Patents

Literature

142results about How to "Increase axial force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

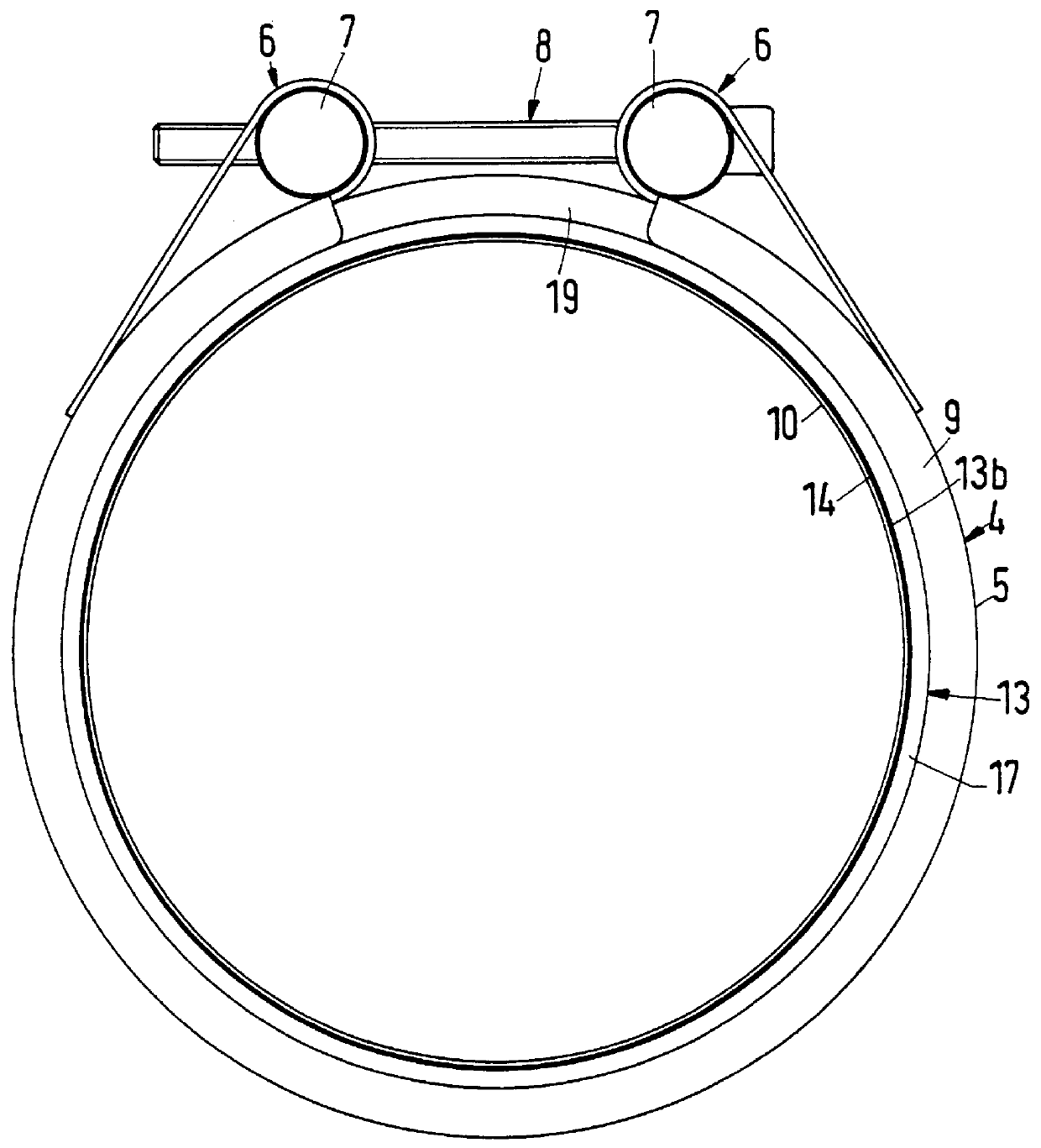

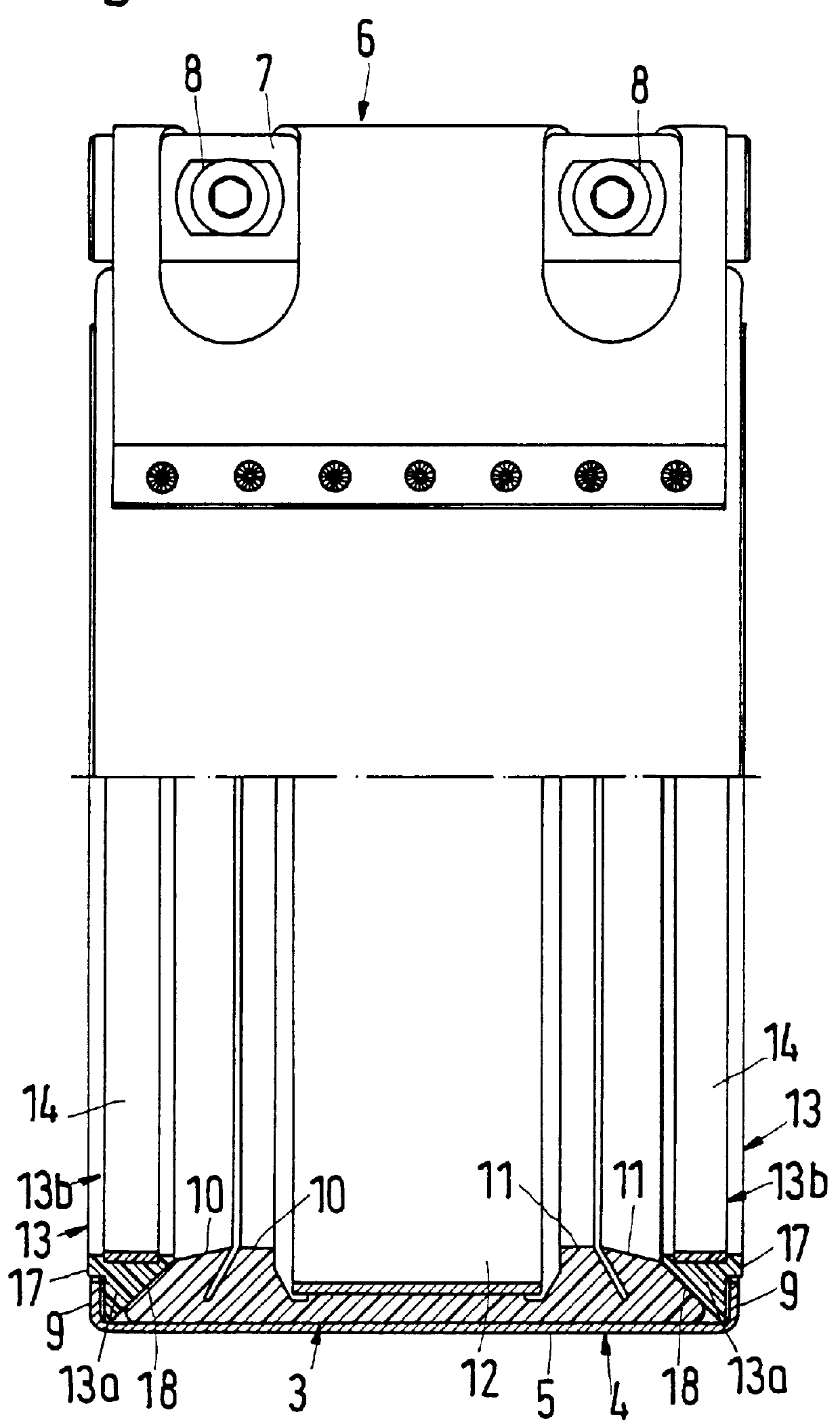

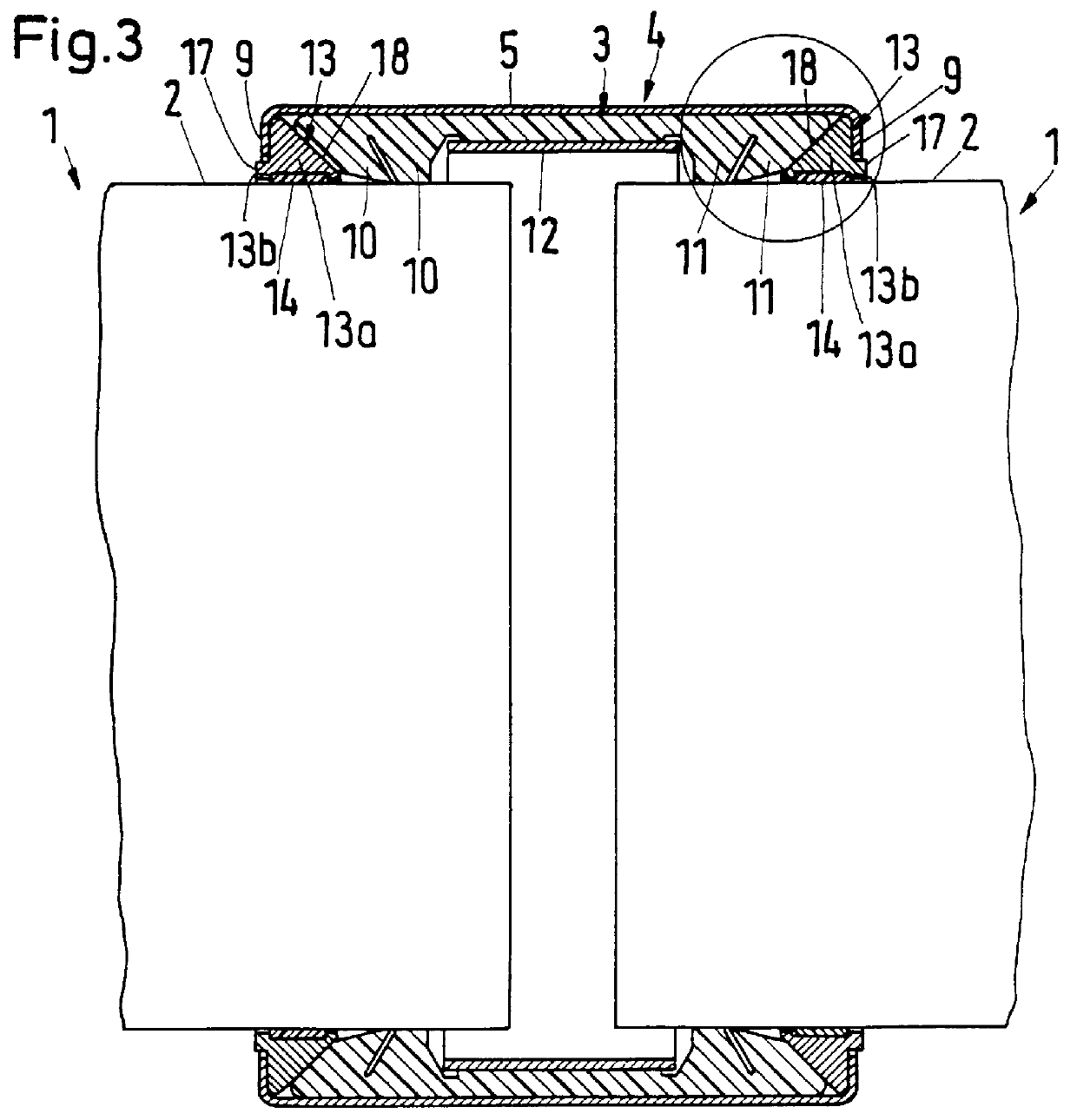

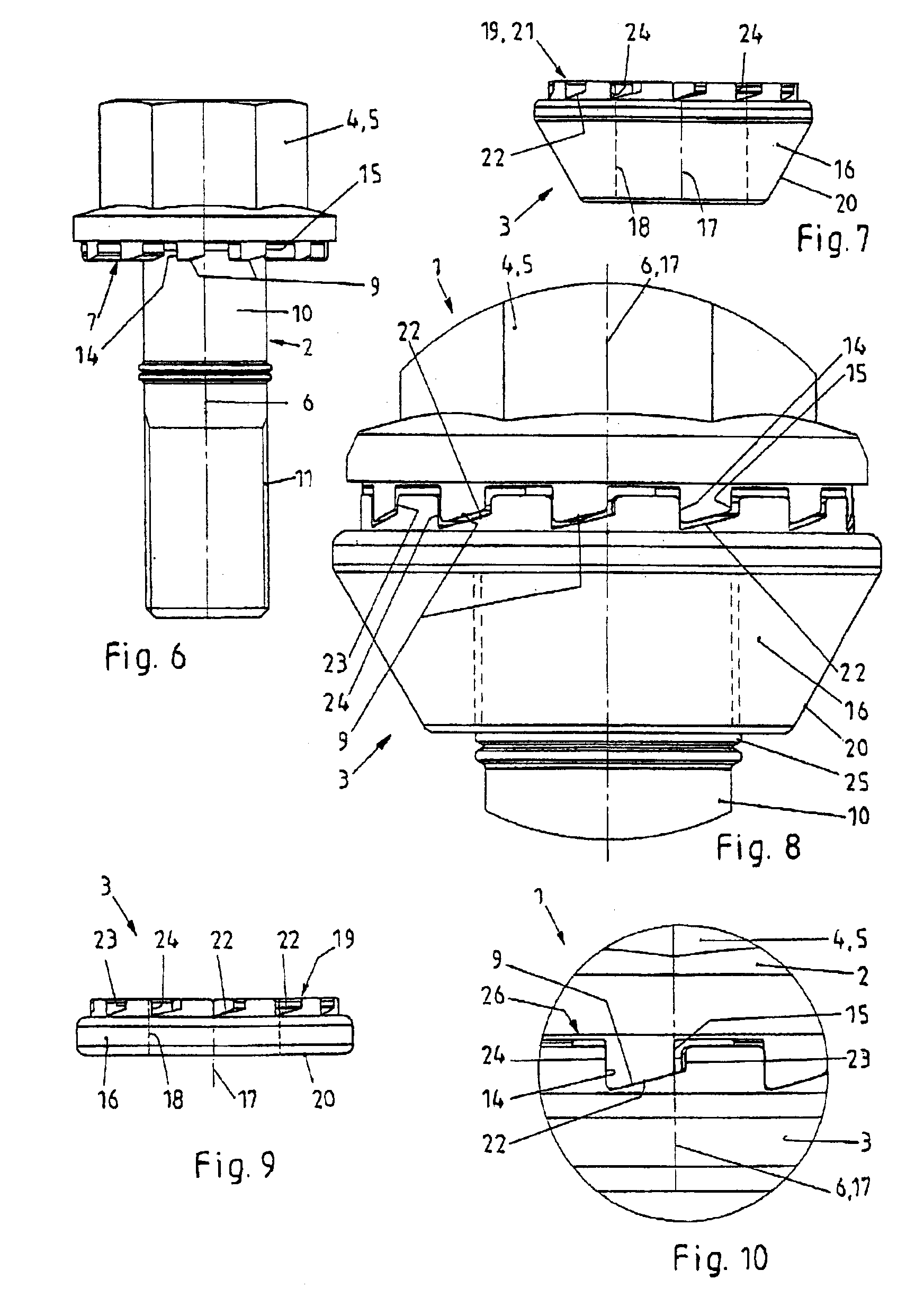

Pipe coupling

InactiveUS6070914AIncrease the cross-sectional areaHigh strengthSleeve/socket jointsFluid pressure sealed jointsCouplingEngineering

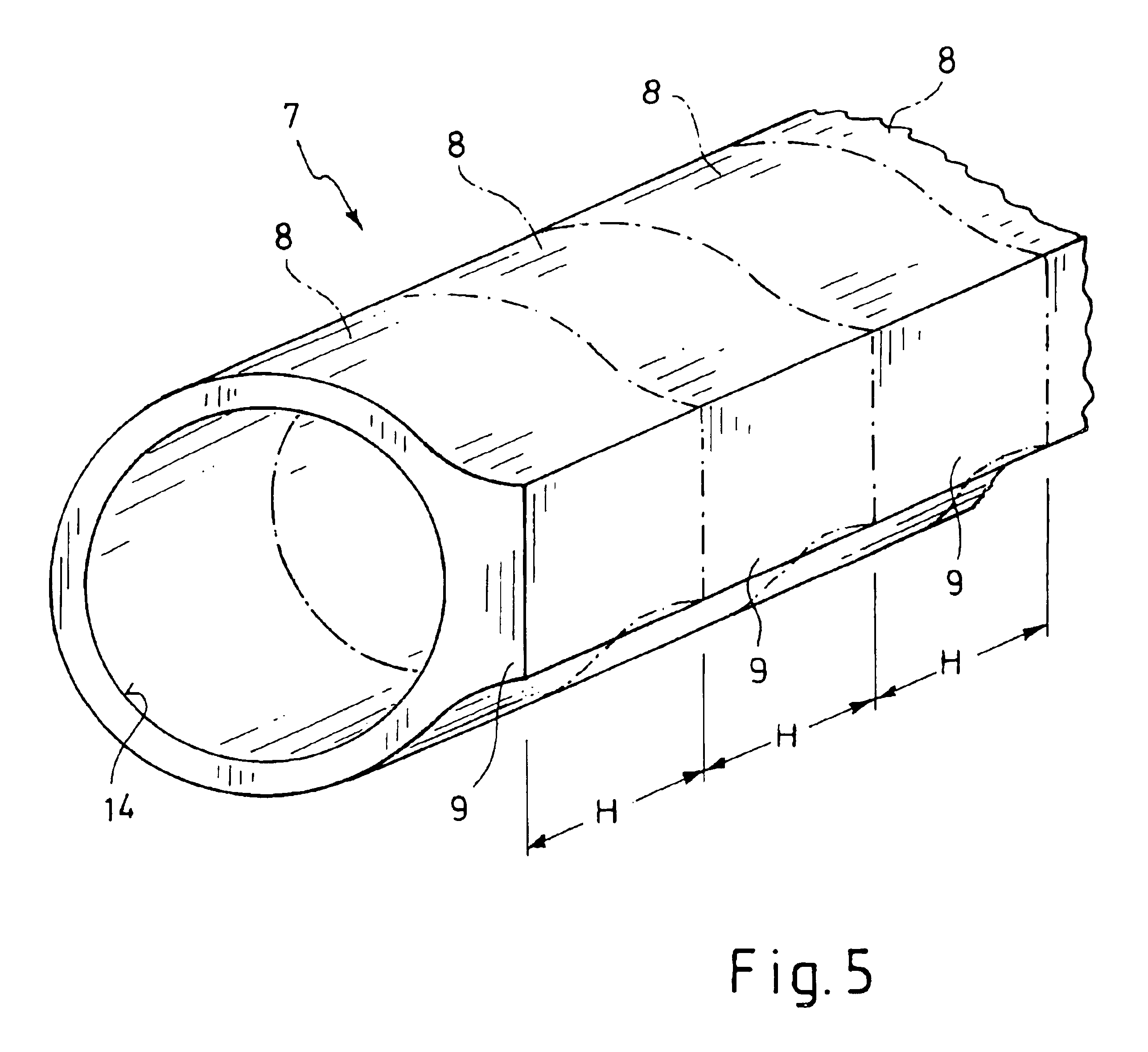

A pipe coupling for connecting pipes having unprofiled end sections includes an elastomeric sealing gasket for holding the unprofiled pipe end sections in a sealed manner. A clamping clip surrounds the sealing gasket. The clamping clip includes a clip strap having a first end and a second end. A first clamping jaw is formed at the first end. A second clamping jaw is formed at the second end. The clamping jaws are drawn together by a tensioning device. The clip strap has radially inwardly directed projecting flanges on each of its axial ends. A first C-shaped clamping ring and a second C-shaped clamping ring are each disposed between the sealing gasket and one of the flanges. Each of the C-shaped clamping rings are supported on a radially inner side of the clip strap. Each of the C-shaped clamping rings have projections projecting from its radially inner face and, when said clip strap is tensioned, the projections of the C-shaped rings engage in the pipe material. The clamping rings are substantially made of plastic and approximately fill the space between the sealing gasket and one of the flanges. The clamping rings may be formed as a single part or from two ring parts. If formed of two parts, the radially inner part may be made of a brass alloy. The projections may be formed as encircling ribs.

