Patents

Literature

80results about How to "Improve sealing and stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

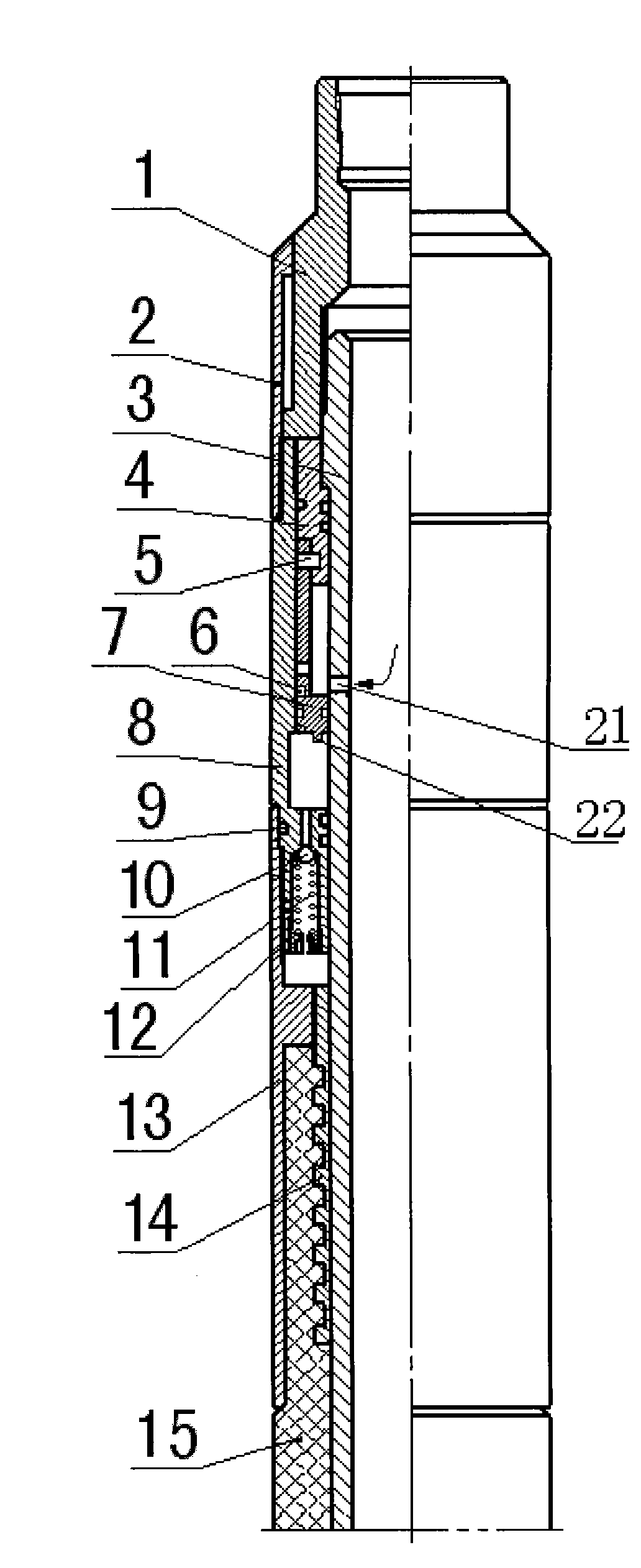

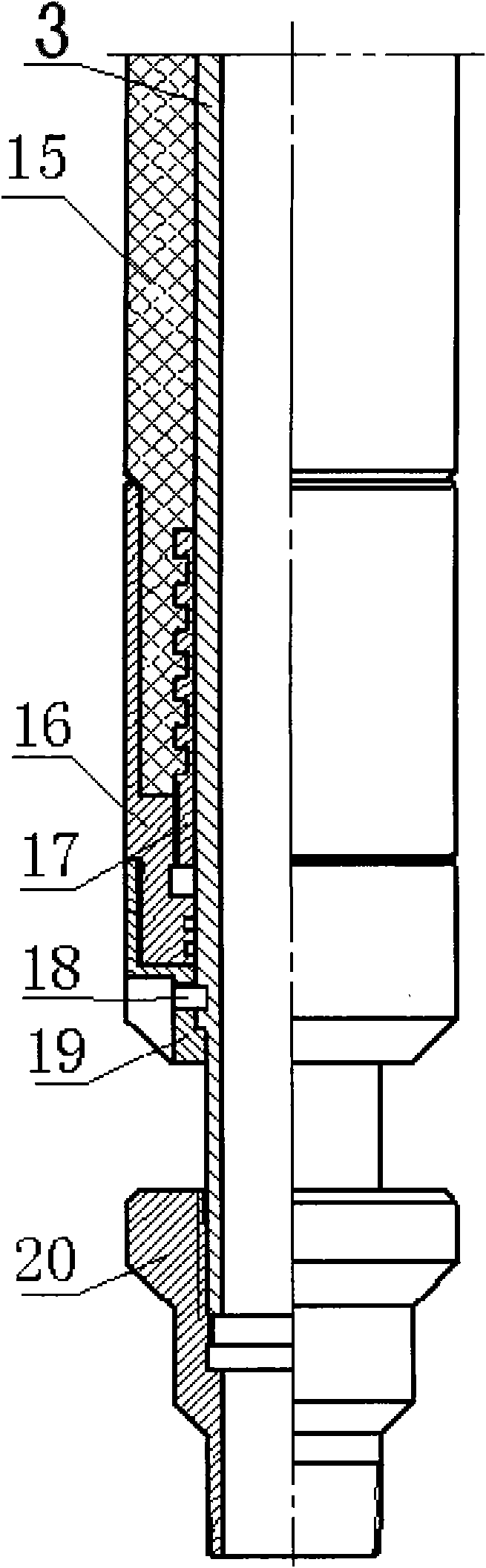

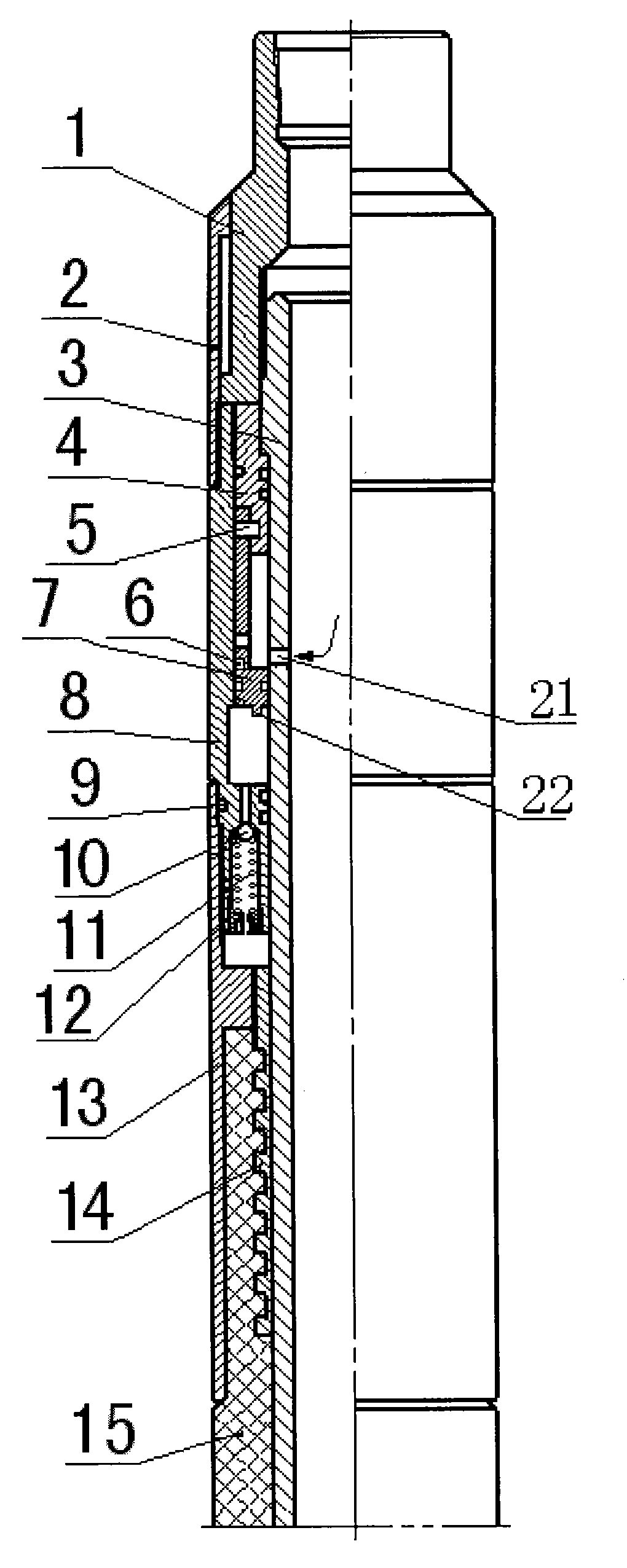

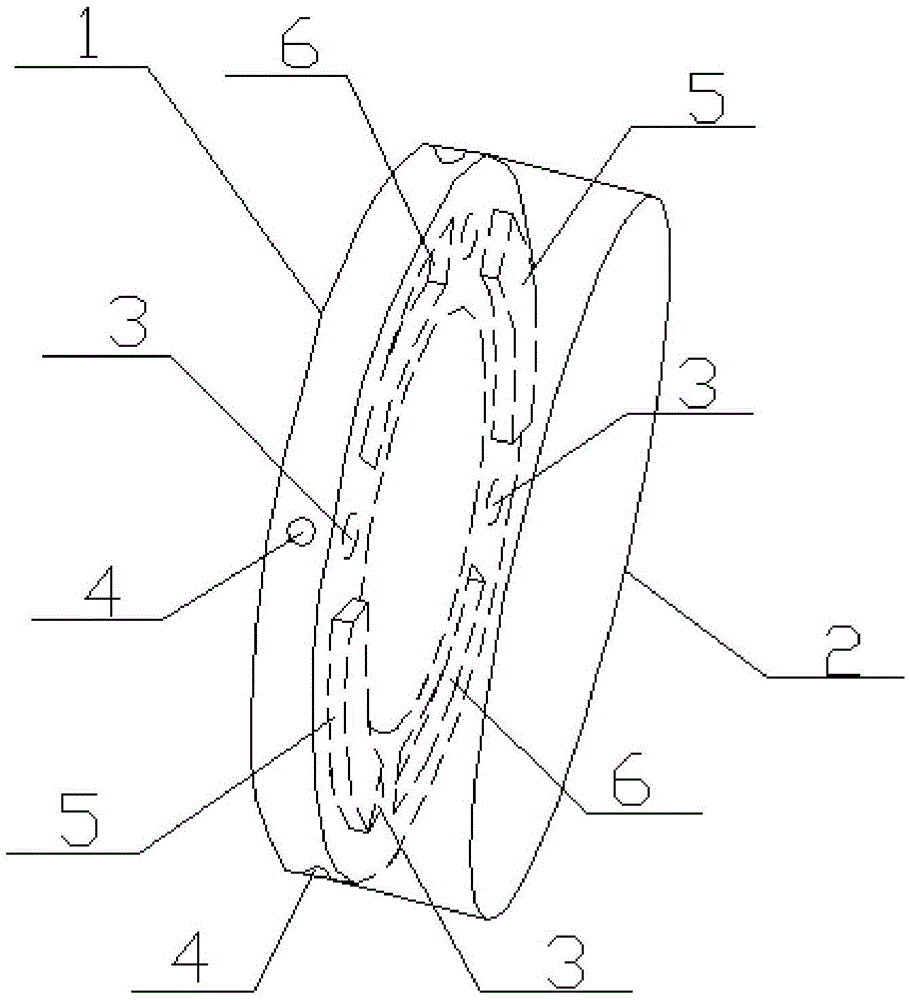

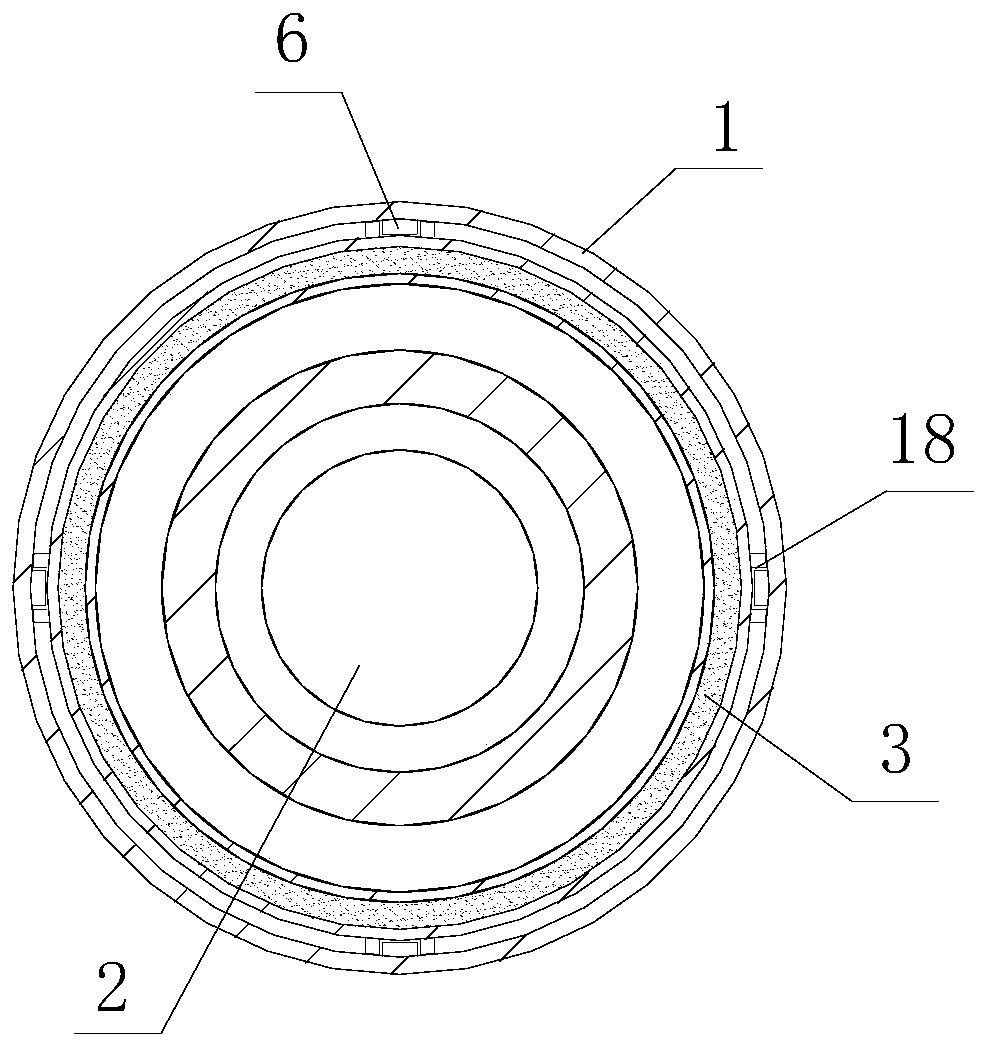

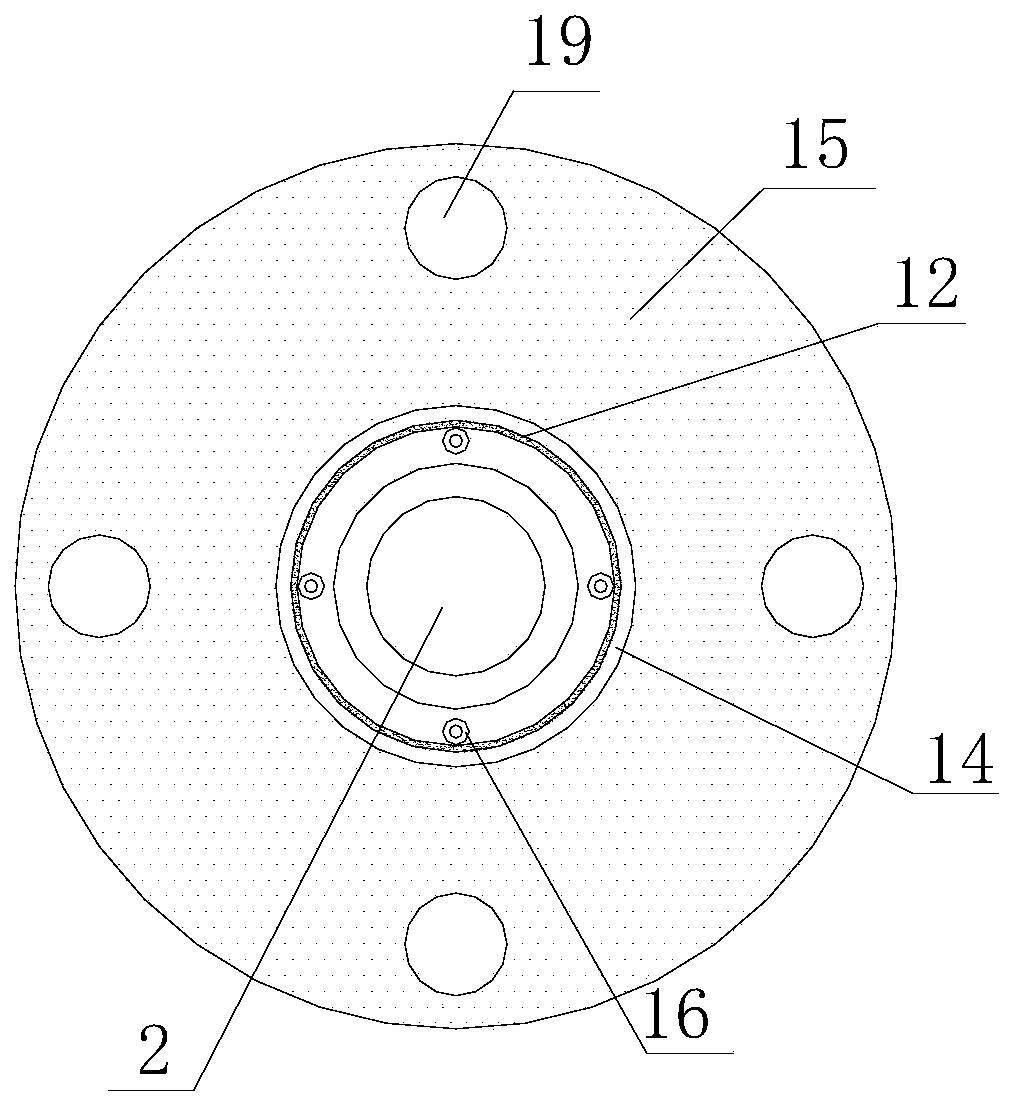

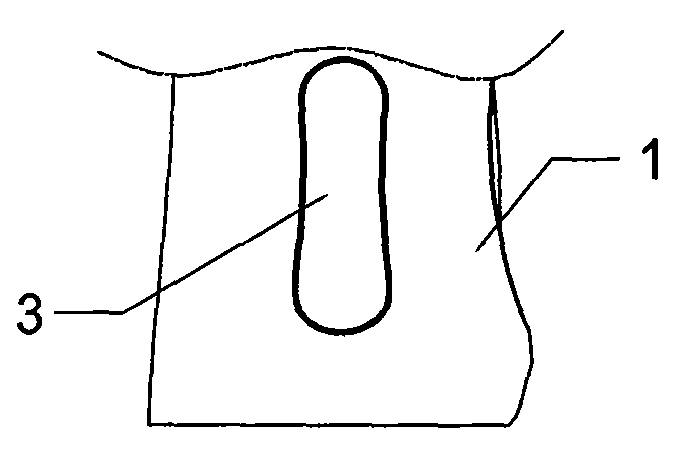

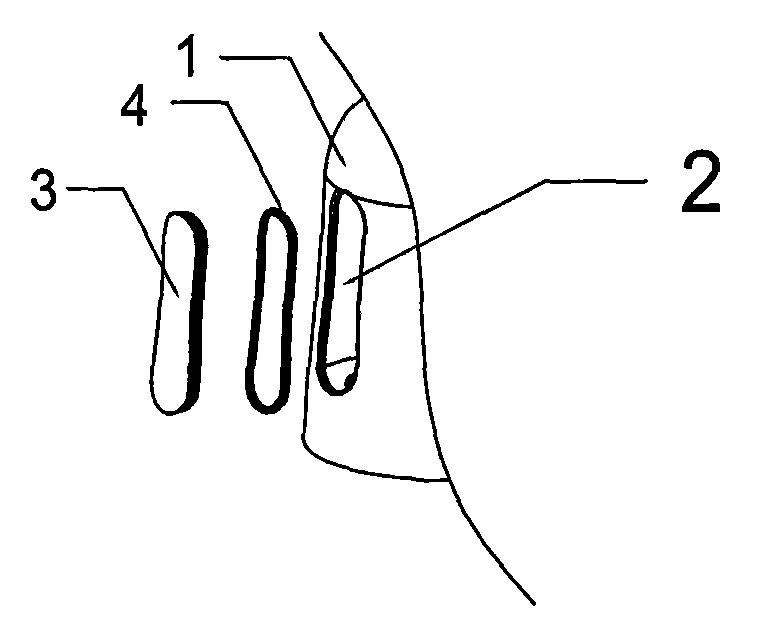

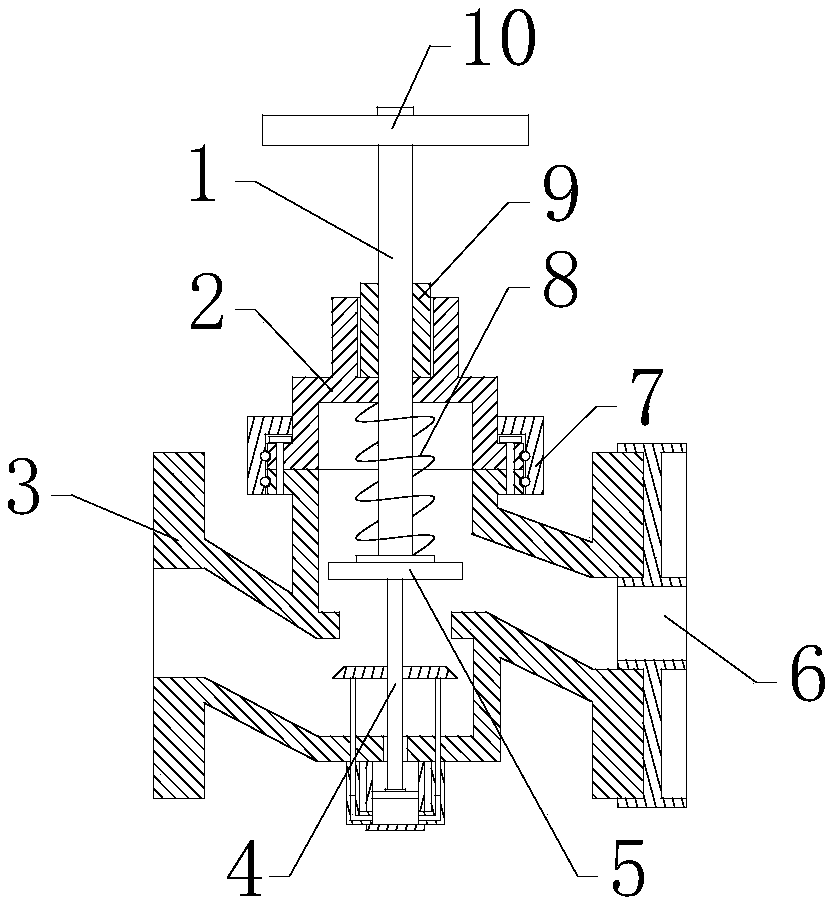

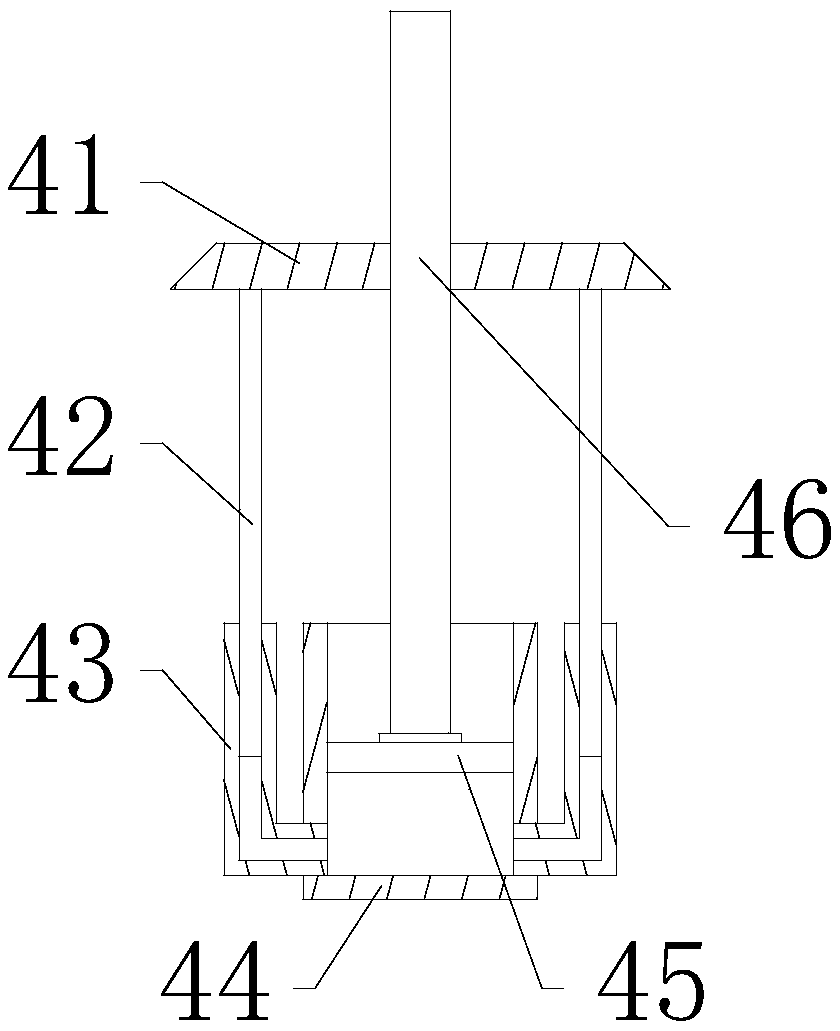

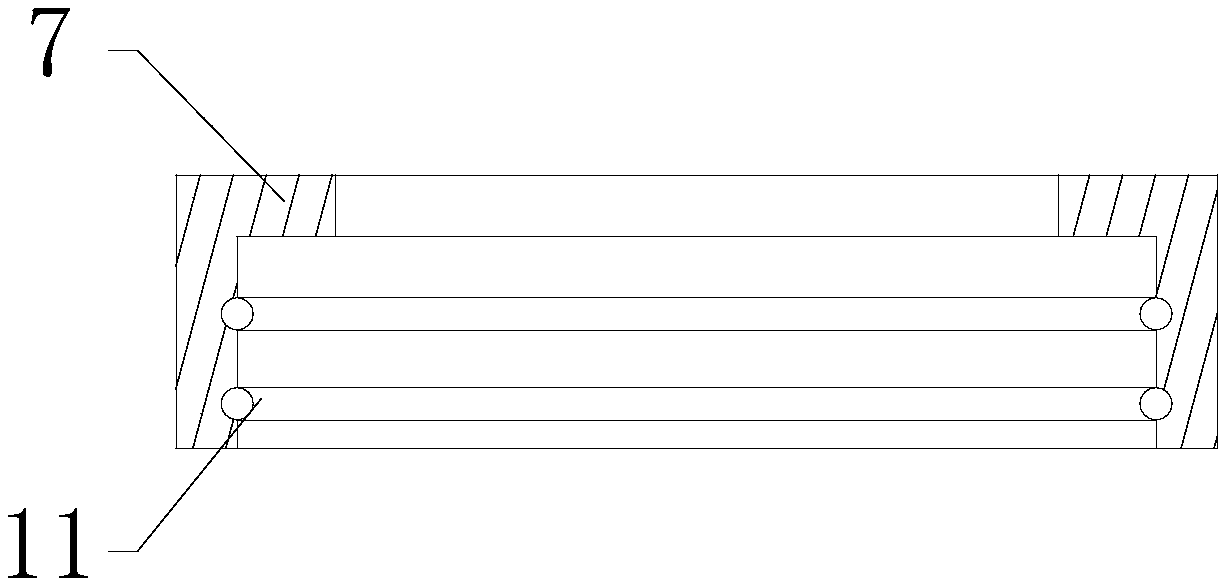

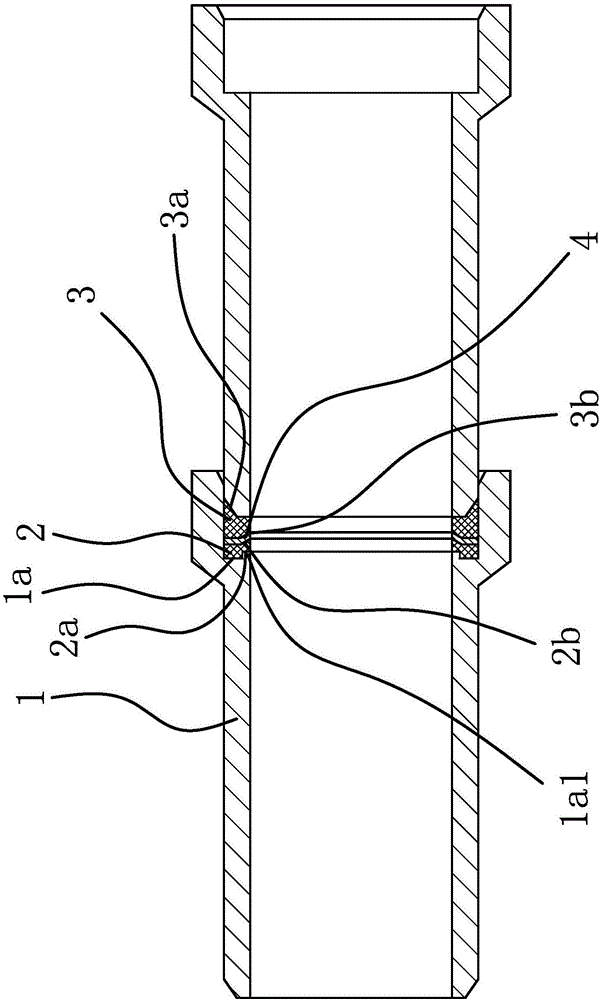

Custom-pressure expandable naked eye packer

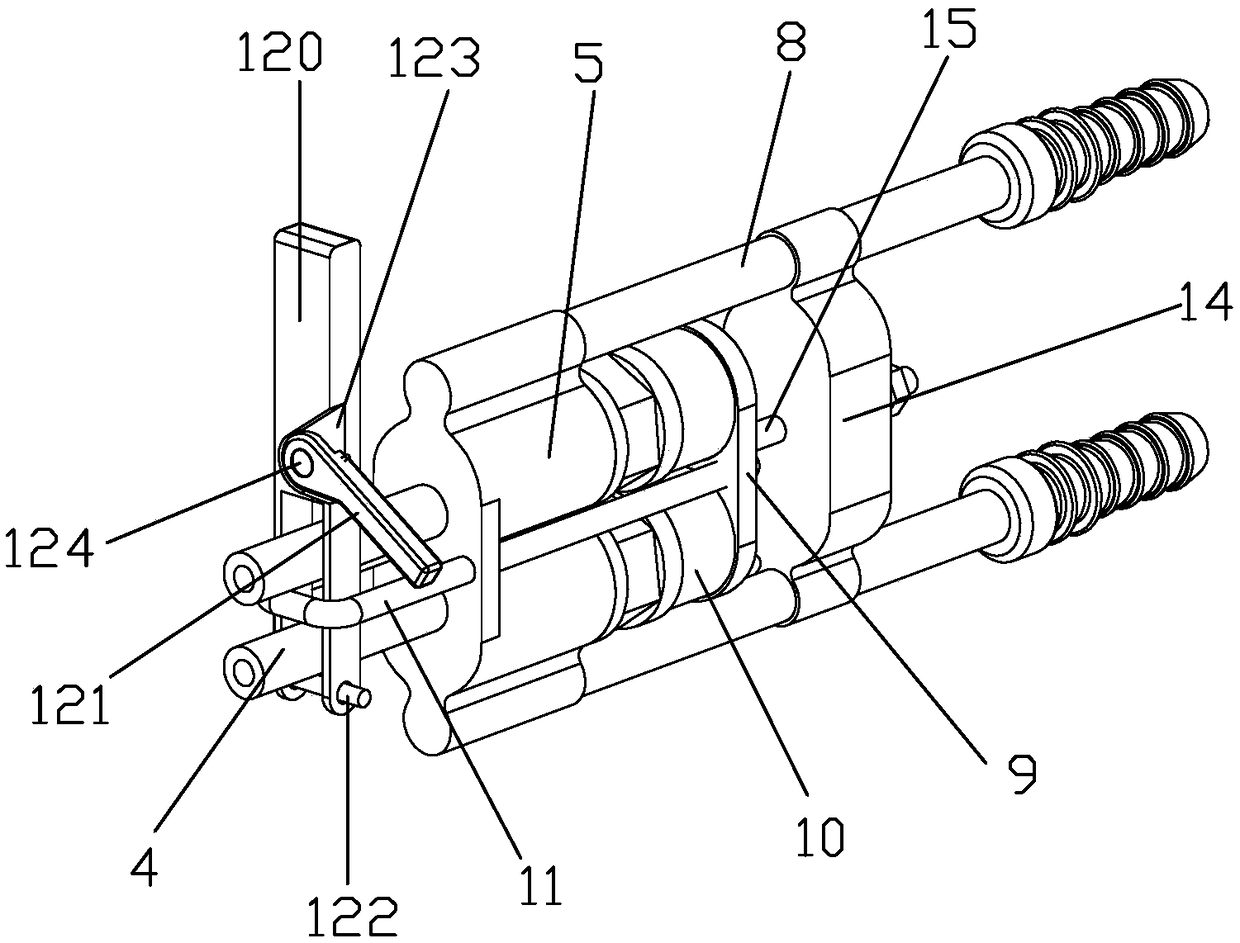

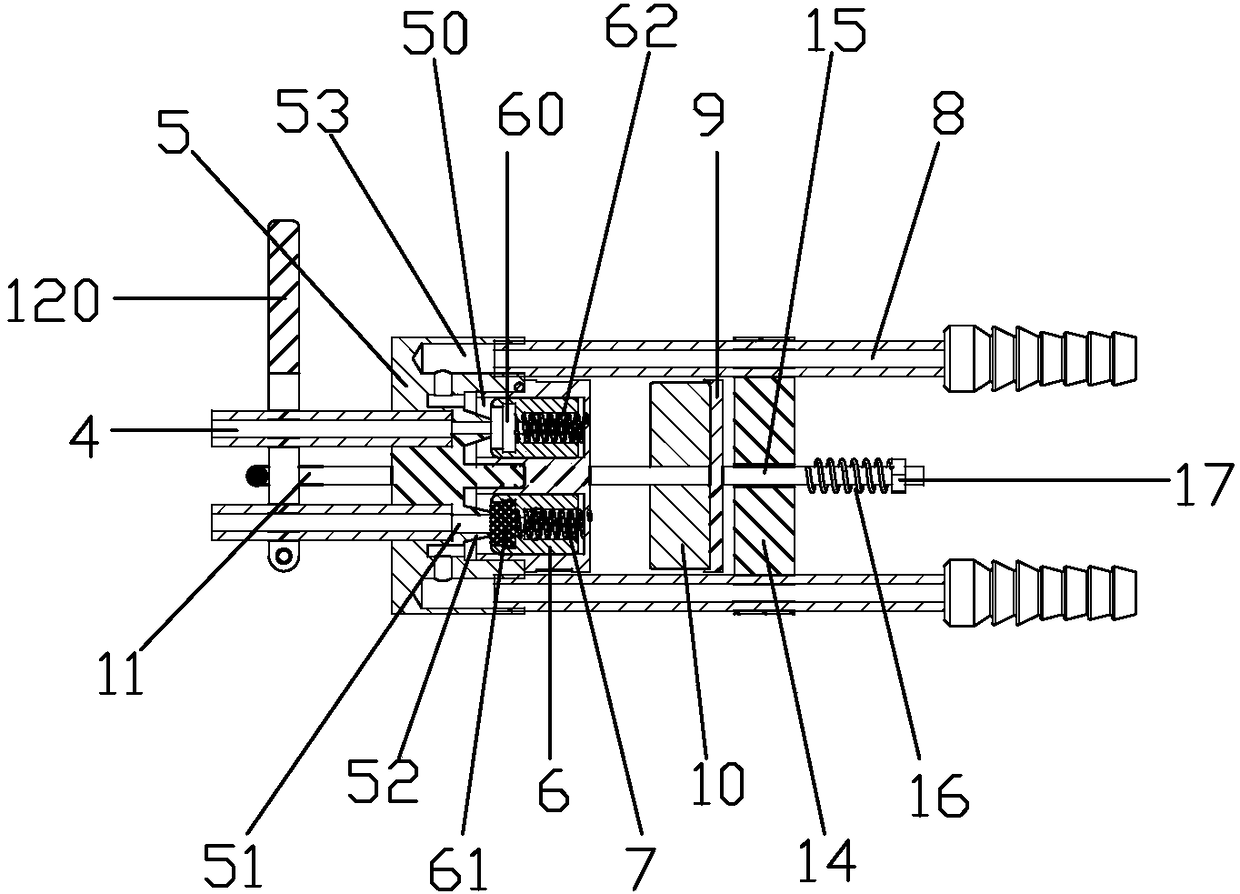

The invention relates to a custom-pressure expandable naked eye packer applied to the technical field of fracture and acidulation oil and gas wells. The lower end of an upper joint is connected with a central tube; the lower end of the central tube is connected with a lower joint, a sealing mechanism is sleeved on the central tube; in the sealing mechanism, an upper connector and a lower connector are respectively vulcanized on the inner walls of both ends of a rubber tube; in a setting mechanism: an upper circular hook cap is sleeved on the outer wall of the lower end of the upper joint; thelower end of the upper circular hook cap is connected with the upper end of a hydraulic cylinder; a circular space between the hydraulic cylinder and the central tube is internally provided with a circular limit ring and a circular setting piston; the lower end of the hydraulic cylinder is connected with an overdraught cap and provided with a uniflow valve; in a decapsulating mechanism, the innerwall of the lower end of a pushing cap is sleeved on the central tube, and the lower end thread of the pushing cap is connected with a lower circular hook cap; and the inner wall of the lower circular hook cap is sleeved on the central tube and fixed with the central tube through a decapsulating pin. The invention has the advantages of meeting the modification requirements of the naked eye oil and gas well on monolayer fracturing and acidified delamination, preventing the rubber tube from expanding unlimitedly in the naked eye and taking the action of protecting the rubber tube.

Owner:PETROCHINA CO LTD

Process for casting seal rainproof complex flanges

ActiveCN105598389APrevent rust and corrosionShort lifeFoundry mouldsFurnace typesLubricationIndustrial engineering

The invention discloses a process for casting seal rainproof complex flanges. The complex flanges comprise first flanges and second flanges. Each first flange and the corresponding second flange are butted to each other in the left-right direction, each first flange comprises a first flange body and a protective cover, at least four first fixing holes are uniformly formed in each first flange body, at least four oil filler holes are further uniformly formed in each first flange body, first lugs are further respectively uniformly arranged on the surface of each first flange body, and first grooves are further respectively uniformly formed in the surface of each first flange body; each second flange comprises a second flange body, at least four second fixing holes are uniformly formed in each second flange body, second lugs are further respectively uniformly arranged on each second flange body, and second grooves are further respectively uniformly formed in each second flange body. The process has the advantages that the process is simple and feasible, the seal rainproof complex flanges cast by the aid of the process are low in casting cost, simple in structure, high in connectivity and good in sealing performance, lubrication can be facilitated when the seal rainproof complex flanges are used, rainproof effects can be realized, the service lives of the seal rainproof complex flanges can be prolonged, and the cost can be reduced.

