A composite sealing end face structure with three-diversity microholes and stepped spiral arc grooves

A compound type and sealing end technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of high leakage, end face scratches, insufficient rigidity of liquid film, etc., to reduce vibration, reduce surface wear, and reduce friction coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

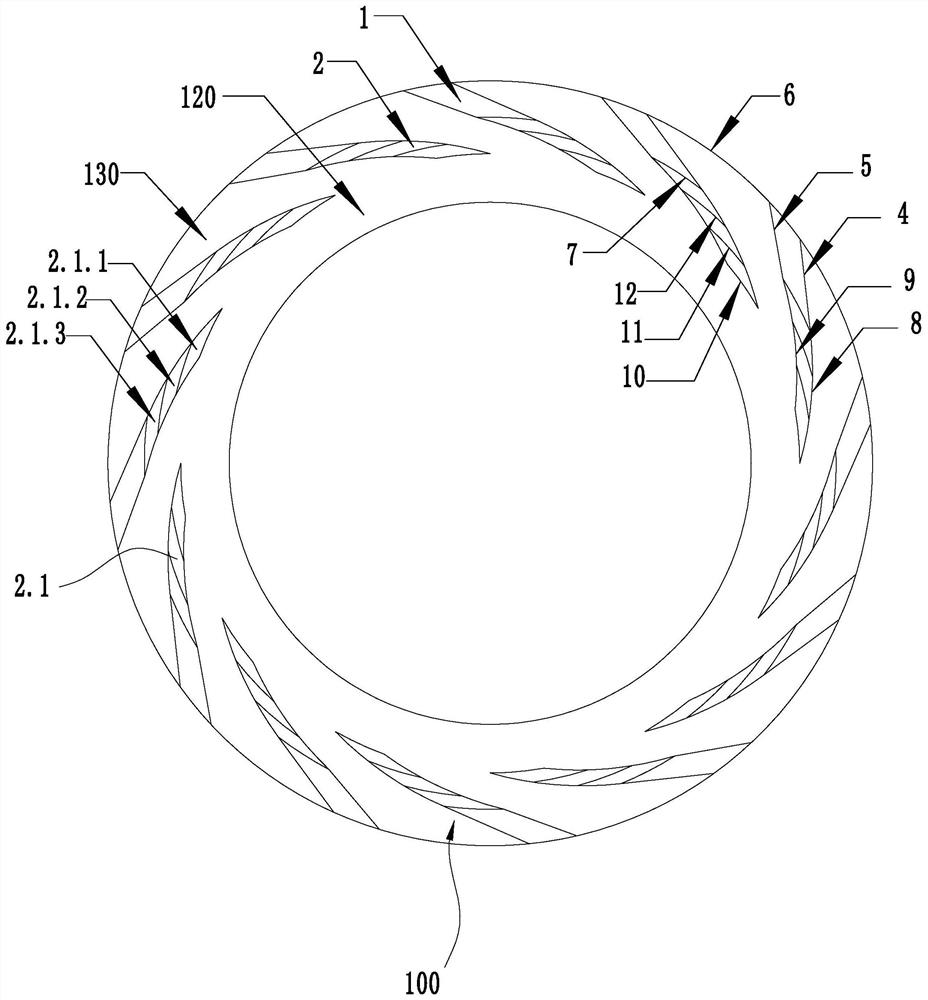

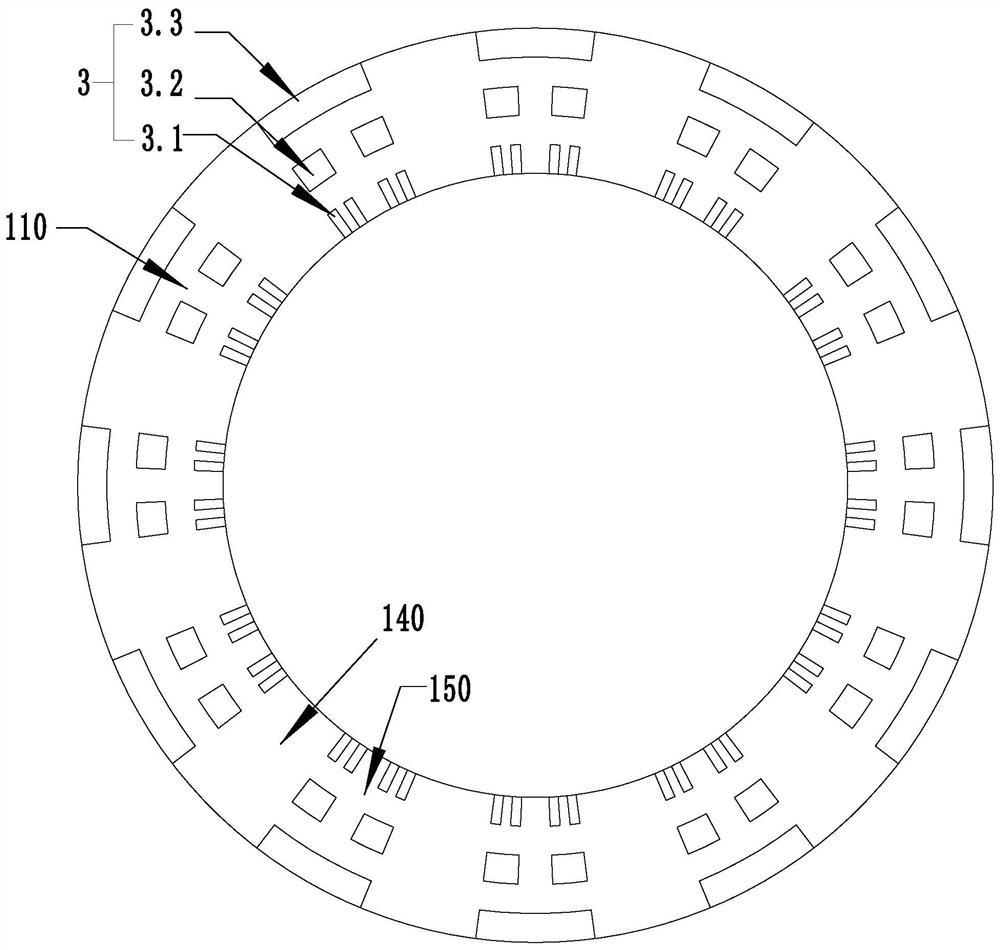

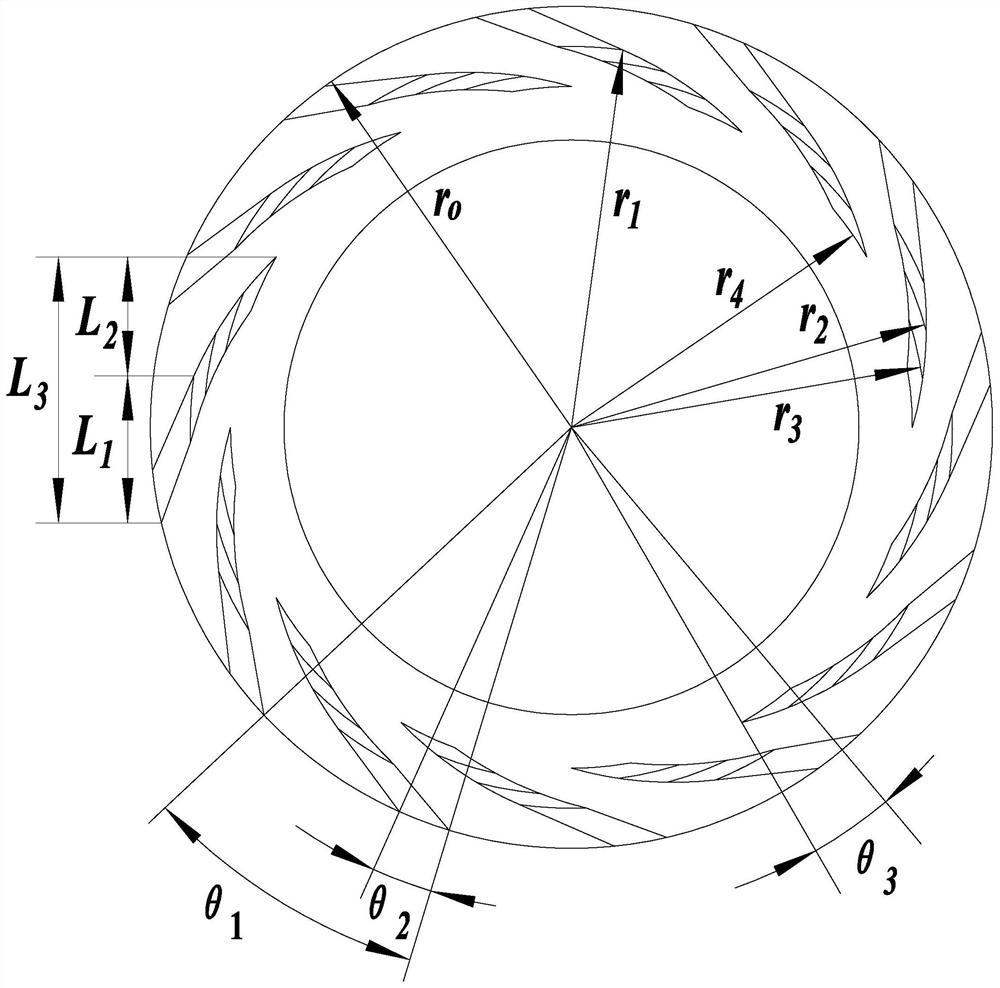

[0030] Such as figure 1 , 2 As shown, the present invention provides a composite sealing end face structure of three-diversity micropores and stepped spiral arc grooves, including a moving ring and a static ring, and one end face of the moving ring fits with one end face of the static ring to form a pair of sealing friction Vice, such as Figure 7 As shown, among them, a number of spirally distributed stepped spiral arc grooves 100 are uniformly arranged on the end face of the moving ring along the circumferential direction, and each stepped spiral arc groove 100 starts from the outer edge of the moving ring to the middle diameter of the moving ring location terminated. Each stepped spiral arc groove 100 includes a basic wire groove 1 and a basic spiral groove 2 arranged along the direction from the outer diameter to the inner diameter, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com