Braking system with combined function of drive-by-wire and power-assisting and with manpower-magnification action

An amplifying and compound function technology, applied in the direction of brakes, brake transmissions, vehicle components, etc., can solve problems such as disadvantages, large size of vacuum boosters, uncontrollable booster size, etc., to achieve small system pressure fluctuations and reduce motor demand. , the effect of smooth switching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

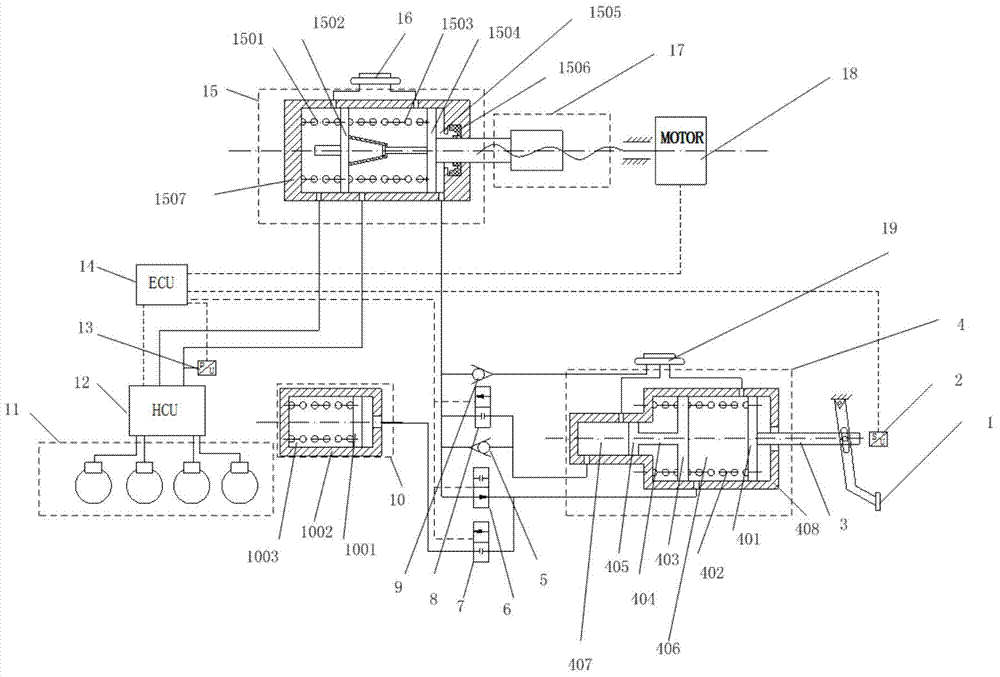

[0025] refer to figure 1 , a brake system with a manpower amplification function of wire control and power-assisted compound functions, including a brake pedal 1, a pedal displacement sensor 2, a push rod 3, a manpower cylinder 4, a first one-way valve 5, and a second one-way valve 9. Normally open solenoid valve 6, first normally closed solenoid valve 7, second normally closed solenoid valve 8, pedal simulator 10, wheel cylinder 11, hydraulic control unit 12, pressure sensor 13, electronic control unit 14, three-chamber main Cylinder 15, master cylinder liquid storage tank 16, manpower cylinder liquid storage tank 19, motion conversion and transmission mechanism 17, motor 18.

[0026] The brake pedal 1 is pin-connected to the push rod 3; the push rod 3 is connected to the rear piston 401 of the manpower cylinder 4; the manpower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com