Owner:YANCHENG AOTONG TESCO FOUNDRY CO LTD

Industrial robot seal joint

The invention relates to an industrial robot seal joint. The industrial robot seal joint comprises a first joint with an outer boss and an inner boss, a second joint with a base hole, and a self-sealbearing arranged between the first joint and the second joint. The second joint rotates around the axis of the first joint. A glyd ring for movable seal is arranged between the first joint and the second joint. The inner circle and the outer circle of the self-seal bearing are provided with a first O-shaped seal ring and a second O-shaped seal ring for static seal between the first joint and the second joint. A seal cavity is formed between the static seal and the movable seal. The glyd ring for the movable seal at the outer portion and the O-shaped rings arranged inside for the static seal are arranged, through combination of the glyd ring and the O-shaped rings, a double-seal structure is achieved, more compact joint seal can be achieved, friction resistance is effectively reduced, sealstability is improved, and entry of outer foreign matter is effectively prevented.

Owner:EFORT INTELLIGENT EQUIP CO LTD

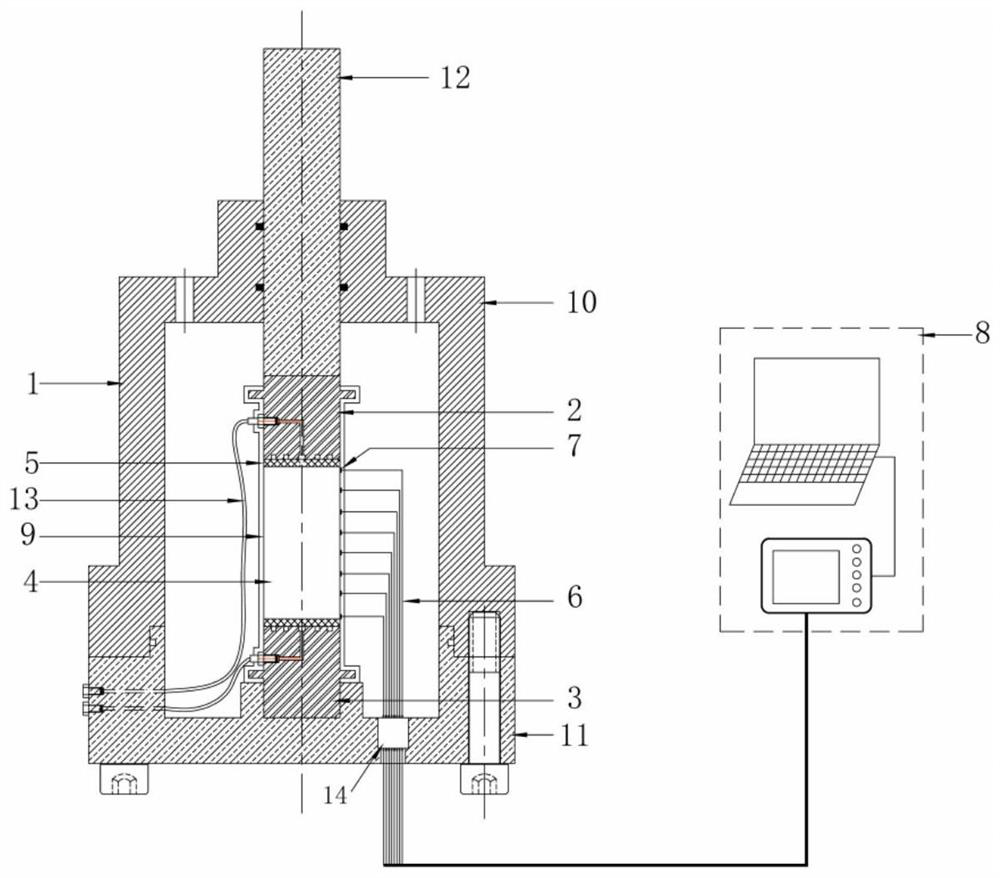

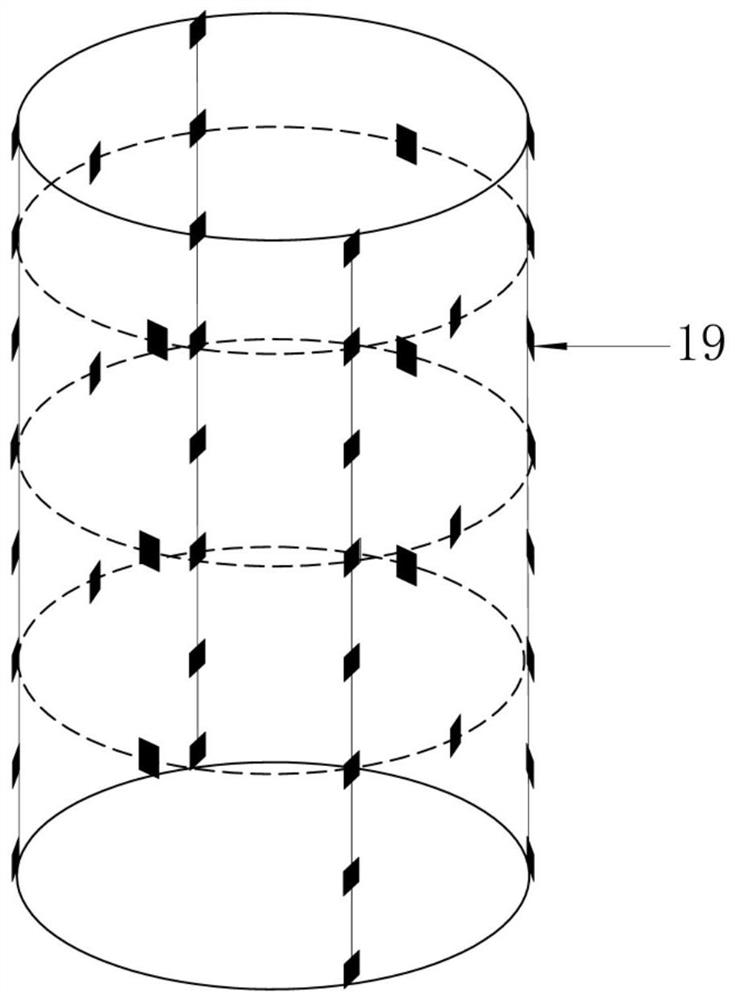

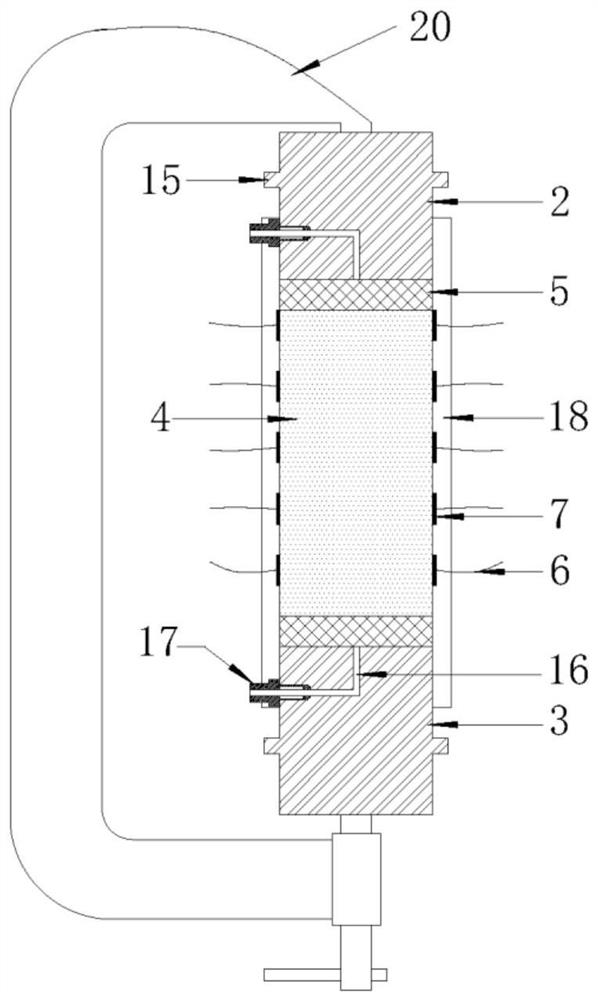

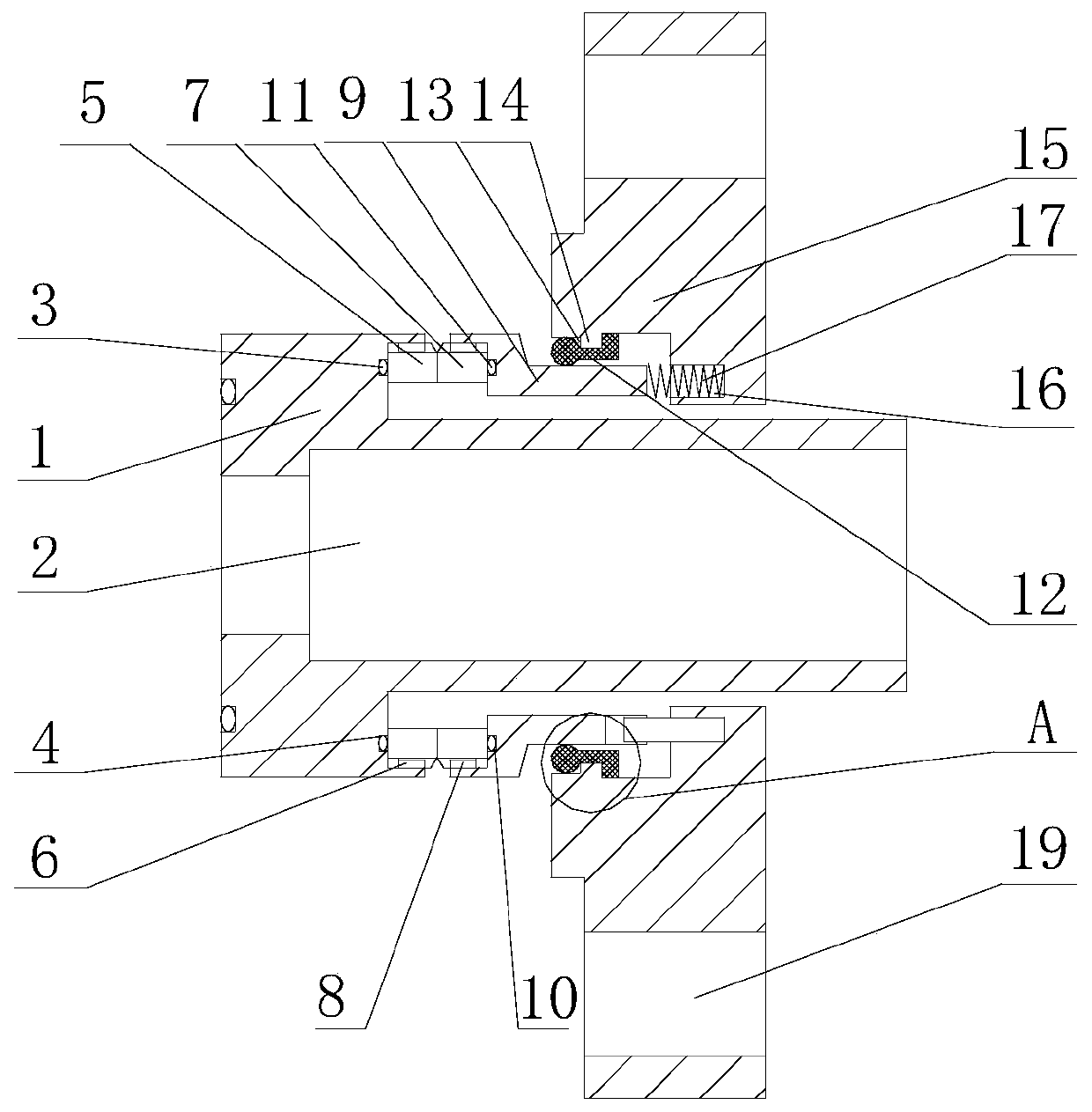

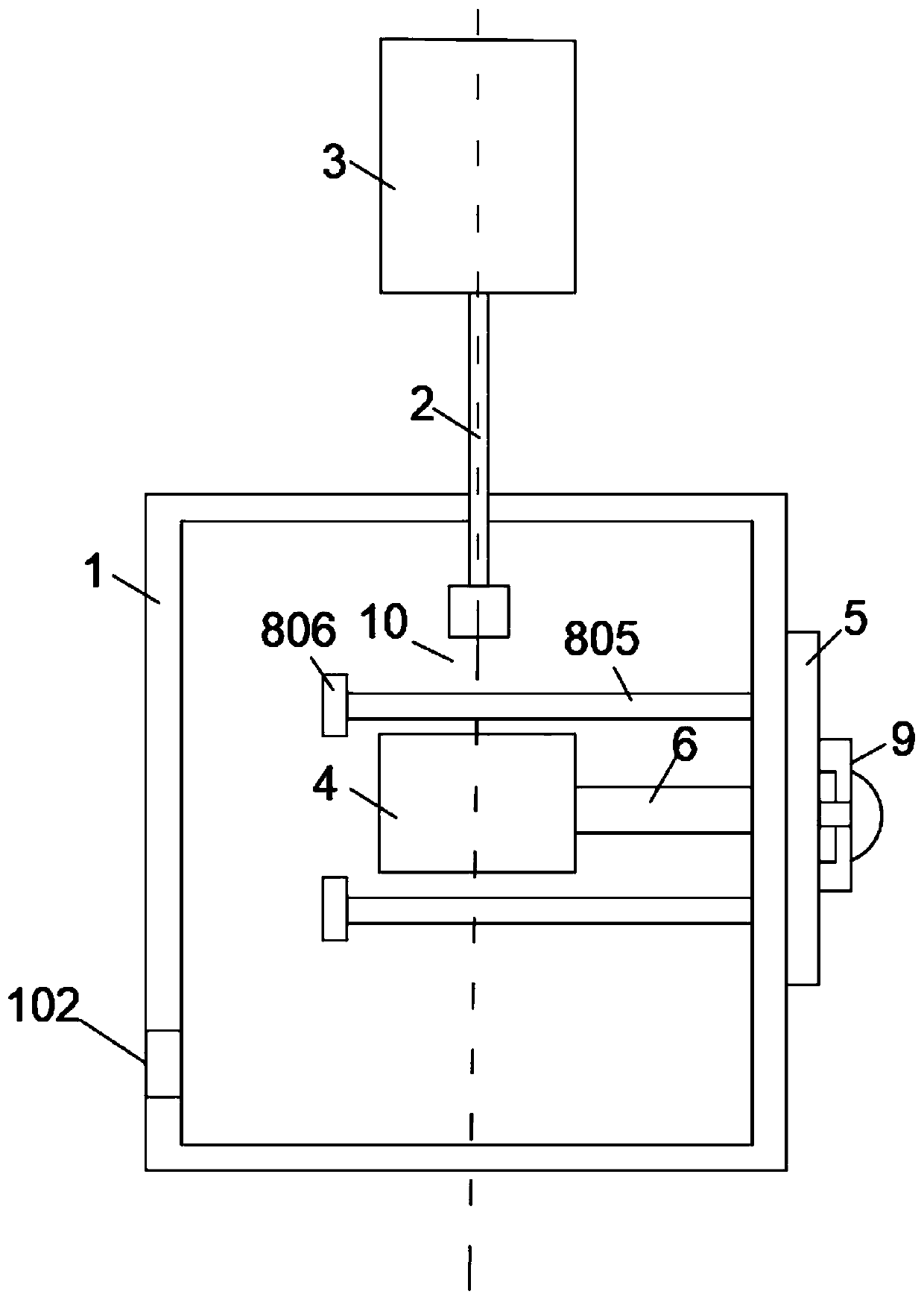

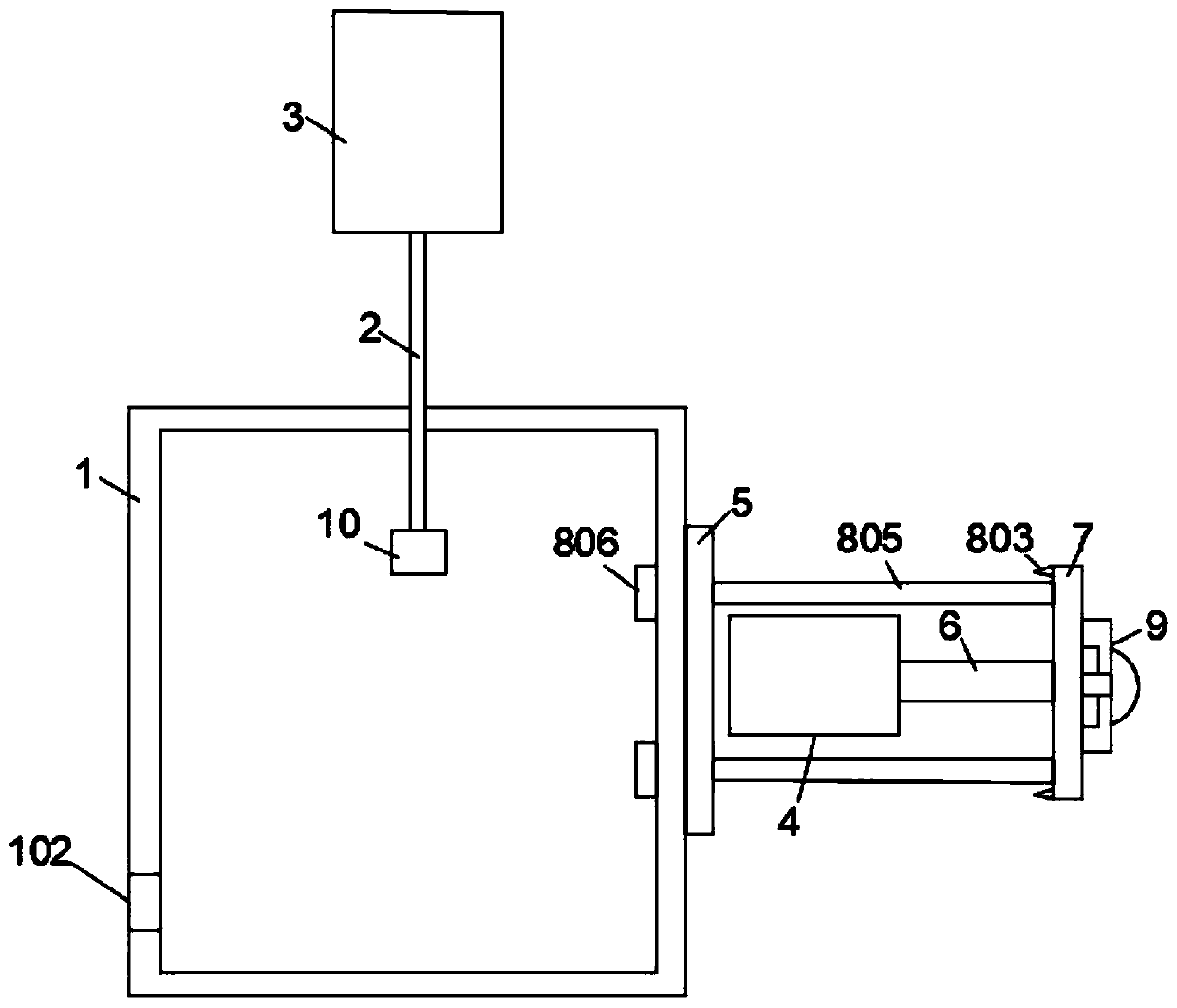

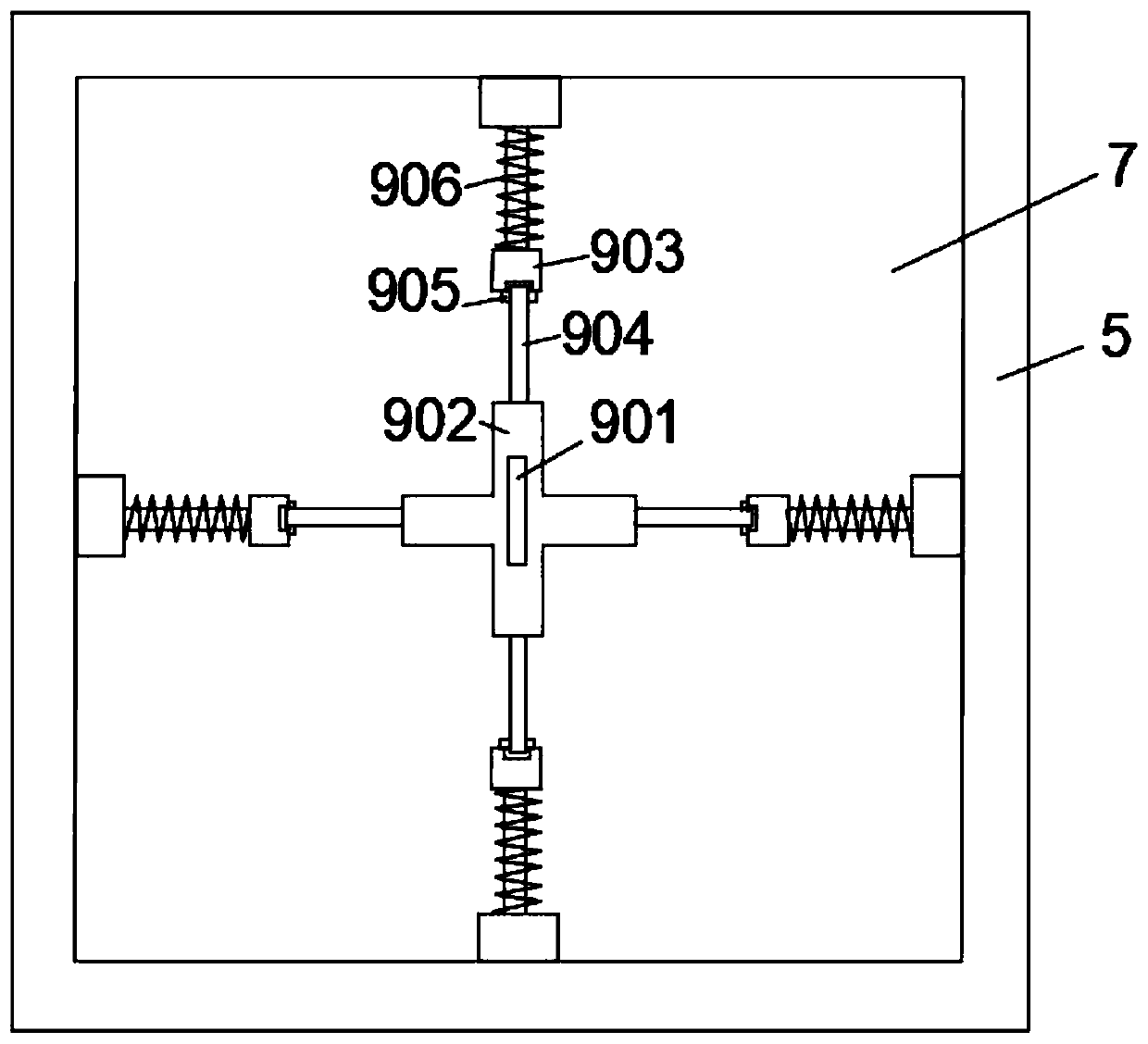

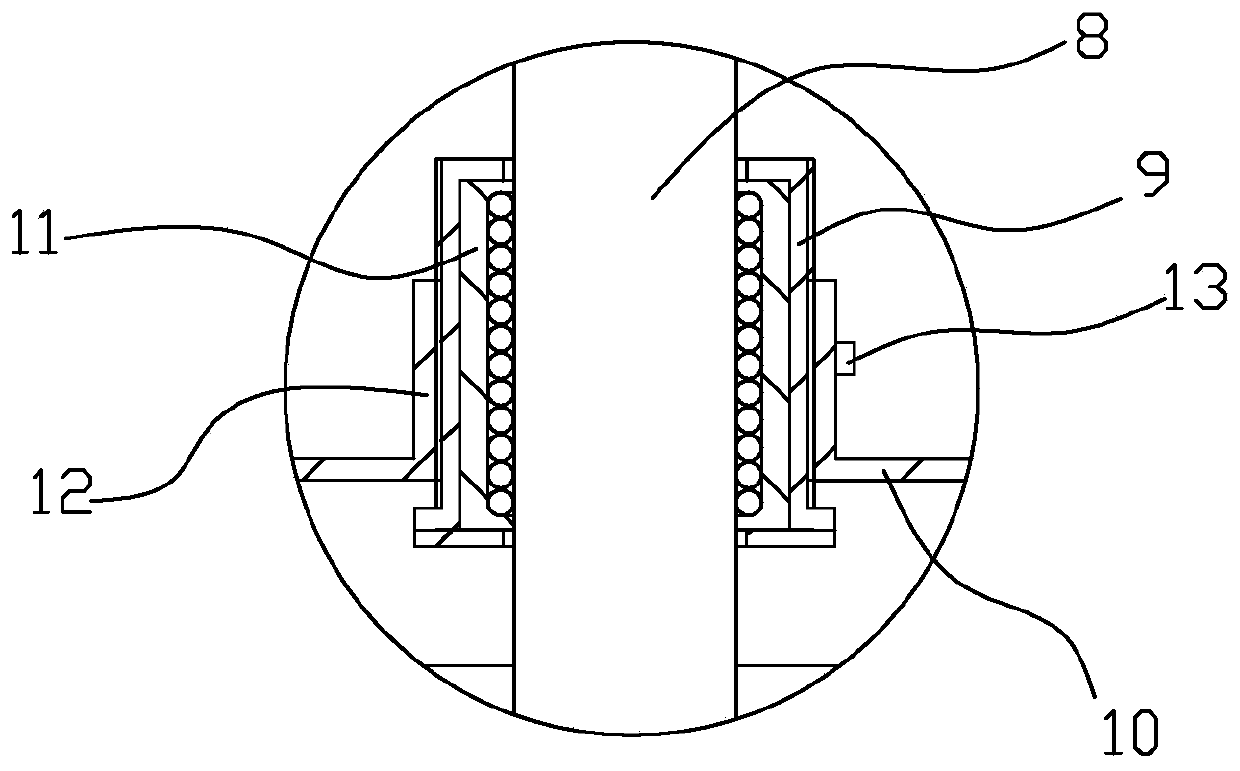

High-voltage triaxial resistivity test system and method considering chemical penetration

ActiveCN112255458AFit tightlyHigh precisionEngine sealsResistance/reactance/impedenceData acquisitionEngineering

The invention discloses a high-voltage triaxial resistivity test system and method considering chemical penetration. The system comprises a pedestal, a pressure-bearing cylinder, a sample assembly, and a data collection and processing system, wherein the sample assembly comprises an upper pressure head, a lower pressure head, a sample, a sealing layer, and detection electrodeS; the upper pressurehead, the sample and the lower pressure head are coaxially arranged in sequence from bottom to top, permeable stones are arranged between the upper pressure head and the sample and between the sampleand the lower pressure head, the lower pressure head of the sample assembly is fixed with the base, and the upper pressure head of the sample assembly is in contact with the piston rod; a plurality ofdetection electrodes are distributed on the side surface of the sample to form an electrode array; flanges are symmetrically arranged on the two sides of the upper pressure head and the two sides ofthe lower pressure head, and the sealing layer wraps and seals the upper pressure head, the lower pressure head, the sample, the flanges and the detection electrodes. The system can effectively seal the detection electrodes distributed in an electrode array on the side surface of the sample and prevent confining pressure liquid from entering the sample, so that three-dimensional resistivity measurement is carried out by using an inversion imaging method in a triaxial test, and the accuracy of a measurement result is ensured.

