Patents

Literature

62results about How to "Reduce the impact of force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

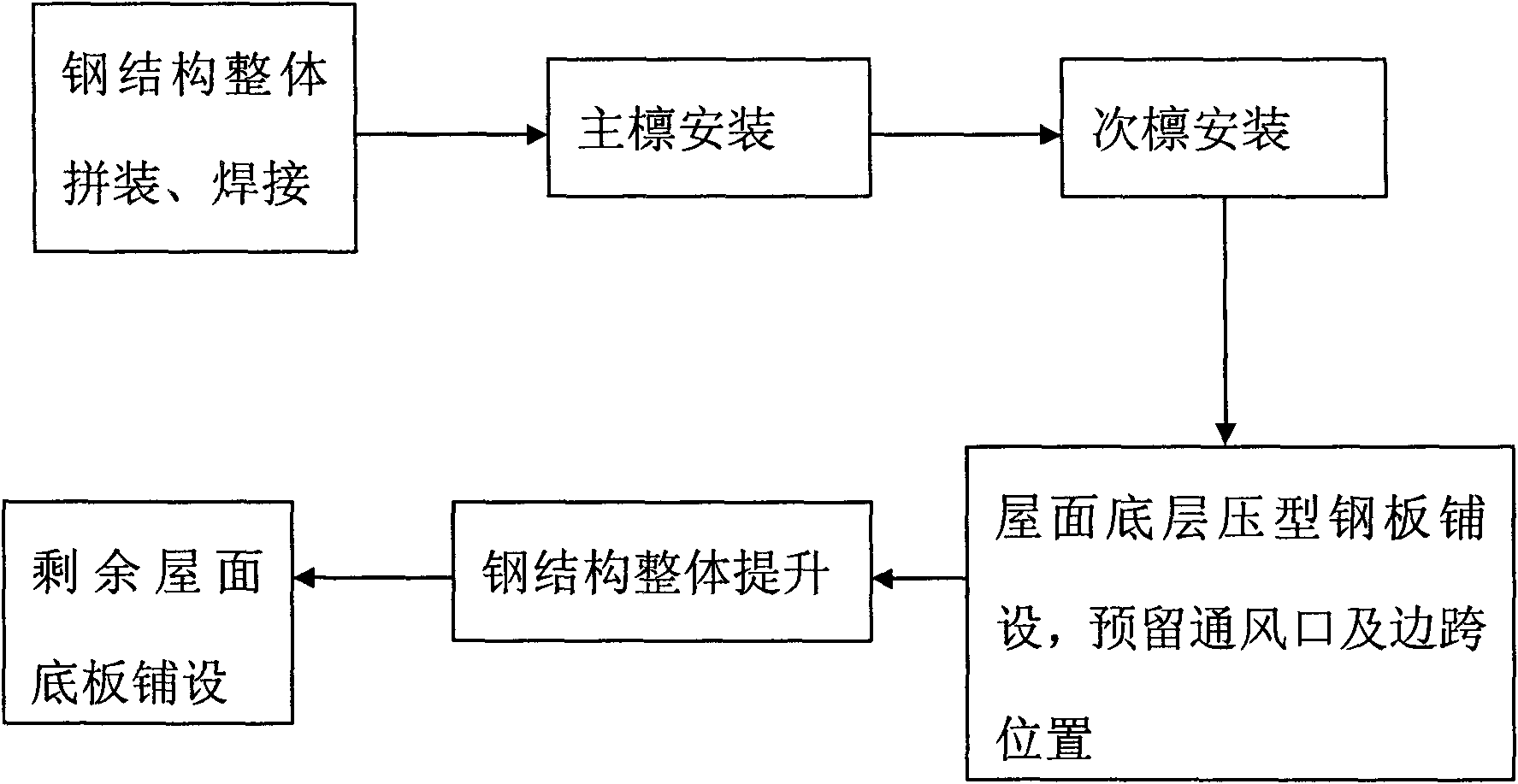

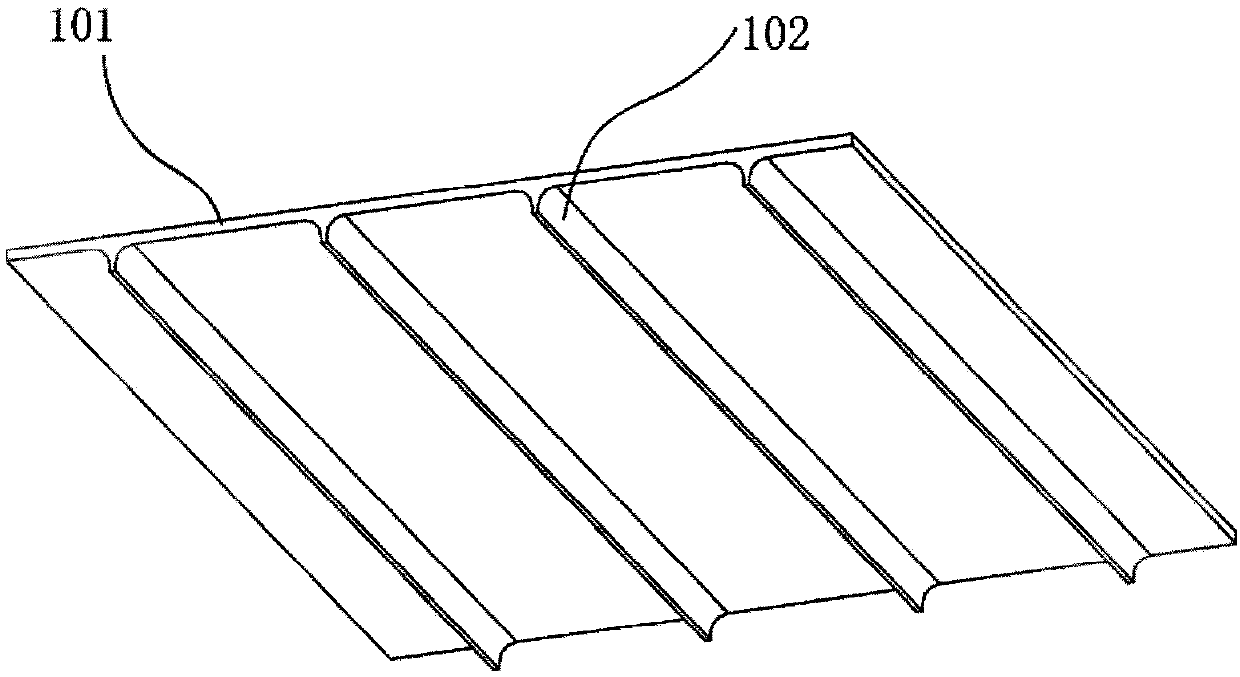

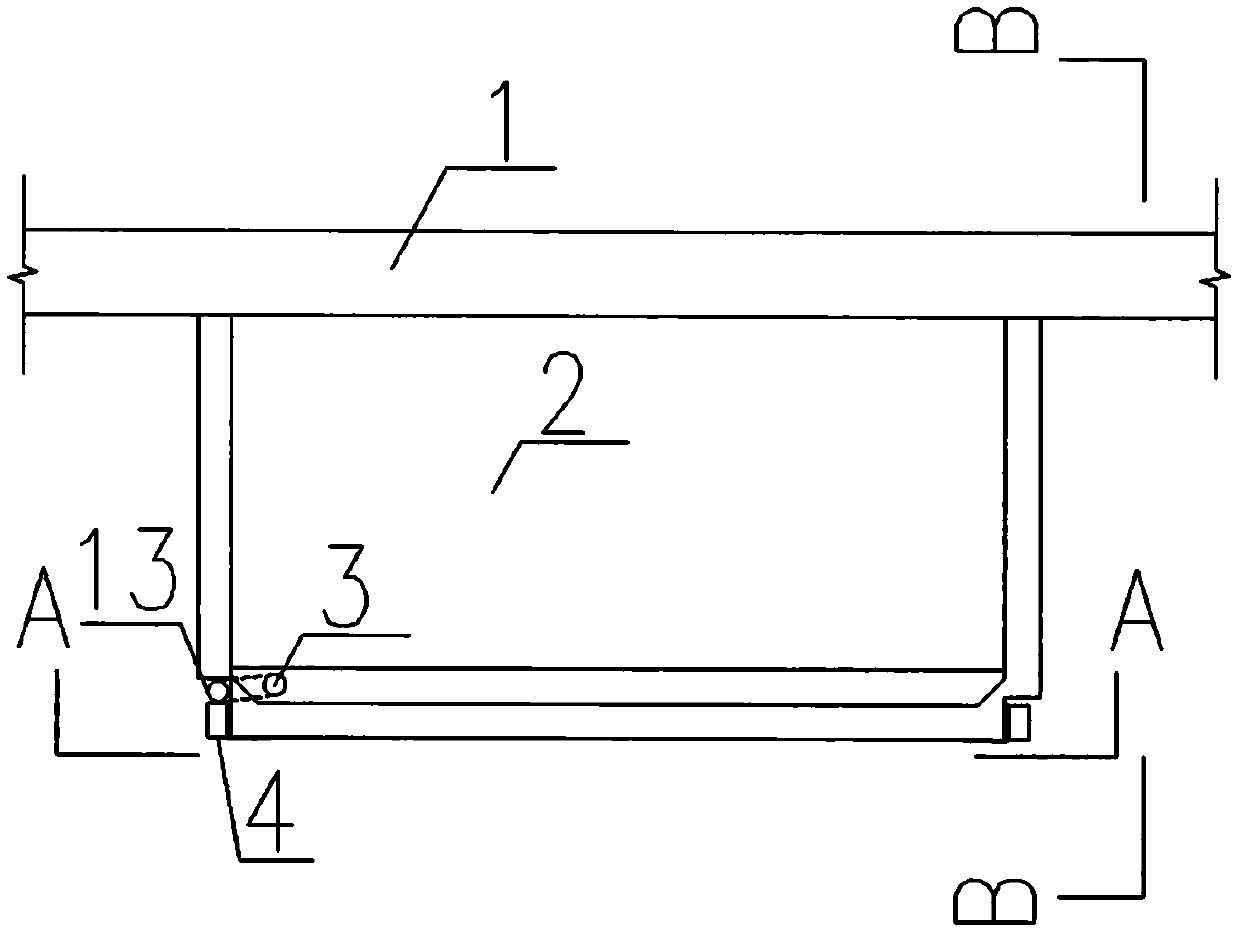

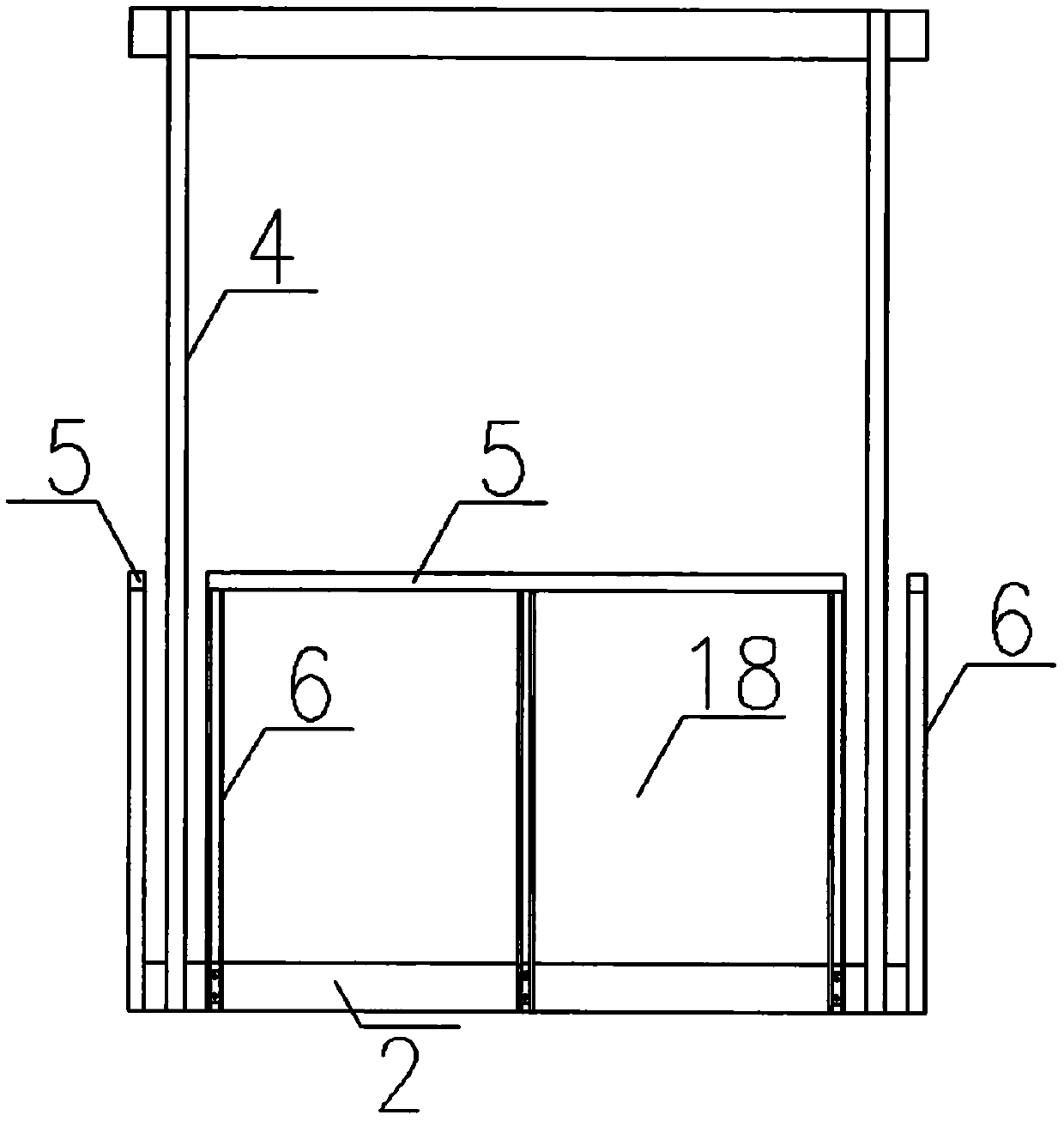

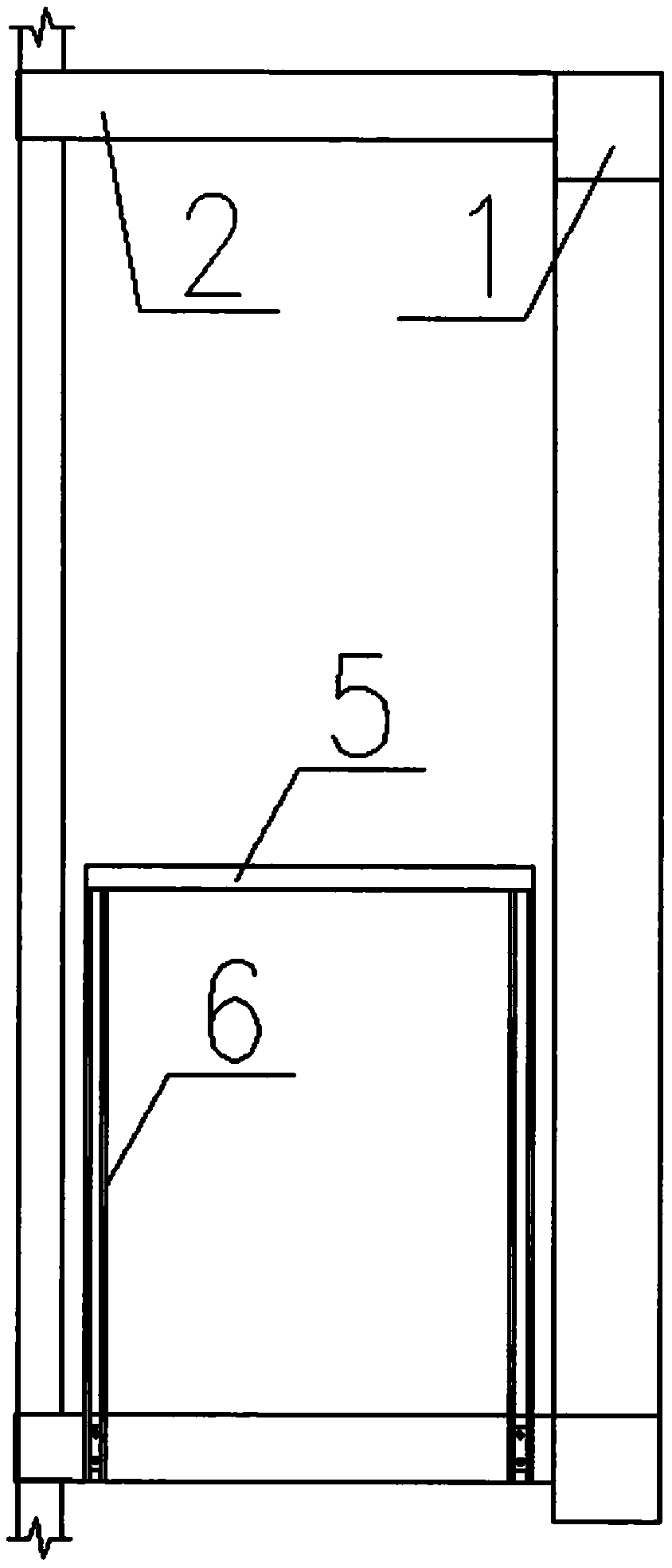

Method for hoisting grid structure and constructing roofing enclosure

InactiveCN101619603AAvoid influenceReduce the impact of forceBuilding roofsRoof toolsPurlinSteel plates

The invention discloses a method for hoisting a net rack structure and constructing a roofing enclosure, comprising the following steps: (1) carrying out the integral ground splicing construction of a steel structural net rack and a steel structural truss according to the conventional construction process; (2) installing a main purlin and a secondary purlin of the roofing enclosure; (3) paving roofing bottom-layer profiling steel plates on positions except for a reserved ventilation opening and a base plate at a side span position; (4) integrally hoisting the steel structural net rack and the steel structural truss, and then installing and fixing the same; and (5) paving the roofing bottom-layer profiling steel plates on the reserved ventilation opening and the side span position. The invention only needs to install safe separation nets, protective barriers and lifelines in areas of the bottom and the circumference of a roofing daylighting band, which are not paved with the roofing base plates; and in addition, compared with an original construction process which needs to fully install the safe separation nets, the protective barriers and the lifelines under a steel structure, the invention greatly saves the input amount of safety protection facilities.

Owner:SHANGHAI CONSTR NO 1 GRP

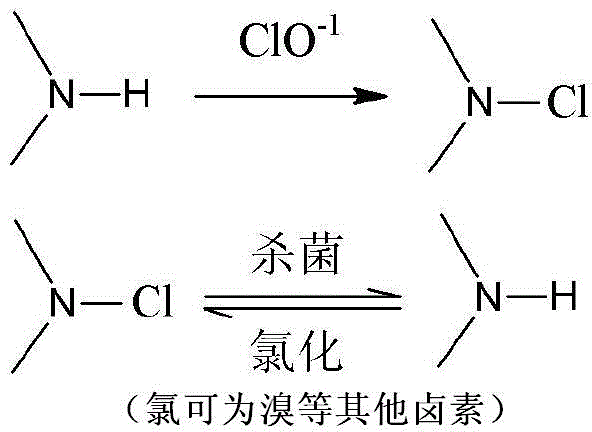

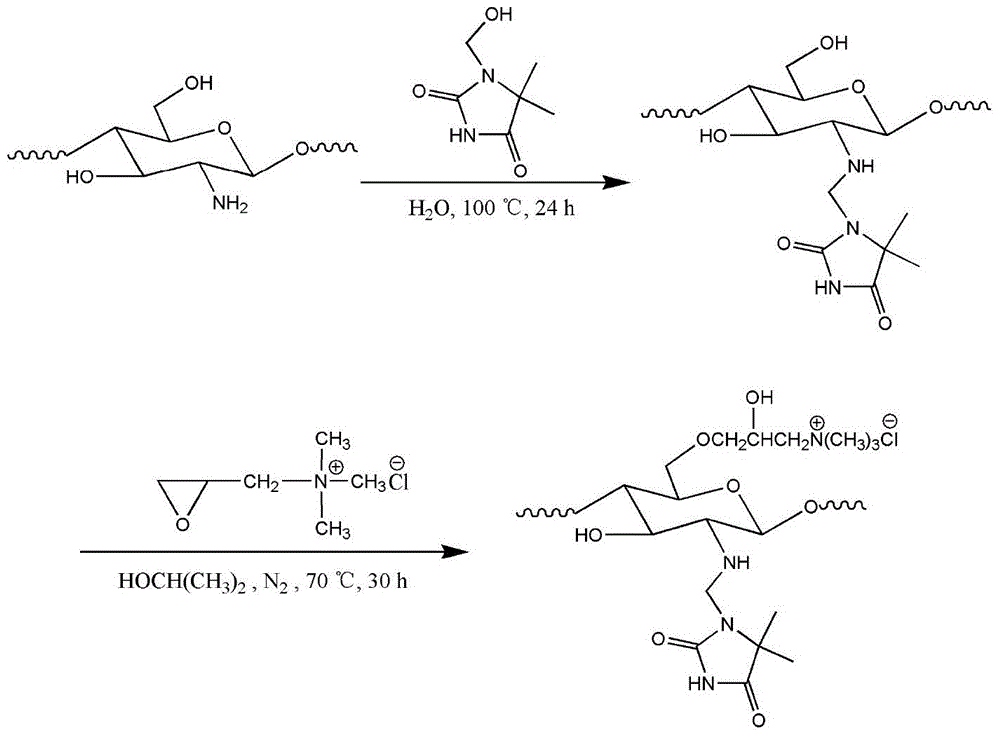

Quaternization hadegen amide modified chitosan and method for preparing antibacterial cotton fabric

ActiveCN104628888AImprove antibacterial propertiesReduce the impact of forceVegetal fibresPolymer scienceFiltration

The invention discloses a method for preparing quaternization hadegen amide modified chitosan. The method comprises the following specific steps: (1) hydroxymethyl hydantoin and chitosan in water, reacting at the temperature of 80-100 DEG C for 24-30 hours, cooling to room temperature after the reaction is ended, performing vacuum filtration, and drying the obtained solids; and (2) mixing the dried solids and 2,3-epoxypropyltrimethylammonium chloride in an isopropanol solution, reacting at the temperature of 60-80 DEG C for 24-32 hours, cooling to room temperature after the reaction is ended, performing vacuum filtration, and drying the obtained solids, thereby obtaining the quaternization hadegen amide modified chitosan. The method disclosed by the invention is easy to operate and low in cost, and the prepared antibacterial cotton fabric has excellent and high-efficiency antibacterial performance and also has good service performance.

Owner:JIANGNAN UNIV

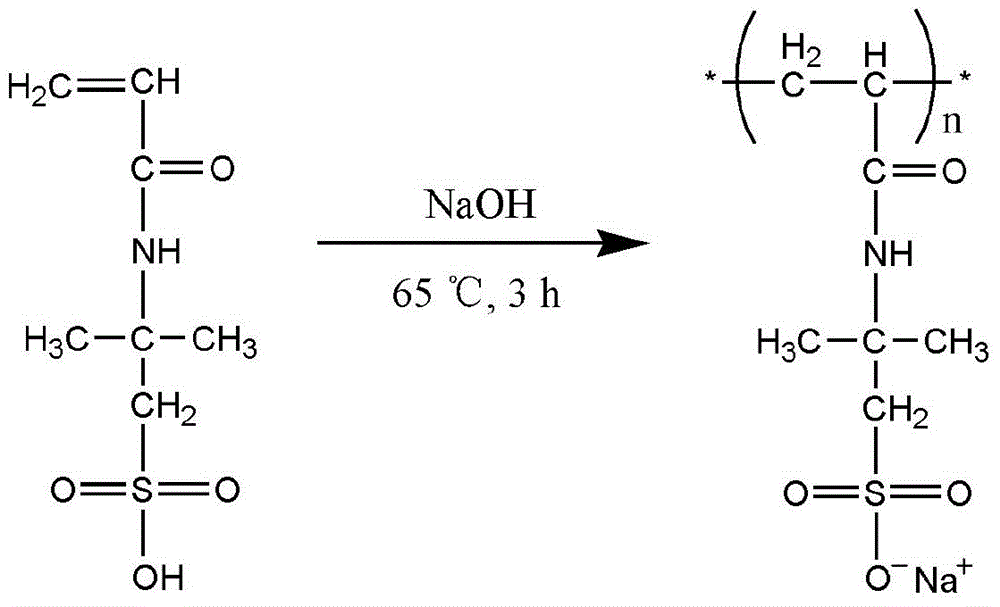

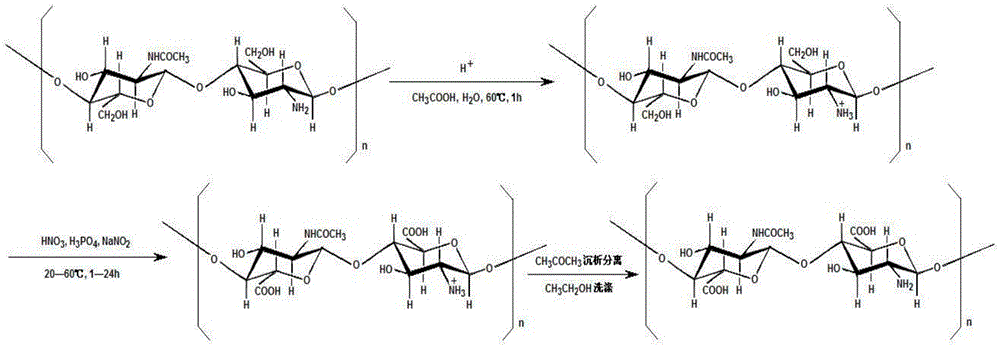

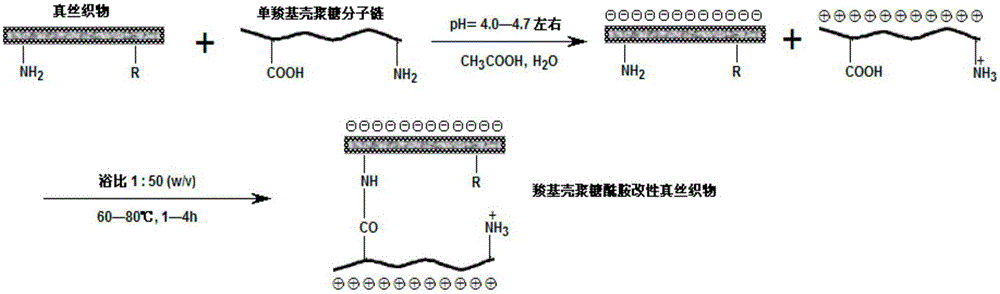

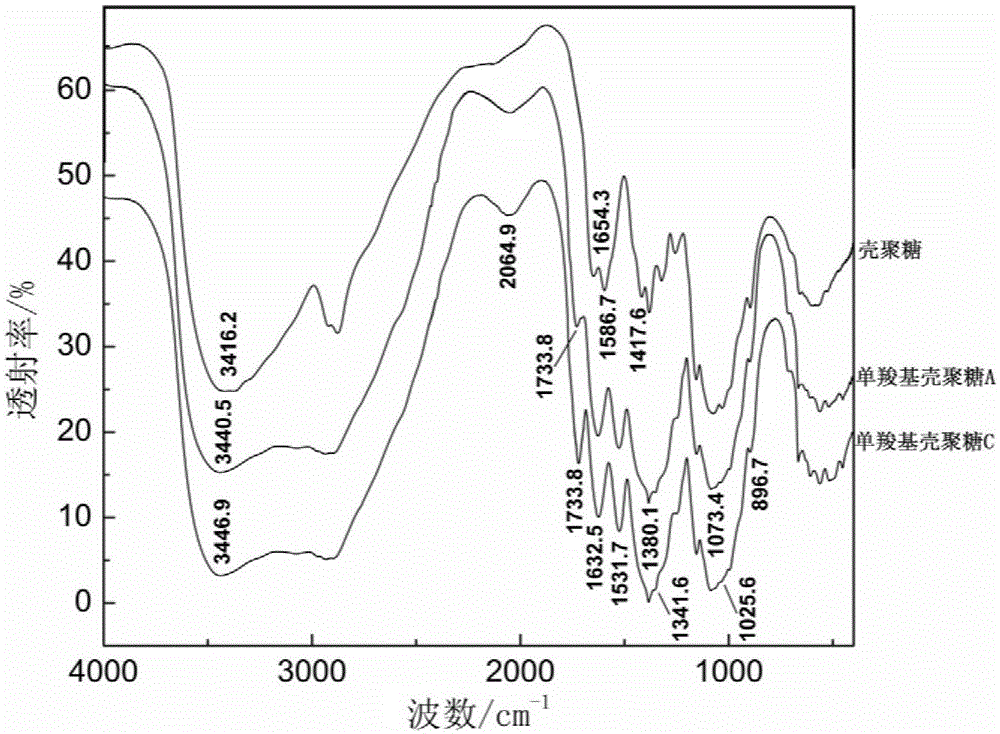

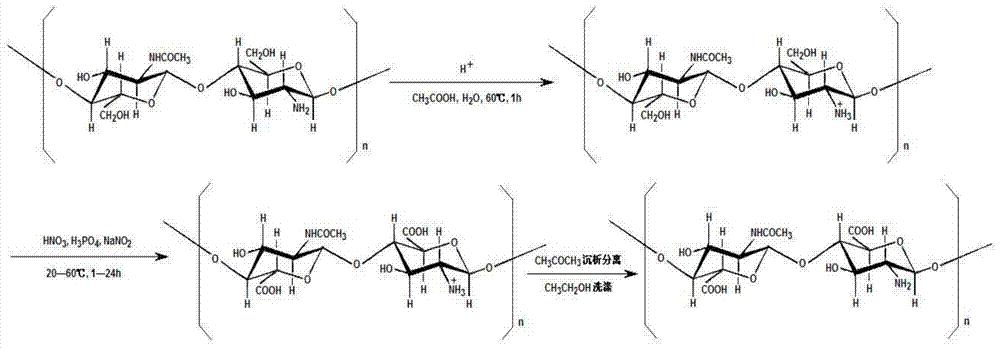

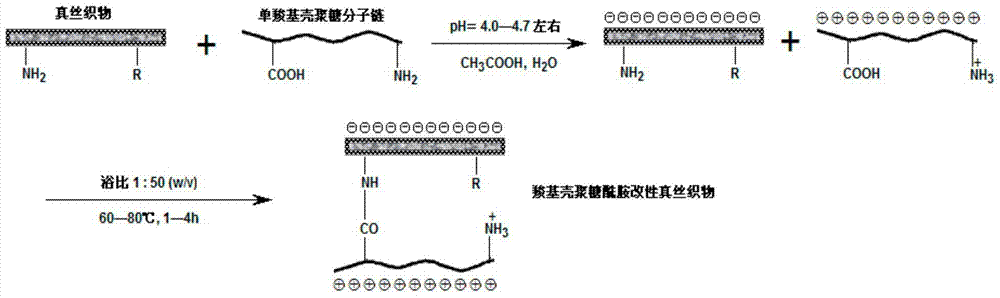

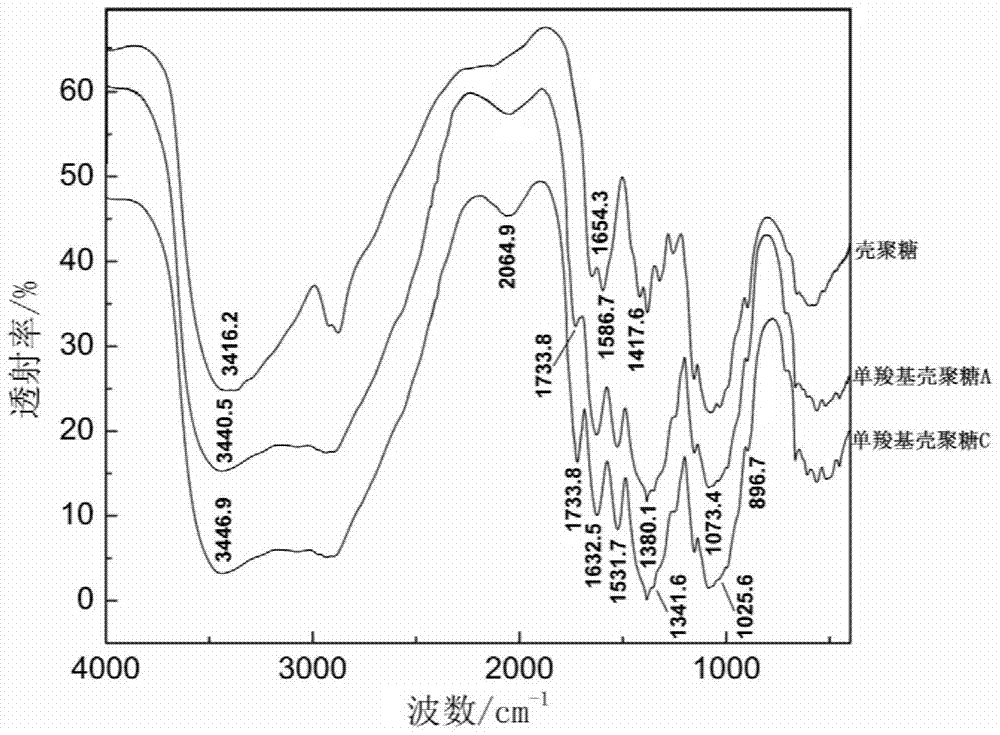

Water-soluble antibacterial monocarboxylic chitosan as well as preparation method and application thereof

ActiveCN105061637AHigh oxidation selectivityQuick responseAnimal fibresPhosphoric acidAntibacterial activity

The invention discloses a water-soluble antibacterial monocarboxylic chitosan as well as a preparation method and application thereof. The preparation method of the monocarboxylic chitosan is characterized by comprising the following steps: dissolving macromolecular chitosan in a diluted acetic acid solution, and then selectively oxidizing part or all of hydroxyl groups at the C6 site of the chitosan into carboxyl groups by utilizing a concentrated nitric acid-concentrated phosphoric acid-sodium nitrite system, thereby obtaining the monocarboxylic chitosan. The water-soluble antibacterial monocarboxylic chitosan disclosed by the invention can be used for carrying out amide modification on real silk fabrics so as to obtain monocarboxylic chitosan amide modified real silk fabrics. The method disclosed by the invention is simple in operation, high in reaction speed and easy to control, the prepared monocarboxylic chitosan amide modified real silk fabrics have lasting and efficient antibacterial activity and good wearability and are environment-friendly, and the negative effects on good real silk characteristics and human health caused by using chemical crosslinking agents in conventional chitosan modification are overcome.

