Patents

Literature

314 results about "Feeler gauge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A feeler gauge is a tool used to measure gap widths. Feeler gauges are mostly used in engineering to measure the clearance between two parts.

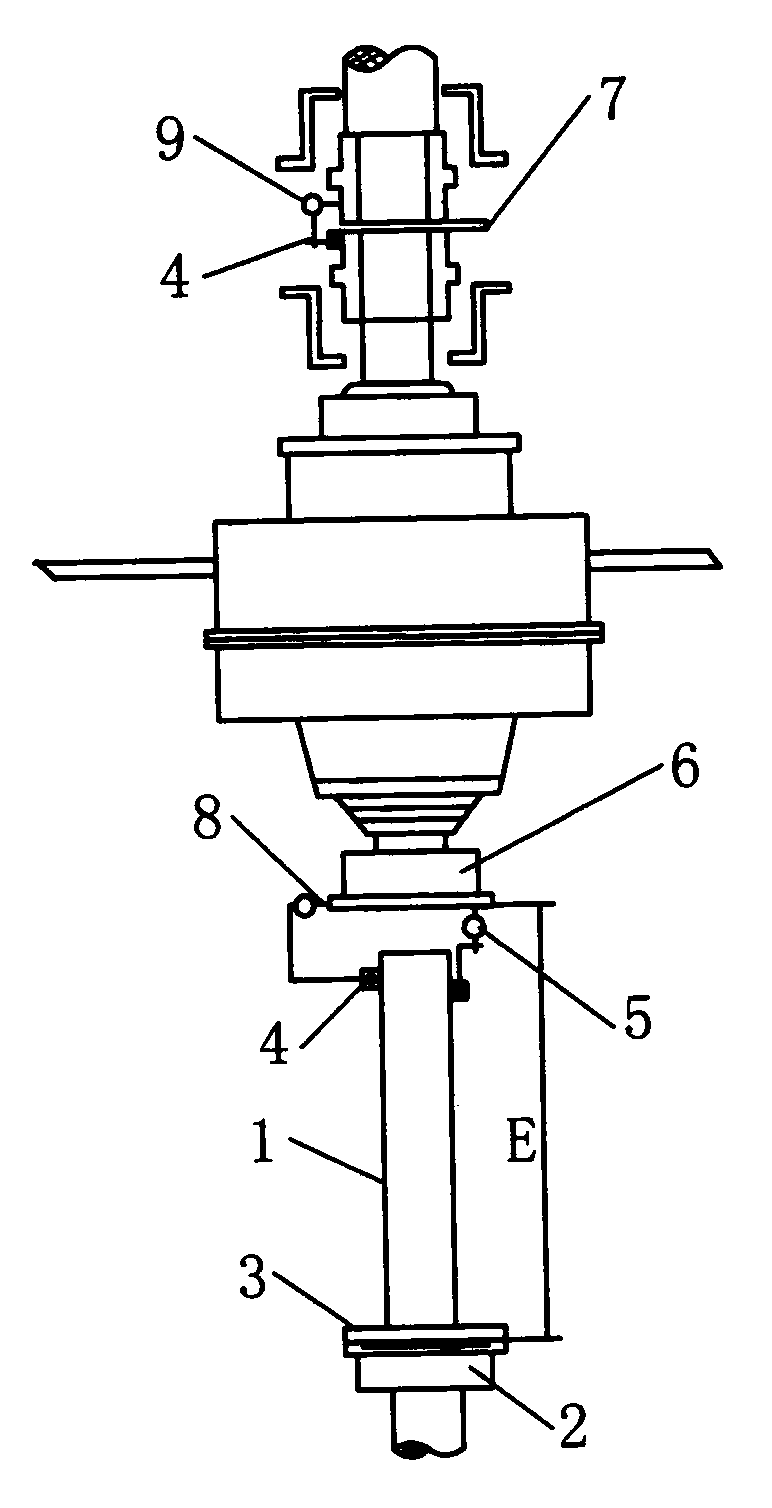

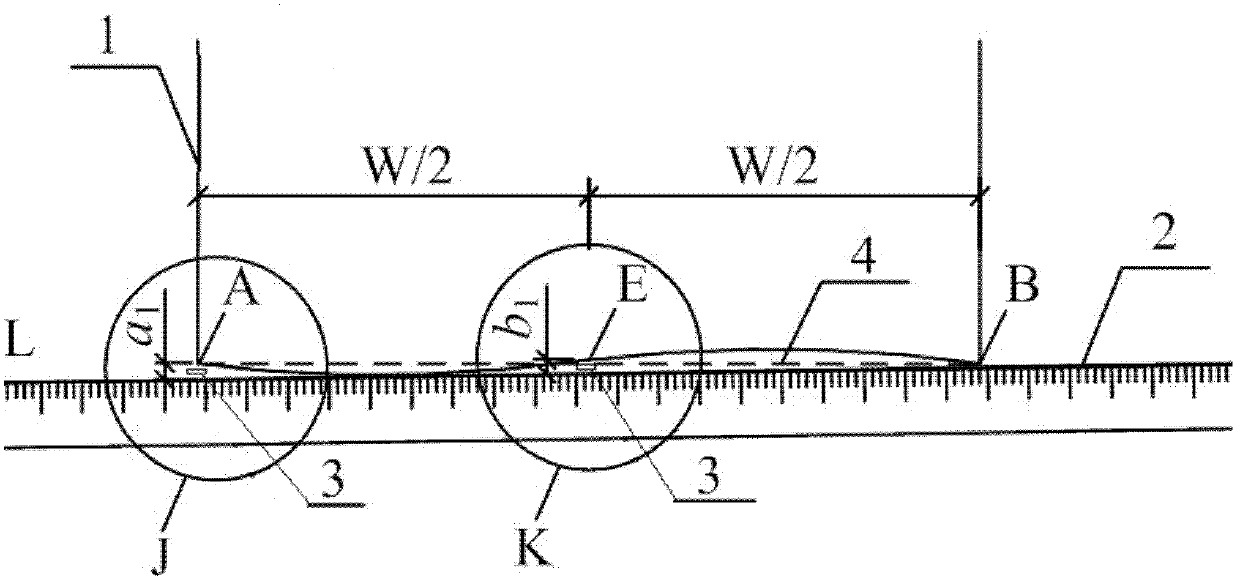

Ballastless track plate seam depth non-destructive detection method and equipment based on vibration

ActiveCN105783799AIntuitiveEasy to measureUsing subsonic/sonic/ultrasonic vibration meansNon destructiveFrequency spectrum

The present invention discloses a ballastless track plate seam depth non-destructive detection method and equipment based on vibration. For the problem that a feeler gauge method, a non-destructive detection method based on ultrasonic wave and a non-destructive detection method used in detecting a ballastless track plate seam depth have large limitation and the need of actual detection is difficult to satisfy in the prior art, the scheme provides the method and the equipment and aims to use an exciting device to allow a track plate edge to generate tiny vibration, and through analyzing the spectral characteristics of the vibration, the depth of a track plate seam is visually, conveniently, efficiently and accurately measured.

Owner:四川升拓检测技术股份有限公司

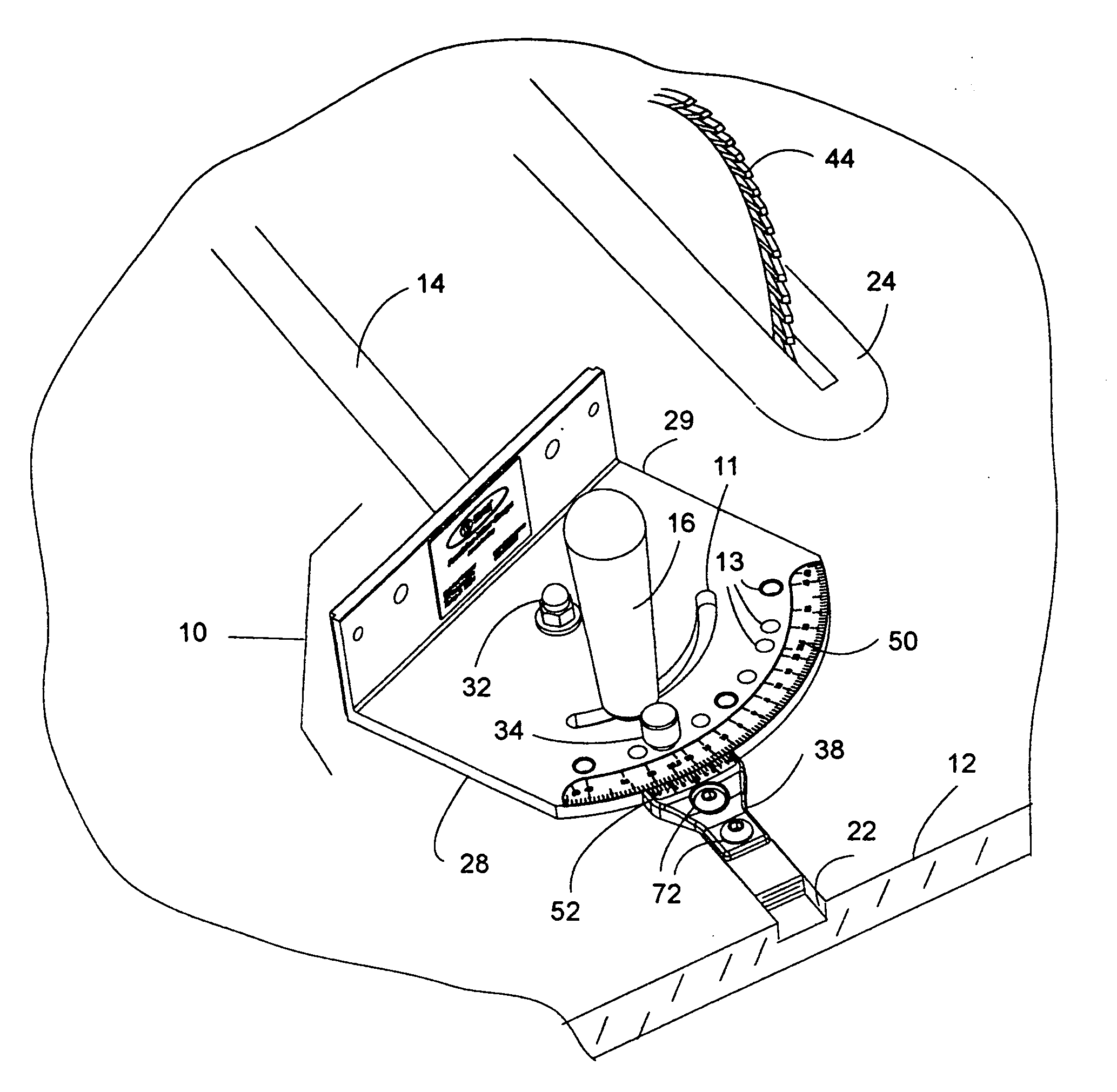

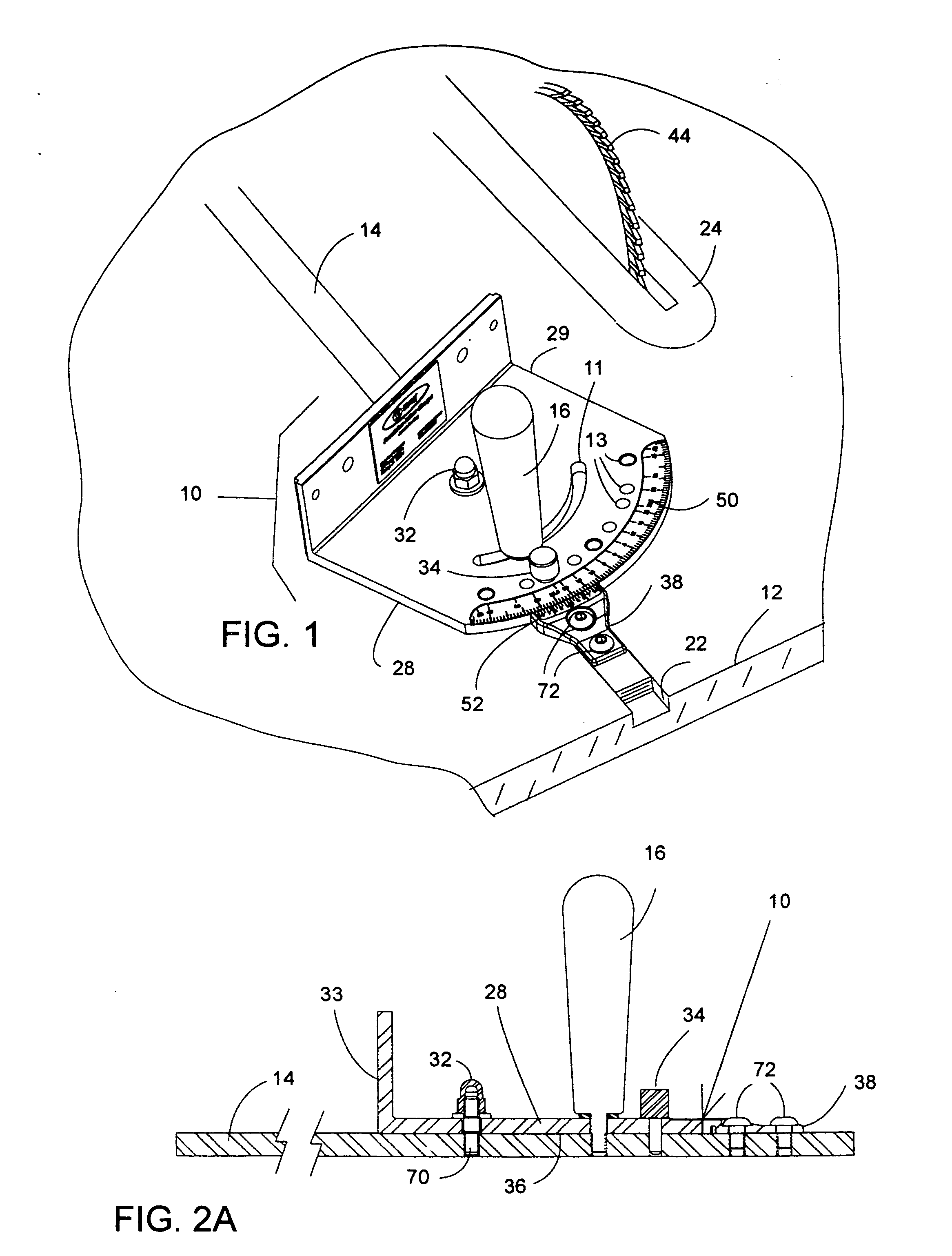

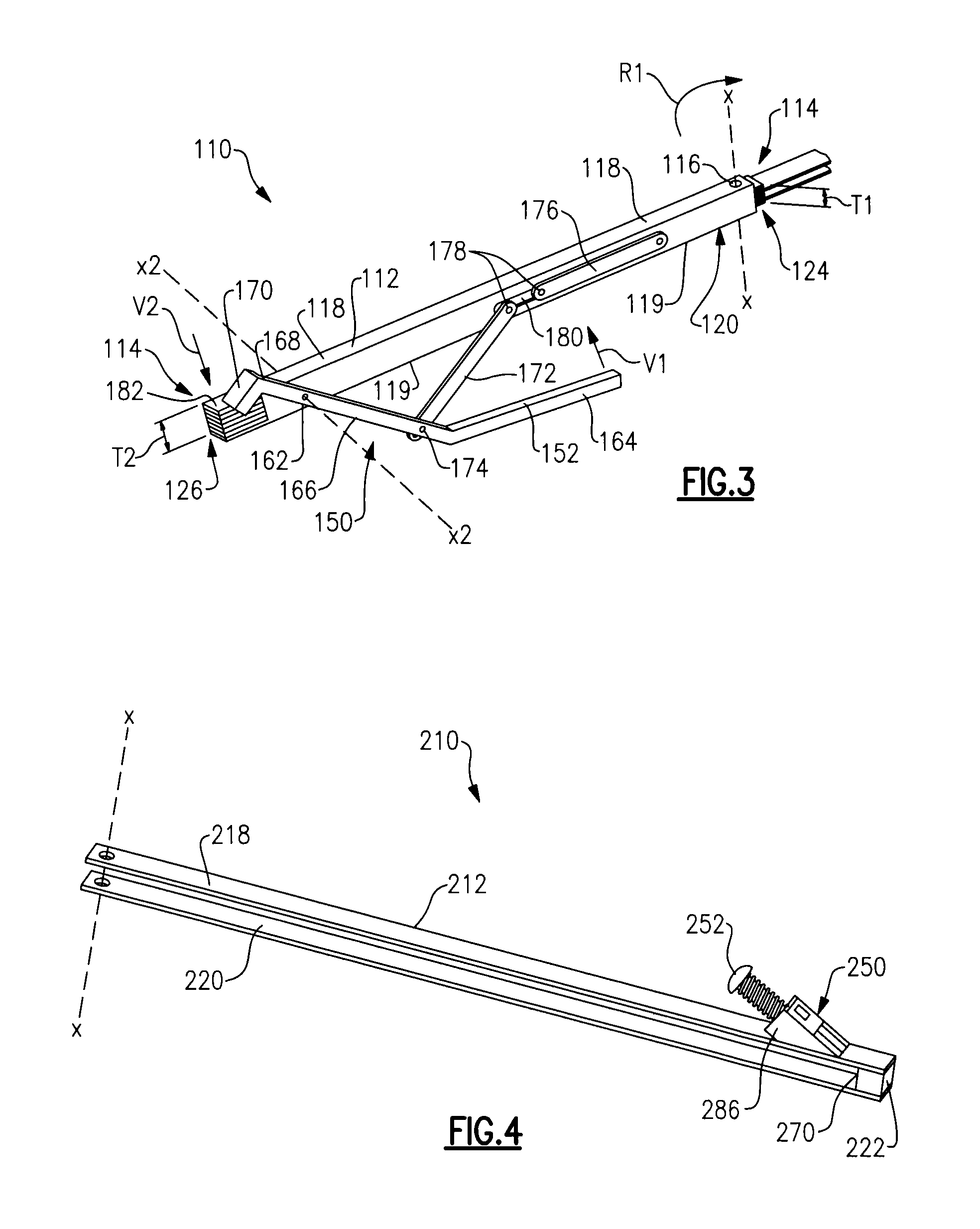

Miter gauge, jig and fixture improvements

InactiveUS20050279200A1Easy to useQuality improvementGuide fencesFeeding devicesCritical positionEngineering

A miter gauge with a machined aluminum head that has a stamped aluminum scale secured in a machined slot. The scale has indicia that facilitate reading the scale including color-coded diamonds, arrow heads and longer lines at key positions. The miter gauge is quickly adjustable to 1 / 100th of a degree using ordinary shop tools such as a feeler gauge or dial caliper. An optional sled is a platform with two pieces of minitrack on each side and a dado in the middle in which the miter gauge can be secured quickly to a bar on the bottom of the sled that slides in the table saw miter gauge. A flip arm stop design with a removable back allows space for a zero clearance board on the front of an L-shaped fence extrusion. A T-shaped fence extrusion with a built-in zero-clearance board has a modified T-slot with an interlocking minitrack which allows the fence to be extended and secured with a standard bolt without the need for machining.

Owner:ALLEN IP

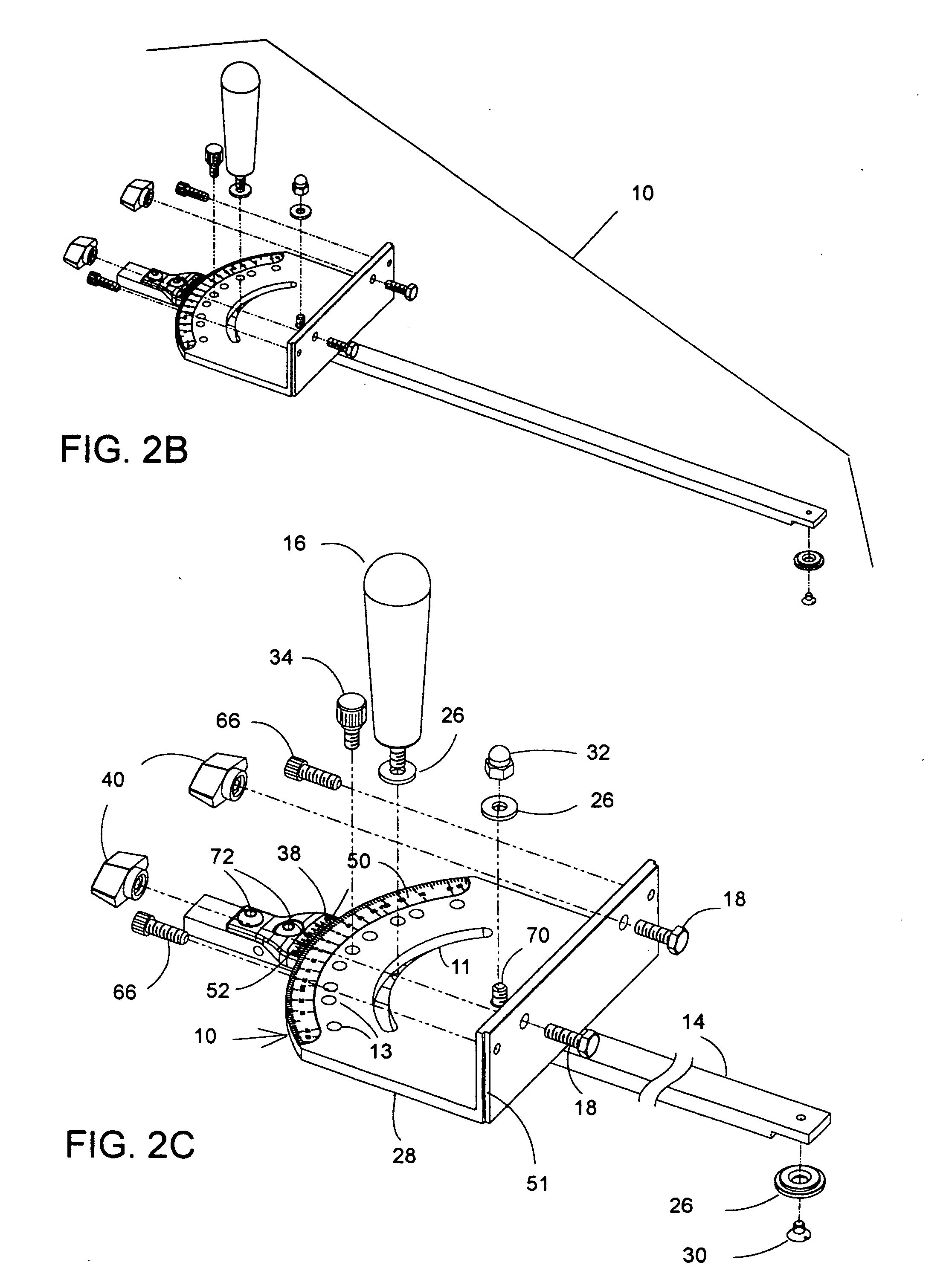

Cargo oil pump and turbine mounting and aligning method

ActiveCN103673813AEasy to understandEasy constructionMechanical measuring arrangementsEngineeringFeeler gauge

The invention relates to a cargo oil pump and turbine mounting and aligning method. The method includes: machining a temporary shaft, using the temporary shaft on a cargo oil pump or a turbine, and using a dial indicator and a feeler gauge to perform position measurement and adjustment so as to realize cargo oil pump and turbine mounting positioning and aligning. The method has the advantages that a floating shaft is replaced by the temporary shaft, instruments are rested on the temporary shaft for alignment and mounting, construction is convenient, tool manufacturing cost is lower, operation is simple, construction staff can understand and master easily, error rate during construction is low, equipment mounting precision is increased, and the method is applicable to cargo oil pump and turbine mounting and aligning.