Owner:CHINA UNIV OF MINING & TECH

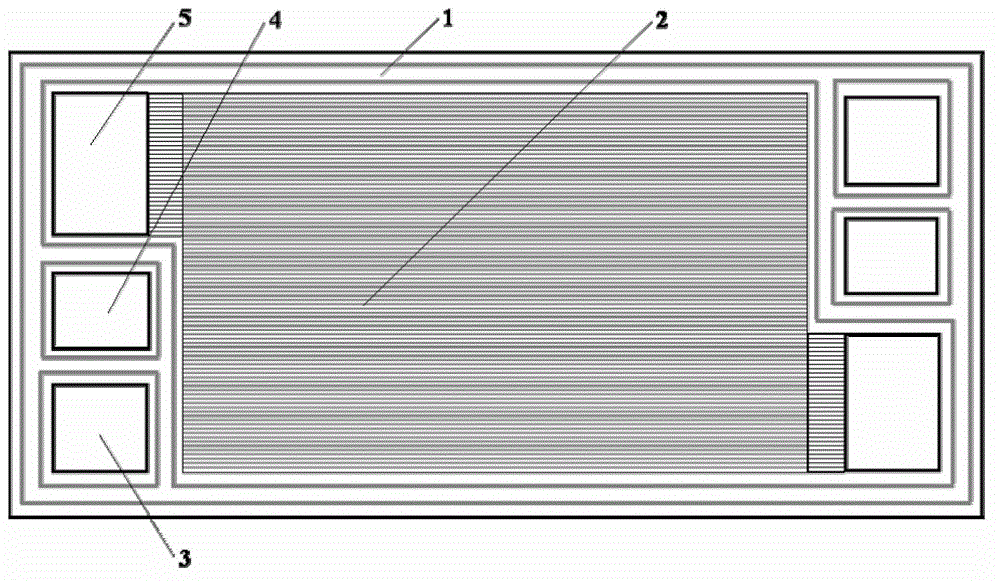

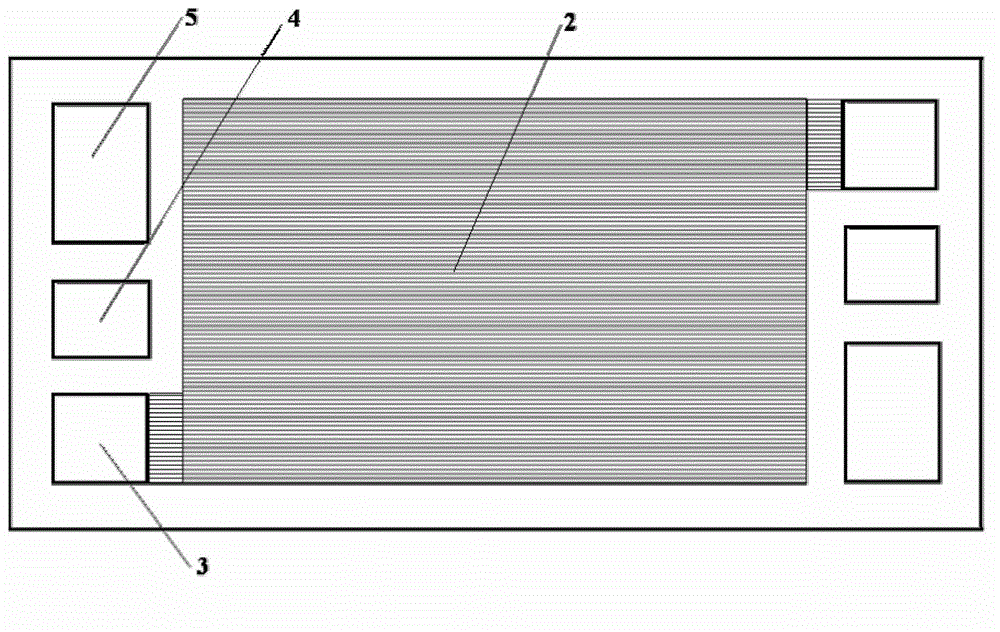

Fuel cell bipolar metal plate with enhanced sealing property

The invention discloses a fuel cell bipolar metal plate with an enhanced sealing property. The fuel cell bipolar metal plate comprises a bipolar plate which is formed by an oxygen polar plate and a hydrogen polar plate which are connected into a whole in a bonding or welding manner; an oxygen gum line frame on the oxygen polar plate and the oxygen polar plate are of an integrated structure, namely, the oxygen gum line frame is pressed and molded together with a runner and a common opening on the oxygen polar plate; and a hydrogen gum line frame on the hydrogen polar plate and the hydrogen polar plate are of a split structure, namely, the hydrogen gum line frame and the hydrogen polar plate are two mutually independent structures, and the hydrogen gum line frame is adhered to the hydrogen polar plate. The fuel cell metal bipolar plate has the beneficial effects that the entire strength and the entire smoothness of the bipolar metal plate are improved; the matching and the alignment in the pile assembling process are facilitated; and the sealing stability of the bipolar metal plate is facilitated, and the reliability of a metal plate pile in the operating process is facilitated, and further the service life of the pile is prolonged.

Owner:SUNRISE POWER CO LTD

Waterproof microphone, implementation method thereof, and electronic product

PendingCN106358102ALow costImprove sealing and stabilityMouthpiece/microphone attachmentsMicrophoneRubber mat

The invention discloses a waterproof microphone, an implementation method thereof, and an electronic product. The waterproof microphone comprises a shell, wherein a sound access hole is formed in the shell; a waterproof membrane component is adhered to the inner side of the shell at the sound access hole part; a limited slot is also arranged in the inner side of the shell; a rubber mat reserving with a sound hole is adhered with a microphone component to form a combination body; the combination body is loaded in the limited slot in the inner side of the shell under the state of being extruded toward the shell side, so that the rubber mat and the waterproof membrane component contact in a sealing way, and are fixed in the limited slot through adhesive dispensing under an extrusion state. According to the waterproof microphone provided by the invention, the rubber mat reserving with the sound hole and the microphone component are fixed through adhesive dispensing under a pressure maintaining state, and an elastic pressing plate in the prior art is replaced, so that the product cost can be remarkably reduced, and compared with the application of the elastic pressing plate, the sealing stability of the fixed manner through adhesive dispensing under the pressure maintaining state is higher, the dimensional requirement on parts is reduced, the design precision can be reduced, and the processing difficulty and the cost are reduced.

Owner:GEER TECH CO LTD

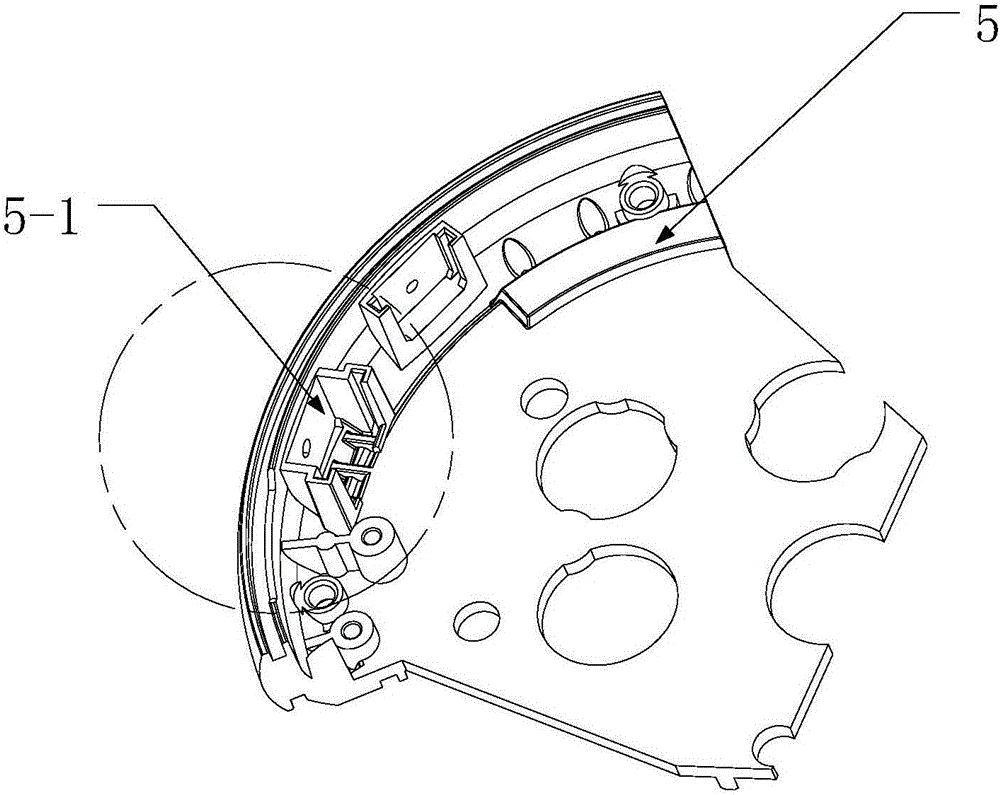

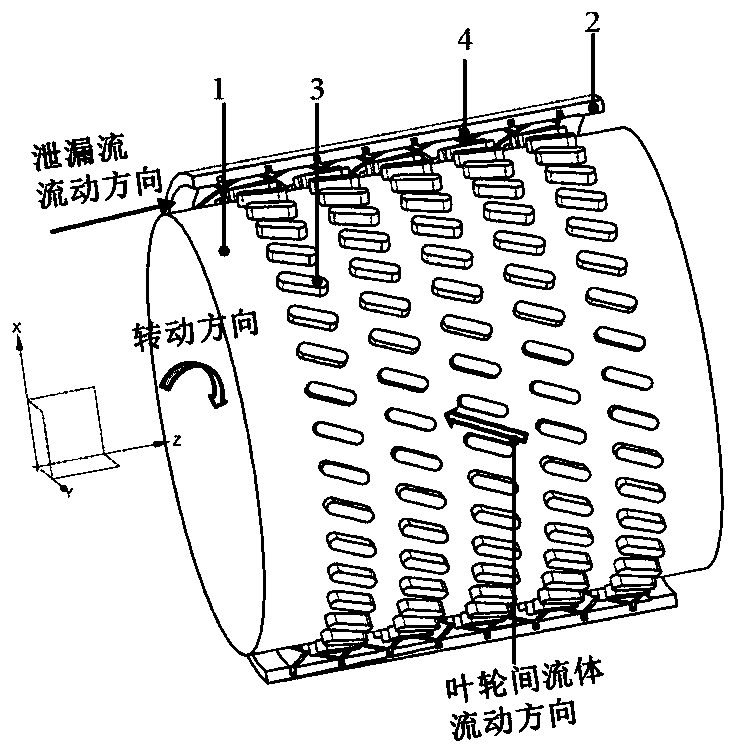

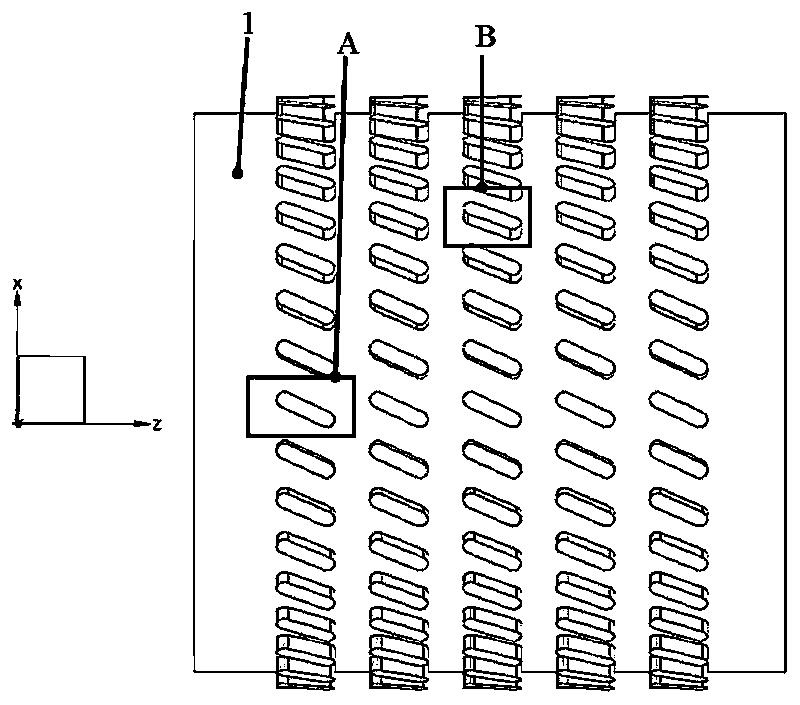

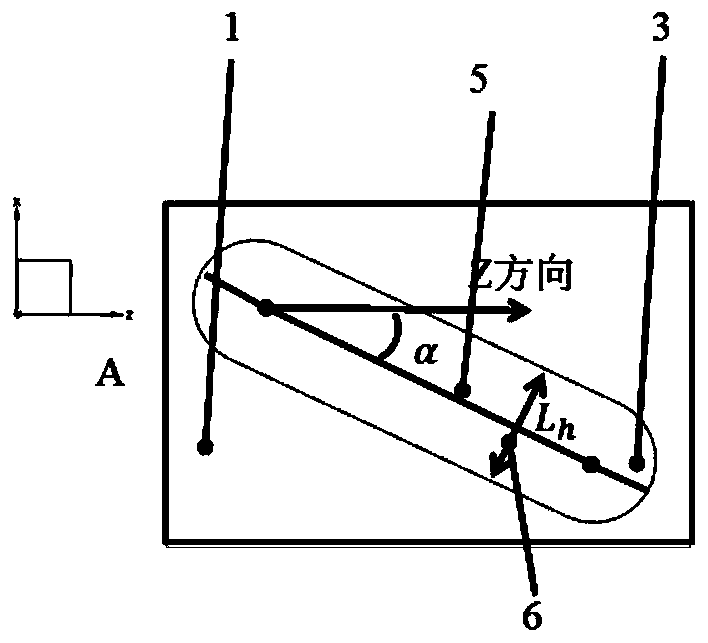

Novel dynamic pressure damping sealing structure

InactiveCN111043317ALimit the development of circumferential swirlImprove sealingEngine sealsImpellerSurface roughness

The invention discloses a novel dynamic pressure damping sealing structure. The structure is characterized by comprising a sealing rotor part and a sealing stator part which is sleeved outside the sealing rotor part and is matched with the sealing rotor part for use, wherein a plurality of micro impellers are arranged on a surface of the sealing rotor part, and a texture structure is arranged on an inner surface of the sealing stator part. When a rotor component rotates, the micro impellers are arranged on a surface of the rotor part, the dynamic pressure pumping effect can be generated, fluidbetween the micro impellers is driven to flow towards the sealed inlet, the axial positive direction leakage flow generated by the pressure difference of a sealing inlet and a sealing outlet is partially counteracted, so purposes of remarkably reducing the sealing leakage flow and improving operation efficiency of the rotary machine are achieved, moreover, the stator part is provided with a texture structure, surface roughness and sealing damping of the stator part can be remarkably improved, circumferential rotational flow development of fluid in a gap between the sealing rotor part and thestator part is effectively restrained, the circumferential component of fluid exciting force is reduced, and thereby a purpose of enhancing system stability is achieved.

Owner:XI AN JIAOTONG UNIV

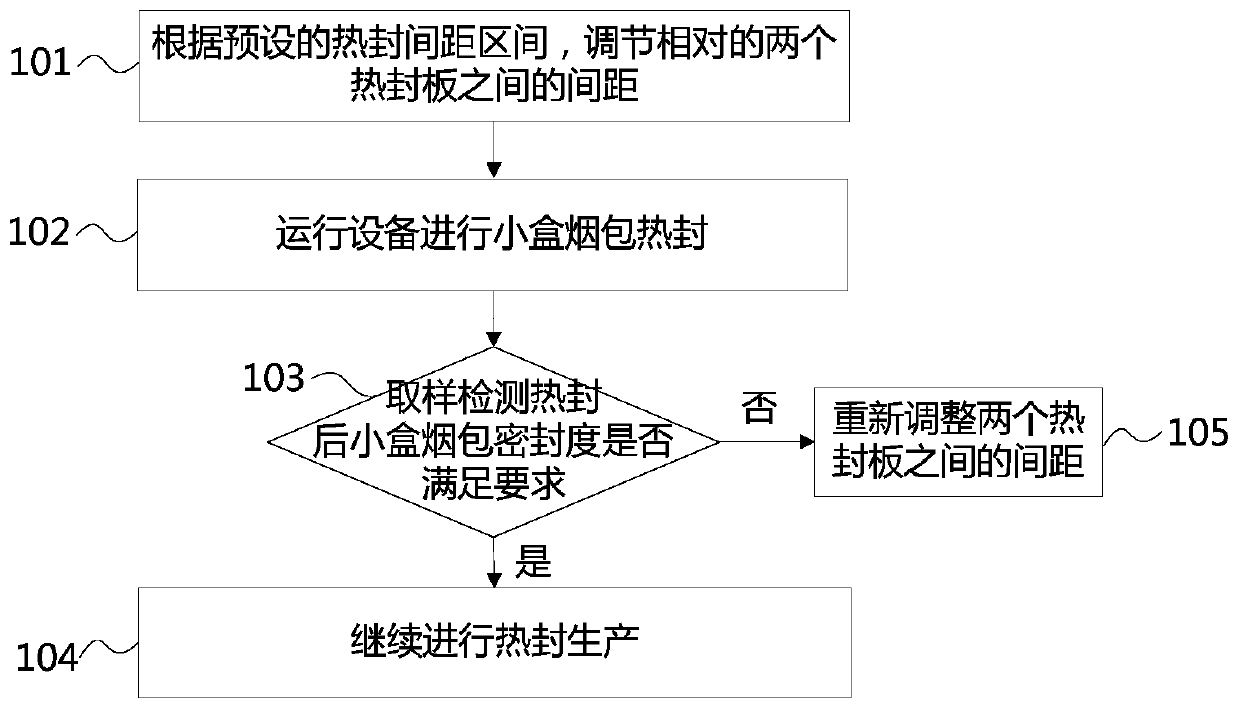

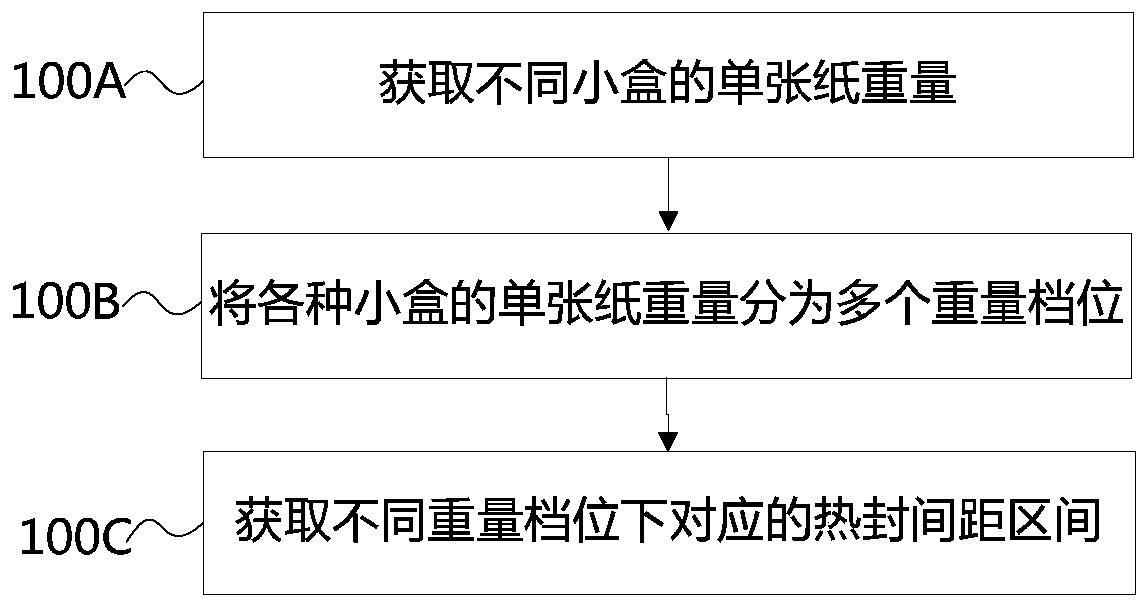

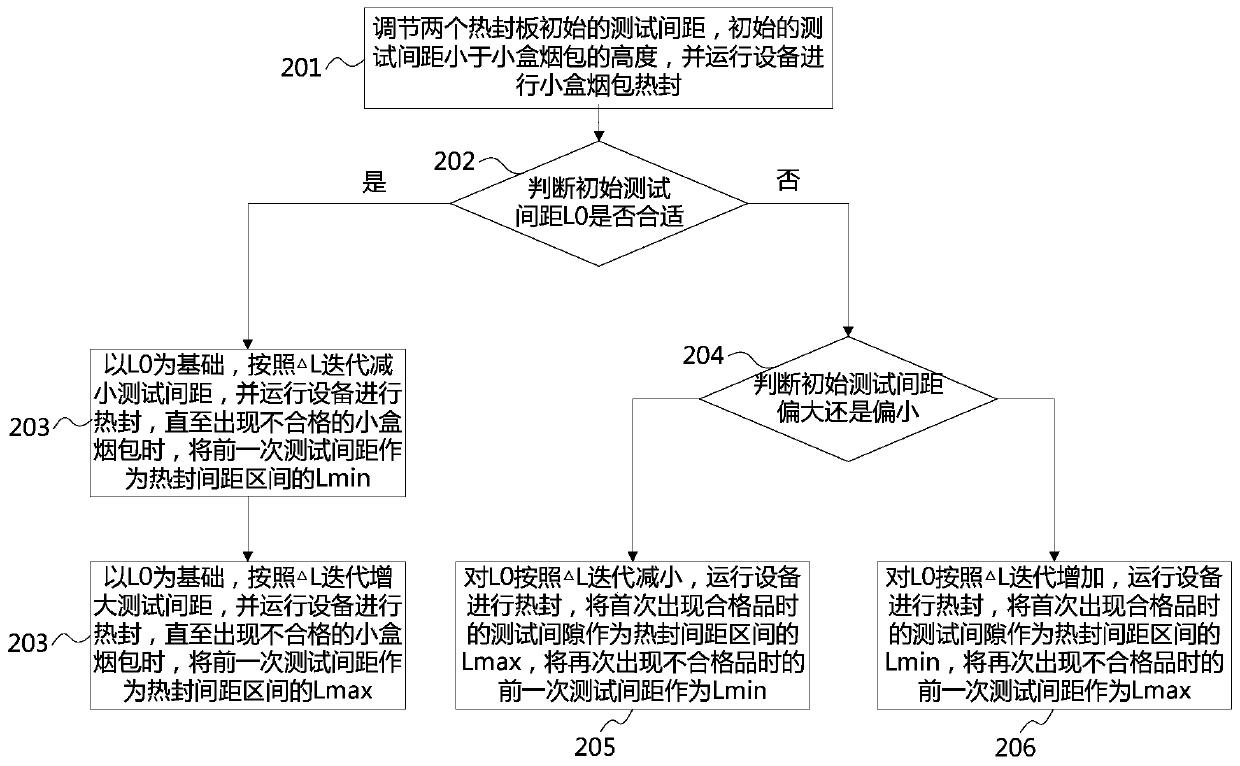

Method for heat sealing small cigarette packet

ActiveCN110027738AImprove sealingReduce quality risks such as mildewPackaging cigarettePackaging cigarsMildewCigarette pack

The invention relates to a method for heat sealing a small cigarette packet. The method comprises the following steps of before heat sealing, adjusting spacing between two opposite heat sealing platesaccording to a preset heat sealing spacing; and operating equipment to carry out heat sealing on the small cigarette packet, detecting whether the sealing of the heat sealed small cigarette packet meets the requirement or not, if yes, continuing heat sealing production, and if no, readjusting the spacing between the two heat sealing plates. According to the method, the spacing between the two heat sealing plates can be preliminarily adjusted according to the preset heat sealing spacing, part of samples can be heat sealed firstly to determine whether the adjusted spacing is appropriate or not,if yes, subsequent production is carried out, and if not, the spacing is readjusted; the sealing performance of the small cigarette pack can be improved by controlling the pressure of the heat sealing plates and the small cigarette pack, the sealing stability of the product during batch production is improved, and the quality risks such as mildew of the cigarette product due to poor sealing are reduced; and moreover, by means of the method, the heat sealing production efficiency can be improved, and unqualified products can be reduced.