Owner:ANHUI AGRICULTURAL UNIVERSITY

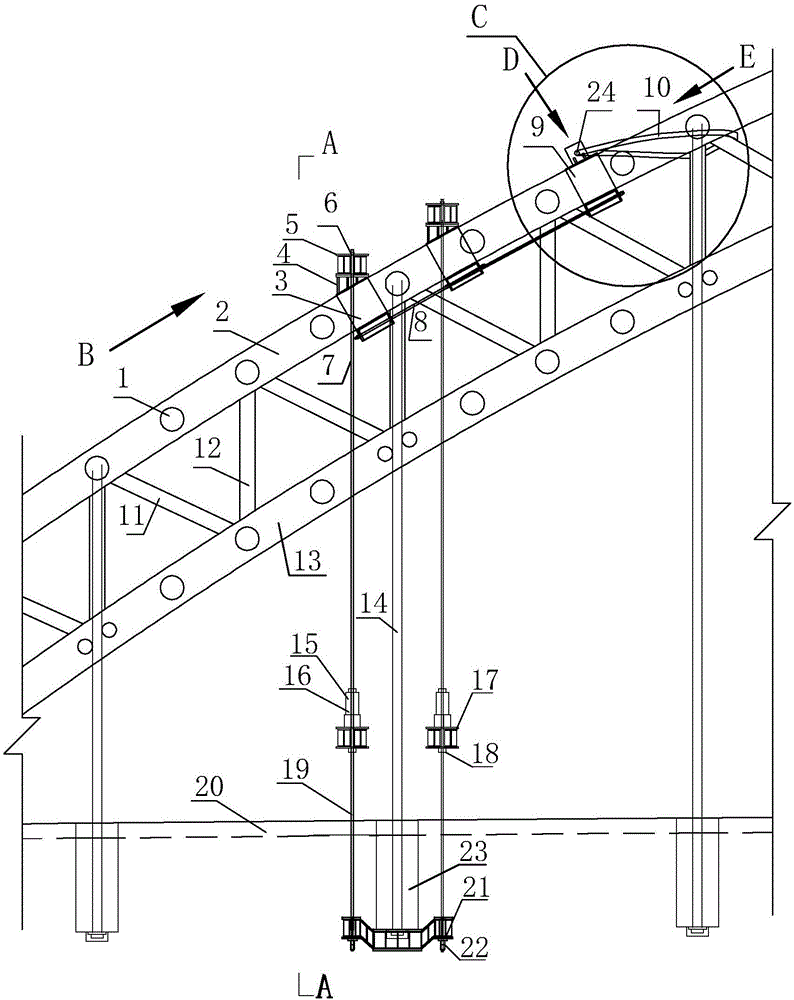

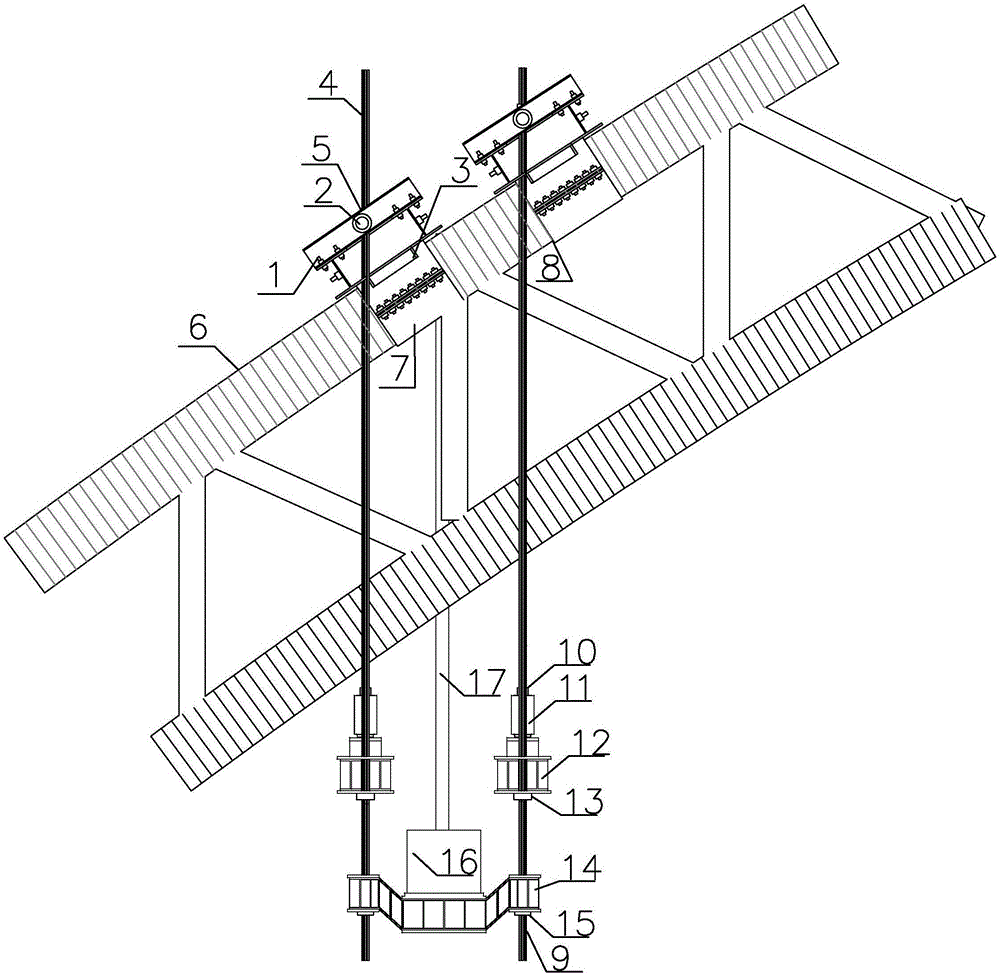

Hoop type tool suspender device for changing steel pipe truss concrete arch bridge suspender

ActiveCN106087770AReduce the impact of forceAnti-slip realizationTruss-type bridgeBridge structural detailsJoistSteel tube

The invention discloses a hoop type tool suspender device for changing a steel pipe truss concrete arch bridge suspender. The device comprises an upper cross beam, a tensioning-end anchorage, upper and lower temporary ropes, a conversion beam, a fixing-end anchorage, a lower joist and a hoop type arch crown anchoring antiskid system consisting of a bolt, a lifting belt, an anchoring hoop, a leveling steel box, an upper cross beam, an antiskid rope and an antiskid hoop, wherein one end of the anchoring hoop is anchored on a steel pipe truss arch ring by the bolt and the lifting belt through a winding way; one end of the antiskid rope is fixedly connected with the bottom of the anchoring hoop, and the other end is fixedly connected with the bottom of the antiskid hoop; and the antiskid hoop and the anchoring hoop are connected through a steel strand or a rigid pull rod. When the device is used for changing the suspender, with the hoop type anchoring antiskid system arranged on the arch, the upper temporary rope is connected with a bridge floor conversion beam, the lower joist is arranged below the lifting rod cross beam, the lower temporary rope is connected with the bridge floor conversion beam, and a jack on the bridge floor conversion beam is tensioned to realize conversion of the suspender force; and moreover, the structure is simple, and the manufacturing and construction cost is low.

Owner:LIUZHOU OVM ENG

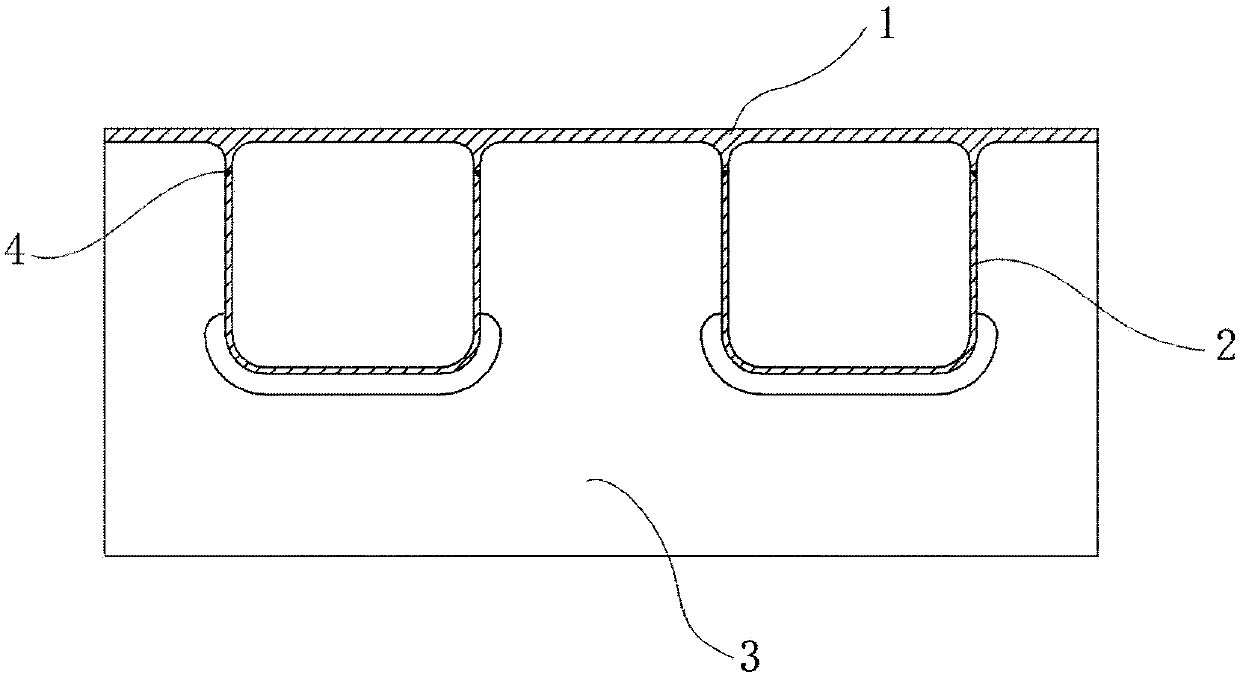

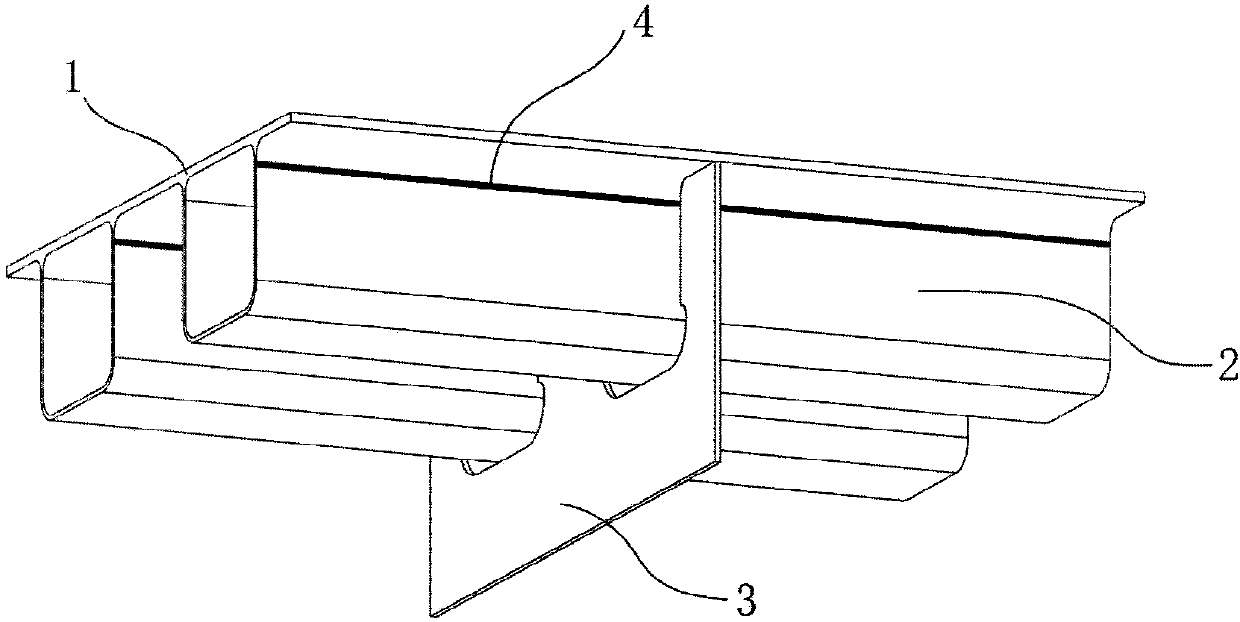

Orthotropic steel bridge deck structure with HRP cover plate

InactiveCN107938508AImprove integrityAvoid stressBridge structural detailsBridge engineeringButt joint

The invention provides an orthotropic steel bridge deck structure with an HRP cover plate. The orthotropic steel bridge deck structure comprises a hot-rolled ribbed cover plate, a plurality of longitudinal stiffened ribs and transverse ribs. The HRP cover plate has the characteristics of good integrity and high rigidity. The connection part between a plane plate and ribs adopts an arc-shaped gradual transition to effectively avoid the problem of excessive local stress on a steel bridge deck under the action of concentrated wheel loads. Welding seams are arranged on the positions, where the stress amplitude is relatively small, of web plates of longitudinal ribs, and the welding process is changed from single-side partial penetration welding to butt-joint complete penetration welding so asto effectively improve the anti-fatigue performance of the steel bridge deck. The orthotropic steel bridge deck structure with the HRP cover plate has the advantages of simple structure, reasonable stress, high durability, convenient maintenance and reinforcement and wide application prospects in the field of steel-structure and composite-structure bridge engineering.

Owner:CHONGQING UNIV

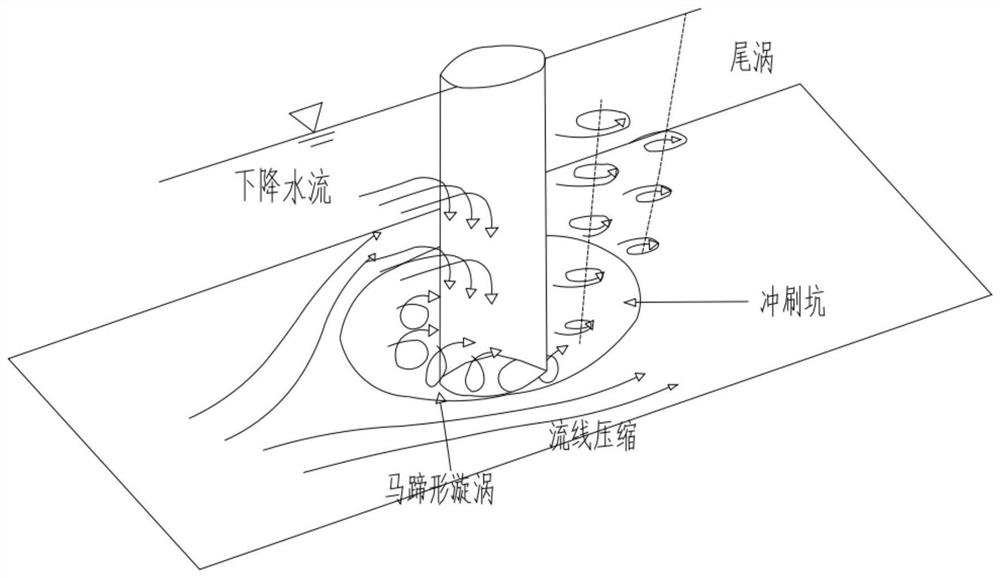

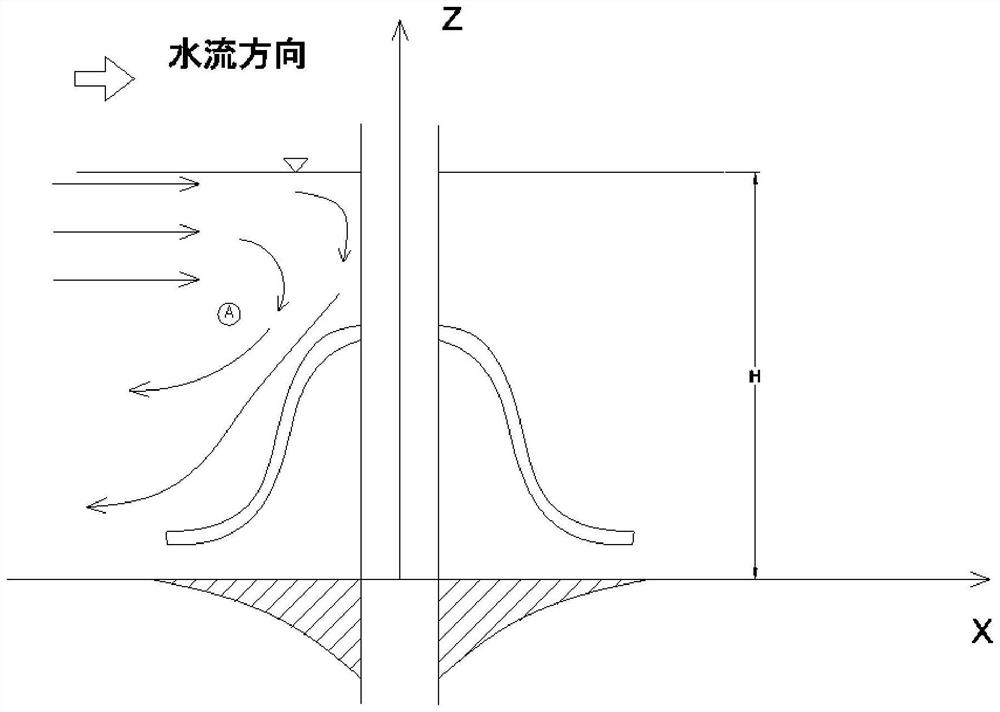

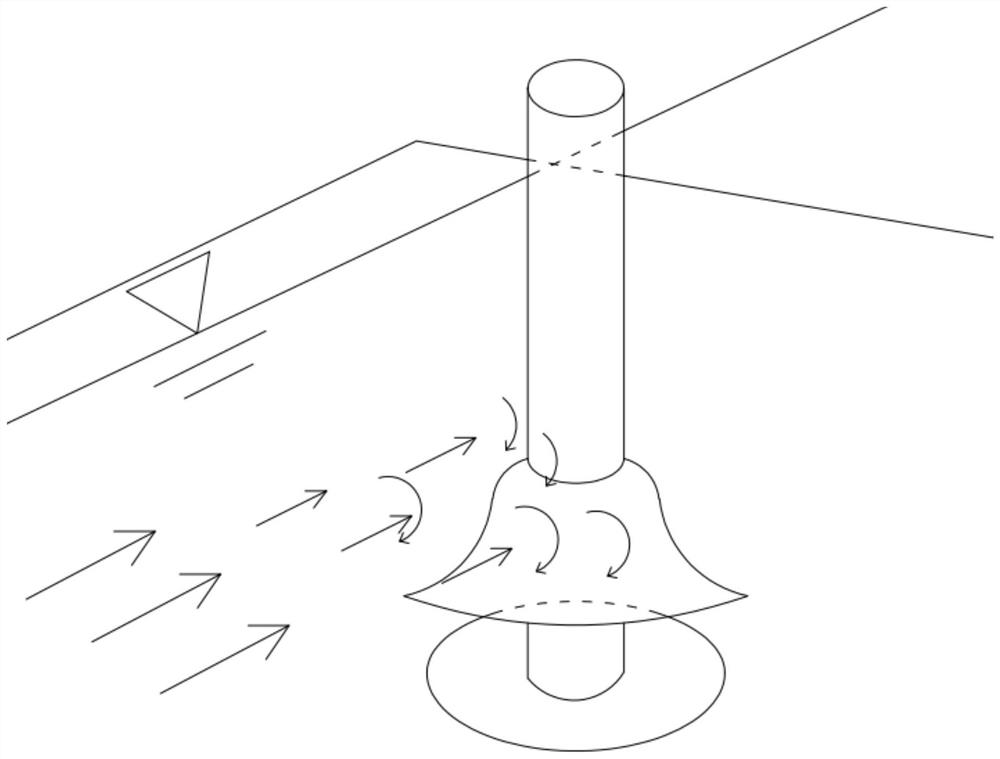

Pier local scouring protection device with rotary normal curved surface

InactiveCN112160288AReduced horseshoe vortexReduce the impact of forceClimate change adaptationBridge structural detailsWater flowRiver bed

The invention discloses a pier local scouring protection device with a rotary normal curved surface. The protection device is sleeved on a pier and is approximately in a bell shape, the thickness of the protection device is 0.5-1 m, and the inner surface of the protection device meets an equation of a standard rotary normal curved surface. The protection device is combined with the reciprocating flow characteristic, front impact water flow can be dispersed, the protection device is lifted away from the periphery of the pier in the tangential direction of a convex surface, and water flow impactis reduced; on the other hand, downward scouring water flow can be guided, downward scouring continues to be carried out, the direct scouring effect of the downward scouring water flow on a bed surface is weakened at the position farther away from the pier along the concave surface, and part of front impact water flow can be counteracted; and meanwhile, horseshoe vortexes around the pier are reduced, scouring of the horseshoe vortexes to a pier riverbed is weakened, and meanwhile the stress influence on the pier is small.

Owner:ZHEJIANG UNIV

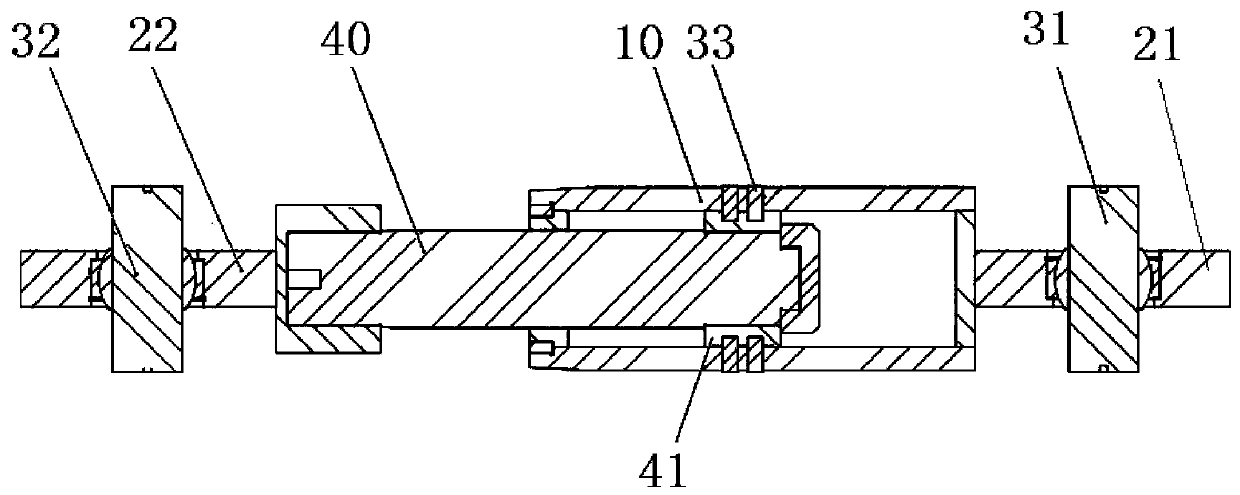

Device for replacing traction friction type anchoring hanger rod and method for replacing steel tube arch bridge hanger rod by using device

ActiveCN105401532AReduce the impact of forceIncrease coefficient of frictionBridge erection/assemblyBridge strengtheningSteel tubeArch bridge

The invention discloses a device for replacing a traction friction type anchoring hanger rod. The device comprises a fixed end anchoring tool, a stretching end anchoring tool, an upper transfer girder, upper and lower steel strands, a lower supporting beam, and a traction friction anchored type arch top anchoring skid resisting system which is mounted on an arch of an arch bridge, wherein the arch top anchoring skid resisting system comprises a friction anchoring device I consisting of two groups of upper and lower riding type clamping devices I and two pull rods I, and a friction anchoring device II consisting of two upper and lower riding type clamping devices II and two pull rods II; the two ends of a pulling cable are respectively anchored on the upper riding type clamping devices I or the upper riding type clamping devices II; a pulling jack is driven to stretch the pulling cable to realize skid resistance of the traction type arch top friction anchoring skid resisting system; four rotary lifting tools for levelling are respectively positioned at the two ends of the two upper riding type clamping devices I and the two upper riding type clamping devices II and rotate through pin shafts so as to adaptively realize levelling of the lifting tools; according to the device, small influences are caused to stress of an original structure during a cable force transfer process of hanger rod replacing; convenience is provided for standard construction; high work efficiency is realized.

Owner:LIUZHOU OVM ENG

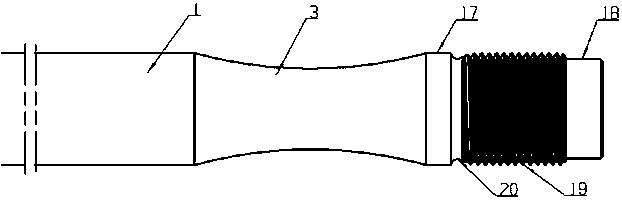

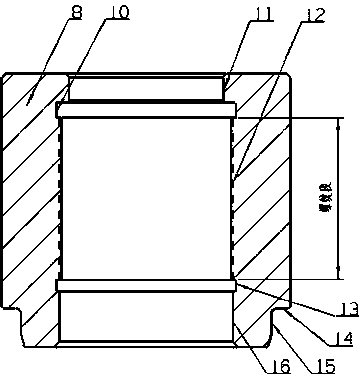

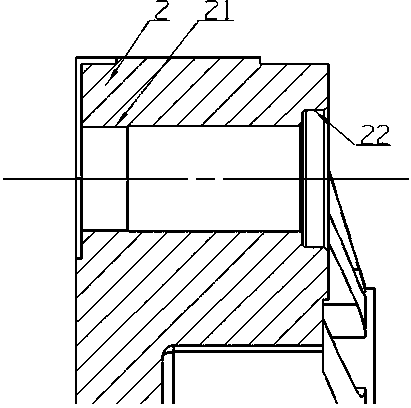

Drag-link mechanism of injection molding machine

A drag-link mechanism of an injection molding machine comprises an injection molding machine head template, a drag link and a nut, wherein the drag link penetrates through the head template and is fixed by the nut; the drag link comprises a threaded section and a supporting shaft section; the nut comprises an internal thread and a supporting sleeve section; and when a threaded section formed when the nut and the drag link are fixed is screwed up, the supporting shaft section and the supporting sleeve section are in clearance fit to form a supporting section. According to the drag-link mechanism, the threaded section of the drag link is protected through the radial constraint applied by the supporting sleeve section of the nut to the supporting shaft section of the drag link, so that bending of the threaded section of the drag link is prevented; in addition, by the aid of positioned matching of the supporting sleeve section and a supporting shaft, the bending of the threaded section of the drag link is protected obviously. Besides, by the aid of positioned matching of an opening supporting sleeve of a drag link hole of the injection molding machine head template and an external supporting shaft section of a drag-link nut, the influence on annular surface stresses during template deformation is weakened, and the threaded section is protected indirectly. An unloading groove is also formed, so that the bending position of the drag link is flexible and controllable.

