Micro-injection electronically-controlled fuel injector with pressure-maintaining structure

An electronically controlled fuel injection and fuel injector technology, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve the problem of small installation space of micro-spray electronically controlled fuel injectors, extended fuel injection duration, and needle valve opening / Long closing time and other problems, to achieve the effect of accelerating the fuel pressure build-up rate, accelerating the needle valve opening rate, and increasing the needle valve opening rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention will be further described below in conjunction with the accompanying drawings.

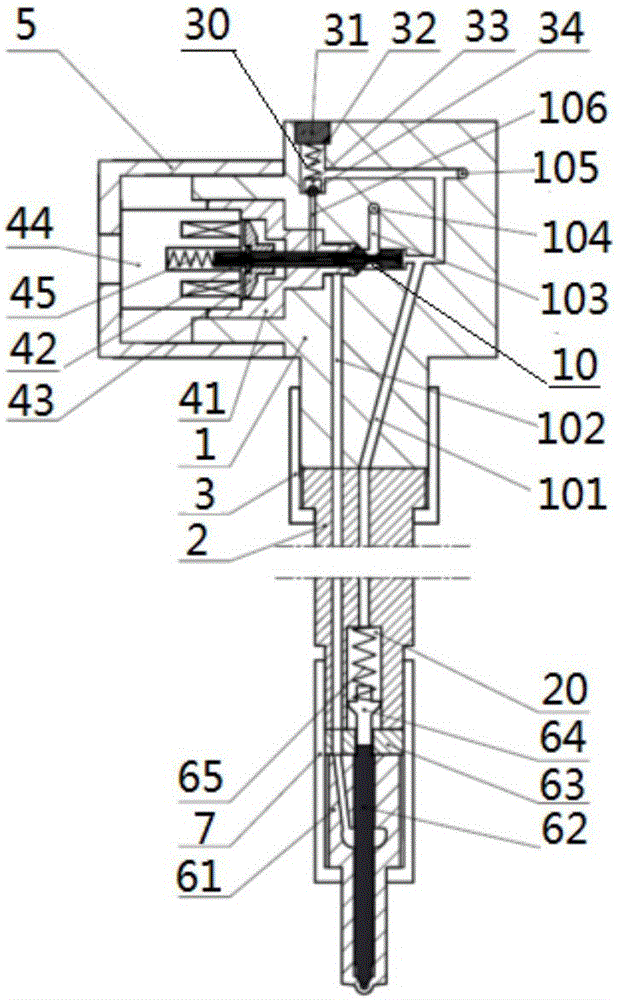

[0034] see figure 1 , figure 2 and image 3 A micro-spray electronically controlled fuel injector with a pressure-holding structure is shown, including:

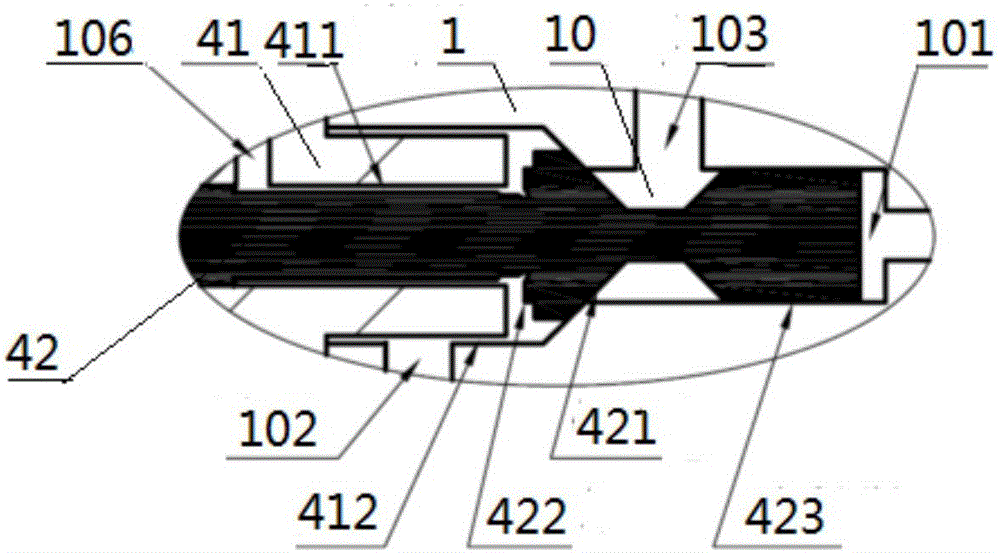

[0035] The upper part of the upper body 1 of a fuel injector is provided with an upper oil chamber 10 and a total oil inlet passage 102 communicated with the upper oil chamber, a total oil return passage 101, an oil inlet passage 103 communicated with an oil inlet interface 104, and a return oil passage. The oil return oil passage 106 connected by the oil interface 105;

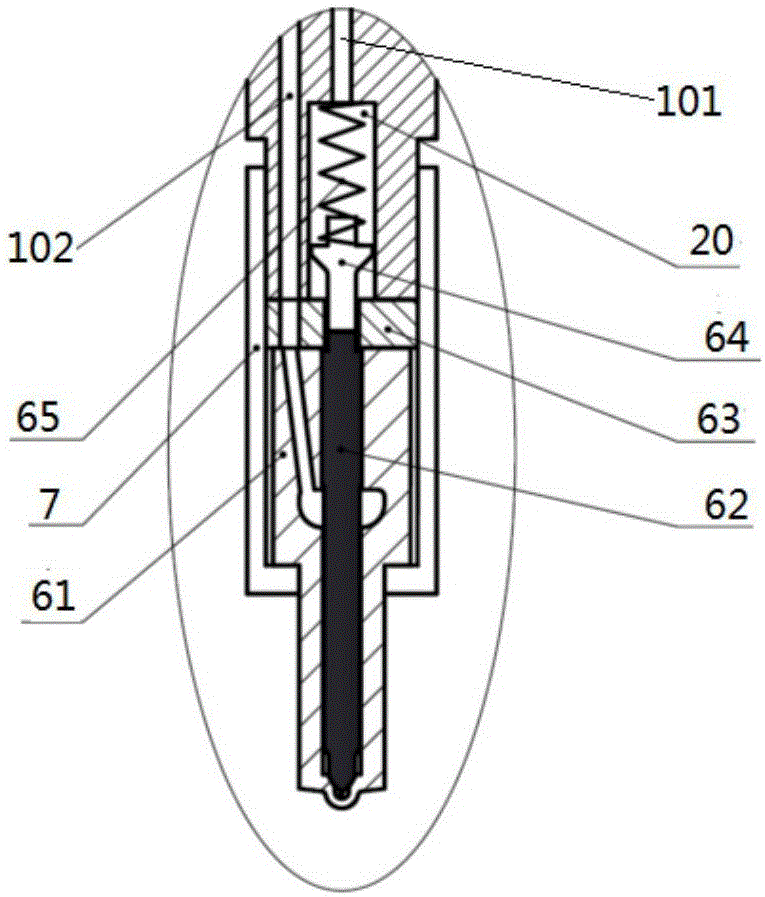

[0036] A fuel injector lower body 2 is connected to the lower end of the fuel injector upper body 1 through the fuel injector tight cap 3, and the lower part of the fuel injector lower body 2 is provided with a lower oil chamber 20, which is connected to the lower oil chamber. The total return oil passage 101 is connected;

[0037] A nozzle member is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com