Owner:中国船舶集团渤海造船有限公司

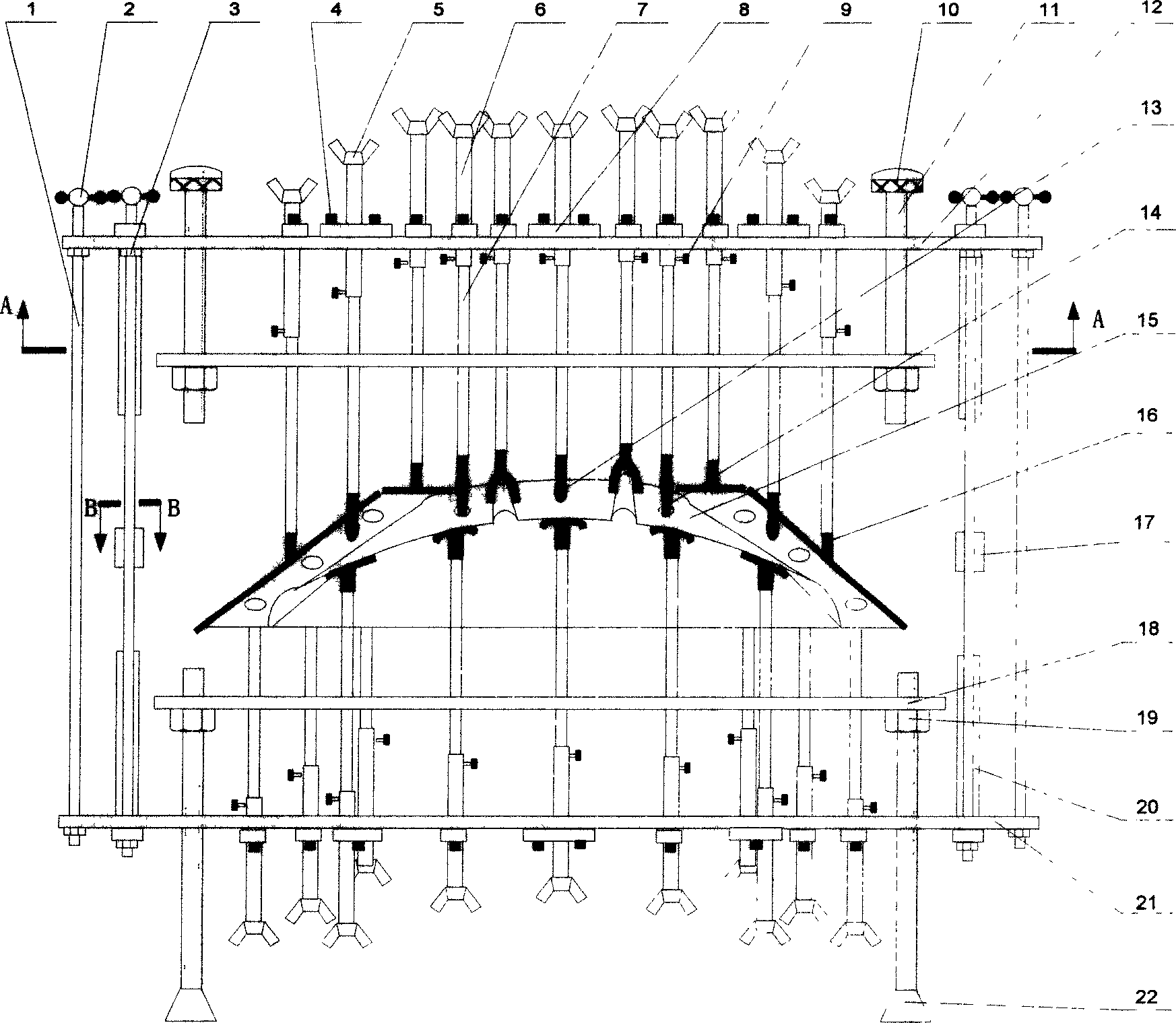

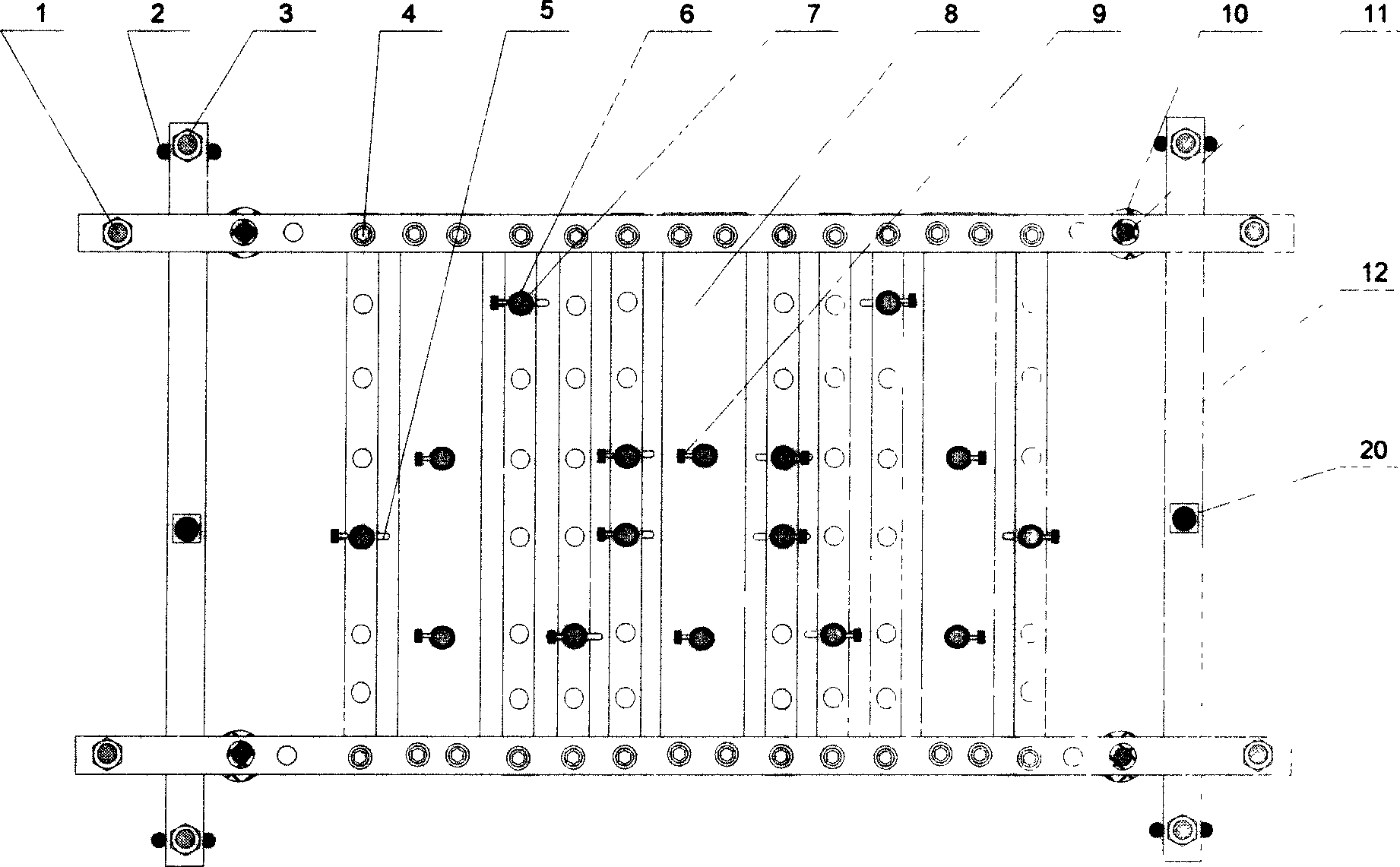

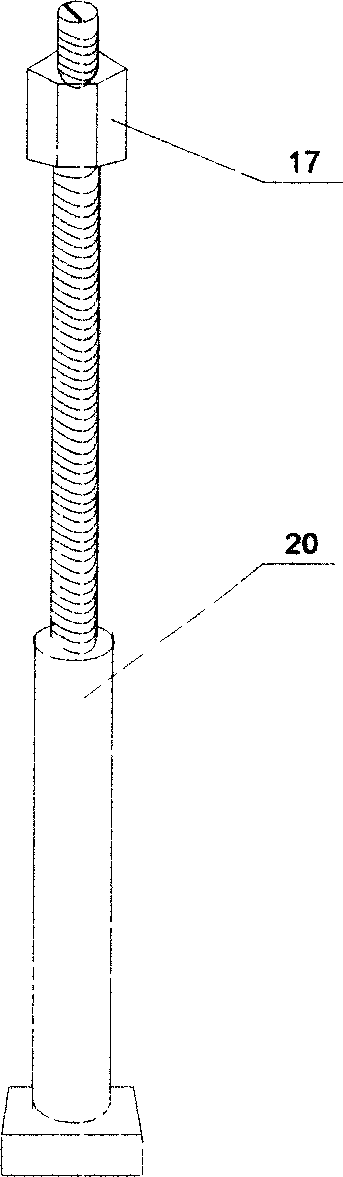

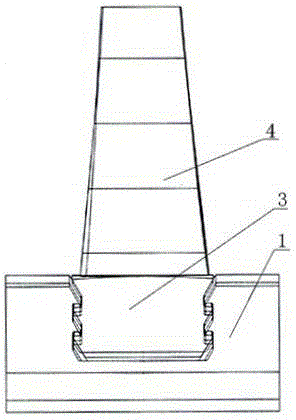

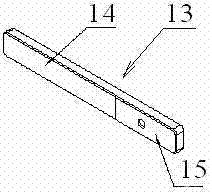

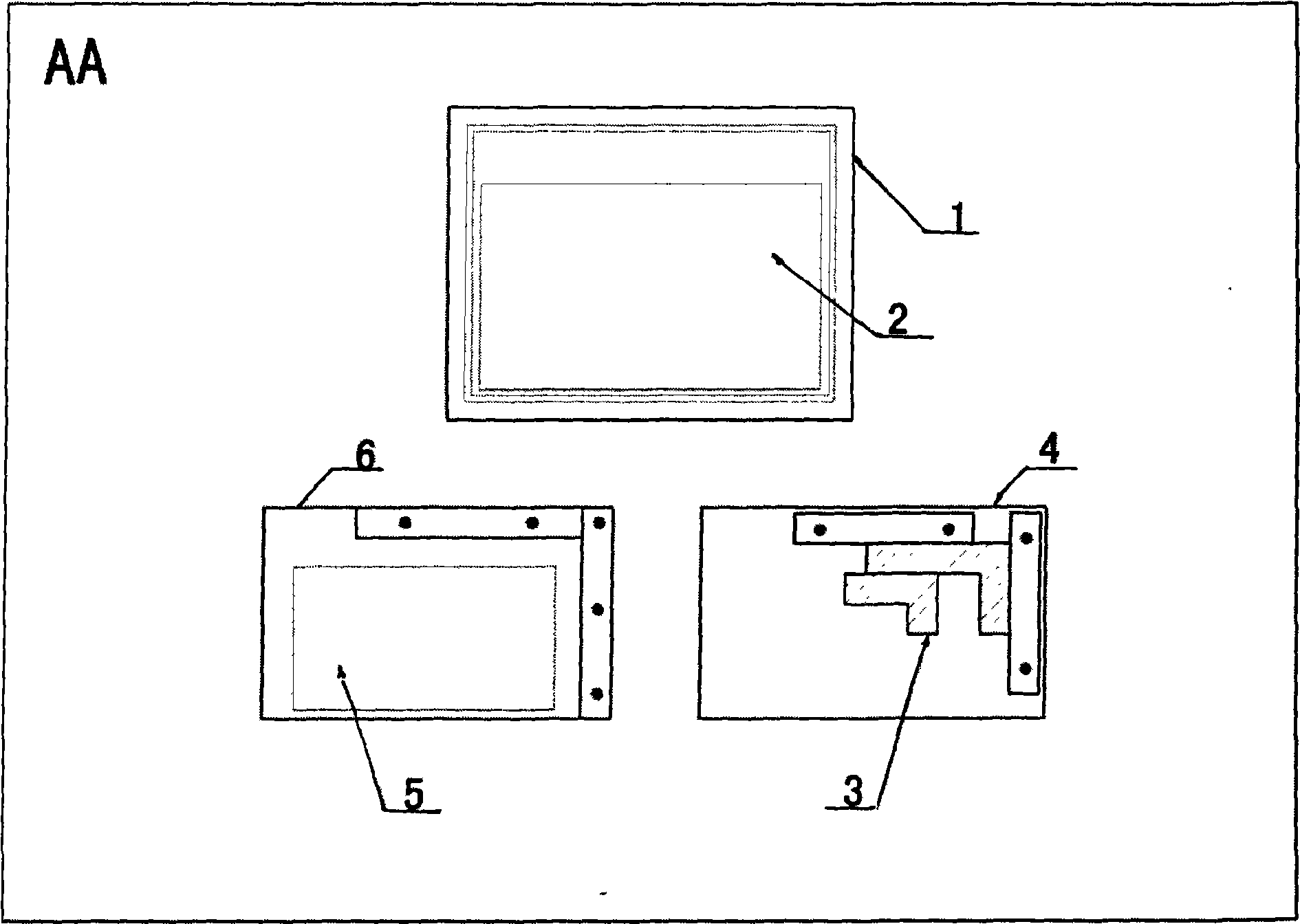

Flexible checking implement for large complicated carved punched thin-wall workpiece

InactiveCN1710374AIncrease flexibilityMeet process requirementsMechanical measuring arrangementsEngineeringFeeler gauge

A flexible detection tool of punching thin wall component with large complicated curve features including two sets of frames being arranged symmetrically and being connected by long foot screws , setting adjustable screw at four edges of frame , applying external through jacked with regulation screw at centre of width edge and a numbers of slats with replaceable scaled pin at length edge , setting two coordinate reference plates in parallel within frame for reading out coordinate value to check whether the value is in the tolerance or not and using filler gauge to check component size.

Owner:SHANGHAI JIAO TONG UNIV

Machining method for moving blade with tooth-form arc on rhombus face of blade root

ActiveCN105081691AThe method design is reasonable and ingeniousSolve the problem of poor positioning and clamping without positioning referenceWork clamping meansPositioning apparatusEngineeringFeeler gauge

The invention relates to a machining method for a moving blade with a tooth-form arc on the rhombus face of a blade root. The method includes the steps that blanking is conducted firstly; centering is conducted, a centre hole is drilled in the center point, and a hexagon is formed; a milling machine positions and clamps the blade and the blade crown end through the centre hole in the center of the blade crown end, and the dimension of the blade root to be machined is reserved; the radial face of the blade root is subjected to rough and finish milling, sawteeth on the radial face of the blade root are obtained through machining, and then the two lateral sides of the blade root are subjected to rough and finish milling and detected through a blade root socket gauge and a feeler gauge; central centre holes in the two ends of a blank are positioned and clamped, and the inner cambered surface and the back cambered surface of a steam channel are subjected to rough and finish milling; and the inner arc profile, back arc profile and adapter position of the steam channel are polished, the blade crown is cut in a liner manner, and machining is completed. The method has the beneficial effects that the design is reasonable and ingenious; the blank is centered in advance, the clamping block blade crown is reserved, and preparation is made for subsequent machining, clamping and positioning; the problem that positioning and clamping are difficult without a positioning reference is solved; and in the later machining process, the blade root socket gauge assists in detection, and single-head pliers can be centered and positioned, so that machining precision is improved, and machining efficiency is greatly improved.

