Headlight module for vehicle, headlight unit for vehicle, and headlight device for vehicle

A technology for headlights and vehicles, which is applied to lighting devices, fixed lighting devices, headlights, etc., can solve the problems of reduced light utilization efficiency and complex optical system structure, and achieves the goal of suppressing the decline in light utilization efficiency and the increase in size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

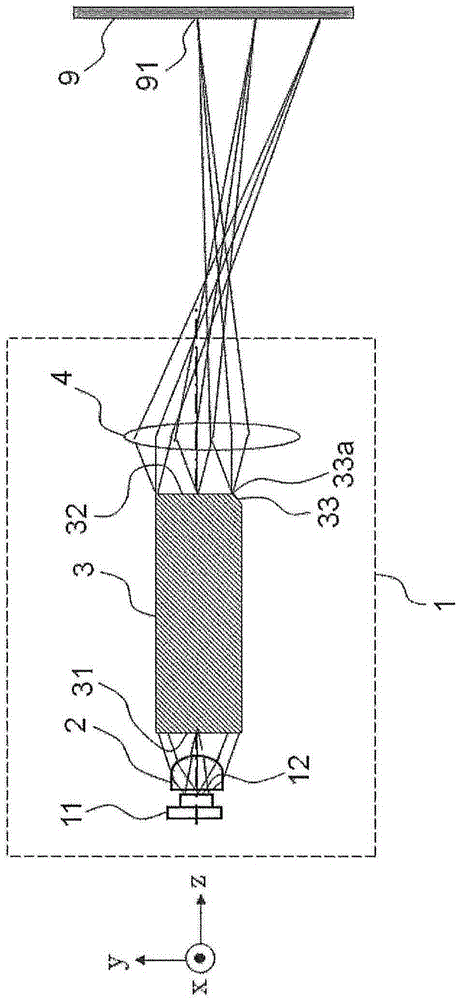

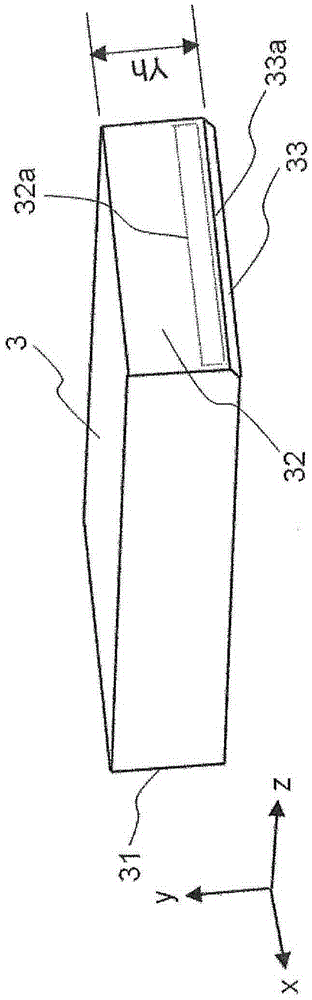

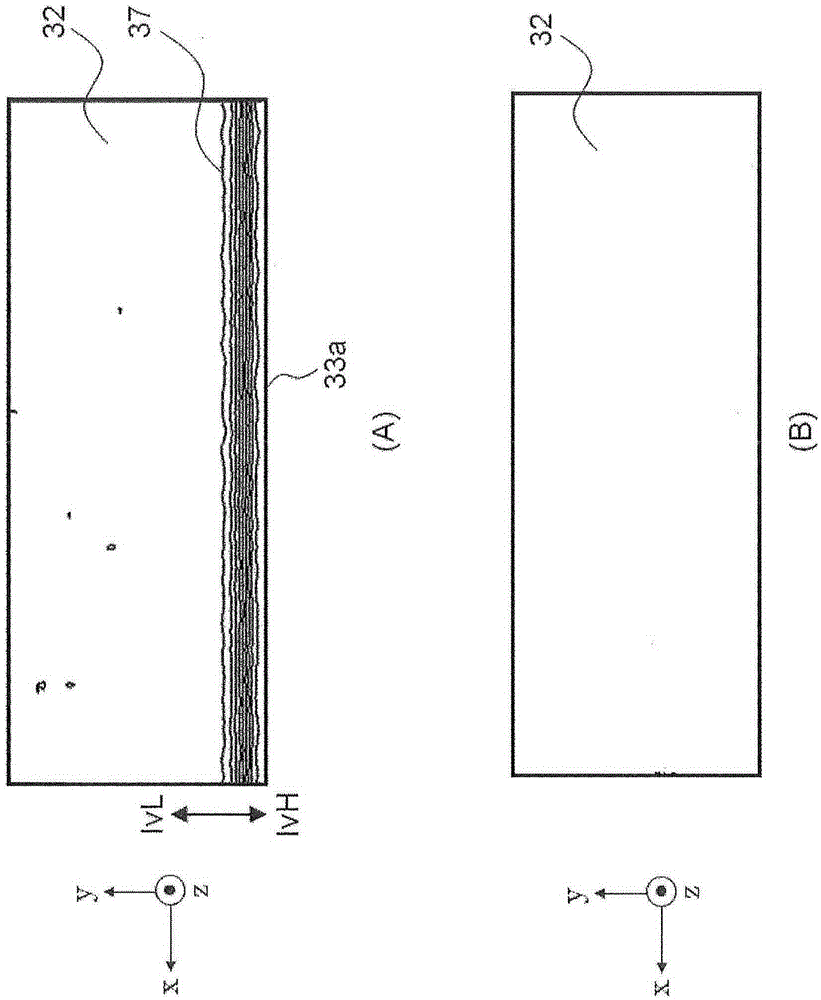

[0045] figure 1 It is a configuration diagram showing the configuration of the vehicle headlamp module 1 according to Embodiment 1 of the present invention. Such as figure 1 As shown, the vehicle headlamp module 1 according to Embodiment 1 includes a light source 11 , a light guide member 3 , and a projection lens 4 . Furthermore, the vehicle headlamp module 1 may include a light distribution control lens 2 . The light source 11 has a luminous area 12 . The light source 11 emits light for illuminating the front of the vehicle from the light emitting surface 12 . As the light source 11, an LED, an electroluminescent element, a semiconductor laser, or the like can be used. However, in the following description, the case where the light source 11 is an LED will be described. Hereinafter, the light source 11 is also called LED11.

[0046] The light distribution control lens 2 is a lens having positive refractive power. The light distribution control lens 2 sets, for example...

Embodiment approach 2