Owner:HAITIAN PLASTICS MACHINERY GRP

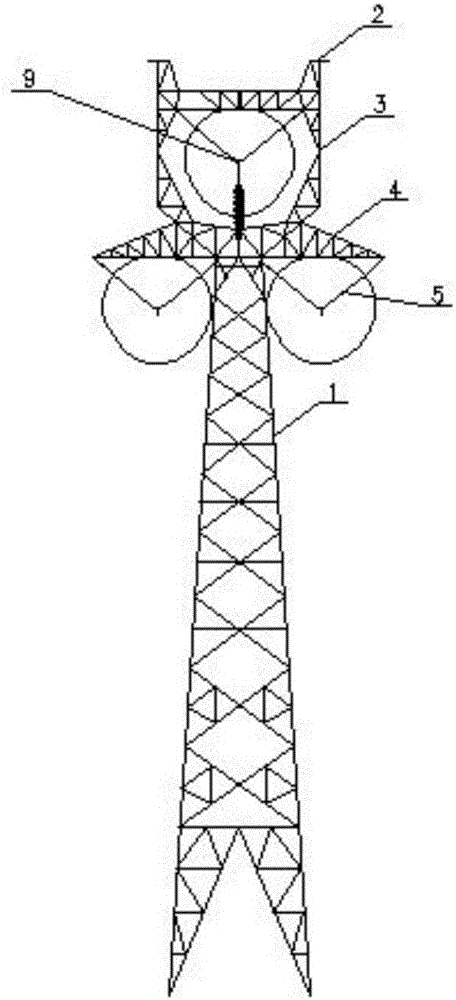

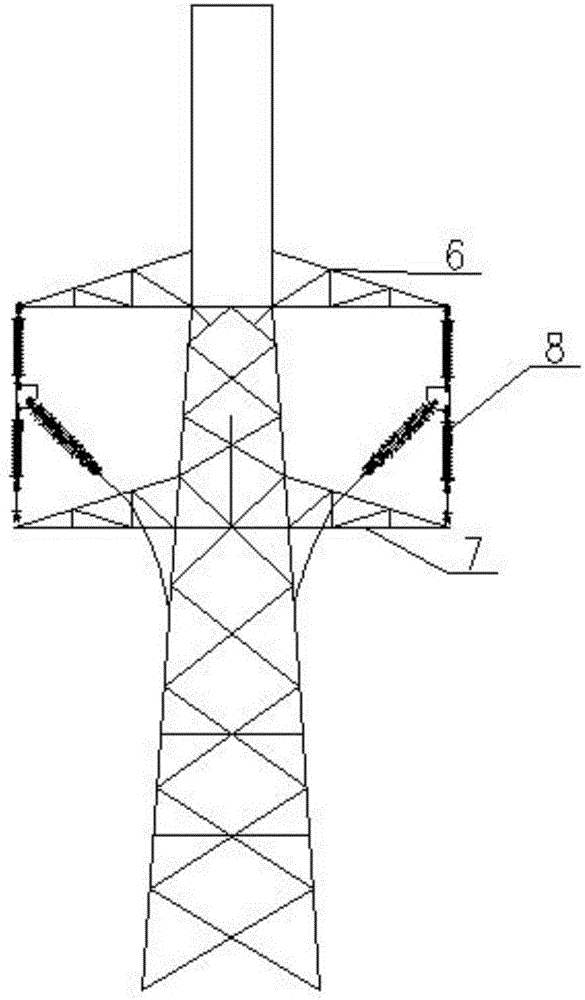

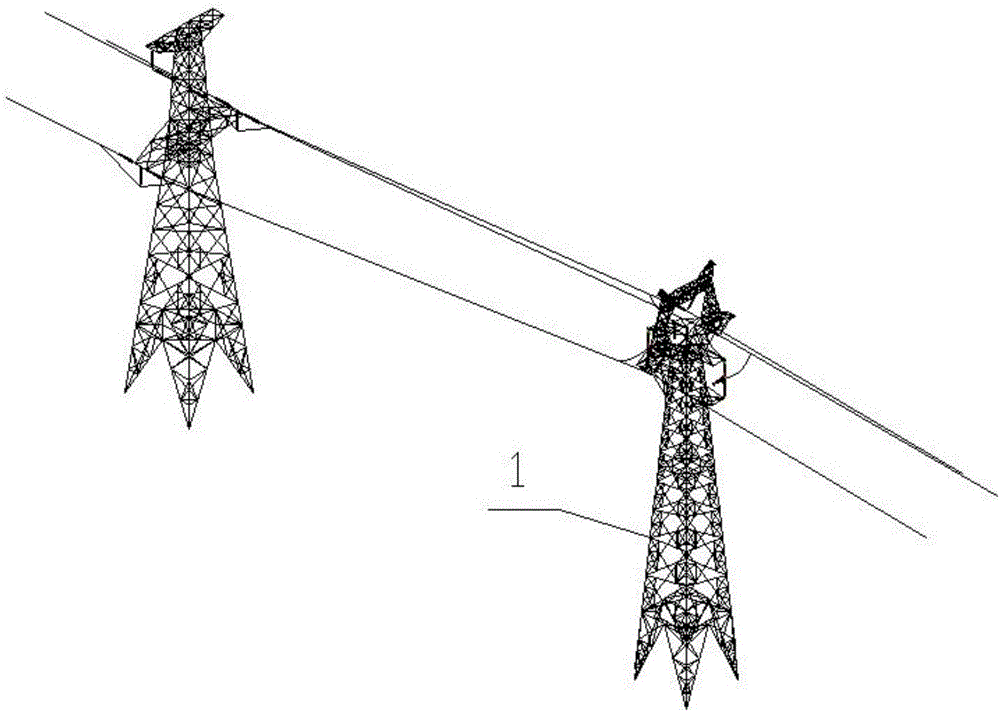

Cat-head type tower for one-way overhead line cable T joint

InactiveCN106555501AReduce the impact of forceLow construction costTowersSpatial arrangements/dispositions of cablesMiddle phaseEngineering

The invention discloses a cat-head type tower for a one-way overhead line cable T joint. The cat-head type tower comprises a tower body, ground wire cross arms, middle-phase wire cross arms, side-phase wire cross arms, upper-layer cable auxiliary cross arms and lower-layer cable auxiliary cross arms; the two layers of ground wire cross arms are located on the uppermost portion of the tower body, arranged to be perpendicular to the line direction and used for hanging ground wires; the middle-phase wire cross arms are located under the ground wire cross arms, V-shaped suspension strings are fixed to the inner upper portions of the middle-phase wire cross arms and used for hanging middle-phase wires, and double-I-type downward cable leading terminals are arranged under wire hanging points arranged in the middle-phase wire cross arms. The cat-head type tower for the one-way overhead line cable T joint has the advantages that the cable T joint is achieved by adopting one base tower, the building cost is low, small area is occupied, little influences on stress of adjacent poles and towers are generated, an original line arrangement mode is not changed, adjacent tower transformation is generally not needed, and the cat-head type tower is suitable for building adjacent linear towers and tension-resistant towers.

Owner:ANHUI HUADIAN ENG CONSULTATING & DESIGN +3

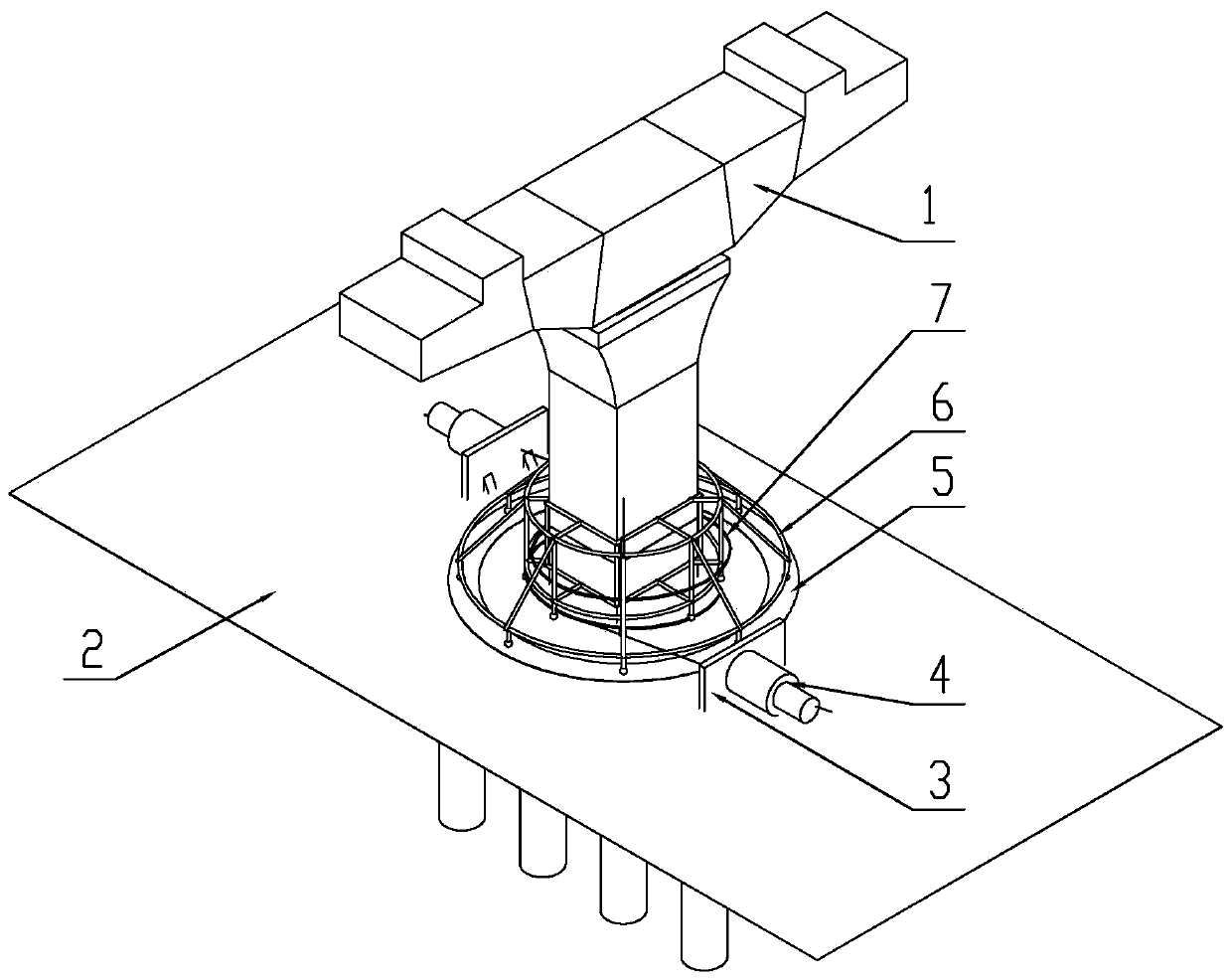

Rotation device for bridge pier and rotation construction method

PendingCN110117936ASave construction spaceAffect trafficBridge structural detailsBridge erection/assemblyEngineeringPolytetrafluoroethylene

The invention provides a rotation device for a bridge pier. The rotation device for the bridge pier includes a rotating part, a reaction part and an anti-overturning part; the rotating part includes arotation jack, a rotation steel strand, a rotating disc lower steel plate, a polytetrafluoroethylene plate, a rotating disc upper steel plate and a rotating shaft; the reaction part includes a reaction pier; and the anti-overturning part includes an anti-overturning clamp and a cement track; the lower end of the reaction pier is fixed to the ground and the side with stiffening ribs of the reaction pier faces the direction of the bridge pier; the rotation jack is installed in the direction, deviating from the bridge pier, of the reaction pier, and the cement track and the bridge pier are concentrically poured on the ground; the anti-overturning clamp is square internally and round externally, hoops around a pier body and is placed on the cement track, and the anti-overturning clamp is wound with the rotation steel strand; and the rotating disc lower steel plate, the polytetrafluoroethylene plate and the rotating disc upper steel plate of the rotating part are sequentially laid in a cylindrical groove of a bearing platform from bottom to top. The rotation device for the bridge pier device is simple in structure and convenient in installation, is applied to the implementation of thebridge pier rotation construction, and has the advantages of low comprehensive cost, short construction period, less influence on the structural force, being capable of saving construction space and the like.

Owner:LIUZHOU OVM MASCH CO LTD

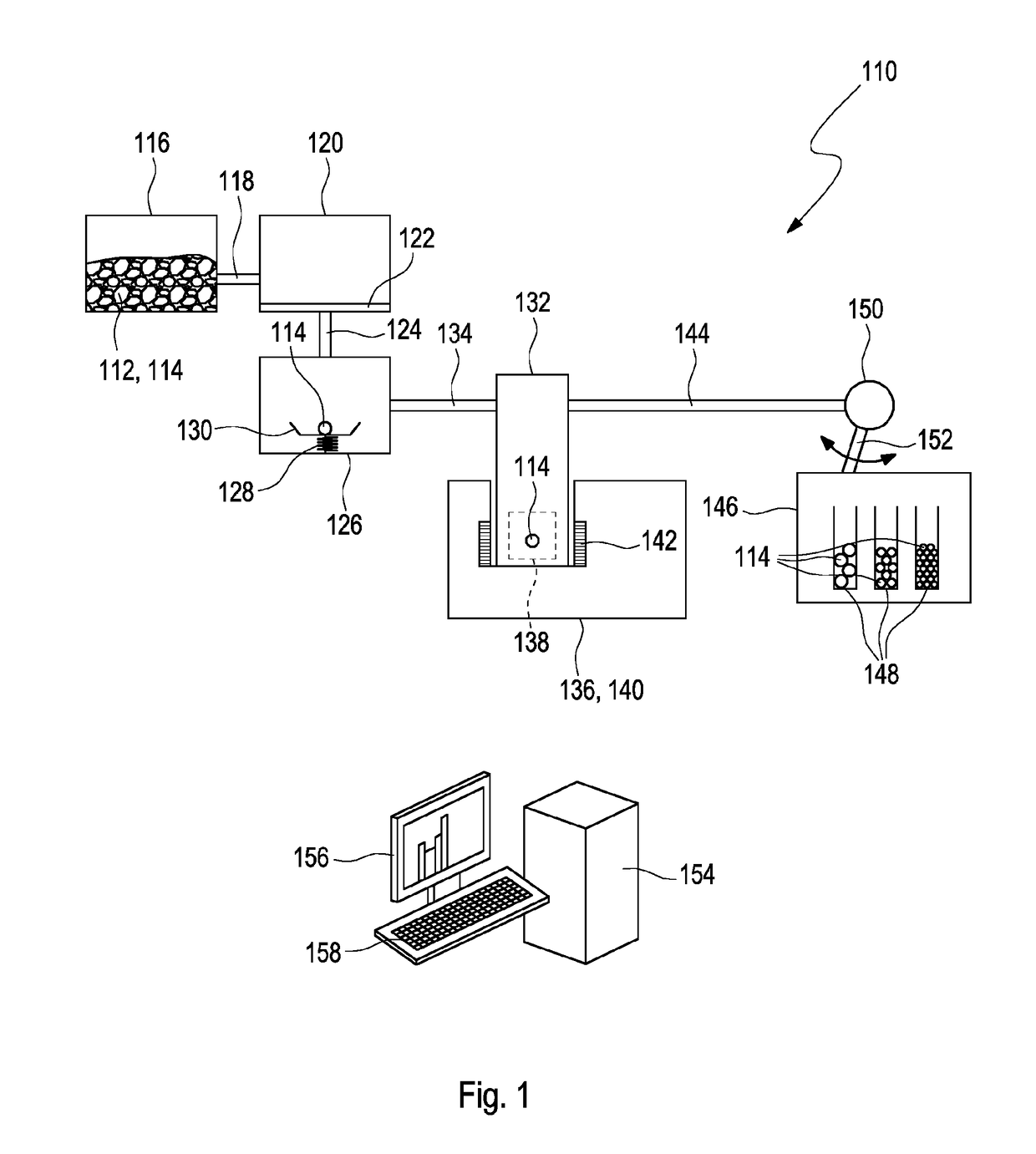

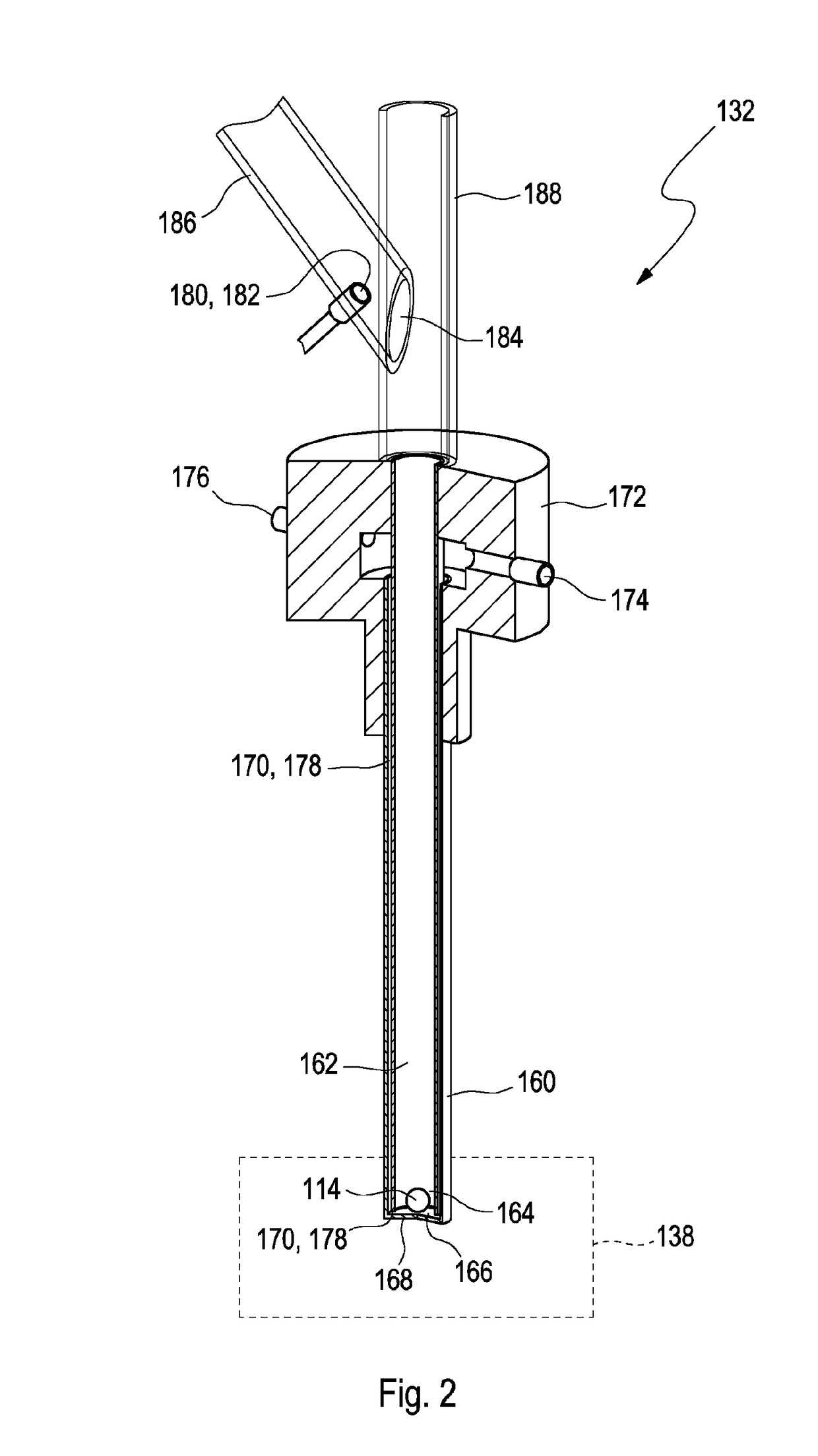

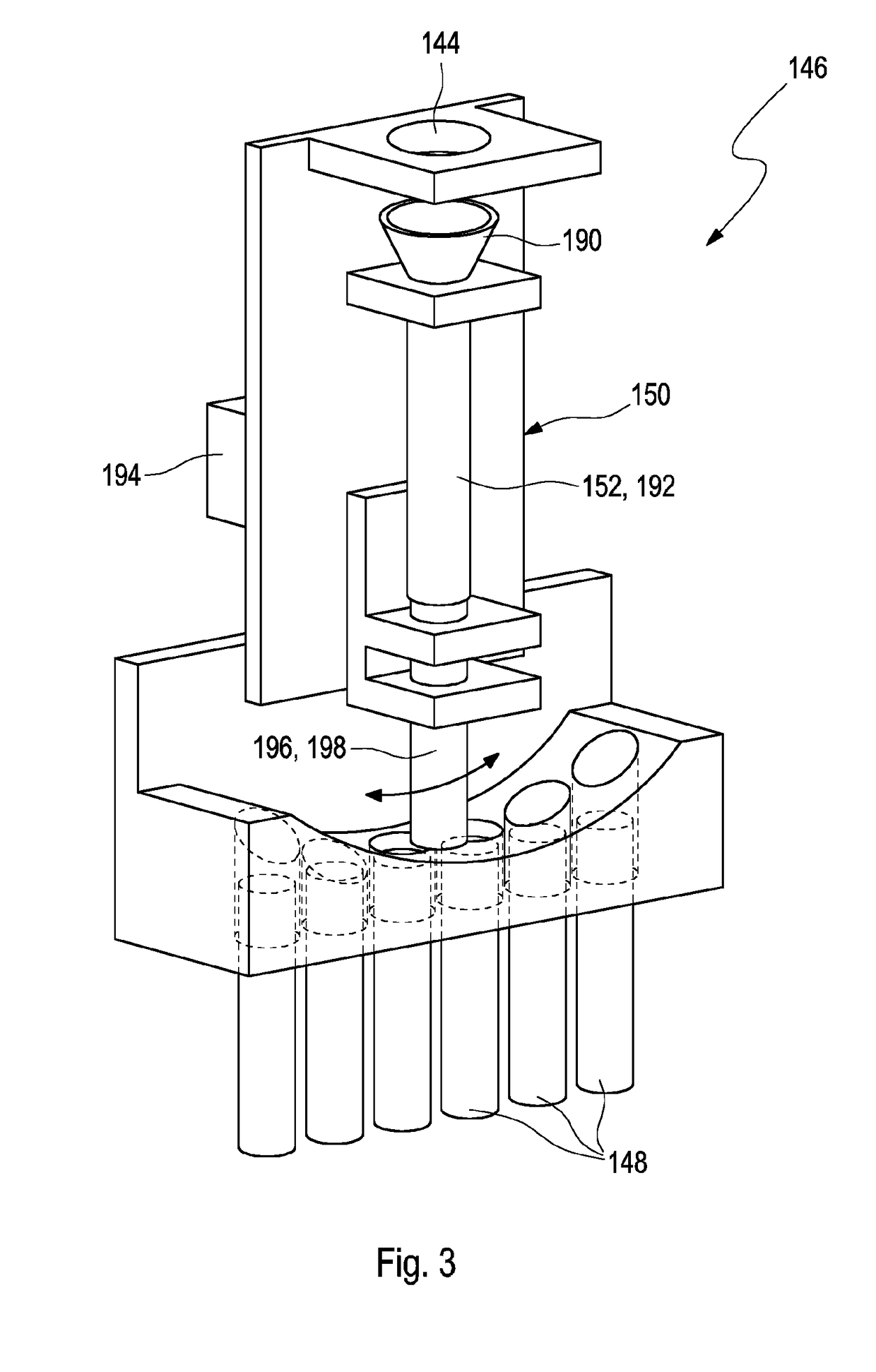

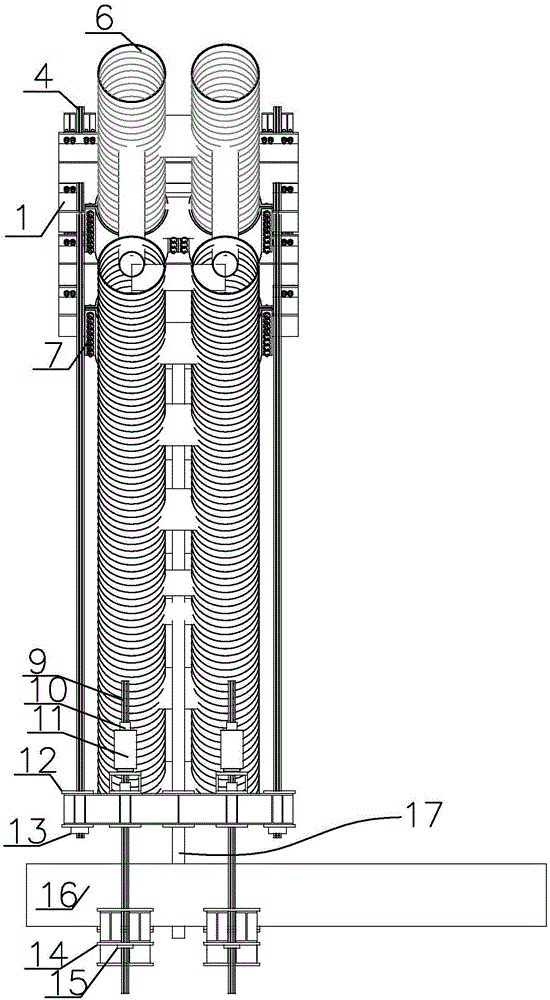

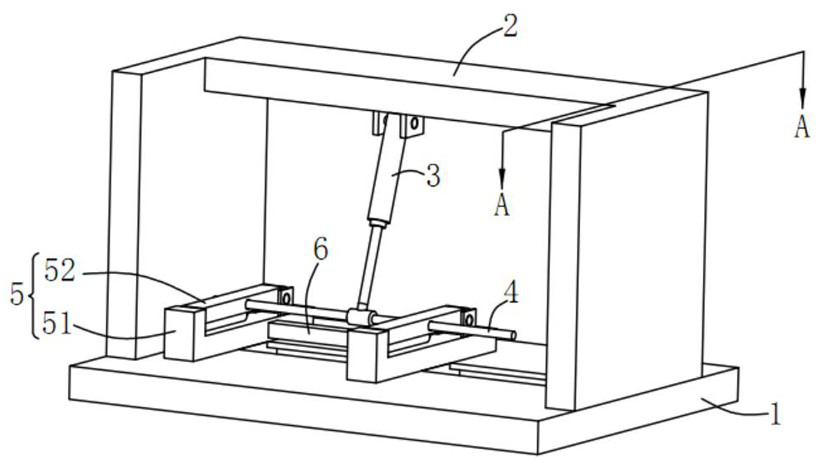

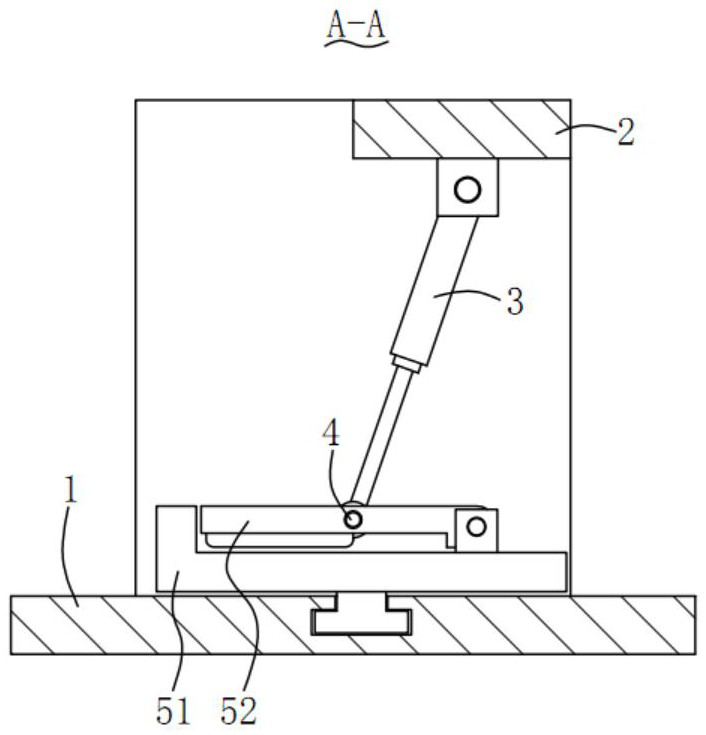

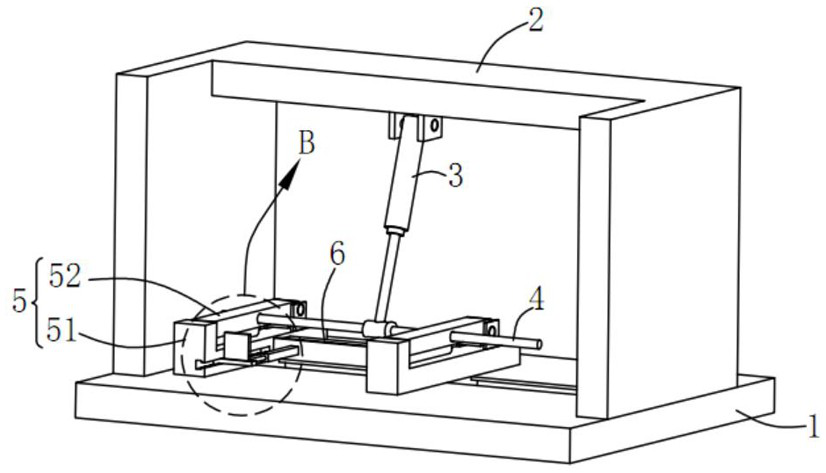

Sampling device for introducing individualized seed grains into a measuring device, system and method for sorting a plurality of seed grains, and uses thereof

ActiveUS20190003931A1Reduce the impact of forceEasy to useMagnetic measurementsWithdrawing sample devicesNMR - Nuclear magnetic resonanceEngineering

The present invention relates to a system (110) and a method for sorting a plurality (112) of seed grains (114). The system (110) comprises an individualizing device (120), a sampling device (132) for introducing the individualized seed grain (114) into a measuring device (136) for the classification of the individualized seed grain (114), a receiving device (146, 200) for receiving the classified seed grain (114) and also a transporting device (118, 124, 134, 144, 152) for the at least partially pneumatic transport of the seed grain (114).The invention also relates to the sampling device (132), which comprises an outer tube (160) for receiving the sampling device (132) into the measuring device (136), a sample chamber (138) of the measuring device (136) being provided within a volume (164) of the outer tube (160). The sampling device (132) also comprises an inner tube (162), which is inserted in the outer tube (160) and has a lower opening (166), whereby the individualized seed grain (114) can be introduced into the volume (164) of the outer tube (160). An intermediate space (170) formed between the outer tube (160) and the inner tube (162) is designed in such a way that the individualized seed grain (114) can be discharged by pneumatic means out of the outer tube (160) through the inner tube (162) into a receiving device (146, 200) for the classified seed grain (114).The system (110) is suitable as an automated high-throughput sorting of seed grains (114) by using the measuring device (136) that is designed for investigations of the seed grains (114) by means of a method of nuclear magnetic resonance (140) and / or an optical measuring method.