Owner:NANTONG ZHONGNENG MACHINERY

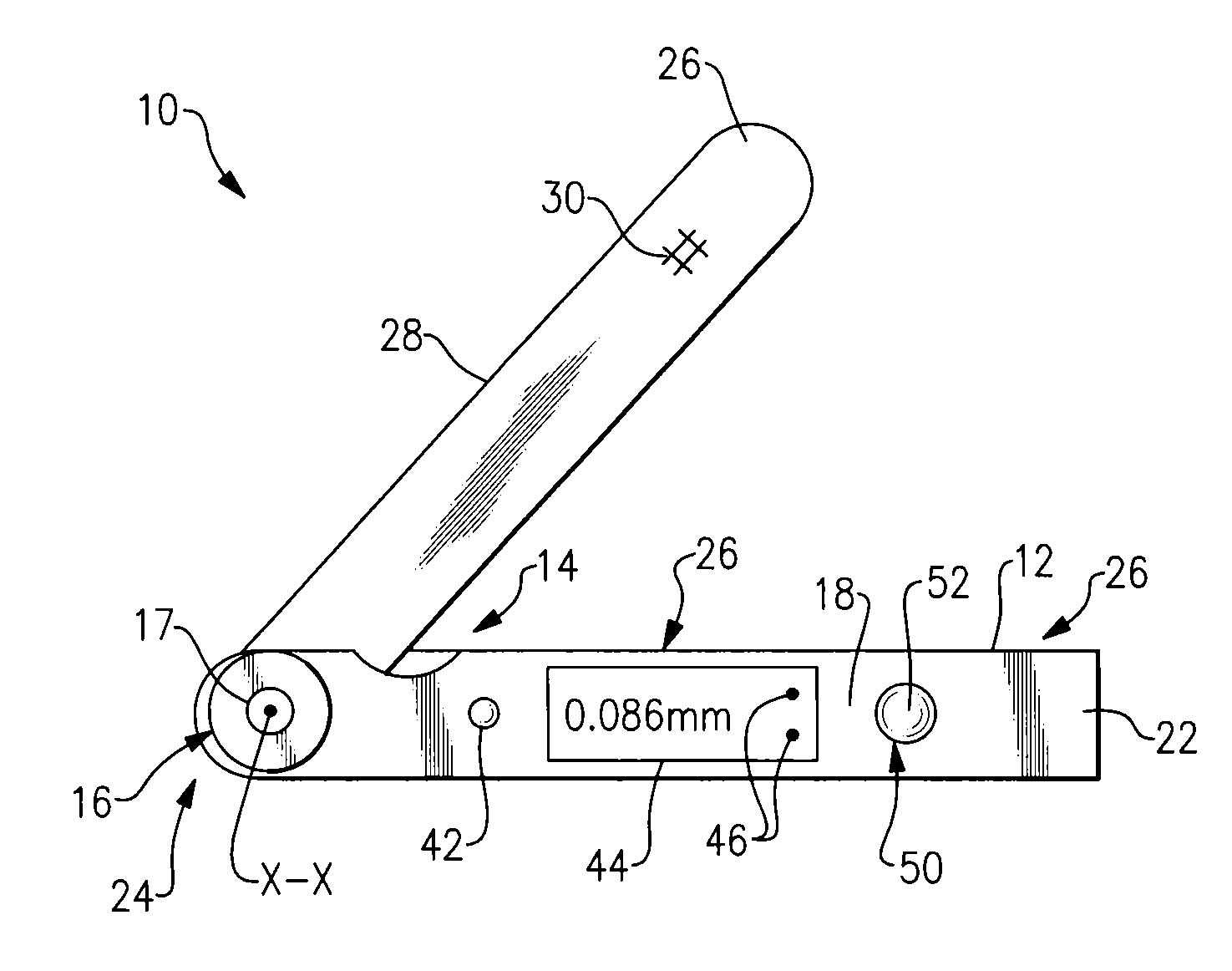

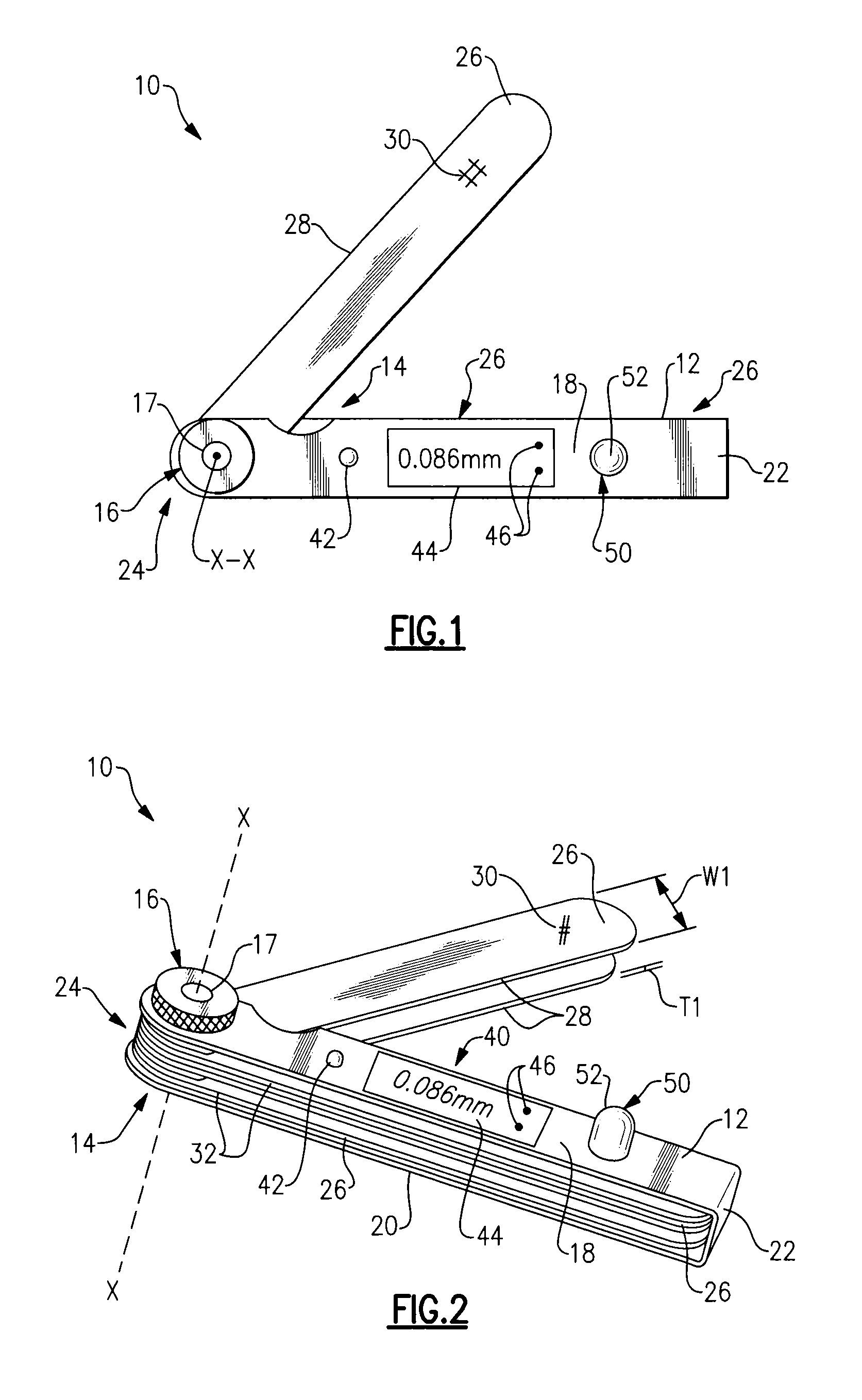

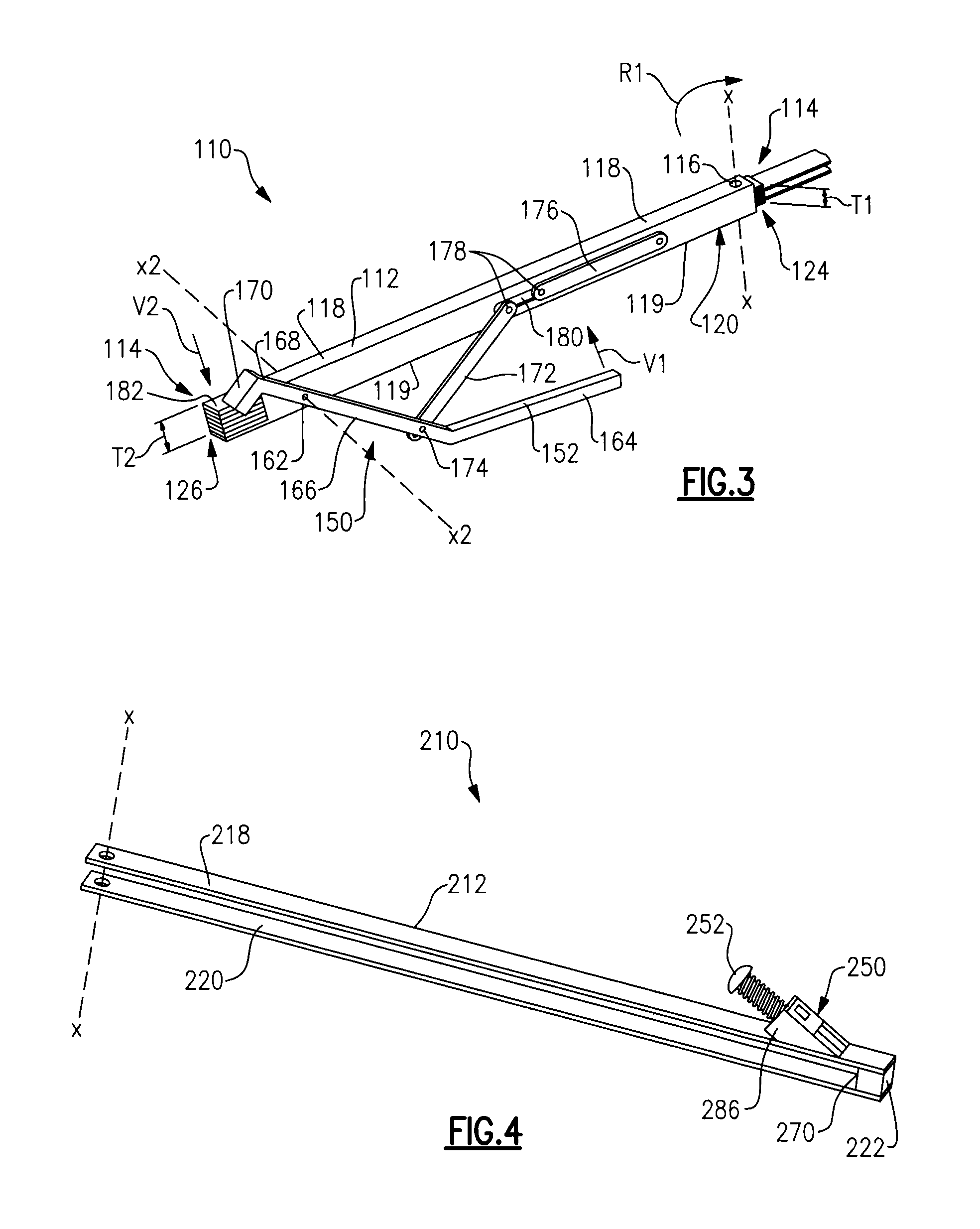

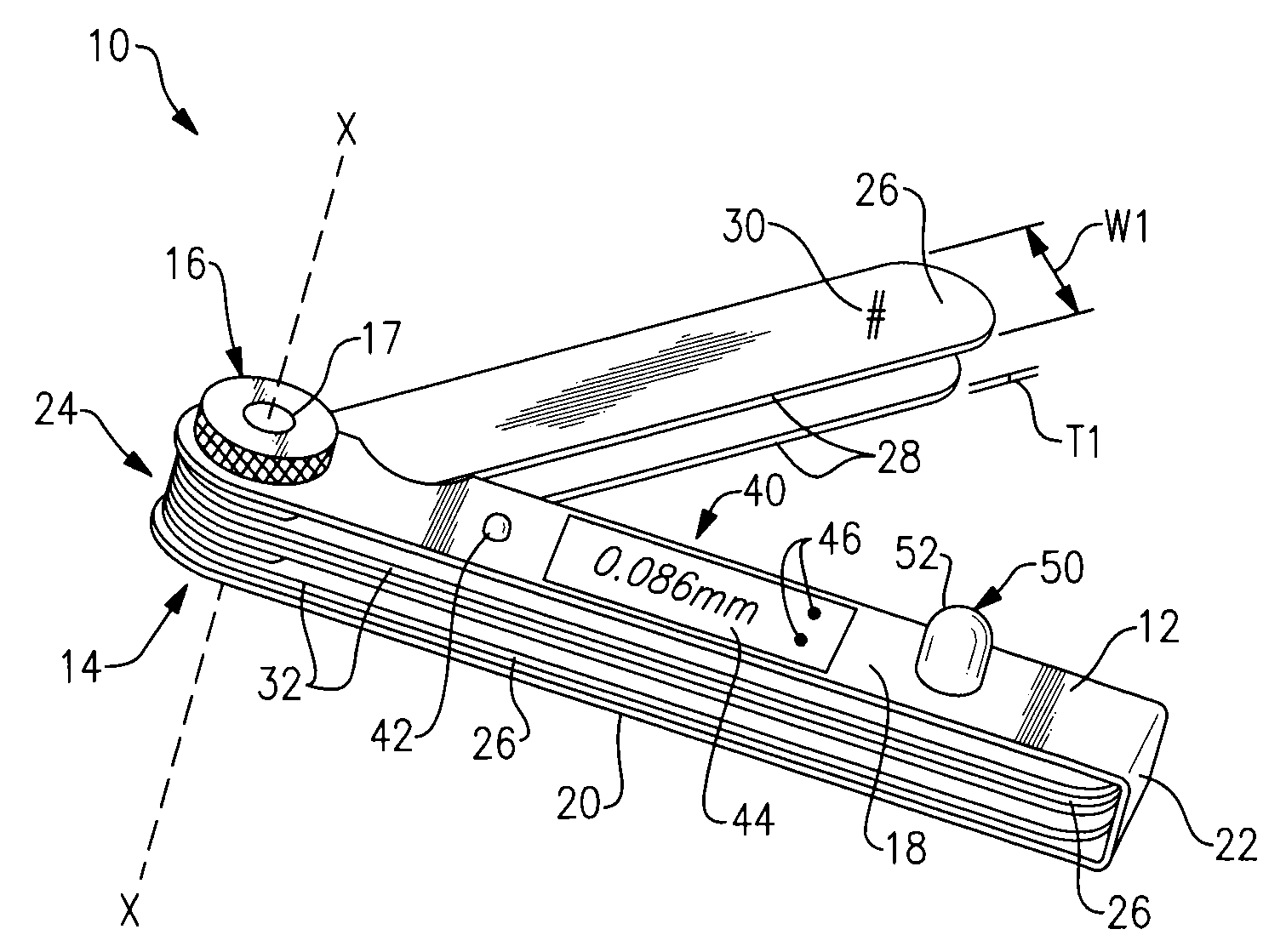

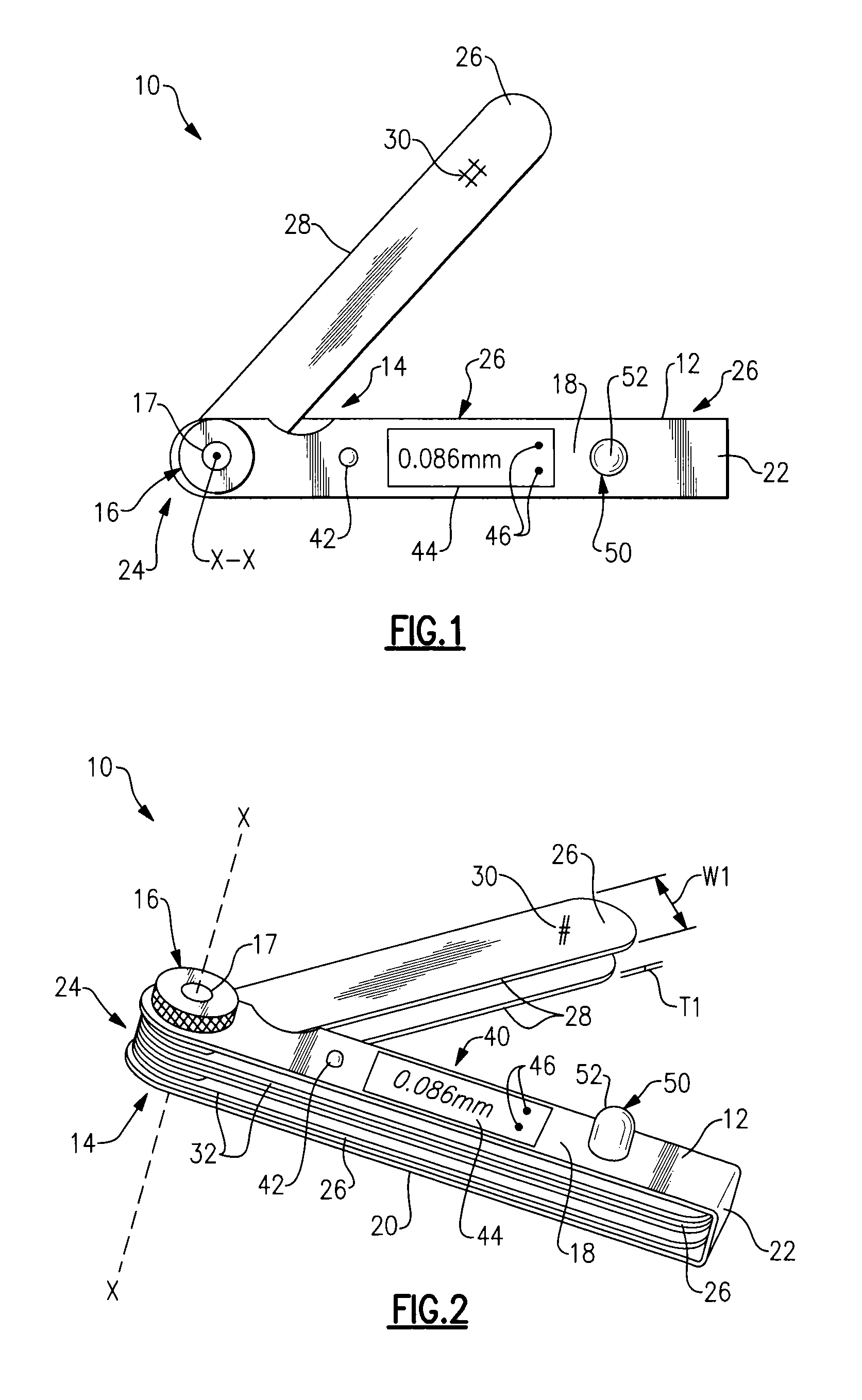

Digital feeler gauge and method of using same

ActiveUS20140109418A1Eliminate spacePlug gaugesMechanical thickness measurementsEngineeringFeeler gauge

The present application provides for feeler gauges. The feeler gauges include a plurality of elongate measuring leaves rotatably coupled on a common axis of rotation with an elongate housing. The leaves may be manually, selectively rotatable between a “home” position wherein the leaves are substantially aligned with the housing and an “extended” position wherein the leaves are spaced from the housing. The leaves may be relatively flexible and substantially flat such that they define a substantially constant thickness. One or more extended leaves may be used to measure the thickness of a clearance or gap. The gauges may be configured to detect, determine or measure the thickness of the leaves that are in the “home” position and / or the “extended” position, and thereby determine the total thickness of a clearance or gap measured by the extended leaves.

Owner:GENERAL ELECTRIC CO

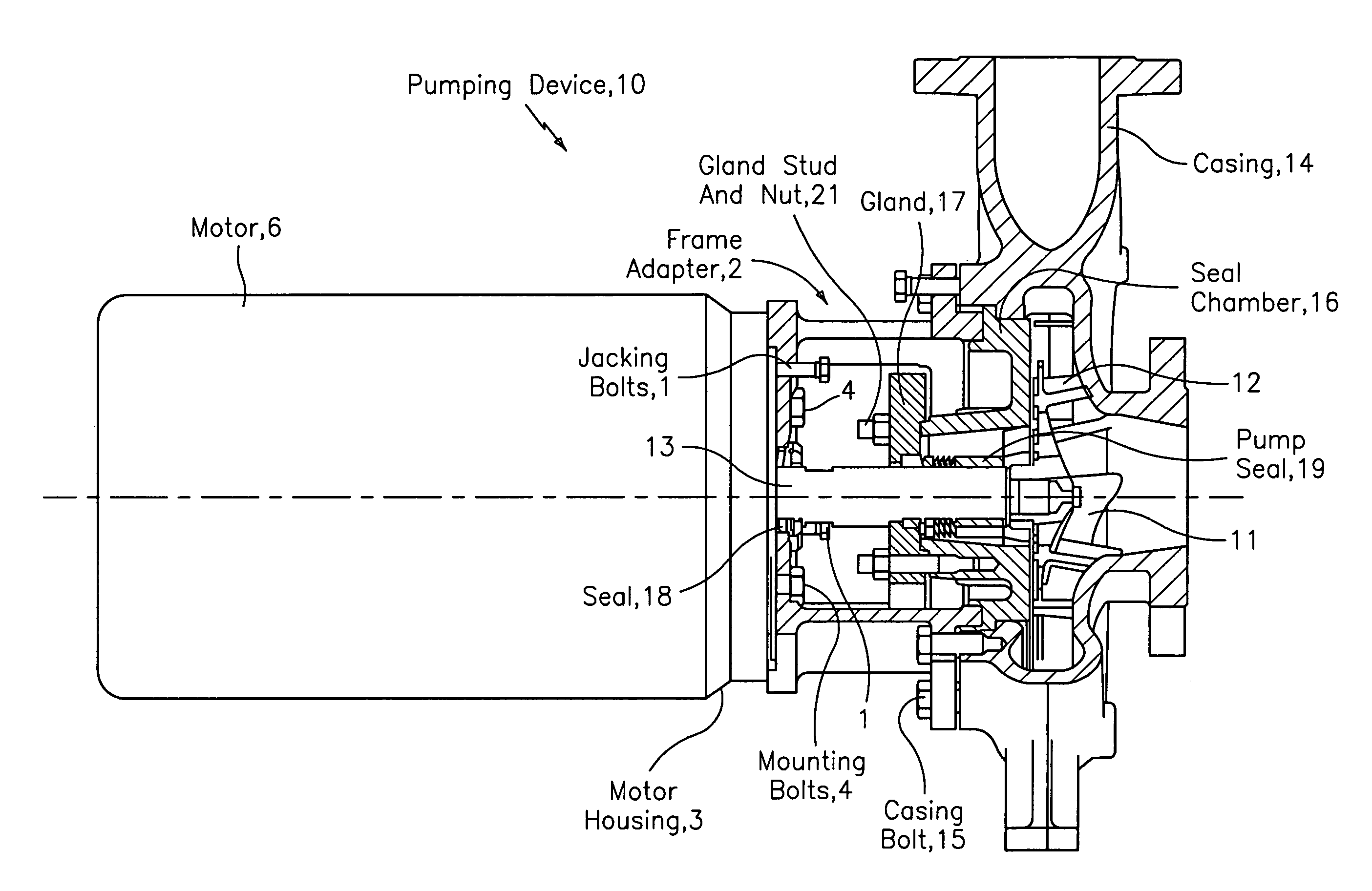

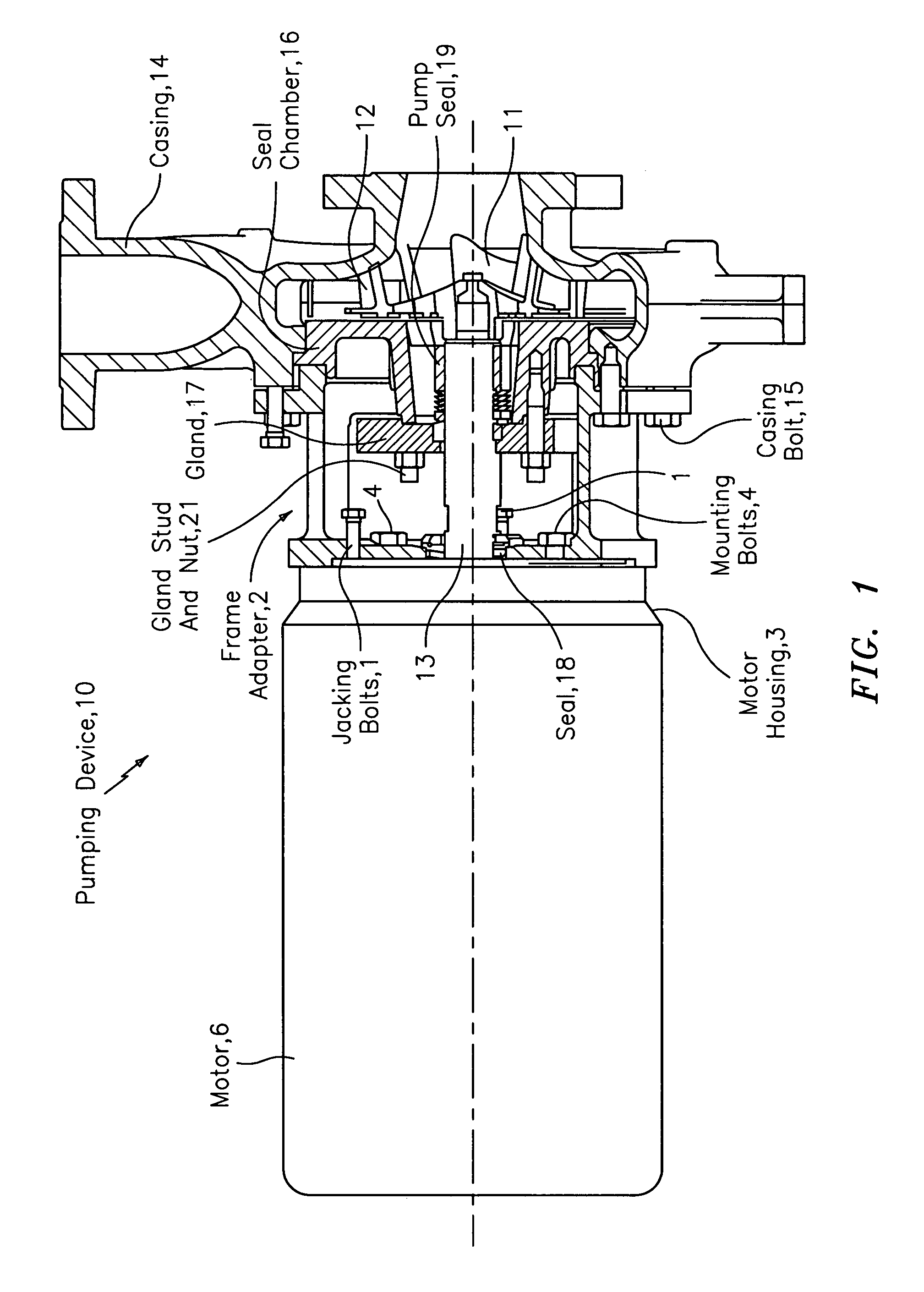

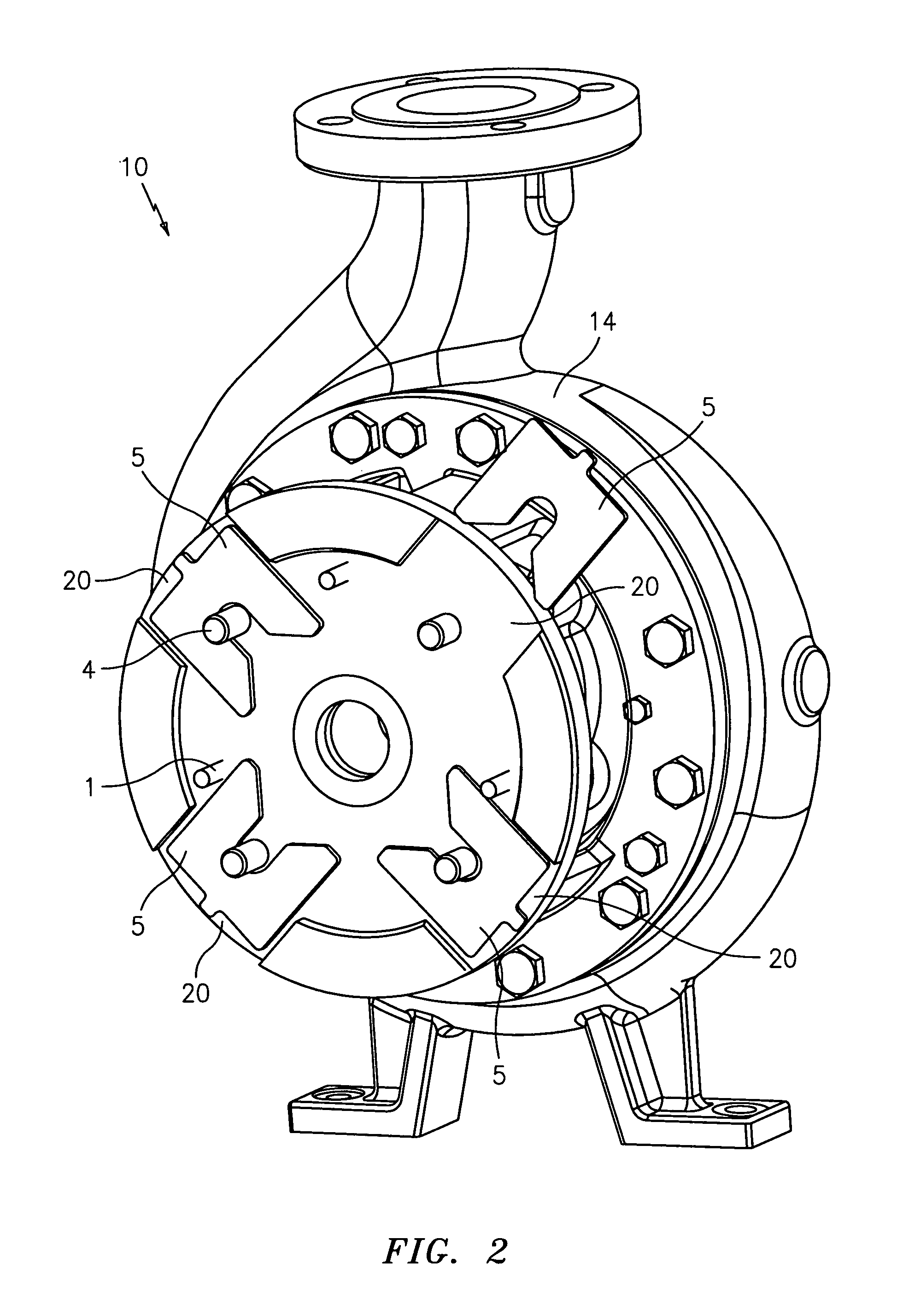

Impeller adjustment device and method for doing the same for close coupled pumps

A method and apparatus are provided for adjusting an impeller in a motor and impeller assembly of a pumping device. The method features steps of: tightening mounting bolts so as to move the motor and impeller assembly of the pumping device forward until the impeller touches a casing; inserting a feeler gauge in radial slots in a frame adapter and measuring a gap between a housing of the motor and the frame adapter; determining a desired impeller adjustment distance based on the gap and the desired impeller running clearance; selecting at least one shim having a thickness that corresponds to the desired impeller adjustment distance; loosening the mounting bolts and threading jacking bolts arranged in the rear of the pump frame adapter so that the jacking bolts push against the housing of the motor, and the shims can then be inserted into the radial slots; inserting the shims into the radial slots; backing out the jacking bolts; and securing the mounting bolts locking the motor and impeller assembly in position so that the impeller is at the desired impeller adjustment distance in relation to the casing. The frame adapter assembly features a frame adapter having four radial slots to enable access to the gap for measurement with a feeler gauge and for insertion of the shim to accurately set the impeller clearance.

Owner:ITT MFG ENTERPRISES LLC

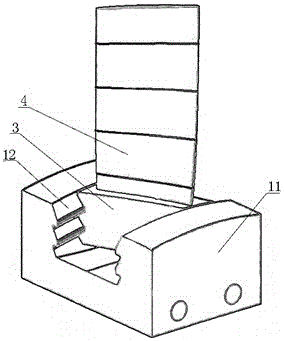

Scraper leveling device and method for manufacturing three-dimensional object

InactiveCN105817623AAchieve levelingAvoid damageAdditive manufacturing apparatusMeasurement devicesData displayEngineering

The invention discloses a scraper leveling device and method for manufacturing a three-dimensional object. The scraper leveling device comprises two or more distance sensors and a display unit used for displaying detection data of the distance sensors. The two or more distance sensors are arranged on a scraper fixing mechanism and located at the same horizontal position, and accordingly a forming base plate and a scraper are leveled according to the data displayed by the display unit and detected by the distance sensors. According to the scraper leveling device and method for manufacturing the three-dimensional object, equipment damage caused by adjustment through a feeler gauge is avoided. Meanwhile, detection is conducted through the distance sensors, accordingly, by means of the scraper leveling device and method for manufacturing the three-dimensional object, the scraper leveling accuracy is higher, and operation is simpler and more standard.