Owner:NORMA GERMANY GMBH

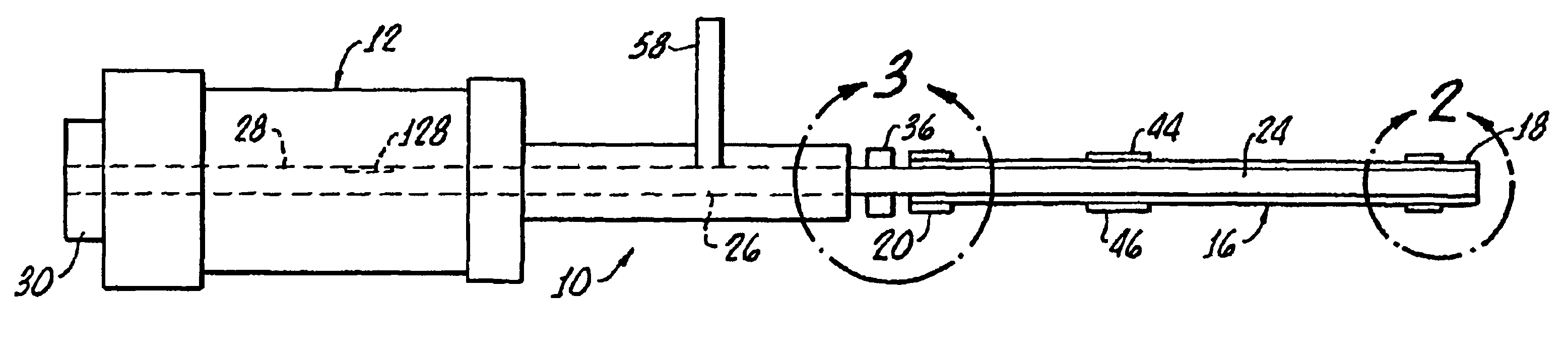

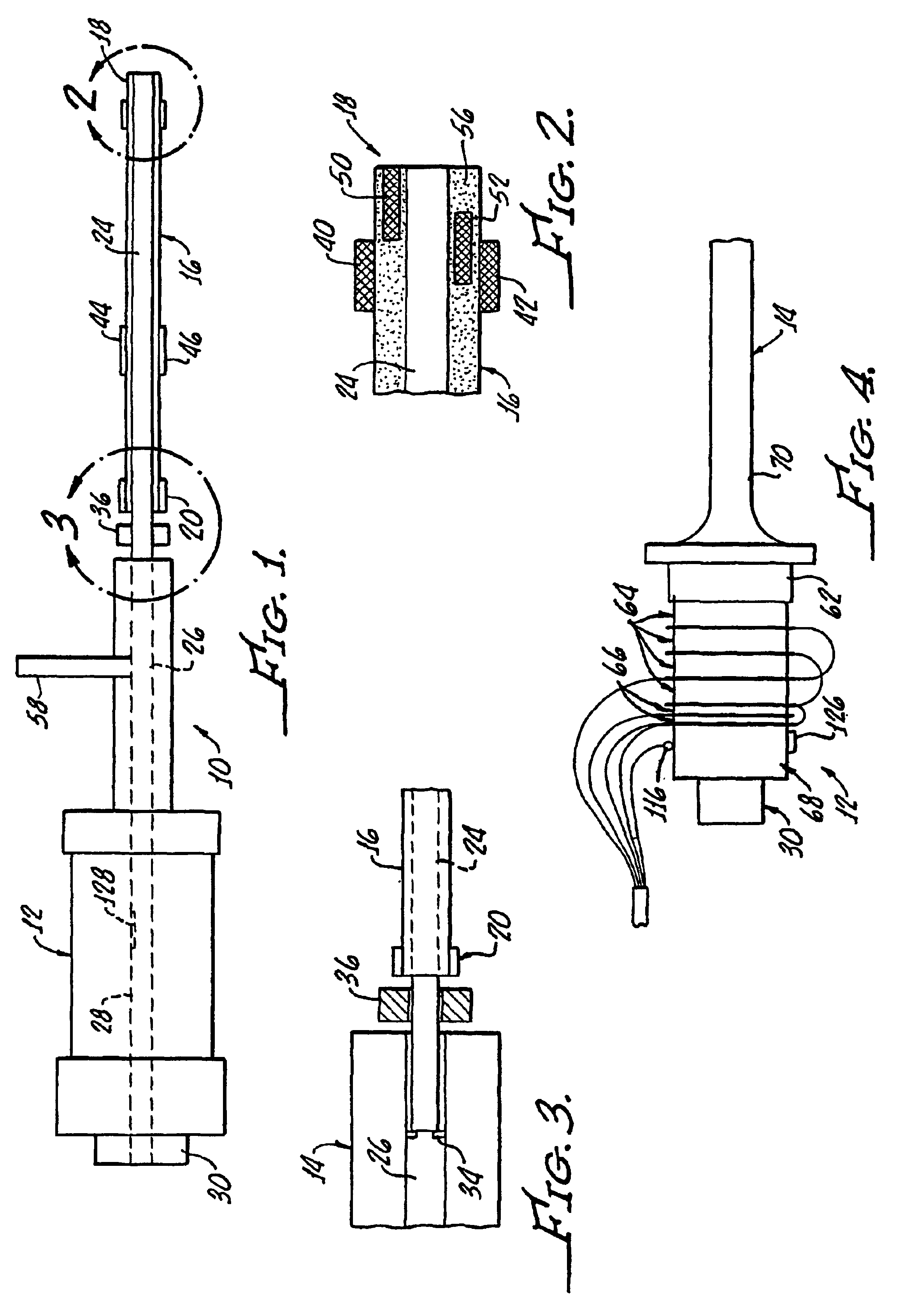

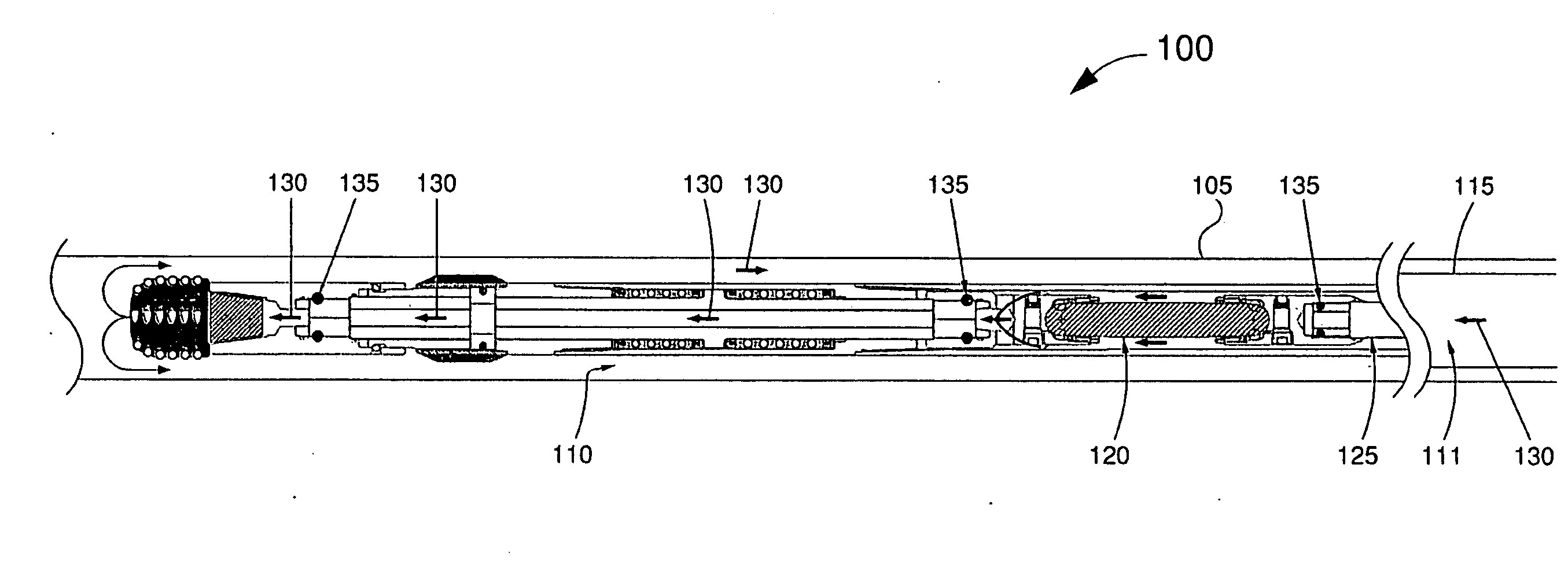

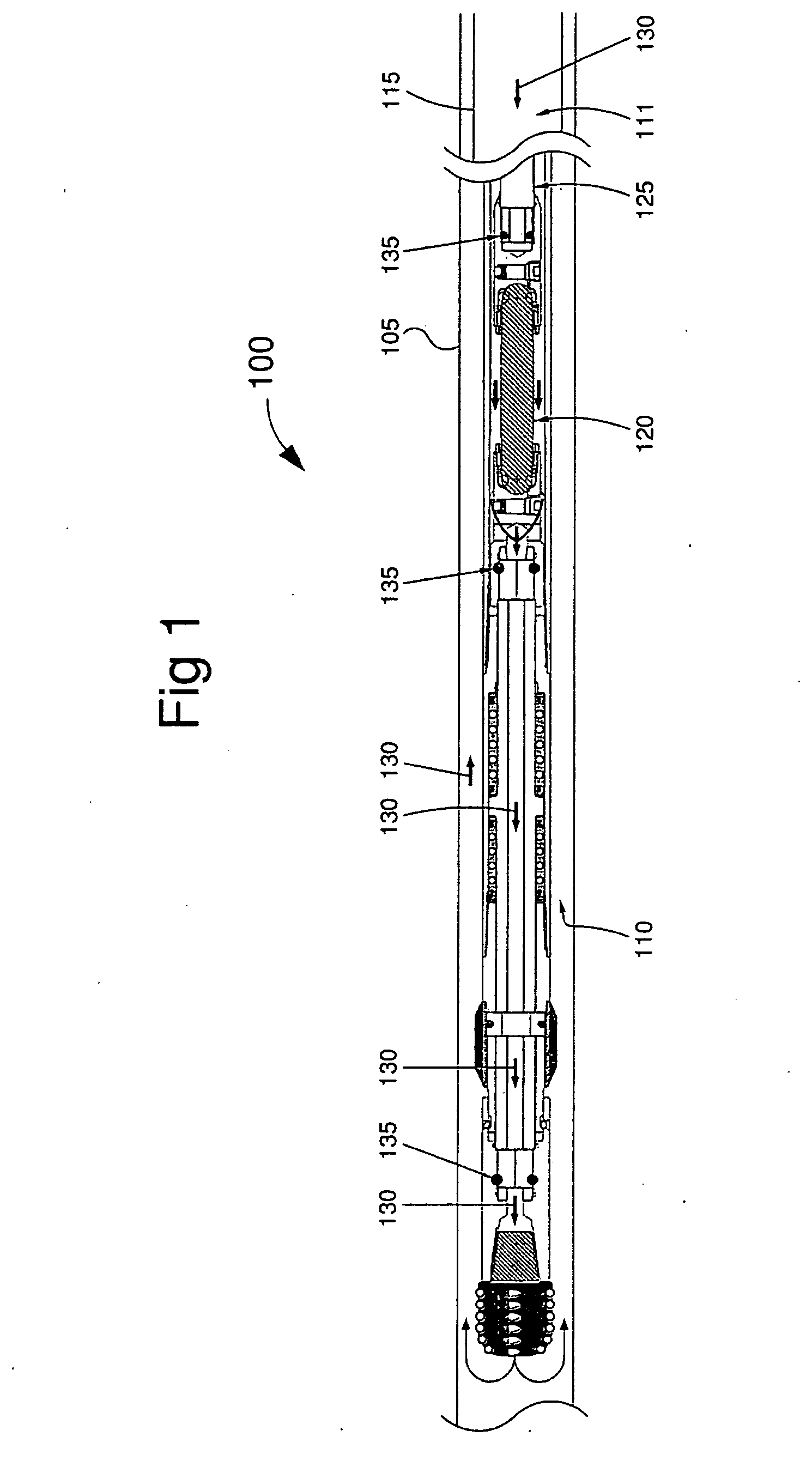

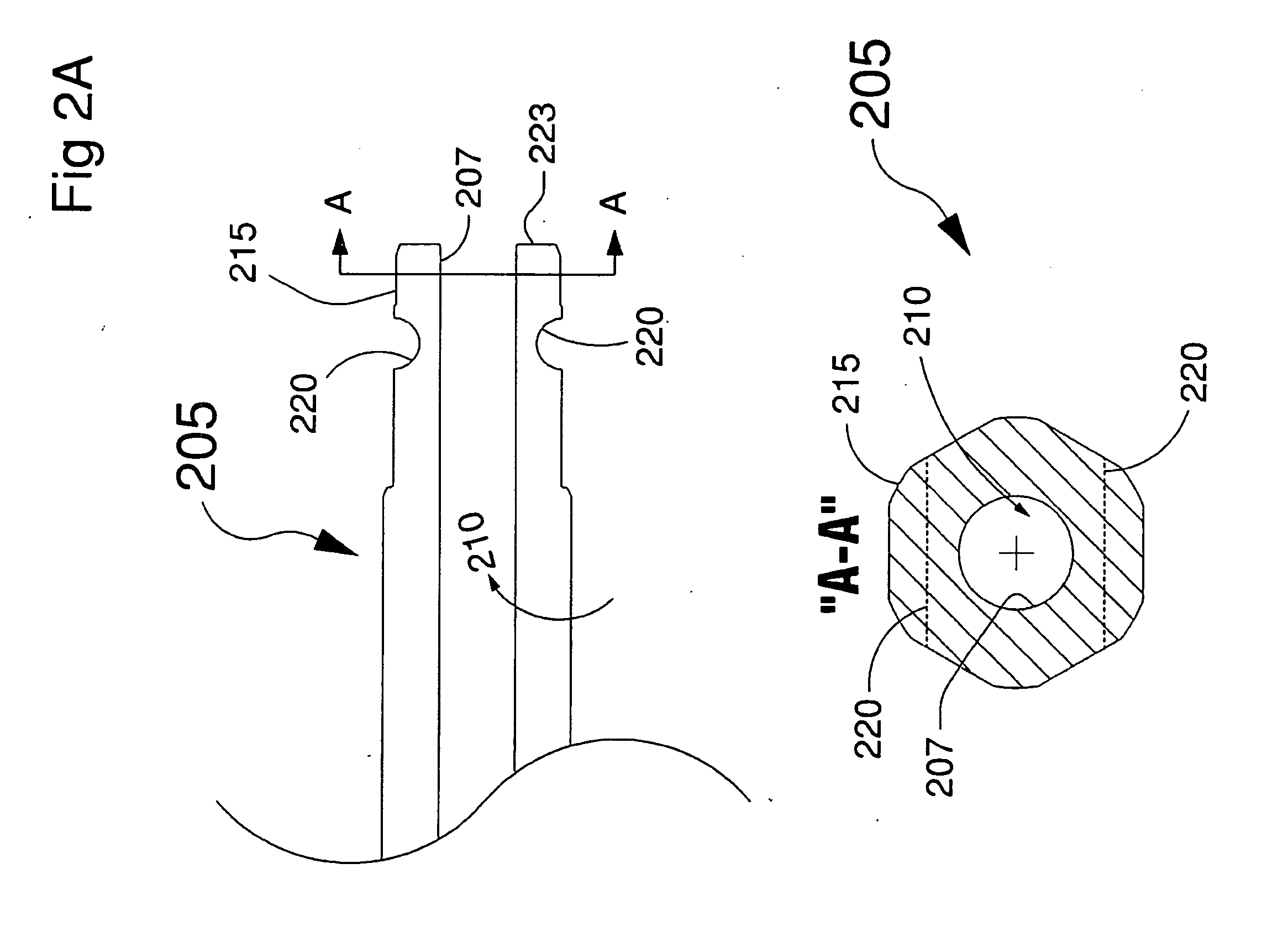

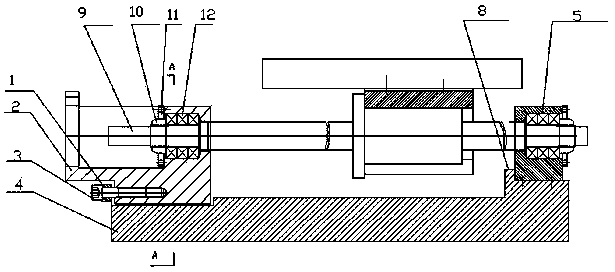

Smart-ultrasonic/sonic driller/corer

Apparatus for probing, sensing, testing penetrating and sampling a medium generally includes an actuator (12) for generating vibrations at ultrasonic frequencies and a horn (14) coupled to the actuator (12) for amplifying the actuator vibrations along with a non-rotating coring and drilling bit (16) for penetrating the medium. A bit (16) includes a drill stem (20) attached to the horn (14) and a bore (26) extends through the bit (16), horn (14) and actuator (12) for withdrawal of samples. A free mass (36) is disposed between the horn (14) and the drill stem (20) for oscillating therebetween in response to the actuator vibration for causing migration of medium debris around and through the actuator bore for effectively self-cleaning of the bit (16). The hammering action of the free mass (36) is used for penetration of the medium and for analysis of the medium though the use of spaced apart accelerometers (92 and 94).

Owner:GYRUS ACMI INC (D B A OLYMPUS SURGICAL TECH AMERICA)

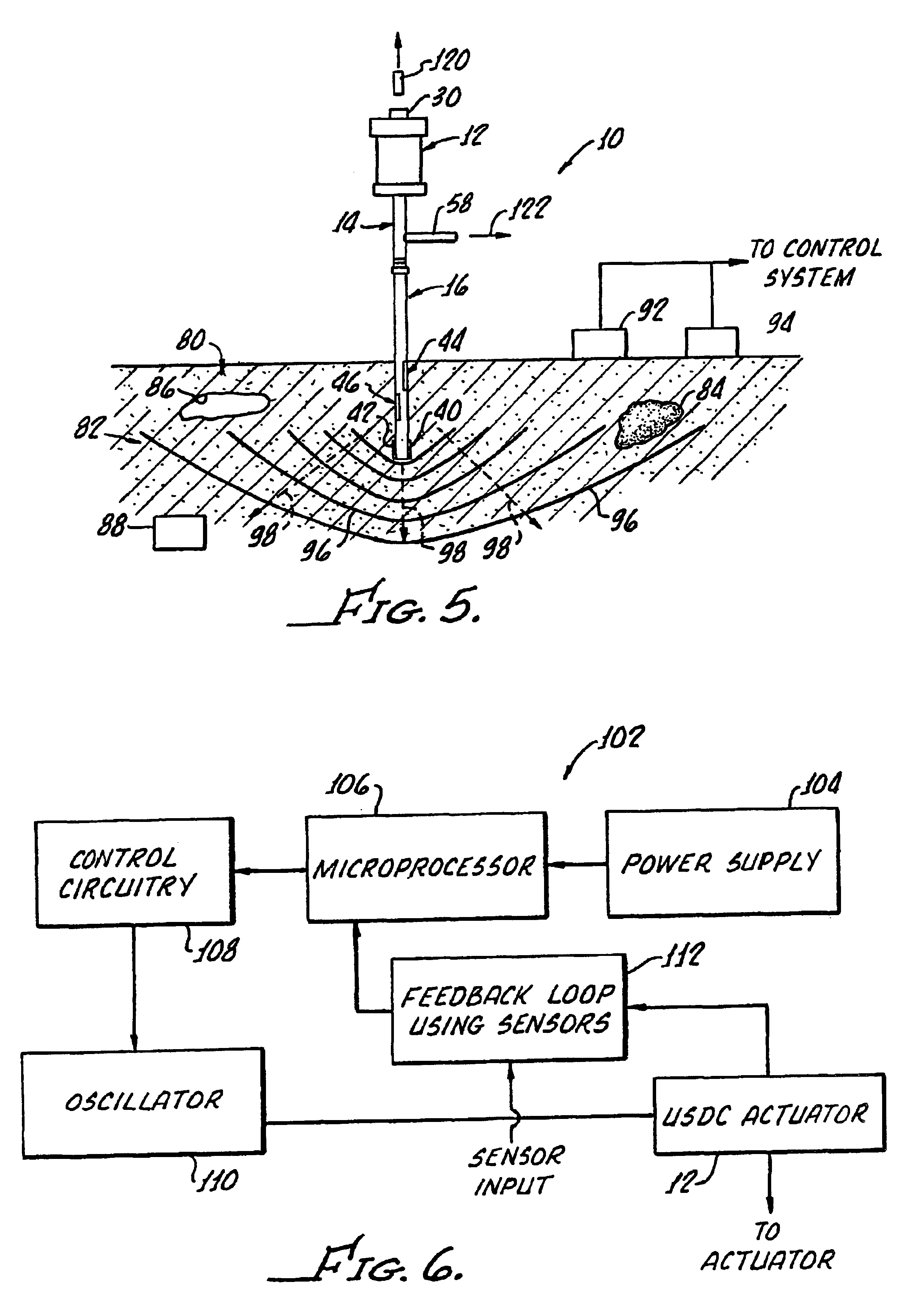

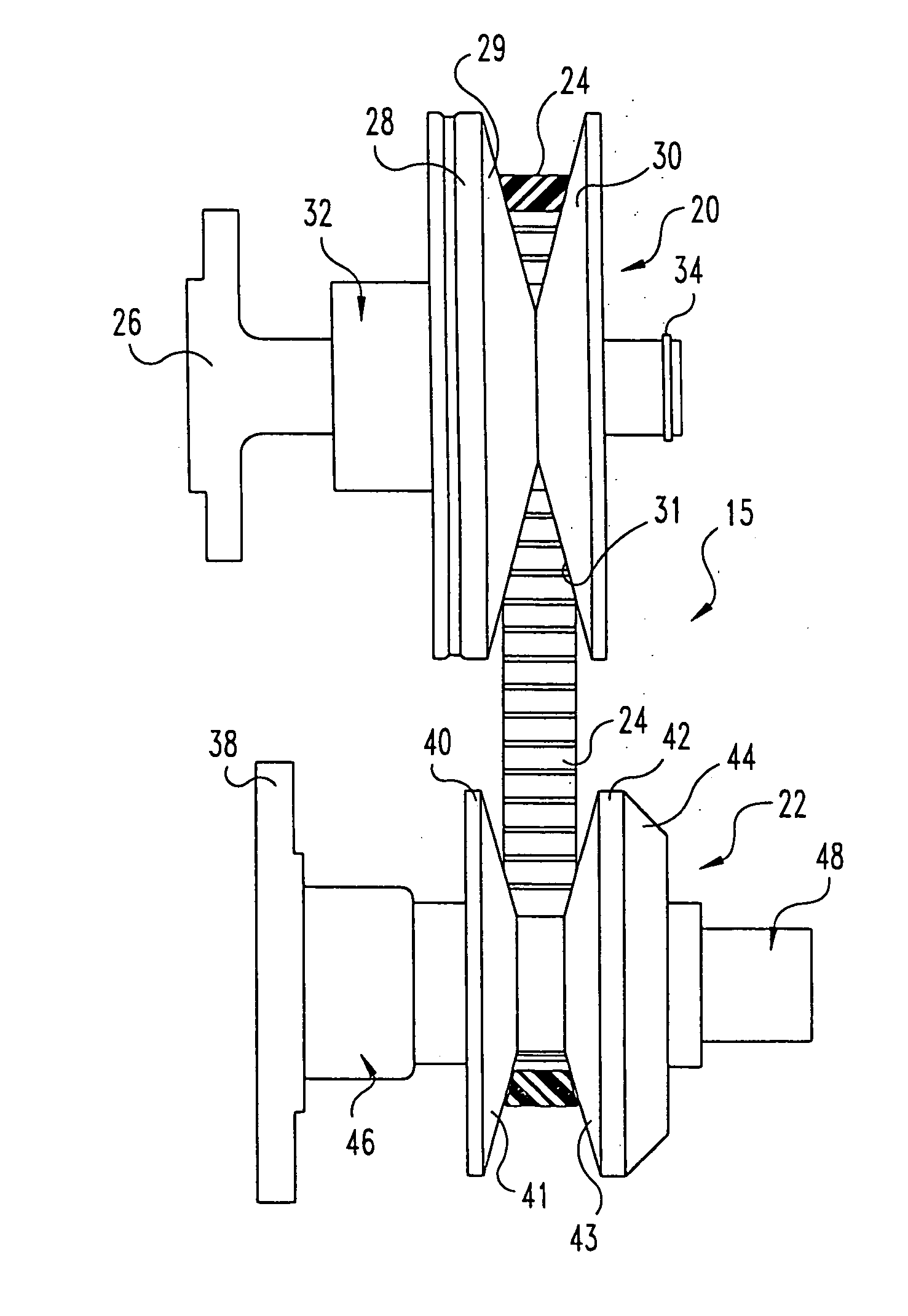

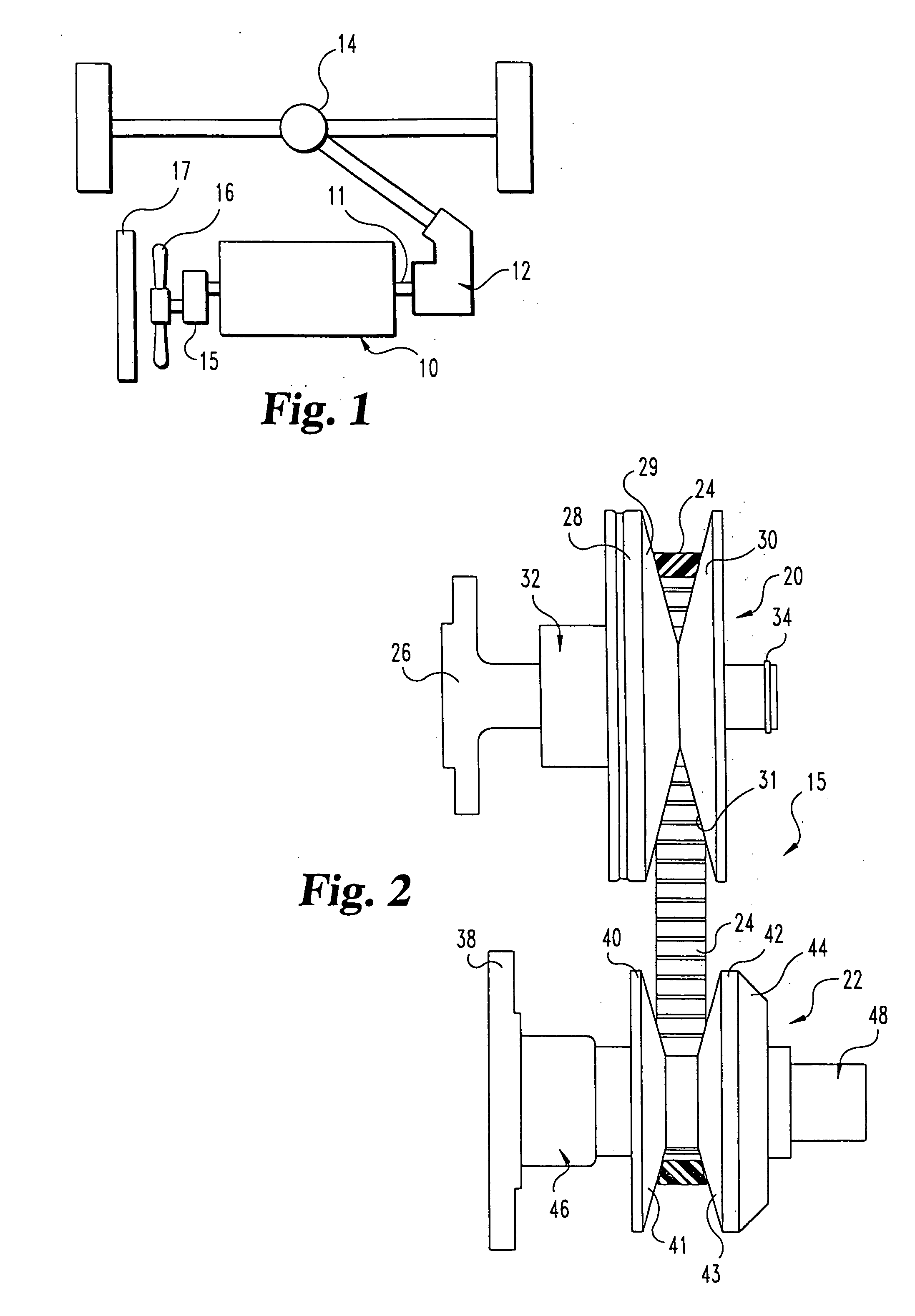

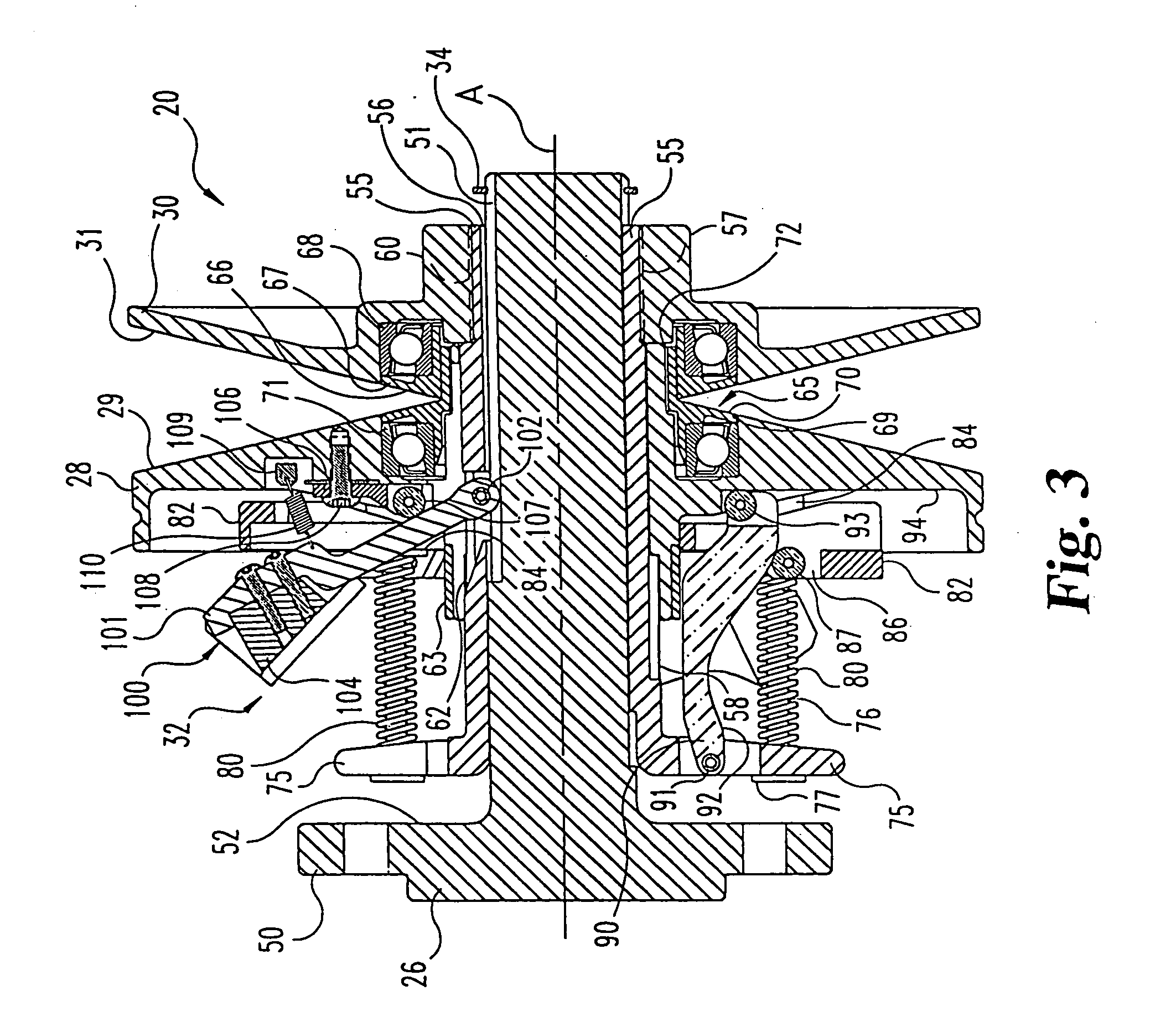

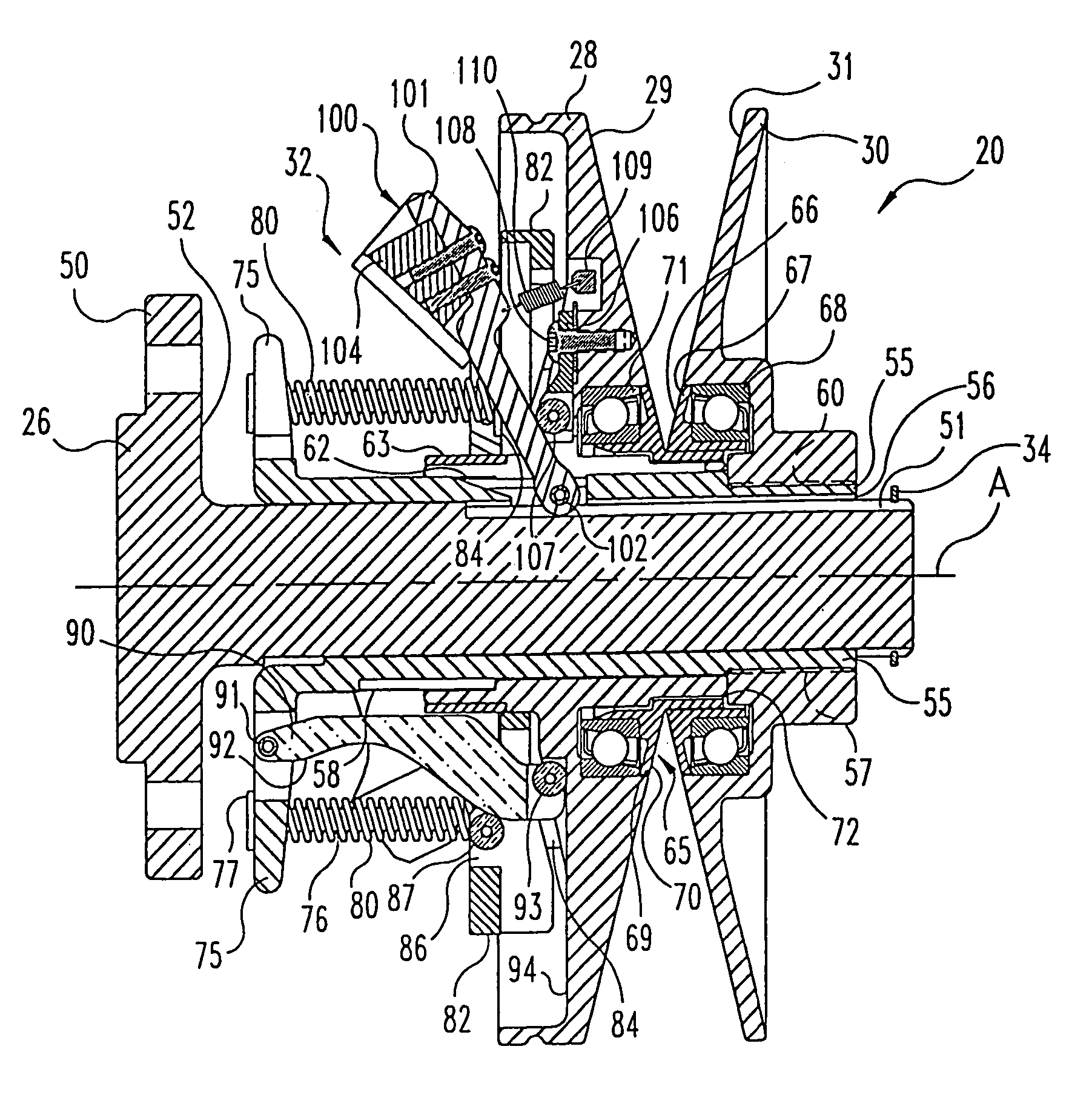

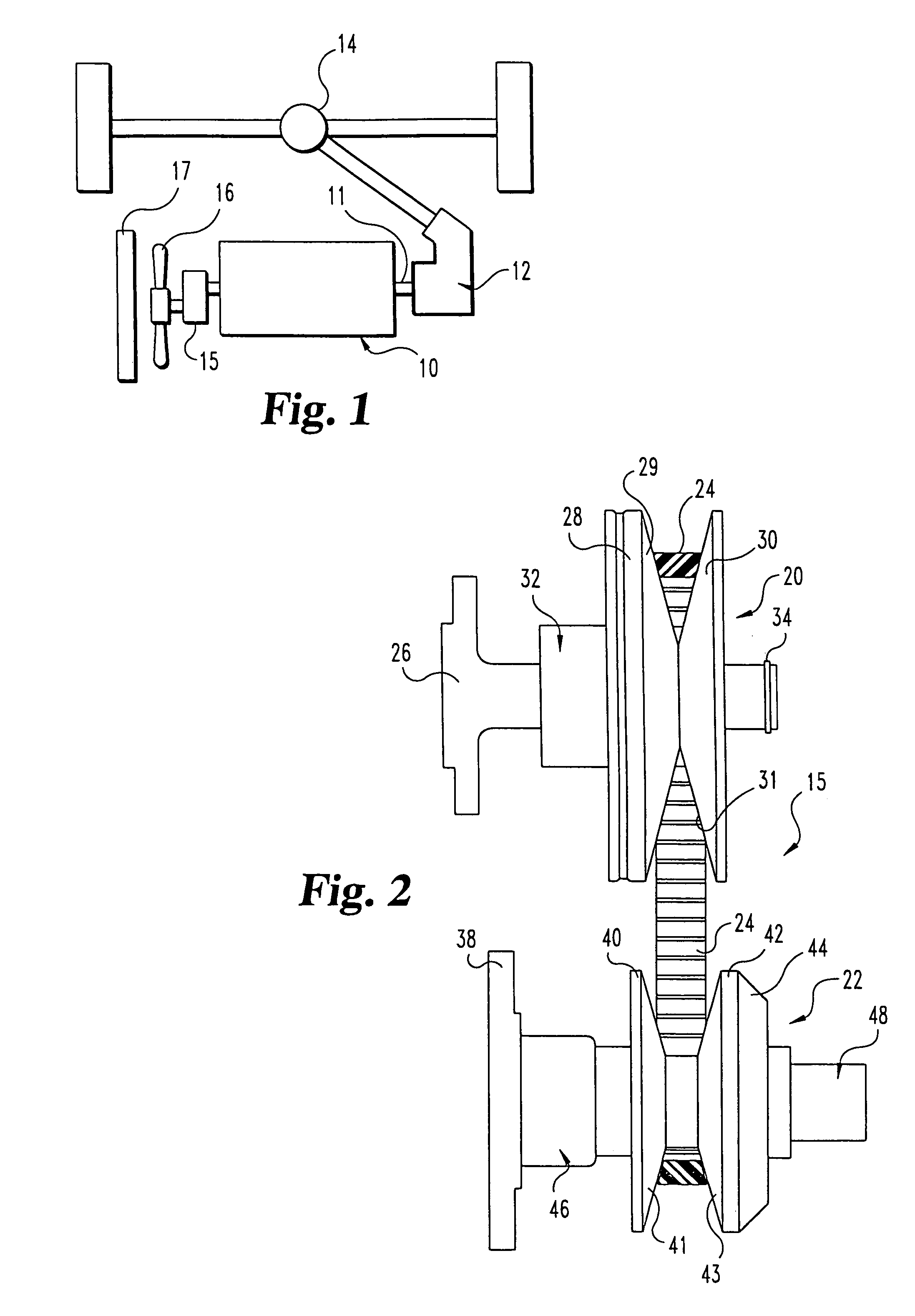

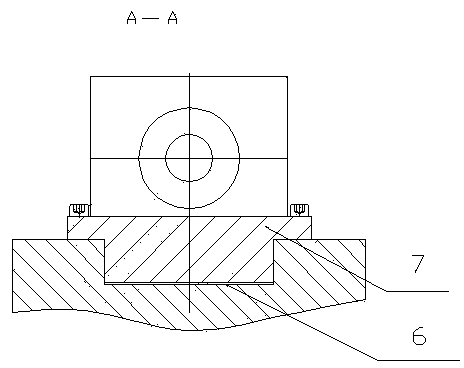

Continuously variable belt drive system

InactiveUS20060019781A1Slide freelyIncrease axial forceGearingPortable liftingAxial pressureTransfer system

A belt-type continuously variable transfer system (15) includes a driving pulley assembly (20), a driven pulley assembly (22) and a V-shaped belt (24) engaged to transfer rotary power therebetween. The driven pulley assembly (22) can include a ratio adjustment mechanism (46) that adjusts the position of a rear sheave (40) relative to a forward sheave (42). The adjustment mechanism (46) includes a motor (170) and a worm gear mechanism (171, 172) that rotates an actuation screw (154). Rotation of the actuation screw (154) is reacted by a split nut (158) so that as the screw (154) rotates is translated along the axis (B) of the driven pulley assembly (22). Translation of the actuation screw (154) exerts pressure against the rear sheave (40) to push it toward the forward sheave (42), thereby altering the drive ratio of the pulley assembly. In one feature, the driven pulley assembly (22) includes a fail-safe mechanism (48) that operates when power is supplied to the motor (170) to hold the split nut (158) together. Once power is disrupted, the fail-safe mechanism (48) allows the components (1 58a-c) of the split nut (158) to be separated, disrupting the threaded engagement with the actuation screw (154). At this point, the actuation screw (154) is driven forward by a compression spring (190), thereby driving the rear sheave (40) forward to a predetermined drive ratio position. In another aspect of the invention, the driving pulley assembly (20) includes an idler pulley portion (65) radially inboard from the normal driving sheave surface (29, 31). As the belt speed decreases, the belt (24) migrates downward within the driving pulley assembly (20) until it falls within the idler pulley portion (65). At this point, the belt (24) is isolated from the rotation of the driving pulley assembly (20). The driving pulley assembly (20) also includes a belt tensioning mechanism (32) that maintains proper belt tension at all speeds and drive ratios. The tensioning mechanism (32) relies upon a pivotably mounted centrifugal weight arm (101) to provide tensioning as a function of speed. A compression spring (80) provides axial pressure to maintain belt tension over all drive ratios. The spring (80) acts against a specially curved cam edge (92) on a pivoting lever arm (90), which arm (90) transfers an axial force to the rear sheave (28) of the driven pulley assembly (20).

