Patents

Literature

60results about How to "Eliminate tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

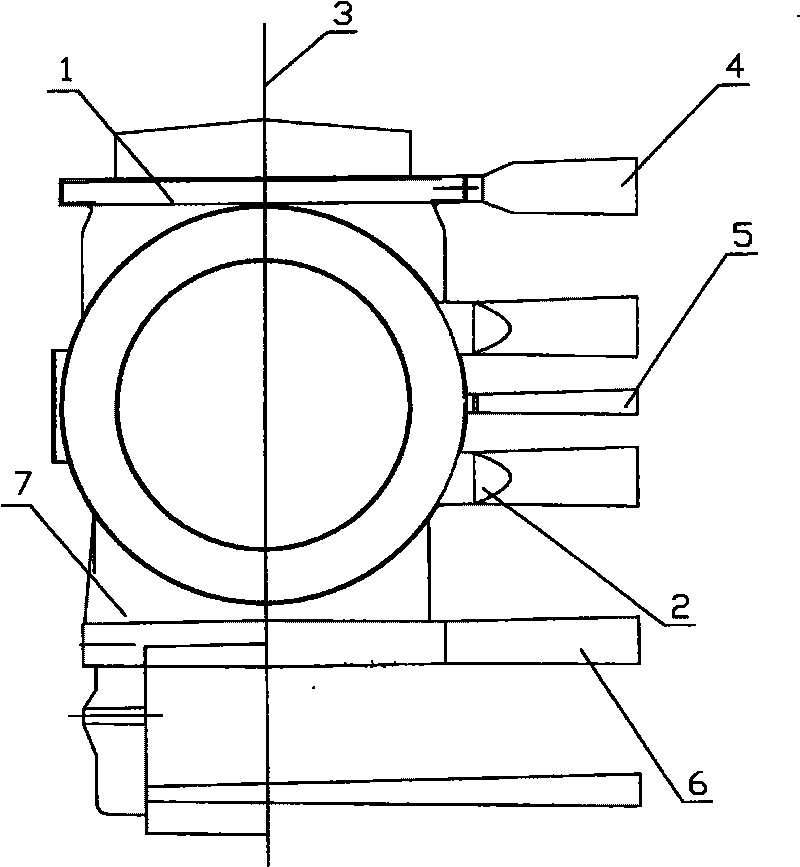

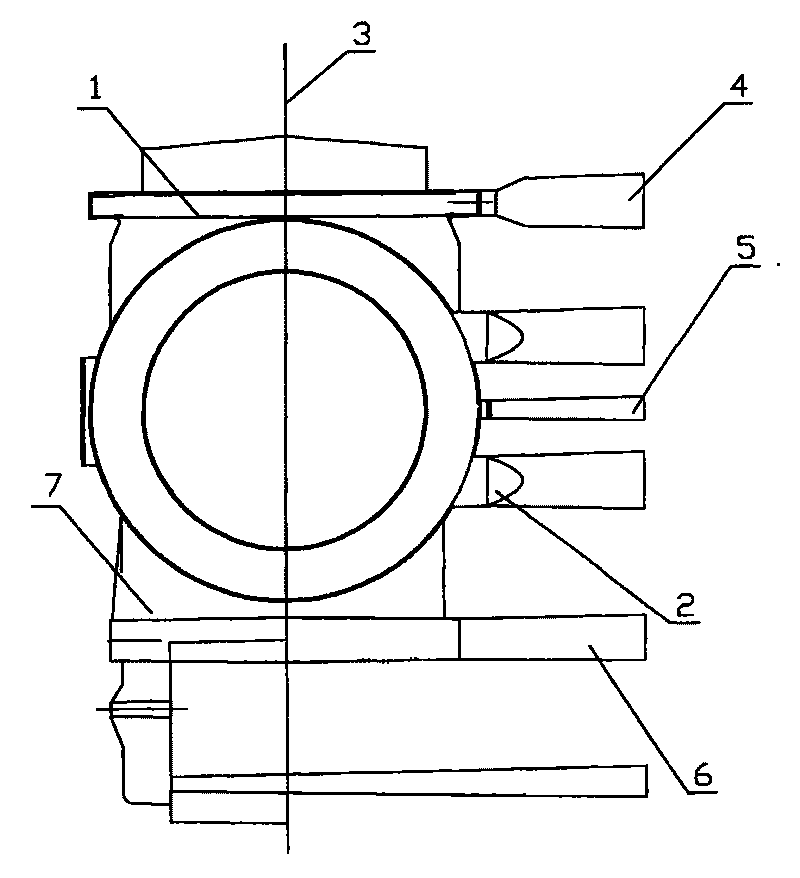

Method for producing voltage-bearing aluminum alloy tank body of ultra-high voltage switch by V-process

ActiveCN101693282AImprove mechanical propertiesImprove quality levelFoundry mouldsFoundry coresFoundryIntermediate frequency

The invention discloses a method for producing a voltage-bearing aluminum alloy tank body of an ultra-high voltage switch by a V-process, comprising the following steps: model making, thin film heating, thin film shaping (film absorbing), coating spraying, sandbox placing, ram-jolting by adding sand , back film covering, film loosening, core setting, box folding, pouring, removing box and shaking out. After the process is improved, an intermediate frequency furnace is utilized to melt and a crucible heat preserving furnace is utilized to modify and refine. When melting in the intermediate frequency furnace, microelements such as tombarthite and the like are replenished and a new non-stirring melting and refining technology is adopted so as to reduce oxide inclusion content in alloy liquid. Modification and refining treatment in the crucible heat preserving furnace ensures high purity degree and high component precision of aluminum liquid, and using pure aluminum alloy liquid can increase the ratio of acquiring qualified pressure-proof tank body foundry products.

