Pincer type brake with force-amplifying mechanisms

A technology of caliper brake and booster mechanism, applied in the direction of brake type, axial brake, brake actuator, etc., can solve the problems of high power, difficult maintenance and high cost of the driving device, and achieve low quality, convenient expansion, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

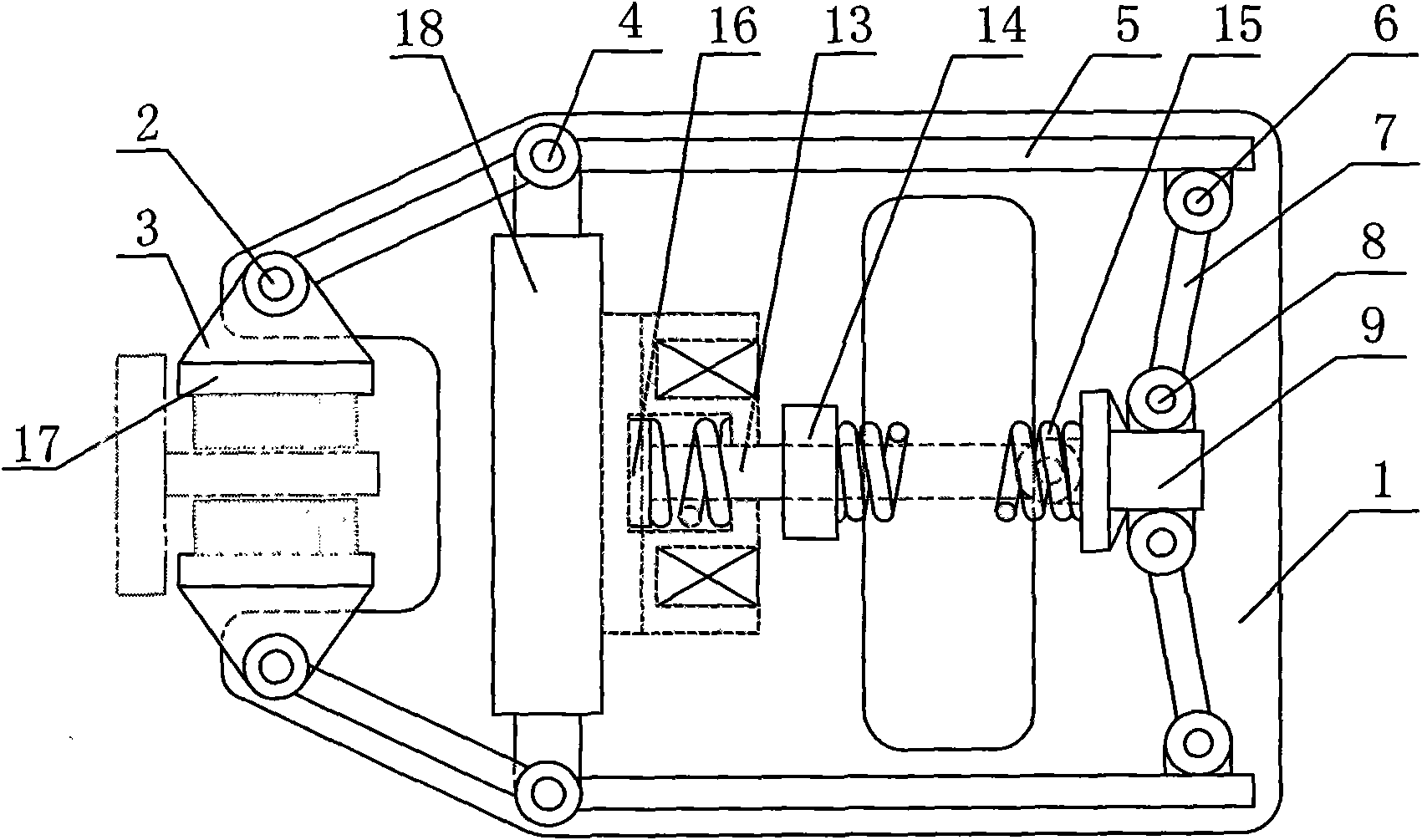

Embodiment 1

[0023] Such as figure 1 As shown, the caliper brake with booster mechanism includes base 1, brake block hinge shaft 2, brake block 3, swing arm front hinge shaft 4, swing arm 5, swing arm rear hinge shaft 6, and brake booster mechanism The connecting rod 7, the brake connecting rod hinge shaft 8, the sliding block 9, the pushing mechanism 13, the guide block 14, the brake spring 15, the brake spring seat 16, the brake lining 17, and the fixed block 18. The pushing mechanism 13 is an electromagnet, a linear motor, an electric push rod, a hydraulic push rod, an electro-hydraulic push rod, a pneumatic push rod or other pushing mechanisms.

