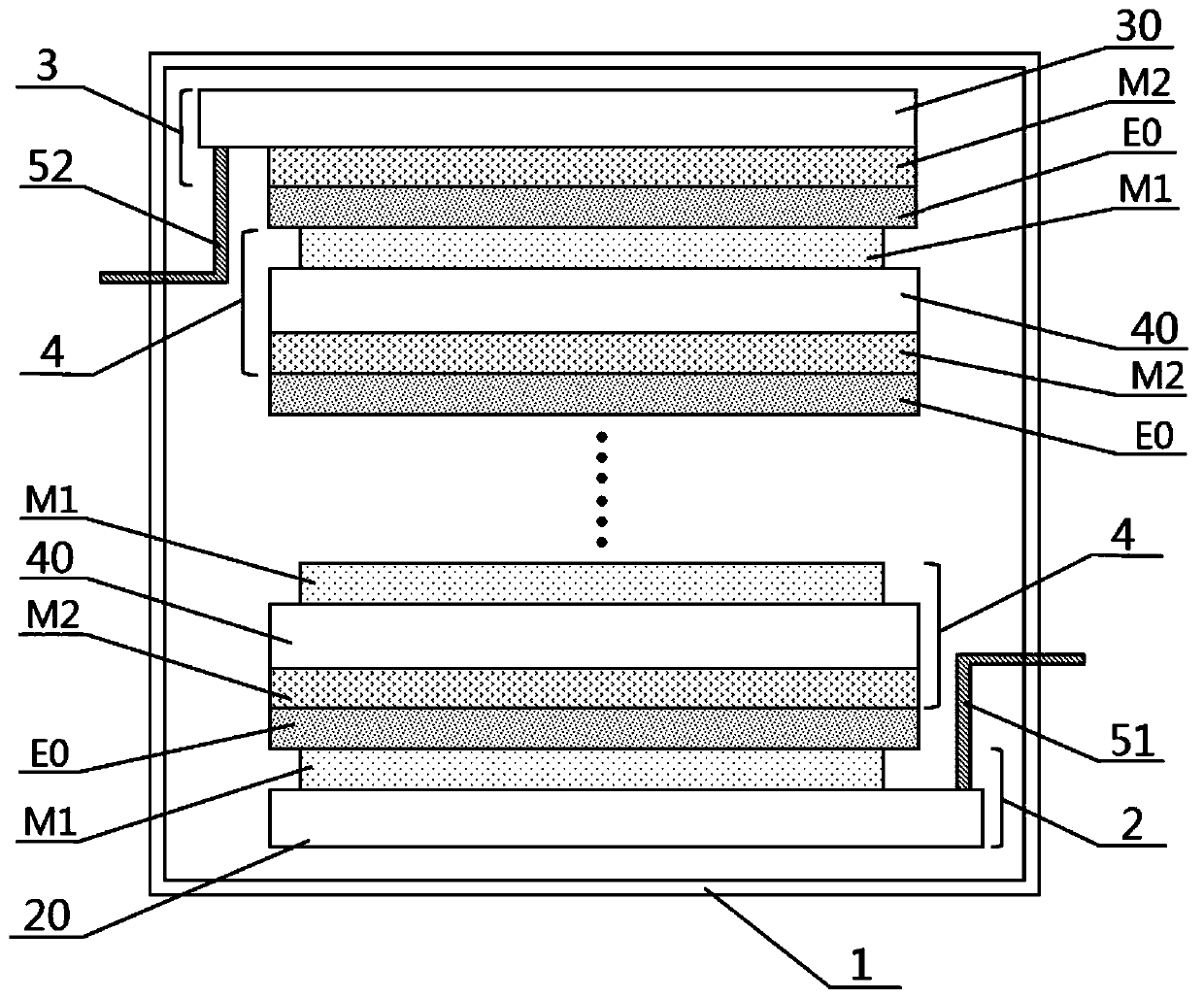

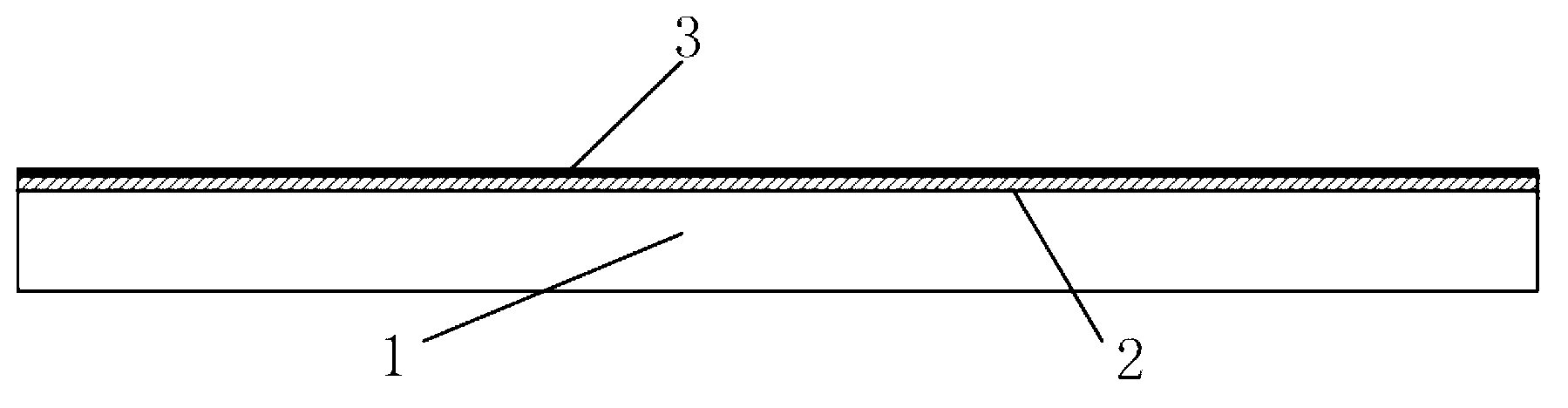

High-voltage single solid-state lithium ion battery and preparation method thereof

InactiveCN110556568AAvoid encapsulationAvoid complexityFinal product manufactureSecondary cellsSolid state electrolyteElectrical battery

The invention provides a high-voltage single solid-state lithium ion battery. The lithium ion battery comprises three or more plate-shaped electrodes which are stacked in sequence, wherein the three or more plate-shaped electrodes are sequentially a negative electrode, at least one bipolar plate electrode and a positive electrode from top to bottom, the plate-shaped electrodes are separated by solid electrolyte layers, and the plate-shaped electrodes and the solid electrolyte layers are bonded together in a thermal compounding mode and packaged into a single battery. According to the battery,internal series connection of the single battery is realized, and the problem of difficult packaging or complex packaging structure caused by using a liquid electrolyte is avoided; the single batteryis adjustable in capacity and voltage, high voltage of the single battery can be conveniently realized, and the problems of heating or poor multiplying power and the like when the conventional lithiumion batteries are externally connected in series are avoided; the connection of the energy storage assembly is optimized, and the internal resistance of the battery is reduced; and the production process and equipment are basically the same as those of the existing lithium ion battery, so that large-scale industrial production is facilitated. The invention also provides a preparation method of the high-voltage single solid-state lithium ion battery.

Owner:安徽坤宇塑金新能源技术有限公司

Manufacturing method of patch type LED (Light-Emitting Diode) module

InactiveCN102779923ASave packaging material and packaging process timeGood consistency of geometric featuresFinal product manufacturePrinted circuit aspectsPatch typeManufacturing line

The invention discloses a manufacturing method of a patch type LED (Light-Emitting Diode) module. The manufacturing method is characterized by comprising the following steps of: preparing materials; providing LED chips with flip chip structures, wherein one face of each LED chip is provided with a metal electrode, and the surface intervals of the metal electrodes are not smaller than 80 mum; arranging: putting the plurality of chips into a braid, wherein the metal electrodes of the LED chips are positioned at the bottom of a braid accommodating space, and the light emitting surfaces of the LED chips are positioned on the opening of the accommodating space; patching: sucking the LED chips out of the braid by using a vacuum suction nozzle, and placing onto a bonding pad of a substrate, wherein the metal electrodes are opposite to the bonding pad, and the light emitting surfaces of the LED chips face upwards; and fixing: correspondingly fixing and communicating the bonding pad and the metal electrodes. A braid loading way is directly adopted for flip chip LED chips, so that encapsulation of a single LED light source is avoided, and the encapsulating materials, encapsulating process time and production line of a single LED light source are saved.

Owner:XIAMEN G WATT LIGHTING TECHNOLOGY INC

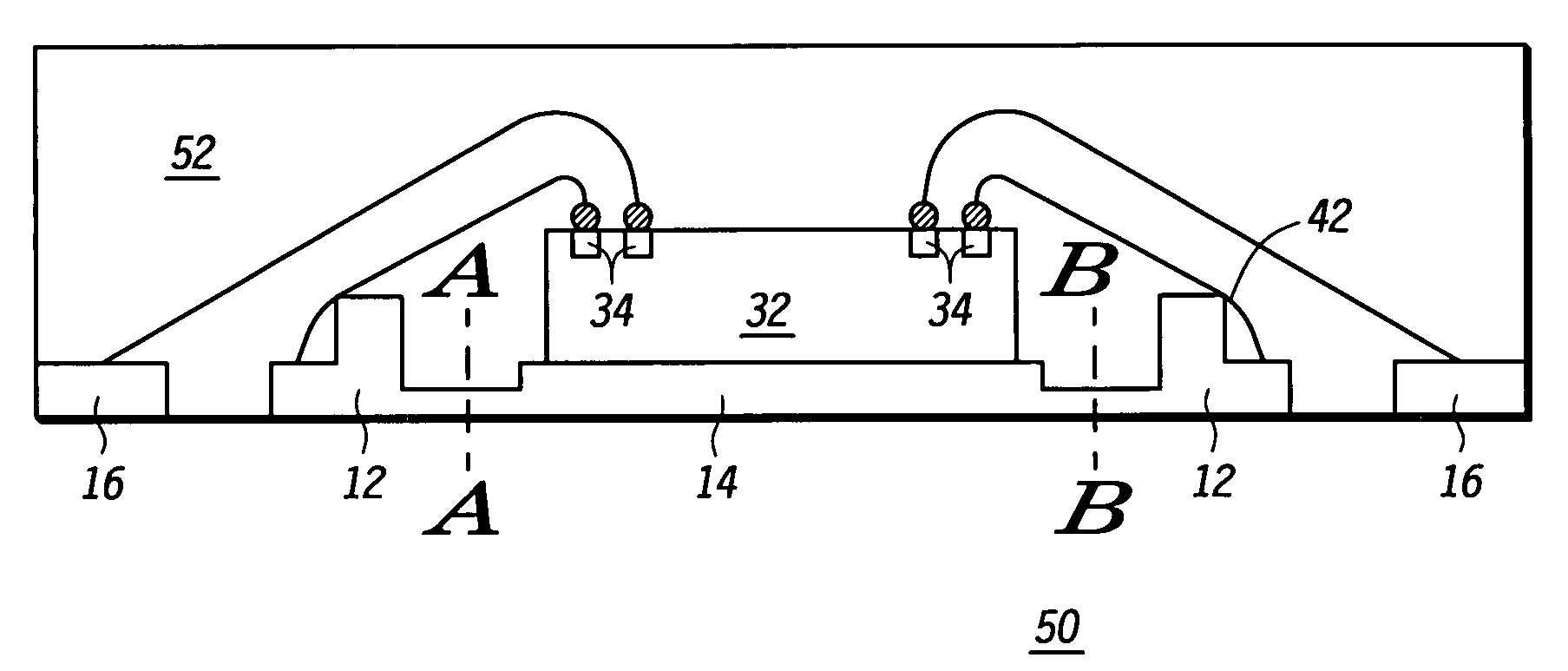

Multi-row lead frame

InactiveUS20070200206A1Avoid wire damageAvoid encapsulationSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringLead frame

A lead frame (10) for a semiconductor device includes a first row of terminals (12) surrounding a die receiving area (14) and a second row of terminals (16) spaced from and surrounding the first row of terminals (12). The first and second rows of terminals (12, 16) have a first height (H1). The terminals (12) of the first row include a step (26) that has a greater height (H2). Bond wires (36) connecting die pads (34) to the first row terminals (12) extend over the second height H2 part of the terminal (12) and are attached to the first height H1 part of the terminal (12). The step (26) insures that the bond wires (36) attached to the stepped terminals (12) have a high wire kink profile so that they are less susceptible to damage in later process steps.

Owner:NORTH STAR INNOVATIONS

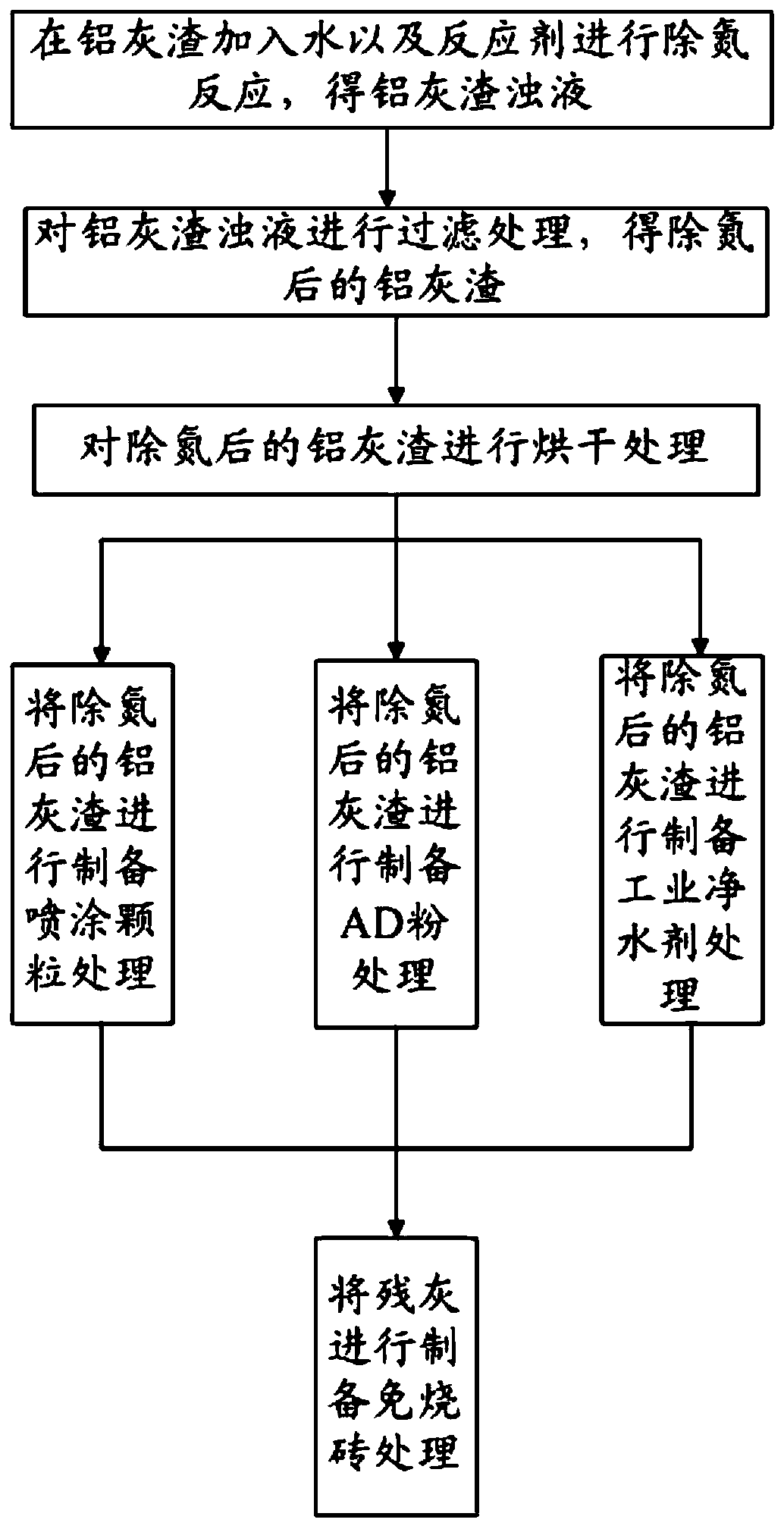

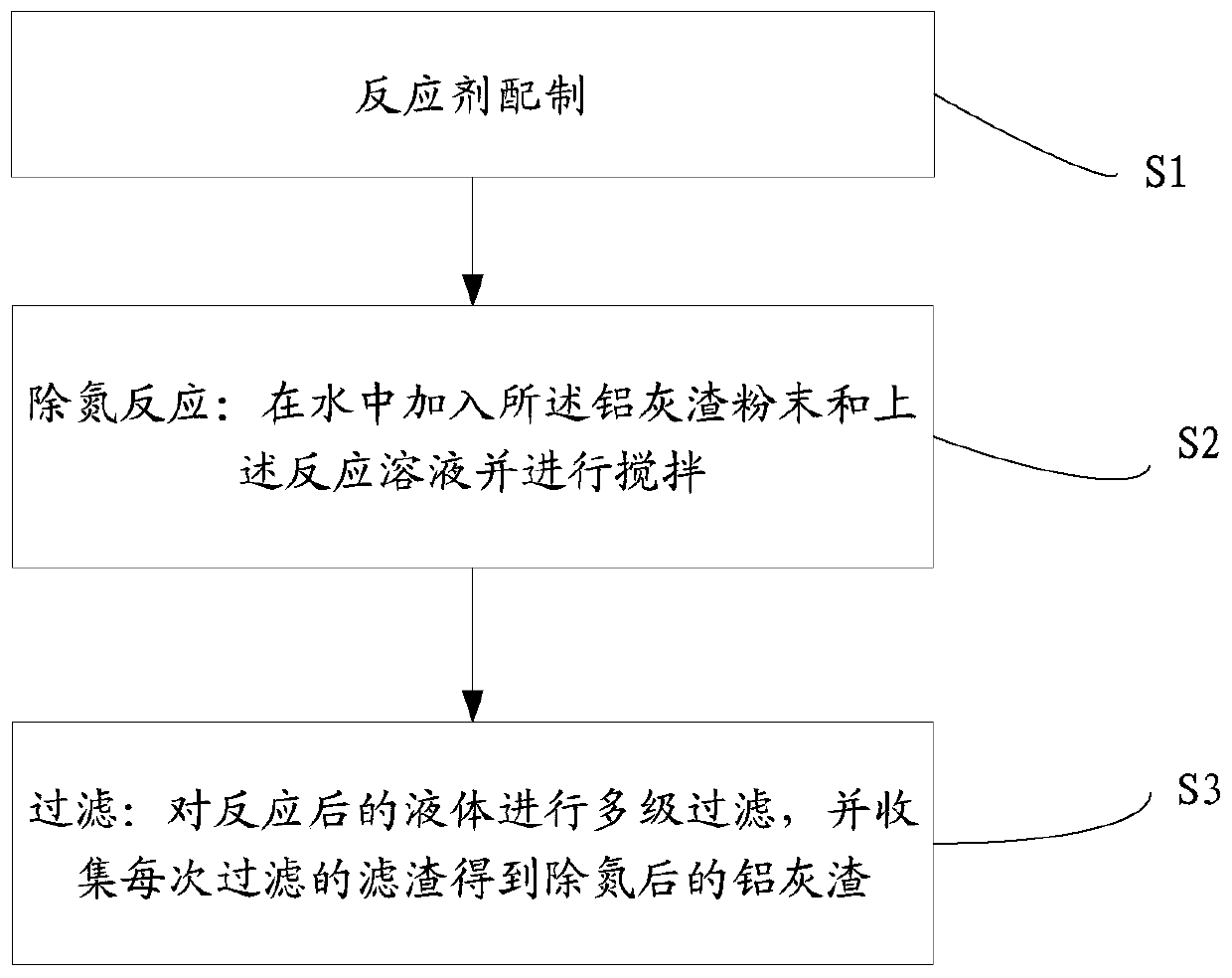

Harmless treatment method and device for aluminum ash residues

InactiveCN110025920AHarmless removalAvoid encapsulationChemical protectionAcetic acidNitrogen removal

The invention discloses a harmless treatment method and device for aluminum ash residues, wherein the aluminum ash residues comprise aluminum nitride. The harmless treatment method comprises the stepsthat water and a reactant are added into the aluminum ash residues for a nitrogen removal reaction to obtain aluminum ash residue turbid liquid, wherein the aluminum ash residue turbid liquid comprises ammonium salts and aluminum ash residues subjected to nitrogen removal, and the reactant comprises one or more of hydrogen peroxide, peracetic acid, calcium oxide, sodium carbonate, acetic acid anddilute sulfuric acid. According to the harmless treatment method and device for the aluminum ash residues, ammonia gas is avoided, the phenomenon that aluminum nitride is coated with aluminum hydroxide is avoided, the nitrogen removal rate is increased, and then the aluminum nitride in the aluminum ash residues is efficiently removed in a low-cost and harmless mode.