Owner:NANYANG HUISEN PRECISION INSTR CASTING

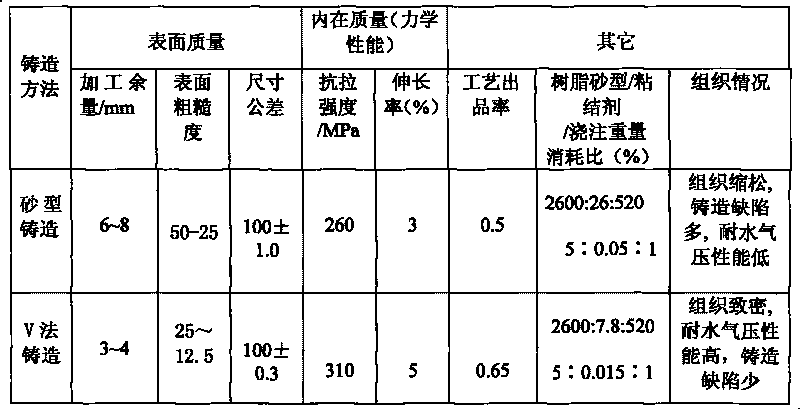

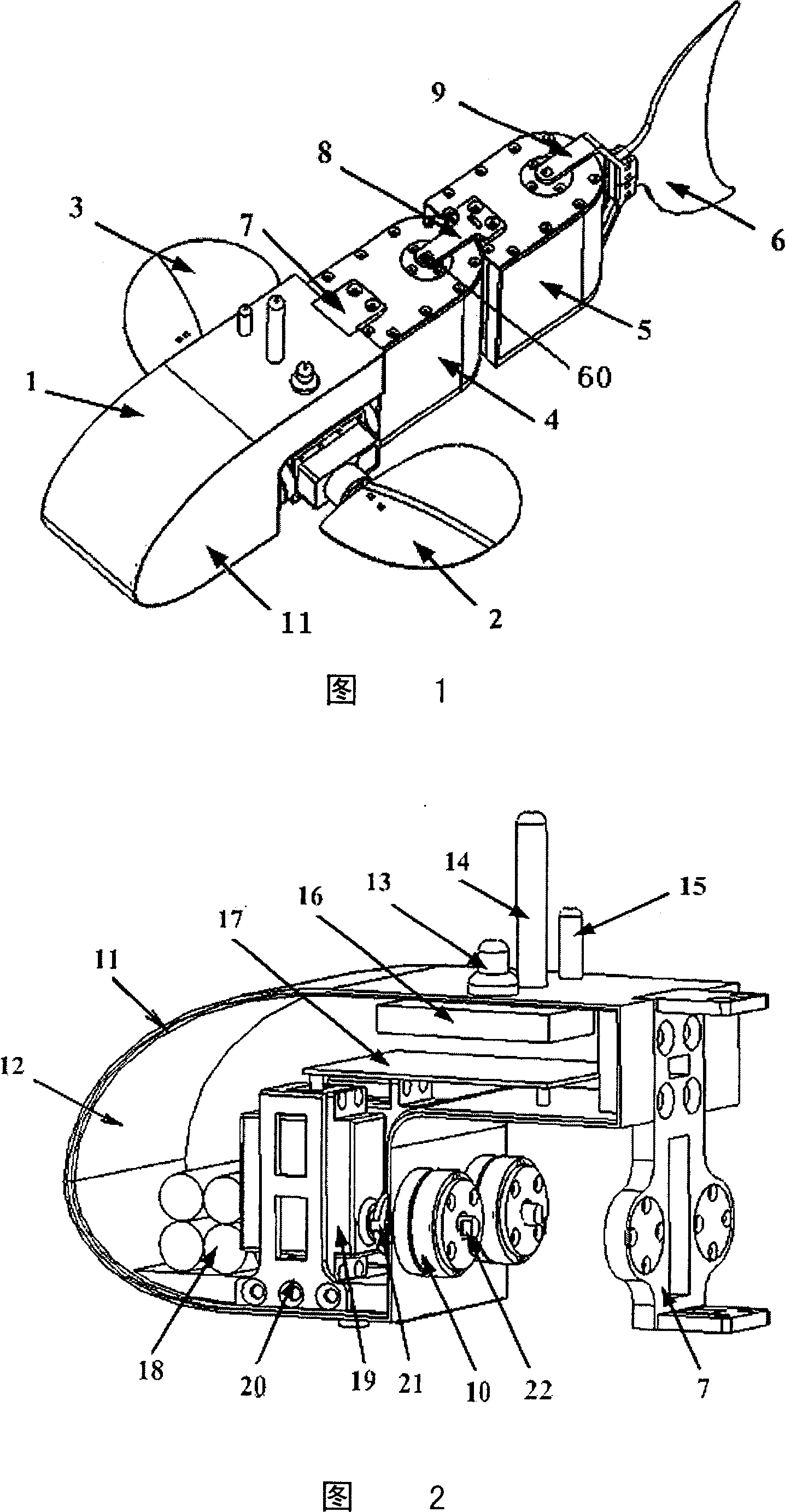

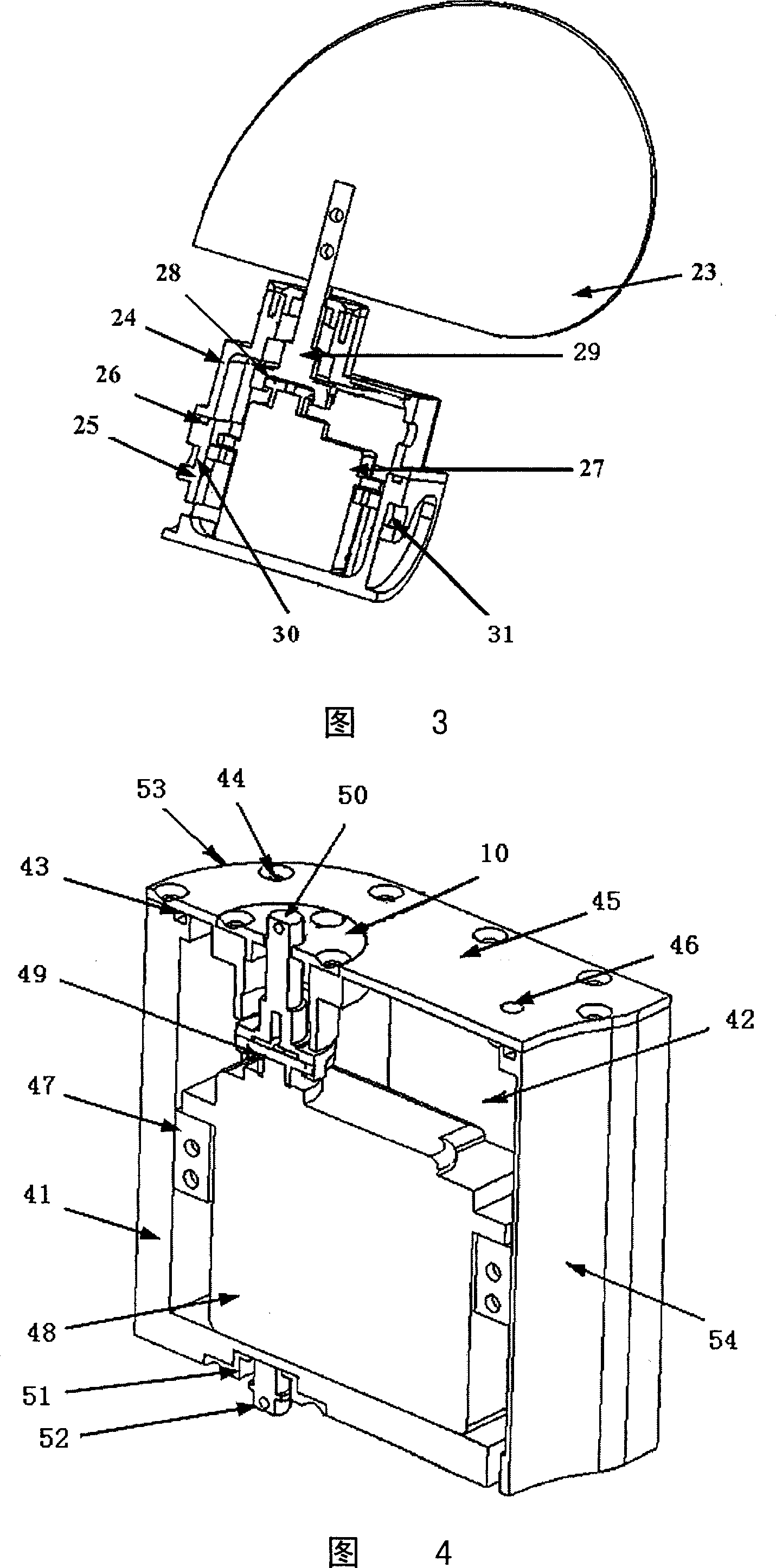

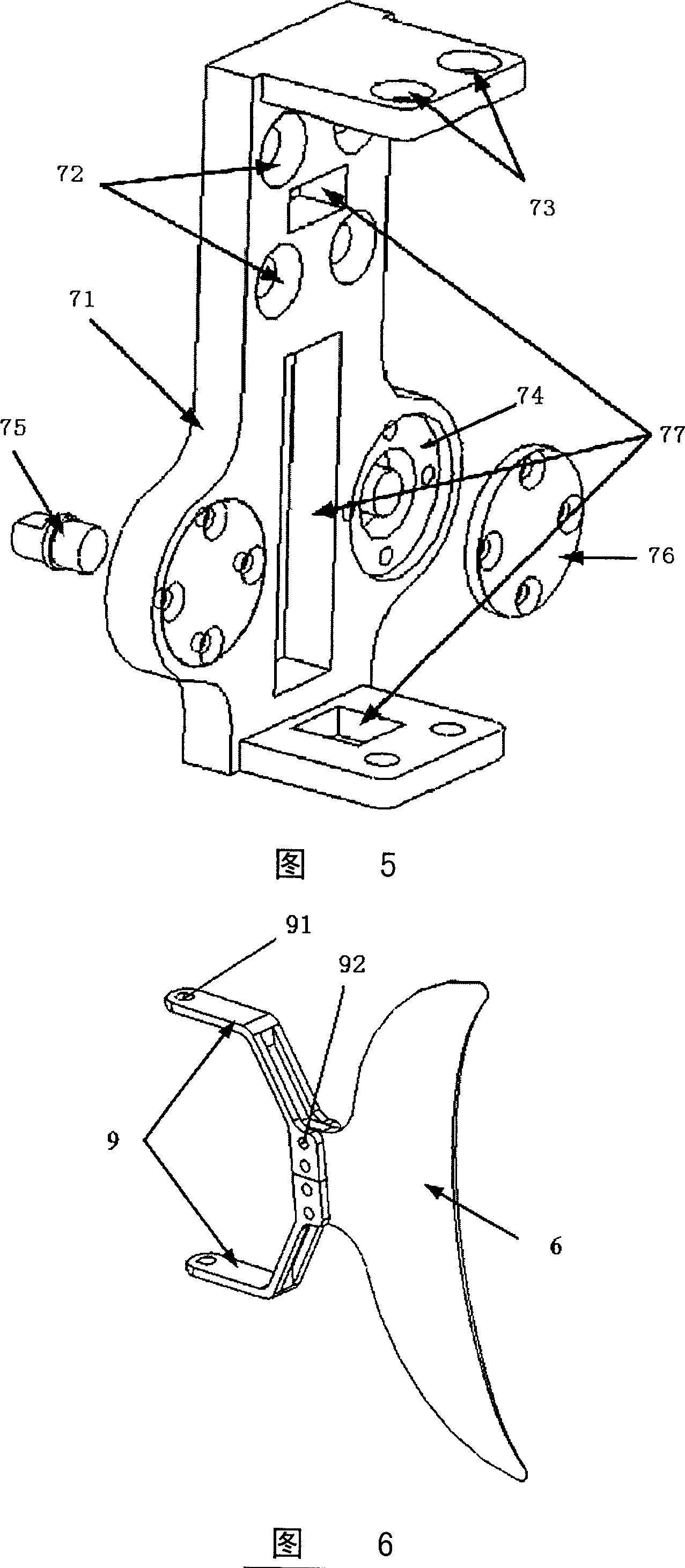

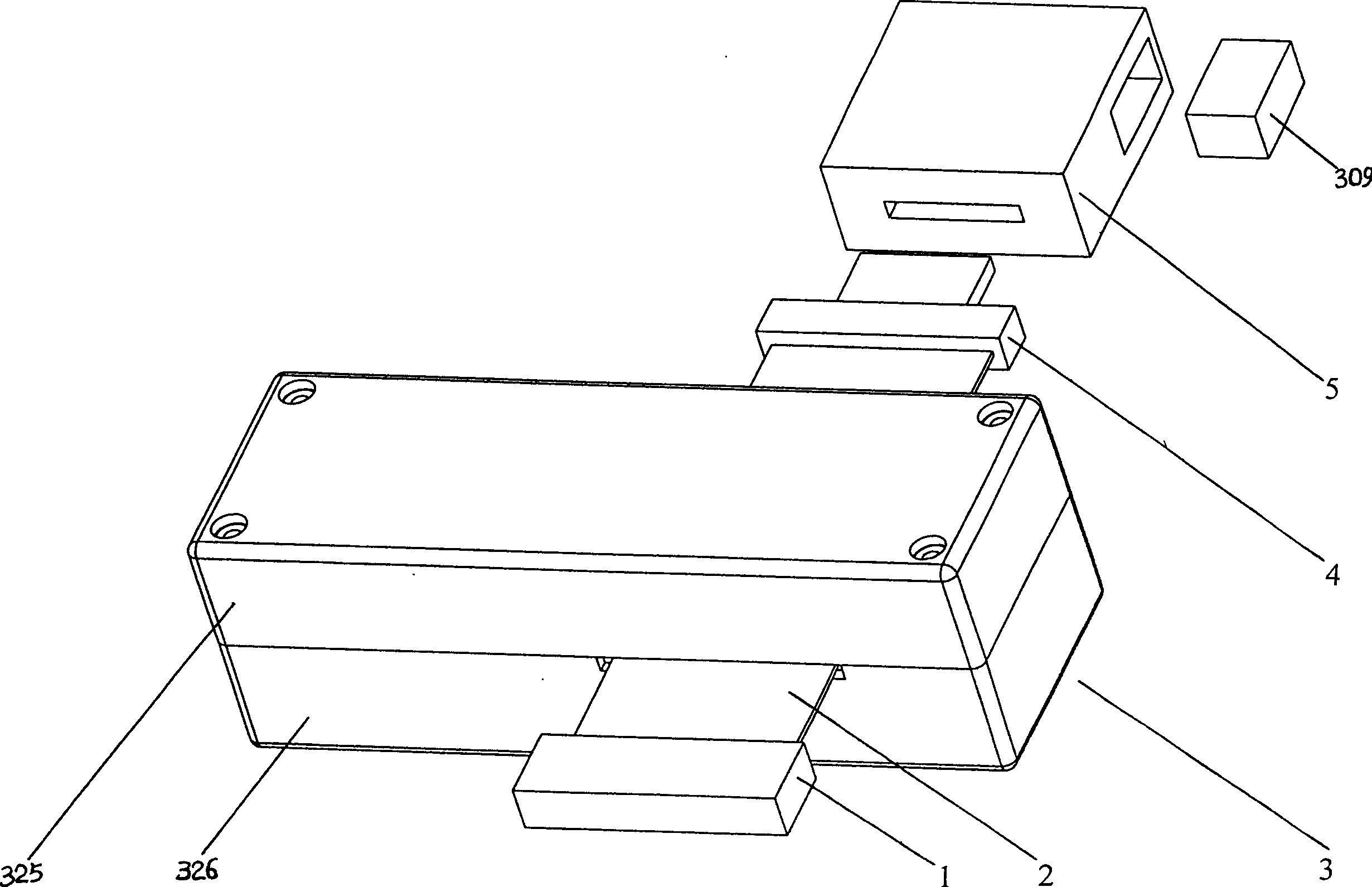

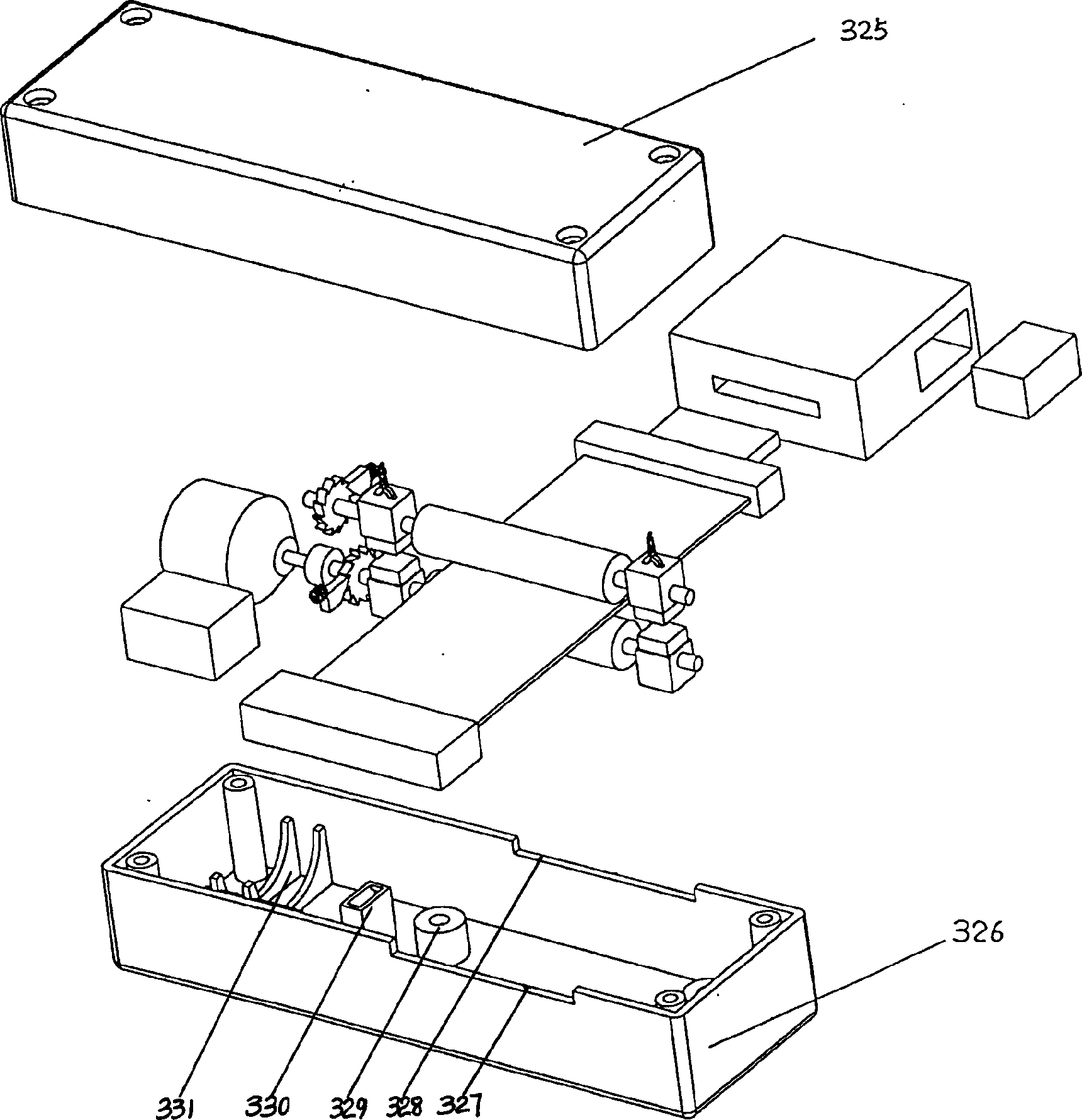

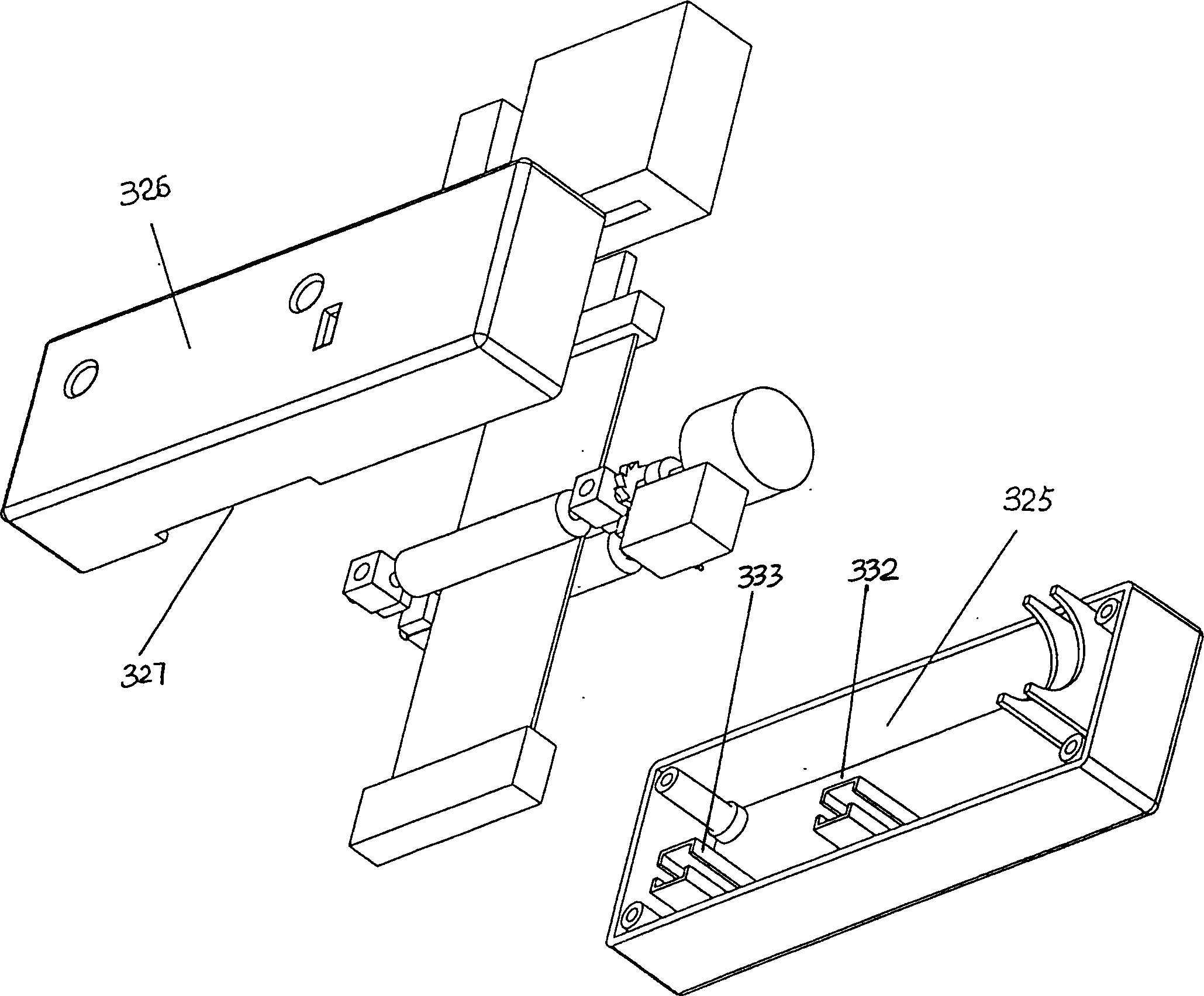

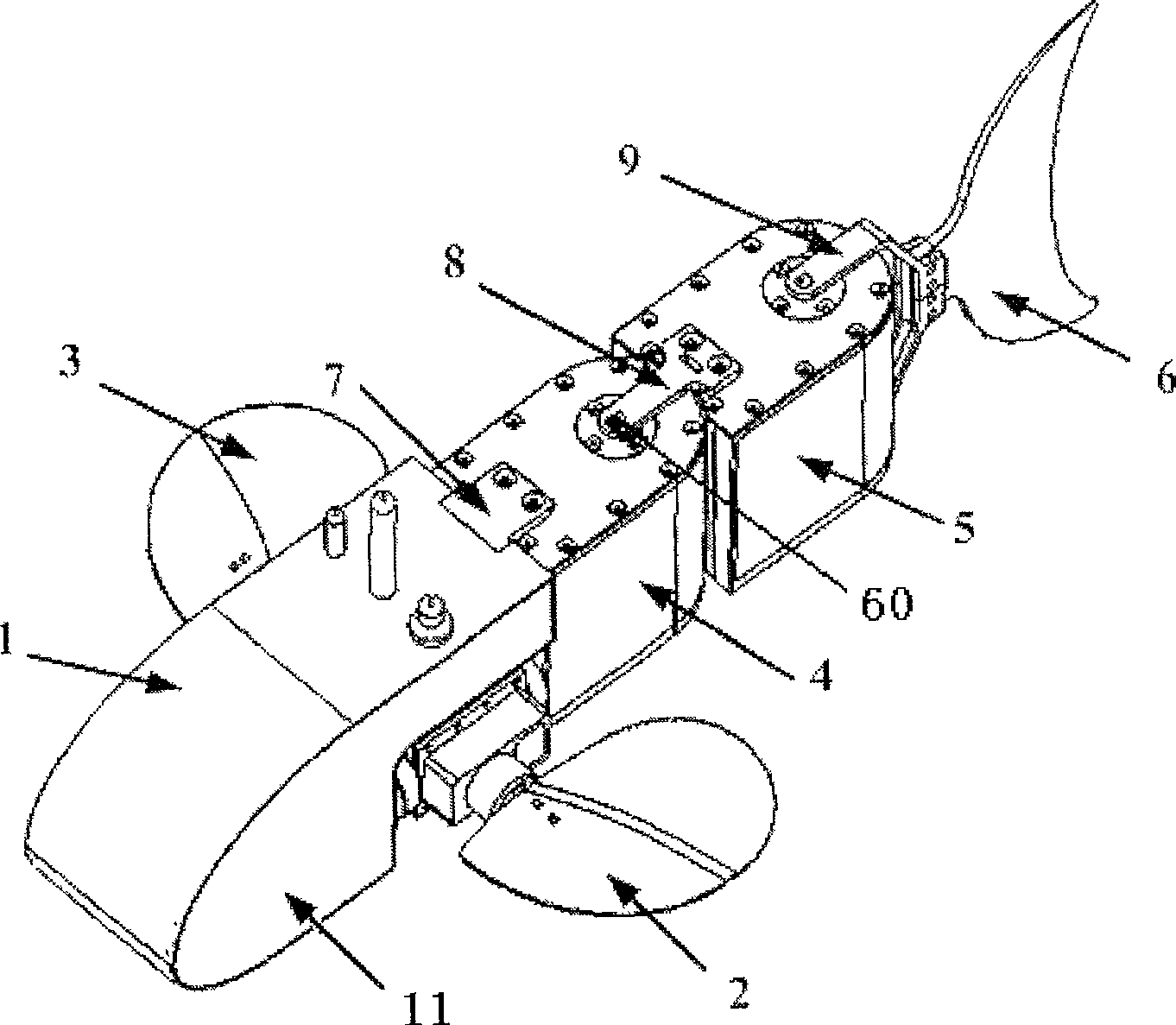

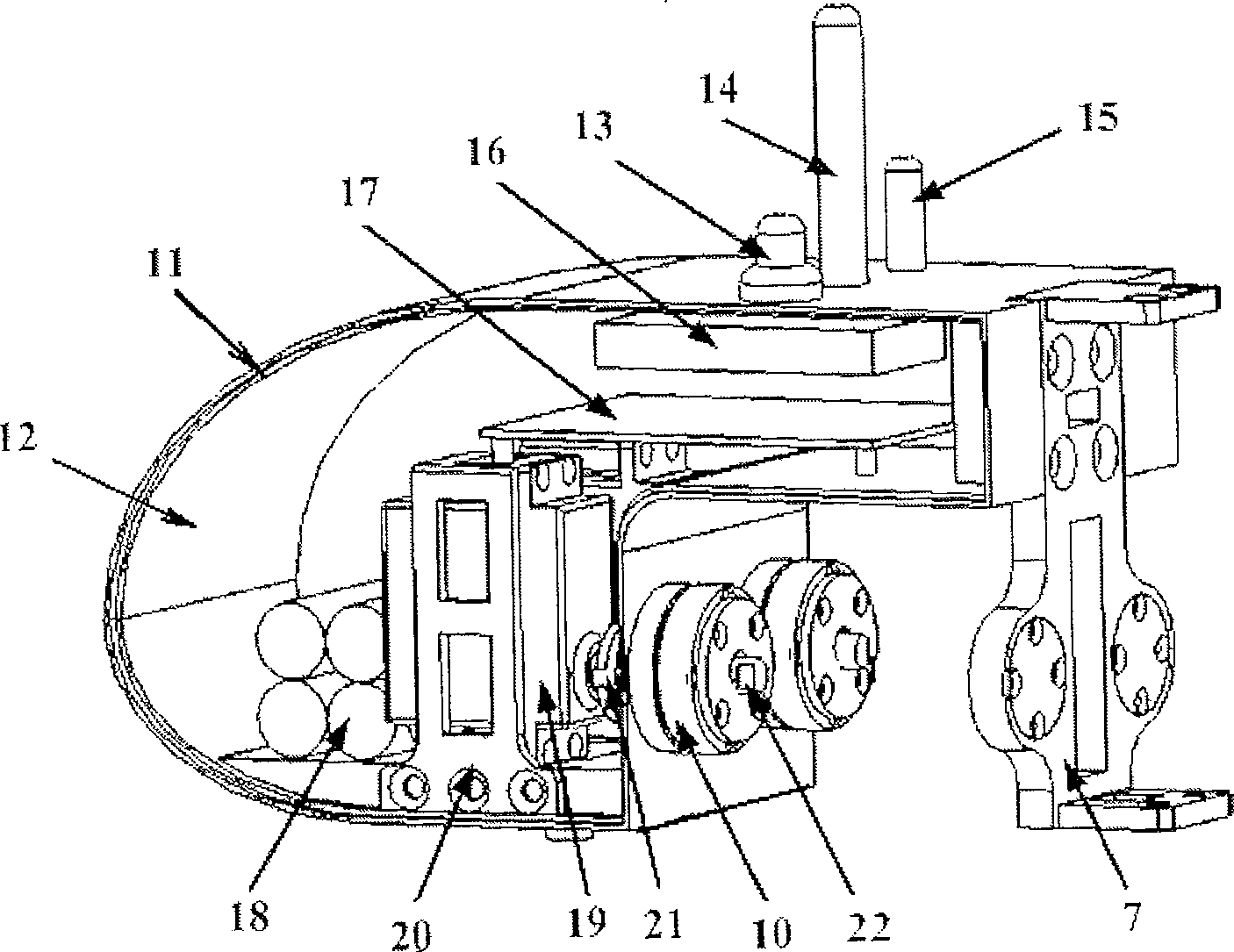

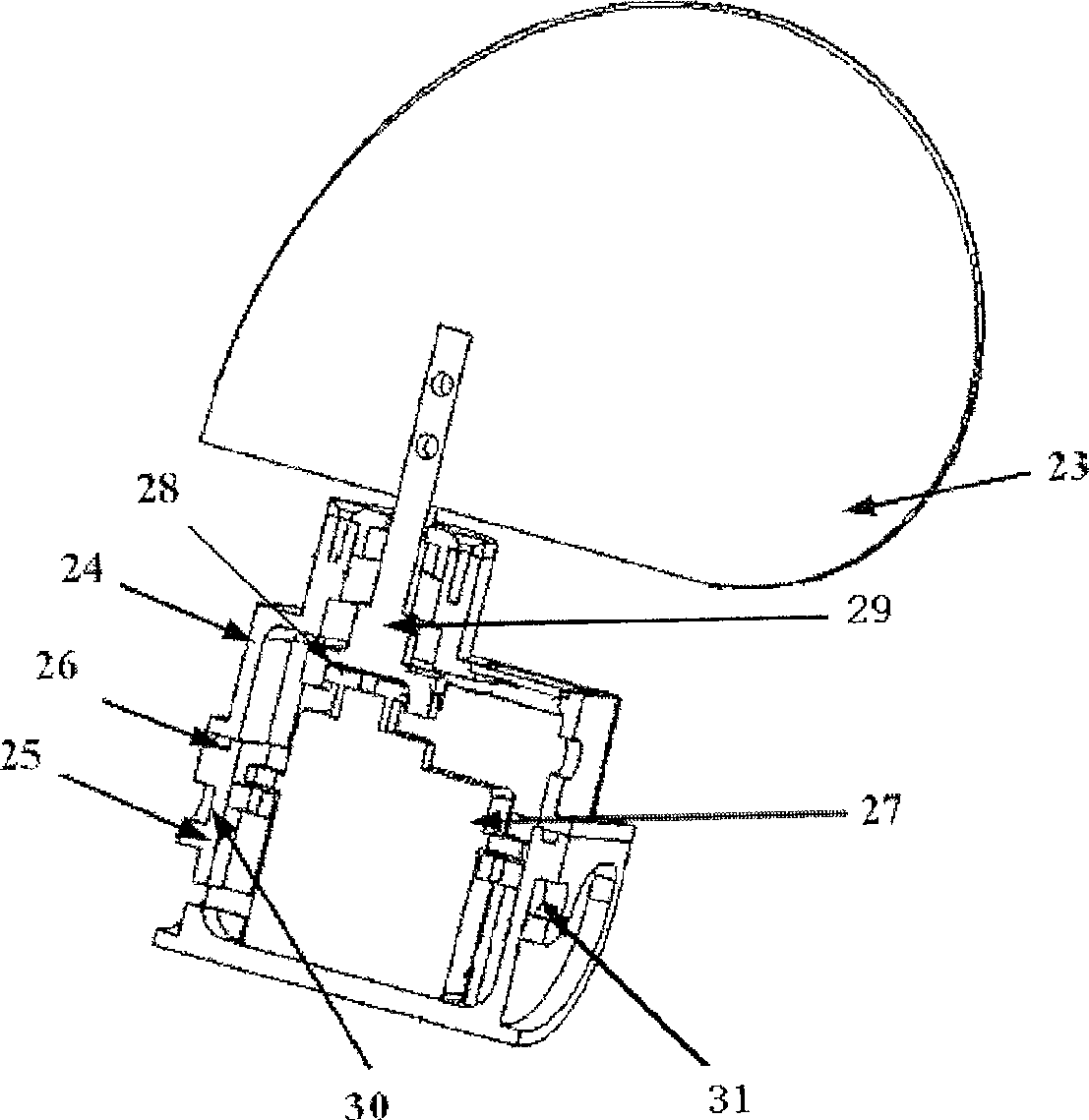

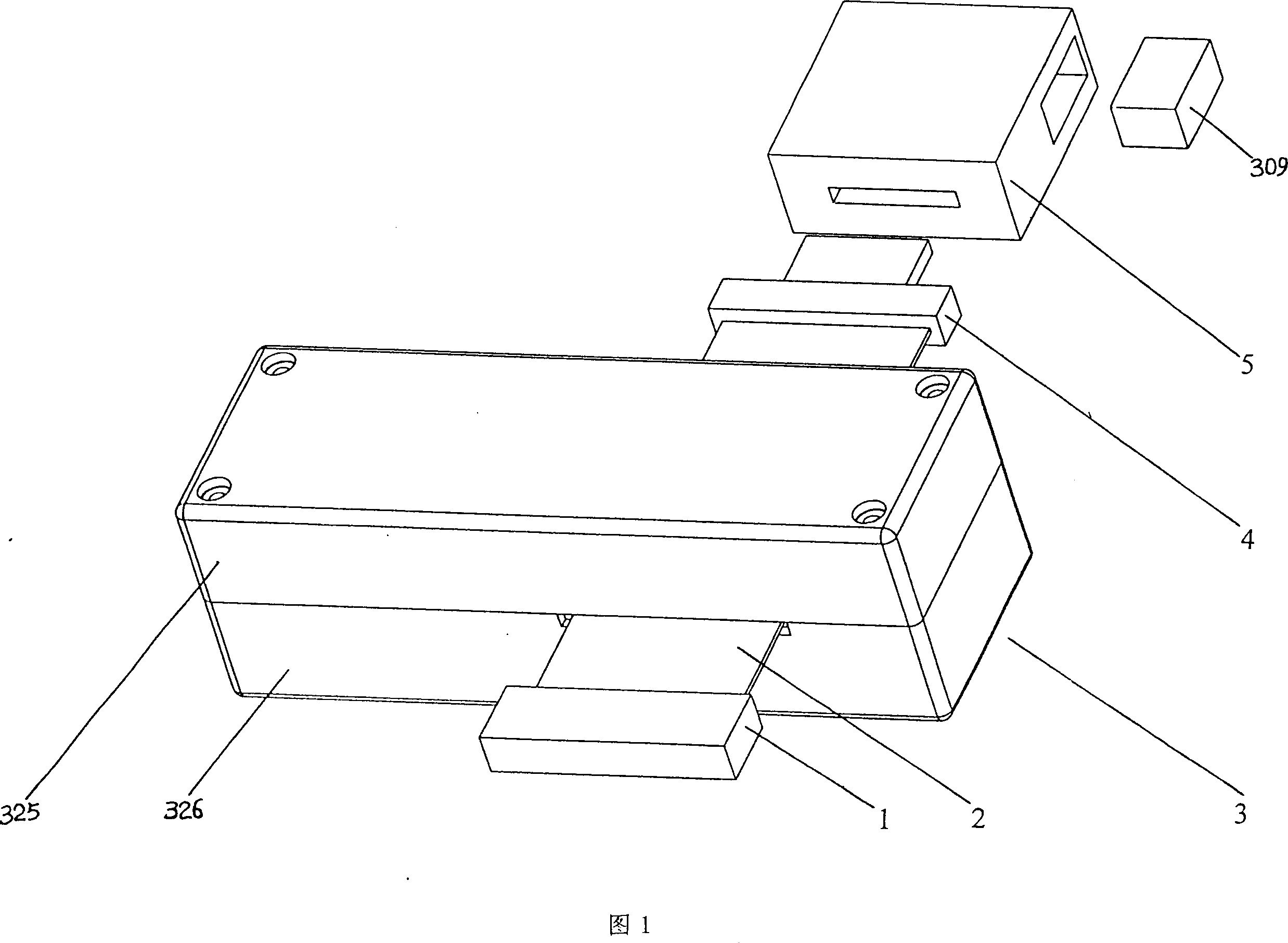

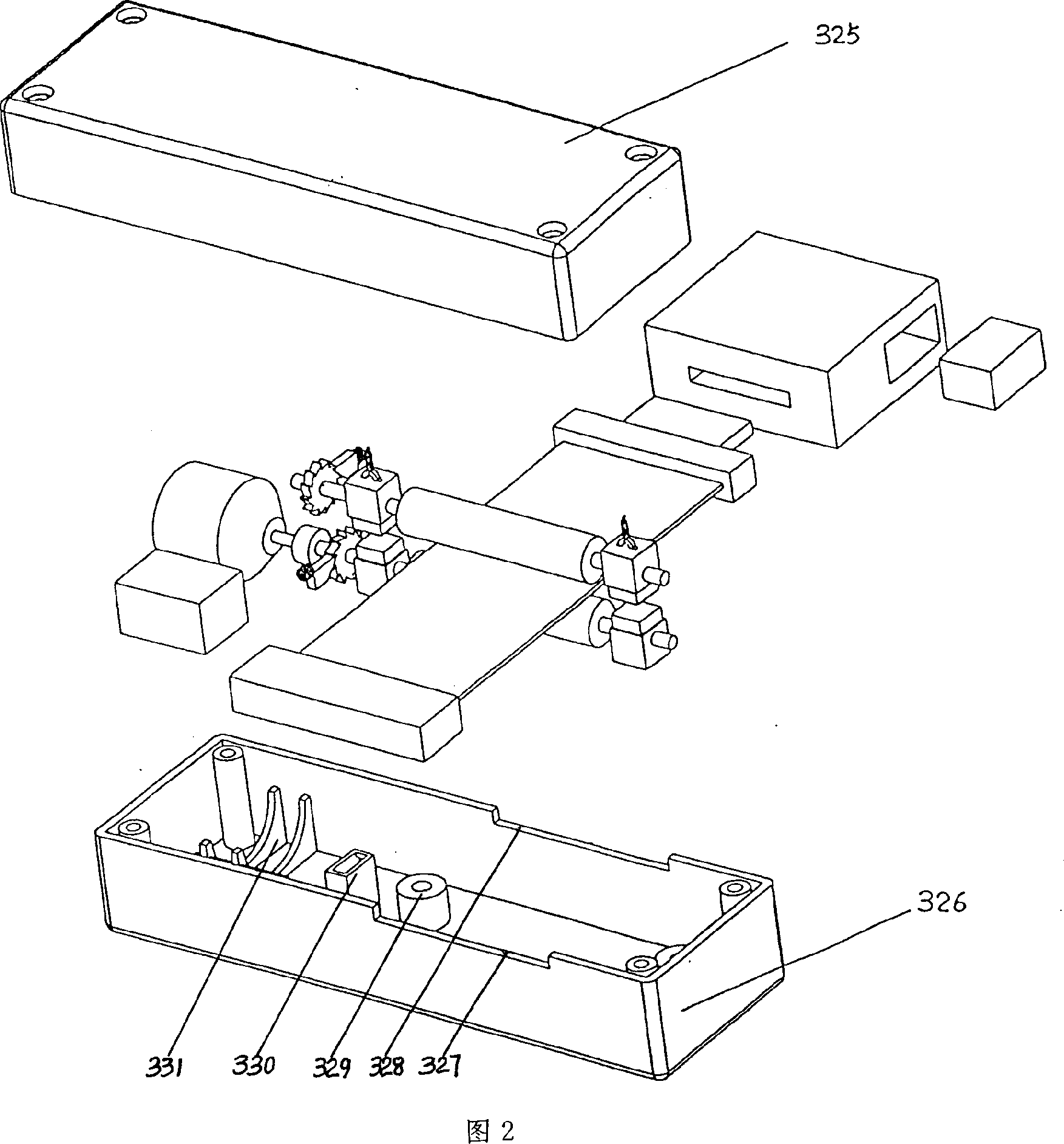

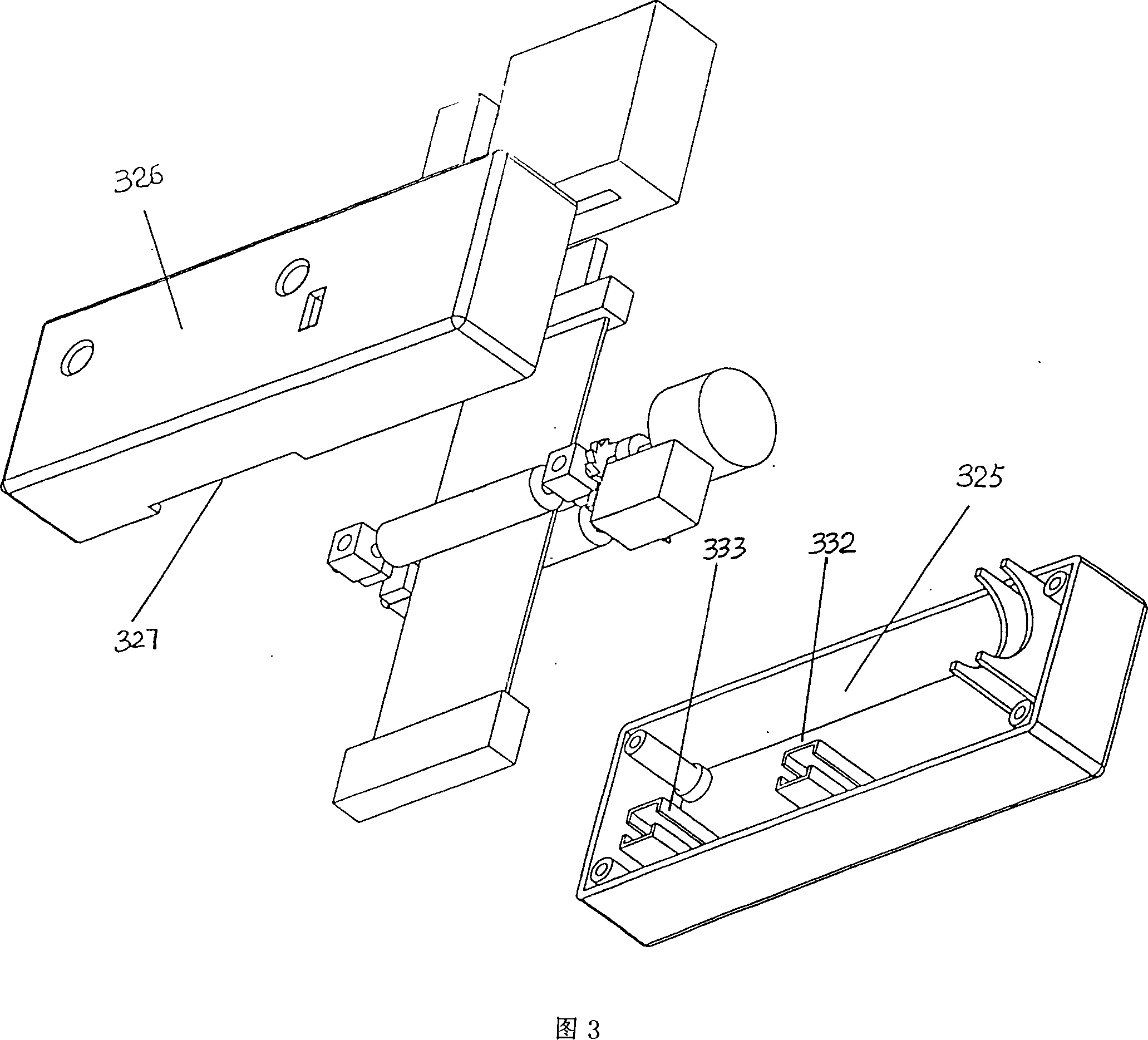

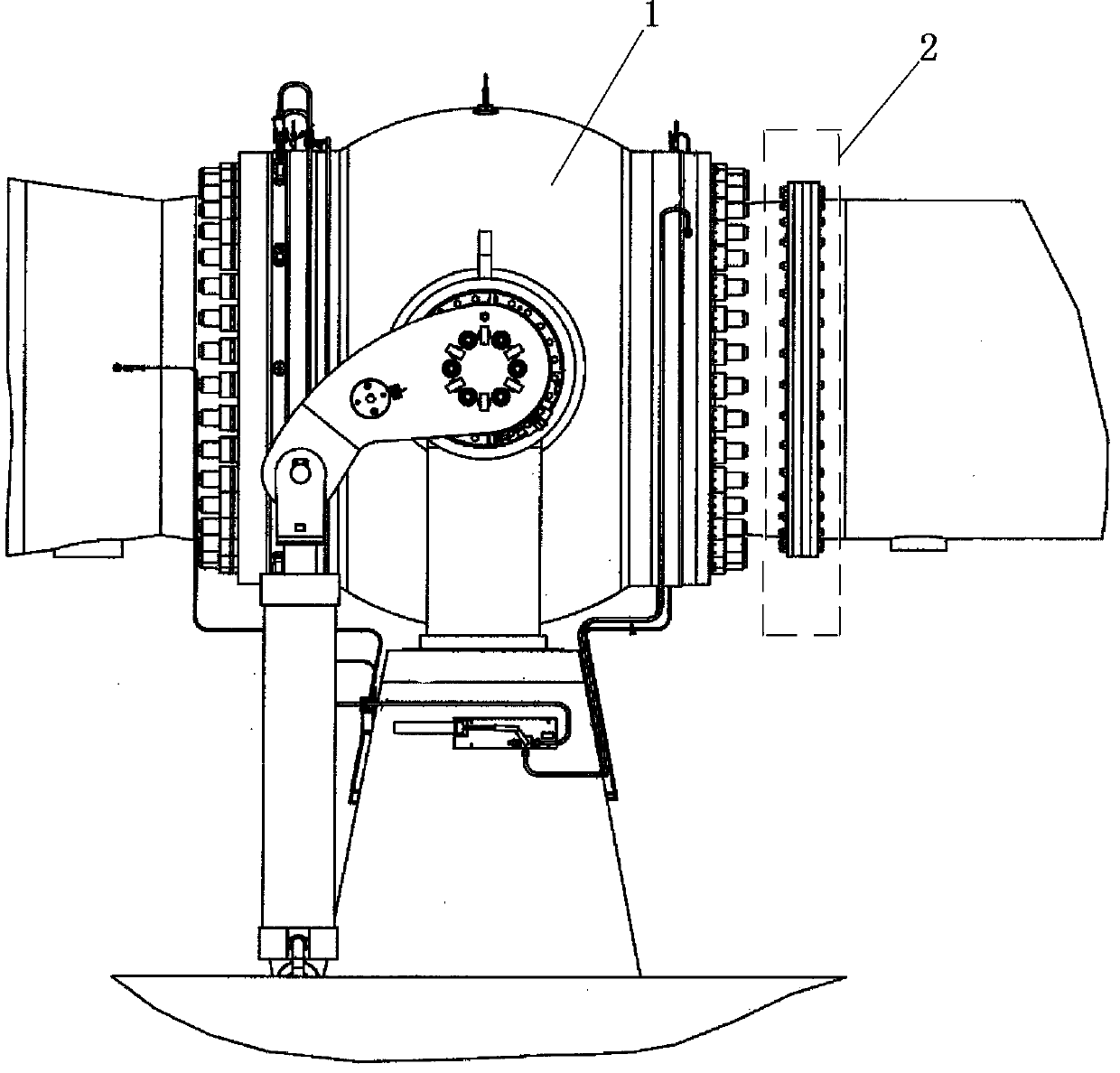

Modularized bionic robot fish

InactiveCN1962358AImprove reliabilityEasy maintenancePropulsive elements of non-rotary typeSpecial purpose vesselsBionicsModularity

The invention relates to a machine fish, wherein it is characterized in that: it comprises a fish head module sealed, left and right chest fin modules, at least two driving modules, and caudal fin; said fish head module has controller and main motor for floating the left and right chest fin modules whose main axles via movable sealing device are connected to the main motor; the left and right chest fin modules both have assist motors to drive the chest fins up and down; the axle of chest fin via the movable sealing device is connected to the assist motors; the driving module via the swing rod is connected; the first driving module via the head-tail connector is fixed on the back of fish head module; the caudal fin via the connector is connected to the back of driving module. The invention can be used in underwater detection, etc.

Owner:PEKING UNIV

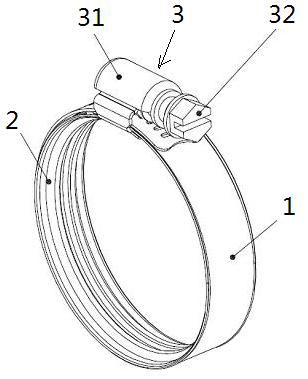

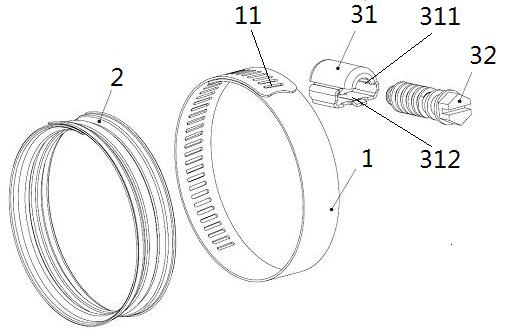

Double clamping groove lining hoop

InactiveCN102691839AGood technical effectReduce the stress areaHose connectionsTransverse forceTemperature difference