[0024] The fixed block 18 and the guide block 14 are fixed on the base 1. The brake block 3 and the brake lining 17 are hinged on the swing arm through the brake block hinge shaft 2. The brake block 3 can swing around the brake block hinge shaft 2, and the swing arm 5 passes through it. Its own ear plate is hinged with the ear plate on the fixed ...

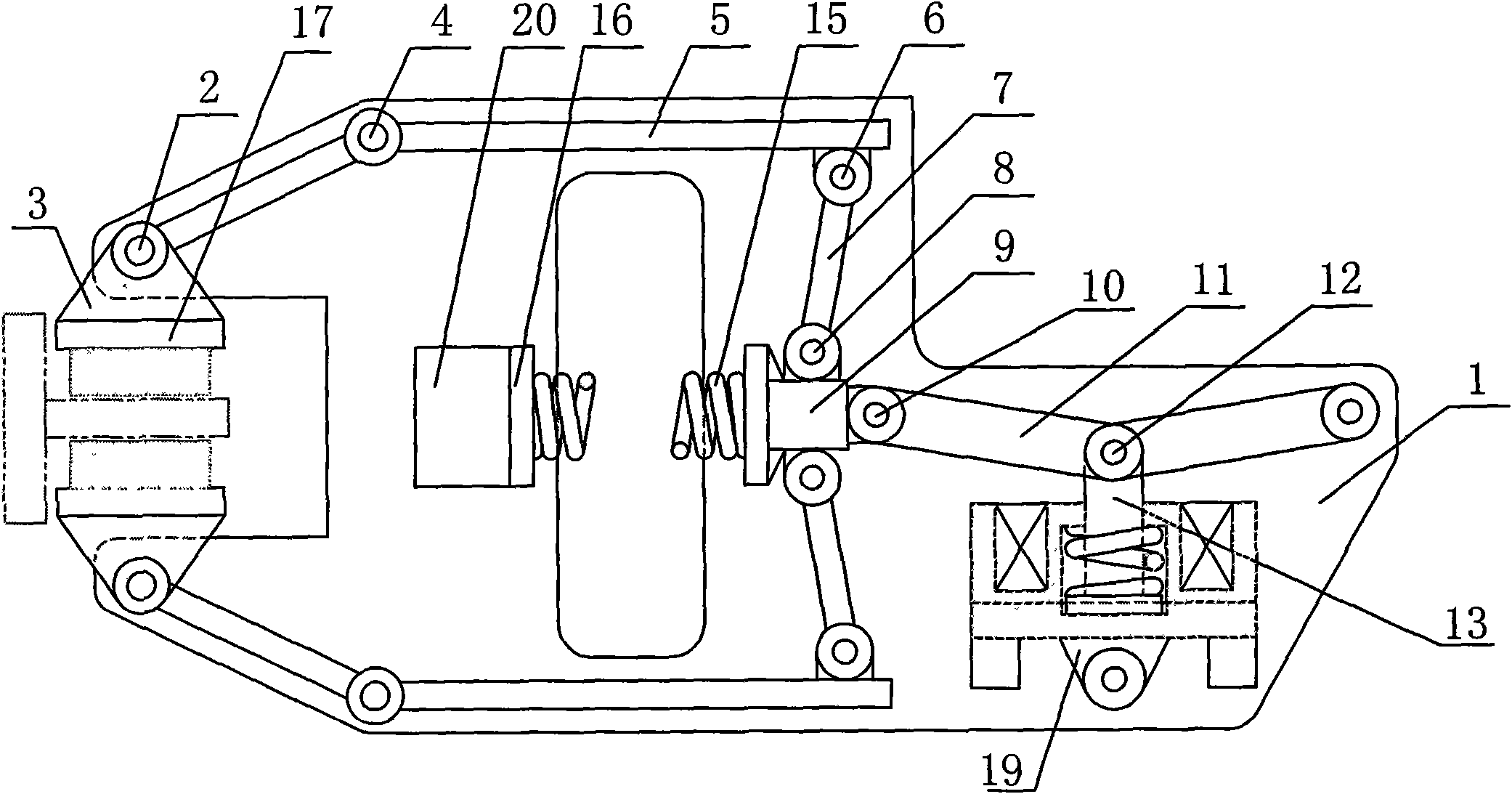

Embodiment 2

[0032] Such as figure 2 As shown, the caliper brake with dual booster mechanism includes base 1, brake block hinge shaft 2, brake block 3, swing arm front hinge shaft 4, swing arm 5, swing arm rear hinge shaft 6, brake booster Mechanism link 7, brake link hinge shaft 8, slider 9, drive booster mechanism link hinge shaft 10, drive booster mechanism link 11, electromagnet hinge shaft 12, push mechanism 13, brake spring 15, Brake spring seat 16, brake lining 17, fixed block II 19, fixed block III 20.