Owner:NANTONG UNIVERSITY

Bioabsorbable substrates and systems that controllably release antimicrobial metal ions

InactiveUS8999367B1Facilitated releaseStay flexibleBiocideInorganic active ingredientsRheniumIridium

Owner:SILVER BULLET THERAPEUTICS

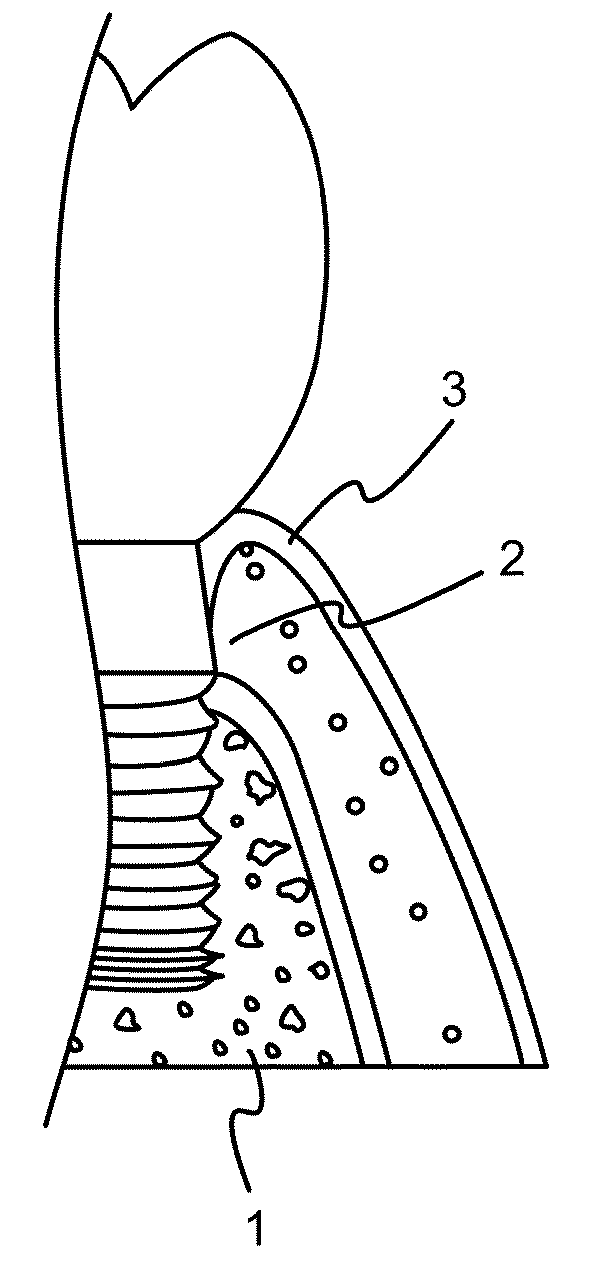

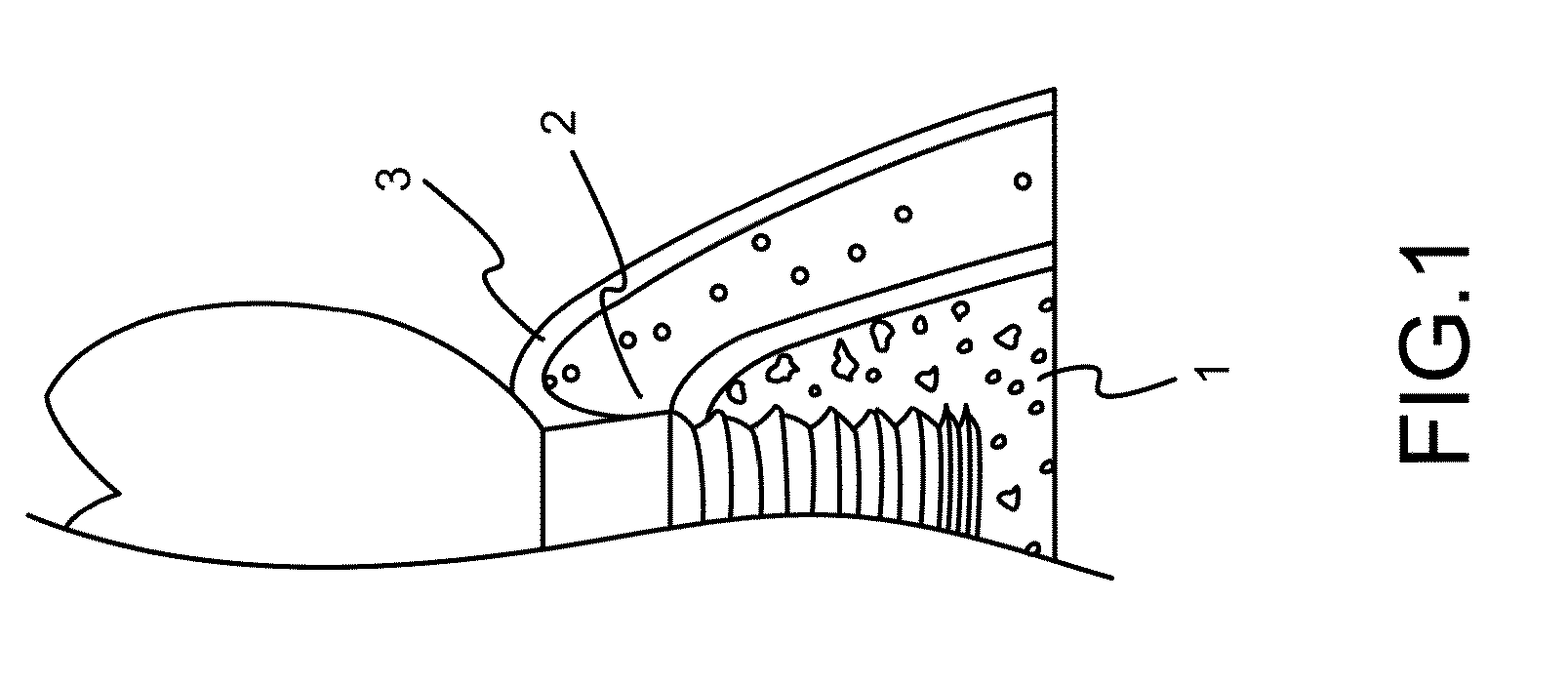

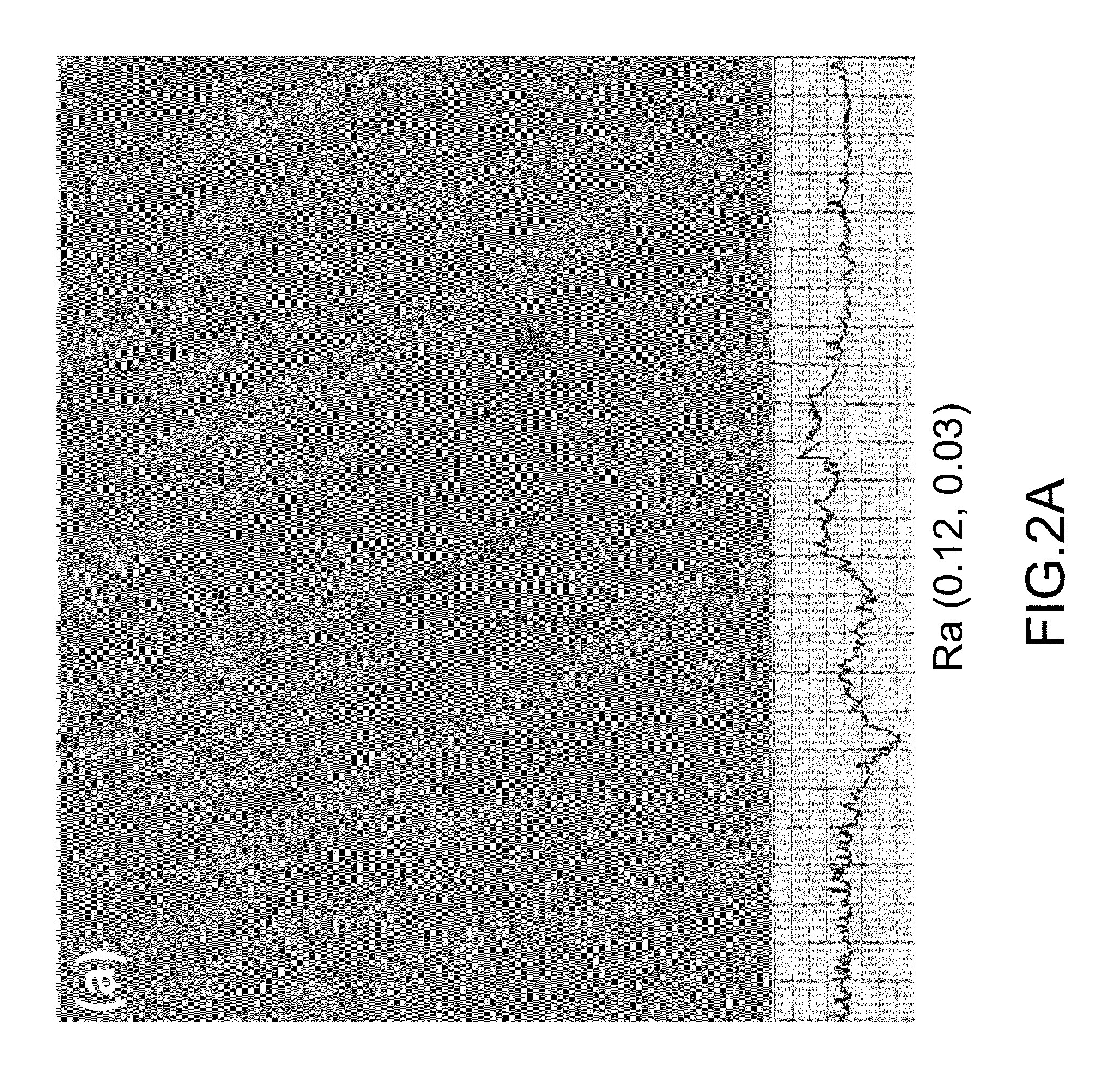

Implant Surface Treatment Method Having Tissues Integrated

ActiveUS20110318835A1Inhibit growthAvoid fibrous encapsulationDental implantsPharmaceutical delivery mechanismIonImplant surface

The present disclosure uses different kinds of surface treatment processes on titanium-made dental implants. The growth and attachment conditions of bone cells (MC3T3-E), fibroblasts(NIH 3T3) and epidermal cells (XB-2) on the metal surface of titanium slices with different surface treatments are observed. Tetra-calcium phosphate is used to perform secondary sand-blasting process to clean up the metal surface and provide calcium ions for osteoblastoma physiology. Thus, by adjusting the cells adhesive and proliferative abilities, the success rate of the clinical applications in dental implant is improved.

