Sealing device for head of gas filter element

A technology of sealing device and filter element, applied in the field of sealing device, can solve the problems of gas pollution in clean air chamber, failure of gas filter element 2, difference in sealing performance, etc., and achieve the effects of improving sealing stability, reducing loss rate and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

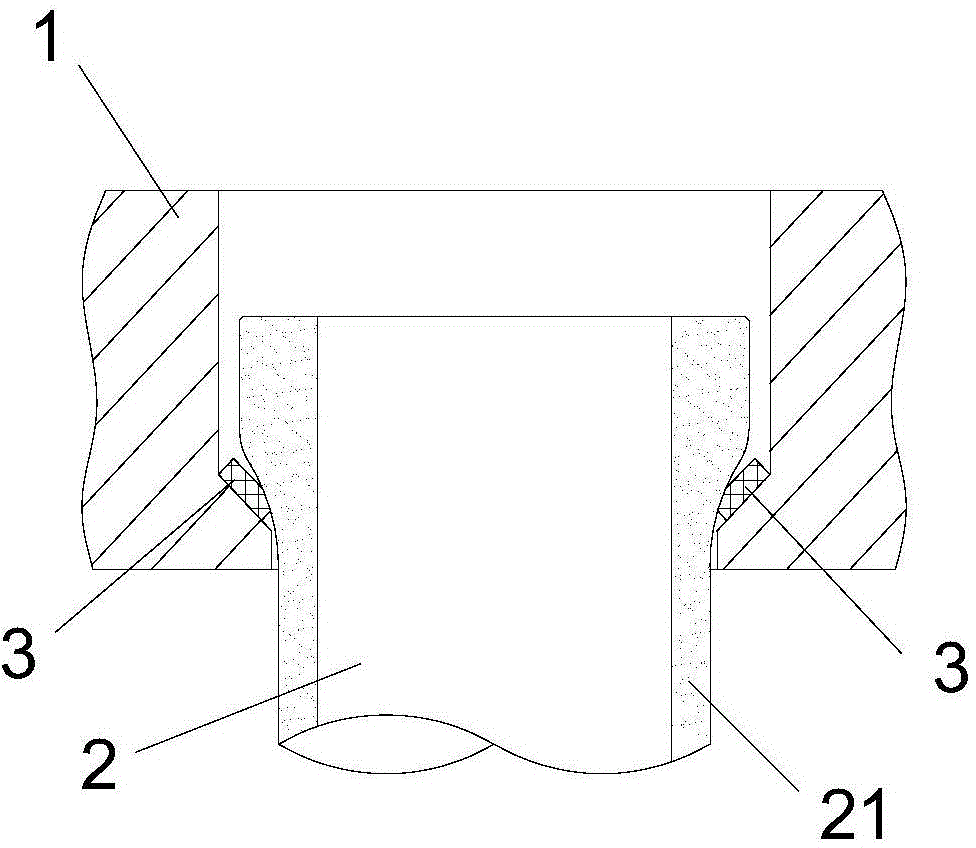

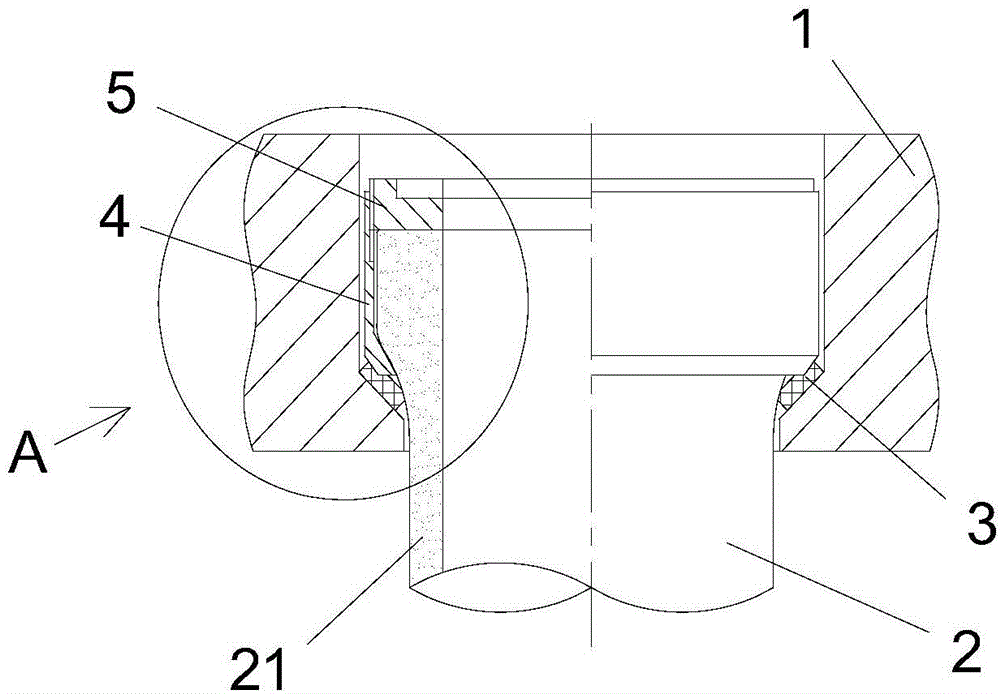

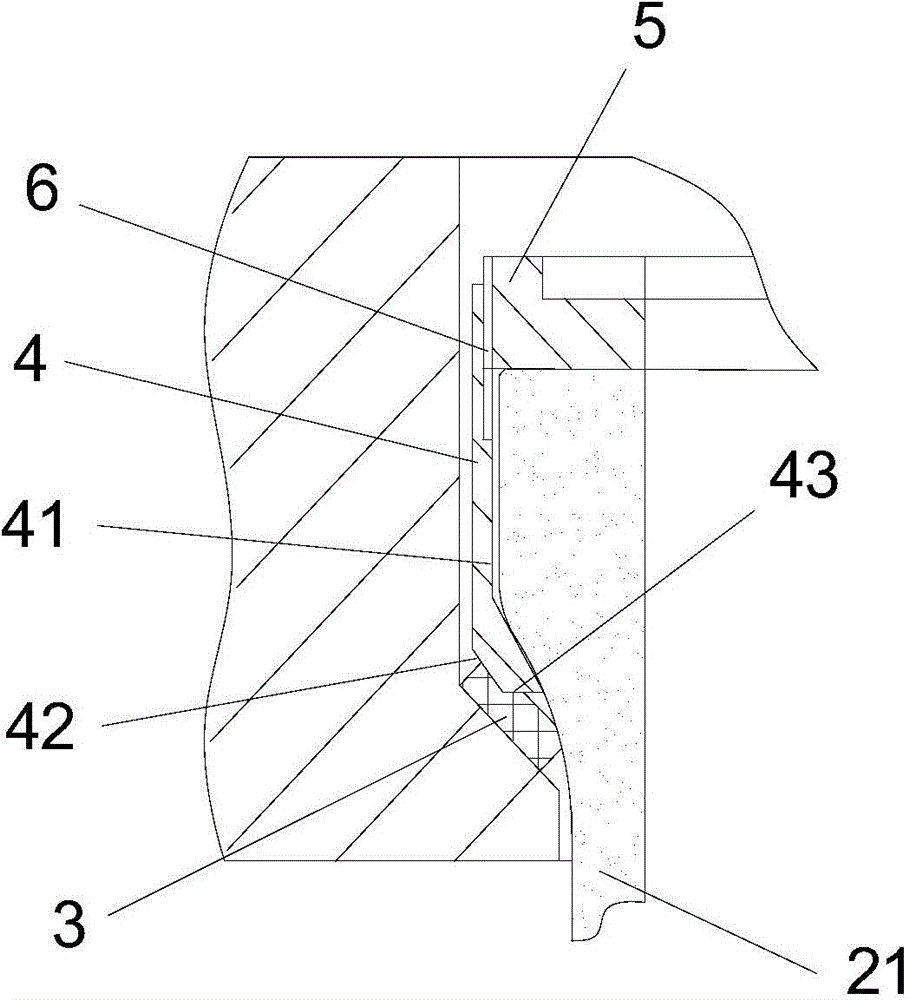

[0017] Such as figure 2 and image 3 The sealing device 4 for the head of the gas filter shown in the present invention is a metal integral structure. The sealing device 4 has a mating surface 41 that can be mated with the outer surface of the head surface layer 21 of the gas filter element 2 , and the sealing device 4 is fastened to the head of the gas filter element 2 through a threaded fastener 5 . The sealing device 4 is also provided with a smooth arc-shaped sealing surface 42 that can contact and seal with the first sealing structure 3 in the orifice plate 1, through the spherical hinge formed between the smooth arc-shaped sealing surface 42 and the first sealing structure 3 structure to seal the original gas, and the spherical hinge structure also makes the gas filter element 2 have a certain swing space, which can eliminate the lateral bending stress of the gas filter element 2, and will not cause the gas filter element 2 to be rigidly broken. Integrity of filter el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com