Owner:CHINA TOBACCO FUJIAN IND +1

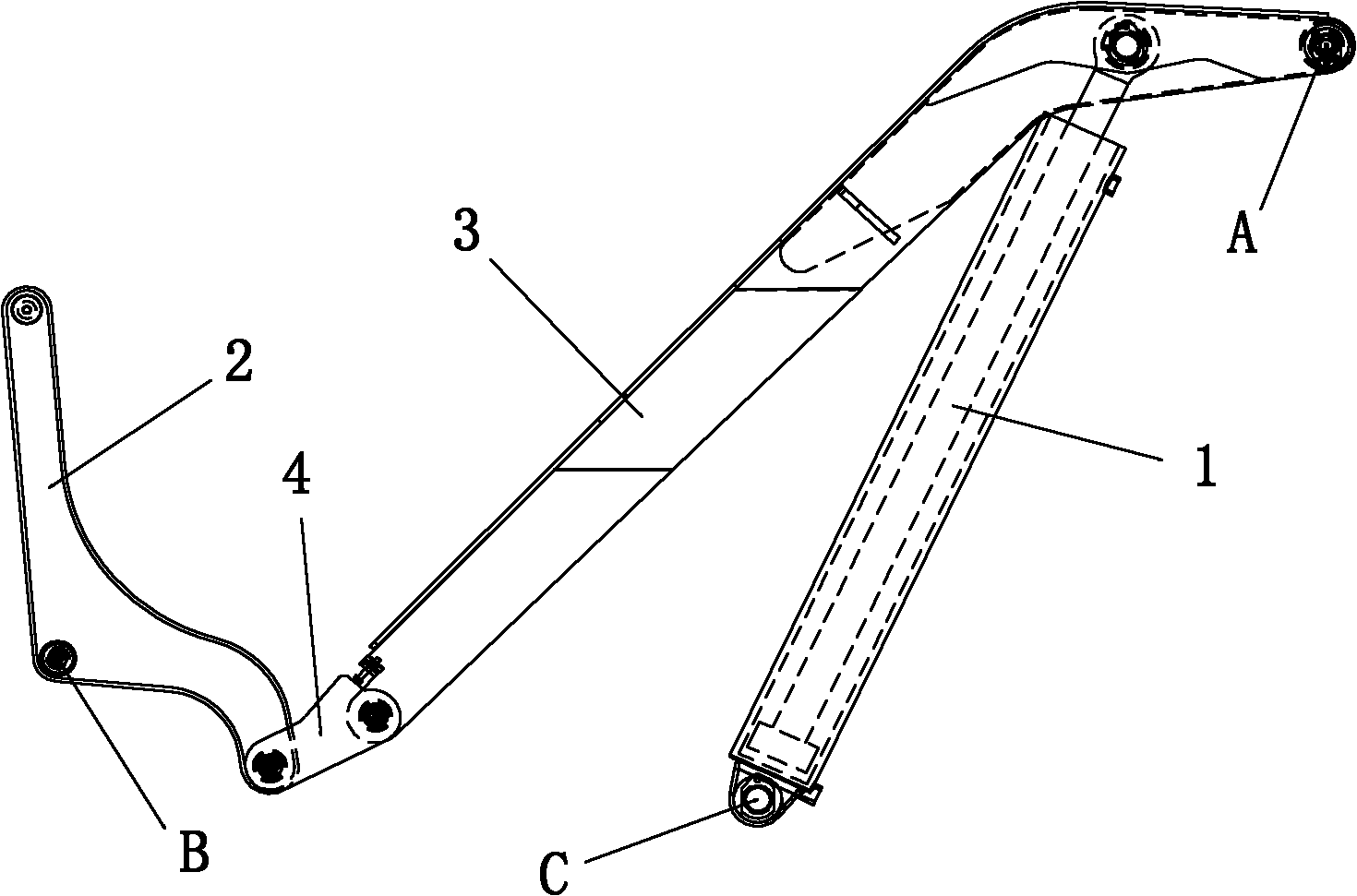

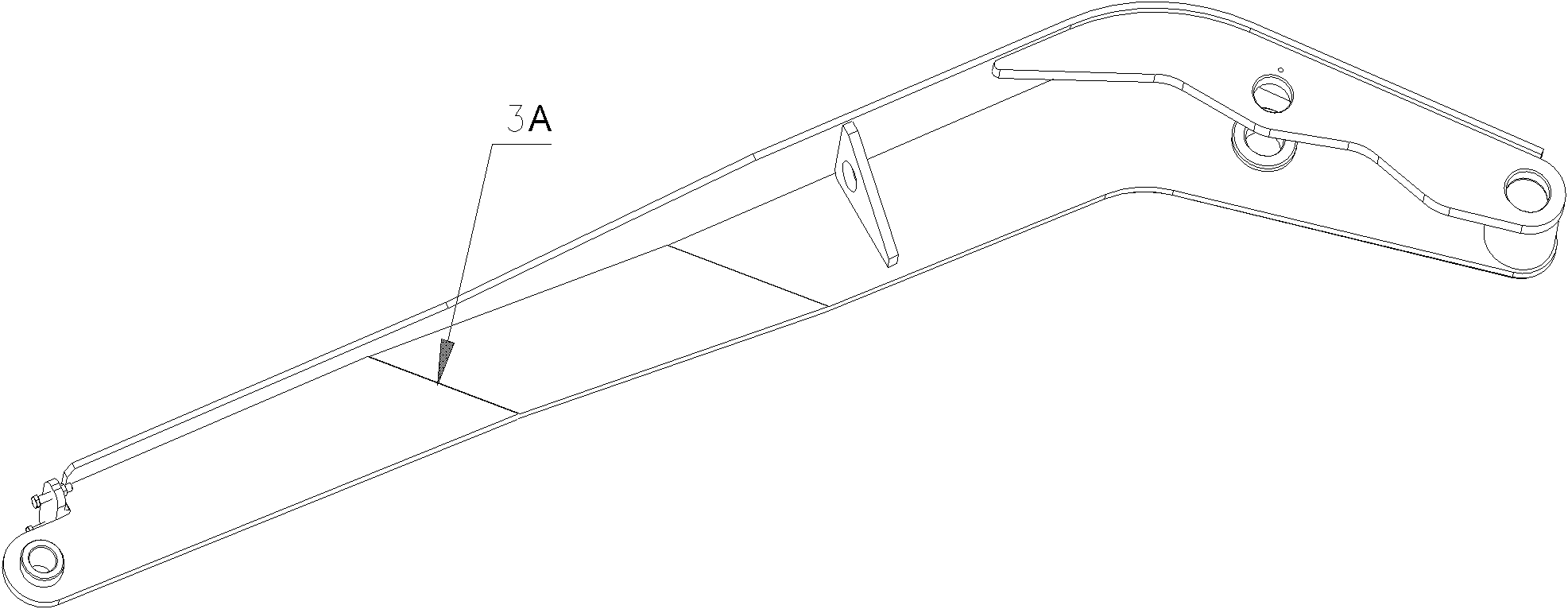

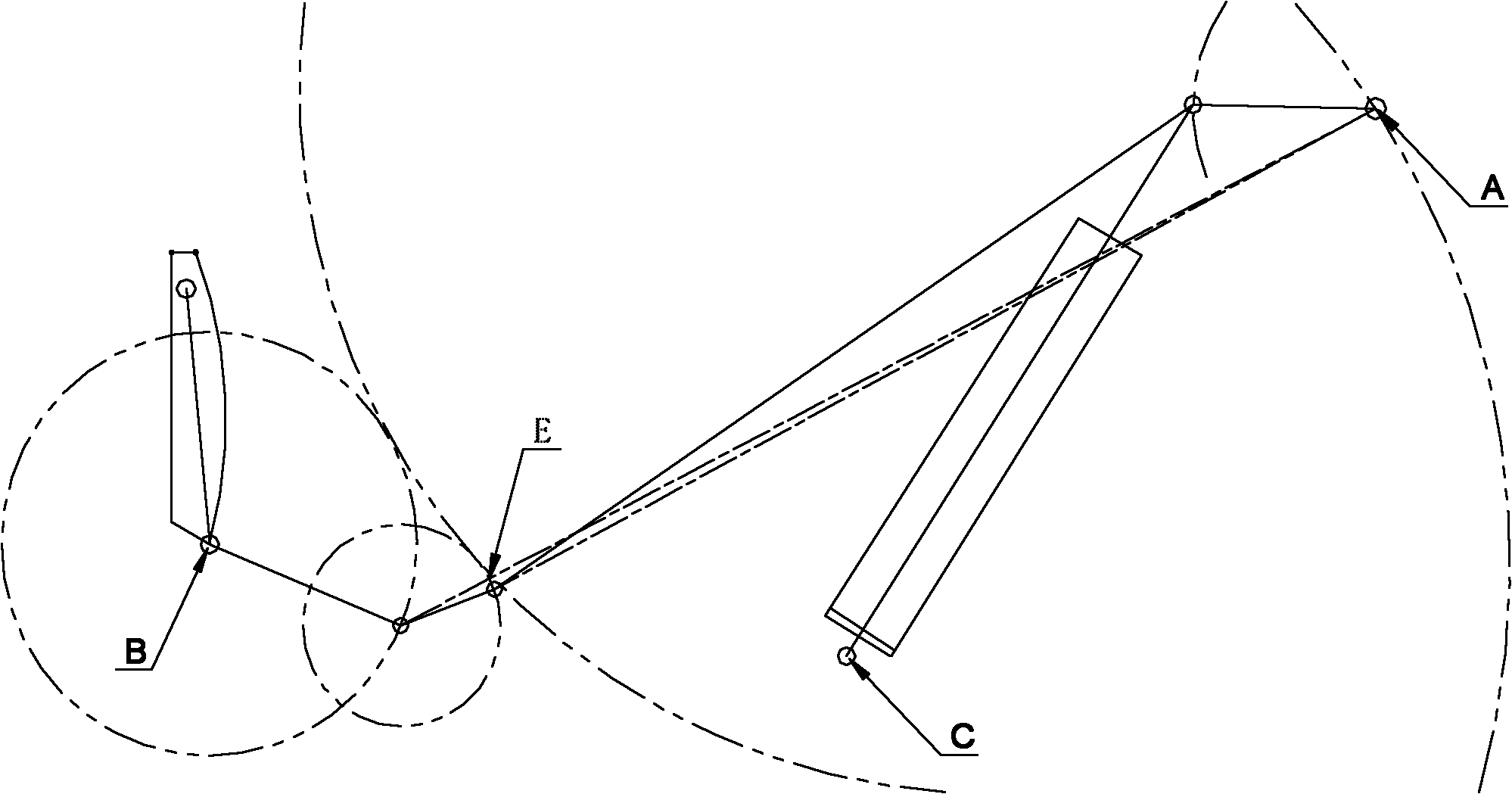

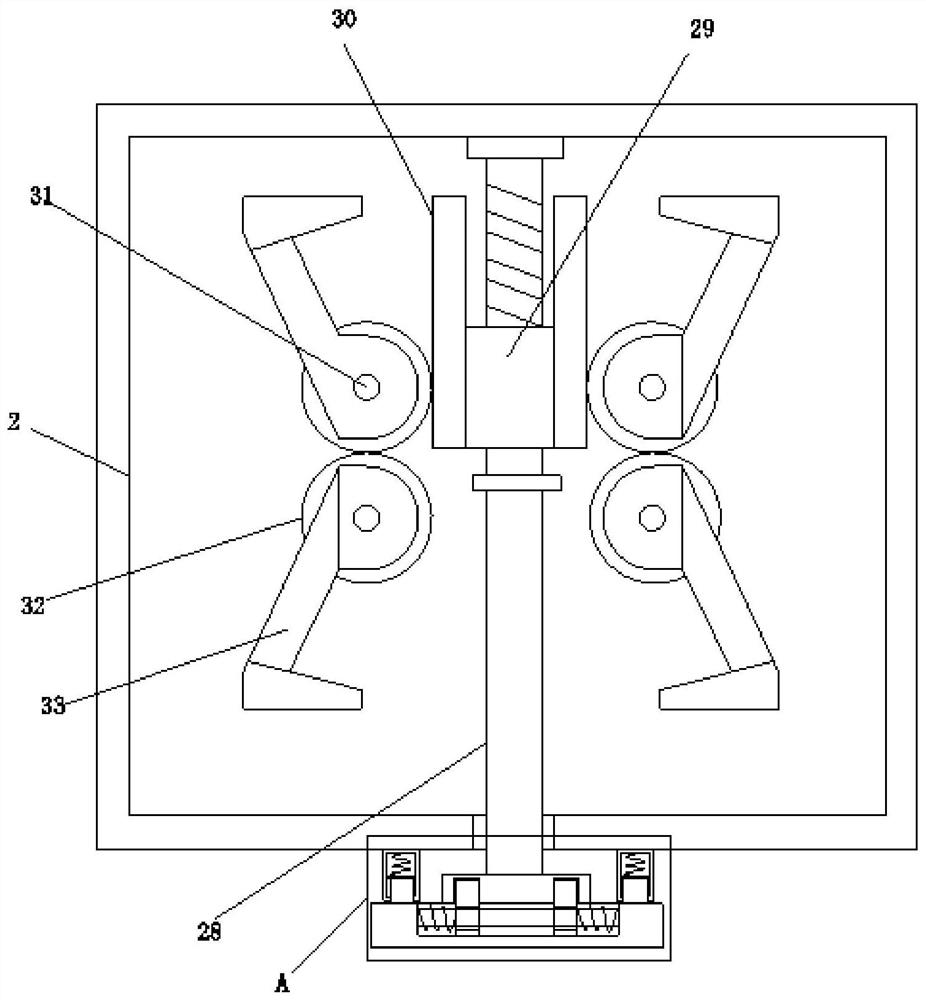

Six-bar mechanism of dumper lifting device

ActiveCN103158597AImprove sealing and stabilitySimplify hydraulic control systemVehicle with tipping movementTransportation itemsVehicle frameHinge joint

The invention provides a six-bar mechanism of a dumper lifting device. The six-bar mechanism of the dumper lifting is capable of completing functions of door opening, unloading, locking and the like through utilization of only one group of big oil cylinders and comprises a frame, a box body, a box door, an oil cylinder, a lifting arm, a door opening arm and a locking bar. The top end of the lifting arm is hinged with a corner position, far away from an overturn shaft, of the box body through a lifting shaft, and the top end of the oil cylinder is hinged with the upper section, close to the lifting shaft, of the lifting arm. The upper portion of the door opening arm is fixed on the end portion of the box door. Two ends of the locking bar are respectively hinged with the tail end of the lifting arm and the lower portion of the door opening arm. The six-bar mechanism in planar motion is formed. In a non-pressure state, the box body is flatly fallen, and the box door is closed. When a small amount of oil is fed, the box door is totally opened, and when a large amount of the oil is fed, the box body turns over and unloads. When the oil cylinder contracts to be the shortest length, pressure is relieved, a hinge joint of the tail end of the lifting arm is located below the connection line of an axial point of the lifting shaft and a hinged joint of the tail end of the door opening arm, the box door is self locked on the box body, and systematic pressure maintaining is not needed. Hydraulic control systems are simplified and cost is reduced.

Owner:CIMC VEHICLES (GROUP) CO LTD +1

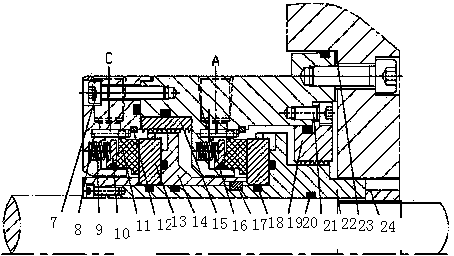

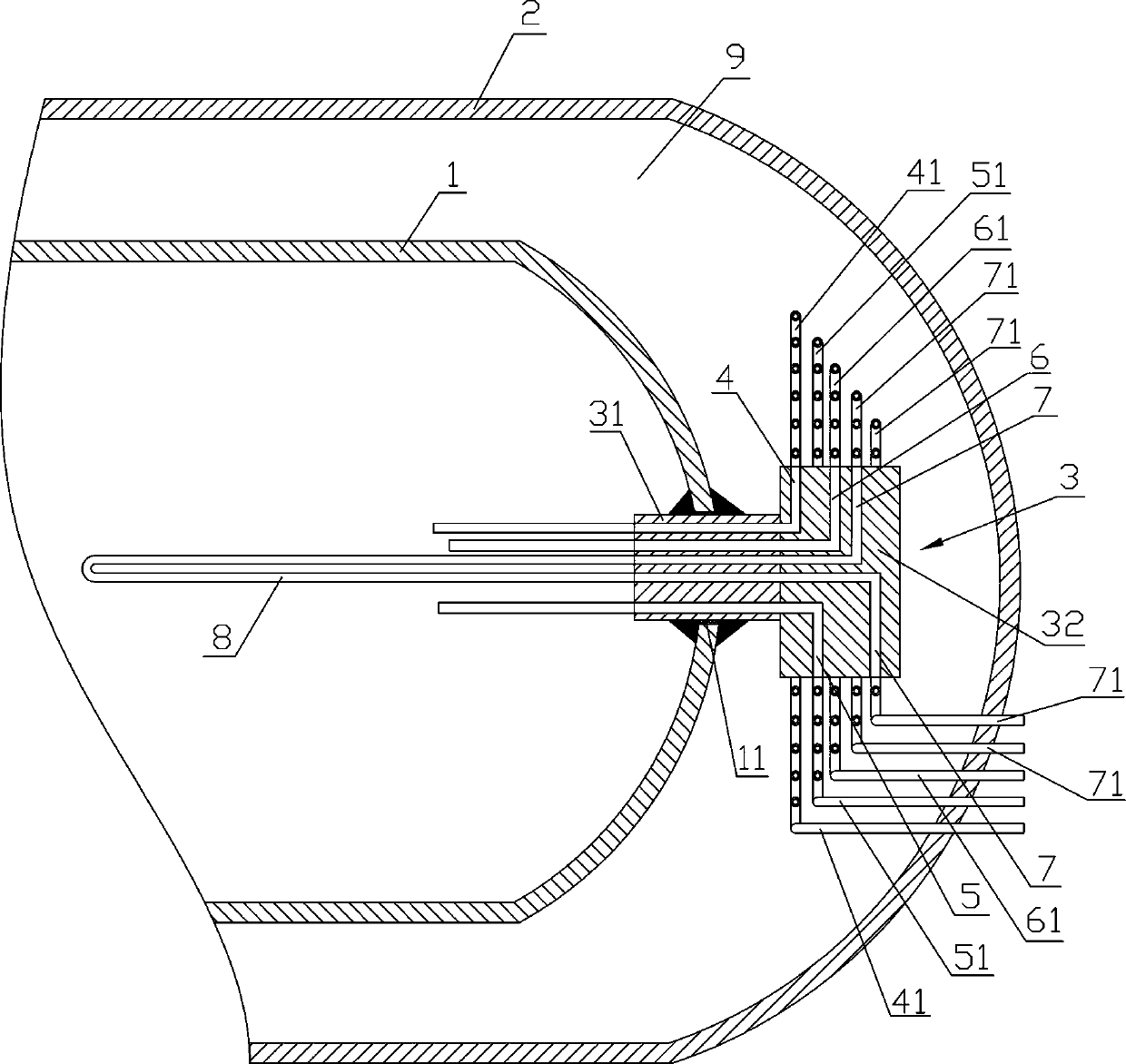

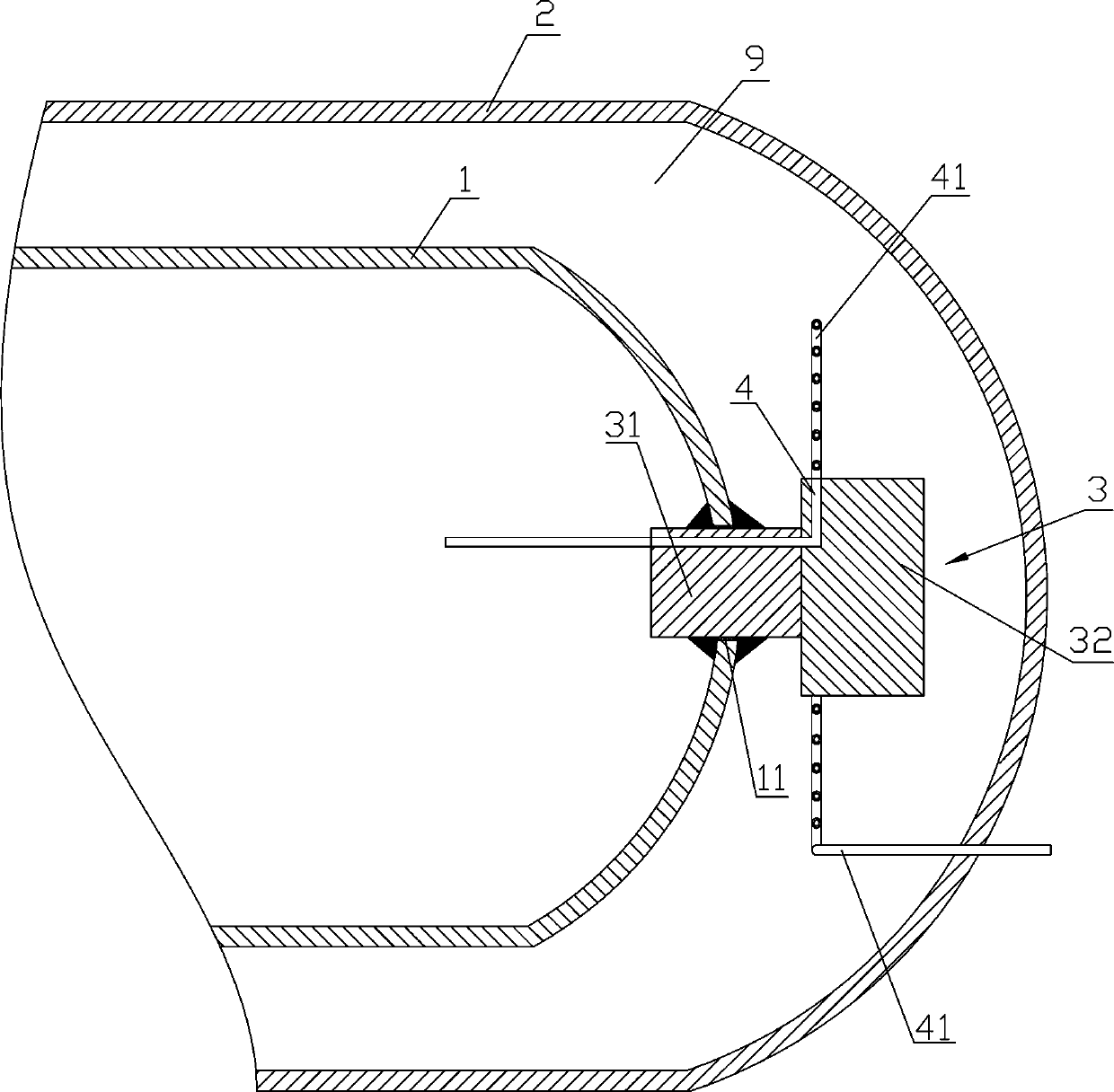

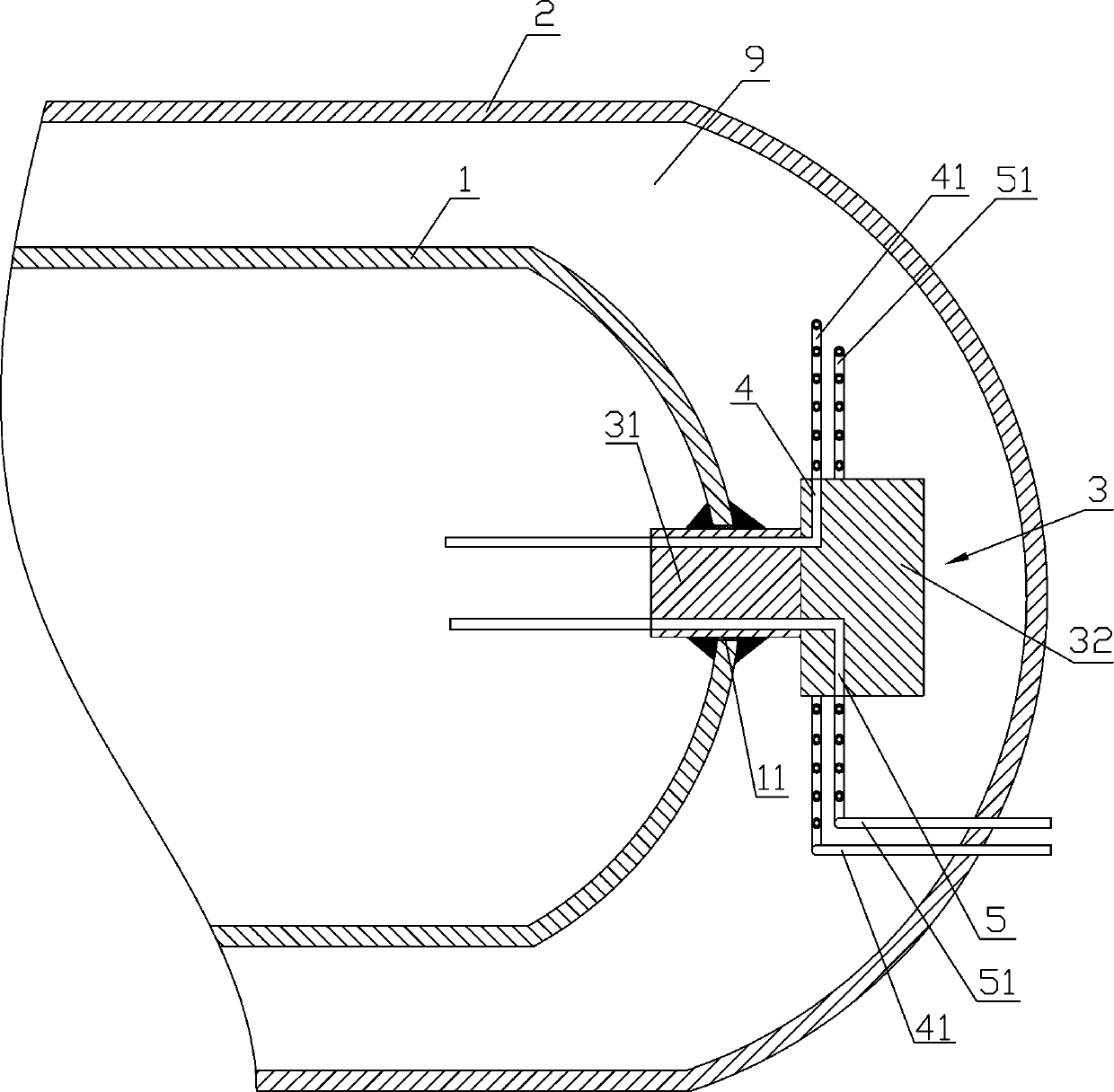

Self-cleaning type polypropylene recycle gas compressor gas film sealing structure

ActiveCN104019240AImprove sealing and stabilitySolve problems such as short service lifeEngine sealsGas compressorEngineering

The invention relates to a self-cleaning type polypropylene recycle gas compressor gas film sealing structure which comprises a machine cleaning liquor inlet, a machine body cone, a structure gland, a shaft, a cleaning liquor outlet, a pushing ring, a fixed ring, a clamping ring, a sealing movable ring, an atmospheric side movable ring base, an atmospheric side labyrinth seal, a medium side fixed ring base and a medium side labyrinth seal. The self-cleaning type polypropylene recycle gas compressor gas film sealing structure is characterized in that a sealing structure body comprises the medium side main seal, a bearing side auxiliary seal and the labyrinth seals, cleaning liquor tangentially enters a sealing cavity of the machine body cone from the machine cleaning liquor inlet to form rotational flow, and particles are taken away from the sealing structure. By means of the self-cleaning type polypropylene recycle gas compressor gas film sealing structure, end face friction abrasions are avoided, the sealing stability is improved, and the problems of being short in service life and the like are solved; due to cleaning, temperature rising of the end face is small, energy consumption is low, the sealing performance and the stability are good, and therefore the self-cleaning type polypropylene recycle gas compressor gas film sealing structure has the advantages that the sealing reliability is good, and the maintenance and repairing cost is reduced.

Owner:DONGYING HISCIEN SEALING TECH

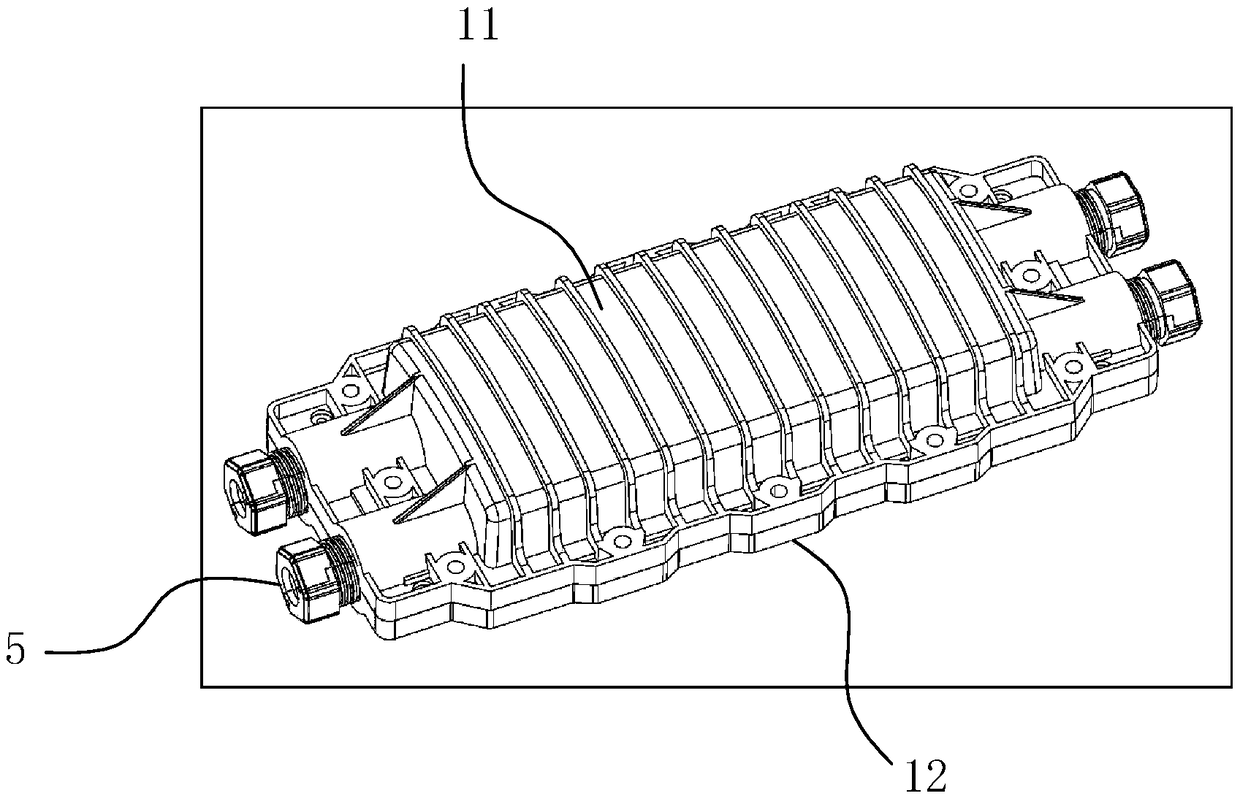

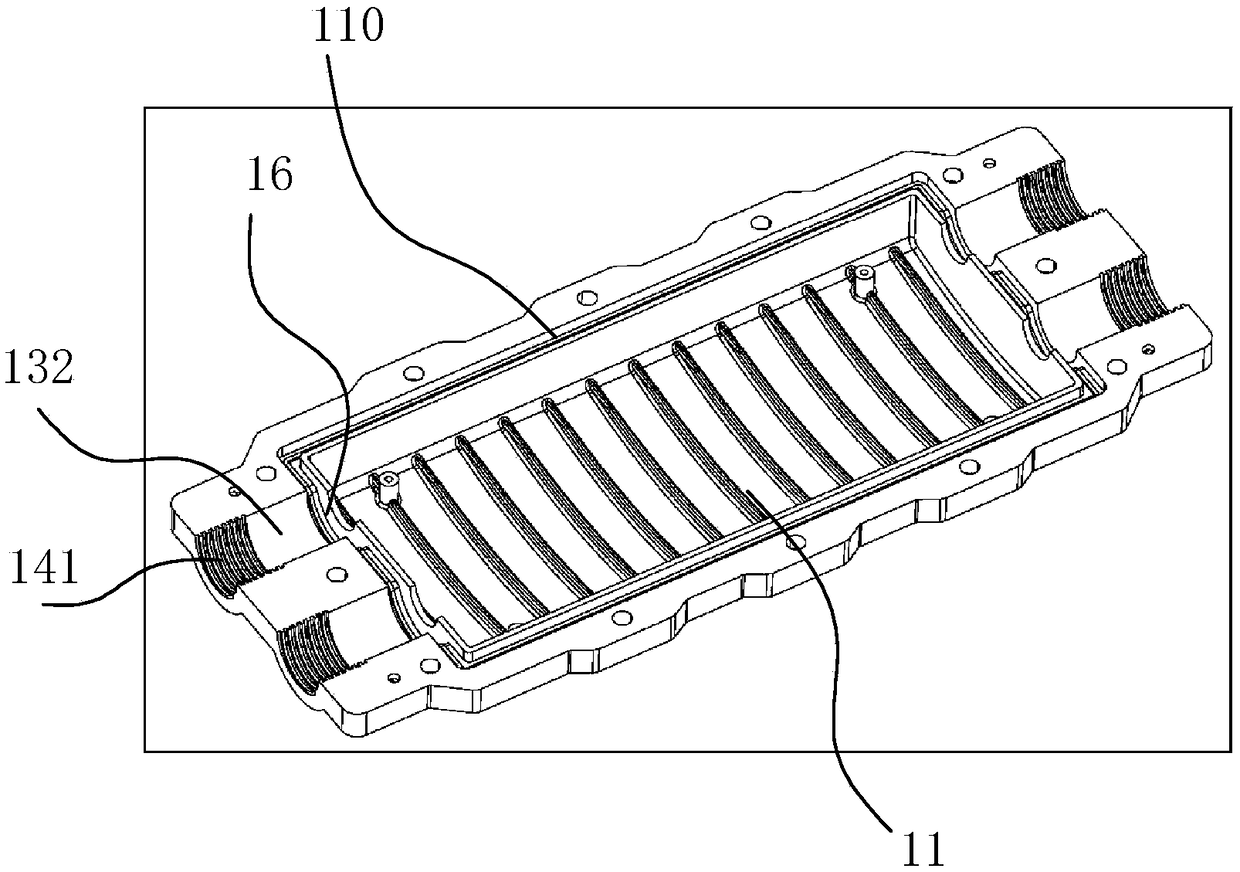

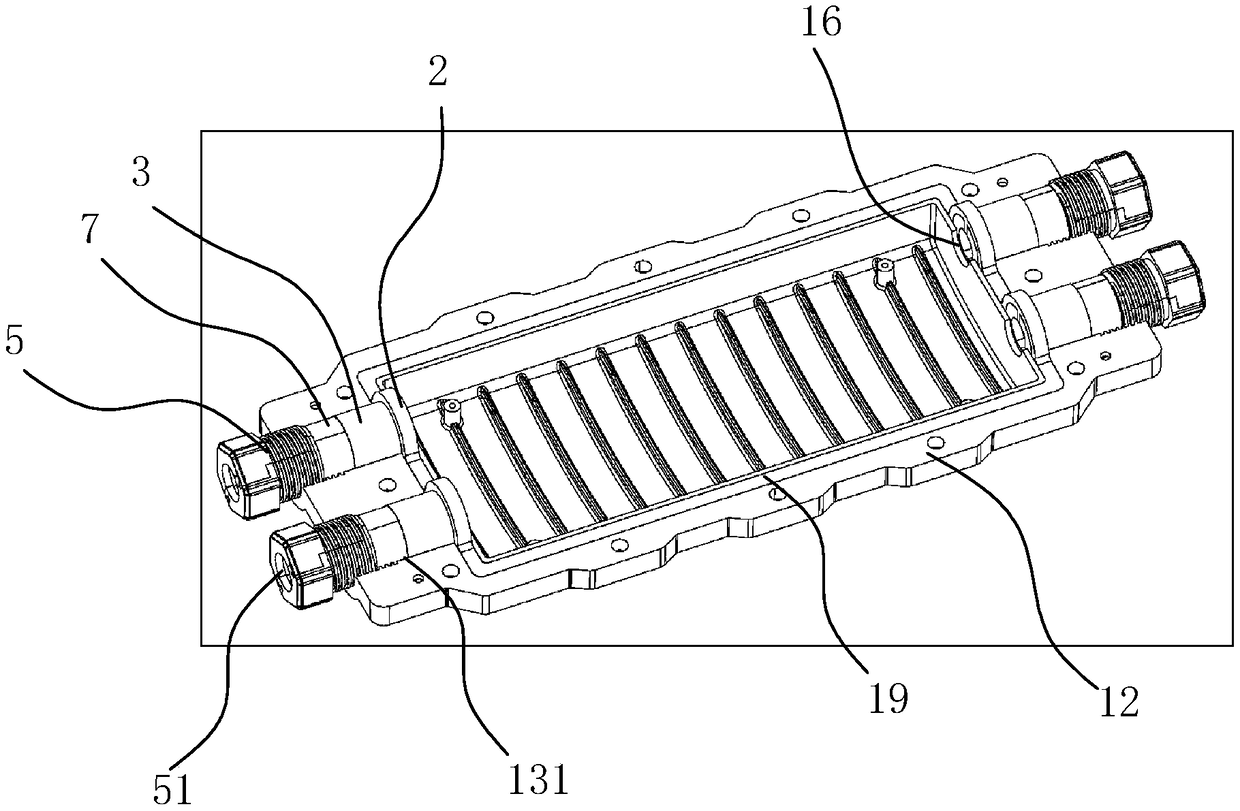

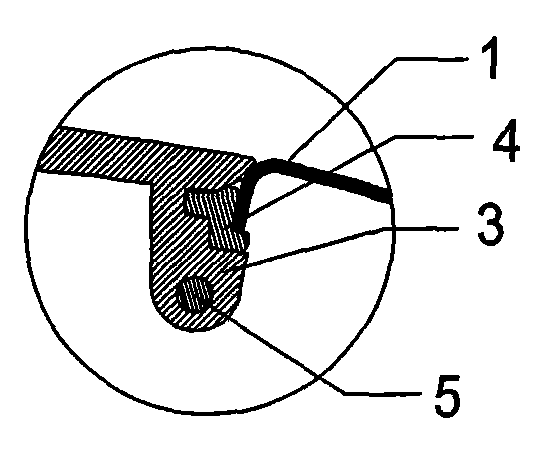

Stepped sealing structure of optical cable connector box

InactiveCN108983380AIncrease the amount of extrusionReduce volumeFibre mechanical structuresEngineeringRetaining ring

The invention discloses a stepped sealing structure of an optical cable connector box. The stepped sealing structure is characterized in that the stepped sealing structure comprises an upper box bodyand a lower box body, the optical cable connector box is provided with an optical cable embedding hole used for allowing an optical cable to penetrate through, the optical cable embedding hole is provided with a retaining ring, an elastic sealing ring and an extrusion member arranged in sequence from the inside to the outside, the retaining ring, the elastic sealing ring and the extrusion member each comprise a penetrating hole used for allowing the optical cable to penetrate through, the retaining ring is fixed in the inner end of the optical cable embedding hole, an end portion of the elastic sealing ring is abutted against the retaining ring, and the retaining ring is formed by a hard inner core and an elastic sealing peripheral member arranged at the periphery of the hard inner core. According to the stepped sealing structure, an area of the optical cable embedding hole of the optical cable connector box adopts stepped sealing, the sealing of the optical cable embedding hole is realized through the elastic sealing ring, the sealing between the upper box body and the lower box body is realized through the elastic sealing peripheral member of the retaining ring, and the sealing structure is more reliable.