Owner:KAOHSIUNG MEDICAL UNIVERSITY

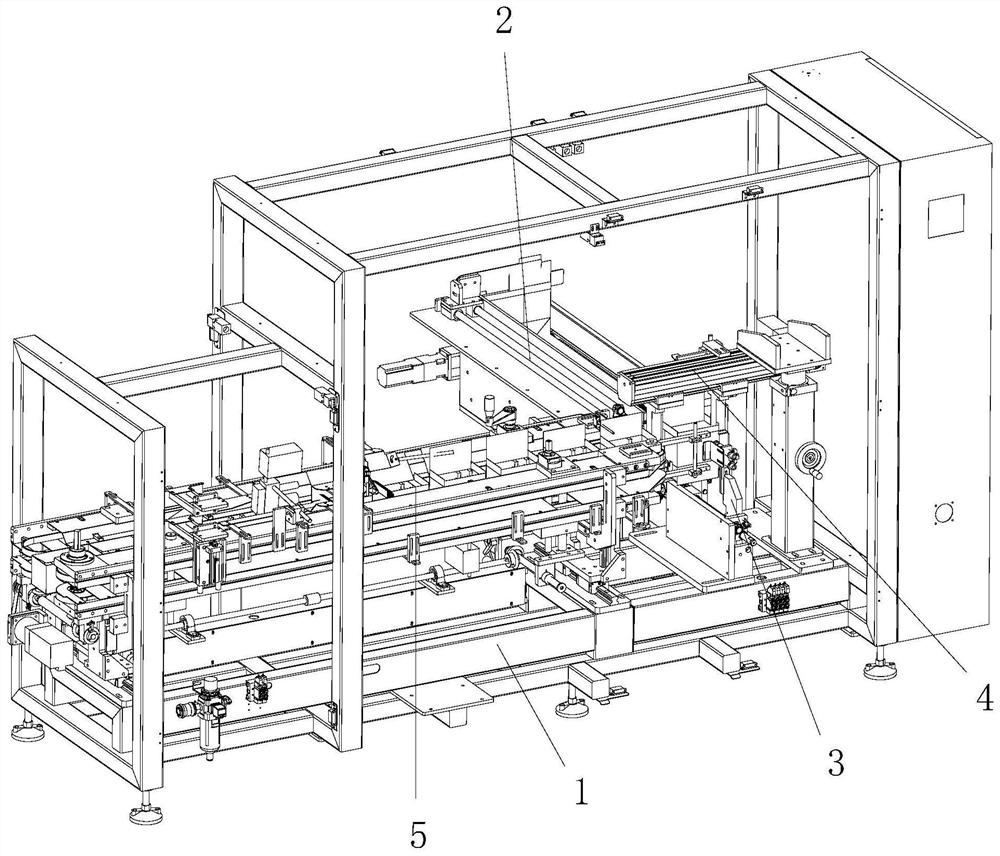

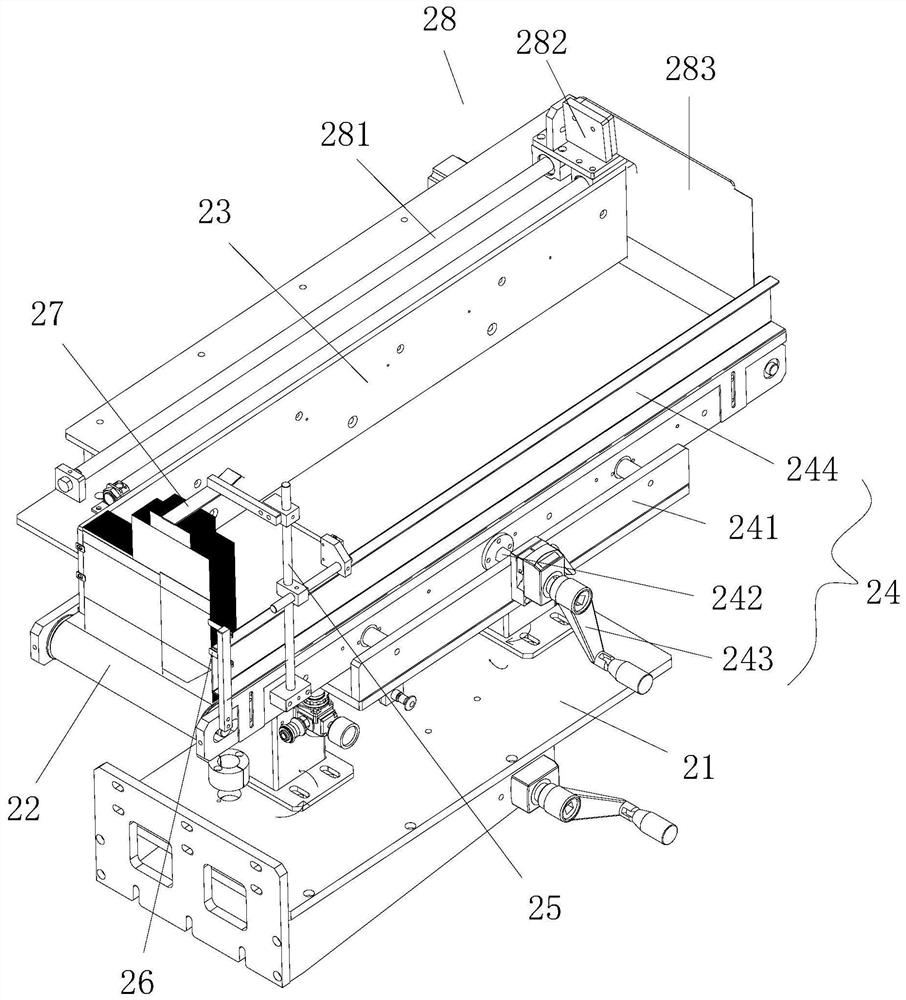

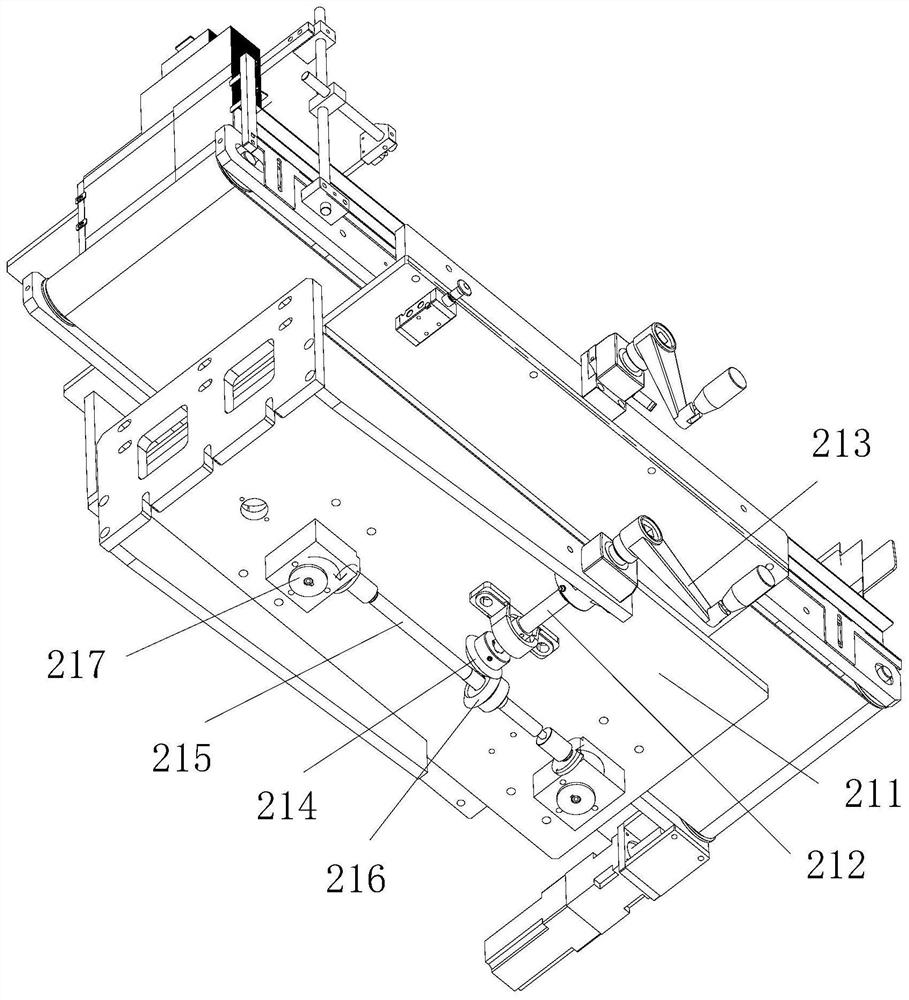

Vertical type boxing machine for coffee capsules with upper covers

PendingCN111994390AAdjust the discharge heightAvoid encapsulationWrapper twisting/gatheringPackaging machinesCartoning machineStructural engineering

The invention discloses a vertical type boxing machine for coffee capsules with upper covers. The vertical type boxing machine for the coffee capsules with the upper covers comprises a paper box feeding unit, a box opening unit, a box feeding unit, a linear box folding, conveying and packaging unit and a coffee capsule feeding unit which are arranged on a rack and are sequentially arranged in a butt joint manner. The linear box folding, conveying and packaging unit is sequentially provided with a paper box feeding station, a lower small tongue folding station, a lower front tongue folding station, a lower rear tongue folding station, a coffee capsule containing station, an upper small tongue folding station, an upper front tongue folding station, an upper large tongue closing station and abox discharging station. By means of the above manner, the vertical type boxing machine is compact in structure, stable in running and suitable for packaging of paper boxes with different sizes, packaging of the paper boxes with the upper covers is achieved, and the problems that in manual boxing, the labor intensity is large, the yield is low, and the boxing quality is poor are solved.

