Patents

Literature

545results about How to "Large braking force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

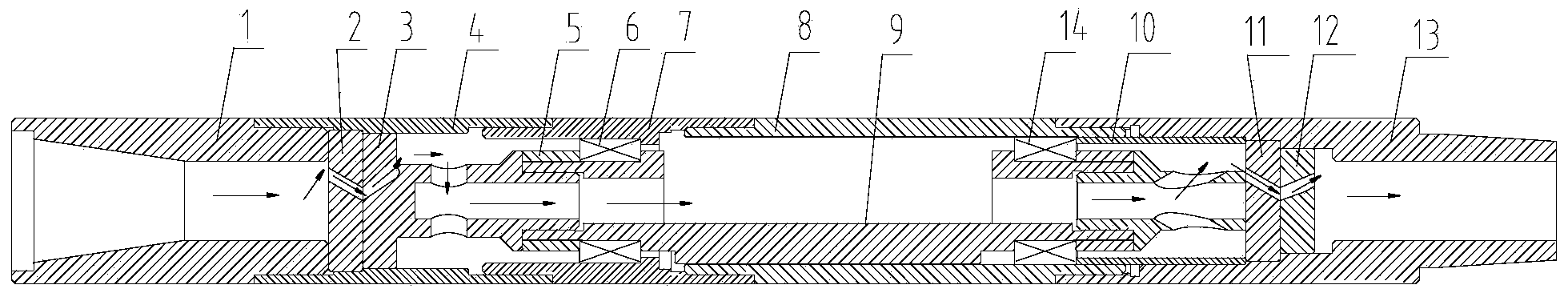

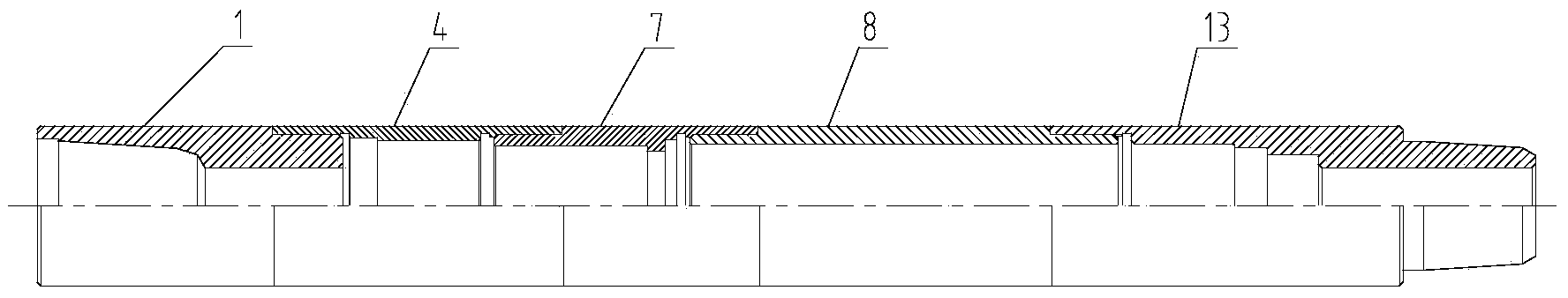

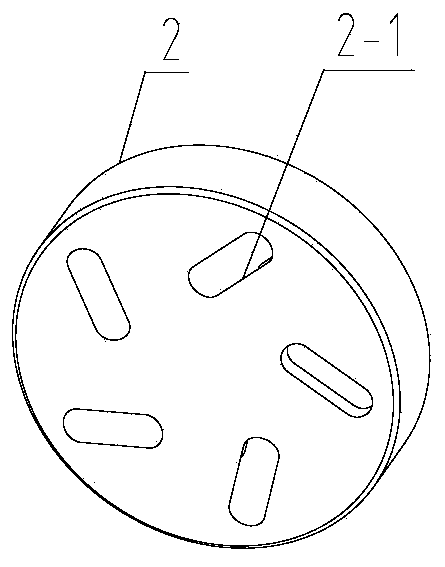

High-temperature resistant vibration tool for horizontal well

ActiveCN104234651AHigh working reliabilityImprove high temperature resistanceVibration devicesUpper jointTemperature resistance

The invention relates to a high-temperature resistant vibration tool for a horizontal well. The high-temperature resistant vibration tool for the horizontal well comprises a shell assembly and a vibration assembly arranged in the shell assembly and is characterized in that the shell assembly comprises an upper joint, an upper joint sleeve, a connection sleeve, a cover and a lower joint which sleeve from top to bottom in sequence; the vibration assembly comprises an upper end turbine, an eccentric shaft and a lower end turbine which are connected in sequence from top to bottom; the vibration assembly is arranged in the shell assembly by an upper end bearing and a lower end bearing; the upper end bearing and the lower end bearing respectively sleeve two end shafts of the eccentric shaft; an upper thrust ring and a lower thrust ring are respectively arranged at two ends of the vibration assembly and are respectively arranged in the upper joint sleeve and the lower joint; a channel for allowing fluid to flow is arranged in each of the shell assembly and the vibration assembly. The high-temperature resistant vibration tool for the horizontal well has the beneficial effects that the work reliability and high temperature resistance of the tool are improved, the deepening depth is increased, and enough drilling and pressing effects are applied.

Owner:JEREH ENERGY SERVICES

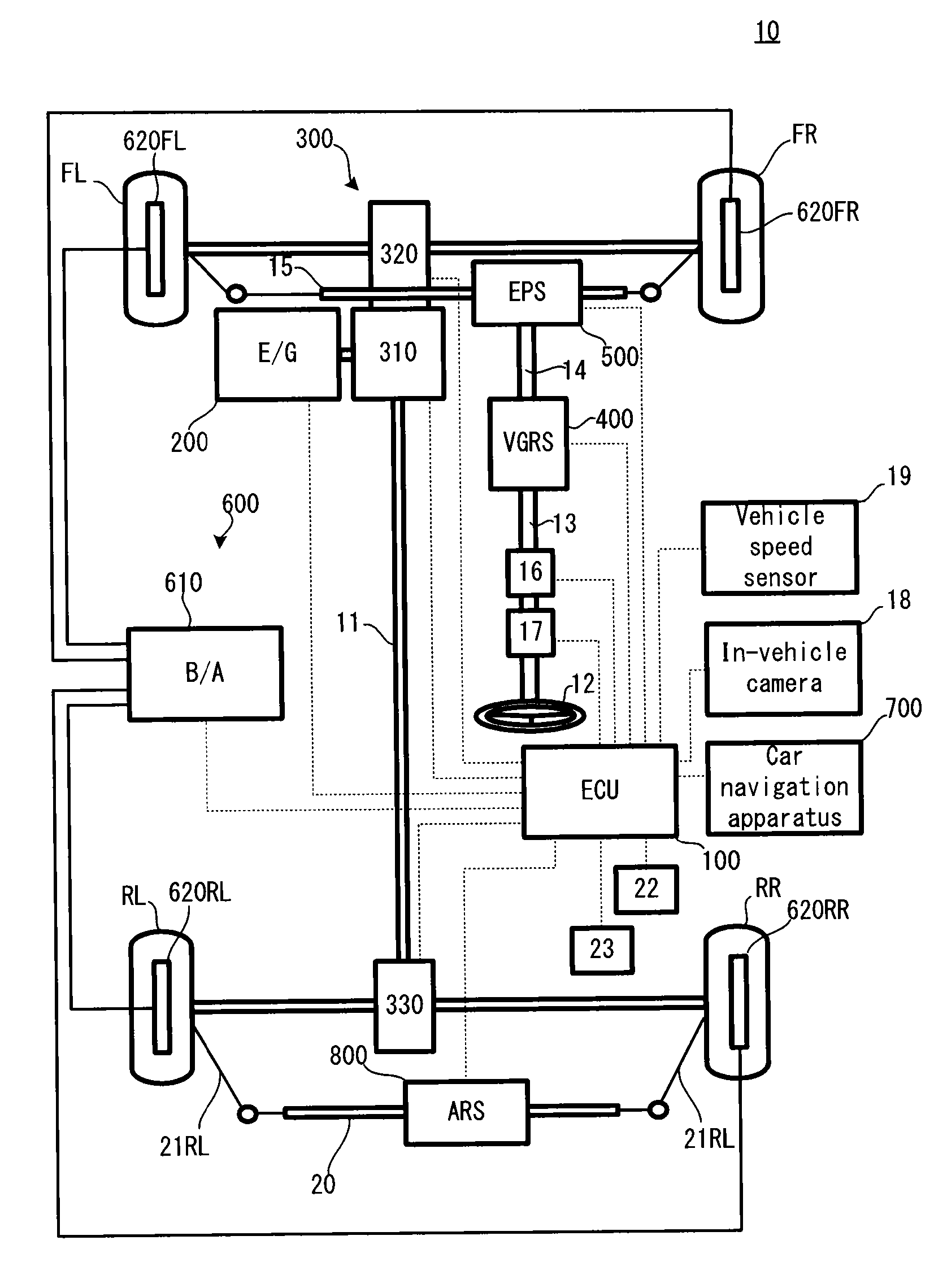

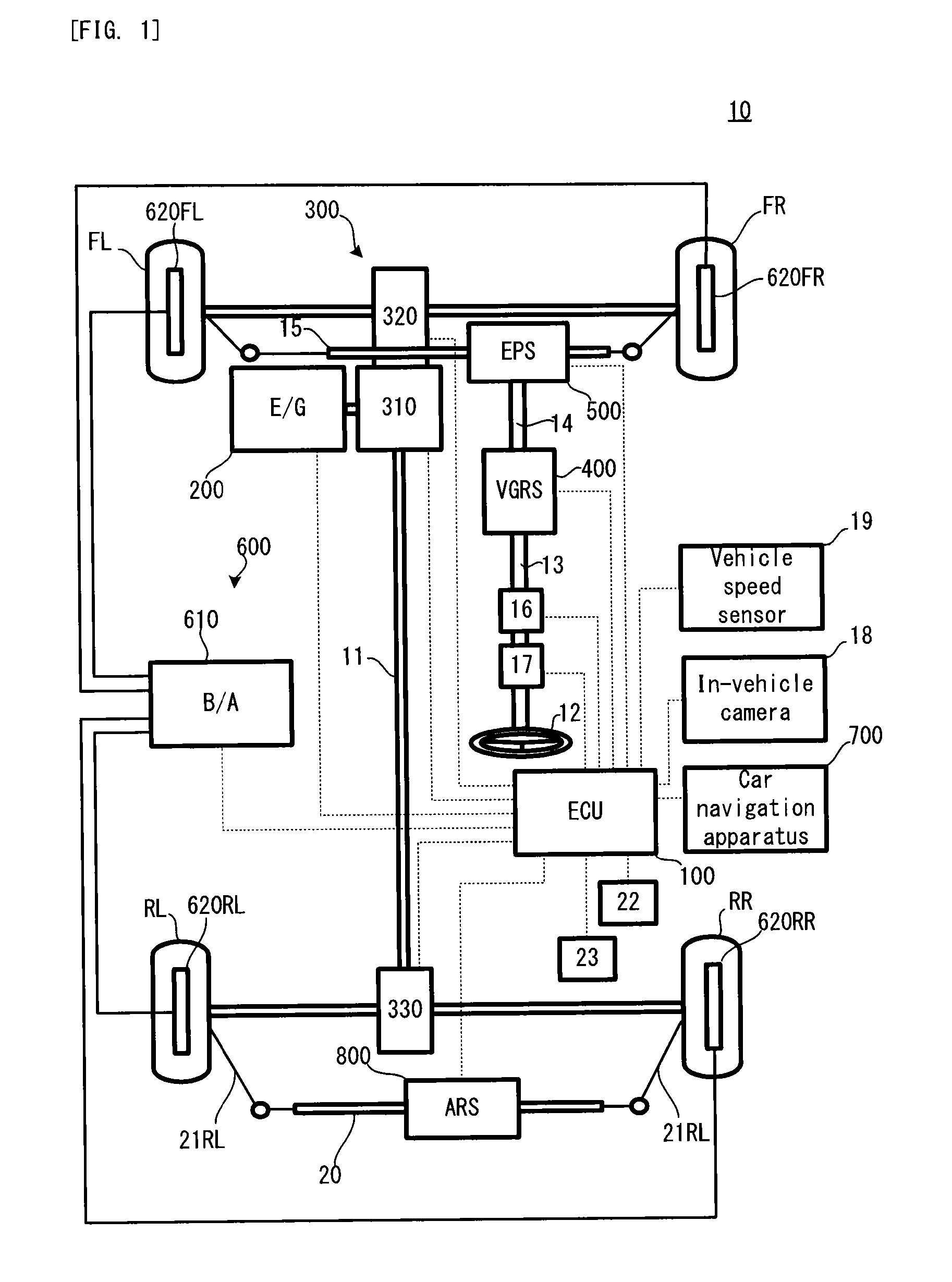

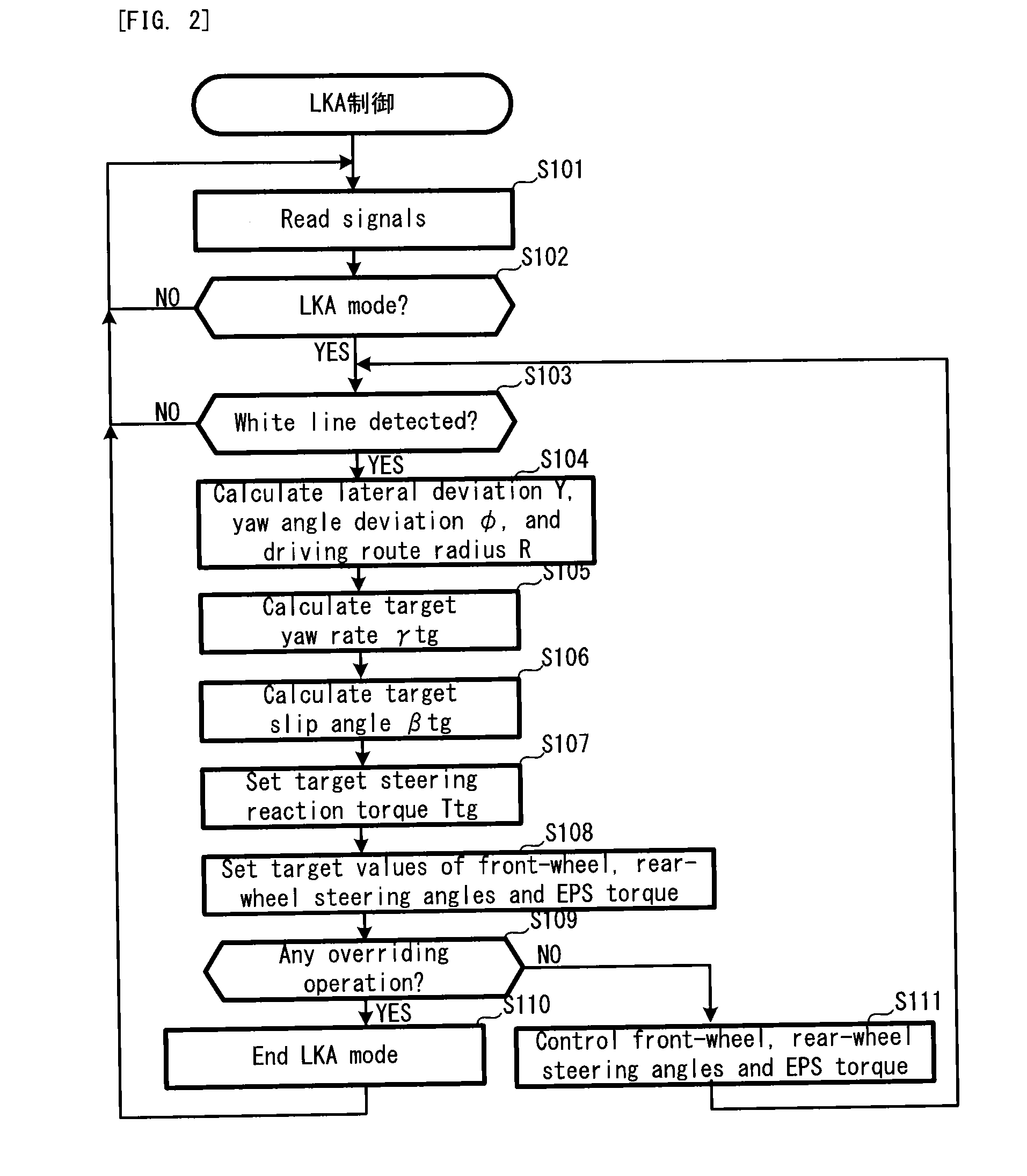

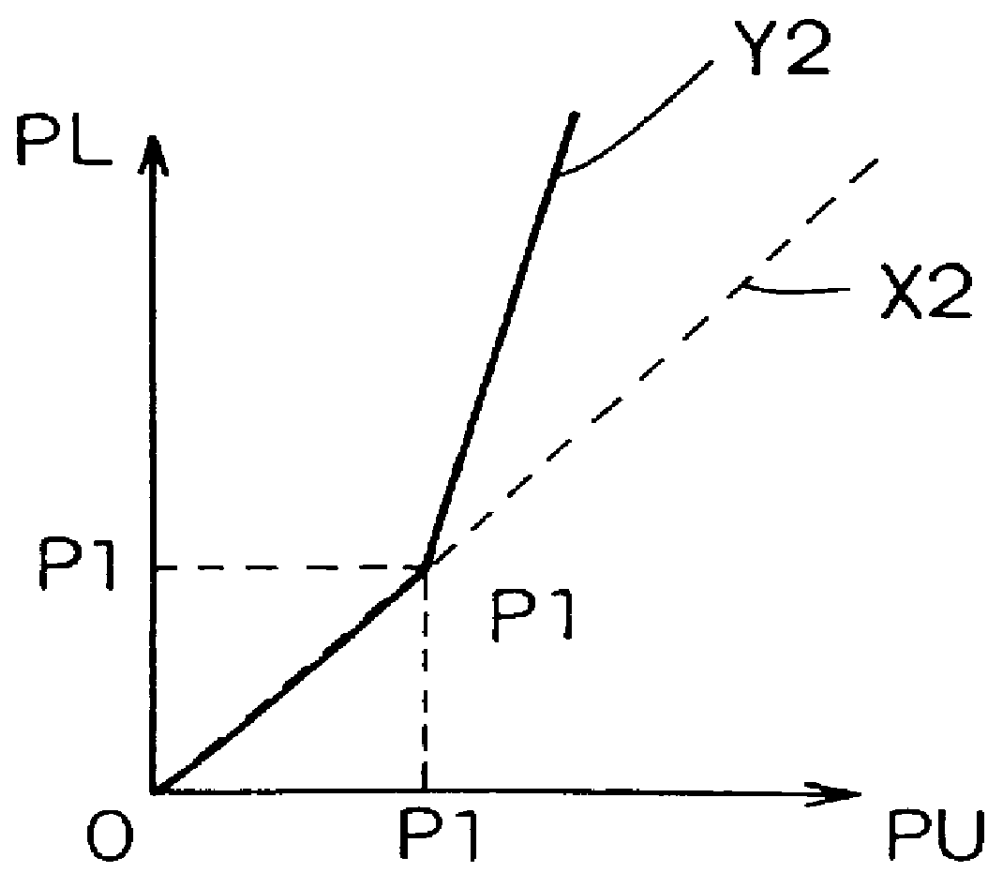

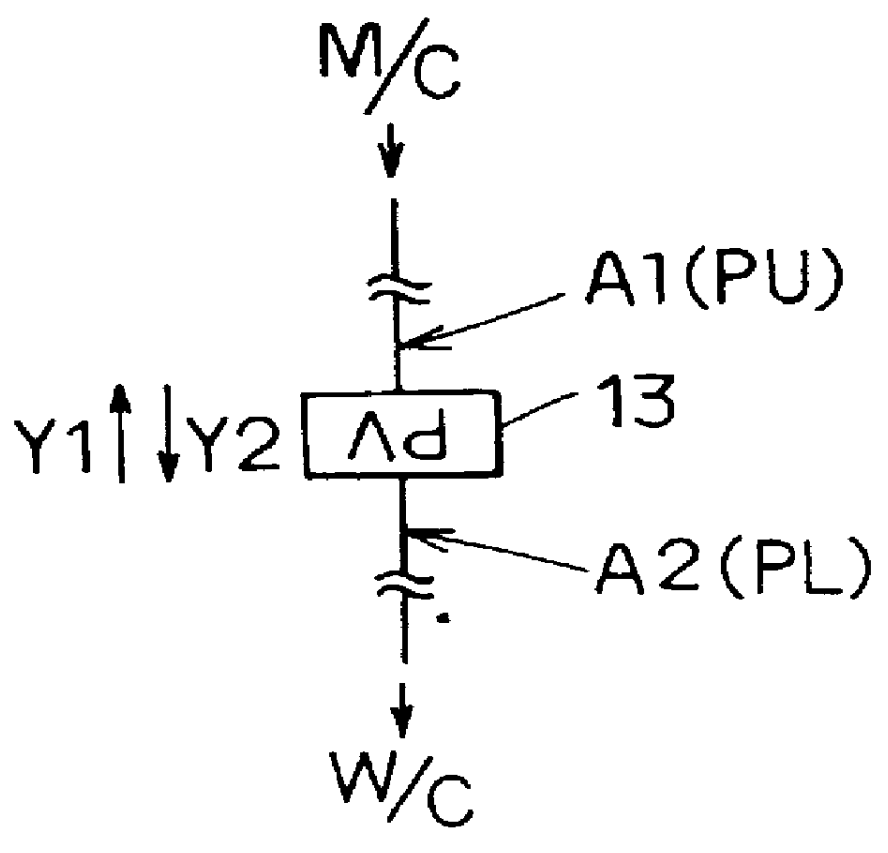

Vehicle steering control apparatus

ActiveUS20130253770A1Easy to driveLarge braking forceAnalogue computers for trafficSteering initiationsSteering controlMotion control

A vehicle motion control apparatus which is configured to control a motion of a vehicle comprising a plurality of apparatuses, each of which is configured to selectively control a slip angle or a yaw rate, is provided with: a behavior controlling device which is configured to perform behavior control in which a plurality of apparatuses are controlled such that a slip angle and a yaw rate are a set target slip angle and a target yaw rate, respectively; a turning state quantity specifying device which is configured to specify a turning state quantity of the vehicle; and a selecting device which is configured to select at least one of the slip angle and the yaw rate to be prioritized, on the basis of the specified turning state quantity in a case where the behavior control needs to be performed by one of the plurality of apparatuses. The behavior controlling device controls the one apparatus such that the selected one has the target value corresponding to the selected one, in the case where the behavior control needs to be performed by the one apparatus.

