Linear compressor supported by three kinds of springs

A technology of linear compressors and coil springs, applied in mechanical equipment, machines/engines, liquid variable capacity machines, etc., can solve the problem of matching the use of cold heads that cannot be used in cryogenic refrigerators, reducing the operating efficiency of linear compressors, and large axial Rigidity and other issues to achieve the effect of reducing size, reducing weight and improving axial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

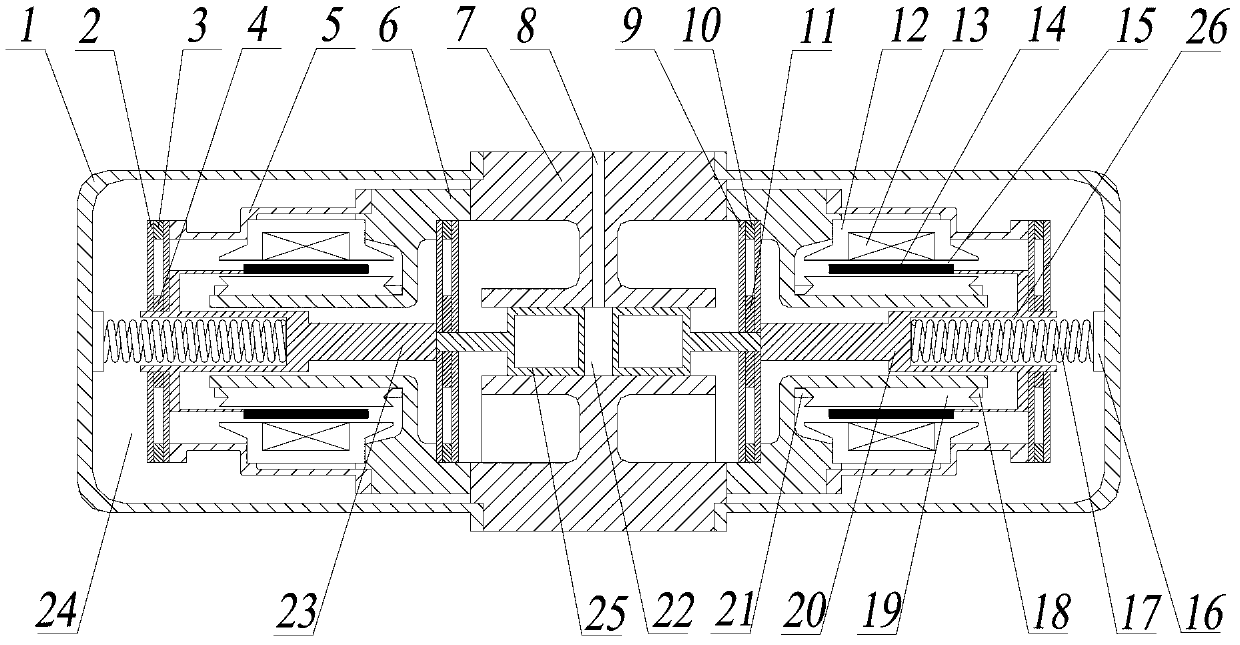

[0025] Such as figure 1 As shown, the linear compressor supported by three types of springs in the present invention mainly includes a bracket assembly, a cylinder-piston assembly, a linear motor assembly and a spring assembly. Wherein the bracket assembly includes a housing 1 and a bracket inside the housing 1 , and the bracket is composed of a main bracket 6 and a secondary bracket 5 . The shell 1 is used to seal the machine body, and the secondary bracket 5 and the main bracket 6 are used to fix the spring assembly, the cylinder piston assembly and the linear motor assembly.

[0026] The cylinder-piston assembly includes a cylinder 7, two pistons 25, and a piston shaft 23. The side wall of the cylinder 7 is provided with intake and exhaust holes 8 , and the two ends of the cylinder 7 are provided with annular mounting platforms for fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com