[0083] Figure 7 It is a configuration diagram showing the configuration of a vehicle headlamp module 10 according to Embodiment 2 of the present invention. right with figure 1 The same structural elements are denoted by the same reference numerals and their descriptions are omitted. and figure 1 The same structural elements are the light source 11 and the projection lens 4 . Like Embodiment 1, the light source 11 is also called LED11. Such as Figure 7 As shown, the vehicle headlamp module 10 according to Embodiment 2 includes LEDs 11 , a light guide member 300 , and a projection lens 4 . Furthermore, the vehicle headlamp module 10 may include a light distribution control lens 20 .

[0084] Unlike the first embodiment, the light distribution control lens 20 of the vehicle headlamp module 10 of the second embodiment is a cylindrical lens having curvature only in the y-axis direction. A "cylindrical lens" refers to a lens in which at least one surface of the lens is form...

Embodiment approach 3

[0099] Figure 9 It is a configuration diagram showing the configuration of a vehicle headlamp module 100 according to Embodiment 3 of the present invention. right with figure 1 The same structural elements are denoted by the same reference numerals and their descriptions are omitted. and figure 1 The same structural elements are the light source 11 , the light distribution control lens 2 , the light guide member 3 and the projection lens 4 . Like Embodiment 1, the light source 11 is also called LED11.

[0100] Such as Figure 9 As shown, the vehicle headlamp module 100 according to Embodiment 3 includes a light source 11 , a light guide member 3 , a projection lens 4 , a rotation mechanism 5 , and a control circuit 6 . The rotation mechanism 5 rotates the light guide member 3 and the projection lens 4 around the optical axis as a whole. "Integral" means to rotate simultaneously, and includes cases where the rotation angle of the light guide member 3 and the rotation ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com