Modularized series joint of collaborative robot

A modular and robotic technology, applied in the direction of manipulators, manufacturing tools, joints, etc., to achieve the effect of compact structure, sensitive feedback, and reduced outer diameter and length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

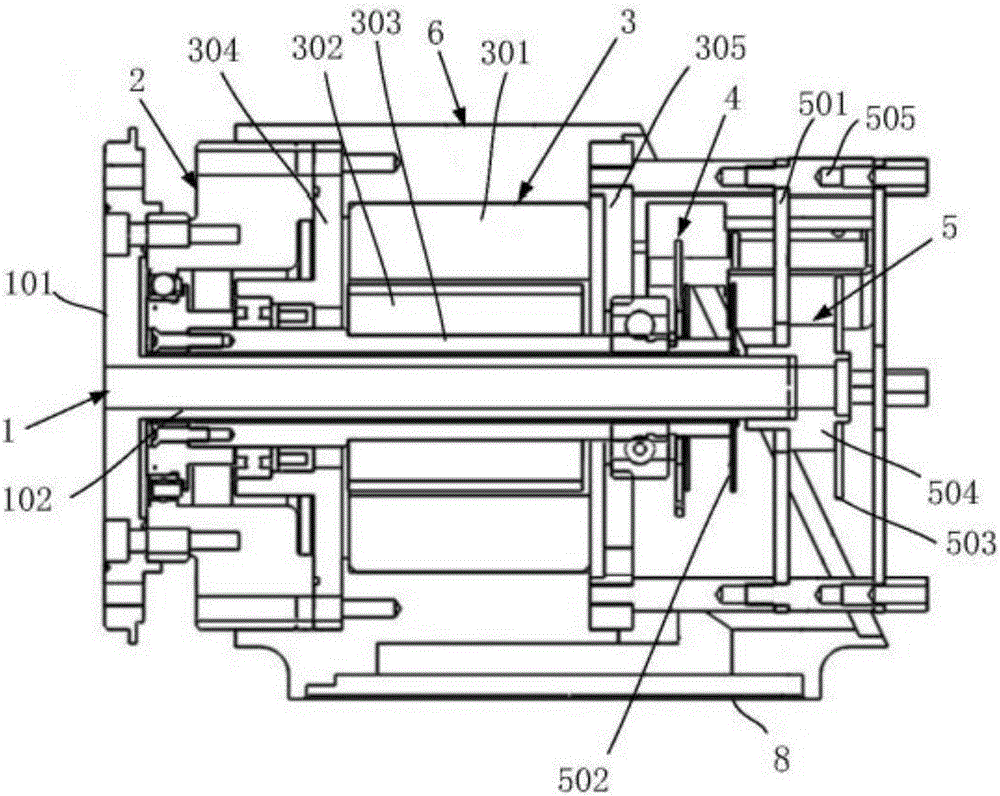

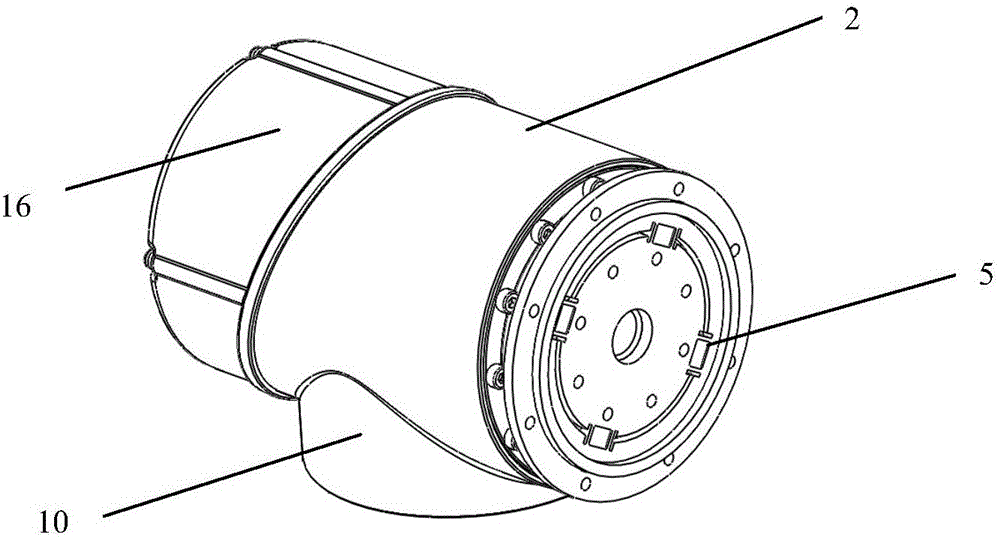

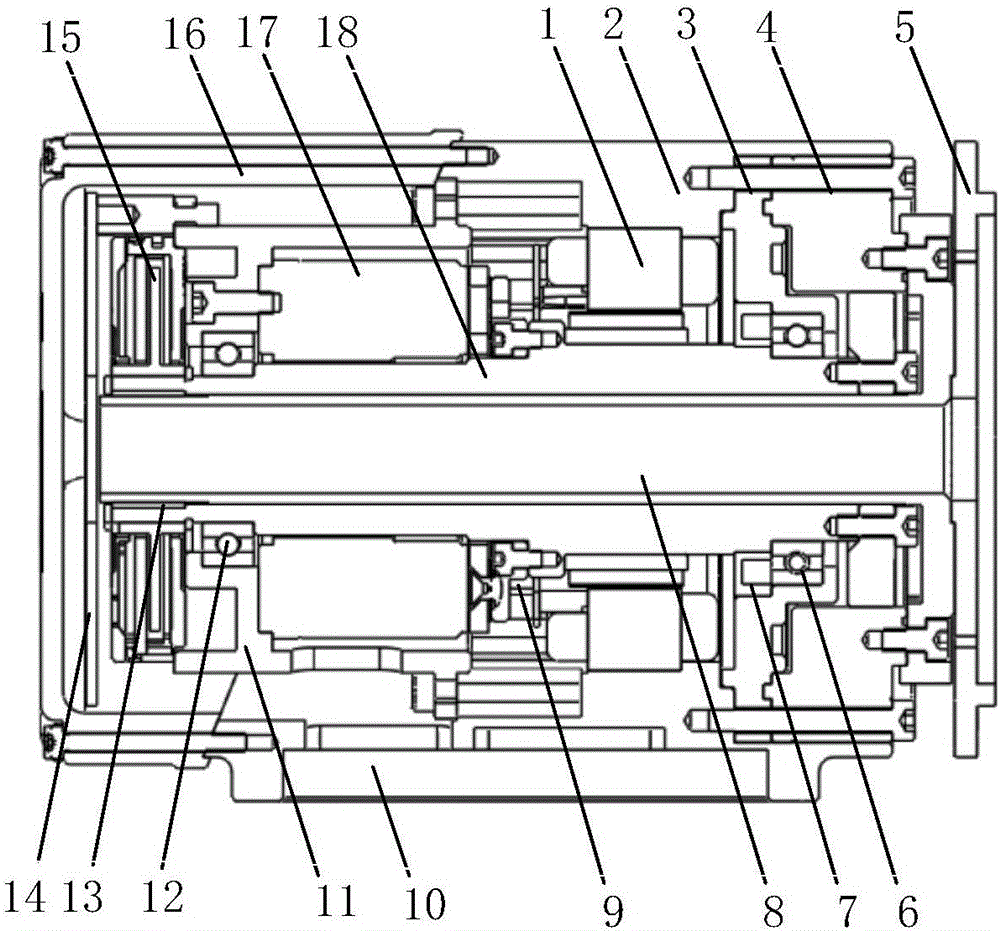

[0040] see Figure 2 to Figure 10 , a modular series joint of a collaborative robot described in a preferred embodiment of the present invention includes a joint housing 2 and a hollow motor 1 placed therein, a harmonic reducer 4, an input shaft 18, an output shaft 8, a torque Sensor 5 , brake 17 , absolute encoder 15 , driver 14 , and harmonic reducer 4 , hollow motor 1 , brake 17 , absolute encoder 15 and driver 14 are connected in series on input shaft 18 in sequence. Wherein the joint housing 2 is provided with a front flange 3 and a rear flange 11 supporting the input shaft 18, and the input shaft 18 is connected with the front flange 3 and the rear flange 11 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com