Owner:HUNAN FARSOON HIGH TECH CO LTD

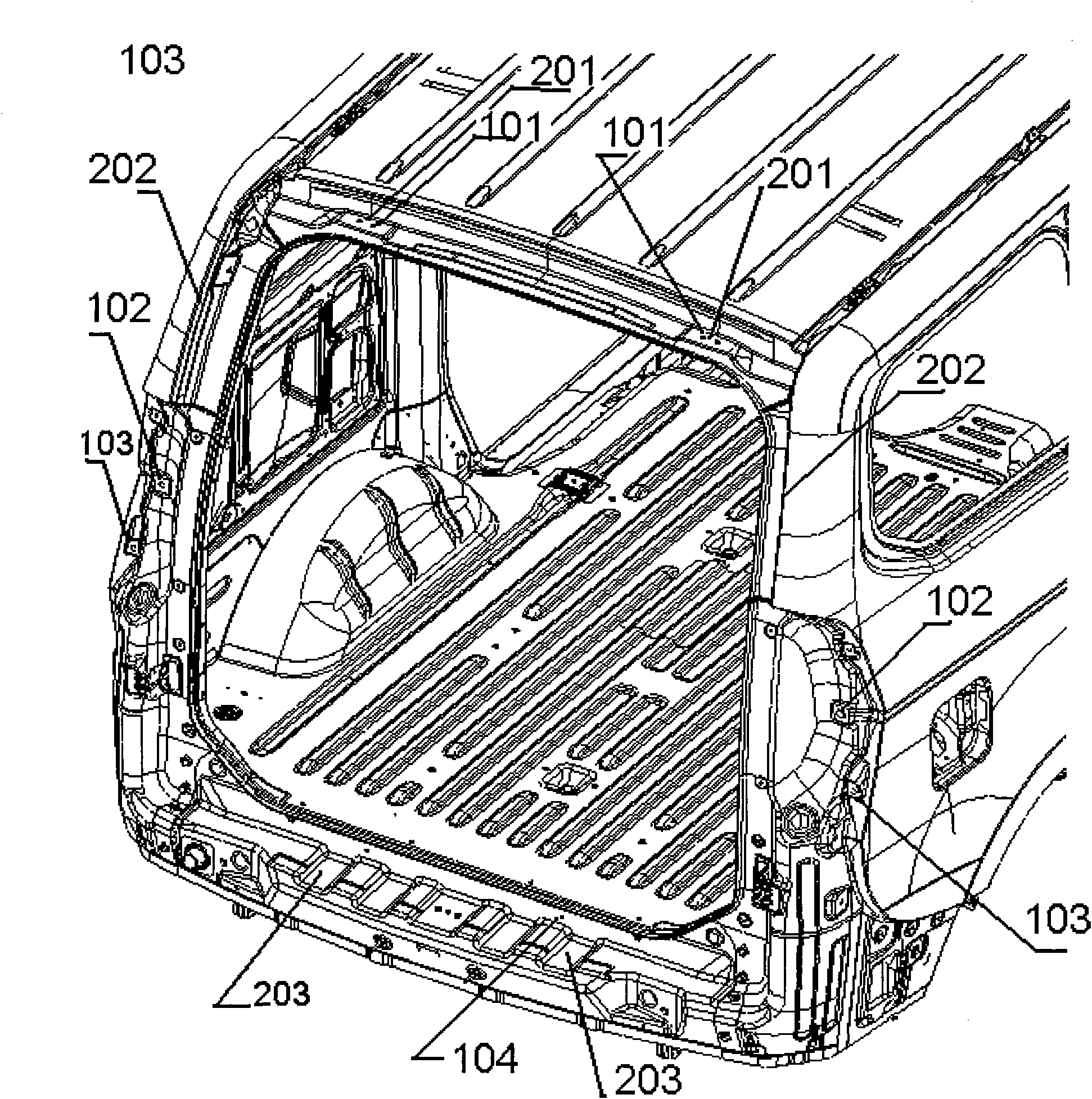

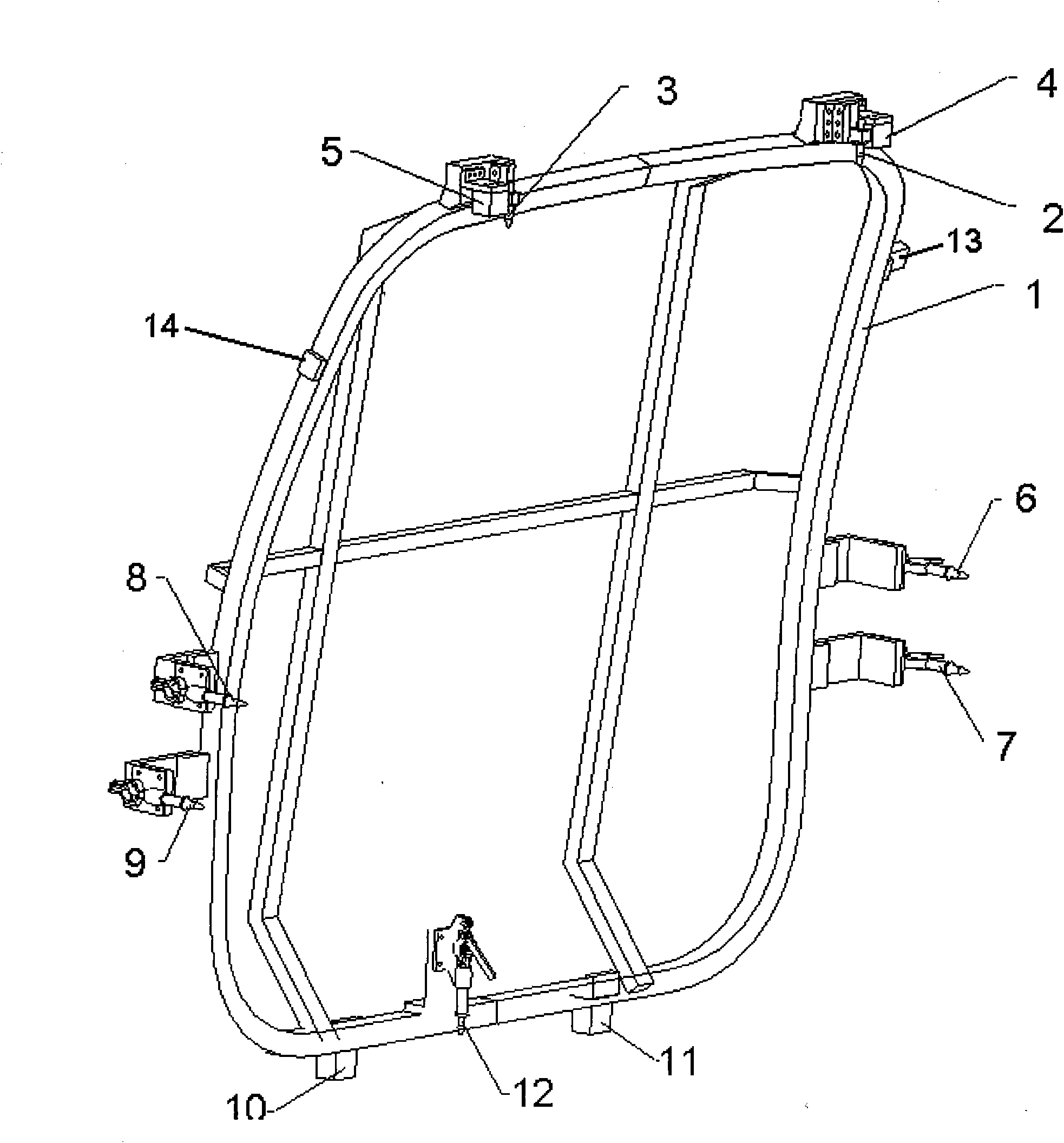

White automobile body tail doorframe checking tool and tail doorframe size detection method

InactiveCN102486364ARealize online detectionTo achieve the purpose of quality controlMechanical clearance measurementsFeeler gaugeEngineering

The invention relates to the field of manufacturing of automobiles, and provides a white automobile body tail doorframe checking tool and a tail doorframe size detection method. The tool comprises a frame as well as a first locating standard pin, a second locating standard pin, a first locating standard block, a second locating standard block, and an auxiliary locating pin which are arranged on the frame and also comprises a measuring pin and a measuring block which are arranged on the frame. The method comprises the following steps: A, debugging a measuring tool on an entire car measuring inspection device, and leading and fastening each pin and each block at theory positions; B, selecting the top of a tail doorframe and a hole as positioning standards, leading the measuring tool on a welded automobile body, and insetting the auxiliary positioning pin and the measuring pin; and C, using a feeler gauge to detect the gap between the measuring pin and the measuring block and the gap between the hole and top of the tail doorframe, if the gaps are within a specialized range, judging that the gaps are qualified, and if the gaps are out of the specialized range, judging that the gaps are disqualified. The tool provided by the invention can be used for simply, conveniently and accurately detecting the size of the tail doorframe, thereby realizing real-time monitoring on the size variation of the tail doorframe, and effectively controlling the appearance quality of an entire car.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

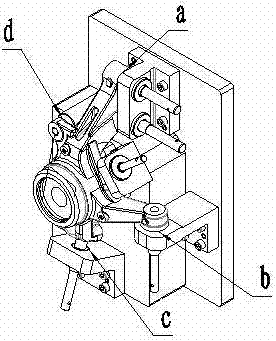

Method for inspecting complex space integration position of steering knuckle type part

InactiveCN102207365ASolve the problem of difficult measurement of spatial positionReasonable methodAngles/taper measurementsMechanical clearance measurementsEngineeringFeeler gauge

The invention, which belongs to the machining inspection technology, discloses a method for inspecting an complex space integration position of a steering knuckle type part. The method includes a step of determining an only position of the part which needs to be inspected in a testing fixture. The step comprises that: a main locating hole of the inspected part is corresponding to a locating shaft which is fixed with a pedestal; other locating holes of the inspected part are corresponding to locating pins which are fixed with the pedestal so that the only position of the inspected part can be determined by the locating shaft and the locating pins. The method includes the step of inspecting a position relation of each hole of the inspected part. The step comprises that: latches are inserted into guide holes liners of bearings, wherein the bearings are fixed with the pedestal; the latches are slide in the liners of the bearings and whether the latches can pass through the holes of the inspected part is determined. The method also includes the step of inspecting distances between every surface and the position relations of every surface of the inspected part. The step comprises that: a feeler gauge is placed in a gap of the inspected part and a bearing surface and in a gap of the inspected part and locating pin surfaces and whether the feeler gauge can be placed into is determined. By using the method, inspections in working operations can be realized. And inspection efficiency is high. Operators do not need high skill quality.

Owner:洛阳古城机械有限公司

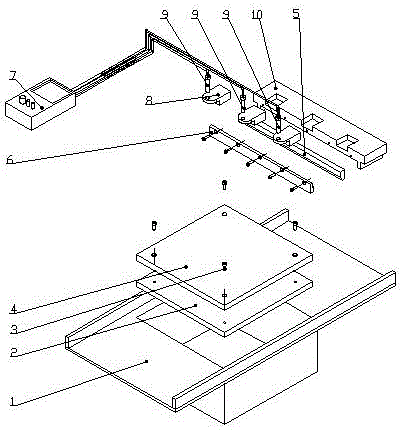

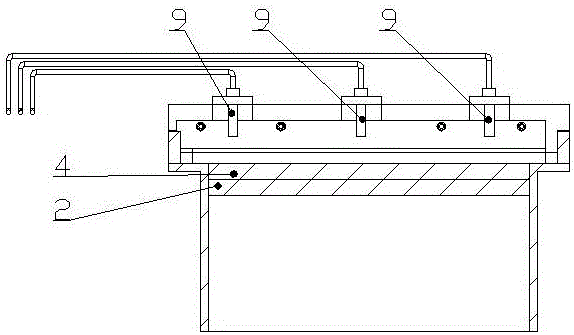

Automatic filler gauge system and automatic stamping machine provided with same

The invention discloses an automatic filler gauge system and an automatic stamping machine provided with the same. Filler gauges are not fixed to the same device all the time but switched from a standby position above a filler gauge box and a working position within an area of a paper carrying plate as the procedure goes on. In the feeding-in process, the filler gauges are moved out of the filler gauge box and put on slide blocks located at the working position; and then, in the recycling process, as the slide blocks move from the working position to the standby position above the filler gauge box, the filler gauges lose support from the paper carrying plate, and therefore both filler gauges which are fed in fall directly and freely from the slide blocks into the filler gauge box for recycling. In this way, the number of file pages between the two filler gauges is not fixed but calculated according to the thickness of a total file and can be free of limitation of fixation positions.

Owner:贤之邦(北京)智能科技有限公司

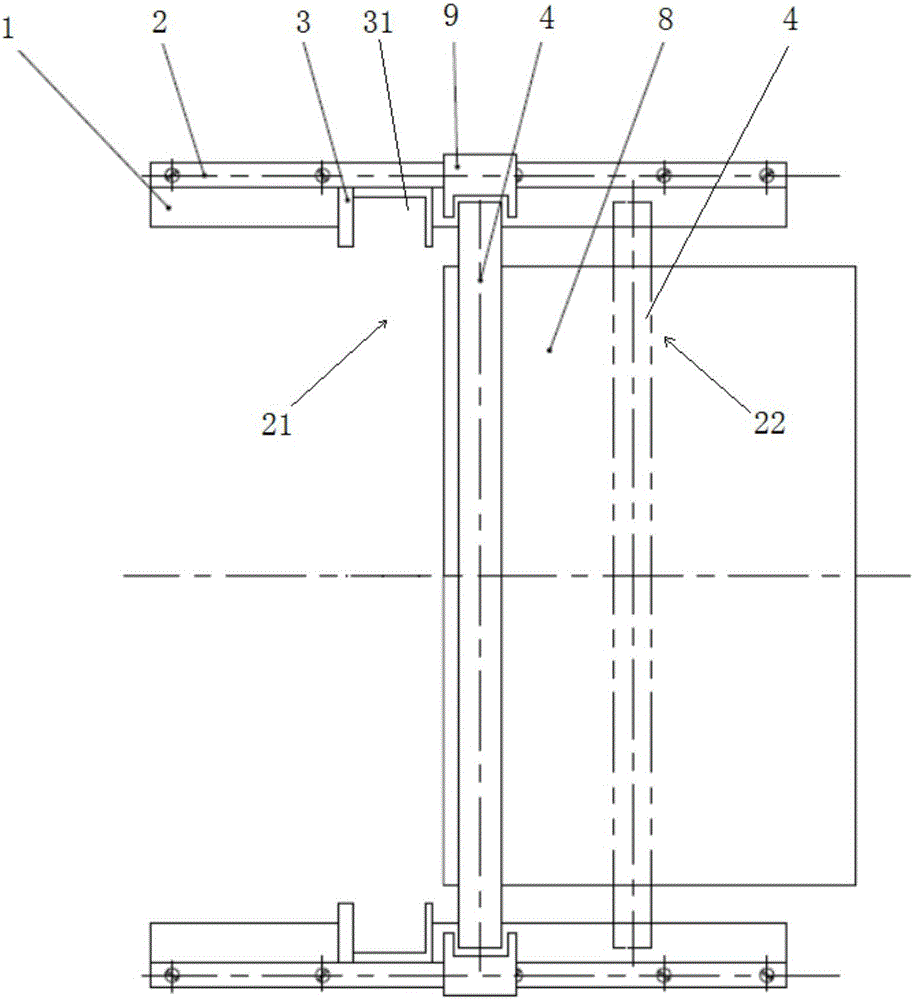

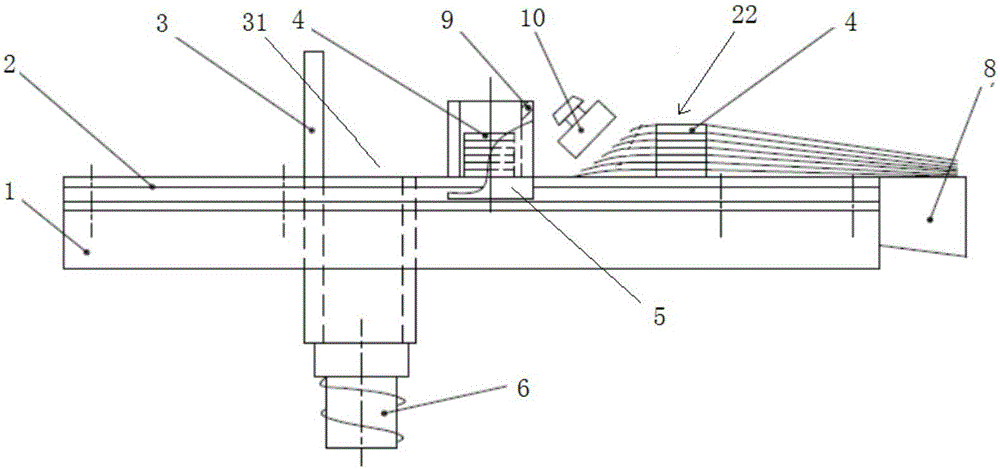

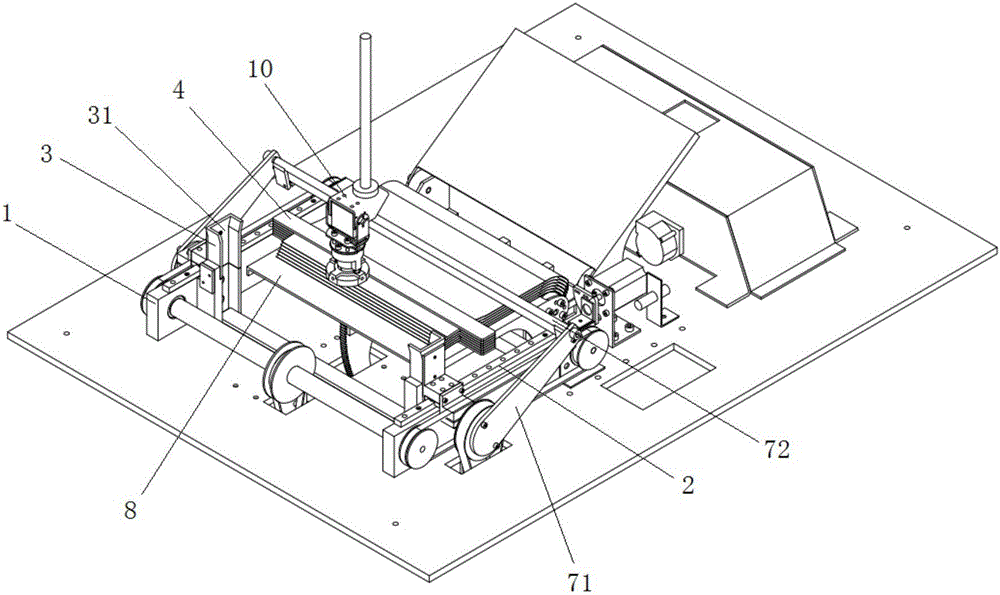

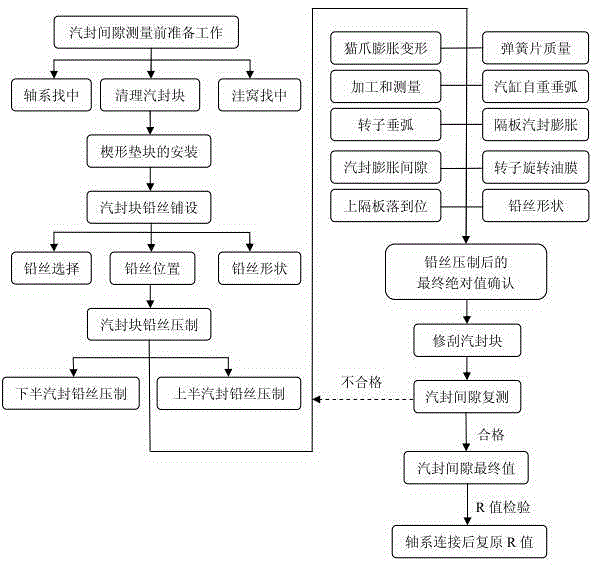

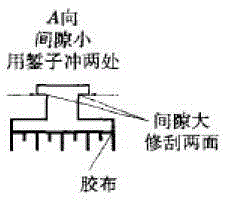

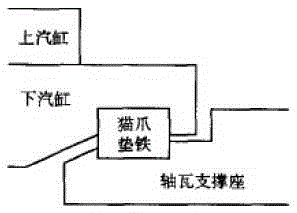

Turbine steam seal clearance adjustment method

InactiveCN105317471ASimple processEasy to operateLeakage preventionMachines/enginesEngineeringFeeler gauge

The invention relates to a turbine steam seal clearance adjustment method. The turbine steam seal clearance adjustment method which is simple in process, convenient to operate and capable of digitally, accurately and truly quantifying the steam seal clearance adjustment quantity is not available at present. The turbine steam seal clearance adjustment method is characterized in that by the adoption of the mode that lead wires are pressed in a circumferential uniform division manner, a clearance, at a horizontal junction surface position, of a lower half cylinder sleeve is measured through a feeler gauge; as for steam seal clearances of other portions, the lead wires of corresponding specifications are pasted to steam seal teeth, ends are fixed, a rotor is hoisted to a working position, the lead wires pasted to the steam seal teeth are each rolled to form a groove mark, and the rotor is hoisted out; the thickness of the remaining portion of the groove mark of each lead wire is measured through a steam seal clearance measuring scale, the thicknesses are actual values of the steam seal clearances, the actual values are compared with design values, and adjustment values of the steam seal clearances are worked out; and then the turbine steam seal clearances are adjusted according to the adjustment values. The turbine steam seal clearance adjustment method is simple in process, convenient to operate and capable of accurately and digitally quantifying the steam seal clearance adjustment quantity.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

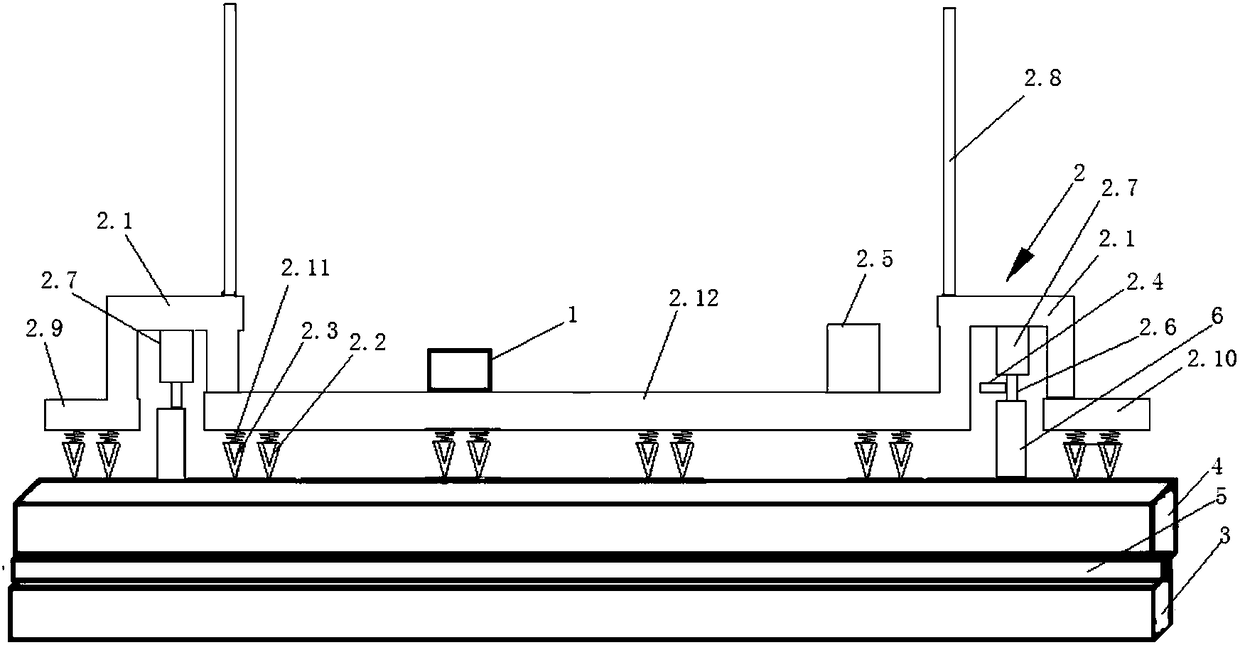

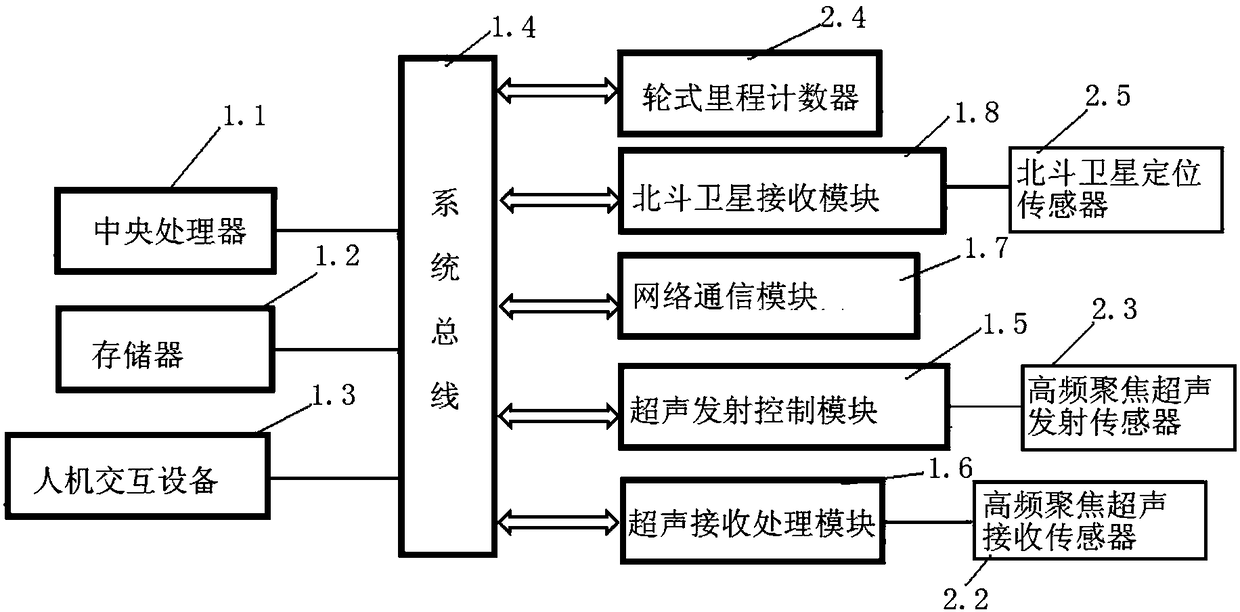

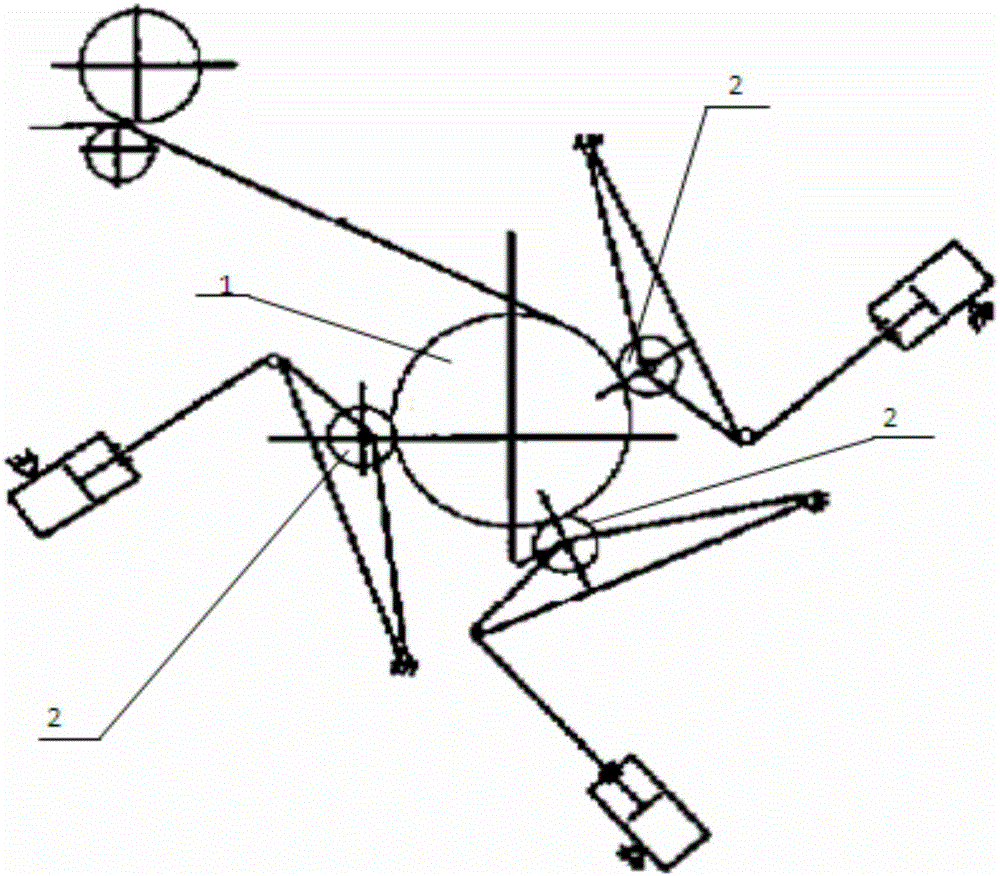

CRTS II slab-type ballastless track mortar bonding quality detection equipment and method

ActiveCN108344801ARealize the detection of bonding quality by high-frequency focused ultrasonic reflection imagingOvercoming technical problems with large limitations in inspectionsAnalysing solids using sonic/ultrasonic/infrasonic wavesBond qualityNetwork communication

The invention relates to CRTS II slab-type ballastless track mortar bonding quality detection equipment. The CRTS II slab-type ballastless track mortar bonding quality detection equipment comprises amain machine and a detection vehicle; the main machine comprises a central processing unit, an ultrasonic emission control module, an ultrasonic receiving processing module, and a network communication module; the detection vehicle comprises a detection vehicle bottom plate, a detection vehicle left side plate, a detection vehicle right side plate, a wheel-type speedometer, a track wheel assembly,two hydraulic rods, two supports, and a plurality of high frequency focusing ultrasonic transmit-receive sensor sets. The CRTS II slab-type ballastless track mortar bonding quality detection equipment is capable of solving a technical problem in the prior art that relatively large limitation is caused by detection on mortar layer open joint and disengagement using tools such as feeler gauges andsteel rulers.