The invention discloses a double clamping groove lining hoop which comprises a hoop strip and a locking component, and is characterized by further comprising a lining adhered to the inner wall of the hoop strip; the lining is a double clamping groove lining comprising a first edge, a second edge and a third edge; the first edge and the third edge are symmetrically arranged; the first edge as well as the third edge comprises a transverse forced part and an inward-tilted supporting part in smooth connection with one end of the transverse forced part; the second edge is an arch part; and the two ends of the second edge are in smooth connection with the bottom of the supporting part of the first edge and the bottom of the supporting part of the third edge respectively in a circular arc-shaped manner to form two convex ridges protruding in the inner diameter direction. As the two convex ridges are arranged on the elastic lining of the hoop, when two pipes are connected through a hose pipe, the two convex ridges form double clamp grooves to reduce the stress area and enlarge pressing force to clamp the hose pipe, so as to ensure firm clamping and eliminate the impacts of poor sealing and leakage caused by high temperature difference variation of a pipeline. The double clamping groove lining hoop has advantages of convenience and fastness in construction and stable system.

Owner:WENZHOU KEBODA AUTO PARTS +2

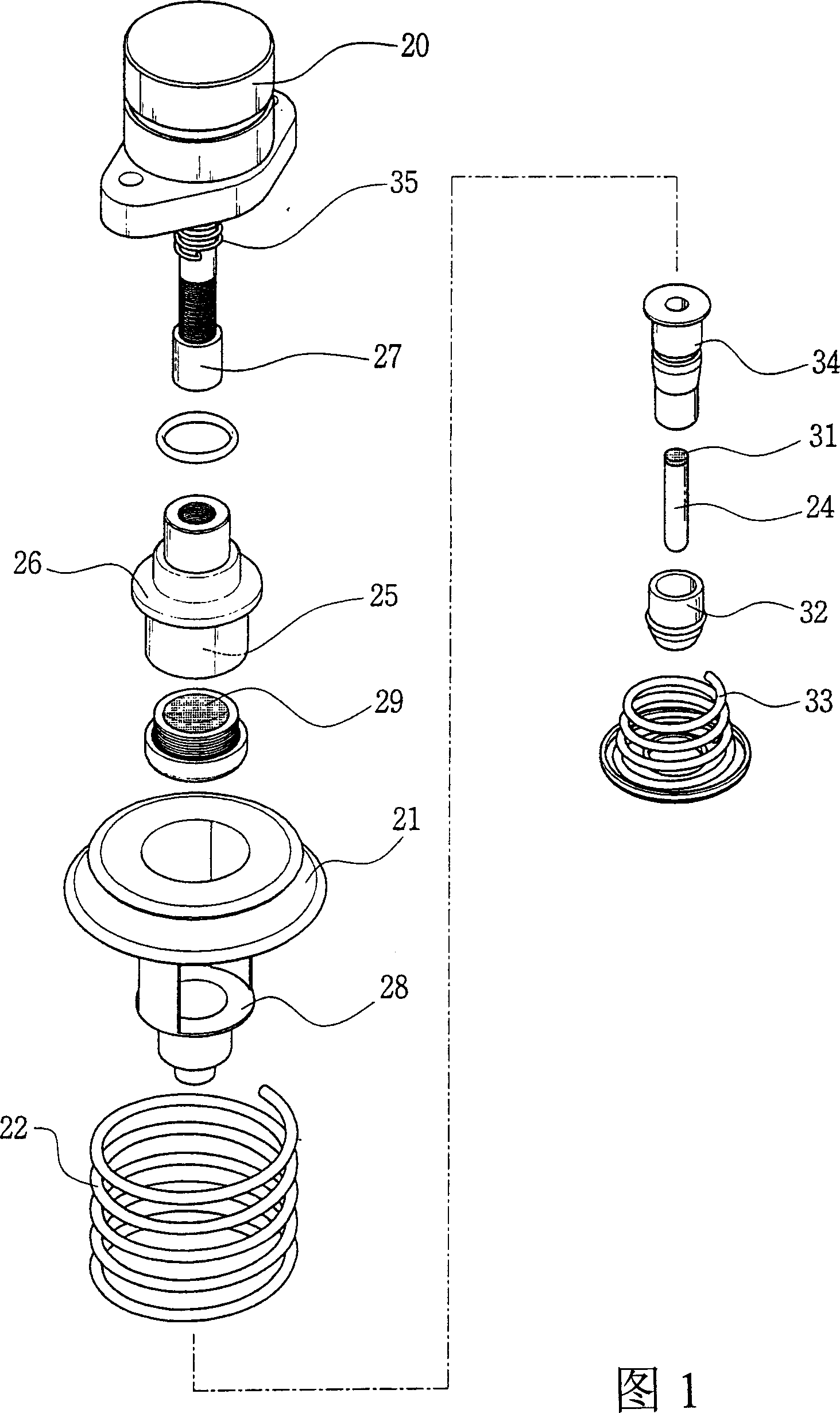

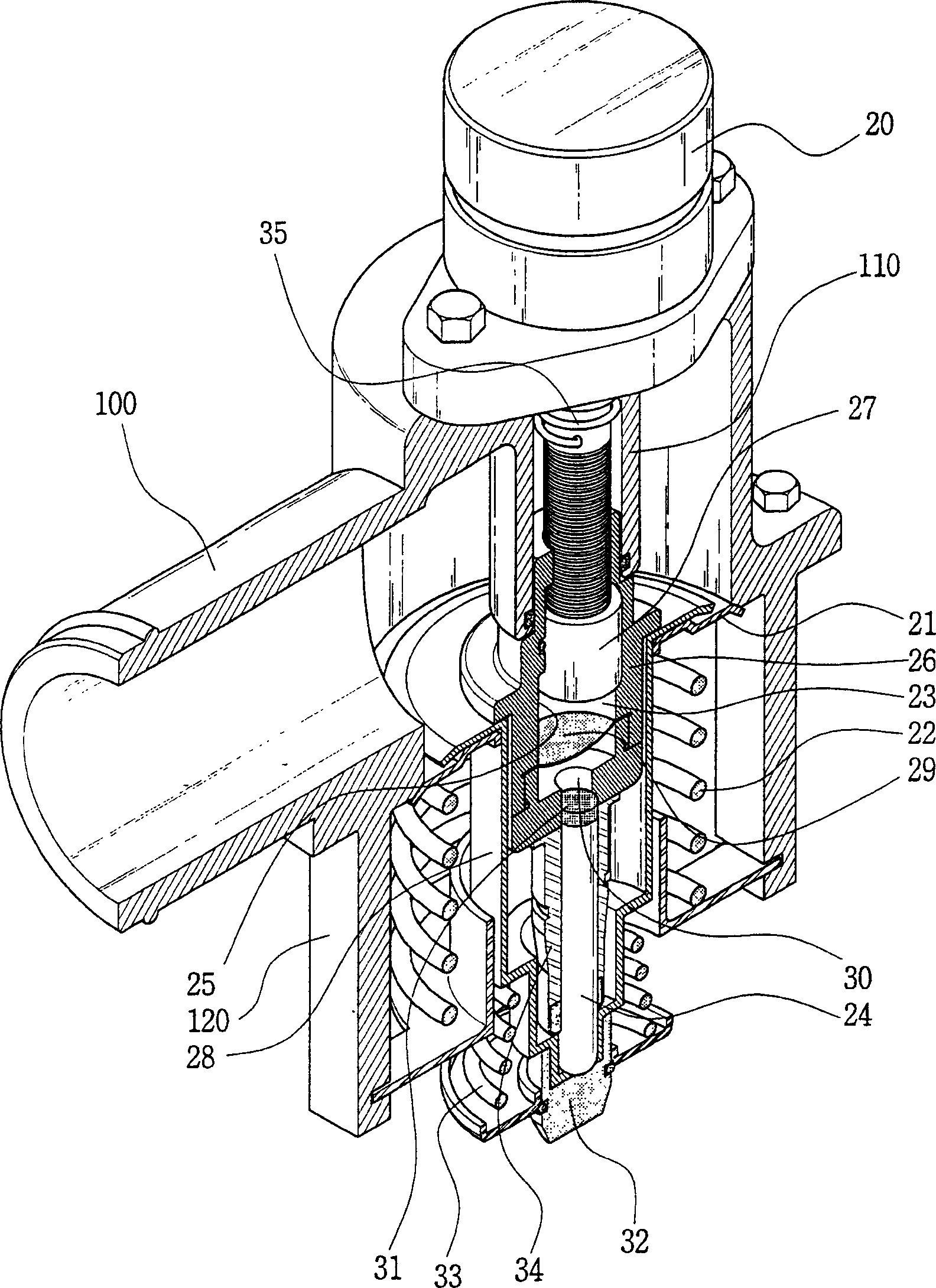

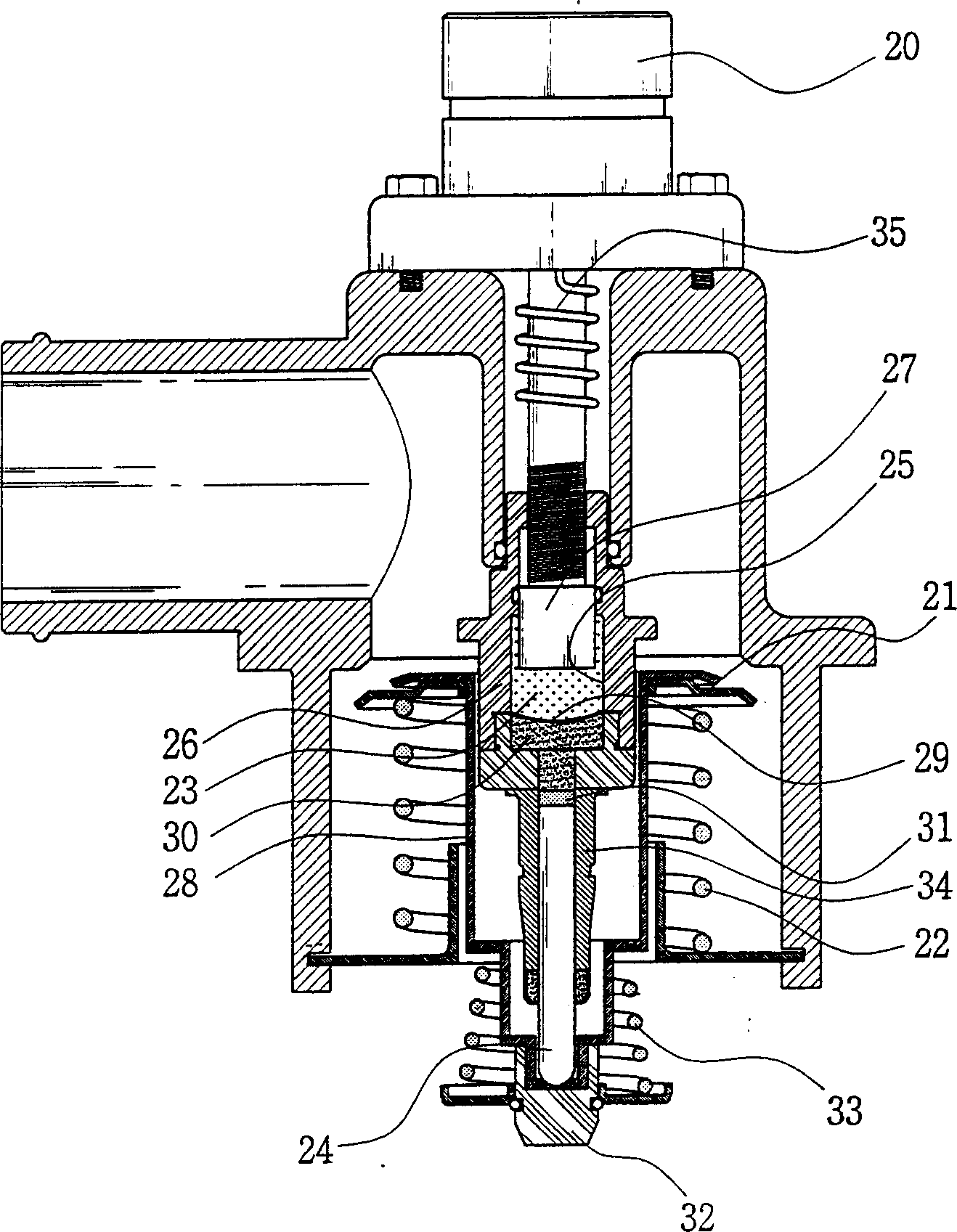

Adjustable electronic thermostatic valve

InactiveCN1436941AEliminate tightnessTemperature control without auxillary powerOperating means/releasing devices for valvesReciprocating motionEngineering

The present invention relates to an adjustable electronic thermostat valve comprising an actuating means (20) provided with a rod (27) for stroking a chamber of an expendable thermal element, so that temperature at which the thermostat valve opens can be easily adjustable based on driving condition of an automobile by changing the volume of the chamber of the expendable thermal element, whereby a cooling efficiency of the engine is maintained in optimized range. As a result, emission of exhaust gas and consumption of fuel is significantly reduced.