Owner:TOYOTA JIDOSHA KK

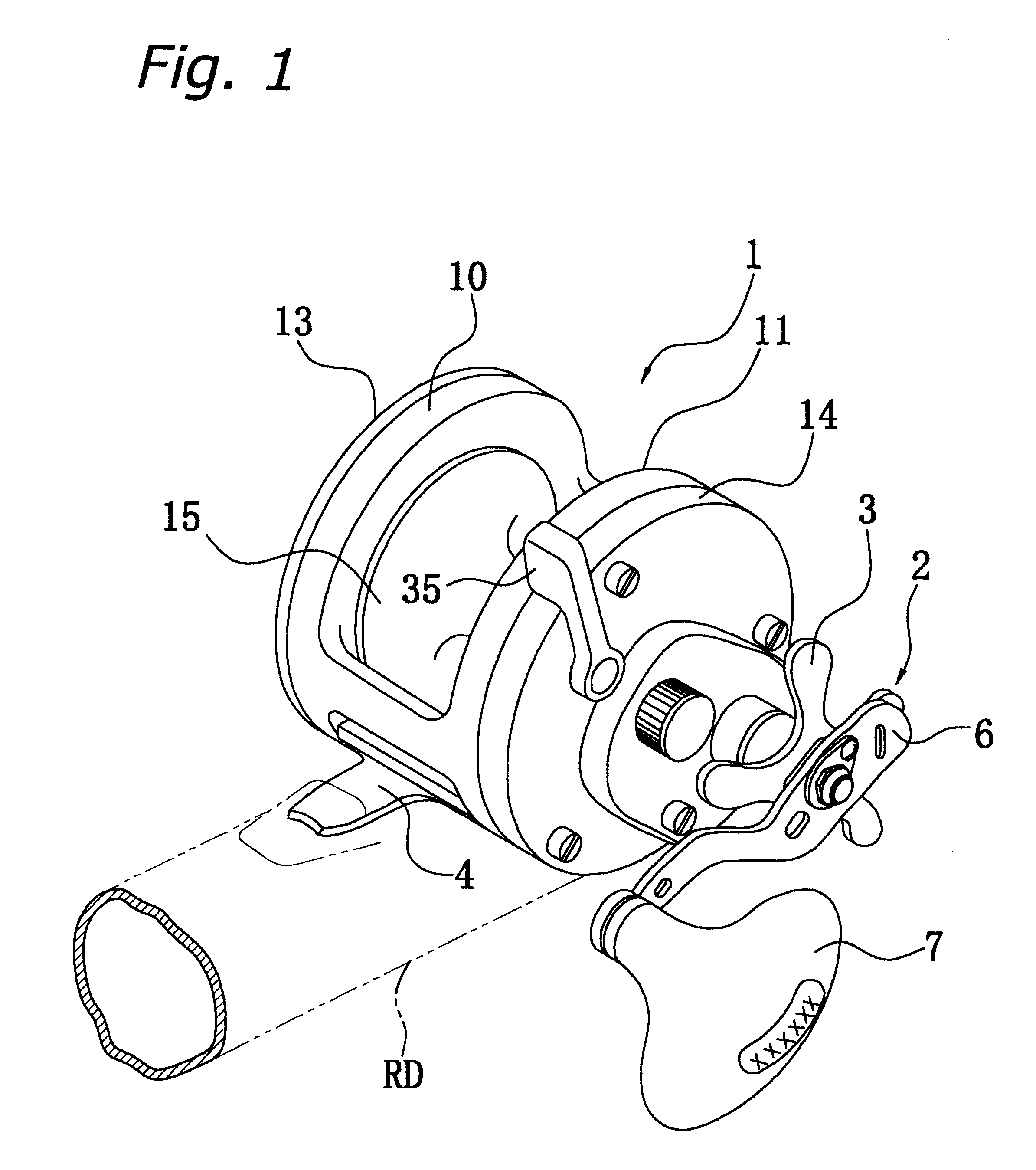

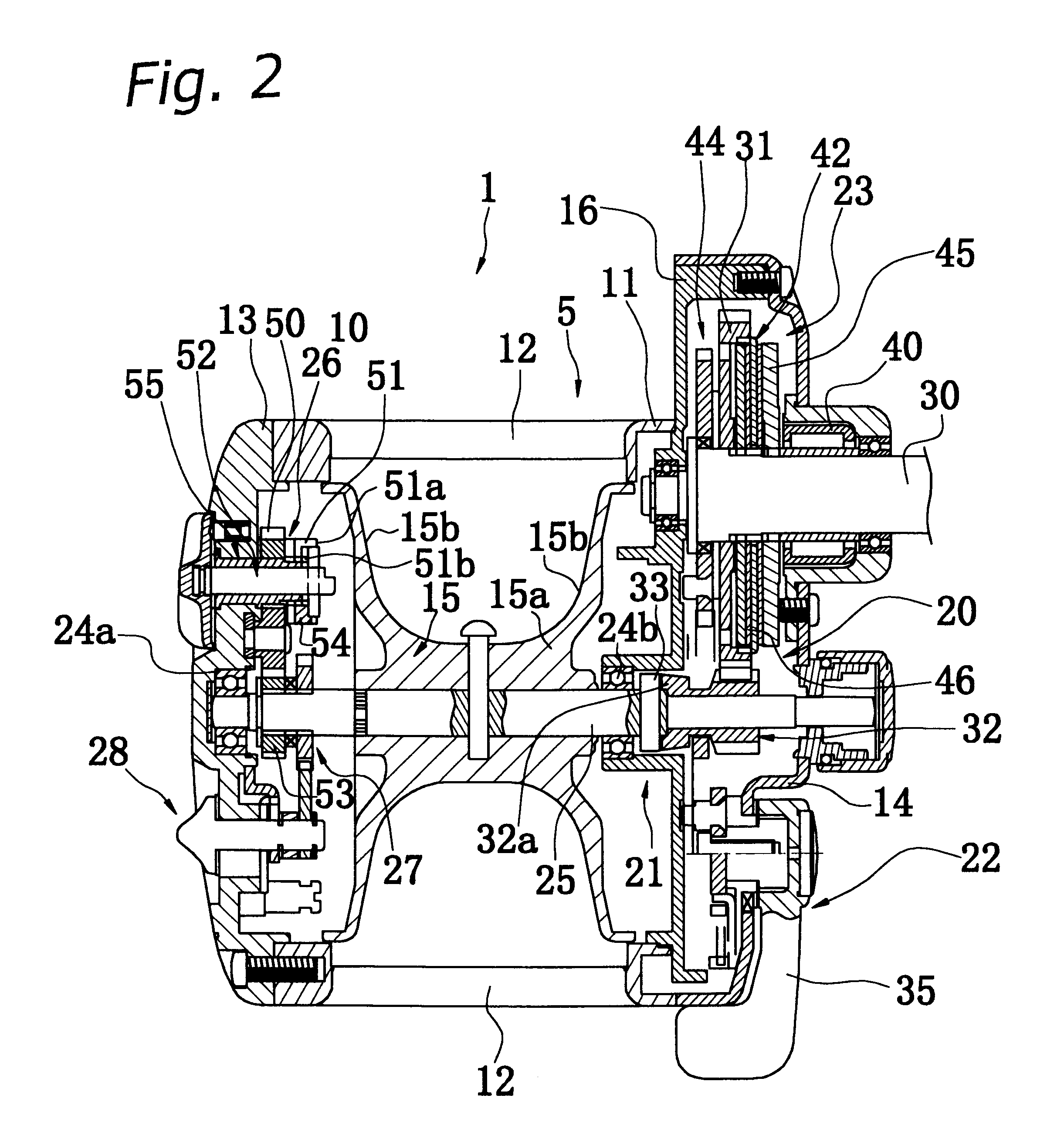

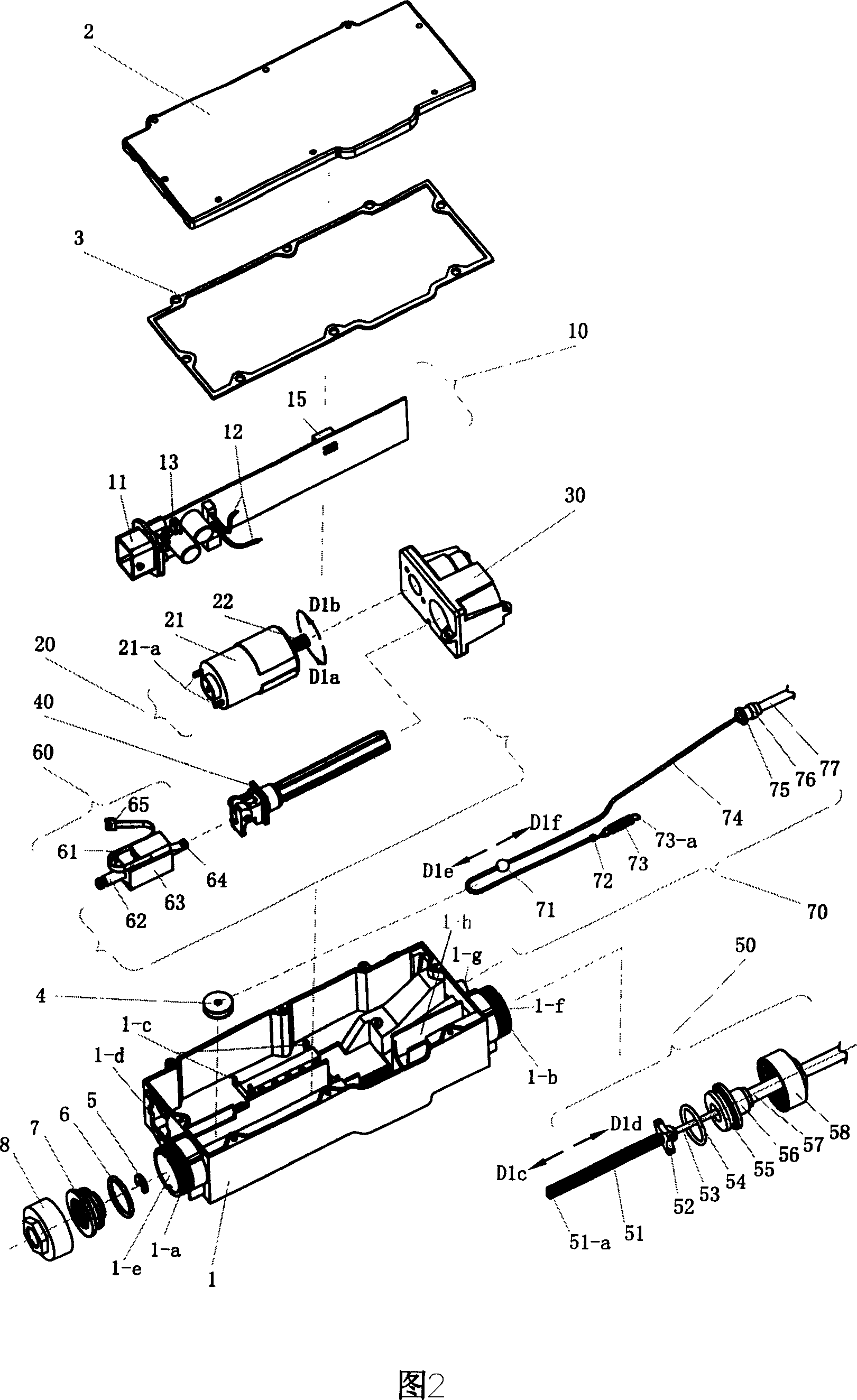

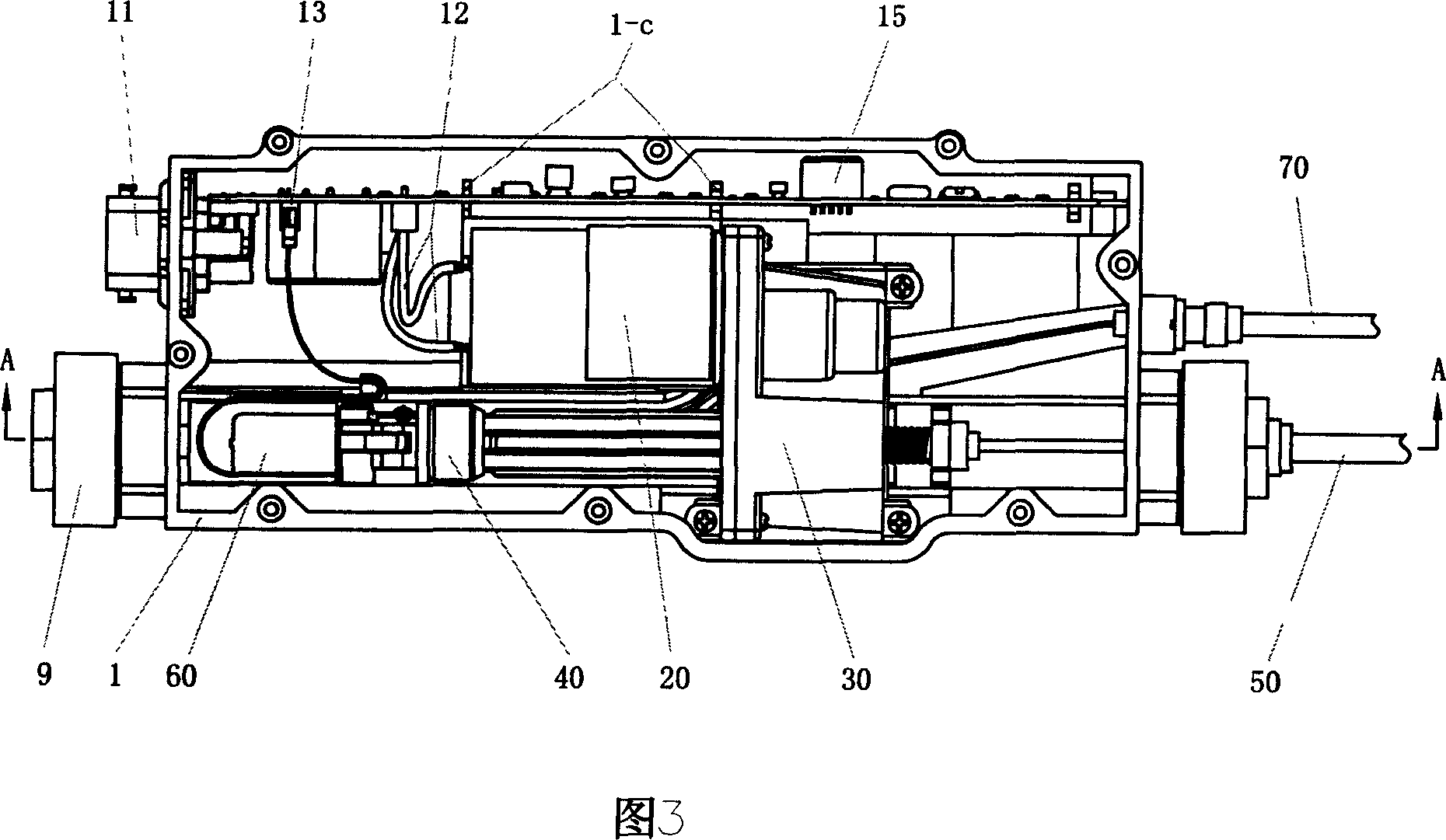

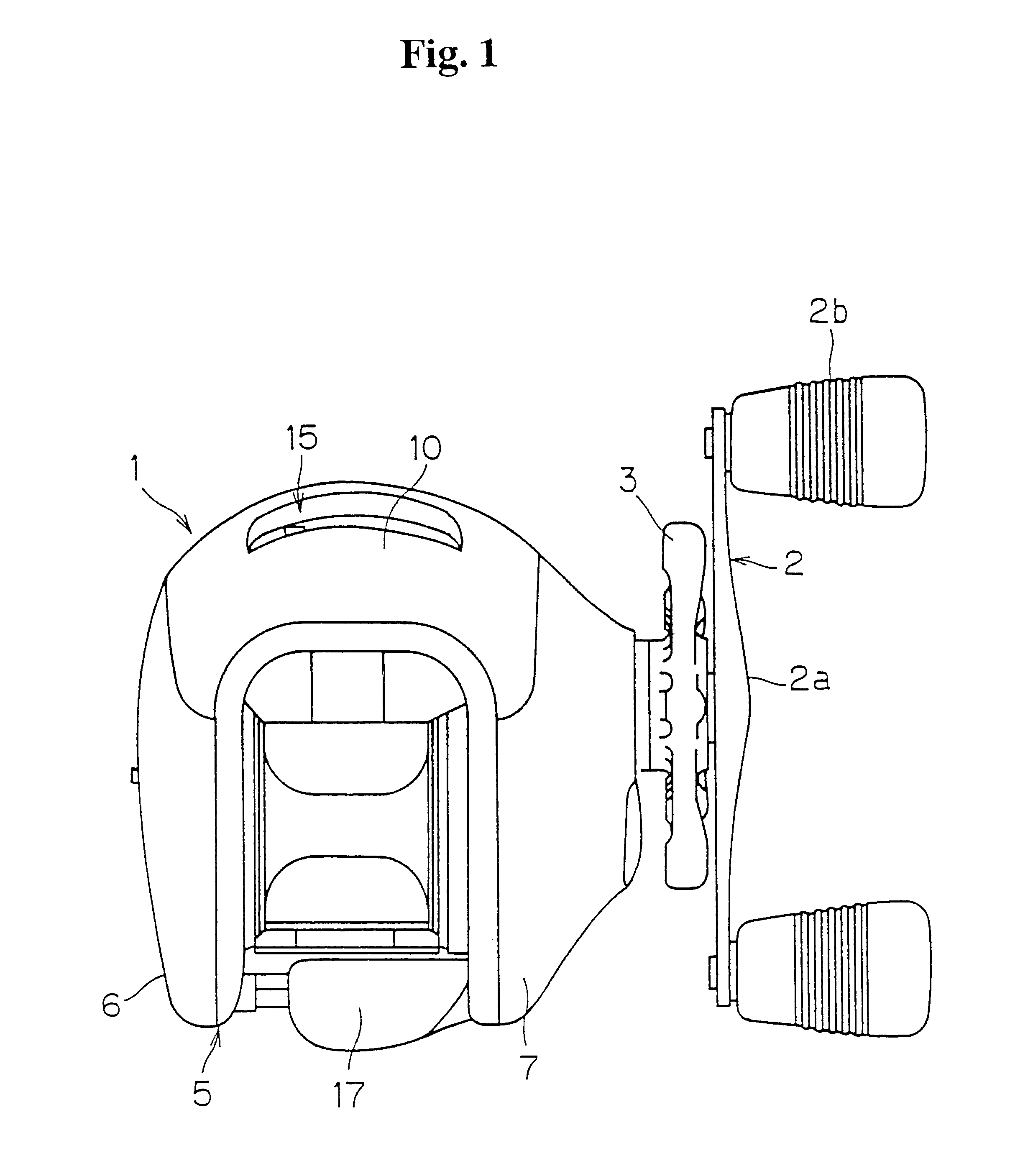

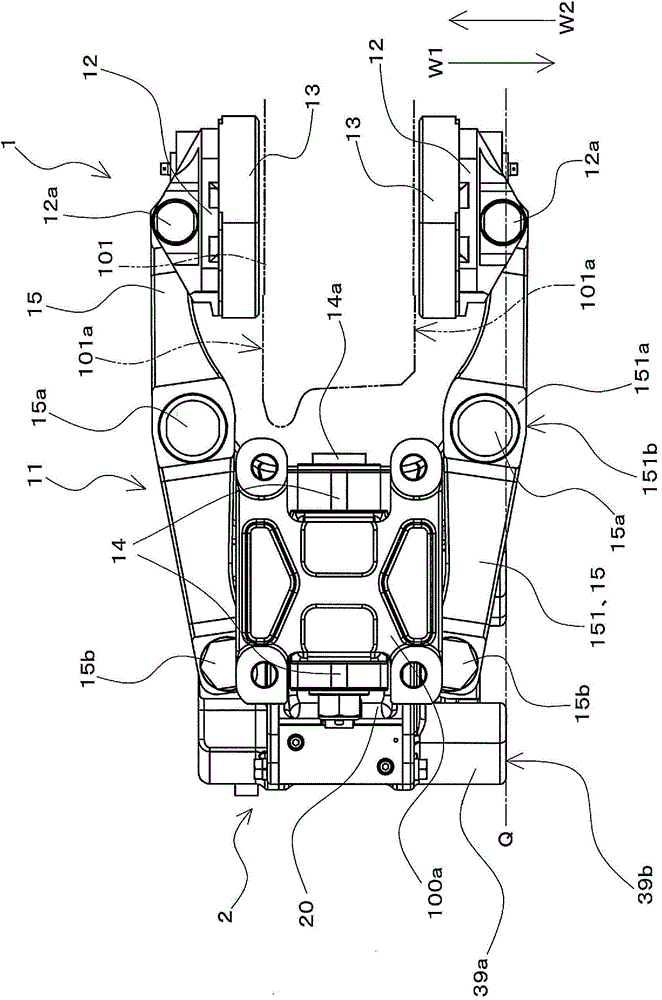

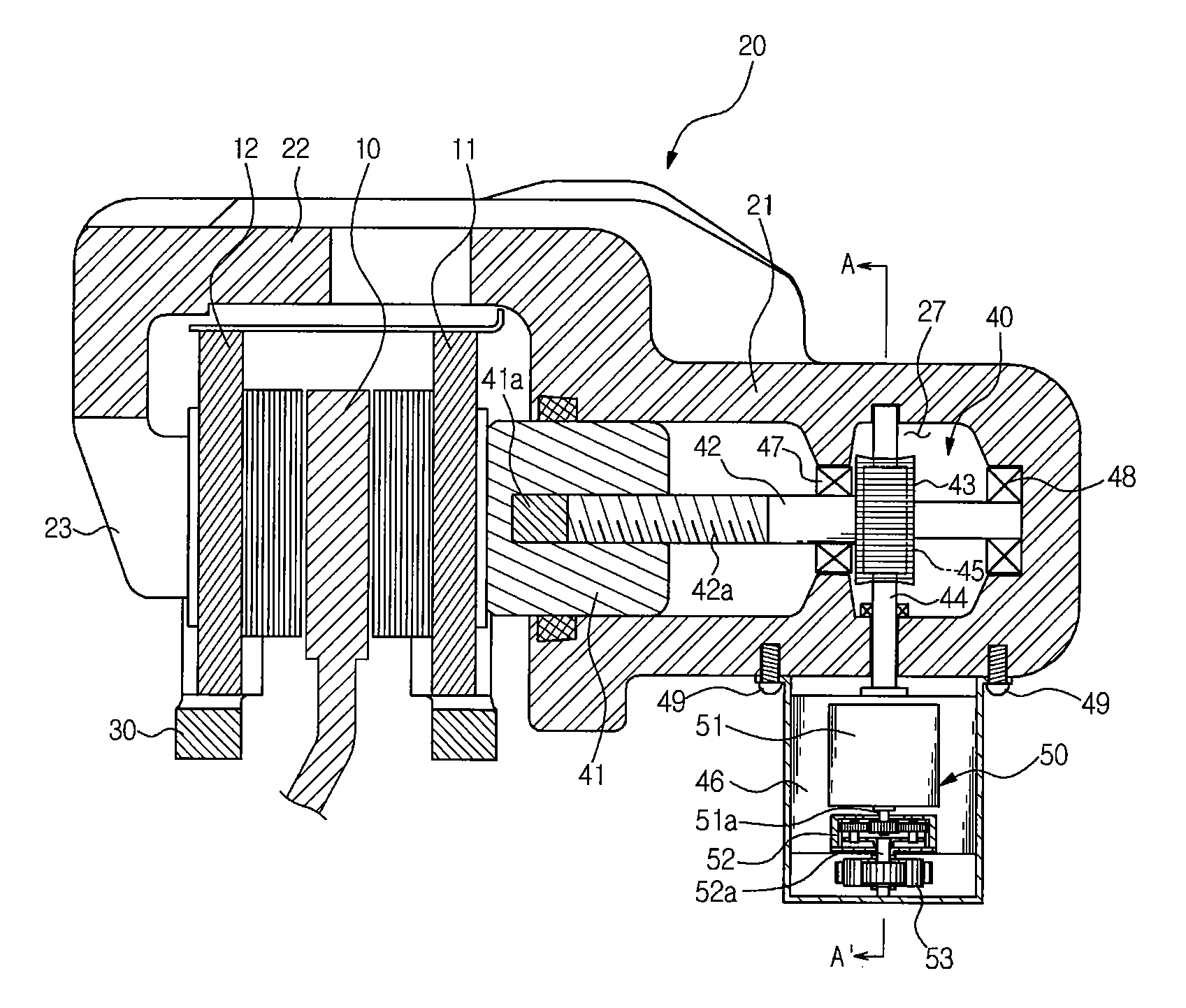

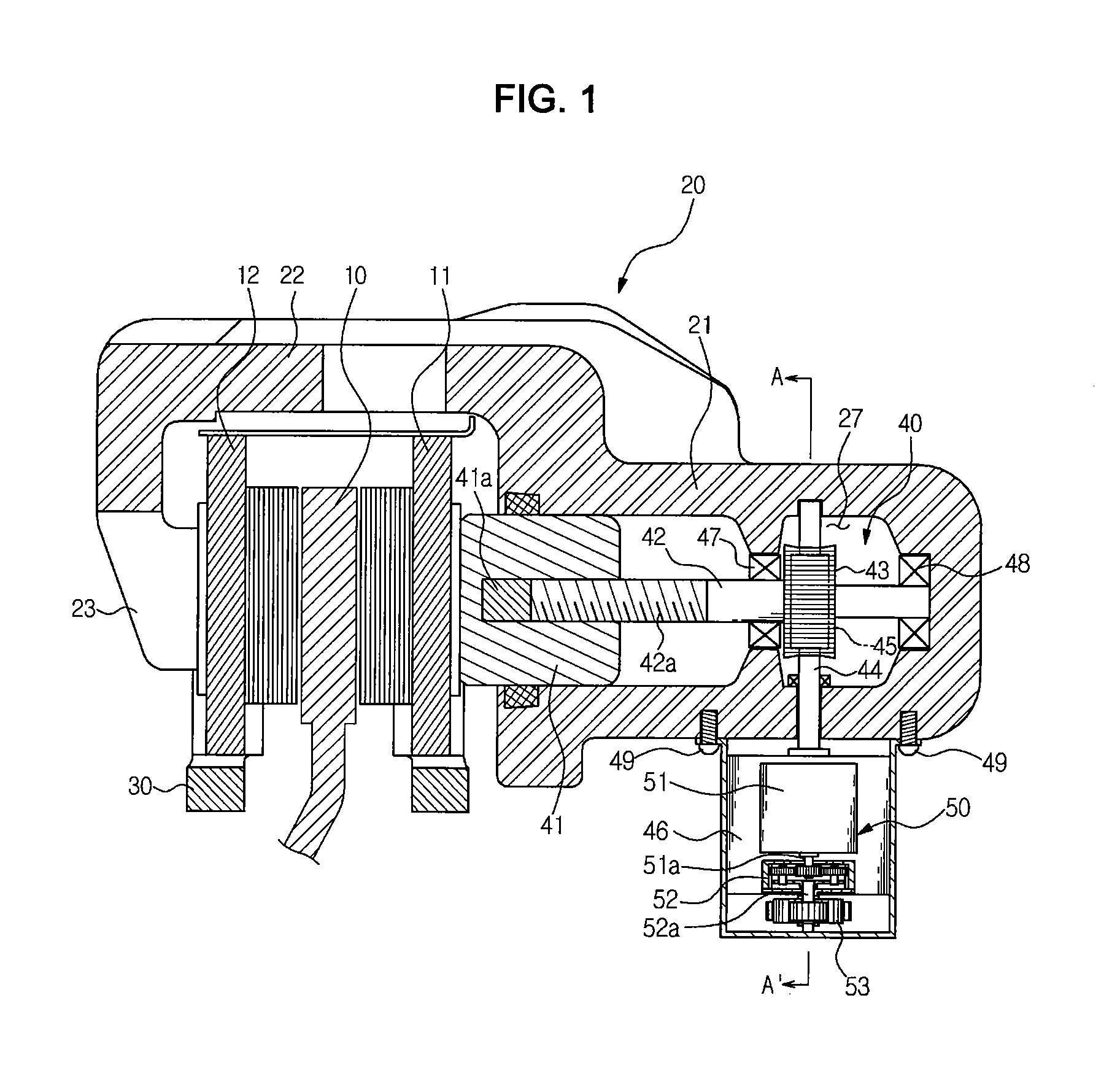

Double bearing reel

A double bearing reel that facilitates operating the braking and sounding mechanisms while fishing. A reel includes a reel body having a handle (2), a spool (15), a clutch mechanism (21), a frictional braking mechanism (26), a sounding mechanism (27), a switching operation mechanism (28), and a drag mechanism (42). The frictional braking mechanism is capable of braking the spool in its braking state regardless of the state of the clutch mechanism and switchable between the braking state and a non-braking state. The sounding mechanism is capable of producing sound in accordance with the rotation of the spool and switchable between an engaged state in which sound may be produced and a disengaged state in which no sound is produced. The switching operation mechanism is capable of switching, at the same time, the states of both the sounding mechanism and the first braking mechanism from the engaged state and the braking state, respectively, to the disengaged state and the non-braking state, respectively, or vice versa. The drag mechanism brakes the rotation of the spool in the line releasing direction while the clutch mechanism is turned on.

Owner:SHIMANO INC

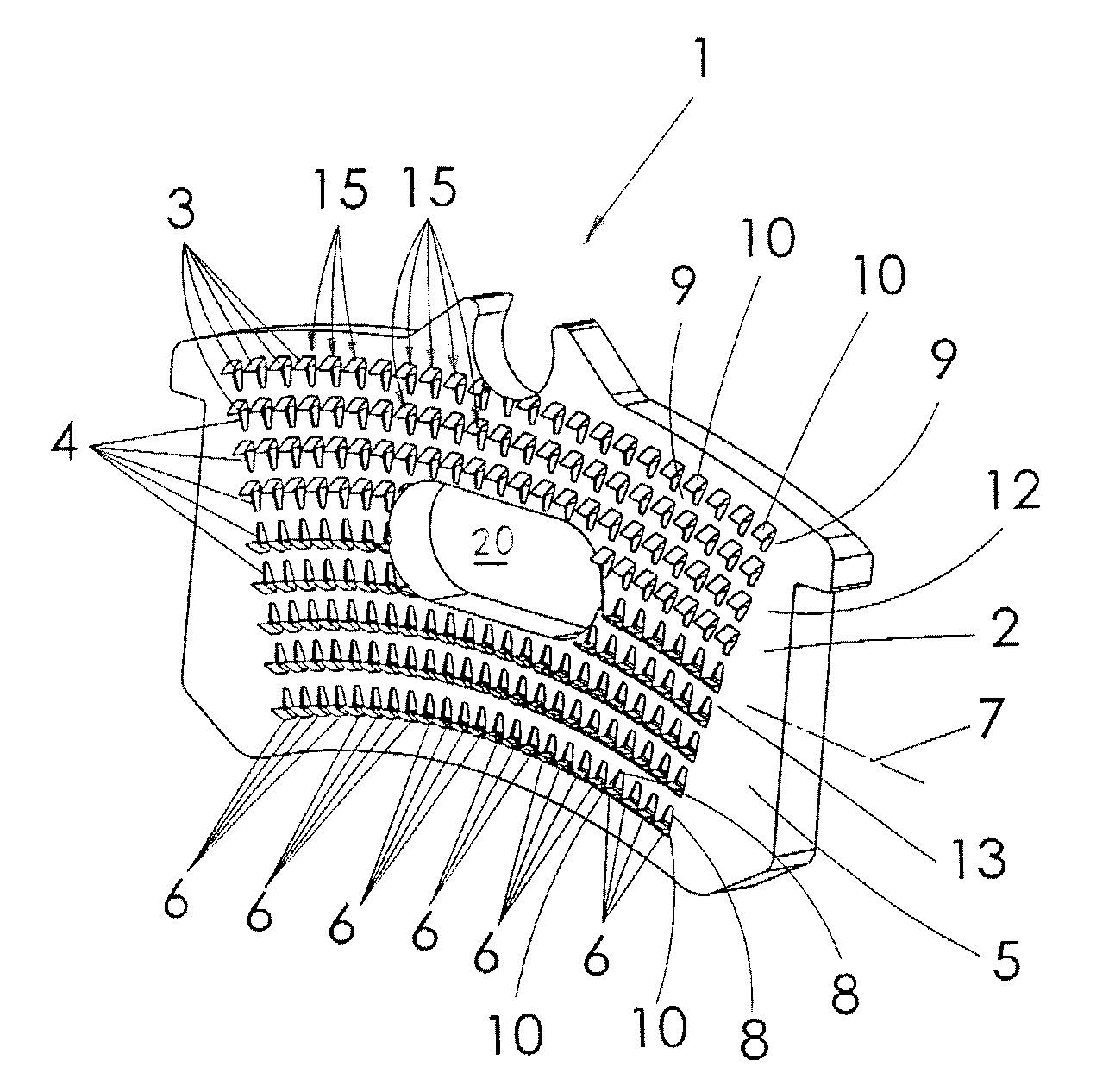

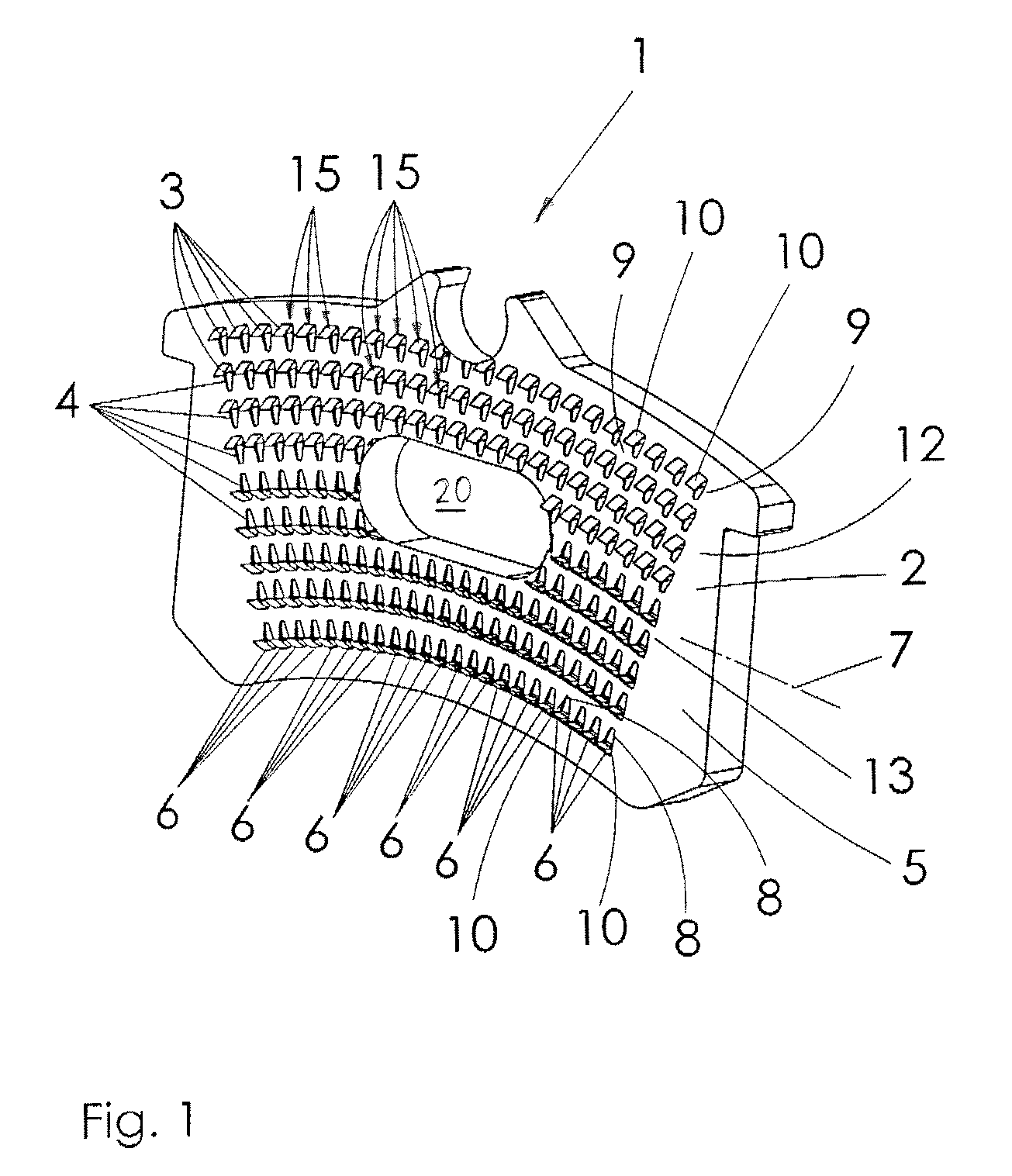

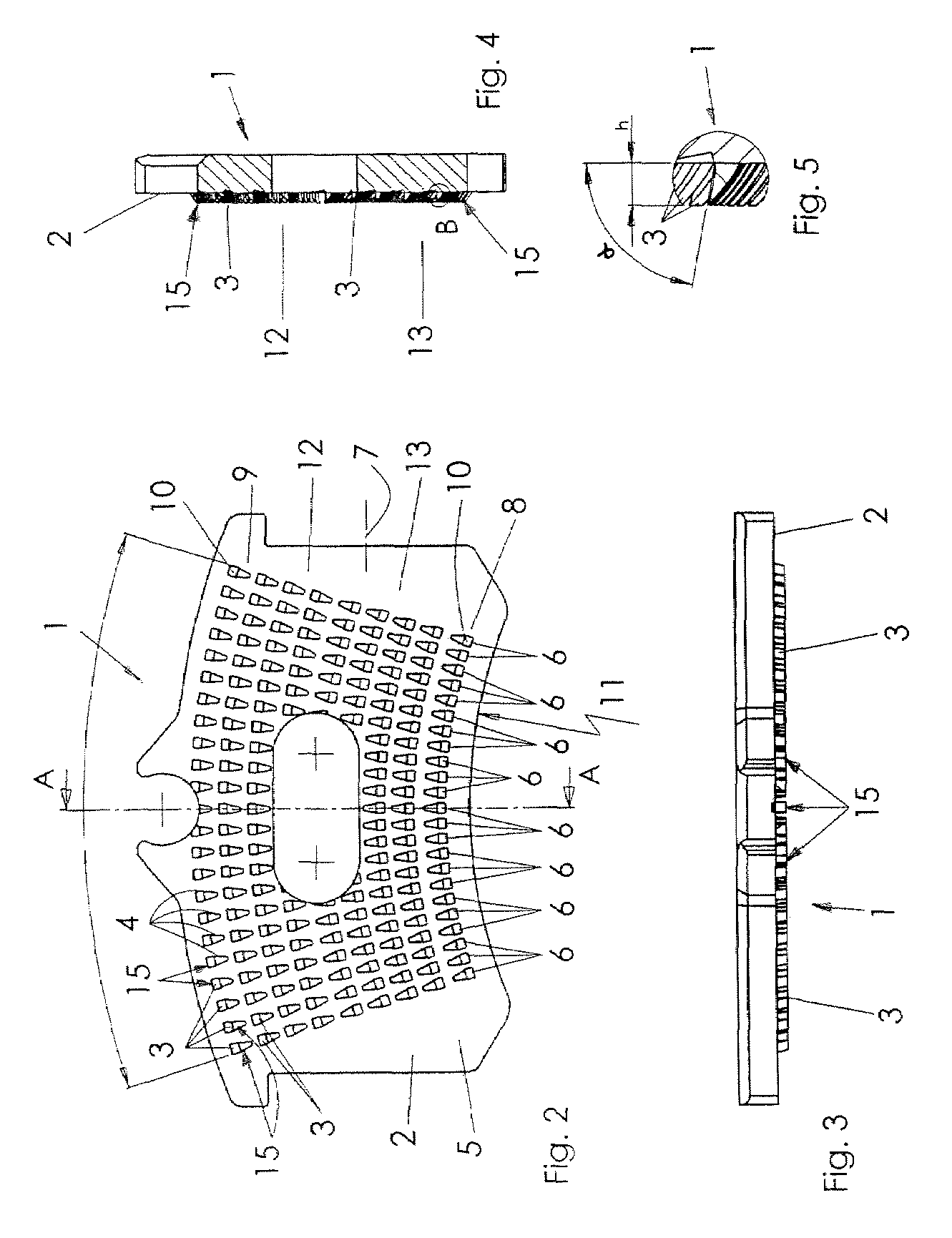

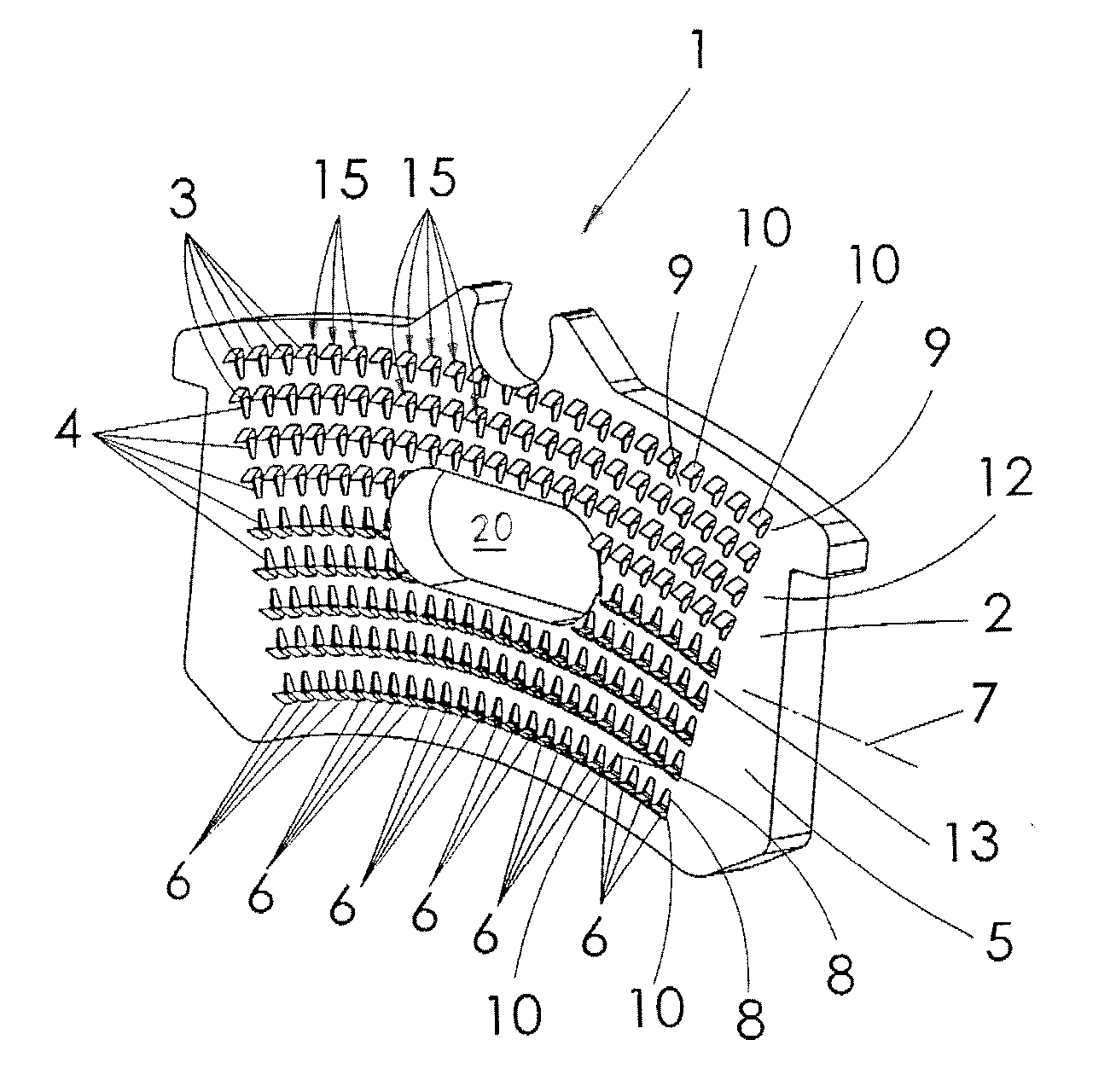

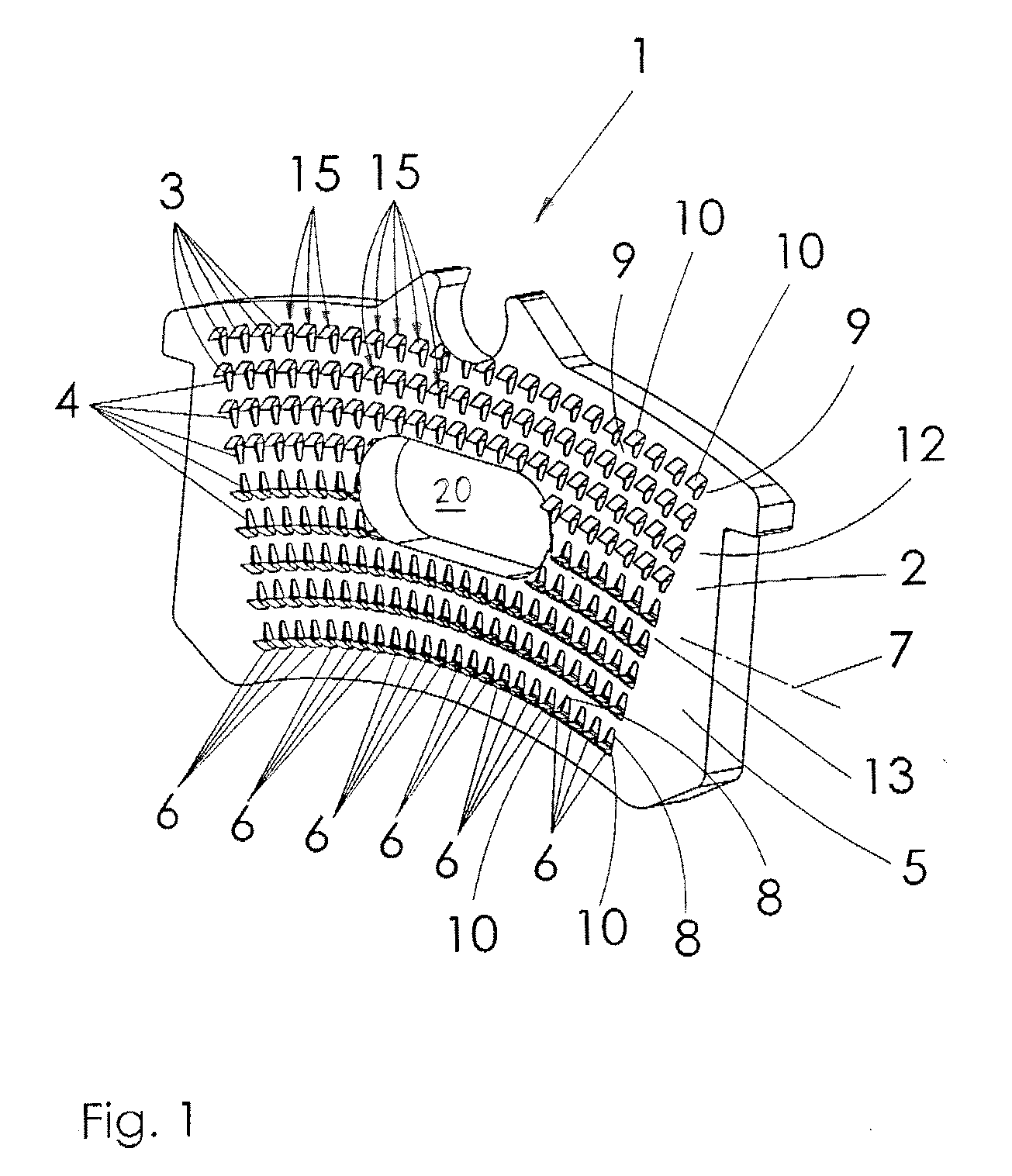

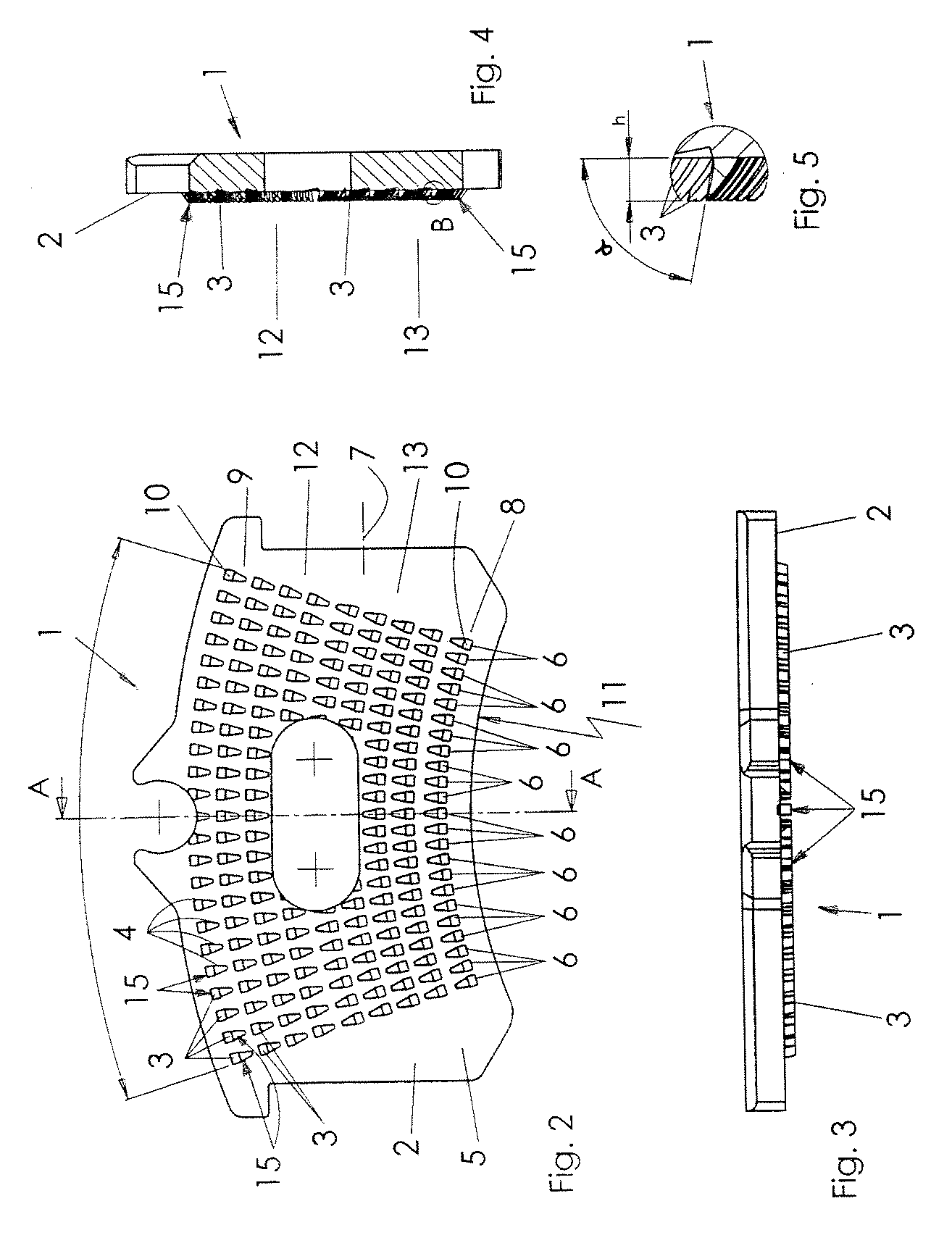

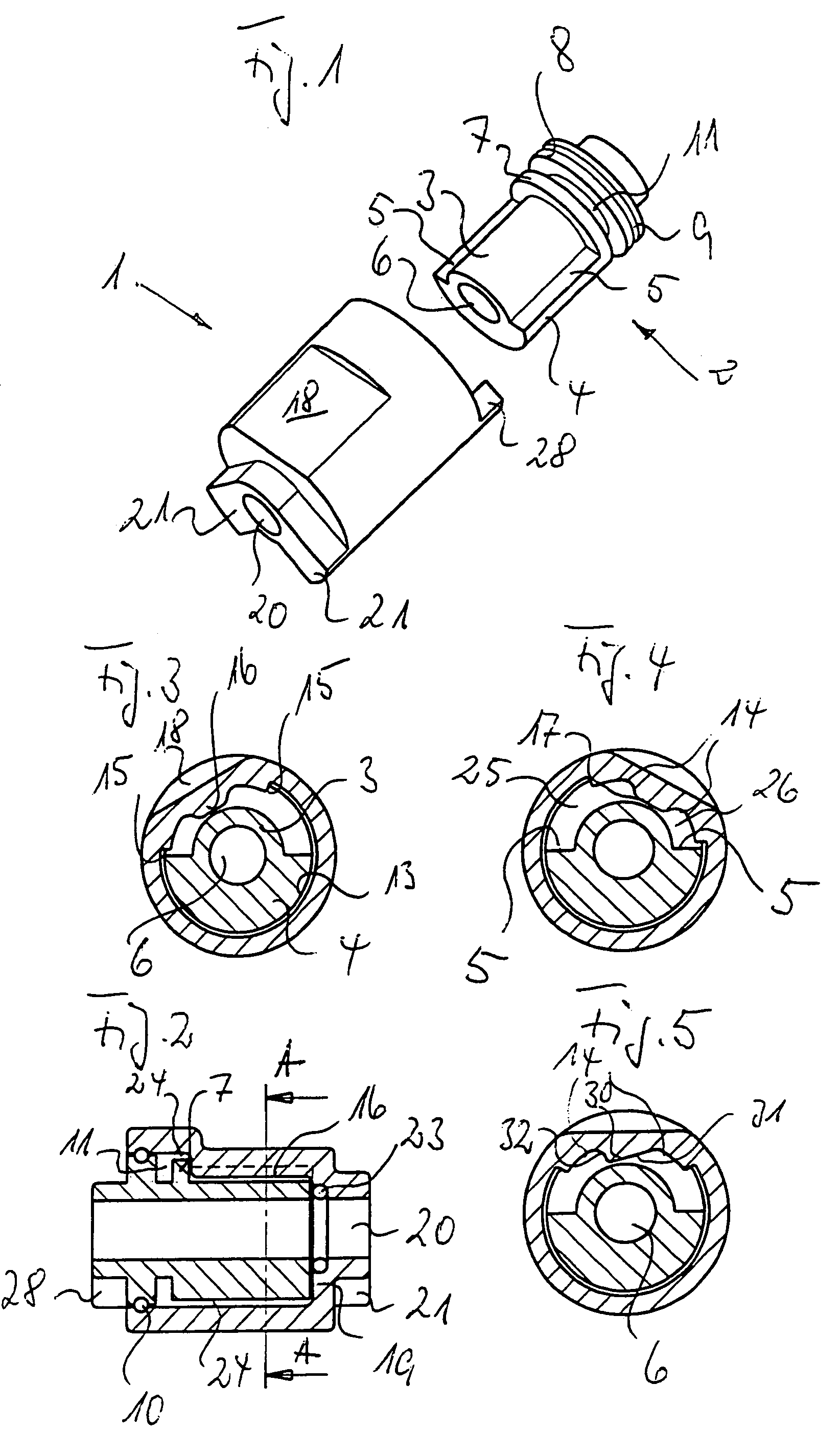

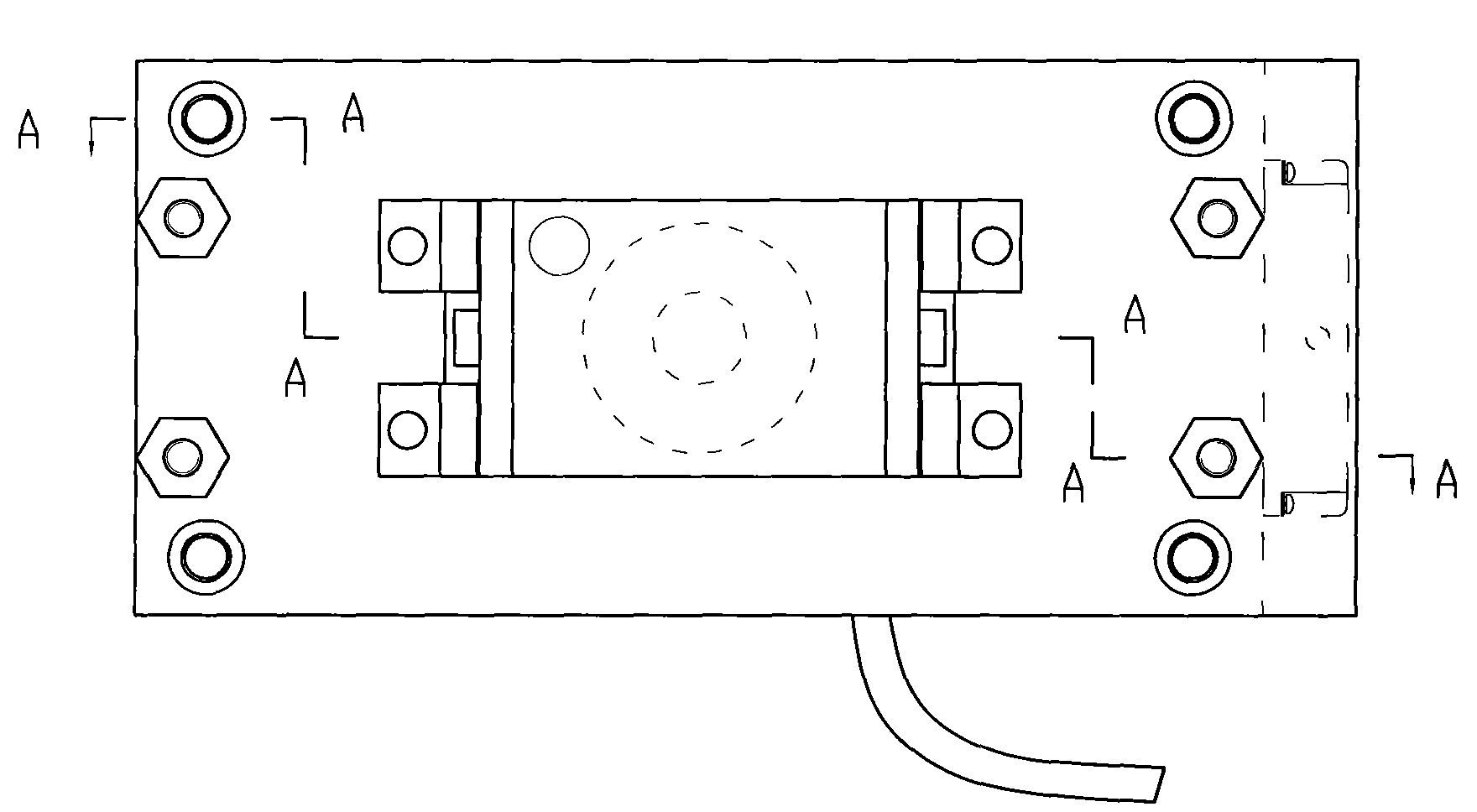

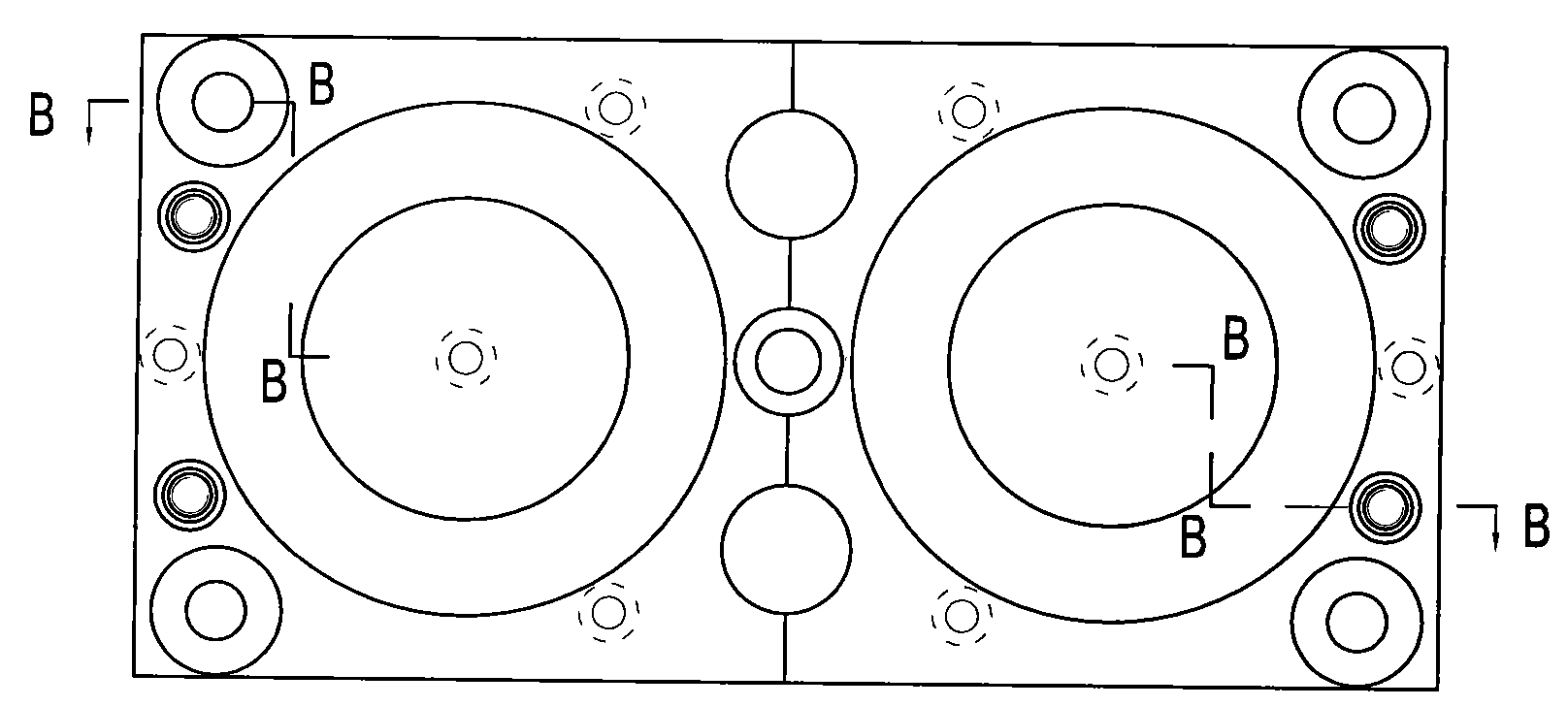

Brake plate

InactiveUS7686142B2Improve stressLarge braking forceMetal-working apparatusBraking membersEngineeringBrake lining

The invention relates to a brake lining carrier plate 1 to hold a friction lining, especially for installation into a vehicle brake system, with holding structures 15, 16 for the friction lining arranged in rows 6 on the lining side 2, whereby each holding structure 15, 16 has a protrusion 3 and a depression 4, whereby the protrusion 3 is made when the depression 4 is formed in the surface 5 through the displacement of material. Said protrusion 3 engages with the friction lining. The holding structures 15, 16 in the rows 6 are arranged in such a way that there is a protrusion 10 at the beginning 8 and at the end 9 of each row 6. In one embodiment, the rows 6 run essentially crosswise to the longitudinal axis 7 of the brake lining carrier plate 1.

