Automobile auxiliary brake-powered speed-reduction friction device and braking method thereof

A friction device and automobile auxiliary technology, applied in hydraulic brake transmission, vehicle parts, transportation and packaging, etc., can solve the problems of low friction coefficient, increase of wheel and ground, limited contact area, etc., achieve simple process, reduce Braking distance and the effect of reducing traffic accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

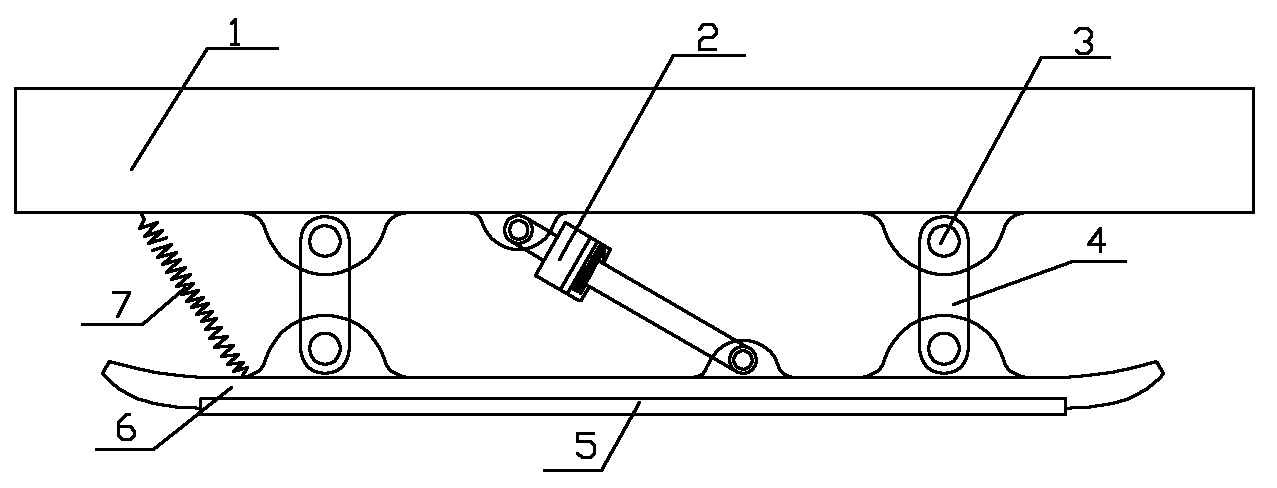

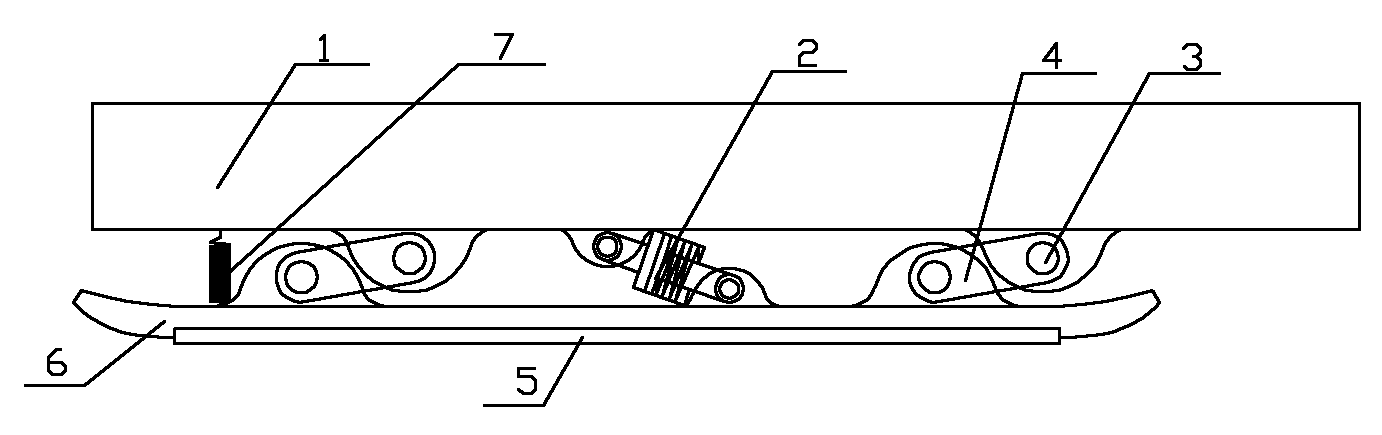

[0043] see figure 1 , figure 2 , figure 1 , figure 2 It is a connection form in which the automobile chassis longitudinal beam 1 is connected to the friction brake pedal 6 in the present invention. The automobile chassis longitudinal beam 1 and the friction brake pedal 6 are directly connected through two connecting rods 4, hydraulic cylinder 2 and spring 7, and the connecting rod 4 are respectively connected with automobile chassis longitudinal beam 1 and friction brake pedal 6 by pin 3, and friction plate 5 is arranged on the following riveting or screw connection of friction brake pedal 6, when the present invention stops working, then just as figure 2 shown.

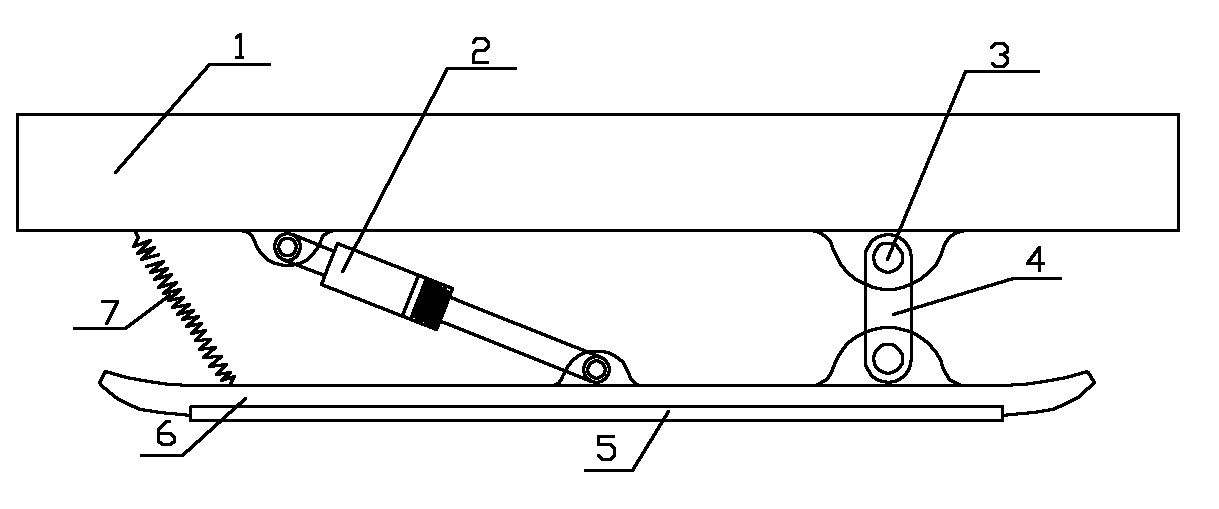

[0044] see image 3 , Figure 4 , image 3 , Figure 4 It is another connection form that the automobile chassis longitudinal beam 1 is connected with the friction brake pedal 6 in the present invention. The automobile chassis longitudinal beam 1 is directly connected with the friction brake pedal 6 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com