Owner:HYUNDAI MOTOR CO LTD +1

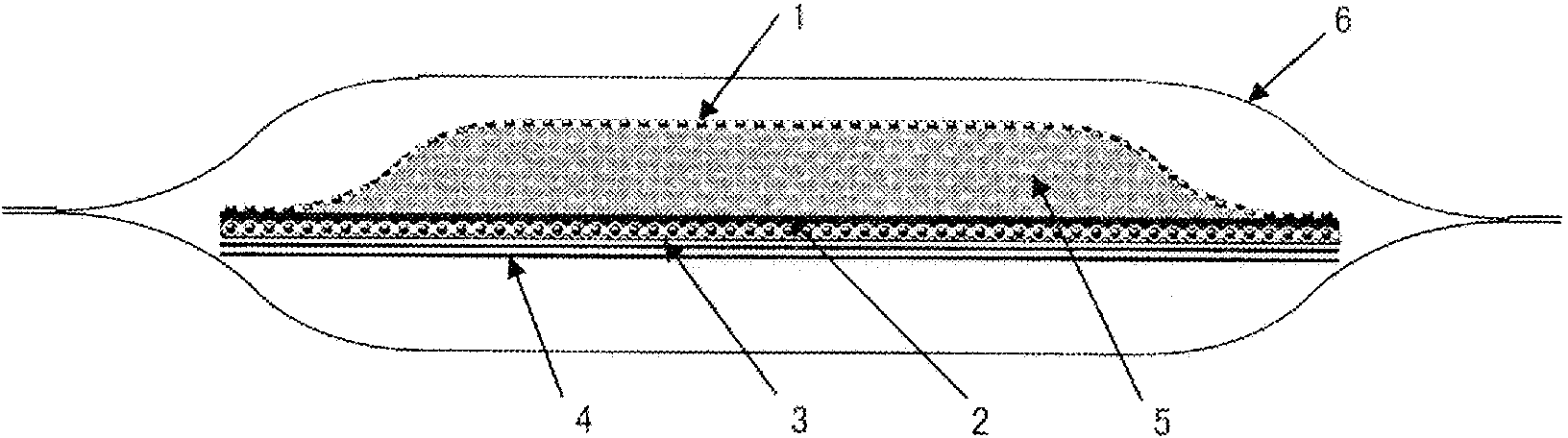

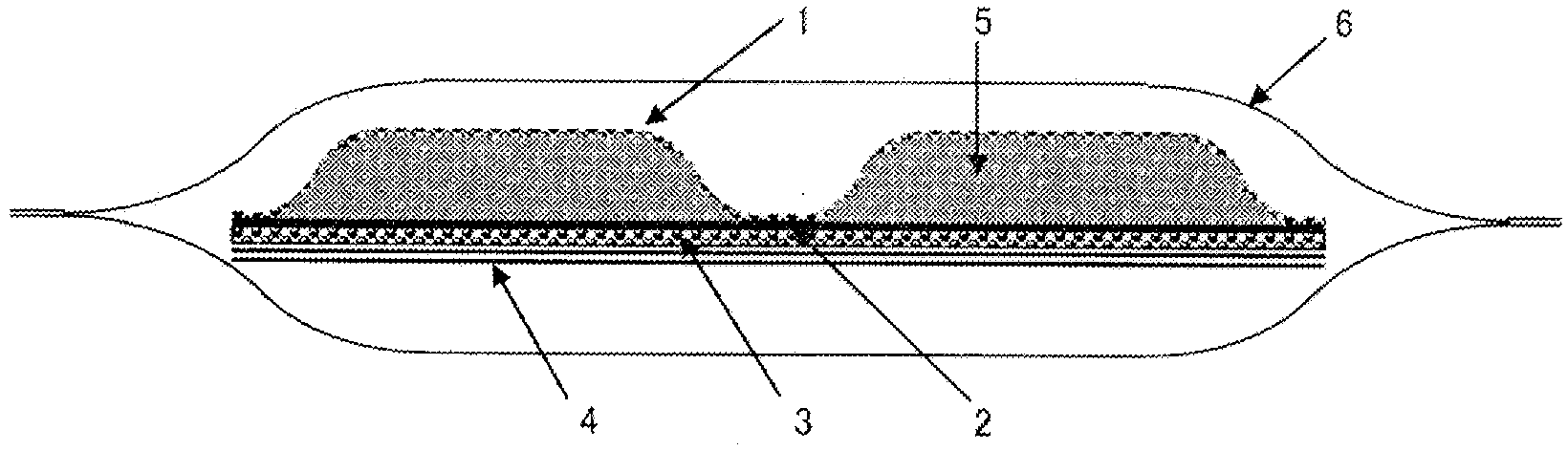

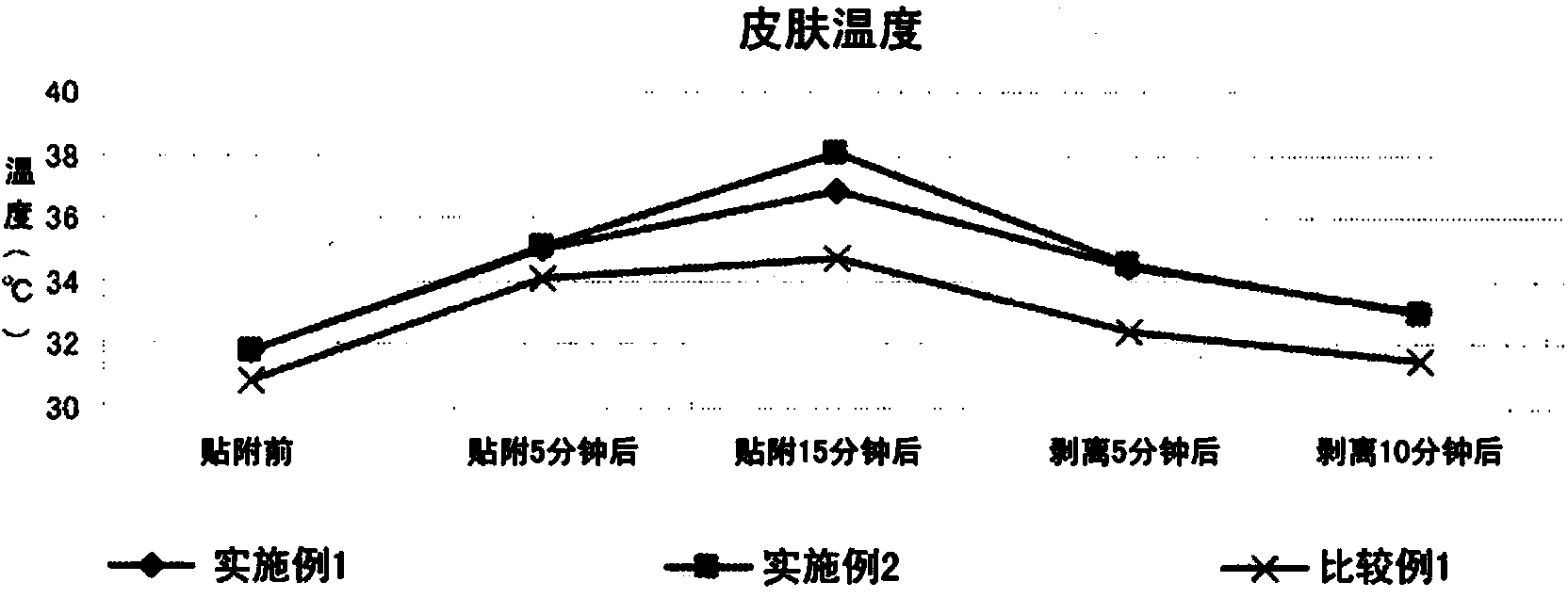

Heat generation tool

InactiveCN104394814ASoothe the coldEffectively warmTherapeutic coolingTherapeutic heatingBoiling pointHeating effect

Provided is a heat generation tool which is capable of easing sensation of coldness when applying to the skin and warming the skin efficiently, supplies oil effectively to the skin, and eases sensation of coldness after peeling from the skin so as to provide a high heating effect even after use. This heat generation tool comprises an adhesive layer, the specific heat at 20°C of the adhesive layer being less than 3 J / g.K. The adhesive layer contains a base and an oil with a specific heat at 20°C of less than 3 J / g.K and a boiling point at 1 atmosphere of 100°C or more, the oil content in the adhesive layer being 30 to 90 weight%.

Owner:KOBAYASHI PHARMA CO LTD

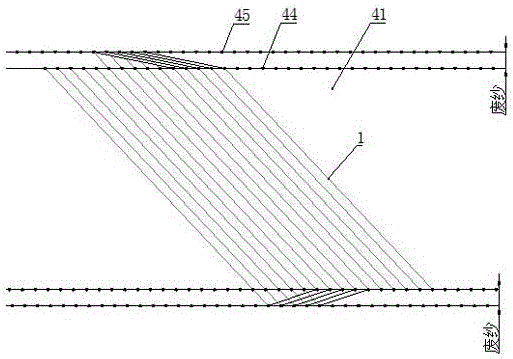

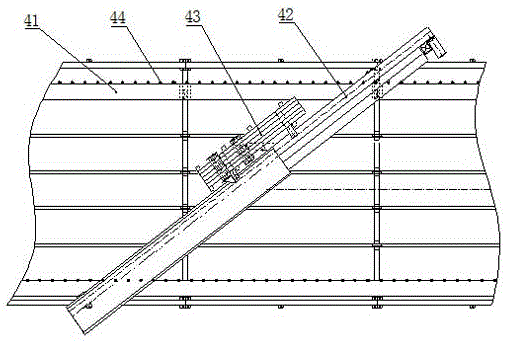

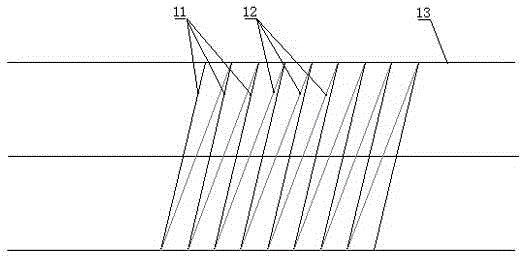

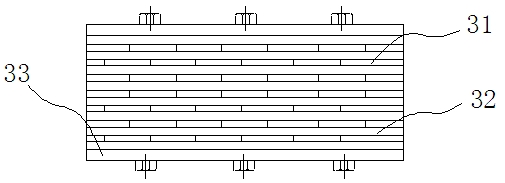

Manufacturing method of multi-axial composite base material

ActiveCN105015105AImprove structural strengthHigh surface finishLamination ancillary operationsLaminationGlass fiberWeft yarn

The invention relates to a manufacturing method of a multi-axial composite base material. The manufacturing method is characterized by comprising steps as follows: a multi-axial glass fiber yarn layer is laid, after a weft yarn laying trolley moves weft yarn layers of the glass fiber yarn layer from one side edge of a conveying belt to the outside of the other side edge of the conveying belt in a fixed direction, weft yarn is hooked on retaining pins of the conveying belt, then the weft yarn laying trolley returns to the starting point in the direction opposite to the original direction, and multiple pieces of continuous Z-shaped weft yarn with the same arrangement are formed on the conveying belt through combination of the weft yarn laying trolley with the direction of the conveying belt during forward and reverse movement; then glass fiber continuous felt is laid, sewn and wound. The manufacturing method has the advantages as follows: glass fiber weft yarn and glass fiber warp yarn are laid on the conveying belt respectively through a weft yarn laying device group and a let-off device, so that the multi-axial glass fiber yarn layer is formed, a layer of the glass fiber continuous felt is laid on the multi-axial glass fiber yarn layer after the multi-axial glass fiber yarn layer passes below a continuous felt unwinding device, then sewing is performed by a multi-needle quilting machine, and finally, the multi-axial composite base material is obtained through winding.