Owner:UNIV HOHENHEIM

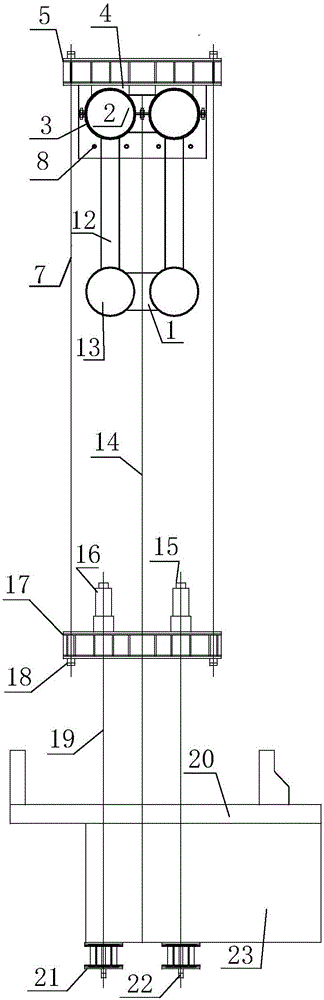

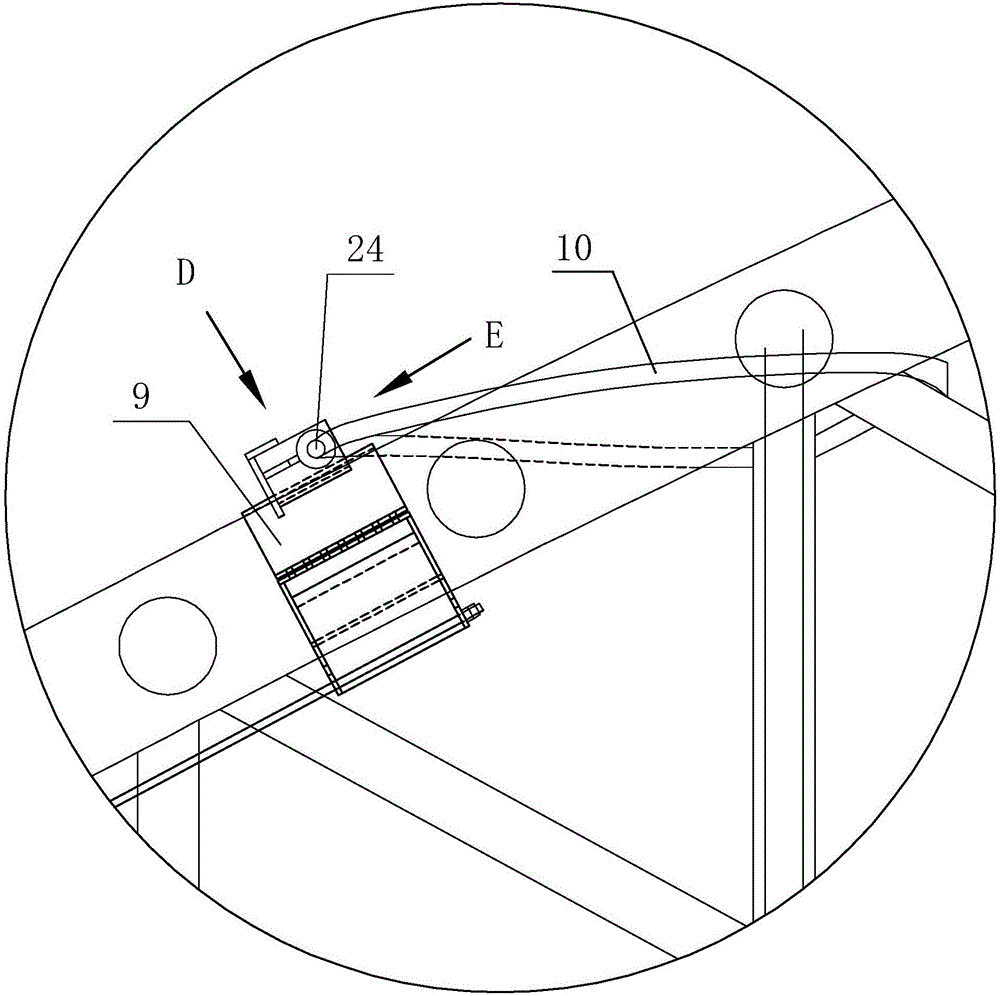

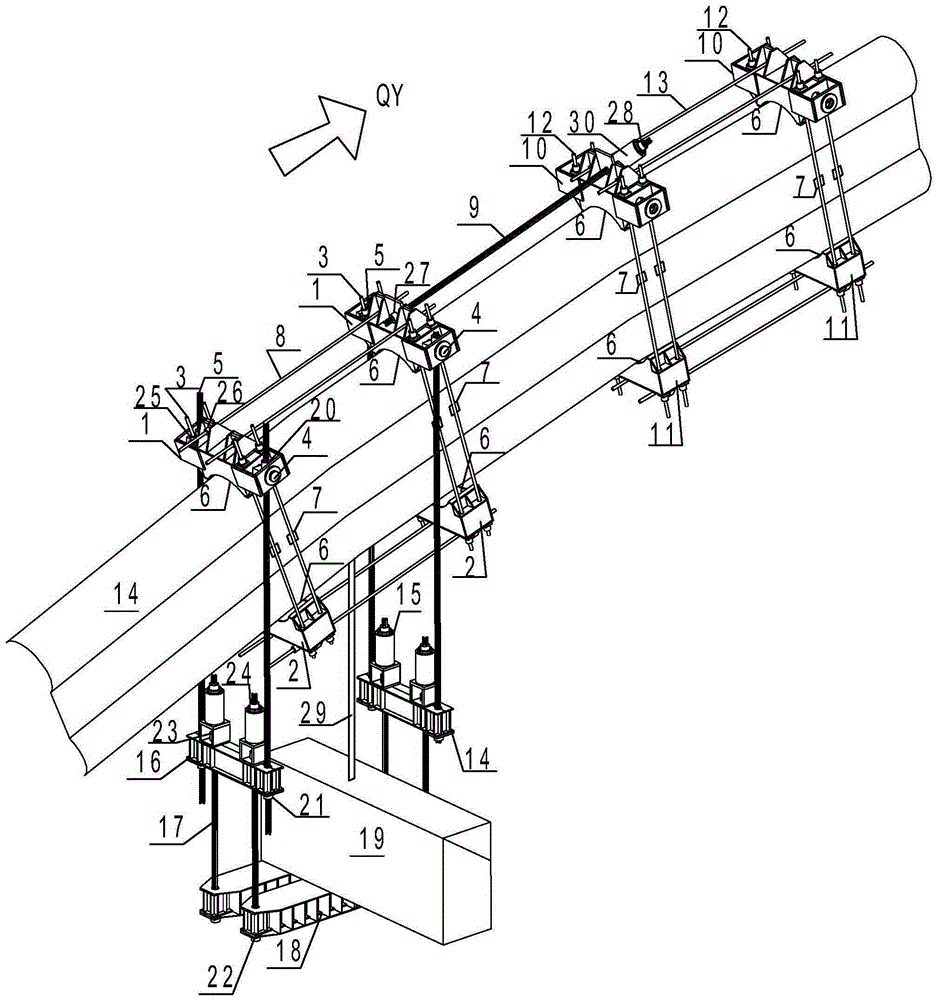

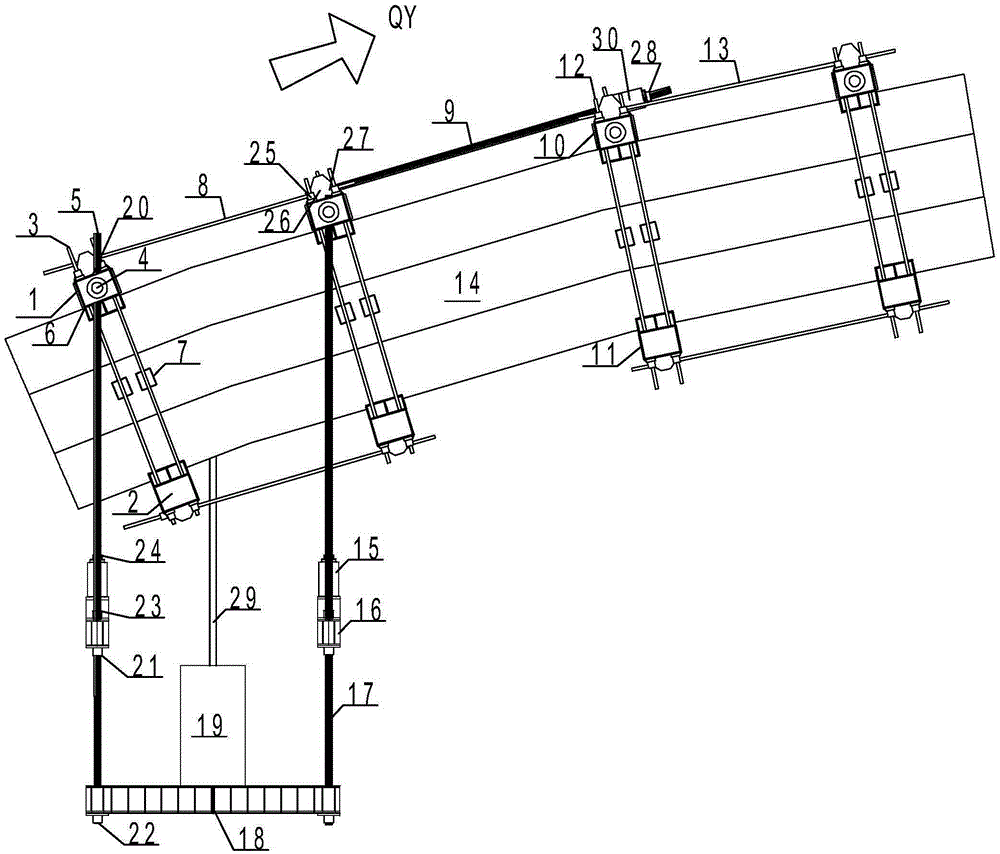

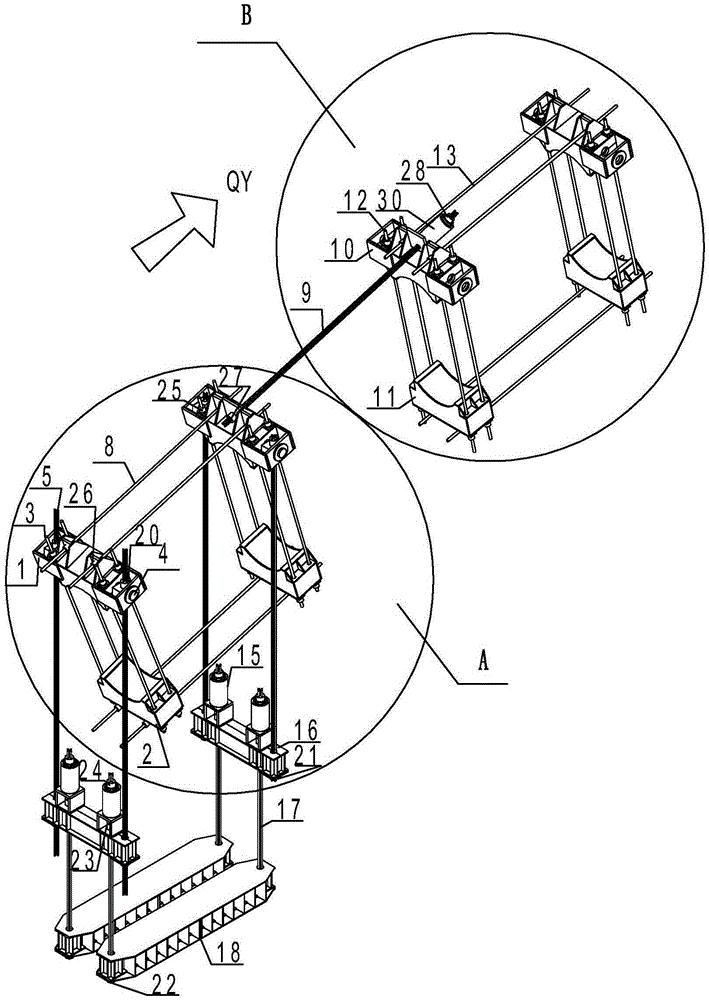

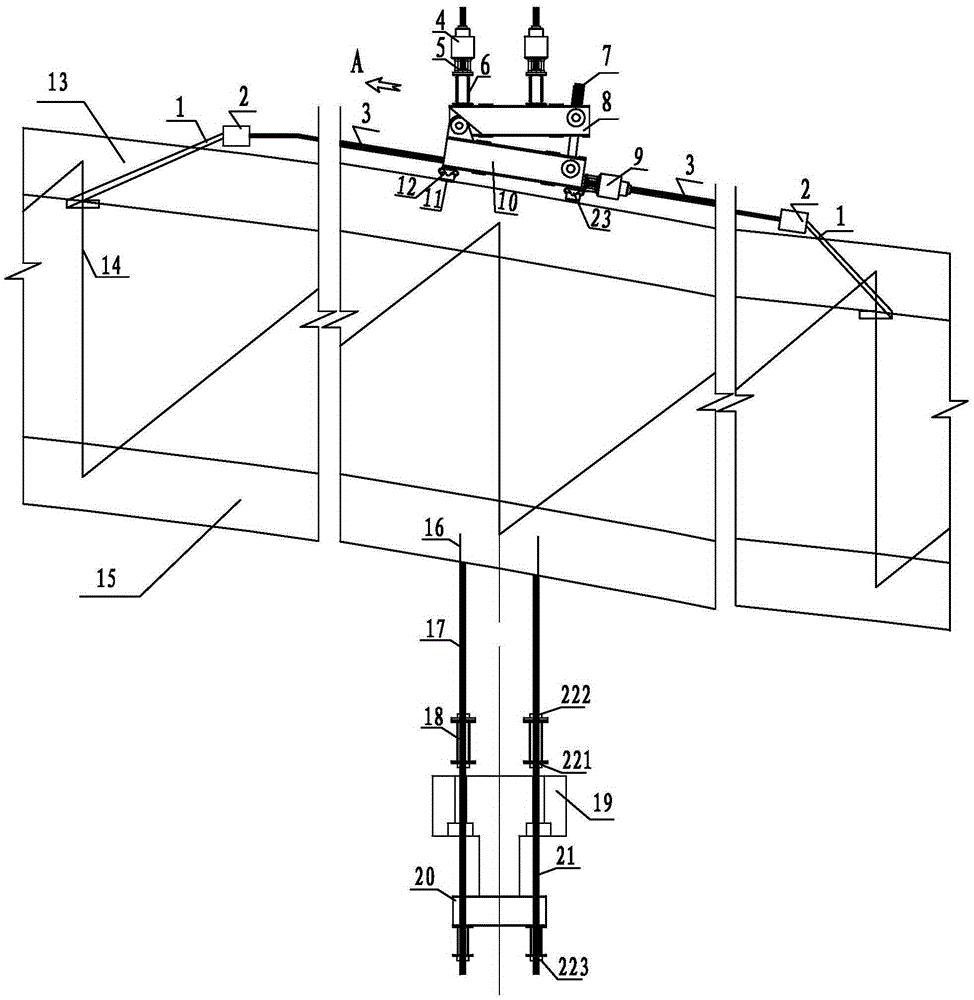

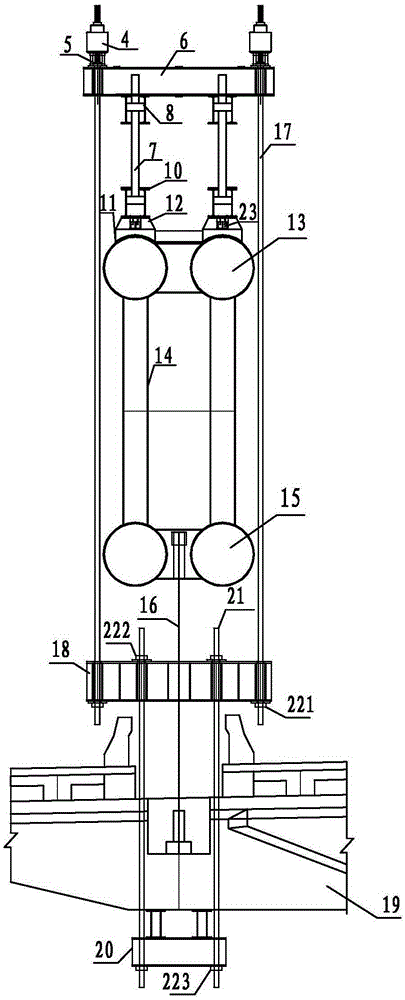

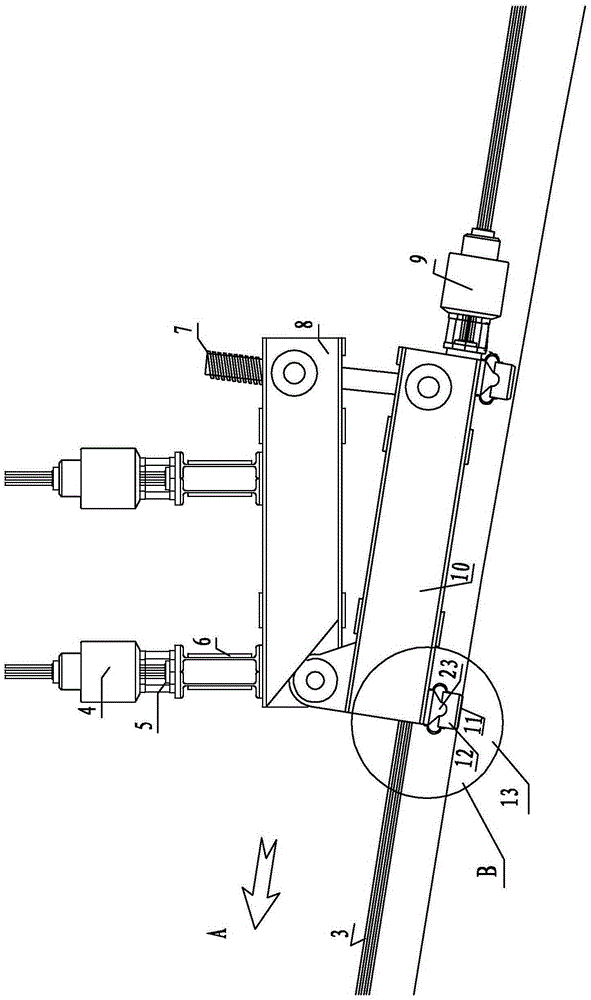

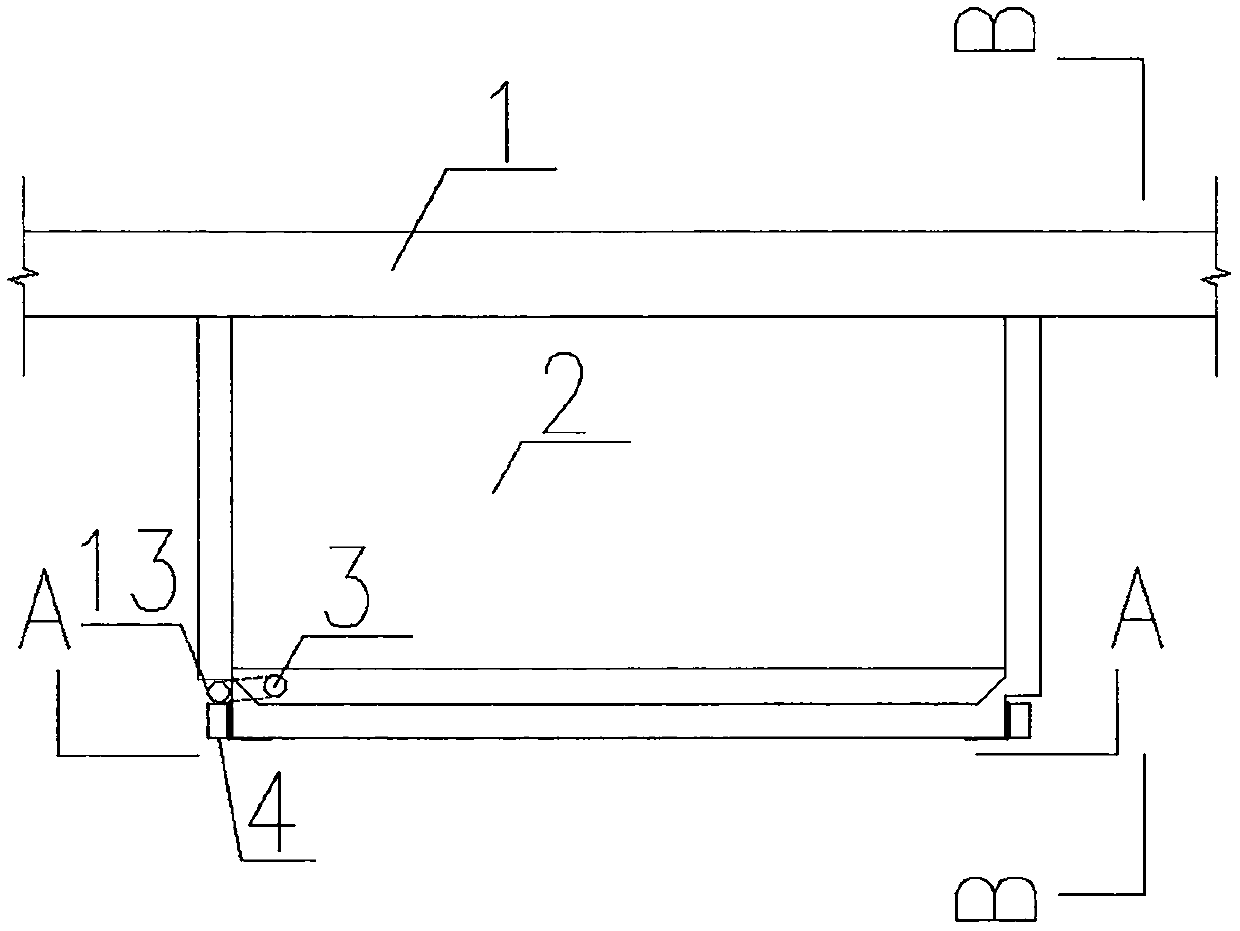

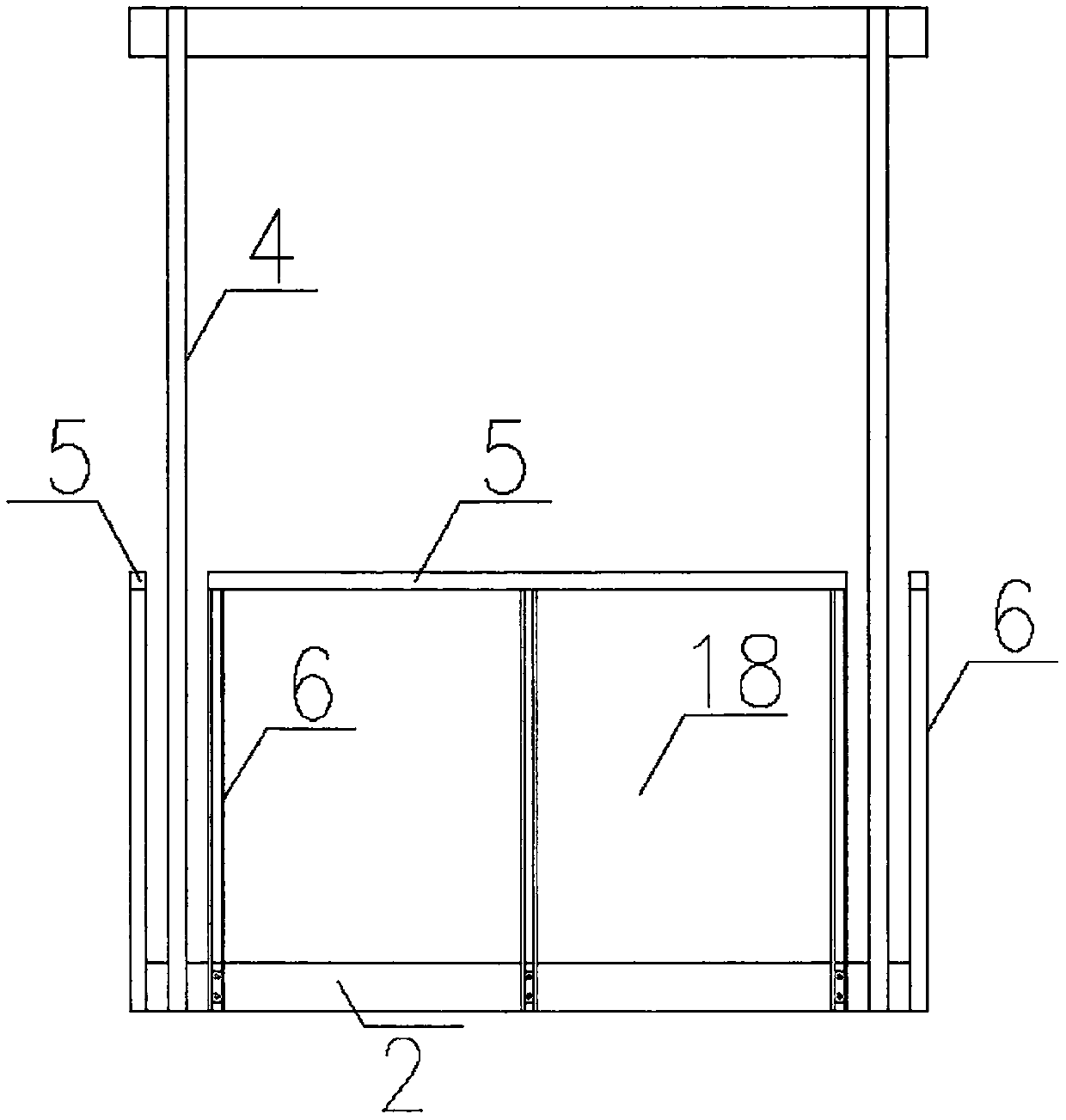

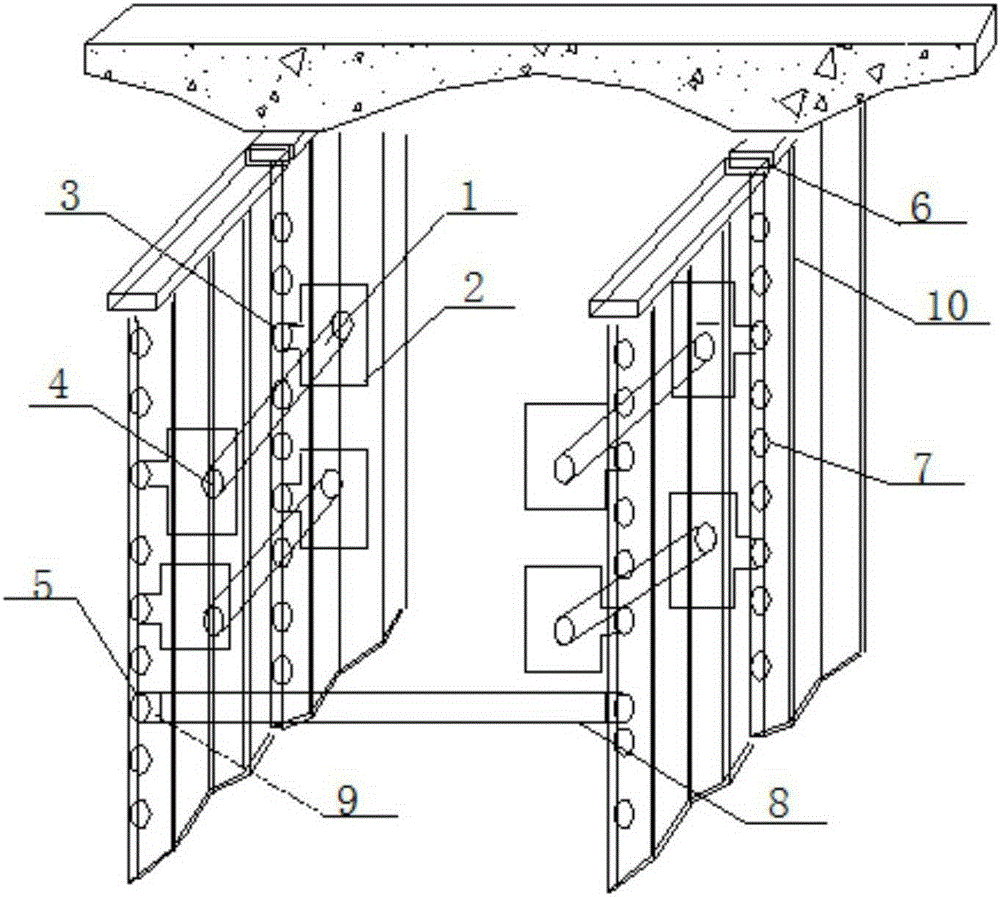

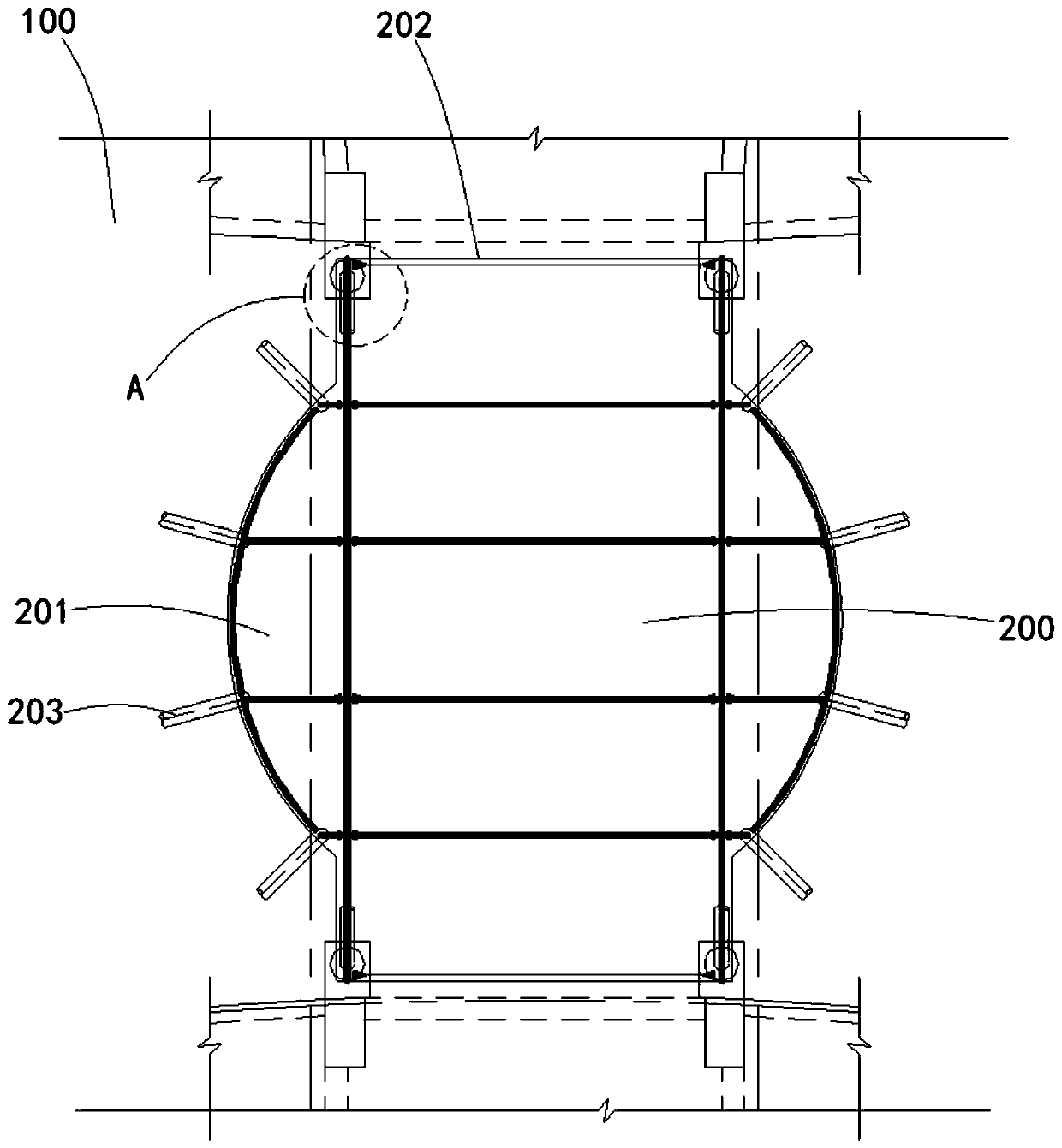

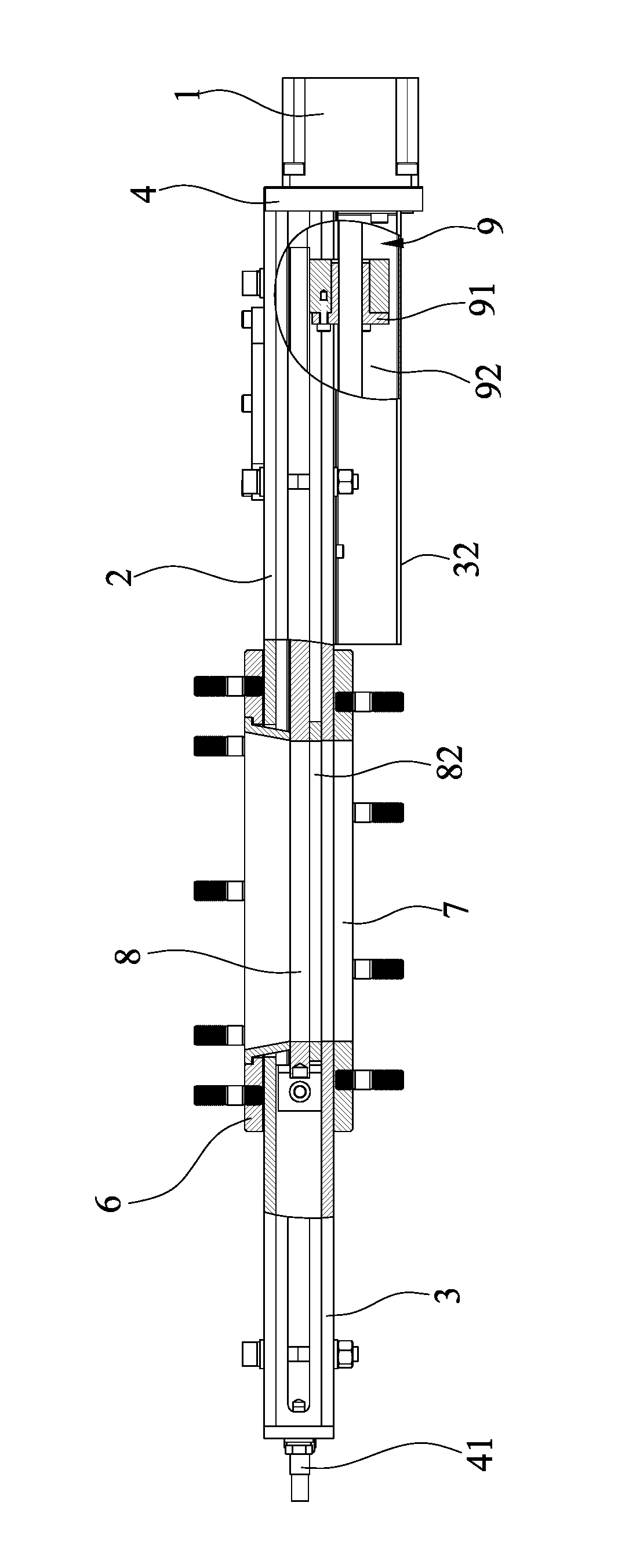

Traction-type tool derrick rig for replacing derricks of steel tube truss-concrete arch bridge

ActiveCN105297631AEnable mobilityReduce the impact of forceBridge erection/assemblyArch-type bridgeJackscrewEngineering

The invention discloses a traction-type tool derrick rig for replacing derricks of a steel tube truss-concrete arch bridge. The traction-type tool derrick rig comprises fixed end anchorage devices, tensioning end anchorage devices, upper conversion beams, temporary derricks, a sling device, and a traction-type arch crown anchorage and anti-slide system composed of hanging belts, anchorage beams, traction ropes, traction jacks, slide shoes, slide plates, travelling mechanisms, levelling mechanisms, cross beams and adjustable screws, wherein one end of each of one hanging belt and one traction rope is anchored at the two sides of the corresponding anchorage beam, the other end of each traction rope is connected with the corresponding traction jack through the corresponding travelling mechanism, the other end of each hanging belt is fixed on a web member, the slide shoes are installed at the bottom of each travelling mechanism, and connected with the travelling mechanism through arc-shaped hinged supports; and one levelling mechanism is located above each travelling mechanism, each adjustable screw penetrates through the corresponding levelling mechanism and the corresponding travelling mechanism, and each adjustable screw, the corresponding levelling mechanism and the corresponding travelling mechanism are connected through pin shafts. According to the device, during a rope force conversion process for derrick replacement, the stress system of the original structure is not changed, the influence on a stress of the original structure is low, the labour working intensity is low, standardized construction is facilitated, the working efficiency is high, and the construction cost is low.

