Brake cylinder device and disk brake device

A brake cylinder and braking force technology, which is applied to brakes with brake parts, brakes with pressure braking surfaces, brakes, etc., can solve the problem of enlarged diameter, inability to increase the output of the transmission device, and large-scale devices And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0078] disc brake

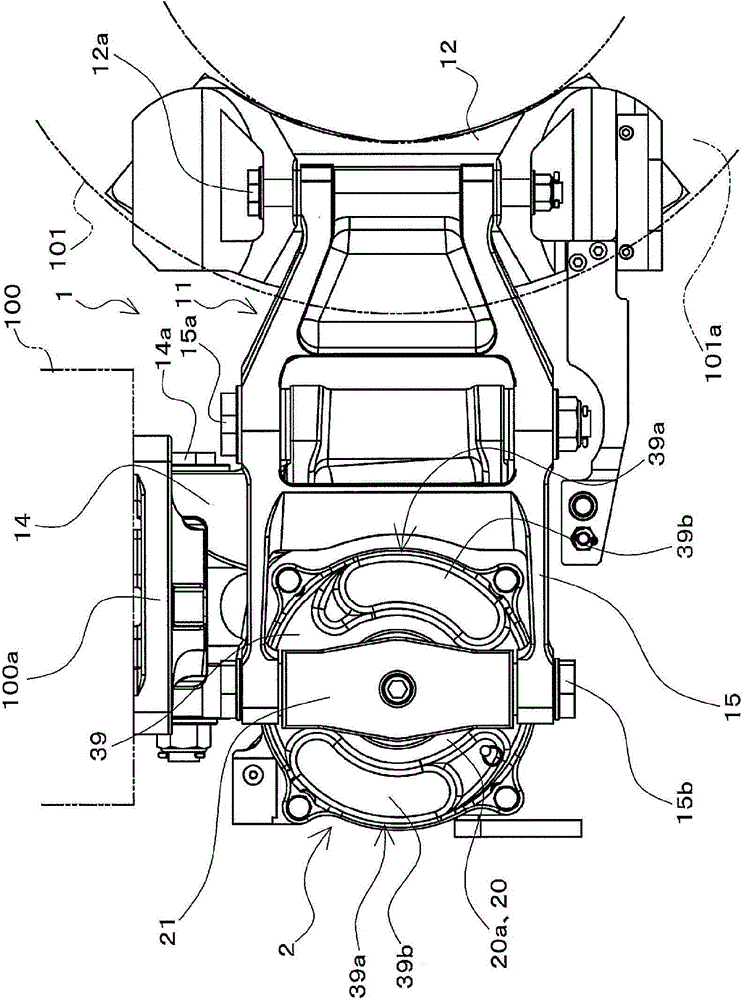

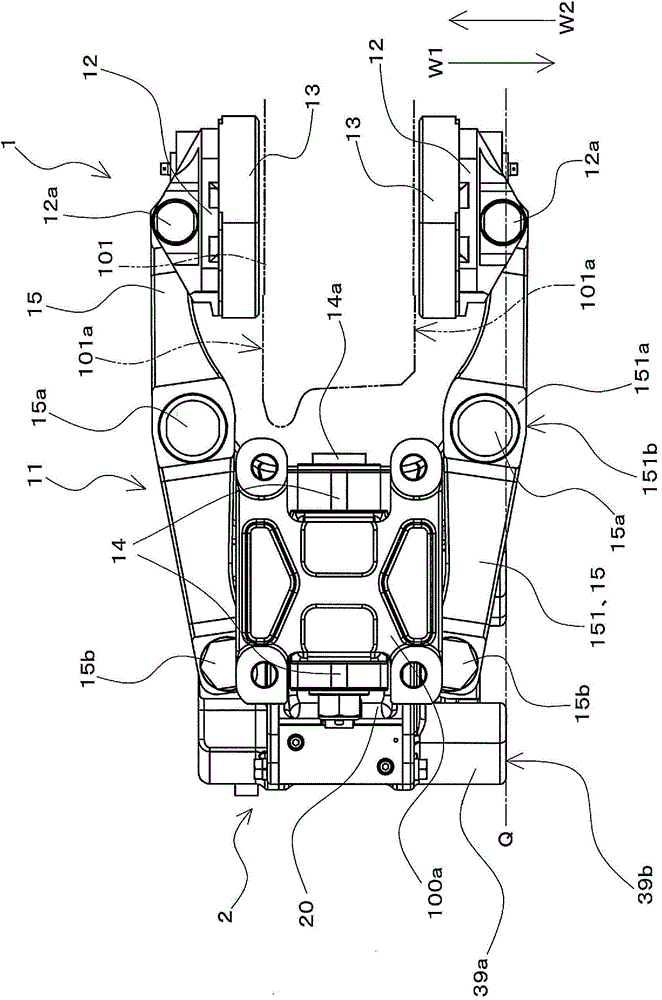

[0079] figure 1 It is a side view of the disc brake device 1 according to the first embodiment of the present invention viewed from the axle direction. in addition, figure 2 is viewed from above figure 1 A plan view of the disc brake device 1 shown. figure 1 and figure 2 The shown disc brake device 1 is configured to include the following members, etc.: a brake cylinder device 2 ; Installation; a pair of back plates (12, 12) as brake shoe holding parts for respectively holding a pair of brake pads (13, 13) as brake shoes.