Owner:AML LANXIDE EURO

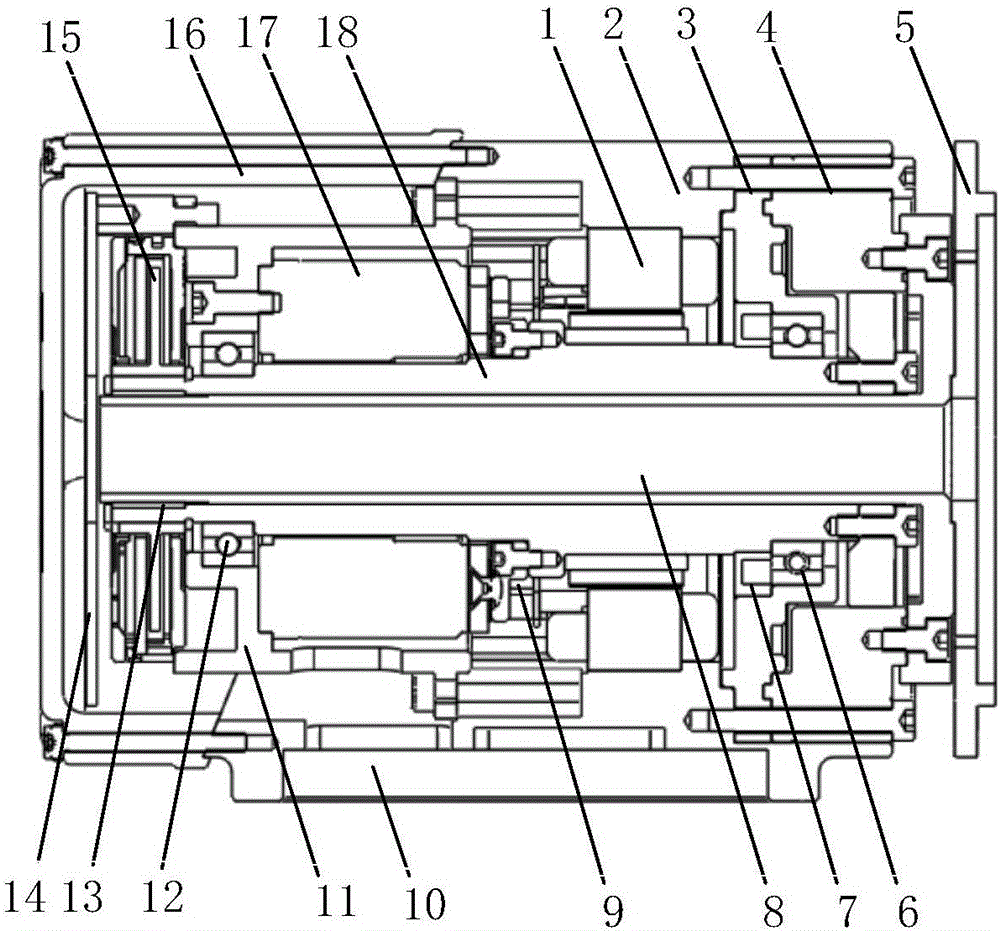

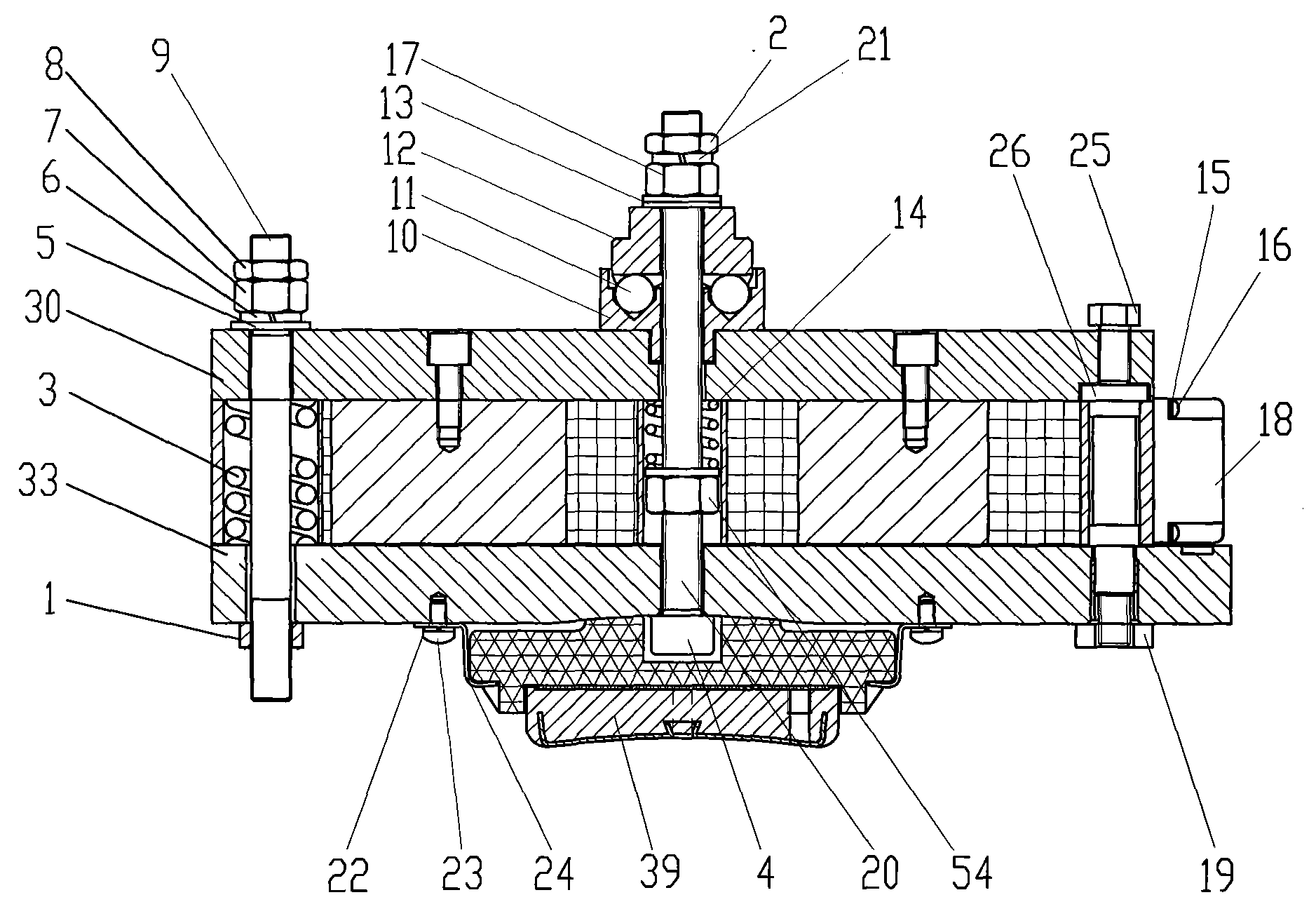

Modularized series joint of collaborative robot

The invention relates to a modularized series joint of a collaborative robot. The modularized series joint comprises a joint shell as well as a hollow motor, a harmonic reducer, an input shaft, an output shaft, a torque sensor, a brake, an absolute value encoder and a driver which are arranged in the joint shell, wherein the harmonic reducer, the hollow motor, the brake, the absolute value encoder and the driver are sequentially connected to the input shaft in series. A joint structure disclosed by the invention is more compact in structure, low in cost, higher in safety and reliability, ingenious, modularized and integrated; a brake structure is simple, convenient to install, reliable in brake performance, and stable; a force feedback system is sensitive in performance, stable, and high in reliability; and in addition, central hole wiring is used for wiring and arrangement, so that wire arrangement is more reasonable, and the wiring is more convenient.

Owner:SUZHOU XINYOUHUA INVESTMENT ADVISOR CO LTD

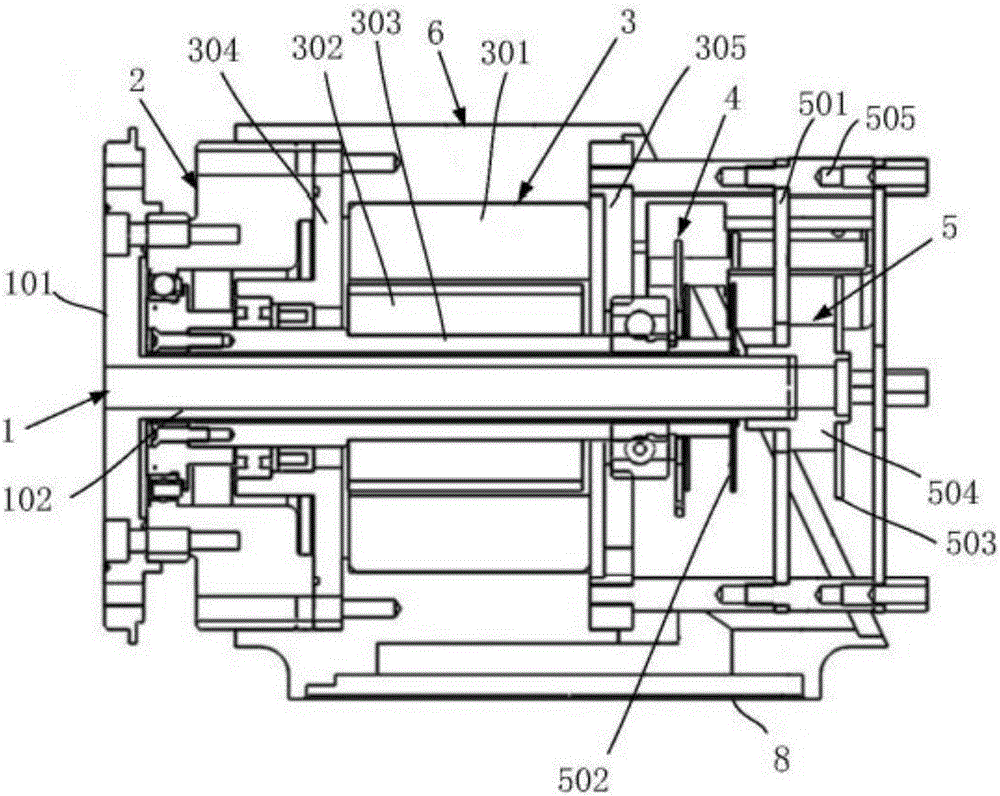

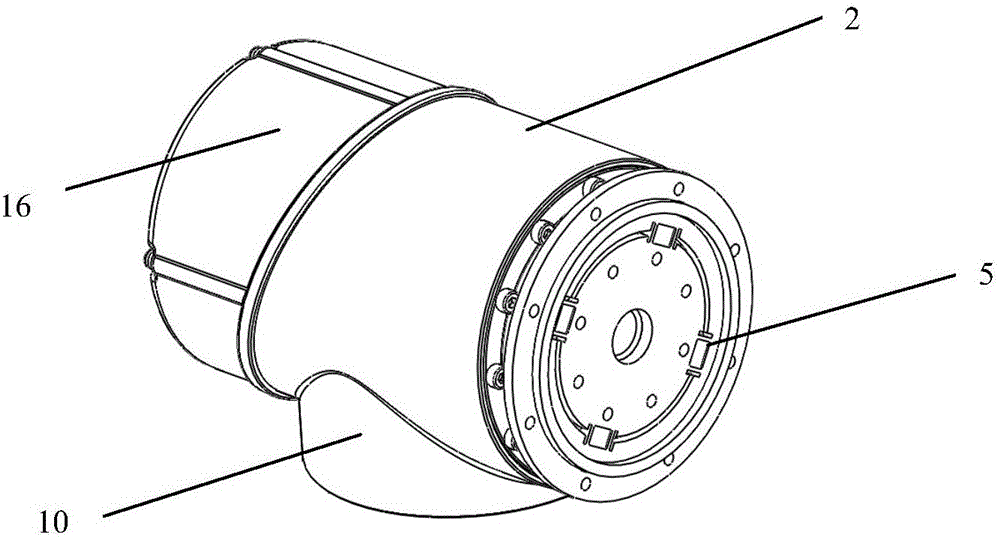

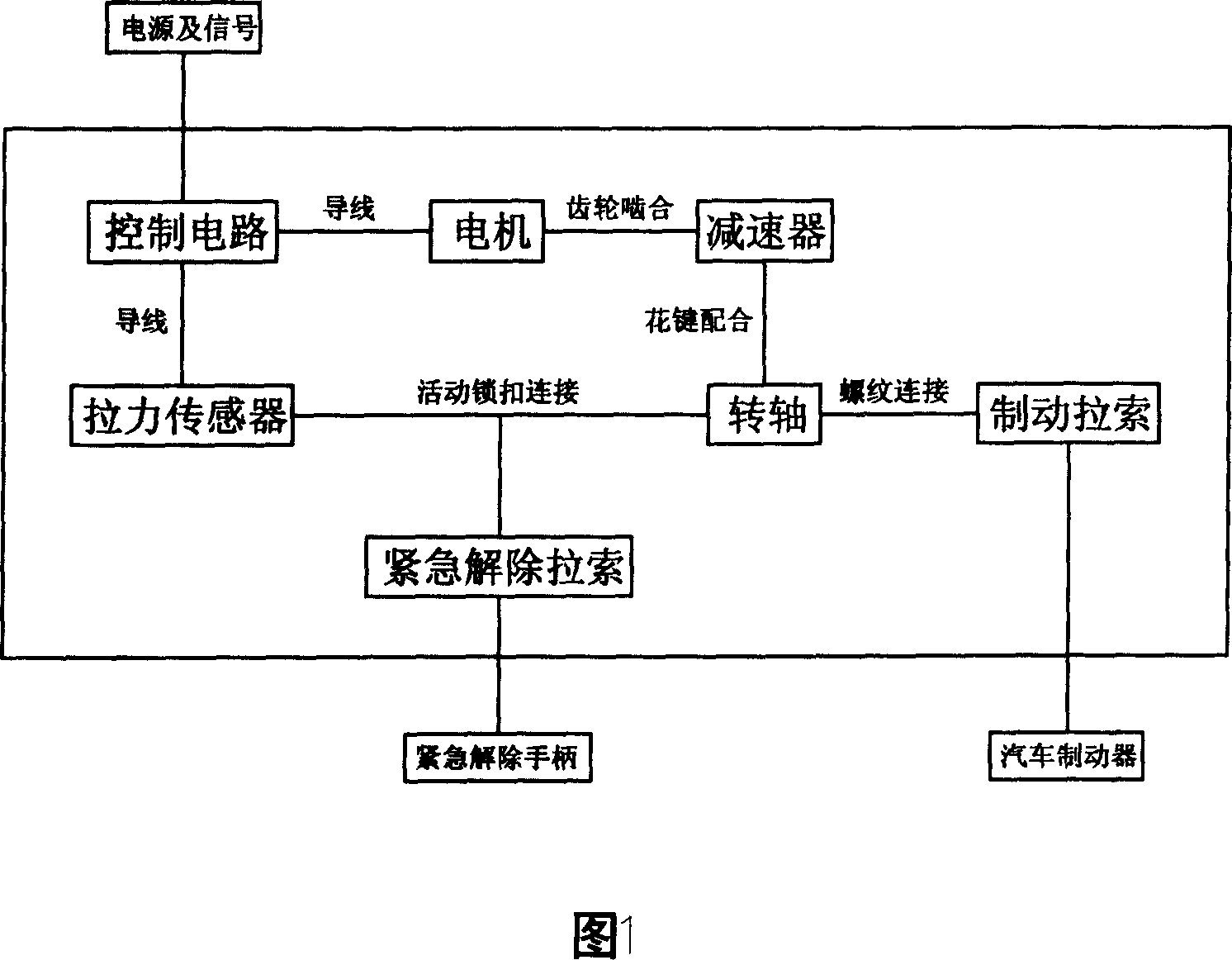

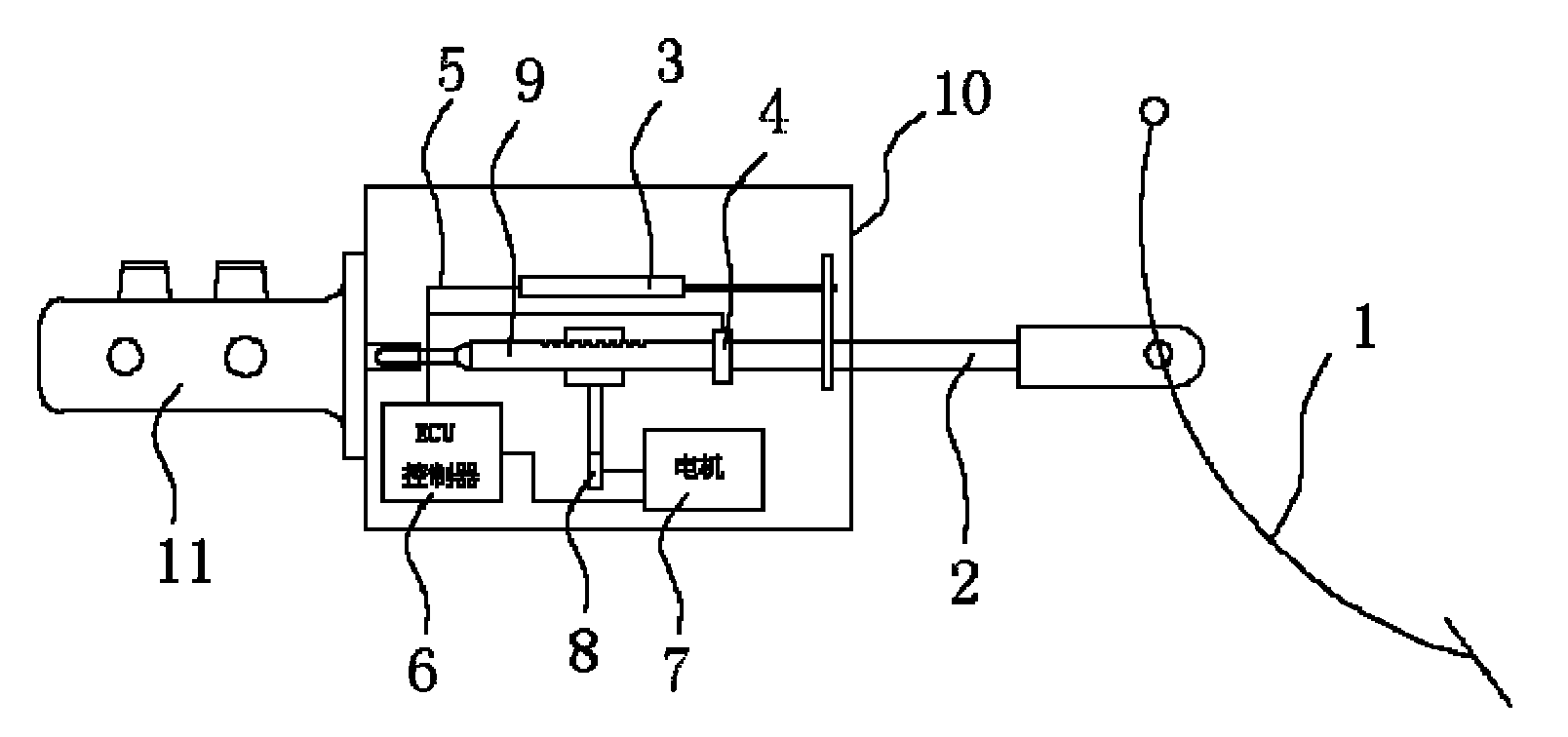

Electric parking and braking device

InactiveCN101032960ARealize self-locking functionIncrease axial forceBraking action transmissionControl circuitSignal acquisition

The electric brake apparatus includes one executing mechanism for braking or brake off; one control module includes one signal acquiring circuit to acquire at least signals of brake switch, engine rotation speed, automobile speed, gear box setting and ignition lock setting, and one control circuit to judge based on the acquired signals and to send command for controlling the executing mechanism; and one emergency release assembly to release the braking state of the brake apparatus in case of self abnormality and incapability of braking. The electric brake apparatus is superior to available manual brake apparatus.