Owner:铁科检测有限公司 +2

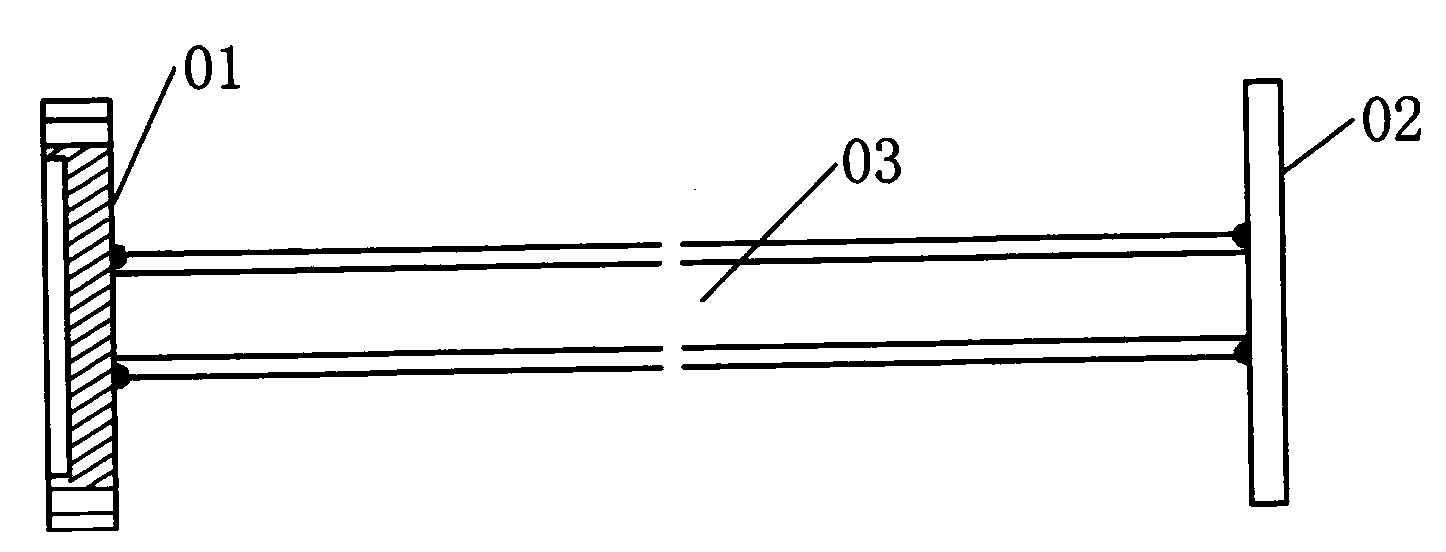

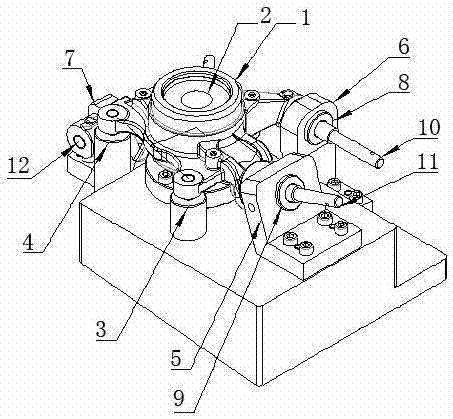

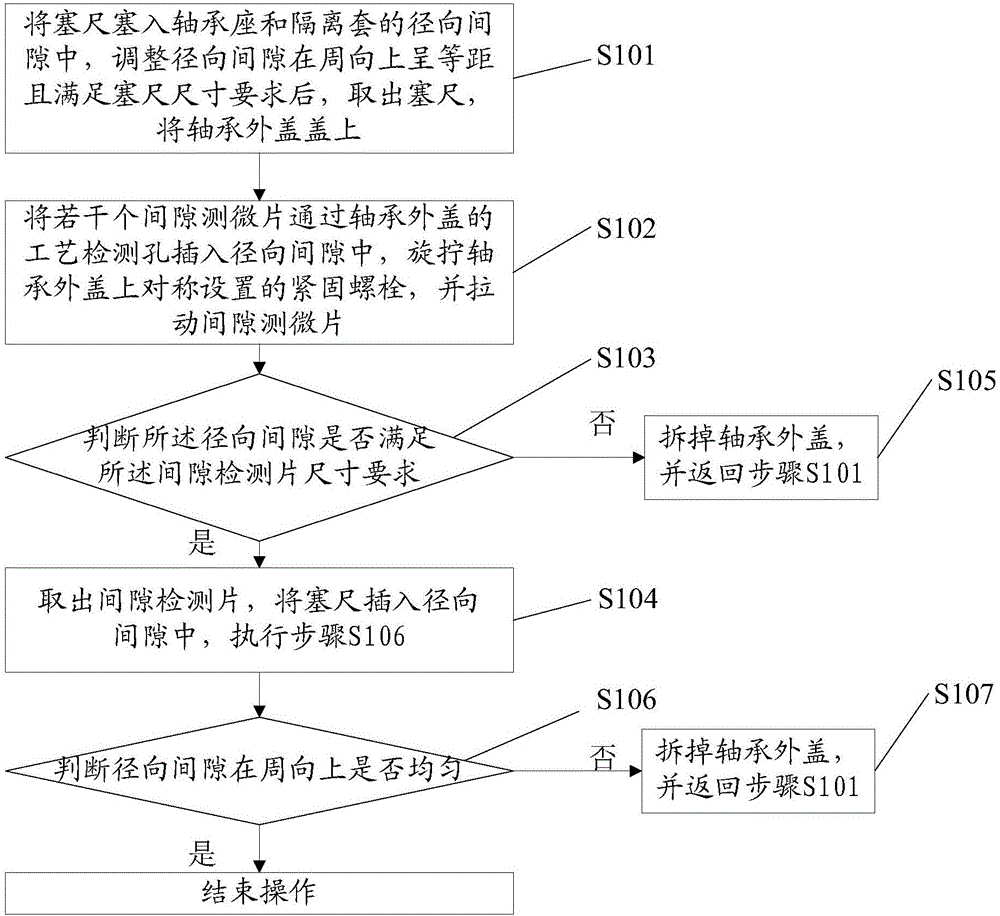

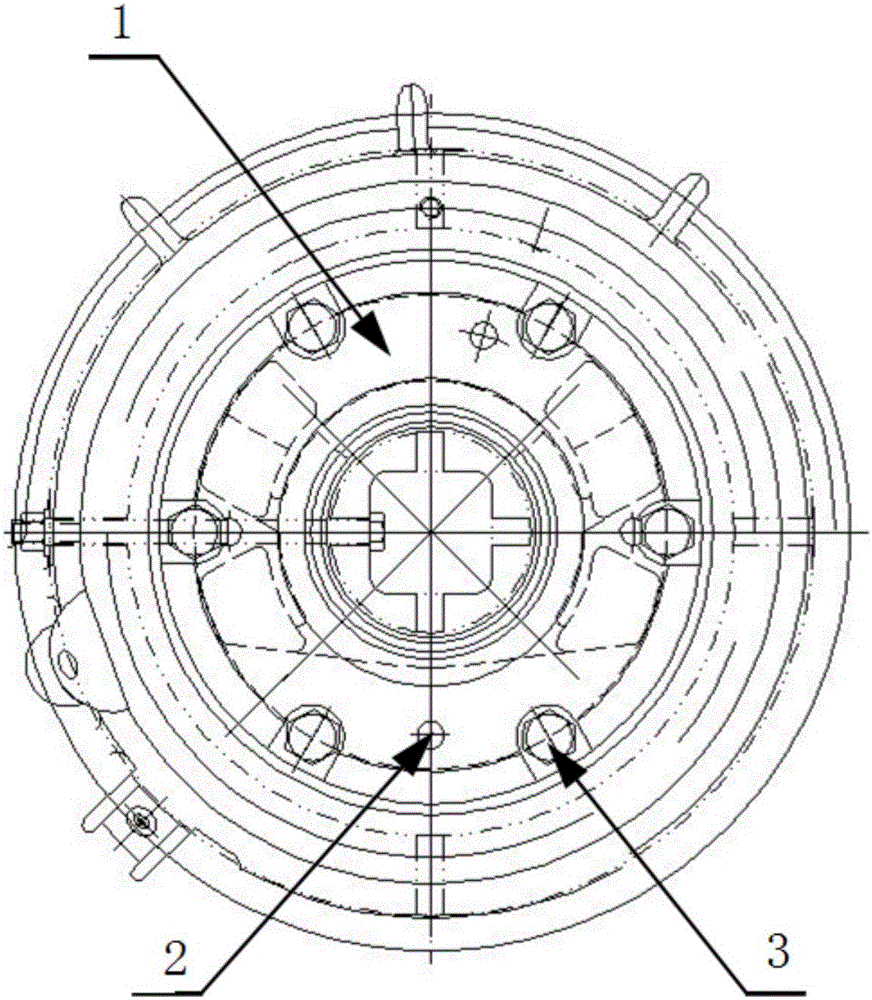

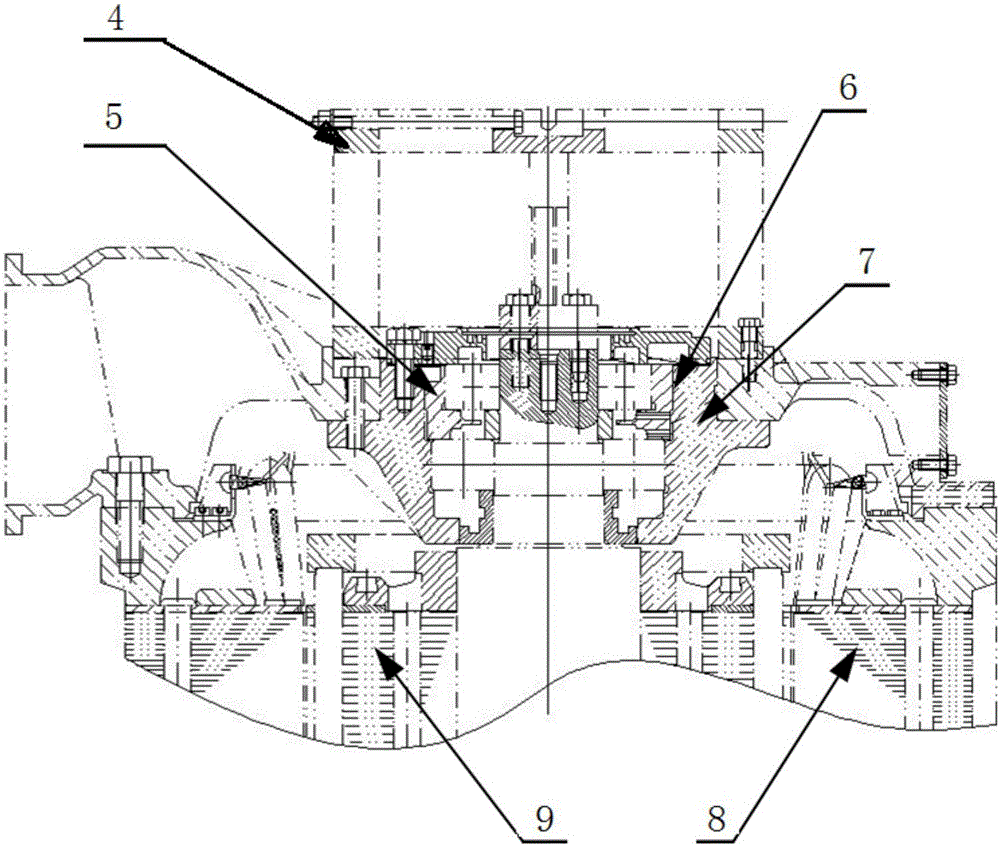

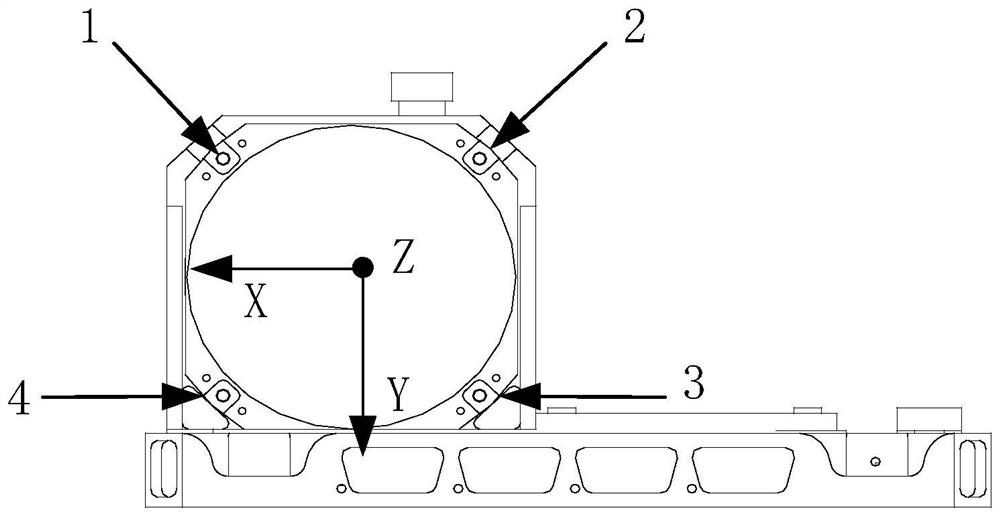

Motor bearing assembling clearance detecting method and device

ActiveCN104949601AAccurate radial clearanceImprove product qualityMechanical clearance measurementsEngineeringFeeler gauge

The invention discloses a motor bearing assembling clearance detecting method. The method comprises steps as follows: S101, a feeler gauge is inserted in radial clearance between a bearing block and an isolating sleeve, the feeler gauge is taken out and a bearing outer cover is put on a bearing after the radial clearance is equally spaced in the circumferential direction through adjustment and meets the size requirements of the feeler gauge; S102, a plurality of clearance detecting pieces are inserted into the radial clearance through process detection holes in the bearing outer cover, fastening bolts symmetrically arranged on the bearing outer cover are screwed tightly, and the clearance detecting pieces are pulled; S103, whether the radial clearance meets the size requirement of the clearance detecting pieces is judged, if yes, the step S104 is performed, and otherwise, the step S105 is performed; S104, the clearance detecting pieces are taken out, the feeler gauge is inserted into the radial clearance, and the step S106 is performed; S105, the bearing outer cover is taken down, and the step S101 is performed again; S106, whether the radial clearance is uniformly spaced in the circumferential direction is judged, if yes, operation ends, and otherwise, the step S107 is performed; S107, the bearing outer cover is taken down, and the step S101 is performed again. The invention further discloses a motor bearing assembling clearance detecting device. The stability of clearance adjustment of the bearing is improved.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

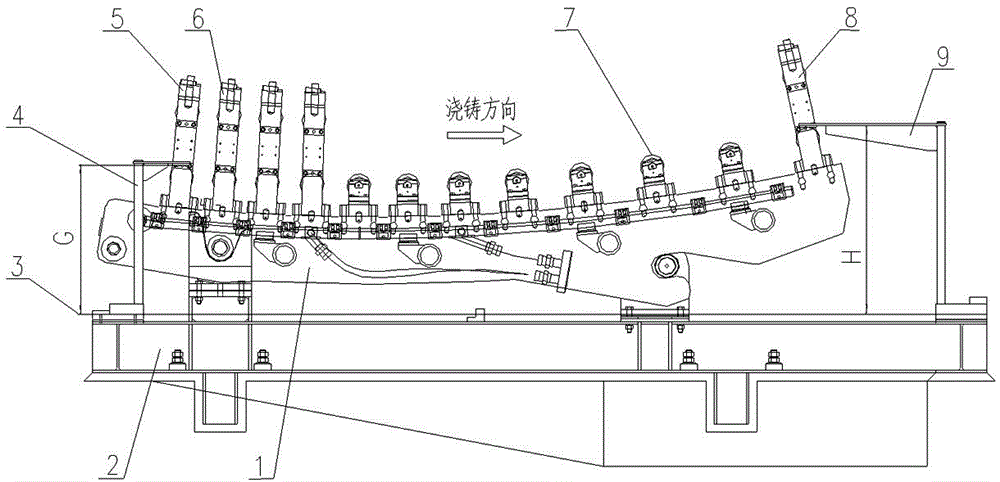

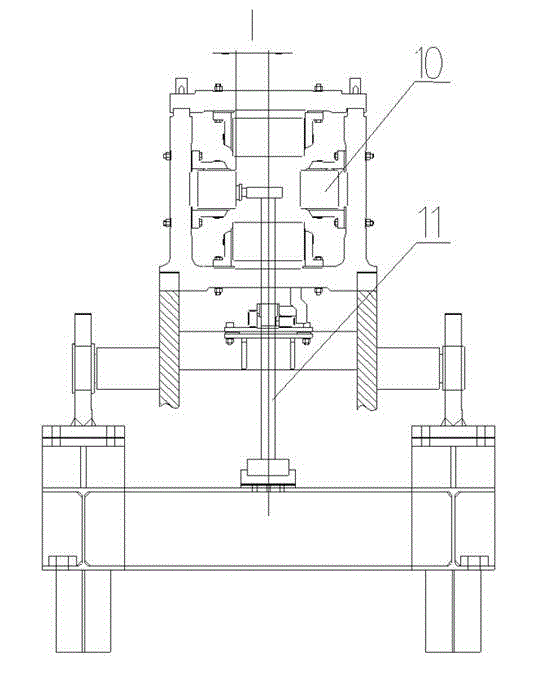

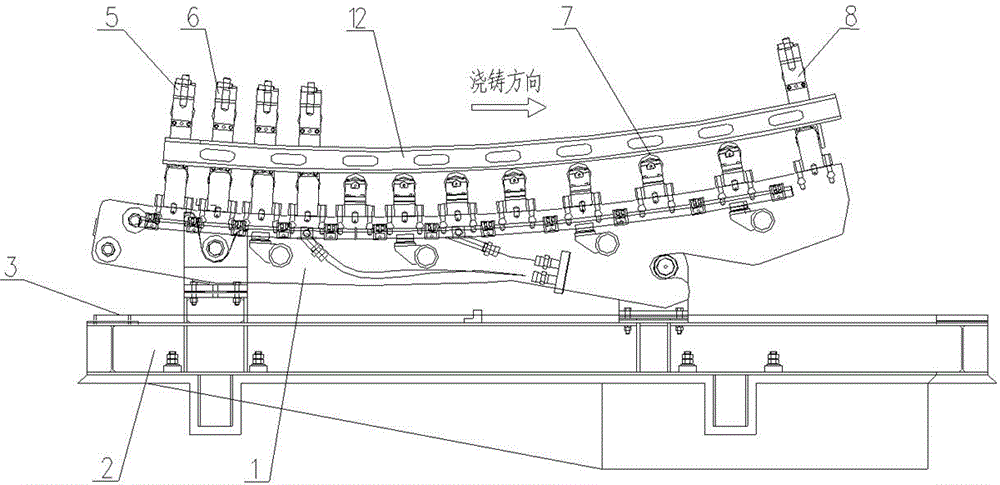

Offline rapid arc-aligning method for movable segment of arc-shaped billet continuous casting machine

The invention discloses an offline rapid arc-aligning method for a movable segment of an arc-shaped billet continuous casting machine. The method comprises the following steps: fixing the inner arc side of the movable segment upwards on an arc-aligning table; measuring the heights from the upper surfaces of outer arc rolls of roll frames at the two ends to a measuring table respectively , and adjusting the heights to specified ranges; measuring the distance between a left side roll or a right side roll of the roll frames at the two ends and a central line respectively, and adjusting the distance to a specified range; placing an arc-aligning sample plate on the outer arc rolls by taking the outer arc rolls of the roll frames at the two ends as supporting points, measuring the amount of clearance between the outer arc roll on each roll frame in the middle and the arc-aligning sample plate by using a feeler gauge, and adjusting the amount of clearance to a specified range; attaching one side face of the arc-aligning sample plate to the side rolls on one side of the roll frames at the two ends in a way of being tangential to two roll surfaces, measuring the amount of clearance between the side roll on each roll frame in the middle and the arc-aligning sample plate by using the feeler gauge, and adjusting the amount of clearance to a specified range; measuring the roll interval between two adjacent inner arc rolls, and adjusting the roll interval to a specified range; measuring the roll interval between two adjacent side rolls, and adjusting the roll interval to a specified range. The offline rapid arc-aligning method has the characteristics of high arc-aligning accuracy and rapidness and convenience in arc alignment.