Owner:LIUZHOU OVM ENG

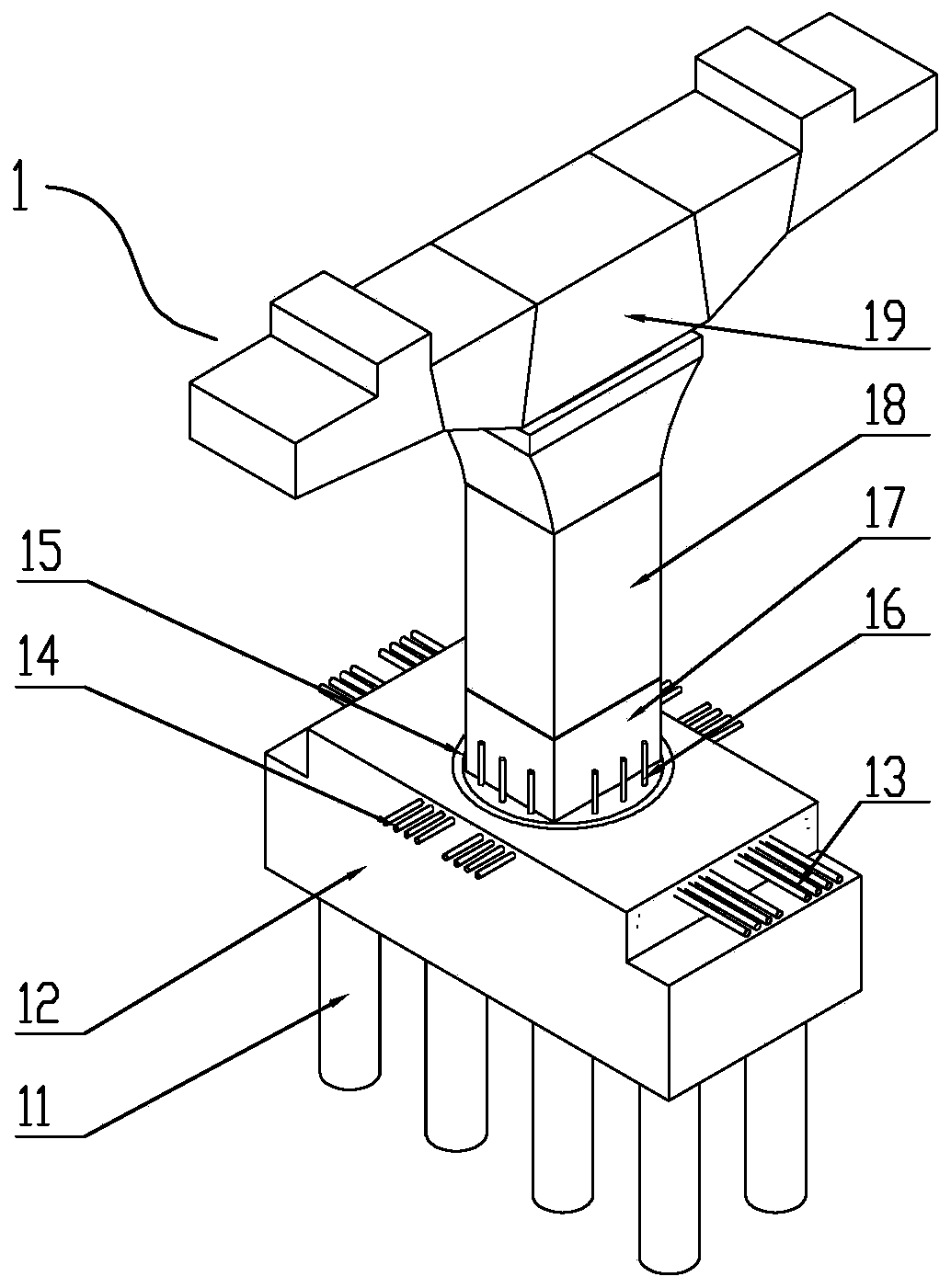

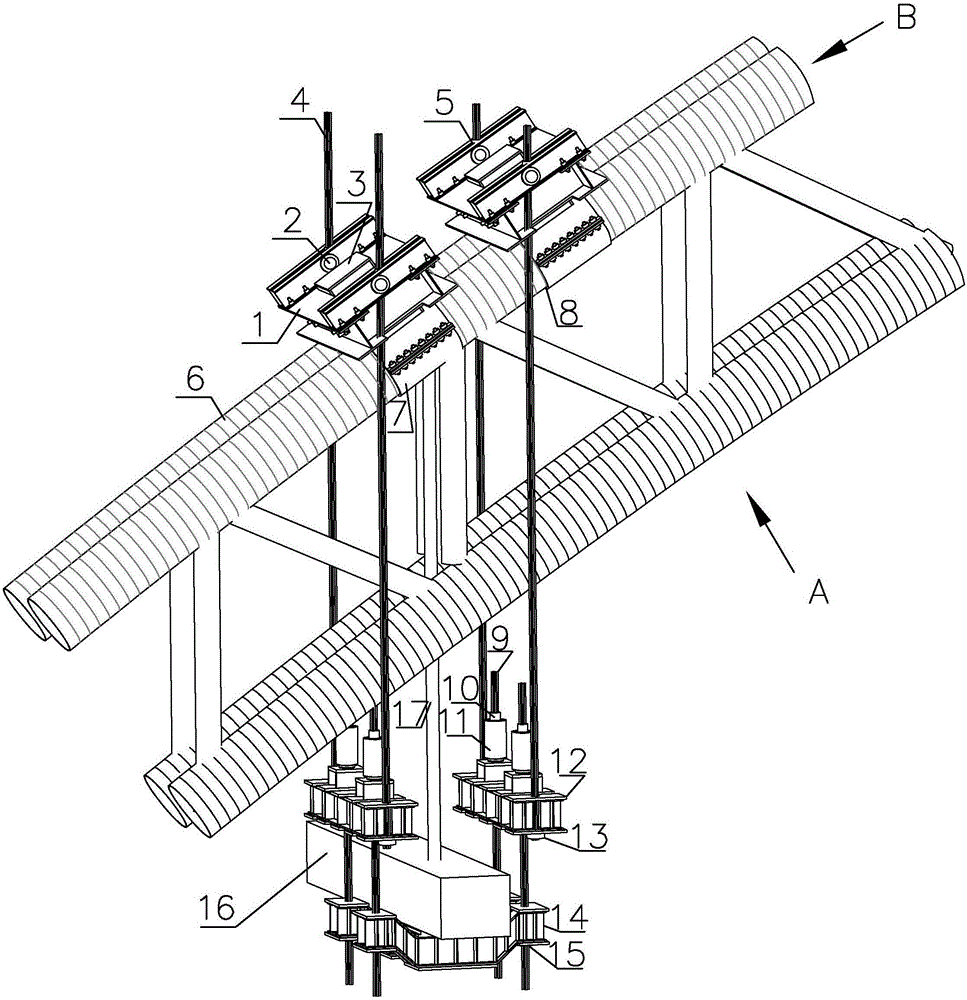

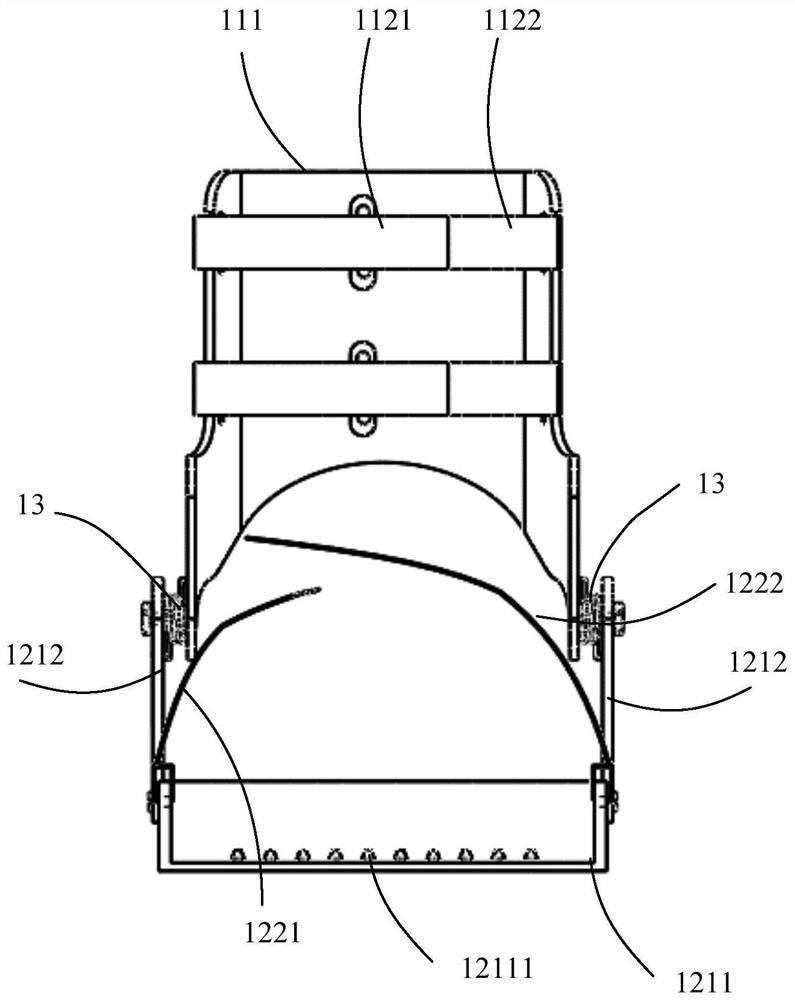

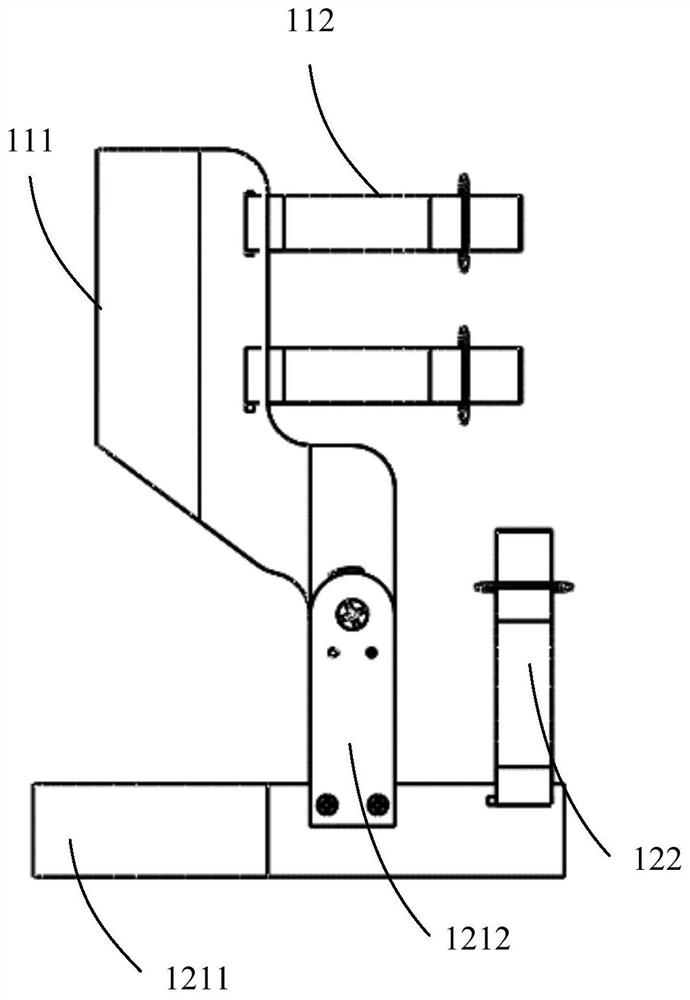

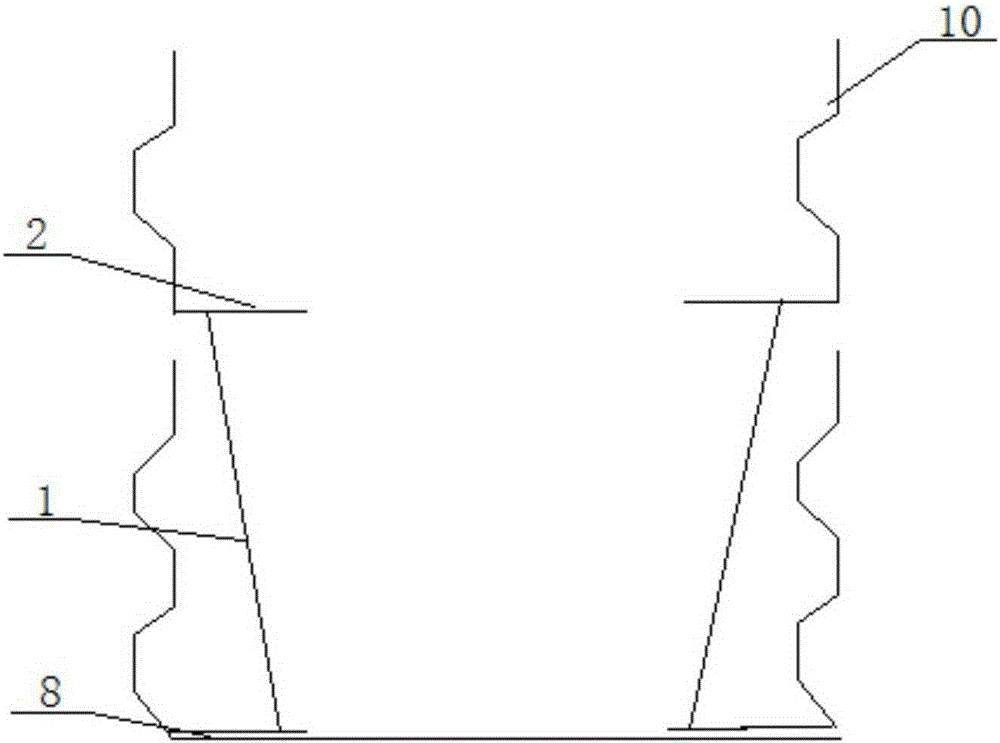

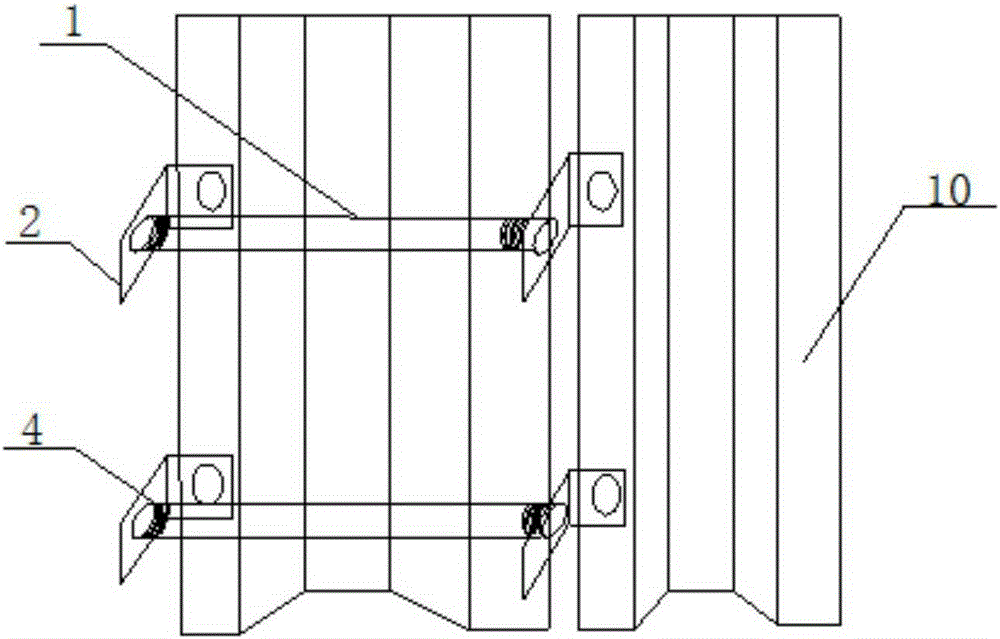

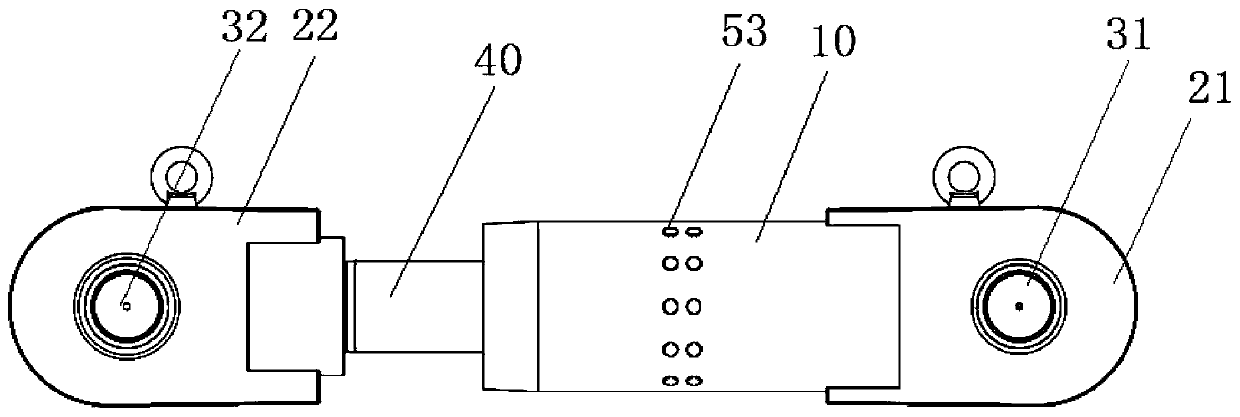

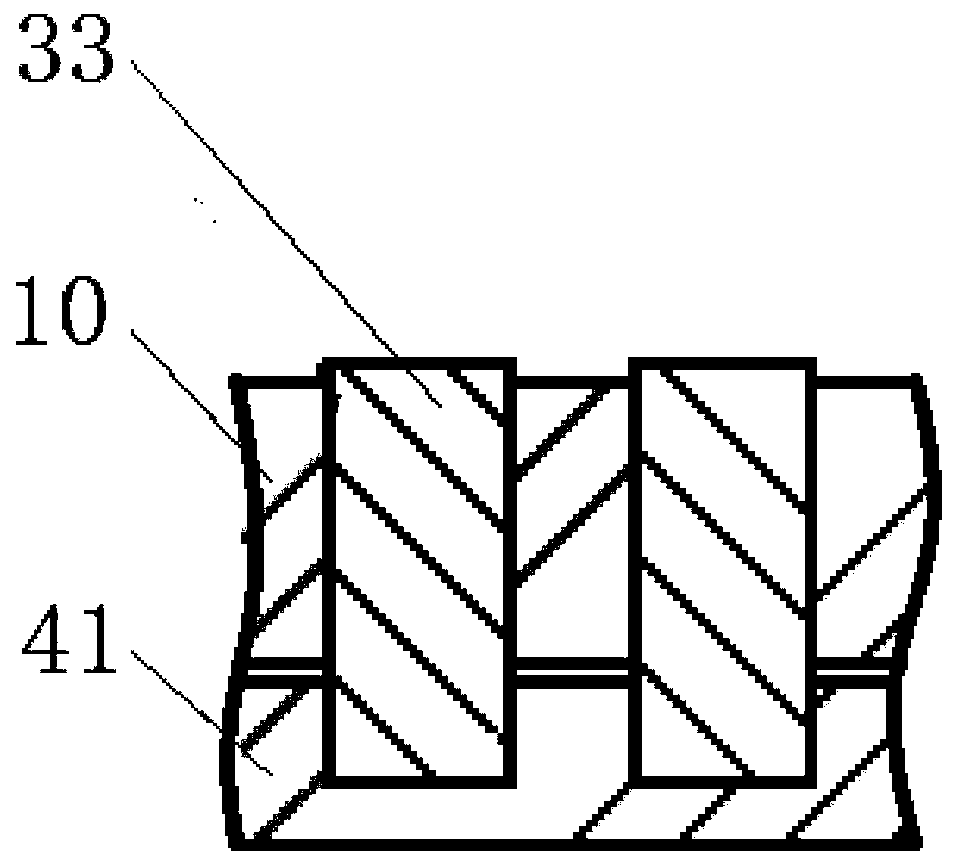

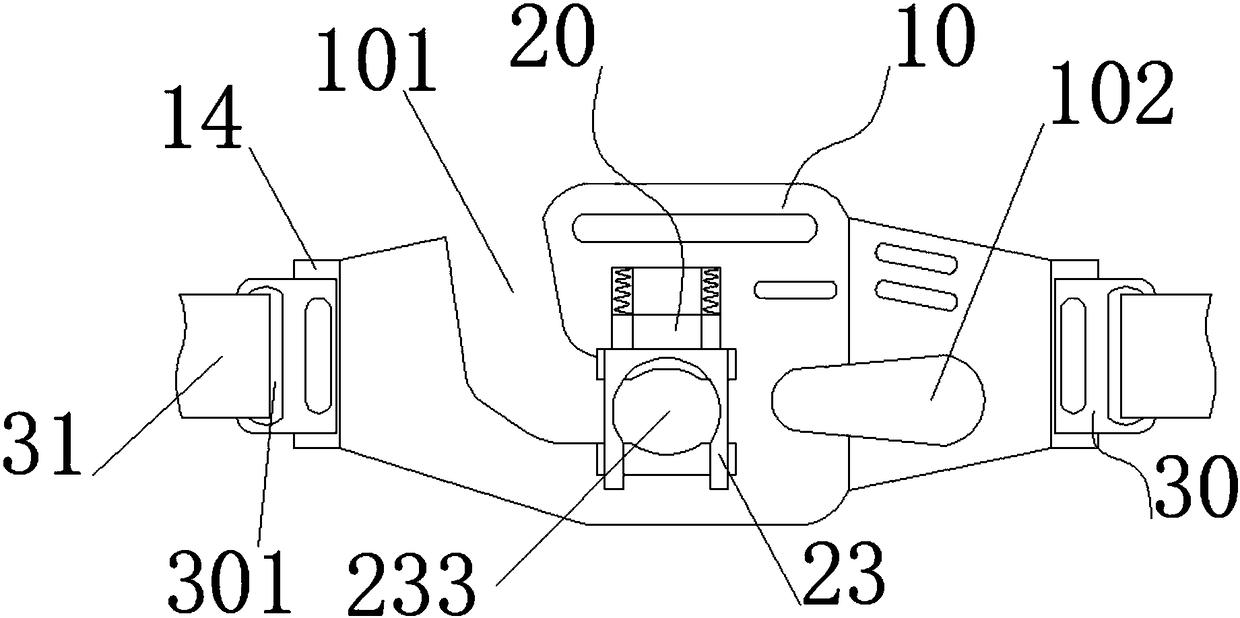

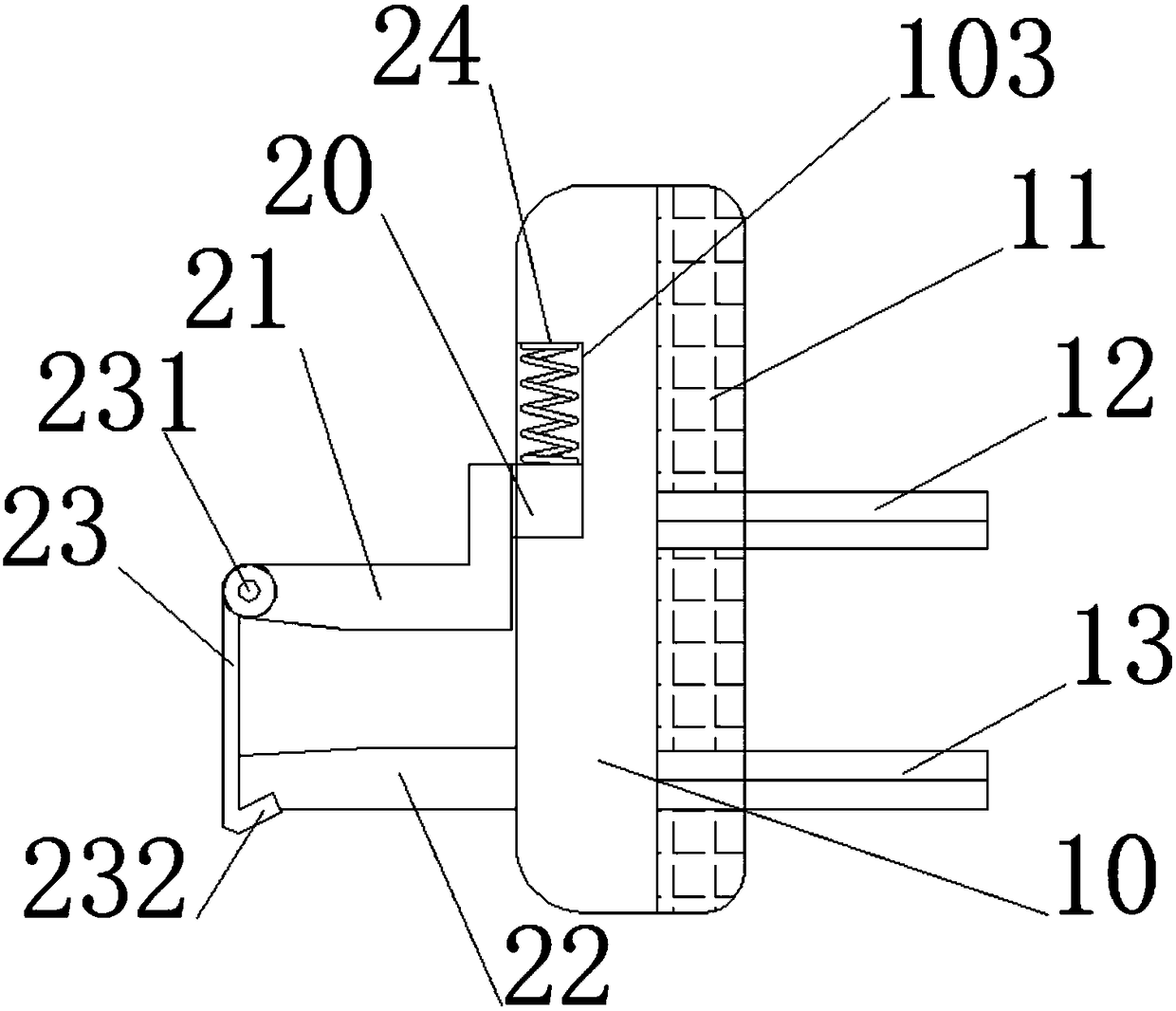

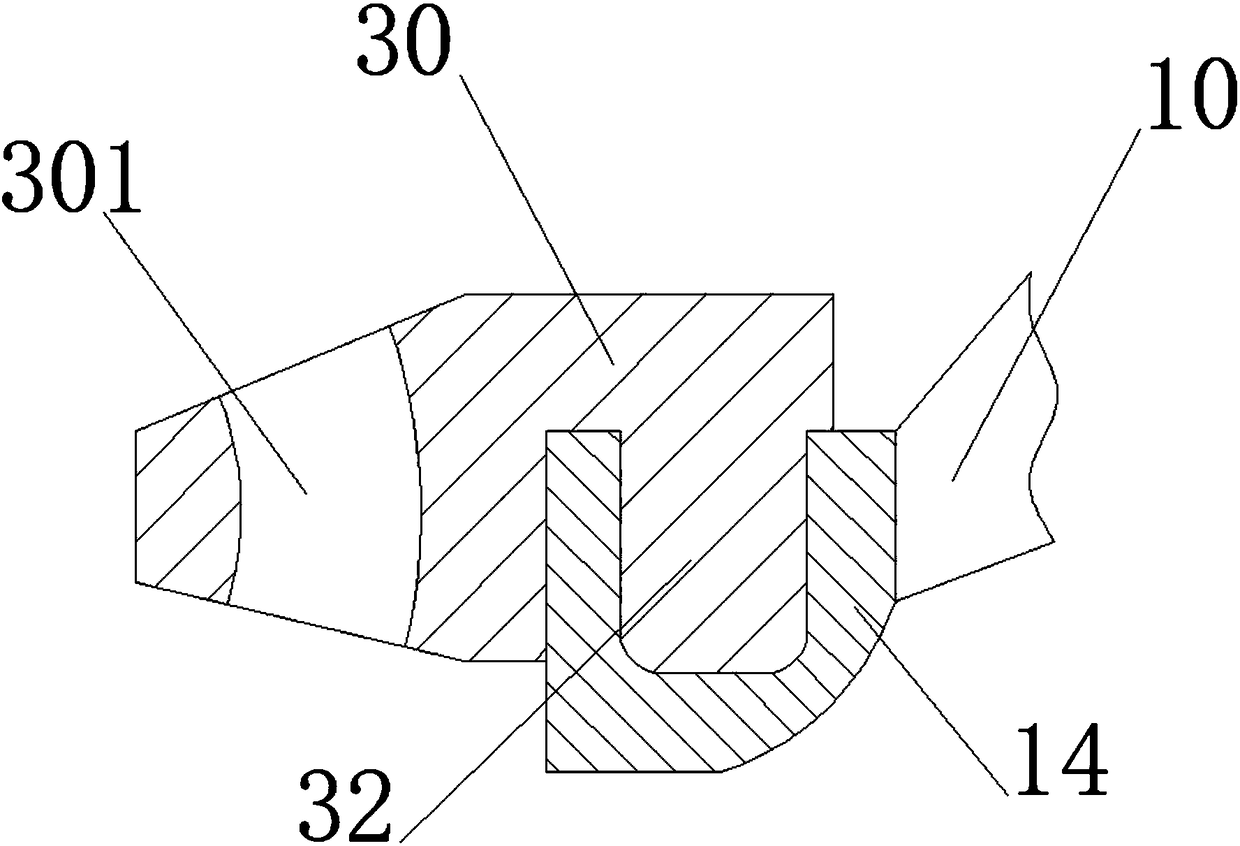

Hold hoop type automatic leveling and anchoring device for replacement of steel pipe concrete arch bridge suspenders and suspender replacing method thereof

ActiveCN106758882ASimple structureReduce construction costsBridge erection/assemblyBridge strengtheningJoistEngineering

A hold hoop type automatic leveling and anchoring device for replacement of steel pipe concrete arch bridge suspenders comprises upper cross beams, tensioning-end anchorage devices I and II, upper and lower temporary ropes, transfer beams, fixed-end anchorage devices I and II,lower supporting beams and two hold hoop type arch apex anchoring and anti-slip systems installed on a steel pipe concrete arch bridge arch, wherein each hold hoop type arch apex anchoring and anti-slip system consists of two rotary lifting appliances, an anti-slip steel box, an upper cross beam, an anti-slip hold hoop and a rubber pad. In a working state, the upper and lower temporary ropes respectively penetrate through the upper cross beam or the lower transfer beam and a jack and are anchored by using the tensioning-end anchorage devices I and II and the fixed-end anchorage devices I and II, and the lower supporting beams support the lower surfaces of suspender cross beams. The rubber pads are arranged between the anti-slip hold hoops and the side faces of the steel pipe arch, the lower-portion cambered surfaces of the anti-slip steel boxes are fixedly connected with the anti-slip hold hoops, one side of each upper-layer #-shaped structure of the upper cross beams tightly attaches to the side face of the corresponding anti-slip steel box, and the other side of each structure is in bolted connection with the corresponding anti-slip steel box through high-strength screws. The hold hoop type automatic leveling and anchoring device is simple in structure, smaller in size, simple and convenient to construct and high in work efficiency.

Owner:LIUZHOU OVM ENG +1

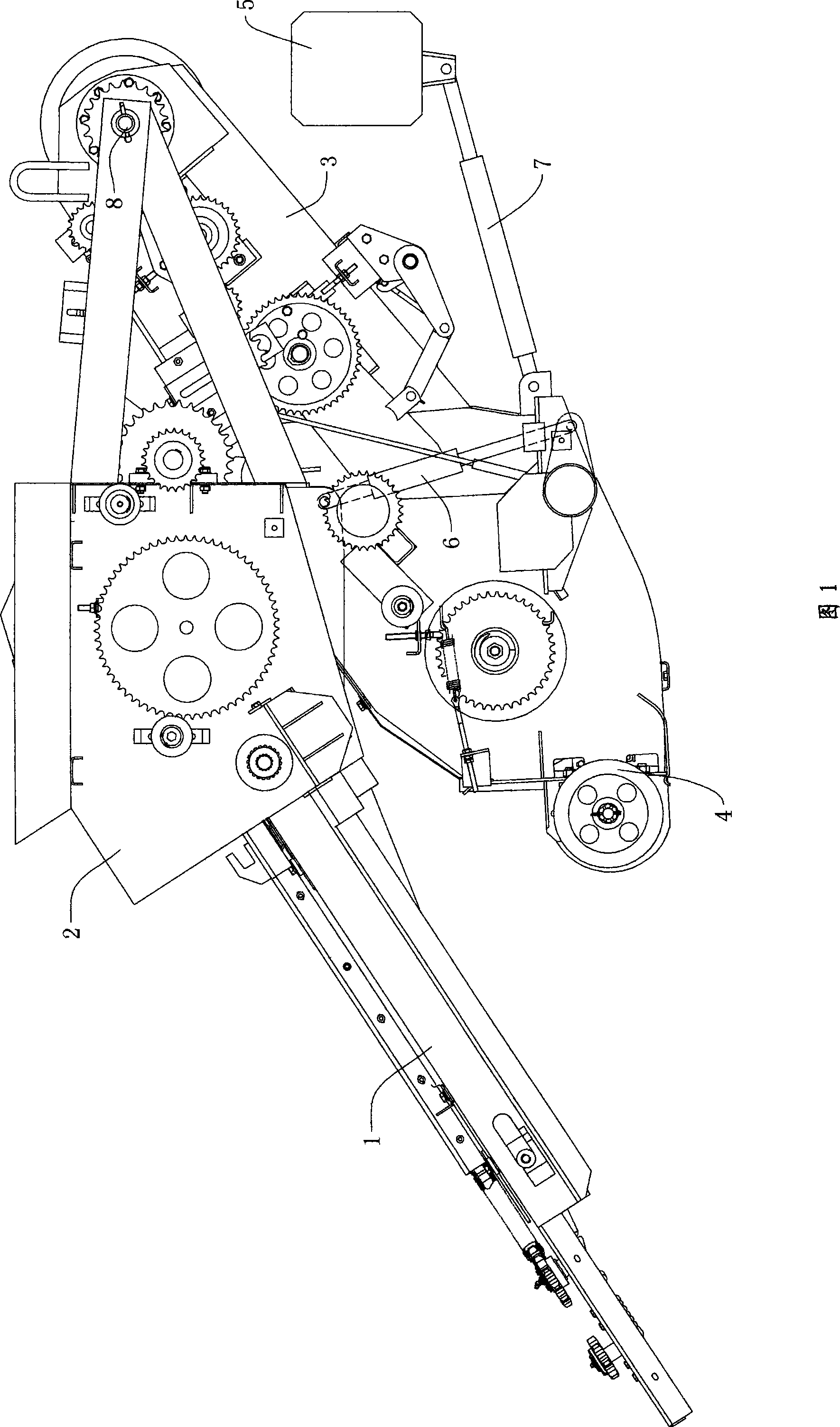

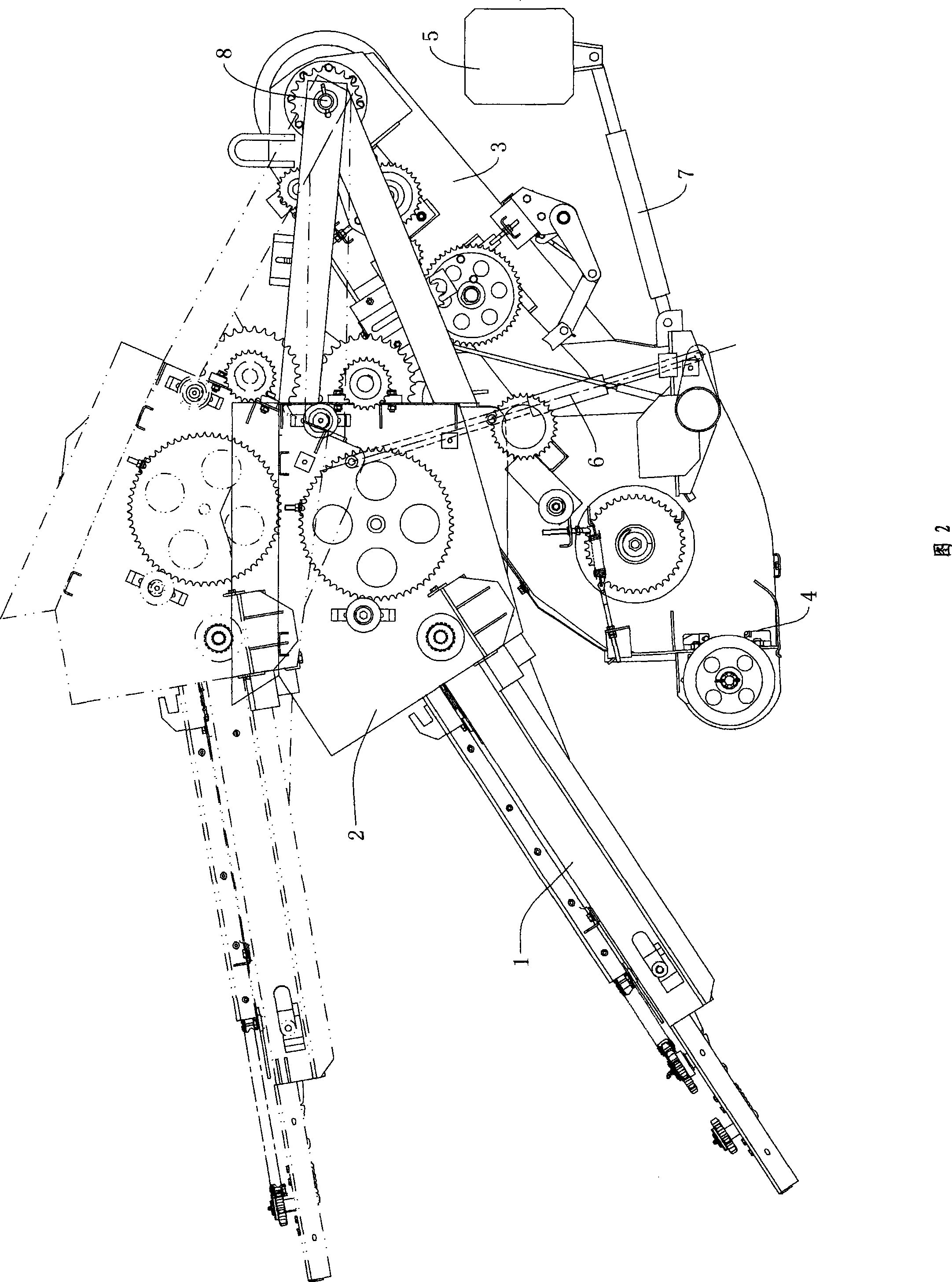

Novel corn harvesting bench

InactiveCN101243745ARealize the cutting operationReduce the impact of forceHarvestersAgricultural science

The invention discloses a new corn header, comprising a corn snapping platform and a stem cutting and feeding device. The invention is characterized in that, the corn snapping platform comprises a corn snapping device and an ears conveying device fixedly connected with each other; the stem cutting and feeding device comprises a stem cutting device and a stem feeding device fixedly connected with each other; the corn snapping platform and the stem cutting and feeding device are respectively hinged at the front part of the body of a corn harvester; a header rotary device used to promote the rotation and the lifting of the corn header is arranged between the stem cutting and feeding device and the body; a header differential device capable of promoting the rotation and the lifting of the corn snapping platform is arranged between the corn snapping platform and the stem cutting and feeding device. The corn header has the advantages that, corn ears snapping and stem cutting are realized at the same time; the structure is compact; corn ears snapping and stem cutting are controlled respectively, so operation, assembling and maintenance are facilitated.