Owner:XIAMEN AUTOSTAR ELECTRONICS CO LTD

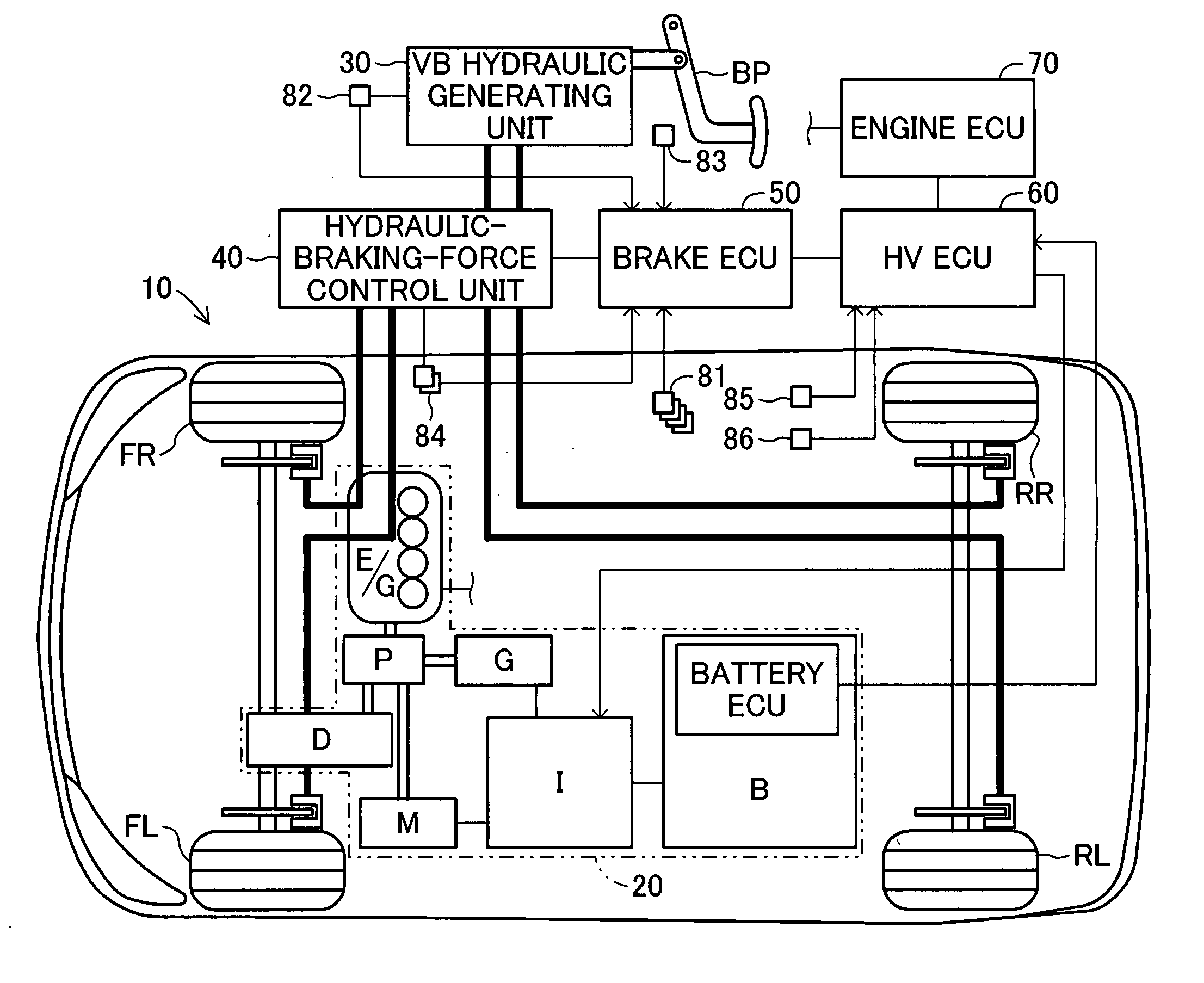

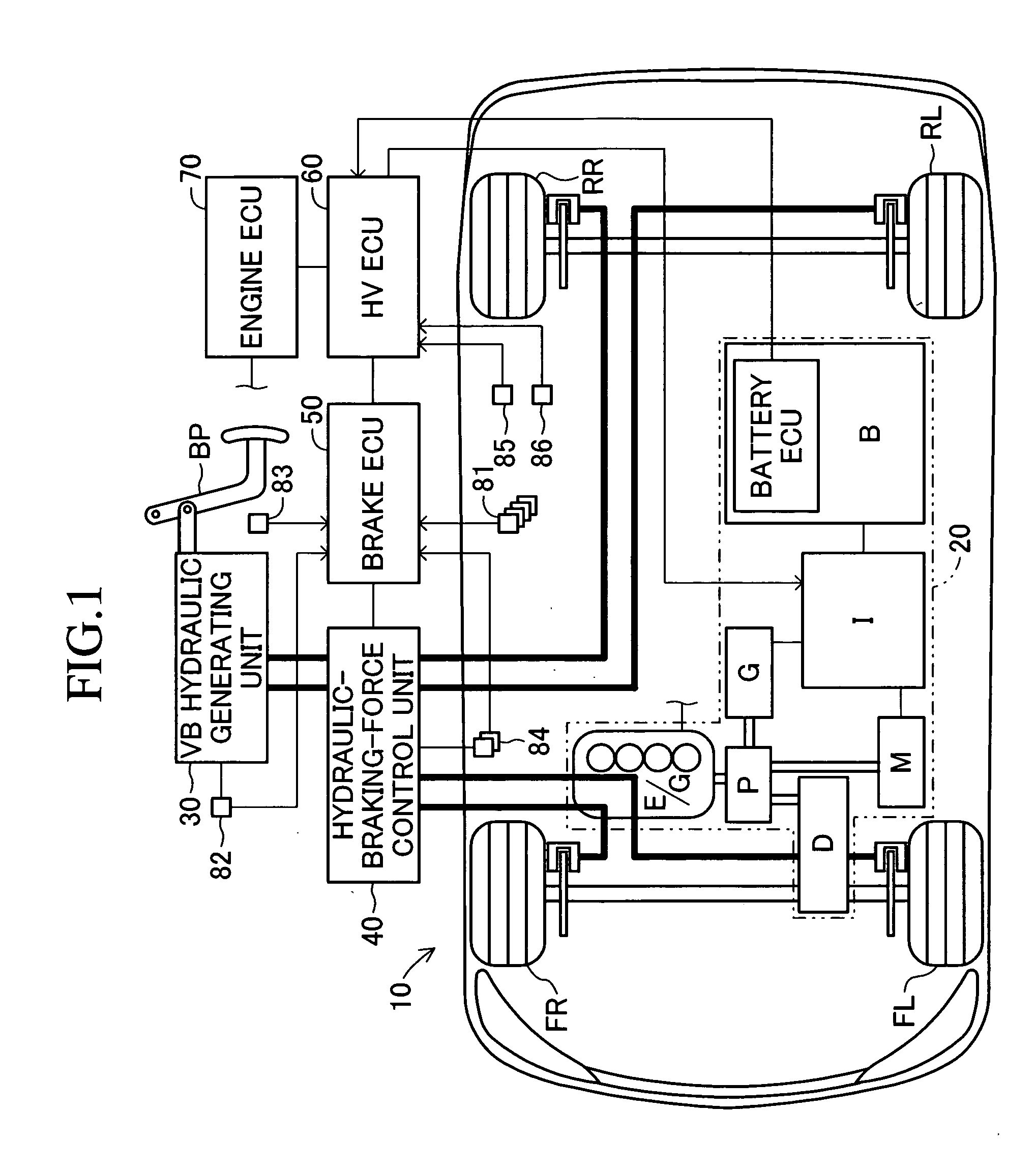

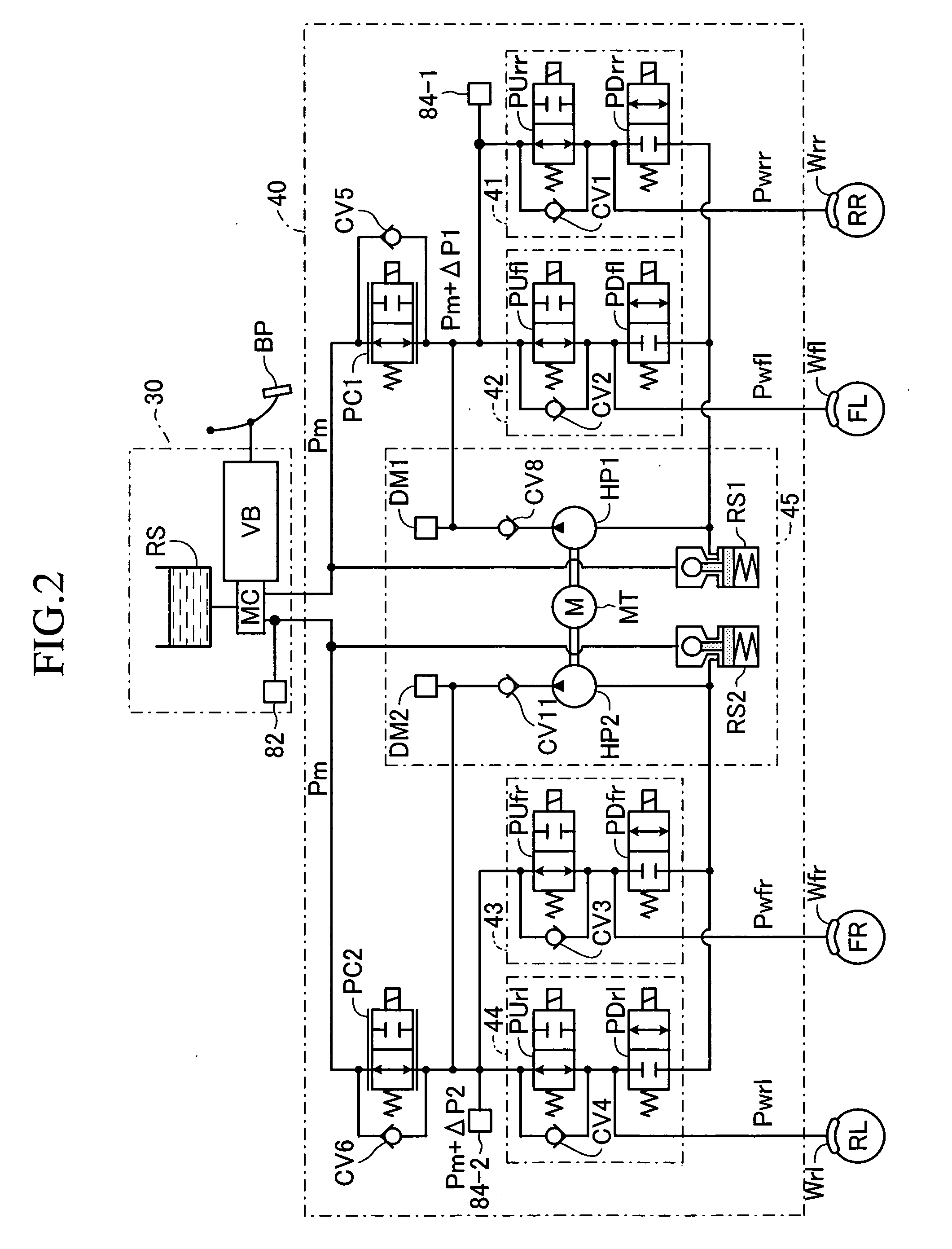

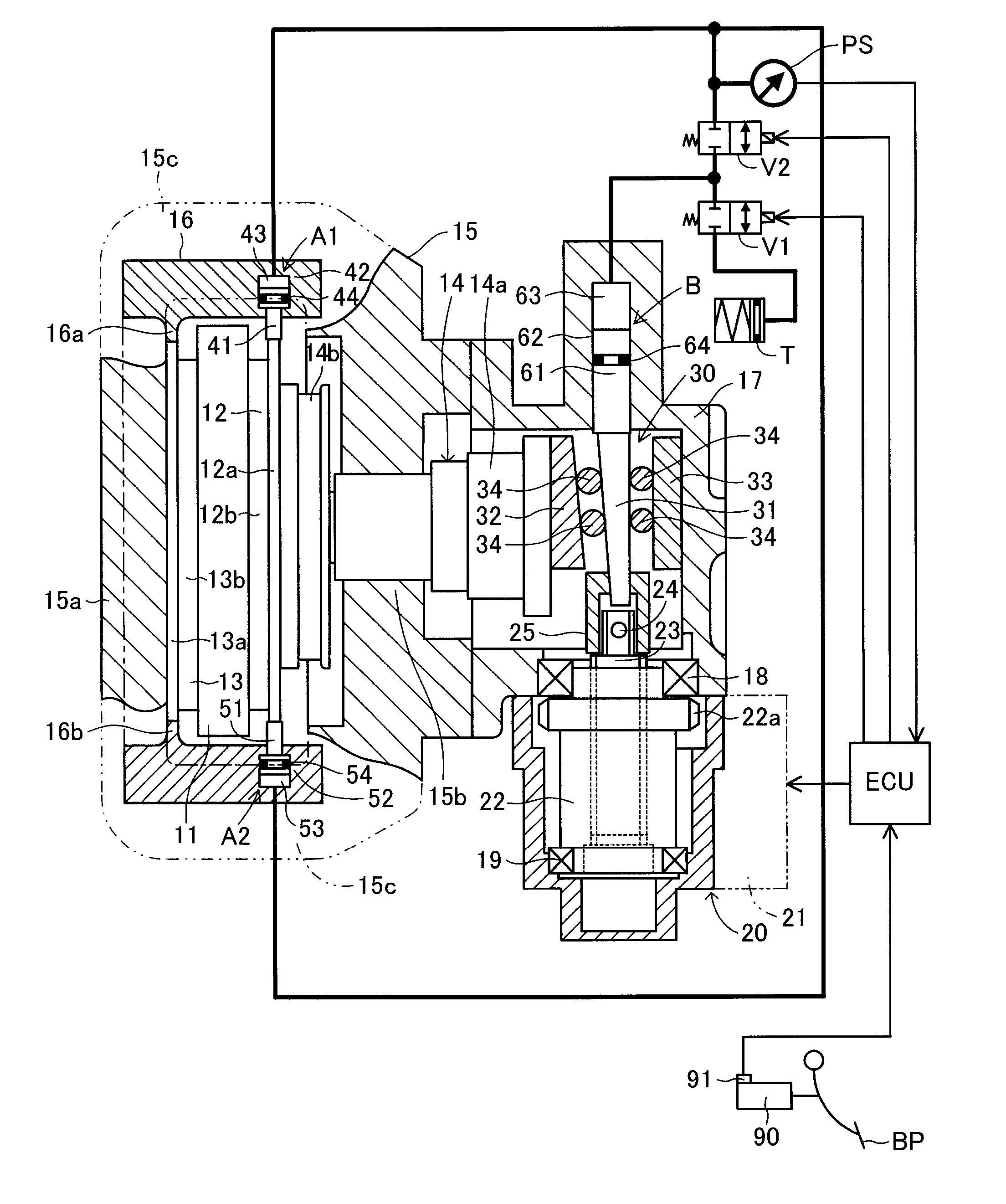

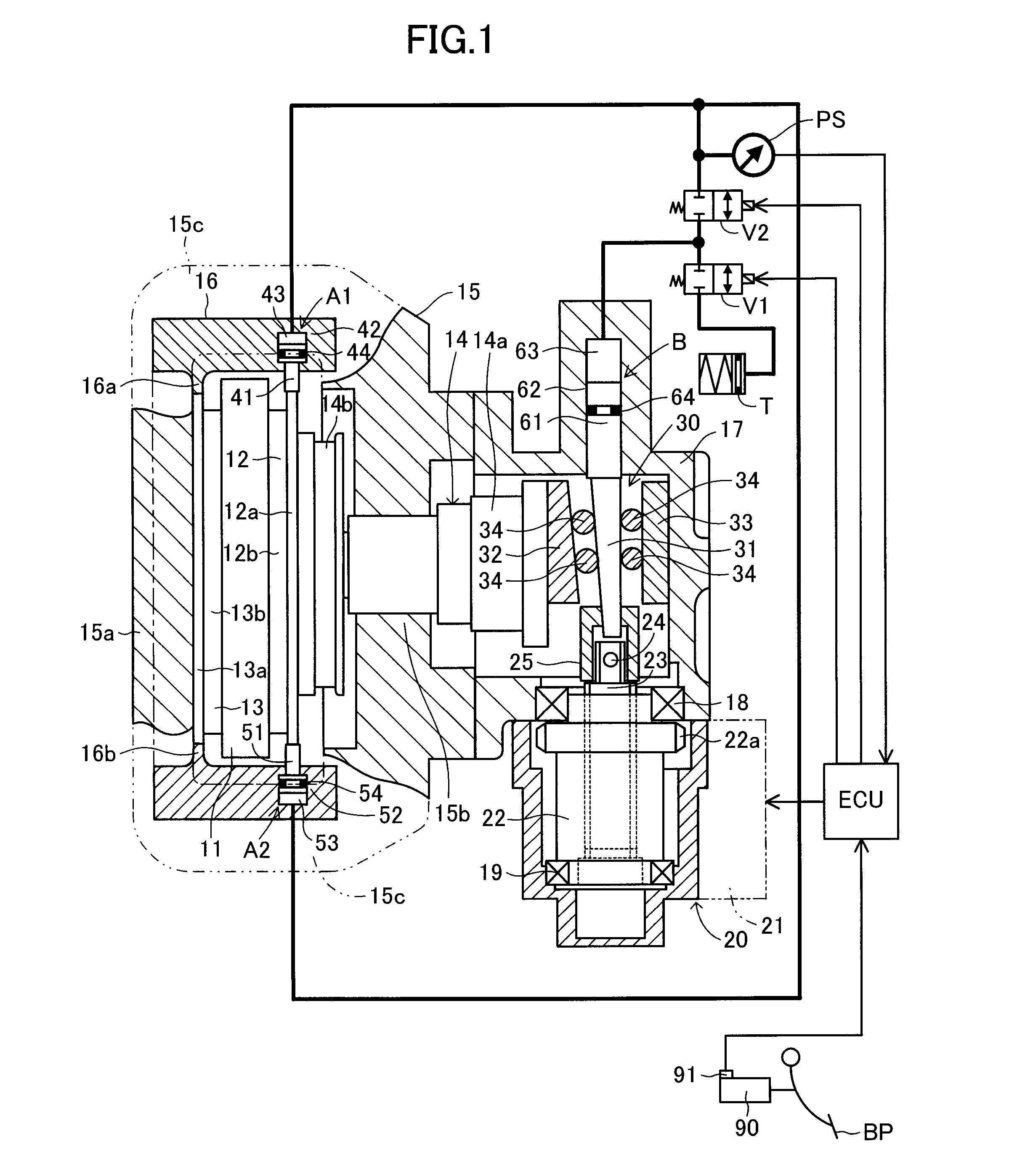

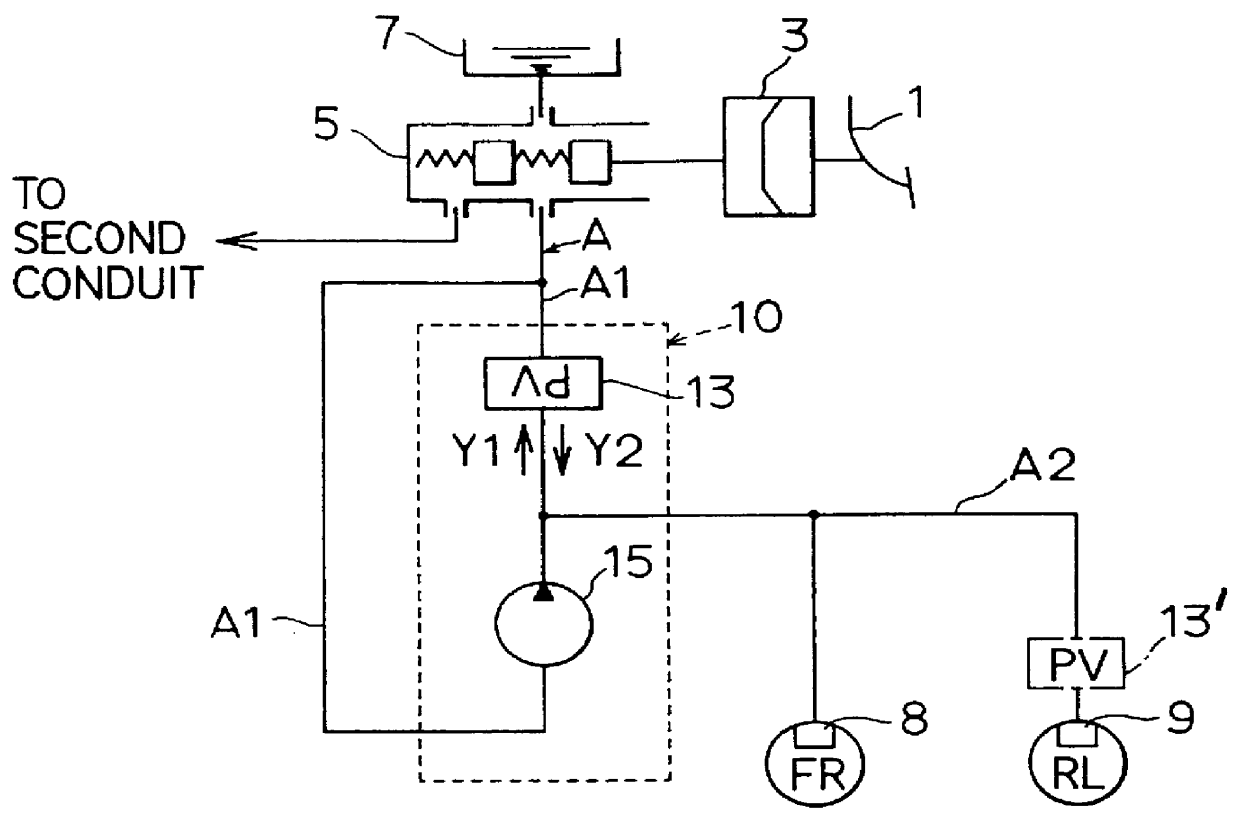

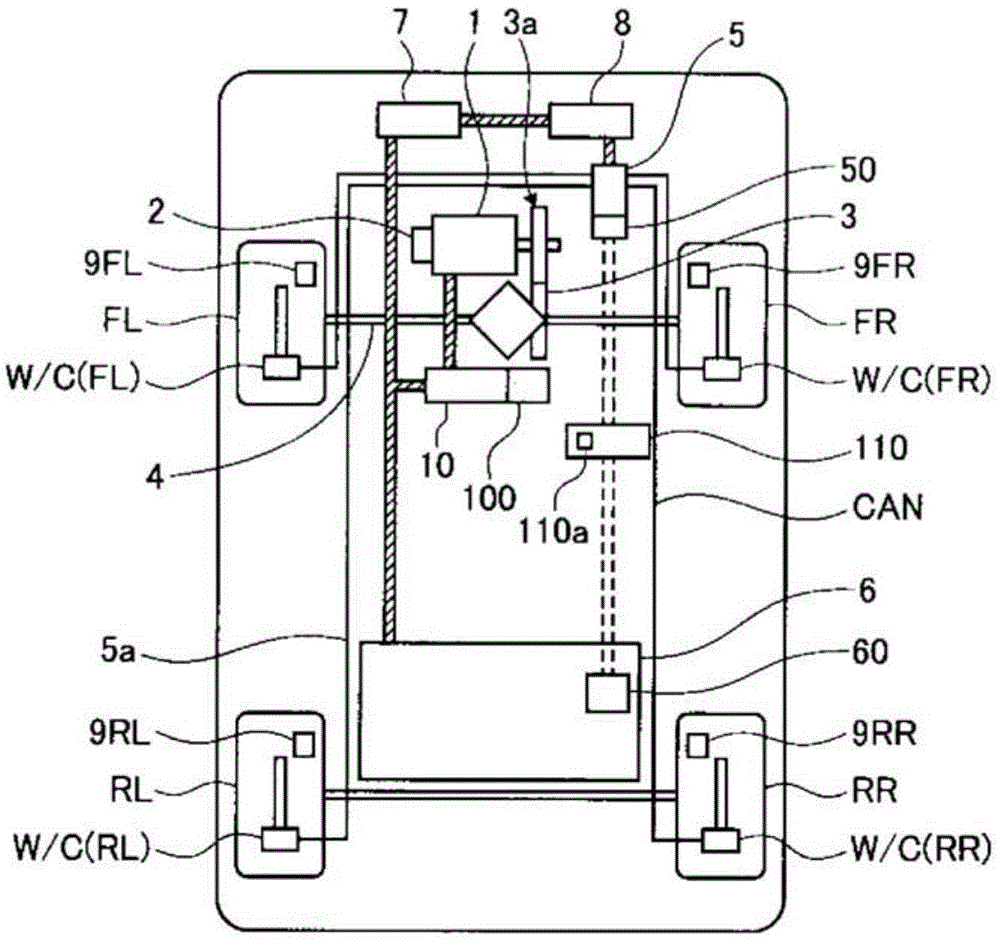

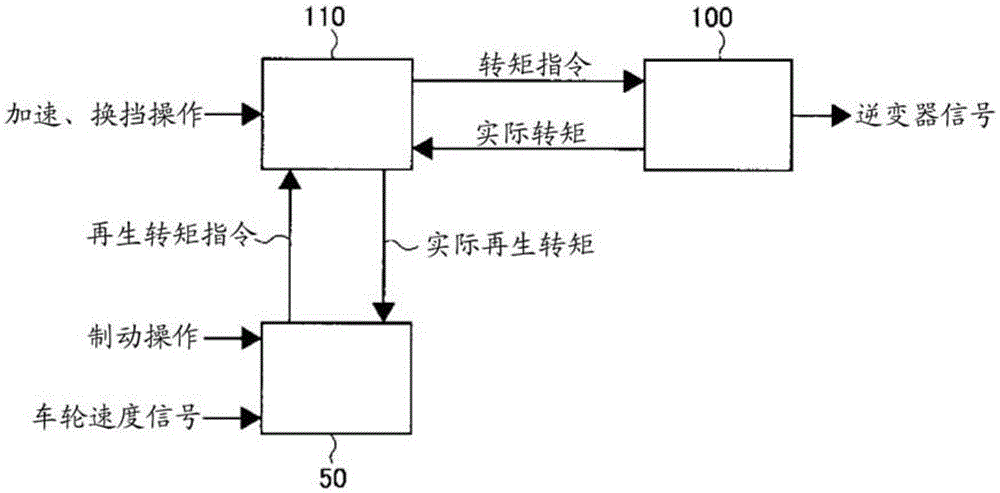

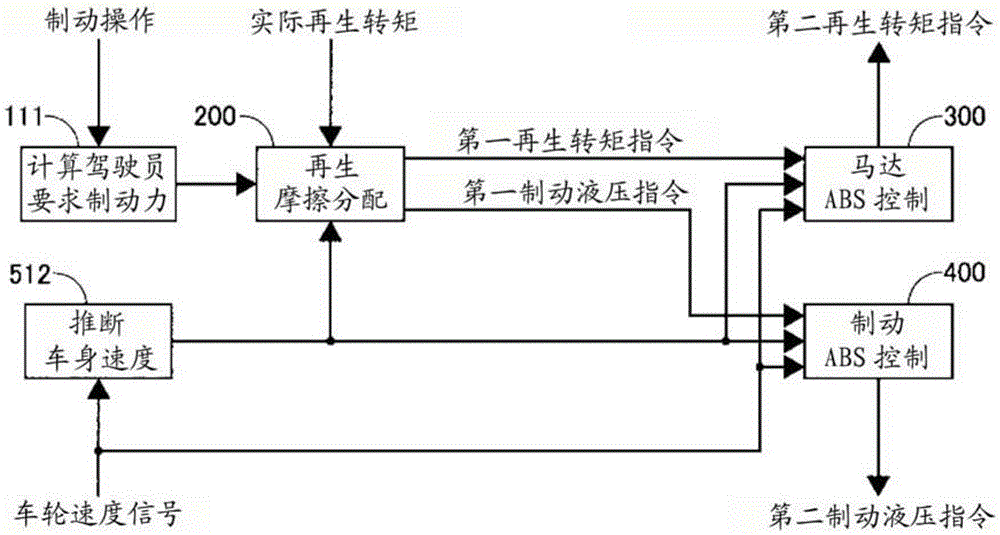

Vehicle-brake control unit

InactiveUS20060125317A1Large braking forceHybrid vehiclesBraking element arrangementsRegenerative brakeMaster cylinder

The unit controls a linear-valve-pressure-difference braking force and a regenerative braking force so that a total braking force obtained by adding a complementary braking force that is “the sum of the increments of the respective hydraulic braking forces by linear-valve pressure differences generated by linear solenoid valves disposed for their respective systems (linear-valve-pressure-difference braking force) and a regenerative braking force” to a hydraulic braking force (VB hydraulic braking force) based on a master-cylinder pressure output from a master cylinder reaches a target value for a brake-pedal pressure. For example, for a vehicle equipped with a cross pipe arrangement, when one of the linear solenoid valves fails, the linear-valve pressure difference of a normal linear solenoid valve is set to a value as twice as large as that when both of the linear solenoid valves are normal.

Owner:ADVICS CO LTD

Brake plate

InactiveUS20060180414A1Improve stressLarge braking forceMetal-working apparatusBraking membersEngineeringBrake lining

The invention relates to a brake lining carrier plate 1 to hold a friction lining, especially for installation into a vehicle brake system, with holding structures 15, 16 for the friction lining arranged in rows 6 on the lining side 2, whereby each holding structure 15, 16 has a protrusion 3 and a depression 4, whereby the protrusion 3 is made when the depression 4 is formed in the surface 5 through the displacement of material. Said protrusion 3 engages with the friction lining. The holding structures 15, 16 in the rows 6 are arranged in such a way that there is a protrusion 10 at the beginning 8 and at the end 9 of each row 6. In one embodiment, the rows 6 run essentially crosswise to the longitudinal axis 7 of the brake lining carrier plate 1.

Owner:AML LANXIDE EURO

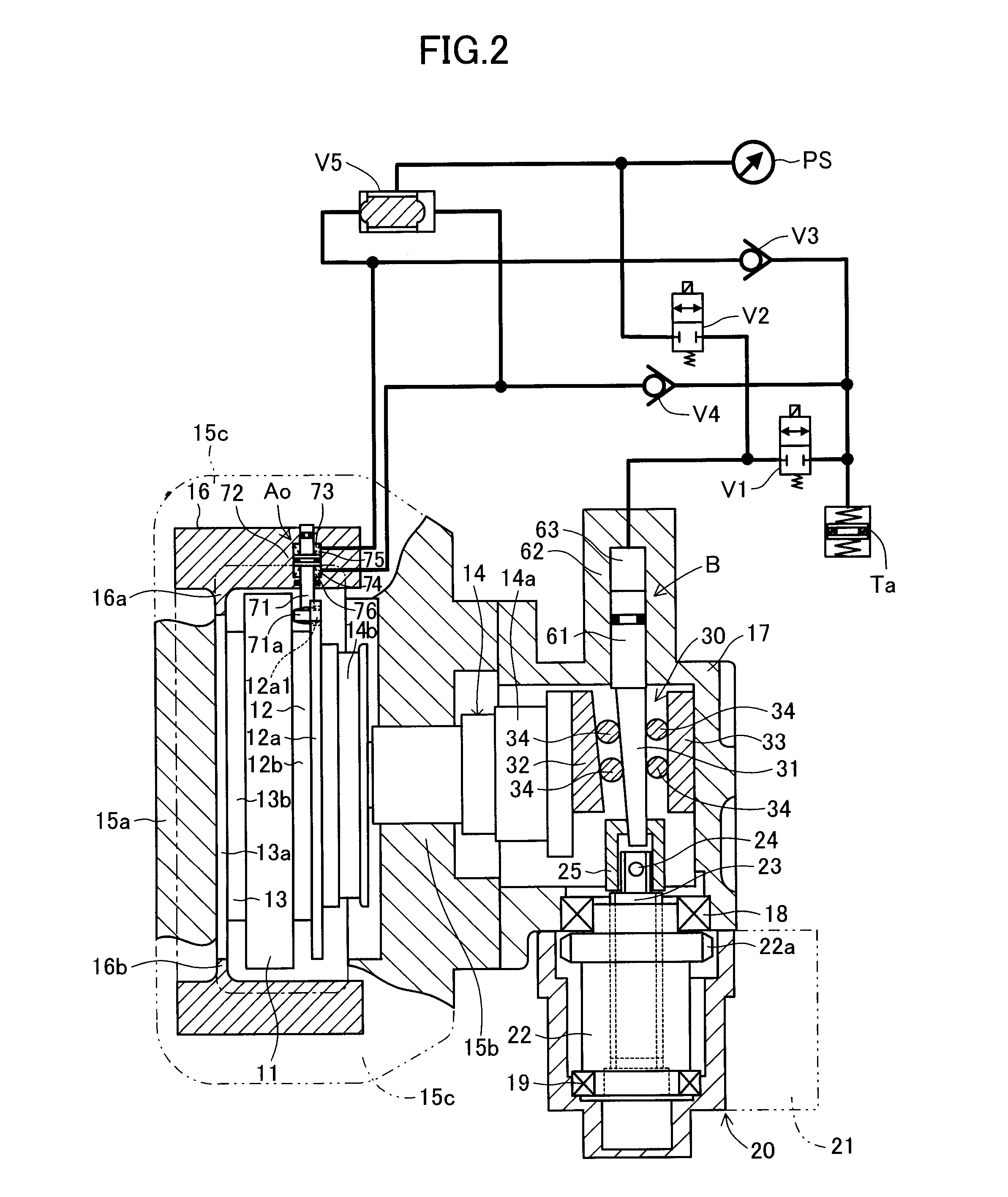

Disc Brake Apparatus

InactiveUS20070045061A1Small sizeLarge braking forceAxially engaging brakesBrake actuating mechanismsEngineeringCalipers

In a disc brake apparatus, by means of an actuator which operates in accordance with an operation force, a braking piston fitted into a cylinder portion of a caliper is axially driven so as to push a pad toward a disc rotor. A friction force in a circumferential direction of the disc rotor between the pad and the disc rotor is taken out as an anchor load, and is converted to a servo load by means of a servomechanism. The servo load is applied to the braking piston. The servomechanism is equipped with a hydraulic mechanism (a pressure-reducing control valve, a pressure-increasing control valve, and a reservoir tank) capable of increasing or decreasing the servo load. An electric controller controls the hydraulic mechanism in accordance with the operation force and the anchor load.

Owner:ADVICS CO LTD

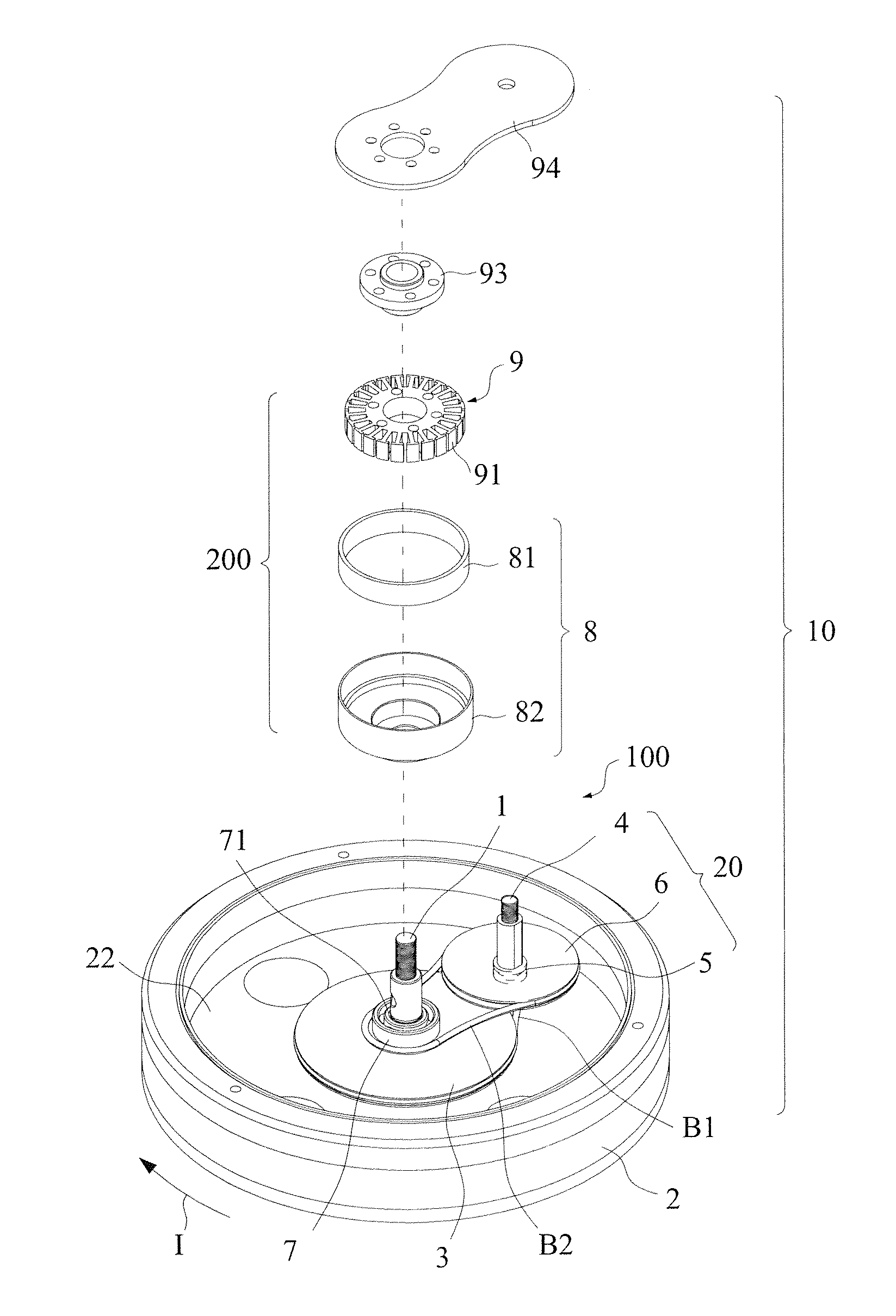

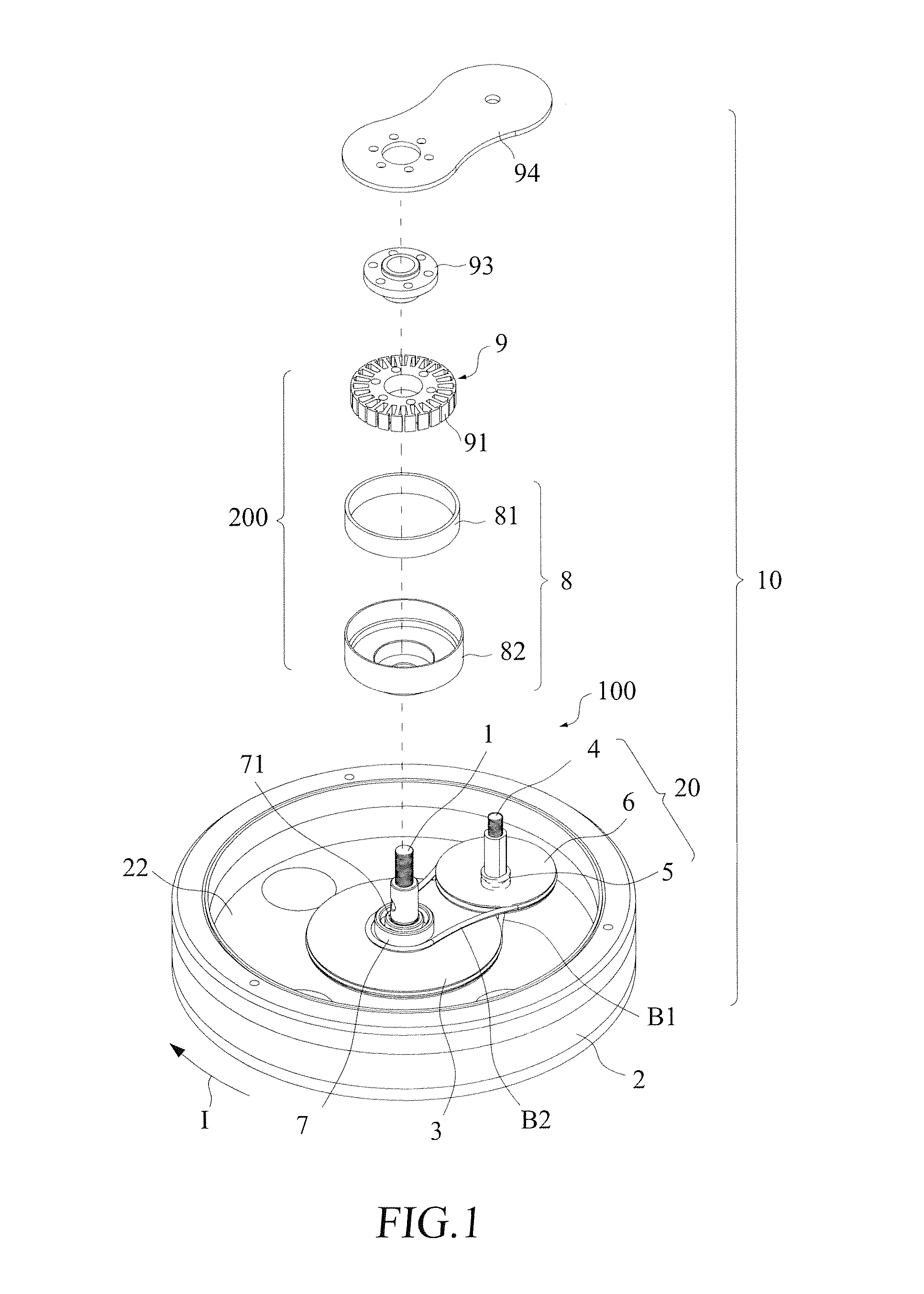

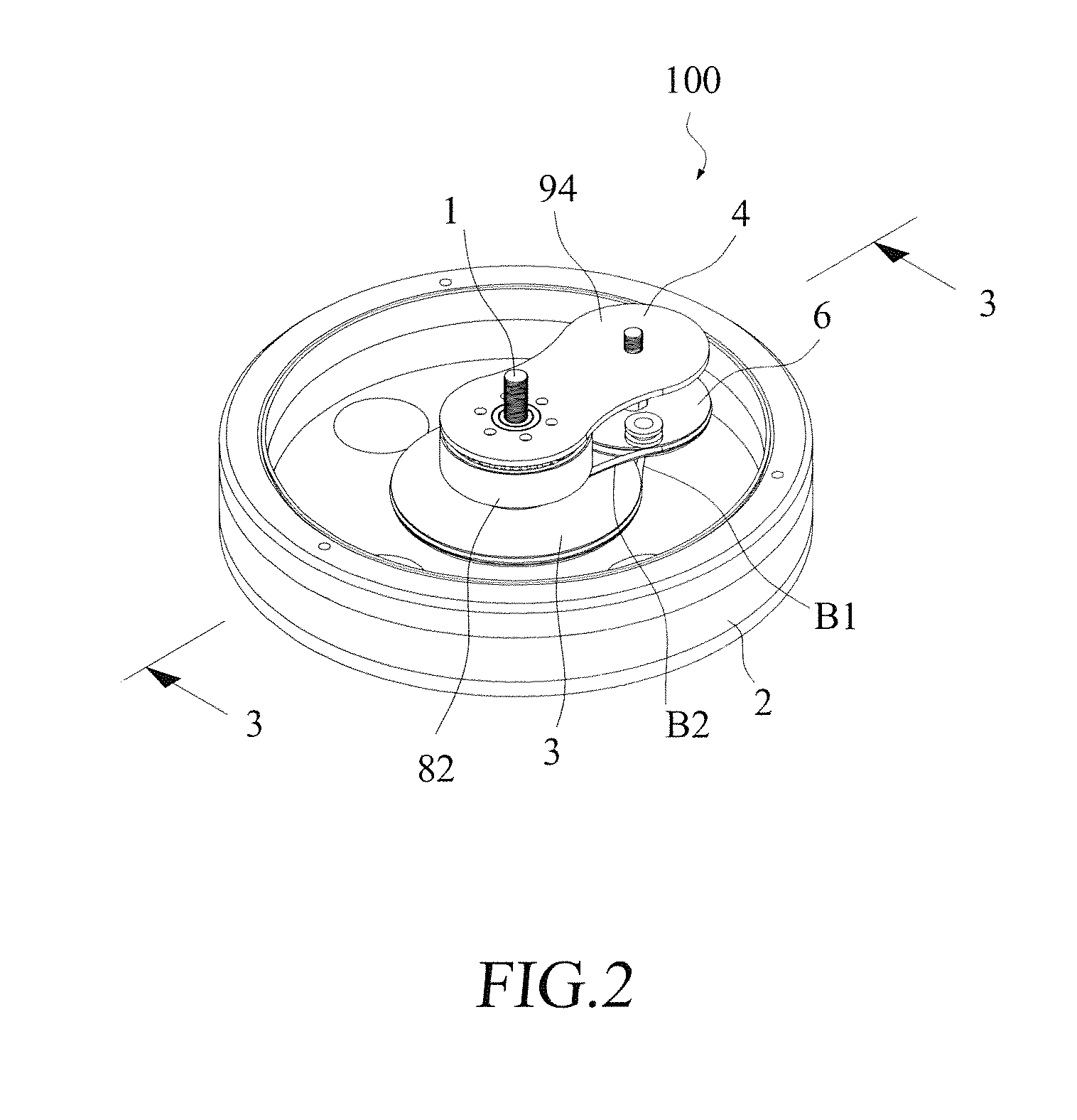

Acceleration mechanism for exercise equipment

InactiveUS20120217758A1Large braking forceReduce volumeFrom muscle energyGearingExercise equipmentRotating disc

A rotary disk acceleration mechanism for exercise equipment includes a stationary axle; a first large rotary disk; at least one acceleration disk assembly; a first belt, which is coupled between the acceleration disk assembly and the first large rotary disk; a first bearing, which is mounted to the stationary axle; a second small rotary disk, which is rotatably mounted by the first bearing to the stationary axle and is coaxial with the first large rotary disk; and a second belt, which is coupled between the acceleration disk assembly and the second small rotary disk, so that the acceleration disk assembly drives, via the second belt, the second small rotary disk to rotate.