Owner:江苏神翌机械有限公司

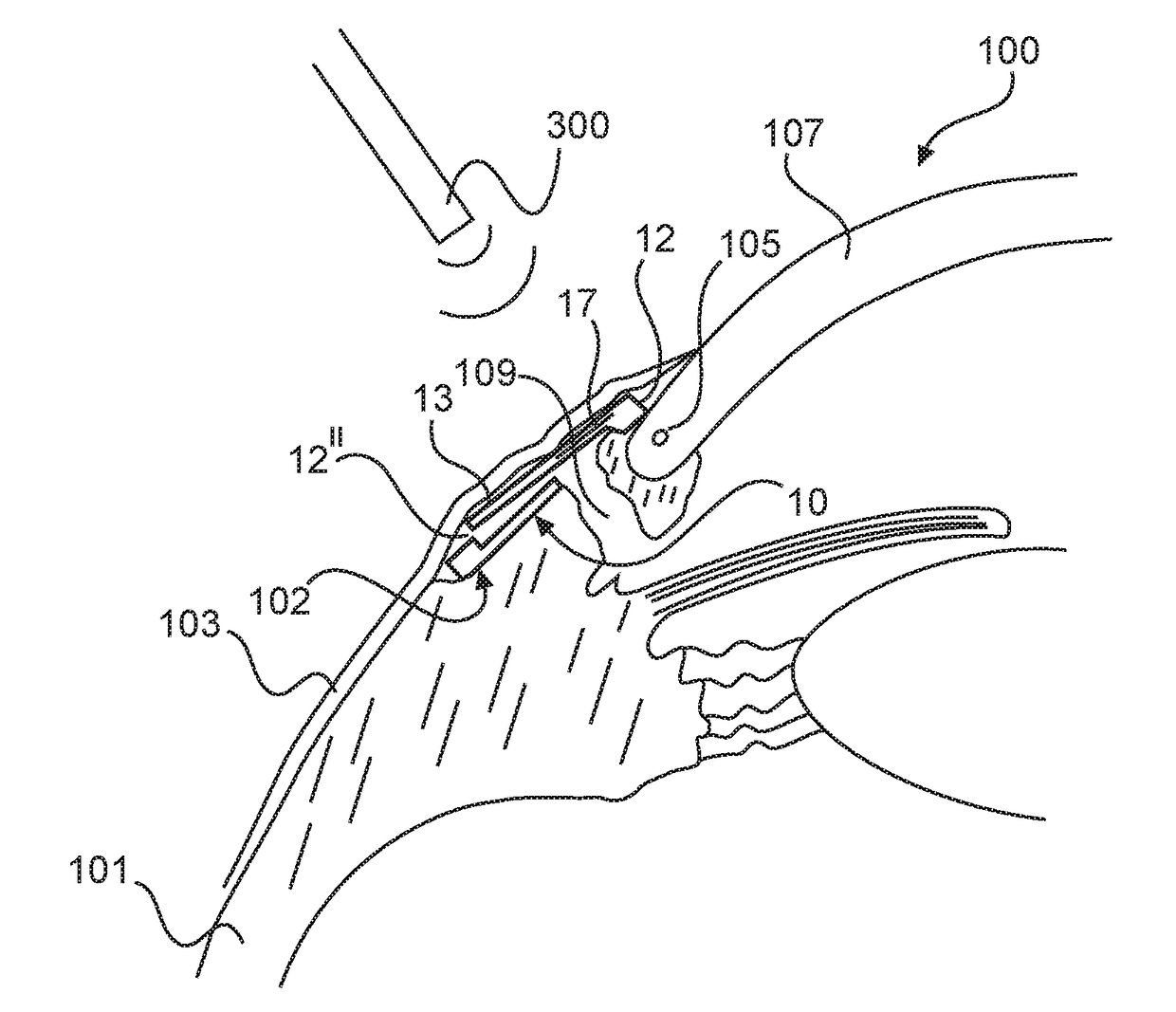

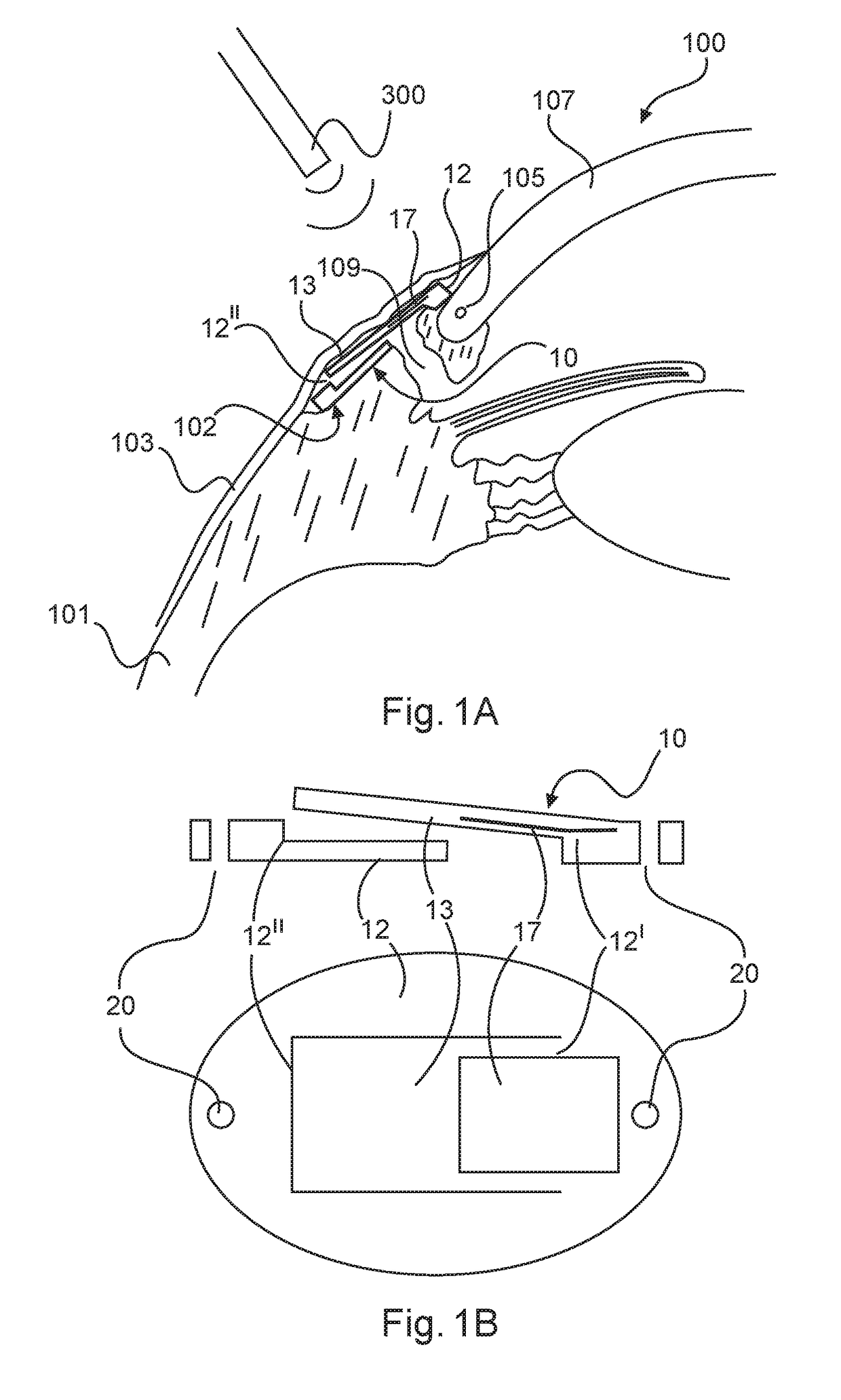

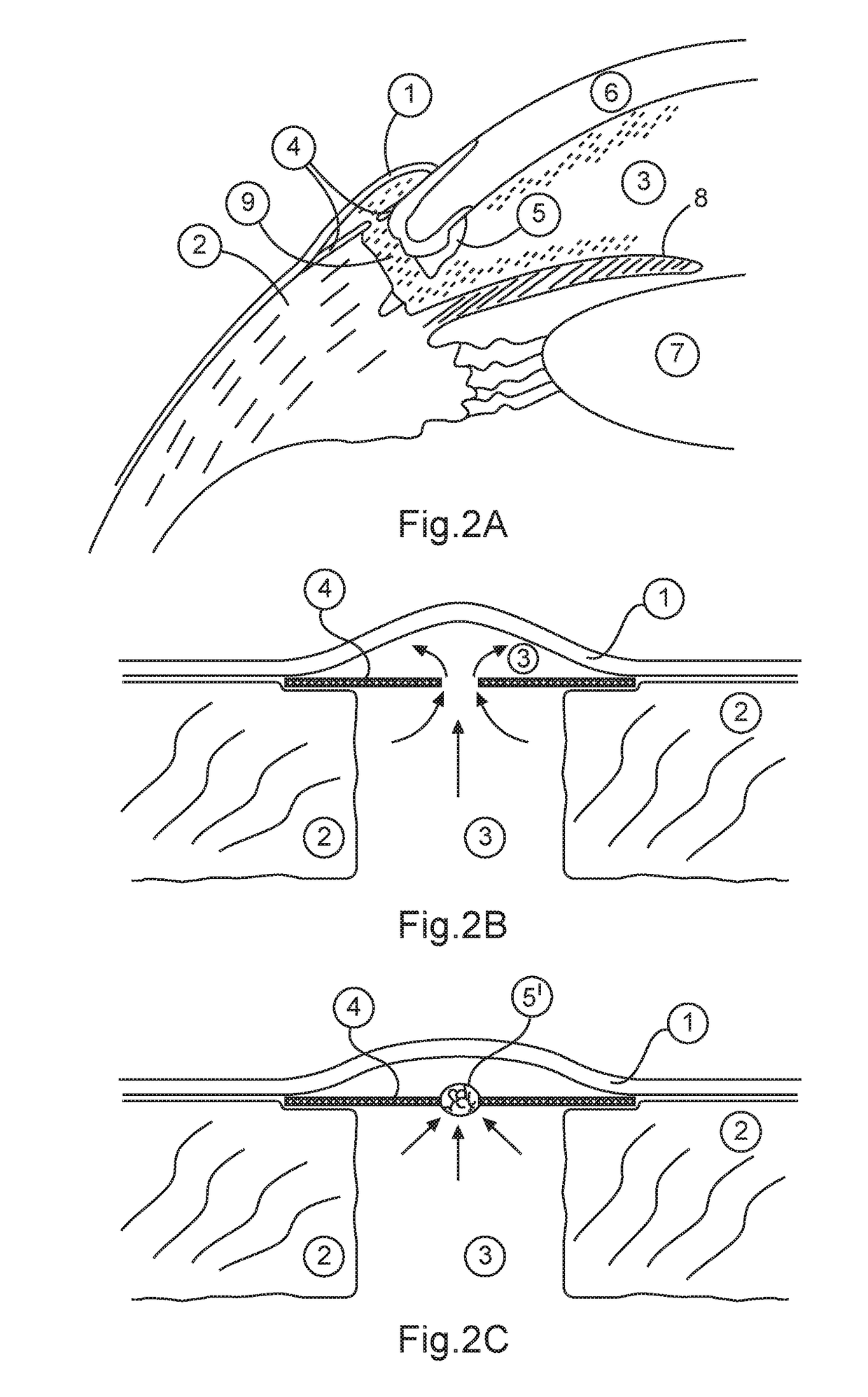

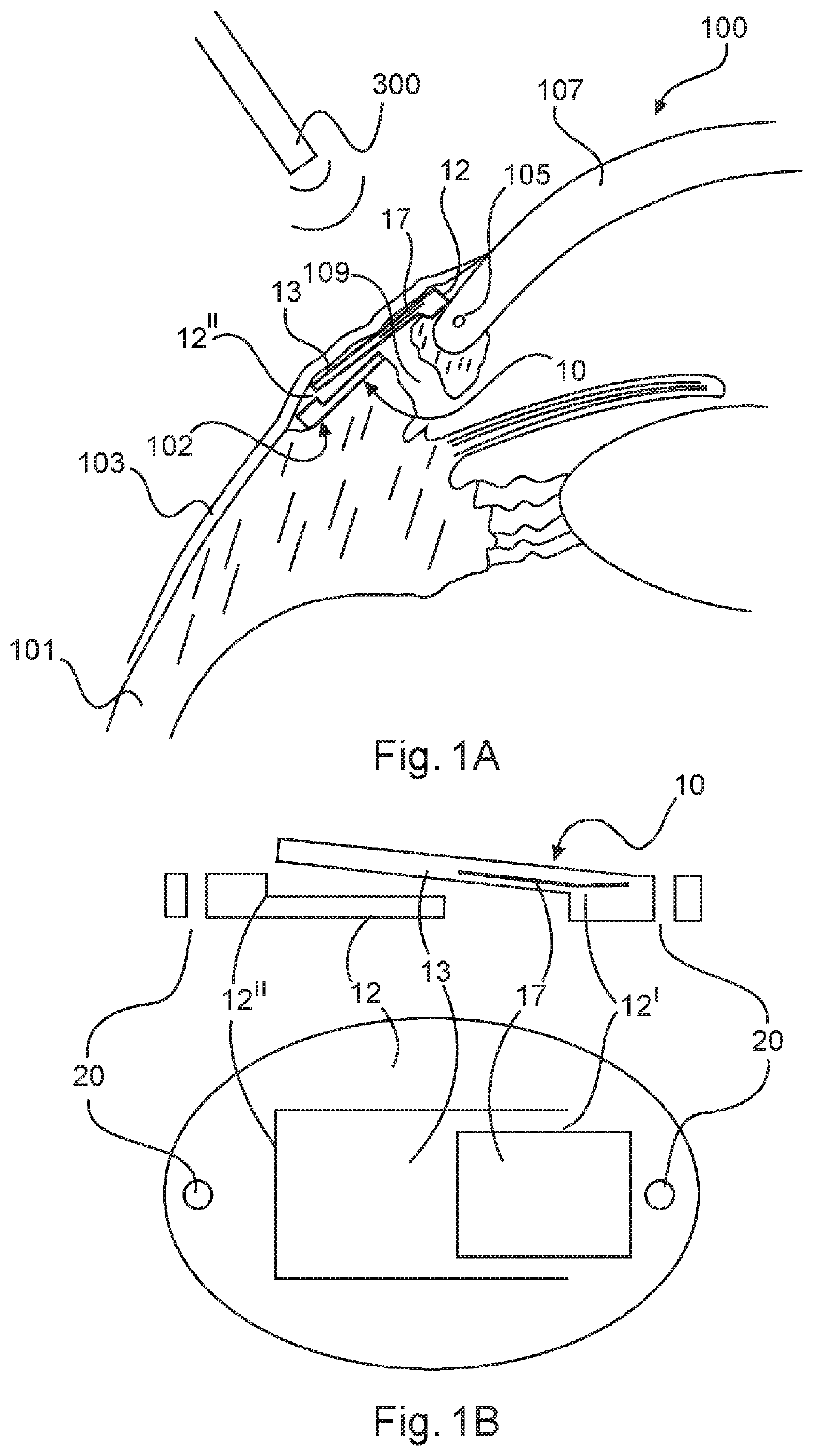

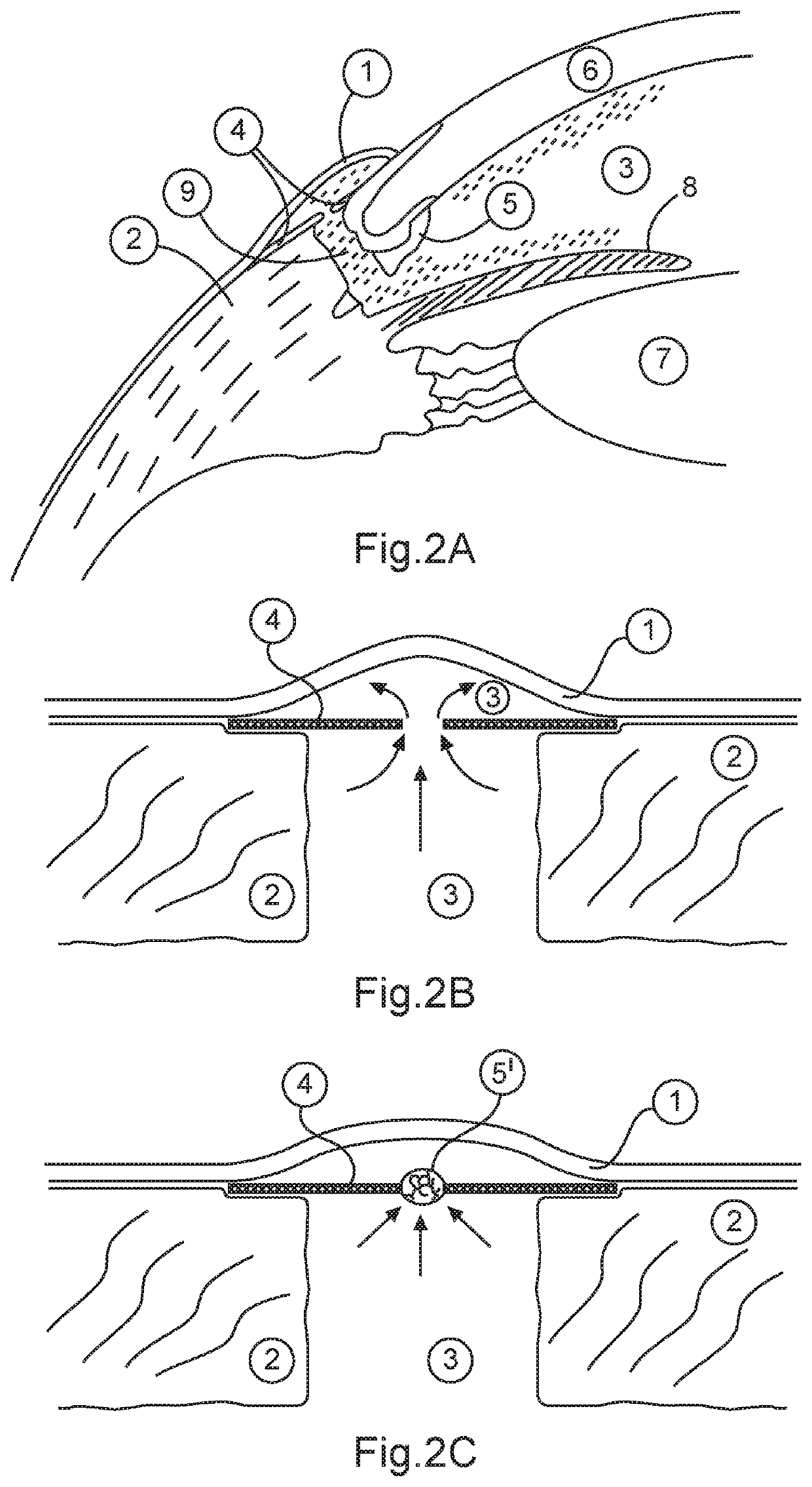

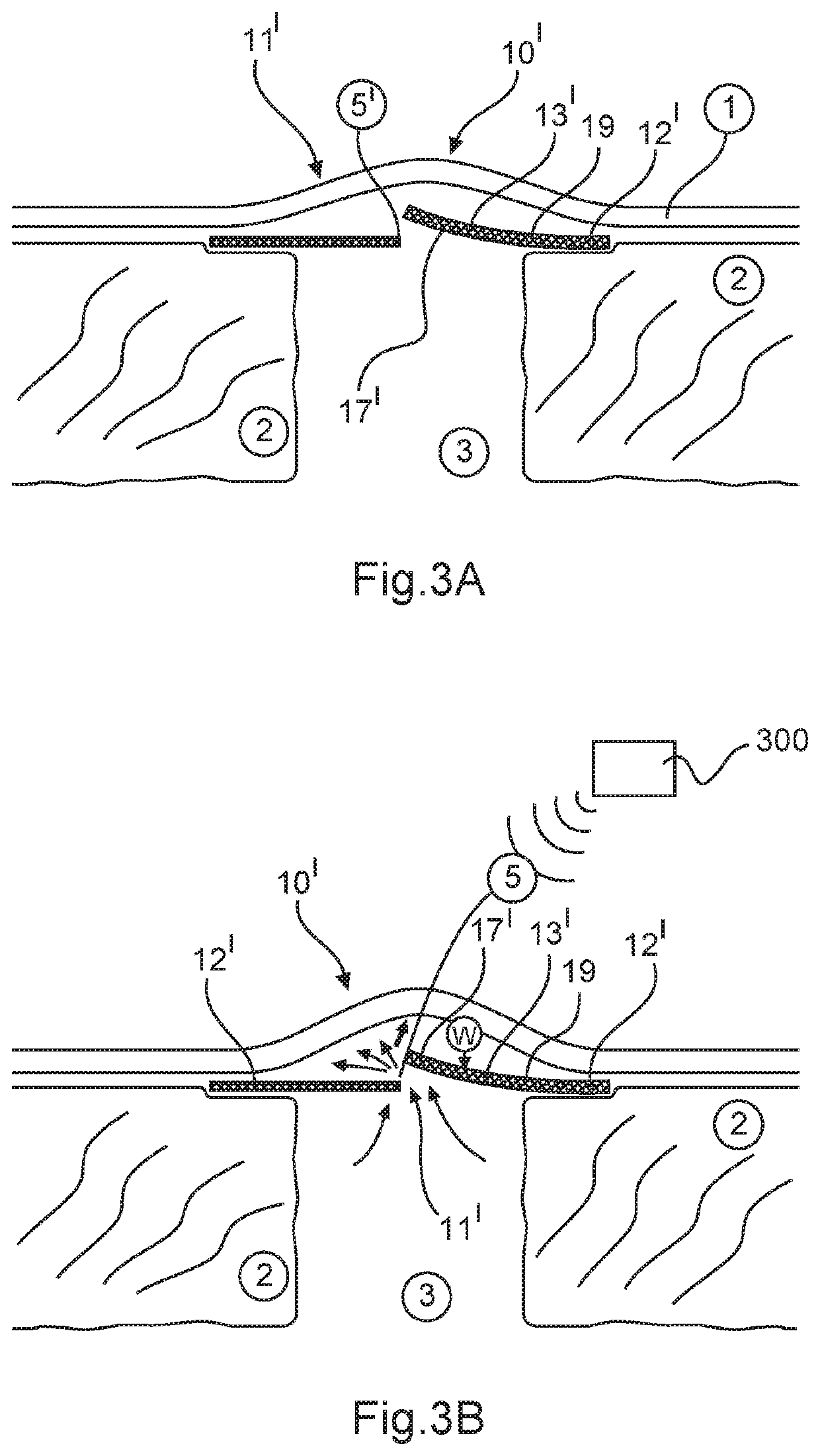

Glaucoma drainage implant

ActiveUS20180250166A1Compact and low-maintenance designAvoid encapsulationLaser surgeryWound drainsGlaucoma drainage implantGlaucoma

A glaucoma drainage implant comprising a pressure relief valve via which aqueous humor can be drained. The pressure relief valve has a pressure relief flap which is movably connected with a base plate of the implant, which is to be embedded in a sclera, wherein the pressure relief flap has an actuation area by means of which the pressure relief flap can be mobilized non-invasively during a post-operative healing phase or thereafter. The actuation area is preferably designed as a thermomechanically active area.

Owner:NIKOLIC MED STEPHAN DR

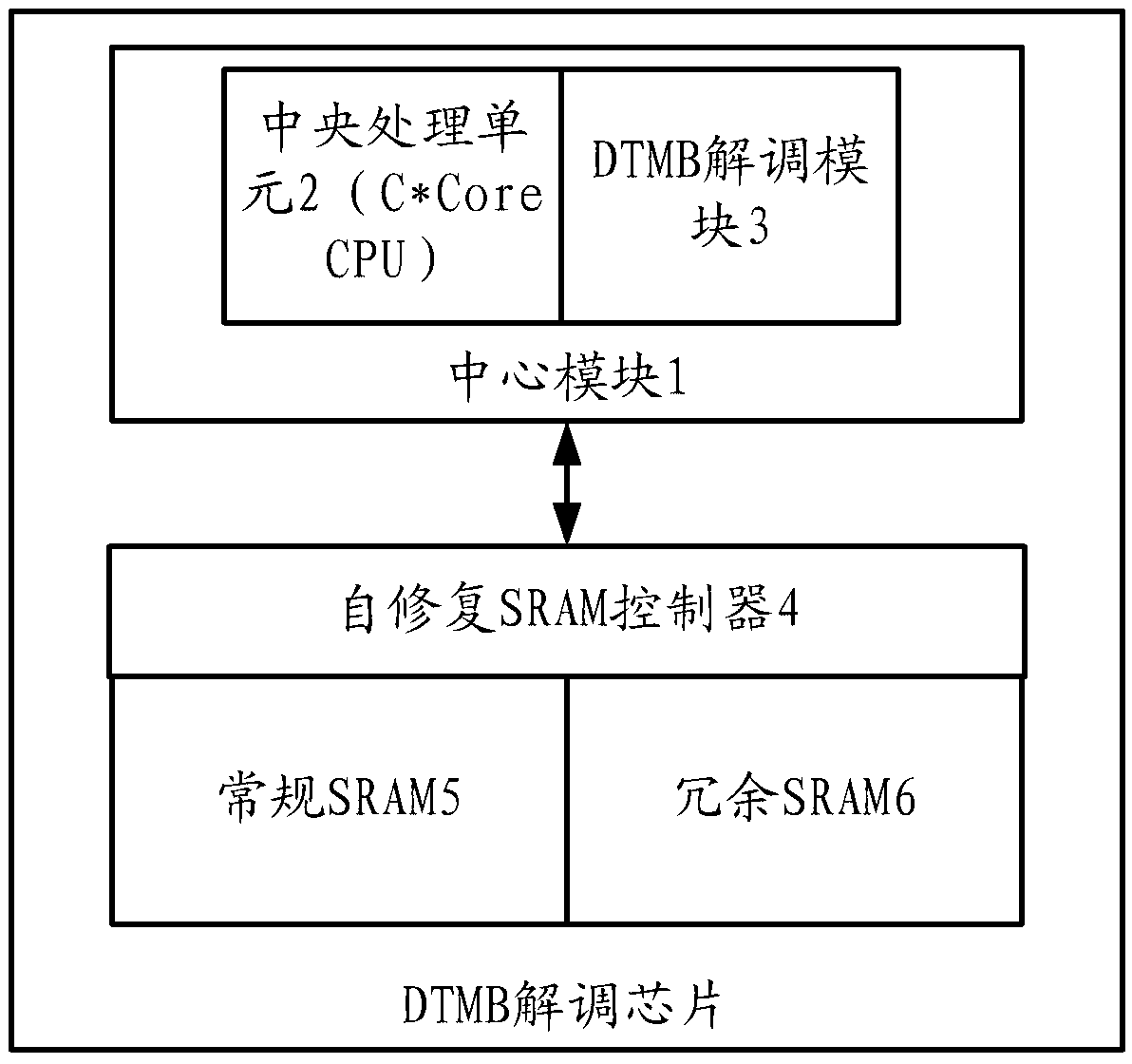

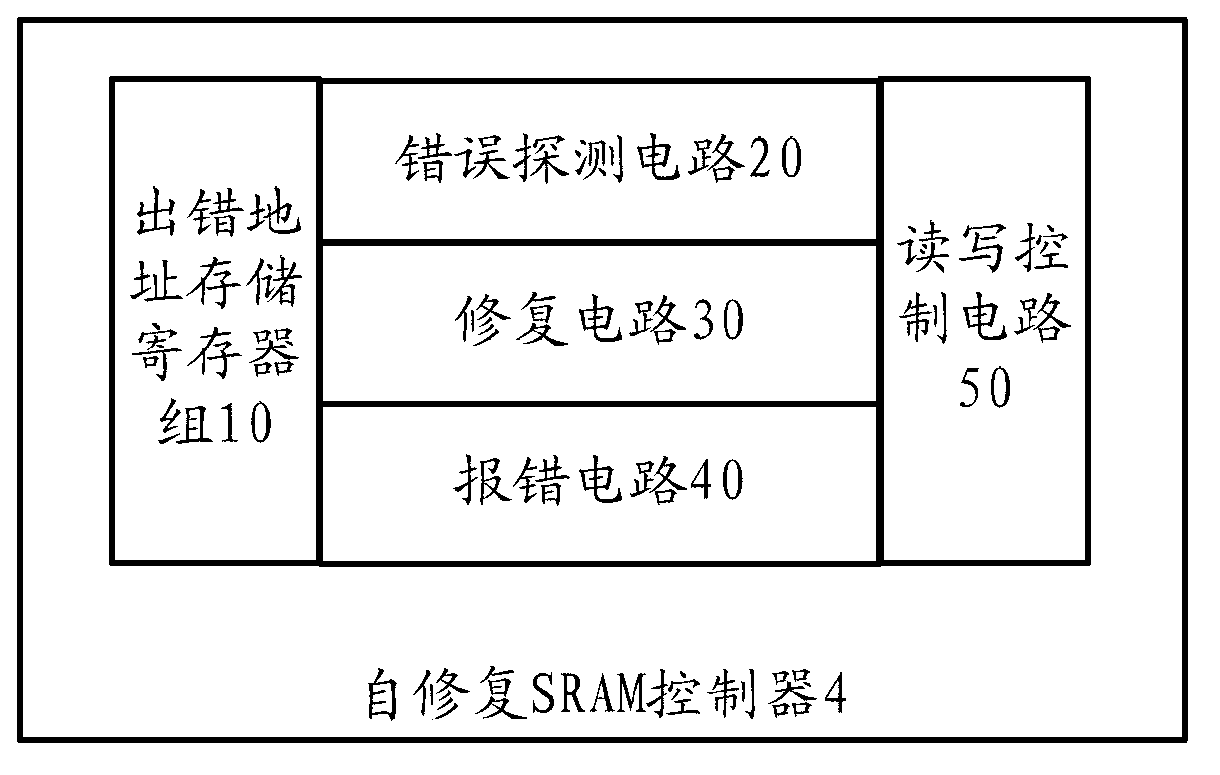

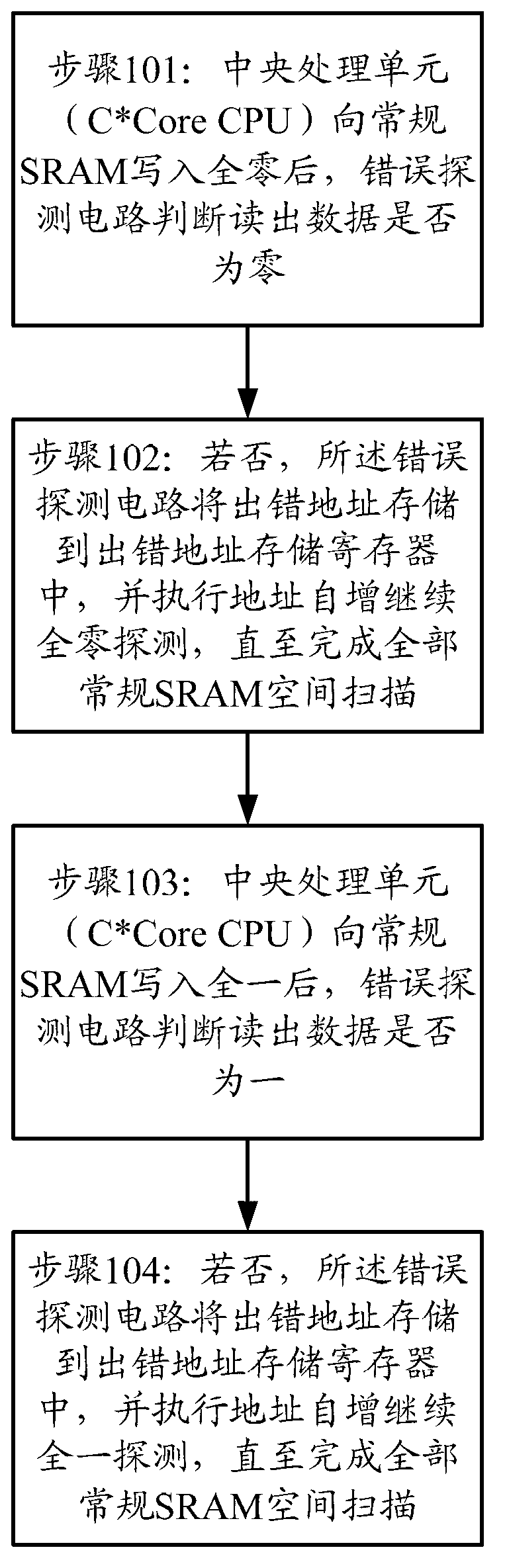

Self-repairing SRAM (Static Random Access Memory) controller design for DTMB (Digital Terrestrial Multimedia Broadcasting) demodulation chip

ActiveCN103310851AAvoid encapsulationOvercome defects that don't workStatic storageStatic random-access memoryProcessor register

The invention discloses a self-repairing SRAM (Static Random Access Memory) controller design for a DTMB (Digital Terrestrial Multimedia Broadcasting) demodulation chip. The controller comprises an error-address storage register group, an error detection circuit, a repairing circuit, an error reporting circuit and a reading-writing control circuit, wherein the self-repairing SRAM controller design is used for storing an error conventional SRAM address; the error detection circuit is used for carrying out error detection on the conventional SRAM, and storing the detected and error address into the error-address storage register group; the repairing circuit is used for mapping the error address into a redundant SRAM when a central module accesses the error address stored in the error-address storage register group and accessing the central module to the redundant SRAM; the error reporting circuit is used for carrying out error detection on the conventional SRAM after the repairing circuit maps the error address to the redundant SRAM, and reporting errors when detecting the error address; the reading-writing control circuit is used for finishing read-writing operation of the central module to the conventional SRAM and the redundant SRAM.

