Water cooling connection device for friction stir welding of high melting point materials

A friction stir welding and connecting device technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of welding equipment not working normally, high transmission shaft and bearing temperature, transmission temperature rise, etc., to avoid damage , high-efficiency connection, and the effect of reducing material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

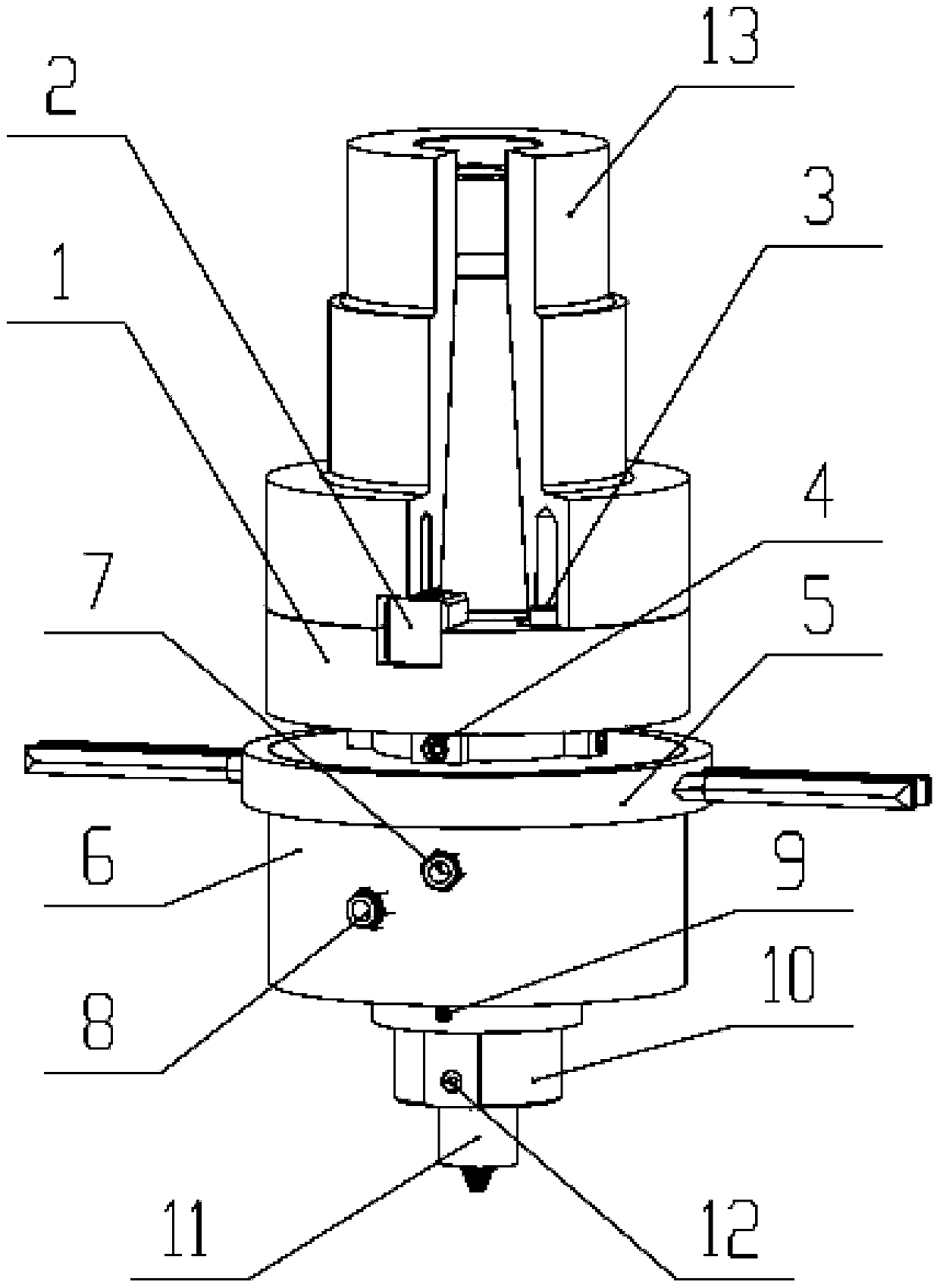

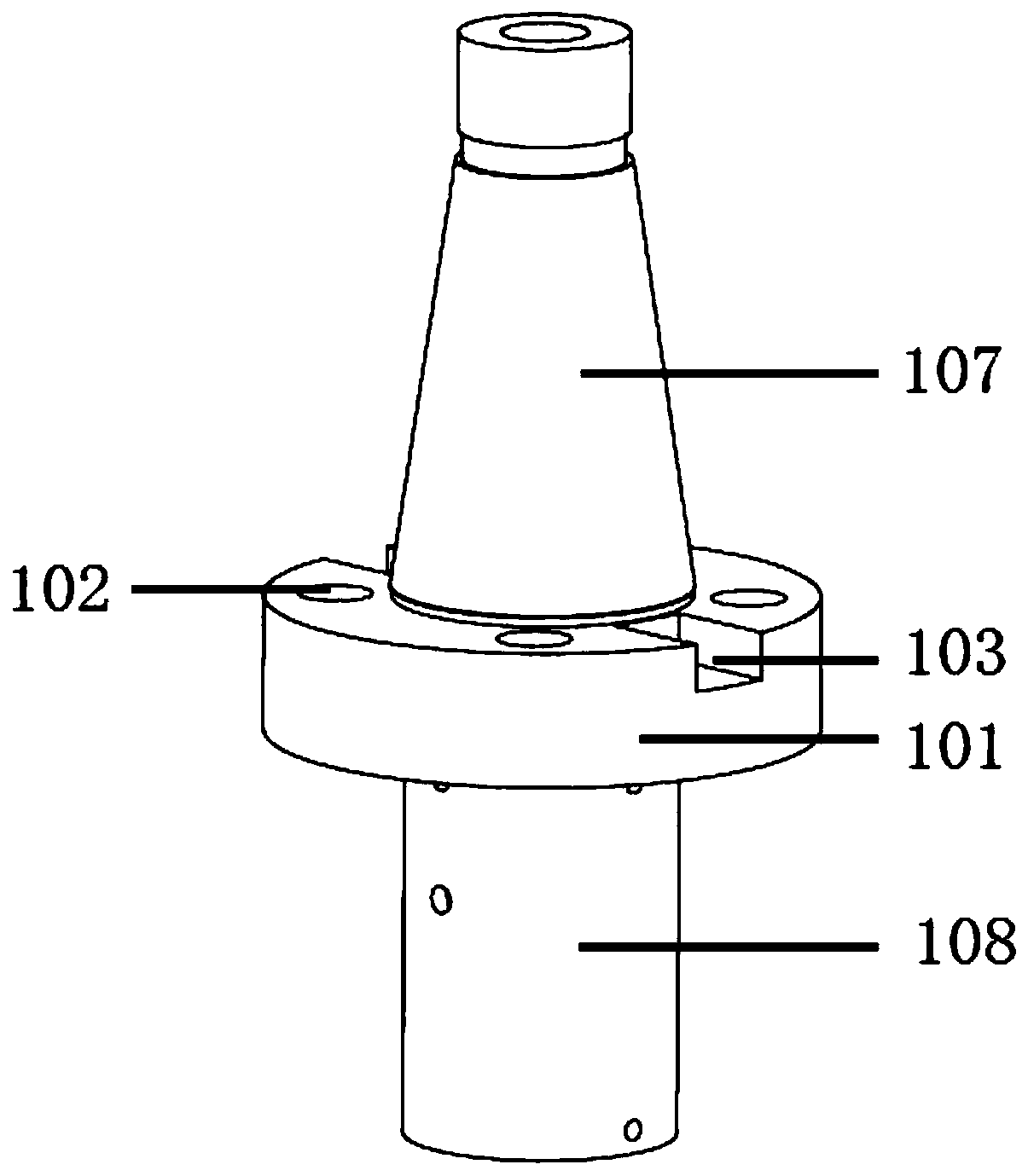