Owner:BION

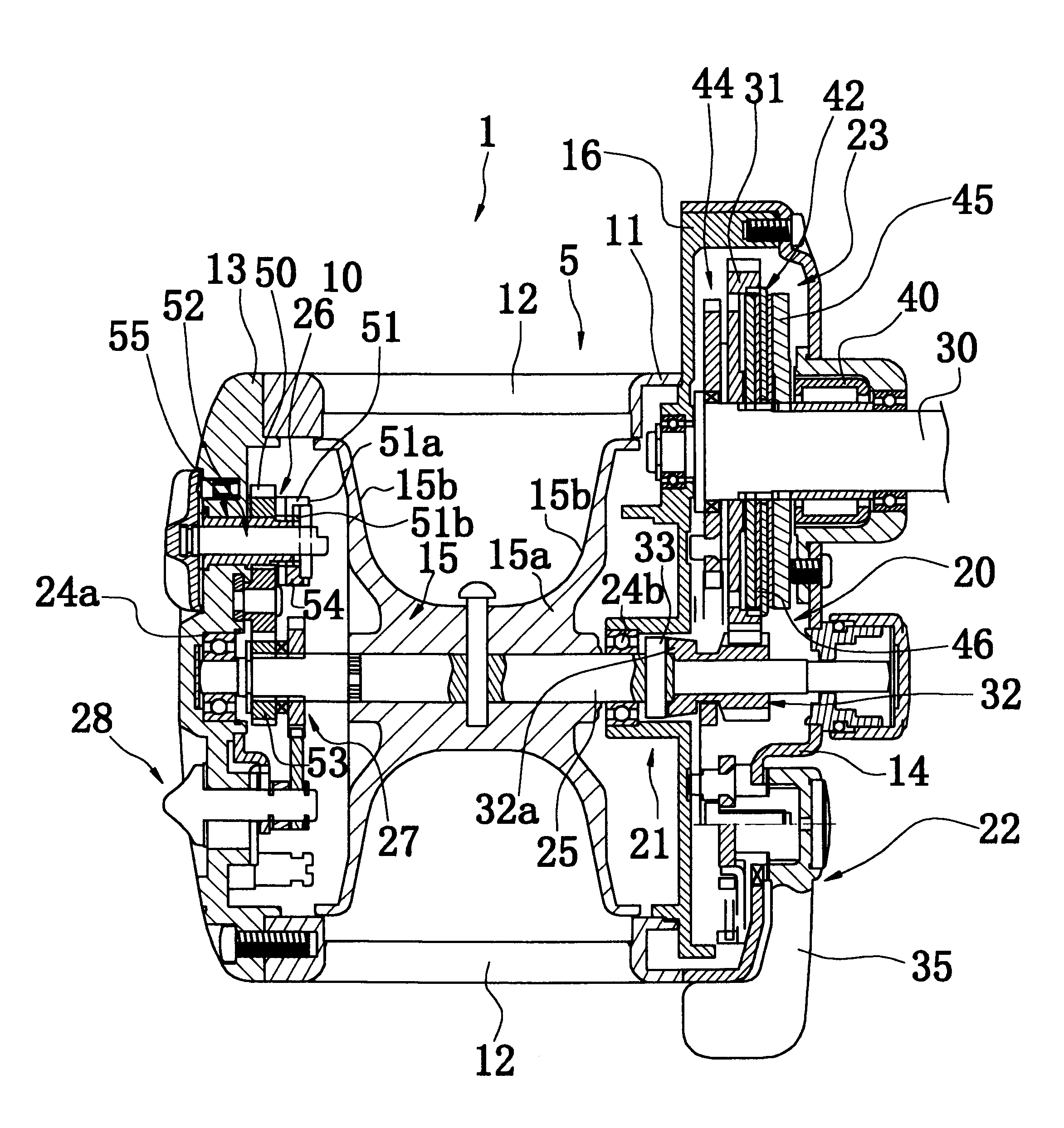

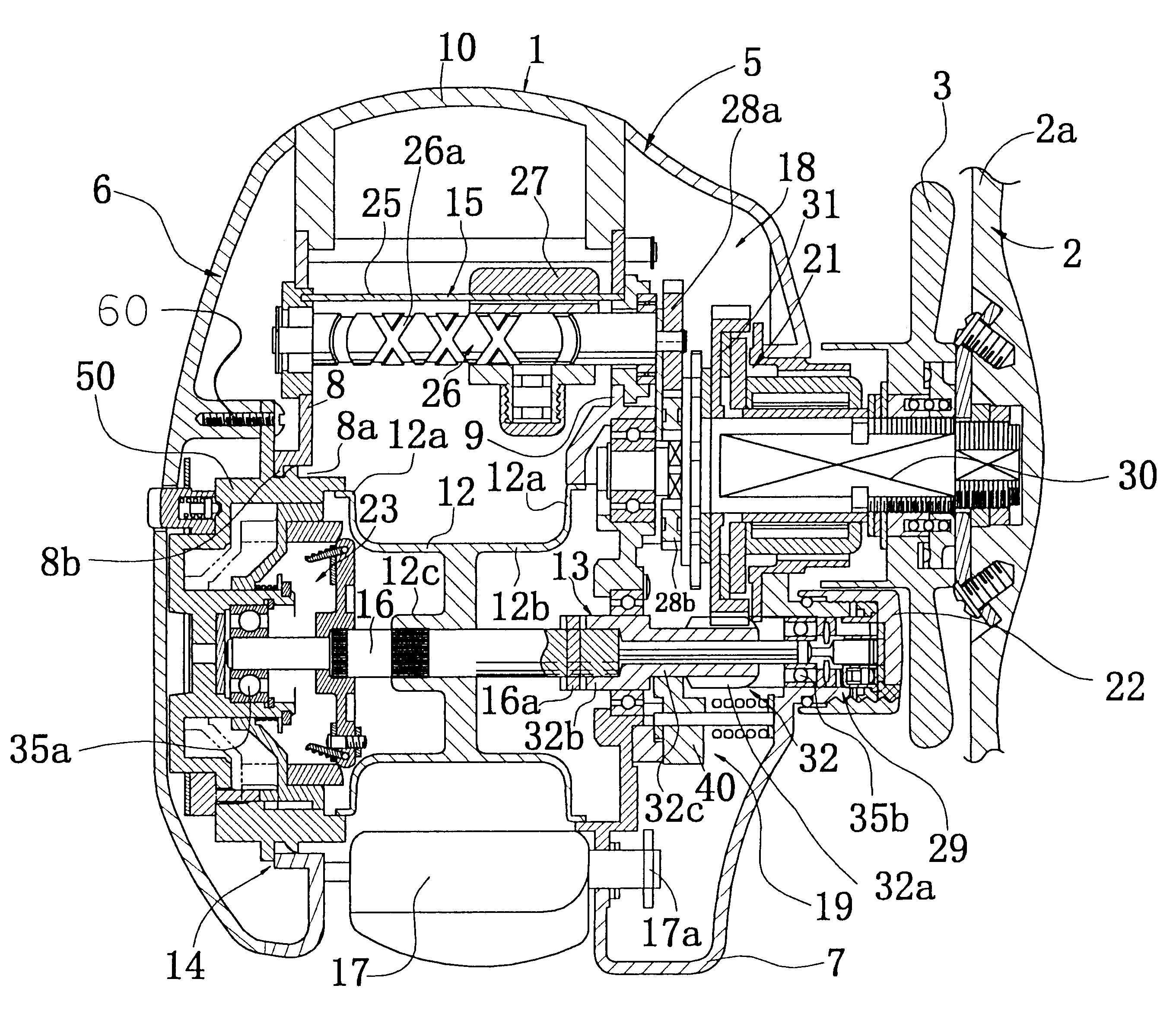

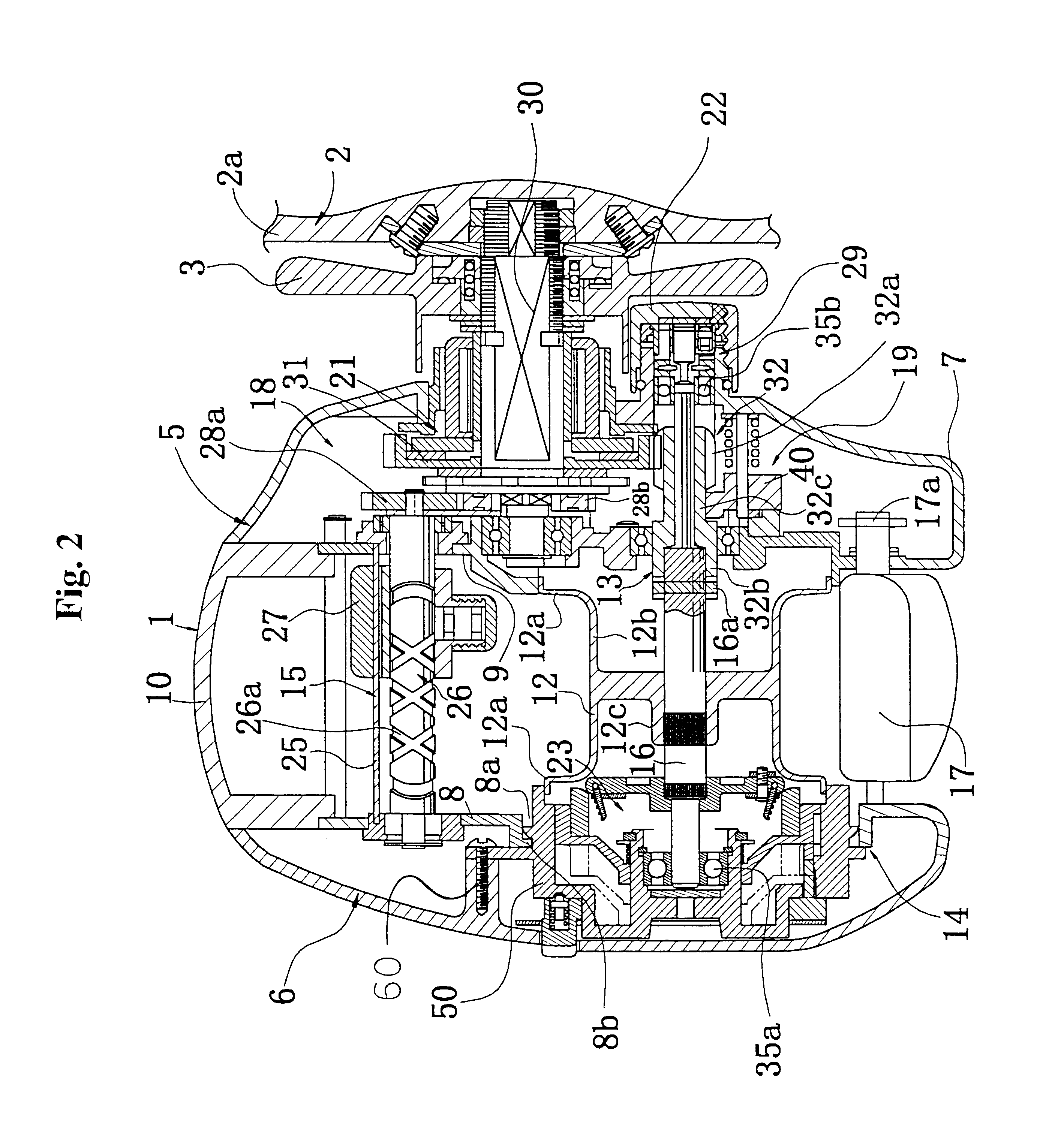

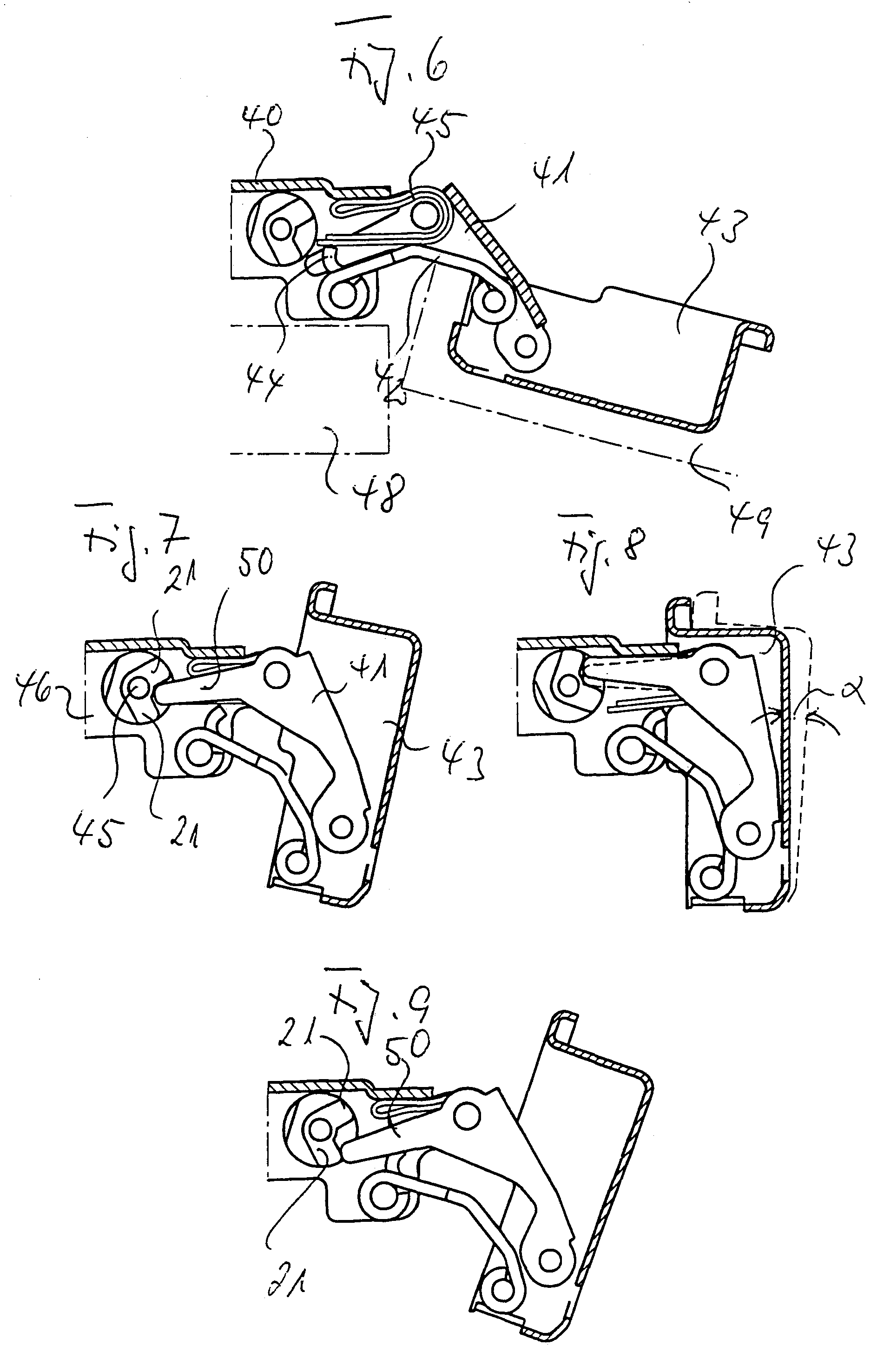

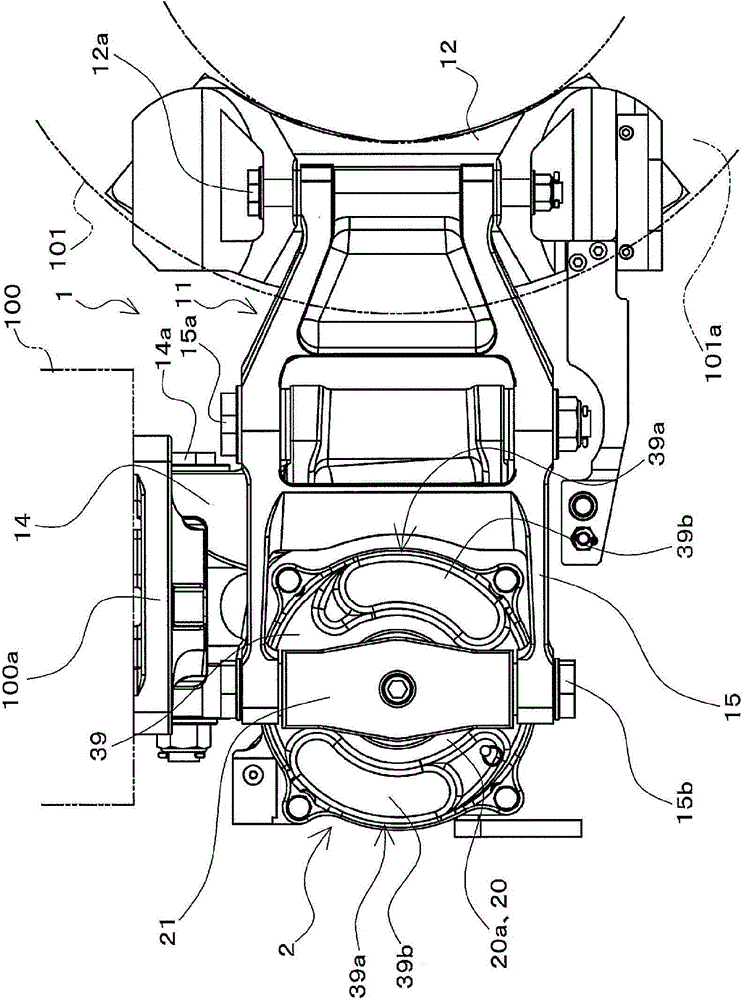

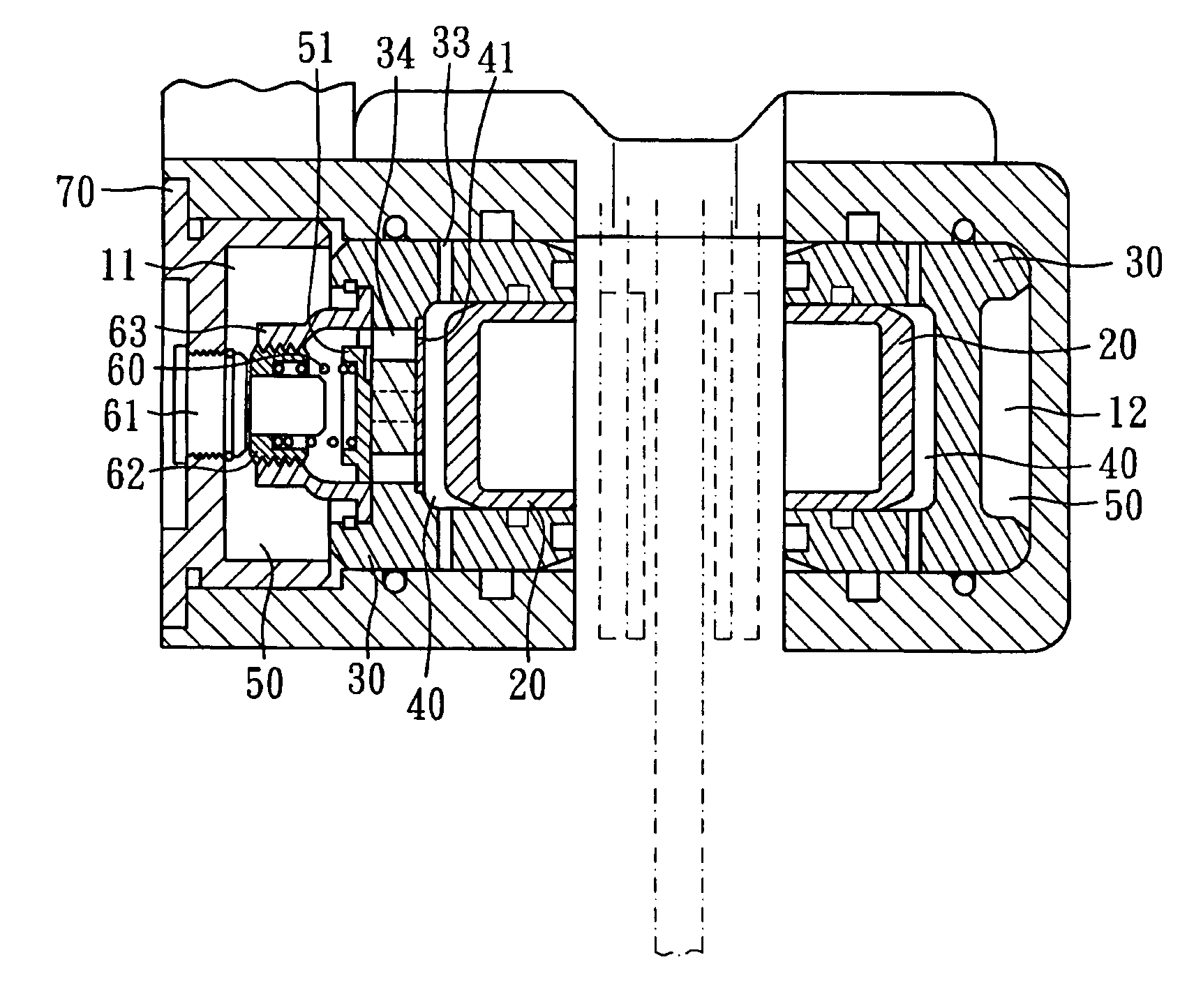

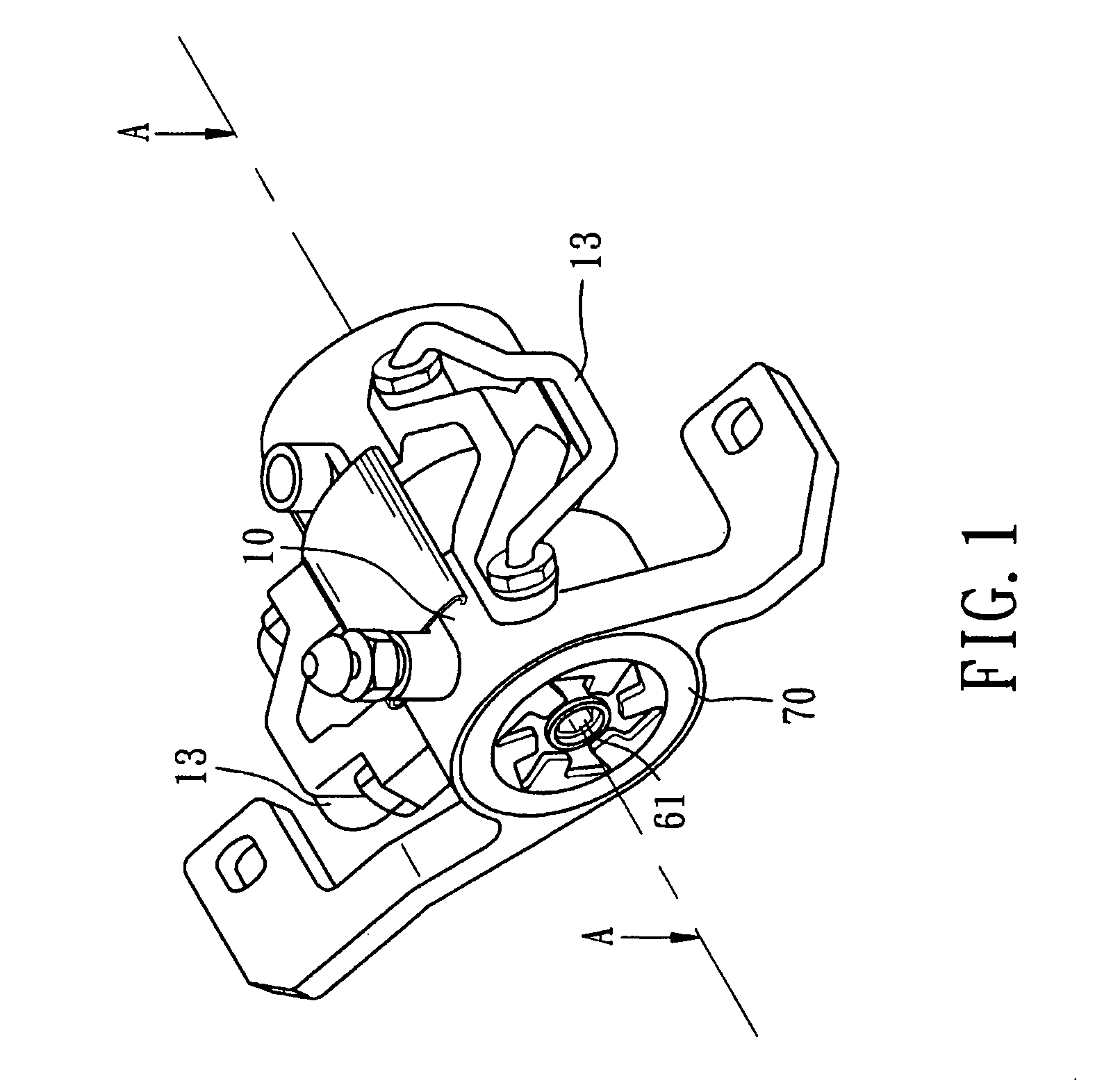

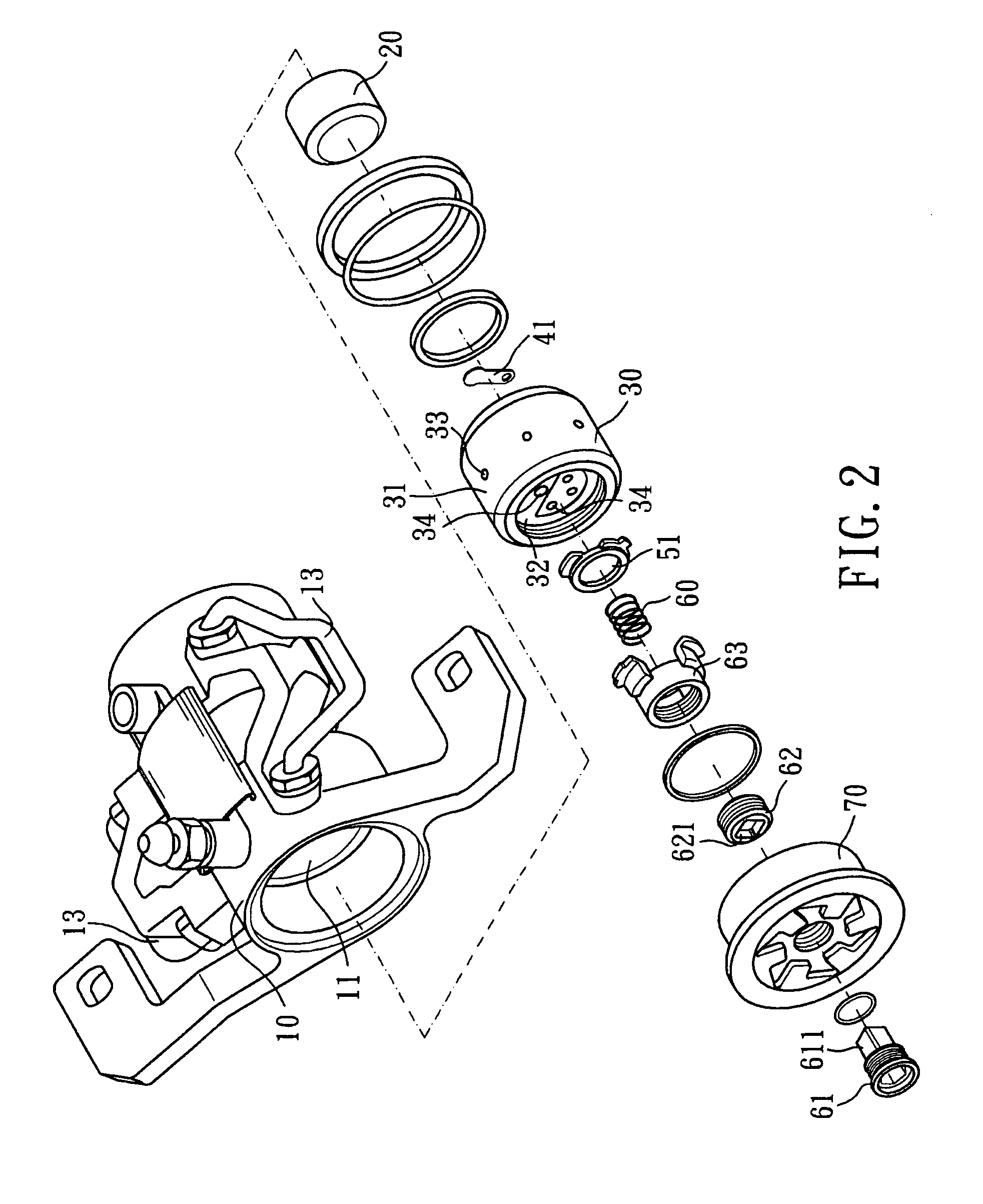

Centrifugal braking device for double bearing reel

A centrifugal braking mechanism is a device for braking a spool that is rotatably supported in a reel body. The braking mechanism uses centrifugal forces in order to produce braking force against rotation of the spool. The braking mechanism includes a plurality of brake members, a brake housing having a cylindrically shaped brake liner, and an adjusting mechanism. Each of the plurality of brake members is configured to move in a radially outward direction relative to the spool in response to rotation of the spool. The brake housing and brake liner are moveable in an axial direction relative to the spool and brake members such that any selected number of the brake members may contact the brake liner to generate the braking force. The adjusting mechanism is used to selectively move the brake housing and brake liner into any of a plurality of axial positions thereby determining the number of brake members that are contactable with the brake liner in response to centrifugal force. The level of braking force desired is determined by the number of brake members that may contact the brake liner.

Owner:SHIMANO INC

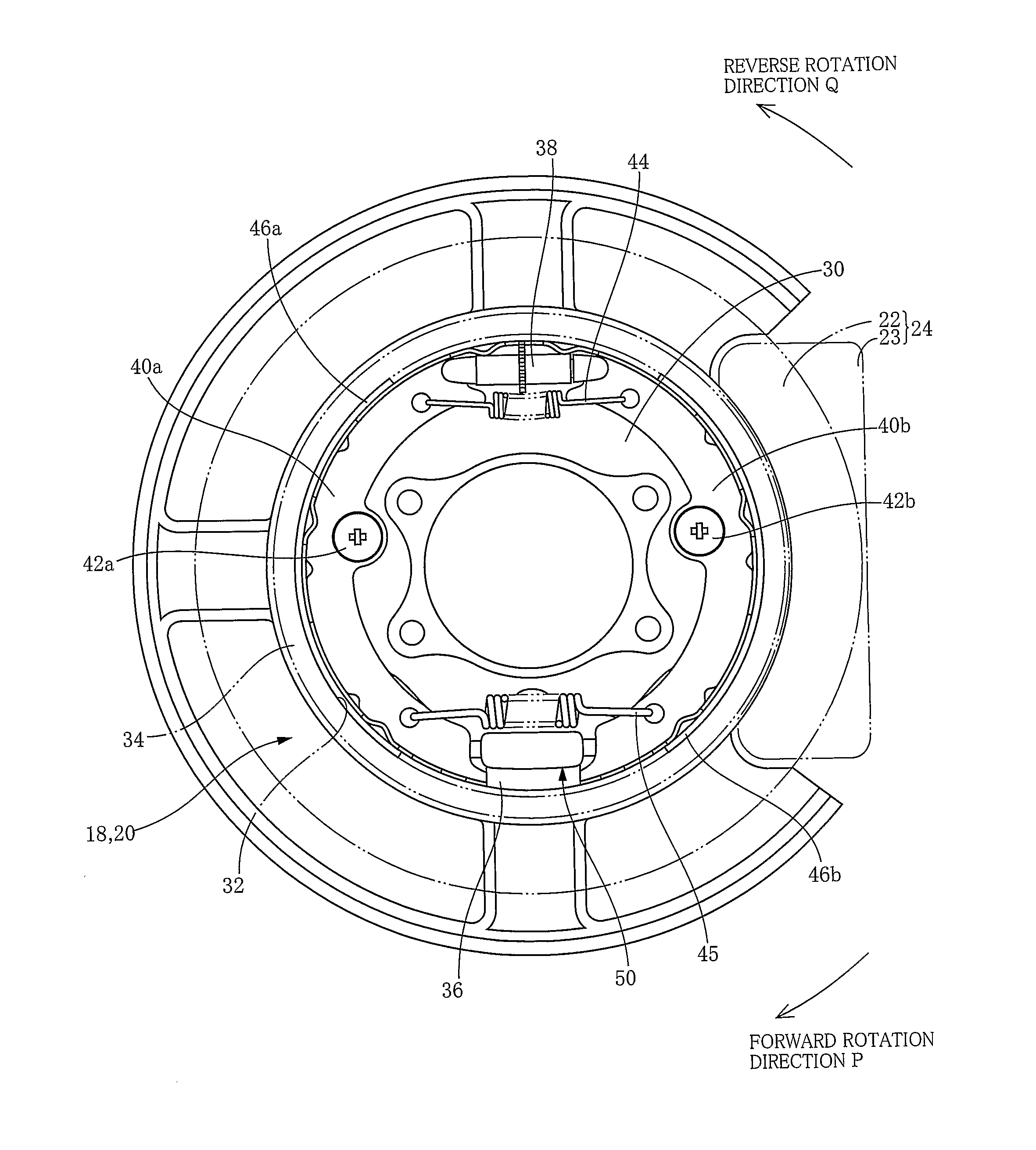

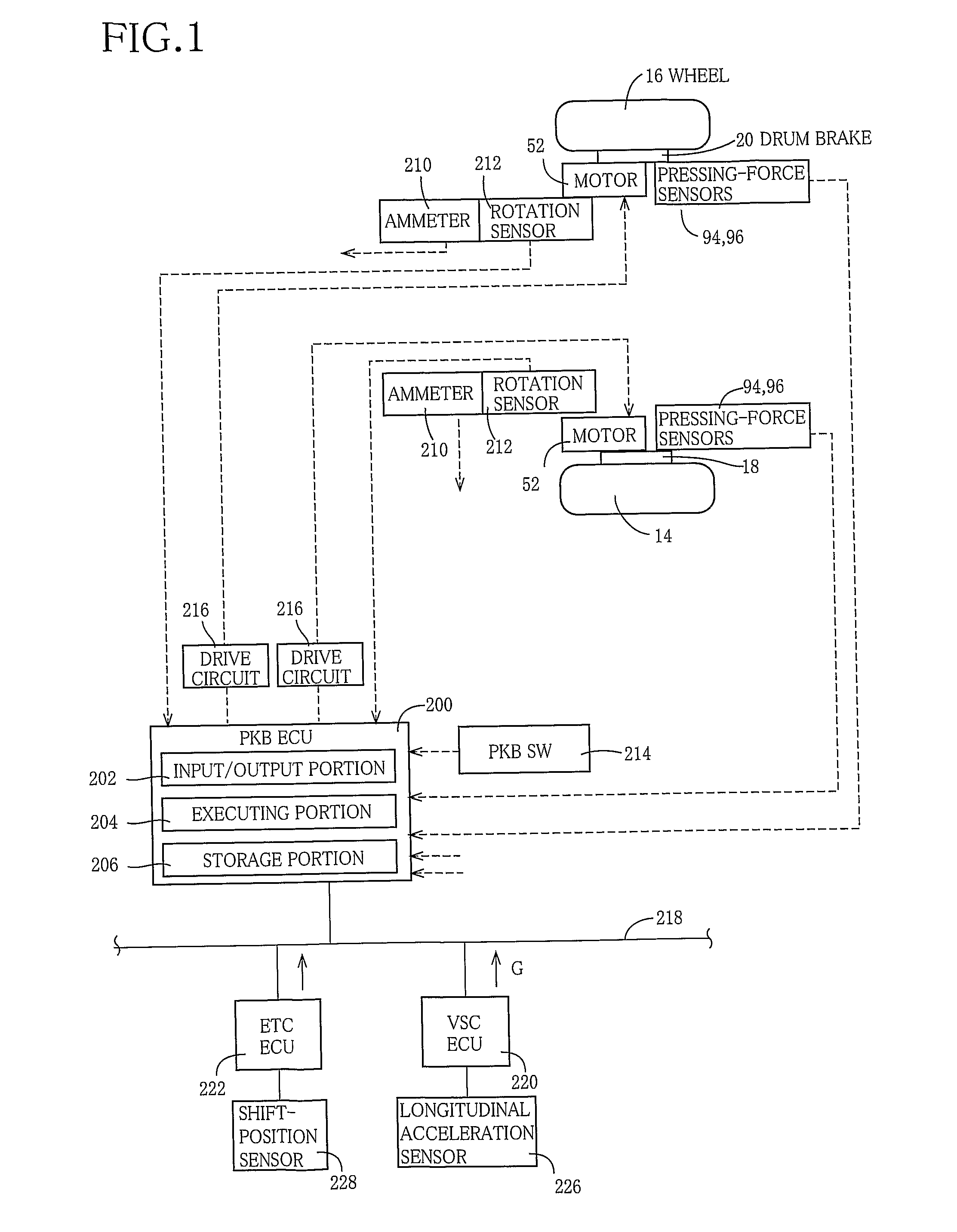

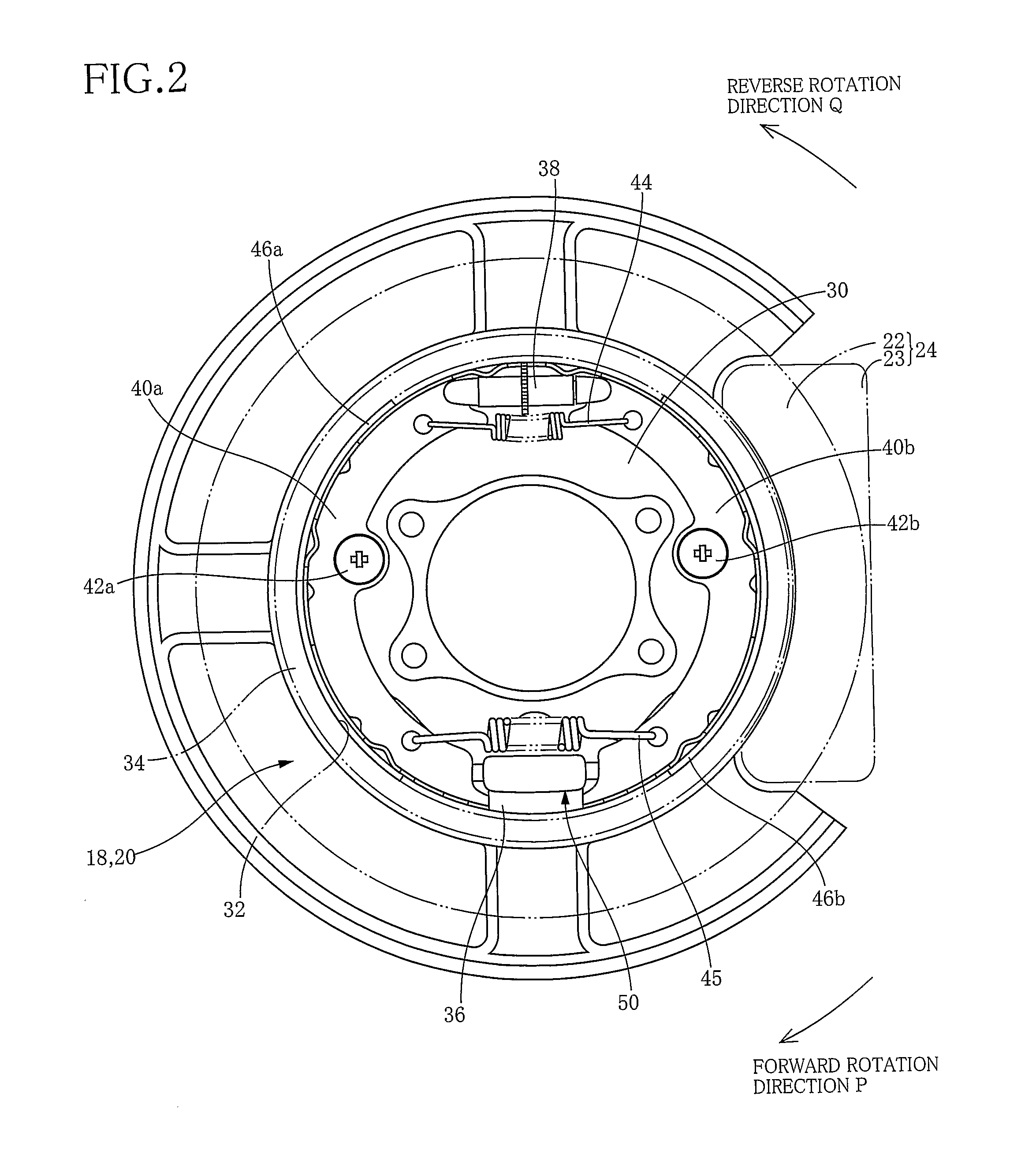

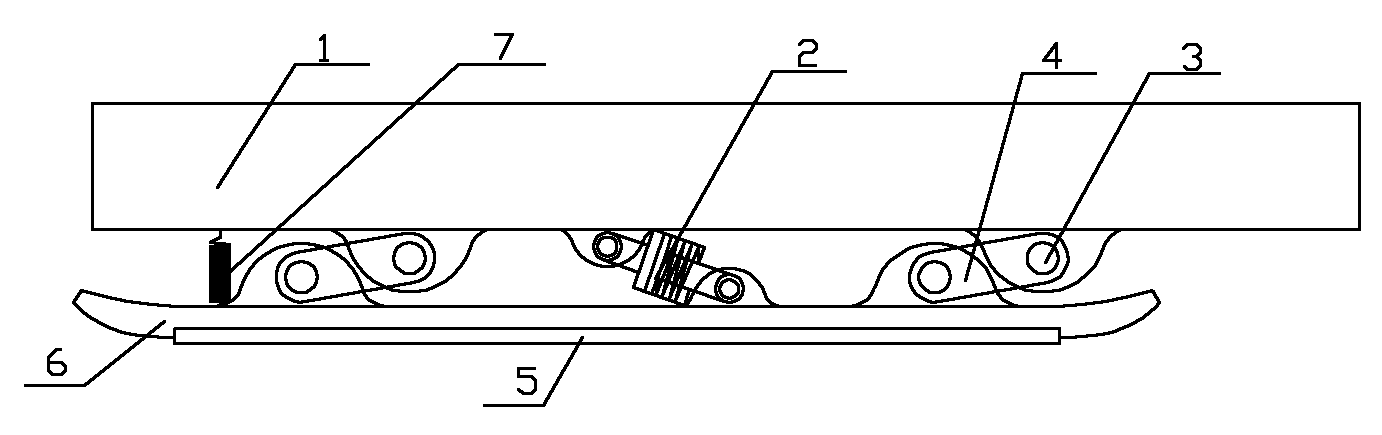

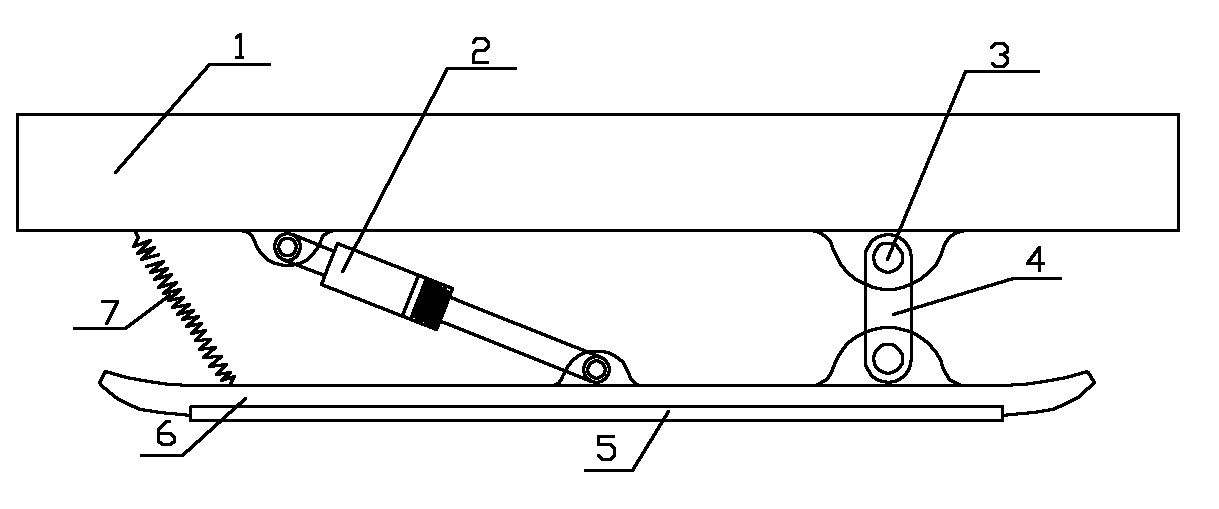

Parking brake system

A vehicle parking brake system for a vehicle including: a non-rotary body; a rotary drum; brake shoes; an anchor member disposed between anchor-member-side end portions of the respective brake shoes; a transmitting member interconnecting transmitting-member-side end portions of the respective brake shoes; and a parking-brake operating apparatus configured to predict a torque application direction in which a torque is to be applied to the wheel during stop of the vehicle, and to press the brake shoes against an inner circumferential surface of the rotary drum, by moving a primary one of the brake shoes that serves as a primary shoe upon application of the torque to the wheel, in a direction away from the anchor member, without moving a secondary one of the brake shoes that serves as a secondary shoe upon application of the torque to the wheel.