Owner:苏州国芯科技股份有限公司

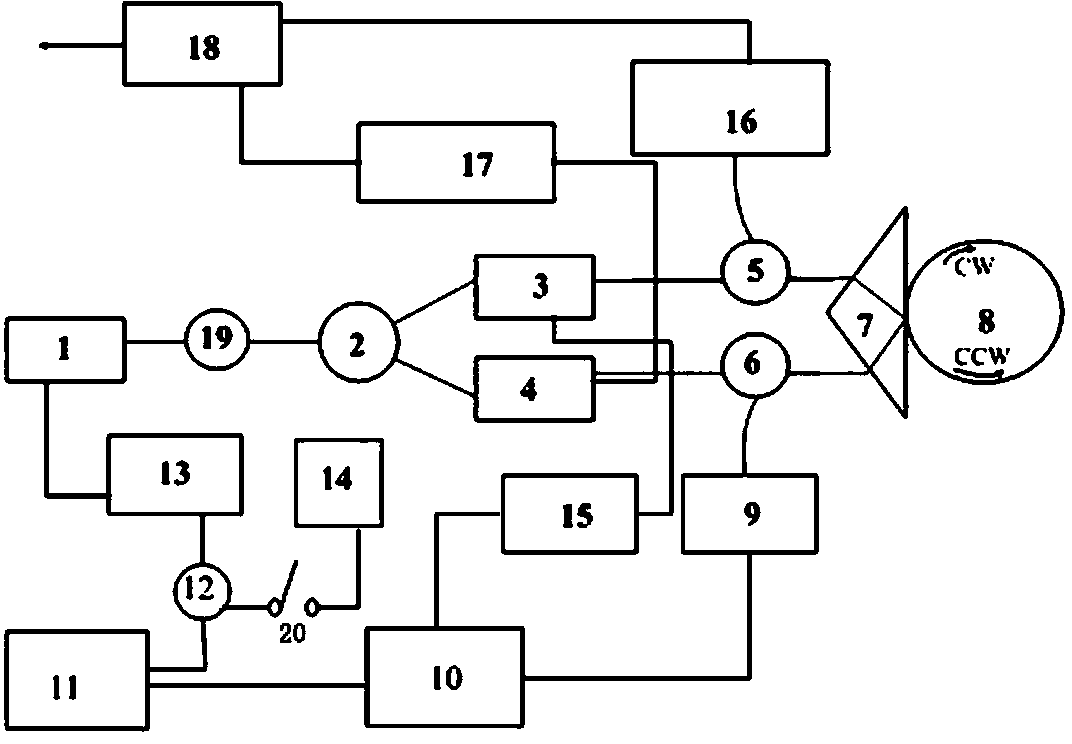

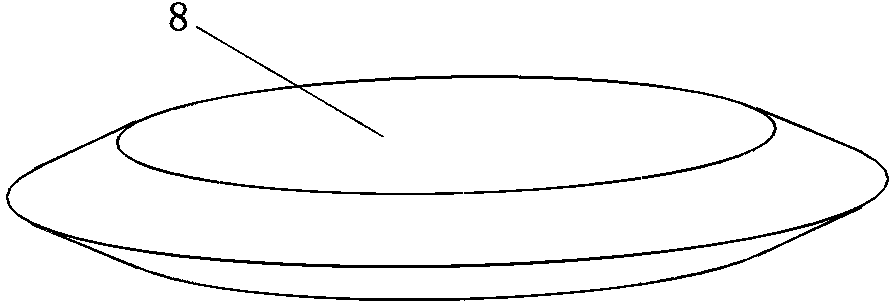

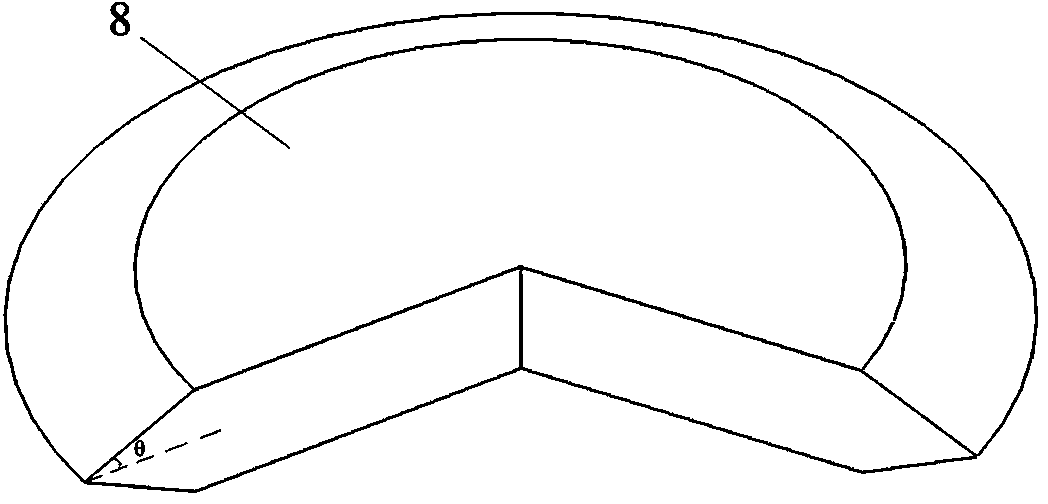

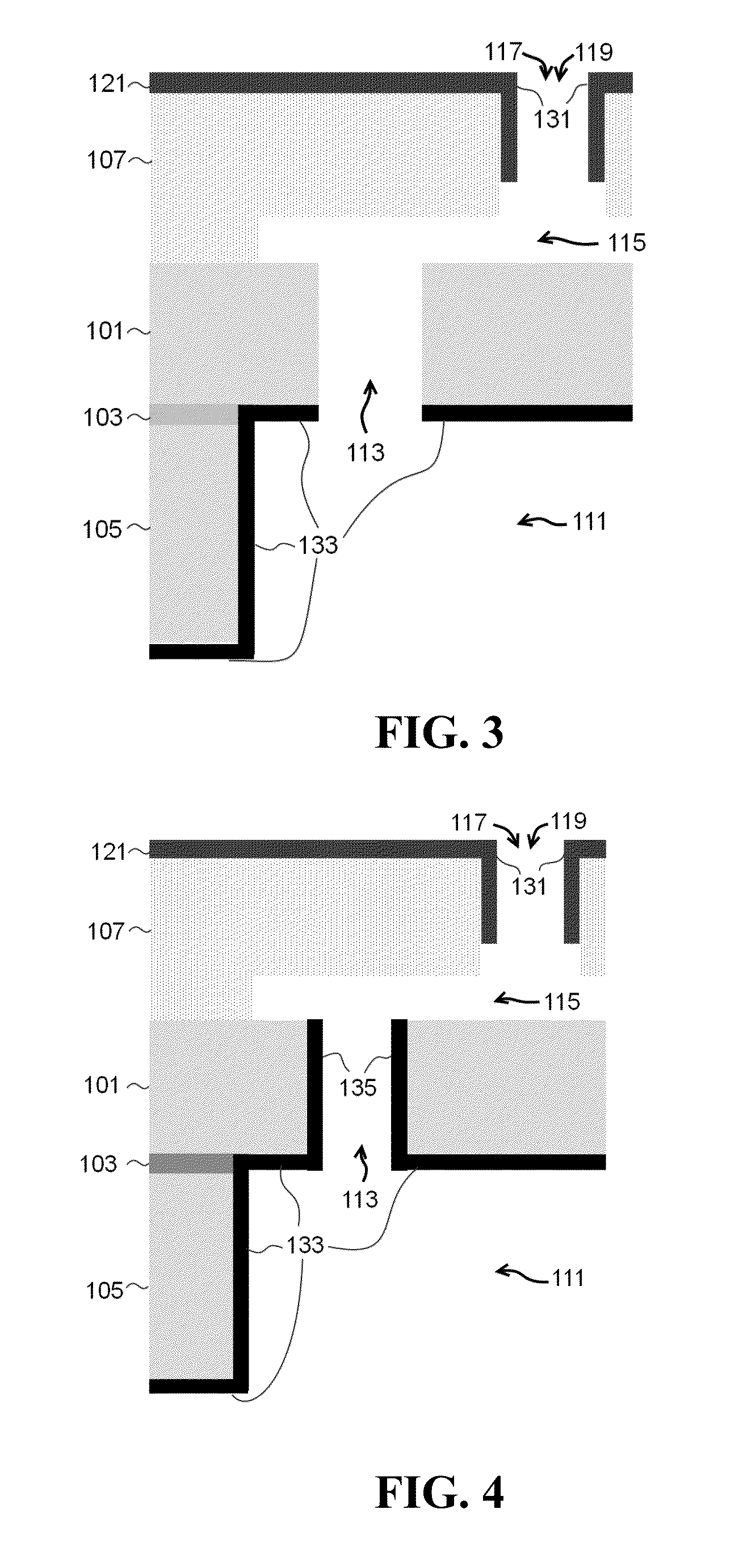

Resonant optical gyroscope based on high-K fluoride resonant cavity

InactiveCN104075703AWide transmission bandHigh transparencySagnac effect gyrometersBeam splitterHigh voltage

The invention discloses a resonant optical gyroscope based on a high-K fluoride resonant cavity. The resonant optical gyroscope comprises a laser, a beam splitter, phase modulators, ring-shaped resonators, a triangular prism, a fluoride wedge-shaped cavity, detectors, lock-in amplifiers, a PI circuit, an adder, a high-voltage amplifier, signal generators and an isolator; the PI circuit is used for modulating optical signals to enable physical quantities extracted from signals output from the detector A and B to be capable of reacting the rotation angle of a carrier, and the frequency of the emergent light of a light source and a modulating voltage of the phase modulators can be respectively changed according to the physical quantities, the feedback of an optical path can be realized, and the purpose that the optical paths propagating in the fluoride wedge-shaped cavity clockwise and anti-clockwise are resonant can be realized.

Owner:ZHONGBEI UNIV

Modified alginates for cell encapsulation and cell therapy

ActiveUS9422373B2Avoid encapsulationImprove propertiesMetabolism disorderUnknown materialsBiocompatibility TestingBiochemistry

Covalently modified alginate polymers, possessing enhanced biocompatibility and tailored physiochemical properties, as well as methods of making and use thereof, are disclosed herein. The covalently modified alginates are useful as a matrix for the encapsulation and transplantation of cells. Also disclosed are high throughput methods for the characterizing the biocompatibility and physiochemical properties of modified alginate polymers.

Owner:MASSACHUSETTS INST OF TECH +1

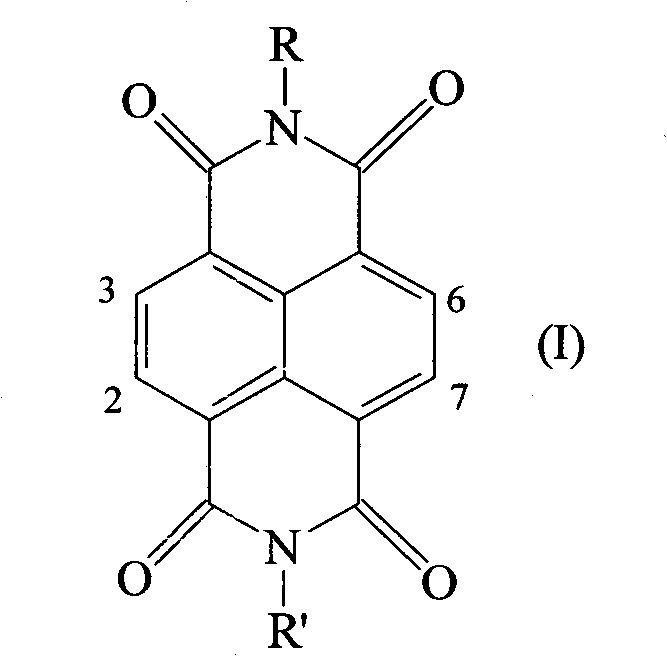

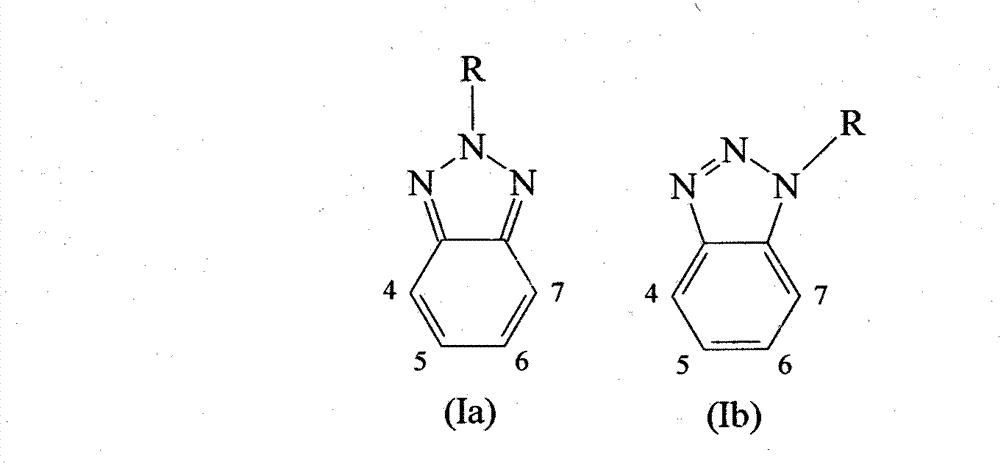

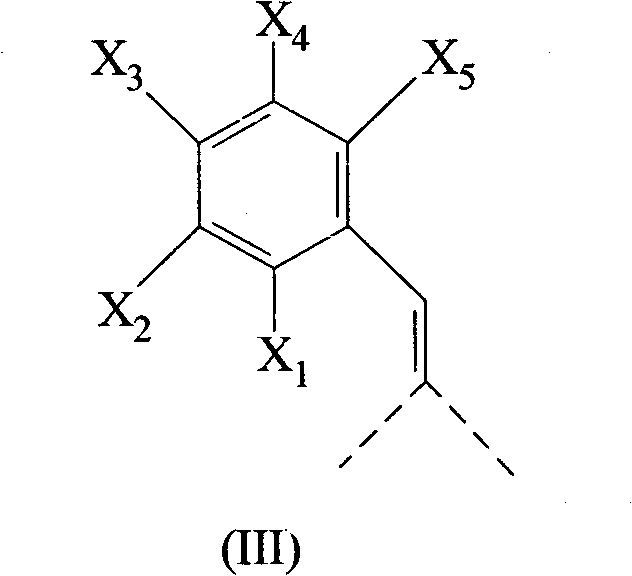

Stabilized photoactive composition and use thereof

ActiveCN103080203AAvoid encapsulationSolid-state devicesSemiconductor/solid-state device manufacturingBenzopyroneUltraviolet

Stabilized photoactive composition comprising: - at least one photoactive organic polymer; - at least one light stabilizer selected from hindered amines; - at least one UV absorber selected from triazines, benzoxazinones, benzotriazoles, benzophenones, benzoates, formamidines, cinnamates or propenoates, aromatic propanediones, benzoimidazoles, cycloaliphatic ketones, formanilides including oxamides, cyanoacrylates, benzopyranones, salicylates, or mixtures thereof. Said photoactive composition can be advantageously used in the construction of photovoltaic devices such as, for example, photovoltaic cells, photovoltaic modules, solar cells, solar modules, on both rigid and flexible supports.

