Adjustable middle support device for machining overlength shaft

An intermediate support and adjustment device technology, which is applied in the direction of metal processing equipment, tool clamps, manufacturing tools, etc., can solve the problems that the deflection cannot be fundamentally eliminated, the processing requirements cannot be satisfied, and the coaxiality does not meet the requirements, etc., and the adjustment can be achieved. The method is simple and light, eliminates the impact of shock, and has the effect of light structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

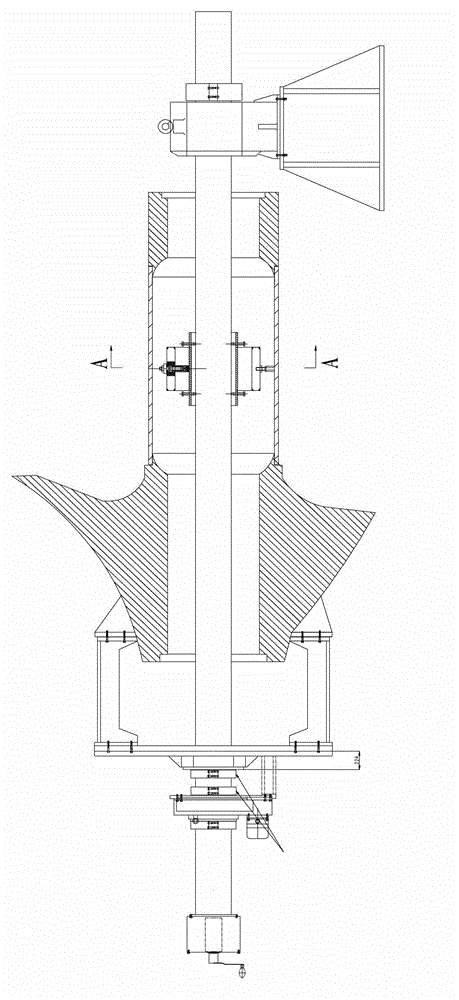

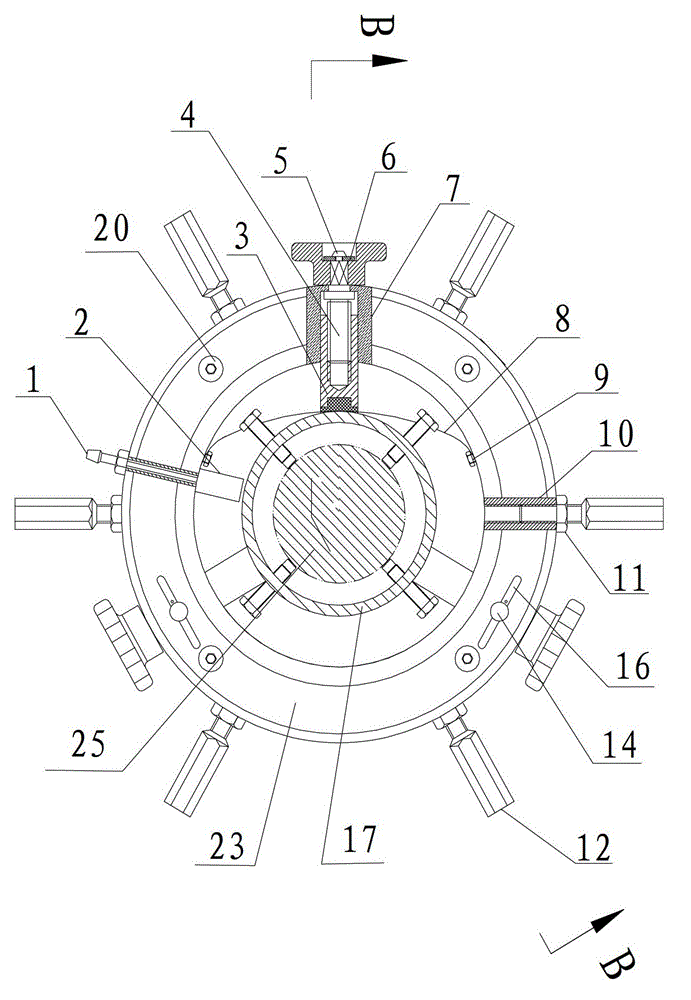

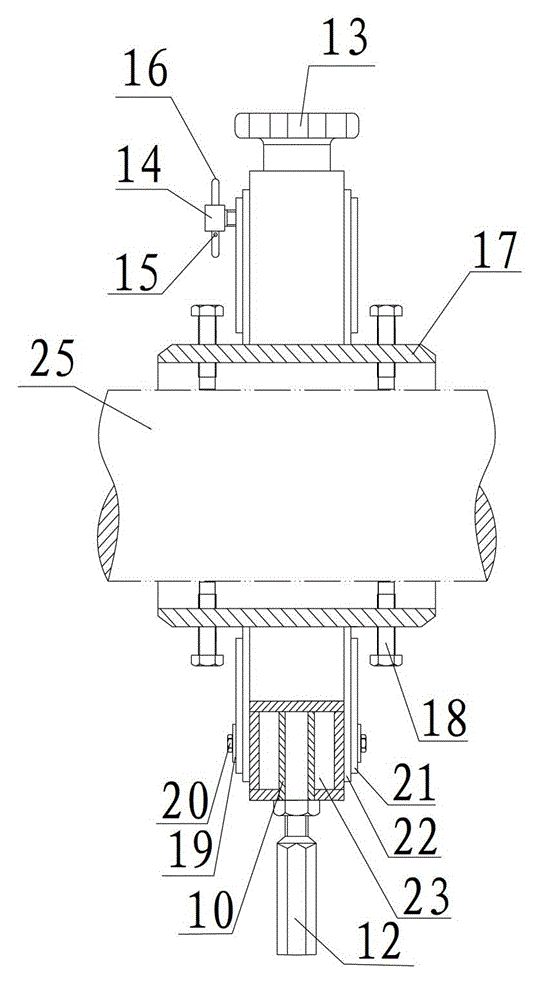

[0024] Attached below Figure 1-7 An embodiment of the present invention is described.

[0025] The adjustable intermediate support device for ultra-long axis processing has a transition sleeve 17 and a support frame 23. The transition sleeve 17 is radially provided with a transition sleeve adjustment device that can adjust the distance between the transition sleeve 17 and the boring bar 25. The support The frame 23 is a hollow circular sleeve and is set on the transition sleeve 17, and the two ends of the support frame 23 are sealed with the transition sleeve 17. The support frame 23 is radially symmetrically provided with a support for adjusting the distance between the support frame 23 and the transition sleeve 17. Frame adjustment device I and the support frame adjustment device II between the adjustable support frame 23 and the inner hole wall of the stern tube. The cavity of the support frame 23 is provided with a rubber hose 2, and one end of the rubber hose 2 is in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com