Owner:WUKUN STEEL

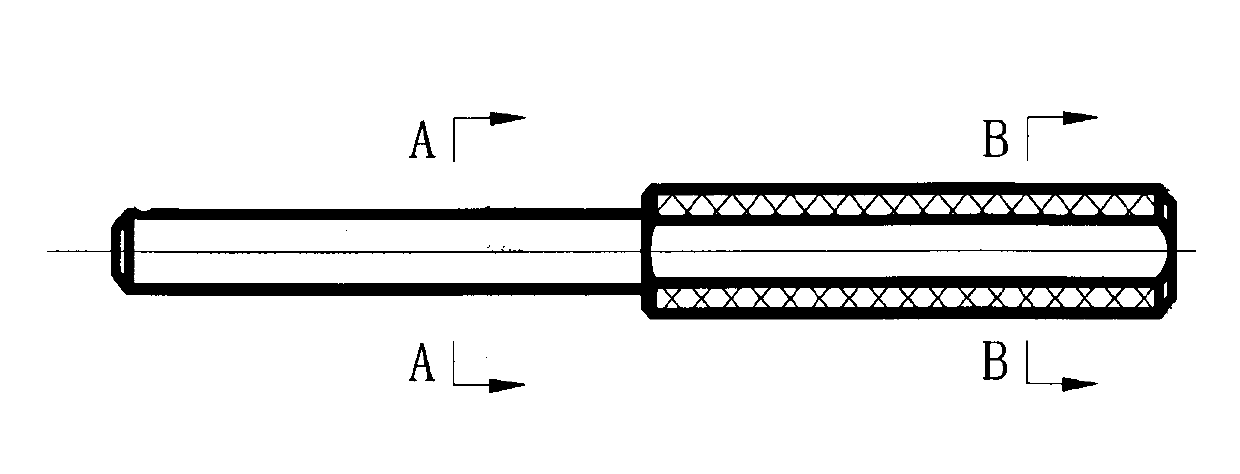

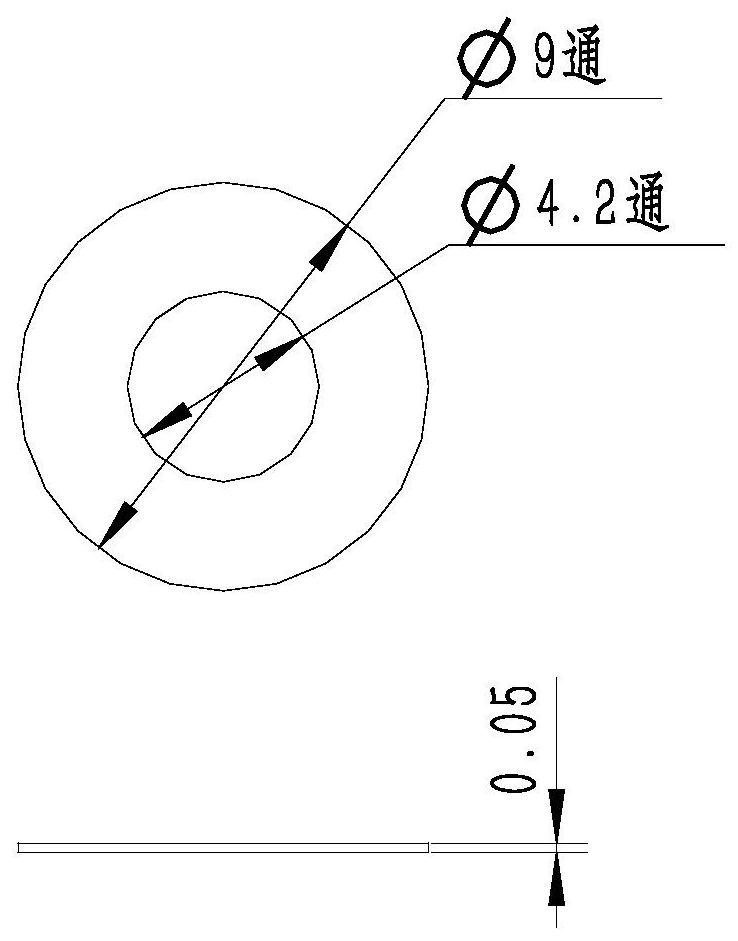

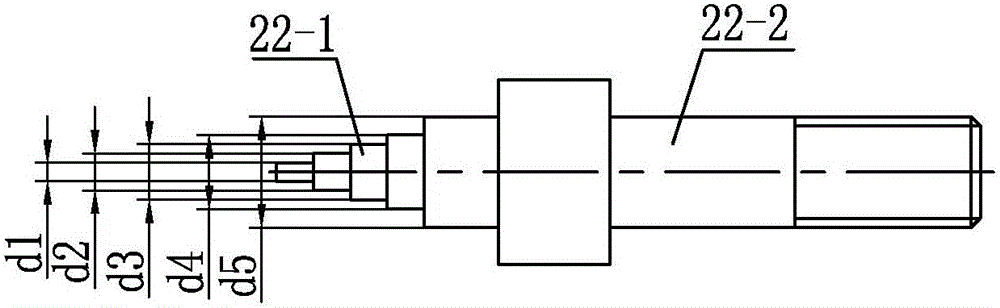

Rhombus plug gauge processing method

ActiveCN103128512ASolve processing difficultiesReduce processing difficultyFeeler gaugeGrinding wheel

The invention provides a rhombus plug gauge processing method includes the following steps of preparing materials, selecting forge piece blanking which is intact in materials, and free from flaws and sand holes, carrying out lathe operator process, miller process, heat treatment process, sand blowing process, surface treatment process, and cutter grinding process, firstly grinding a D surface and a surface parallel to the D surface until required sizes are reached, then enabling a rhombus plug gauge to be clamped on a sine platform, enabling the grinded D surface and the surface parallel to the D surface to face the left side face and the right side face of the sine platform, wherein two non-grinded surfaces face the upper surface and the lower surface of the sine platform, calculating thickness of a feeler gauge according to angle of the rhombus, enabling the feeler gauge to be cushioned under the sine platform, enabling a grinding wheel to begin to carry out cutting feed along the track of the grinding wheel, firstly grinding an E surface, then turning the rhombus plug gauge to begin to grind a surface parallel to the E surface after the E surface is well grinded, carrying out fitter process, and carving marks. The rhombus plug gauge processing method reduces processing difficulty of the rhombus plug gauge, and ensures accuracy requirements of the rhombus plug gauge.

Owner:SHENYANG AIRCRAFT CORP

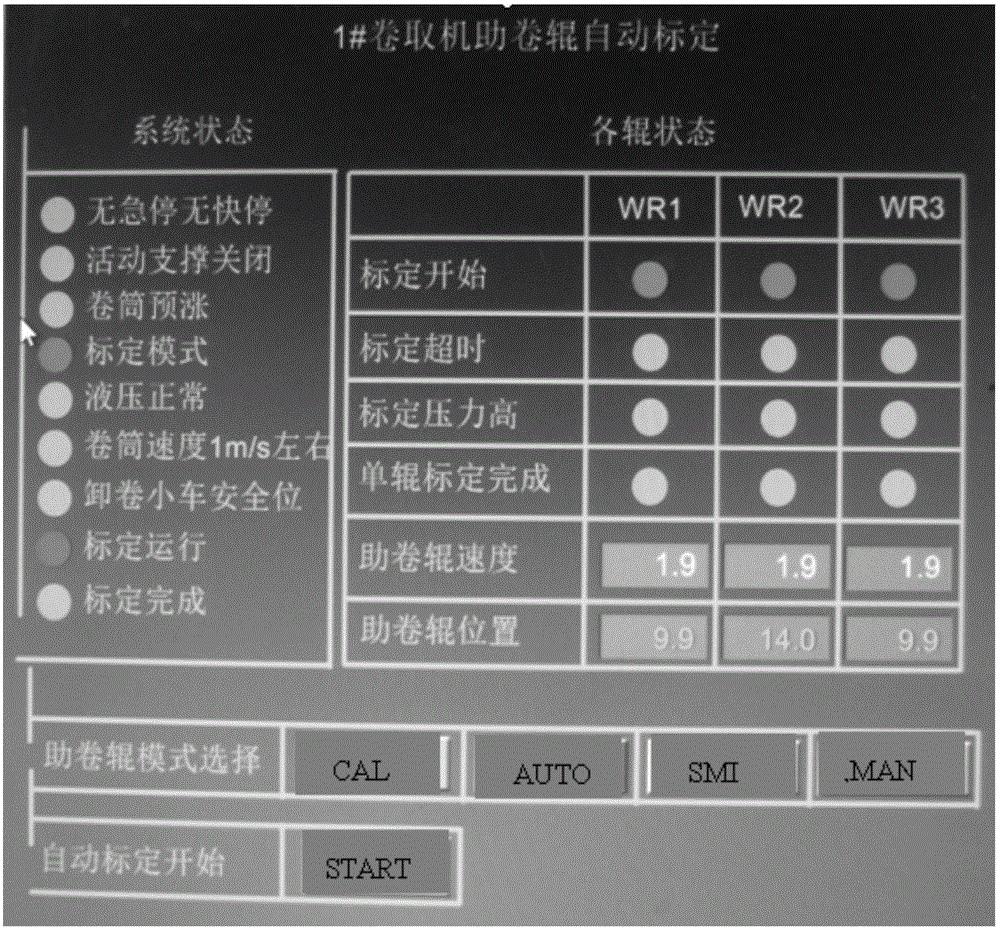

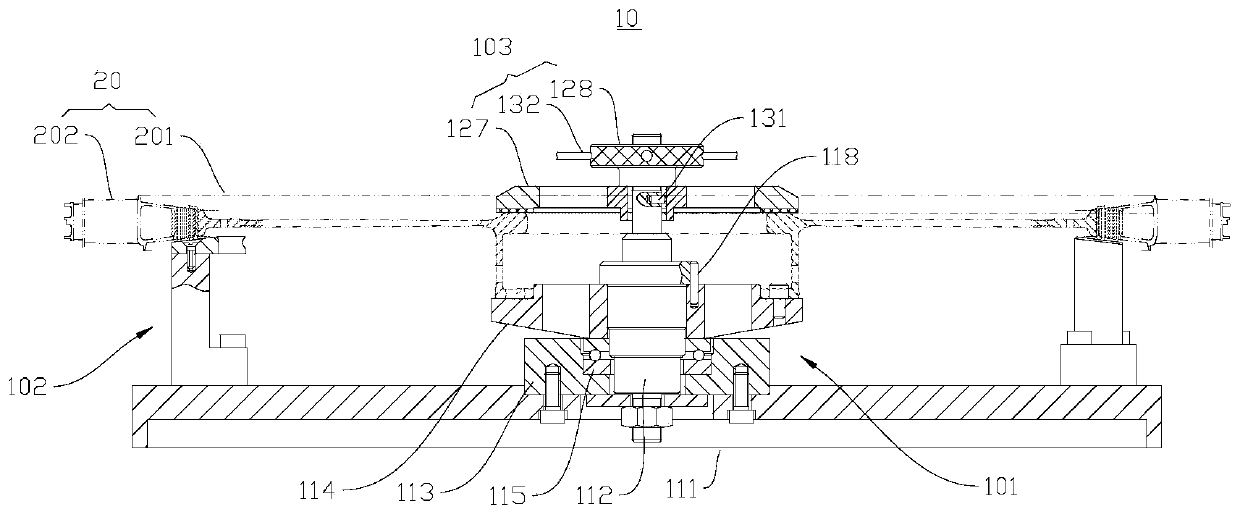

Coiling machine wrapper roller roll-gap automatic calibration and precision verification method

InactiveCN106269877AReduce insecurityEliminate errorsMetal rolling arrangementsControl systemWorking environment

The invention discloses a coiling machine wrapper roller roll-gap automatic calibration and precision verification method which comprises the following calibration steps in specific: (1) selecting a to-be-calibrated wrapper roller on an OPU operation panel; (2) turning on a wrapper roller calibration picture to switch the working mode of the coiling machine wrapper roller to the calibration operation mode (CAL); (3) switching the state of a coiling block to the pre-rising state on the OPU operation panel; and (4) clicking calibration START on the calibration picture, wherein the selected calibrated wrapper roller gradually presses and leans against the coiling block from 10.0 mm roll-gap state, and when the speed feedback of the wrapper roller reaches 0.8 m / s, a system identifies that the roll-gap of the wrapper roller at the moment is 0 mm and transmits the information to a control system through a position sensor. With adoption of the coiling machine wrapper roller roll-gap automatic calibration and precision verification method, unsafe factors during the calibration process are eliminated, the operation is convenient, limitation from the onsite working environment is prevented, the situation that the wrapper roller roll-gap is sequentially measured manually through a feeler gauge is avoided, error caused by manual measurement is eliminated, and the precision is greatly improved.

Owner:SHANDONG IRON & STEEL CO LTD

Digital feeler gauge and method of using same

The present application provides for feeler gauges. The feeler gauges include a plurality of elongate measuring leaves rotatably coupled on a common axis of rotation with an elongate housing. The leaves may be manually, selectively rotatable between a “home” position wherein the leaves are substantially aligned with the housing and an “extended” position wherein the leaves are spaced from the housing. The leaves may be relatively flexible and substantially flat such that they define a substantially constant thickness. One or more extended leaves may be used to measure the thickness of a clearance or gap. The gauges may be configured to detect, determine or measure the thickness of the leaves that are in the “home” position and / or the “extended” position, and thereby determine the total thickness of a clearance or gap measured by the extended leaves.

Owner:GENERAL ELECTRIC CO

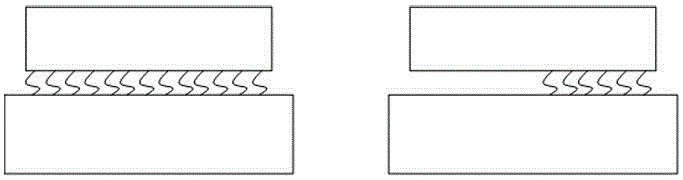

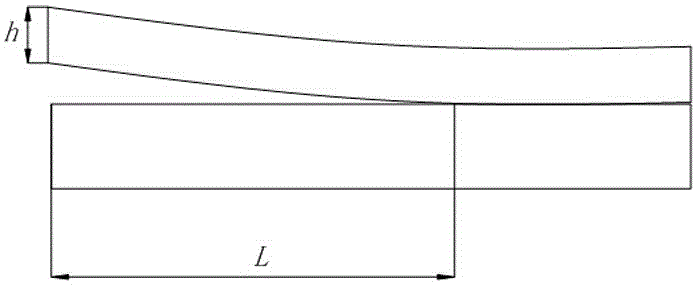

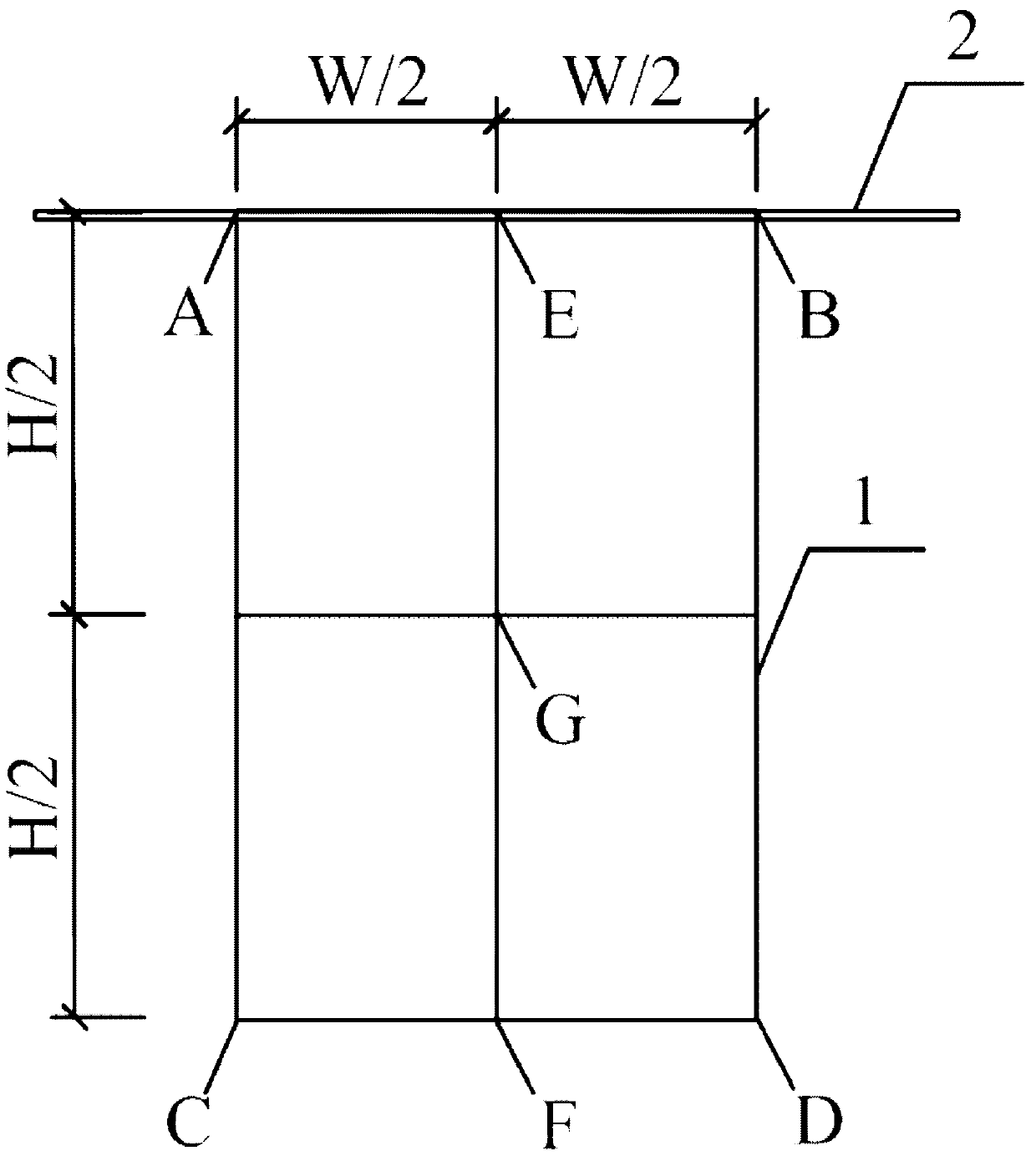

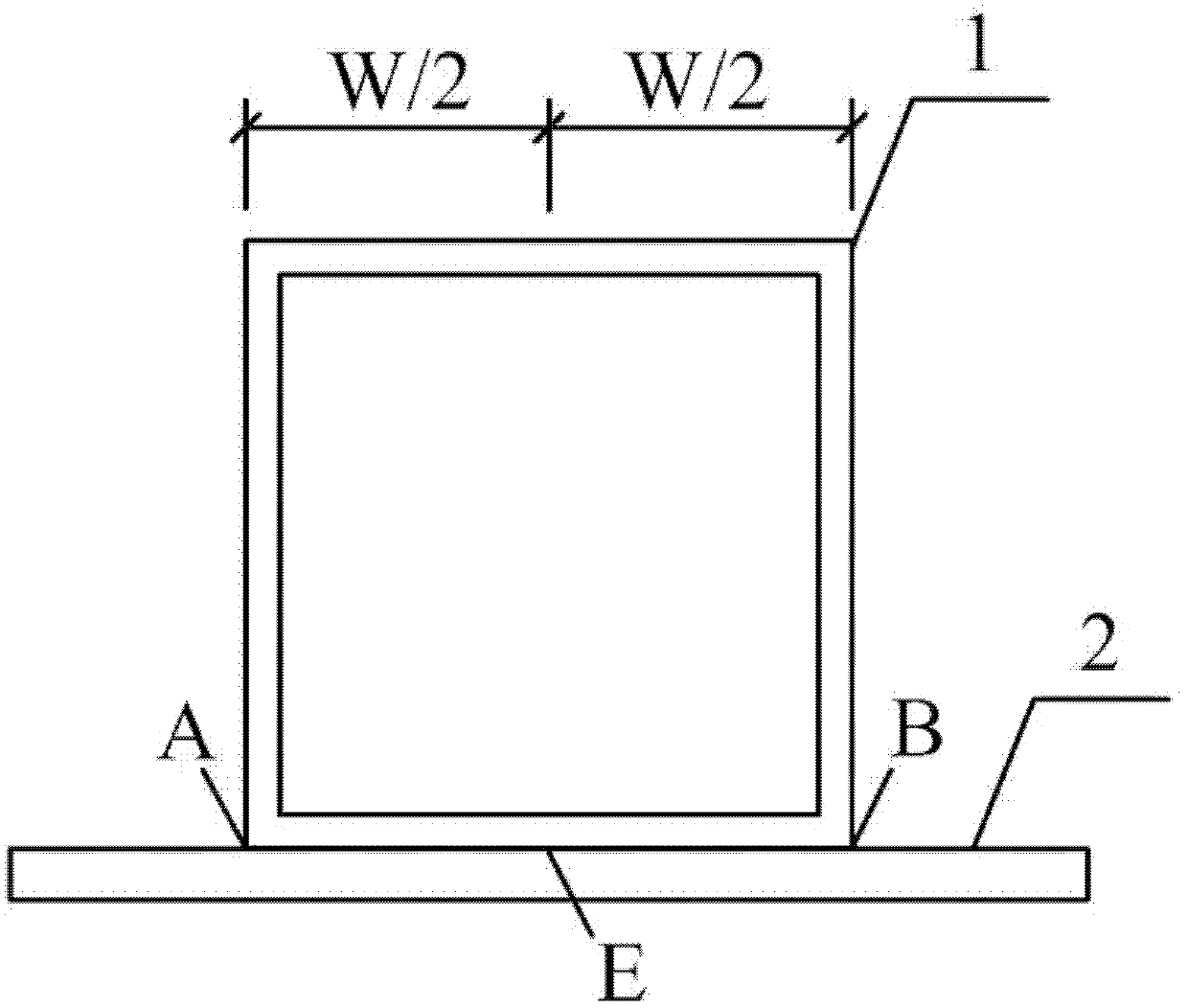

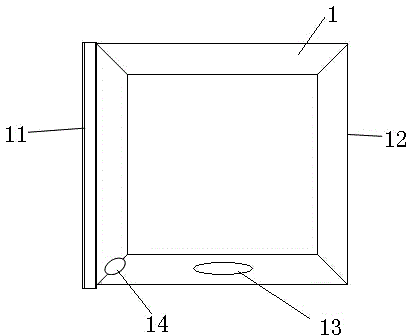

Method for measuring local geometric initial defects of steel member with box-shaped section

InactiveCN102607386AEasy to useEasy to prepareMechanical roughness/irregularity measurementsTechnical standardFeeler gauge

The invention belongs to the technical field of steel structures in structural engineering and particularly relates to a method for measuring local geometric initial defects of a steel member with a box-shaped section. The method comprises the following steps: respectively measuring vertical distances c1 and c2 from midpoints of two opposite edges on the outer surface of each of four steel plates of the measured steel member with a box-shaped section to a plane formed by four vertexes of the outer surface of the steel plate; measuring the vertical distance c3 from the center of the outer surface of each of four steel plates to the plane formed by the four vertexes of the outer surface of the steel plate; respectively calculating the local geometric initial defect values delta 1, delta 2, delta 3 and delta 4 of the outer surfaces of the four steel plates; and in comparison with the technical standards of the steel member with a box-shaped section, judging the quality of the steel member with a box-shaped section. According to the method, a steel rule and a feeler gauge which are common measurement tools are used for measuring the local geometric initial defects of the steel member with a box-shaped section; and the method has no special requirements on the site and auxiliary fixing devices for the steel member and is applicable to the measurement of local geometric initial defects of the steel member with a box-shaped section and the experimental study on stability performance of the steel member.