Owner:BORGWARNER INC

Connection for well bore drilling tools

InactiveUS20100044113A1Great rotational torqueReduce the possibilityDrilling rodsDrilling casingsEngineeringMechanical engineering

Owner:COILED TUBING RENTAL TOOLS

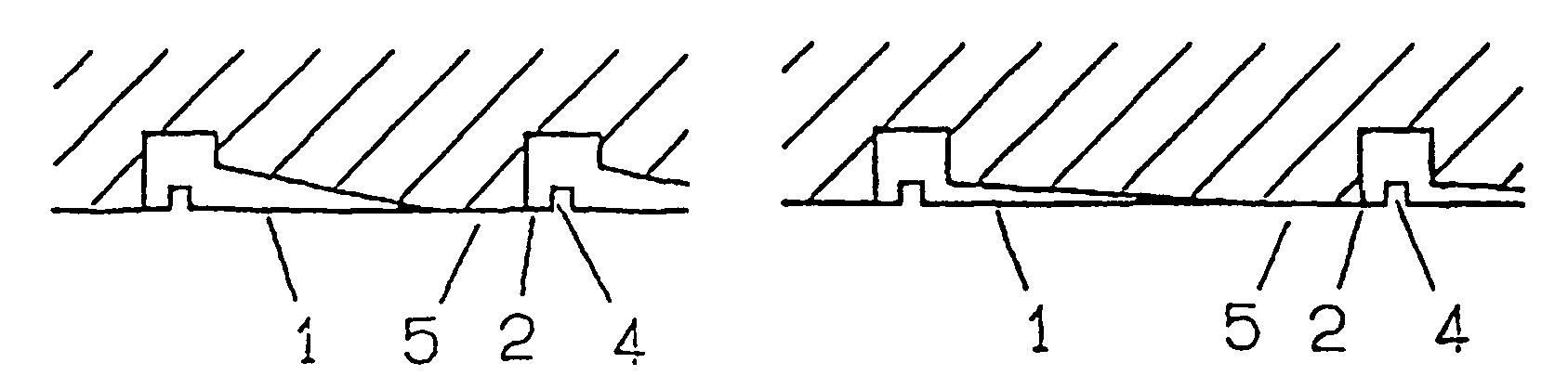

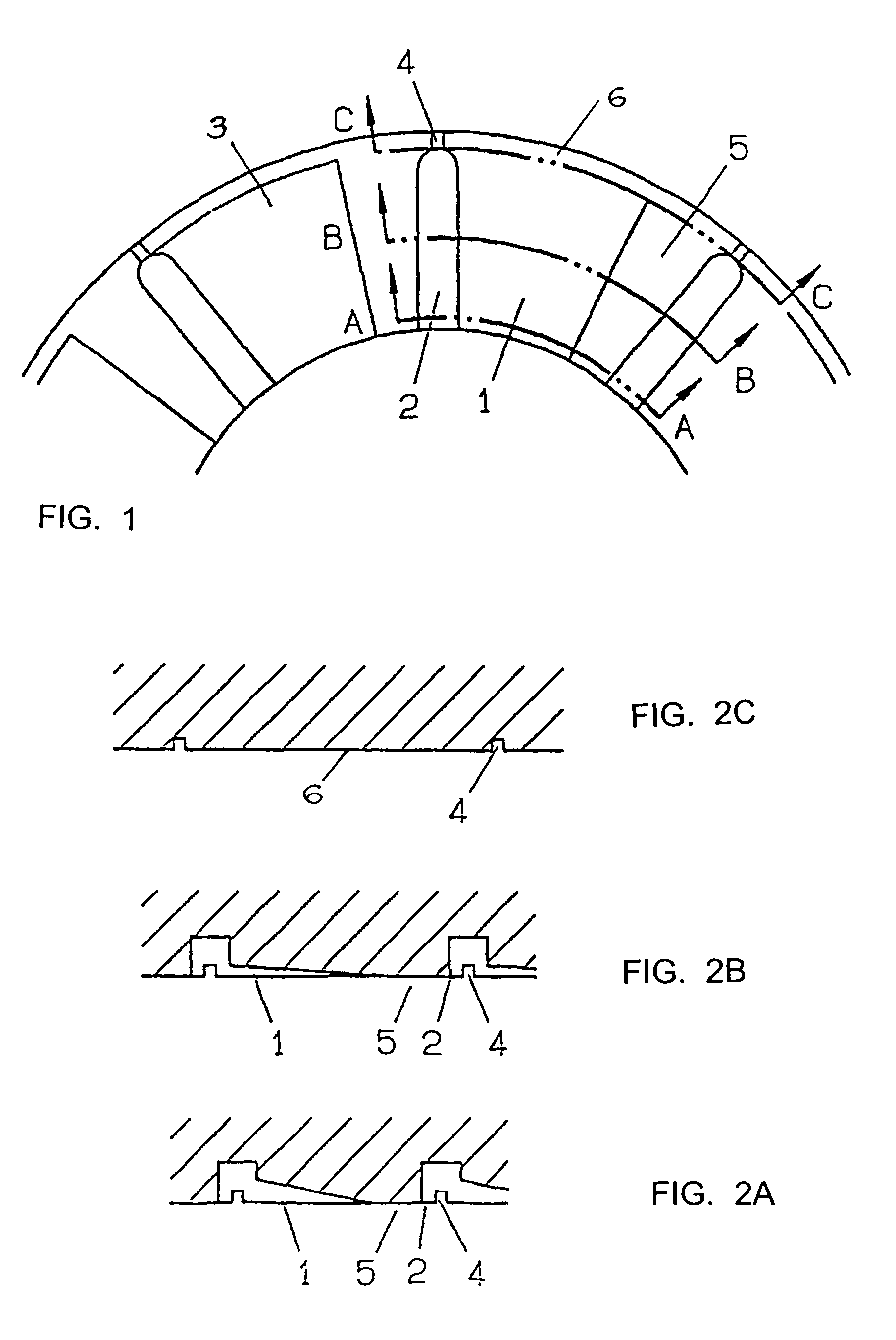

Axial thrust bearing

InactiveUS7470064B2Reduce wearEasy to compressCrankshaftsGas turbine plantsTurbochargerThrust bearing

An axial thrust bearing for axially supporting a rotating shaft of an exhaust gas turbocharger connected to a lubricating oil circuit includes a profiled annular bearing surface which contacts an essentially flat sliding surface, the bearing surface having a plurality of radially extending grooves which are open on the outside circumference, a plurality of coplanar flat trap surfaces located between respective pairs of adjacent grooves, and a plurality of wedge surfaces located between adjacent pairs of respective grooves. Each wedge surface forms a lubricating oil gap which narrows circumferentially toward an adjacent flat trap surface and which narrows radially toward the outside circumference.

Owner:MAN ENERGY SOLUTIONS SA

Detachable fastener including a screw element and a securing ring

A detachable fastener includes a screw element and a securing ring. The screw element and the securing ring each include cooperating wedge-shaped surface tooth arrangements and two different pairs of stop surfaces. The wedge-shaped surface tooth arrangements face one another and form sliding surfaces sliding upon one another in a loosening direction of rotation resulting in an increase of the axial force. The first pair of stop surfaces transmits torque in a tightening direction of rotation. The second pair of stop surfaces transmits torque in a loosening direction of rotation. The stop surfaces are arranged with a clearance existing between one another such that the wedge-shaped surface tooth arrangements can slide upon one another without skipping.

Owner:KAMAX HLDG

Continuously variable belt drive system

A continuously variable belt drive system including a driving pulley assembly, a driven pulley assembly, and a V-shaped belt engaged to transfer rotary power therebetween is disclosed herein. The driving pulley assembly includes an idler pulley portion. As the belt speed decreases, the belt migrates downward within the driving pulley assembly until it falls within the idler pulley portions, thereby isolating the belt from the rotation of the driving pulley assembly. The driving pulley assembly also includes a belt tensioning mechanism that maintains proper belt tension at all speeds and drive ratios. The tensioning mechanism relies upon a pivotably mounted centrifugal weight arm to provide tensioning as a function of speed. A compression spring provides axial pressure to maintain belt tension over all drive ratios. The spring, acts against a curved cam edge on a pivoting lever arm, which arm transfers an axial force to the rear sheave of the driven pulley assembly.

Owner:BORGWARNER INC

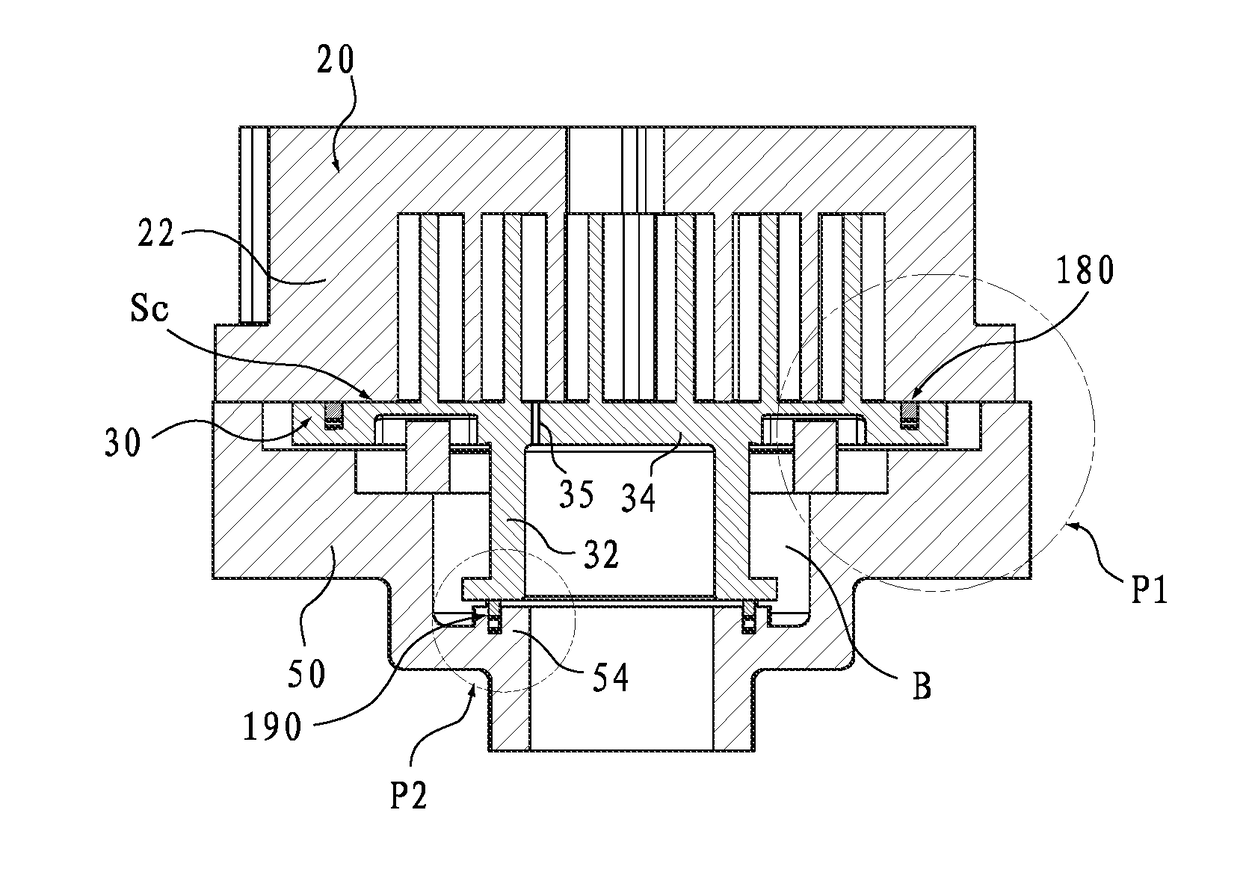

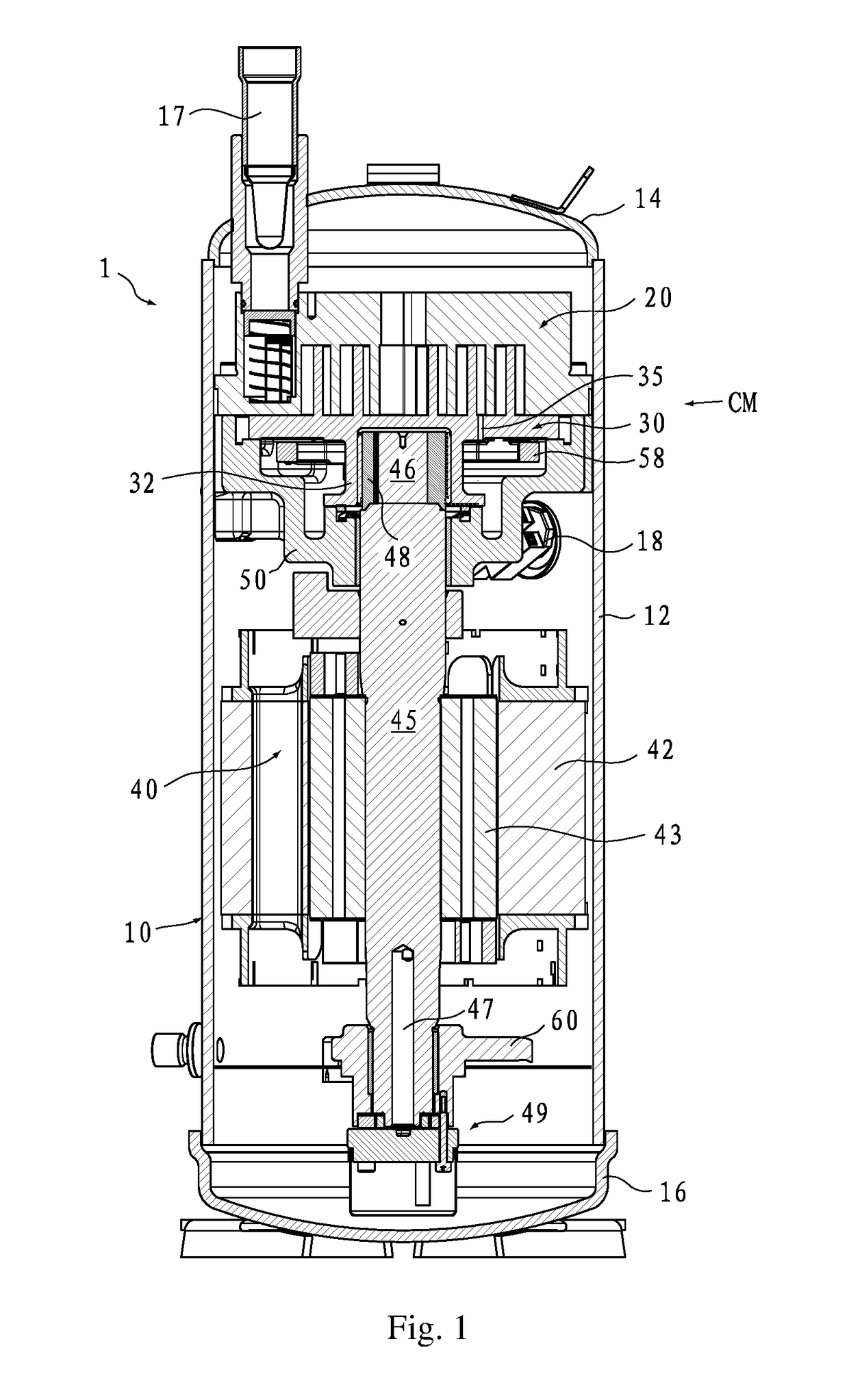

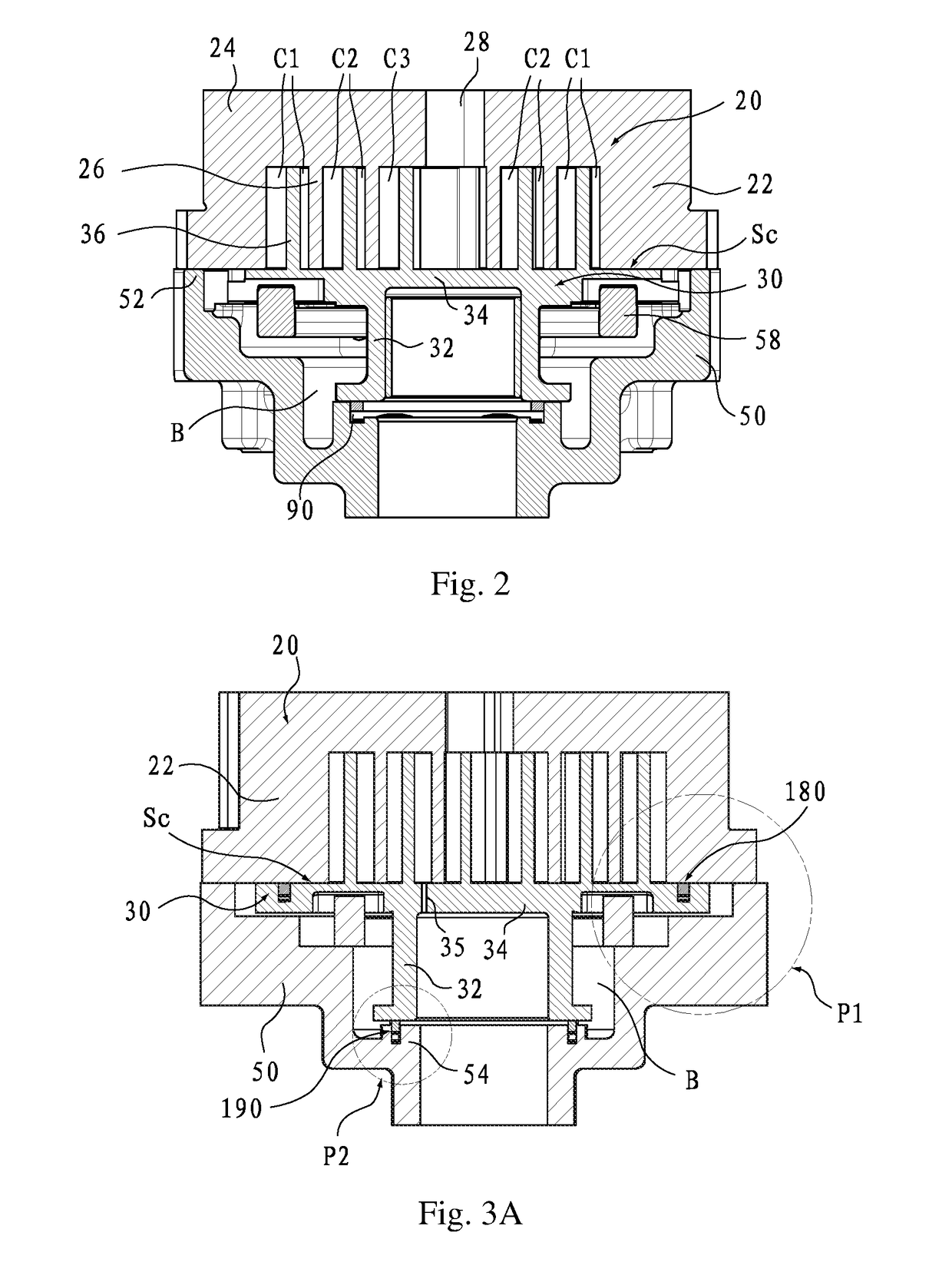

Scroll compressor

ActiveUS20180023570A1Expand the adjustment rangeDesigning can be facilitatedSealing arrangement for pumpsSealing arrangements for enginesEngineeringMain bearing

A scroll compressor is provided, comprising: a compression mechanism comprising a non-orbiting scroll member and an orbiting scroll member, wherein the orbiting scroll member is axially displaceable between an engagement position and a disengagement position; a main bearing housing adapted to support the compression mechanism; a back pressure chamber formed between the orbiting scroll member and the main bearing housing, wherein the back pressure chamber is in communication with at least one of the compression chambers via a communication passage provided in the orbiting scroll member or the non-orbiting scroll member and is adapted to apply a back pressure to the orbiting scroll member to bias the orbiting scroll member toward the engagement position; and a first sealing means provided between the back pressure chamber and a suction zone of the compression mechanism and capable of maintaining sealing when the orbiting scroll member is axially displaced.