Owner:LOVOL HEAVY IND CO LTD

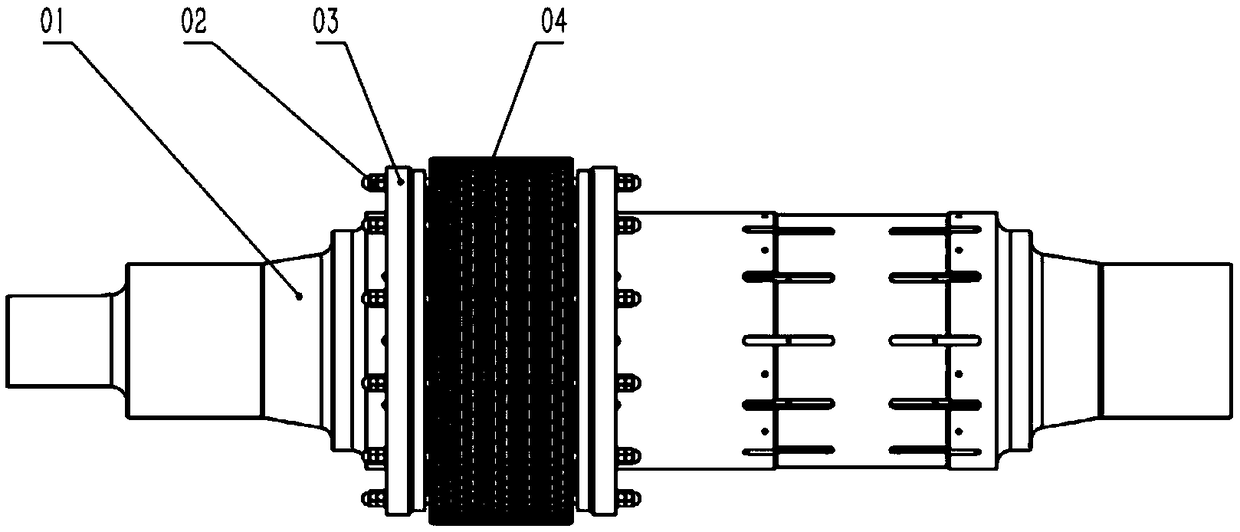

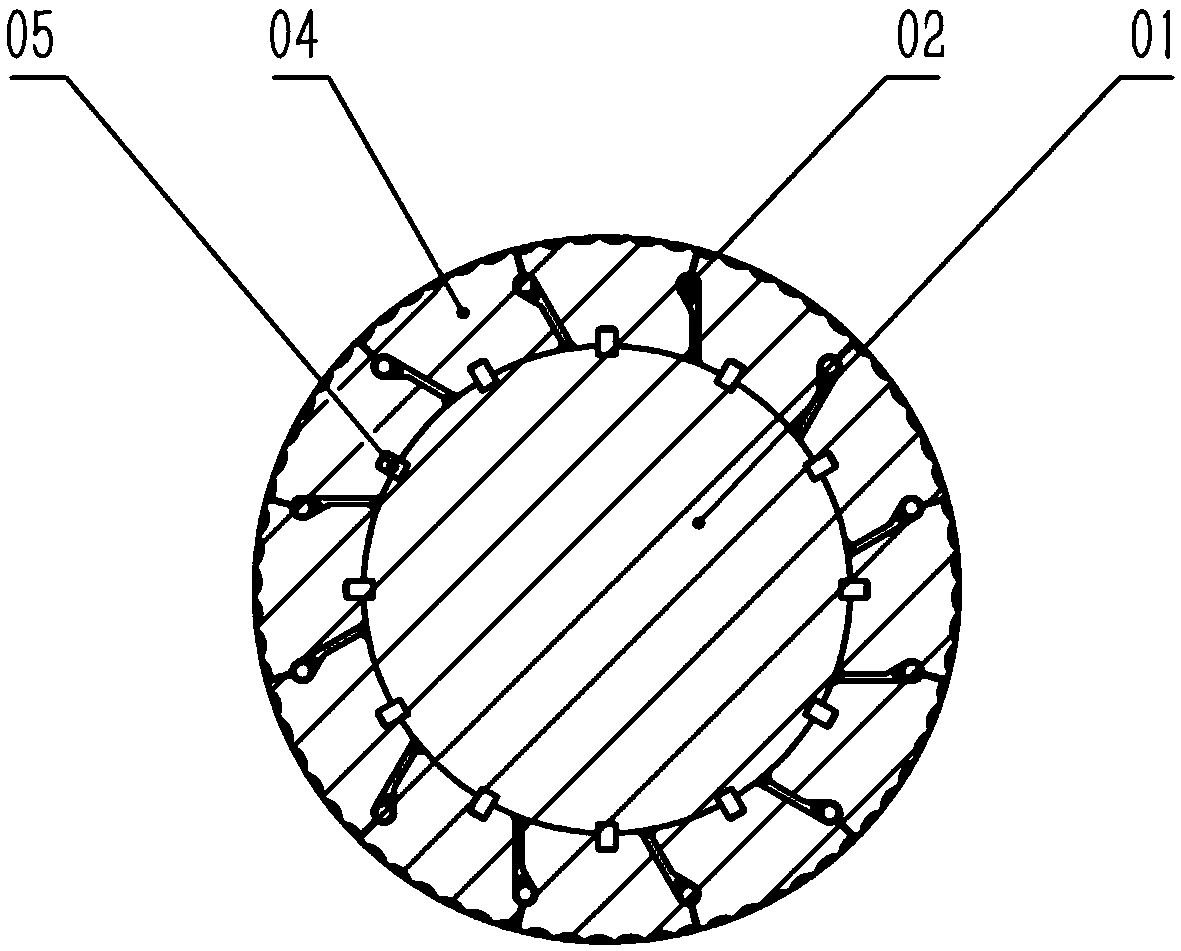

Tile-type combined roller cover

PendingCN109277048AImprove stressReduce the impact of forceGranulation by pressingMortise and tenonHoneycomb

The invention relates to the technical field of extrusion forming equipment, in particular to a tile-type combined roller cover. The tile-type combined roller cover comprises a roller cover block, roller cover hoops, screw rod fasteners, roller cover keys and a roller shaft. The roller cover block is provided with pillow-shaped concave bags which are arranged in a honeycomb mode, bosses with a taper are arranged at two sides of the roller over block, a concave-convex mortise and tenon structure is arranged on the inner arc surface, and key grooves are formed in the inner arc surface; the roller cover hoops are provided with bosses with a taper, and grooves are formed in the position, corresponding to the roller cover keys, of the inner arc face; each screw rod fasteners comprises a long screw rod penetrating through the roller cover and the roller cover hoops at two ends, and comprises hexagonal nuts and cover-type nuts which are arranged at two ends; each roller cover key is providedwith a stepped hole for containing a hexagon socket cap screw; and the roller shaft is provided with an annular groove for installing the roller cover block, two groups of tile-type combined roller covers are installed, the key grooves for the roller cover keys are arranged in the groove, and a threaded hole is formed in the center of the bottom of each key groove.

Owner:杭州新蓝科技有限公司

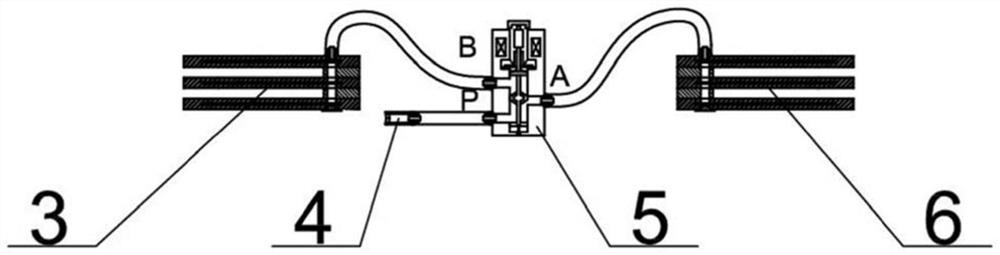

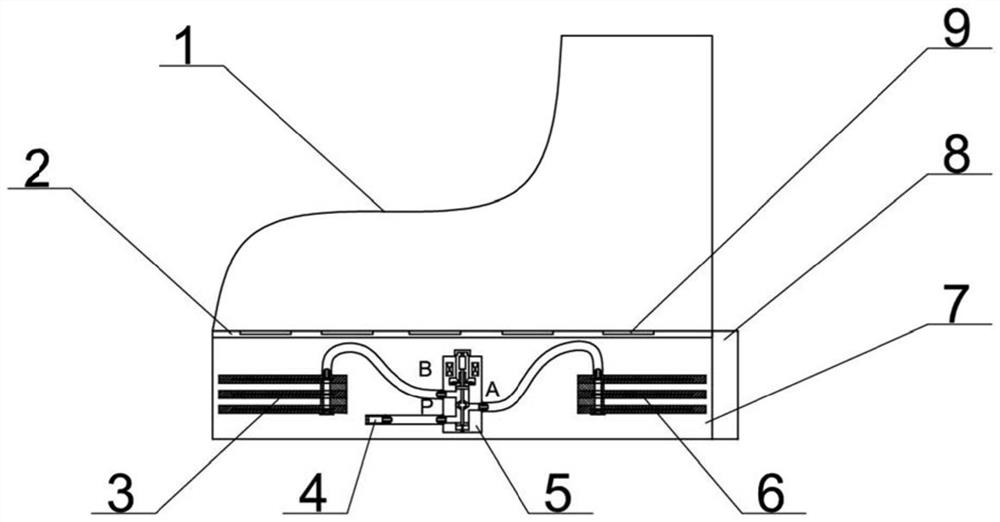

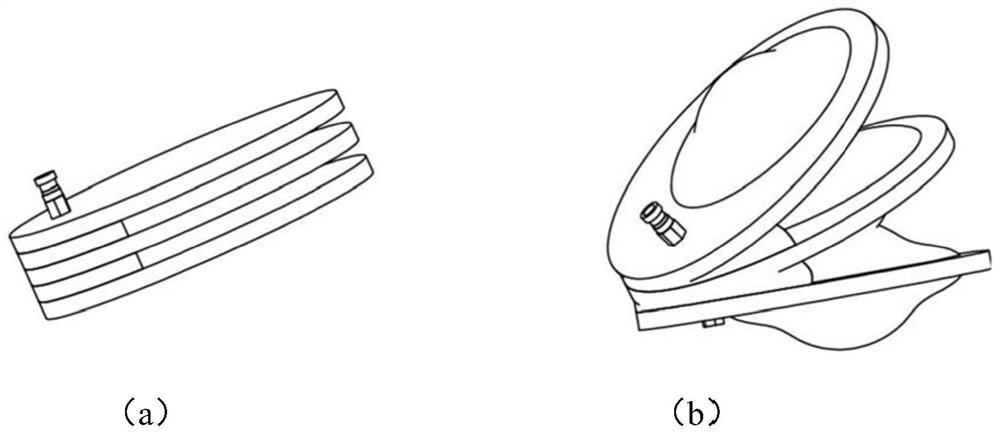

Power-assisted mechanism and power-assisted shoes

The invention discloses a power-assisted mechanism and a power-assisted shoe. The power-assisted mechanism comprises a front sole pneumatic muscle located at the front sole part, a heel pneumatic muscle, a non-return inflation inlet and a two-position three-way electromagnetic valve, wherein the heel pneumatic muscle is located at the heel part; the non-return inflation inlet is further included; a port B of the two-position three-way electromagnetic valve is connected with the front sole pneumatic muscle, a port A of the two-position three-way electromagnetic valve is connected with the rear heel pneumatic muscle, a port P of the two-position three-way electromagnetic valve is connected with the non-return inflation port, and the two-position three-way electromagnetic valve is configured as follows: in a ready inflation state, the port P is communicated with the port A, and the port B is not communicated with the port A; in a heel landing state, the port P is not communicated with the port A, and the port B is communicated with the port A; in a tiptoe landing state, the port P is not communicated with the port A, and the port B is not communicated with the port A; in a heel off-ground state, the port P is not communicated with the port A, and the port B is communicated with the port A; and when the tiptoe is off the ground, the port P is not communicated with the port A, and the port B is not communicated with the port A. The power-assisted shoe comprises a sole and a power assisting mechanism, wherein the power assisting mechanism is arranged in the shoe sole, and the power assisting mechanism is the power assisting mechanism.