Owner:胡肖平

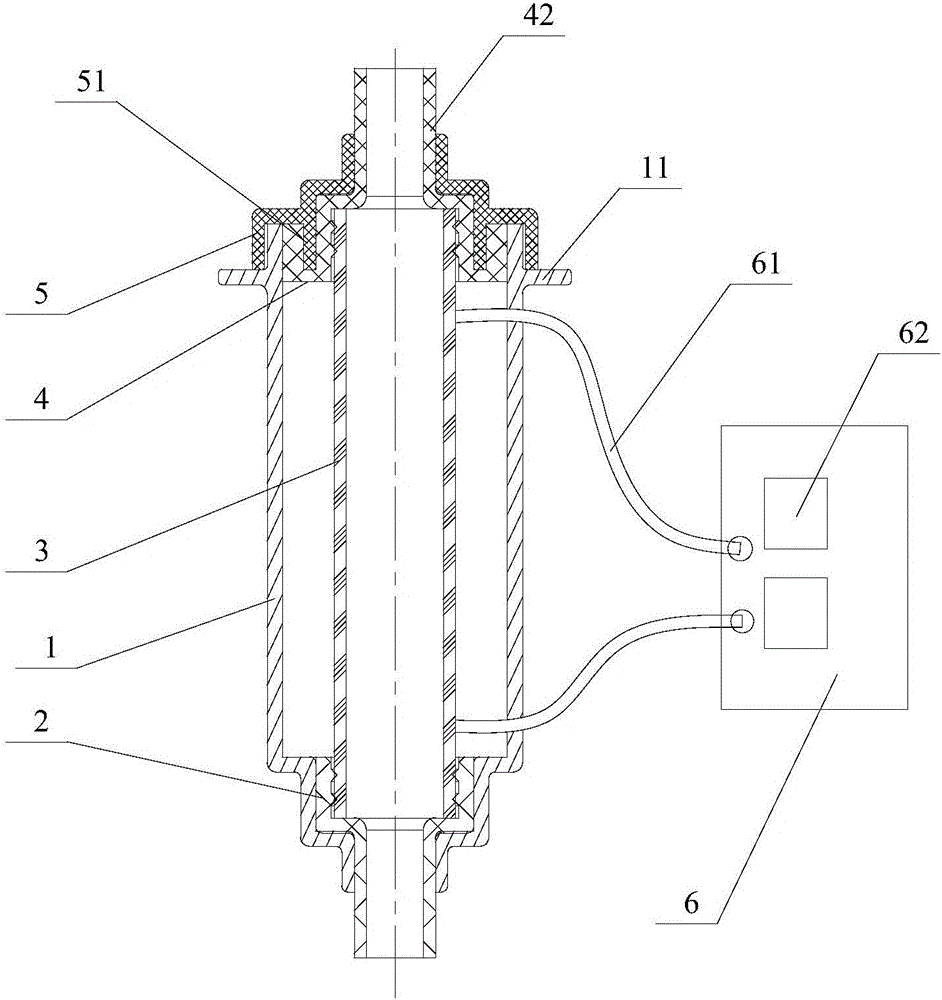

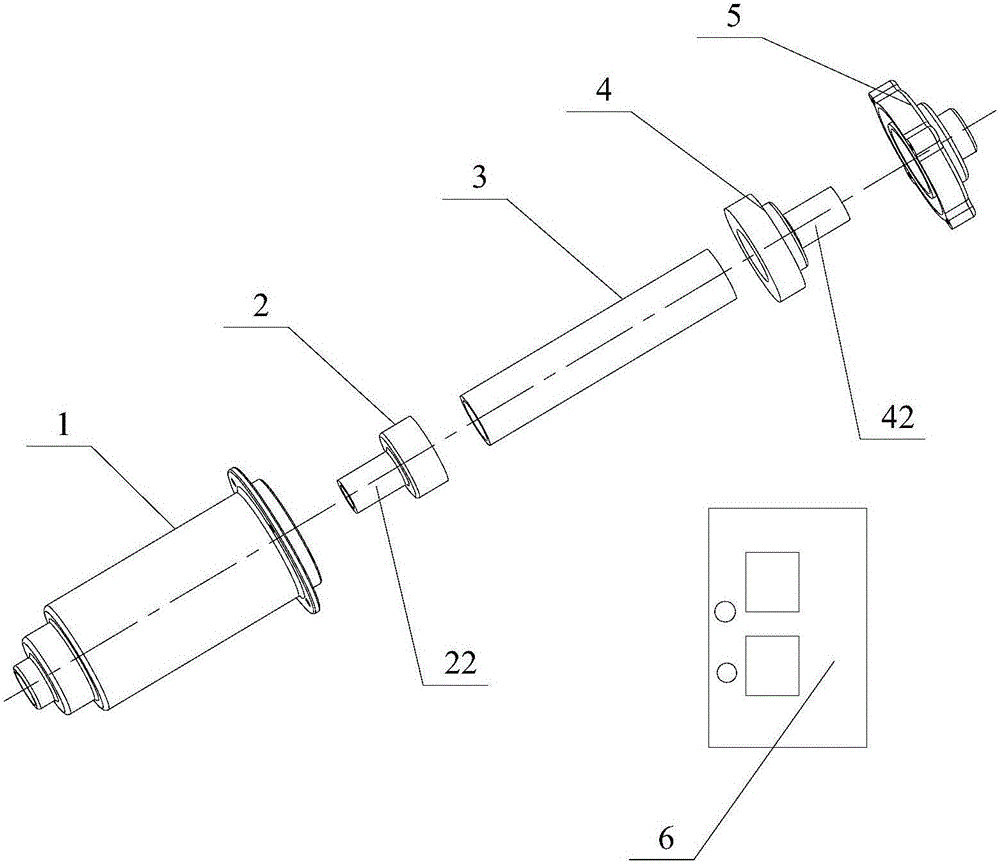

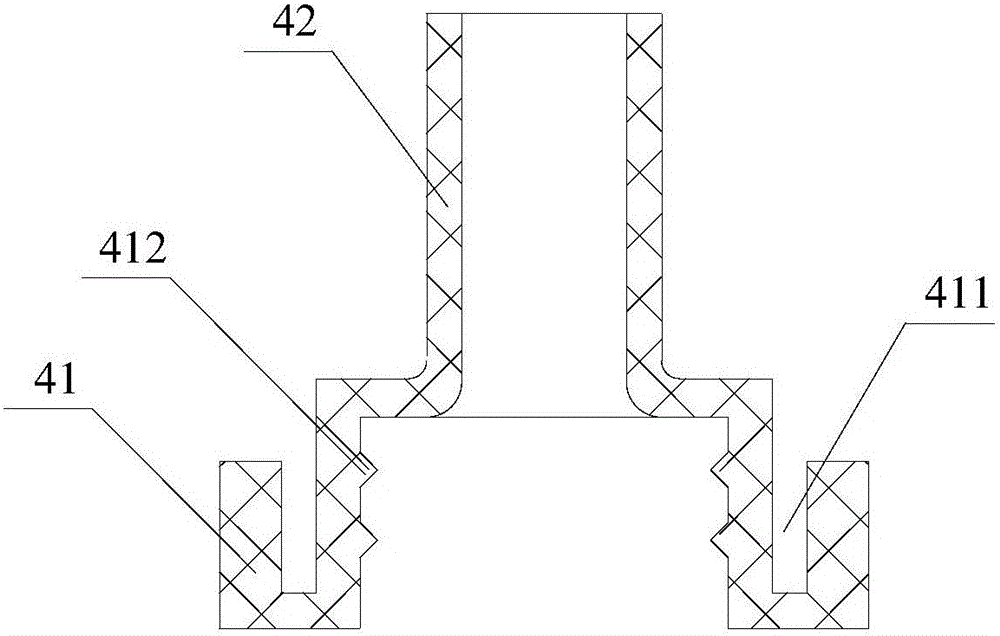

Multi-protection quartz tube heating apparatus

ActiveCN106028482AAvoid safety hazardsWon't scatterOhmic-resistance heating detailsHeating element shapesEngineeringControl circuit

The invention discloses a multi-protection quartz tube heating apparatus. The multi-protection quartz tube heating apparatus comprises a quartz heating tube, the two ends of the quartz heating tube are respectively provided with a positive electrode and a negative electrode, the apparatus further comprises a detection control circuit board connected with the positive electrode and the negative electrode, the detection control circuit board is provided with a detection module, and when the detection module detects damage to a heating membrane of the quartz heating tube or tube bursting, power supply of the negative electrode and the positive electrode are automatically cut off. According to the invention, in a work process, in case of the damage to the heating membrane of the quartz heating tube or the tube bursting, the detection control circuit board can timely detect such dangerous conditions and automatically cut off the power supply of the positive electrode and the negative electrode so as to avoid more safety hidden risks.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Mechanical sealing assembly capable of avoiding material accumulation

The invention relates to a mechanical sealing assembly capable of avoiding material accumulation. The assembly comprises a shaft sleeve and a stationary ring, wherein a rotating shaft penetrates through the inside of the shaft sleeve, the right end of the shaft sleeve is connected with a movable ring sealing gasket through a left clamping groove, the left end of the stationary ring is provided with the movable ring, and the outer end of the movable ring is connected with the shaft sleeve through a clamping block and a connecting groove; the upper end of the stationary ring is connected with astationary ring seat through a connecting block and the connecting groove, and the right end of the stationary ring is provided with a stationary ring sealing gasket; the right end of the stationary ring sealing gasket is connected with the stationary ring seat through a right clamping groove, the outer end of the stationary ring seat is provided with a sealing ring, and the outer end of the sealing ring is connected with a gland through a fixing groove and a convex block; the left surface of the gland is provided with a placement groove, a supporting spring is arranged inside the placement groove, and a receiving groove is formed in the periphery of the gland. The mechanical sealing assembly capable of avoiding material accumulation can prevent materials from being accumulated in a gap between the gland and the stationary ring seat, and slip-off of the sealing ring is avoided.

Owner:张家港爱斯诺机械密封有限公司

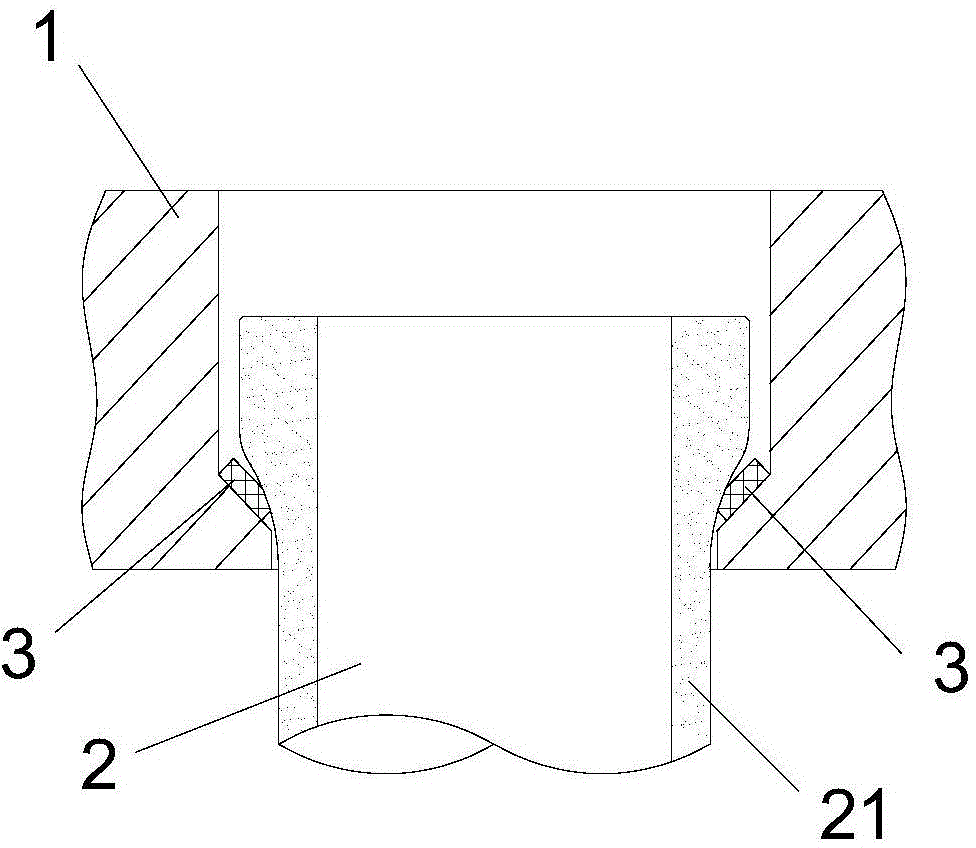

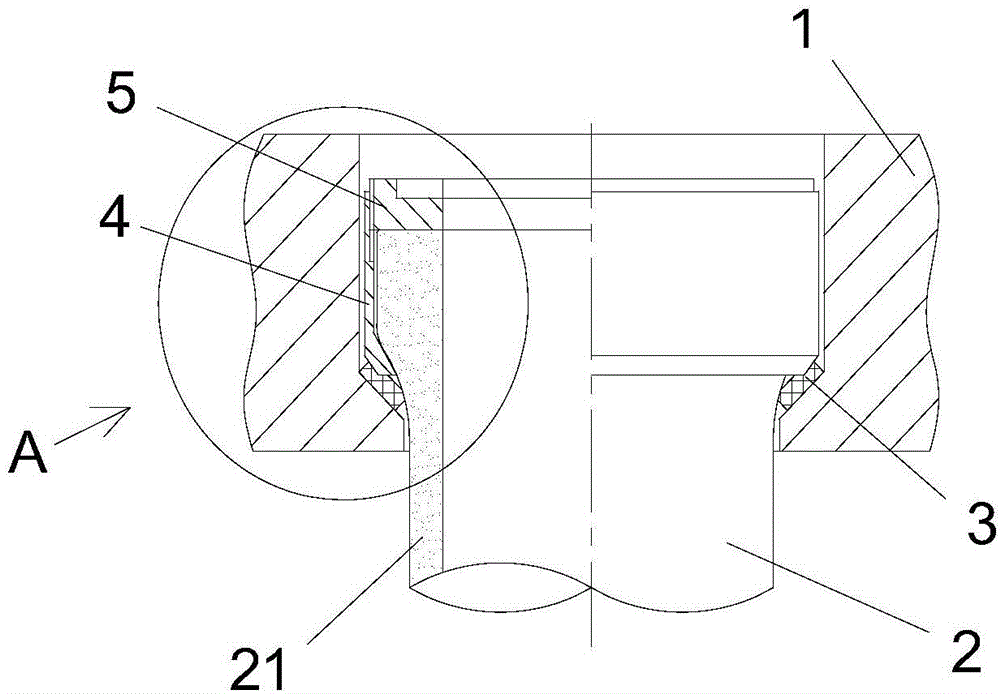

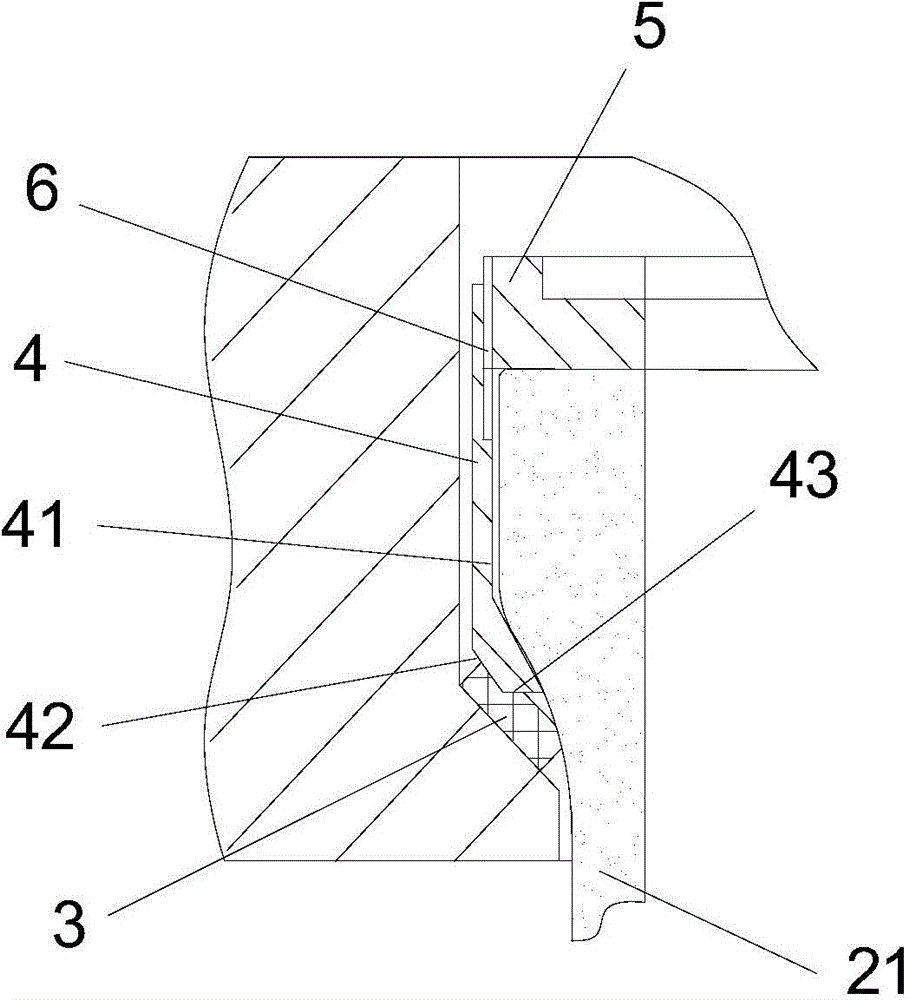

Container with observation window

InactiveCN101803871AHigh mechanical strengthImprove sealing and stabilityWater-boiling vesselsBeverage vesselsEngineeringStainless steel wire

The invention belongs to the field of household appliance manufacture, and in particular relates to a container with an observation window. The container comprises a kettle body (1); the side wall of the kettle body (1) is provided with the observation window (2); a transparent scale (3) is arranged on the observation window (2); and a high temperature-resistant and ageing-resistant sealing ring (4) is arranged between the transparent scale (3) and the observation window. The container is characterized in that: the transparent scale (3) is provided with a shaping metal wire (5) which is a stainless steel wire; the shaping metal wire (5) is injected in an outer ring sizing material of the transparent scale (3); a clamping groove (6) is formed on the outer ring side of the transparent scale (3); and the shaping metal wire (5) is fixed in the clamping groove (6). The container with the structure has the advantages of good sealing property and long service life.

Owner:严绍基

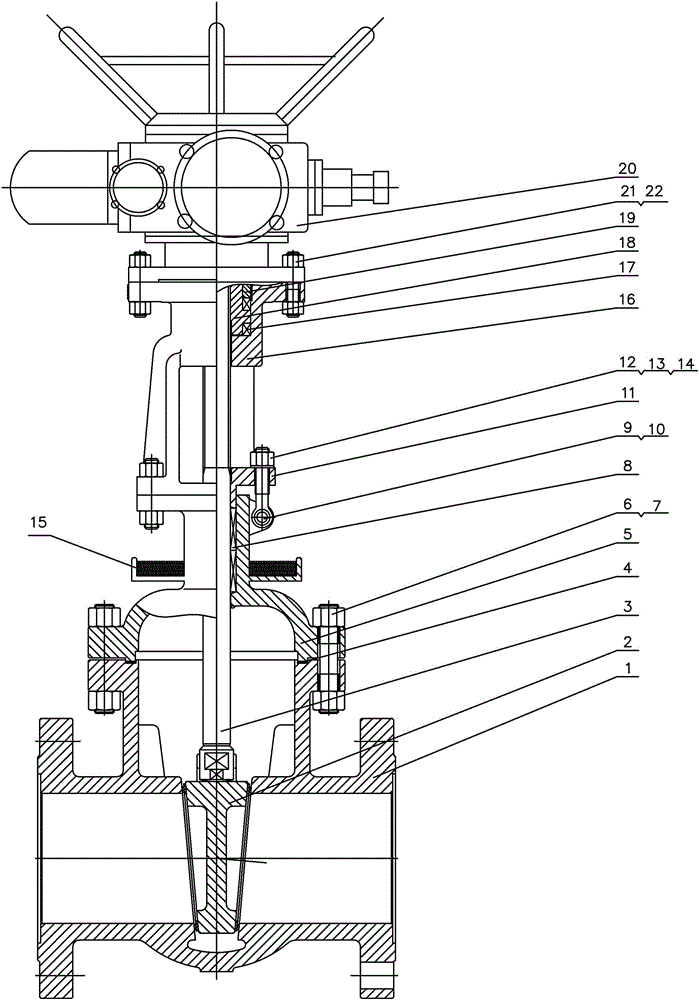

Combined water-cooling high-temperature wedge type single-disc gate valve

InactiveCN105318026AImprove cooling effectExtended service lifeSlide valveValve housingsNeck partsEngineering

The invention discloses a combined water-cooling high-temperature wedge type single-disc gate valve. The combined water-cooling high-temperature wedge type single-disc gate valve comprises a valve body, a gate plate, a valve rod and a valve cover, wherein the gate plate is arranged in a chute in the middle part of the valve body; the upper end of the gate plate is connected with the valve rod; the upper half part of the valve rod is matched with sealing fillings in a sealing box arranged at the upper part of the valve cover, stretches out from a filling gland arranged at the upper part of the sealing box and then is connected with an actuator through the matching of a T-shaped nut on a support arranged at the upper end of the valve cover; the actuator drives the gate plate to do up-and-down motion so as to realize turning on and off of a valve; the valve cover on the valve body is fixed through a first fastener; a combined annular water-cooling heat-dissipation water tank is arranged on the outer part of the valve cover; circulating water is arranged in the water tank. According to the structure designed by the invention, the neck part of the valve cover is provided with a heat dissipation device, the temperature in the position of a packing box is obviously reduced, the using performance of fillings is directly enhanced, the service life of the fillings is prolonged, the sealing stability of the fillings is increased, and the possibility of causing sealing leakage is obviously reduced.

Owner:HUBEI TAIHE PETROCHEM EQUIP

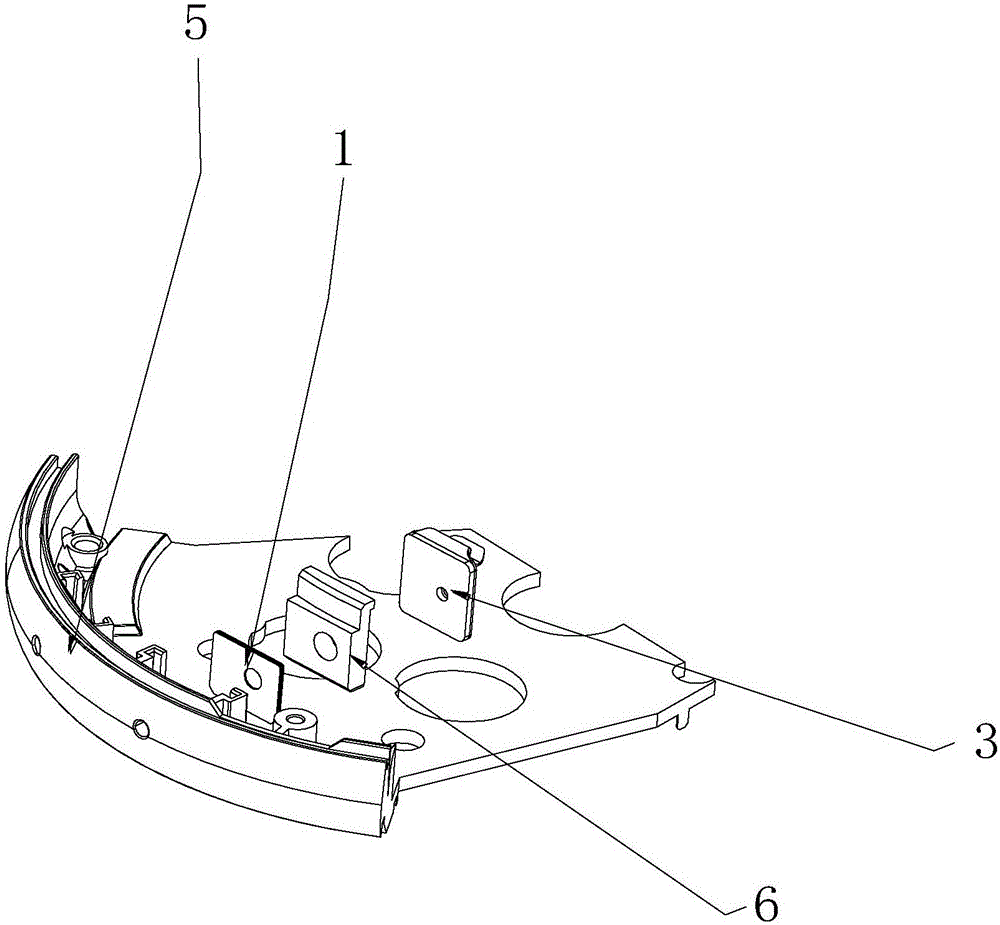

Adsorption electrode

PendingCN112107308AIncrease operational difficultyReduce machining accuracyDiagnostic recording/measuringSensorsEngineeringPolymer chemistry

The invention provides an adsorption electrode. The adsorption electrode comprises an electrode suction cup, electrode sponge, an electrode patch, an electrode jack part and an electrode crown spring,wherein the electrode suction cup serves as an adsorption electrode shell and is made of a deformable material; the electrode sponge is arranged in the electrode suction cup; the electrode patch is arranged at the top of the inner side of the electrode suction cup, and the upper end and the lower end of the electrode patch are meshed with the electrode suction cup; the electrode jack part penetrates through the wall of the electrode suction cup and is electrically connected with the electrode patch; and the electrode crown spring is arranged in a hole of the electrode jack part and is in contact with the inner wall of the electrode jack part by virtue of elastic force.