Owner:TSINGHUA UNIV

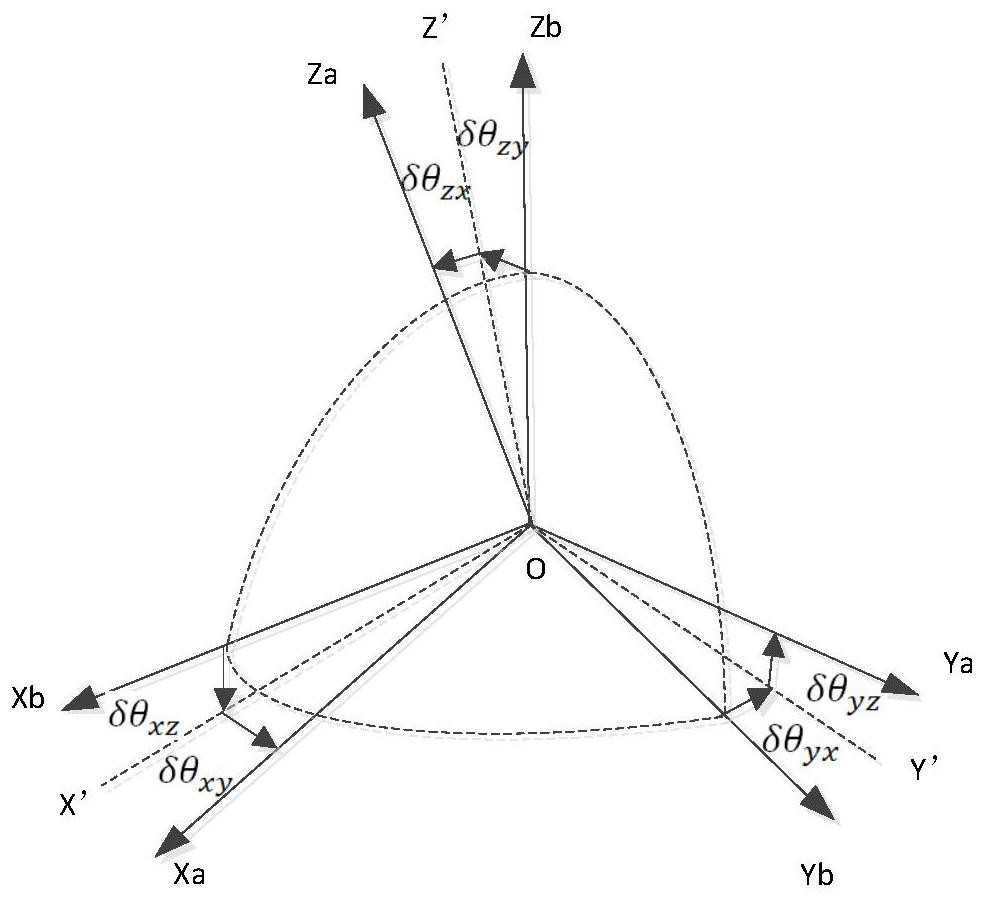

Method for calibrating and compensating installation errors of single-axis gyroscope

InactiveCN111664868AReduced measurement accuracyGuaranteed measurement accuracyMeasurement devicesGyroscopeEngineering

The invention discloses a method for calibrating and compensating installation errors of a single-axis gyroscope, belongs to the technical field of installation errors of fiber-optic gyroscopes and inertial measurement devices of the fiber-optic gyroscopes, particularly relates to a method for calibrating and compensating the installation errors of a fiber-optic gyroscope in an inertial measurement device of the single-axis gyroscope, and can be applied to the technical field of assembly of the inertial measurement devices. According to the method, the installation error angles relative to allthe axial directions are measured through projection of the angular velocity caused by installation errors on a sensitive shaft, then, the height needing to be compensated is calculated according tothe size of the gyroscope, the gasket meeting the compensation requirements is machined through a feeler gauge, and the effects of reducing the installation errors and improving the measurement precision of the gyroscope are achieved.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

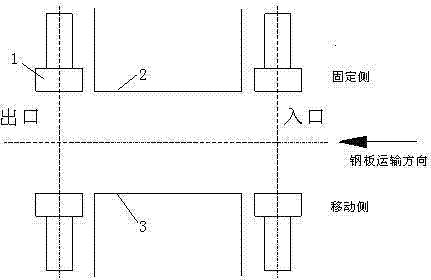

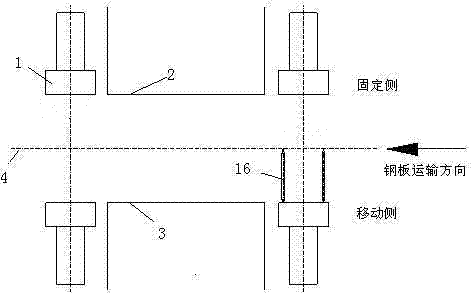

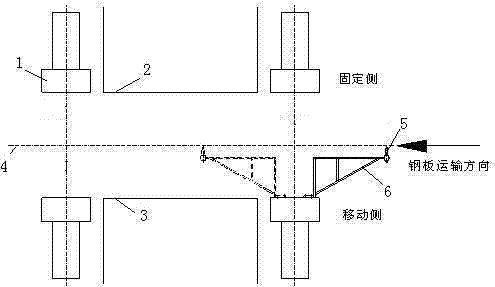

Adjustment method for pinch roll of double-sided shears

InactiveCN102489622AImprove installation accuracyPrevent deviationMetal-working feeding devicesPositioning devicesSheet steelEngineering

An adjustment method for a pinch roll of double-sided shears is disclosed, and is characterized by comprising the following process steps of: (1) adjusting the elevation of the roll surface of a lower pinch roll: measuring the relative elevations of the upper surfaces of side-trimming shear blades by a level at first, and then re-measuring by the level; (2) adjusting the parallelism of the pinch roll: pulling steel wires in front of and behind the double-sided shears and adjusting the steel wires to be parallel with the blades of the double-sided shears at first, and then adjusting bolts and nuts by adjusting the parallelism, so as to shift the roll ring of the pinch roll forwards and backwards along a horizontal direction; and (3) adjusting the deflection of the pinch roll: measuring on the end part of the roll ring of the pinch roll by a feeler gauge and a frame-type level. A pinch roll of double-sided shears is measured and adjusted by the adjustment method for a pinch roll of double-sided shears disclosed by the invention, so that the installation accuracy of the pinch roll is greatly increased; the deviation of the pinch roll can be efficiently prevented, and the deviation phenomenon of steel plate during the feeding and transportation processes of the pinch roll is avoided, so that the phenomena such as bad shearing quality are reduced.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

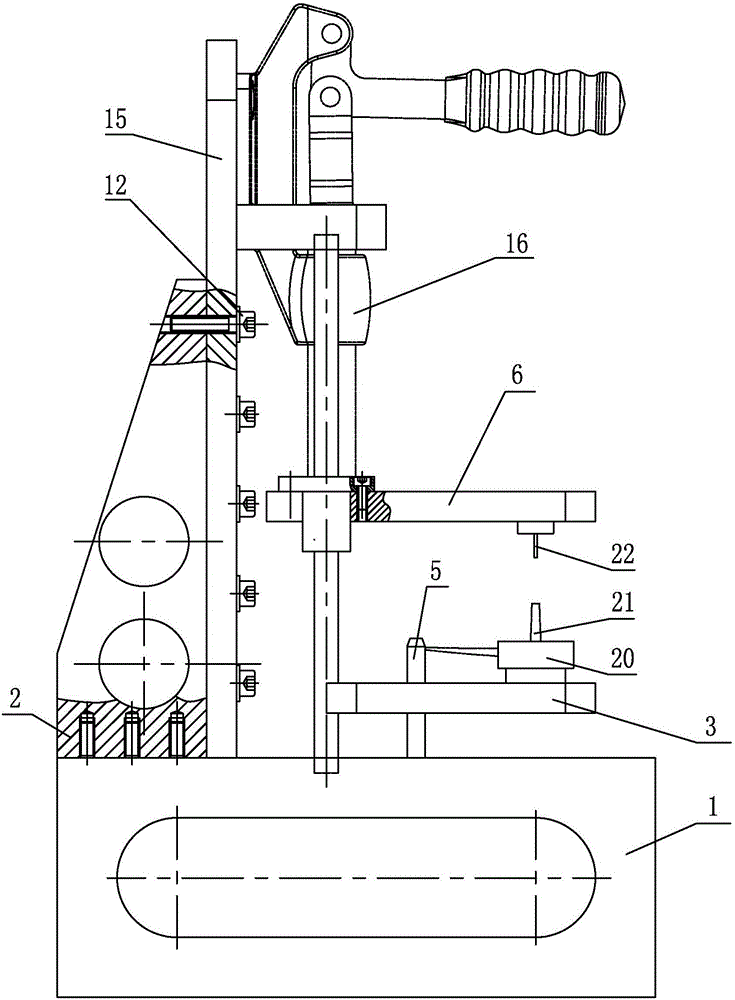

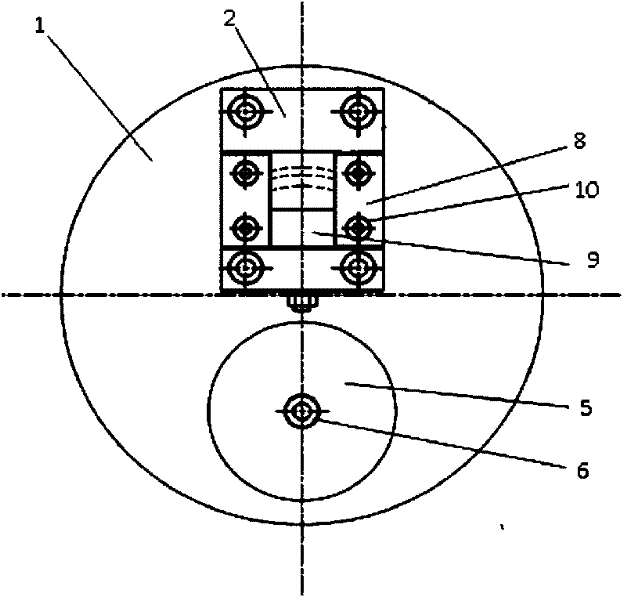

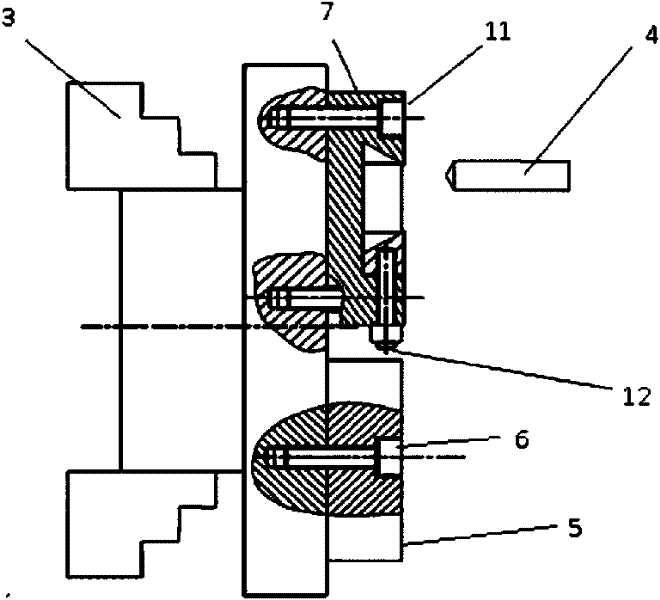

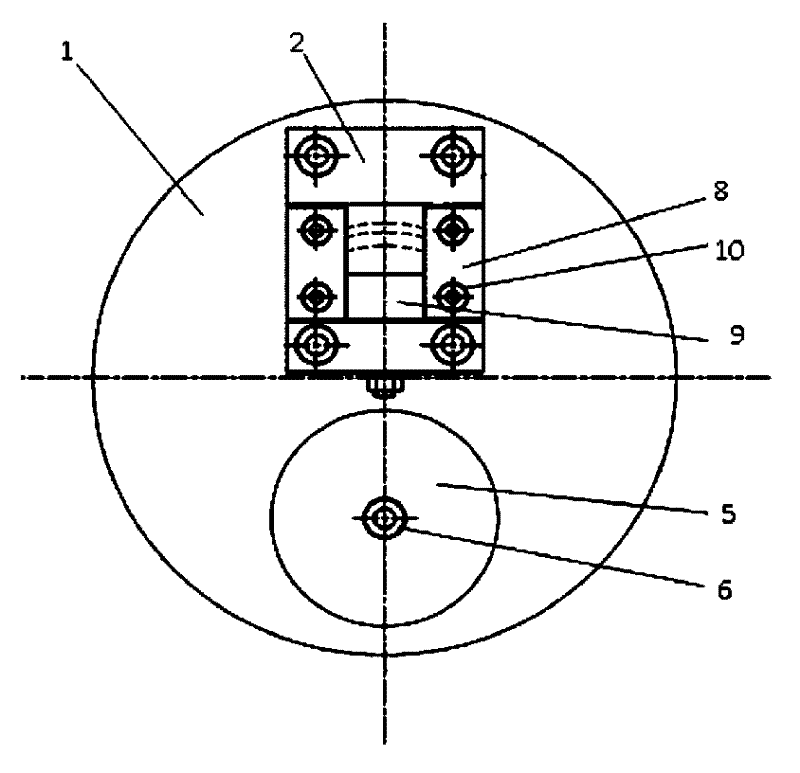

Micro-clearance assembling device and micro-clearance assembling method for low pressure turbine blade of aircraft engine

ActiveCN110370201ARealize multiple repeated assemblyGuaranteed stabilityWork holdersTurbine bladePass rate

The invention discloses a micro-clearance assembling device and a micro-clearance assembling method for a low pressure turbine blade of an aircraft engine and belongs to the technical field of aircraft engines. The device comprises a bearing assembly, and a supporting assembly and a compaction assembly separately arranged on the bearing assembly. The bearing assembly comprises a base and a bearingstructure arranged in the middle of the base. The supporting assembly is distributed around the bearing structure and comprises a supporting seat fixed to the base. The compaction assembly comprisesa pressure plate connected to the bearing structure. The device is high in accuracy, can reflect clearance data of the assembled blade by measurement of a feeler gauge, and can guarantee that the gapis with a specified range, so that the assembling percent of pass is improved. The device is good in operability, and operating staff trained simply can take the post, so that the operating difficultyis reduced greatly. The device is high in universality and can be widely applied to micro-clearance assembly of other blades.

Owner:CHENGDU ENGINE GROUP

Diamond wire saw cutting monocrystalline silicon wafer and polycrystalline silicon wafer sorting inspection method

The invention relates to a diamond wire saw cutting monocrystalline silicon wafer and polycrystalline silicon wafer sorting inspection method, which comprises that 1, an automatic sorting machine divides silicon wafers into A silicon wafers, A- silicon wafers and unidentified silicon wafers; 2, an operator picks out the dirty wafers and the dense line mark wafers from the unidentified silicon wafers, the dirty wafers are re-washed, and enter the step 1 so as to be sorted, the B wafers and the C wafers are sorted from the dense line mark wafers through visual inspection, the un-determined denseline mark wafers enter the step 1 and are subjected to wafer running sorting, and when the batch of the unidentified silicon wafers are generated, a step 3 is performed; 3, when the batch of the unidentified silicon wafers are generated, the operator performs reselection by using a wafer multifunctional parameter detector, a digital vernier caliper, a concentricity template, a feeler gauge and asurface roughness tester; 4, sampling inspection is performed; 5, classification boxing is performed; and 6, storage is performed. According to the present invention, by matching the automatic sortingmachine, the manual initial selection, the manual reselection and the sampling inspection, the wafers are divided into the A silicon wafers, the A- silicon wafers, the B wafers and the C wafers.

