Main shaft remaining gap eliminating construction for direct driving rotary distance motor apparatus

A direct-drive, spindle technology, applied in electromechanical devices, control of mechanical energy, electrical components, etc., can solve the problems of increasing the wear and noise of each component, affecting product life, and unable to detach the heavy body for modular application, etc. Achieve the effect of improving product life, eliminating spindle clearance, simplifying assembly work and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

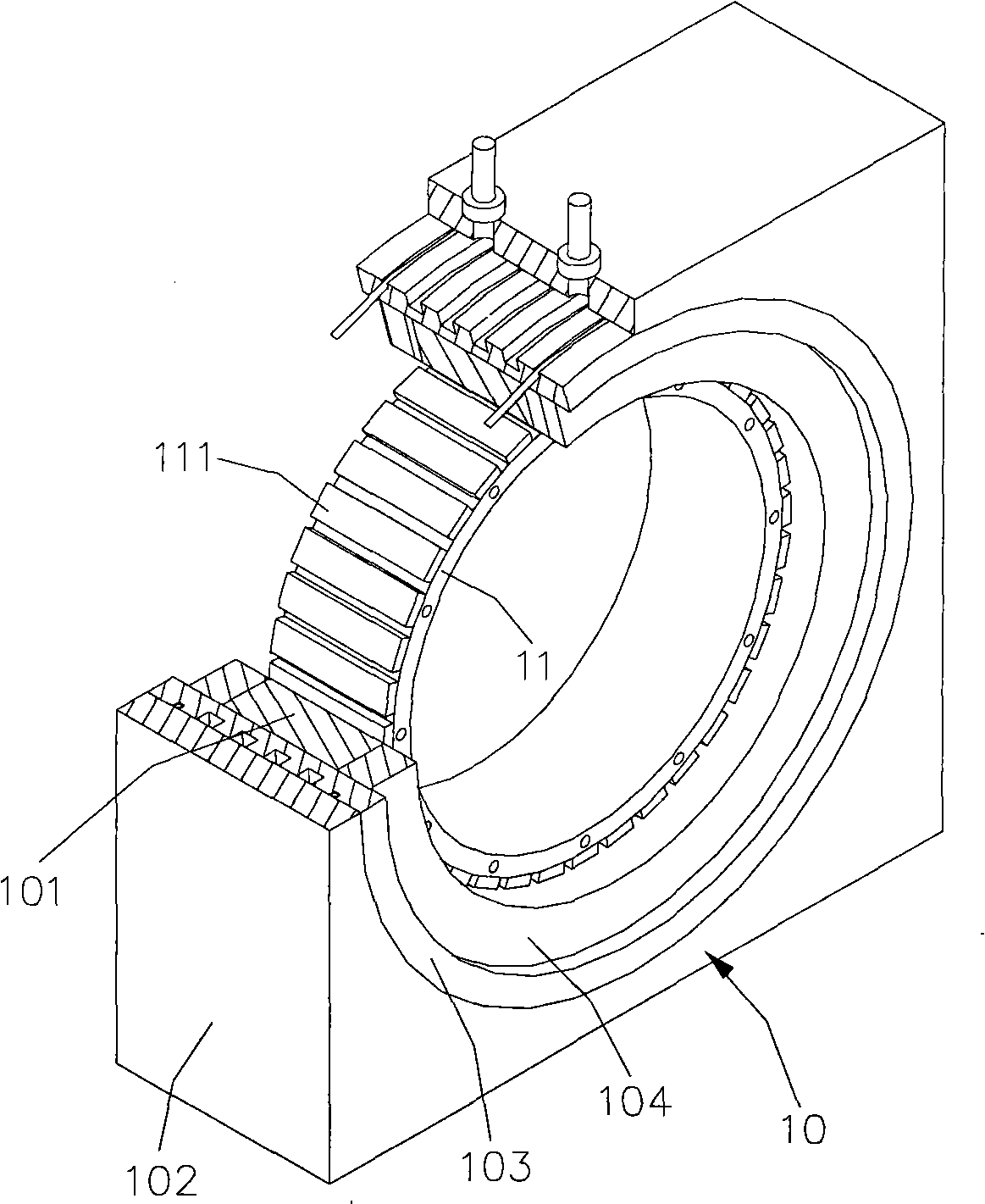

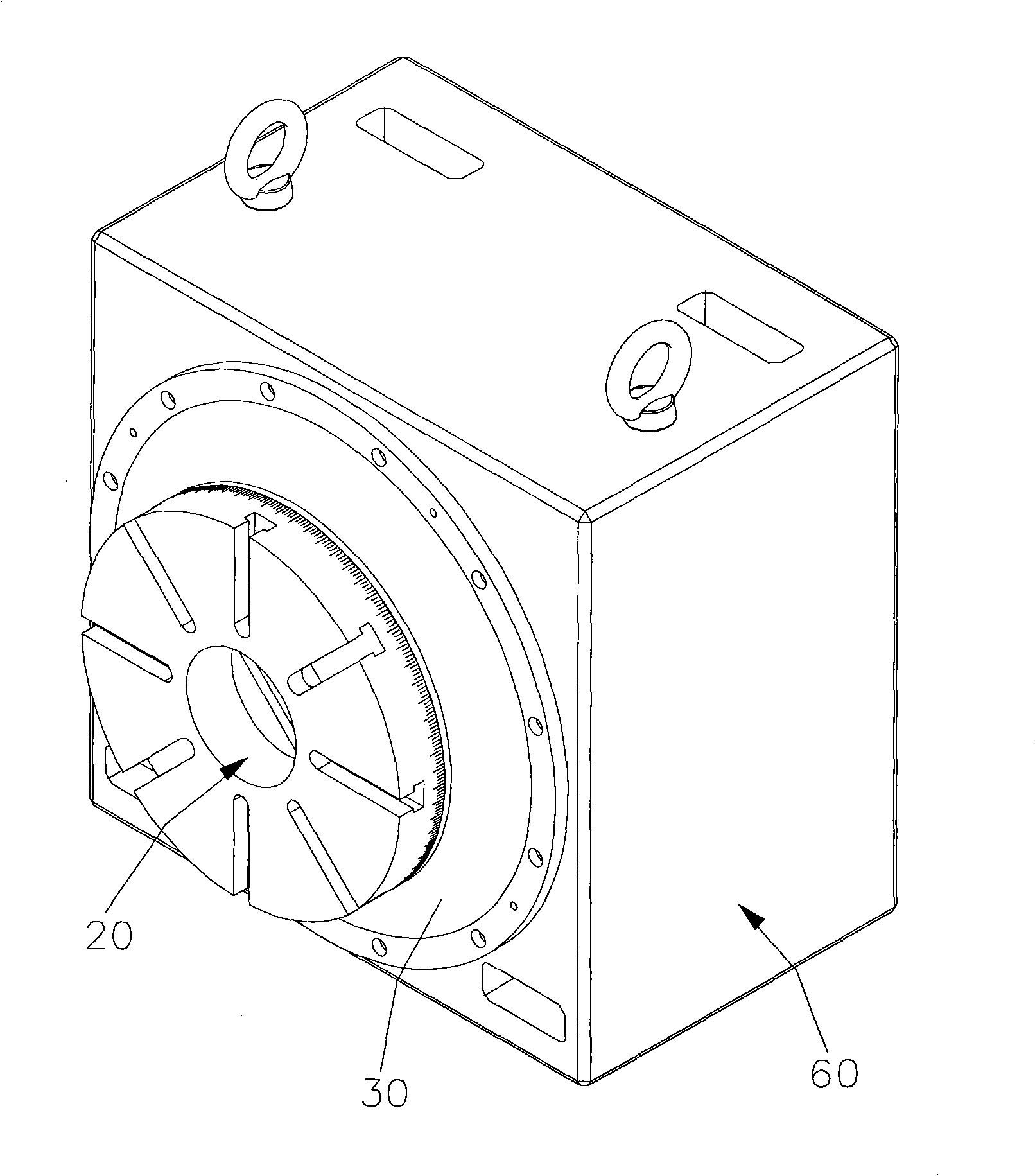

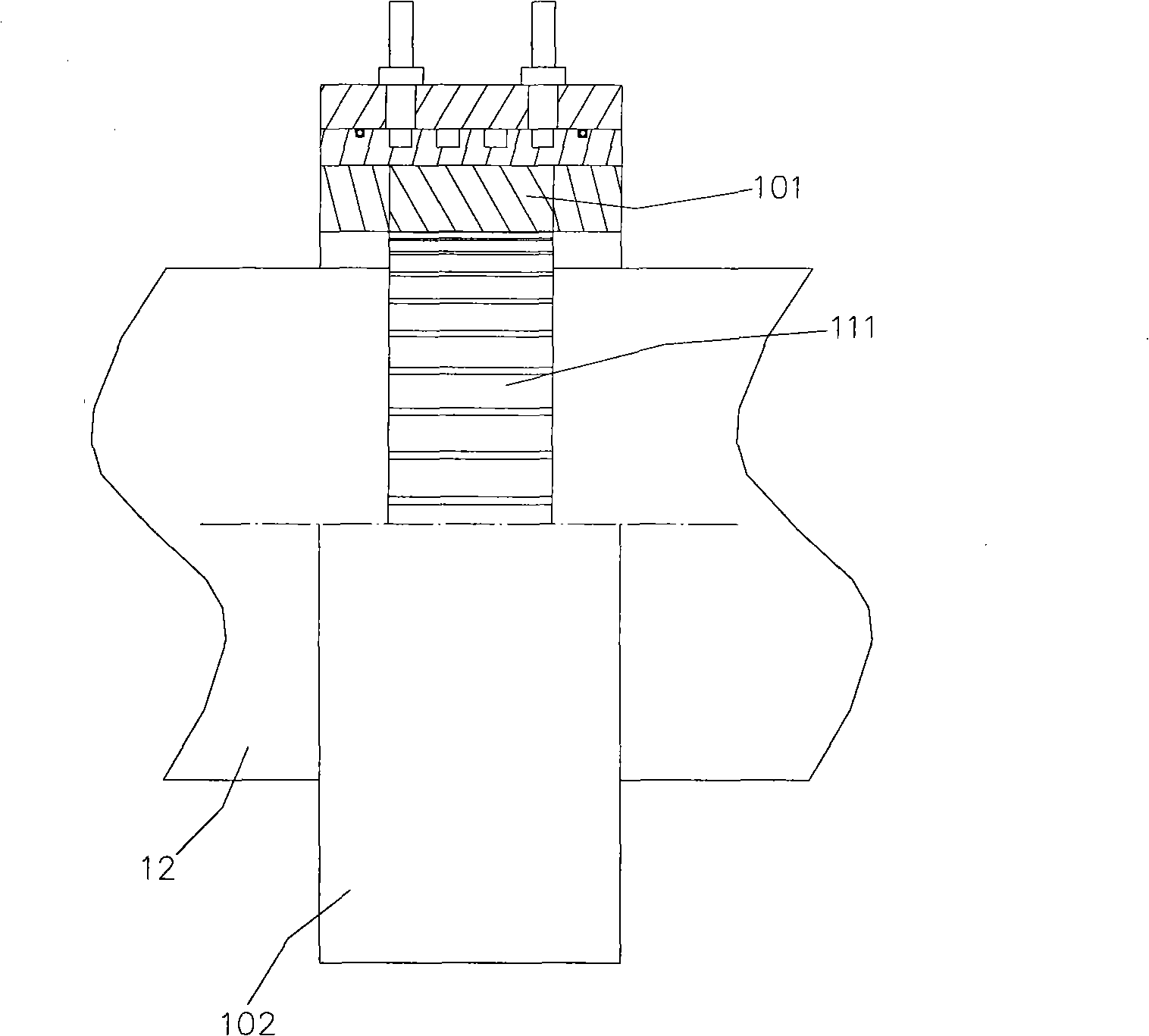

[0021] Please refer to the embodiment of the present invention image 3 , 4 And 5, the main shaft clearance elimination structure of the direct drive torque motor device of the present invention includes a main shaft 20, a braking element 30, a bearing assembly 40, a direct drive torque motor 50, a body 60, and a position detection element 70 And an adjusting nut 80; Its structure description is as follows:

[0022] The outer diameter of the main shaft 20 is gradually tapered from one end to the other end to make the first level 21, the second level 22, the third level 23, the fourth level 24 and an external thread segment 25, and the external thread segment 25 is made on the end of the main shaft 20;

[0023] The braking element 30 has an inner side corresponding to the first level 21 of the main shaft 20 and a positioning portion 31 on the outer side;

[0024] The bearing assembly 40 includes a first oil seal 41, a main bearing 42, a second oil seal 43 and an auxiliary ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com