Method for laminating pole core of generator rotor of hydroelectric generating set before pre-pressing

A technology of generator rotor and magnetic pole iron core, applied in the direction of manufacturing stator/rotor body, etc., can solve the problems of unsafe, inconvenient operation of vertical laminations, and the position and quantity cannot meet the size requirements, so as to improve the quality and The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A hydroelectric generator rotor magnetic pole core lamination method before preloading, the adjustment piece is filled into the magnetic pole core, and the process is as follows:

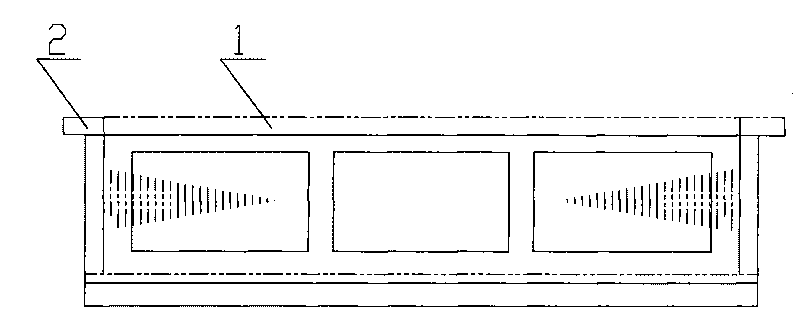

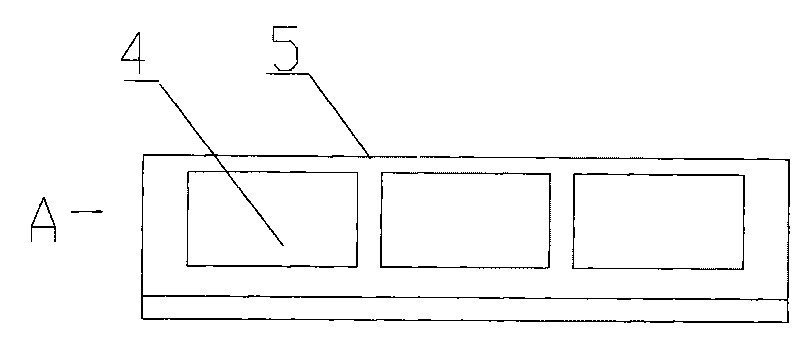

[0026] 1) Place the frame 5 in a horizontal direction, with a detection hole 4 in the middle of the frame 5, and two parallel ribs on the upper part, which are used to support the lower end surface of the magnetic pole punching piece pole shoe, so that the magnetic pole punching pieces are neat and consistent;

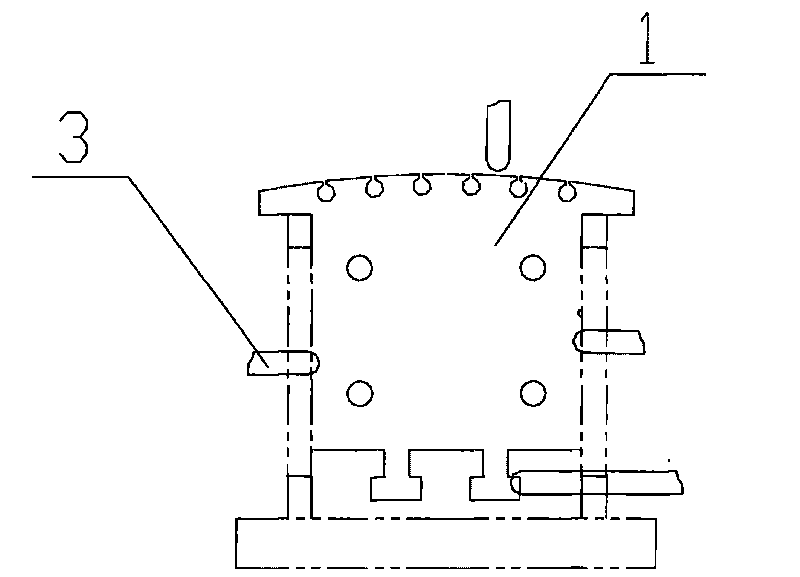

[0027] 2) The magnetic pole pressing plate 2 compresses the pre-stacked magnetic pole punching piece 1, and the size error and shape error of each part are measured by the feeler gauge 3;

[0028] 3) Add an adjustment sheet in the middle of the pre-stacked magnetic pole punching sheet on the shelf (the adjustment sheet is spot-welded with the adjacent sheet);

[0029] 4) After penetrating the magnetic pole tensioning screw and damping strip, pressurization is completed.

[0030] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com