Owner:JIANGSU JIUDING UNIVERSAL WIND ENERGY

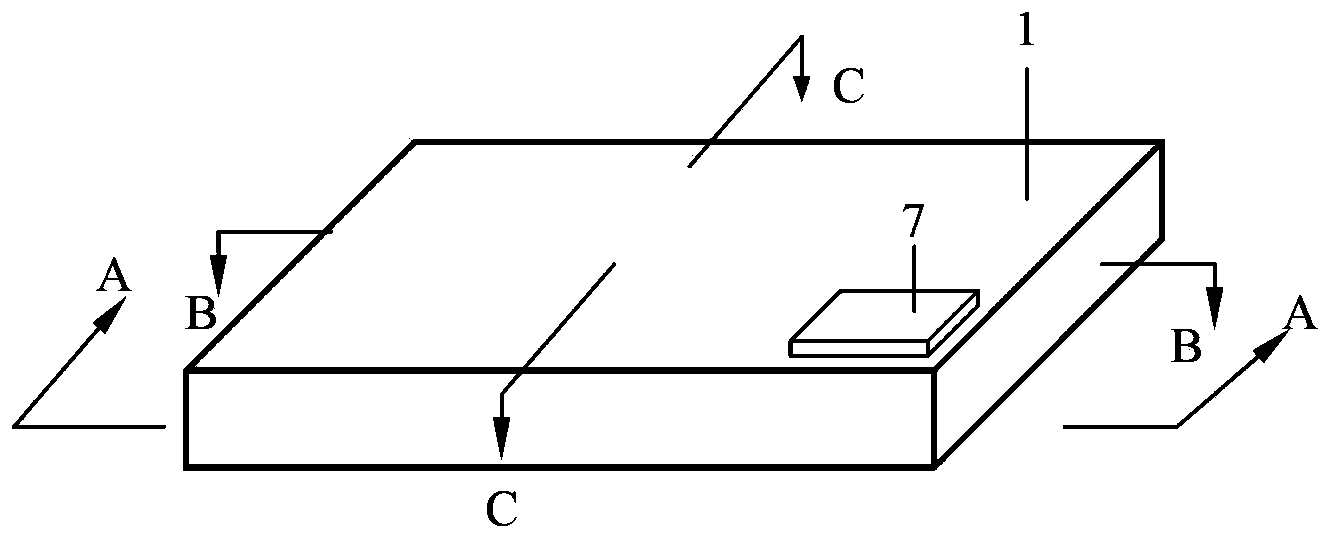

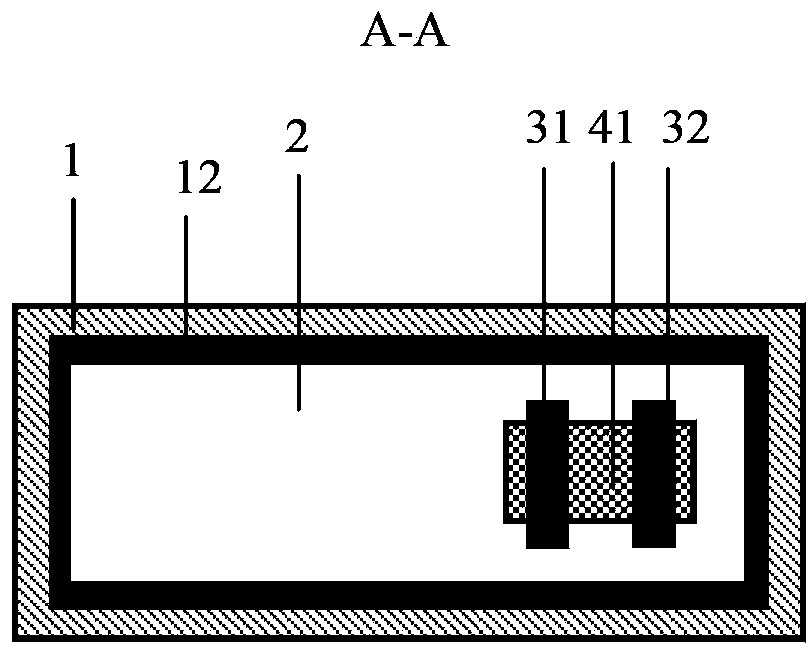

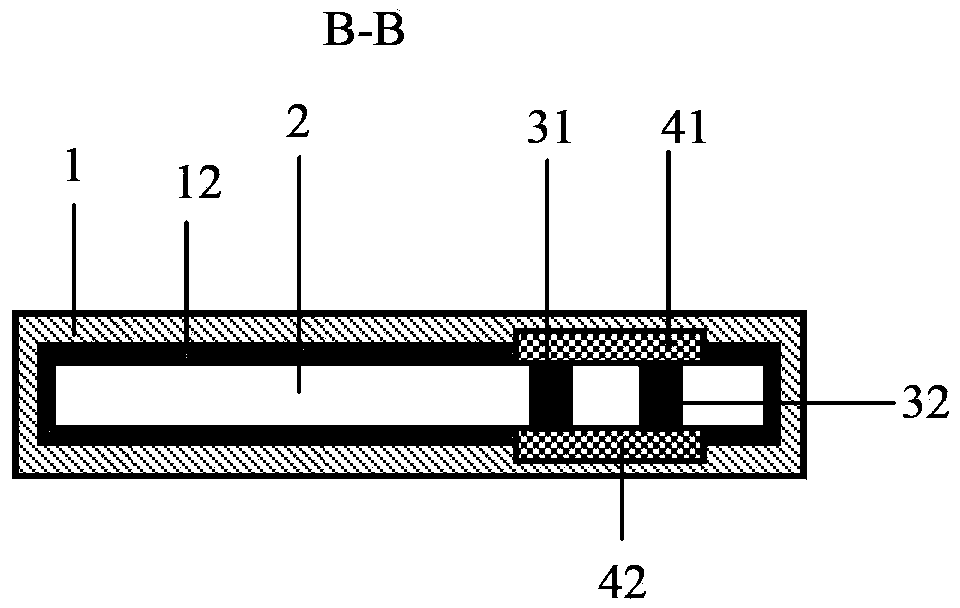

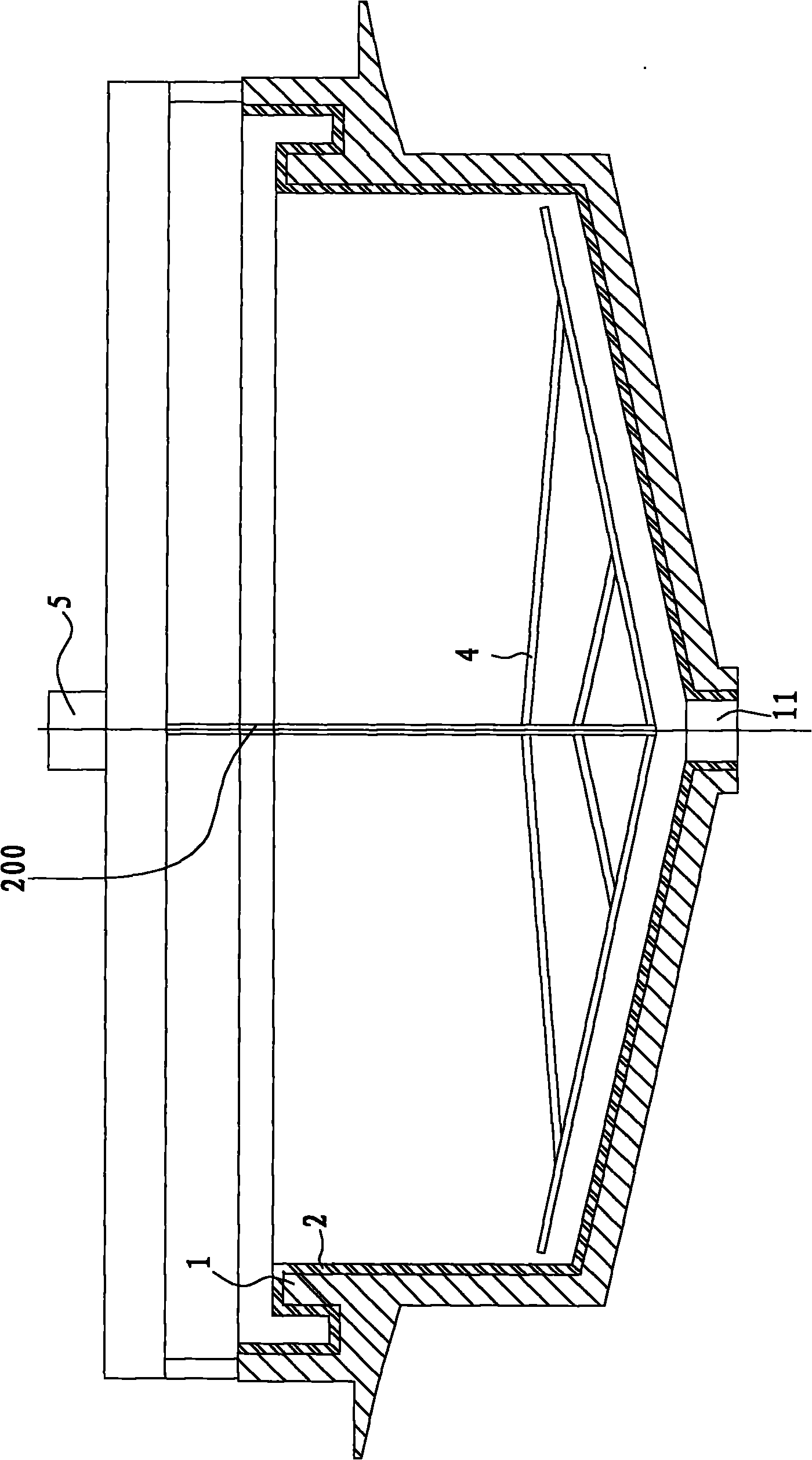

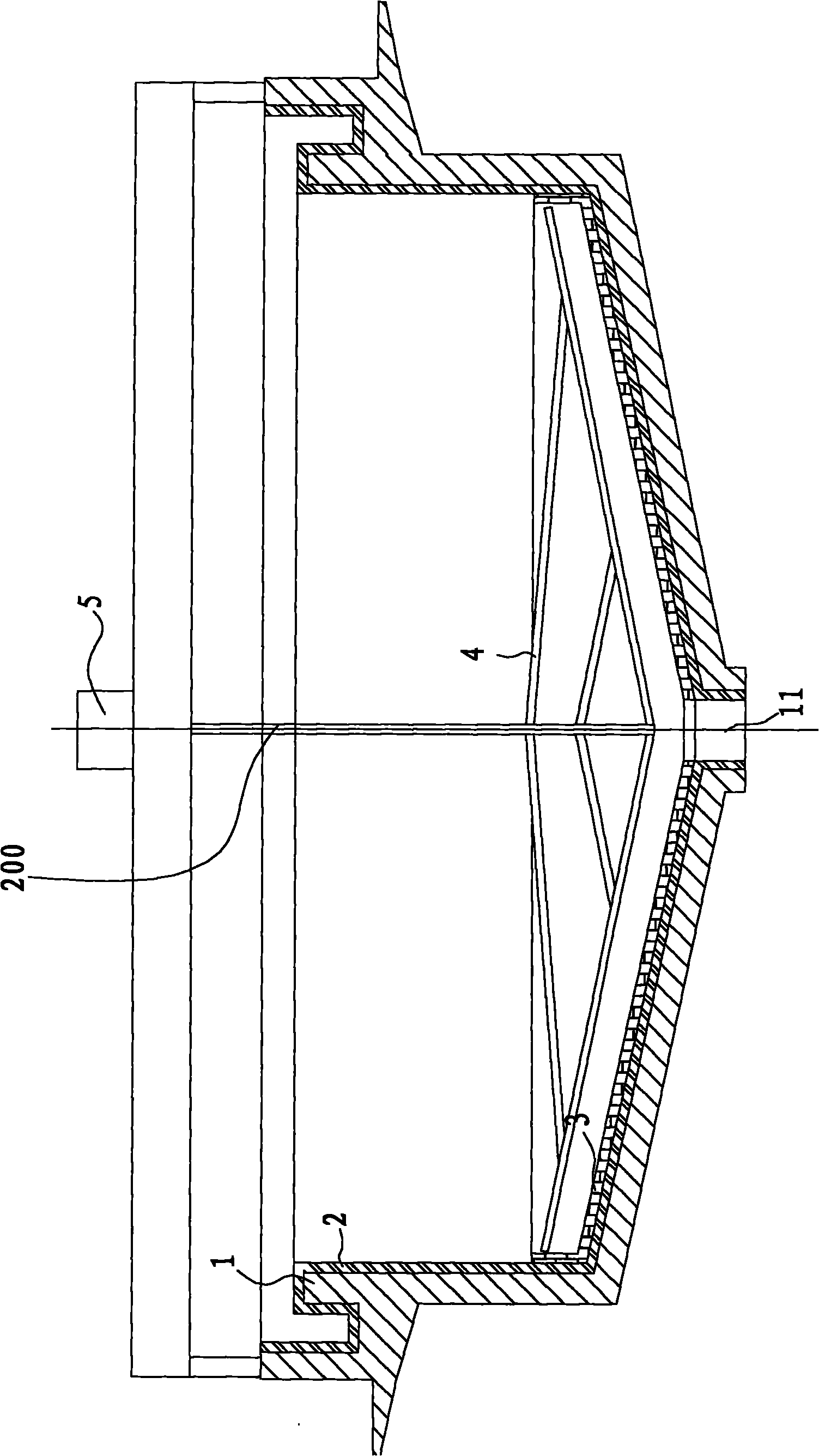

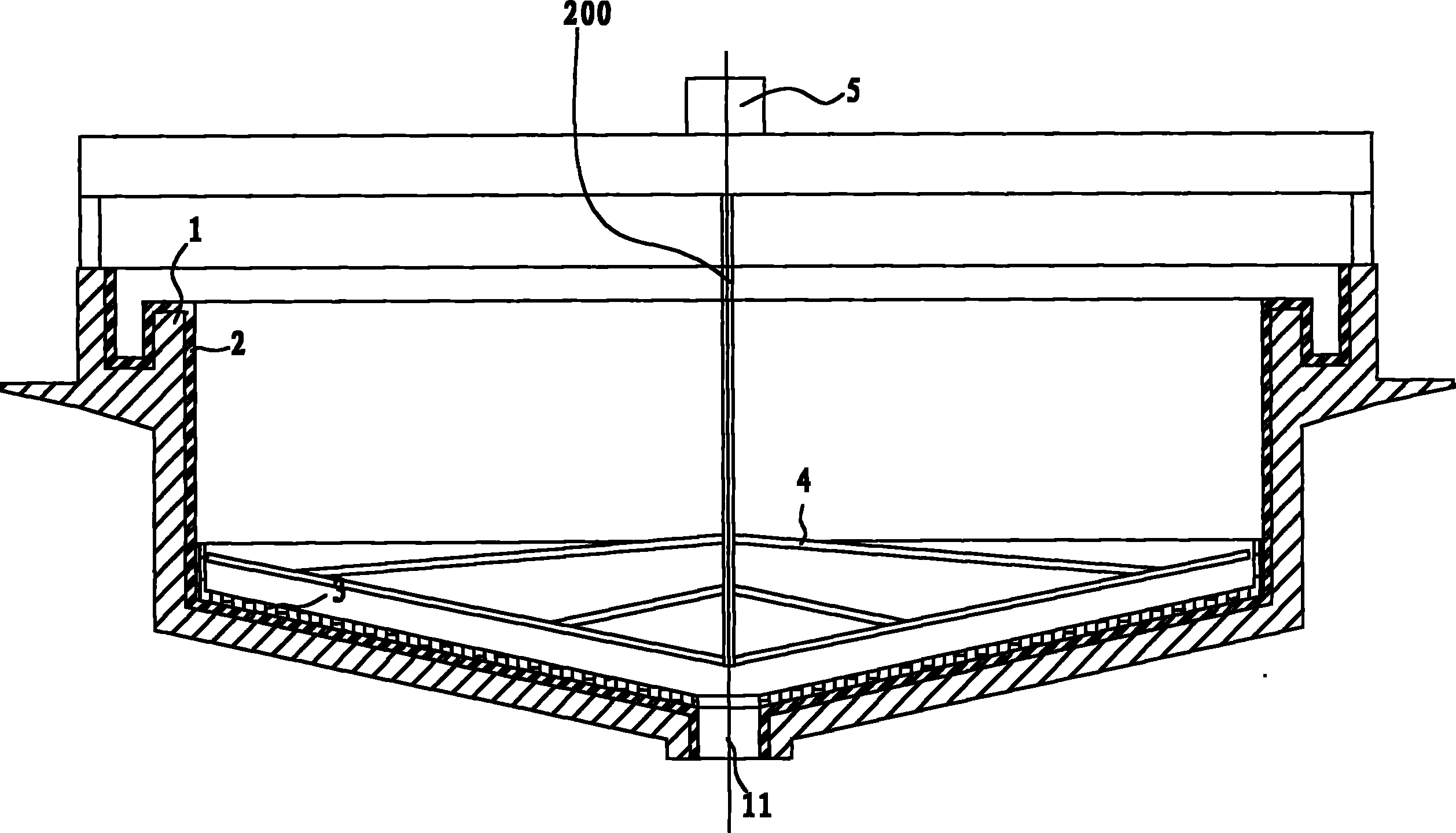

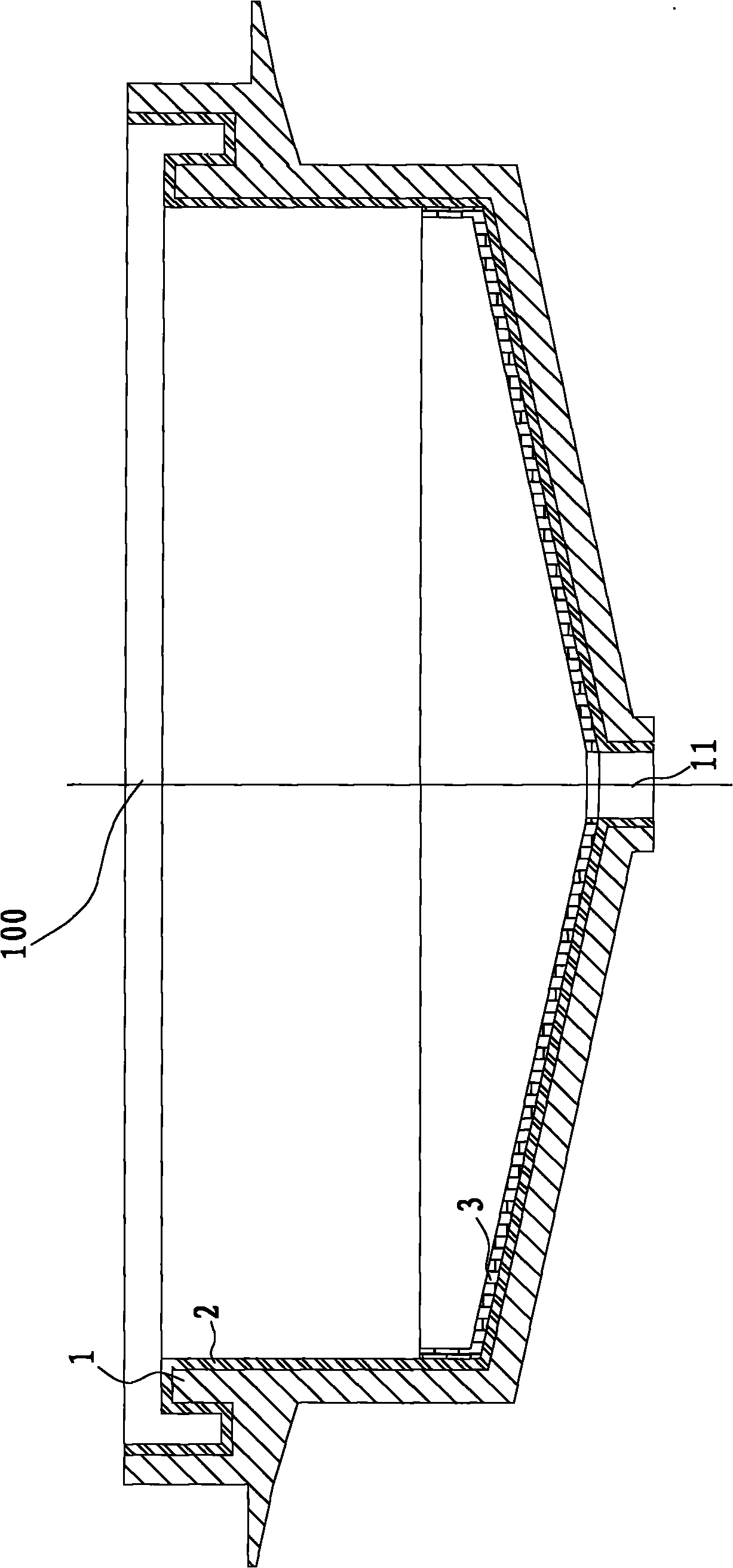

Integrated cavity type conductive fluid heat spreader

ActiveCN104125753AEliminate tightnessPrevent leakageCooling/ventilation/heating modificationsMagnetic polesEngineering

The invention provides an integrated cavity type conductive fluid heat spreader which includes a cavity (1), the heat absorbing end, flow, liquid, fluid pool, driving pump and a heat radiating end together in one room, the internal cavity structure, and the inner surface is an insulating layer (12); runner type electrode for (31, 32), arranged on the cavity surface, which is used as a channel and the direction of fluid flow regulator; a magnet for (41, 42), in the cavity body and the direction of the magnetic poles and the electrode is arranged on the current direction is vertical range setting; conductive fluid (2), the filling in the cavity; power supply chip (7) which is arranged in the cavity, the outer surface of the electrodes used to provide the input current. According to the heat spreader is provided by the invention greatly reduces the production and packaging process, completely avoid the fluid leakage; the compact volume, heat transfer capacity significantly; the cavity electrode on the position can be set flexibly, significantly enhance the electromagnetic driving force, resulting in the enhancement of heat transfer and flow effect is strong; between different parts of the body temperature of the fluid cavity different mixing efficiency is high, the heat transport capability is strong.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Not-to-tighten safety bet

InactiveCN1640731AModerate adjustment of slackEliminate tightnessBelt anchoring devicesEngineeringBelt safety

The properly tightening safety belt comprises belt, winder, inserting board, fastener and limiter. The limiter comprises casing with side belt port and upper and lower rotating shafts; the lower rotating shaft is fitted movably to two lower shaft seats with electromagnet and has fixing and closing sleeve and ratchet mechanism; the upper rotating shaft is provided with fixing and closing sleeve, two movably fitted shaft seats in slide rail and with spring, ratchet mechanism and electromagnet; and there may be motor for driving the lower rotating shaft. With automatic or hand limiter, the properly tightening safety belt has properly adjustable tightness, and may be used widely in automobile, airplane, high speed train, etc.

Owner:陈小华

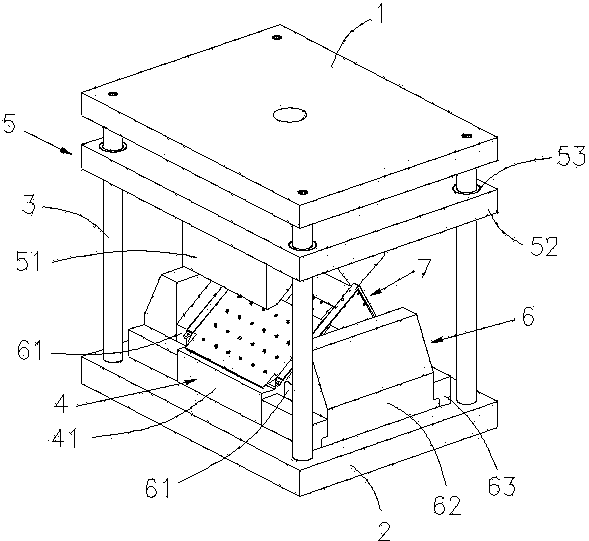

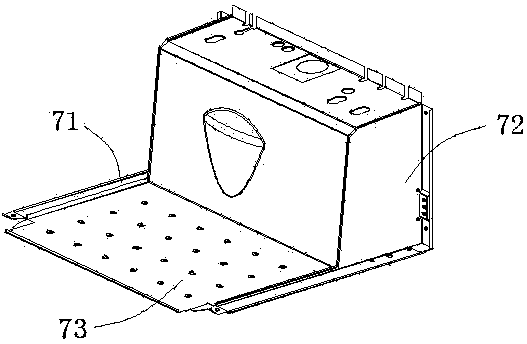

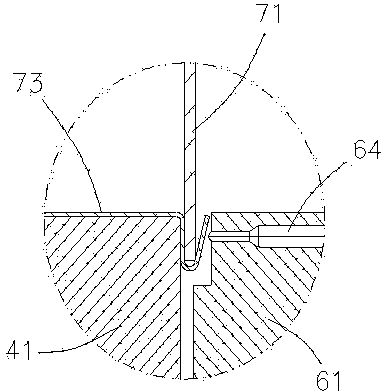

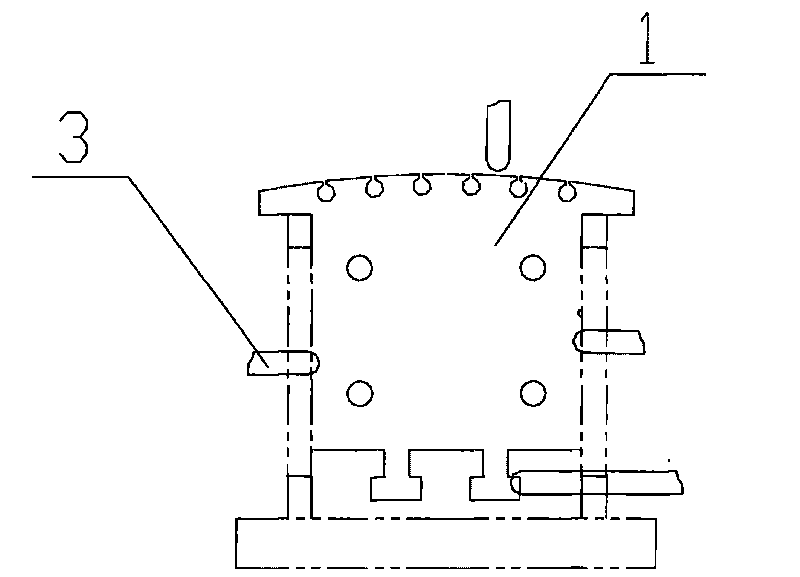

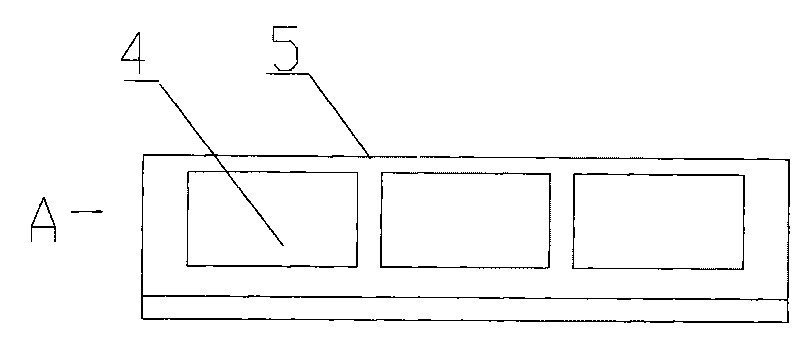

Side pressing and riveting device of refrigerator bottom steel and assembling method of refrigerator bottom steel

The invention provides a side pressing and riveting device of refrigerator bottom steel. The side pressing and riveting device comprises a supporting device, a hold-down device and pressing and riveting devices. The invention further provides an assembling method of the refrigerator bottom steel. The assembling method of the refrigerator bottom steel comprises the following steps that a bottom steel plate is arranged on the supporting device; the hold-down device moves downwards until the hold-down device tightly presses against the bottom steel plate; a left side plate and a right side plate are sequentially inserted into V-shaped grooves in the two side edges of the bottom steel plate; the pressing and riveting devices move towards each other, so that the V-shaped grooves in the bottom steel plate are tightly wrapped on the edge of the left side plate and the edge of the right side plate under the action of the pressing and riveting devices; punching pins in the pressing and riveting devices enable laminated pits to be formed in the edge of the bottom steel plate, the edge of the left side plate and the edge of the right side plate; When the assembly process is finished, the refrigerator bottom steel is taken down after the pressing and riveting devices and the hold-down device are removed. According to the side pressing and riveting device of the refrigerator bottom steel and the assembling method of the refrigerator bottom steel, it is guaranteed that the left side plate and the right side are connected with the bottom steel plate solidly without falling off, welding spots and sealing auxiliary materials are eliminated, production efficiency is improved, and the percent of pass of products is guaranteed.

Owner:合肥市航嘉电子技术有限公司

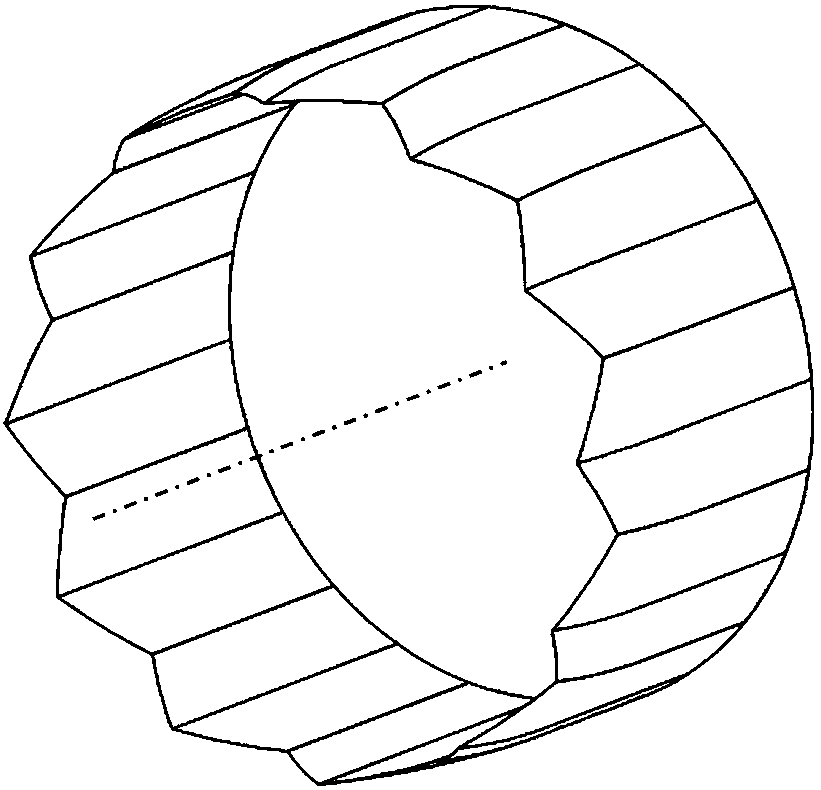

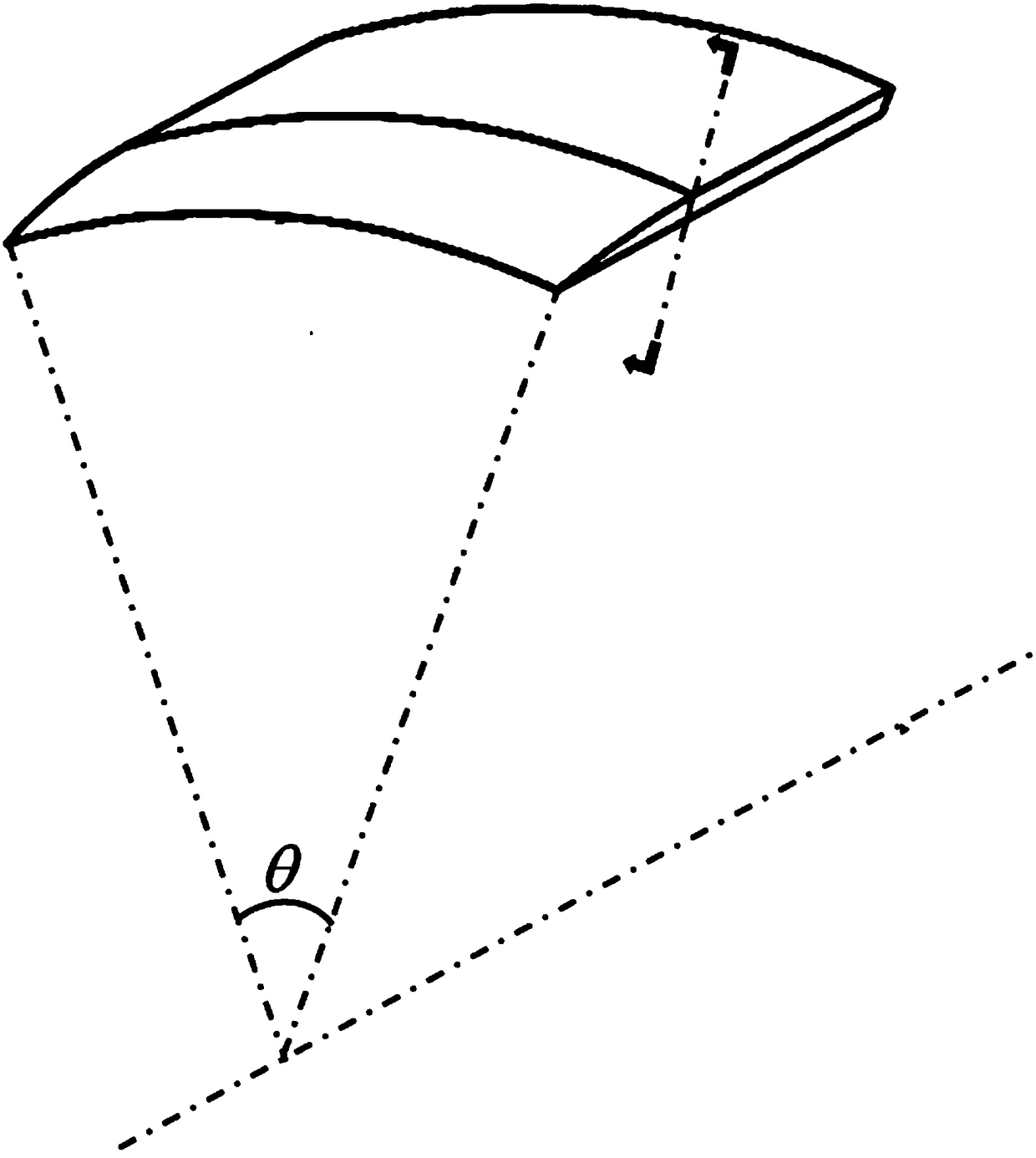

Hypersonic axisymmetric air inlet channel lip and design method thereof

ActiveCN108412618ASimple manufacturing processImprove boot performanceTurbine/propulsion air intakesInlet channelFlight vehicle

The invention relates to a design method of an air inlet channel lip of a hypersonic flight vehicle, and belongs to the technical field of hypersonic air inlet channel application. According to the design method, an air inlet channel is arranged on an engine of the flight vehicle, and the front end of the air inlet channel is a sawtooth-shaped lip; and the sawtooth-shaped lip comprises a pluralityof lip blades, the side walls of the lip blades are connected in an end-to-end mode to form the closed sawtooth-shaped lip, the center of the sawtooth-shaped lip is taken as a revolving axis line, and the lip blades are arranged in an array mode by taking the revolving axis as an array axis. According to the design method of the air inlet channel lip of the hypersonic flight vehicle, a moving mechanism is not introduced, so that the weight and the complexity of the system are prevented from being increased, and the problems of connection, sealing, cooling, control and the like are prevented from occurring; the machining and manufacturing process is simple, the starting performance of the axisymmetric air inlet channel can be improved, meanwhile, the compression performance of the axisymmetric air inlet channel is not influenced, and the capture flow is reduced, so that the working efficiency of the air inlet channel is guaranteed, and the starting performance of the air inlet channelis improved.

Owner:NAT UNIV OF DEFENSE TECH

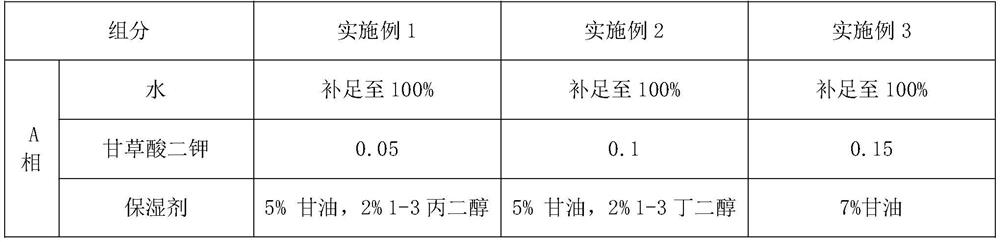

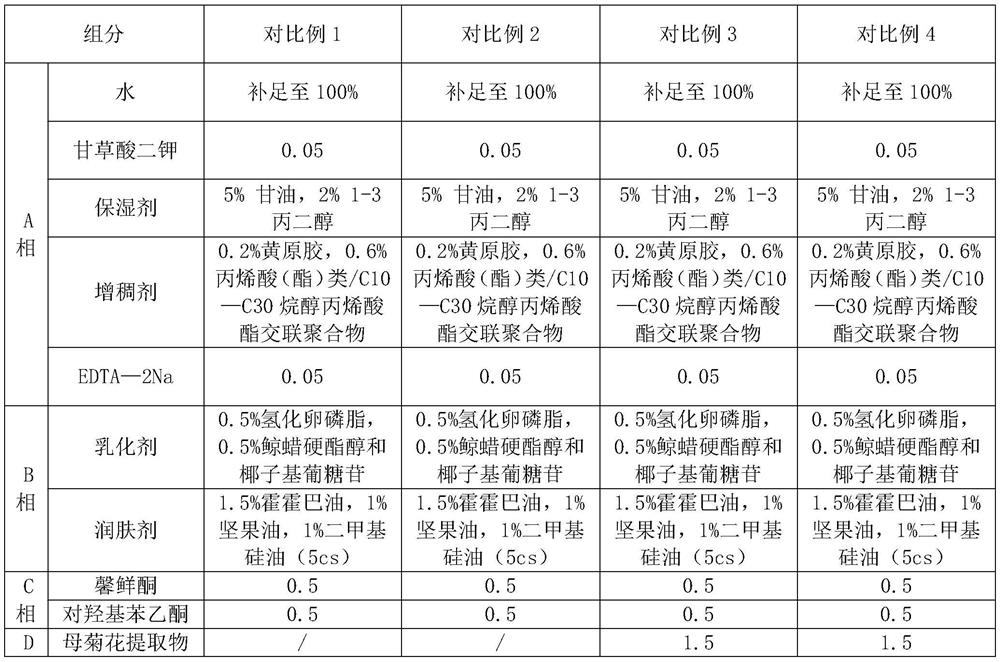

Skin-calming and moisture-preserving presenile-resistant composition

InactiveCN111973508AInhibition of permeabilityImprove the immunityCosmetic preparationsToilet preparationsBiotechnologyGrape seed

The invention belongs to the field of daily chemicals, and provides a skin-calming and moisture-preserving presenile-resistant composition. The skin-calming and moisture-preserving presenile-resistantcomposition comprises the following ingredients in percentage by weight: 0.02 to 0.2 percent of dipotassium glycyrrhizinate, 1 to 3 percent of chamomilla recutita flower extracts, 1 to 15 percent ofa presenile-resistant composition, 1 to 20 percent of a humectant, 0.05 to 1 percent of a thickening agent, 0.5 to 2.5 percent of an emulsifying agent, 1 to 10 percent of an emollient and the balancepure water, wherein the presenile-resistant composition is prepared from acetyl hexapeptide-8, bifida ferment lysate, tea extracts, grape seed extracts and blackberry leaf extracts. Through the reasonable compatibility of various ingredients, the composition provided by the invention has the advantages that all ingredients achieve synergistic interaction, so that the free radical elimination efficiency is improved, and the senescence is delayed from a deep layer; the self repair capability of cells is improved; the redness is relieved; the skin barrier is repaired; the damage to the skin caused by various light sources is relieved and restored; and deep water supplementation is provided for the skin to achieve the timely senescence-resistant effect.