Owner:TOYOTA JIDOSHA KK

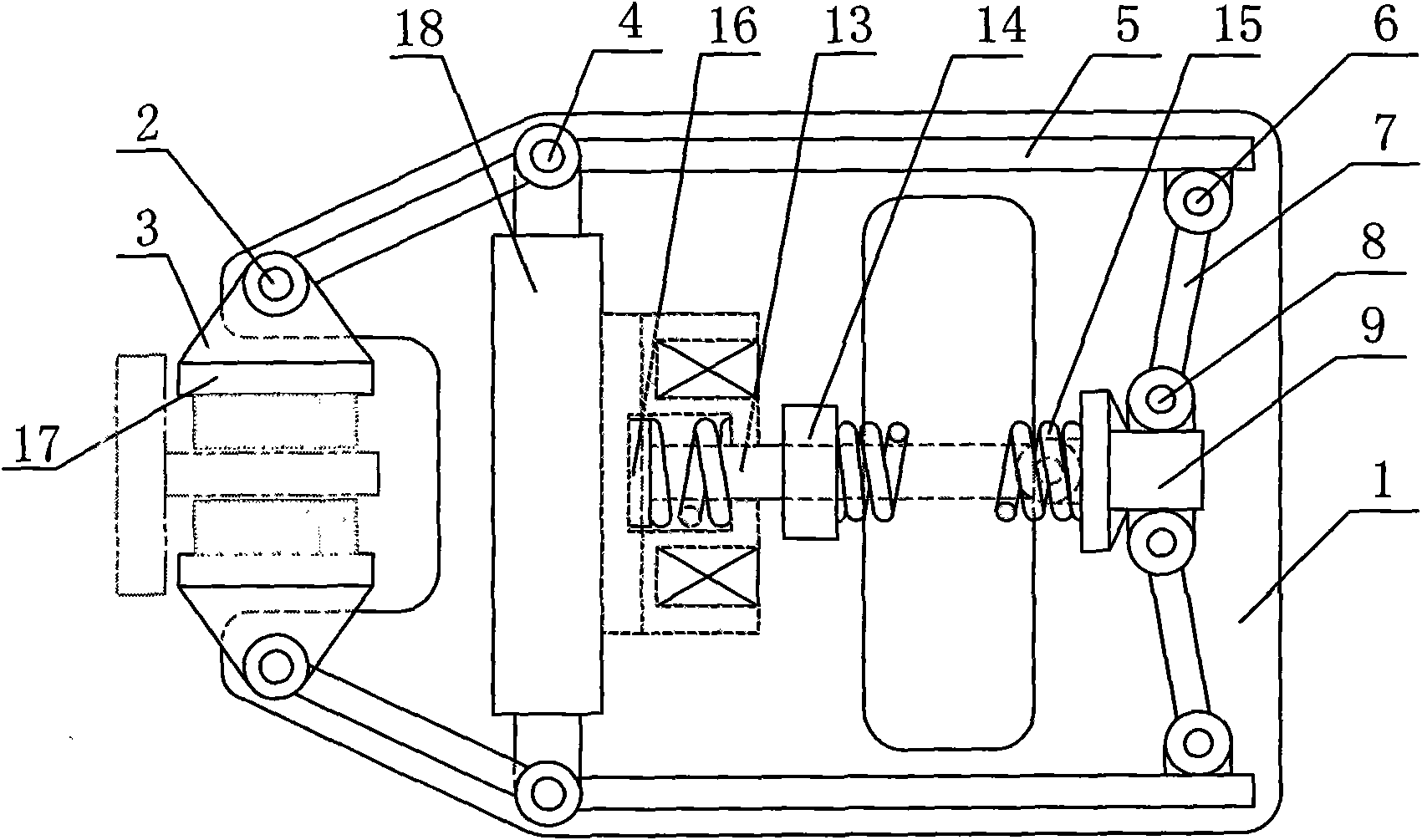

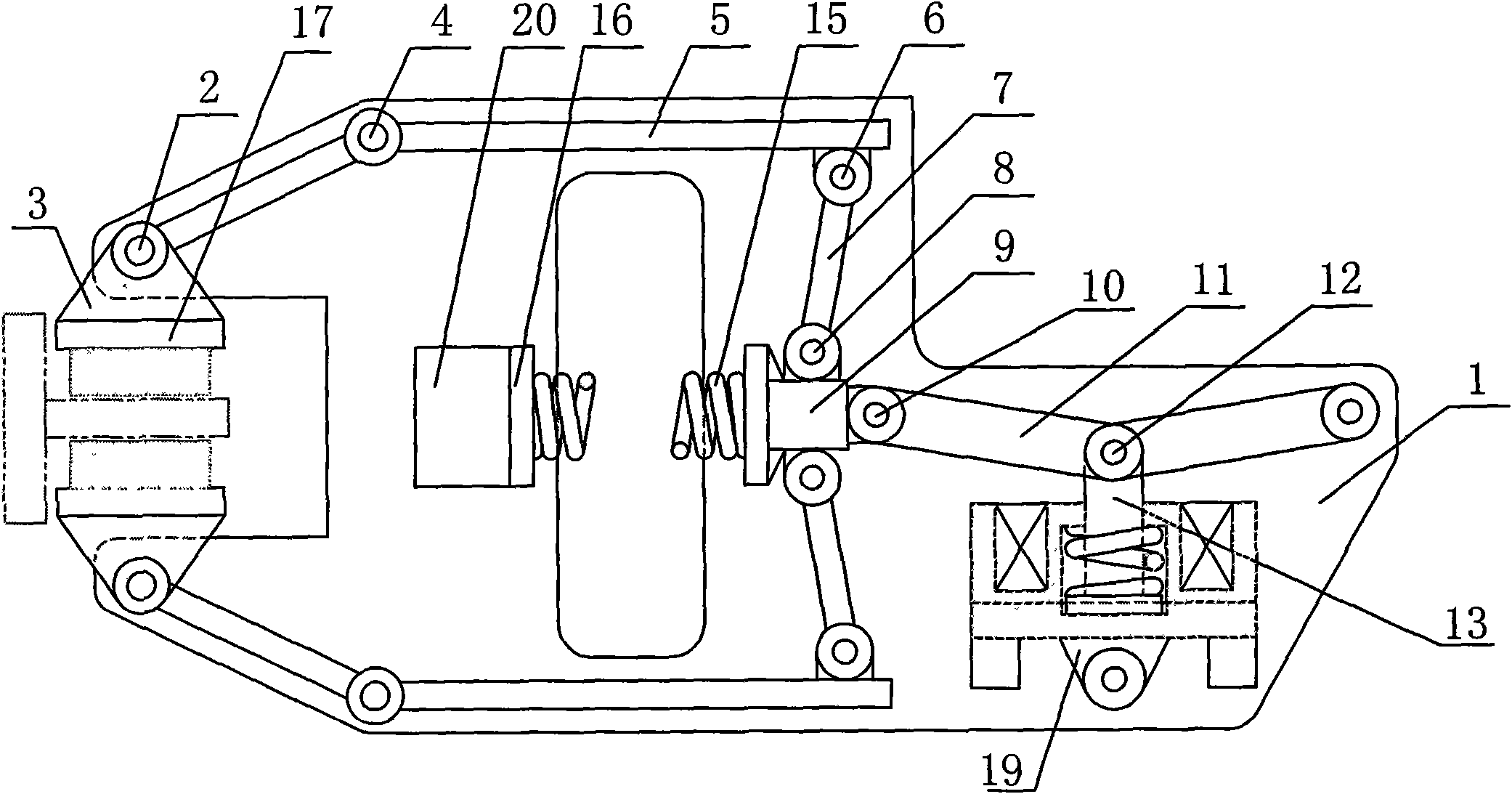

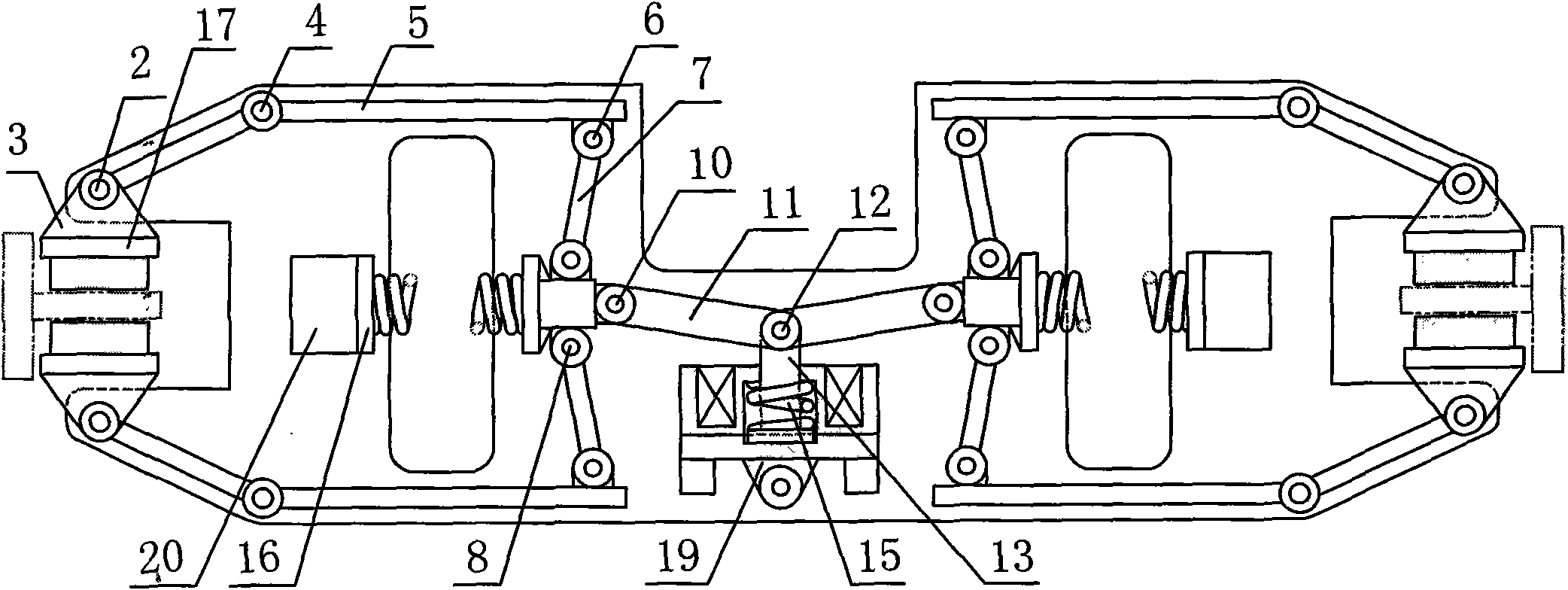

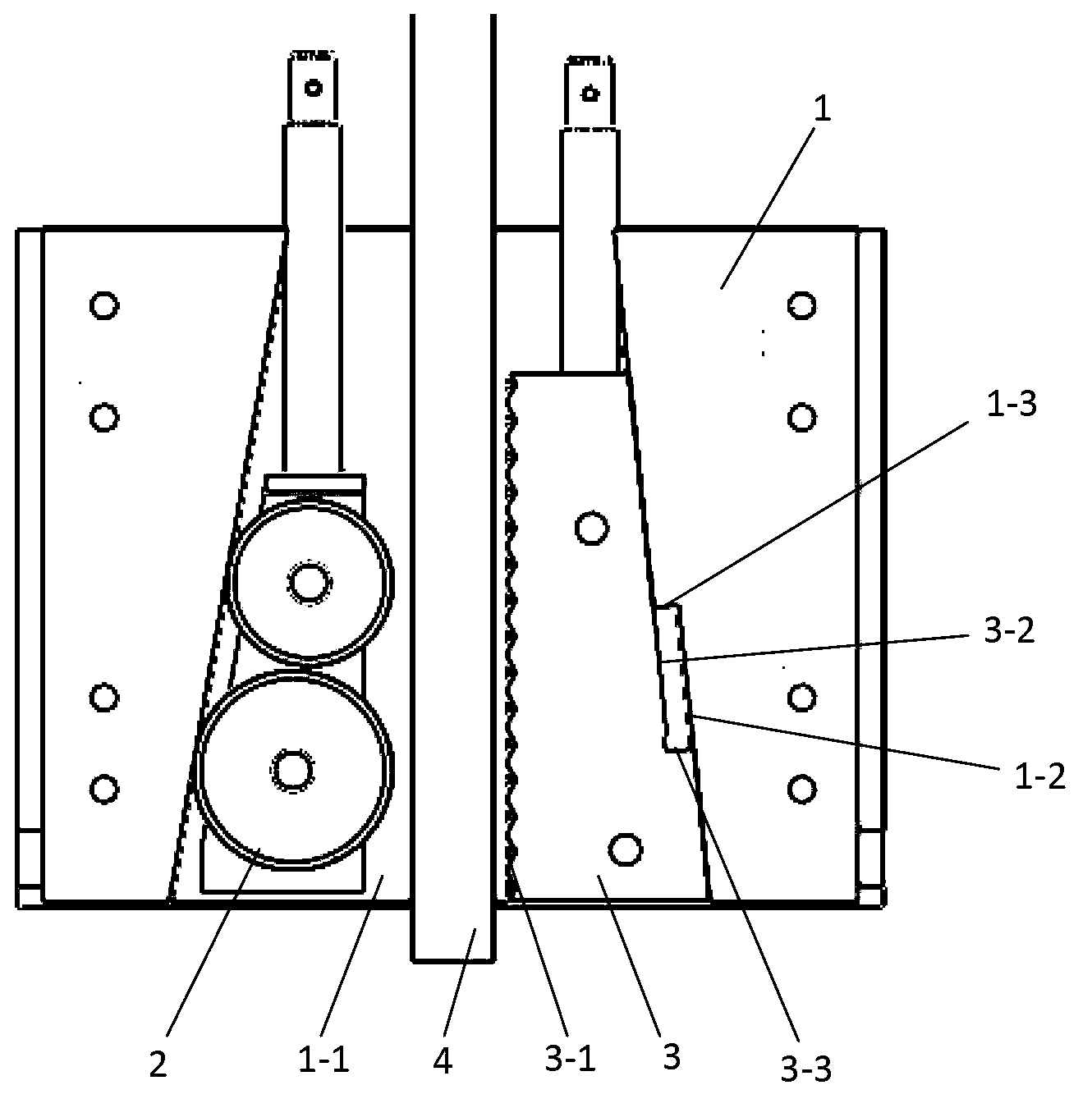

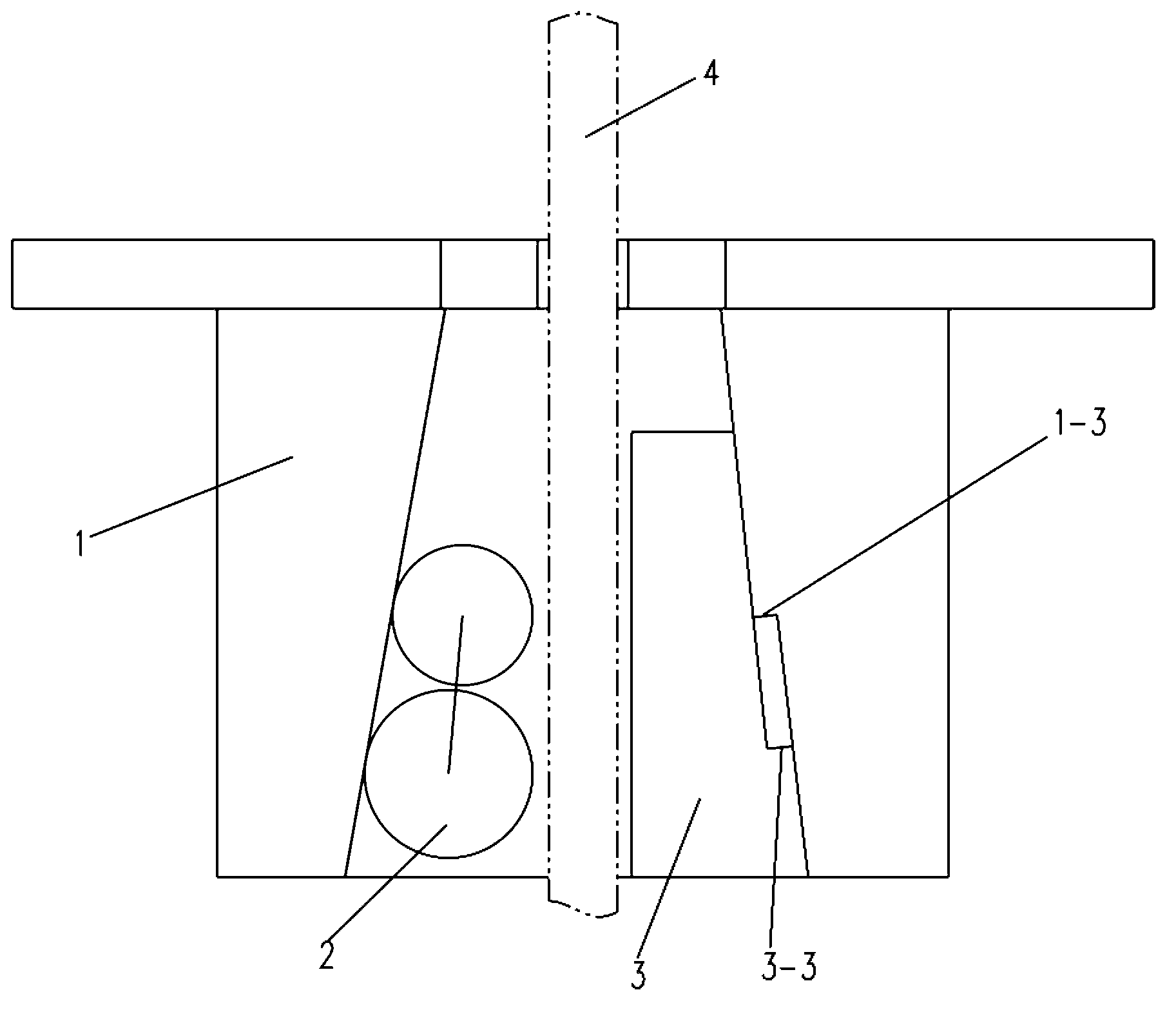

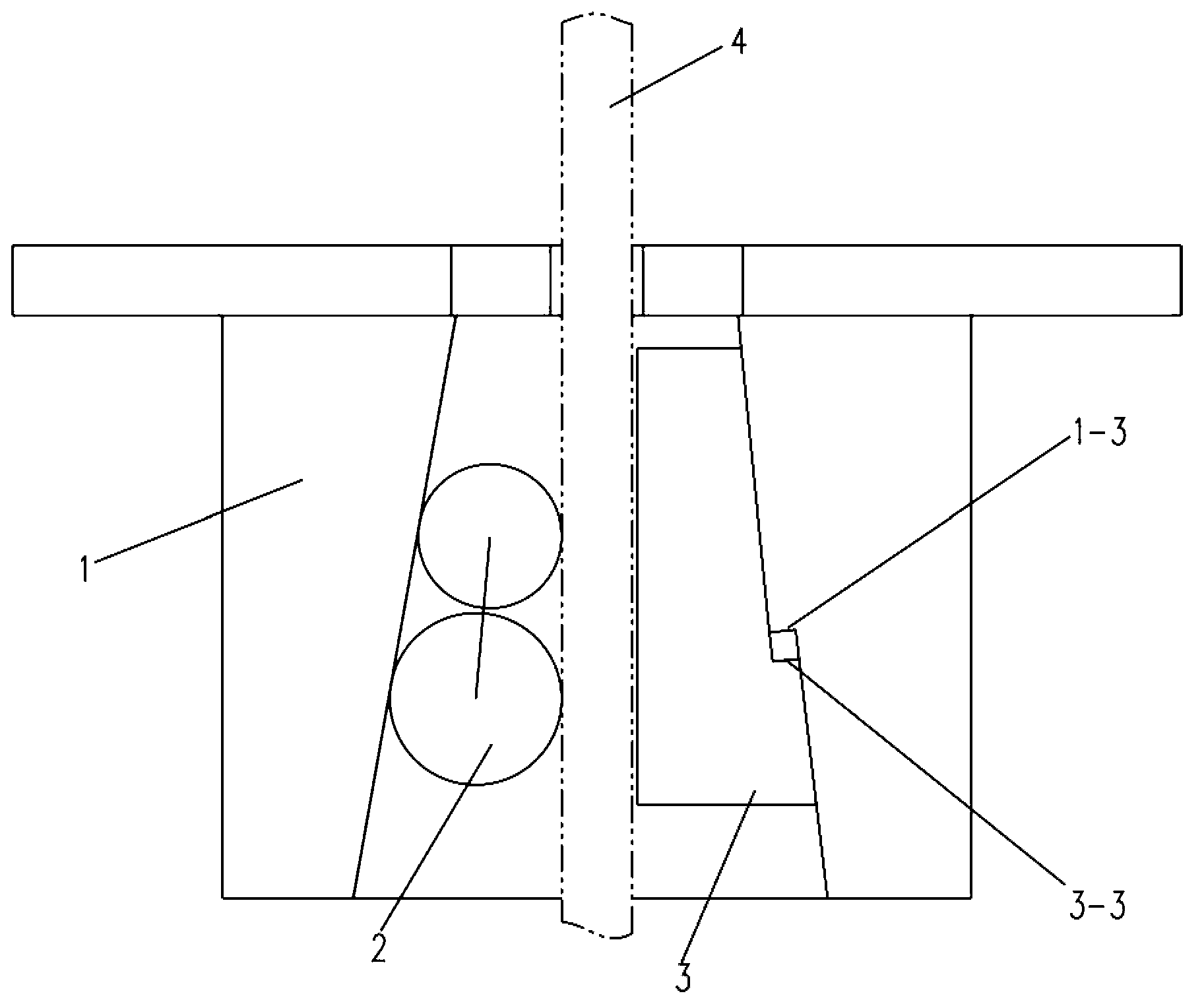

Pincer type brake with force-amplifying mechanisms

InactiveCN101907140AReduce weightReduced uniformity of wearAxially engaging brakesBrake actuating mechanismsWear resistantOrder of magnitude

The invention discloses a pincer type brake with force-amplifying mechanisms, which can be used in straight-line elevators, hoisters and similar railbrake braking occasions. The pincer type brake comprises a swingable drive rod type force-amplifying mechanism and a brake rod type force-amplifying mechanism, wherein the drive rod type force-amplifying mechanism is connected with an electromagnet, and the brake rod type force-amplifying mechanism is connected with a brake spring; and the force-amplifying mechanisms are articulated with swingable brake arms, the ends of the brake arms are connected with swingable brake blocks used for braking, and the action surfaces of the brake blocks are wear-resistant brake bushes. Because the pincer type brake is provided with one or more force-amplifying mechanisms, the specification size of the brake spring and the powers, the sizes and the weights of the electromagnet and other pushing mechanisms are greatly reduced, the braking force and the driving force are greatly increased, and the pincer type brake is at least 1-2 orders of magnitude higher than the common force-amplification free brake. Because the force-amplifying mechanisms are symmetrically arranged, the two brake arms can be accurately controlled to swing in the same swing angle, thereby the biased action force on brake rails is avoided, the braking reliability is improved, and the braked members are accurately braked in the required positions.

Owner:HENAN POLYTECHNIC UNIV

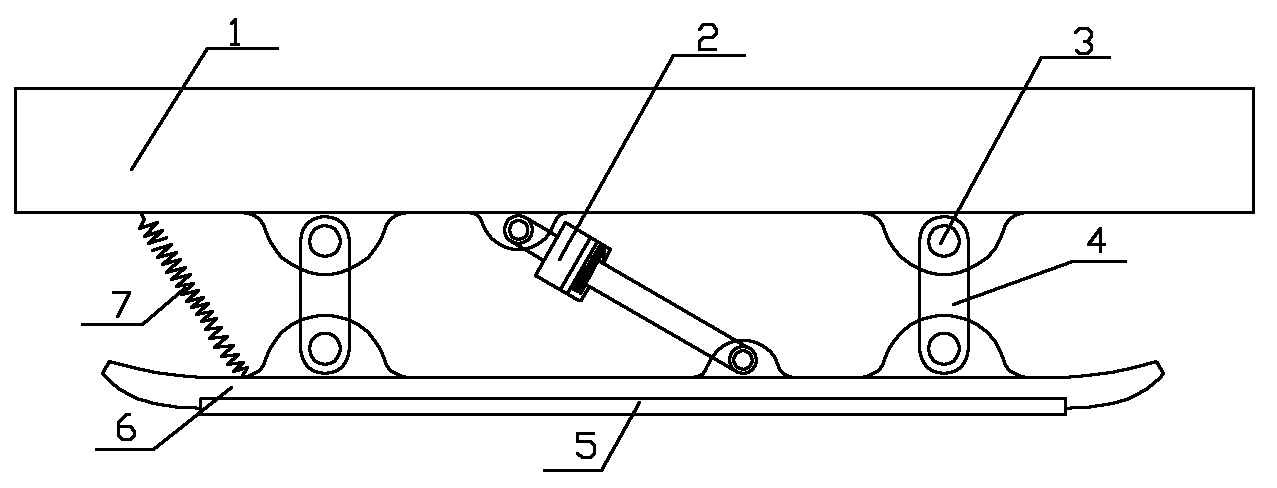

Automobile auxiliary brake-powered speed-reduction friction device and braking method thereof

InactiveCN102009644AReduce the temperatureLarge braking forceBraking element arrangementsFluid braking transmissionRuns down a slopeControl circuit

The invention relates to an automobile brake device and a braking method thereof, in particular to an automobile auxiliary brake-powered speed-reduction friction device and a braking method thereof. The automobile auxiliary brake-powered friction device comprises an automobile chassis longitudinal beam, wherein the lower part of the automobile chassis longitudinal beam is provided with a friction brake pedal; a friction plate is arranged below the friction brake pedal; and a transmission mechanism which is connected with a control circuit is also arranged between the automobile chassis longitudinal beam and the friction brake pedal. The device and the method can increase a braking force effectively by using the friction force generated by friction between the friction brake pedal and the ground when an automobile is braked in emergency or runs down a slope continuously, so that the braking distance in emergent brake is reduced or traffic safe accidents caused by the braking failure of a drum brake at an overhigh temperature when the automobile runs down the slope continuously.

Owner:于宥源

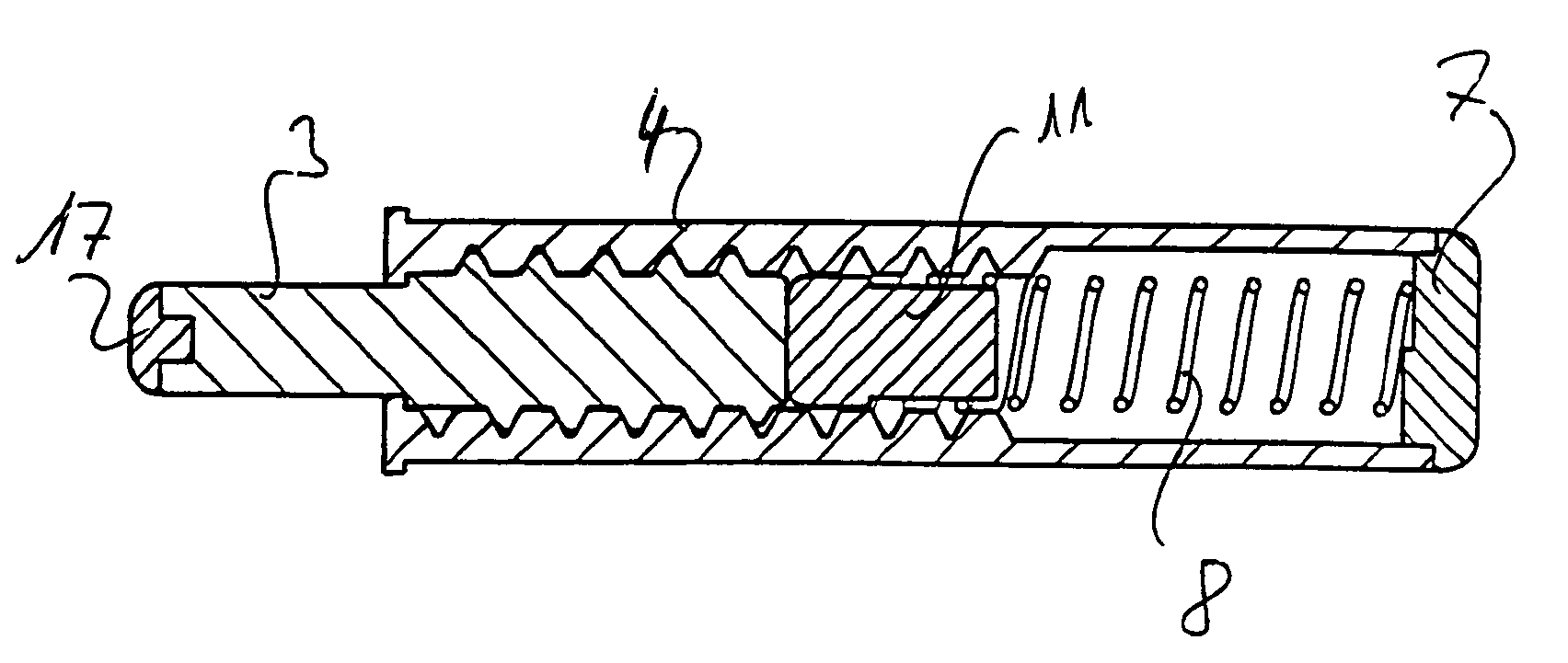

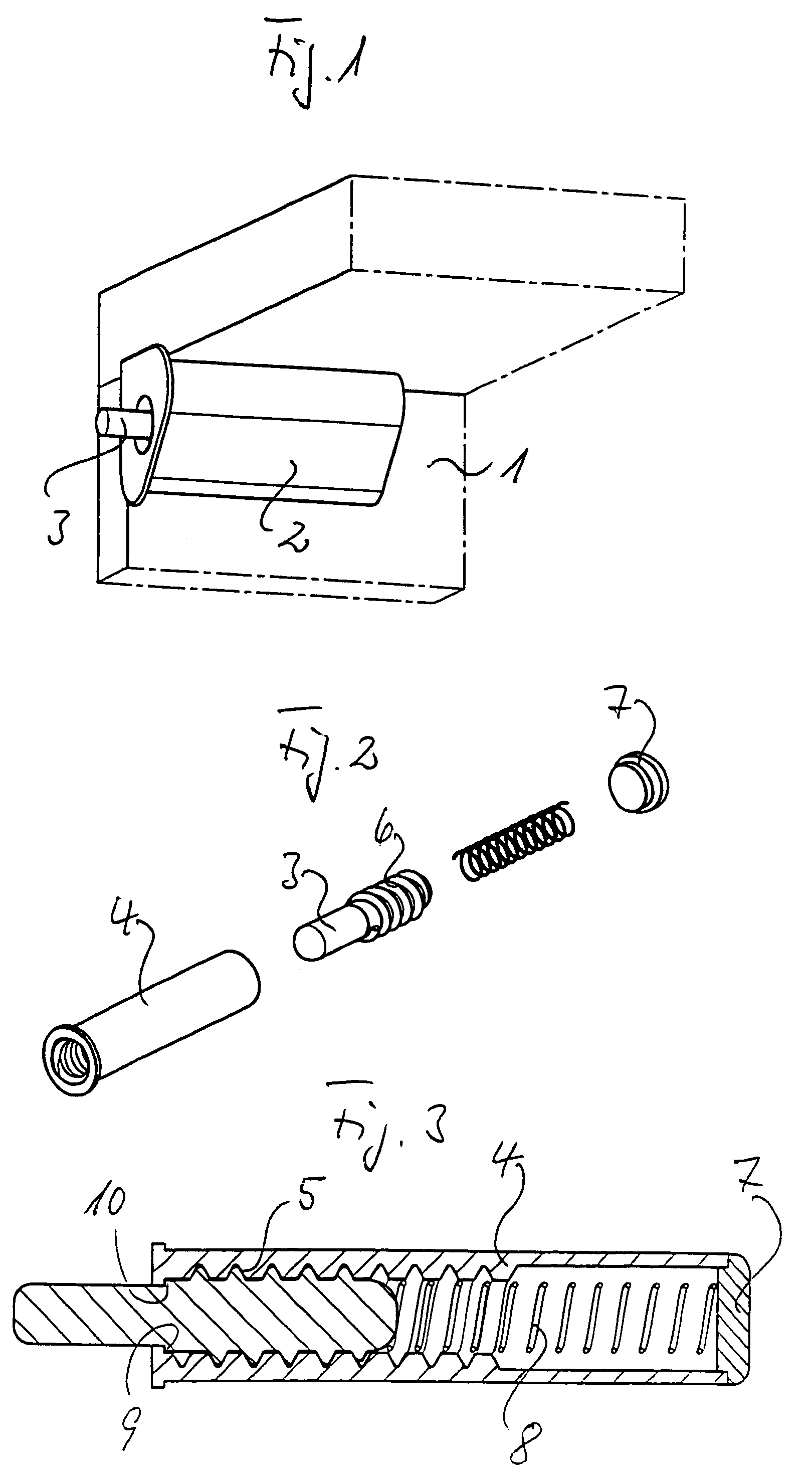

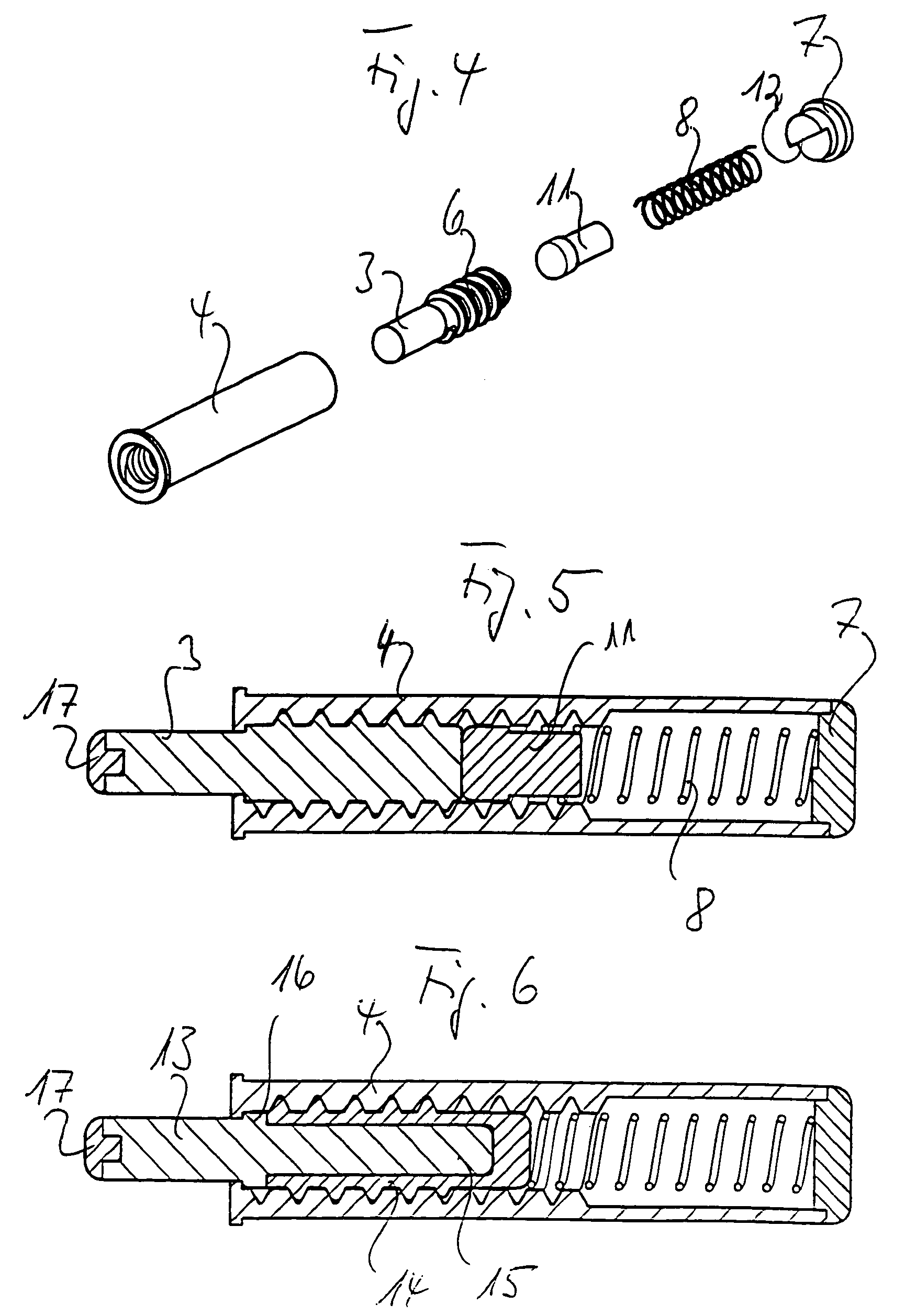

Spiral-action damper

InactiveUS7234569B2Improve braking effectLarge braking forceSpringsBuilding braking devicesSpring forceSelf locking

The invention relates to a damping device for movable furniture parts, for example for doors or drawers, comprising a piston or plunger which is slidably guided in a hollow body, e.g. a cylinder, with said piston or plunger being impinged upon by spring force into its pushed-out position. According to the invention, the hollow body comprises at least one section of a spiral-shaped stay of the internal screw thread, and / or the piston or plunger comprises at least one section of a spiral-shaped stay of the external screw thread. The stays of the screw threads are glidingly supported one on top of the other, or cams or journals of the hollow body or of the piston or plunger are supported on a screw-thread section of the other component. The pitch of the stays of the screw threads is greater than the pitch at which self-locking occurs.

Owner:ARTURO SALICE

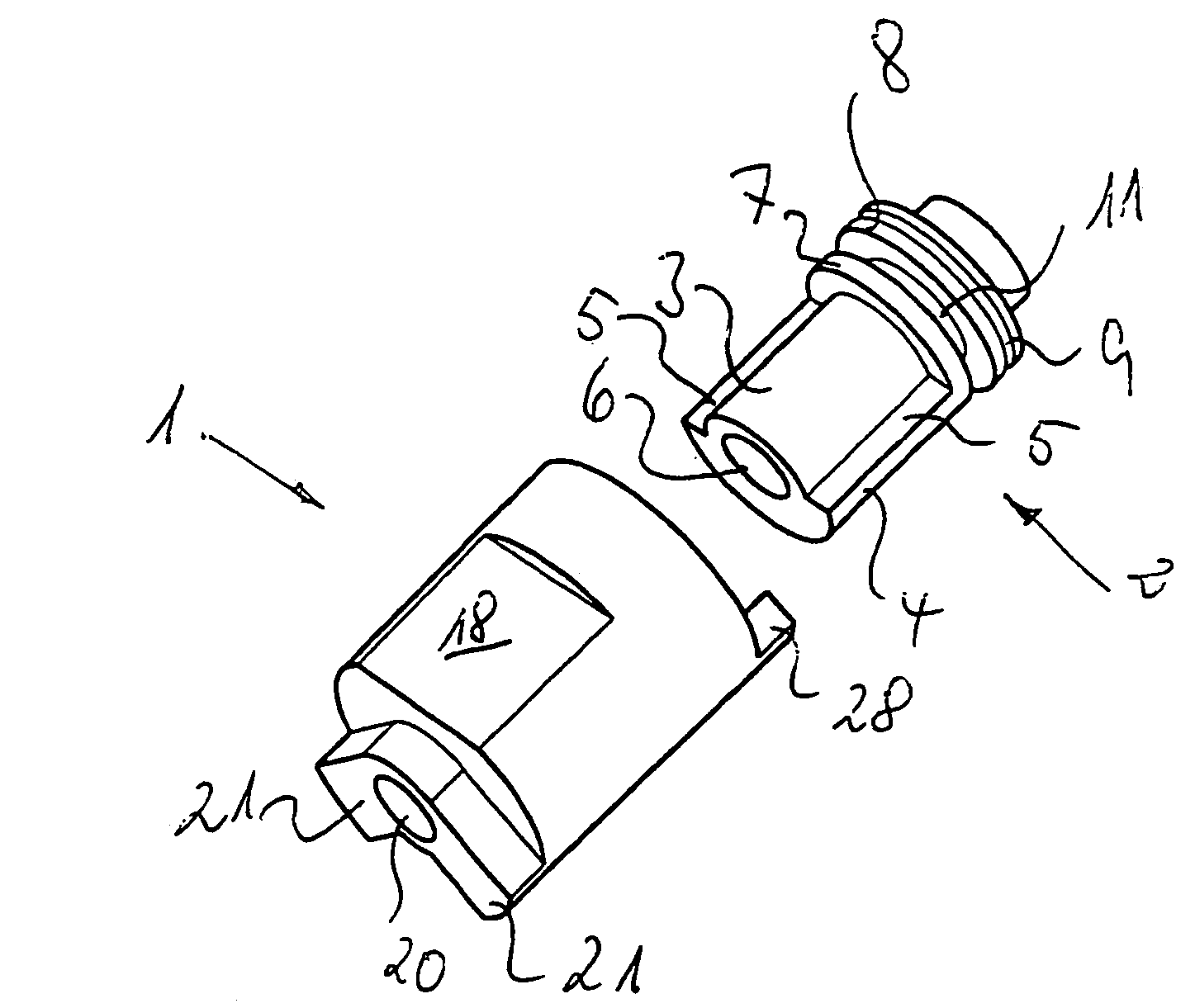

Pivot-action damper

InactiveUS7243398B2Large braking forceLower resistanceSpringsBuilding braking devicesEngineeringThrottle

A pivot-action damper which for example dampens the impact effect of the closing movement of doors, furniture doors or flaps displays excellent braking force or damping force, even over small angular regions as a result of an outer cylindrical body which encompasses an inner body which is pivotable in relation to said outer cylindrical body. Between the two bodies there are two chambers, separated from each other by a gap or a throttle position, with said chambers containing a liquid. This liquid is displaced from one chamber to the other as a result of the rotation of the two bodies in relation to each other.