Owner:杭州昆泰机器人有限公司

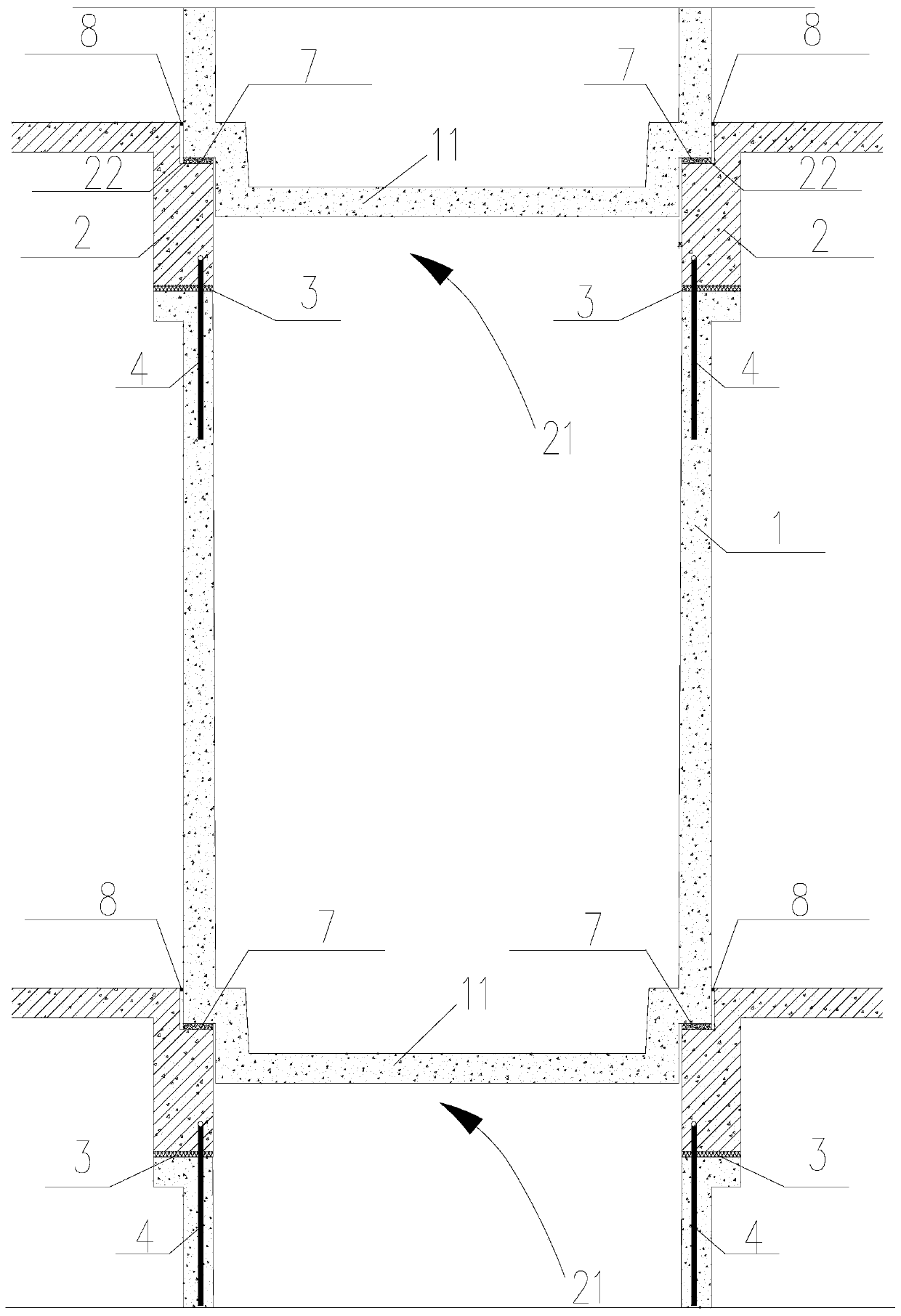

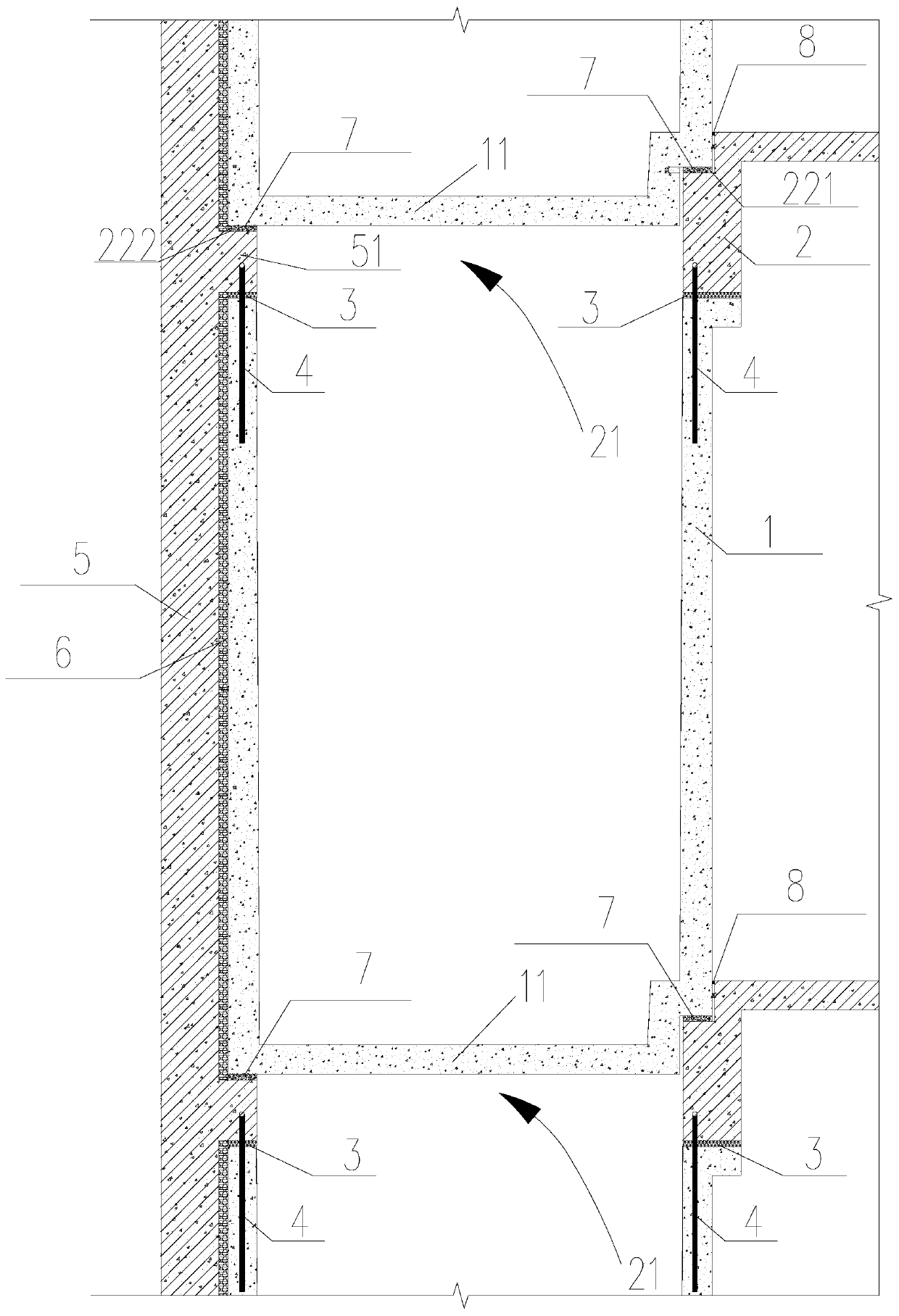

Replacing or newly-added fabricated balcony structure for old houses and construction method of replacing or newly-added fabricated balcony structure

InactiveCN110359723AReduce the impact of forceIncrease the building usable areaBuilding repairsWork periodResidence

The invention relates to a replacing or newly-added fabricated balcony structure for old houses and a construction method of the replacing or newly-added fabricated balcony structure to mainly solve the technical problems that existing old residence communities are not provided with balconies, and balconies need to be added. The replacing or newly-added fabricated balcony structure comprises a primary structure and further comprises a newly-added fabricated balcony structure body connected with an external wall lower ring beam of the primary structure in an anchored mode. The newly-added fabricated balcony structure body comprises a newly-added column foundation, newly-added steel stand columns, a newly-added prefabricated concrete balcony plate, newly-added steel handrails and newly-addedglass baffles, wherein the newly-added prefabricated concrete balcony plate is arranged on the outer side of an external wall lower ring beam of the primary structure of each layer in a connected mode, the newly-added steel stand columns are arranged at the outer side end of the newly-added prefabricated concrete balcony plate in a connected mode, and connecting pieces are arranged between the newly-added steel stand columns and the newly-added prefabricated concrete balcony plate of each layer. The replacing or newly-added fabricated balcony structure has the remarkable advantages that the newly-added fabricated balcony is easy and convenient to build, the work period is short, and construction is free and flexible.

Owner:BEIJING ZHUFU ARCHITECTURE AFFAIRS CO LTD

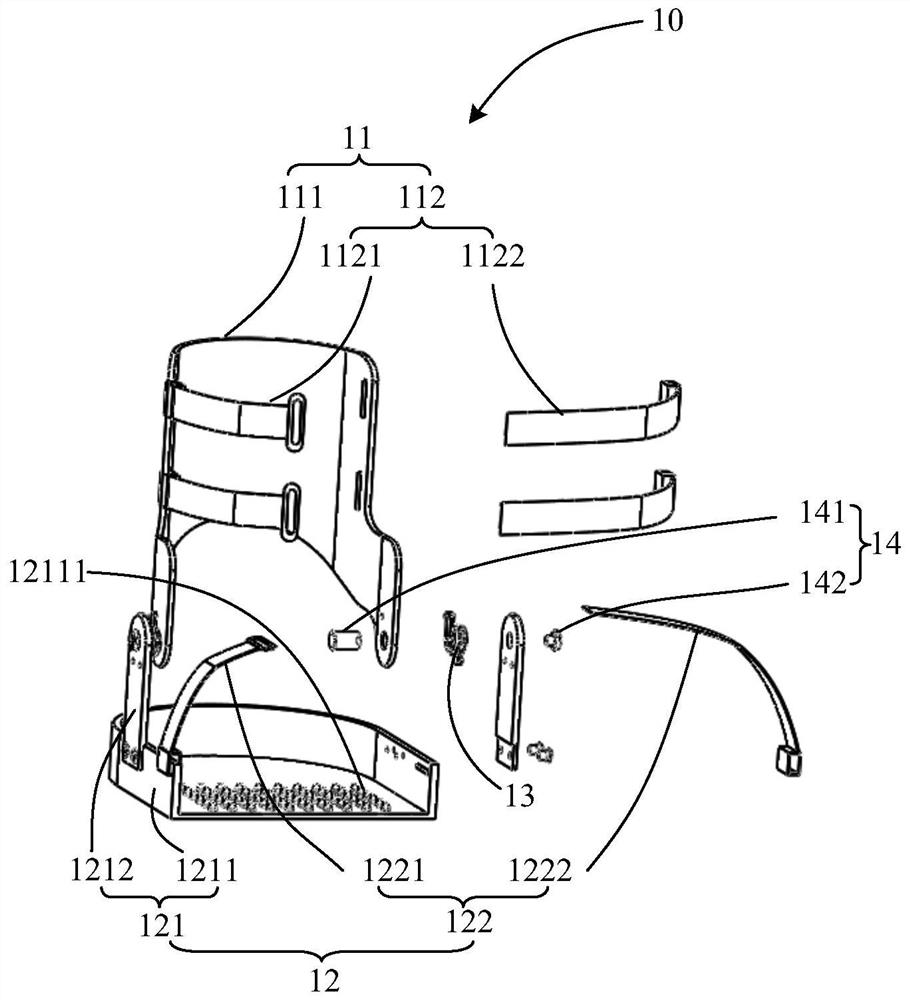

Ankle joint assisting exoskeleton device and assisting shoes

InactiveCN111604886ASmall binding forceReduce the impact of forceProgramme-controlled manipulatorFootwearEngineeringPhysical therapy

The invention relates to an ankle joint assisting exoskeleton device and assisting shoes. The device comprises a leg assembly, a foot assembly and an elastic part, wherein the leg assembly comprises aleg frame, the leg frame is used for being wound around a leg of a user, the foot assembly is rotationally connected with the leg frame and used for being worn on a foot of the user, and the elasticpart is arranged at the joint of the leg frame and the foot assembly and used for generating elastic deformation or restoring to the natural state when an included angle between the leg frame and thefoot assembly changes within a preset angle range so as to store or release energy. The ankle joint assisting exoskeleton device can store negative work in the walking process of the user and feed thenegative work back to the user when positive work needs to be done so as to provide walking assistance for the user, and the influence on leg muscle power generation of the user can be greatly reduced.

Owner:SHENZHEN INST OF ADVANCED TECH

Externally-arranged fabricated balcony structure adopting steel reinforced concrete, and construction method of externally-arranged fabricated balcony structure

InactiveCN110056202AShort construction periodReduce the impact of forceBuilding repairsBalconiesReinforced concreteResidence

The invention relates to an externally-arranged fabricated balcony structure adopting steel reinforced concrete, and a construction method of the externally-arranged fabricated balcony structure. Thetechnical problems that an existing old residence is not provided with balconies, thus the building use function cannot meet the current high-quality living needs of people, and the balconies need tobe additionally arranged to enable the life of residents to be more comfortable are mainly solved. The externally-arranged fabricated balcony structure has the most significant advantages that an externally-arranged fabricated balcony is simple and convenient, short in construction period, free and flexible, and if a technology is applied and popularized, the significant practical significance forexternally arranging the fabricated balcony in the old residence is achieved.

Owner:BEIJING ZHUFU ARCHITECTURE AFFAIRS CO LTD

Corrugated steel web temporary fixation structure independent of template

ActiveCN105350460AAvoid misalignmentRealize small adjustmentsBridge erection/assemblyBox girderBuilding construction

The invention discloses a corrugated steel web temporary fixation structure independent of a template. The corrugated steel web temporary fixation structure comprises a plurality of corrugated steel web sections, longitudinal steel supports and transverse steel supports; the multiple corrugated steel web sections are combined to form a square structure, every two adjacently-arranged corrugated steel web sections are fixedly connected through the corresponding longitudinal steel supports, and every two oppositely-arranged corrugated steel web sections are fixedly connected through the corresponding transverse steel supports; and the number of the longitudinal steel supports for connecting two adjacent corrugated steel web sections is two, and the two longitudinal steel supports are arranged in parallel. By means of the temporary fixation measures, the problem that during construction at present, steel webs are fixed through bottom dies or side dies, consequently, sampling wastes time, and plane deviations are caused on the steel webs before and after pouring is carried out is solved, and influences of the deviations of the steel webs on box girder stress are reduced.

Owner:JSTI GRP CO LTD +2

Damper with limiting and shearing functions

PendingCN110924289AReduce the impact of forceMaintain smooth and solid performanceBridge structural detailsEarthquake resistantEngineering

The invention relates to the technical field of bridge earthquake resistance. The invention relates to a damper, in particular to a damper with limiting and shearing functions. The damper comprises adamper body, the damper body comprises a cylinder body, a first pin shaft hole is formed in one end of the cylinder body, a first pin shaft is arranged in the hole, a piston rod penetrates out of theother end of the cylinder body and then is connected with a second pin shaft base, a second pin shaft hole is formed in the piston rod, a second pin shaft is arranged in the hole, and a third pin shaft hole facilitating pin shaft insertion is formed in the cylinder body; the other end of the piston rod is located in the cylinder body and provided with a piston, the piston is provided with a fourthpin shaft hole facilitating insertion of the pin shaft, a third pin shaft is arranged in the third pin shaft hole, one end of the third pin shaft is located in the third pin shaft hole, and the otherend of the third pin shaft is located in the fourth pin shaft hole. And the third pin shaft is a shear pin. The rigid supporting effect can be achieved on the low-speed occasion, the damping effect is achieved when the high-speed or external force impact effect is large, and the stability and the firmness of a building structure in daily use can be effectively kept.

Owner:MAGEBA SHANGHAI BRIDGE PROD CO LTD

Construction method of flexible connecting structure between prefabricated components and building bodies

InactiveCN110206160AReduce the impact of forceReduce internal forceBuilding insulationsTongue and grooveArchitectural engineering

Owner:HUNAN CONSTR ENG GRP COR +1

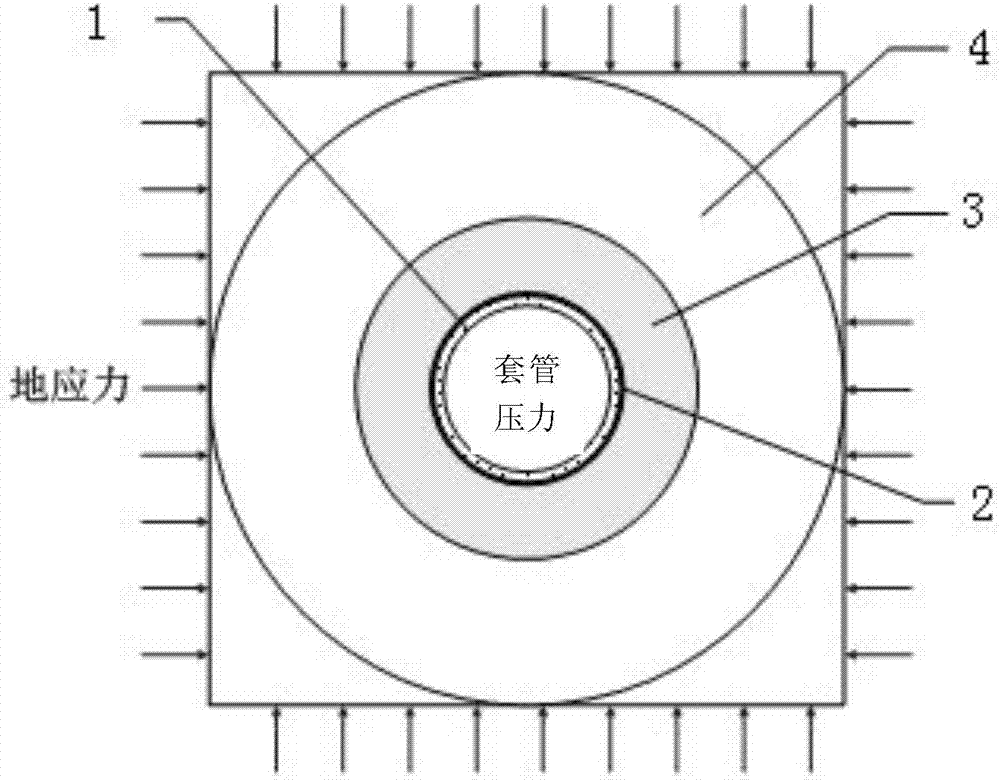

Prevention device and method for seal integrality failure of casing annulus of gas well

PendingCN107327285AReduce the impact of forceAvoid failure damageSealing/packingElastic modulusRing protection

The invention relates to a prevention device and method for a seal integrality failure of a casing annulus of a gas well. The prevention device comprises a sleeve adhered to the periphery of a casing for conducting force bearing protection on a cement ring. The elasticity modulus of the sleeve is 5-10 MPa, the Poisson ratio of the sleeve is 0.25-0.5, and the thickness of the sleeve is 4-8 mm. A layer of buffer medium is additionally arranged on the periphery of the casing, so that casing deformation caused by the pressure change of a downhole is absorbed totally or to a certain extent, the influence of the inner pressure of the casing on the cement ring is reduced, failure destruction of the cement ring when the inner pressure of the casing is too high is avoided, and the seal integrality failure of the casing annulus, and problems of under-pressure and channeling of the annulus due to the seal integrality failure of the casing annulus are prevented.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Tracheal intubation fixing apparatus for anesthesia departments

The invention discloses a tracheal intubation fixing apparatus for anesthesia departments. The tracheal intubation fixing apparatus comprises a fixing seat, an upper fixing sheet slide seat and bandage fixing seats. The upper fixing sheet slide seat is slidably connected onto the fixing seat, the bandage fixing seats are positioned on the outer side of the fixing seat and are detachably connectedwith the fixing seat, a cannula groove, a sputum suction hole and an upper fixing sheet slide groove are formed in the fixing seat, and a sponge pad, an upper tooth pad, a lower tooth pad and bandageclamp seats are arranged on the fixing seat; an upper fixing sheet and a lower fixing sheet are arranged at the front of the fixing seat. The tracheal intubation fixing apparatus has the advantages that the upper fixing sheet can slide by the aid of a spring by a certain distance, and accordingly cannulas can be conveniently preliminarily clamped; a fastening clamp sheet arranged on the upper fixing sheet can be clamped with the lower fixing sheet, accordingly, the cannulas can be fixed and constrained without influence on vision of patients, influence on stress of devices can be reduced in fixing procedures, and the cannulas can be conveniently fixed.