Owner:OPAL COSMETICS HUIZHOU

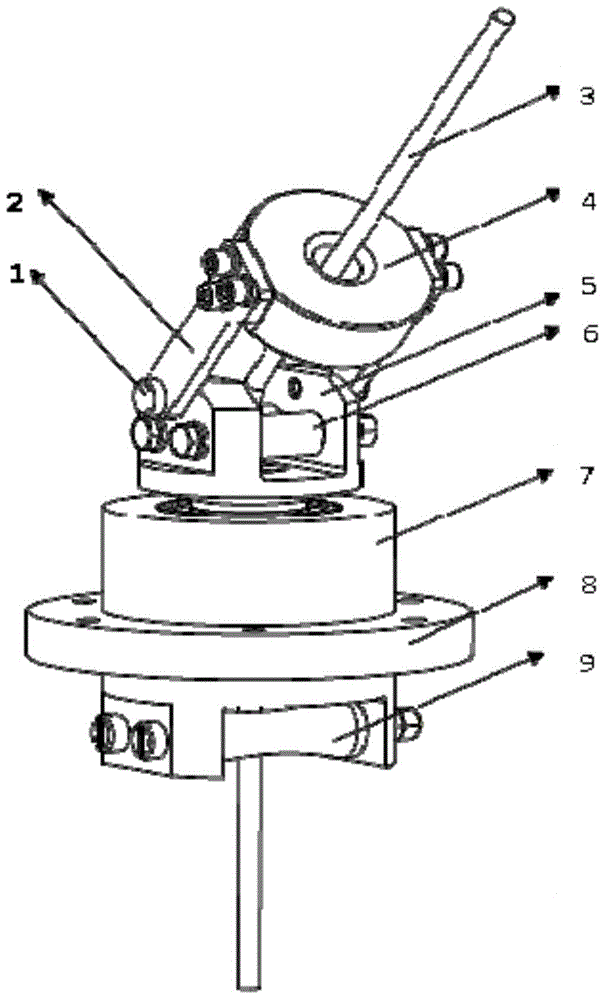

Underwater adaptive mooring cable tension device

InactiveCN104691708AReduce the required powerReduce power consumptionWaterborne vesselsBuoysUnderwaterThrust bearing

The invention discloses an underwater adaptive mooring cable tension device which is mounted on a cable arranging device of an underwater winch of a main floating body of a submerged buoy and comprises a rotary seat, a cable access opening, a base and tension roller trains. The rotary seat is mounted on the base, is connected with the base by a thrust bearing and a radial bearing and can rotate by 360-degree angles on the horizontal plane. The cable access opening is connected onto the rotary seat by hinge support arms, and the hinge support arms can rotate around hinge shafts. The tension roller trains are arranged in the rotary seat and the base, and a mooring cable which is fed into the underwater adaptive mooring cable tension device from the cable access opening and penetrates the rotary seat and the base can be clamped by the tension roller trains. The underwater adaptive mooring cable tension device has the advantages that the rotary seat can rotate, the hinge support arms can rotate around the shafts, accordingly, the direction of tension for pulling a floater in the cable access opening can keep in the longitudinal direction of the mooring cable, loosening, tightening and shaking of the mooring cable due to fluctuation of waves and transverse acting force which is applied to the mooring cable under the effect of sea current can be effectively eliminated, and the environmental adaptability and the severe sea condition resistance of the underwater winch can be improved.

Owner:STATE OCEAN TECH CENT

Method for laminating pole core of generator rotor of hydroelectric generating set before pre-pressing

InactiveCN101764473AMeet technical requirementsEliminate tightnessManufacturing stator/rotor bodiesEngineeringMechanical engineering

The invention relates to a method for laminating the pole core of the generator rotor of a hydroelectric generating set before pre-pressing, belonging to the technical field of generators. The method for laminating the pole core of the generator rotor of the hydroelectric generating set before pre-pressing is that adjustment sheets are filled in the pole core, and is characterized in that: 1) a horizontal placing rack is adopted, and two parallel ribs are arranged at the upper part of the placing rack and are used to support the lower end surfaces of the pole shoes of pole laminations to enable the pole laminations to be tidy and uniform; 2) the pre-laminated pole laminations are tightly pressed, and the deviations of the dimension and the form of all parts from the required dimension and the required form are measured; 3) the adjustment sheets are added among the pole laminations pre-laminated on the placing rack; and 4) the pole core is assembled and pressed after the pole core is penetrated through a pole tie bolt and damper bars. The invention has the advantages that the method is simple, the requirements on the lamination of different types of pole laminations are satisfied, the assembling quality of the pole core is good, the production efficiency is high and the like.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

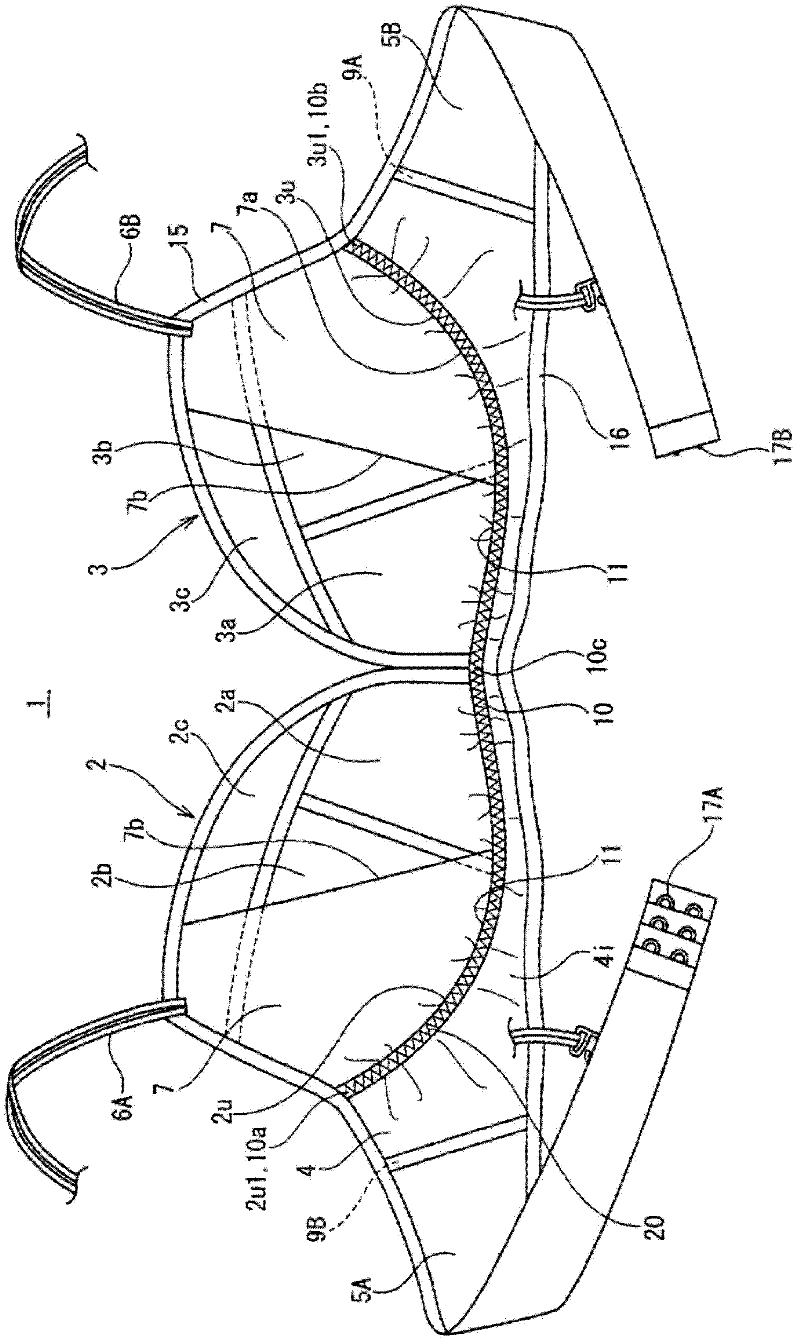

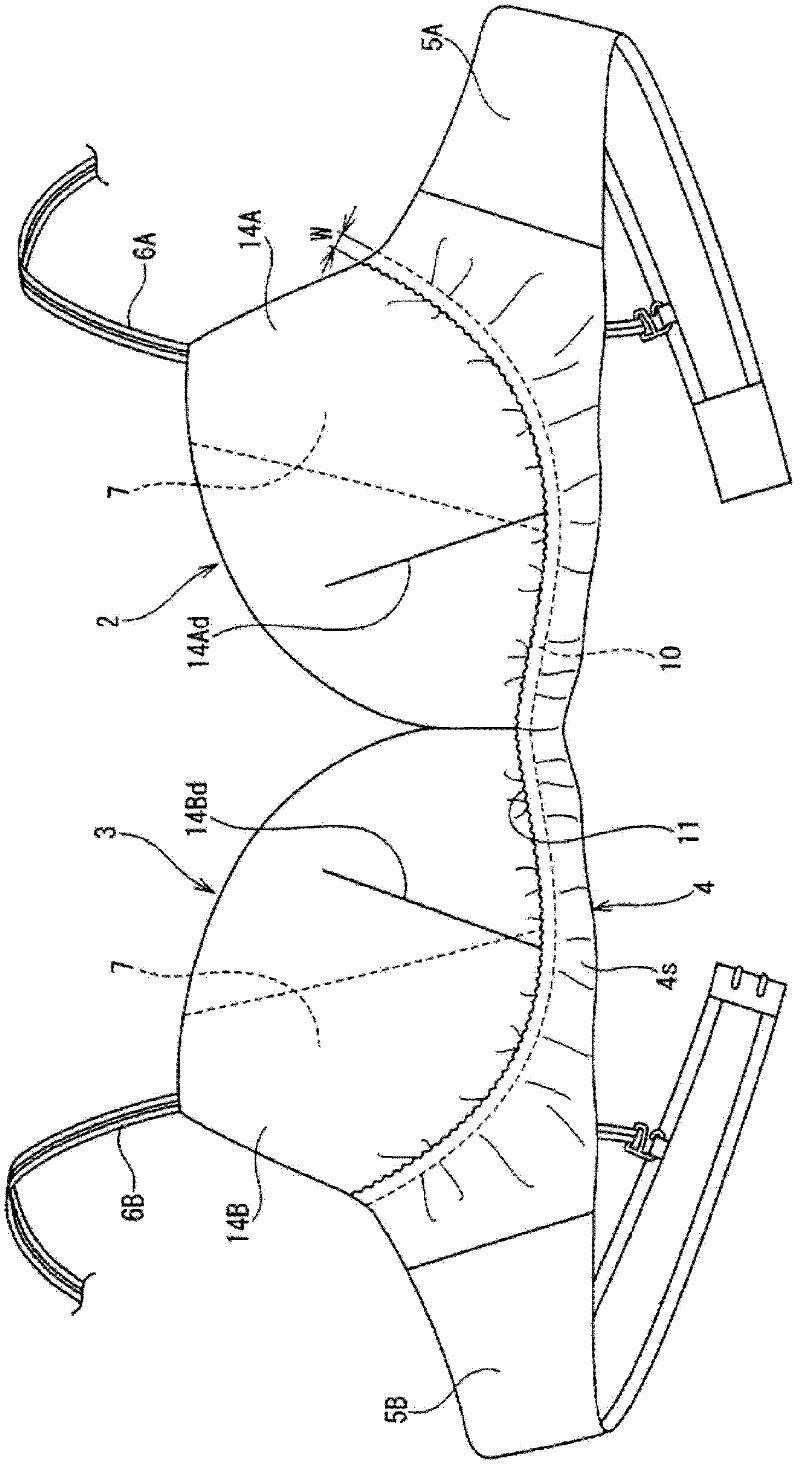

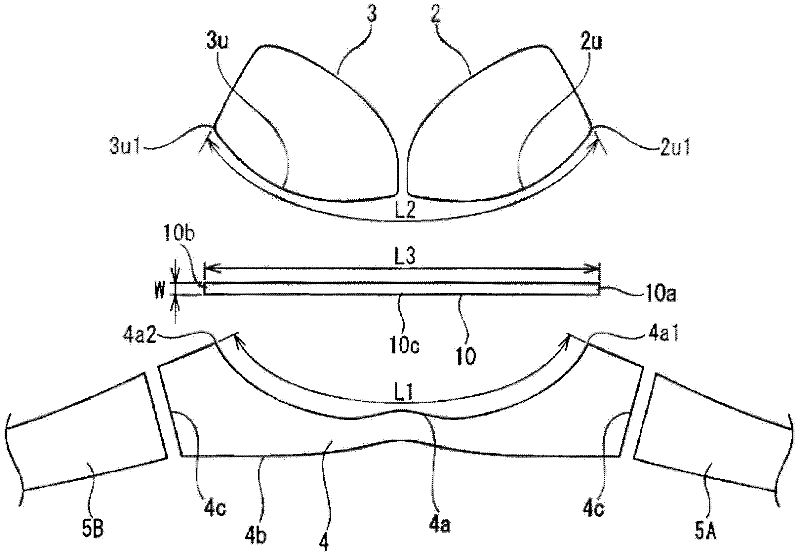

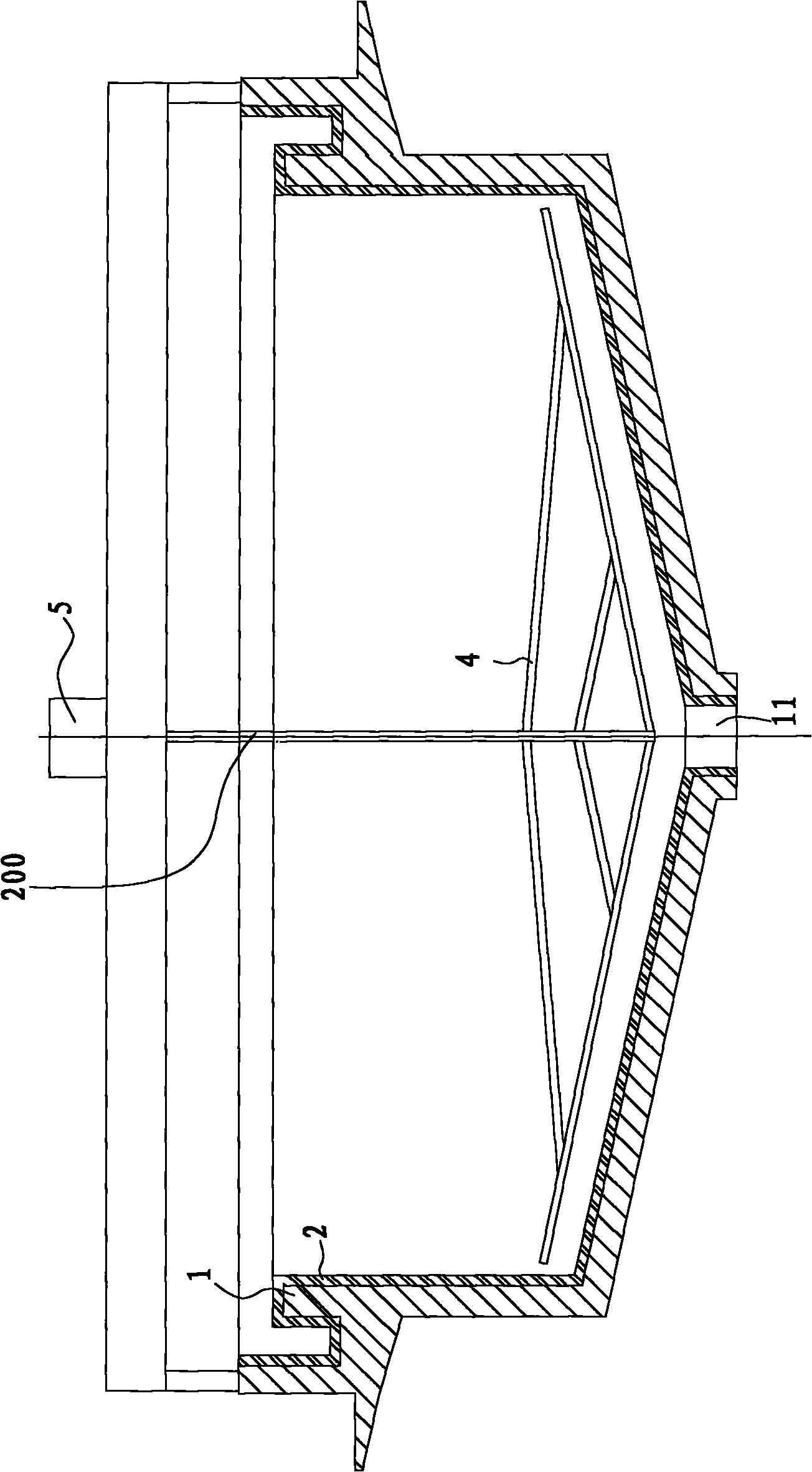

Clothing with cup parts

Disclosed is a clothing with cup parts which has excellent breast-shaping properties in spite of being non-wire. In the clothing, the marginal edges of the fabrics (2, 3) in the right and left cups along the verge's line and the marginal edge of a support fabric (4), which is joined together with the marginal ends of the fabrics in the right and left cups, are sewed on a stretch tape (10) with making gathers (11). When worn, the gathered parts of the fabrics in the cups can be three-dimensionally shaped due to the tension of the aforesaid stretch tape.

Owner:WACOAL

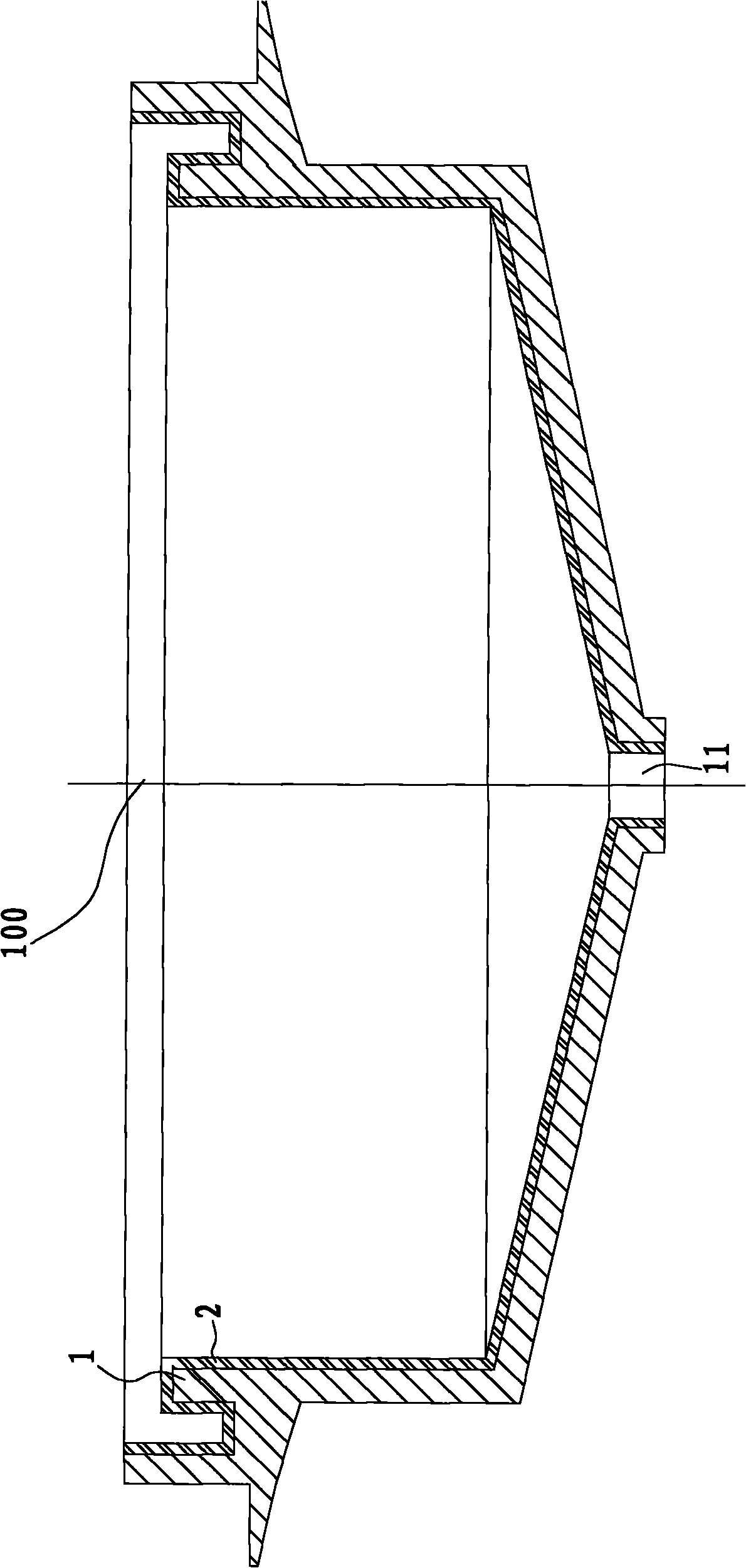

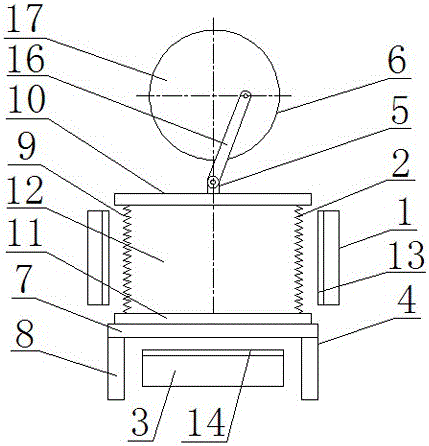

Thickener

InactiveCN101837202ALow costEliminate tightnessSedimentation settling tanksBiochemical engineeringAnti-corrosion

The invention discloses a thickener. The thickener comprises a shell, a drag line positioned in the shell and a drive device which drives the drag line to rotate, wherein the shell comprises a tank body and anti-corrosion rubber lining layers; the top of the tank body is open, and the bottom of the tank body is provided with a sand-holding hole; and the anti-corrosion rubber lining layers are arranged at the side wall of the inner circumference and the inner bottom wall of the tank body and the inner circumferential wall of the sand-holding hole. The thickener of the invention can be suitable for concentrated corrosive ore pulp and has low manufacturing cost.