Owner:ARTURO SALICE

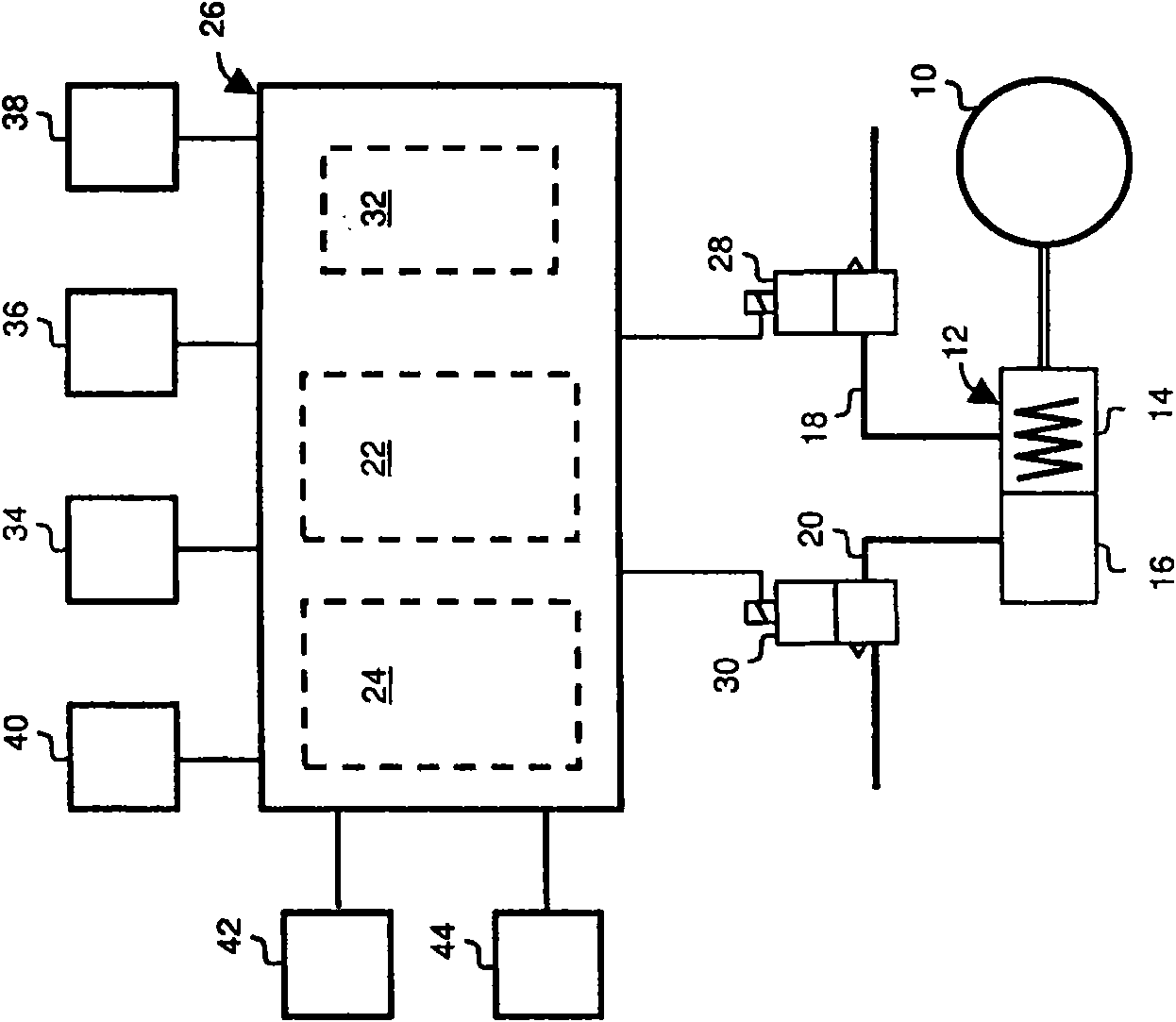

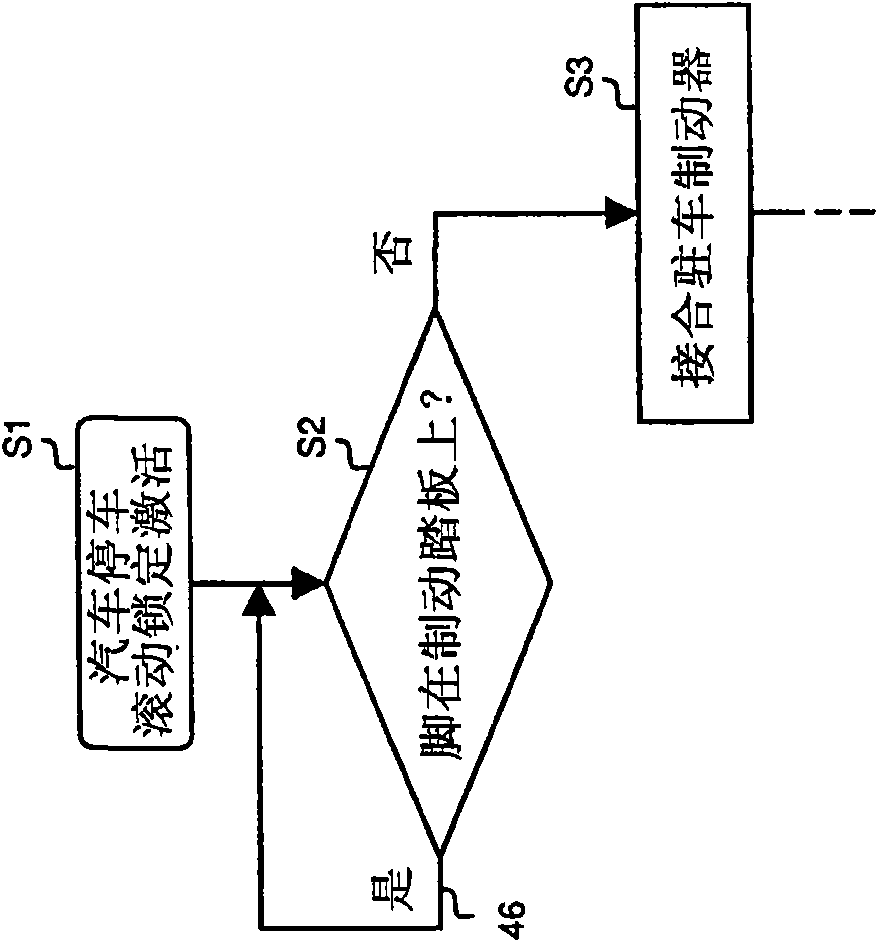

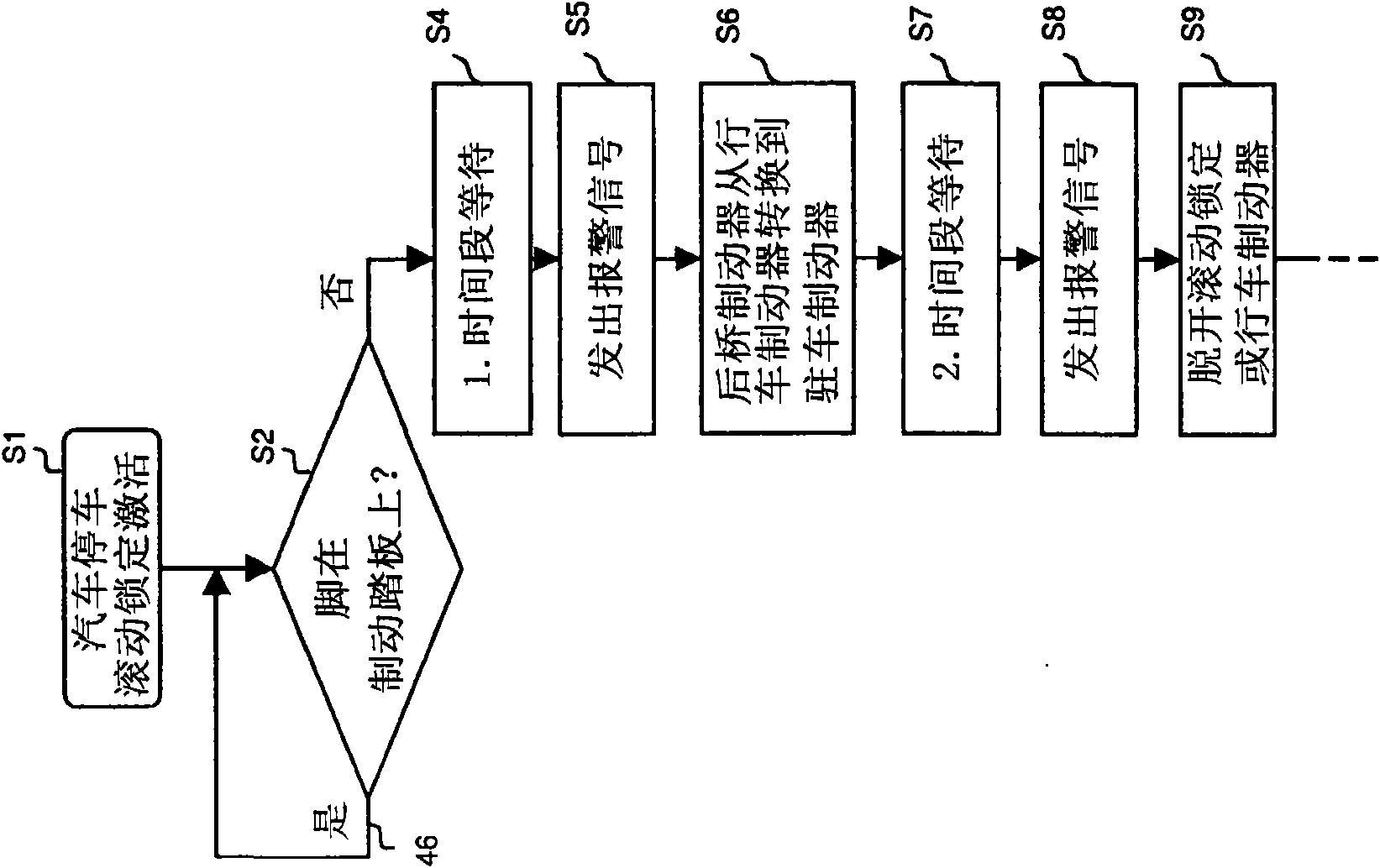

Method and devices for operating a motor vehicle brake device

ActiveCN101568454AImprove securityLarge braking forceAutomatic initiationsHand actuated initiationsParking brakeVehicle brake

The invention relates to a method for operating a brake device of a motor vehicle, comprising a service brake (16) and a parking brake (14). Upon activation of a rolling brake function (S1), and achieving a full stop of the vehicle, monitoring (S2) of an actuating element occurs with regard as to whether a driver has contact with an actuating element. In order to improve the safety of the rolling brake function, the invention provides that, if the monitoring (S2) finds that the driver has no contact with the actuating element, the parking brake (14) is applied (S3), or a braking pressure (14) is controlled using the service brake (16), the braking pressure corresponding to the maximum braking pressure (S10) that can be generated by the parking brake (14), by means of an electric or electronic brake device (26) for controlling the service brake (16) and the parking brake (14). The invention further relates to a corresponding method, wherein a monitoring (S11) of the vehicle occurs with regard to a possible displacement of the vehicle, and if the monitoring shows that the vehicle has been set in motion, braking is applied (S12) to all wheels of the vehicle that are connected to service brake (16) by means of the control device (26) via the service brake (16). The invention also relates to devices that are configured accordingly.

Owner:WABCO EURO BVBA SPRL

Brake control apparatus for a vehicle

InactiveUS6158824ALarge braking forceIncrease braking powerBraking action transmissionAutomatic initiationsWheel cylinderBrake control

An operated quantity of a brake pedal is detected based on a signal from a stroke sensor. A starting criterion to start brake assisting is determined with respect to an operational speed of the brake pedal in response to the operated quantity of the brake pedal. An operated-quantity change is calculated by differentiating the operated quantity of the brake pedal. It is determined whether the operated-quantity change exceeds the starting criterion. If the operated-quantity change exceeds the starting criterion, brake assisting is started by driving a pump to increase wheel cylinder pressure.

Owner:DENSO CORP

Electromagnetic brake, friction piece thereof and friction piece manufacture method

The invention discloses an electromagnetic brake, a friction piece thereof and a friction piece manufacture method. The electromagnetic brake comprises an iron core assembly, a magnetic roof assembly, a friction member and a manual brake release assembly, wherein the magnetic roof assembly comprises a magnetic roof; the manual brake release assembly comprises a bolt; the iron core assembly comprises an iron core bottom plate, an iron core outer ring, an iron core inner ring, a coil and a skeleton; the friction member is arranged on the outer side surface of the magnetic roof; the friction member and the magnetic roof are transversally positioned; the friction member is made of metal; the middle part of the outer side surface of the magnetic roof concaves inwards to form a spherical surface shape; the middle part of the outer side surface of the friction member convexes outwards to form the spherical surface shape which fits the inwards concave spherical surface part of the outer side surface of the magnetic roof, or, the middle part of the outer side surface of the magnetic roof outwards convexes to form the spherical surface shape, and the middle part of the outer side surface of the friction member concaves inwards to form the spherical surface shape which fits the outwards convex spherical surface part of the outer side surface of the magnetic roof. The electromagnetic brake has the advantages of big braking force, stable and reliable braking, convenient and simple assembly, energy saving, fast release, short time delay, low noise and the like.

Owner:HANGZHOU HUNING ELEVATOR PARTS CO LTD

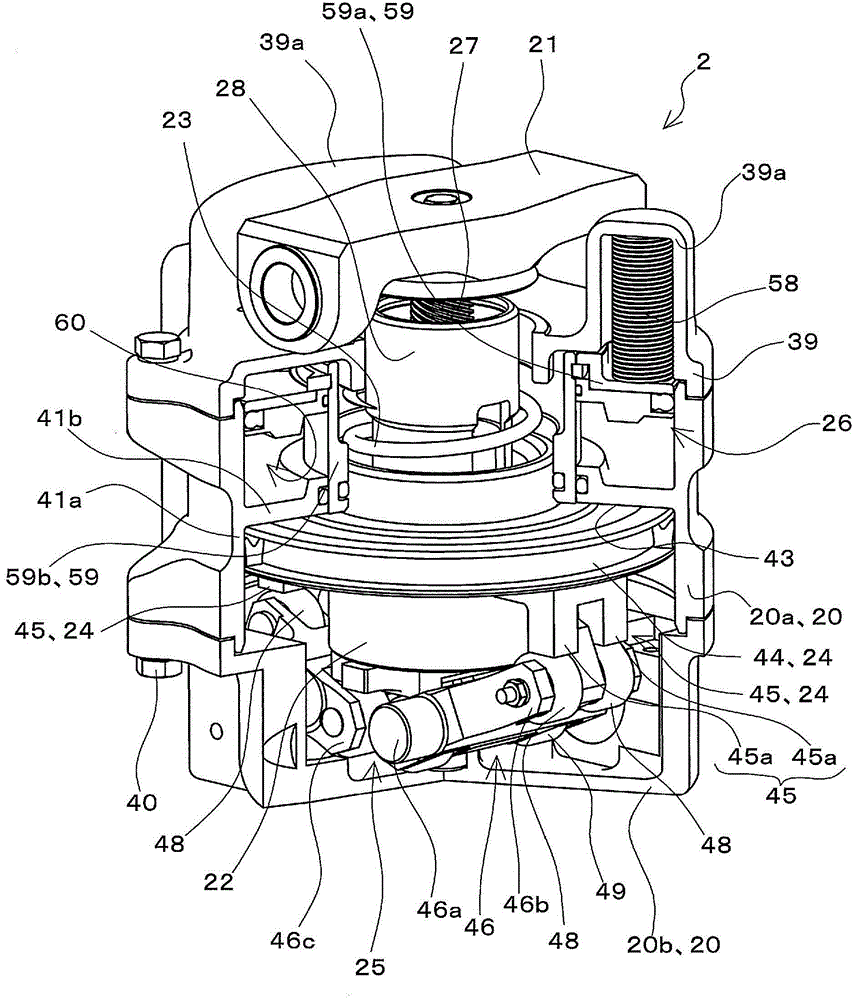

Brake cylinder device and disk brake device

ActiveCN103958916ASuppression of upsizingLarge braking forceAxially engaging brakesBrake wear compensation mechanismEngineeringMechanical engineering

Provided is a compact brake cylinder device capable of increasing the brake force output from a brake output unit that moves along with a rod, without requiring the device to be made larger. A piston (24) sections off a pressure chamber (43) within a main cylinder (20a), surrounds the axial periphery of a rod (22), and moves in a direct line parallel with the direction of motion of the rod (22). With the supply of a pressure fluid to the pressure chamber (43) the piston (24) moves outward relative to the main cylinder (20a) in opposition to the biasing force of a rod-biasing spring (23). An oscillating member (46) of a force-multiplying mechanism (25) is biased by the piston (24) moving in the outward direction, oscillates, and biases the rod (22), causing the rod (22) to move in the forward direction. In this way, the force-multiplying mechanism (25) multiplies the drive force from the piston (24) so as to act on the rod (22). The brake output unit (21) moves in the forward direction along with the rod (22) and outputs brake force.

Owner:NABLESCO CORP

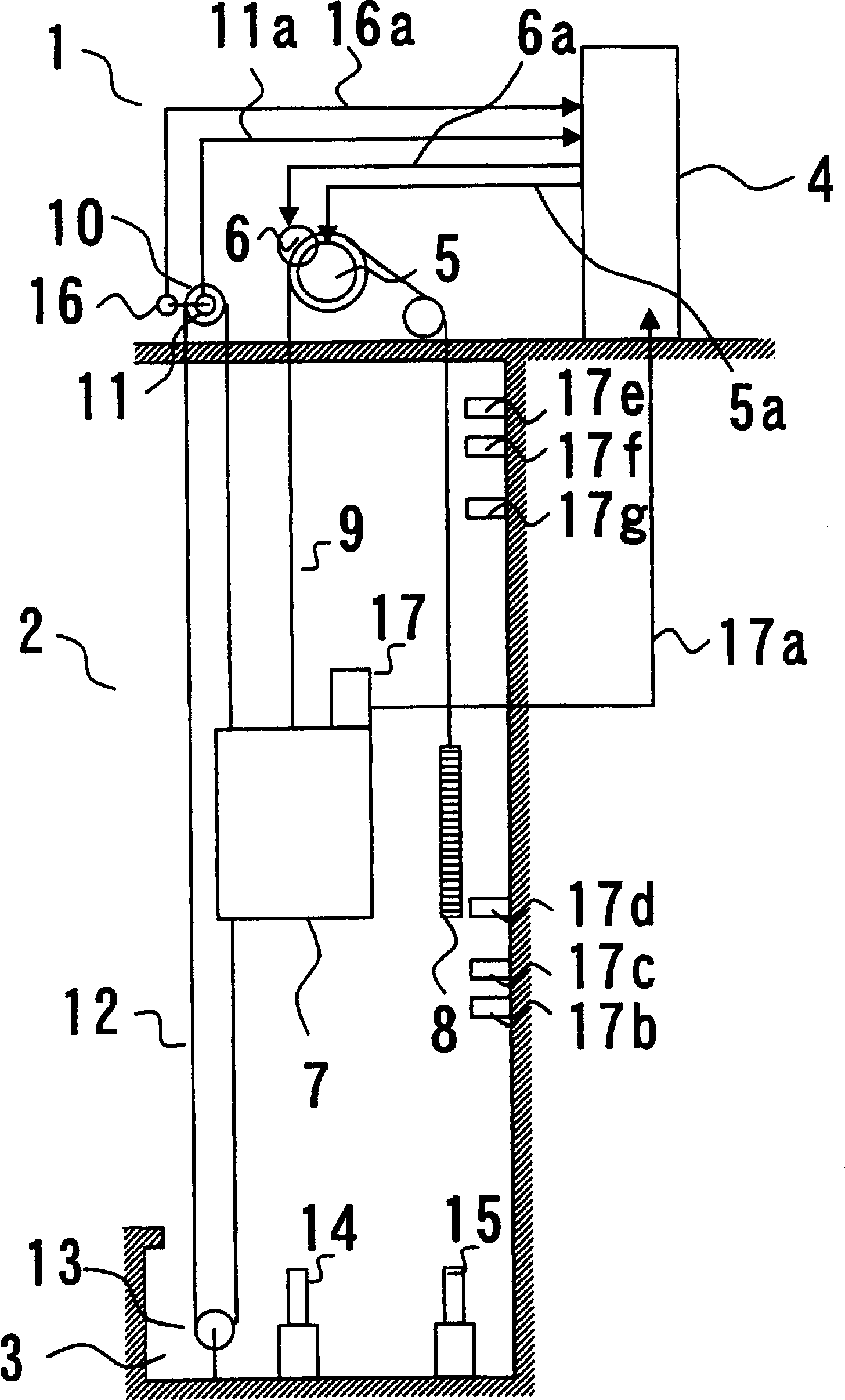

Instantaneous type safety gear for elevator

The invention discloses an instantaneous type safety gear for an elevator, which comprises a gear body which is provided with a channel with a trapezoidal section, wherein the channel is wide at the bottom and narrow at the top; double pin roller groups and a wedge block are mounted on two sides in the gear channel respectively; the double pin roller groups and the wedge block can move up and down along a corresponding gear body inclined surface; one side surface, corresponding to the gear body inclined surface, of the wedge block forms a step, and correspondingly, a step is formed on the inclined surface of the gear body; and when the safety gear is triggered to act until the action is completed, the step of the wedge block is contacted with the step on the gear body inclined surface. According to the instantaneous type safety gear, the matched steps are arranged on the wedge block and the corresponding gear body inclined surface to replace a steel plate in the prior art; and in comparison, the instantaneous type safety gear provided by the utility model has the advantages of larger braking force and simple structure, simplifies the elevator structure, and reduces the elevator load bearing and elevator manufacturing cost.

Owner:HANGZHOU HUNING ELEVATOR PARTS CO LTD

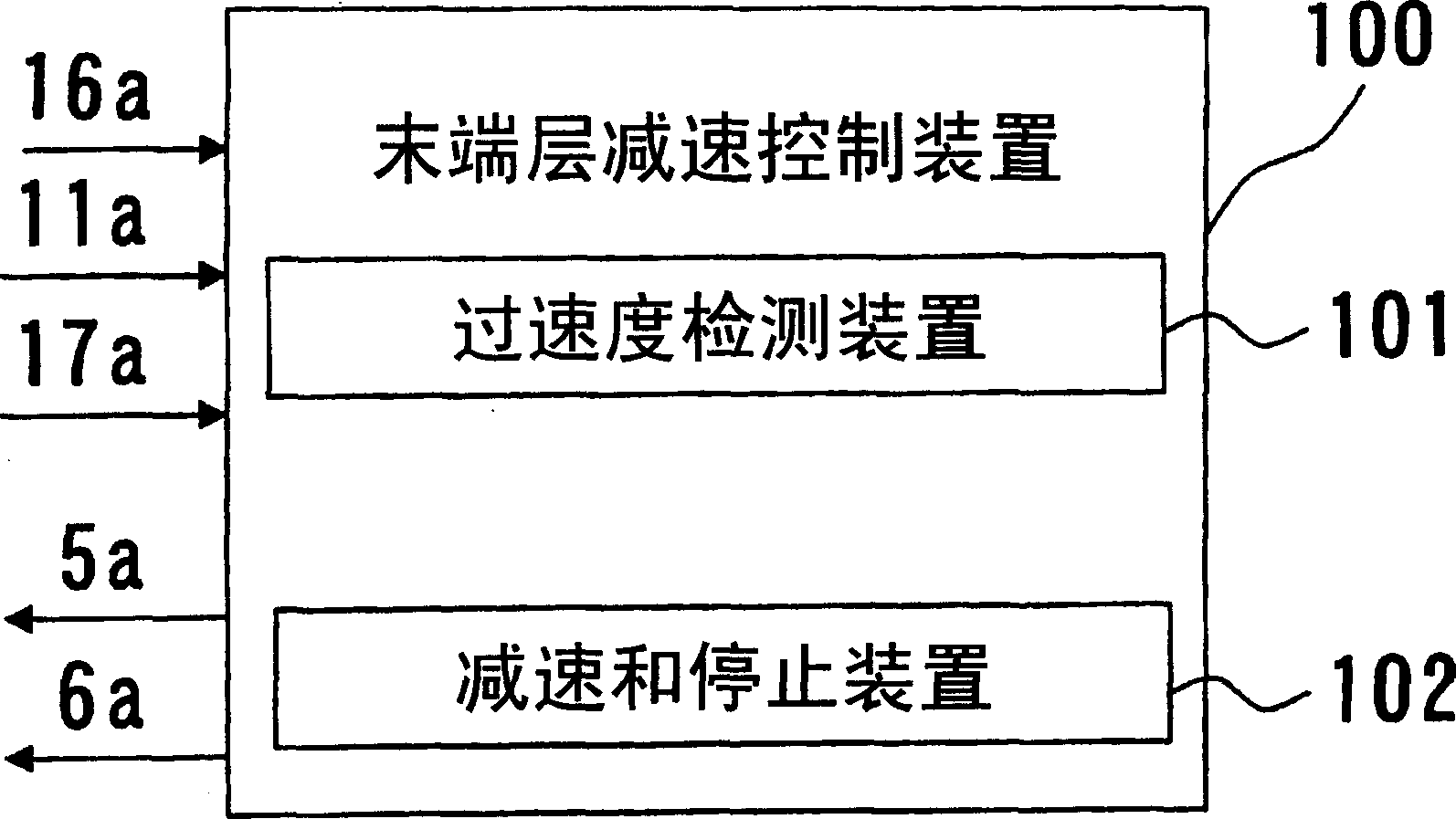

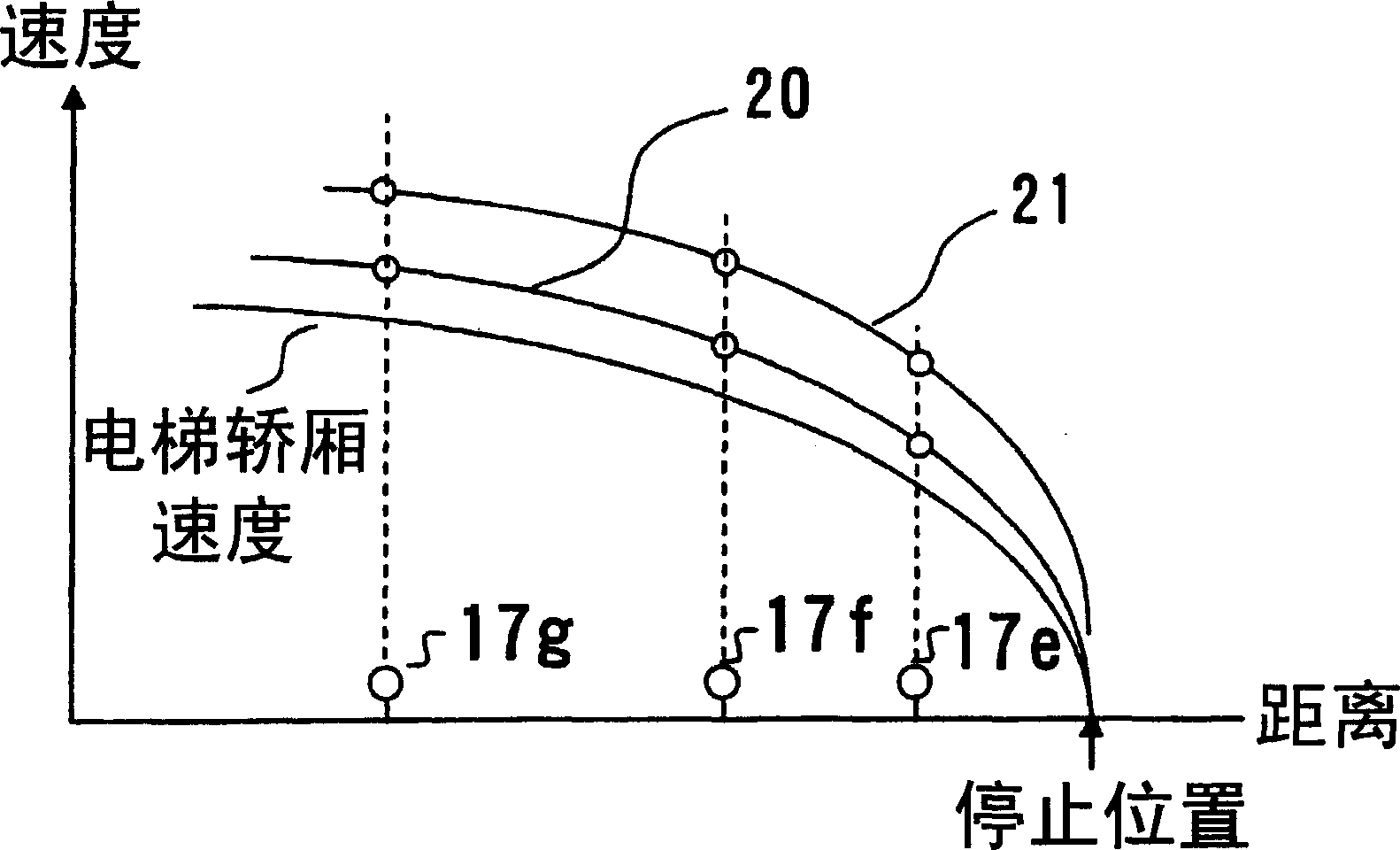

Elevator controlling device

An elevator control device comprising: an overspeed detection device for judging whether the speed of an elevator car at a predetermined position is less than or equal to an overspeed corresponding to a distance from an end, and a deceleration stop for forcibly performing deceleration and stopping when the overspeed is exceeded device, wherein the overspeed includes a first overspeed and a second overspeed, the deceleration stop device has a comparator and a motor controller, the comparator compares the second overspeed with the speed of the elevator car, and when the second overspeed is reached When the brake signal is sent to the mechanical brake, the motor controller will send a control command corresponding to the difference between the first overspeed and the elevator car speed to the motor of the winch when the first overspeed is reached. When the second overspeed is reached, a control command is sent to the motor corresponding to the difference between the second overspeed and the speed of the elevator car.

Owner:HITACHI LTD

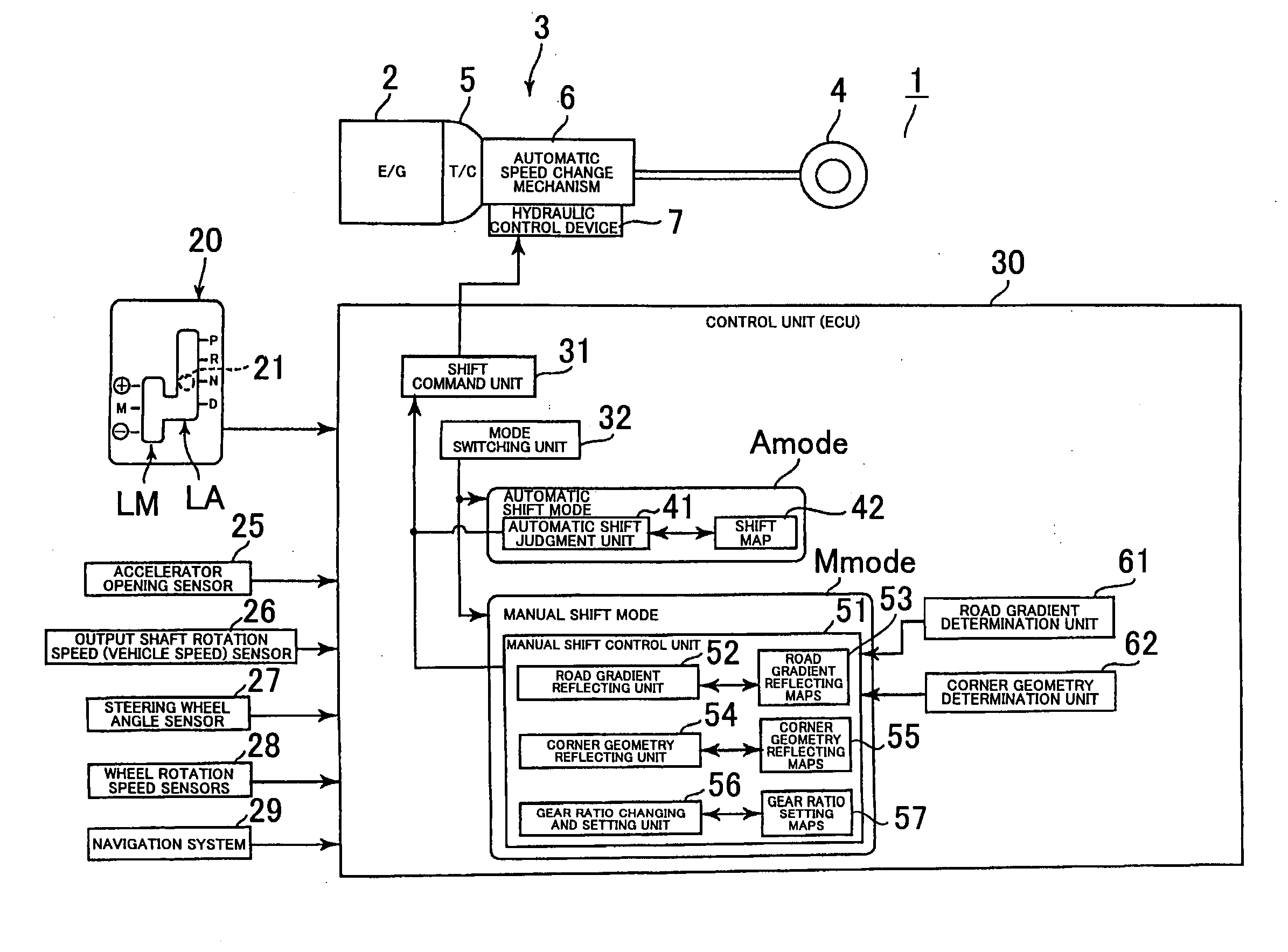

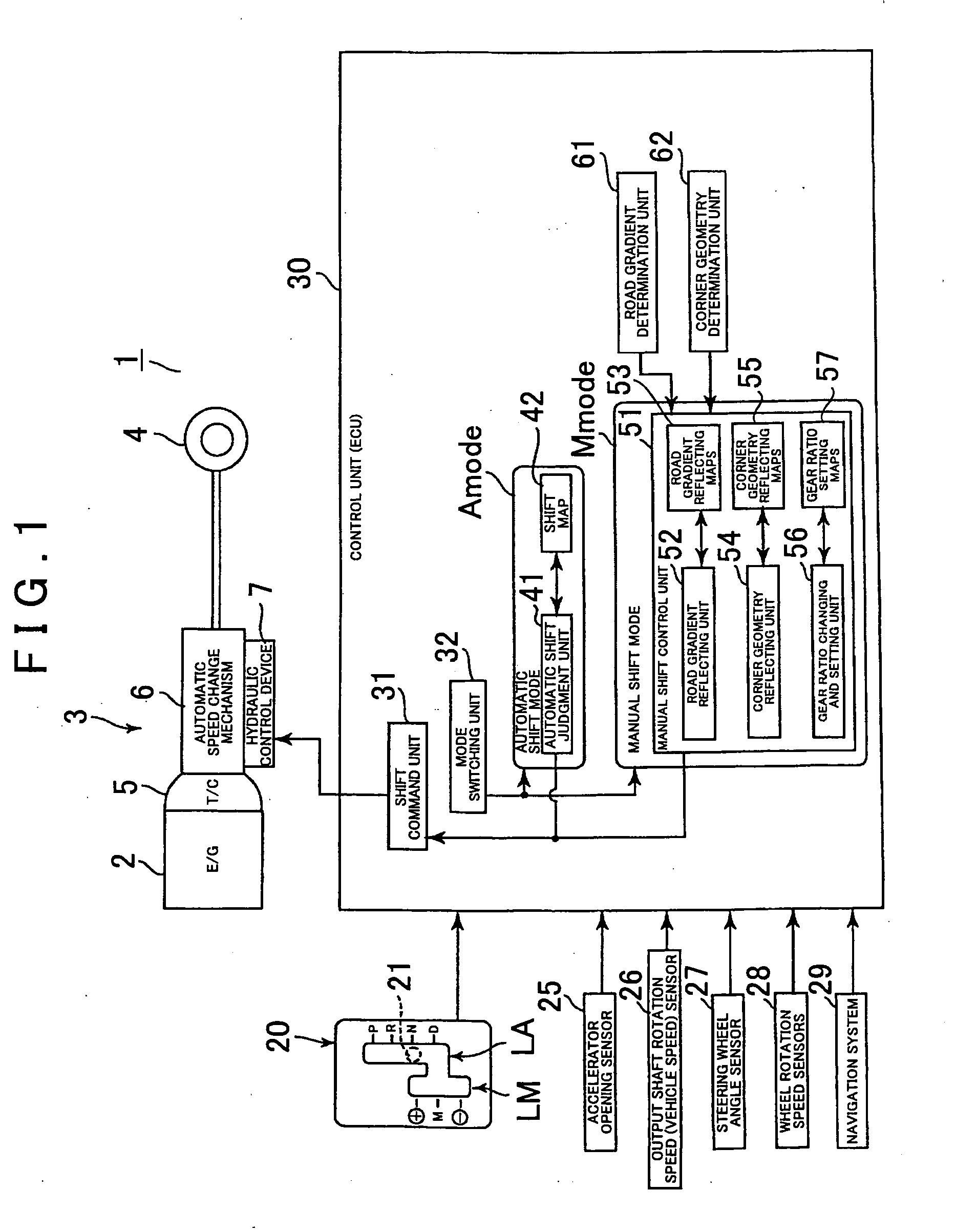

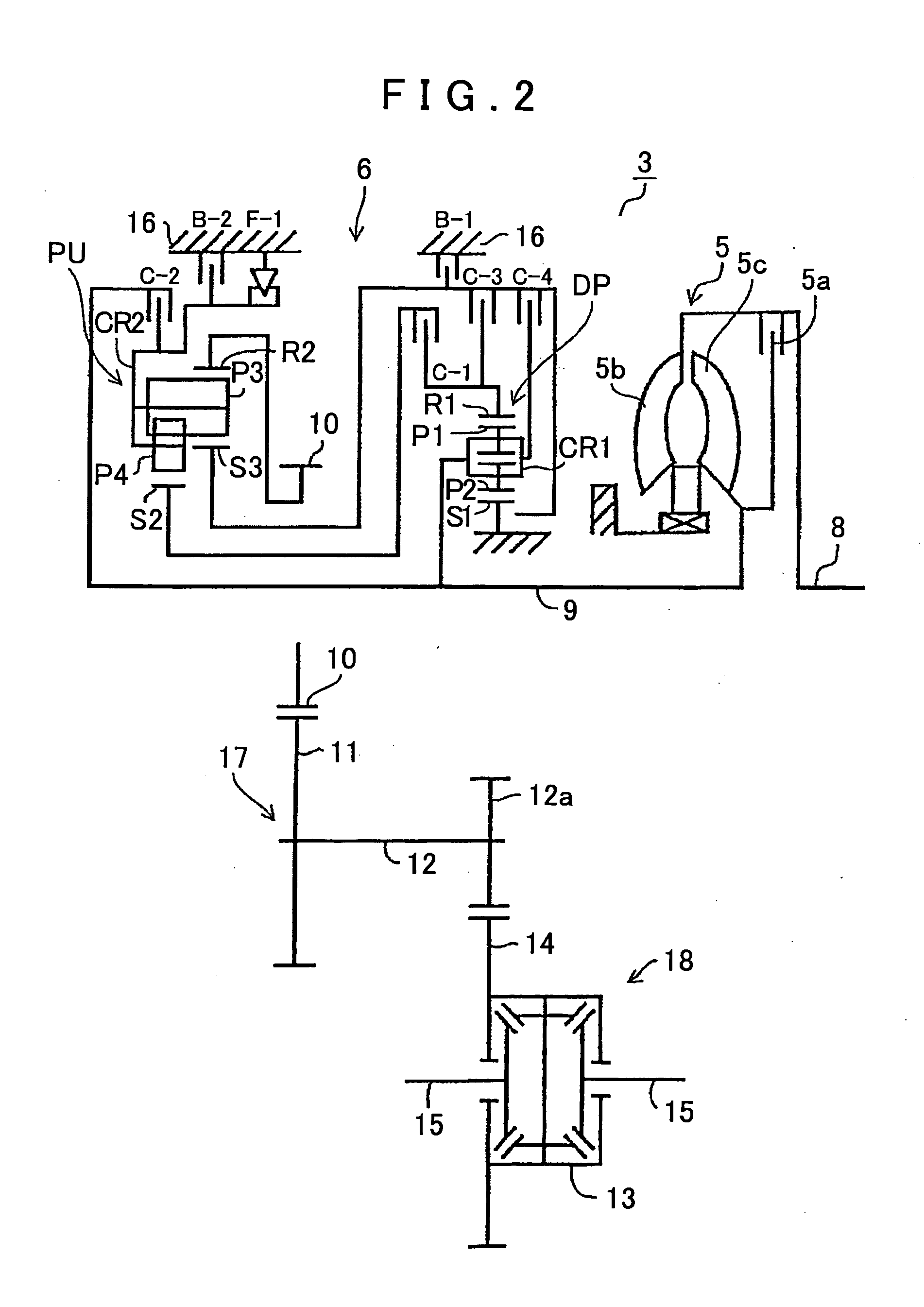

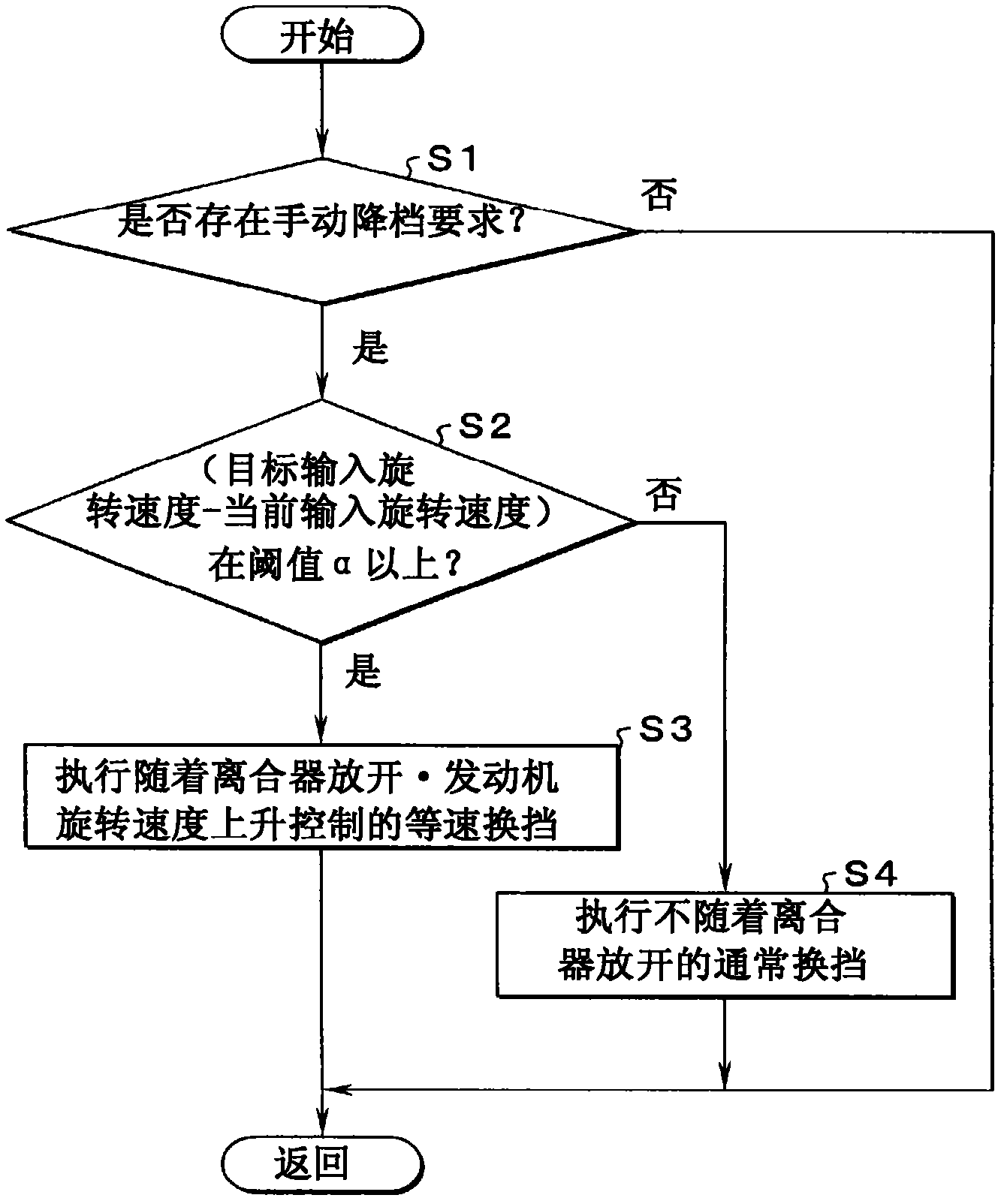

Control device for automatic transmission

InactiveUS20090171542A1Large engine brake forceOperation is troublesomeDigital data processing detailsGearing controlAutomatic transmissionEngineering

A control device for an automatic transmission capable of operating in an automatic shift mode in which a gear ratio is automatically selected based on driving conditions of a vehicle, and also capable of operating in a manual shift mode in which the gear ratio is changed based on an upshift command or a downshift command by manual operation of a manual operation device, the control device includes a manual shift control unit that changes and sets the gear ratio after downshift depending on road conditions when the downshift command has been operated by the manual operation device in the manual shift mode, and performs the downshift to the gear ratio that has been changed and set.