Owner:EMERSON CLIMATE TECH (SUZHOU) CO LTD

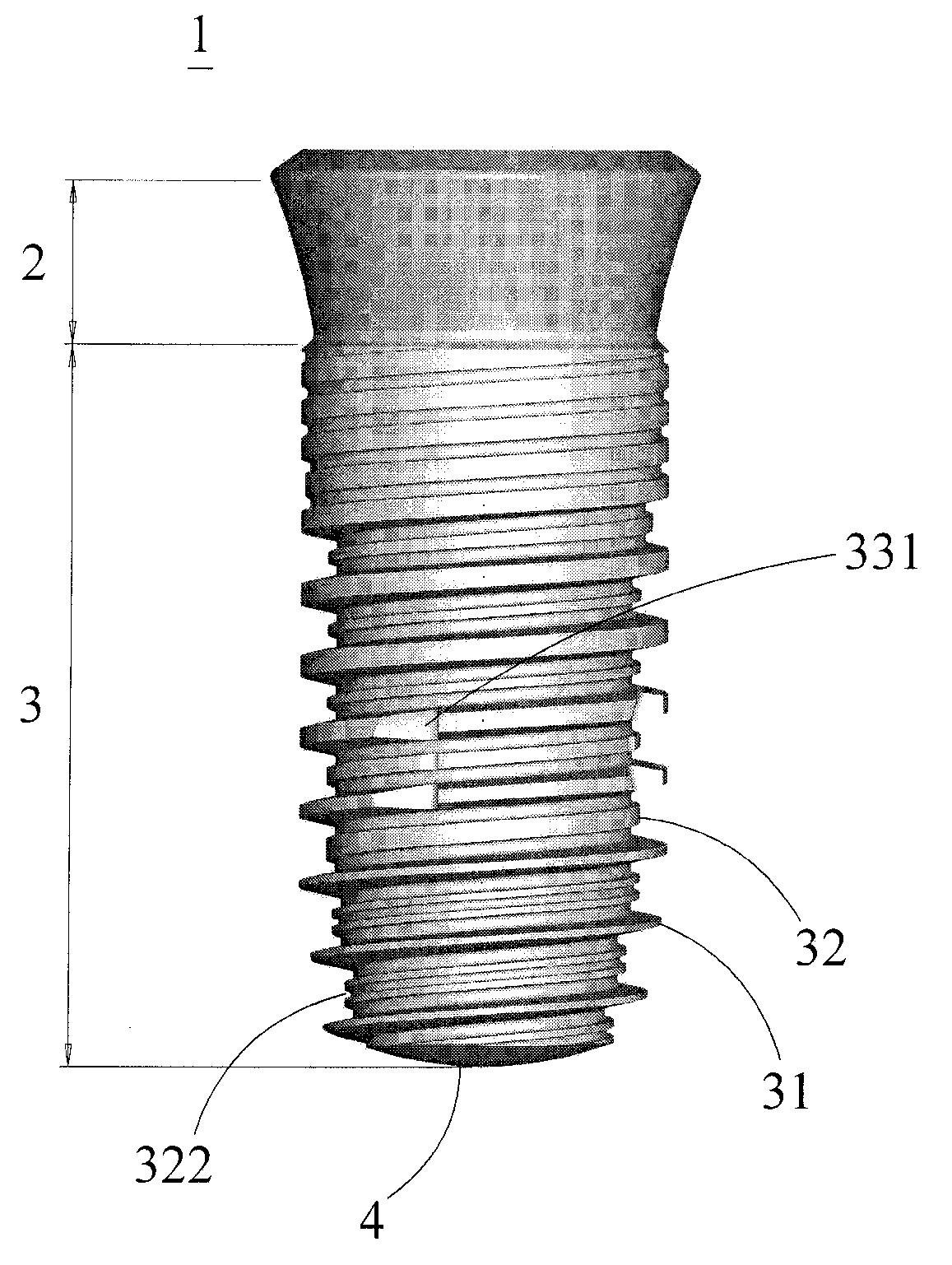

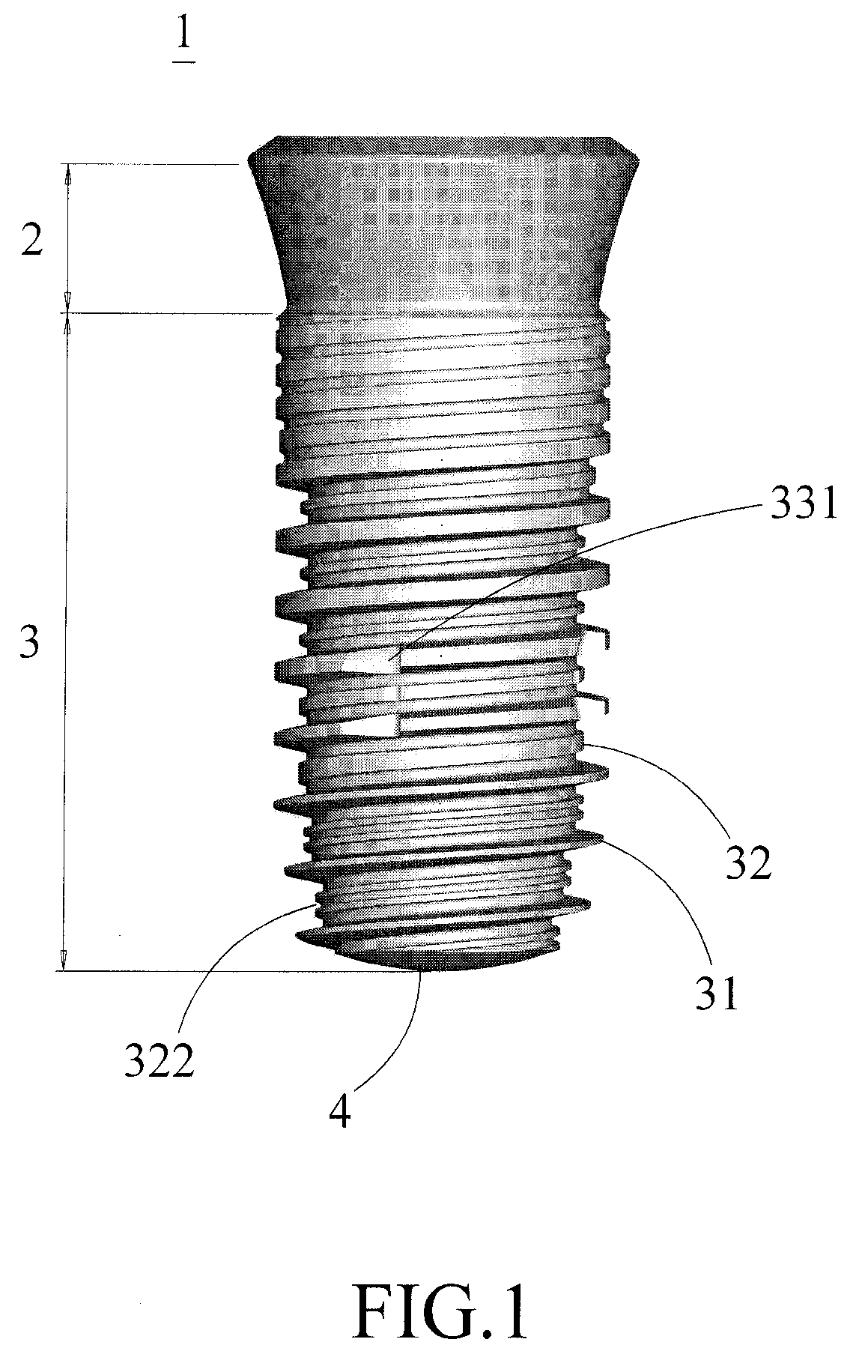

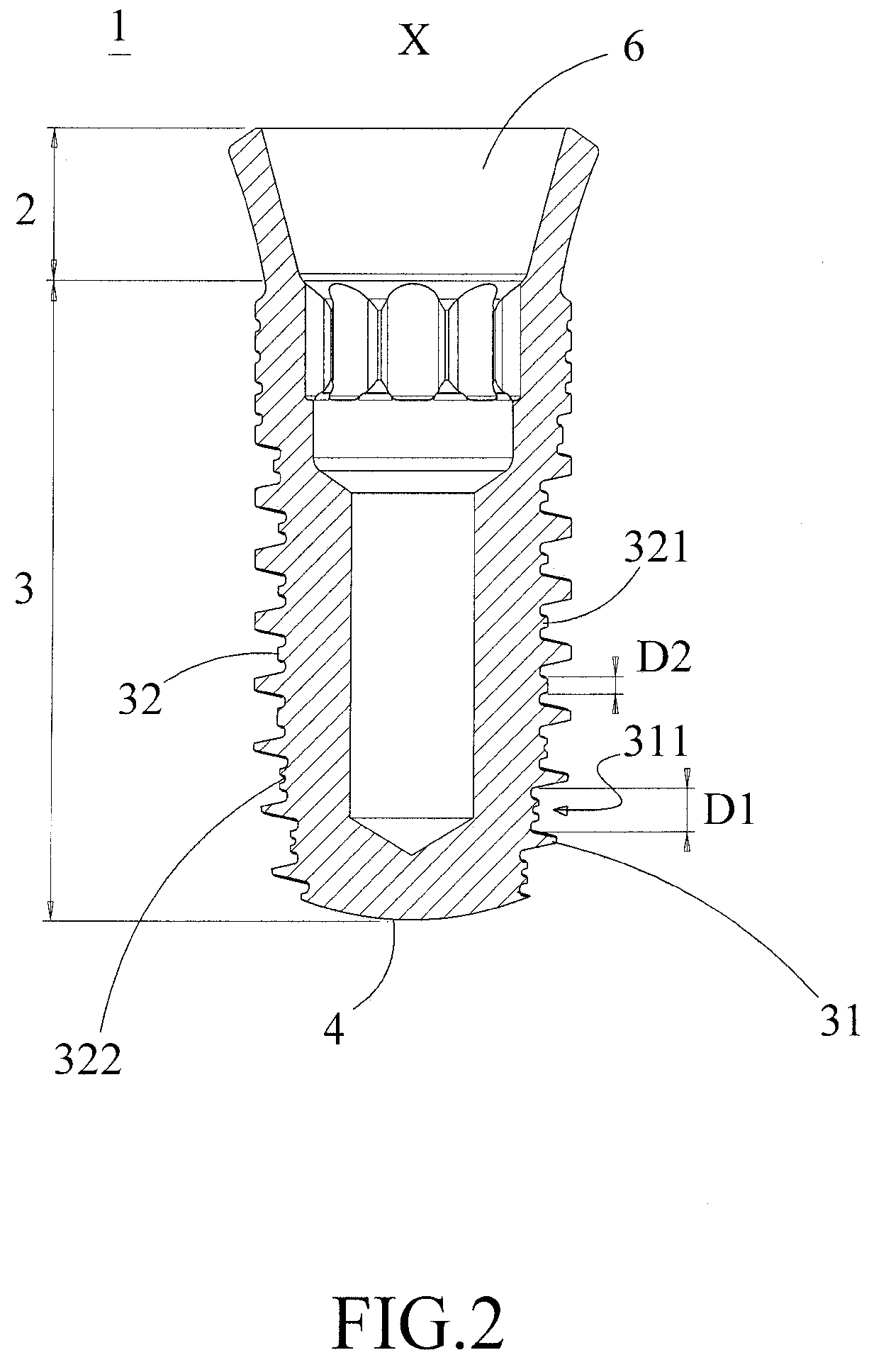

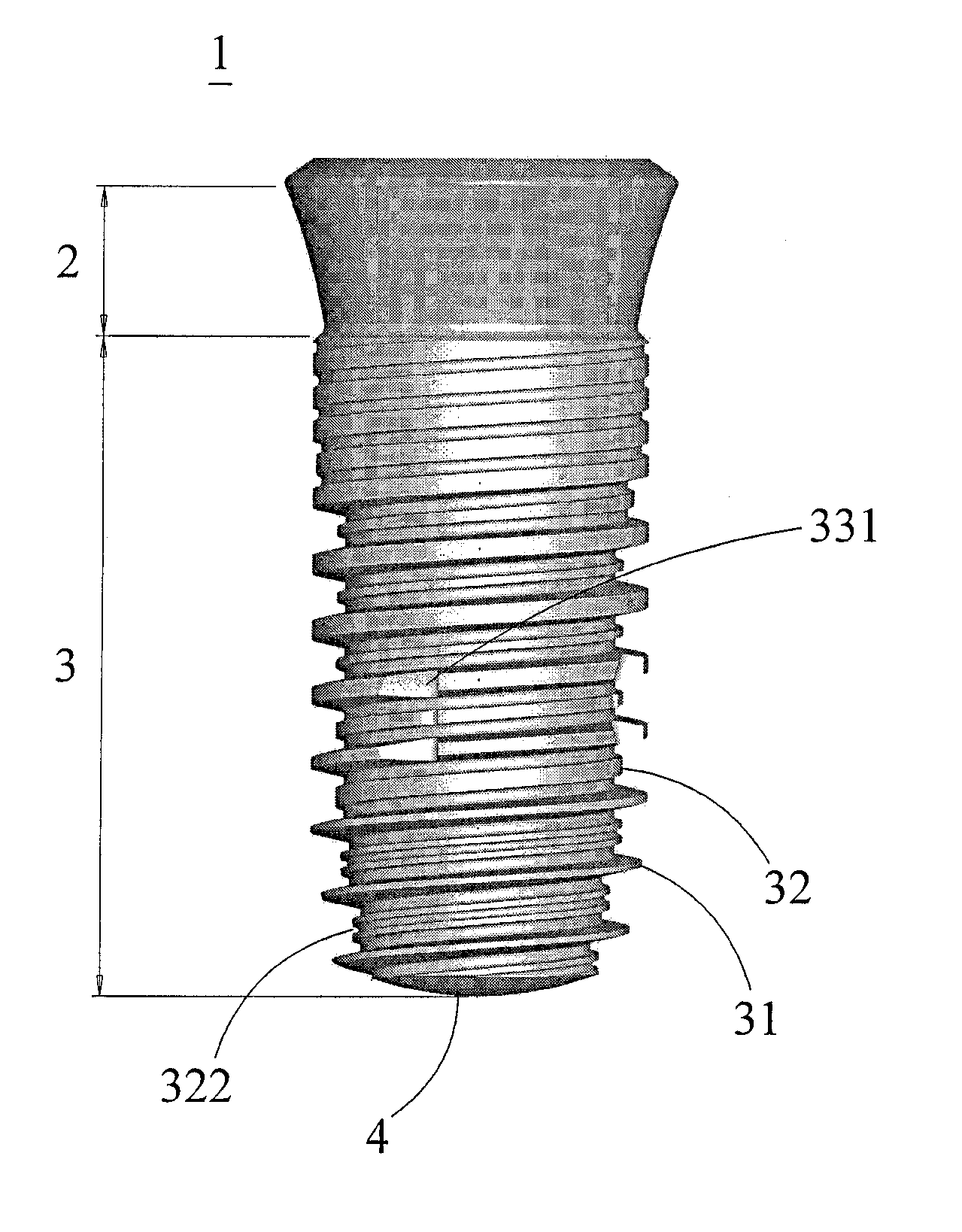

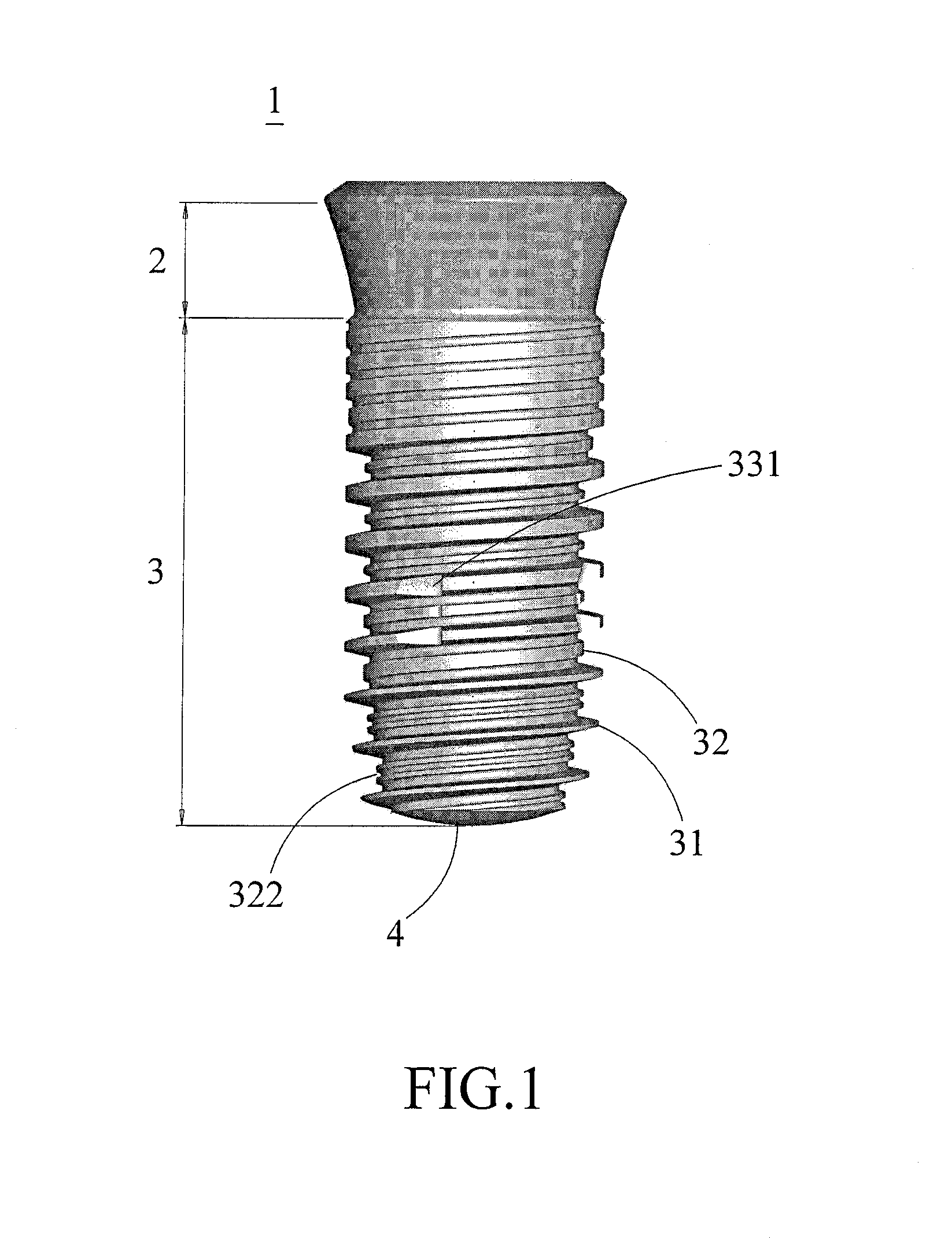

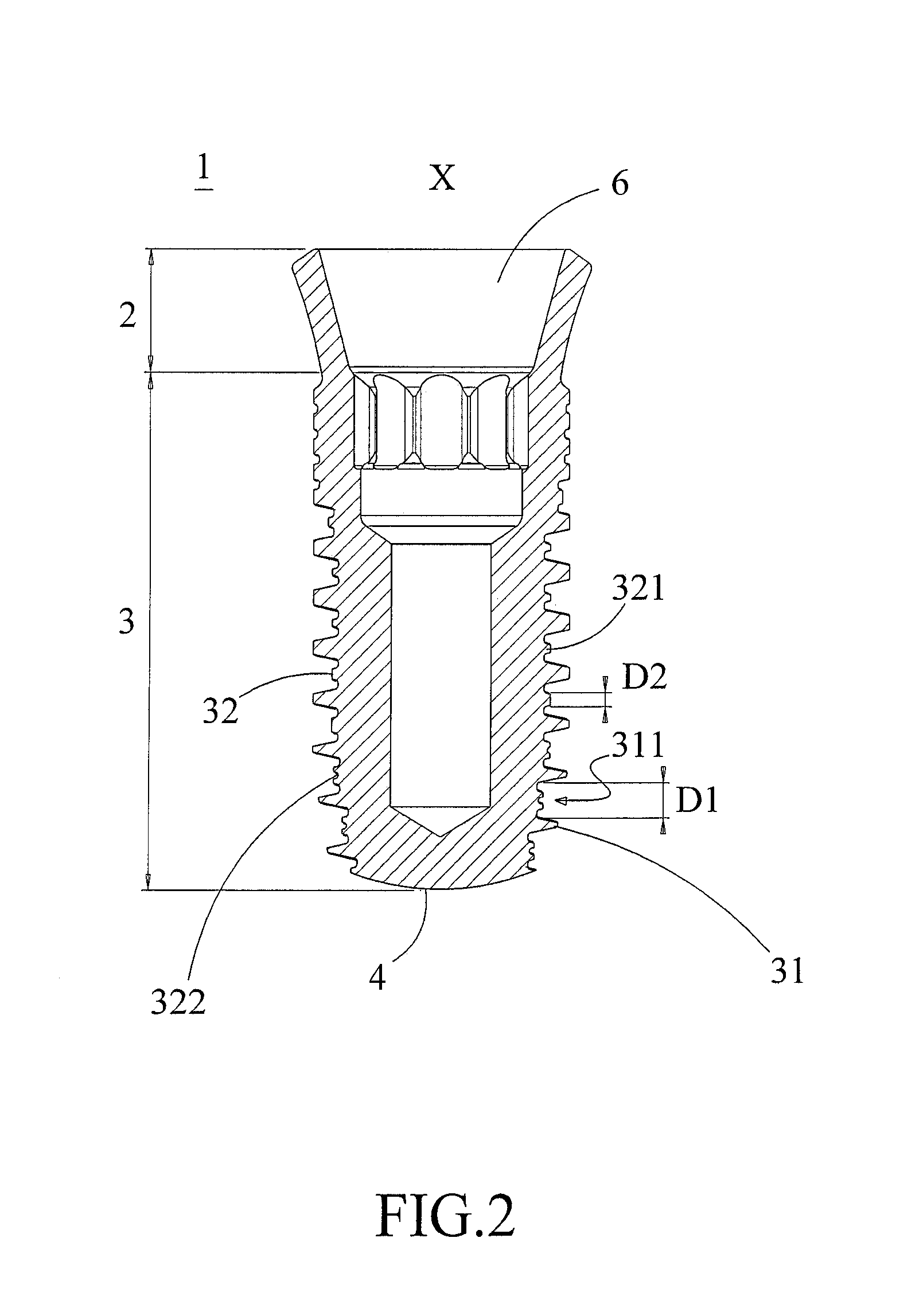

Artificial Root for Dental Implantation and Method for Manufacturing the Same

An artificial root for dental implantation and a method for manufacturing the artificial root are provided. The artificial root comprises a neck portion, an end portion opposite the neck portion, a body portion and a multiplex thread structure which is formed on the body portion. The multiplex thread structure comprises a first thread and a second thread in which the first thread forms a root portion with a specific first width for the second thread, which has a crest portion of a specific second width, to be accommodated into the root portion. The multiplex thread structure is partially configured in such a way that the second width of the crest portion is simultaneously increased when the first width of the root portion is gradually increased.

Owner:BIODENTA SWISS

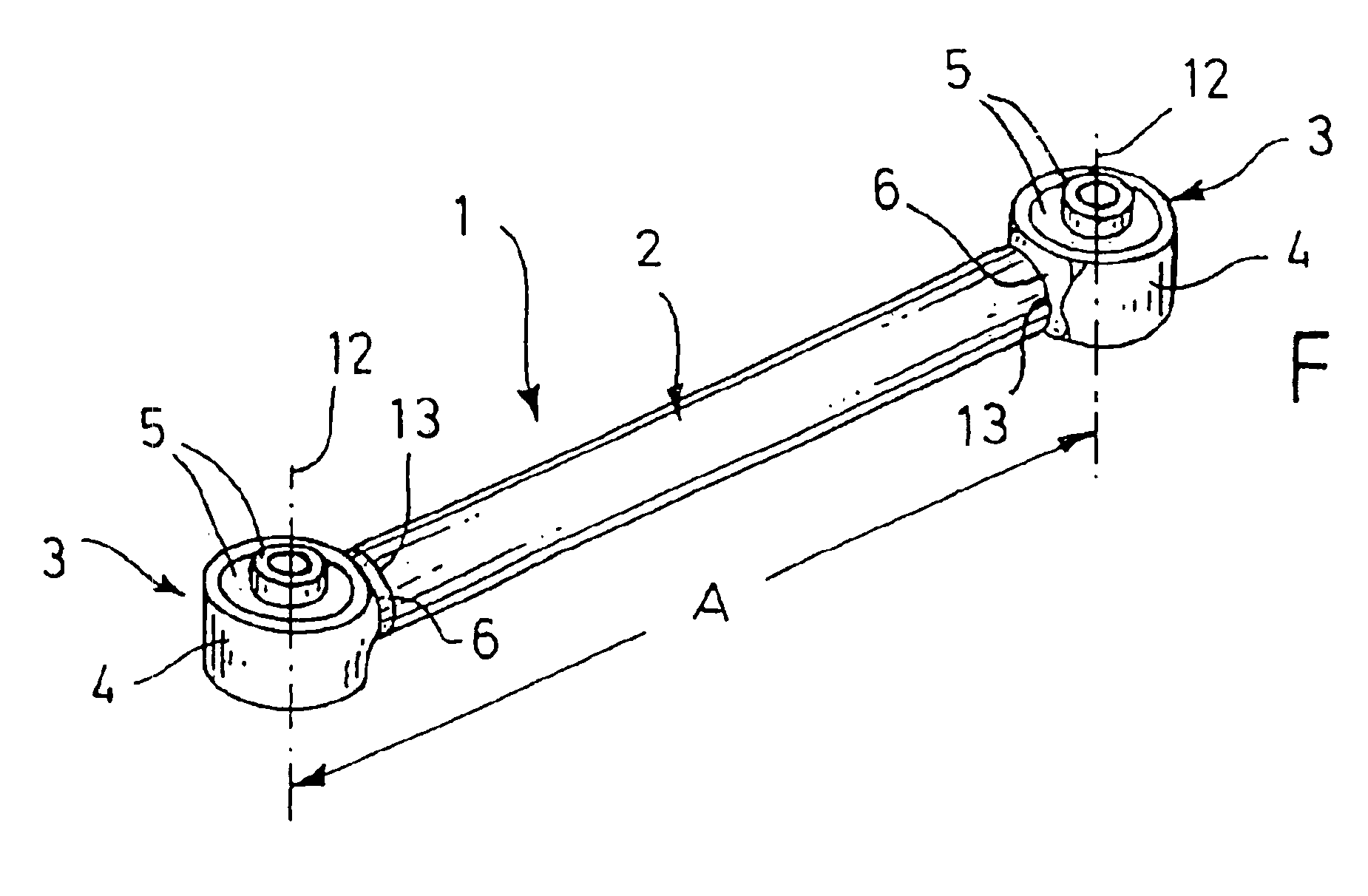

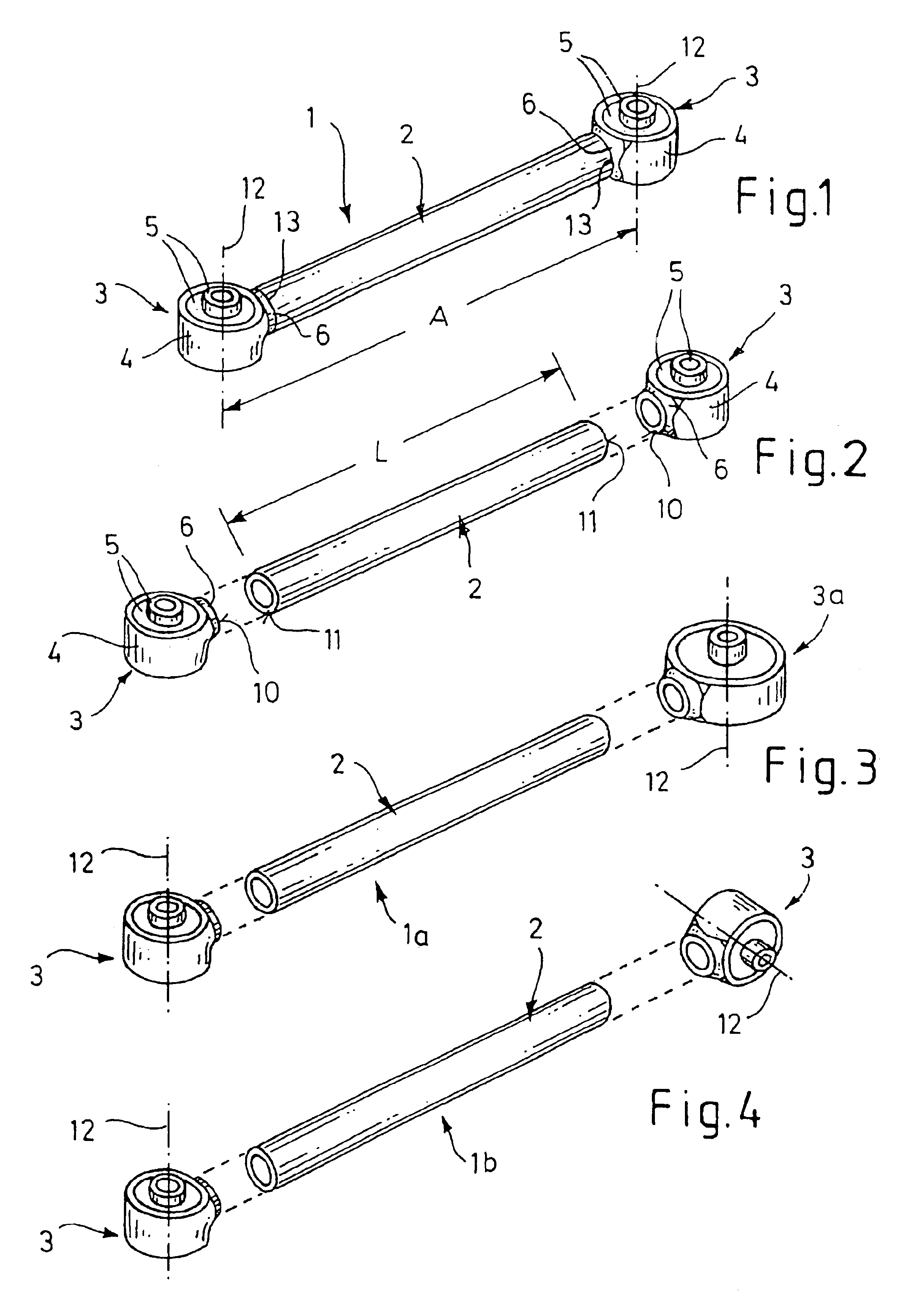

Control arm, and method of making a control arm

InactiveUS6913273B2Reduce weightEliminates working stepSteering linkagesFluid steeringFriction weldingMaterial removal

A control arm includes a connection tube and two mounting eyes respectively attached to opposite ends of the tube. Each mounting eye has a sleeve and a rubber-metal element vulcanized into the sleeve. In a method of making such a control arm, an elongate tubular member is sized to a sleeve blank of a length commensurate with the tube. Parallel thereto, an extruded profile is made with a cross sectional configuration of the sleeve and subsequently sized to the axial height of the sleeve. Rubber-metal elements are vulcanized into the sleeve blanks which together with the tube are then clamped, axially shiftable, in a friction welding machine for subsequently fabricating protruding collars on the sleeves through material removal and joining the end surfaces of the protruding collars with the end surfaces of the tube. While still clamped, the tube and the mounting eyes are calibrated through cold upsetting and the joints are smoothed.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

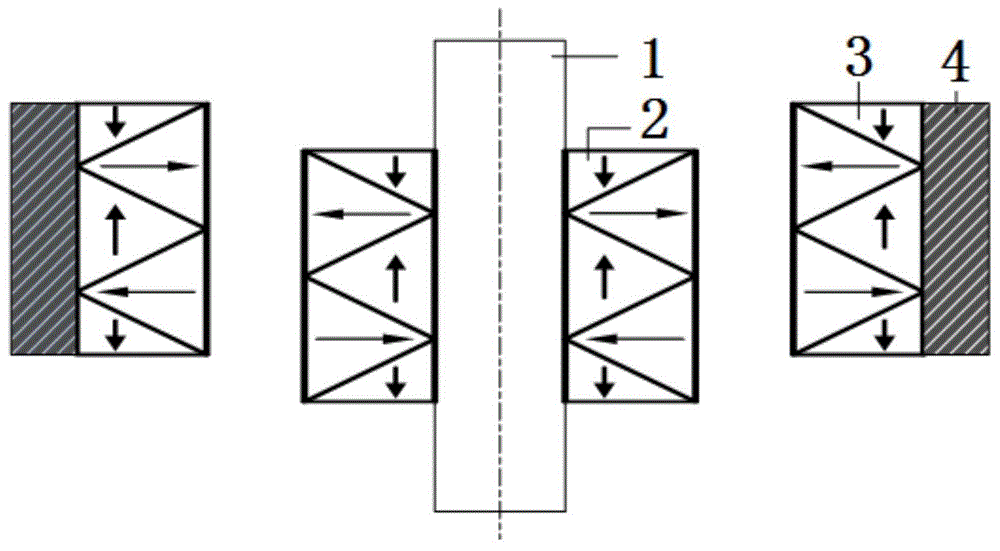

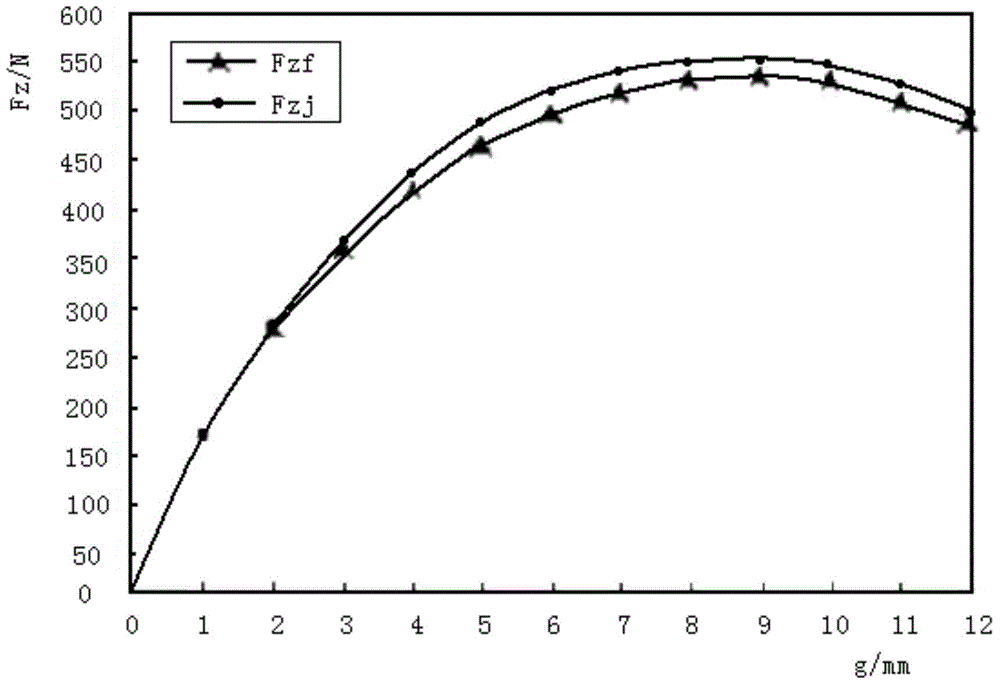

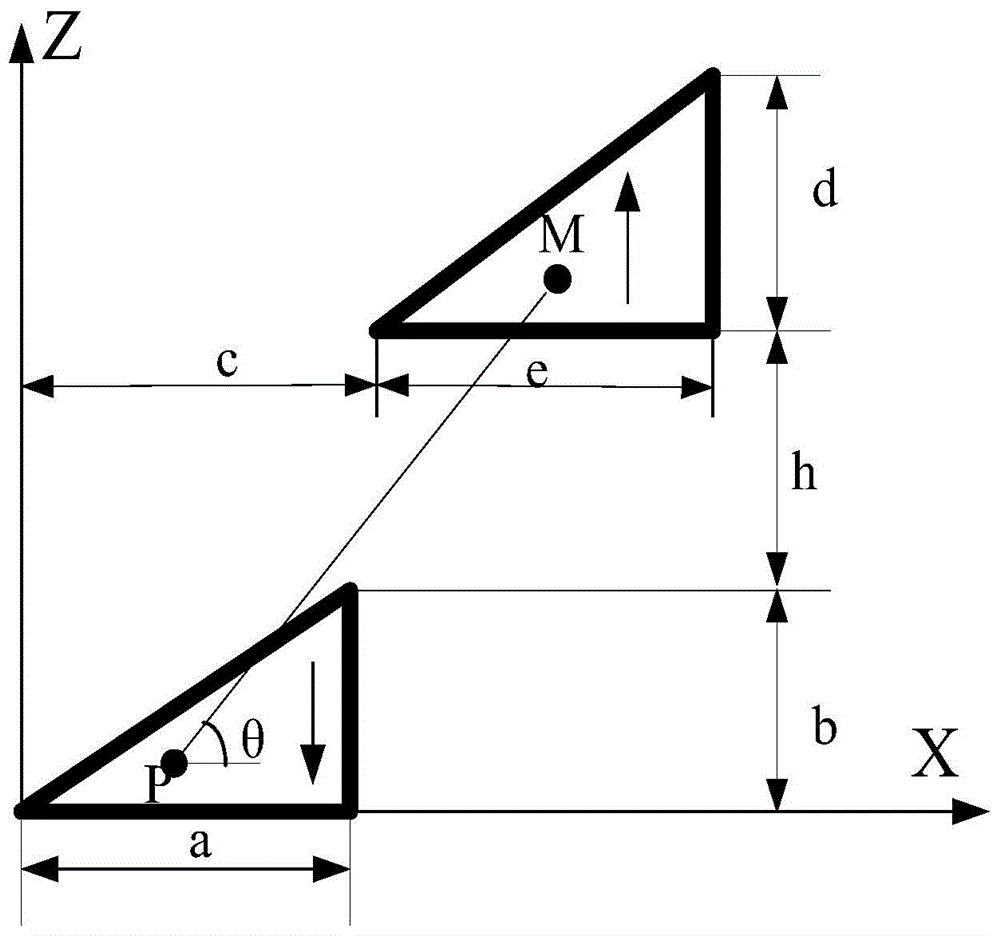

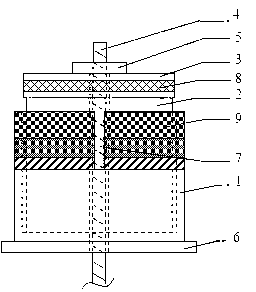

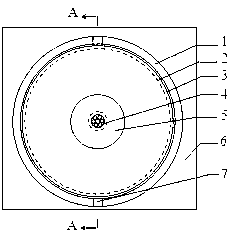

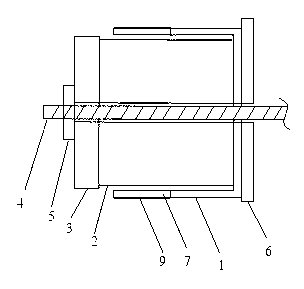

Halbach permanent magnetic bearing obtained by lap piling of permanent magnetic rings having triangular sections

The invention discloses a Halbach permanent magnetic bearing obtained by lap piling of permanent magnetic rings having triangular sections. The Halbach permanent magnetic bearing comprises a rotor and a stator corresponding to the rotor. Multiple movable magnet rings are piled around the shaft of the rotor. Multiple static magnet rings are piled on the inner circle surface of the stator. The multiple static magnet rings and multiple movable magnet rings are respectively piled to form cylindrical structures. The movable magnet rings and the static magnet rings are obtained by lap piling of the permanent magnetic rings having triangle sections according to a Halbach array. The movable magnet rings and the static magnet rings comprise the permanent magnetic rings having triangle sections and different radiuses. The invention also discloses a magnetic force determination method of the Halbach permanent magnetic bearing obtained by lap piling of the permanent magnetic rings having triangle sections. The device and method have the advantages that obvious improvement of a radial force or an axial force is realized, a permanent magnet material is saved, an operation process is simple and accuracy is high.

Owner:XIAN UNIV OF TECH

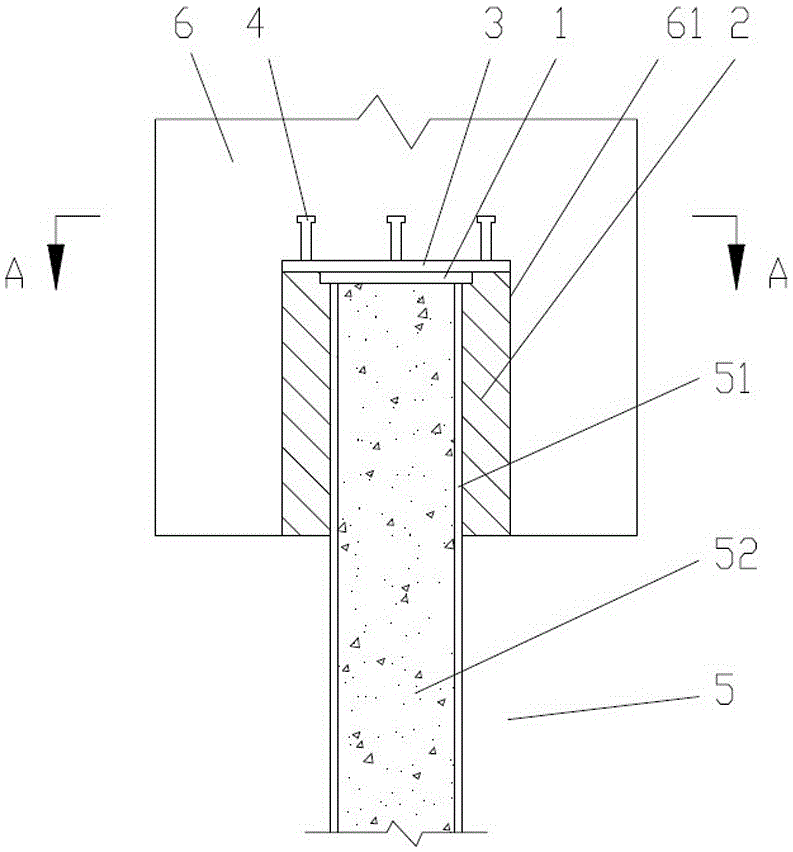

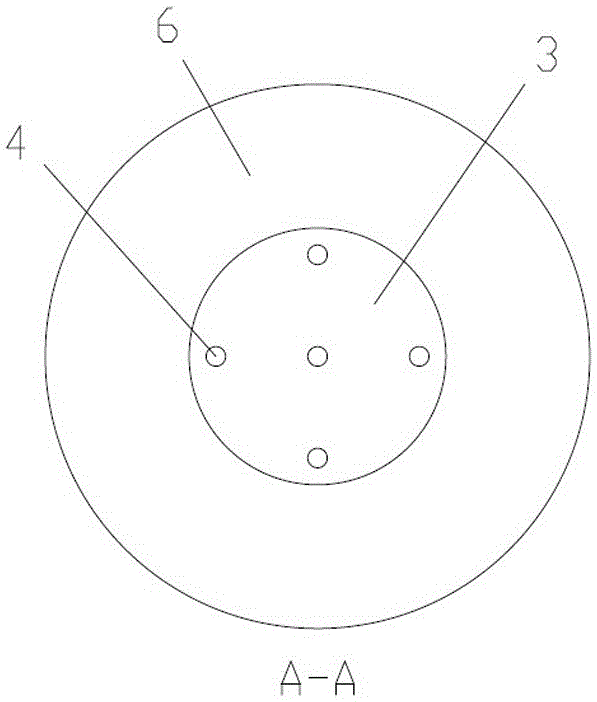

Flexible connection structure for pile and pile cap and construction method

InactiveCN105887875AIncrease stiffnessPrevent local bucklingBridge structural detailsBulkheads/pilesPile capStructural engineering

The invention relates to a flexible connection structure for a pile and a pile cap. The flexible connection structure comprises a top end steel plate, an elastic sleeve, an embedded steel plate and a plurality of shear nails, wherein the pile is a steel pipe concrete pile which comprises a steel pipe; concrete is poured into the steel pipe; the top end steel plate is welded and fixed at the top end of the steel pipe; the elastic sleeve sleeves the top end steel plate and the steel pipe; the multiple shear nails are welded and fixed at the tops of the embedded steel plate; the multiple shear nails and the embedded steel plate are arranged in the pile cap; the pile cap sleeves the top end of the pile, and a blind hole matched with the elastic sleeve is formed in a position, located on the embedded steel plate, on the pile cap; the bottom of the embedded steel plate is in contact with the tops of the elastic sleeve and the top end steel plate. The invention further relates to a construction method of the flexible connection structure for the pile and the pile cap. According to the flexible connection structure, a pile head and the pile cap rotate relatively, so that a transverse displacement allowance of the top structure is increased; meanwhile, the bending moment of the pile can be obviously reduced due to the transverse displacement.

Owner:FUZHOU UNIV

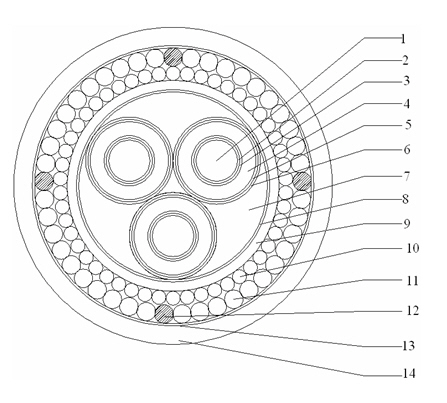

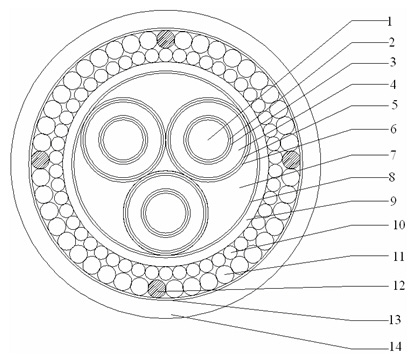

Seismic-resistant electrical cable

InactiveCN102157242AEven by forceLow elastic modulusPower cables with screens/conductive layersCopper conductorElastomer

The invention relates to a seismic-resistant electrical cable comprising a conductor, a semiconductive layer, a conductor shielding layer, an insulating layer, an insulating shielding layer, a copper strip shielding layer, an elastic body packing, a wrapping layer, an isolating sleeve, a thin round steel wire armoring layer, a thick round steel wire armoring layer, a copper conductor, an isolated layer and an outer sheath. The seismic-resistant electrical cable is characterized in that a semiconductive band layer is wrapped outside the conductor; insulating materials, packing materials, isolating sleeve materials and outer sheath materials are all elastic body polymers; and double-layer steel wire armoring is adopted for the armoring layers. The invention has higher shearing rigidity, bending rigidity and damping ratio, obvious effects of shear resistance, bending moment, axial force, torsion, and the like, and excellent seismic-resistant and seismic-proof capacity.