Owner:JIANLIPU BEIJING MEDICAL TECH

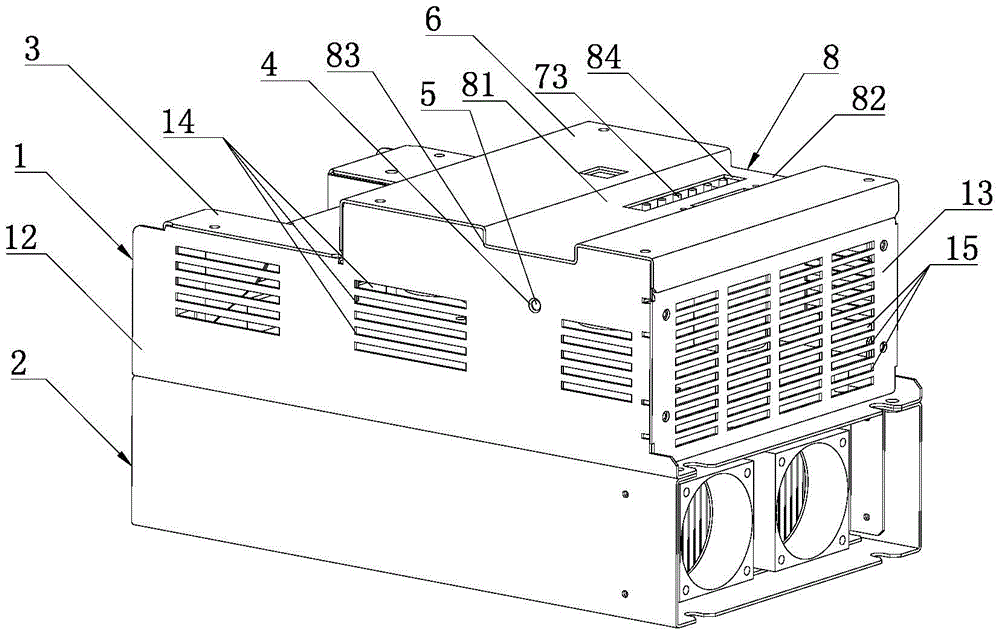

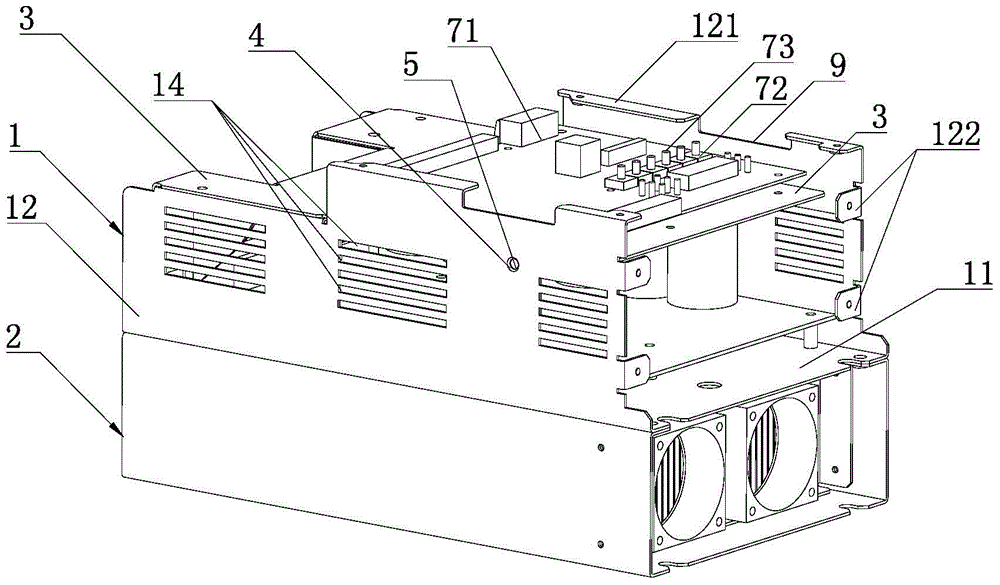

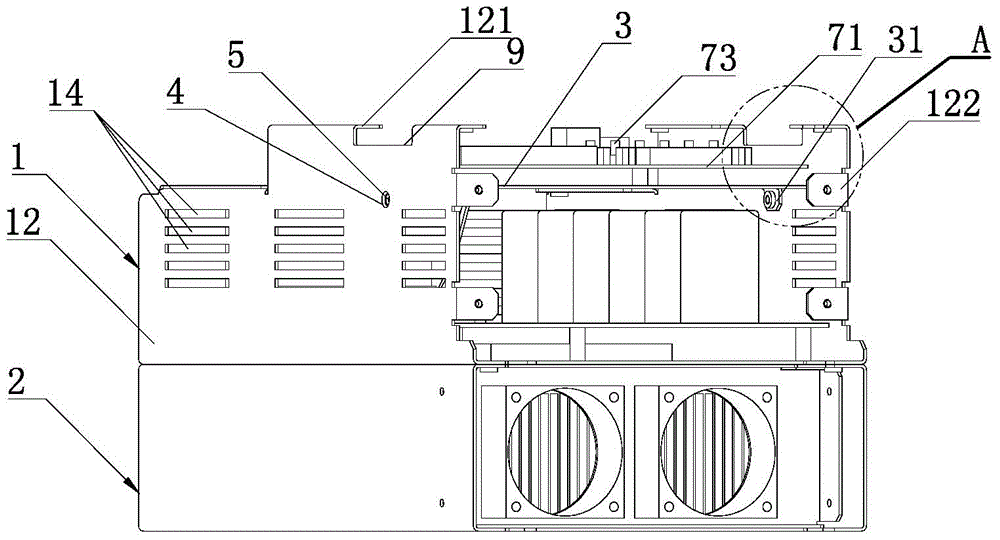

Servo driver housing

InactiveCN105491841AImprove sealing and stabilityGuaranteed smoothMagnetic/electric field screeningHermetically-sealed casingsEngineeringMechanical engineering

The invention discloses a servo driver housing. The servo driver housing includes an upper box body and a lower box body which are formed by steel sheet coated with Al-Zn alloy and are mutually matched; a shield plate is arranged in the upper box body, wherein the shield plate is parallel to a bottom plate of the upper box body and is tightly attached to inner walls of two symmetric side plates of the upper box body; two symmetric side edges of the shield plate are vertically downward provided with at least one first connection sheet which is parallel to the two side plates of the upper box body and has a screw hole, in an integrated extension manner; positions of the two side plates of the upper box body, corresponding to the screw holes of the first connection sheets, are provide with cone holes having a hole diameter which progressively become smaller from outside to inside; the shield plate passes through the cone holes and the screw holes of the first connection sheet through sunk screws and is fixed to the two side plates of the upper box body; and ends of the sunk screws are positioned in the cone holes. The advantages are that: the ends of the sunk screws are positioned in the cone holes, so that the surfaces of the side plates of the connected upper box body are not protruded, thereby facilitating a flat housing surface; and the sunk screws and the cone holes can be tightly matched, so that the mechanical strength of the whole housing can be enhanced.

Owner:NINGBO ANXIN CNC TECH

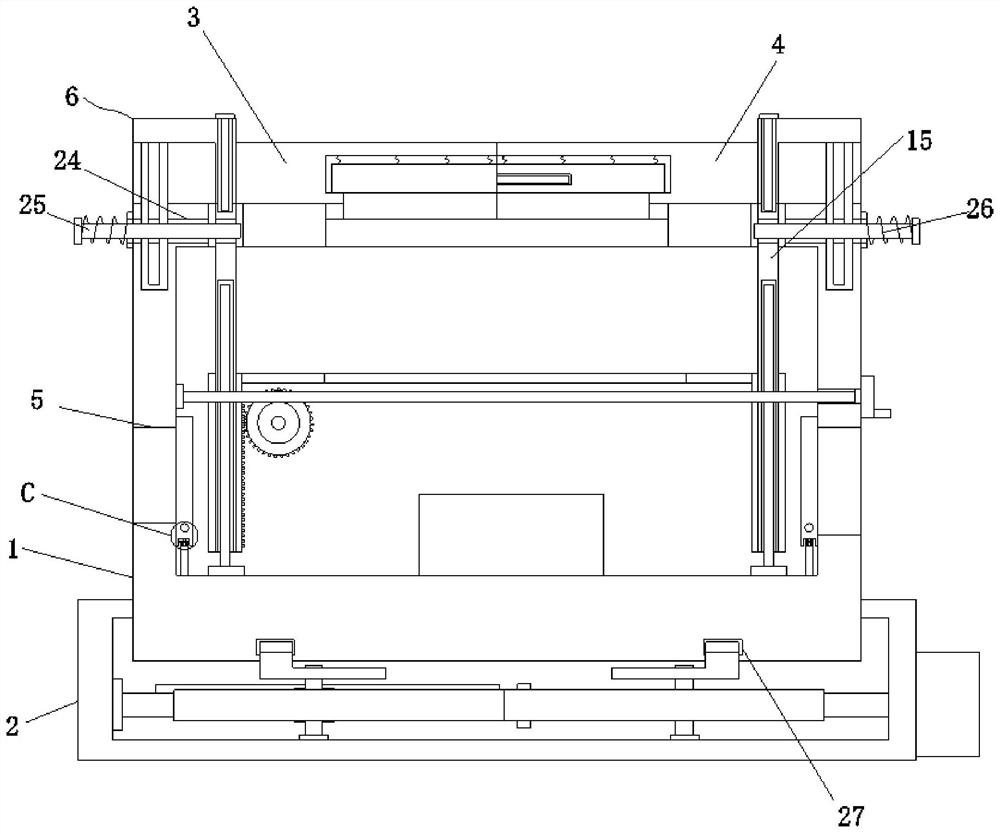

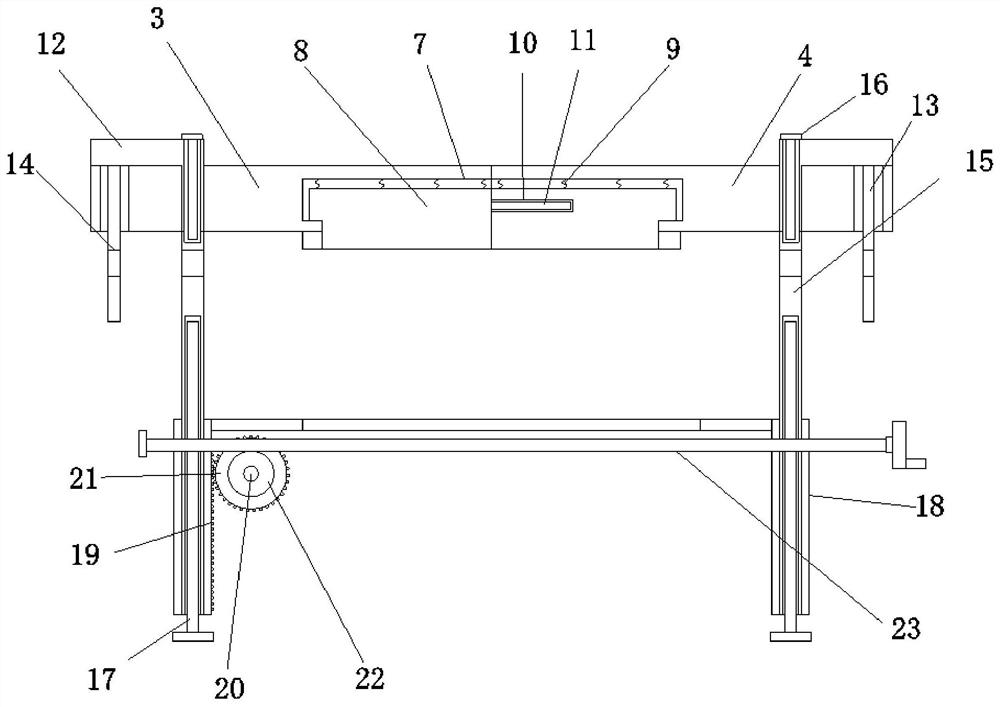

Servo motor driver structure easy to install and installation method thereof

ActiveCN113852233AEasy to installImprove ventilationMechanical energy handlingCooling/ventillation arrangementElectric machineryServo

The invention relates to the technical field of motor driving, discloses an easy-to-mount servo motor driver structure and a mounting method thereof, and solves the problems that the servo motor driver structure is inconvenient to mount and cannot be sealed and protected. The structure comprises a driver shell, and a mounting seat is arranged at the bottom end of the driver shell; a sealing piece is arranged at the top end of the driver shell, the driver shell is connected with the mounting base through a mounting mechanism, ventilation openings are symmetrically formed in the two sides of the bottom end of the driver shell, and a shielding mechanism connected with the ventilation openings is arranged in the driver shell; by means of the driver shell, the mounting base and the mounting mechanism, convenience is brought to connection of the driver shell and the mounting base, then the design of the sealing connecting mechanism and the fastening set is matched, convenience is effectively brought to sealing of the driver shell by the sealing piece, and protection of the servo motor in the driver shell is achieved.

Owner:深圳锐特机电技术有限公司

Spherical valve overhaul sealing control method

ActiveCN107859755AEnsure safetyRealize anti-opening self-locking functionPlug valvesValve housingsWater turbineEngineering

The invention discloses a spherical valve overhaul sealing control method which is characterized in that the spherical valve overhaul sealing control method comprises the following steps that a, the area of an opening cavity of a movable sealing ring in a spherical valve, the area of an upstream high pressure cavity, the area of an upstream input cavity and the area of a downstream pressure cavityare set; b, normal overhaul is carried out, a water turbine is shut down, a valve body of the spherical valve is fully closed through a servomotor, the movable sealing ring is put in, water in a downstream pipeline of the spherical valve is drained, and the movable sealing ring is pressed under the pressure of the upstream input cavity and the pressure of the upstream high pressure cavity; c, extreme overhaul is carried out, the upstream input cavity is subjected to pressure loss, the opening cavity is subjected to pressure buildup, and the movable sealing ring is pressed; and d, after the overhaul, a by-pass line is opened for carrying out pressure balance on the upstream side and the downstream side of the spherical valve. The free input and withdrawing of overhaul sealing in a normal overhaul state can be realized, the situation that the overhaul sealing is not opened during misoperation can be guaranteed, the safety of a maintainer is ensured, and the spherical valve overhaul sealing control method has the characteristics of convenience in operation, safety and reliability.

Owner:DONGFANG ELECTRIC MACHINERY

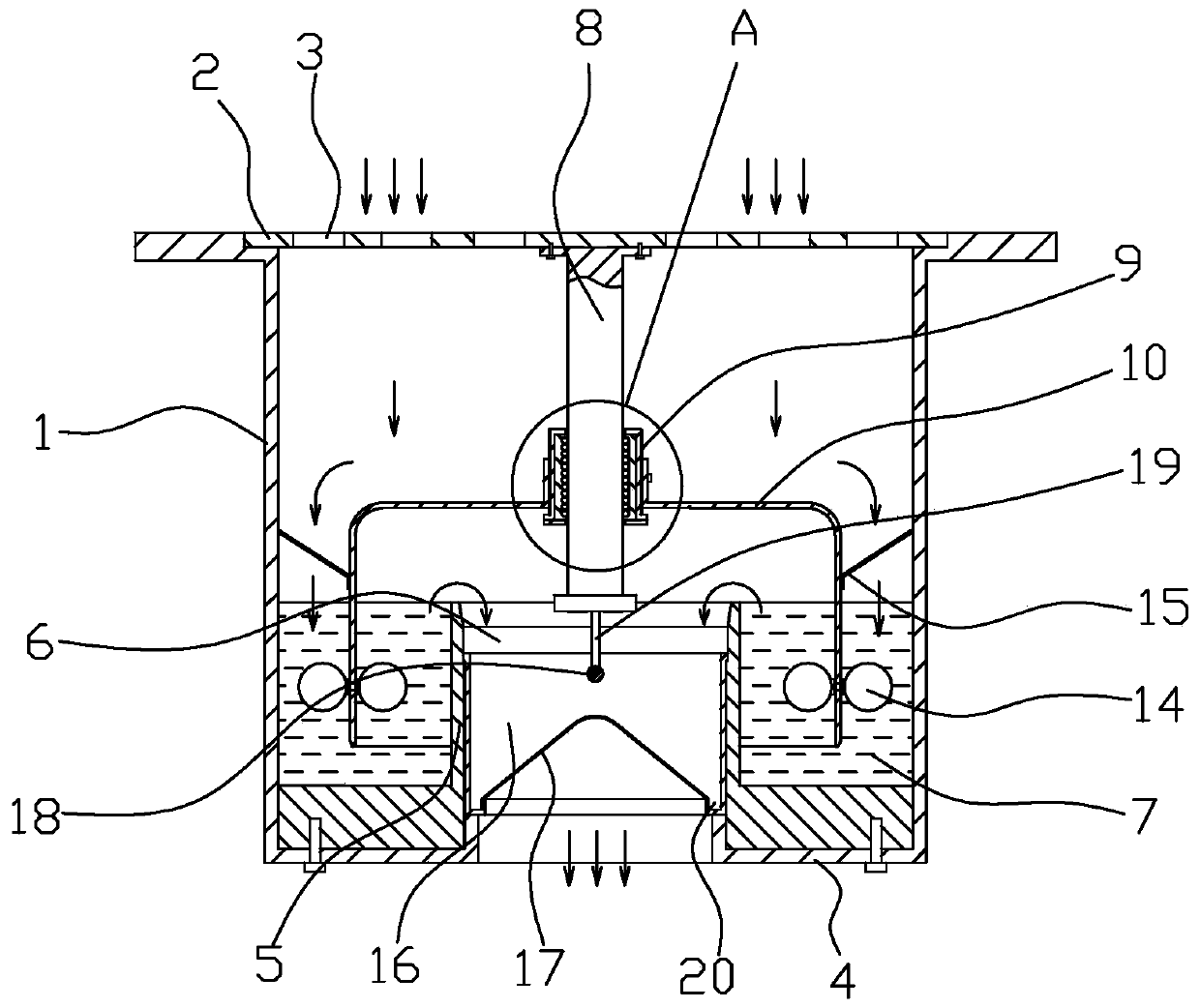

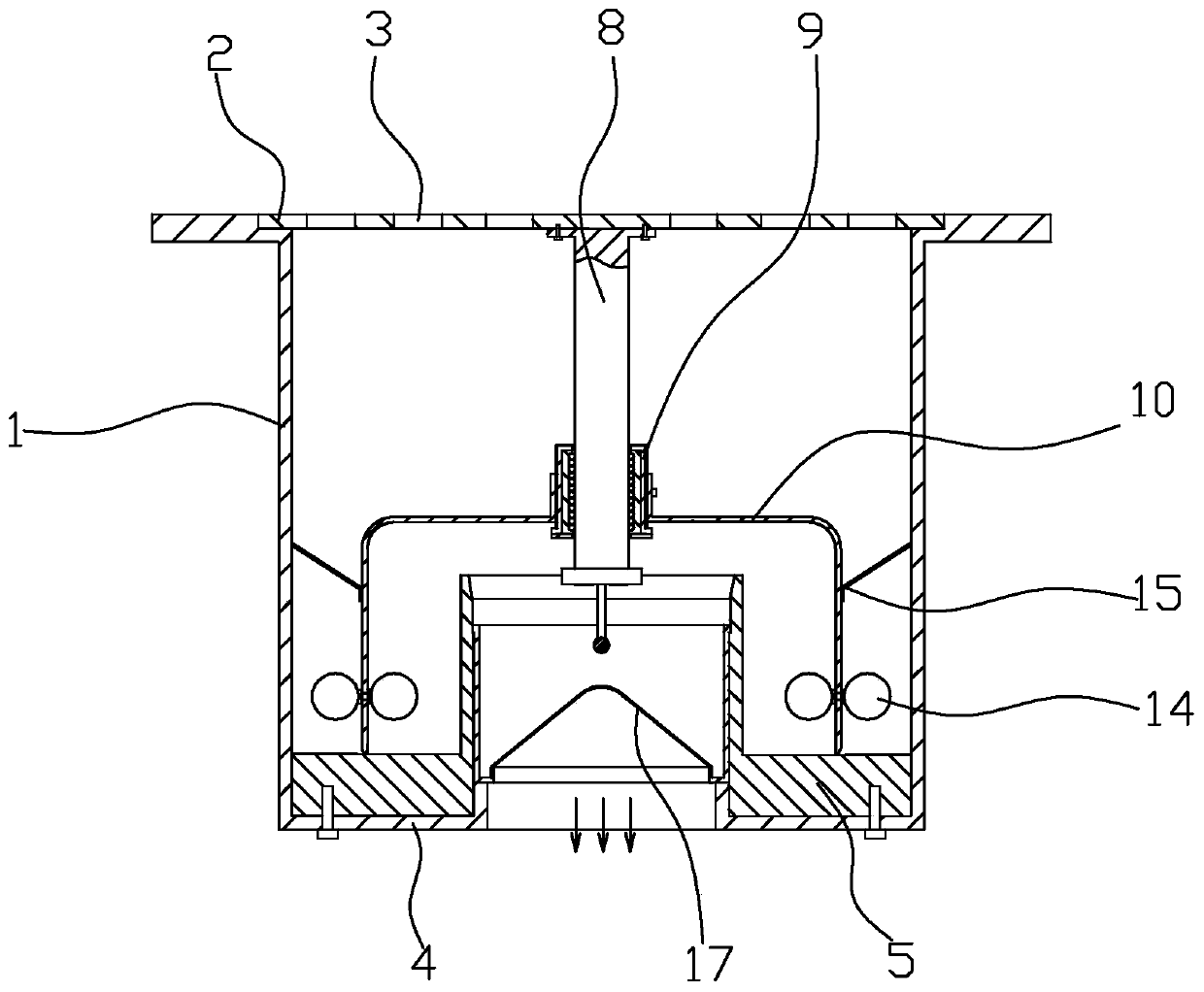

Ink extrusion device for ink bag

ActiveCN110550284ATightly boundImprove sealing and stabilityUnpacking by expelling contentsMechanical engineeringLinkage concept

The invention relates to an ink extrusion device for an ink bag. The device comprises a box body with a negative pressure opening, a flow guide pipe penetrating through the top of the box body and extending into the box body, the ink bag communicating with one end, far away from the box body, of the flow guide pipe, a transfer groove arranged in the box body and is provided with an opening facingthe flow guide pipe, a through hole formed in the side surface of the box body, a support frame arranged along the outer edge of the through hole, a pull rod arranged in the through hole and used forpulling the transfer groove to enter and exit the box body, a sealing plate arranged at one end, far away from the transfer groove, of the pull rod, an elastic extrusion mechanism used for sealing thethrough hole, and a lifting linkage mechanism matched with the support frame and used for maintaining the sealing stability of the elastic extrusion mechanism. According to the device, ink in the inkbag flows to the transfer groove under the negative pressure state, through the arrangement of a splash-proof mechanism, the situation that when the ink in the ink bag starts to flow to the transfergroove, the ink is splashed outside due to the fact that the flow speed is too large is avoided, the material waste is avoided, and the production cost is reduced.

Owner:杭州盛浙电子有限公司

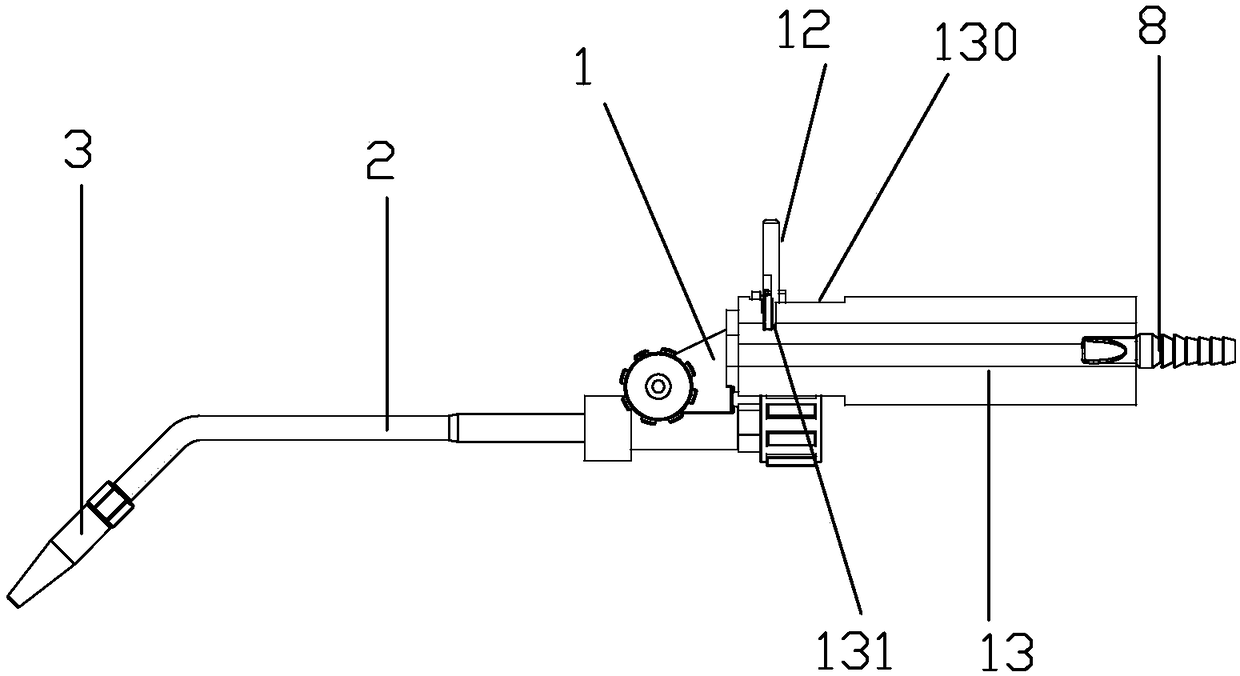

Magnetic control type energy-saving welding gun structure

PendingCN108213648AQuick responseReduce wasteOperating means/releasing devices for valvesMultiple way valvesEngineeringMagnet

The invention relates to the technical field of welding guns, and discloses a magnetic control type energy-saving welding gun structure. The magnetic control type energy-saving welding gun structure comprises a connecting base and a gas ejector pipe; two parallel connecting pipes are arranged on the connecting base; a valve seat is arranged at the gas inlet ends of the connecting pipes; two independent valve cavities are formed in the valve seat; two gas outlet runners communicating with the valve cavities in a one-to-one correspondence manner are formed in the front end of the valve seat; thetwo connecting pipes are connected to the outer ends of the gas outlet channels in a one-to-one correspondence manner; valve elements made of ferromagnets are arranged in the valve cavities; pressuresprings are arranged at the rear ends of the valve elements; two parallel gas inlet pipes capable of communicating with the valve cavities are further arranged on the valve seat; a sliding base is arranged between the two gas inlet pipes; permanent magnets corresponding to the valve elements in a one-to-one manner are arranged on the sliding base; a pull rod is arranged on the sliding base; a permanent magnet forward-moving driving mechanism is arranged on the pull rod; a permanent magnet reset mechanism is arranged between the two gas inlet pipes; and a shell is arranged on the outer side ofthe valve seat. According to the magnetic control type energy-saving welding gun structure, the gas on-off state control response is fast, gas waste can be reduced, and gas energy can be saved.

Owner:上海晶珊电子科技有限公司

A long-term deodorant floor drain structure

The invention relates to the technical field of sanitary products, and discloses a long-acting anti-odor type floor drain structure, which includes a floor drain shell and a cover body. The cover body is provided with a water inlet hole, and the lower end of the floor drain shell is provided with a support ring. An annular water seal cup is fixed on the upper side of the support ring, the center of the water seal cup is provided with a liquid outlet channel, an annular cavity is formed between the water seal cup and the inner wall of the shell, and the center of the bottom surface of the cover is fixed with a A vertical slide bar, the slide bar is provided with a sliding sleeve, the outer side of the sliding sleeve is fixed with an isolation cover facing the opening, the opening end of the isolation cover extends into the annular cavity, and the inner wall of the isolation cover 1. A number of floating balls are evenly fixed on the outer wall at the same height. The invention has the beneficial effects of being able to maintain long-term sealing and effectively preventing the odor from escaping from the sewer.