Owner:AISIN AW CO LTD

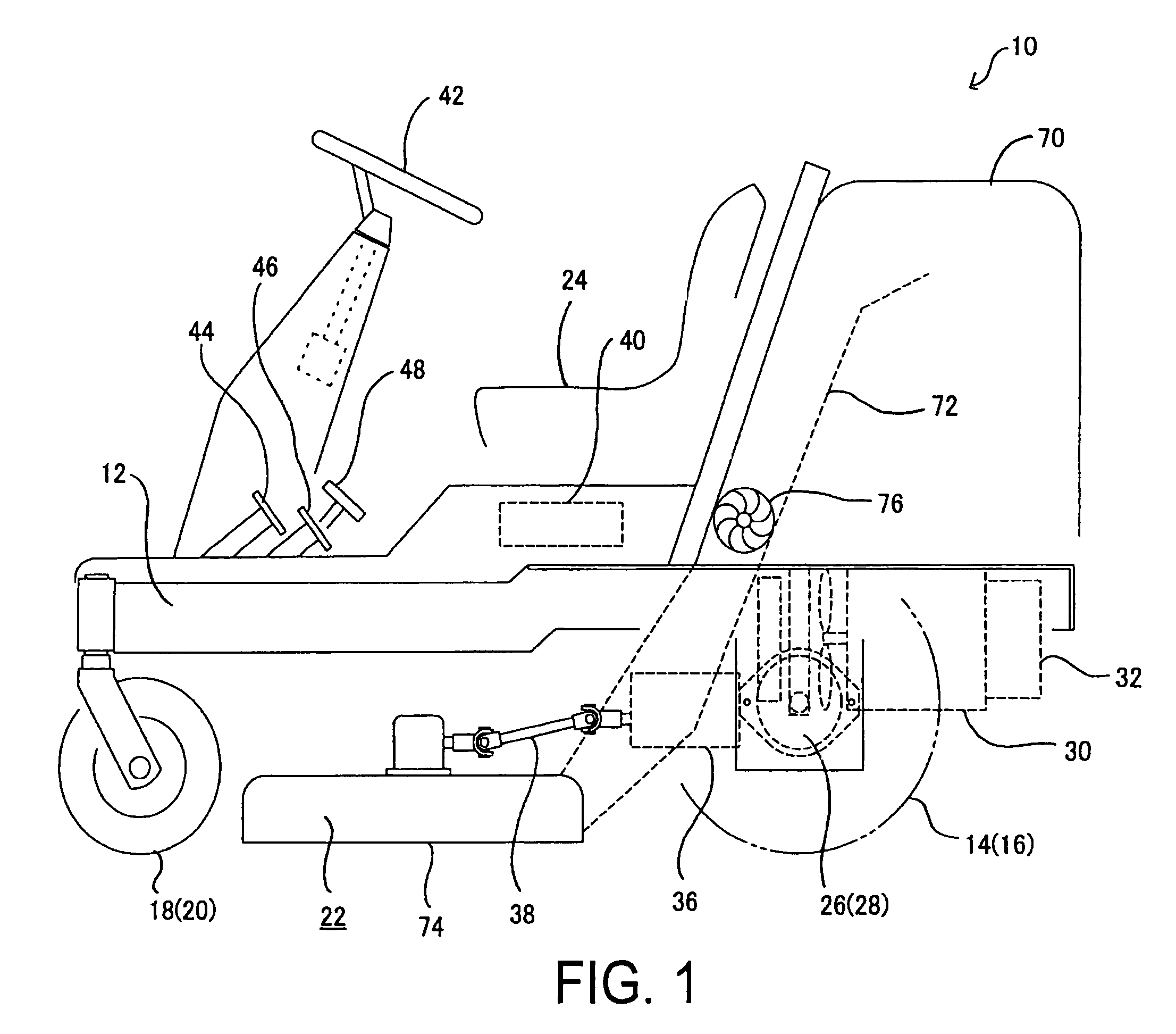

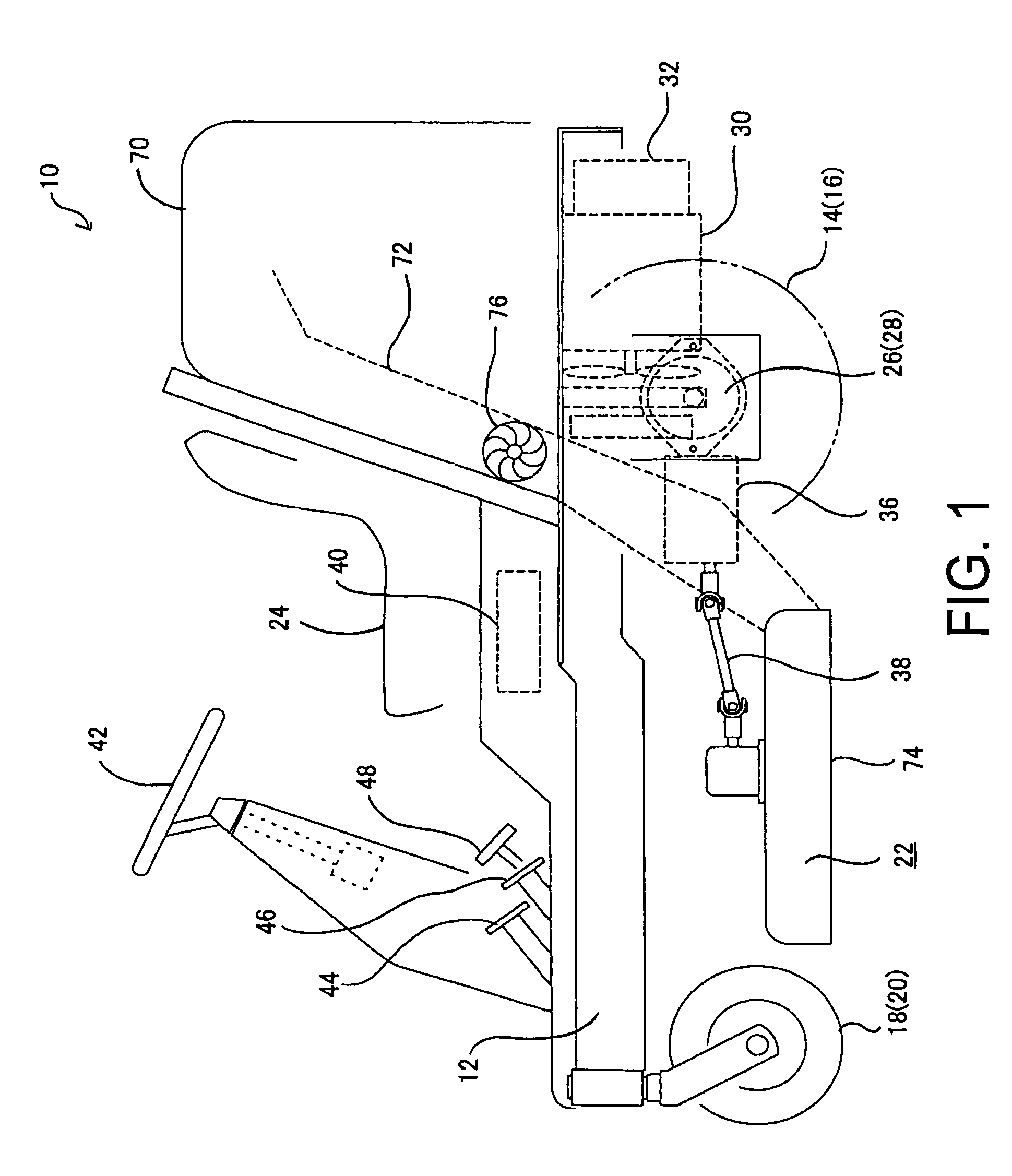

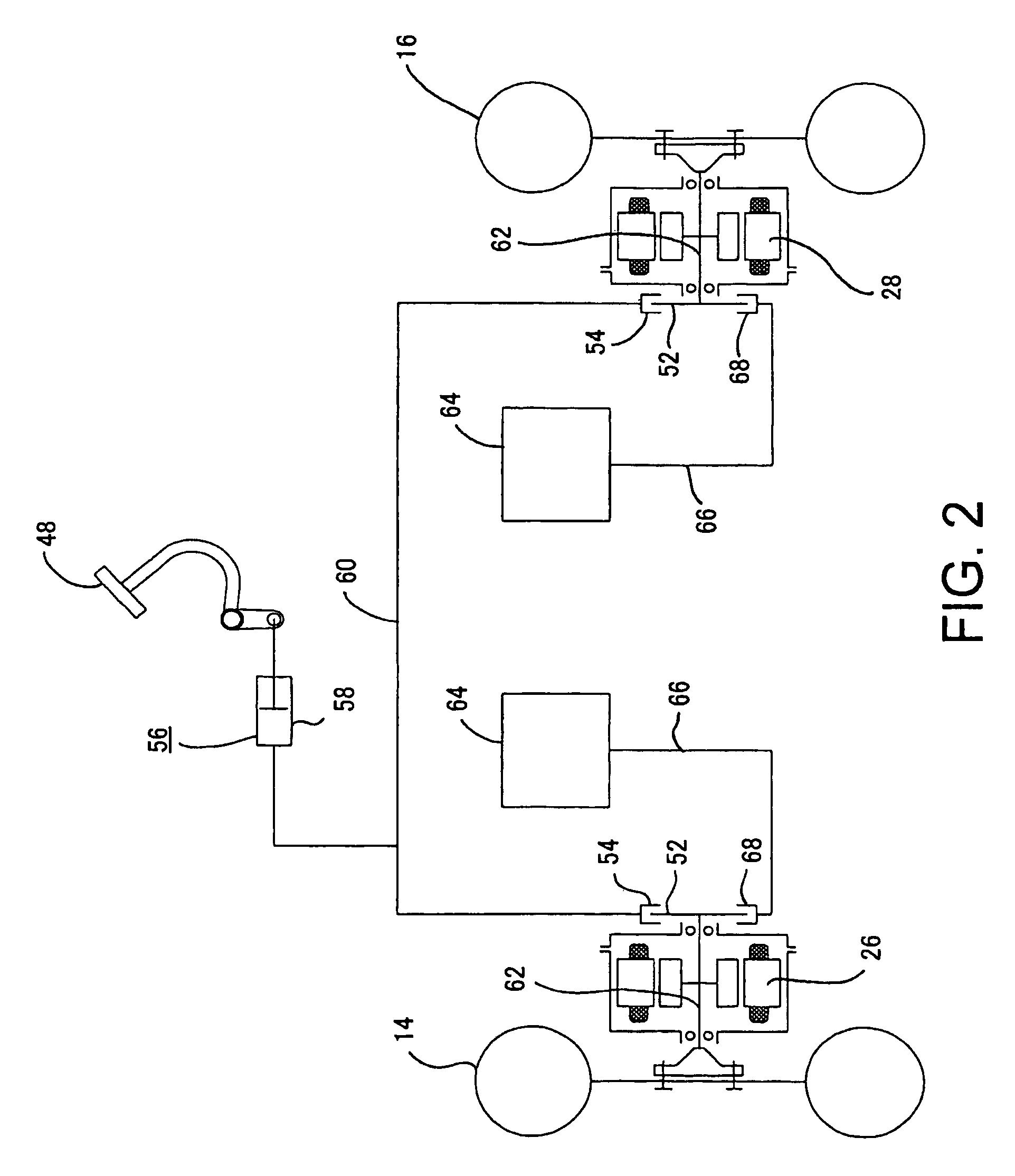

Electric ground working vehicle

ActiveUS7975786B2Efficient executionReduce speedMowersPlural diverse prime-mover propulsion mountingRegenerative brakeElectric power

There is provided an electric ground working vehicle including a left wheel and a right wheel, at least one caster, a working apparatus, an acceleration operating element for performing acceleration instructions, a turn operating element for performing turn instructions, and a control unit. The left wheel and the right wheel are independently driven by left and right electric motors respectively. The control unit controls a regenerative brake driving unit so that electric power is regenerated from the left and right electric motors to an electric power source unit when the acceleration operating element is not operated during traveling to regeneratively brake the left and right wheels. The control unit controls the brake force of the wheels so that the brake force of the wheel at the inside of a turn, among the left wheel and the right wheel, can be made greater than the brake force of the wheel at the outside of a turn when the acceleration operating element is not operated during traveling and turn instructions are inputted from the turn operating element.

Owner:KANZAKI KOKYUKOKI MFG

Hydraulic caliper brake assembly for a bicycle

InactiveUS7971689B2Simple oil circuitImprove cooling effectFluid actuated brakesBraking action transmissionEngineeringCalipers

A hydraulic caliper brake assembly for a bicycle comprises a caliper body; a first chamber installed in the caliper body; a first piston installed in the first chamber; a second piston installed in the first chamber; an inner chamber formed between the first piston and the second piston for receiving brake oil; an outer chamber installed between the second piston and the caliper body for receiving brake oil; and an outer valve installed in the second piston for switching flowing of the brake oil between the inner chamber and outer chamber. When a small force is applied, the brake oil will flow into the inner chamber; by closing the outer valve, the first piston is pushed to have the effect of speed reduction; when the braking force is increased, by opening the outer valve, the second piston is pushed to have the effect of emergent braking.

Owner:ASHIMA LTD

Control device for electric vehicle

ActiveCN105492266ALarge braking forceHigh speedPropulsion by batteries/cellsVehicular energy storageElectric vehicleBrake force

Provided is a control device for electric vehicles, capable of stabilizing vehicle behavior when performing slip control of drive wheels. This control device for electric vehicles comprises: a motor connected to drive wheels of a vehicle, via a differential gear and a drive shaft, and generating braking / driving torque for the drive wheels; and a mechanical braking device capable of generating braking force independently from the drive wheels. The control device for vehicles is configured such that when a drive wheel slip rate of at least a prescribed value is detected: the torque absolute value of the motor is reduced such that the drive wheel slip rate reaches a target motor slip rate; and a larger braking force is applied by the mechanical braking device to the drive wheel out of the right and left drive wheels that has the higher wheel speed than is applied to the drive wheel having the lower wheel speed.

Owner:HITACHI ASTEMO LTD

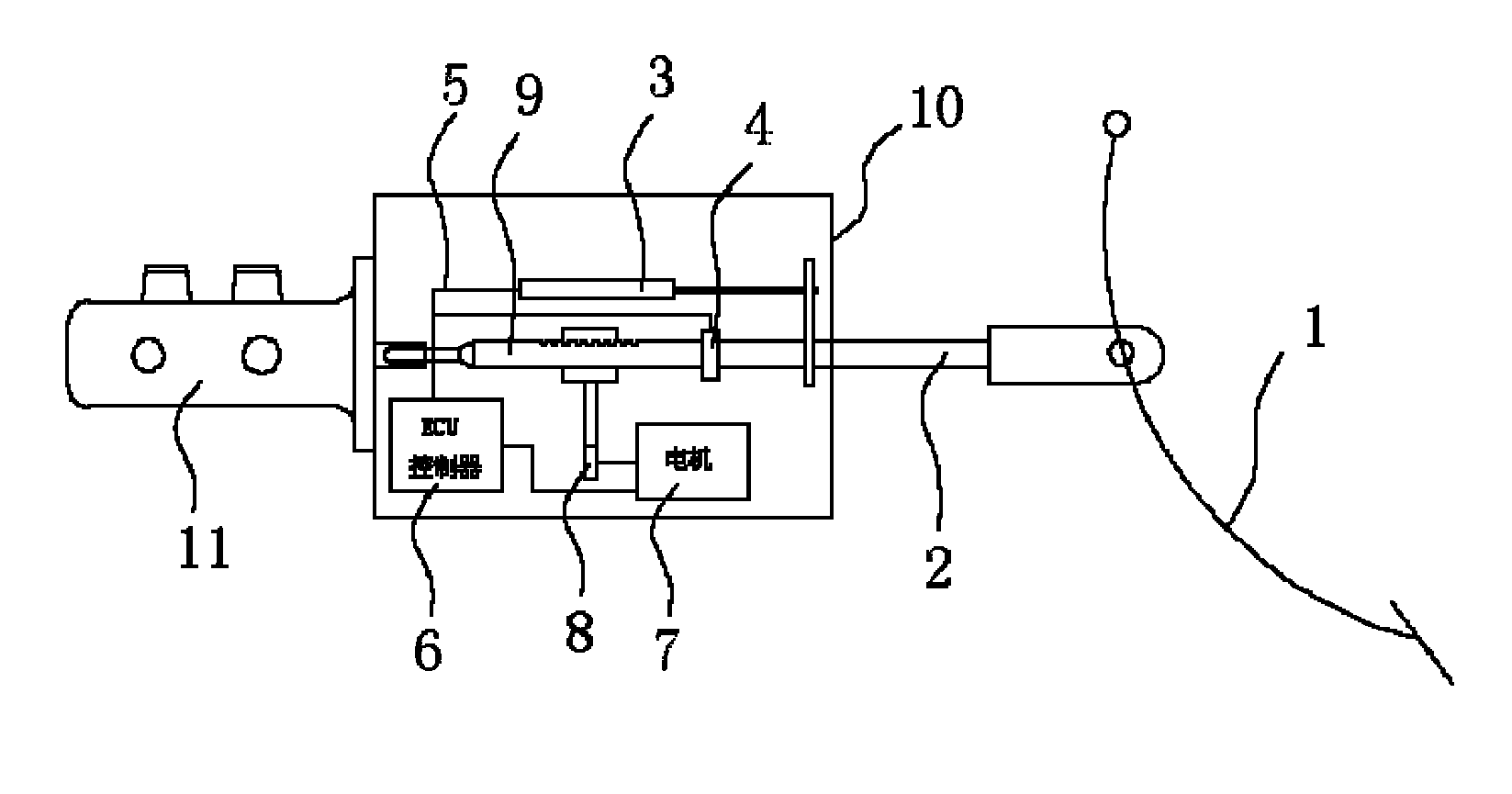

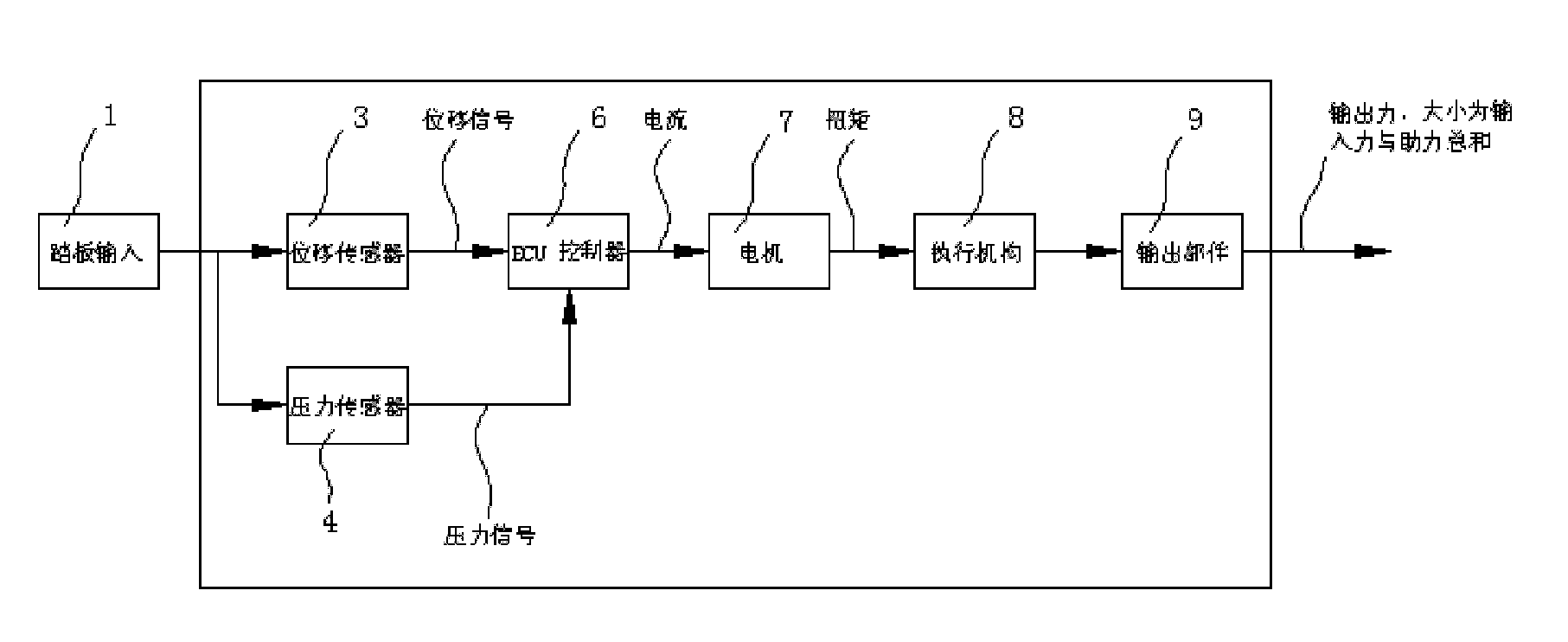

Electric power assisting device of braking system and running method of electric power assisting device

ActiveCN102442292AIdeal driving feelImprove securityBraking action transmissionControl signalElectric power system

The invention relates to an electric power assisting device of a braking system and a running method of the electric power assisting device. The electric power assisting device comprises a pressure sensor, a controller assembly, an actuating mechanism and a direct drive motor, wherein the pressure sensor is connected with a brake pedal and used for acquiring pressure signals from the brake pedal, the controller assembly is connected to the pressure sensor by a connecting wire harness or connected to the pressure sensor wirelessly and is used for receiving the pressure signals and carrying out logic operation, furthermore, the controller assembly is connected to the direct drive motor by a connecting wire harness or connected with the direct drive motor wirelessly and is used for transmitting control signals obtained via logic operation to the direct drive motor, and the direct drive motor is in drive connection with the actuating mechanism and drives the actuating mechanism to realize electric power boosting.

Owner:CHERY AUTOMOBILE CO LTD

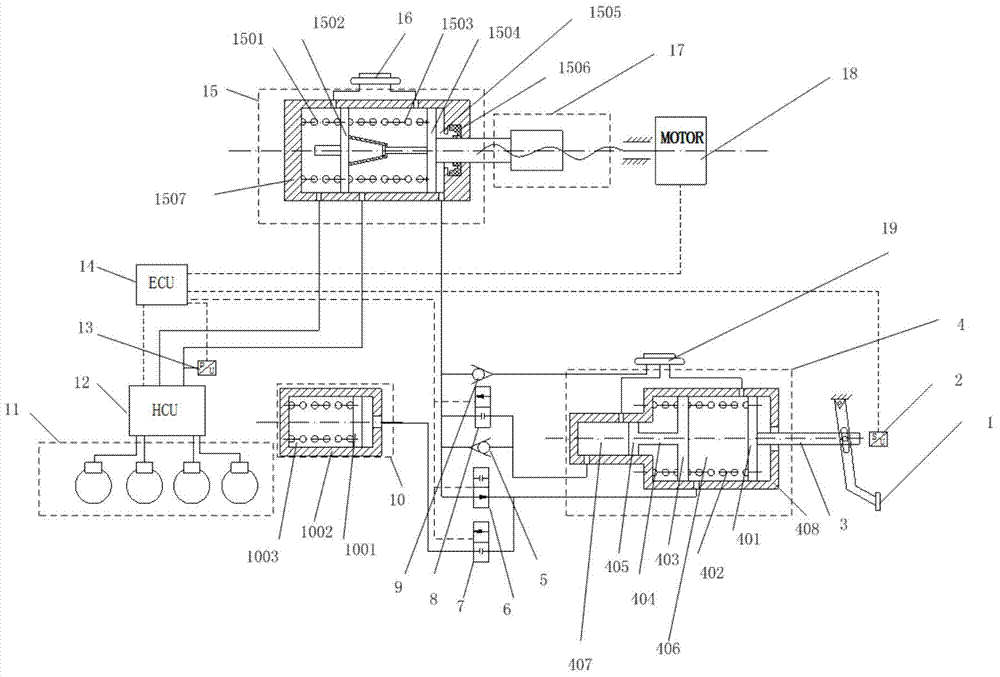

Braking system with combined function of drive-by-wire and power-assisting and with manpower-magnification action

InactiveCN104709263AImprove reliabilityLarge braking forceBraking action transmissionElectric machineryHydraulic control unit

The invention discloses a braking system with combined function of drive-by-wire and power-assisted and with a manpower-magnification action. Functions such as electric braking power-assisting, active braking and regenerative braking can be achieved, control can be conducted on a motor, a hydraulic control unit and several magnetic valves according to the collected signal of a brake pedal displacement sensor and a master cylinder pressure sensor through an electronic control unit, and choice on each braking mode is realized. When the system works under the drive-by-wire mode, the motor is controlled by the brake pedal displacement sensor to push the master cylinder piston to output the brake pressure to a wheel cylinder, and a brake pedal and a friction brake are coupled completely at the moment; when the system works under the electric power-assisting mode, the pedal effort is input into a master cylinder back cavity after being amplified through a human-powered cylinder, a first piston of the master cylinder is pushed, at the same time, the motor output torque is controlled by the electronic control unit, the electronic control unit exerts assisting power on the first piston of the master cylinder, and the brake pressure is output to the wheel cylinder; when the system works under the active braking mode, the electronic control unit controls the motor output torque to make the main cylinder to output the brake pressure to the wheel cylinder.

Owner:JILIN UNIV

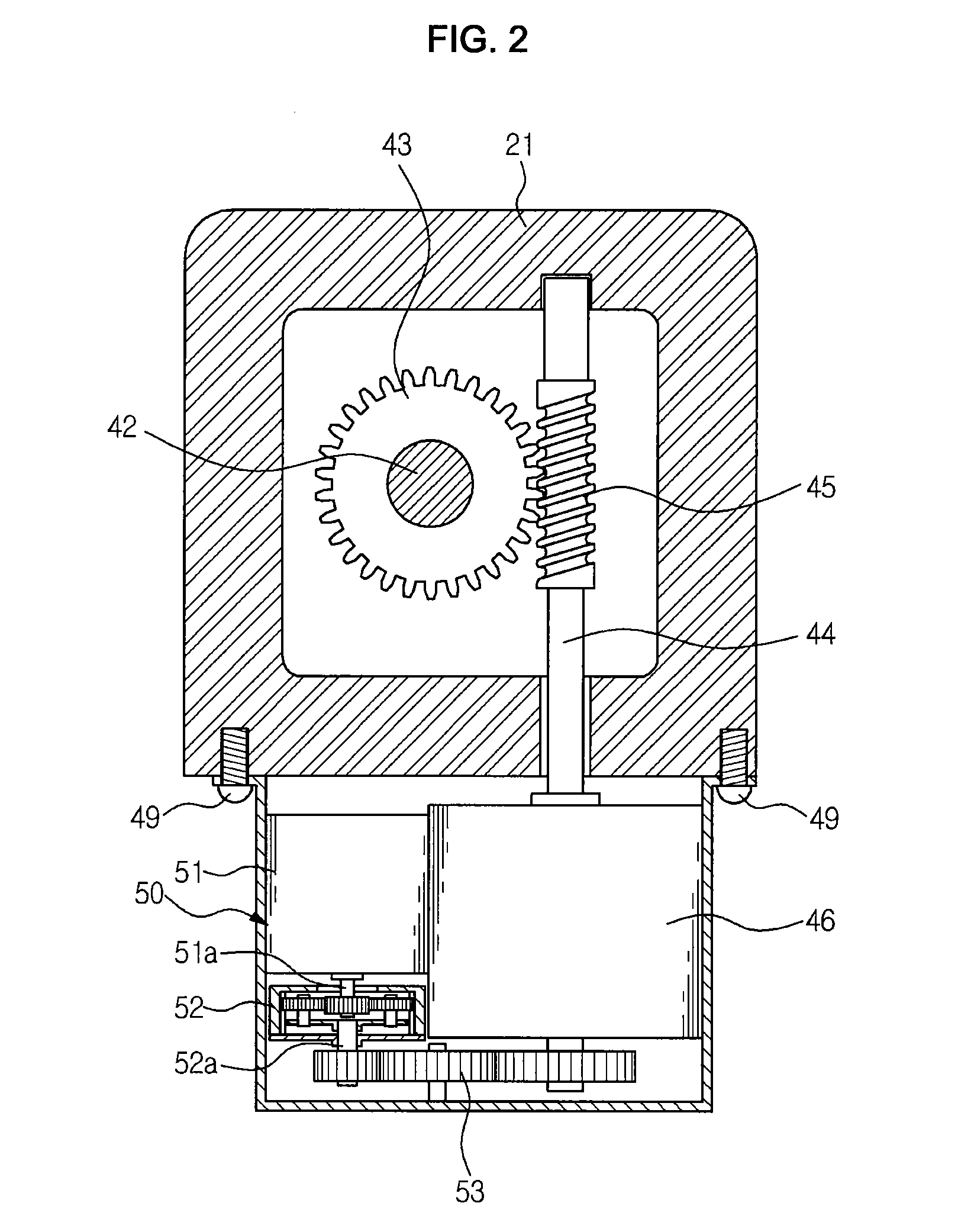

Electric disk brake

ActiveUS20100126811A1Reduce motor speedPowerfulMechanically actuated brakesElectrodynamic brake systemsDrive shaftCalipers

Disclosed is an electric disc brake. The electric disc brake includes friction pads for pressing a disc, a carrier for supporting the friction pads, a caliper housing supported by the carrier such that the caliper housing moves back and forth to press the friction pads, and a pressing device for pressing the friction pads. The pressing device includes a pressing member moving back and forth in the caliper housing to press one of the friction pads, a screw shaft coupled to the pressing member, a worm wheel coupled to the screw shaft, a driving shaft crossing the screw shaft and having a worm gear engaged with the worm wheel, a motor for rotating the driving shaft in a forward direction or a reverse direction, and an auxiliary pressing device.

Owner:HL MANDO CORP

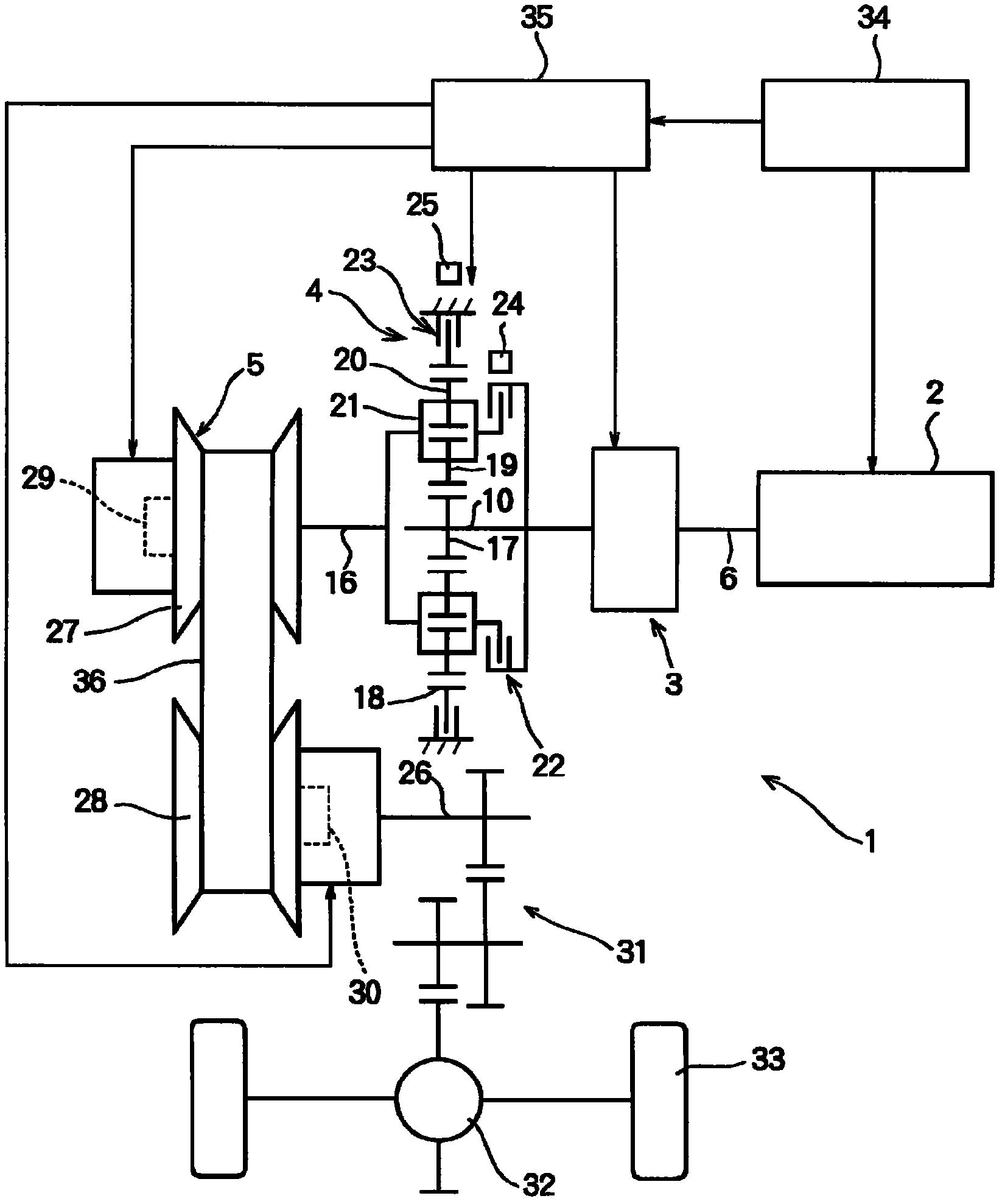

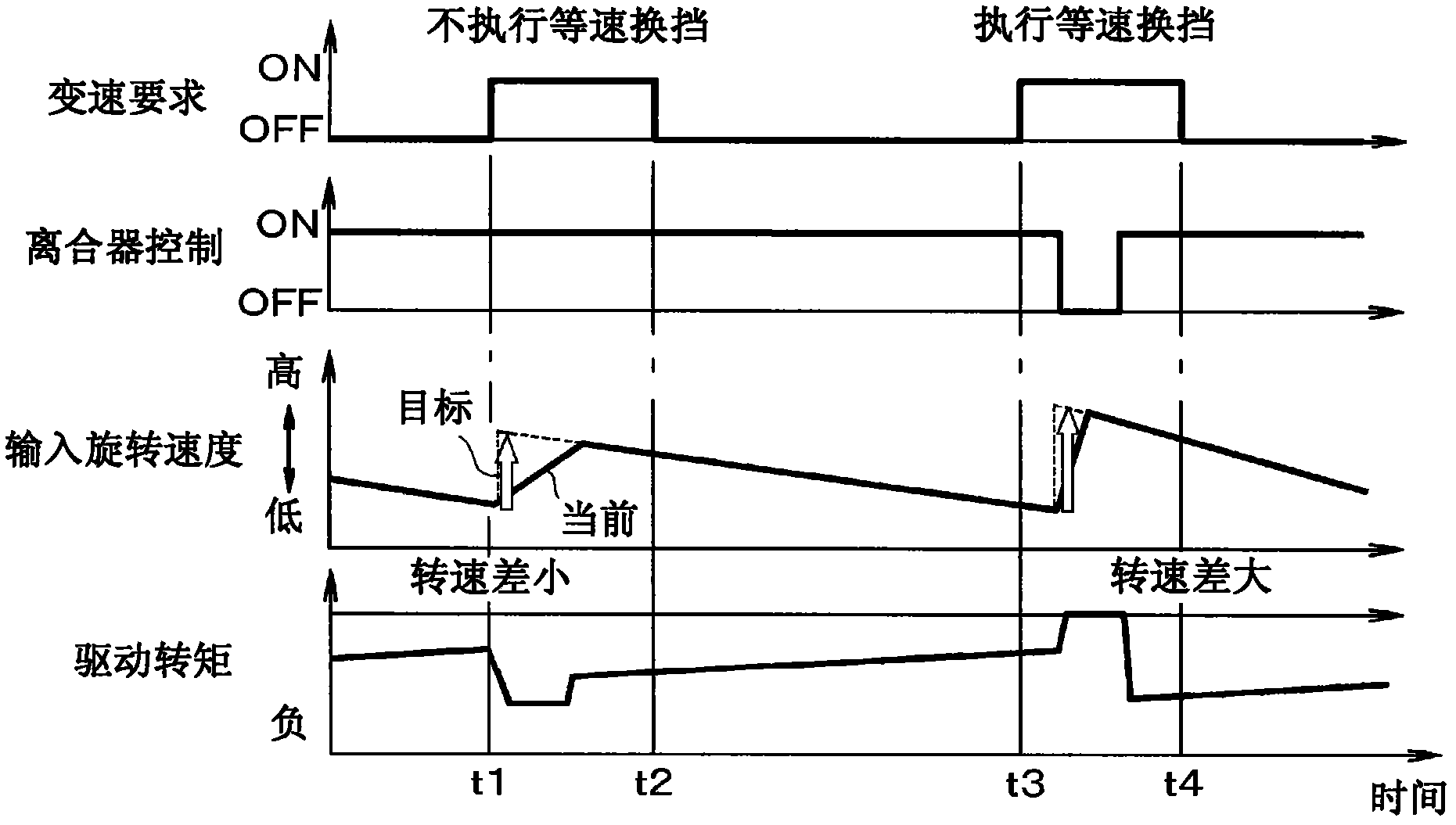

Driving force control device

InactiveCN102361787ASmall torque capacityAvoid equivalent inertial mass increaseGearingGearing controlEngineeringInternal combustion engine

Provided is a driving force control device capable of suppressing shifting shocks when a speed ratio is stepwise changed by a continuously variable transmission. The driving force control device has the continuously variable transmission connected in a power transmittable manner to the output shaft of an internal combustion engine through a clutch so that the device can change the speed ratio of the continuously variable transmission stepwise. The driving force control device comprises a shift deciding means (Step S1) for deciding whether or not the torque capacity of the clutch is relatively high and whether or not the speed ratio of the continuously variable transmission is stepwise changed while the vehicle is running, and a first shifting means (Step S3) for lowering the torque capacity of the clutch, when the speed ratio of the continuously variable transmission is stepwise changed, before the speed ratio is changed by the continuously variable transmission, synchronizing the rotating speed of the internal combustion engine, while the speed ratio is being changed by the continuously variable transmission, with the input rotating speed after the speed ratio is changed by the continuously variable transmission, and raising the torque capacity of the clutch after the speed ratio is changed by the continuously variable transmission.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com