Integrated cavity type conductive fluid heat spreader

A conductive fluid and expander technology, which is applied in the field of thermal expanders, can solve the problems of high filling volume of precious metal fluid, limited space size, and reduced practicability, so as to achieve enhanced heat transfer and flow effects, reduce manufacturing and packaging procedures, Avoid the effects of fluid leakage and encapsulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

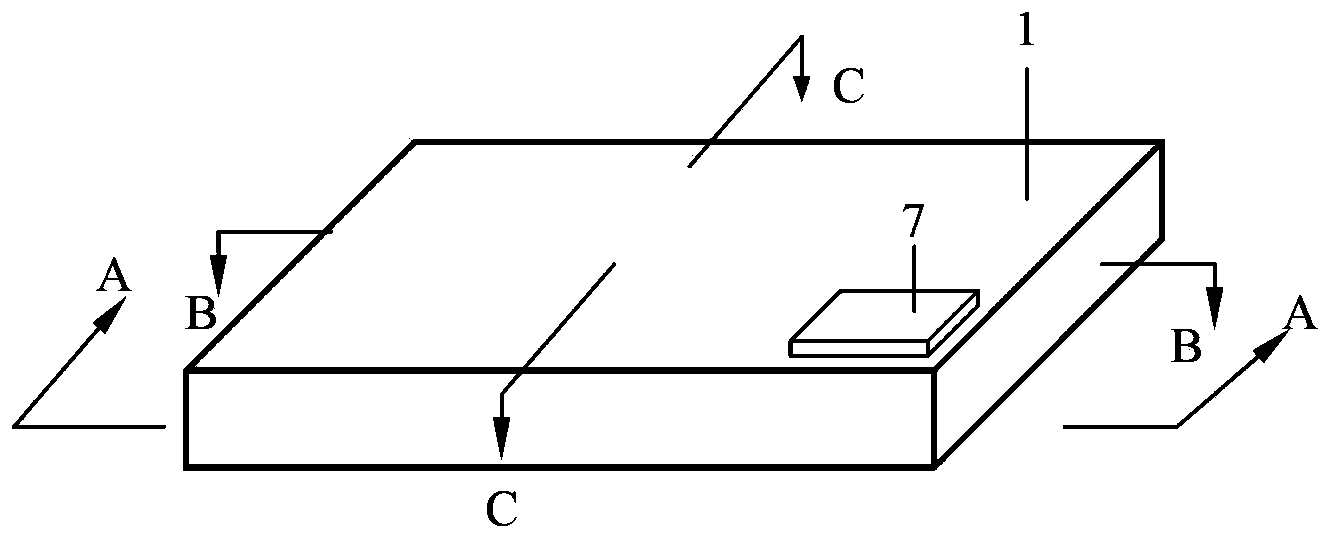

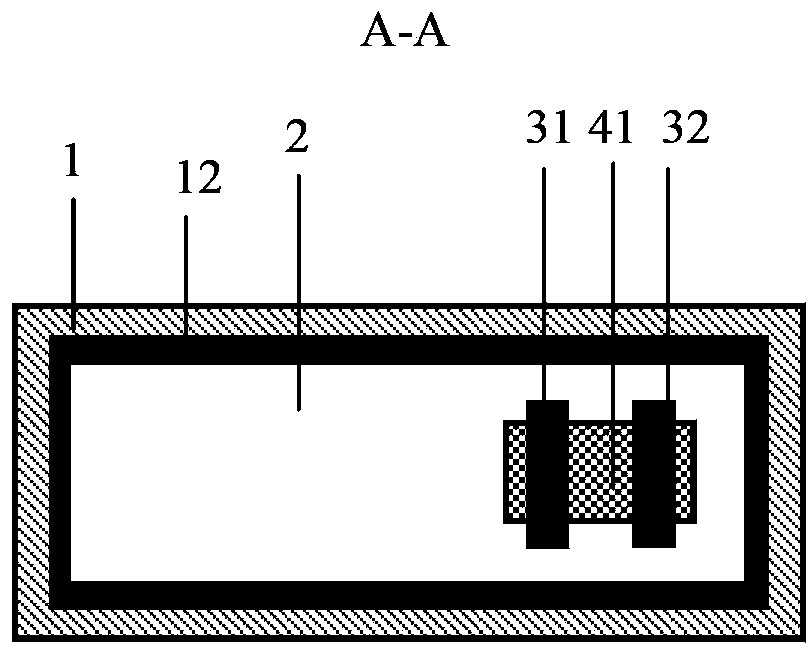

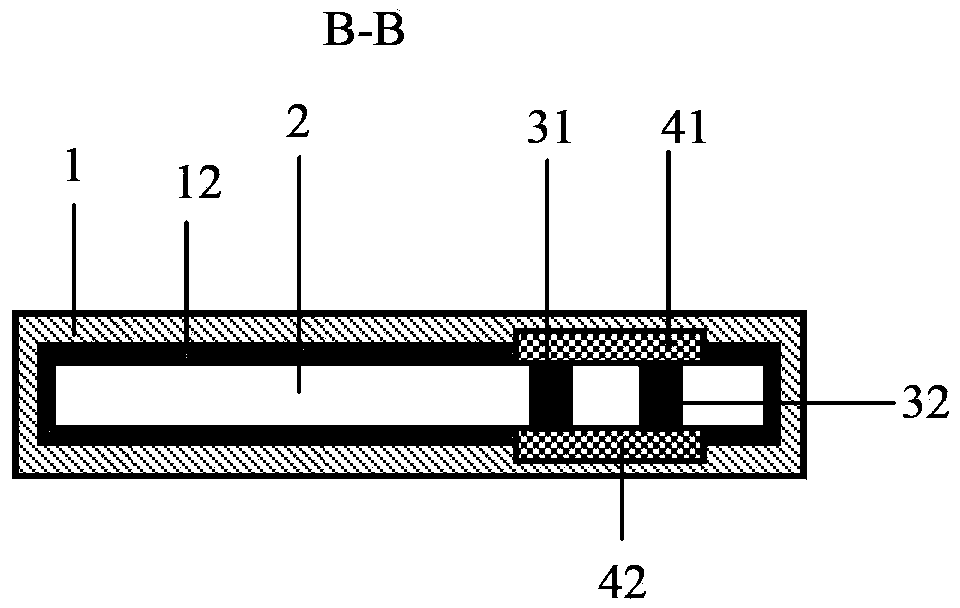

[0062] figure 1 It is a schematic diagram of the appearance of the integrated electromagnetic-driven cavity-type conductive fluid heat expander of the present invention (also a schematic structural diagram of an embodiment); figure 2 for figure 1 Schematic diagram of the A-A section (planar cross-section); image 3 for figure 1 Schematic diagram of the B-B section (longitudinal cross-section); Figure 4 for figure 1 Schematic of the C-C profile (transverse cross-section). As shown in the figure, the integrated electromagnetically driven cavity type conductive fluid heat expander of the present invention includes:

[0063] A cavity 1 with a thin-walled hollow structure inside, the heat-absorbing end, the flow channel, the liquid, the driving pump, the fluid pool and the heat-dissipating end are combined into one to form a cavity; thus a blade-type heat expander can be formed;

[0064] When the material of the cavity 1 is metal, its inner surface is an insulating layer 12...

Embodiment 2

[0076] Figure 5 It is a schematic diagram of the appearance of an integrated electromagnetically driven cavity-type conductive fluid heat spreader with ribs 13 on one side of the present invention; hot. All the other structures are identical to Example 1.

Embodiment 3

[0078] Image 6 It is a schematic diagram of the appearance of an integrated electromagnetically driven cavity-type conductive fluid thermal expander with ribs on both sides of the cavity of the present invention; to enhance heat transfer. All the other structures are identical to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com