Owner:ENI SPA

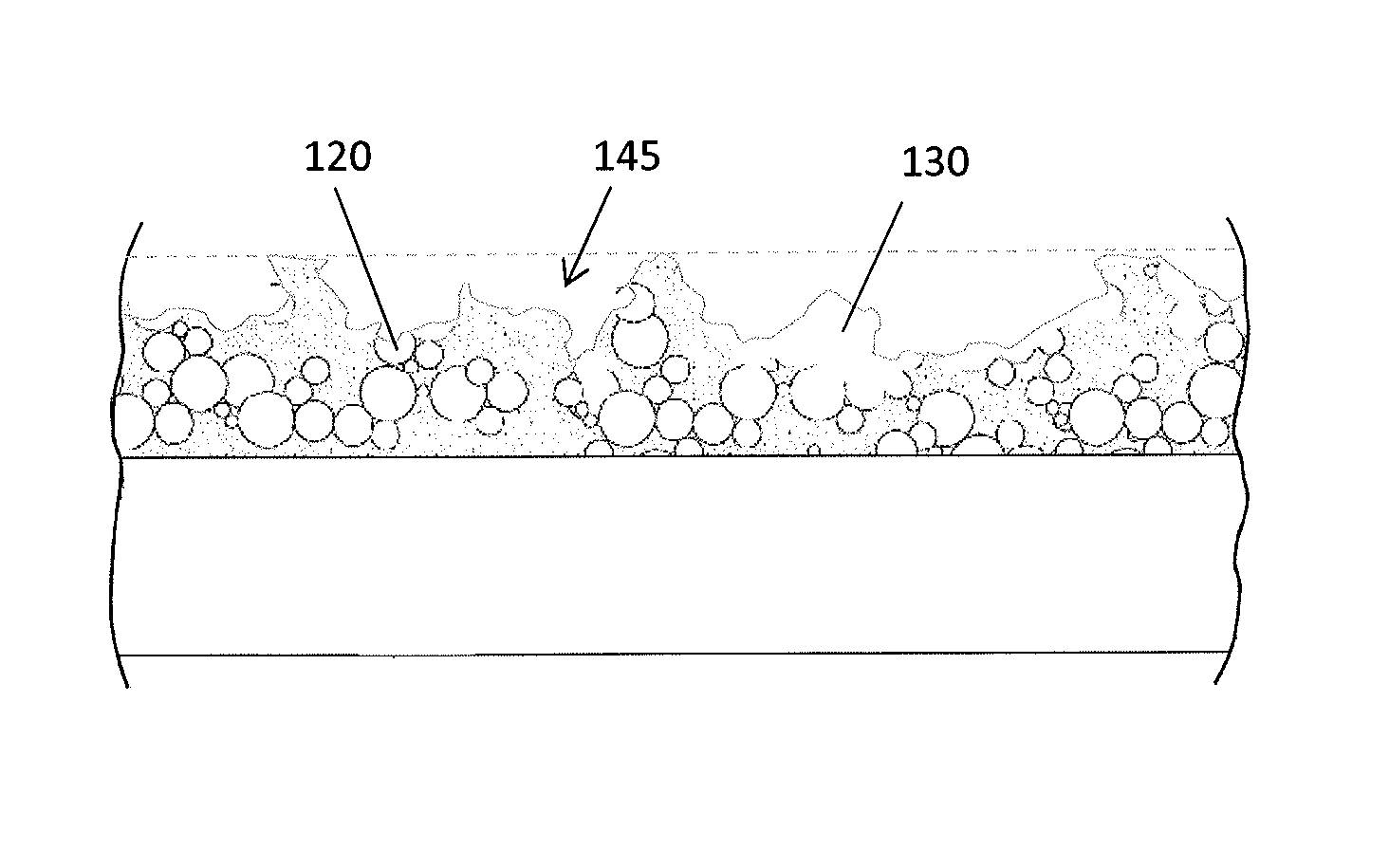

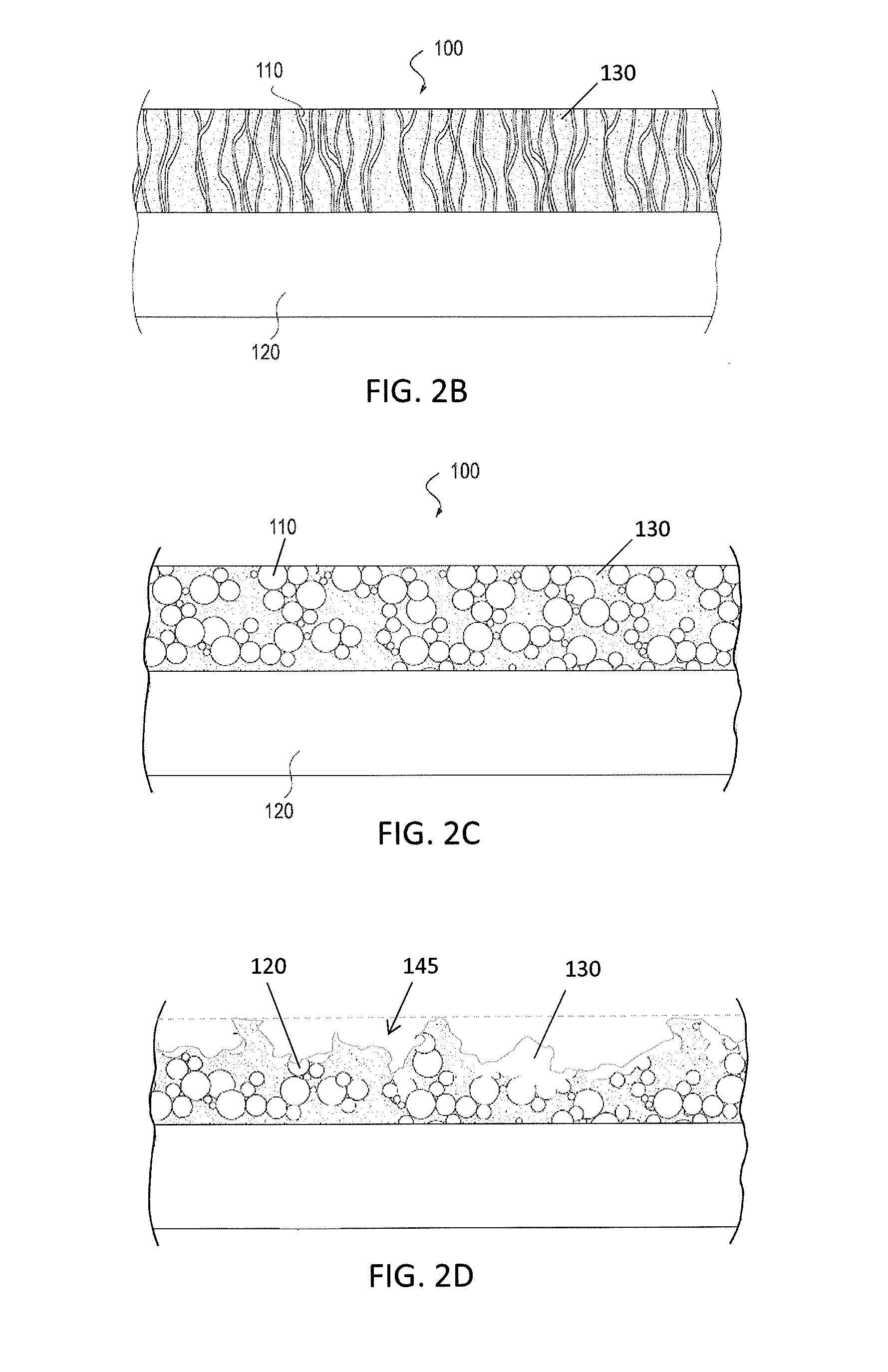

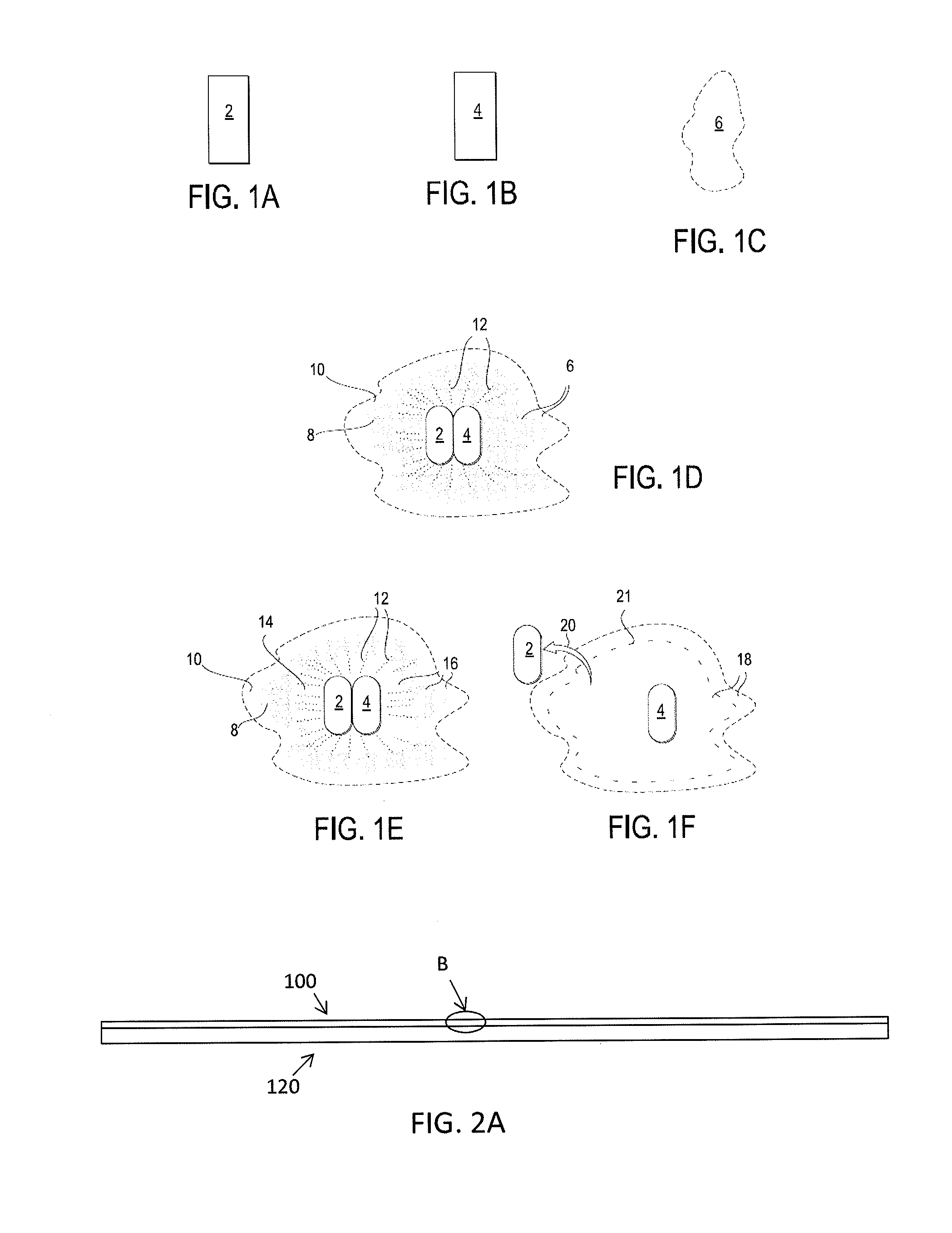

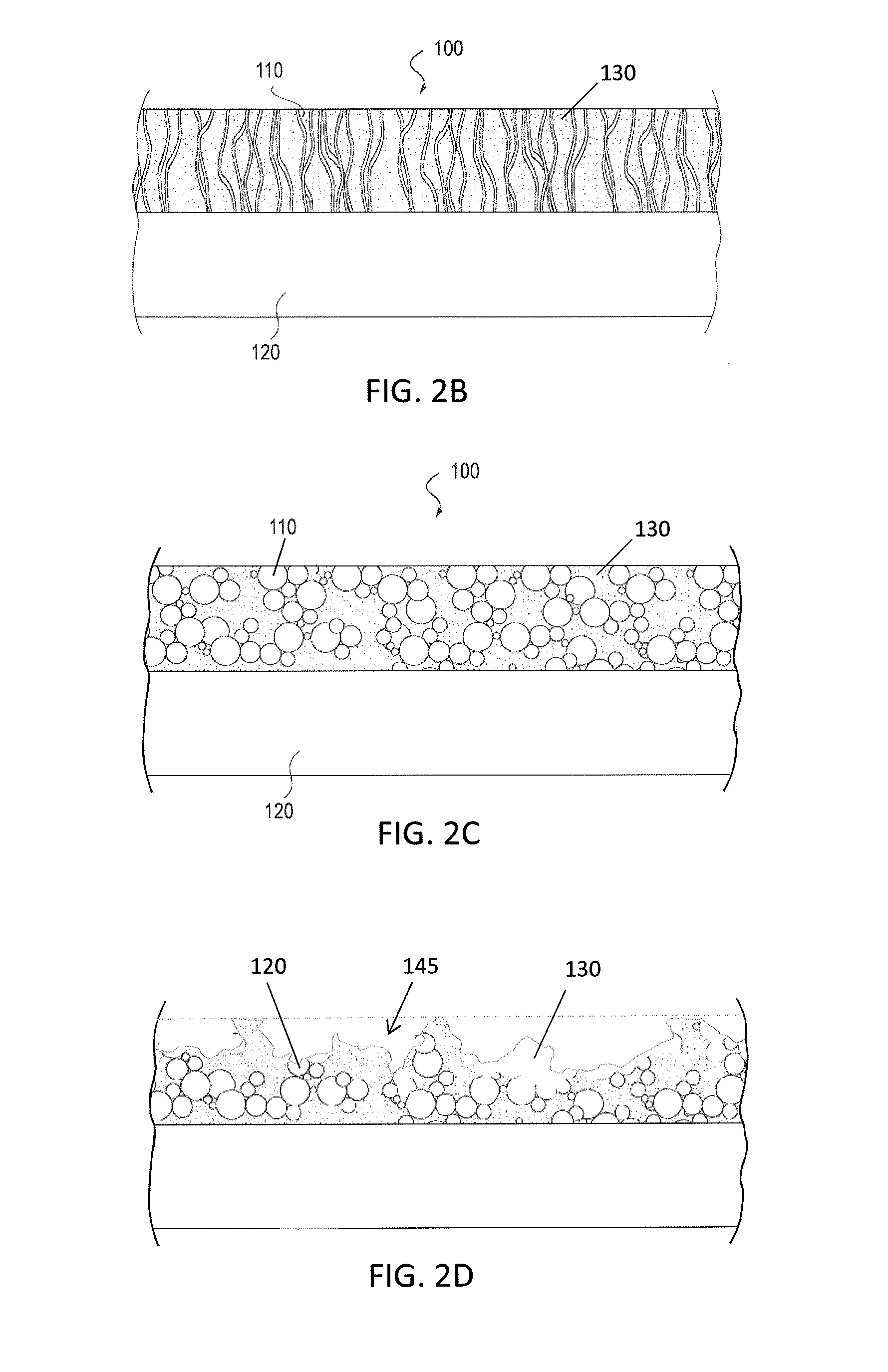

Bone implant and systems and coatings for the controllable release of antimicrobial metal ions

InactiveUS20180093013A1Sustained releaseAvoid entrapmentHeavy metal active ingredientsBiocideIridiumRhenium

Antimicrobial metal ion coatings and implants including them. In particular, described herein are coatings including an anodic metal (e.g., silver and / or zinc and / or copper) that is co-deposited with a cathodic metal (e.g., palladium, platinum, gold, molybdenum, titanium, iridium, osmium, rhodium, manganese, niobium or rhenium) on a substrate so that the anodic metal is galvanically released as antimicrobial ions when the apparatus is exposed to a bodily fluid. The anodic metal may be at least about 25 percent by volume of the coating, resulting in a network of anodic metal with less than 20% of the anodic metal in the coating fully encapsulated by cathodic metal. The implant may be configured as an implant such as a bone-screw or intramedullary rod-like body configured to receive a treatment cartridge having a coating as described.

