Scraper leveling device and method for manufacturing three-dimensional object

A three-dimensional object and leveling device technology, applied in the field of additive manufacturing, can solve the problems of low precision, time-consuming, equipment damage, etc., and achieve the effects of avoiding equipment damage, high accuracy, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

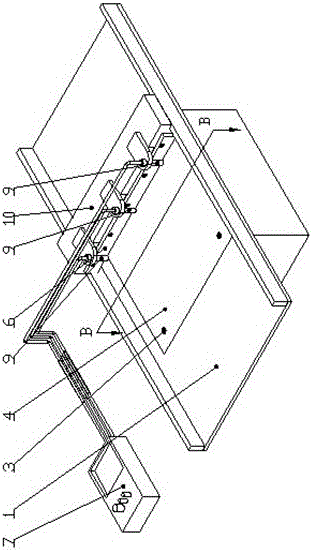

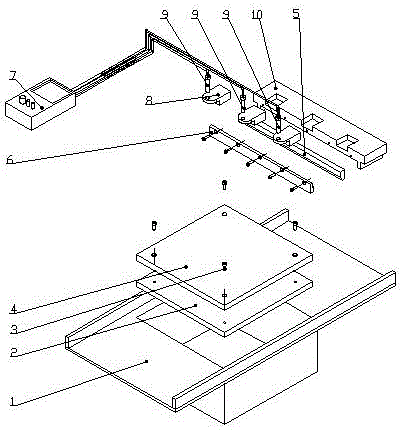

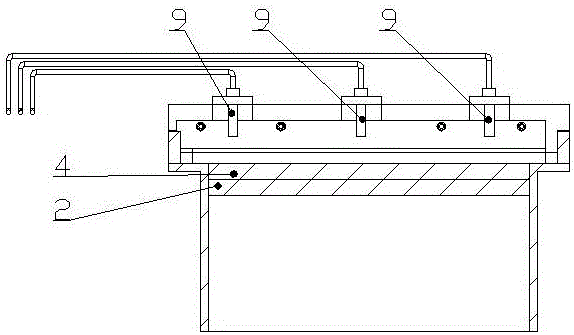

[0026] In order to allow those skilled in the art to better understand and realize the technical solution of the present invention, further detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

[0027] In order to solve the above-mentioned technical problems caused by using a feeler gauge to level the scraper in the prior art (see background technology), the inventor of the present invention has obtained a method for leveling the scraper through creative work. The main core of the method is: Firstly, the forming substrate is leveled through the data detection of the distance sensor, and then the gravity of the leveled forming substrate and the scraper is used to ensure the leveling of the scraper. The whole technical solution has higher accuracy, simpler operation and more standardization.

[0028] Based on the above innovative ideas of the inventor, the present invention provides a scraper leveling device and a leveli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com