Owner:江苏天地龙电缆有限公司

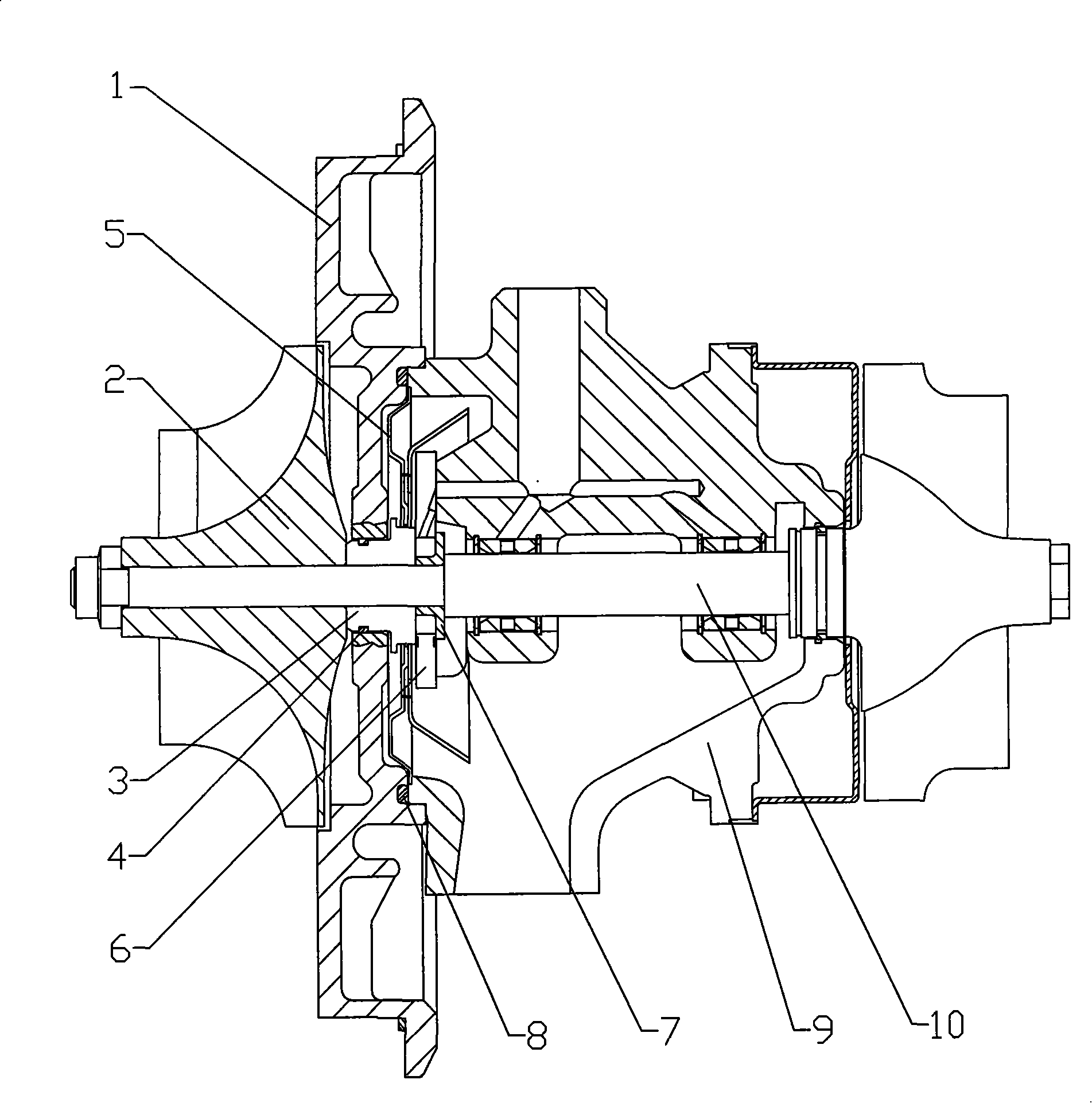

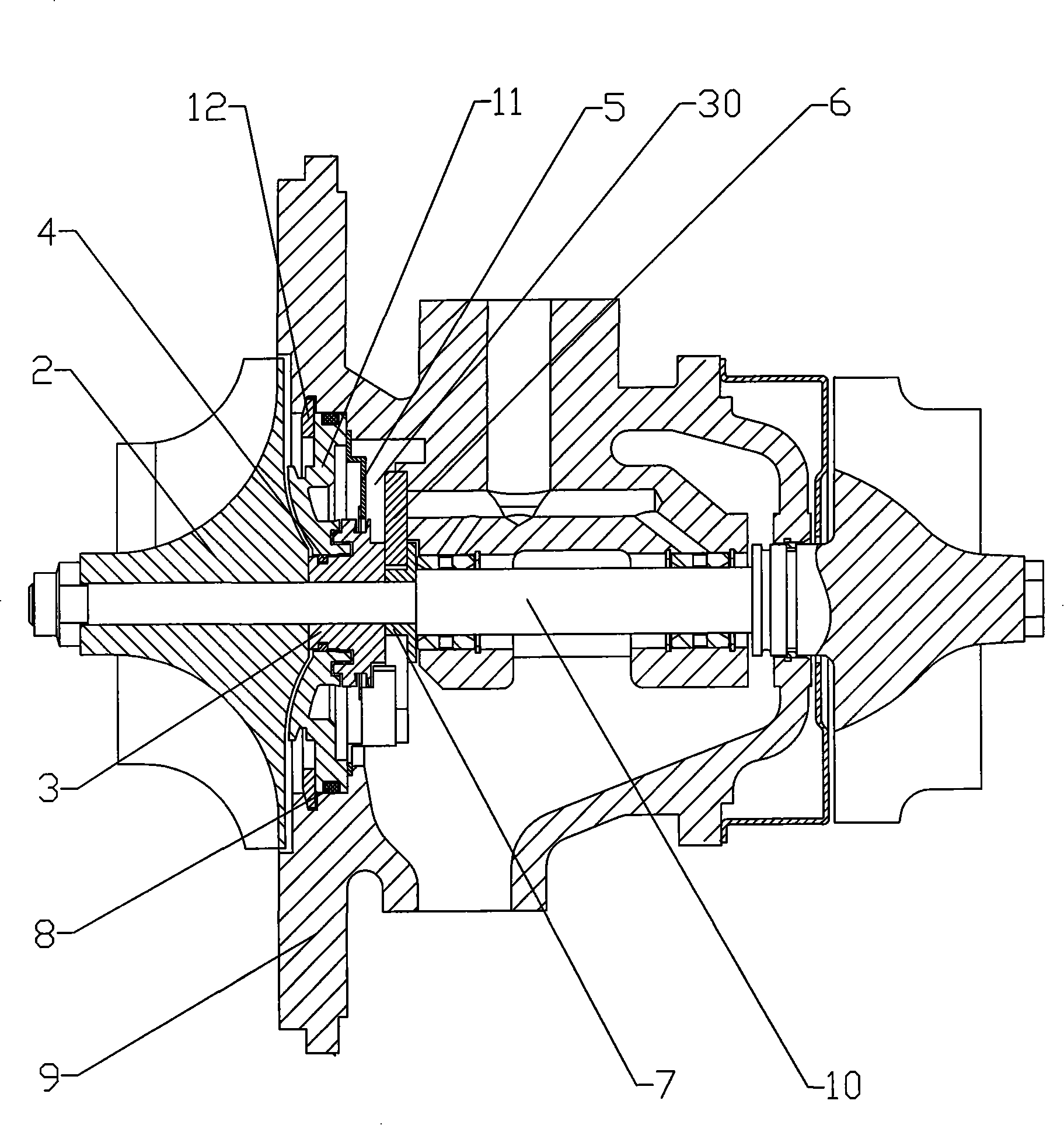

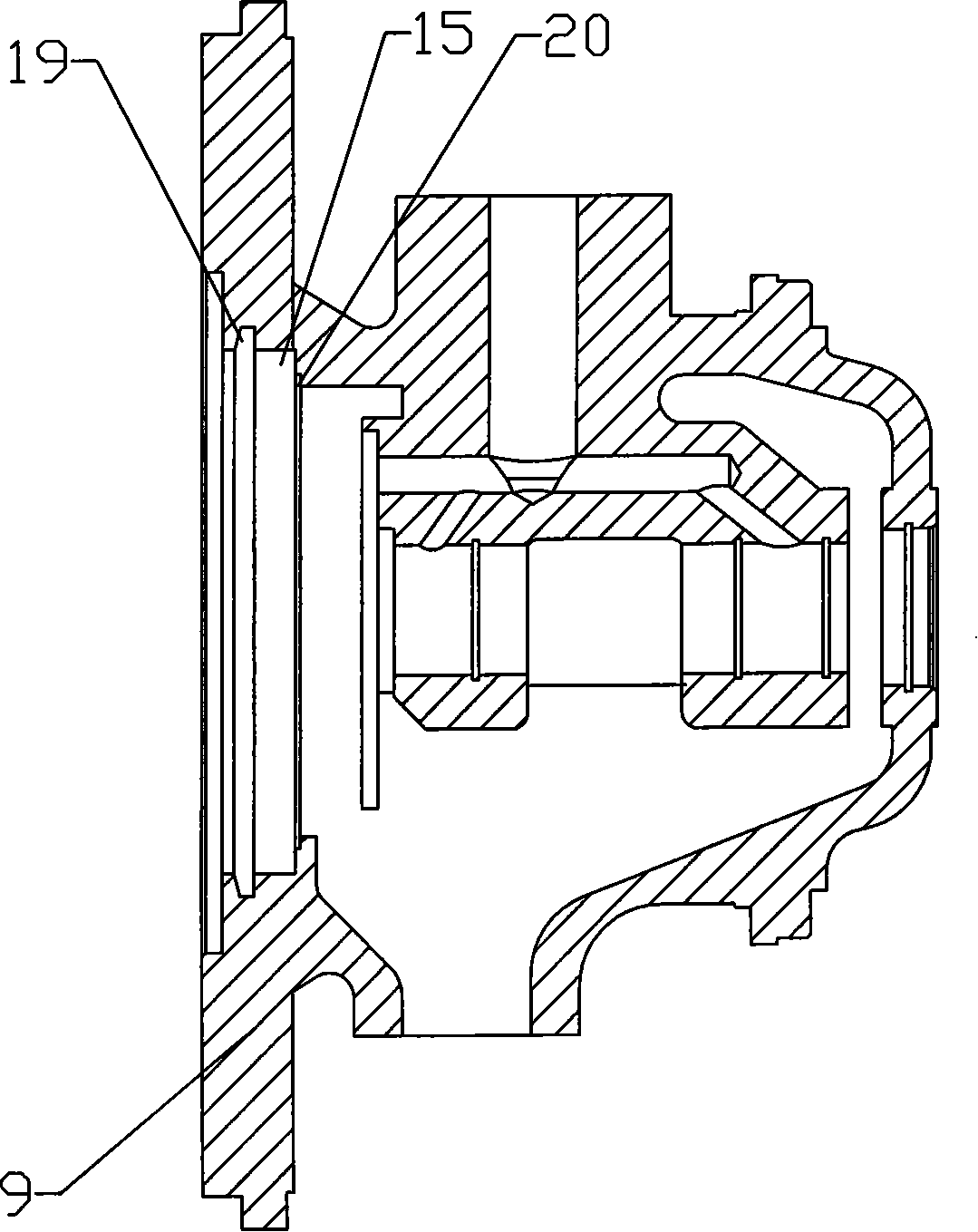

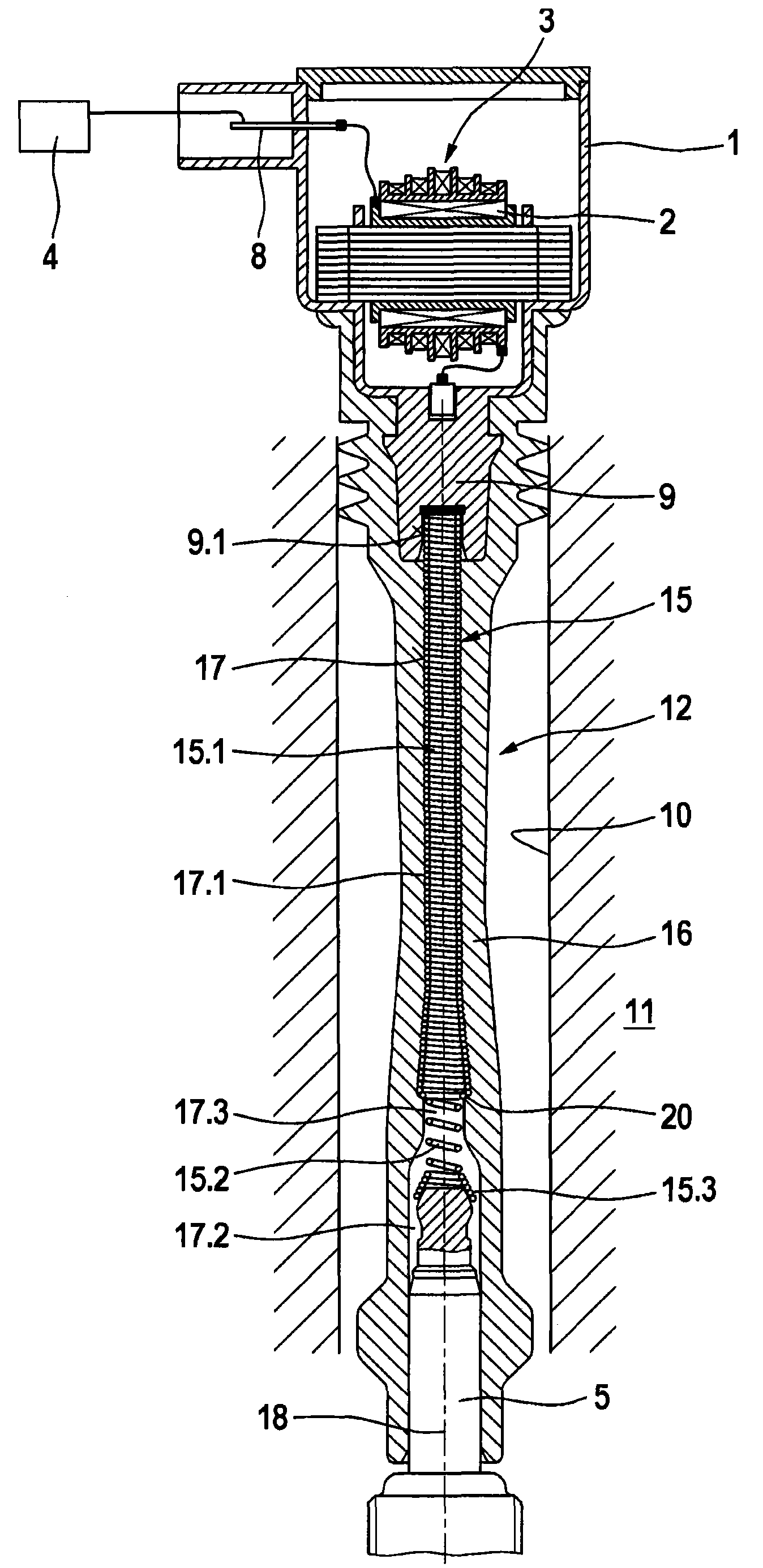

Exhaust-driven turbo-charger central rotor device

InactiveCN101187333AEfficient use ofAvoid deformationEngine sealsMachines/enginesImpellerTurbocharger

The invention discloses a kernel rotor device of an exhaust-gas turbocharger, comprising a middle casing, a thrust sleeve, a thrust bearing, an oil baffle, and a shaft gland, wherein a blade wheel is arranged on a turbine shaft on one end of the shaft gland, the middle casing on the one end of the blade wheel is provided with a chamber, a sealing ring sleeve base is arranged in the chamber, and the sealing ring sleeve base comprises a ring-shaped component which is sealed with the inner walls of the chamber and a lantern ring which is dynamically sealed by the shaft gland and is arranged on the turbine shaft. A ring-shaped connecting member is fixedly connected between the ring-shaped component and the lantern ring, one lateral side of the ring-shaped connecting member which faces the blade wheel is provided with an arc-shaped end face which is relative to the shape of the blade wheel. The original connection between a linking disk and the middle casing is changed into the connection of the middle casing and the sealing ring sleeve to remove the linking disk with large size, thereby avoiding deformation of the product. The original projection sealing is changed into notch sealing to enlarge the oil return space of the product, and the original screw pressing is changed into a circlip pressing, thereby providing conveniences for assembly, easily adopting an automatic assembly line, and reducing the cost of the product.

Owner:KANGYUE TECH

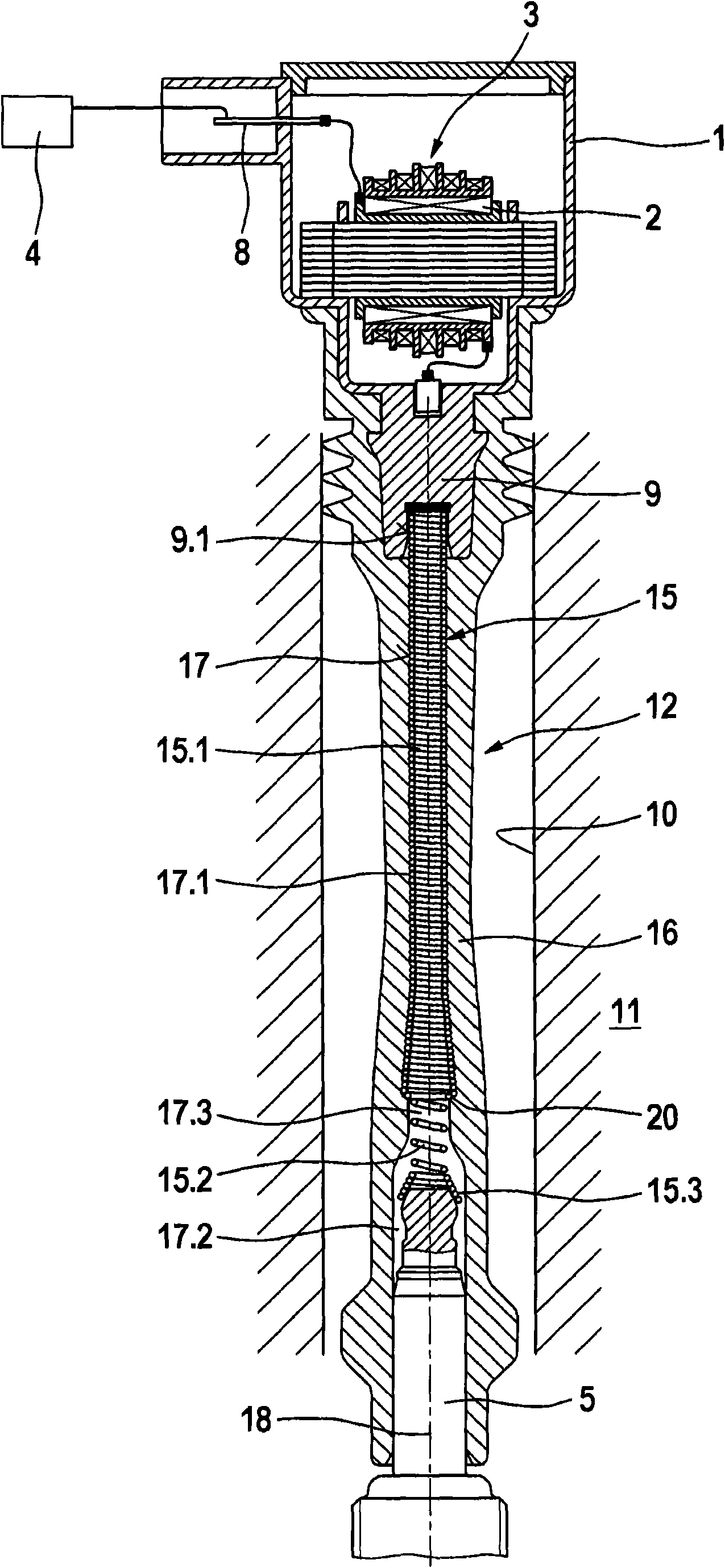

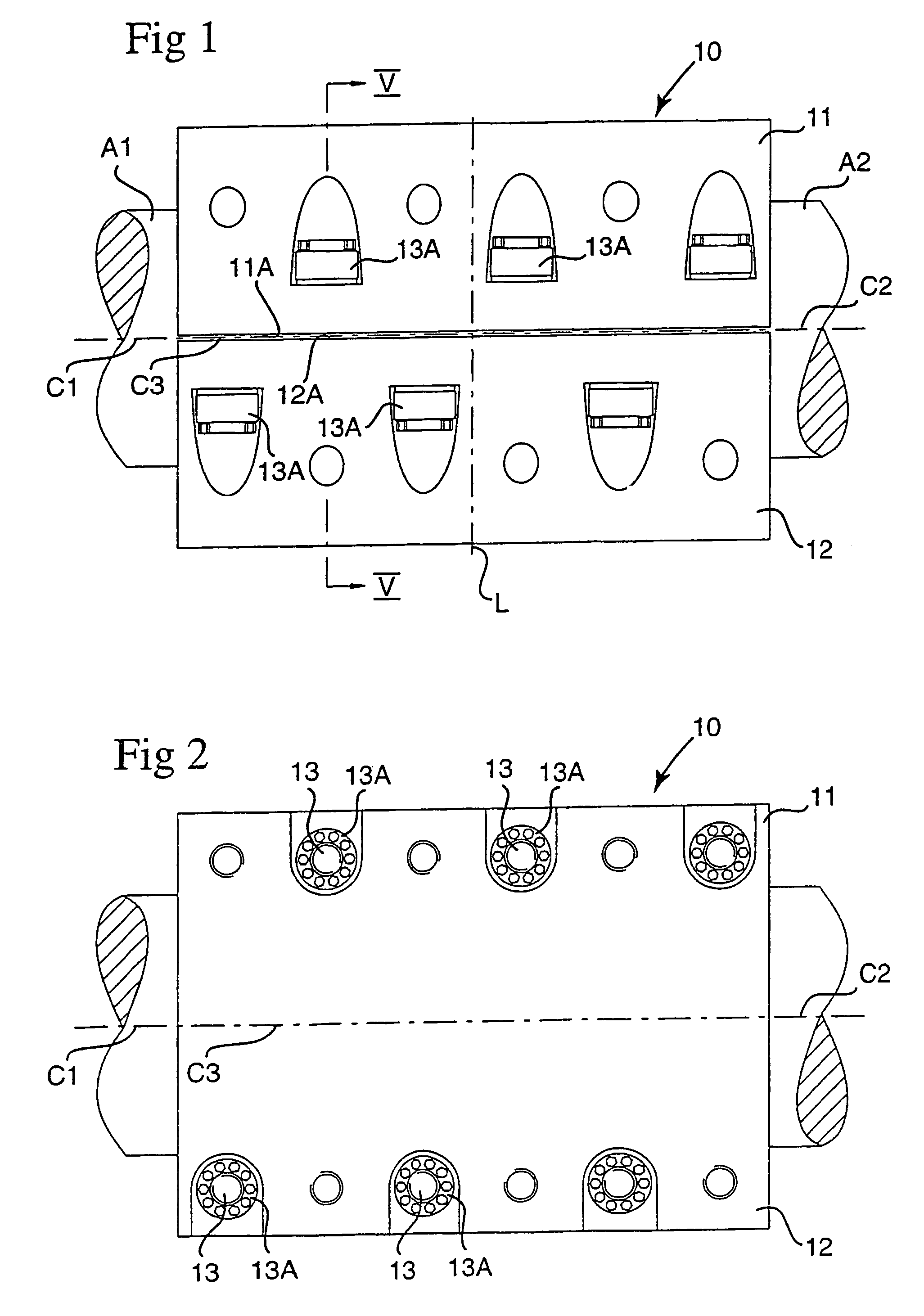

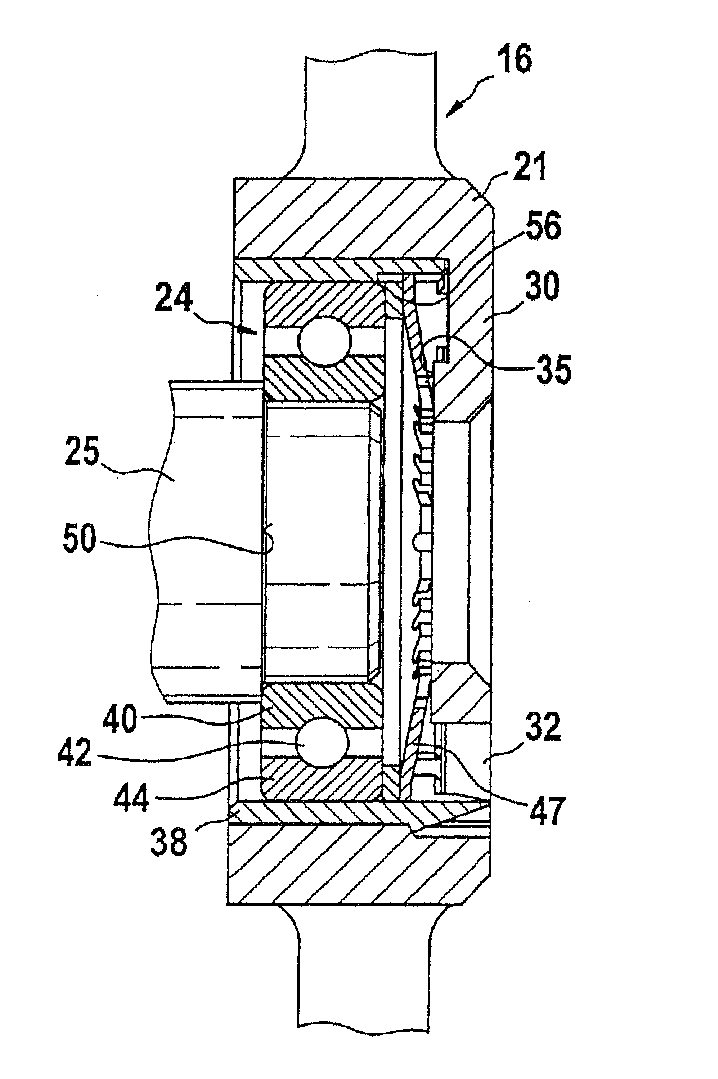

Ignition coil

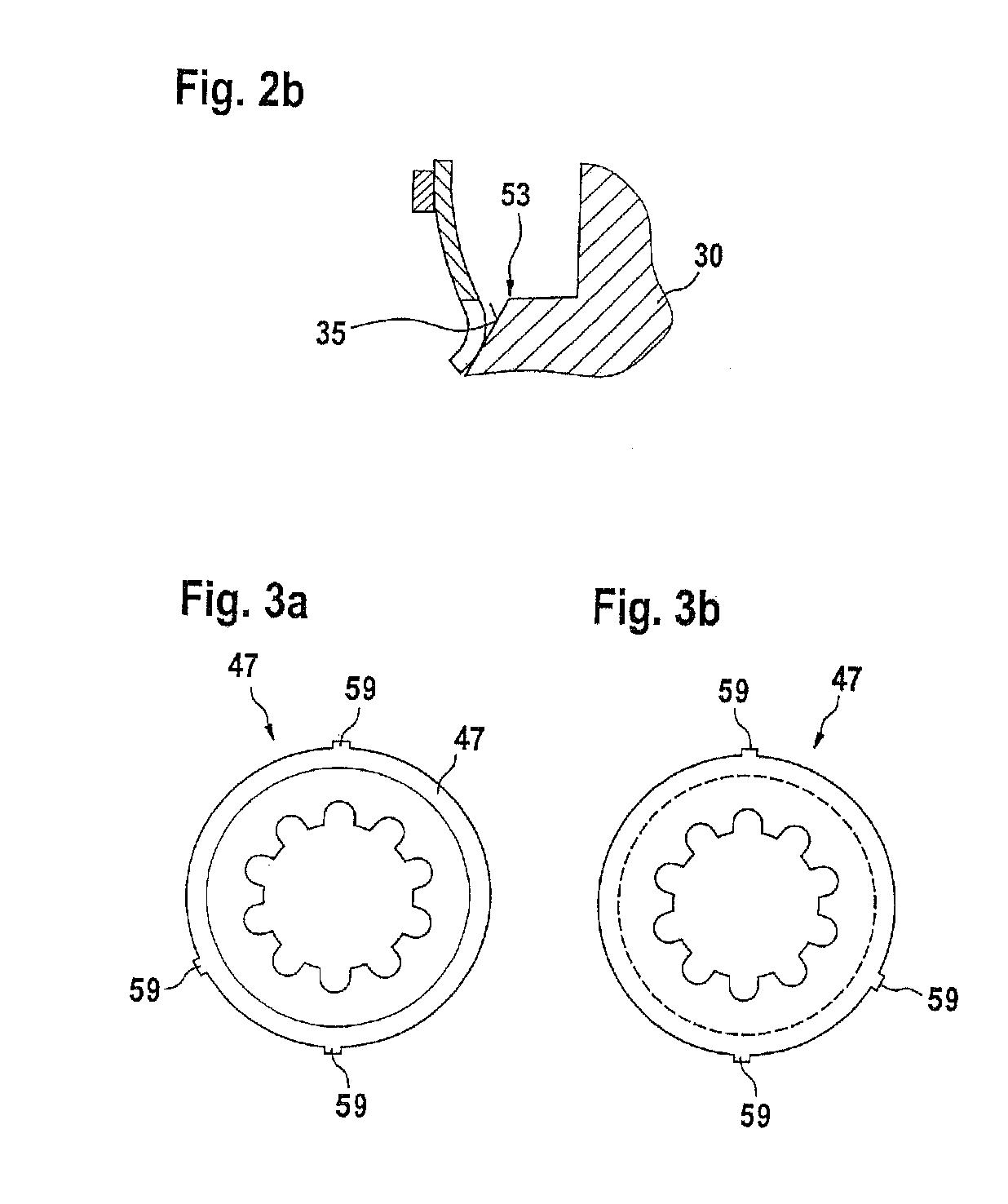

InactiveCN102016290AReduce manufacturing costsIncrease axial forceSparking plugsTransformersElectricityIgnition coil

Known ignition coils have a high-voltage connection, a spring for electrically connecting the high-voltage connection to a spark-plug and an elastic protective jacket that surrounds the spring. The windings of the spring lie in a block against one another in a block section that faces the high-voltage connection and are interspaced in a spring section designed to contact the spark-plug. To permitthe ignition coil with the elastic protective jacket to be pushed easily onto the spark-plug, said protective jacket is reinforced by the integration of two metal sleeves. However, the disadvantage of these sleeves is that they involve higher production costs and increase the diameter of the protective jacket. In addition, the sleeves reduce the flexibility of the protective jacket. In the ignition coil according to the invention, the rigidity of the protective jacket is increased without additional components, thus cutting production costs and reducing the diameter of the protective jacket. According to the invention, the end of the block section (15.1) of the spring (15), facing the spring section (15.2), is supported on at least one support shoulder (20) of the protective jacket (16).