Owner:CHINA ENFI ENGINEERING CORPORATION

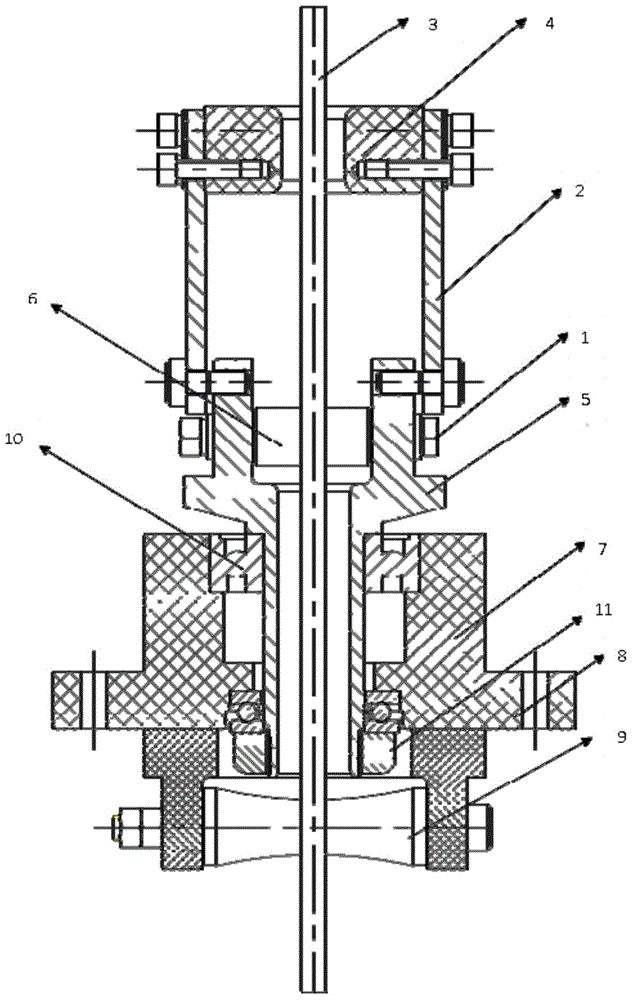

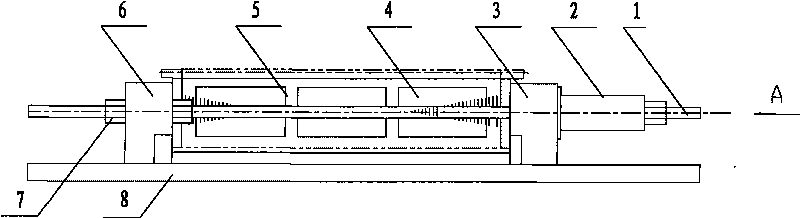

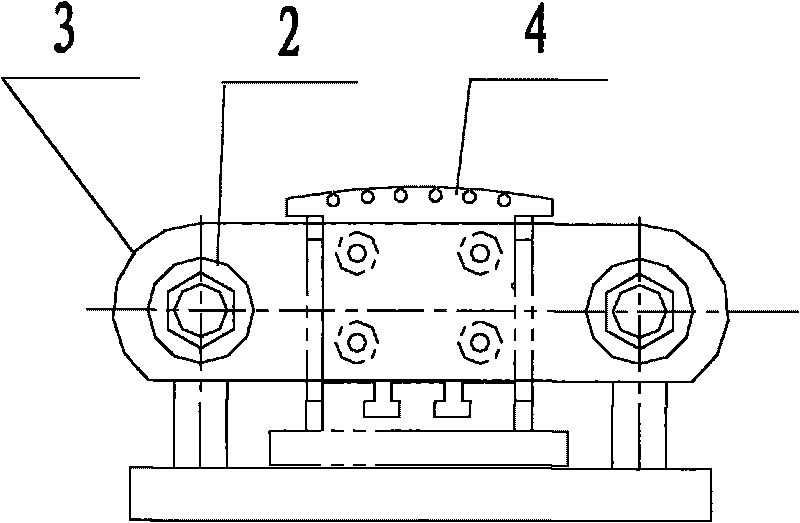

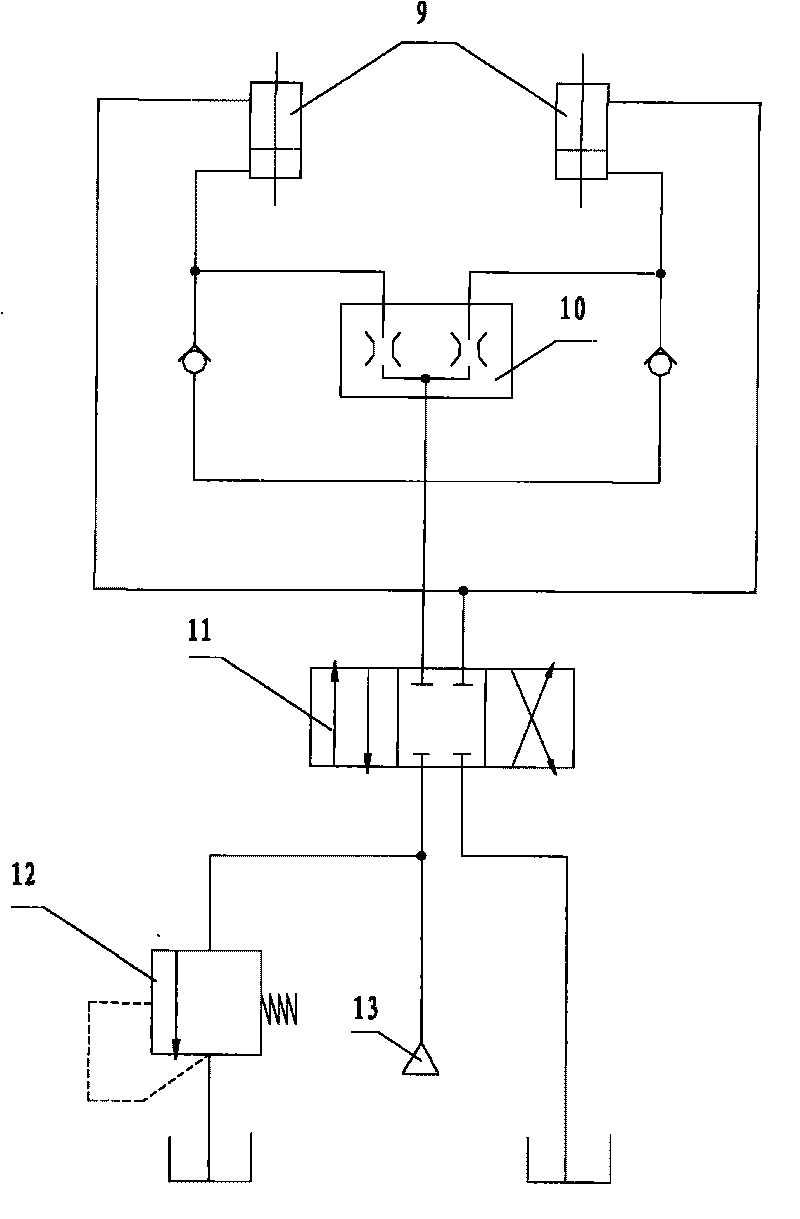

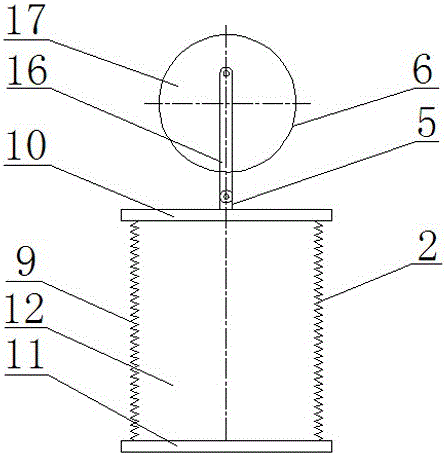

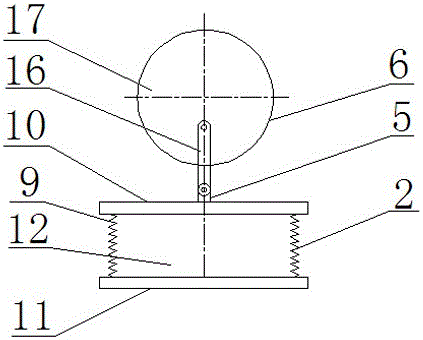

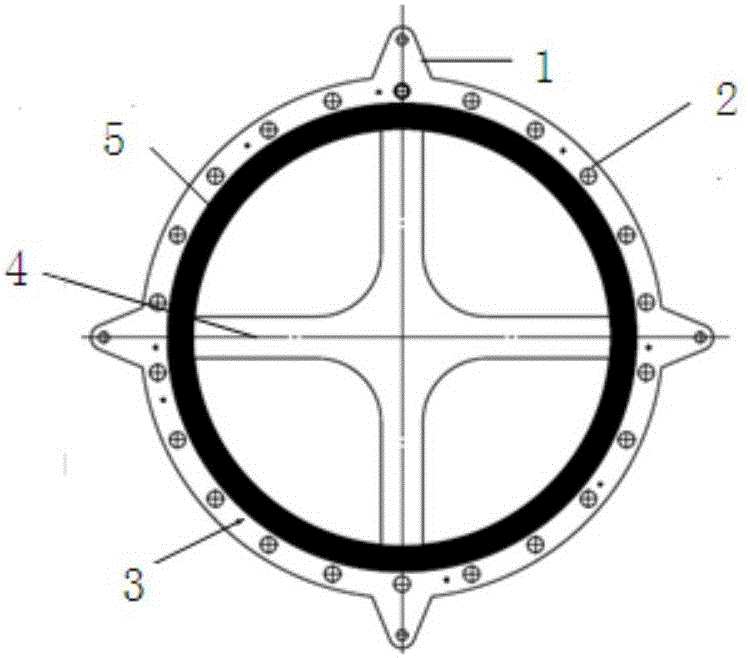

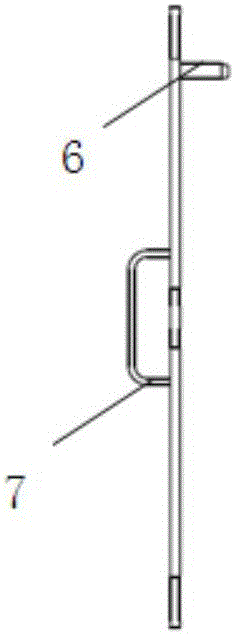

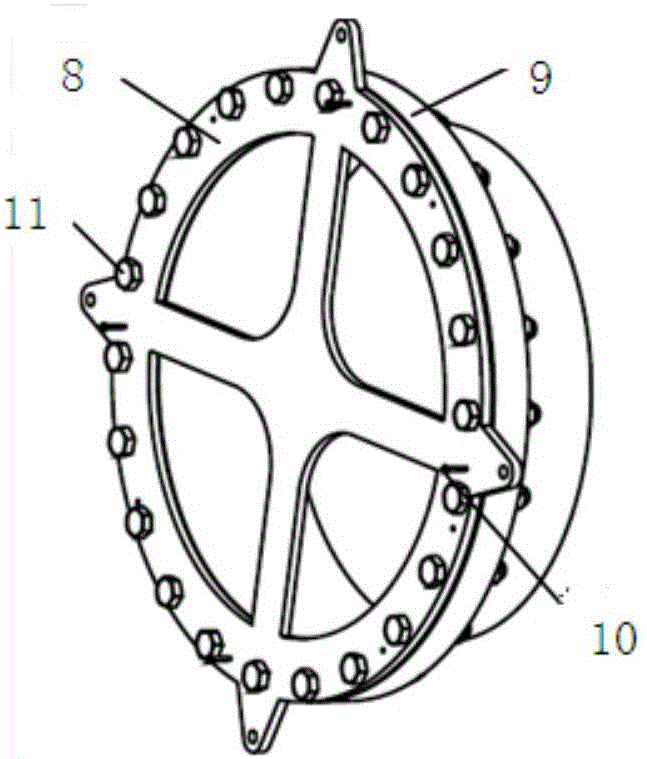

Pole core press mounting device of generator rotor of hydro-power generating unit

InactiveCN101699725AMeet technical requirementsEliminate tightnessManufacturing stator/rotor bodiesEngineeringHydro power

The invention relates to a pole core press mounting device of a generator rotor of a hydro-power generating unit, belonging to the technical field of generators. The invention is characterized in that the press mounting device is provided with a support, stretching cylinders and a hydraulic transmission system, wherein the stretching cylinders are arranged at two sides of a pole core on the support, and the hydraulic transmission system is a hydraulic transmission mechanism and mechanical transmission mechanism in which the two stretching cylinders move synchronously. The invention ensures that the pole core is press mounted, laminated and penetrated in a stretching screw, satisfies the pole core press mounting requirements of a rotor of a large or medium-sized hydro-power generating unit, has high compactness and flatness requirements of the pole core, ensures the pole core assembling quality of the large or medium-sized hydro-power generating unit and improves the production and processing efficiency.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

Fibroin shower gel with whitening and skin protection effects and preparation method thereof

InactiveCN106473986AMild performanceLess irritatingCosmetic preparationsToilet preparationsShower gelIrritation

The invention discloses fibroin shower gel with whitening and skin protection effects and a preparation method thereof. The fibroin shower gel is prepared from the following raw materials: 60 to 75 parts of fibroin powder, 4 to 16 parts of ethylene glycol distearate, 1 to 4 parts of jasmine essential oil, 2 to 6 parts of lecithin, 8 to 10 parts of radix lithospermi powder, 3 to 6 parts of radix zanthoxyli extracting liquid, 5 to 8 parts of fructus gleditsiae, 5 to 10 parts of tea polyphenol, 5 to 10 parts of polyethylene glycol monostearate, 12 to 18 parts of sodium dodecyl sulfate, 2 to 8 parts of honeysuckle flower extract, 6 to 10 parts of dipotassium glycyrrhizinate, 5 to 15 parts of glycerol, 1 to 5 parts of wool grease and 30 to 40 parts of water. According to the fibroin shower gel with the whitening and skin protection effects and the preparation method thereof, disclosed by the invention, efficient nourishing components are added, so that the fibroin shower gel has the most basic cleaning effect and has moderate performance and no irritation on skin; the fibroin shower gel can be used for effectively nourishing and whitening the skin and removing a tense feeling of the skin after bathing.

Owner:JIANGSU AIXISHI TECH SERVICE CONSULTATION CO LTD

Thickener shell

InactiveCN101837203ALow costEliminate tightnessSedimentation settling tanksBiochemical engineeringAnti-corrosion

The invention discloses a thickener shell. The thickener shell comprises a tank body and anti-corrosion rubber lining layers, wherein the top of the tank body is open, and the bottom of the tank body is provided with a sand-holding hole; and the anti-corrosion rubber lining layers are arranged at the side wall of the inner circumference and the inner bottom wall of the tank body and the inner circumferential wall of the sand-holding hole. The thickener shell of the invention can be suitable for concentrated corrosive ore pulp and has low manufacturing cost.

Owner:CHINA ENFI ENGINEERING CORPORATION

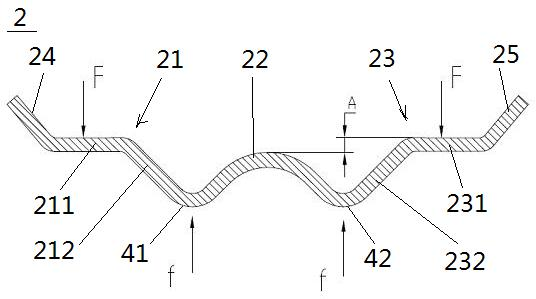

Welded corrugated pipe type work doing unit of heat engine

InactiveCN106089487AEliminate tightnessEliminate lubricationHot gas positive displacement engine plantsSheet steelEngineering

The invention relates to the technical field of heat engine devices, in particular to a welded corrugated pipe type work doing unit of a heat engine. The welded corrugated pipe type work doing unit of the heat engine comprises a heater, a welded corrugated pipe, a cooling device, a rack, a hinged support and a transmission mechanism. The rack is formed by welding a square steel plate to supporting legs. The welded corrugated pipe is composed of a hollow metal pipe, a top end plate and a bottom end plate. The upper end of the hollow metal pipe is connected with the top end plate, and the lower end of the hollow metal pipe is connected with the bottom end plate. The bottom end plate is installed on the top of the square steel plate. The cooling device is installed at the bottom of the square steel plate. The heater is installed around the outer pipe wall of the hollow metal pipe. The top end plate is connected with the transmission mechanism through the hinged support. A gas medium is fed into an inner cavity of the hollow metal pipe. According to the welded corrugated pipe type work doing unit of the heat engine, because the non-frictional type welded corrugated pipe is used for replacing an air cylinder and piston structure, the problems of seal, lubrication, friction resistance and the like between an air cylinder and a piston are solved, and the machining difficulty and the production cost are lowered.

Owner:宋日升

Coating technology of coating of flange sealing surface

ActiveCN105782639AEliminate slight deformationEliminate tightnessCorrosion preventionPipe protection against corrosion/incrustationCoated surfaceSand blasting

The invention discloses a coating technology of a coating of a flange sealing surface. The coating technology comprises the steps of I, carrying out sand blasting on the flange sealing surface; II, smearing the surfaces of a sealing water wave line, connecting fastening bolts and mold drawing bolts on a sealing surface of a mold with a mold release agent; III, smearing the sealing water wave line surface and the flange sealing surface with paint, enabling the middle part of the flange to form a raised peak ridge, and then scraping the paint to the flat; IV, locating the flange; V, fastening the mold and the flange together, and cleaning the overflowing paint; VI, after a coating is solidified, carrying out mold drawing; VII, detecting the flatness and profile of the water wave-shaped sealing coating of the flange sealing surface; VIII, carrying out sand blasting on the sealing surface of a matched flange; IX, smearing the surface of the flange sealing surface coating with the mold release agent; X, smearing the sealing surfaces of the flange and the matched flange with paint, and scraping the paint to be flat; XI, fastening the flange and the matched flange, controlling the thickness of the coating, and cleaning the overflowing paint; and XII, after the coating is solidified, carrying out mold drawing. According to the coating technology, pressure resistant coating protection can be carried out on the pressure bearing sealing surface, and the problem of long-acting corrosion protection is solved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

A modularized bionic robot fish

InactiveCN100465065CImprove reliabilityEasy maintenancePropulsive elements of non-rotary typeSpecial purpose vesselsModularityEngineering