[0033] The swing arm front hinge shaft 4, the fixed block II 19, and the fixed block III 20 are fixed on the base 1. The swing arm 5 is hinged with the swing arm front hinge shaft 4 through its own ear plate, and the swing arm 5 passes through the upper ear plate. It is hinged with the brake booster linkage 7 and the rear hinge shaft 6 of the swing arm; the brake booster linkage 7 is hinged with the slider 9 through the brake linkage hinge 8; the brake spring 15 is hinged through the...

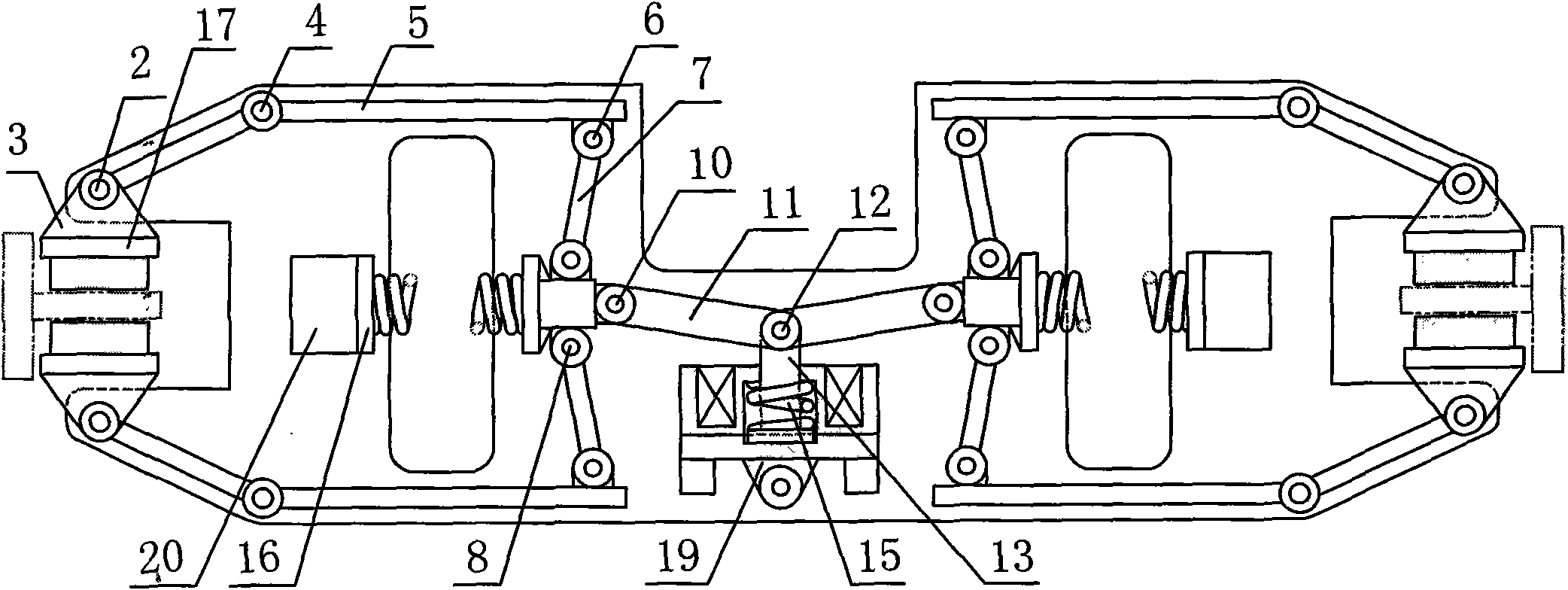

Embodiment 3

[0041] Such as image 3 Shown, a two-way caliper brake with a double booster mechanism. It is arranged symmetrically on the basis of embodiment 2, and becomes a two-way brake with multiple booster mechanisms working synchronously. Other connections are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com