Owner:ROBERT BOSCH GMBH

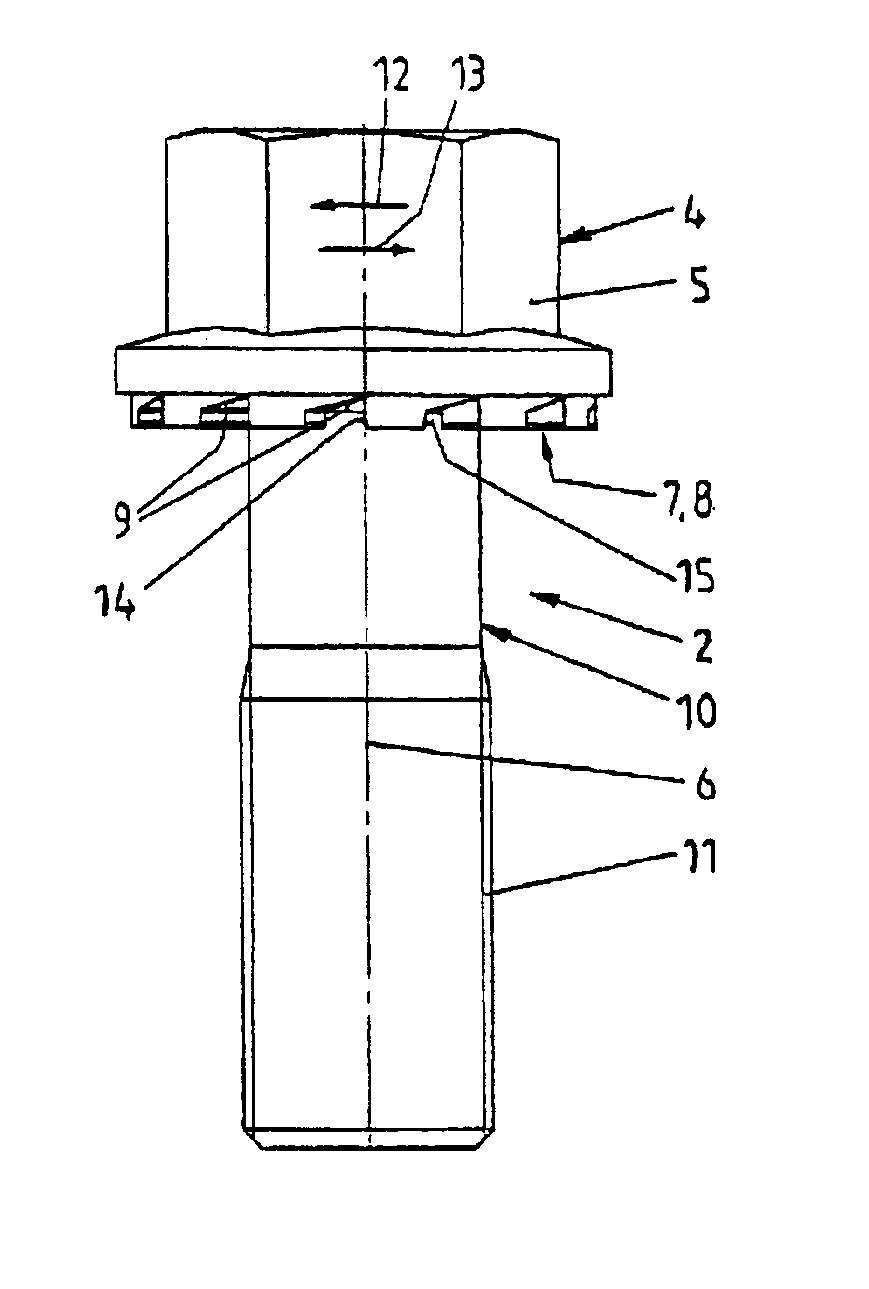

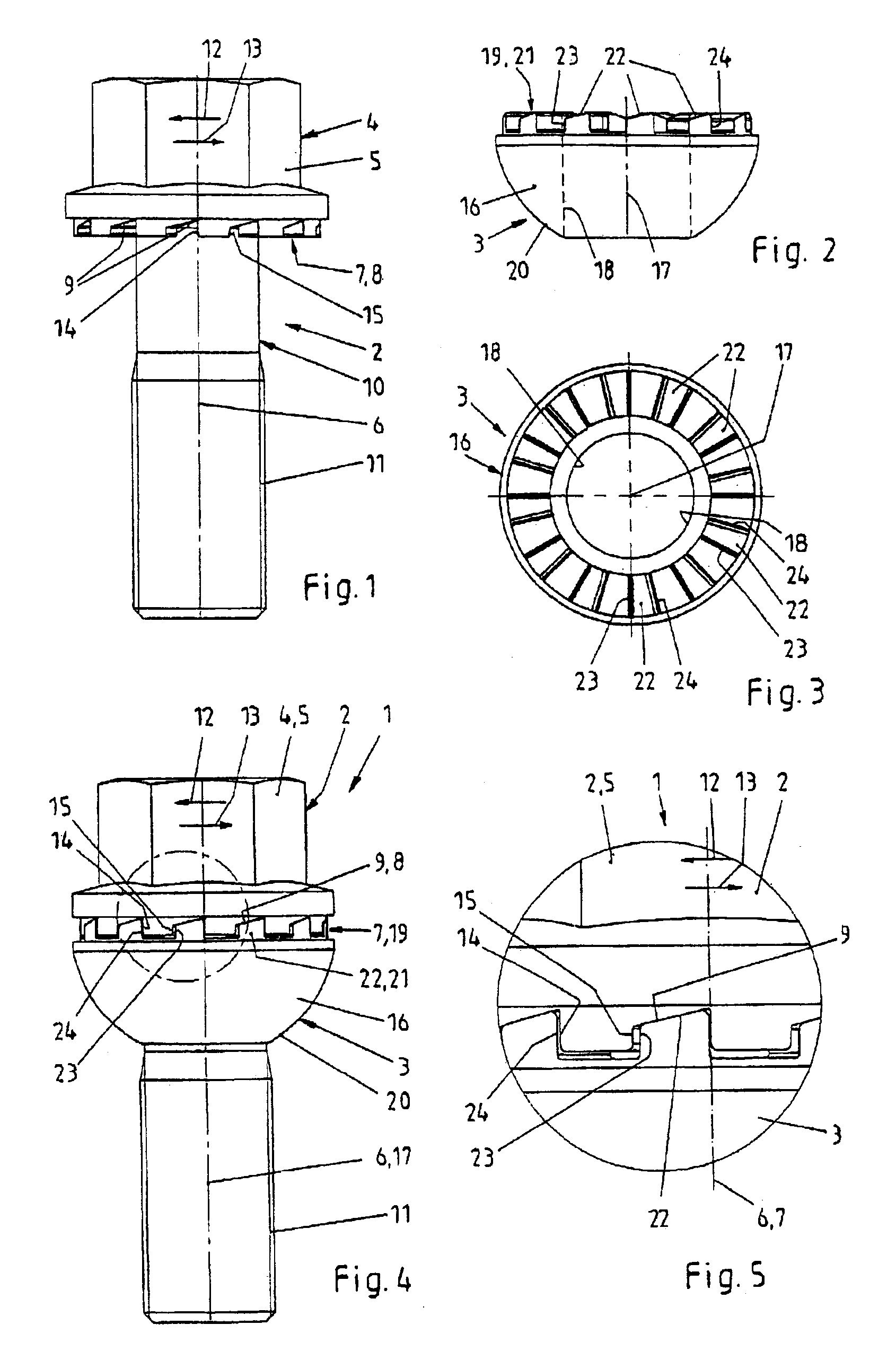

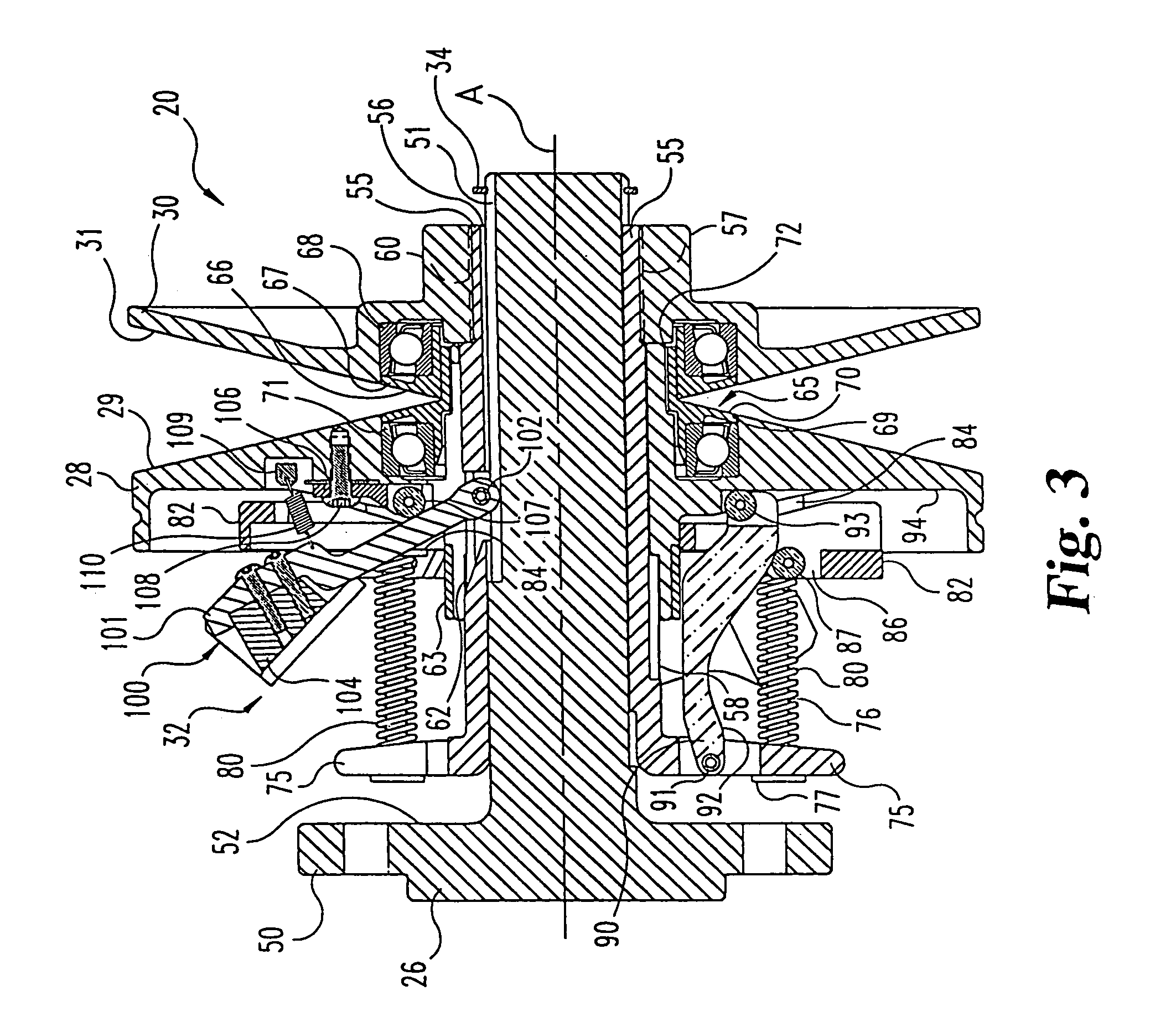

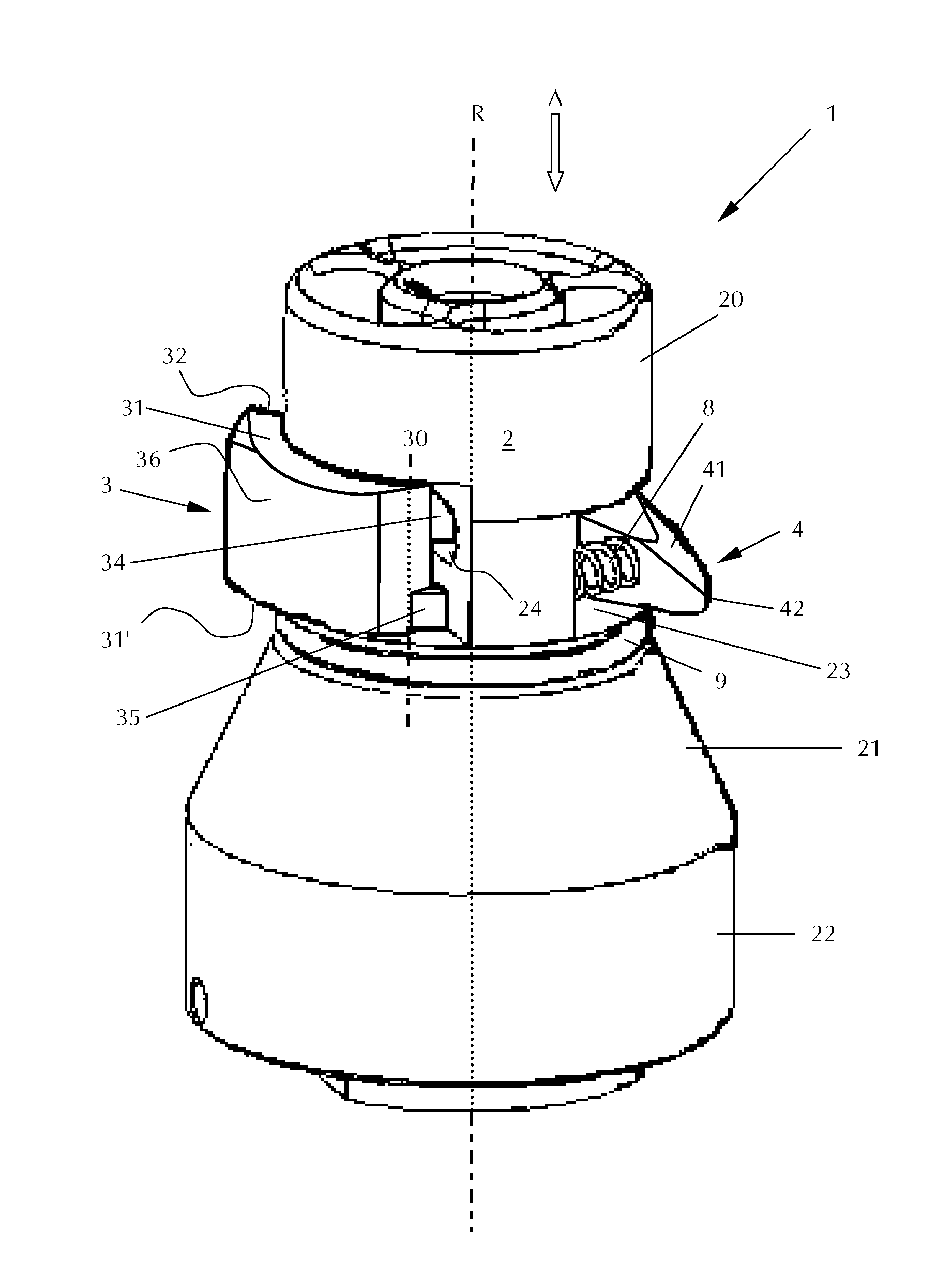

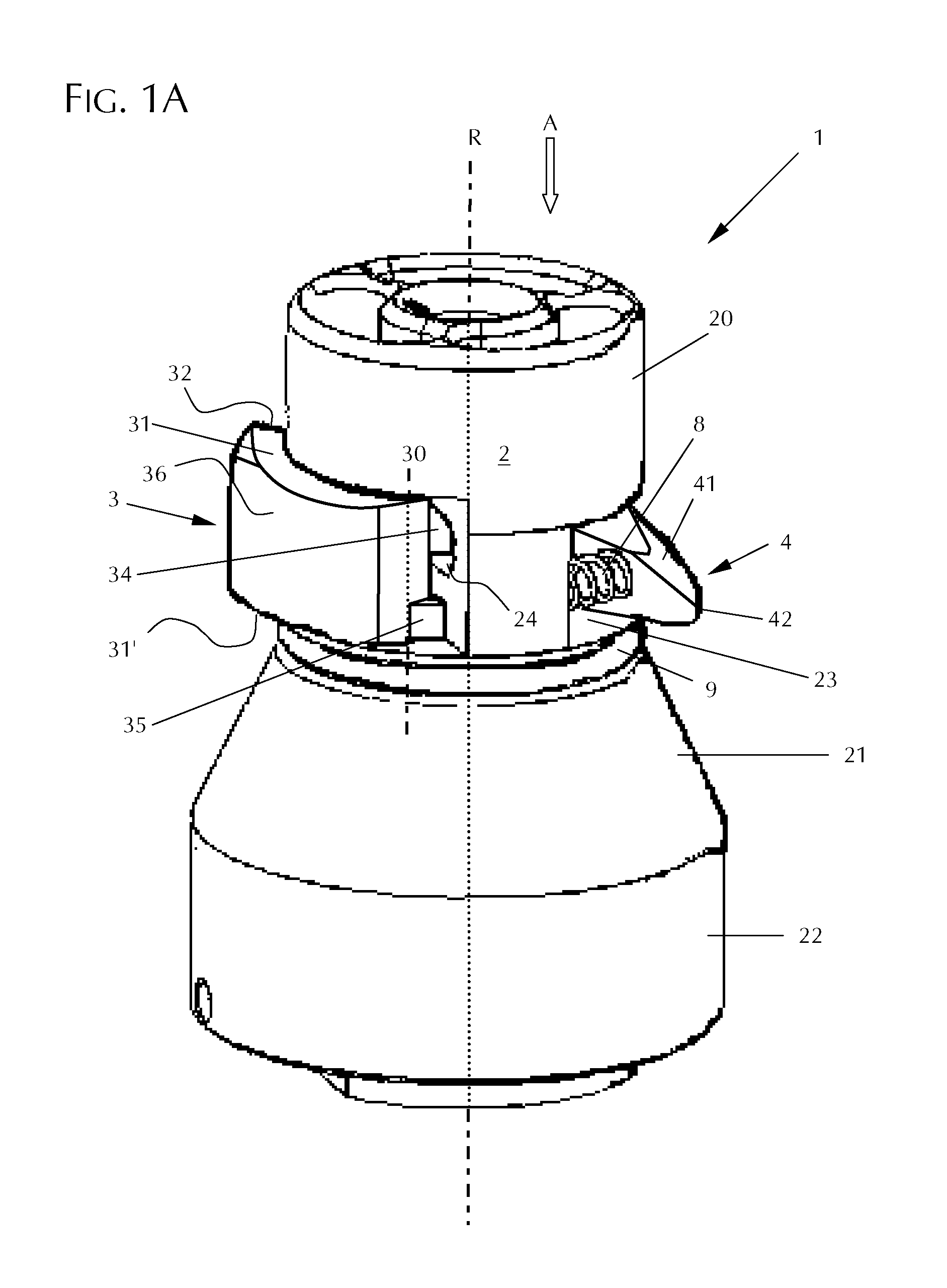

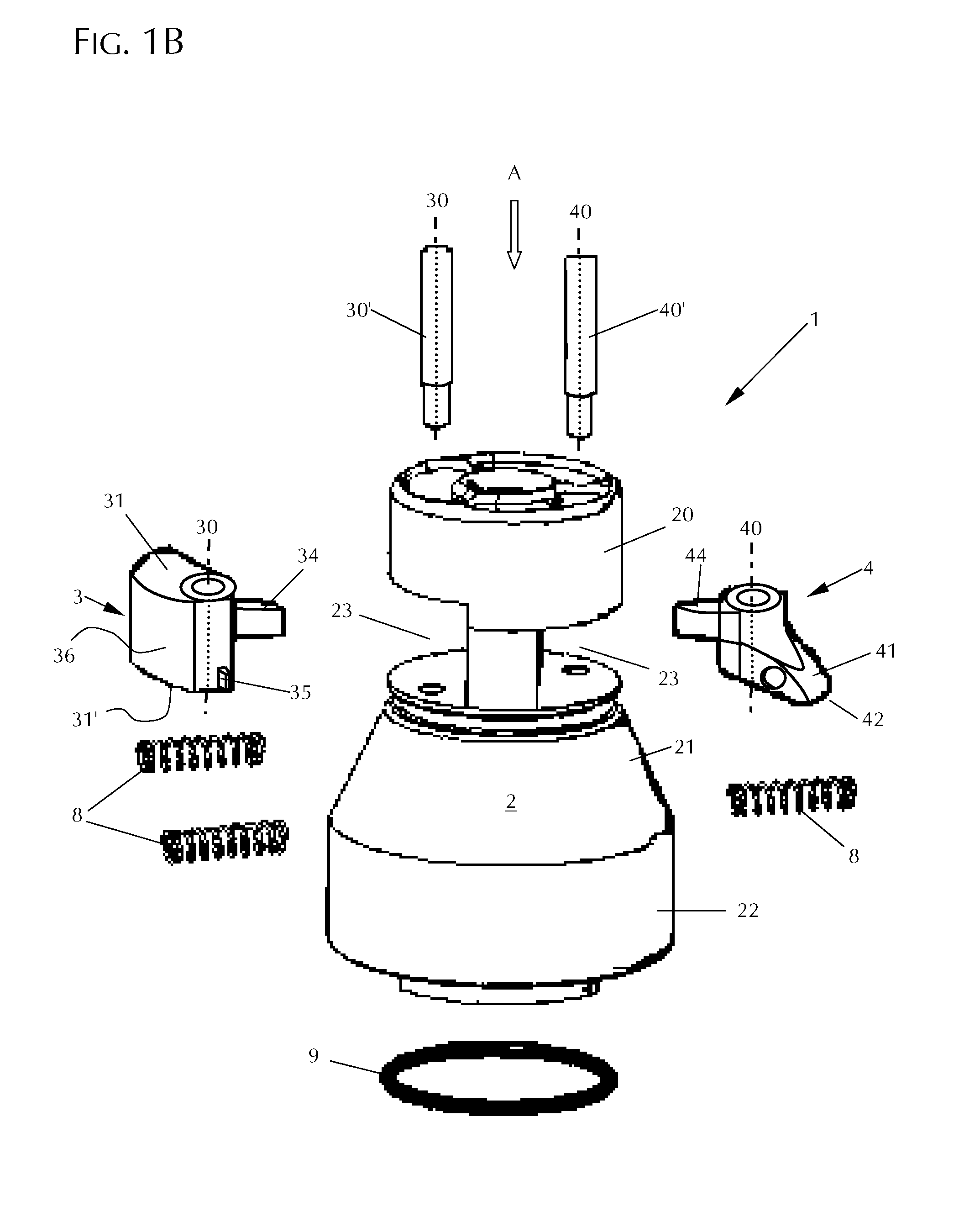

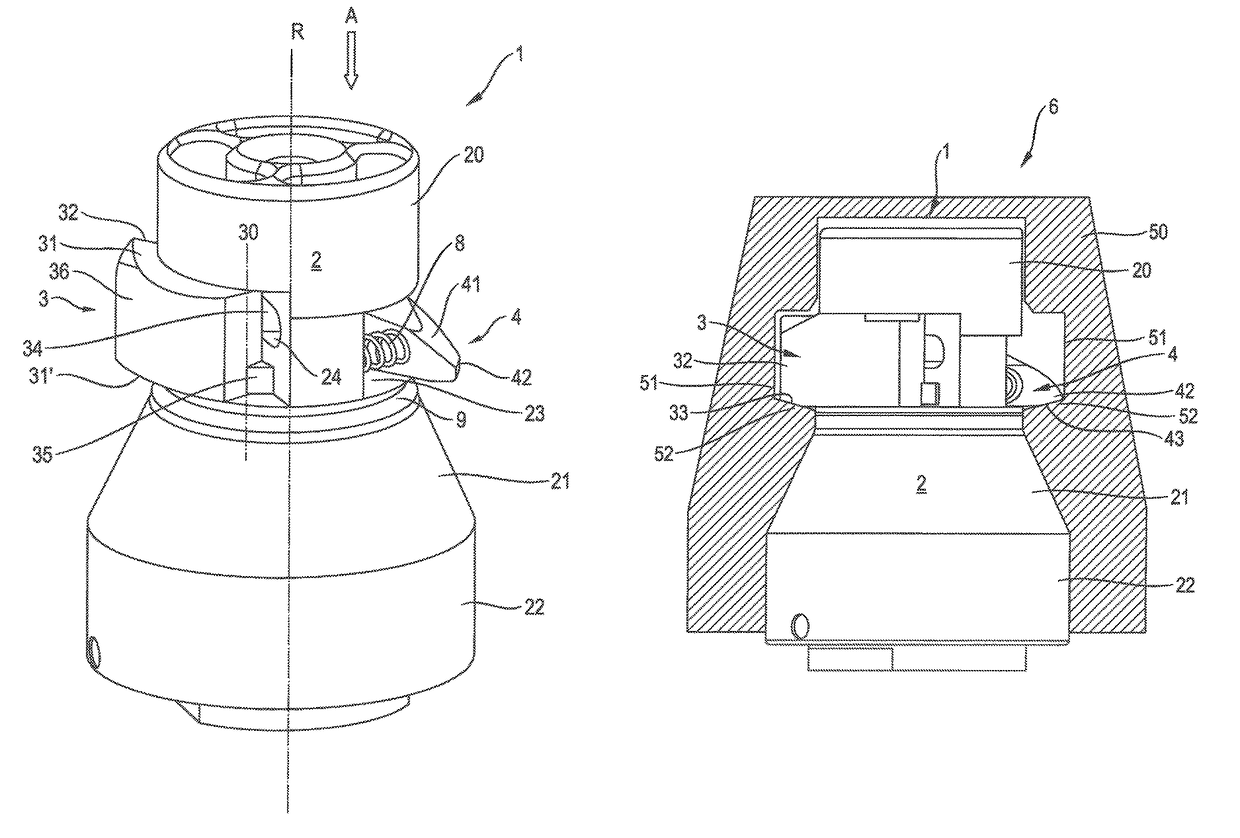

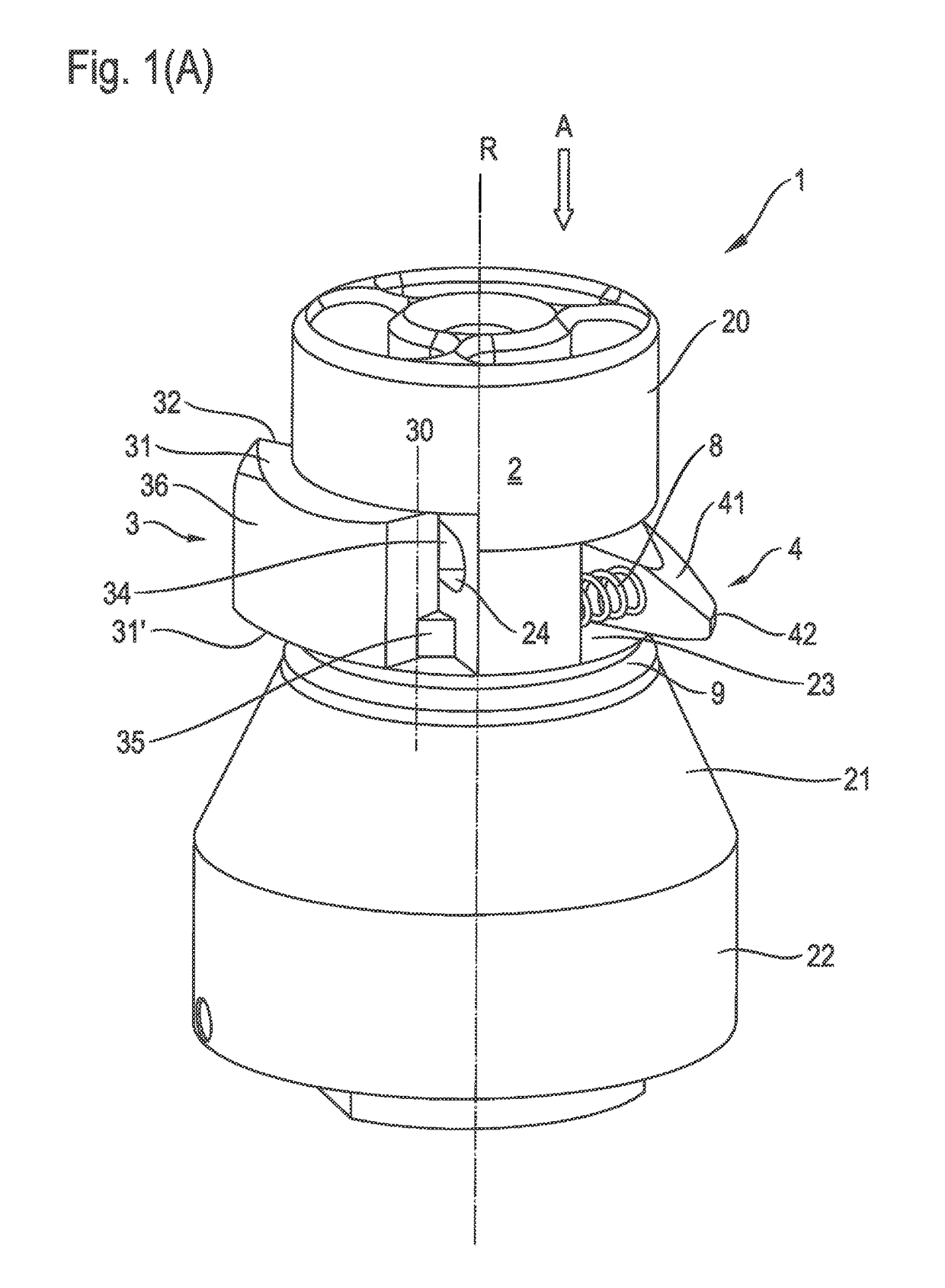

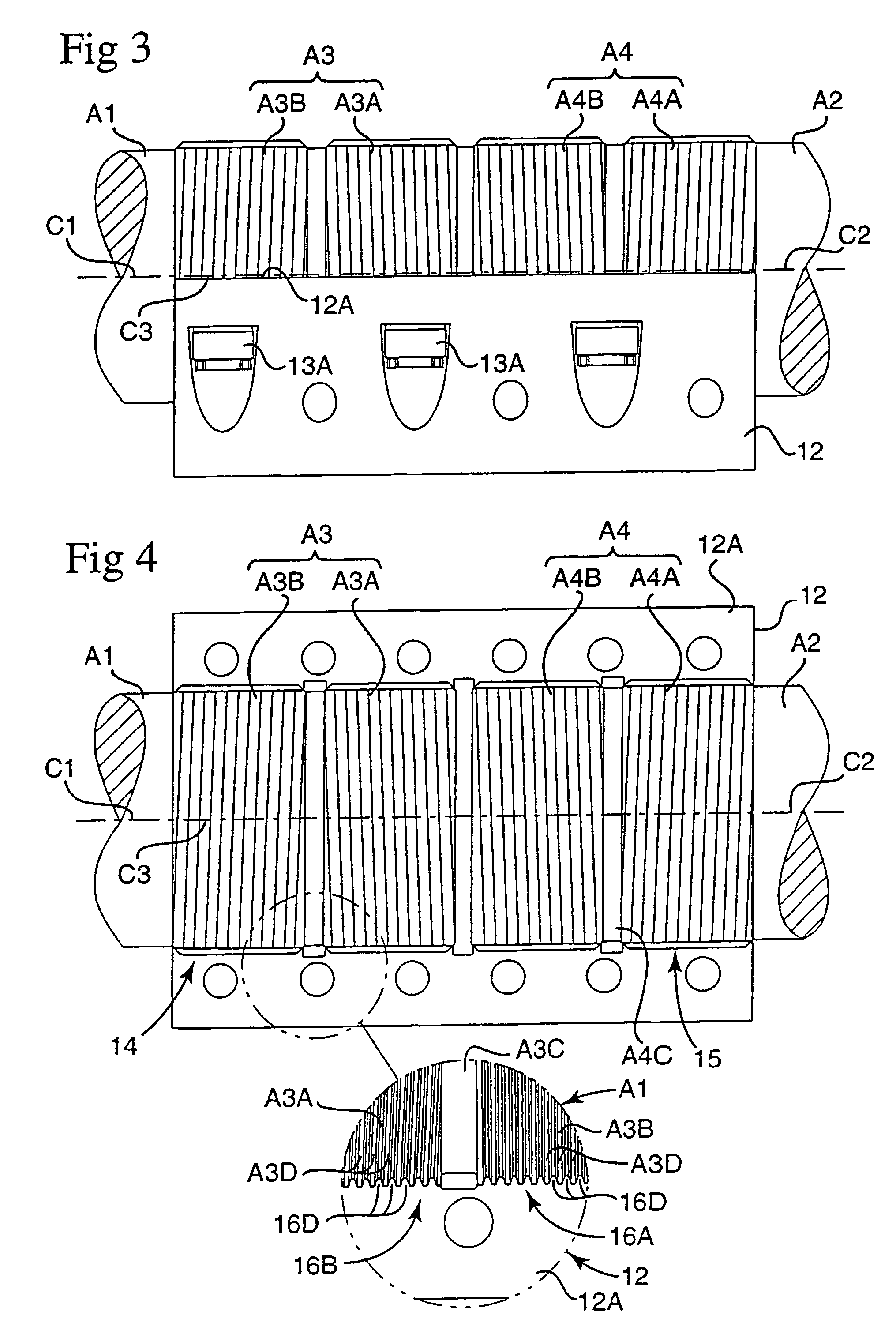

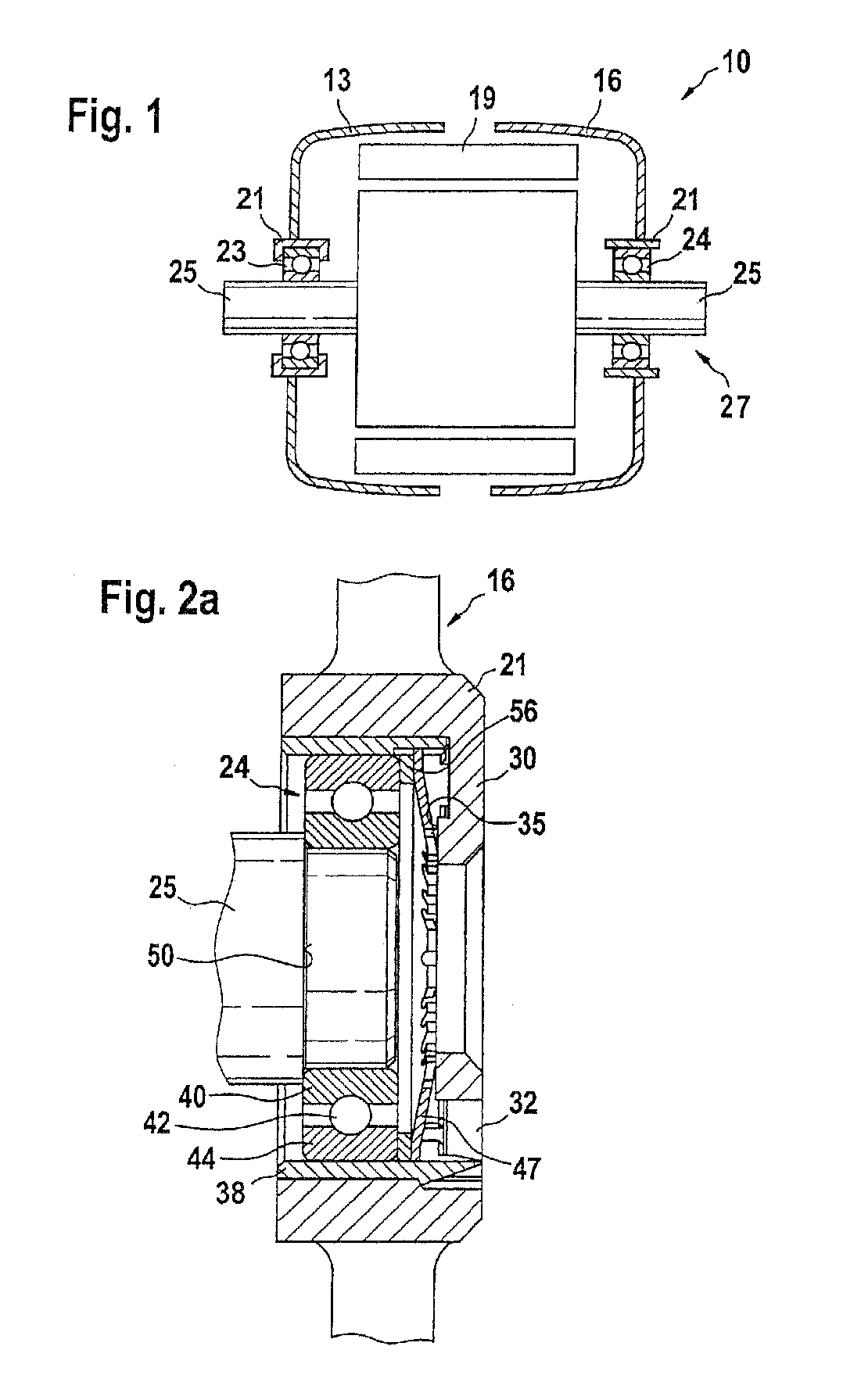

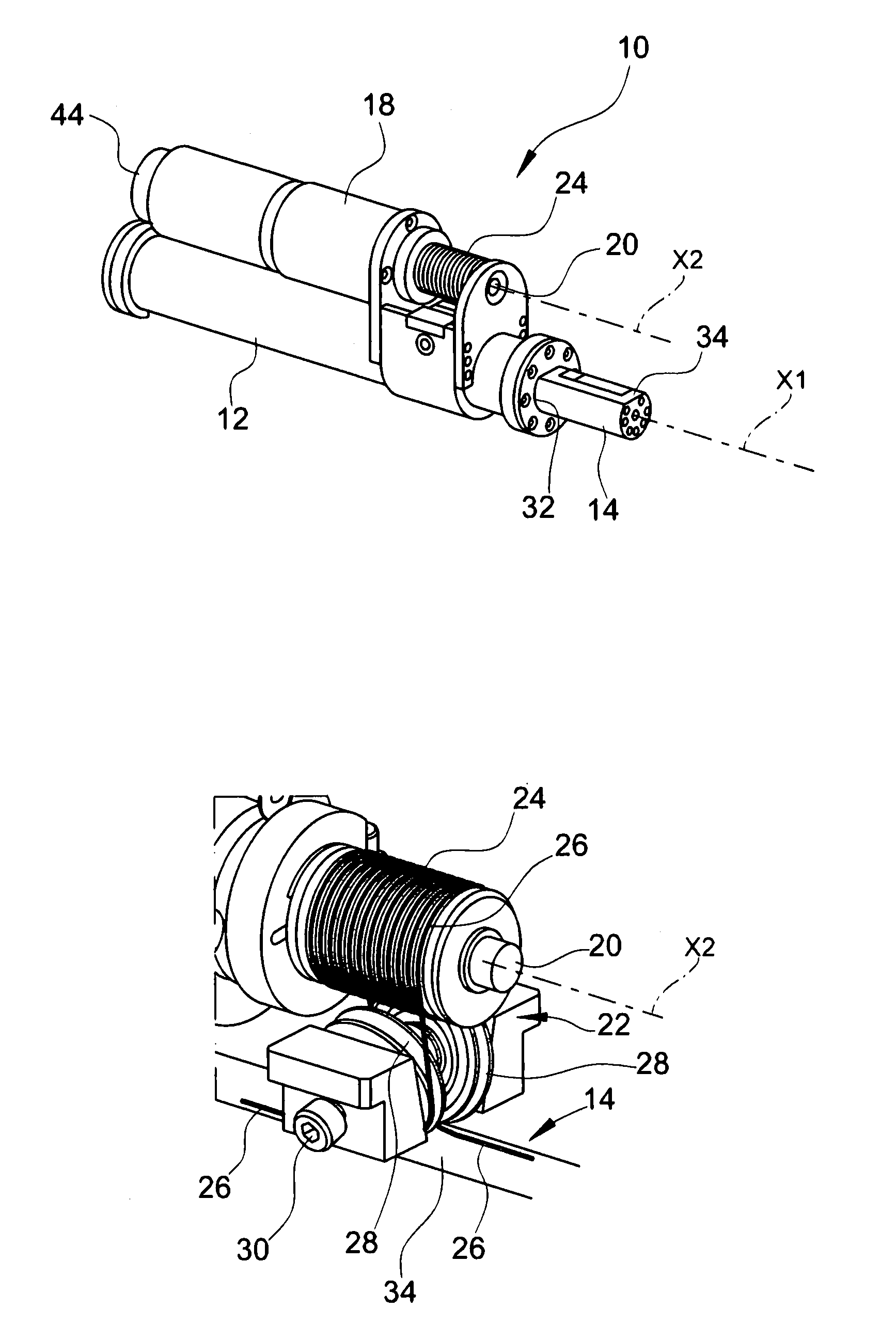

Centrifuge Drive Head For Releasably Connecting A Driving System To A Rotor Of A Centrifuge, A Set And A Centrifuge Comprising The Drive Head

The present invention relates a centrifuge drive head for releasably connecting a driving system to a rotor of a centrifuge. The centrifuge drive head comprises a base body mounted for rotation about an axis of rotation (R) and at least a first and a second coupling element, mounted on the base body for swinging outwardly about a swivel axis. The first and second coupling elements differ from each other.The present invention further relates to a set for a centrifuge, which comprises, in addition to the centrifuge drive head, a hub of a rotor, into the recess of which the first and / or second coupling element can be swiveled depending on their configuration, and also to a centrifuge.

Owner:QIAGEN

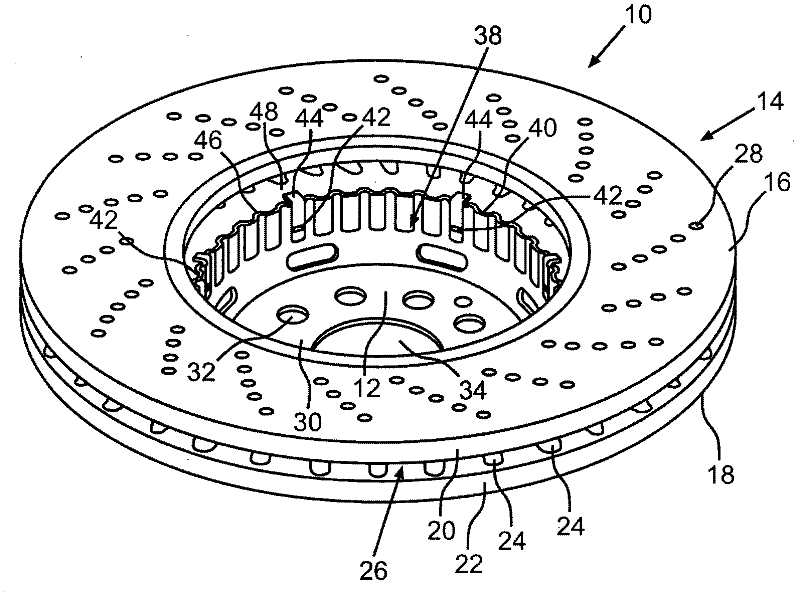

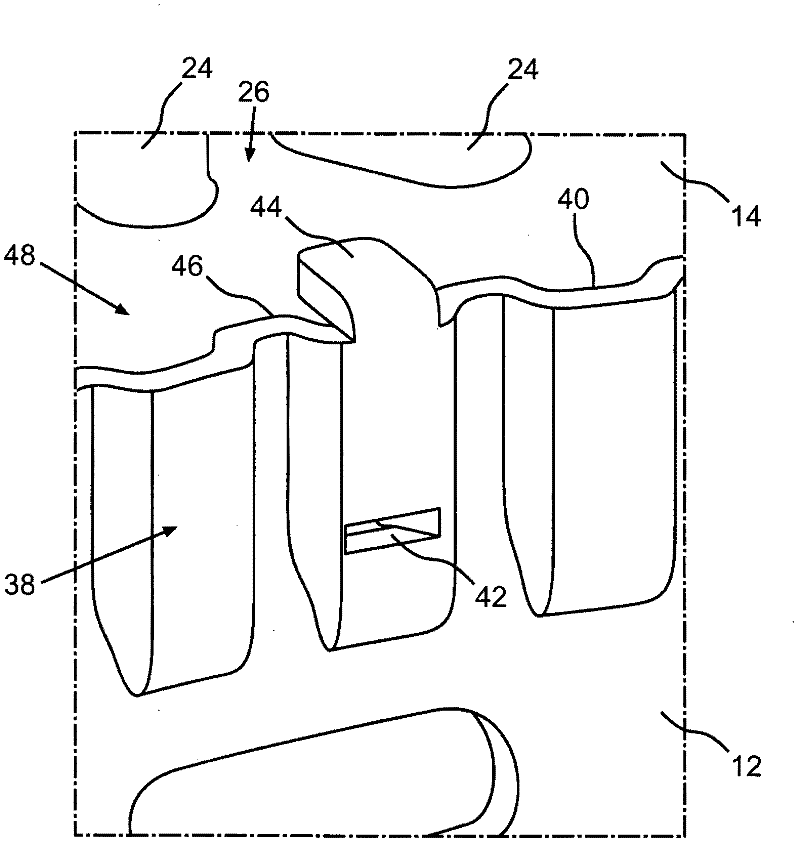

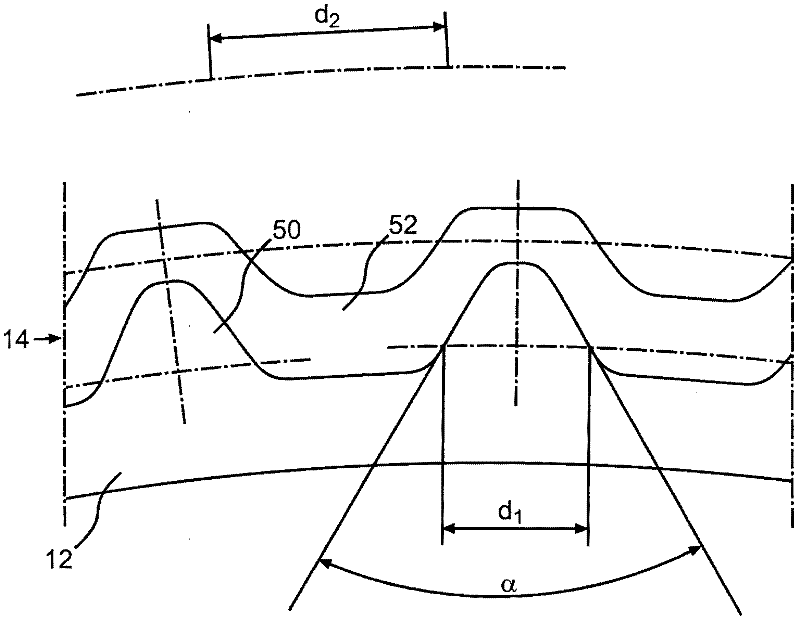

Brake disk

The invention relates to a brake disk (10) for a motor vehicle, having a brake disk chamber (12) and a friction ring (14) coaxially disposed thereto, wherein an external lateral surface (38) of the brake disk chamber has a profile which engages a complementary profile of an internal lateral surface (40) of the friction ring (14) for transmitting torque, and wherein the friction ring (14) is disposed in an axially secured manner at the brake disk chamber (12), wherein at least one strap (42) for axially securing same is formed at the external lateral surface (38) of the brake disk chamber (12).

Owner:DAIMLER AG

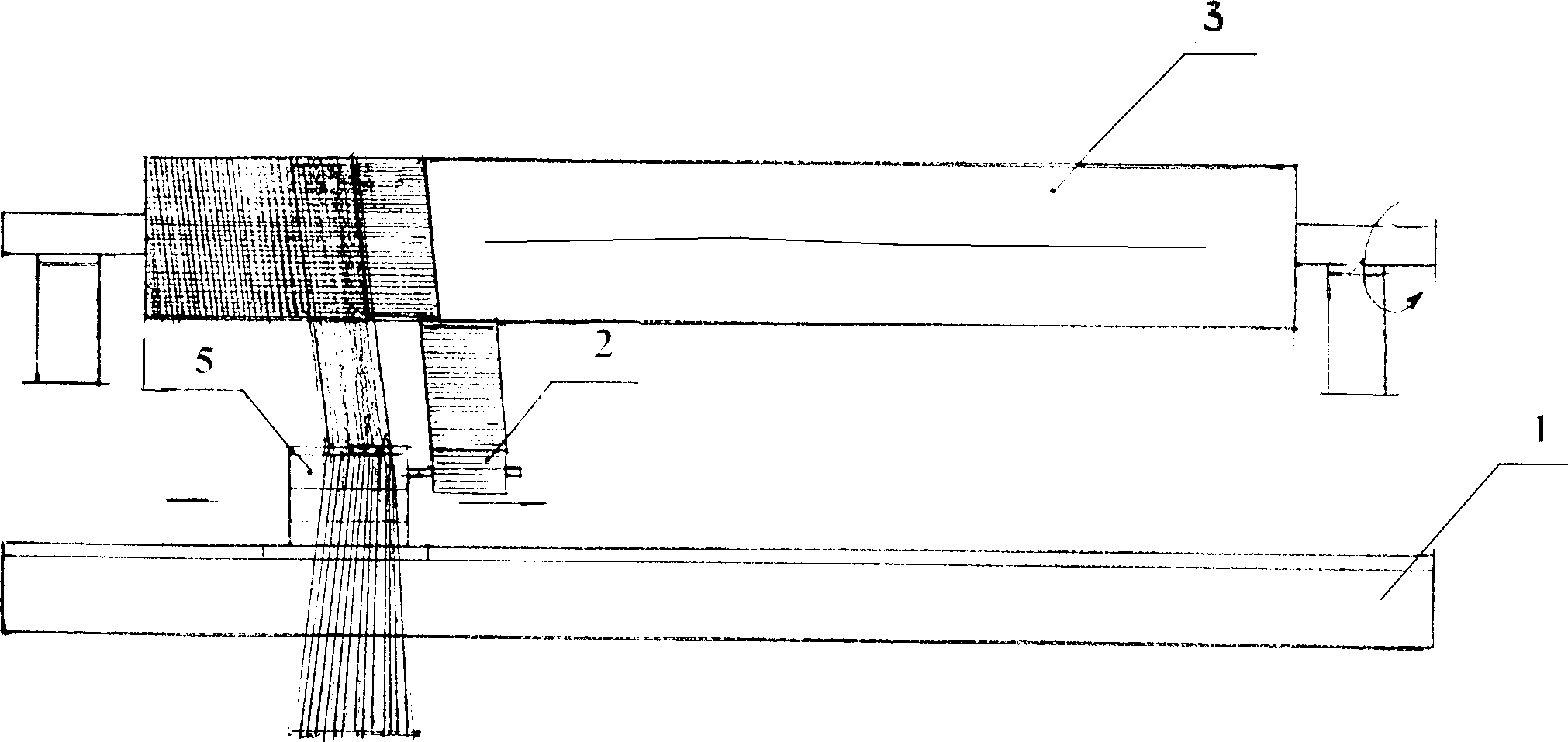

Fibre winding method of glass fiber reinforced plastics pipeline at zero degree

A zero-degree fibre winding method for making the glass fibre reinforced plastic pipe includes such steps as winding the non-woven fabric and glass fibres, which have been immersed in resin, respectively on the surface of formwork from its lower part in tangent direction, winding the unidirectional or latticed glass fibre close is same mode, spraying resin, winding annular fibre layer, adding sand, and repeating the steps 2 and 3.

Owner:天津市天联滨海复合材料有限公司

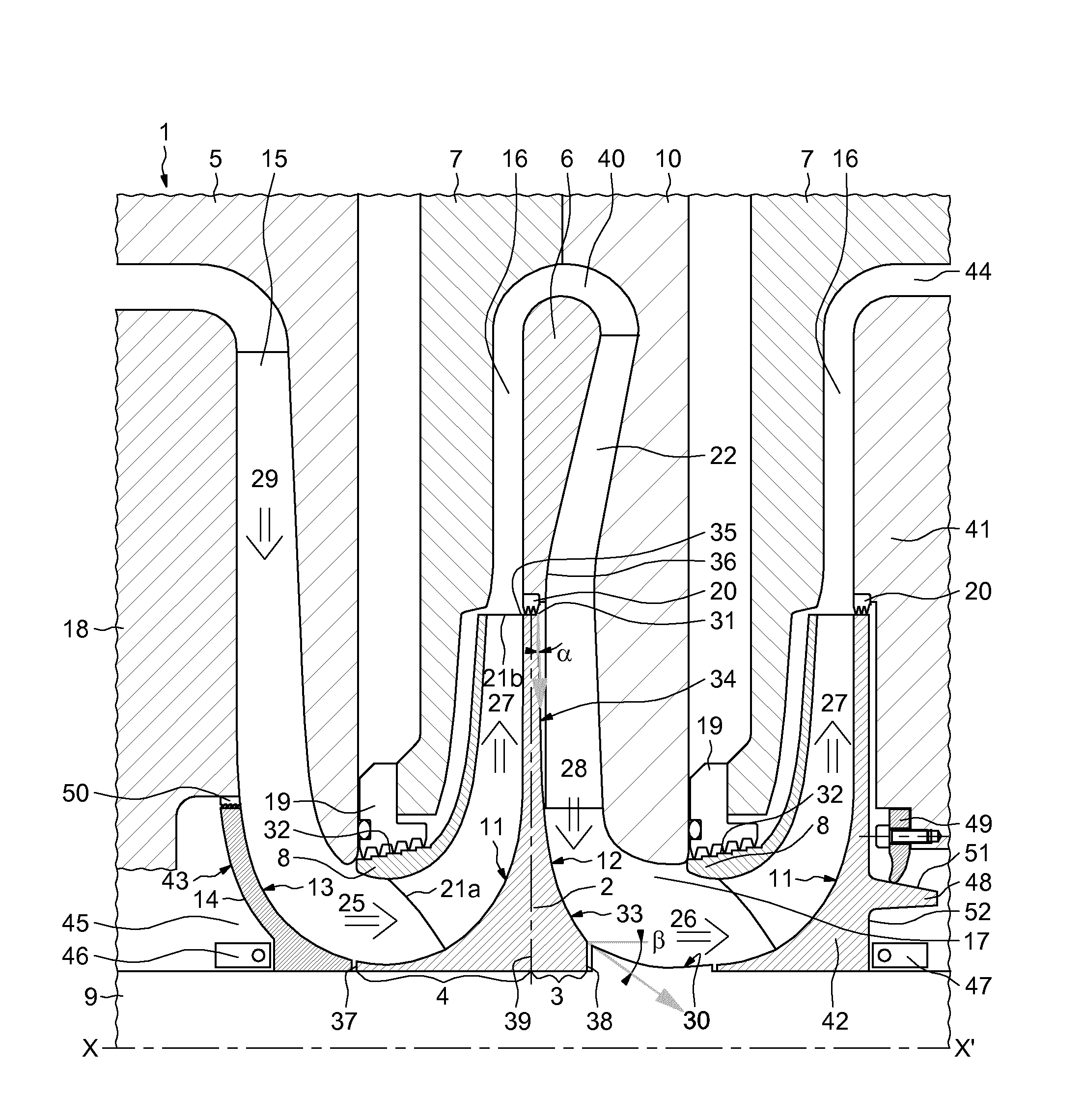

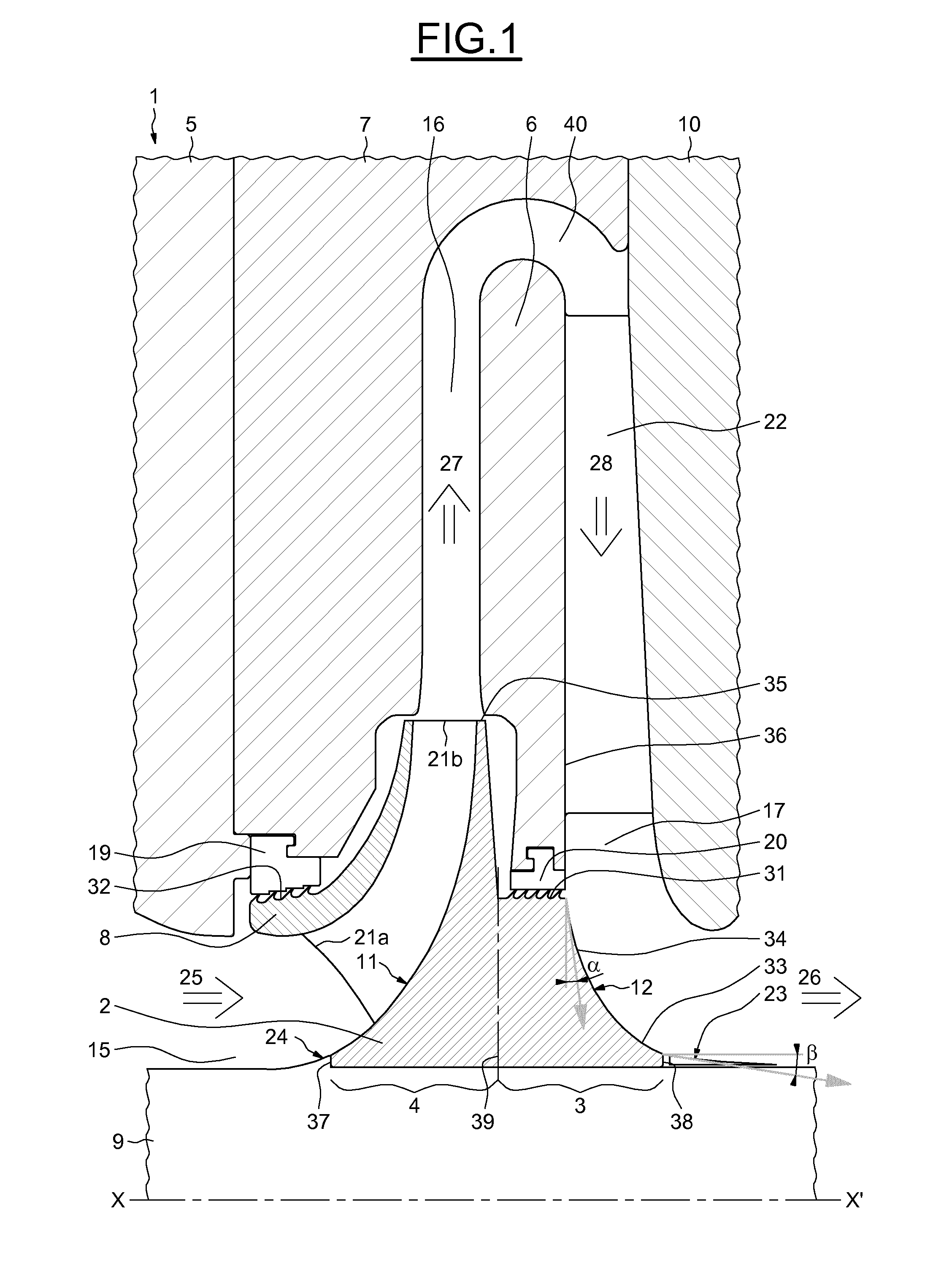

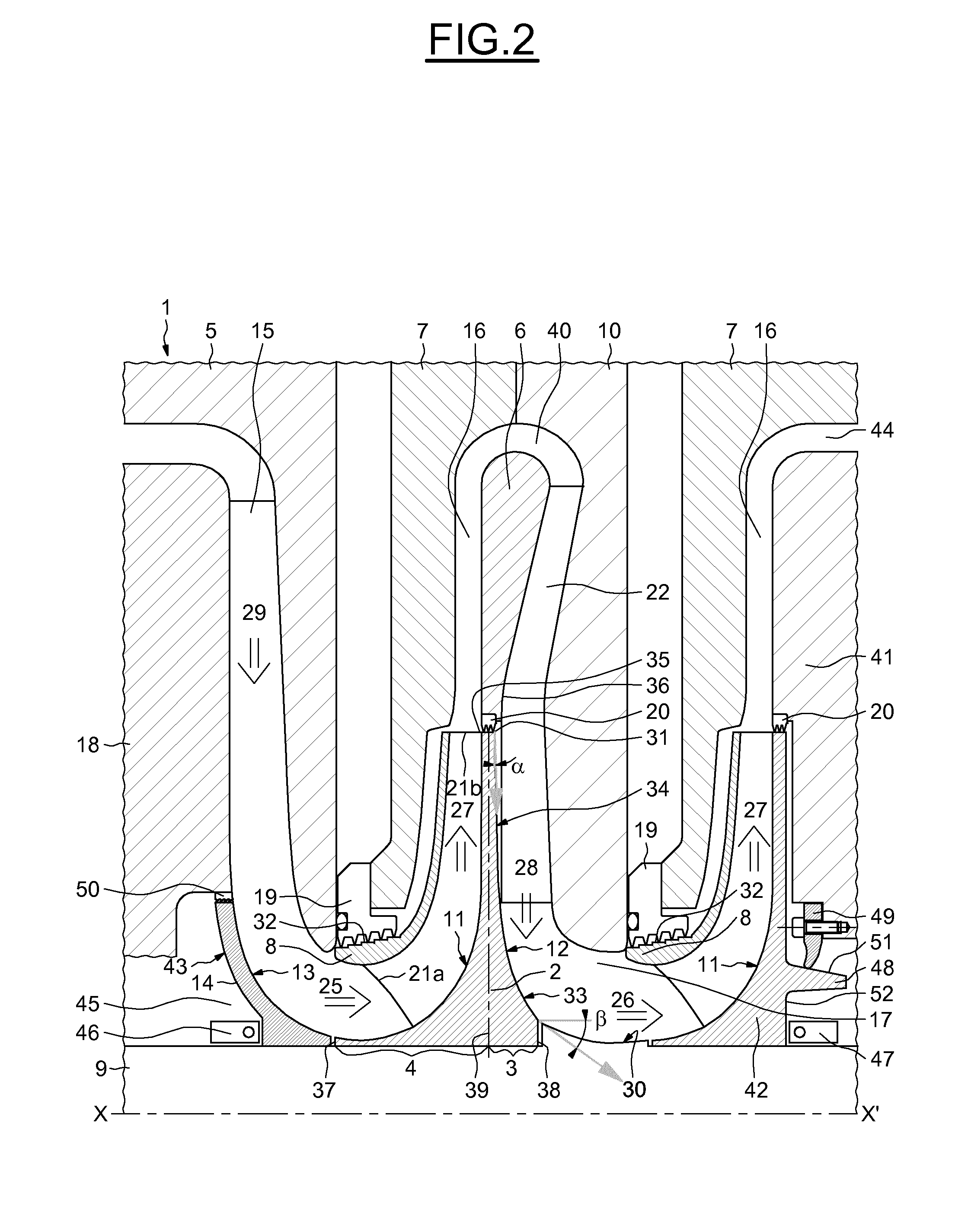

Device for generating a dynamic axial thrust to balance the overall axial thrust of a radial rotating machine

ActiveUS20160195100A1Axial force compensationShorten the lengthPump componentsBlade accessoriesImpellerAxial thrust

An impeller wheel assembly for a radial rotating machine, comprises a bladed hub portion of an impeller wheel, with a first radially outward facing, fluid deflecting surface having a curvature profile designed to deflect an axial fluid flow into a radial centrifugal flow, and comprising a deflector portion with a second radially outward facing, fluid deflecting surface. The second radially outward facing surface has a curvature profile designed to deflect a radial centripetal fluid flow into an axial fluid flow.

