Pipe bending device of pipe bending machine applied for molding heat transferring tube of nuclear power evaporator

A nuclear power evaporator and pipe bending device technology, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the difficulty of ensuring parallelism and perpendicularity, it is difficult to ensure parallelism and perpendicularity, and it is impossible to locate both ends and other issues to achieve the effect of verticality guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below through specific examples.

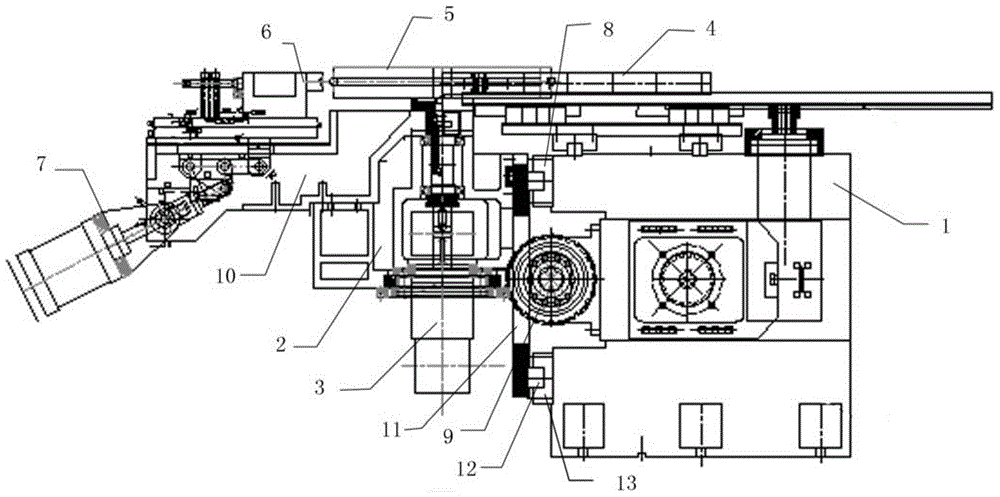

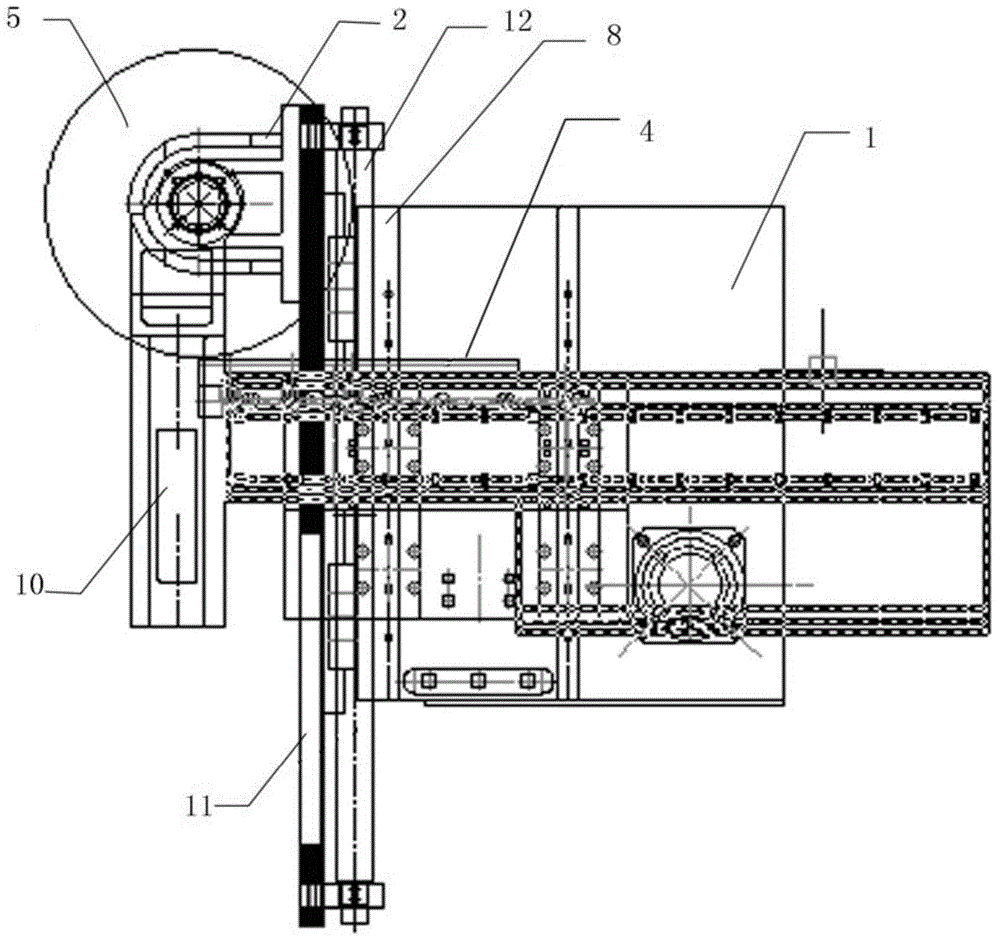

[0017] Such as figure 1 , 2 As shown, a pipe bending device of a pipe bending machine used for forming heat transfer tubes of nuclear power evaporators includes a machine head 1 and an auxiliary pushing device 4, and the auxiliary pushing device 4 is slidably installed on the On the machine head 1, the pipe bending device also includes a machine base 2 slidably installed on the machine head 1, the sliding direction of the machine base 2 is perpendicular to the axial direction of the steel pipe, and the machine base 2 is connected with the machine base driving device 9 ; the main shaft 3 installed on the machine base 2; the bending wheel mold 5 installed on the upper end of the main shaft 3; the pipe bending arm 10 installed on the machine base 2 is rotated, and the pipe bending arm 10 is driven by the arm driving device to rotate around the main shaft 3; The clamping device 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com