Owner:PEKING UNIV

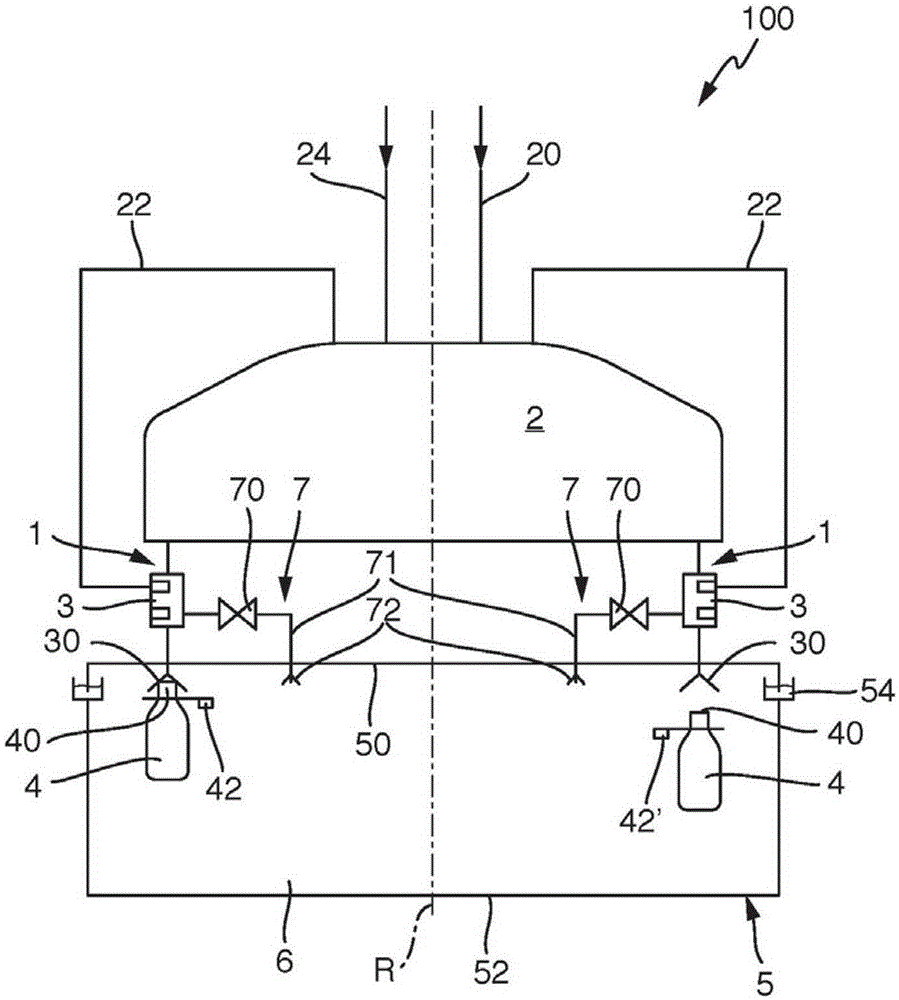

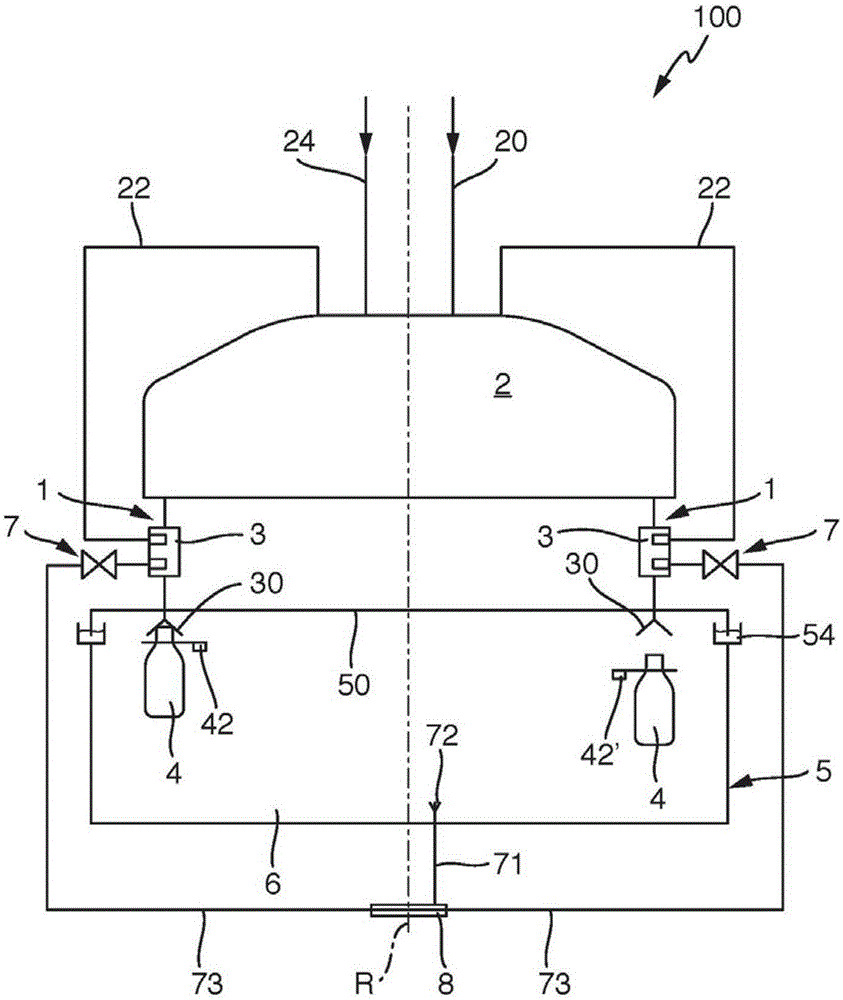

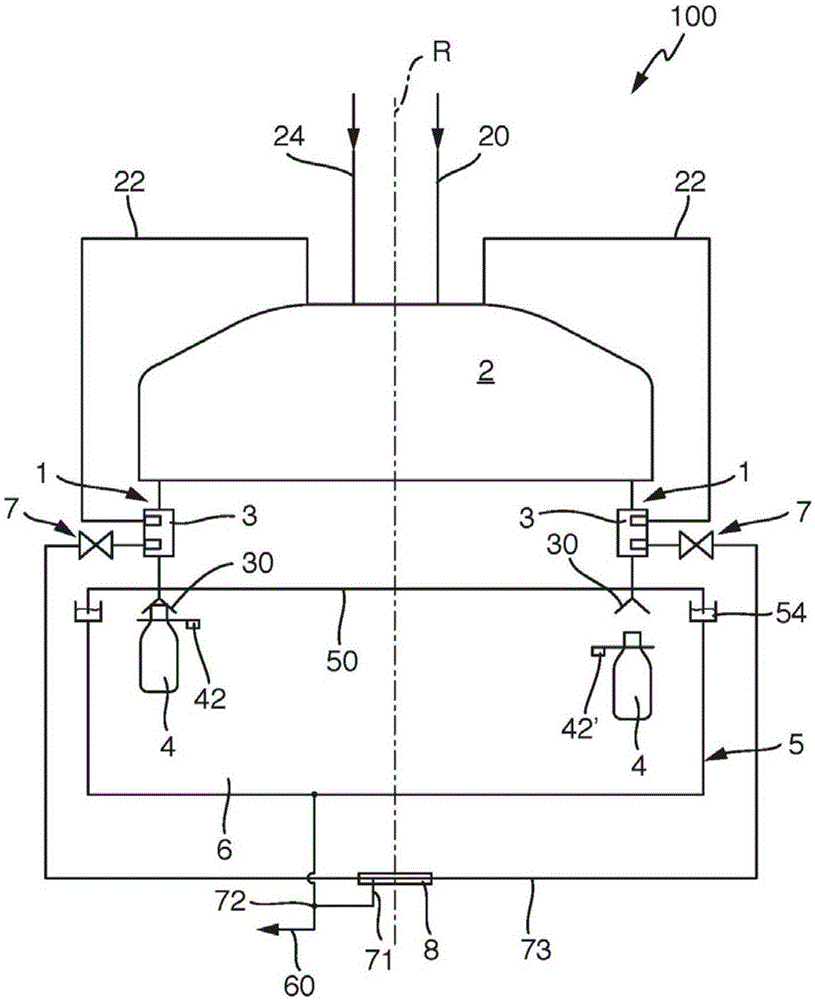

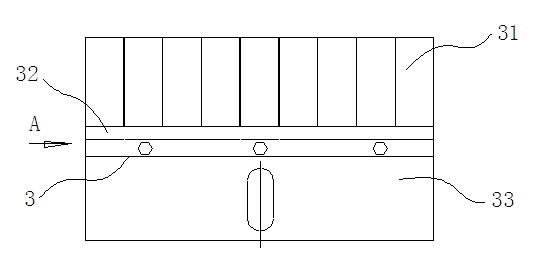

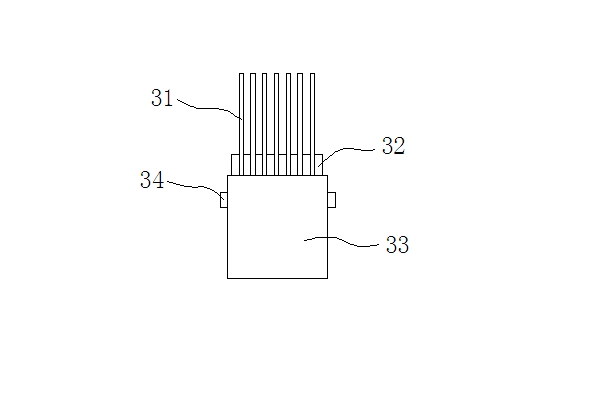

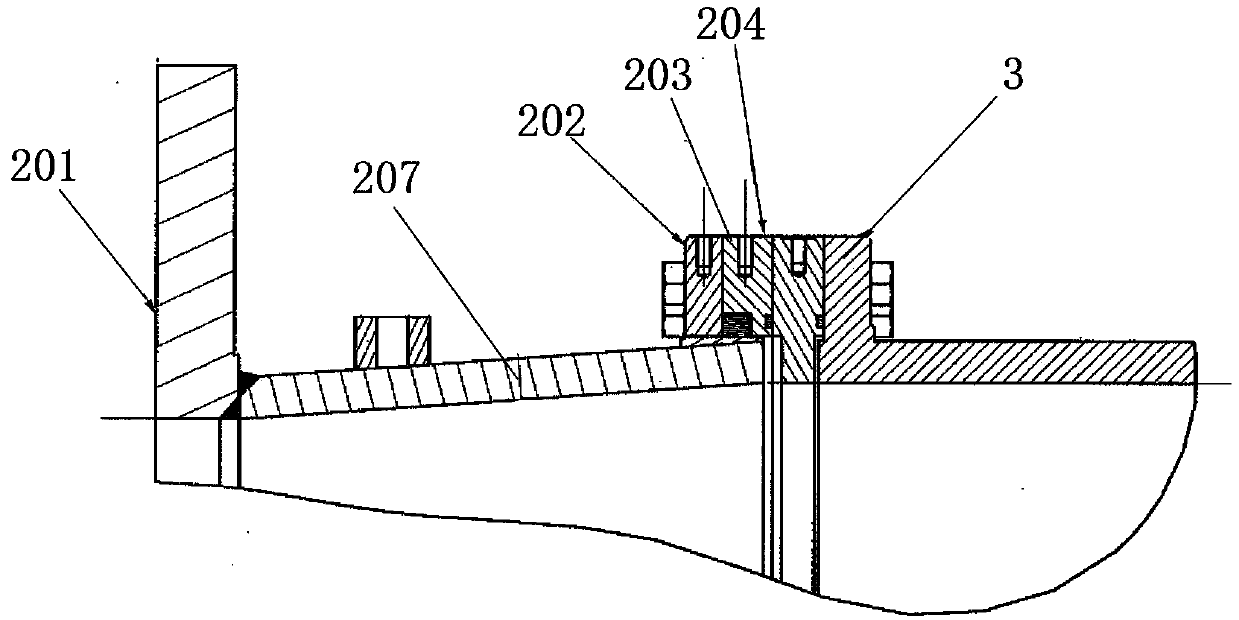

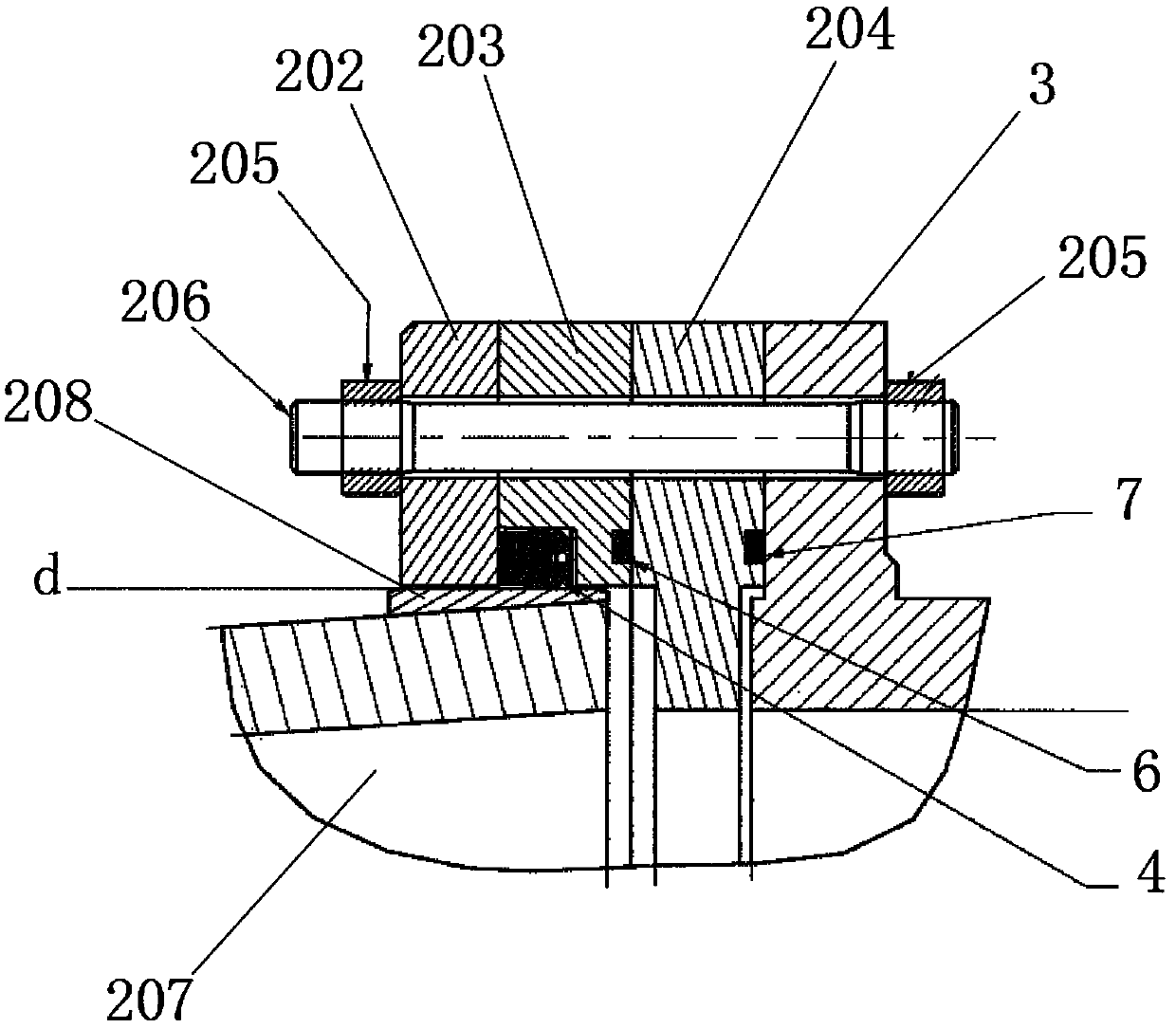

Device and method for filling a container with a carbonated filling product

ActiveCN105584653AWill not polluteReduce formationFilling using counterpressurePackage sterilisationEngineeringCarbonation

The invention relates to a device and method for filling a container(4) with a carbonated filling product. The device is characterized in that a filling valve (3)is used for filling the container (4) to be filled; a releasing device (7) provided with a releasing valve (70) is used to releasing the overpressure in the filled container (4); a sterilization area (6) is provided with a flowing outlet (30) accommodating the filling valve (3), and the flowing outlet is used for the connection with a container opening (40) of the container (4) to be filled; and the releasing device (7) is used for the communication with the sterilization area (6) for releasing the overpressure in the sterilization area.

Owner:KRONES AG

Propolis body wash

The invention relates to propolis body wash. The propolis body wash is prepared from the following components in parts by weight: 6 to 12 parts of sodium cocoyl glycinate, 10 to 20 parts of cocamidopropyl betaine, 3 to 7 parts of acrylic copolymer, 1 to 2 parts of propolis, 1 to 3 parts of lemon essential oil, 1 to 2 parts of hyaluronic acid, 1 to 3 parts of methylisothiazolinone, 1 to 2 parts of sodium hydroxide, 1 to 3 parts of citric acid, and 10 to 20 parts of water. The propolis body wash is mild in formula, not only capable of removing skin contaminants, eliminating the inflammation and sterilizing, but also capable of having a moisturizing, moistening and protecting the skin, capable of eliminating the tension of the skin after taking shower, and suitable for all types of skin.

Owner:彭期华

Flexible steel sheet contact sealing devices and combined sealing structure thereof

ActiveCN101915310AEliminate tightnessLittle effect of currentEngine sealsCombustion processAir preheaterEngineering

The invention relates to flexible steel sheet contact sealing devices and a combined sealing structure thereof. The flexible steel sheet contact sealing device comprises a component mounting substrate which is provided with a plurality of layers of wearable flexible steel sheets in elastic sealing contact with a sector plate end face or an axial curved plate of a rotary air preheater; and guard strips are arranged among the flexible steel sheets. The combined sealing structure comprises the flexible steel sheet contact sealing devices; the working end faces of the flexible steel sheets are provided with a plurality of notches; the flexible steel sheets are arranged in parallel along the width direction and are arranged in a staggered mode along the thickness direction; the flexible steel sheet contact sealing devices are arranged in parallel along the width direction of the flexible steel sheets; and the corresponding flexible steel sheets on adjacent flexible steel sheet contact sealing devices are seamlessly butted. The invention provides the flexible steel sheet contact sealing devices and the combined sealing structure thereof, which can reduce the capacity of a boiler fan andfulfill the aim of reducing the service power consumption rate of a thermal power plant.

Owner:NINGBO FUSHIDA ELECTRIC ENG +1

Chinese medicinal shinyleaf prickly ash root nourishing and itch-relieving shower gel

ActiveCN102579307BBasic CleansingMild performanceCosmetic preparationsToilet preparationsPolyolShower gel

The invention discloses a Chinese medicinal shinyleaf prickly ash root nourishing and itch-relieving shower gel, and relates to the technical field of daily chemical products. The shower gel is prepared from a cationic surfactant, an anionic surfactant, a conditioner, a nonionic surfactant, an ampholytic surfactant, a polyol moistening agent, a pearling agent, shinyleaf prickly ash root extract, natural tea extract, high-efficiency nourishing components, citric acid, sodium citrate, sodium chloride, essence, Kathon and proper water. The shower gel has basic cleaning effect, mild performance, low irritation to skin, and can be used for effectively nourishing skin, eliminating skin tension after shower and effectively relieving itch.

Owner:LMZ YANGZHOU HOTEL SUPPLIES +2

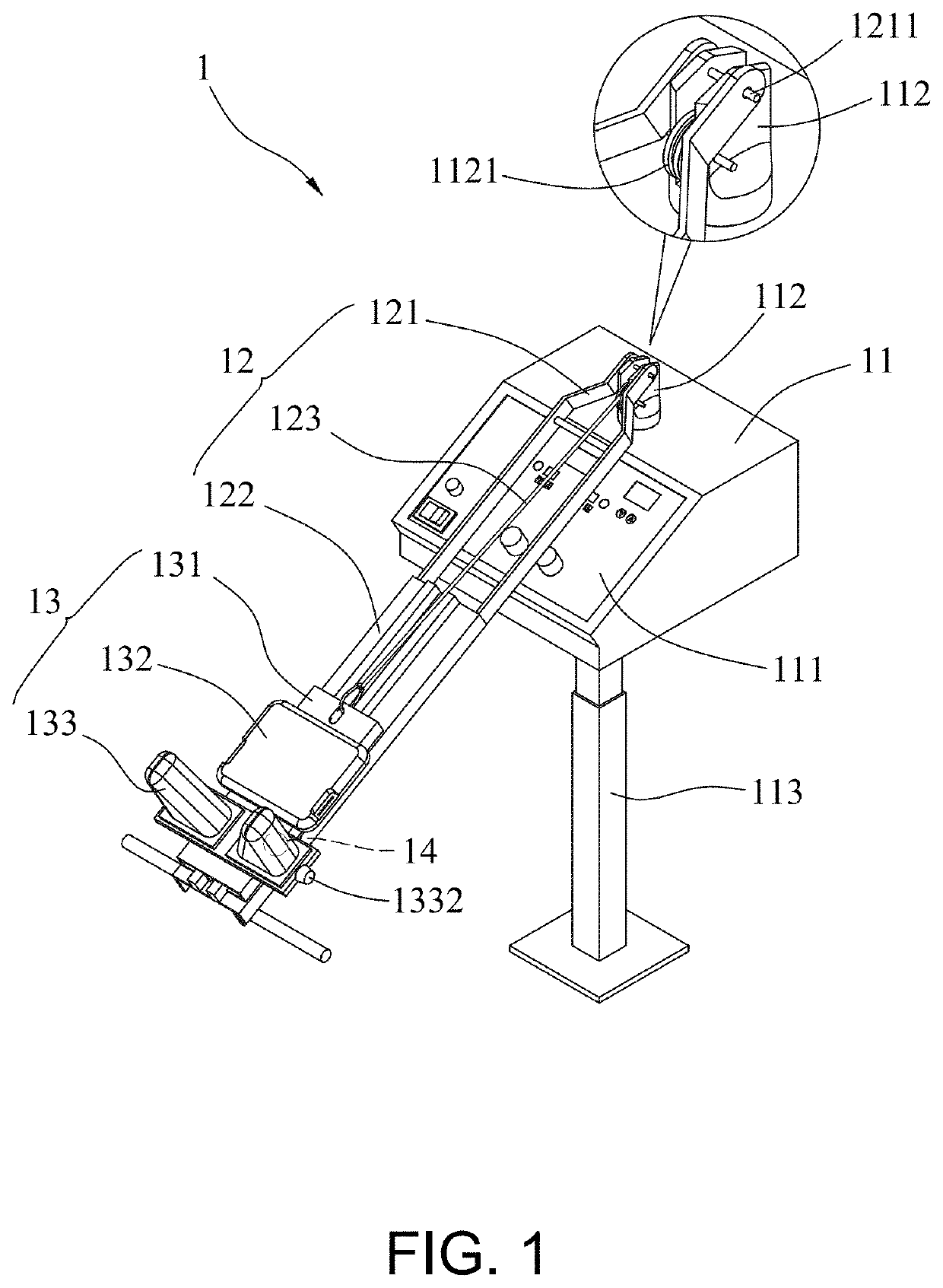

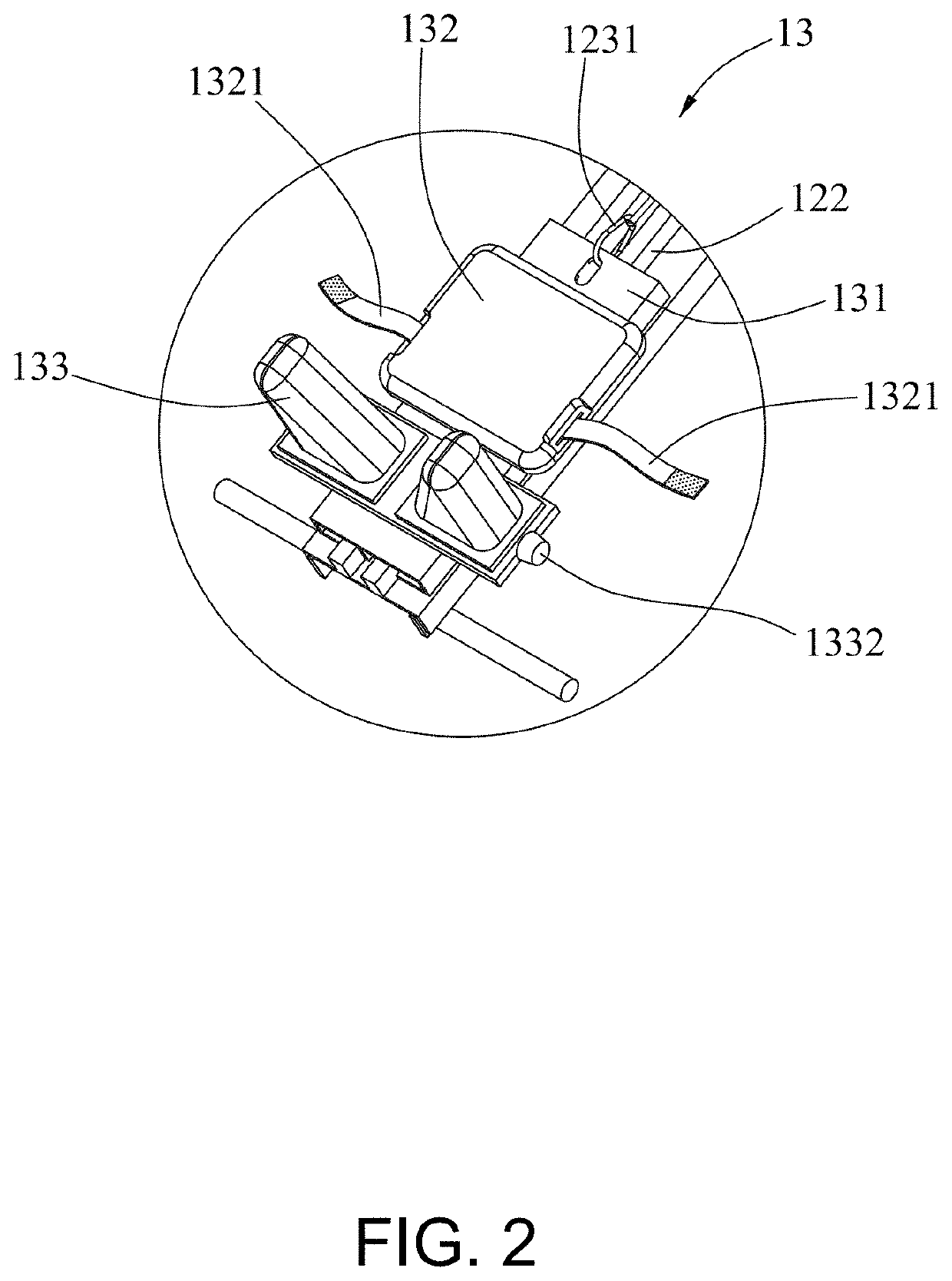

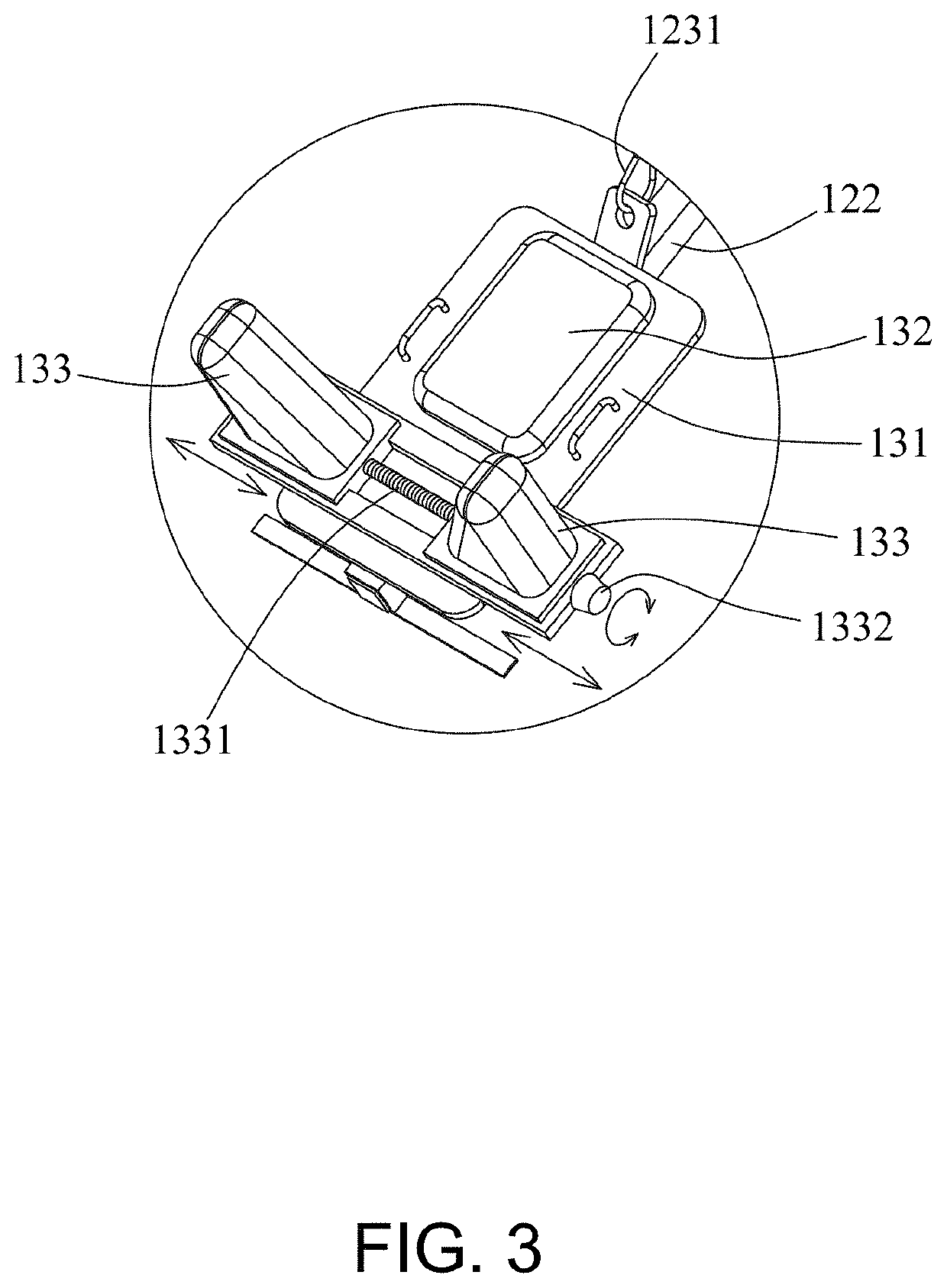

Cervical spine traction device, equipment and method

PendingUS20210186795A1Tension force of the neck muscle can be relaxedEliminate tightnessPillowsDiagnosticsPhysical medicine and rehabilitationMassage

The present disclosure relates to a cervical spine traction device, equipment and method, wherein a built-in program code determines a cervical spine stretching force according to a sensed weight of a user. The cervical spine traction device has a main controller, a fixing unit, a movable unit and thermal massage units. By storing the program code in the main controller, the optimal traction data comprising a cervical spine stretching distance, the cervical spine stretching force and a cervical spine stretching time can be calculated according to the weight and height of the user lying down on the platform. Further, by sensing the temperature of the neck of the user and massaging the neck, the tension force of the neck muscle can be relaxed, the tightness of the user can be sufficiently eliminated, and the cervical spine of the user is corrected.

Owner:NAT TAIPEI UNIV OF TECH

Not-to-tighten safety bet

InactiveCN1305715CModerate adjustment of slackEliminate tightnessBelt anchoring devicesEngineeringBelt safety

The properly tightening safety belt comprises belt, winder, inserting board, fastener and limiter. The limiter comprises casing with side belt port and upper and lower rotating shafts; the lower rotating shaft is fitted movably to two lower shaft seats with electromagnet and has fixing and closing sleeve and ratchet mechanism; the upper rotating shaft is provided with fixing and closing sleeve, two movably fitted shaft seats in slide rail and with spring, ratchet mechanism and electromagnet; and there may be motor for driving the lower rotating shaft. With automatic or hand limiter, the properly tightening safety belt has properly adjustable tightness, and may be used widely in automobile, airplane, high speed train, etc.

Owner:陈小华

Leakage control device for ball valve telescopic joint of pump storage group

The invention discloses a leakage control device for a ball valve telescopic joint of a pump storage group. A horizontal U-shaped seal ring is arranged in a ball valve downstream telescopic joint; the position of an open slot of the horizontal U-shaped seal ring is provided with a combined O-shaped seal ring; the combined O-shaped seal ring is separated into at least two sections; the at least two sections are connected by an instant adhesive; the thickness of the instant adhesive is smaller than the diameter of the combined O-shaped seal ring. According to the leakage control device for the ball valve telescopic joint of the pump storage group disclosed by the invention, the problem that the horizontal U-shaped seal ring deforms and cannot be tightly sealed due to the weight of the telescopic joint can be eliminated, and even if the horizontal U-shaped seal ring has deformation, the open slot of the horizontal U-shaped seal ring cannot be tightly sealed with equipment, but as the existence of the combined O-shaped seal ring, the horizontal U-shaped seal ring also can be tightly sealed with the equipment as well, and a gap cannot exist. Under the action of water pressure in a pipeline, an aqueous medium can flow through multiple sections of the combined O-shaped seal ring as well to enter the open slot of the horizontal U-shaped seal ring to expand the open slot of the horizontal U-shaped seal ring, and therefore, seal and water-stop effects are exerted.

Owner:STATE GRID CORP OF CHINA +2

Cane sugar bath lotion

InactiveCN110801415AMild in naturePromote regenerationCosmetic preparationsToilet preparationsSucroseGlycerol

The invention discloses cane sugar bath lotion. The cane sugar bath lotion consists of sodium laureth sulfate, cane sugar, glycerine, cocamidopropyl betaine, a pummelo leaf extract, hyaluronic acid, butanediol, propylene glycol, sodium hydroxide, citric acid, methylisothiazolinone, essence and water. The cane sugar bath lotion is mild in nature and free from stimulation to skin, can eliminate harmful bacteria on the surface of skin while cleaning skin, can promote skin cell metabolism, can effectively moisturize and nourish skin, and can eliminate the feeling that the skin is tight after people bath.

Owner:陈建容

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com