Owner:ZHEJIANG SCI-TECH UNIV

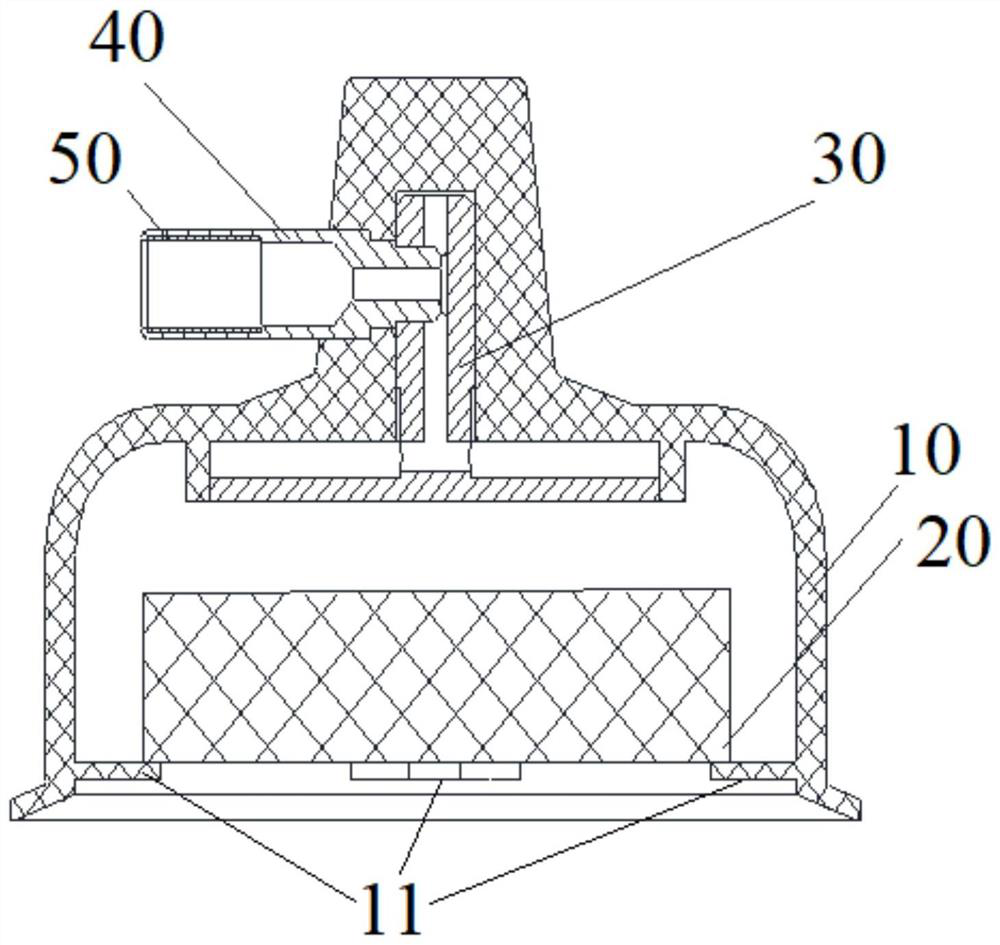

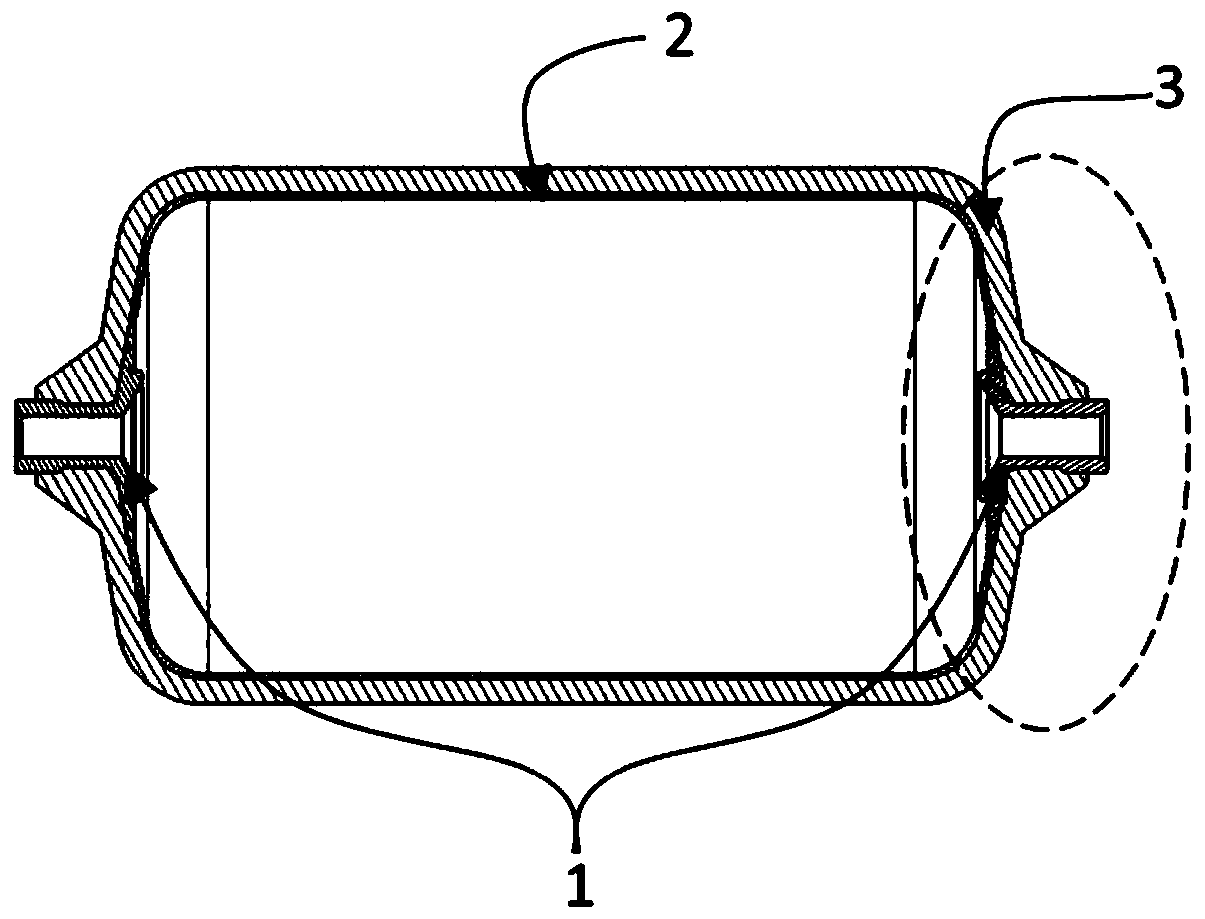

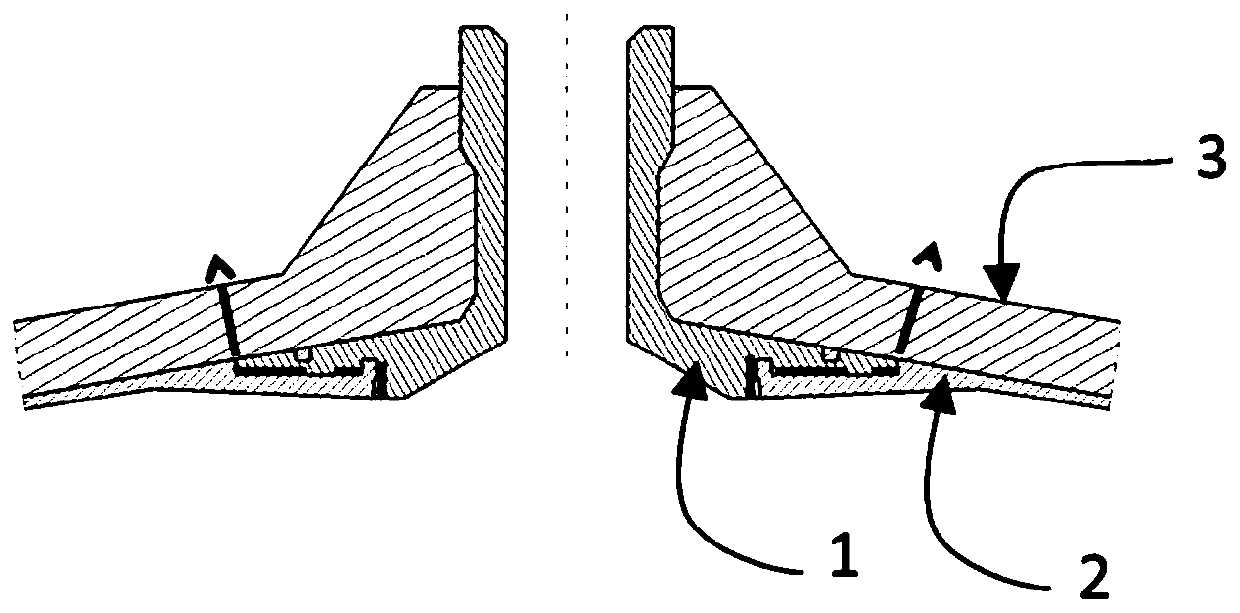

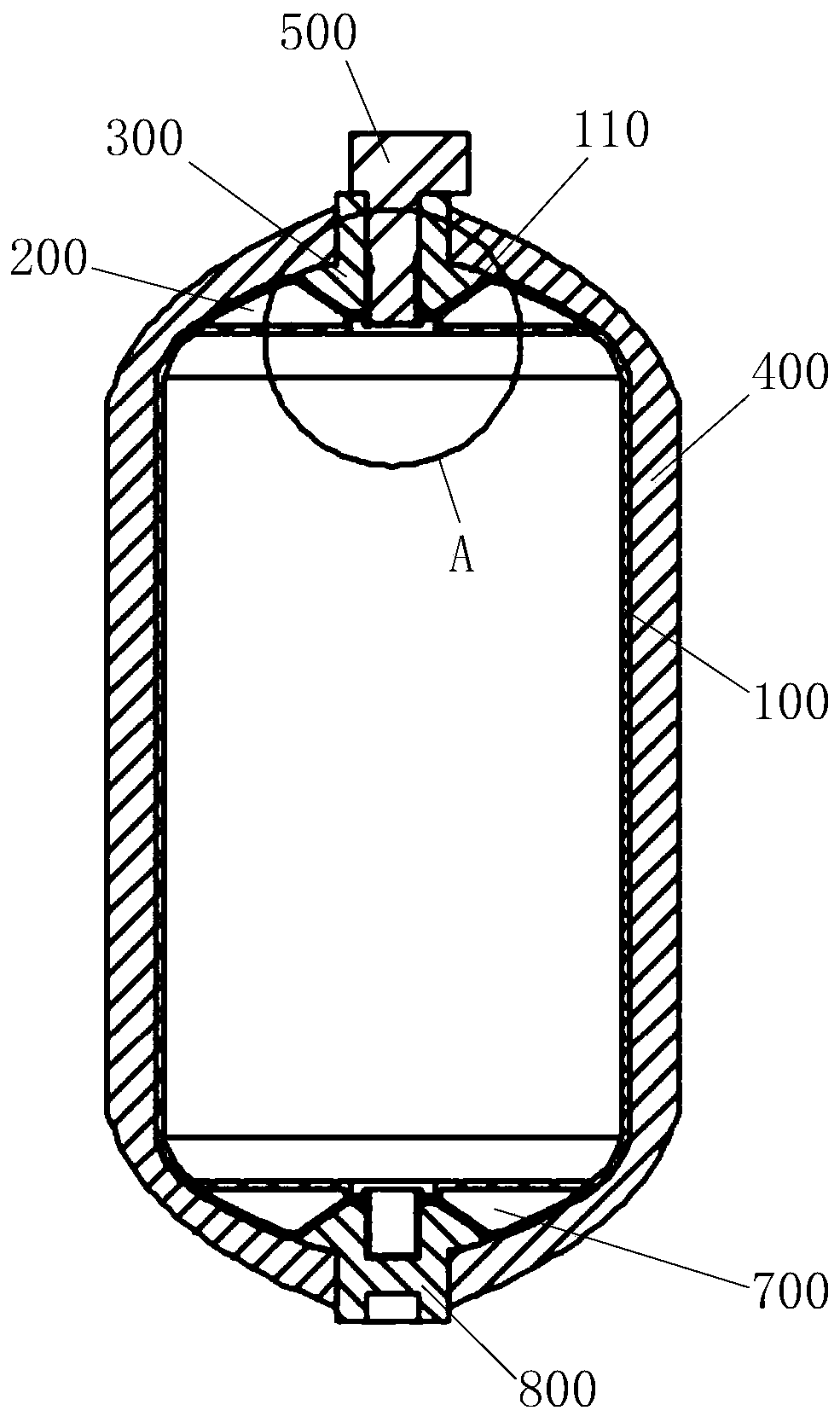

Deep-cooling high-pressure hydrogen storage bottle

PendingCN109707991AImprove sealing and stabilityExtended service lifeContainer filling methodsPressure vesselsInsulation layerHydrogen channel

The invention discloses a deep-cooling high-pressure hydrogen storage bottle. The deep-cooling high-pressure hydrogen storage bottle comprises an inner cylinder body and an outer cylinder body. The inner cylinder body is arranged in the outer cylinder body through a supporting component. An interlayer between the inner cylinder body and the outer cylinder body is vacuumized to form a vacuum heat insulation layer. An inner bottle opening with internal threads is formed in a sealing head of the inner cylinder body. A bottle opening sealing piece is connected to the interior of the inner bottle opening in a threaded mode. The edge of the inner bottle opening and the threaded section of the bottle opening sealing piece are welded and sealed. An L-shaped first hydrogen channel is formed in thebottle opening sealing piece. An inner end opening of the first hydrogen channel is located on the inner end surface of the bottle opening sealing piece, and an outer end opening of the first hydrogenchannel is located on the side wall of the outer end of the bottle opening sealing piece. A first communicating pipeline which surrounds the bottle opening sealing piece is arranged in the vacuum heat insulation layer and penetrates through the outer cylinder body outwards. An inner end opening of the first communicating pipeline is in welding communication with the outer end opening of the firsthydrogen channel. The deep-cooling high-pressure hydrogen storage bottle is long in service life and good in heat insulation performance.

Owner:ZHANGJIAGANG RES INST OF HYDROGEN ENERGY CO LTD +1

Marine mechanical valve with high sealing performance

InactiveCN109667937ATo achieve the purpose of re-blockingRealize the function of secondary leakage preventionOperating means/releasing devices for valvesLift valveEngineeringMechanical valve

The invention provides a marine mechanical valve with high sealing performance. The marine mechanical valve comprises a sealing plate, ejector rods, L-shaped gas guiding pipelines, a sleeve, a pistonplate and a connecting rod, wherein the connecting rod is fixed to the lower end of a valve plate; the lower end of the connecting rod extends from the lower end of a valve cavity to be rotatably connected with the upper end of the piston plate through bearings; the piston plate is located inside the sleeve; the sleeve is fixed to the lower end surface of the valve cavity; the L-shaped gas guidingpipelines are fixedly connected to the lower left side and the lower right side of the sleeve; the upper ends of the L-shaped gas guiding pipelines are slidably connected with the ejector rods; the ejector rods are fixed to the lower end surface of the sealing plate; the connecting rod is sleeved with the sealing plate; the sealing plate is located directly under the valve plate; and both the sealing plate and the ejector rods are arranged inside the valve cavity. In this way, the purpose of re-blocking is achieved, so that the sealing effect is improved, the function of secondary leakage prevention is achieved, and the leakage prevention effect is improved.

Owner:TIANJIN QICHANG VALVE MFG

Seal assembly in concrete drain pipe

ActiveCN106641505APrecise positioningImprove sealing and stabilitySleeve/socket jointsState of artEngineering

The invention provides a seal assembly in a concrete drain pipe. The seal assembly in the concrete drain pipe belongs to the field of mechanical technique, and solves the problem of low stability in the prior art. According to the seal assembly in the concrete drain pipe, the concrete drain pipe comprises a long-tubular body; a concave connecting seat is arranged on the end part of the body; the seal assembly is located at the end part of the body and comprises a seal ring I and a seal ring II; the seal ring I and the seal ring II are made of flexible materials; a connecting structure for tightly connecting the seal ring I and the seal ring II is arranged between the seal ring I and the seal ring II; and when two adjacent bodies are connected in series, the seal ring I and the seal ring II are tightly pressed between the two bodies. The seal assembly in the concrete drain pipe is high in stability and good in sealing performance.

Owner:浙江宏泰构件股份有限公司

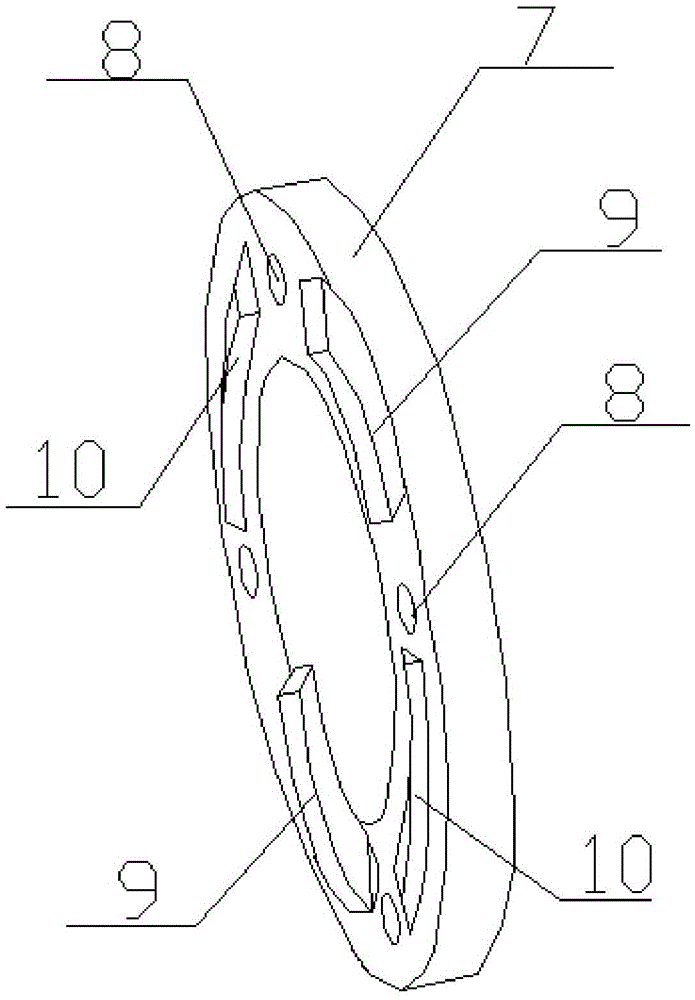

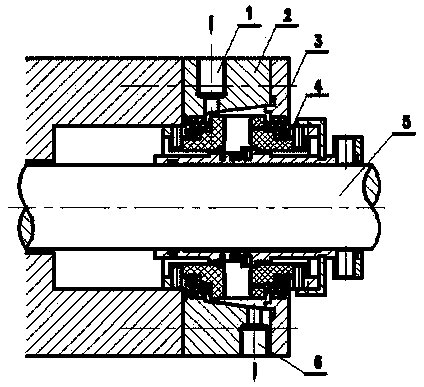

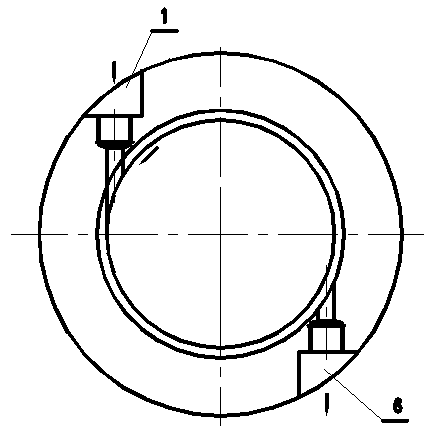

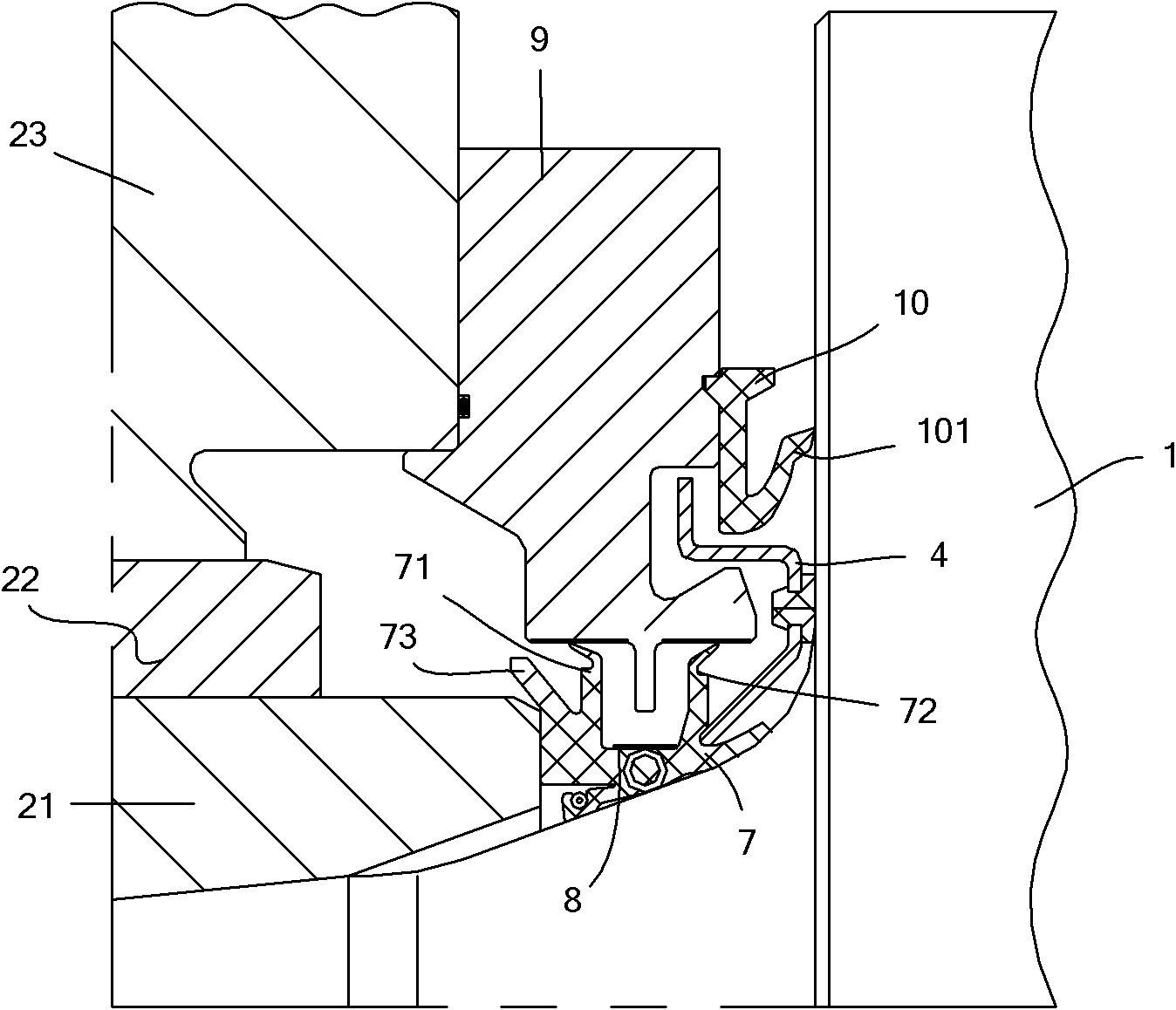

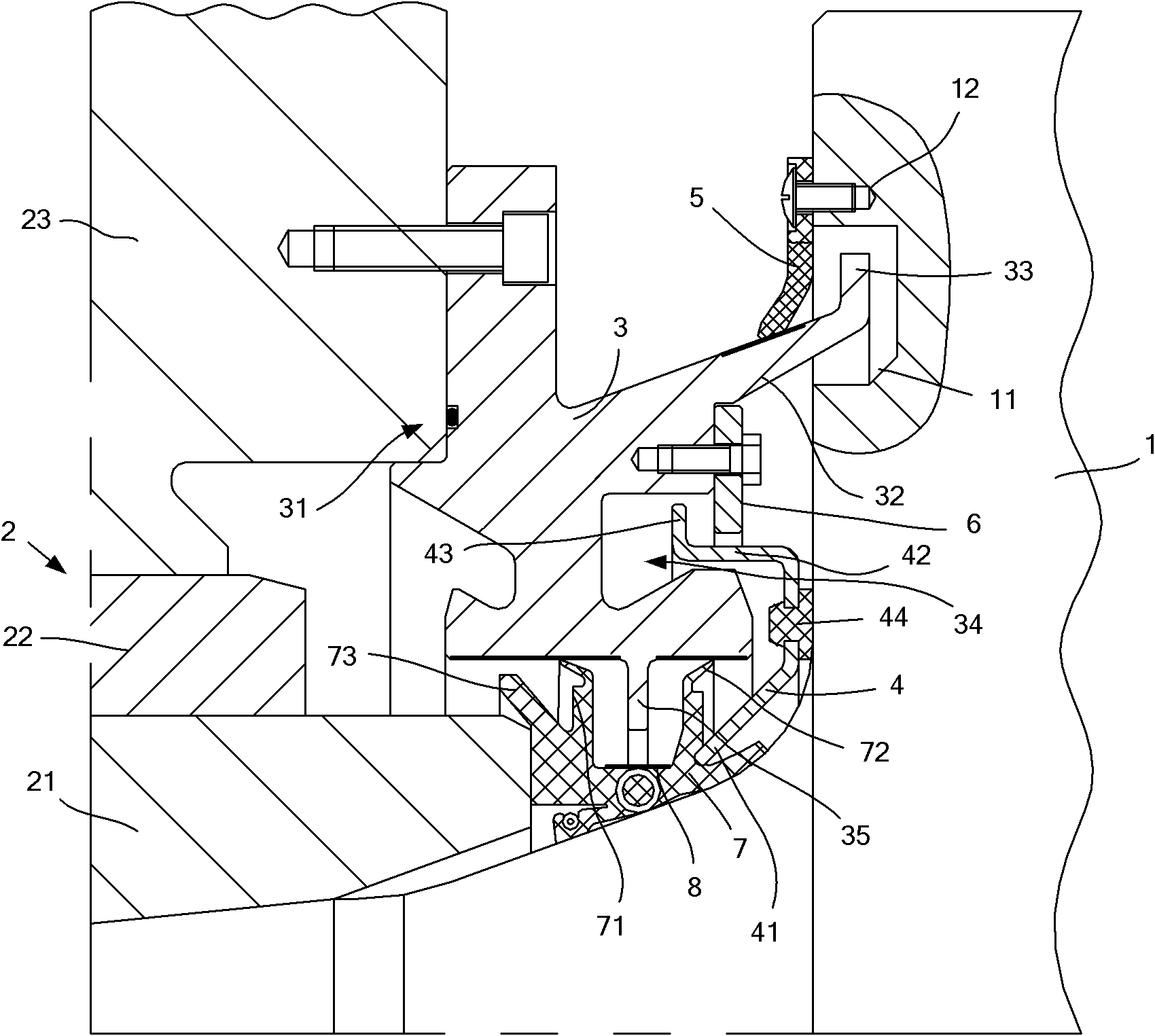

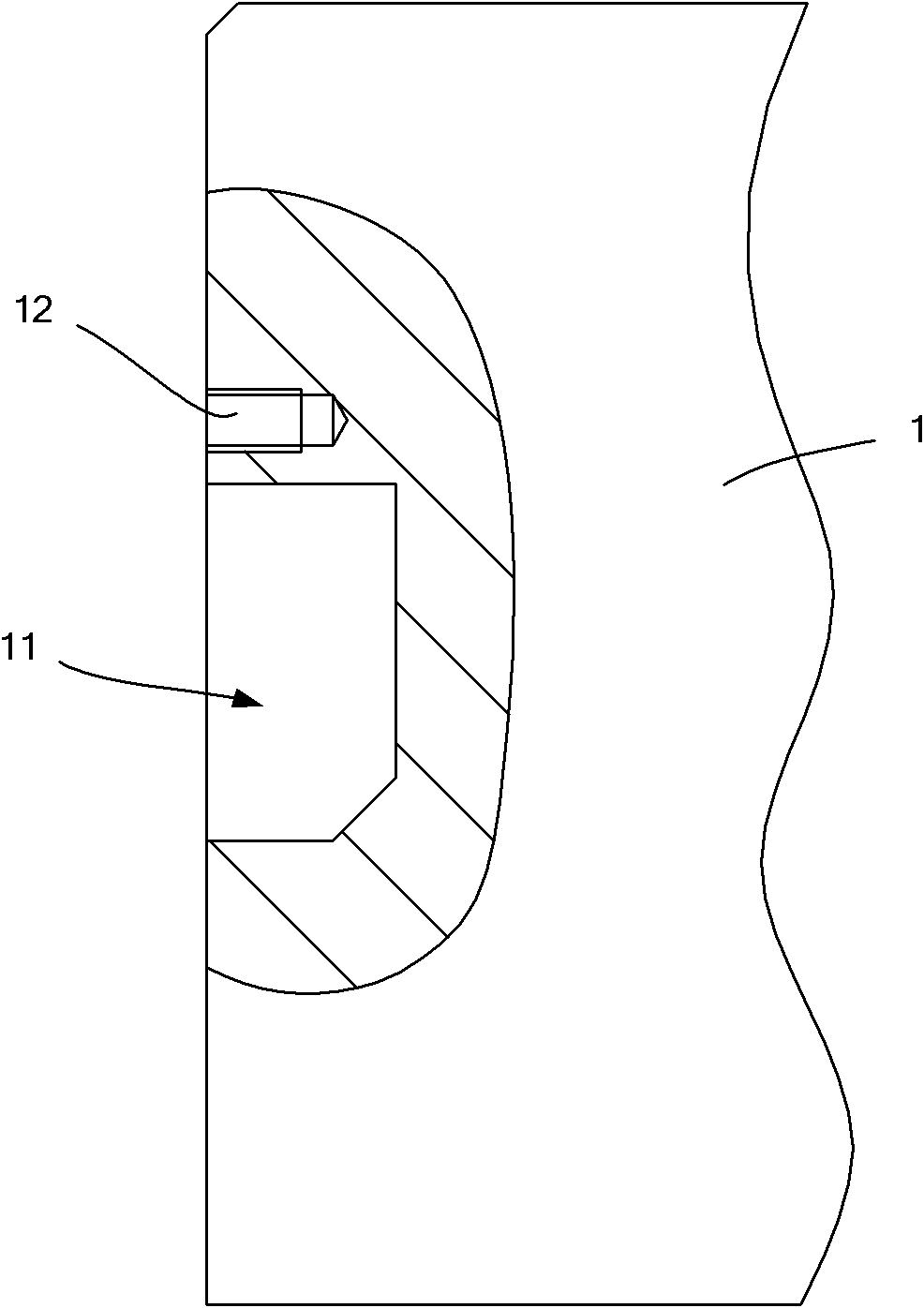

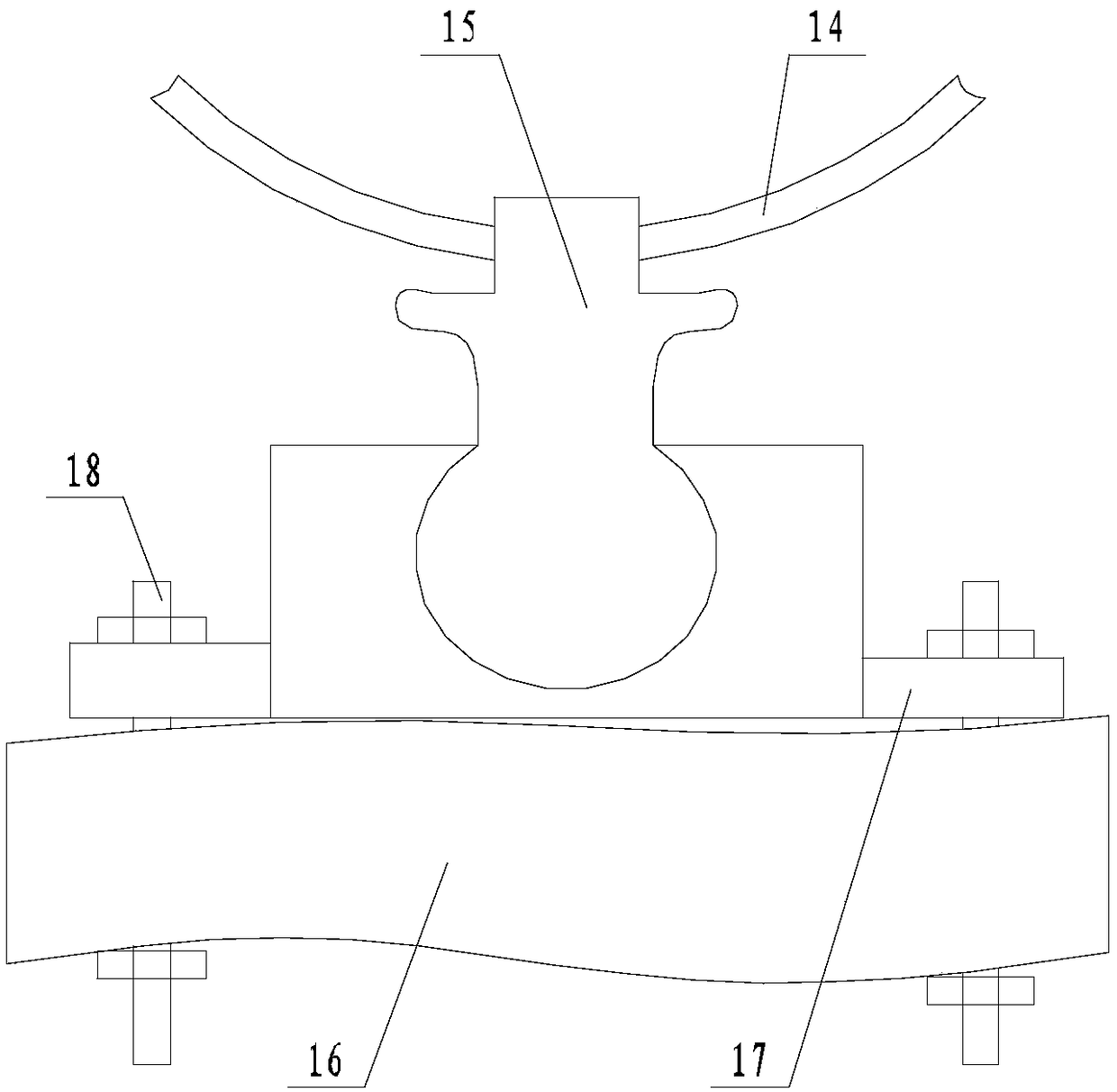

Roll neck sealing device of oil film bearing

This invention discloses a roll neck sealing device of an oil film bearing, which comprises a sealing cover, a foot-shaped sealer, a buffer ring, a water retaining ring, and a retaining cushion, wherein an annular bump is arranged on the middle part of an inner circumference face of the sealing cover; one face of the sealing cover is fixedly mounted on a bearing base of a rolling mill; the other face thereof is provided with an annular water retaining arm inclined towards the outer side; the inner side of the annular water retaining arm is provided with an annular groove; the foot-shaped sealer is mounted among an oil film bearing taper sleeve, a sealing cover and a roller shaft neck so as to form an oil sealing part and a water sealing part; the longitudinal cross section of the buffer ring is U-shaped; an inside support leg of the buffer ring is capable of supporting the foot-shaped sealer; an outside support leg is extended into the annular groove; the terminal of the outside support leg is provided with a roundabout structure; the bottom surface of the buffer ring is capable of supporting the end face of the roller shaft neck; the outer side of the water retaining ring is mounted on the end face of the roller shaft neck; the inner circumference face of the water retaining ring is compressed on the outer side face of the water retaining arm; and the retaining cushion is mounted between the water retaining arm and the annular groove and is extended so as to shield an opening of the annular groove. The sealing device disclosed by this utility model improves sealing effect and stability of the oil film bearing.