Owner:SILVER BULLET THERAPEUTICS

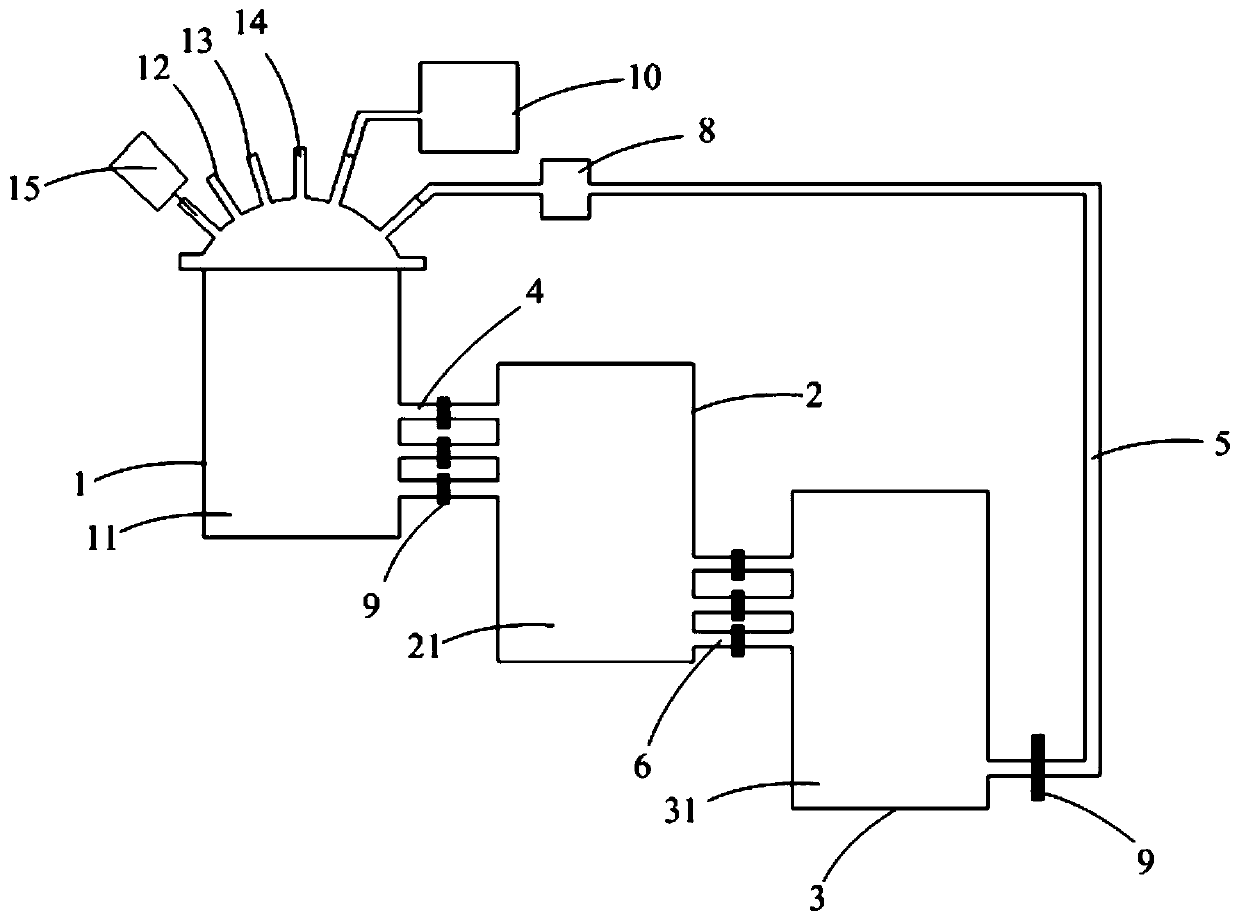

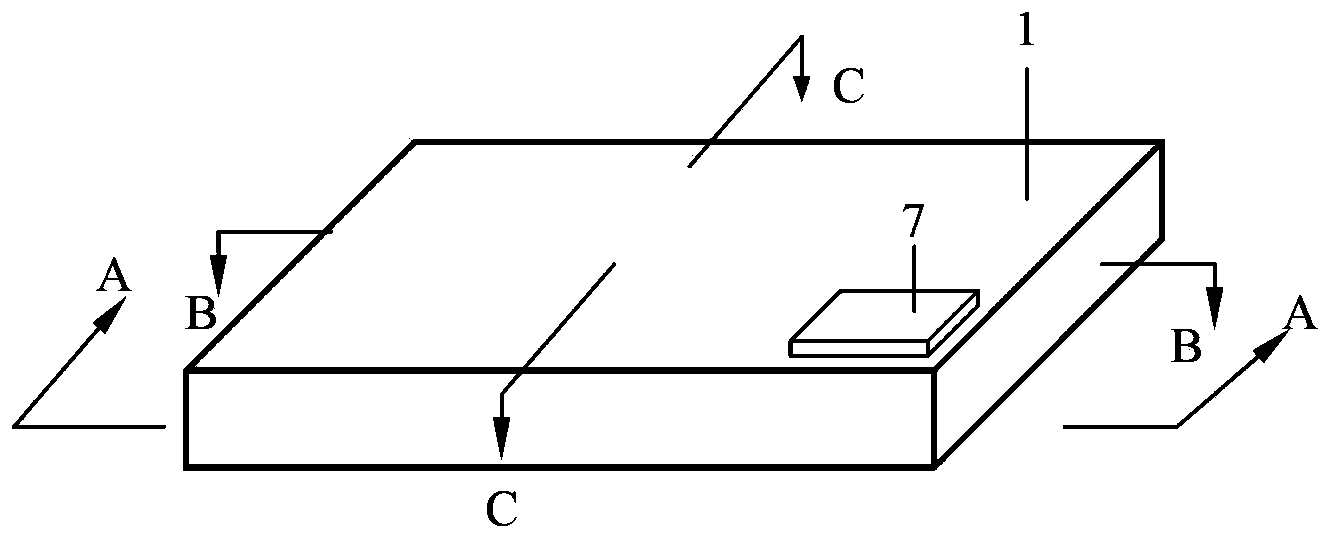

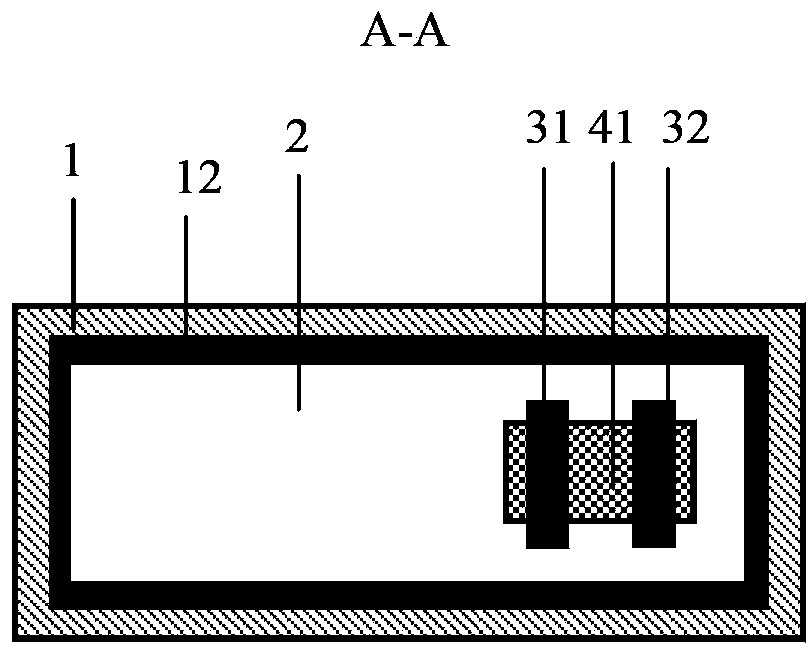

Integrated cavity type conductive fluid heat spreader

ActiveCN104125753AEliminate tightnessPrevent leakageCooling/ventilation/heating modificationsMagnetic polesEngineering

The invention provides an integrated cavity type conductive fluid heat spreader which includes a cavity (1), the heat absorbing end, flow, liquid, fluid pool, driving pump and a heat radiating end together in one room, the internal cavity structure, and the inner surface is an insulating layer (12); runner type electrode for (31, 32), arranged on the cavity surface, which is used as a channel and the direction of fluid flow regulator; a magnet for (41, 42), in the cavity body and the direction of the magnetic poles and the electrode is arranged on the current direction is vertical range setting; conductive fluid (2), the filling in the cavity; power supply chip (7) which is arranged in the cavity, the outer surface of the electrodes used to provide the input current. According to the heat spreader is provided by the invention greatly reduces the production and packaging process, completely avoid the fluid leakage; the compact volume, heat transfer capacity significantly; the cavity electrode on the position can be set flexibly, significantly enhance the electromagnetic driving force, resulting in the enhancement of heat transfer and flow effect is strong; between different parts of the body temperature of the fluid cavity different mixing efficiency is high, the heat transport capability is strong.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

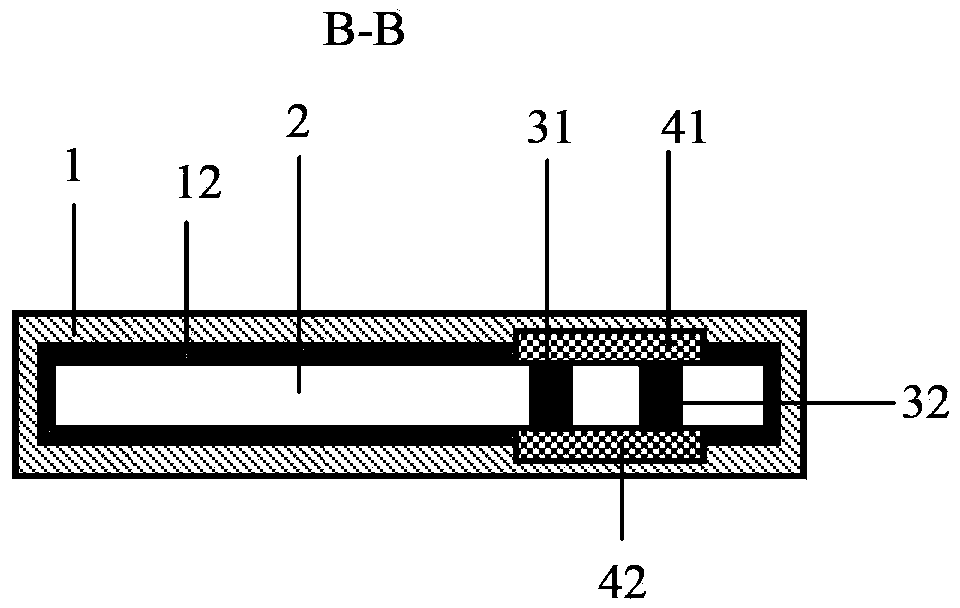

Nanochanneled device with electrodes and related methods

ActiveUS20150088102A1Long-term releaseAvoid encapsulationNanomedicineMedical devicesEngineeringBiomedical engineering

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

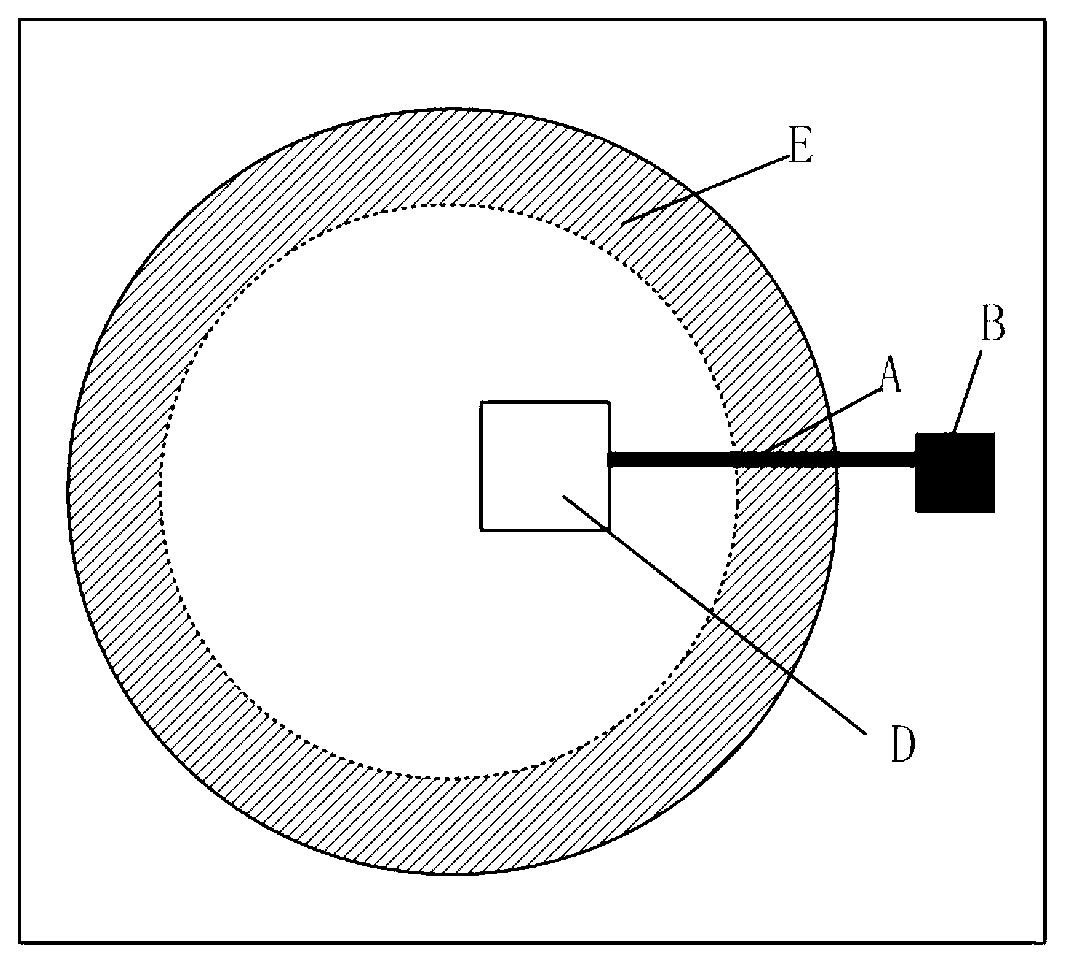

Method for preparing self-packaging of MEMS (micro electro mechanical systems) device based on surface sacrificial layer technology

InactiveCN103072941AAvoid complicated encapsulation processAvoid encapsulationDecorative surface effectsChemical vapor deposition coatingProcess qualityEtching

The invention provides a method for preparing self-packaging of an MEMS device based on a surface sacrificial layer technology. The method comprises that a substrate protective layer, a lower electrode and a lower electrode protective layer are deposited and prepared on a substrate, and the surface of the lower electrode protective layer is subjected to chemical-mechanical polishing; a first sacrificial layer and an MEMS device structural layer are prepared through the surface sacrificial layer technology; a metal layer is deposited on the structural layer; a second sacrificial layer and a packaging layer are prepared through the surface sacrificial layer technology, and interconnection portions in and out of a packaging area are prepared; and all sacrificial layers are subjected to wet etching, and the MEMS device structural layer is released and self-packaging is completed by an adhesion effect. The method is applicable to infrared sensors and the like of MEMS devices with movable structures, so that self packaging of the MEMS devices can be achieved, the packaging period can be shortened, the process quality and the yield are improved, and the packaging cost is reduced.

Owner:PEKING UNIV

Enhancement of antimicrobial silver, silver coatings, or silver platings

ActiveUS9452242B2Improve antibacterial propertiesEnlarge regionSurgeryPretreated surfacesIridiumRhenium

Antimicrobial metal ion coatings. In particular, described herein are coatings including an anodic metal (e.g., silver and / or zinc and / or copper) that is co-deposited with a cathodic metal (e.g., palladium, platinum, gold, molybdenum, titanium, iridium, osmium, niobium or rhenium) on a substrate (including, but not limited to absorbable / resorbable substrates) so that the anodic metal is galvanically released as antimicrobial ions when the apparatus is exposed to a bodily fluid. The anodic metal may be at least about 25 percent by volume of the coating, resulting in a network of anodic metal with less than 20% of the anodic metal in the coating fully encapsulated by cathodic metal.

Owner:SILVER BULLET THERAPEUTICS

Glaucoma drainage implant

ActiveUS10912675B2Avoid encapsulationLimited functionLaser surgeryWound drainsAqueous humorGlaucoma drainage implant

Owner:NIKOLIC MED STEPHAN DR

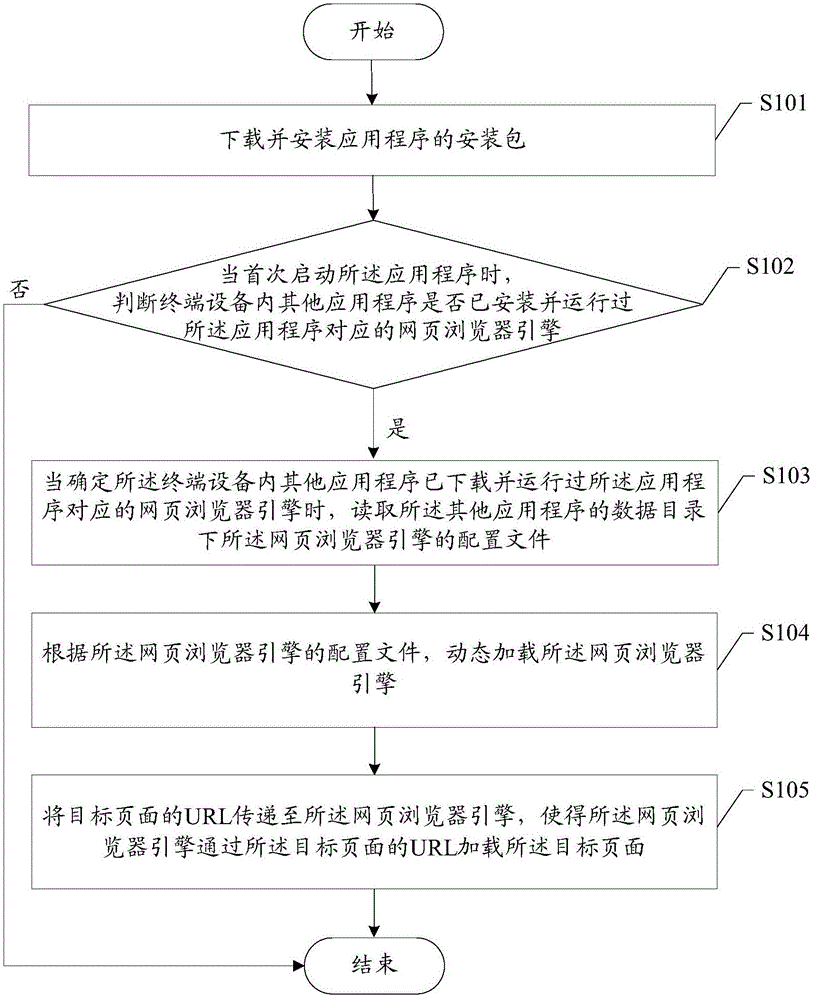

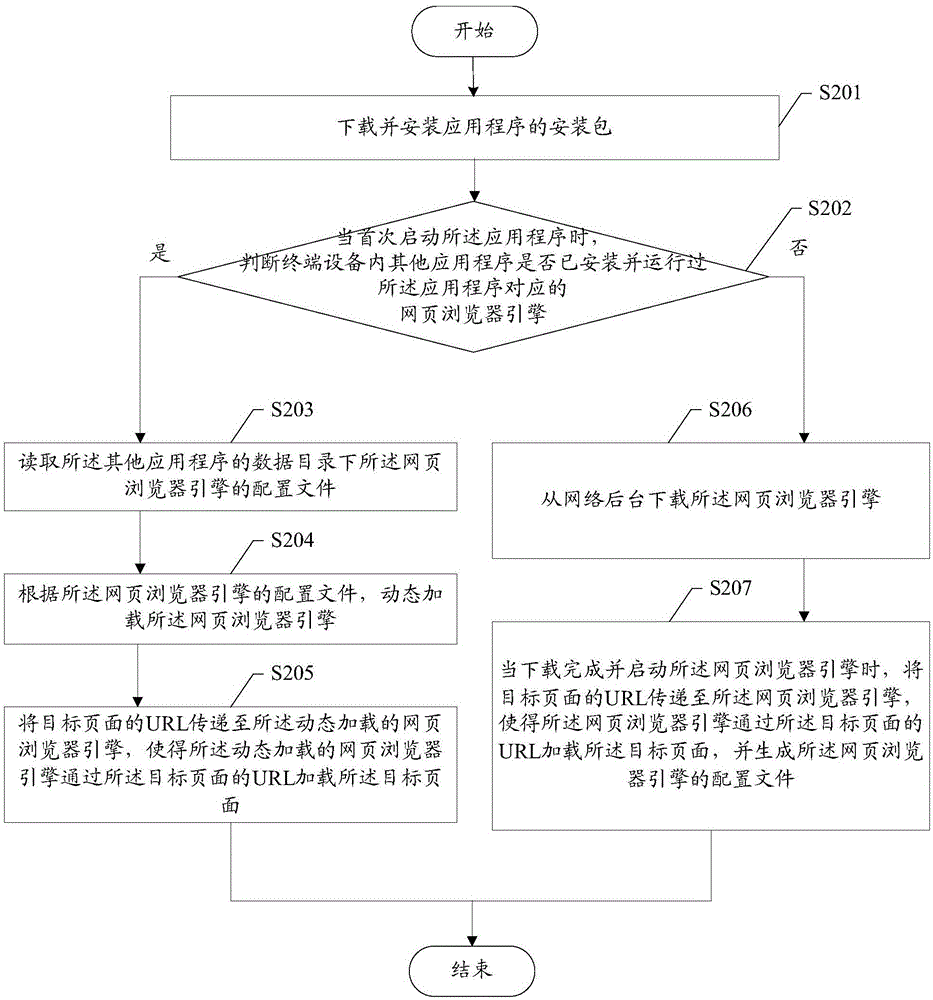

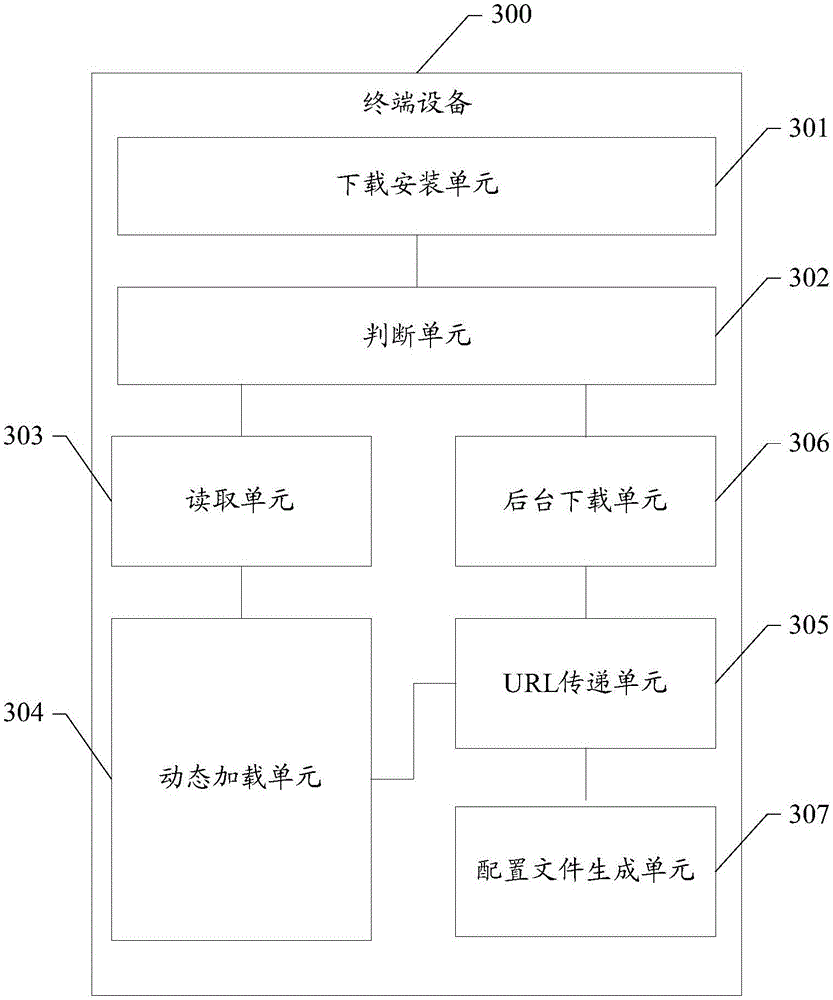

Terminal equipment and execution method of application program of terminal equipment

InactiveCN106406920AAvoid encapsulationSave storage resourcesProgram loading/initiatingWeb browserTerminal equipment

The invention discloses terminal equipment and an execution method of an application program of the terminal equipment. The method comprises the following steps of: downloading and installing an installation package of the application program; when the application program is started for the first time, judging whether the other application programs in the terminal equipment install and operate a webpage browser engine corresponding to the application program or not; when the other application programs in the terminal equipment install and operate the webpage browser engine corresponding to the application program, reading configuration files, under data directories of the other application programs, of the webpage browser engine; dynamically loading the webpage browser engine according to the configuration files of the webpage browser engine; and transferring a URL of a target page to the webpage browser engine to ensure that the webpage browser engine loads the target page through the URL of the target page. Through above scheme, the resources are saved when a same webpage browser engine is shared by a plurality of application programs.