[0080] A pair of brake pads ( 13 , 13 ) are attached to the caliper main body 11 via a back plate 12 . Furthermore, the disc brake device 1 is configured such that a pair of brake pads (13, 13) pinches a disc-shaped brake disc 101 when the brake cylinder device 2 operates to generate a braking force. The disk 101 is a disk on the axle side that rotates as wheels (not shown) of the railway vehicle rotate. In addition, the brak...

no. 2 Embodiment approach

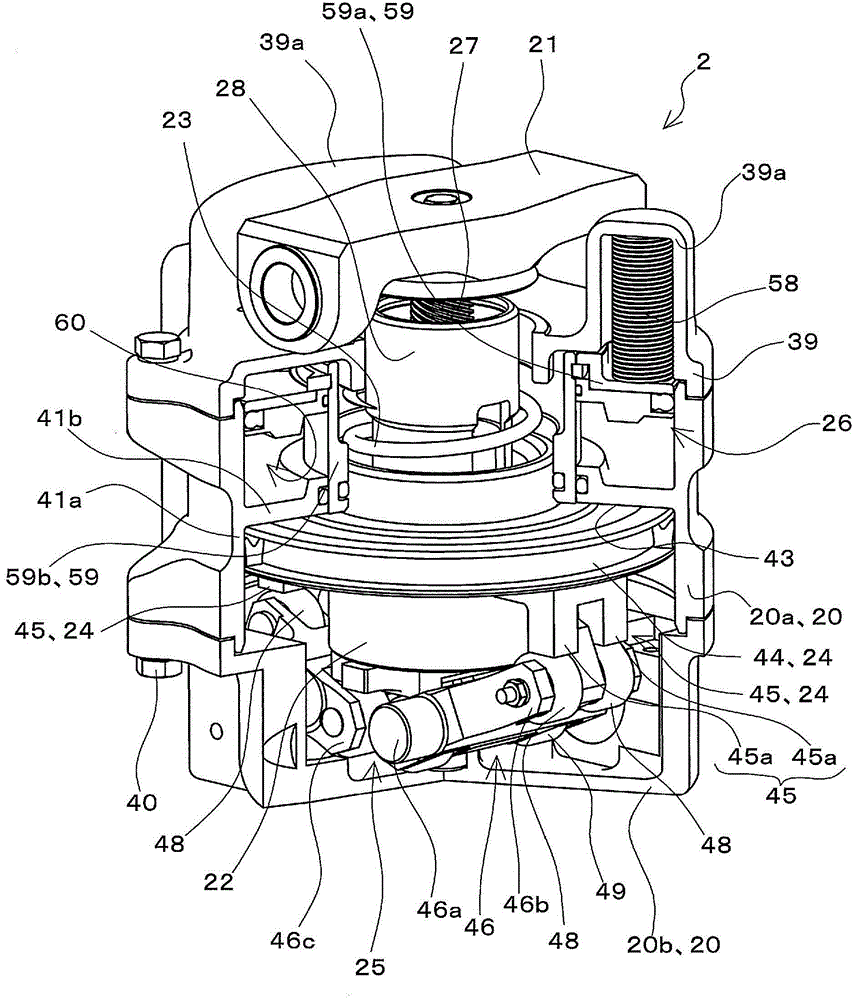

[0182] Next, a second embodiment of the present invention will be described. Figure 16 It is a perspective view of a brake cylinder device 3 according to a second embodiment of the present invention, and is a diagram showing an internal structure in a cutaway section. A disc brake device according to a second embodiment of the present invention includes Figure 16 brake cylinder unit 3 shown, and with figure 1 and figure 2 The disc brake device 1 of the first embodiment shown is configured in the same manner. That is, the disc brake device of the second embodiment is configured to include the brake cylinder device 3 , the caliper main body 11 , a pair of back plates ( 12 , 12 ), and the like.

[0183] In addition, in the following description of the second embodiment, the elements having the same configuration as those of the first embodiment are denoted by or referred to by the same reference numerals in the drawings, and description thereof will be omitted. Hereinafter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com