Owner:TAIYUAN HEAVY IND

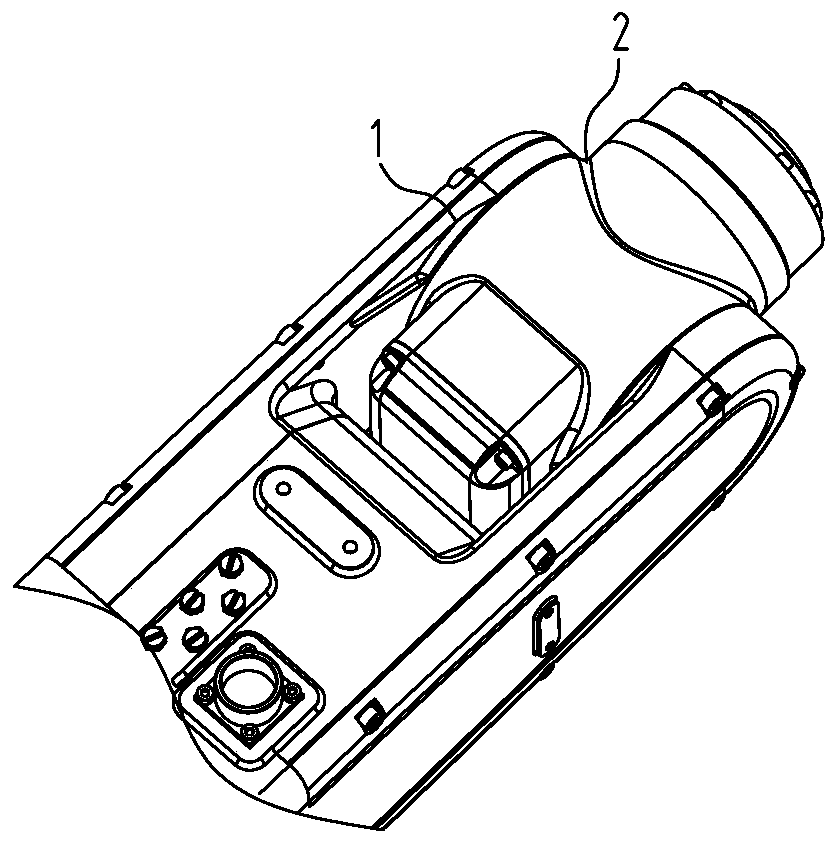

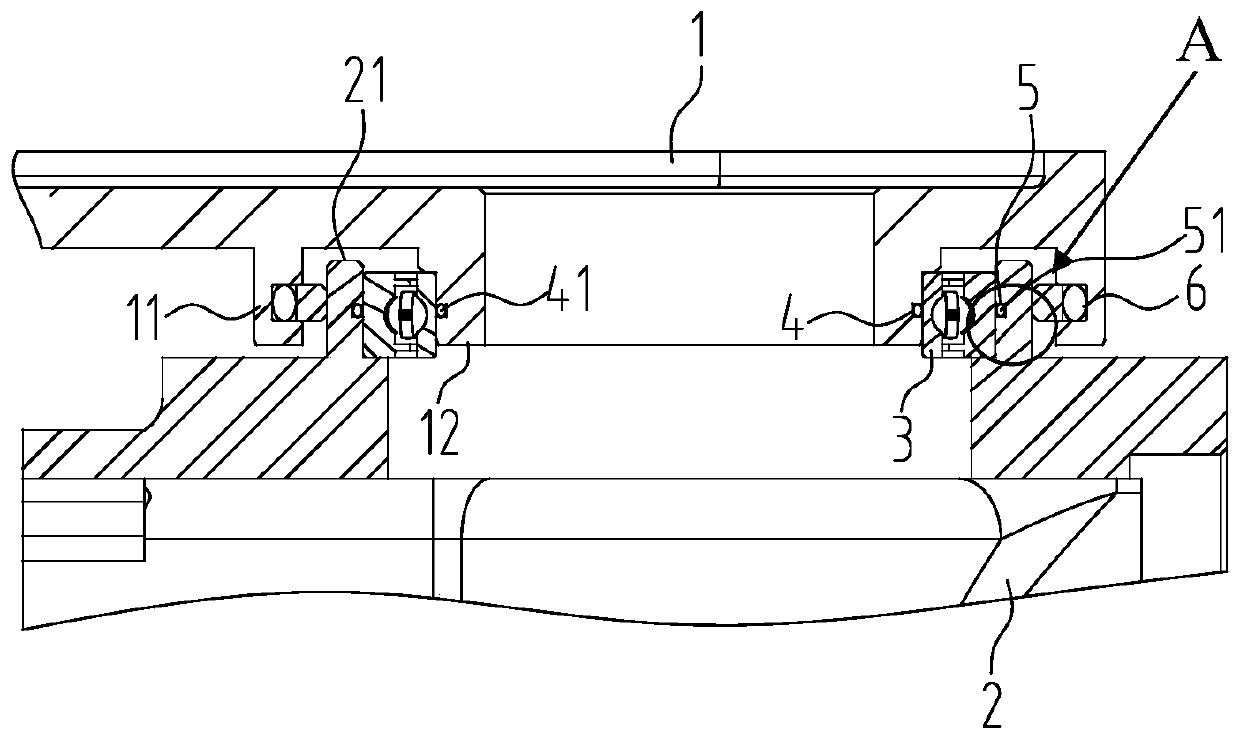

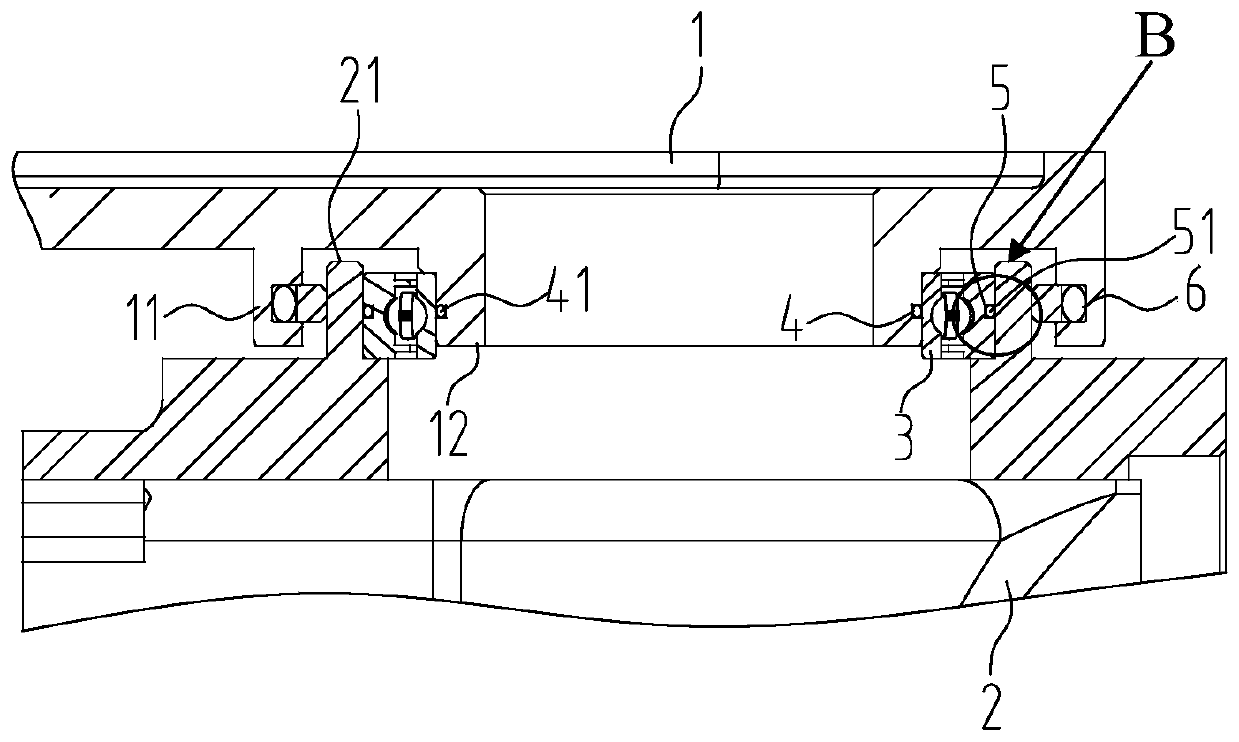

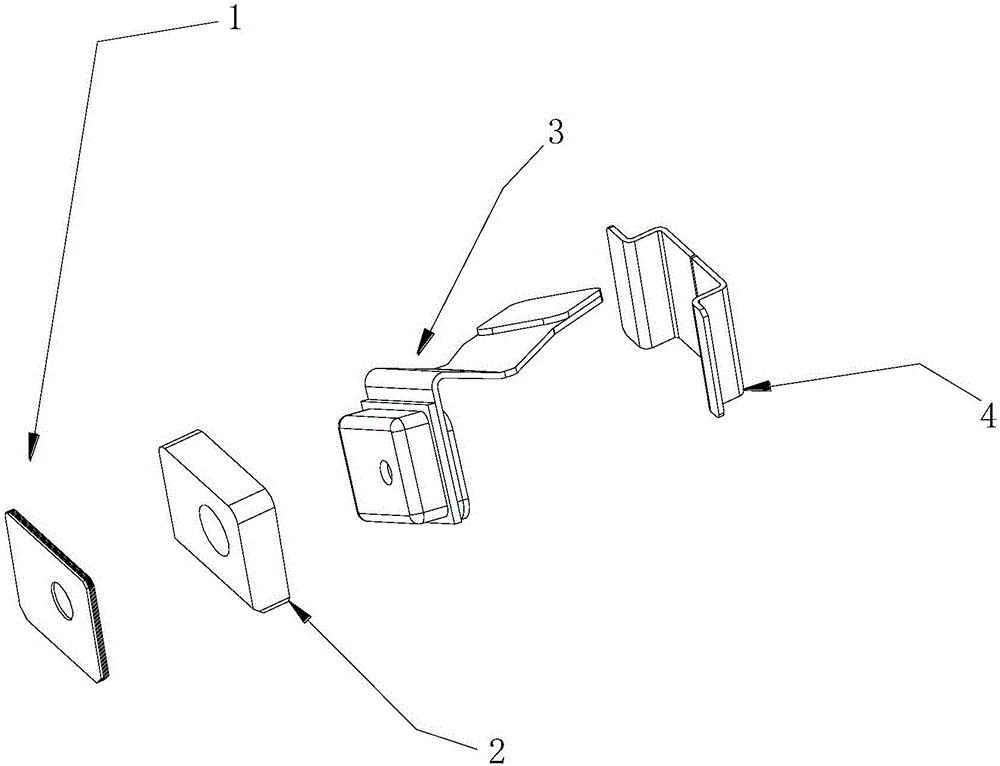

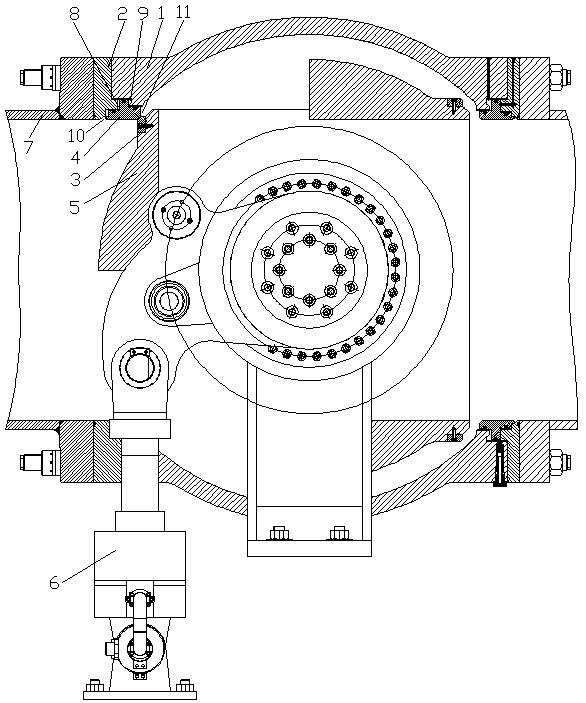

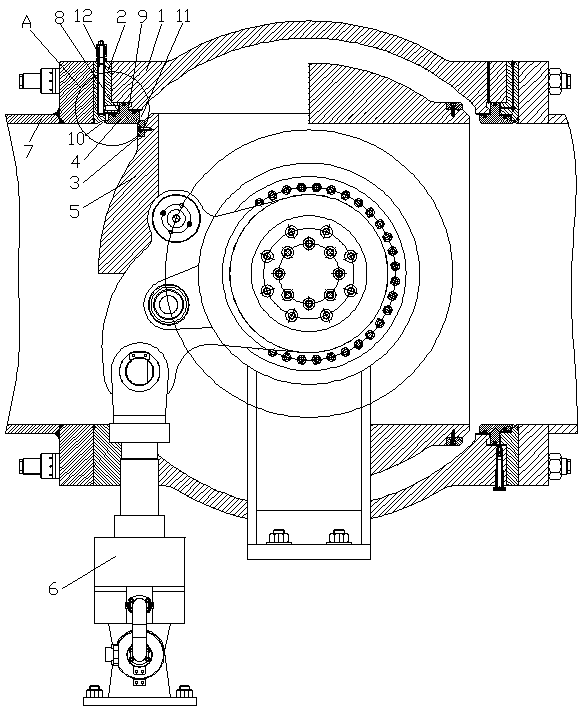

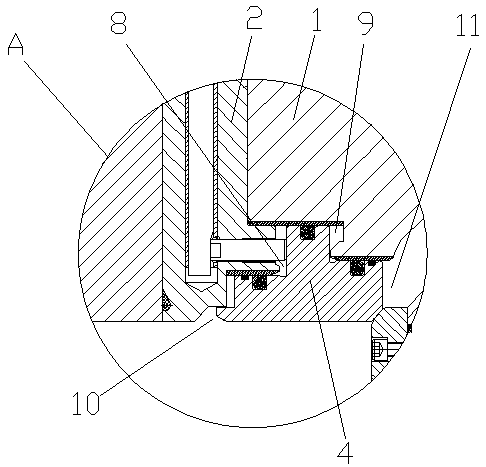

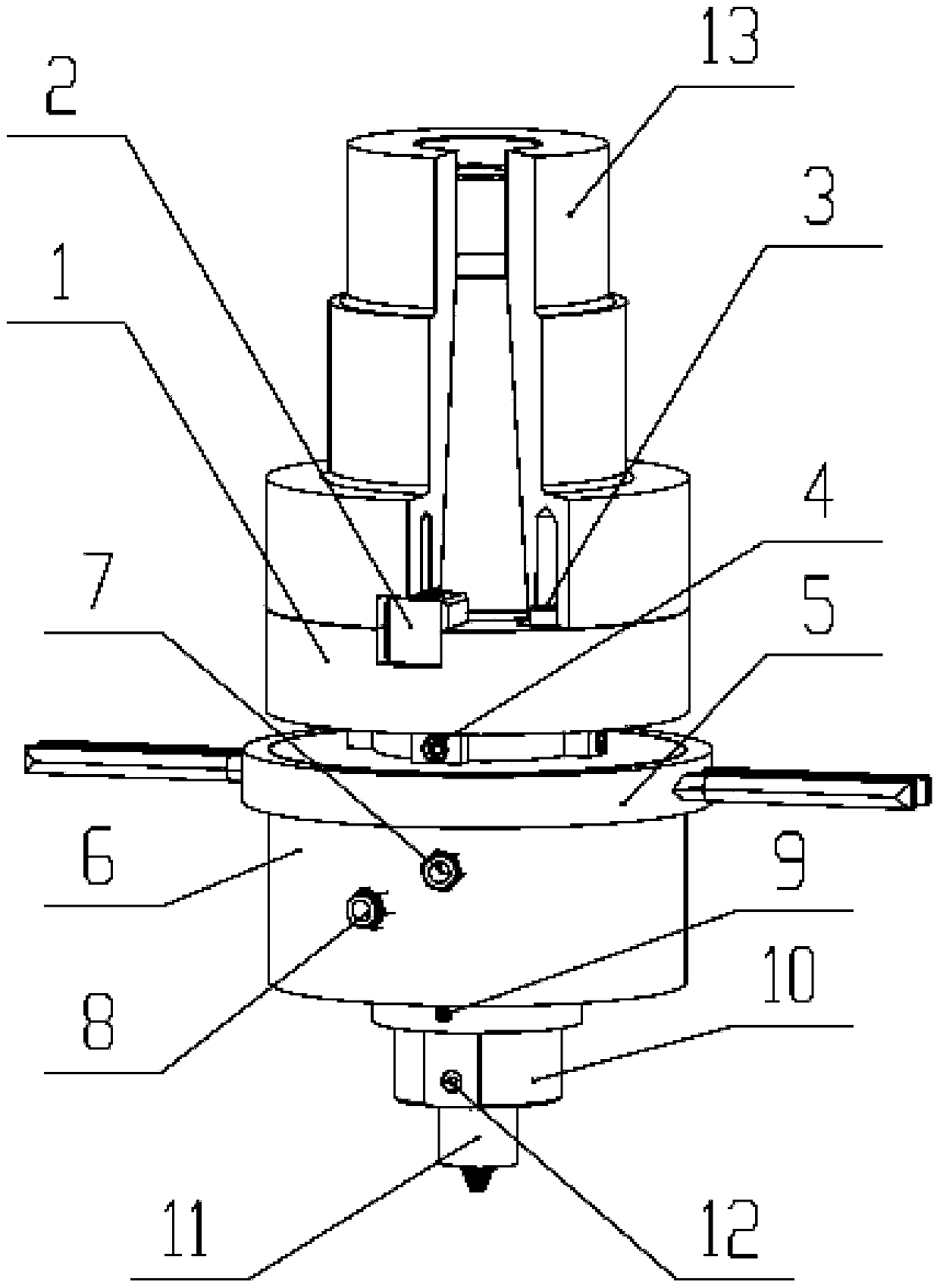

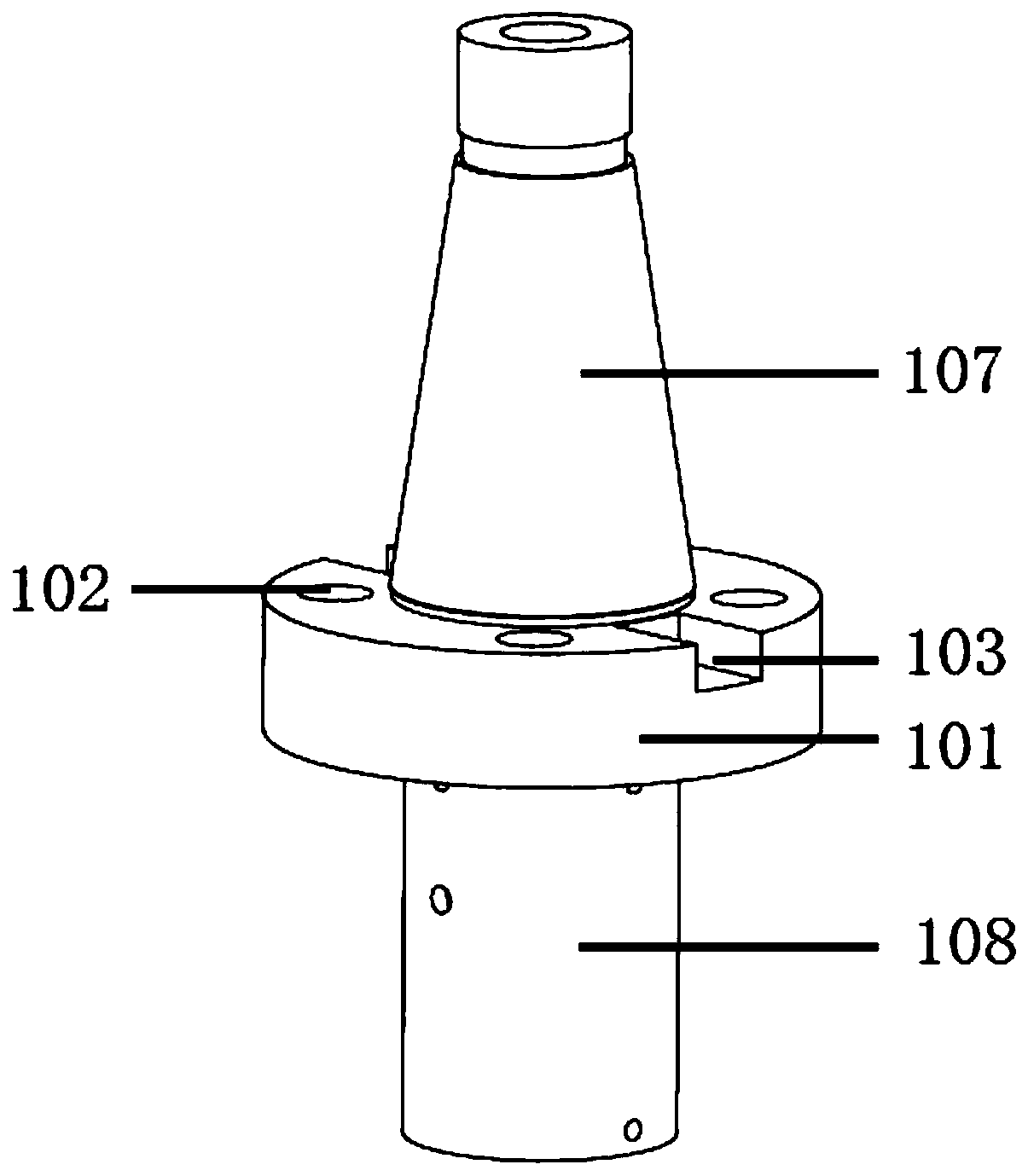

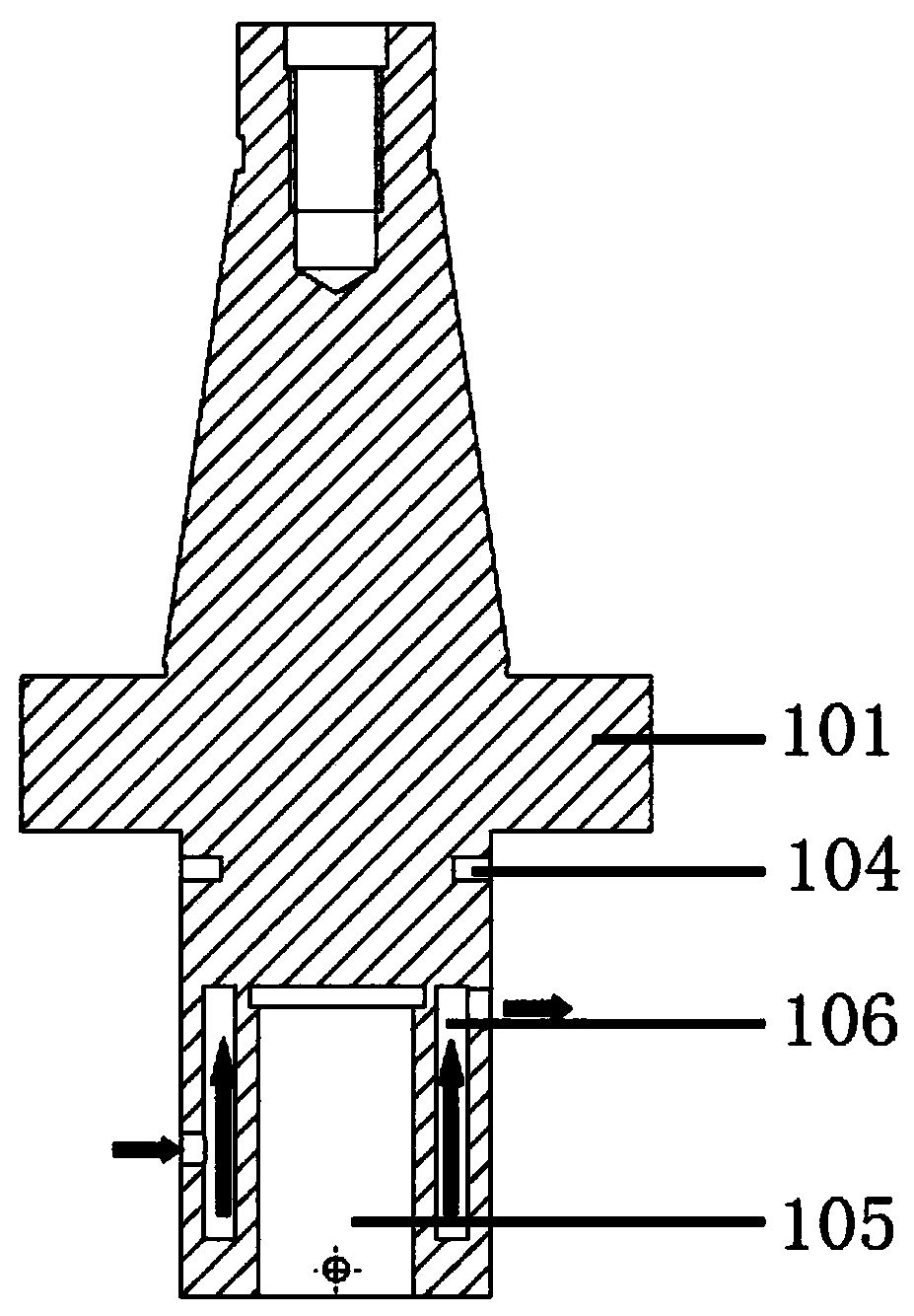

Water cooling connection device for friction stir welding of high melting point materials

ActiveCN108044229BGuaranteed coaxialityImprove sealing and stabilityNon-electric welding apparatusCircular coneMaterials science

Owner:一重集团天津重工有限公司

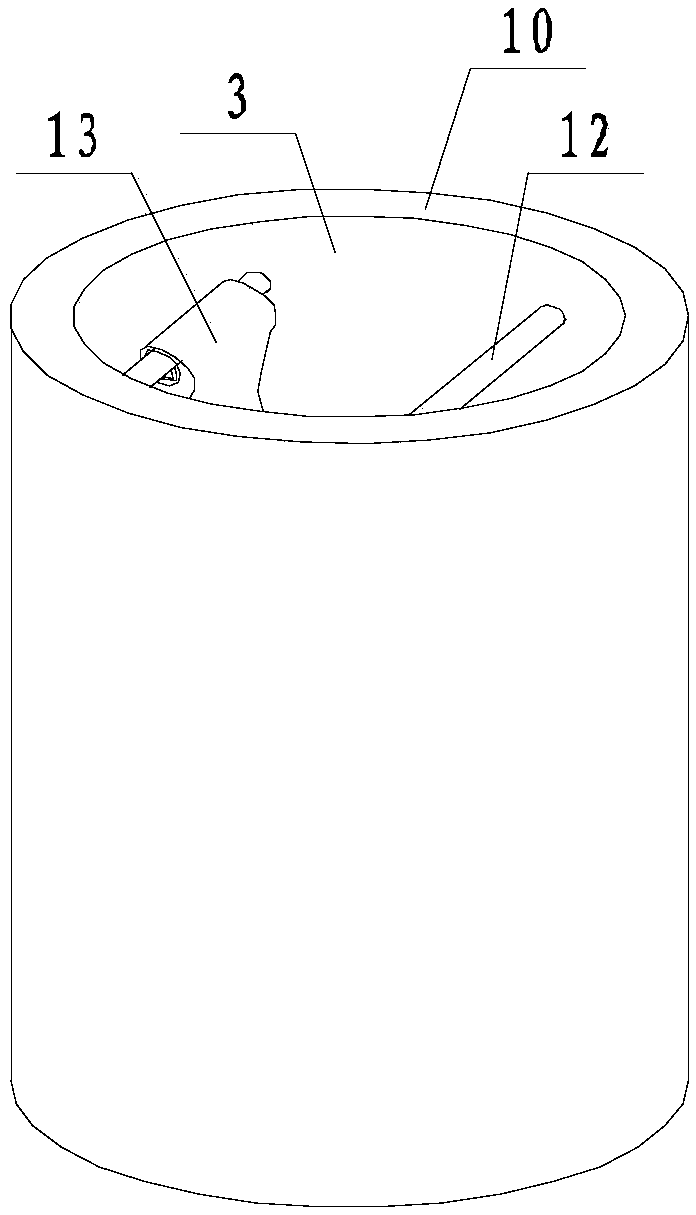

High-pressure composite container

ActiveCN110185918AHigh strengthImprove pressure bearing capacityVessel mounting detailsVessel manufacturingHigh pressureBottle

The invention discloses a high-pressure composite container. The high-pressure composite container comprises a barrel body, a first sealing head, a first metal end head, a composite reinforcing layerand a bottle opening valve, a bottle opening is formed in the barrel body, the first sealing head is fixedly arranged at the end portion of the barrel body, the first sealing head is provided with a first through hole communicating with the bottle opening, the first metal end head is fixedly connected with the first sealing head, the first metal end head is provided with a second through hole communicating with the first through hole, the composite reinforcing layer is fixedly wound outside the first metal end head, the first sealing head and the barrel body, the bottle opening valve sequentially penetrates through the second through hole and the first through hole and then is in sealing fit with the bottle opening. According to the provided high-pressure composite container, by adopting the form of combining the first sealing head, the first metal end head and the barrel body, the strength and the pressure-bearing capability of the end portion of the high-pressure composite containerare improved, meanwhile, through of cooperation among the first sealing head, the first metal end head and the bottle opening, the sealing stability is improved.

Owner:YAPP AUTOMOTIVE PARTS

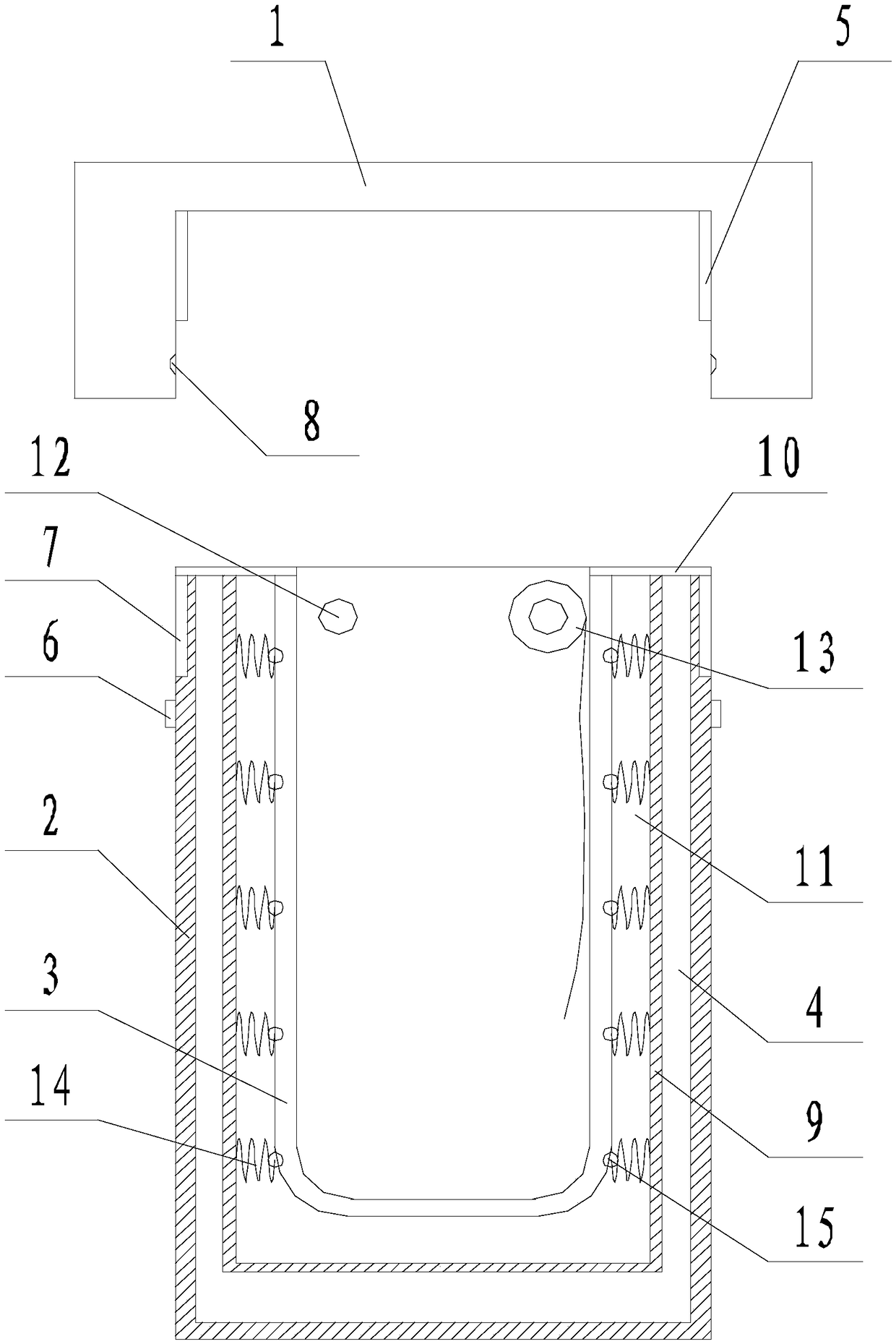

Low-cost damping potassium nitrate transfer container

The invention discloses a low-cost damping potassium nitrate transfer container. The low-cost damping potassium nitrate transfer container comprises a container body and a cover; an outer shell, an isolation layer and a liner are distributed on the container body in sequence from outside to inside; the outer shell, the isolation layer and a mounting plate surround a first isolation cavity; the liner, the isolation layer and the mounting plate surround a second isolation cavity; the first isolation cavity is filled with ceramic particles; the second isolation cavity is filled with silicon dioxide; two parallel shaft rods are fixed in the liner, and are symmetrically distributed along the axis of the liner; a coiled diaphragm sleeves one shaft rod; an internal thread is arranged at the top edge of the outer shell; a rubber sealing ring is arranged under the internal thread; an external thread is arranged on the inner side wall of the cover; a lap of groove is formed under the external thread; the section of the groove is arched; and when the outer shell is connected with the cover, the groove is aligned to the rubber sealing ring. The low-cost damping potassium nitrate transfer container achieves the purposes of reduction of the maintenance cost in moderate-distance transportation of potassium nitrate, guarantee of the transportation safety and efficient damping.

Owner:什邡市治谋化工有限公司

Sealing device for head of gas filter element

ActiveCN104633114AImprove sealing and stabilityExtended service lifeEngine sealsDispersed particle filtrationProduct gasSurface layer

The invention relates to a sealing device for the head of a gas filter element. The sealing device is provided with a matching face capable of being in matched connection with the outer surface of the surface layer of the head of the gas filter element and a sealing face capable of being in contact with a first sealing structure in a pore plate in a sealing mode. According to the sealing device for the head of the gas filter element, the head of the gas filter element and the pore plate can be kept in good sealing for a long time, the sealing stability between the gas filter element and the pore plate is obviously improved, the situation that the head of the gas filter element is broken due to transverse bending stress is avoided, the service life of the gas filter element is effectively prolonged, and the loss rate of the gas filter element is obviously lowered.

Owner:CHENGDU INTERMENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com