Six-bar mechanism of dumper lifting device

The technology of a six-bar mechanism and a lifting device is applied in the field of the lifting device of a dump truck and the link mechanism of the lifting device of the dump truck, which can solve the problems of complex control system and high product cost, simplify the hydraulic control system and improve the stability. performance and sealing, and the effect of improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the technical solution of the present invention, further detailed description will be given below in conjunction with the accompanying drawings and embodiments.

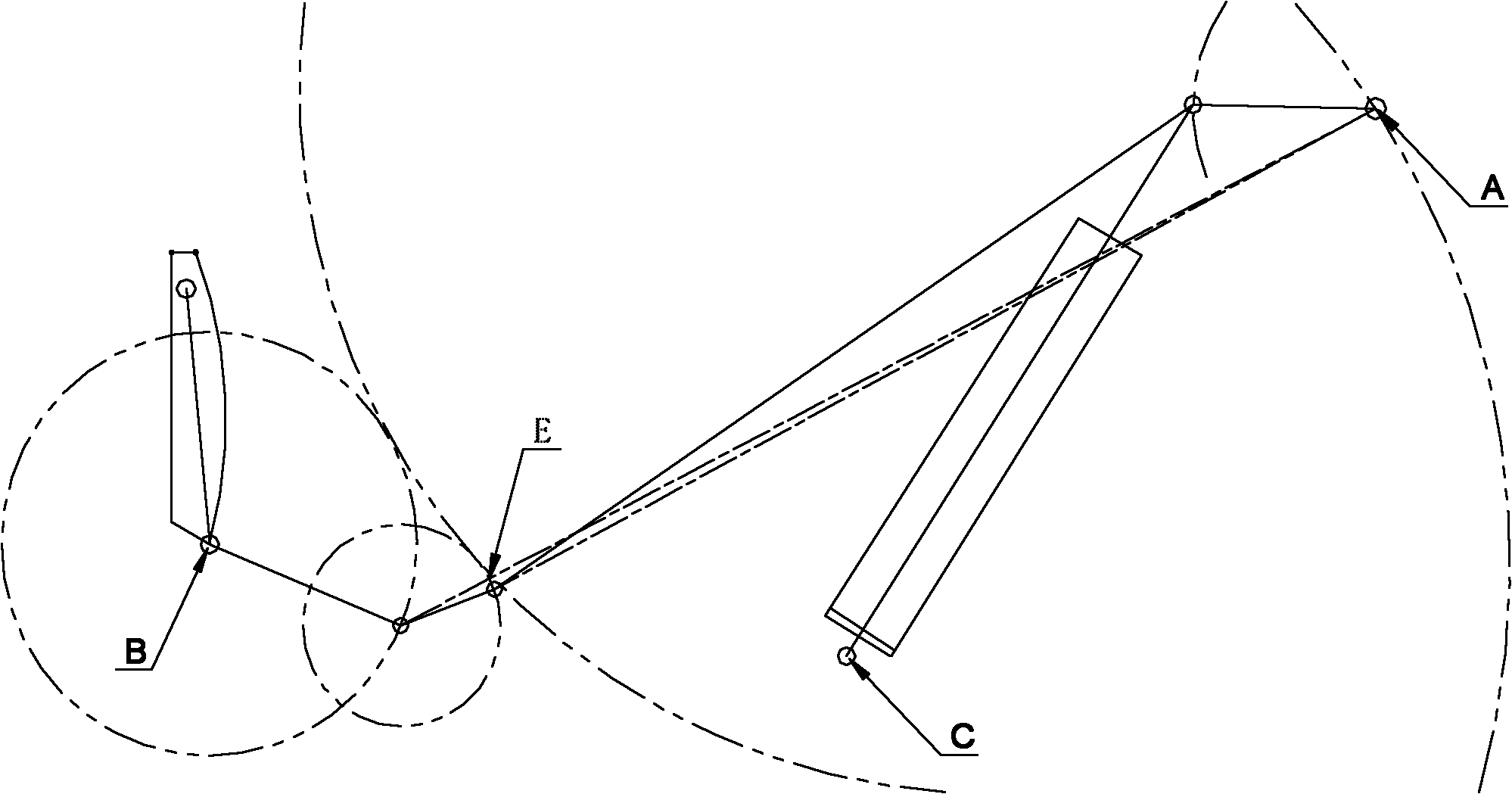

[0018] The six-bar mechanism of the dump truck lifting device of the present invention is mainly to upgrade the traditional structure, only one set of hydraulic oil cylinders is reserved, and the functions of door opening, lifting and locking are simultaneously completed through the mechanical six-bar mechanism.