Owner:江苏金晖光伏有限公司

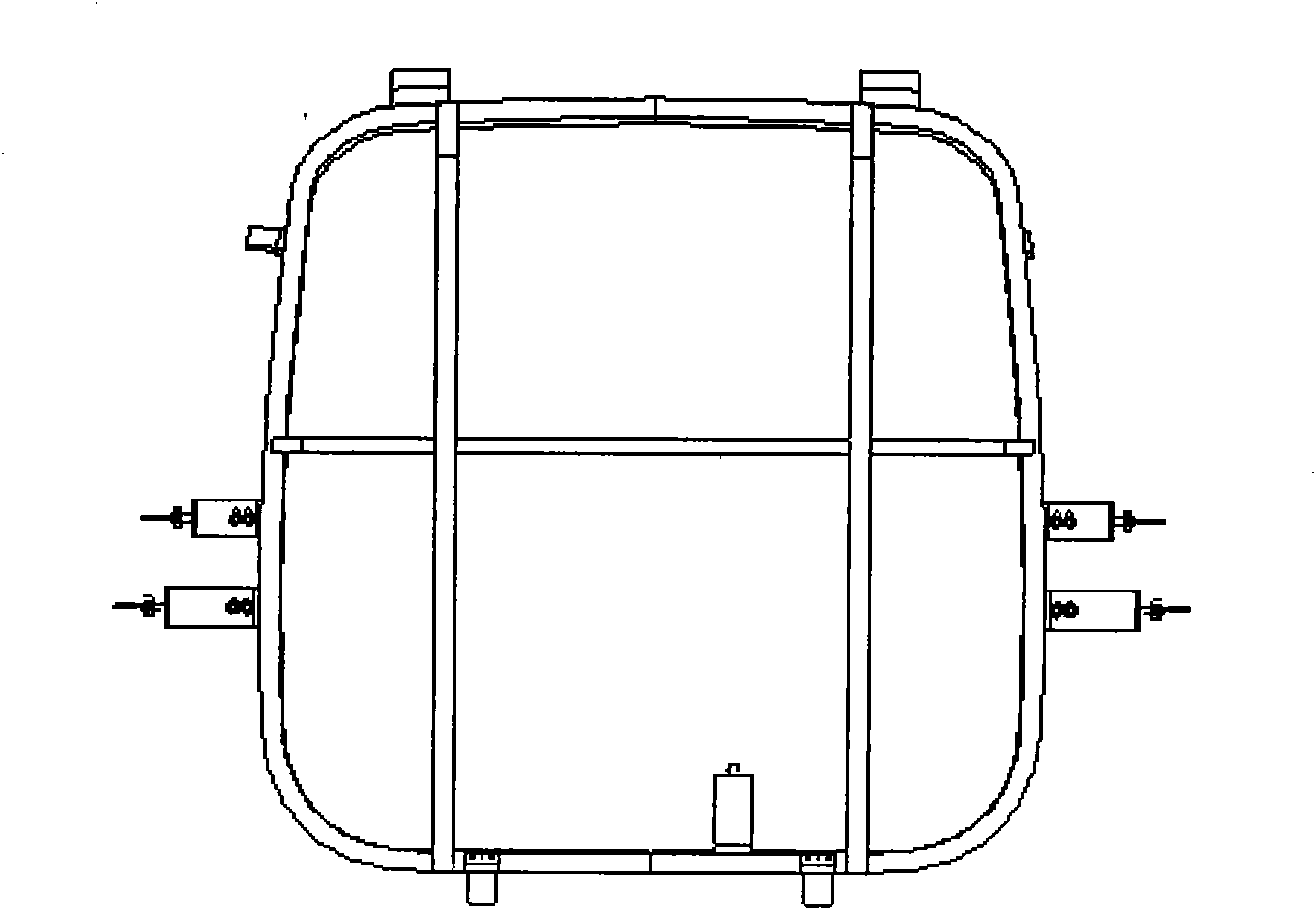

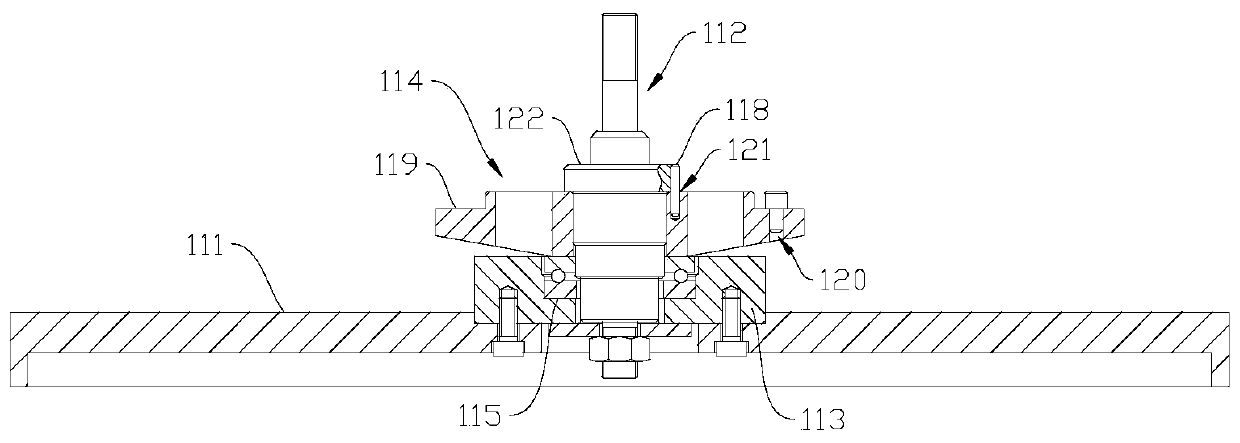

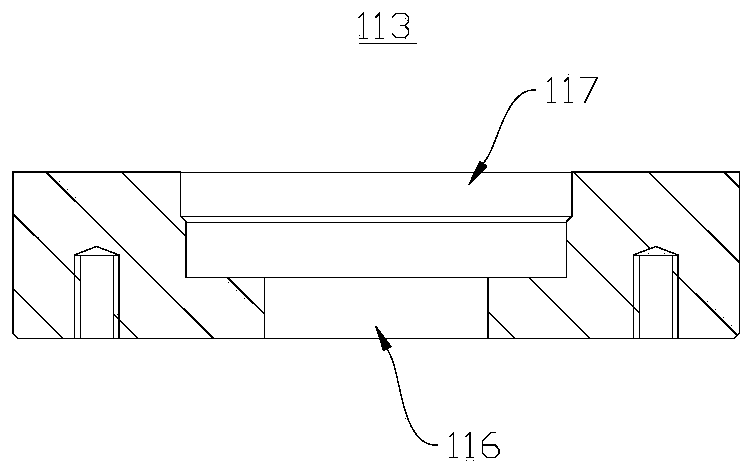

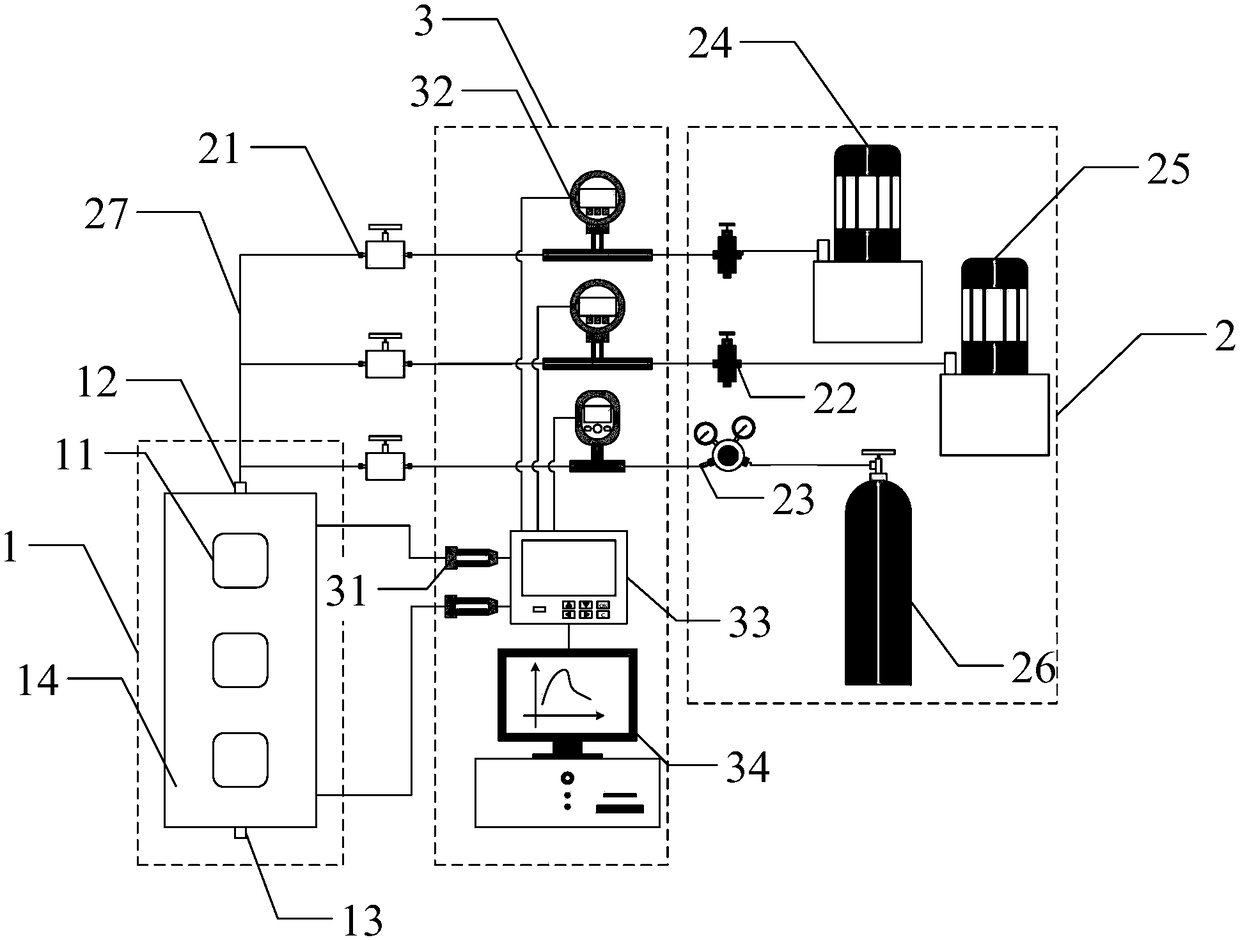

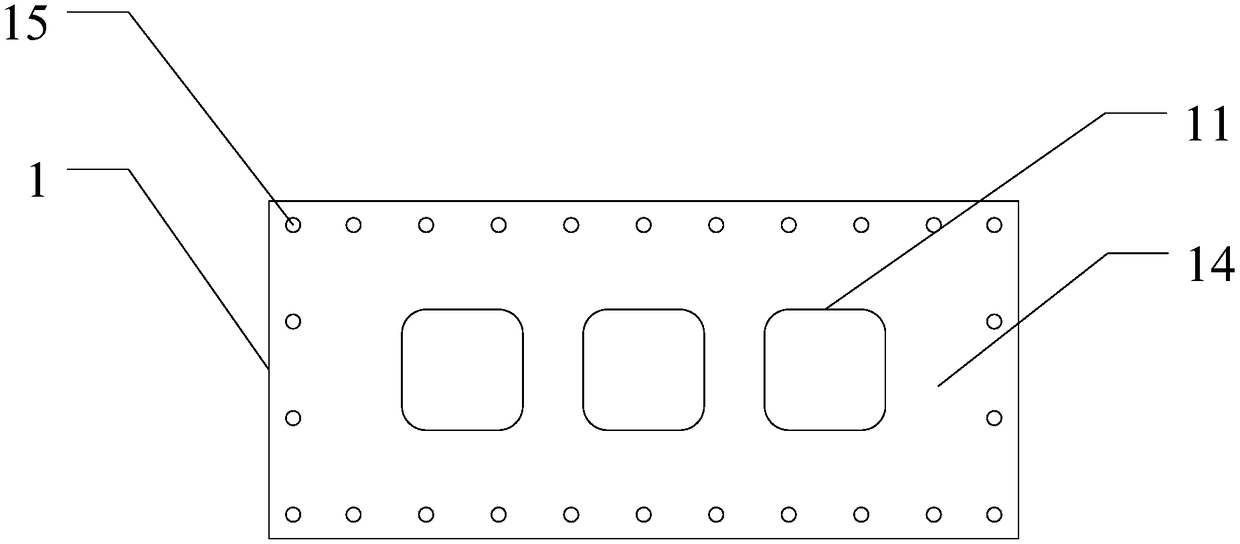

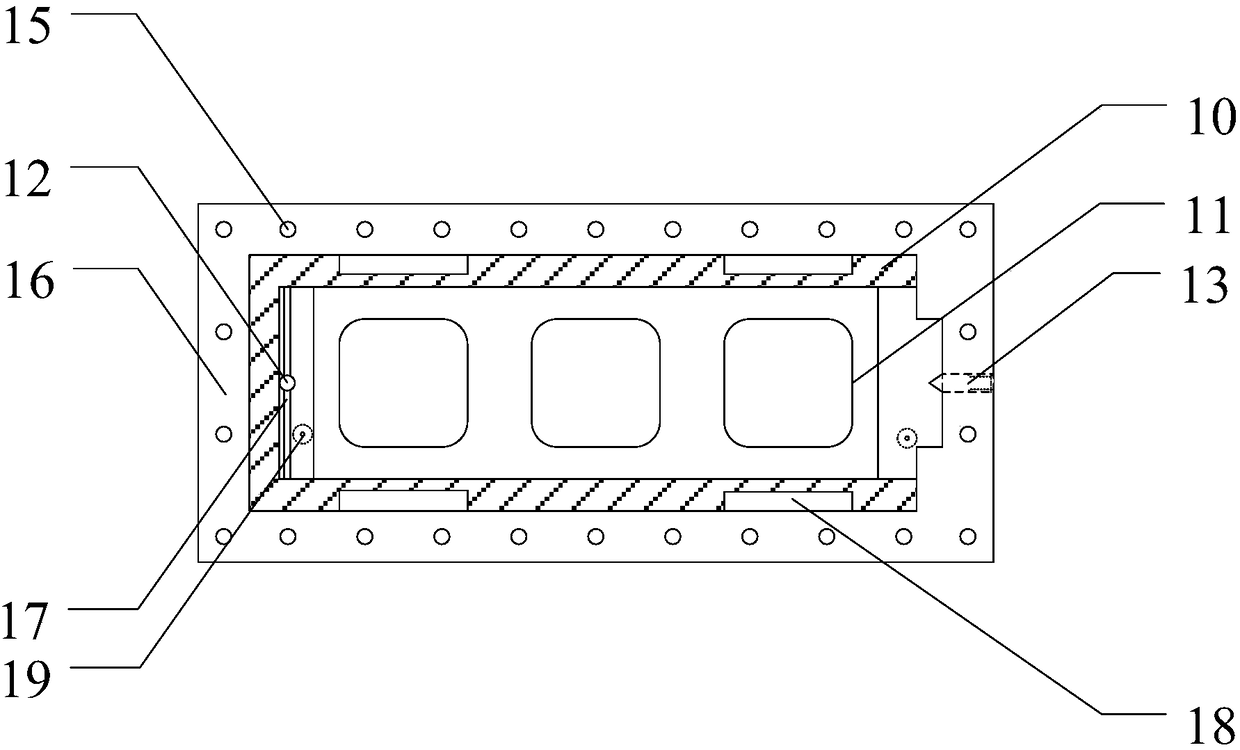

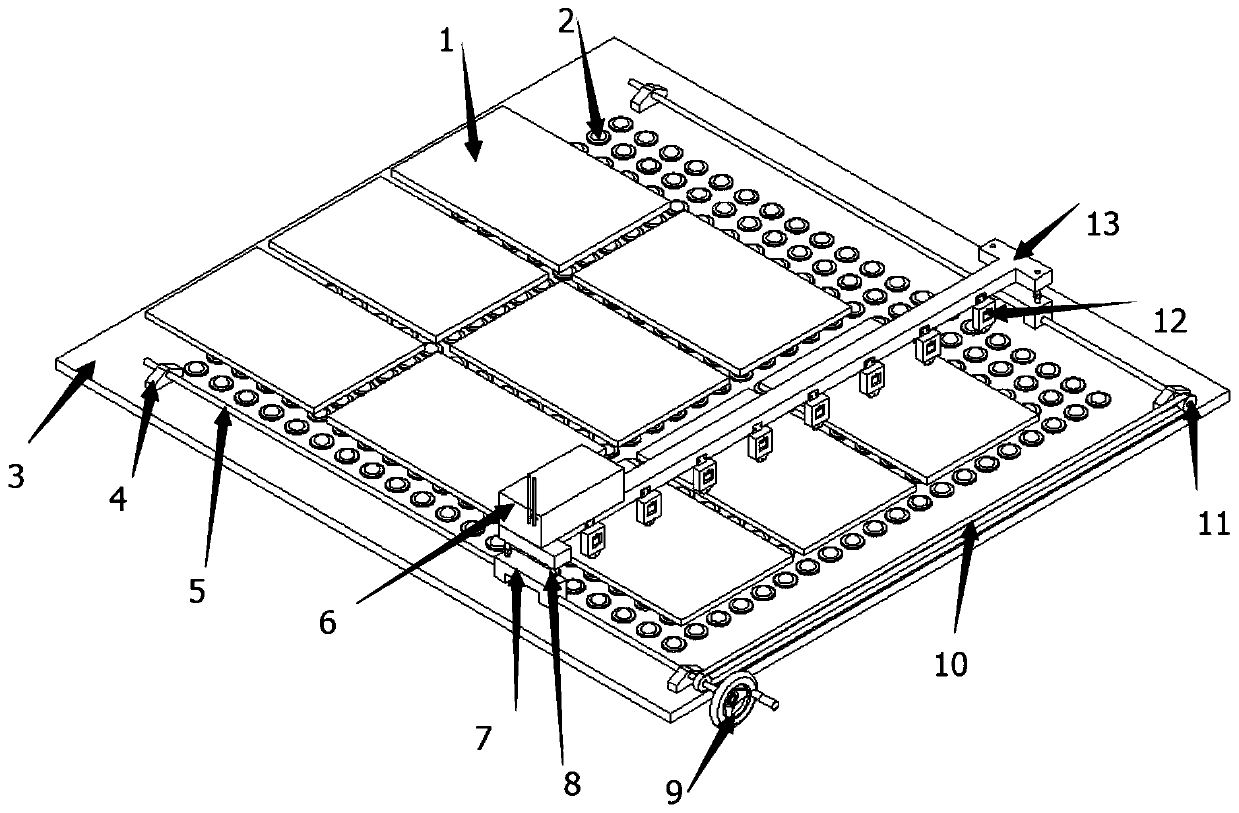

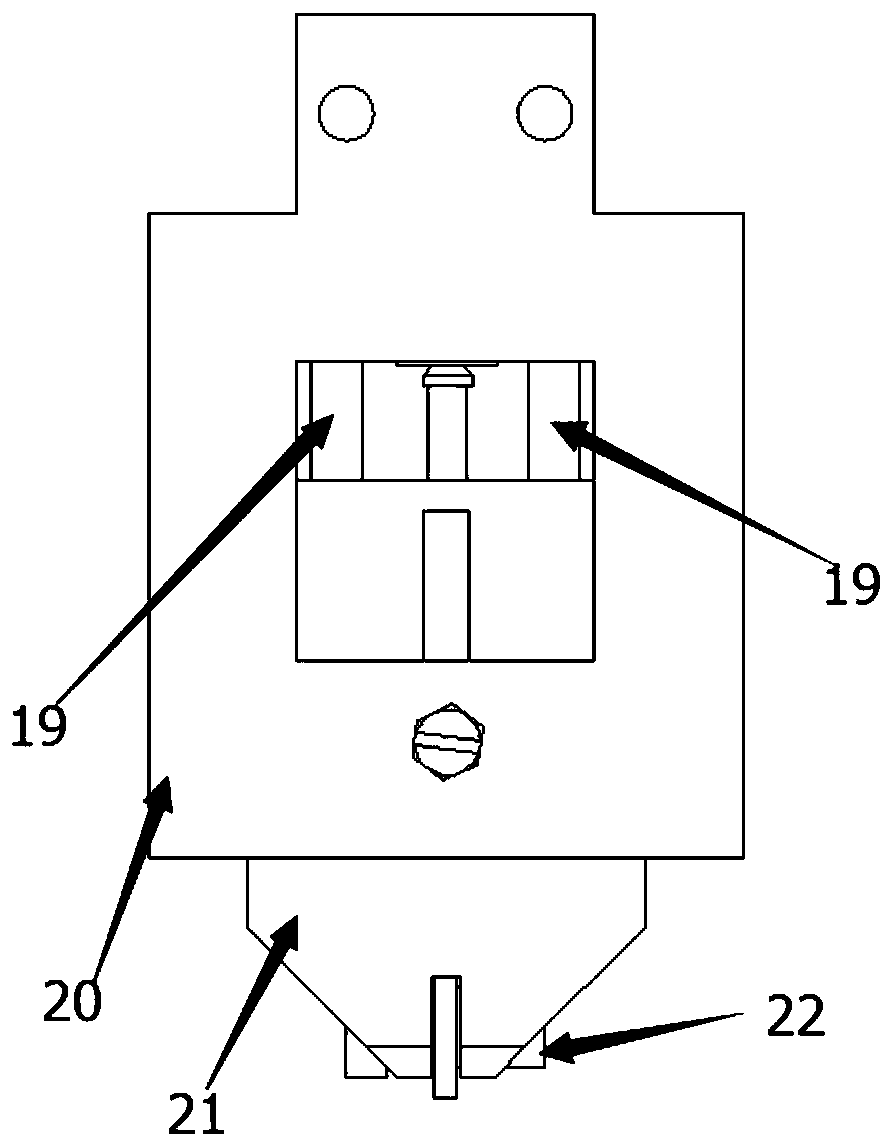

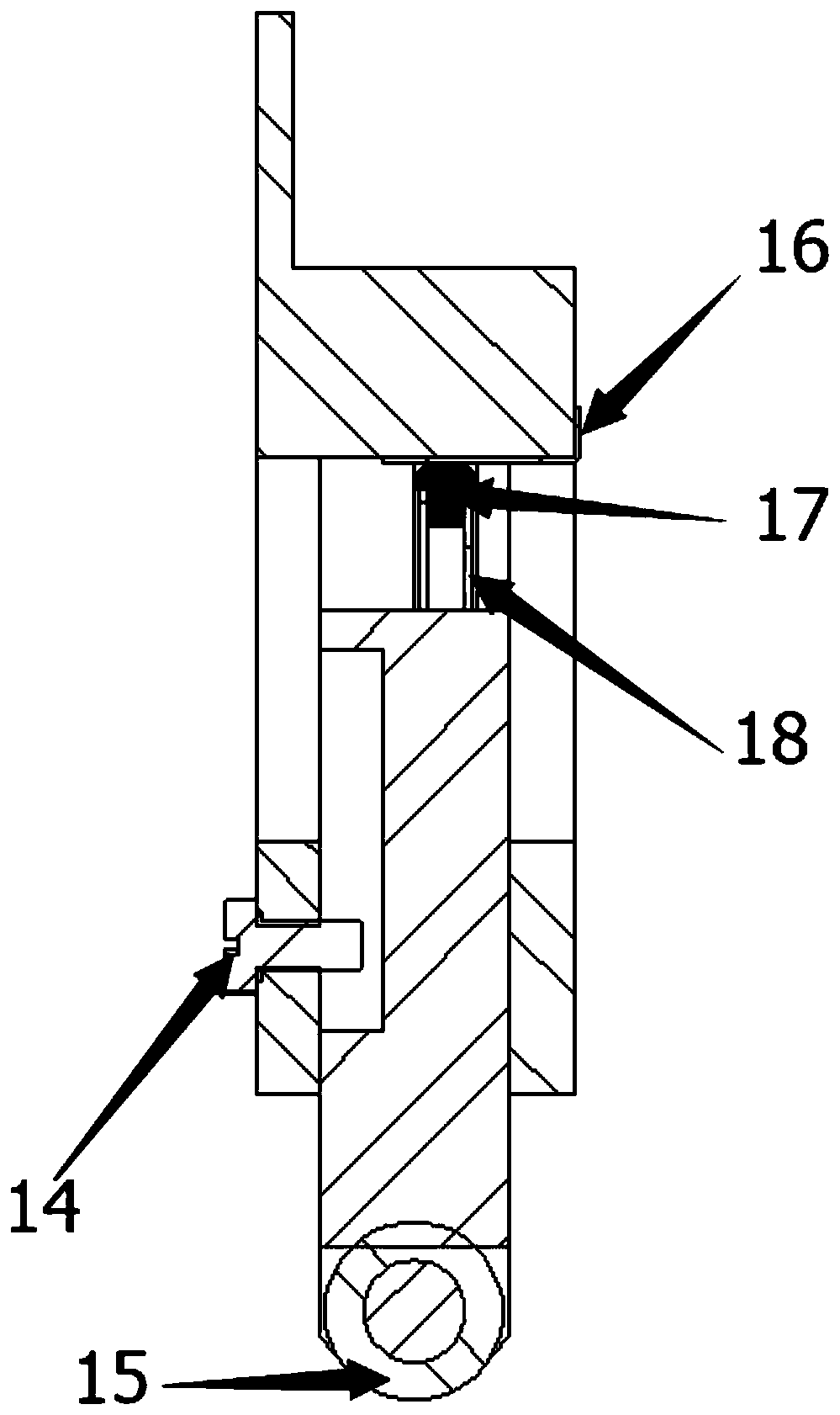

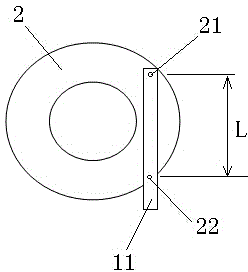

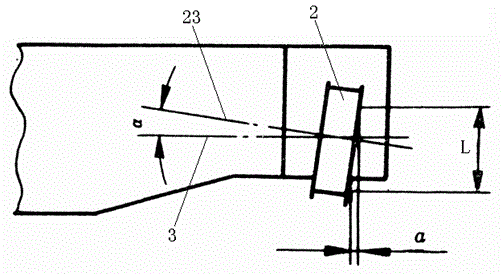

Fracture-width adjustable type inner visible three-dimensional fracture permeating device

ActiveCN108195738ALess materialLow costPermeability/surface area analysisData acquisitionEngineering

The invention provides a fracture-width adjustable type inner visible three-dimensional fracture permeating device. The device comprises a permeating instrument, an air-liquid supplying control systemand a data acquiring analyzing system, wherein the permeating instrument mainly comprises an upper cover steel plate, a silica gel plate, toughened glass plates, cellophane which is attached to a 3Dprinted coarse fracture surface, and a lower coiled steel plate; a water guide channel is formed between the two toughened glass plates to which the cellophanes are attached, and the opening degree ofthe water guide channel is adjusted through a feeler gauge; the fiver parts of the permeating instrument are connected and sealed through high-strength bolts; an electric pressure testing pump and ahigh-pressure air pipe are used for supplying pressure to an air-liquid supplying part; the fluid pressure is adjusted by a control part through a valve; permeating pipelines are connected through oxygen rubber tubes, and each connecting part is sealed through a combination gasket; the data acquiring analyzing part comprises a pressure sensor, a flow meter and a paper-free recorder; and data are transmitted to the paper-free recorder through the pressure sensor and the flow meter, and the data are acquired and analyzed through a computer.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Flatness out-of-tolerance continuous measurement device and measurement method thereof

PendingCN110186371AReduce difficultyShorten the timeElectric/magnetic roughness/irregularity measurementsMechanical roughness/irregularity measurementsContinuous measurementMeasurement device

The invention discloses a flatness out-of-tolerance continuous measurement device and a measurement method thereof. The measurement device comprises a base platform, the device further comprises a guide travel mechanism arranged on a base platform, a height adjusting mechanism arranged on the guide travel mechanism and used for adjusting the height of a mounting rack, and a detection mechanism arranged on the mounting rack and used for performing flatness testing by contacting and extruding on a workpiece surface of the base platform. The precision of the measurement device is more precise than a feeler gauge, and lower than the three-coordinate detection and laser plane interferometer measurement, the operation is convenient, the measurement can be continuously performed, and the flatnessmeasurement difficulty and time of the measurement plate parts can be greatly reduced.

Owner:芜湖力钧轨道装备有限公司

Method and apparatus for bonding wafer

ActiveCN101510516AHigh strengthImprove sealingSemiconductor/solid-state device manufacturingRoom temperatureEngineering

The invention discloses a method for bonding wafers, and a device thereof. The method includes the processing steps of: preparing bonding wafer glue; baking wafers to be bonded; preheating a clamp frame of a wafer to be bonded and a movable clamp on the clamp frame; putting the prepared glue onto a glued iron plate of an electric cooker for heating; arranging the heated wafer on the heating glued iron plate so as to allow that the heating glue fully dissolves and permeates into the surface of each wafer; using a tool to rub the wafer so as to ensure even permeation on the surface of the wafer; putting a steelyard weight in the clamp frame and the movable clamp on the clamp frame and then extruding the clamp by two hands so as to remove unwanted glue, while a right angle is required to be tested to be 90 degrees plus or minus 1 degree by a try square and the planeness is required to be measured to be less than 0.2mm by a knife straight edge and a feeler gauge; and taking the wafer out of the clamp after the wafer is cooled at room temperature. The method has the advantages of improving the bonding strength of the wafer as well as full dissolution and even permeation of the wafer and the glue, enhancing the leak tightness between the wafers and increasing various quality indicators of final products while reducing damage to products in the follow-up processing.

Owner:NANJING DEYAN ELECTRONICS

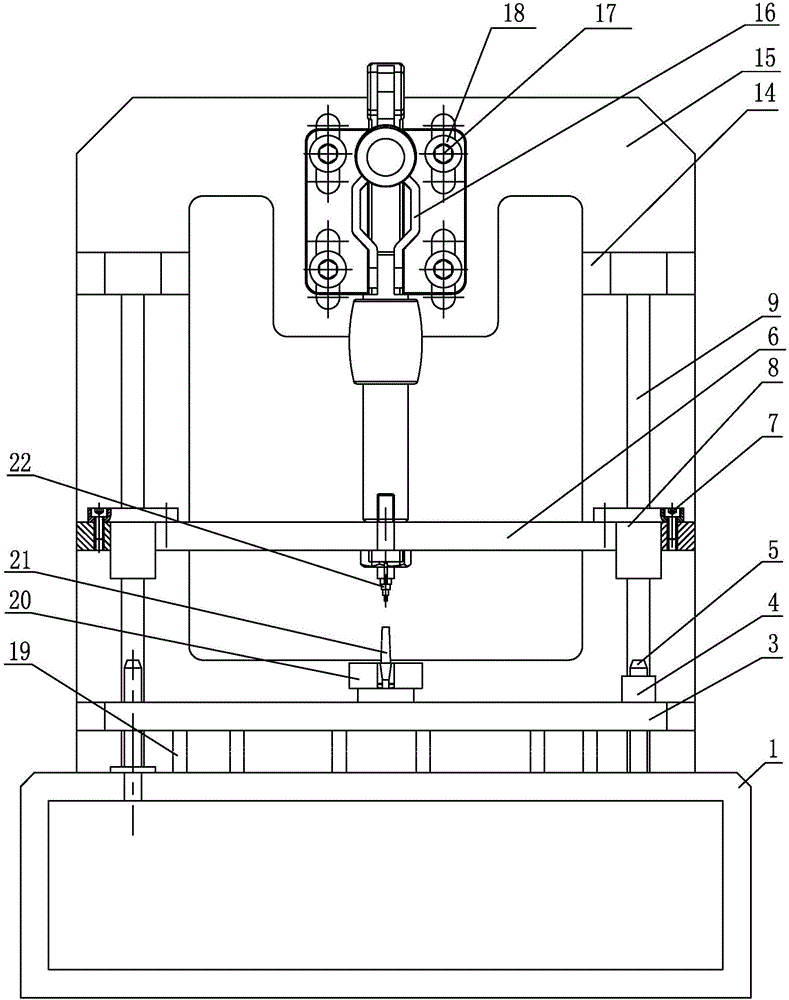

Instrument pointer shaft detector

ActiveCN105783675AEliminate manual errorsGuaranteed parallelismAngles/taper measurementsOptical axisFeeler gauge

The invention discloses an instrument pointer shaft detector, relates to shaft detectors and aims at solving the problems that in traditional detection a pointer shaft is placed in a small optical axis manually, a non-key part is detected by a filler gauge, the size of a key part of the pointer shaft is obtained via theoretical reckoning, and further a detection result is fuzzy and inaccurate and has large error. The detector comprises a pedestal, a pointer plate, a probe plate, a vertical plate, a rapid clamp, a pointer fixing seat, two guide posts, two upper linear bearings and two lower linear bearings, wherein the vertical plate is fixedly mounted on the pedestal, the lower end of each guide post is provided with one lower linear bearing, the pointer plate is mounted on the two lower linear bearings, the middle of the pointer plate is provided with the pointer fixing seat, the probe plate is mounted on the two upper linear bearings, the middle of the probe plate is provided with the pointer shaft, the vertical plate over the probe plate is provided with the rapid clamp, and the pressure head end of the rapid clamp abuts against the probe plate. The detector is used for instrument pointer shaft detection.

Owner:AEROSPACE HI TECH HLDG GROUP

Rapid measuring method for lifting-trolley-wheel perpendicular divergence

InactiveCN106153005AGuaranteed safe operationImprove measurement accuracyIncline measurementFast measurementSlant angle

The invention discloses a rapid measuring method for lifting-trolley-wheel perpendicular divergence. The method includes the steps that a measuring face of a frame-type level meter is attached to the perpendicular plane of a wheel, a leveling bubble of the frame-type level meter is adjusted to be located at the middle position, and the measuring basis is determined; the measuring face and an upper measuring point and a lower measuring point of the perpendicular plane of the wheel are selected, the distance is measured, and according to the slant angle of a bubble of a main water level device of the frame-type level meter, a feeler gauge is added to the attaching face of the upper measuring point and the lower measuring point; the practical perpendicular divergence angle of the wheel is calculated according to the distance between the upper measuring point and the lower measuring point and the thickness value of the inserted feeler gauge, and is compared with the specified perpendicular divergence angle of the wheel, and if the difference exists, the perpendicular divergence amount of the wheel needs to be adjusted. The method is not limited by presence and absence of a measuring hole and measurement environment vibration, the measuring accuracy and the measuring efficiency are improved, the lifting-trolley-wheel perpendicular divergence amount is grasped in time, and safe operation of a lifting trolley is guaranteed.

Owner:SHANGHAI JINYI INSPECTION TECH

Optical glass scratching testing device

InactiveCN101750254ASimple structureEasy to operateMaterial strength using repeated/pulsating forcesMaterials testingBiochemical engineering

The invention relates to an optical glass scratching testing device which belongs to the technical field of material testing. The optical glass scratching testing device comprises a tray, a clamp and a scratching instrument, wherein the clamp is arranged on the tray; the scratching instrument is arranged opposite to the tray and the clamp; a feeler gauge is arranged between the bottom of the clamp and the tray; and the included angle between the clamp and the tray is adjustable. The invention can obtain different scratching speeds by adjusting the speed of mainshaft of the lathe, and obtain different scratching depths by adjusting the included angle between the clamp and the tray. The invention has the advantages of simple structure, convenient operation and high testing accuracy.

Owner:SHANGHAI JIAO TONG UNIV

Setter plate applied to low-temperature co-sintering ceramic sintering

The invention provides a setter plate applied to low-temperature co-sintering ceramic sintering. The setter plate is characterized in that the setter plate is a quasi flat plate with a cavity structure and utilizes high-temperature ceramic formation; the specific implementation method comprises a conventional multilayer ceramic manufacturing process and a conventional blanking and grinding process; the surface roughness is lower than 1.6, the surface evenness is smaller than 15 microns and the upper-lower flatness is lower than 1 degree; the existing types of low-temperature co-sintering ceramic sintering can be met. The invention has the beneficial effects that the manufacturing cycle of the setter plate is simple and short, the service cycle is long, the setter plate resists corrosion, oxidization and adhesion, is low in cost and does not sinter with low-temperature co-sintering ceramic, and the evenness of the sintered low-temperature co-sintering ceramic is smaller than 1 micron per millimeter and meets a 0.10 mm feeler gauge test; the manufacturing process of the low-temperature co-sintering ceramic is simplified, the package process of the low-temperature co-sintering ceramic is effectively improved, the electrical performance of required devices is optimized, and the setter plate can be widely applied to the low-temperature co-sintering ceramic sintering process.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com