Owner:宋青见 +3

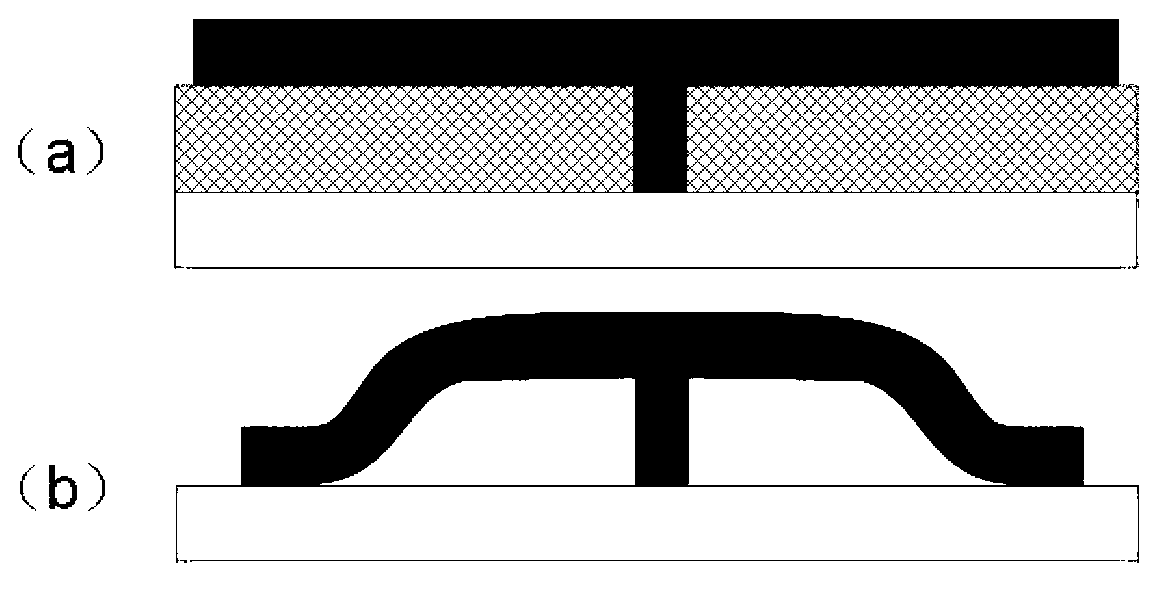

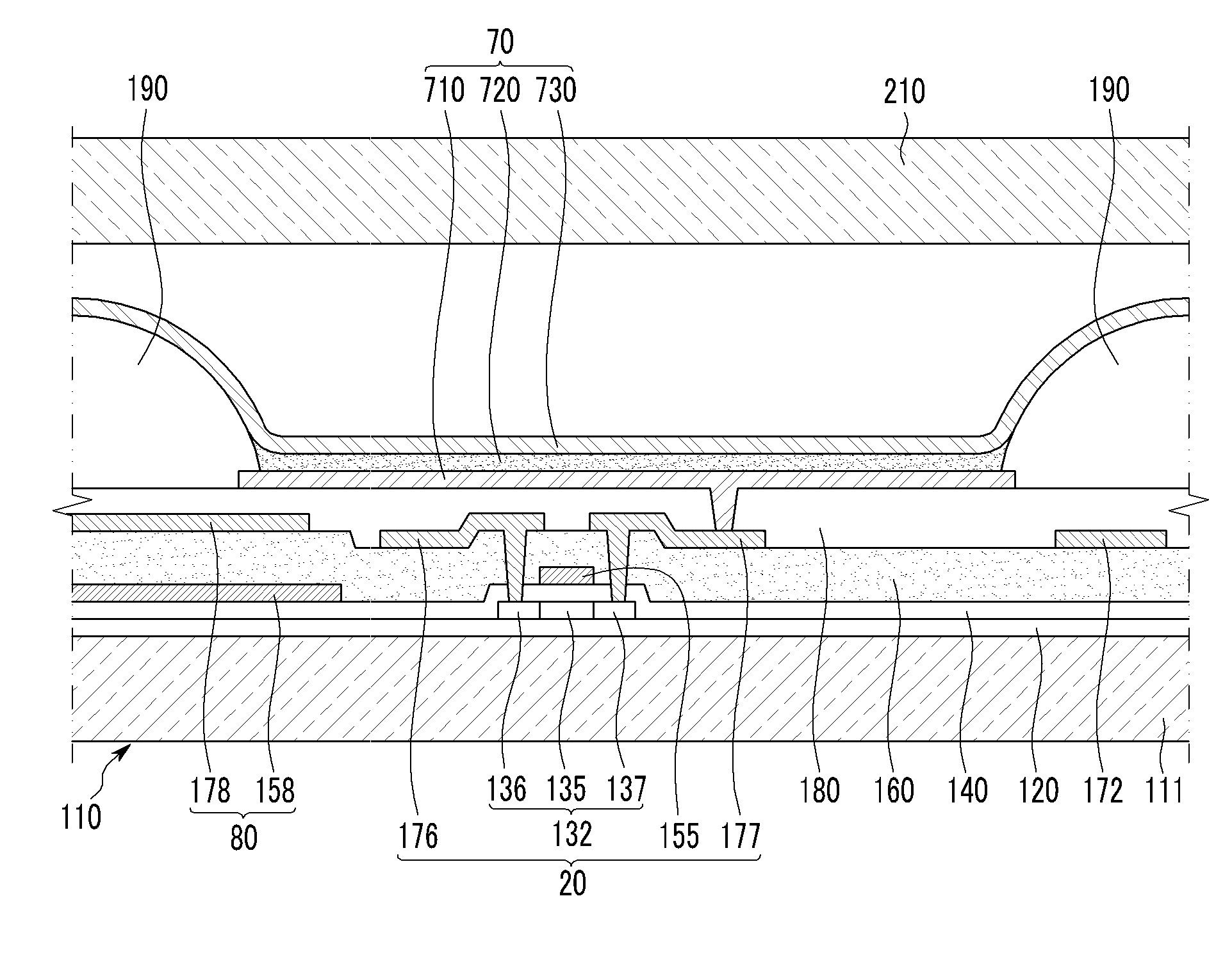

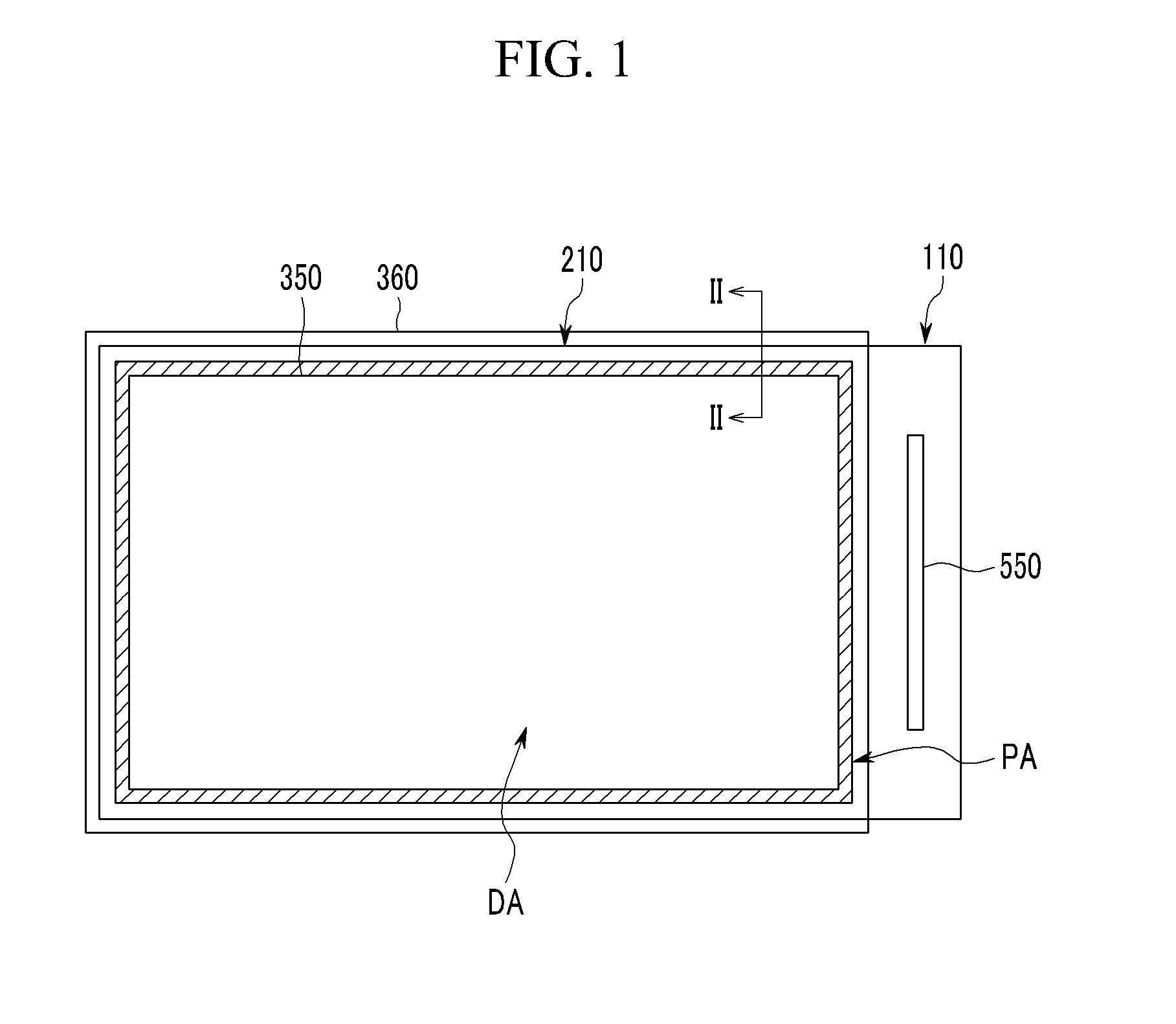

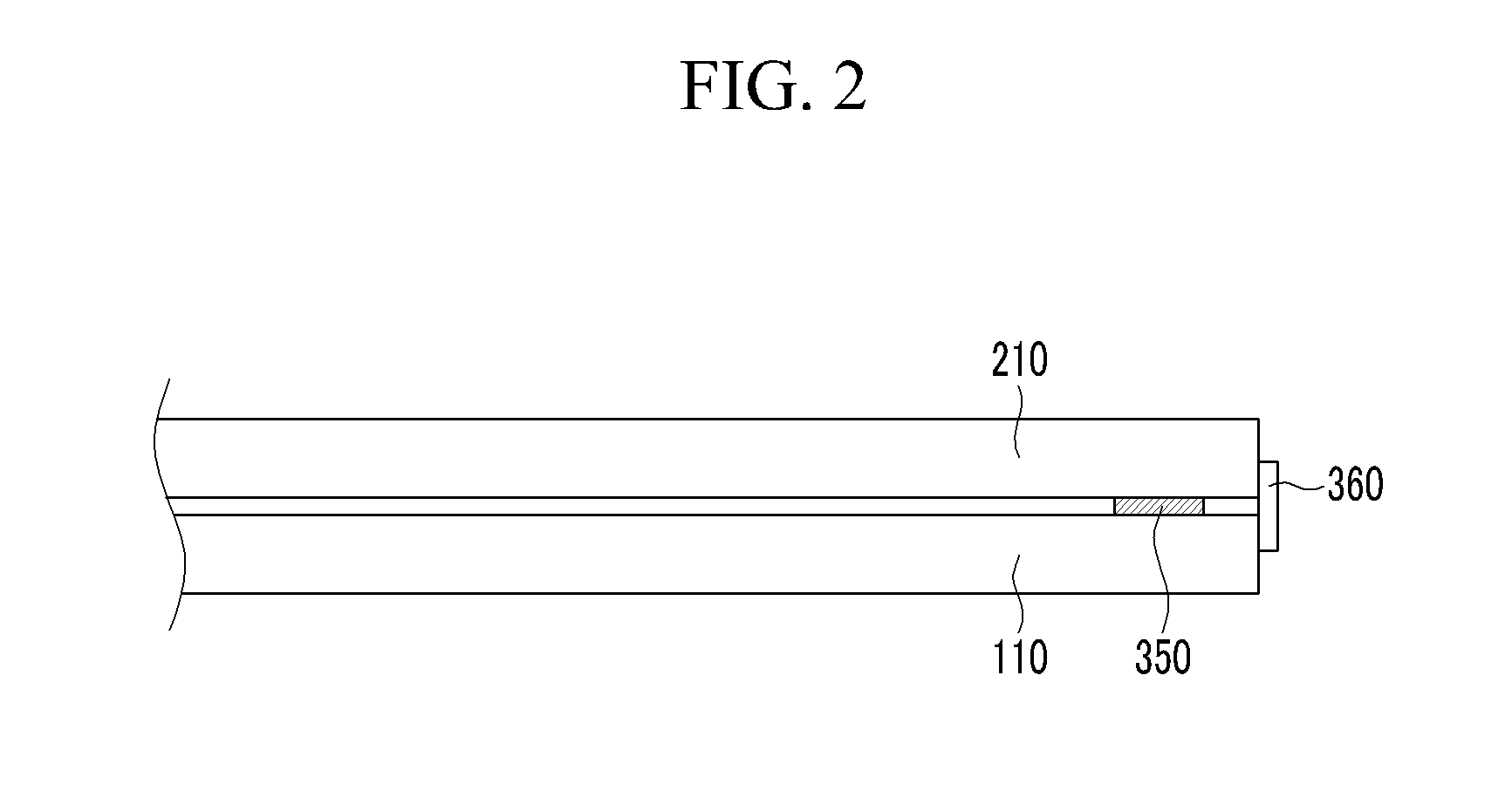

Organic light emitting diode display and manufacturing method thereof

InactiveUS20110278550A1Increased durabilityIncrease resistanceSolid-state devicesSemiconductor/solid-state device manufacturingStress concentrationHigh fracture

An organic light emitting diode (OLED) display includes a display substrate, an encapsulation substrate facing the display substrate; a soft sealant disposed between the display substrate and the encapsulation substrate and adhering the display substrate and the encapsulation substrate to each other; and a brittle sealant connecting a side of the display substrate and a side of the encapsulation substrate. Therefore, the organic light emitting diode (OLED) display does not generate cracks on the attachment surface of the soft sealant and display substrate and encapsulation substrate because the soft sealant has a high fracture toughness even though a stress concentration phenomenon occurs on the attachment surface of the soft sealant, the display substrate and encapsulation substrate. Therefore, it is possible to prevent the display substrate and encapsulation substrate from being easily broken because of the external impact or deformation thereof.

Owner:SAMSUNG DISPLAY CO LTD

Enhancement of antimicrobial silver, silver coatings, or silver platings

ActiveUS20160136335A1Good effectImprove antibacterial propertiesBiocideFrom normal temperature solutionsIridiumRhenium

Antimicrobial metal ion coatings. In particular, described herein are coatings including an anodic metal (e.g., silver and / or zinc and / or copper) that is co-deposited with a cathodic metal (e.g., palladium, platinum, gold, molybdenum, titanium, iridium, osmium, niobium or rhenium) on a substrate (including, but not limited to absorbable / resorbable substrates) so that the anodic metal is galvanically released as antimicrobial ions when the apparatus is exposed to a bodily fluid. The anodic metal may be at least about 25 percent by volume of the coating, resulting in a network of anodic metal with less than 20% of the anodic metal in the coating fully encapsulated by cathodic metal.

Owner:SILVER BULLET THERAPEUTICS

Compositions and methods for controlled delivery of inhibitory ribonucleic acids

ActiveUS9241898B2Easy modular assemblyAvoid encapsulationPowder deliverySugar derivativesDiseaseInternalization

Polymeric nanoparticles encapsulating inhibitory ribonucleic acids (RNAs) and methods of their manufacture and use are provided. Advantageous properties of the nanoparticles include: 1) high encapsulation efficiency of inhibitory RNAs into the nanoparticles, 2) small size of the nanoparticles that increases cell internalization, and 3) sustained release of encapsulated inhibitory RNAs by the nanoparticles that allows for administration of an effective amount of inhibitory RNAs to cells or tissues over extended periods of time. Encapsulation efficiency of inhibitory RNAs into the nanoparticles is greatly increased by complexing the inhibitory RNAs to polycations prior to encapsulation. Methods of using the polymeric nanoparticles for treating or inhibiting diseases or disorders are provided.

Owner:YALE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com