Container with observation window

An observation window and observation window technology are applied in the field of containers with observation windows, which can solve the problems of waste, water leakage, and easy deformation of containers, and achieve the effects of improving service life, improving mechanical strength, and improving sealing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

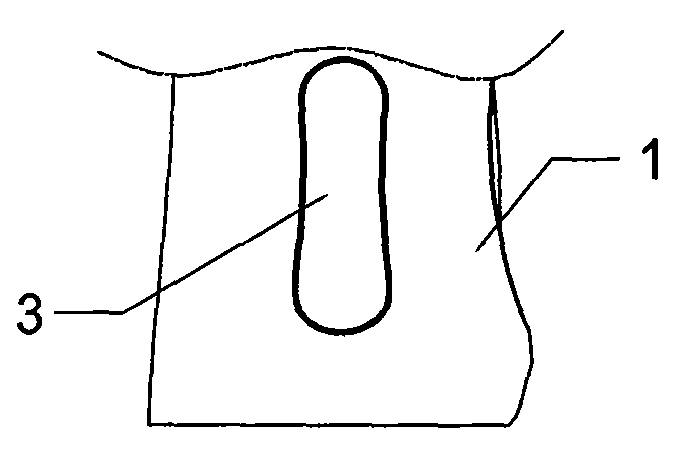

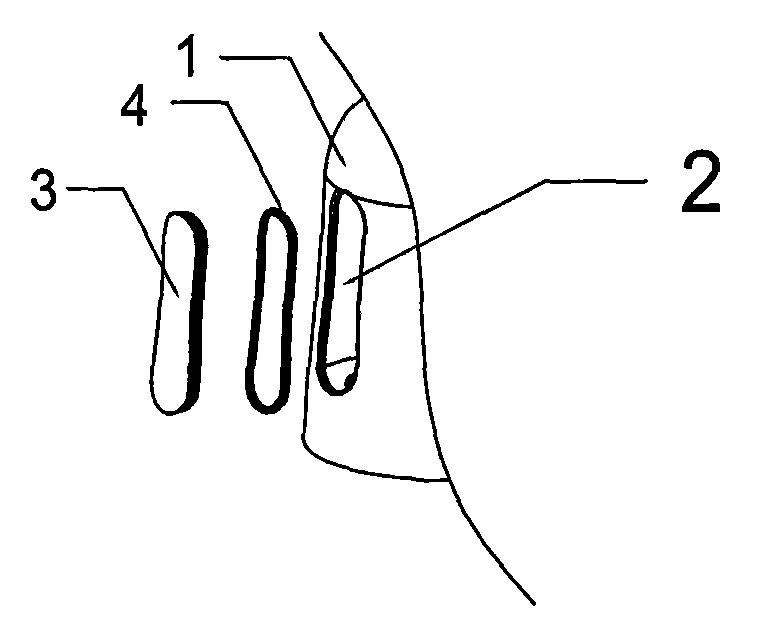

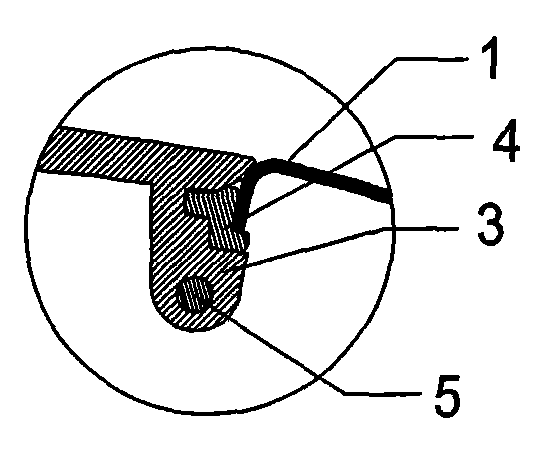

Embodiment 1

[0015] Example one: such as Figure 1-Figure 3 As shown, the container with an observation window according to the present invention includes a pot body 1, an observation window 2 is opened on the side wall of the pot body 1, a transparent ruler 3 is installed on the observation window 2, and one of the observation window 2 and the transparent ruler 3 There is a high temperature and aging resistant sealing ring 4, usually made of silicone rubber. In order to prevent the transparent scale 3 from deforming under the action of thermal expansion and contraction, which affects the sealing performance, when the transparent scale 3 is injected, the transparent scale 3 The shaped metal wire 5 is placed in the outer ring compound in advance.

Embodiment 2

[0016] Embodiment two: such as Figure 4 , Figure 5 As shown, the main structure is the same as the first embodiment. The difference is that a slot 6 is opened on the outer ring side of the transparent scale 3, and the shaped metal wire 5 is fixed in the slot 6 of the transparent scale 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com