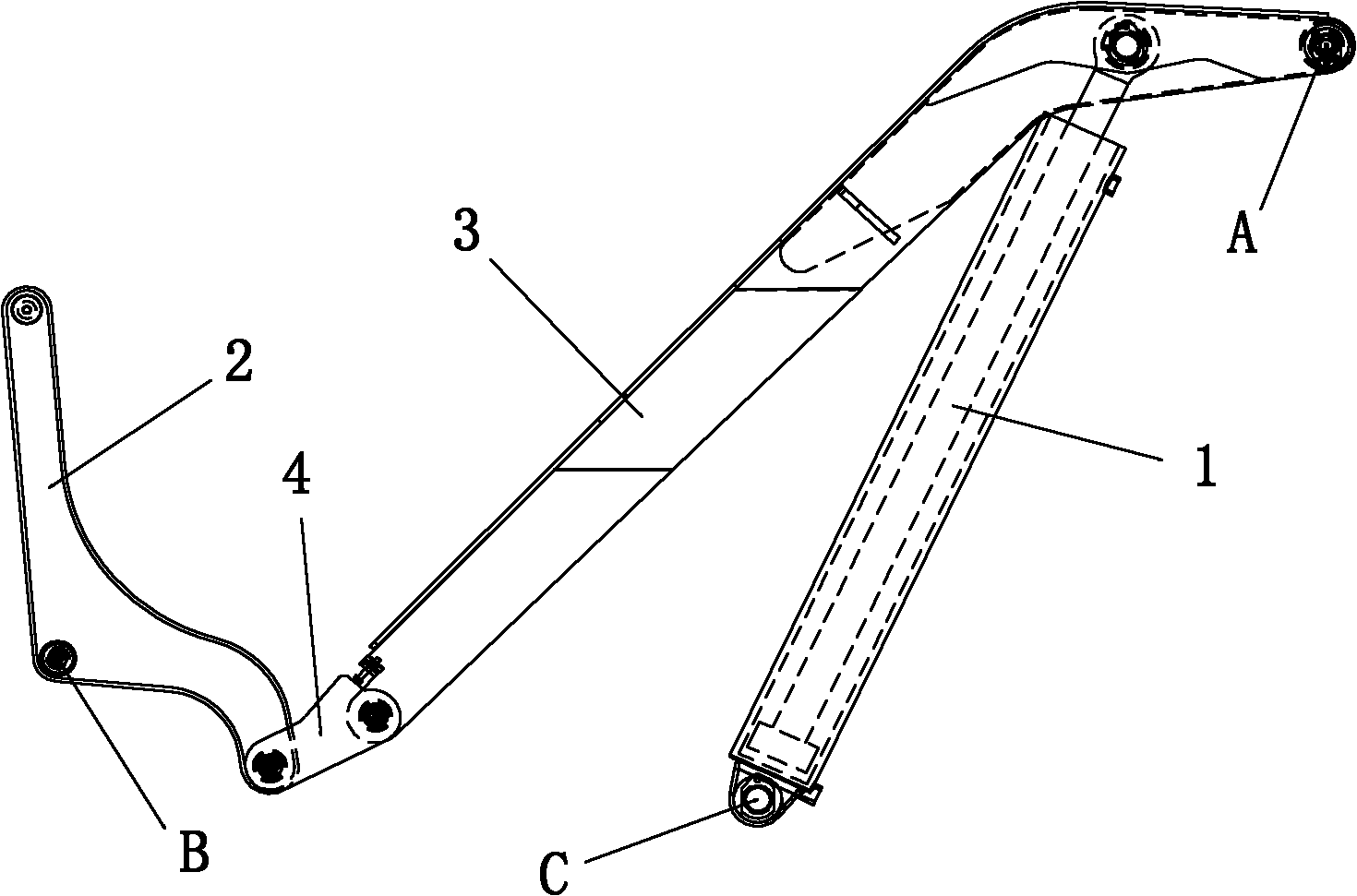

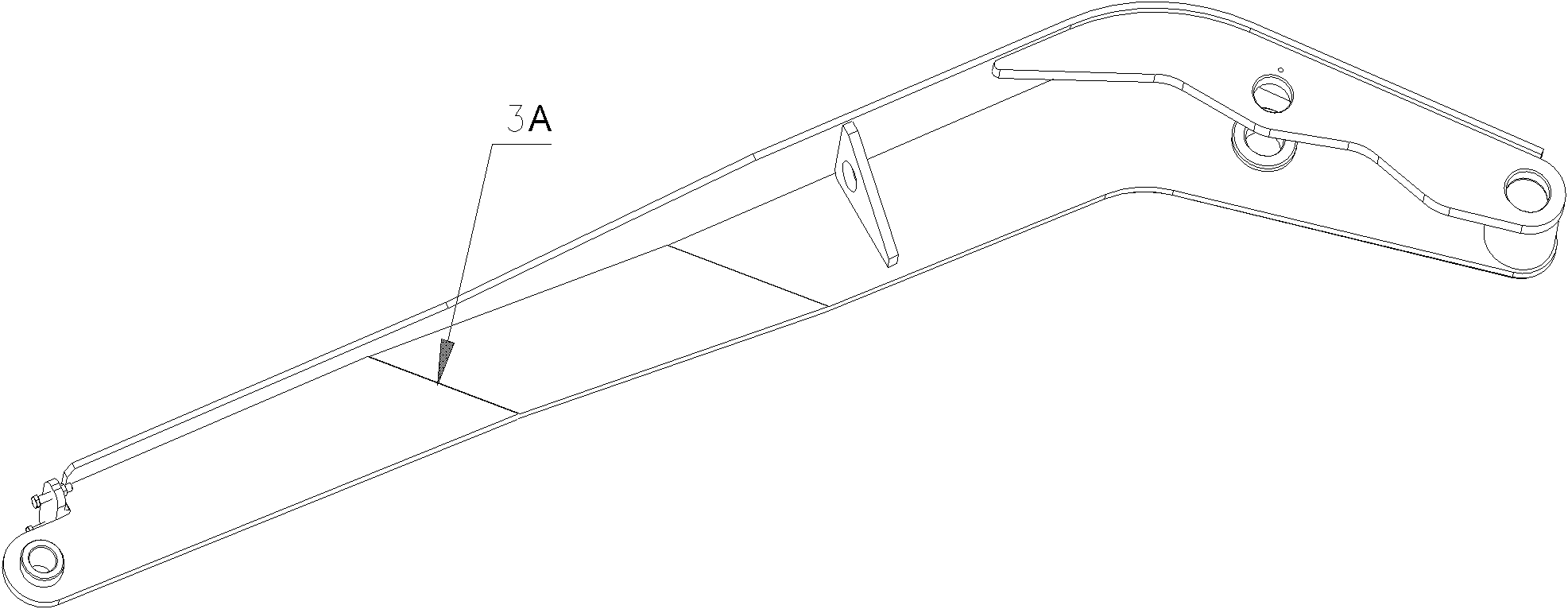

[0019] The six-bar mechanism of the dump truck lifting device of the present invention is used for such as Figure 6 The embodiment of the shown mine wide-body rollover dump truck has the main functions of opening the box side door and lifting the box. The hinge relationship of the oil cylinder, lifting arm, door opening arm and locking lever in the embodiment is as follows: figure 1 As shown, the shape of the door opening arm 2 is app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com