Hydraulic disk type brake

一种制动器、油压的技术,应用在制动器、制动器类型、轴向上制动器等方向,能够解决车辆旋摆、无法相对运动、车辆轮胎死锁等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

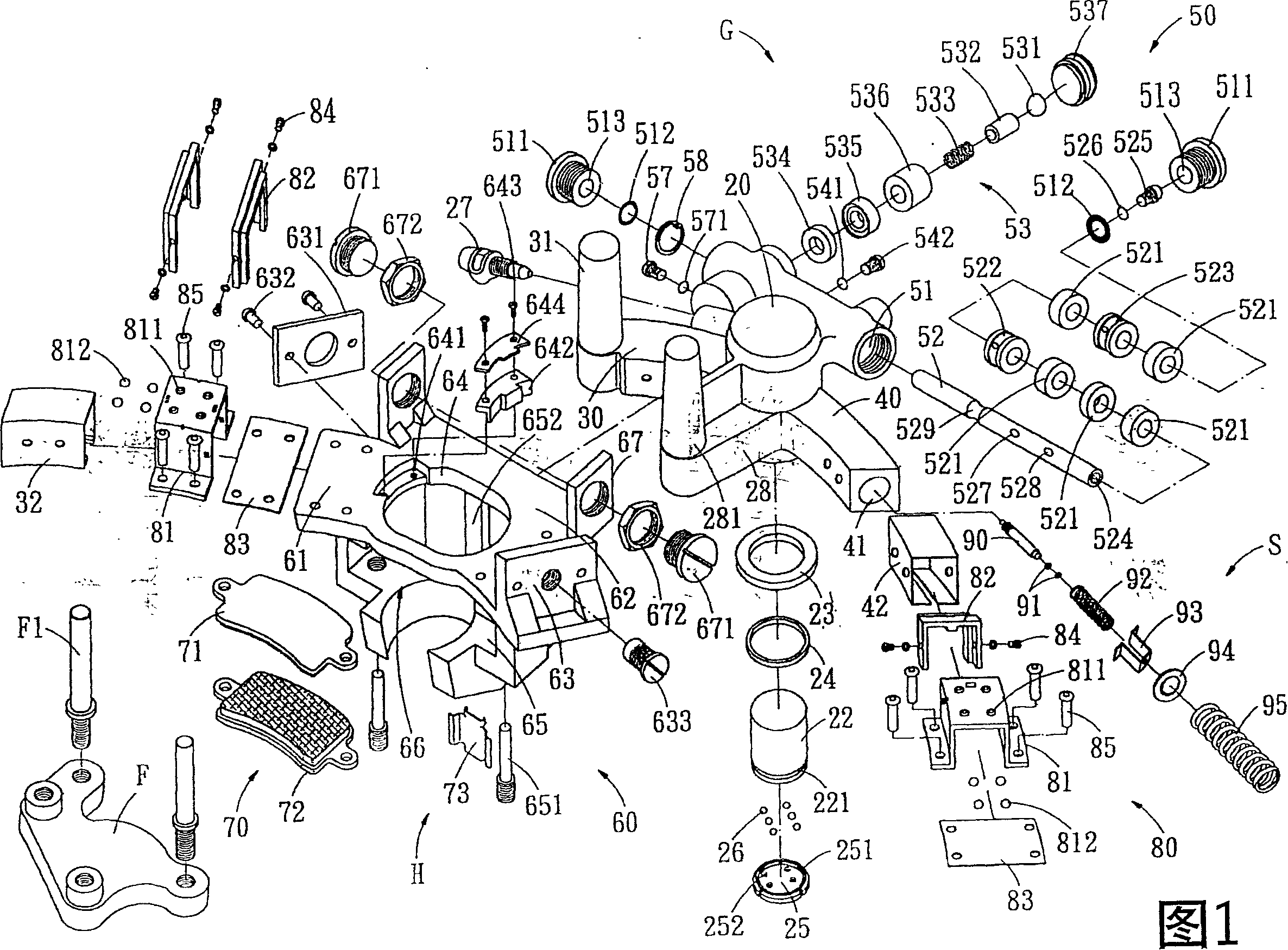

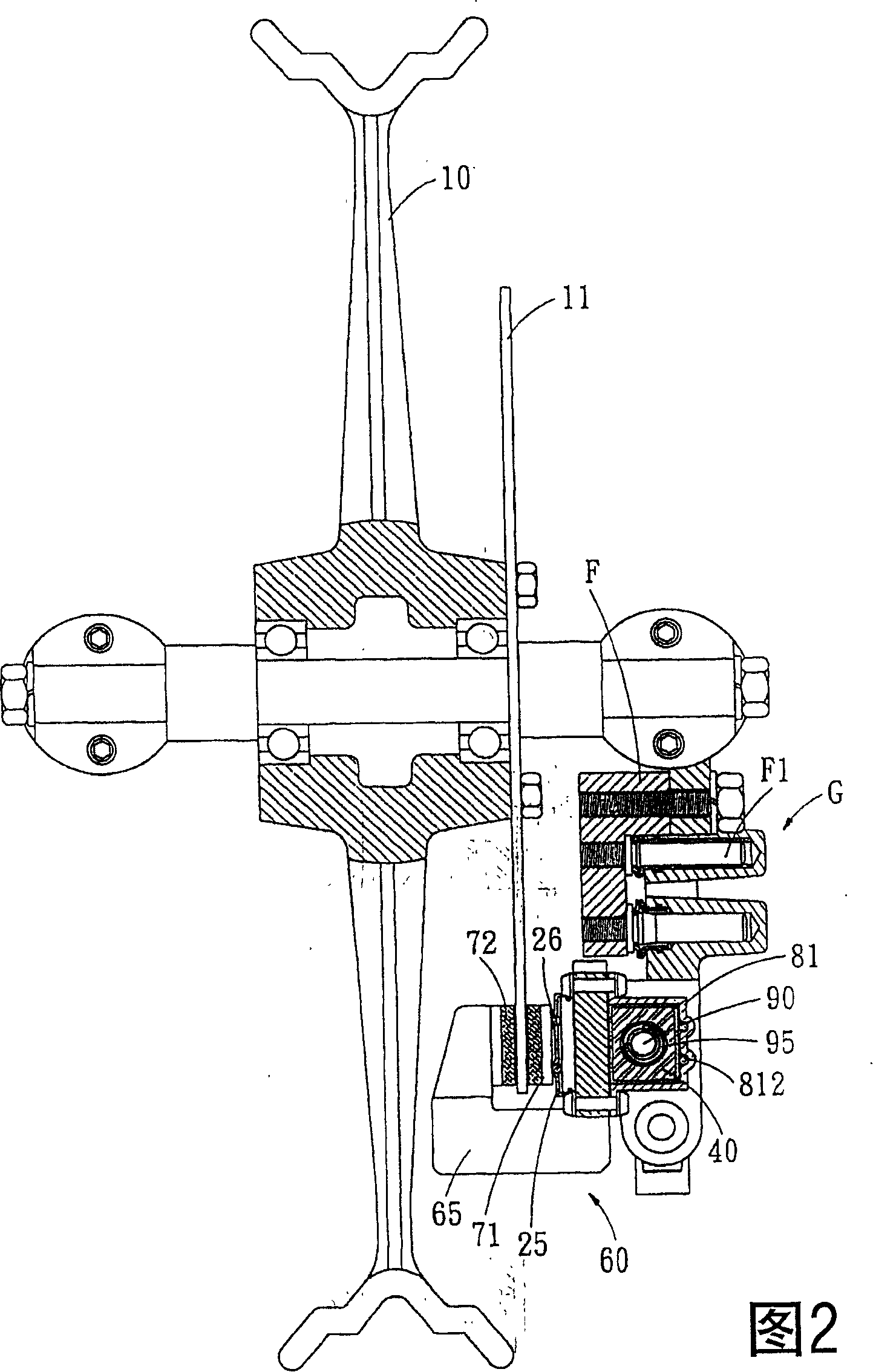

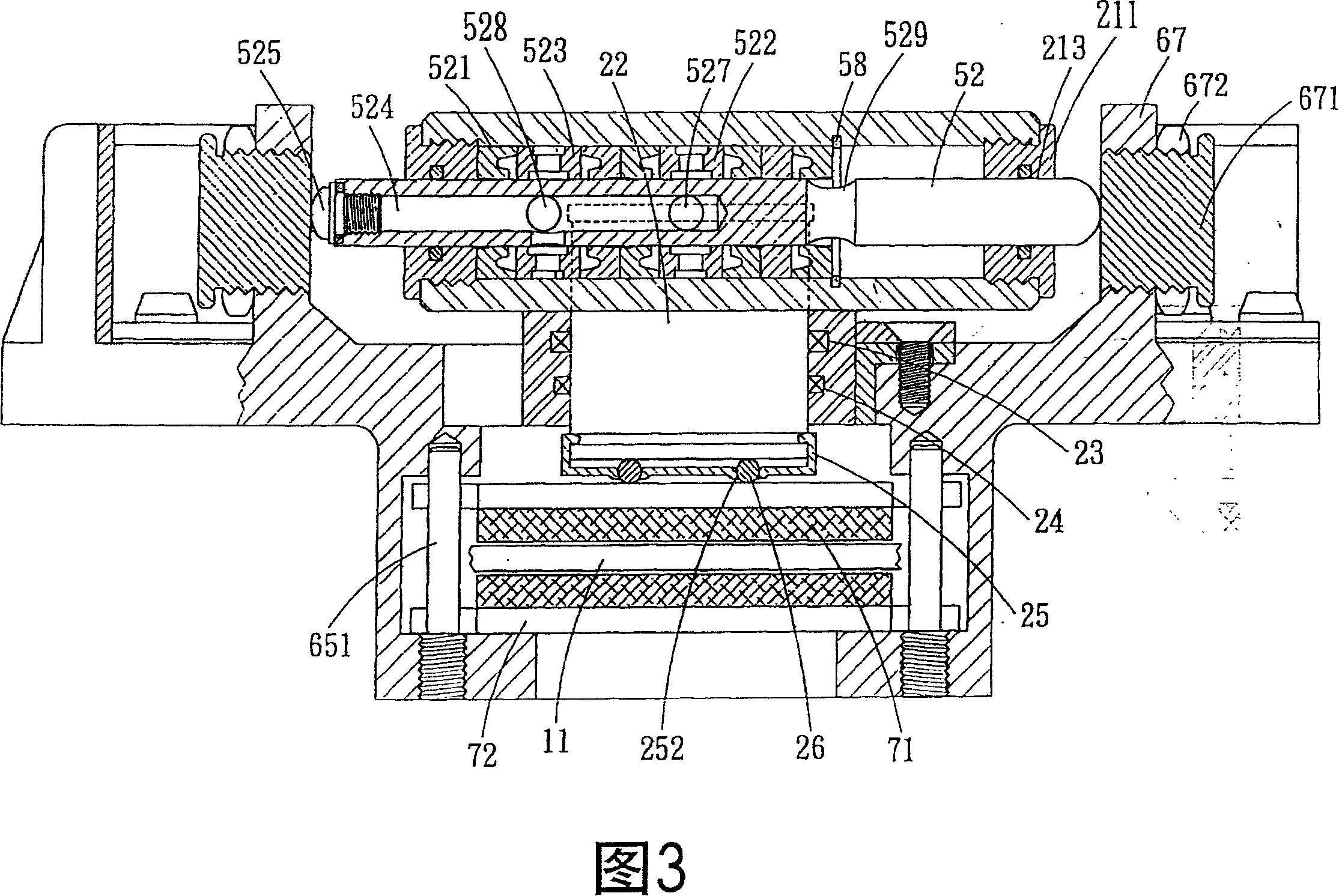

[0112] In order to achieve the above-mentioned purpose, adopted technology, means and other effects, hereby enumerate a preferred embodiment and describe it in detail with the accompanying drawings. It is believed that the purpose, characteristics and other advantages of the creation of this case have a deep and specific understanding; First please refer to Fig. 1, 2, 3, 4, 5, the present invention is assembled on a vehicle wheel frame 10, and corresponds to the brake disc 11 of the vehicle, which includes: a body G, a sliding seat H , a spring set S and a positioning plate F and other main components, and the hydraulic oil W flows through the oil pressure groove and the control valve group in the body G, wherein:

[0113] The positioning plate F is fixedly positioned on the vehicle wheel frame 10 with screw locks, and two protruding positioning studs F1 are mounted on the corresponding side of the positioning plate F with screws.

[0114] The body G is provided with a shell s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com