Owner:THE FIRST PEOPLES HOSPITAL OF NANTONG

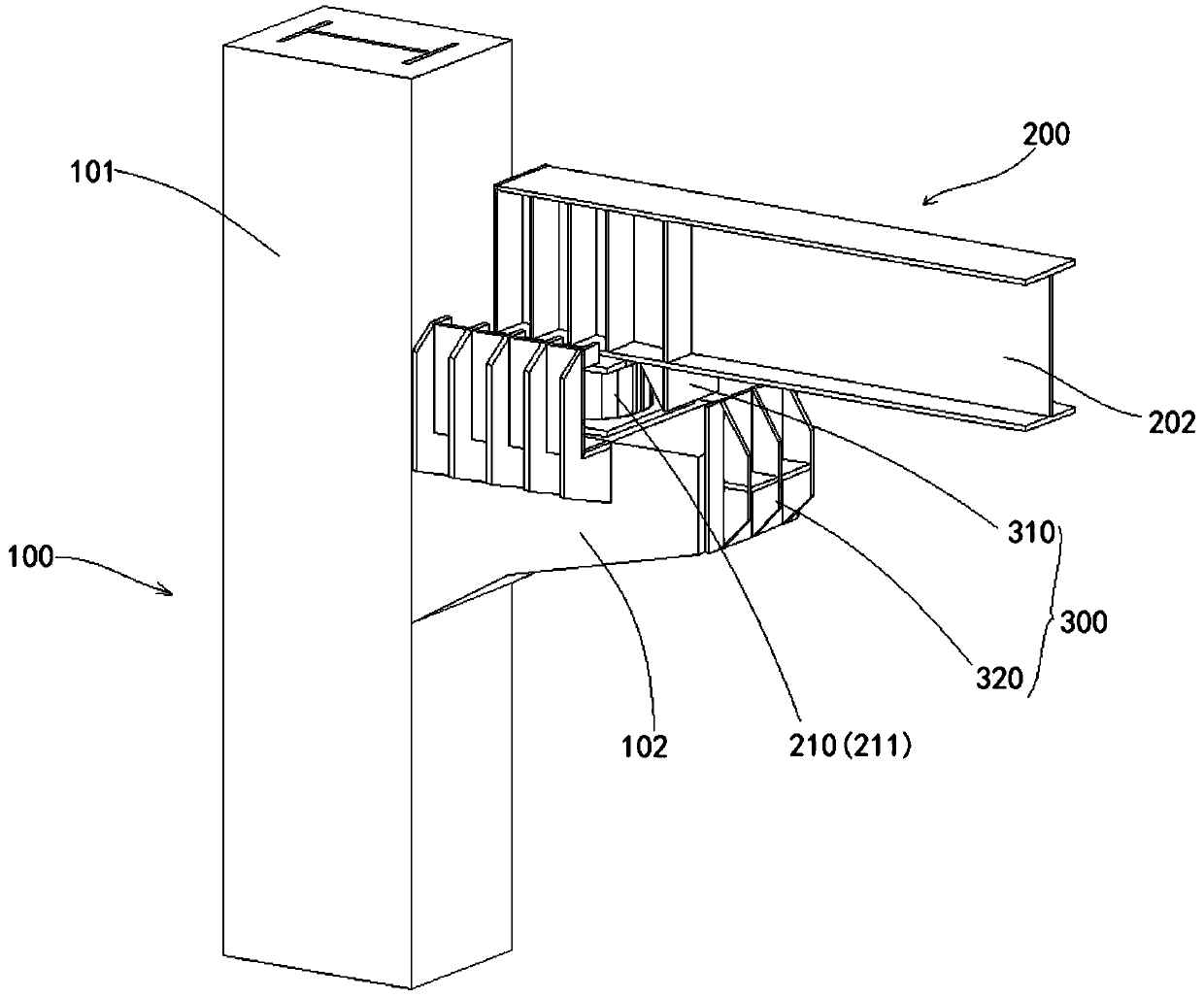

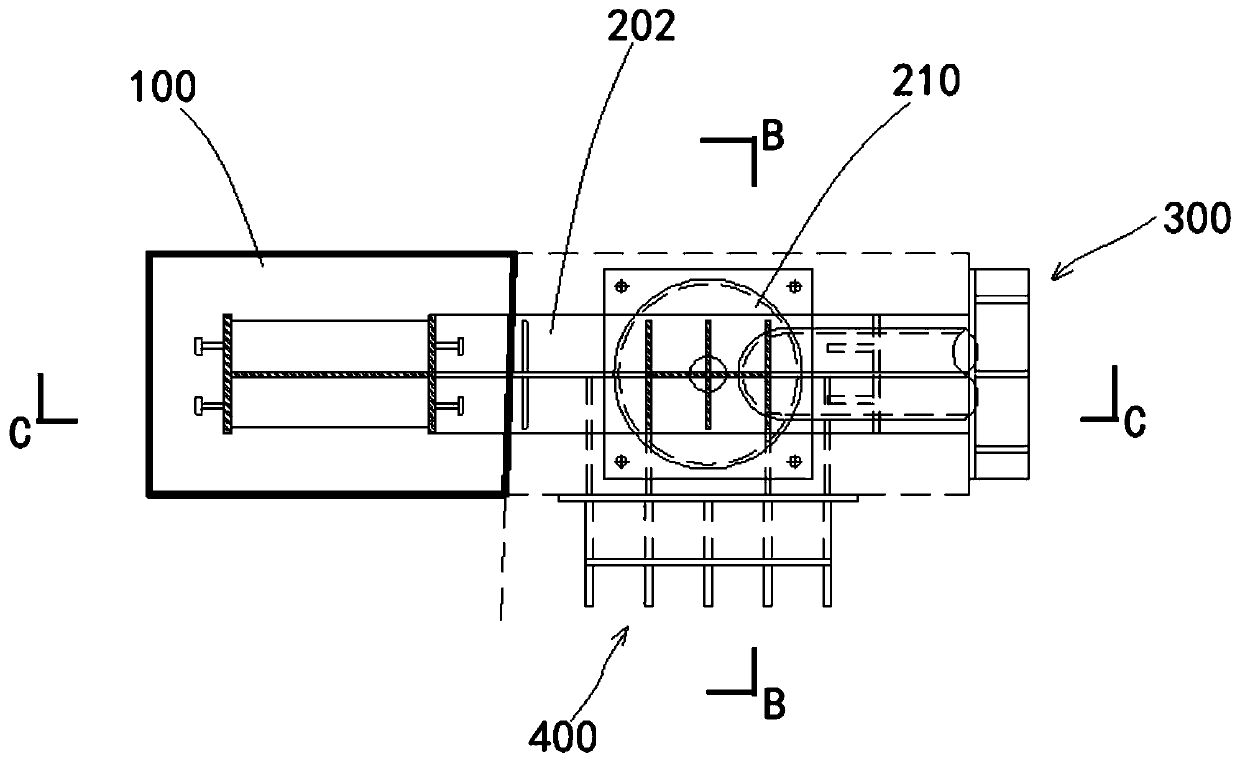

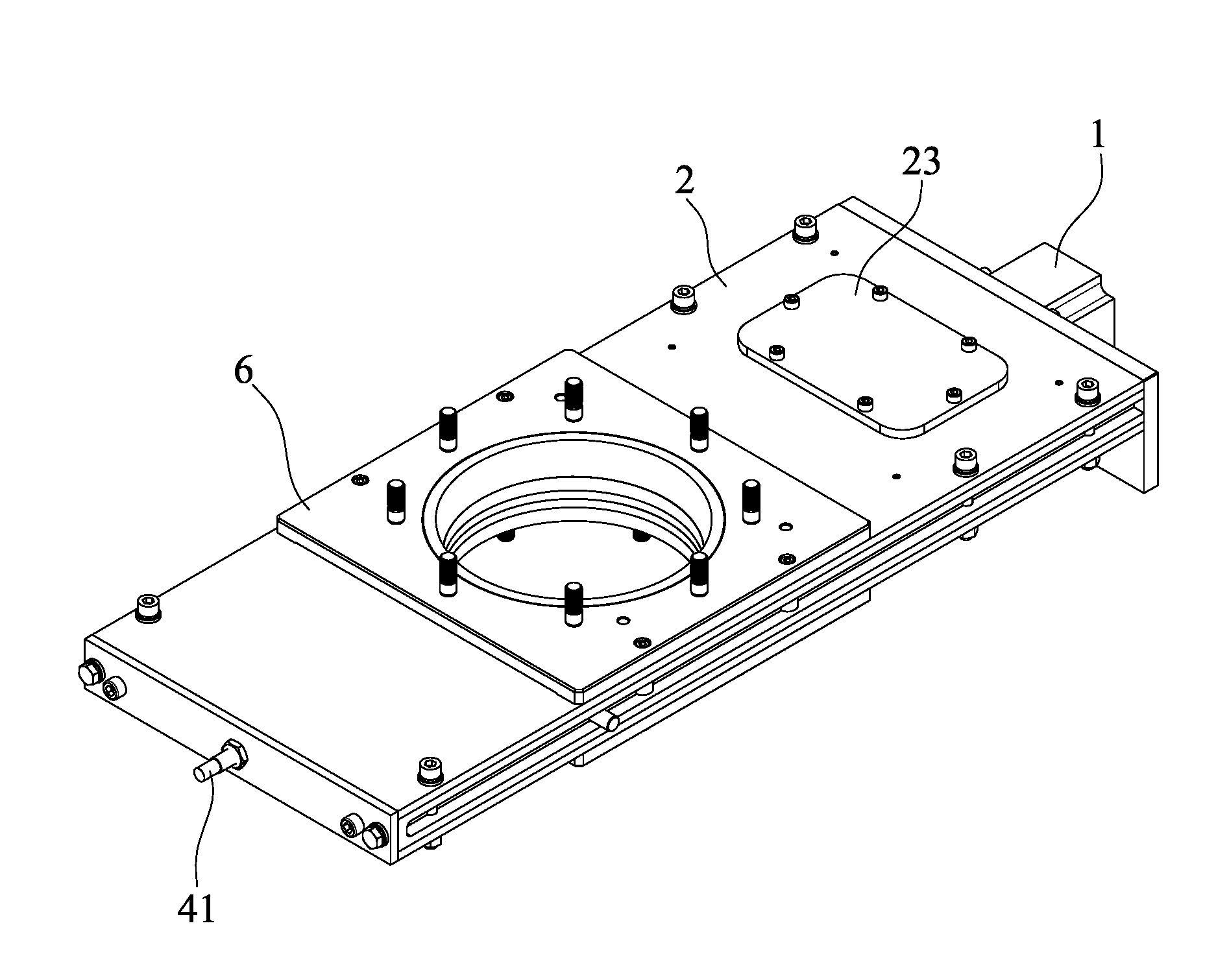

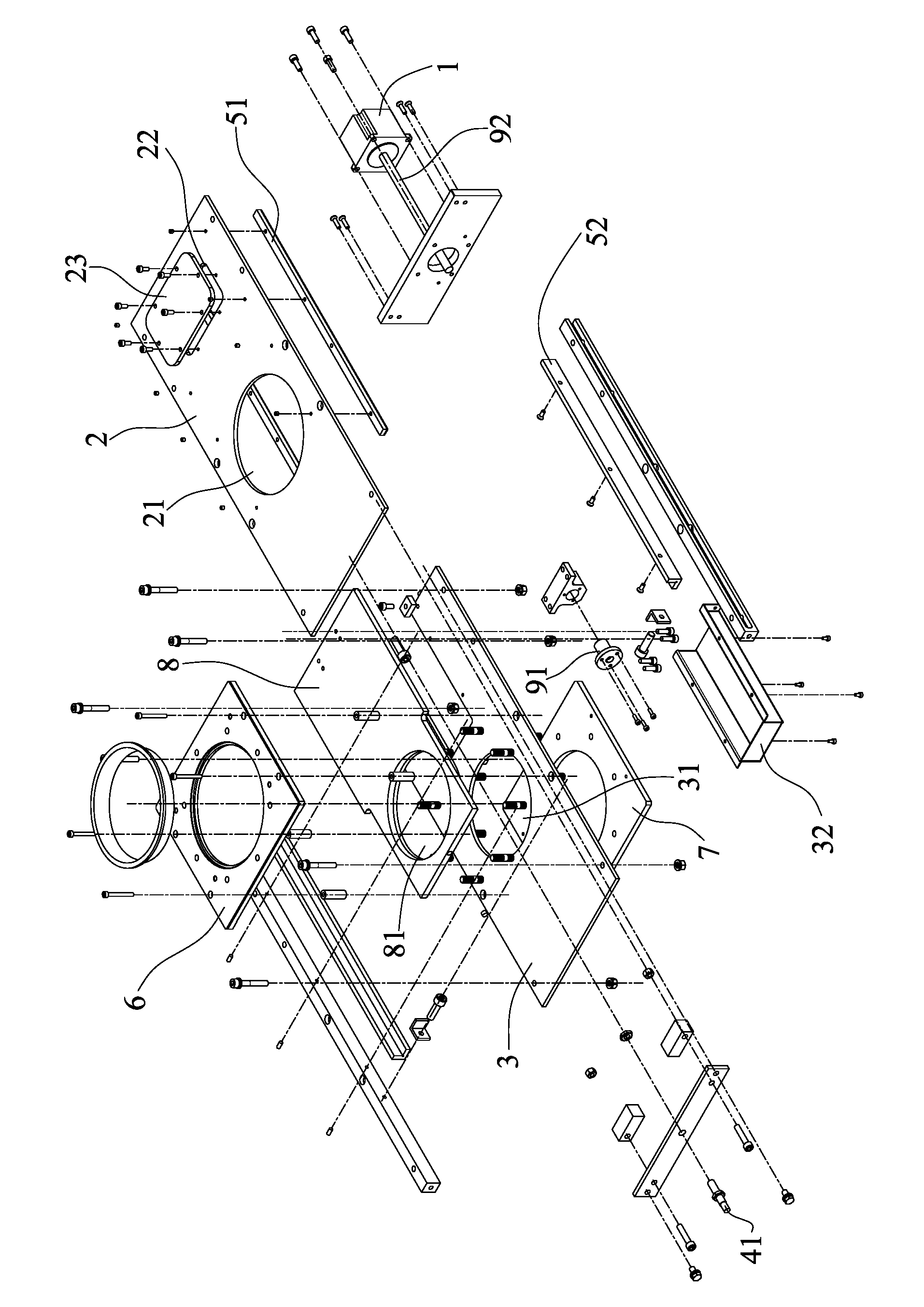

Connected building

PendingCN111411692AReduce translationReduce movement distanceProtective buildings/sheltersExtraordinary structuresArchitectural engineeringLap joint

The invention relates to a connected building. The connected building comprises main frame structures, orridor structures, longitudinal limiting components and transverse limiting components; two or more main frame structures are arranged side by side, the corridor structures are arranged between every two adjacent main frame structures, and the ends of the corridor structures are in lap joint with the main frame structures through buffer limiting structures; the longitudinal limiting components are arranged on the side edges of the buffering limiting structures and used for limiting longitudinal translation of the corridor structures in the length direction; the transverse limiting components are arranged on the side edges of the buffering limiting structures and used for limiting transverse translation of the corridor structures in the width direction; and the limiting directions of the two longitudinal limiting components located at the two ends of the corridor structures are opposite, and the limiting directions of the two transverse limiting components located at the two ends of the corridor structures are opposite. According to the connected building, the corridor structuresdo not affect the main frame structures, can be firmly connected with the main frame structures and are not prone to falling off from the main frame structures.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

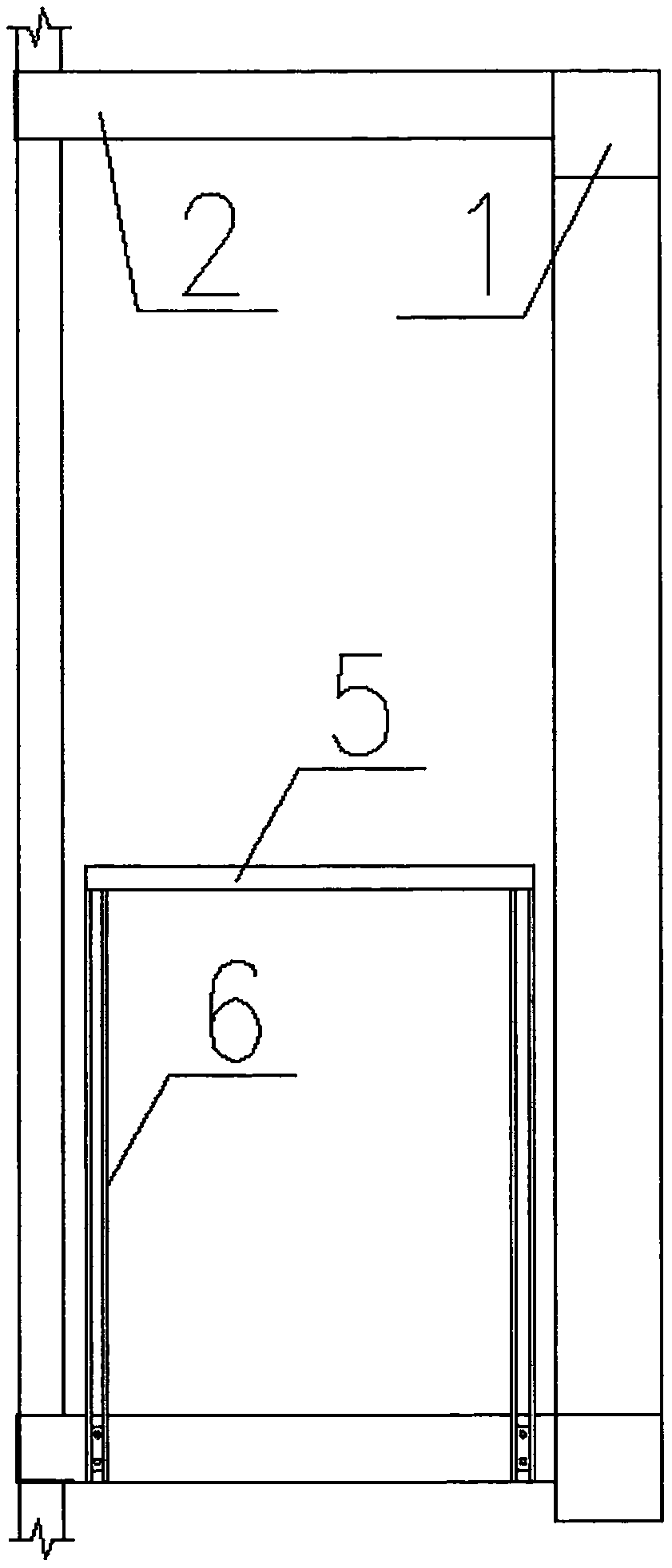

Electric gate valve

ActiveCN102537393BSolve the problem of difficult closing operationWith self-cleaning functionOperating means/releasing devices for valvesSlide valveEngineeringAir tightness

The invention discloses an electric gate valve, which comprises a motor, an upper end cap, a lower end cap, a valve frame, two sliding rails, an inlet flange, an outlet flange and a valve plate. The upper end cap is mounted on the valve frame and provided with a feed port, the inlet flange is mounted on the feed port of the upper end cap, the lower end cap is mounted on the valve frame and provided with a discharge port, the outlet flange is mounted below the discharge port of the lower end cap, the two mutually parallel sliding rails are arranged between the upper end cap and the lower end cap and mounted on the valve frame and the upper end cap, the motor is mounted on the valve frame, a circular opening is arranged on the valve plate, the valve plate is connected with the motor through a transmission mechanism and moves between the two sliding rails, and a self-cleaning ring is arranged at the bottom of the opening of the valve plate and attached to the lower end cap. The electric gate valve has a self-cleaning function and is high in bearing performance, low in friction resistance, light in weight and fine in air tightness.

Owner:XIAMEN MEIGANQIDONG MATERIAL CONVEYING ENG

A detection device for tensile strength of solder bar

ActiveCN114459905BReduce the impact of forceMaterial strength using tensile/compressive forcesDrive shaftClassical mechanics

The invention provides a detection device for the tensile strength of a solder bar. The detection device for the tensile strength of the solder bar includes: a support; a mounting frame, the mounting frame is mounted on the support; a first telescopic element, one end of the first telescopic element is rotatably mounted on the The top of the installation frame; the transmission shaft, the transmission shaft is installed on the other end of the first telescopic member; two clamp assemblies, the clamp assembly includes a fixed splint and a flip splint. The testing device for the tensile strength of the solder bar provided by the invention has a fast feeding speed on the two fixed splints. When installing the sample, the sample can be placed directly above the two fixed splints, which is convenient for hands-free operation during the clamping process. No manual support is required. After the hand is released, the two flip splints are controlled to rotate downward synchronously through the first telescopic part, and at the same time, the solder bar sample is held and clamped. After clamping, the solder bar in the clamped state is pulled by the second telescopic part. Stretching for tensile strength testing.

Owner:深圳市帝腾锡业有限公司

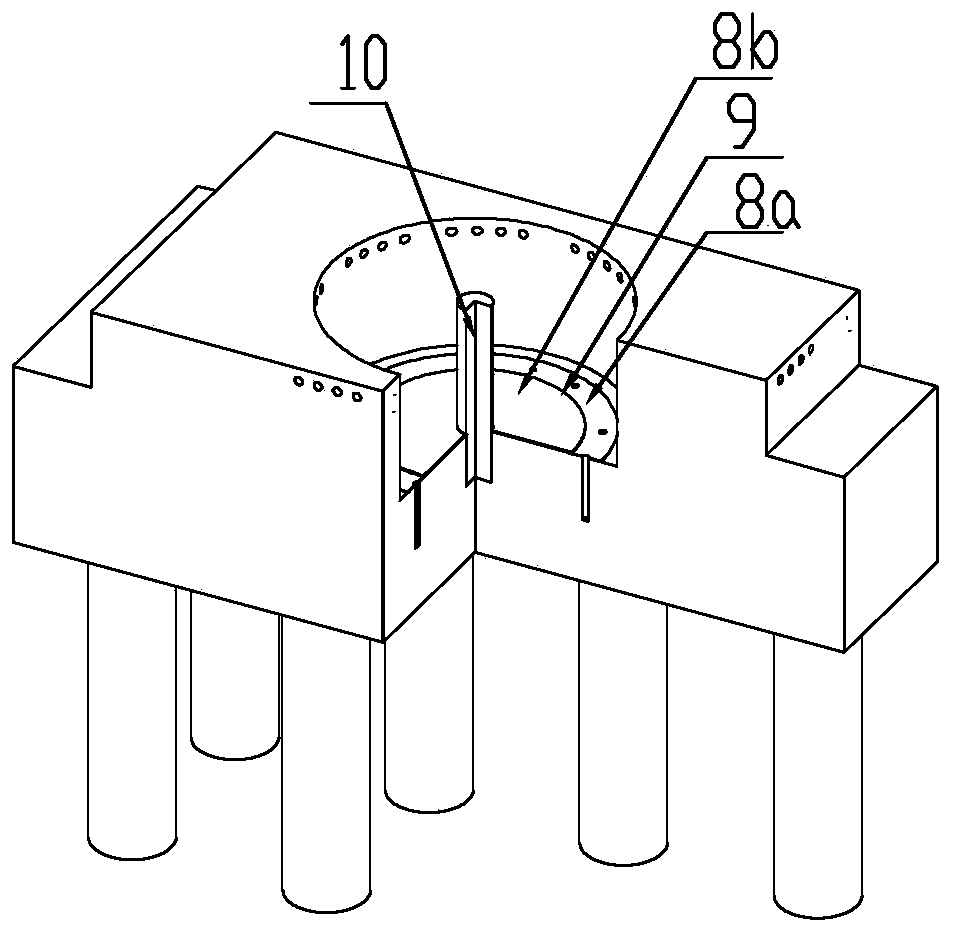

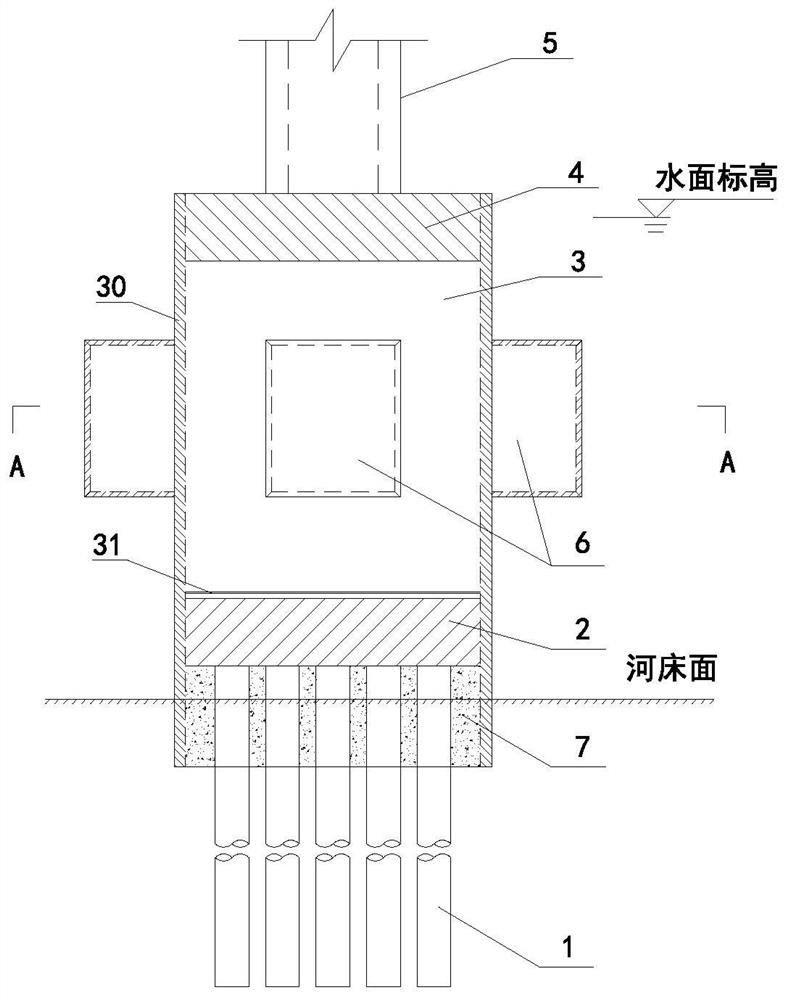

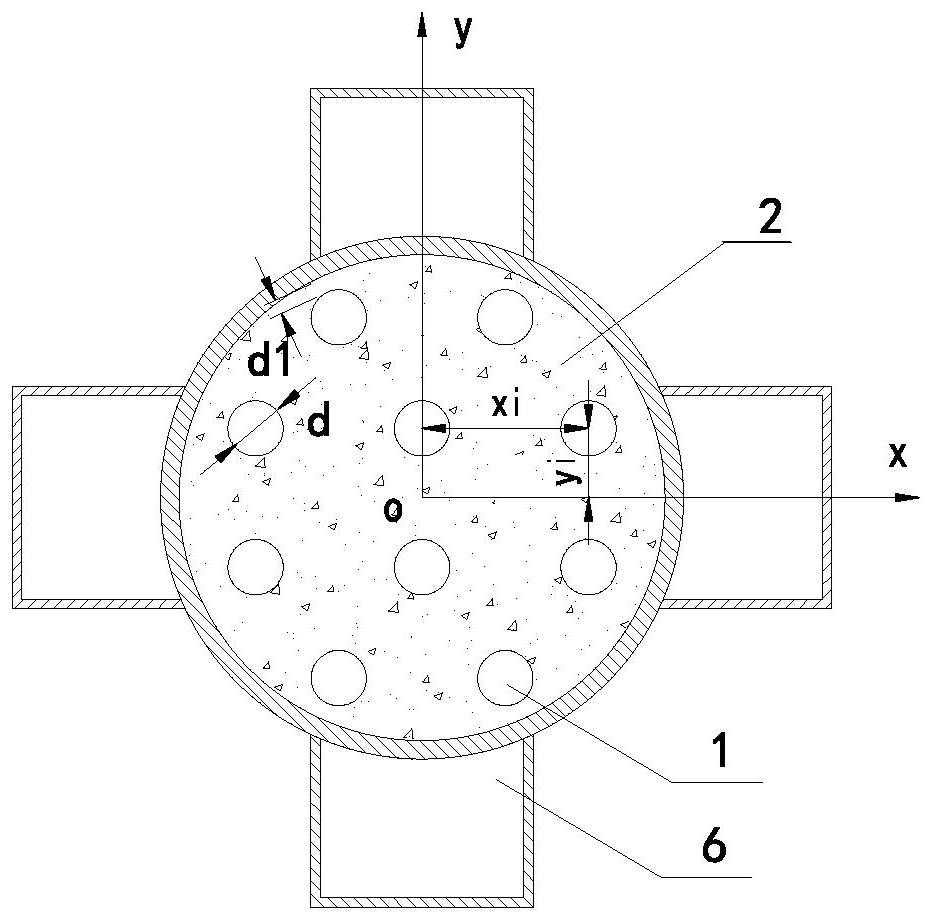

Buoyancy compensation type combined foundation and construction method

The invention relates to a buoyancy compensation type combined foundation and construction method. The buoyancy compensation type combined foundation comprises a plurality of supporting piles, a bearing platform, a main buoyancy tank, a conversion layer and a bottom sealing layer. The bottom sealing layer is arranged at the bottom of the bearing platform. The supporting piles form pile groups, andthe top ends of the pile groups penetrate the bottom sealing layer and are connected with the bearing platform. The main buoyancy tank is arranged on the bearing platform. The conversion layer is arranged on the main buoyancy tank and used for bearing a column body so as to transmit the upper structure load to the main buoyancy tank. According to the buoyancy compensation type combined foundationand construction method, the main buoyancy tank is large in buoyancy, the vertical load effect transmitted into the supporting piles is greatly reduced, the design of the supporting piles is controlled by the section strength of the pile bodies, and the influence of a deep soft covering layer on pile foundation design is reduced. The buoyancy compensation type combined foundation has the advantages of being small in pile foundation scale, reasonable in economic index and the like. The group piles formed by the supporting piles mainly bear vertical force, the main buoyancy tank bears most of horizontal force and bending moment transmitted by the upper portion, the free pile length portion of a traditional pile foundation is replaced, the horizontal load bearing capacity of the foundation is improved, and the influence of water depth, local scouring and stormy waves on foundation stress can be reduced.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

A kind of water-soluble antibacterial monocarboxyl chitosan and its preparation method and application

ActiveCN105061637BHigh oxidation selectivityQuick responseAnimal fibresPhosphoric acidAntibacterial activity

The invention discloses a water-soluble antibacterial monocarboxylic chitosan as well as a preparation method and application thereof. The preparation method of the monocarboxylic chitosan is characterized by comprising the following steps: dissolving macromolecular chitosan in a diluted acetic acid solution, and then selectively oxidizing part or all of hydroxyl groups at the C6 site of the chitosan into carboxyl groups by utilizing a concentrated nitric acid-concentrated phosphoric acid-sodium nitrite system, thereby obtaining the monocarboxylic chitosan. The water-soluble antibacterial monocarboxylic chitosan disclosed by the invention can be used for carrying out amide modification on real silk fabrics so as to obtain monocarboxylic chitosan amide modified real silk fabrics. The method disclosed by the invention is simple in operation, high in reaction speed and easy to control, the prepared monocarboxylic chitosan amide modified real silk fabrics have lasting and efficient antibacterial activity and good wearability and are environment-friendly, and the negative effects on good real silk characteristics and human health caused by using chemical crosslinking agents in conventional chitosan modification are overcome.

Owner:ANHUI AGRICULTURAL UNIVERSITY

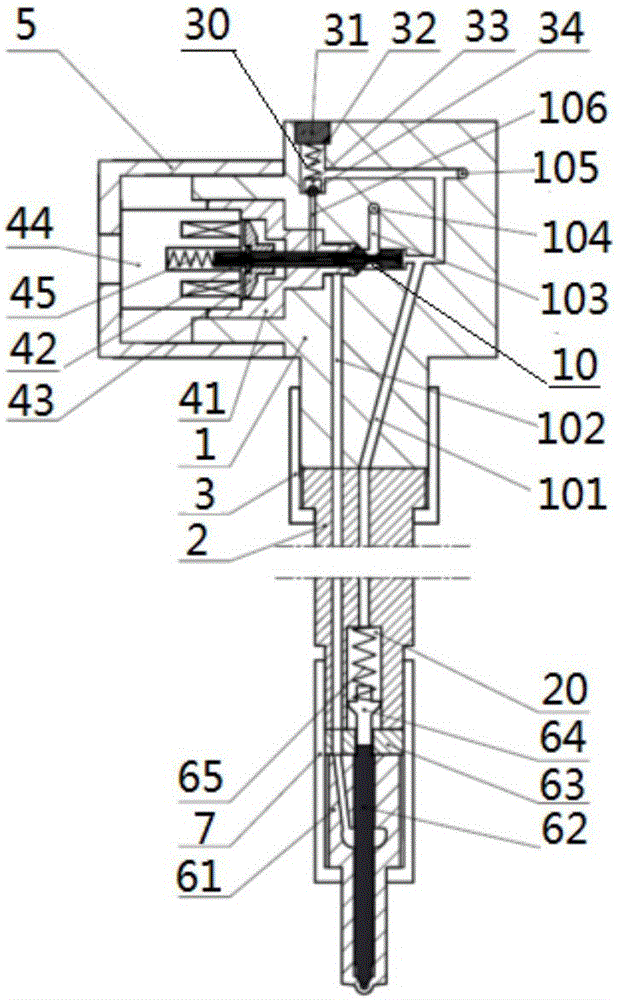

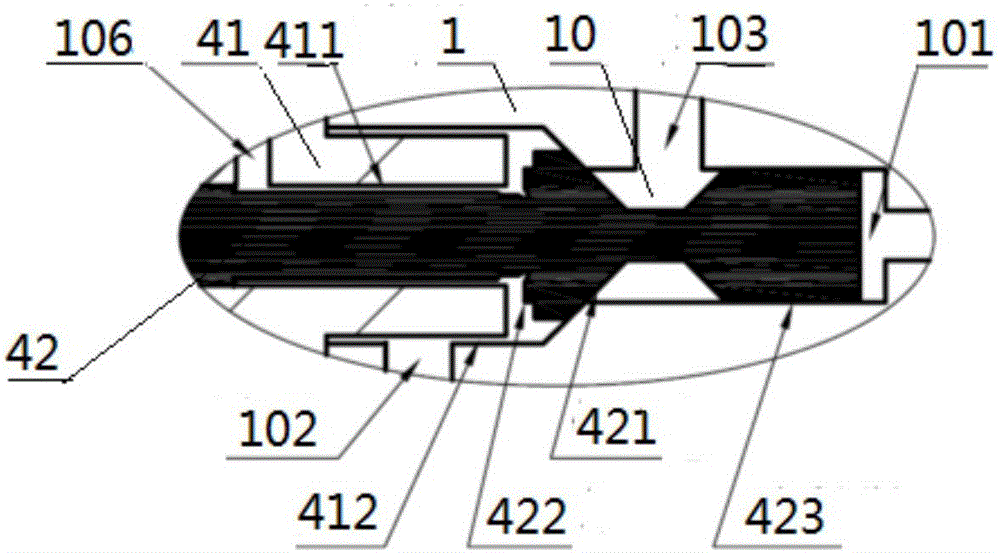

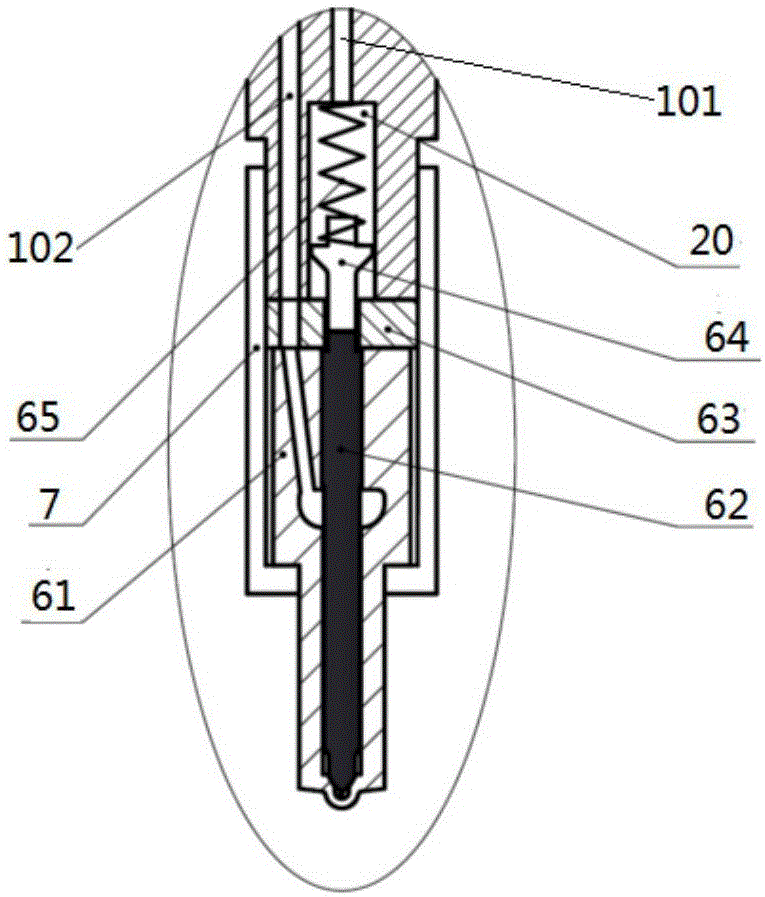

Micro-injection electronically-controlled fuel injector with pressure-maintaining structure

ActiveCN107524551AAccelerate the pressure build rateIncrease open rateFuel injection apparatusMachines/enginesInlet channelEngineering

The invention relates to a micro-injection electronically-controlled fuel injector with a pressure-maintaining structure. According to the micro-injection electronically-controlled fuel injector, an upper fuel cavity as well as a main fuel inlet channel, a main fuel return channel, a fuel inlet channel and a fuel return channel which communicate with the upper fuel cavity are formed in the upper body of the fuel injector; the lower body of the fuel injector is connected to the lower end of the upper body of the fuel injector through a fuel injector fastening nut, a lower fuel cavity is formed in the lower body of the fuel injector, and the lower fuel cavity communicates with the main fuel return channel; a nozzle member is connected to the lower end of the lower body of the fuel injector through a nozzle fastening nut and communicates with the lower fuel cavity, and further communicates with a main fuel channel penetrating through the lower body of the fuel injector; and an electromagnetic valve is connected to the left side of the upper part of the upper body of the fuel injector through an electromagnetic valve fastening nut, one end part of a control valve element of the electromagnetic valve stretches in the upper fuel cavity, and the other end part of the control valve element is abutted against an electromagnetic valve return spring arranged at the central part of an electromagnet. According to the micro-injection electronically-controlled fuel injector disclosed by the invention, a fuel inlet process and a fuel return process can be mutually independent, so that the influence of the mutual interference of fuel flowing in the fuel inlet process and the fuel return process on a fuel injection process is avoided; and the opening speed of a needle valve can be increased, so that the injection characteristic of a micro-injection fuel system is improved.

Owner:CHONGQING HONGJIANG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com