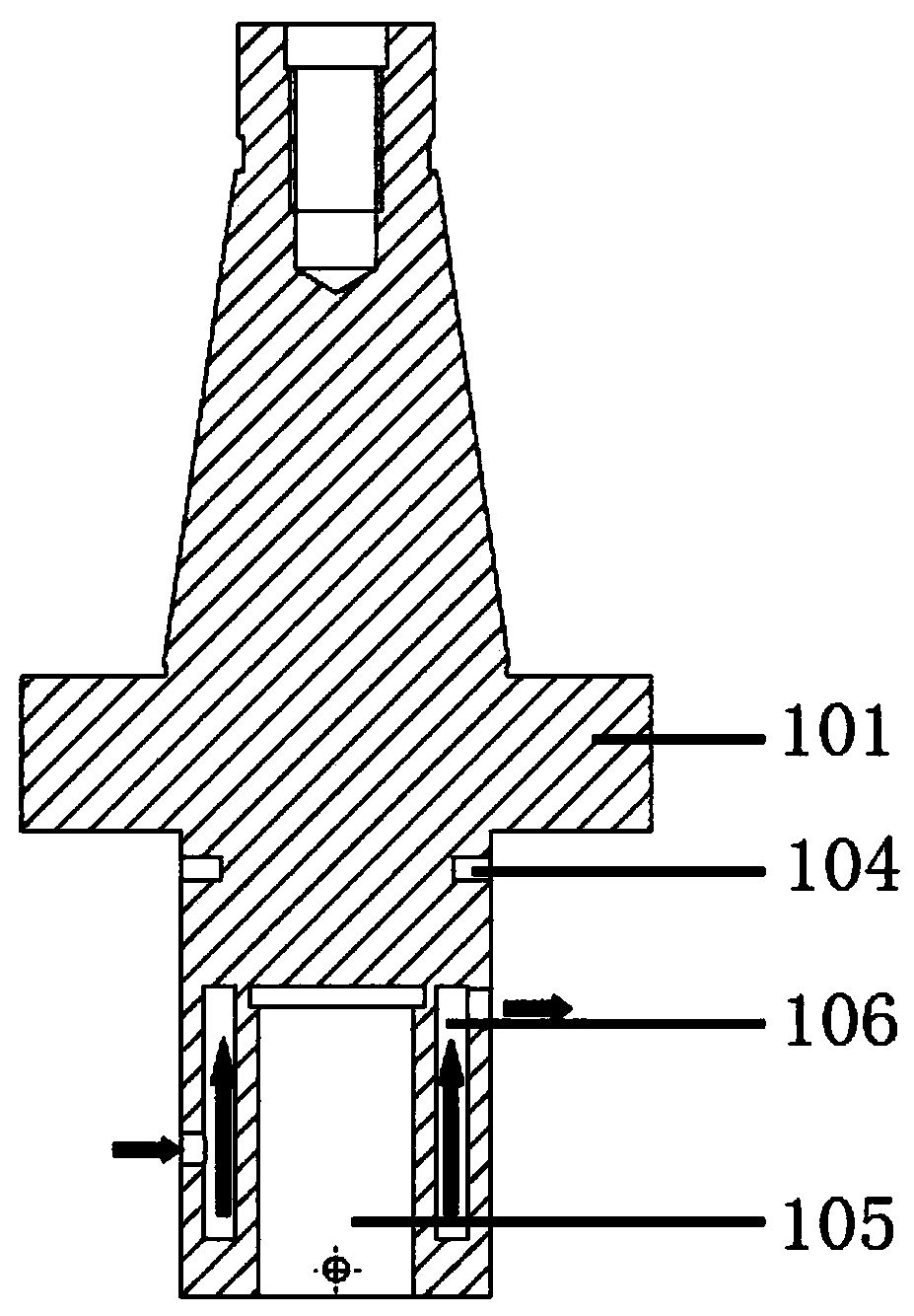

[0023] Such as Figure 1 to Figure 5 As shown, a water-cooled connection device for friction stir welding of high melting point materials, including a main shaft 13, a cooling handle 1 and a stirring head 11; Shoulder 101, the outer wall of the cooling handle 1 on the top of the shaft shoulder 101 is processed with a conical surface 107 matched with the taper hole of the main shaft 13, and the center of the cooling handle 1 at the bottom is processed with a mounting hole 105 for installing the stirring head 11, so that The stirring head 11 is installed on the lower part of the cooling handle 1, and the cooling handle 1 is installed on the lower part of the main shaft 13. The bottom of the cooling handle 1 is fixed with a stirring head transition sleeve 10 through the fastening screw I9, so that the cooling handle 1 and the stirring head transition sleeve 10 are closely attached, and the stirring head transition sleeve 10 is connected with the stirring head through the fastenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com