Owner:THERMODYN

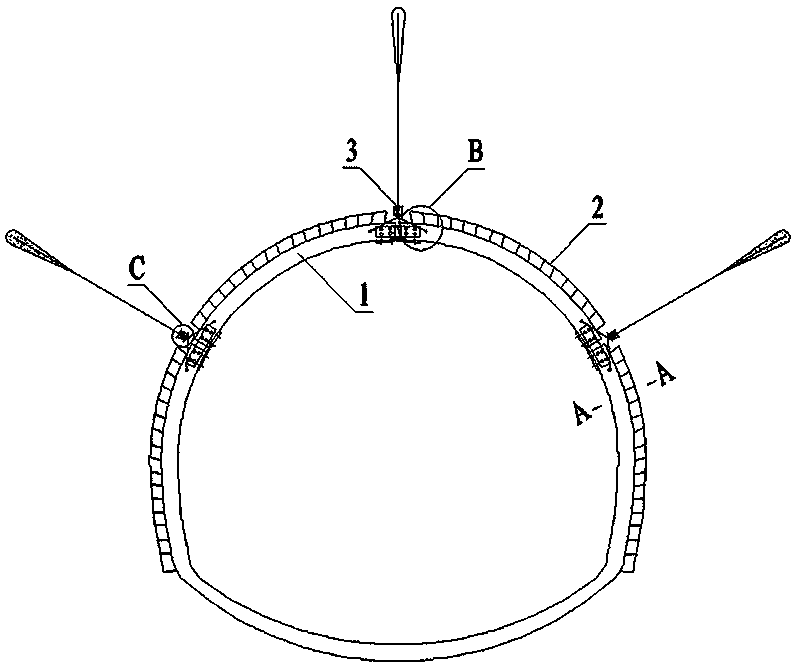

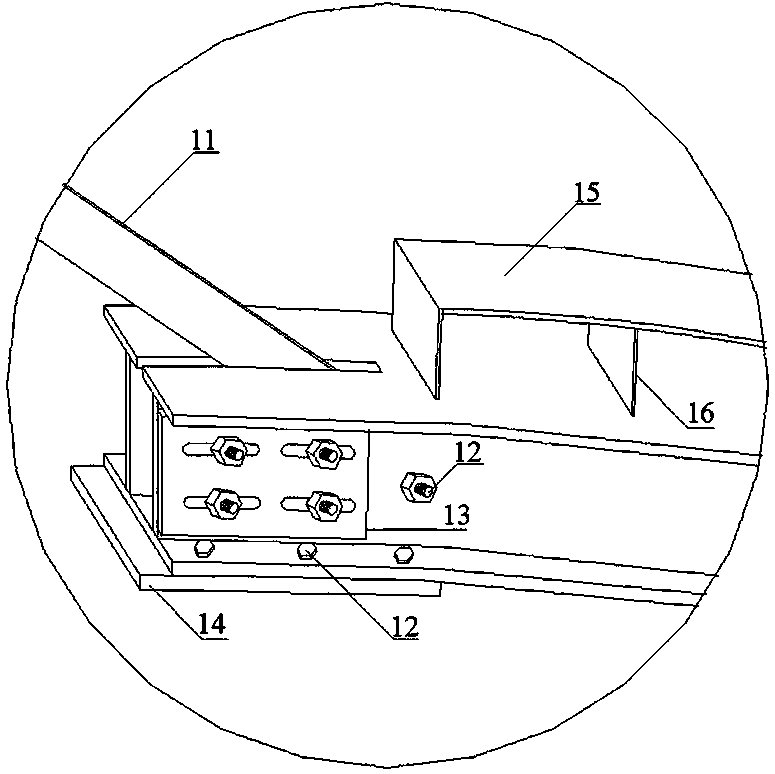

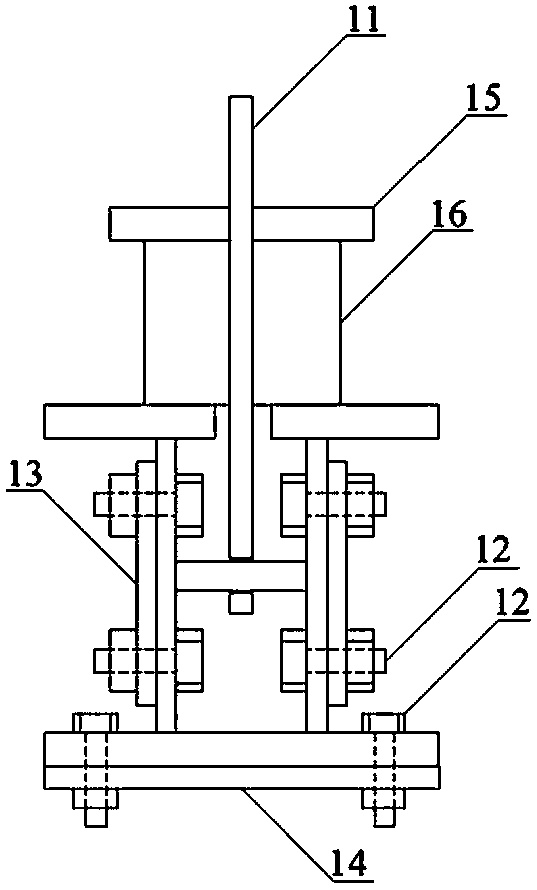

Anchor rod-steel frame integrated yielding primary support structure and construction method thereof

ActiveCN108386211AReasonable structural stressPracticalUnderground chambersTunnel liningStructural stressEngineering

The invention discloses an anchor rod-steel frame integrated yielding primary support structure and a construction method thereof, and belongs to the field of tunneling. The anchor rod-steel frame integrated yielding primary support structure comprises a steel arch frame, a buckling energy-dissipating structure, a yielding anchor rod and a force conversion rod, wherein the steel arch frame consists of two arc-shaped arch sections or more; every two adjacent arc-shaped arch sections are connected through a web connecting plate and a lower wing edge connecting plate; the buckling energy-dissipating structure is welded on the outer edge of the steel arch frame; the yielding anchor rod is arranged on a joint of every two adjacent two steel arch frames; one end of a force transmitting rod is connected with a tray on the yielding anchor rod, and the other end of the force transmitting rod is connected with the force conversion rod; and the other end of the force conversion rod is hinged in acavity formed by two webs of the steel arch frame through high-strength bolts. In a yielding process, radial force, on the support structure, of surrounding rocks is converted into circumference force, so that structural stress is more reasonable, and cooperative deformation of the surrounding rocks and the support structure is realized; and the problems that a current tunnel primary support system is twisted and deformed, and even damaged under action of high crustal stress, and the like are solved, and the deformation and damages of the surrounding rocks are effectively controlled.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Centrifuge drive head for releasably connecting a driving system to a rotor of a centrifuge, a set and a centrifuge comprising the drive head

ActiveUS9718067B2Increase axial forceOvercome disadvantagesCouplings for rigid shaftsCentrifugesCouplingEngineering

A centrifuge drive head for releasably connecting a driving system to a rotor of a centrifuge. The centrifuge drive head comprises a base body mounted for rotation about an axis of rotation (R) and at least a first and a second coupling element, mounted on the base body for swinging outwardly about a swivel axis. The first and second coupling elements differ from each other in at least one of outer shape, mass, material and / or mounting height on the base body.

Owner:THERMO ELECTRONICS LED GMBH

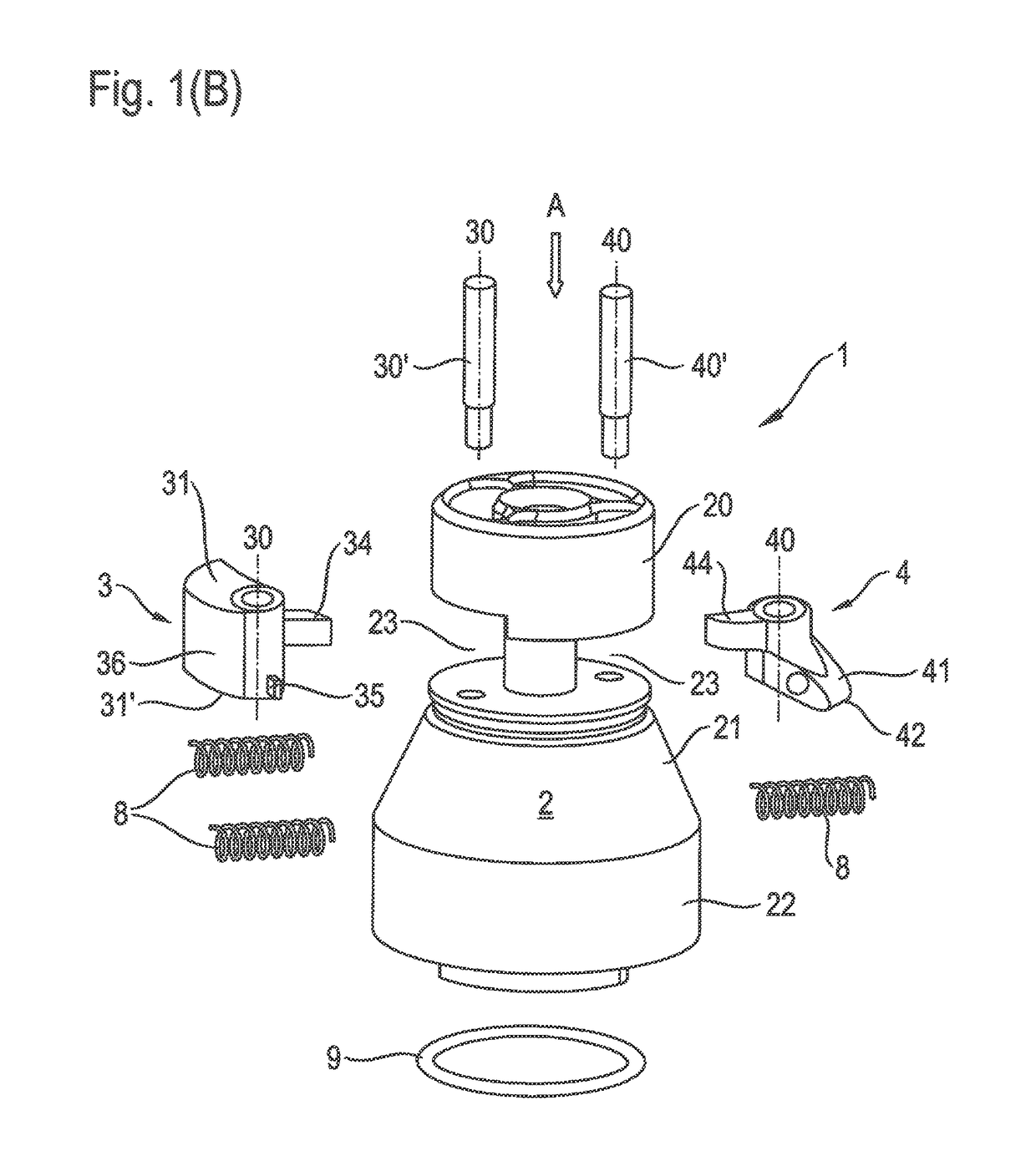

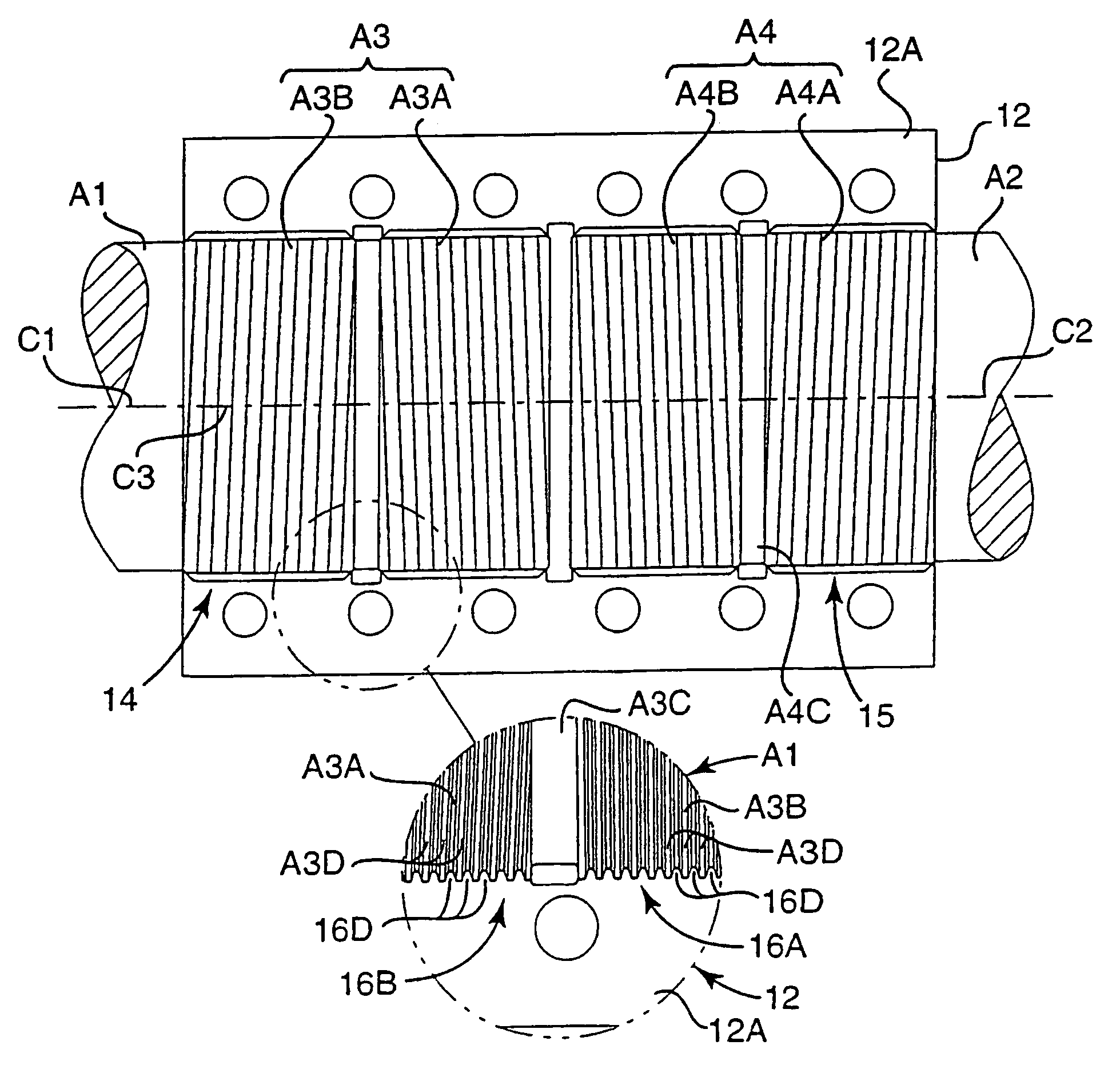

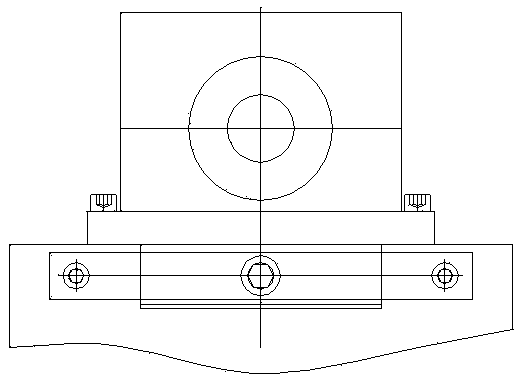

Shaft coupling

InactiveUS7118300B2Simple designReadily be dimensionedRopes and cables for vehicles/pulleyShaftsCouplingEngineering

In a shaft coupling having a pair of complementally shaped, detachably joinable coupling sleeve halves (11, 12) which can be clamped together by means of clamping elements to form a split coupling sleeve provided with at least one seat (14) for a first shaft member (A1) which is to be non-rotatably connected with a second shaft member (A2, A2′) so that the first and second shaft members are aligned. The sleeve halves include retaining elements for positively locking the first shaft member (A1) against rotational movement relative to the coupling sleeve, wherein the retaining elements include a plurality of elongate force transmitting elements (16D) in the seat (14, 15)

Owner:ROLLS ROYCE AB

Artificial root for dental implantation and method for manufacturing the same

An artificial root for dental implantation comprises a neck portion, an end portion opposite the neck portion, a body portion and a multiplex thread structure which is formed on the body portion. The multiplex thread structure comprises a first thread and a second thread in which the first thread forms a root portion with a specific first width for the second thread, which has a crest portion of a specific second width, to be accommodated into the root portion. The multiplex thread structure is partially configured in such a way that the second width of the crest portion is simultaneously increased when the first width of the root portion is gradually increased.

Owner:BIODENTA SWISS

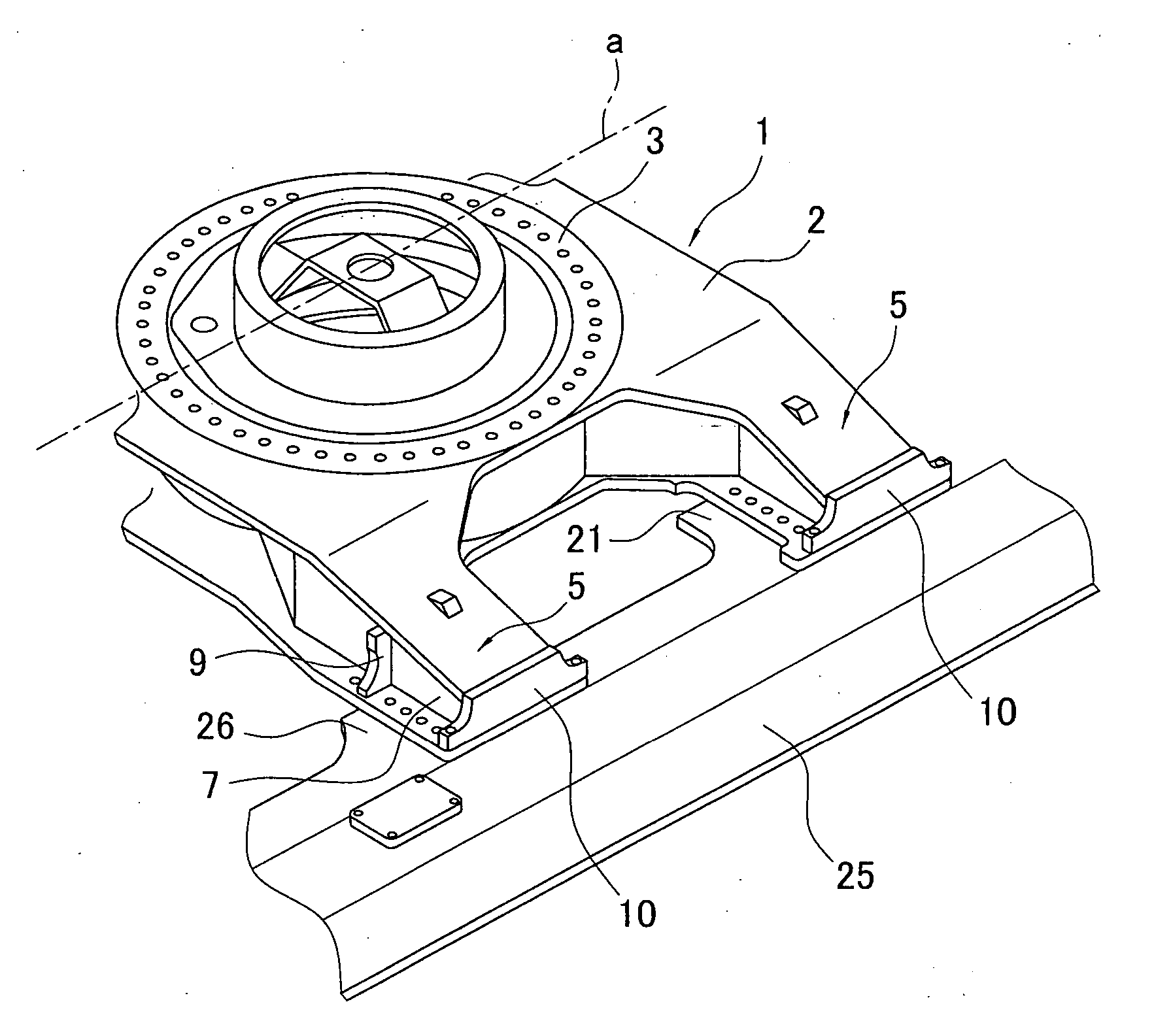

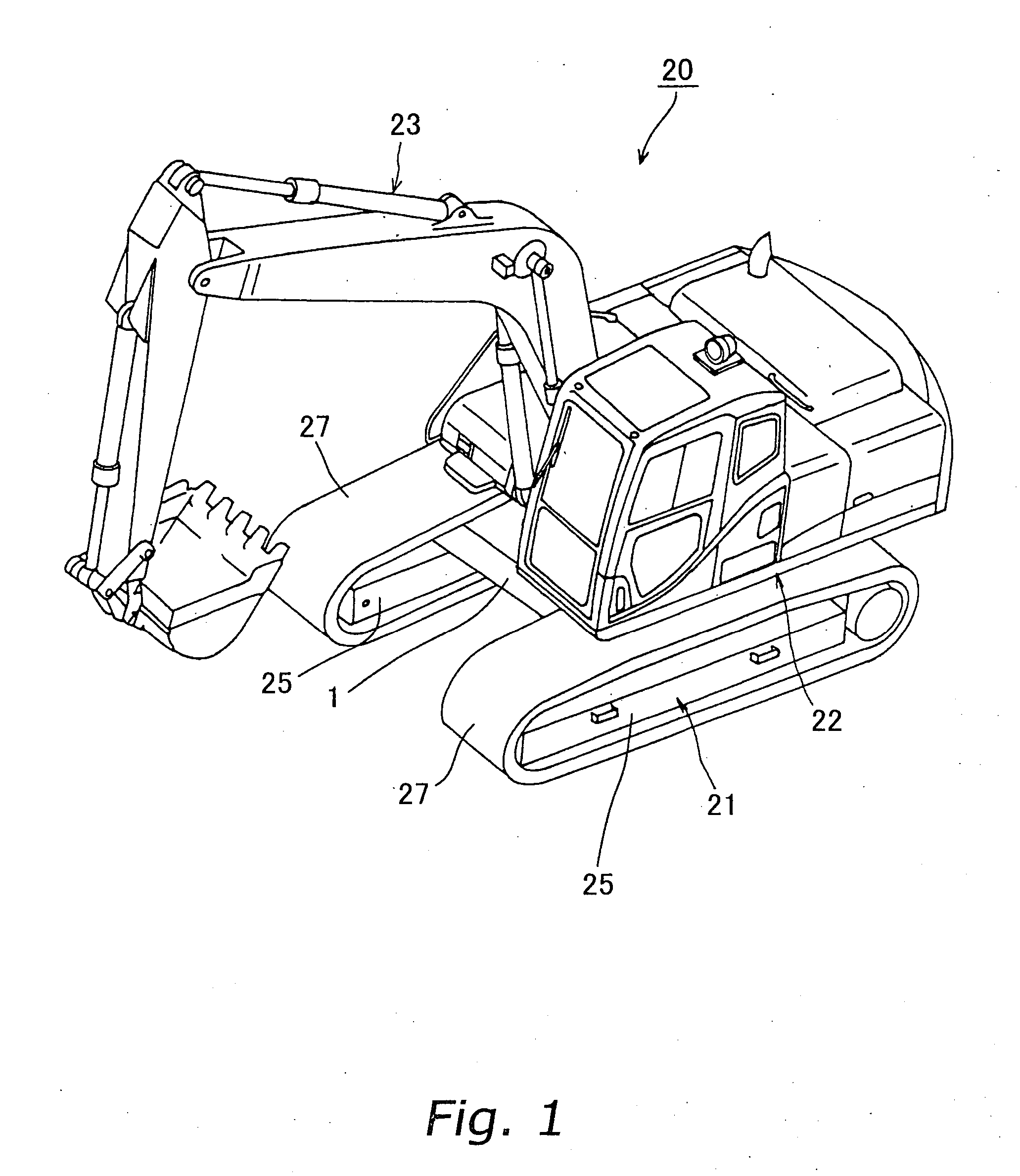

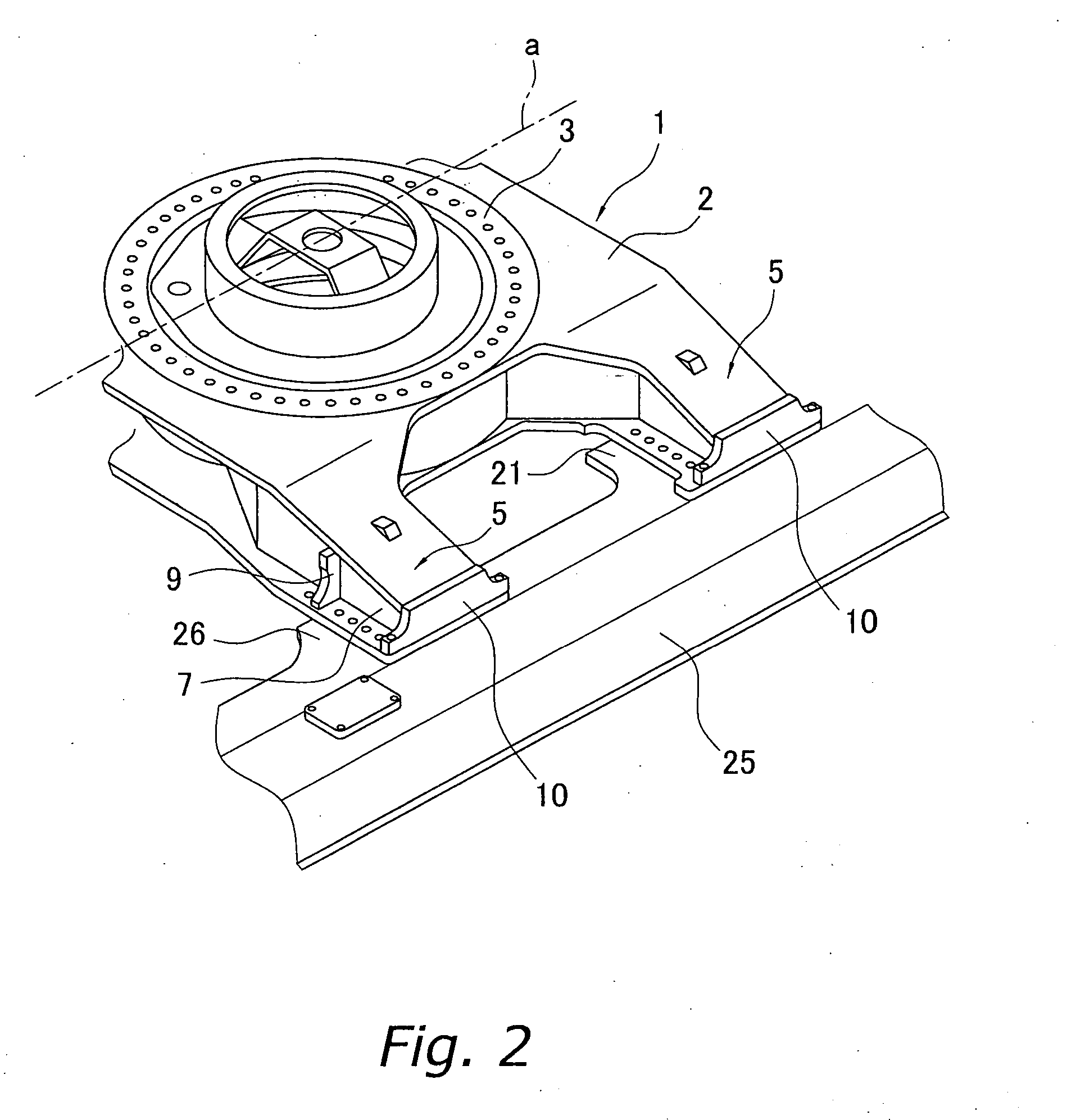

Crawler Frame Mounting Structure For Construction Machinery

ActiveUS20070290526A1Increase axial forceIncreased durabilityVehicle seatsUnderstructuresArchitectural engineeringBuilding construction

A mounting structure for a center frame and crawler frames of a base carrier of a construction machine, which can increase durability without complicating the structure is provided. A crawler frame mounting structure for a construction machine includes a center frame configured to rotatably support an upper rotating body, fastening portions for fastening the center frame to crawler frames on right and left sides by front and rear leg portions, and end plates having widths wider than the width between attachment positions of a pair of vertical plates. The end plates including tie bolt holes formed on both right and left ends are welded.

Owner:KOMATSU LTD

Anchor cable yield device capable of realizing working load visualization

An anchor cable yield device capable of realizing working load visualization comprises a pressure plate, a limiting cylinder, a yield metal column, a pressure plate and an anchor cable lock sequentially sleeved on an anchor cable. A reflective stripe group is attached to the upper portion of the outer wall of the limiting cylinder, and reflective stripes are attached to the outer wall of the pressure plate. The section, attached with the reflective stripe group, of the limiting cylinder is provided with a plurality of observation slots, the relative positions of the reflective stripes on the outer wall of the pressure plate and the reflective stripe group on the outer wall of the limiting cylinder can be observed through the observation slots, and accordingly real-time working load conditions of the anchor cable can be visually judged. By means of the anchor cable lock applying pretightening force to the anchor cable, working load of the anchor cable in yield deformation can be controlled effectively to be within the ultimate load of the anchor cable. The anchor cable yield device is simple in structure, easy for field mounting, convenient to maintain and effective in use.

Owner:CHINA UNIV OF MINING & TECH

Electrical machine

ActiveUS7465101B2High strengthExtended service lifeBelleville-type springsShaftsSpring forceEngineering

An electrical machine has a rotatably supported rotor, at least one bearing for supporting the rotor in a hub, a spring element having an axially-acting spring force which acts on the bearing and also bearing against the hub with the spring force, the spring element being configured as a disc spring functionable back and forth across a flat position of the spring element, the spring element, in an outer region, bearing against an outer ring of the bearing and, in an inner region, bearing against a hub projection, the hub projection being substantially annular in shape and having a conical spring-support surface that declines outwardly in a radial direction.

Owner:SEG AUTOMOTIVE GERMANY GMBH

Electric hand tool machine having a tool locking system

InactiveCN101204739AImprove gripIncrease axial forcePortable percussive toolsChucksHand heldEngineering

The invention relates to an electric hand tool machine (1) having a tool locking system (25), which for the purpose of unlocking has an actuating element (16) that is displaceable counter to spring action axially into an unlocking position, wherein the actuating element (16) is fixable in unlocking position by means of a bayonet catch (41).

Owner:ROBERT BOSCH GMBH

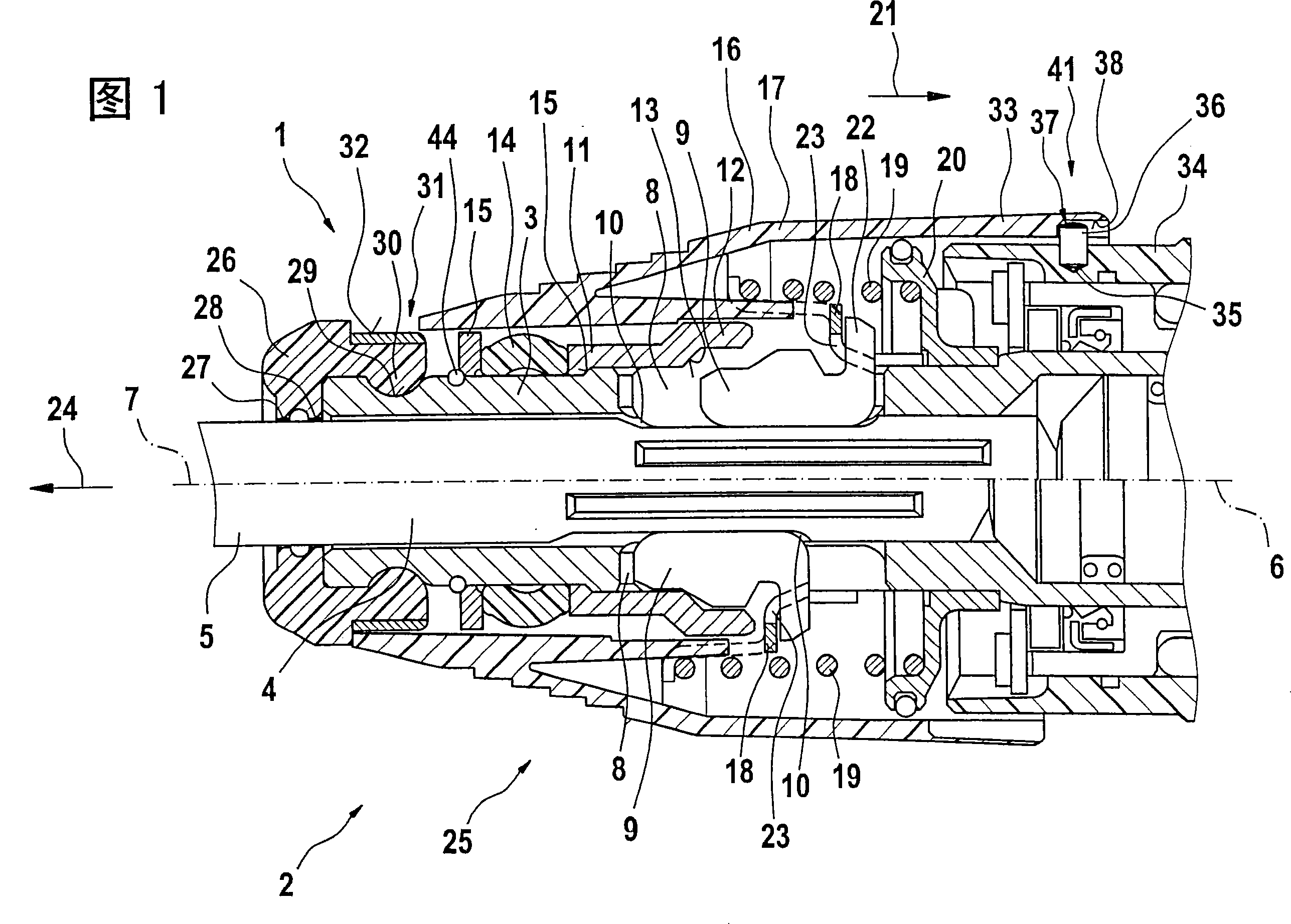

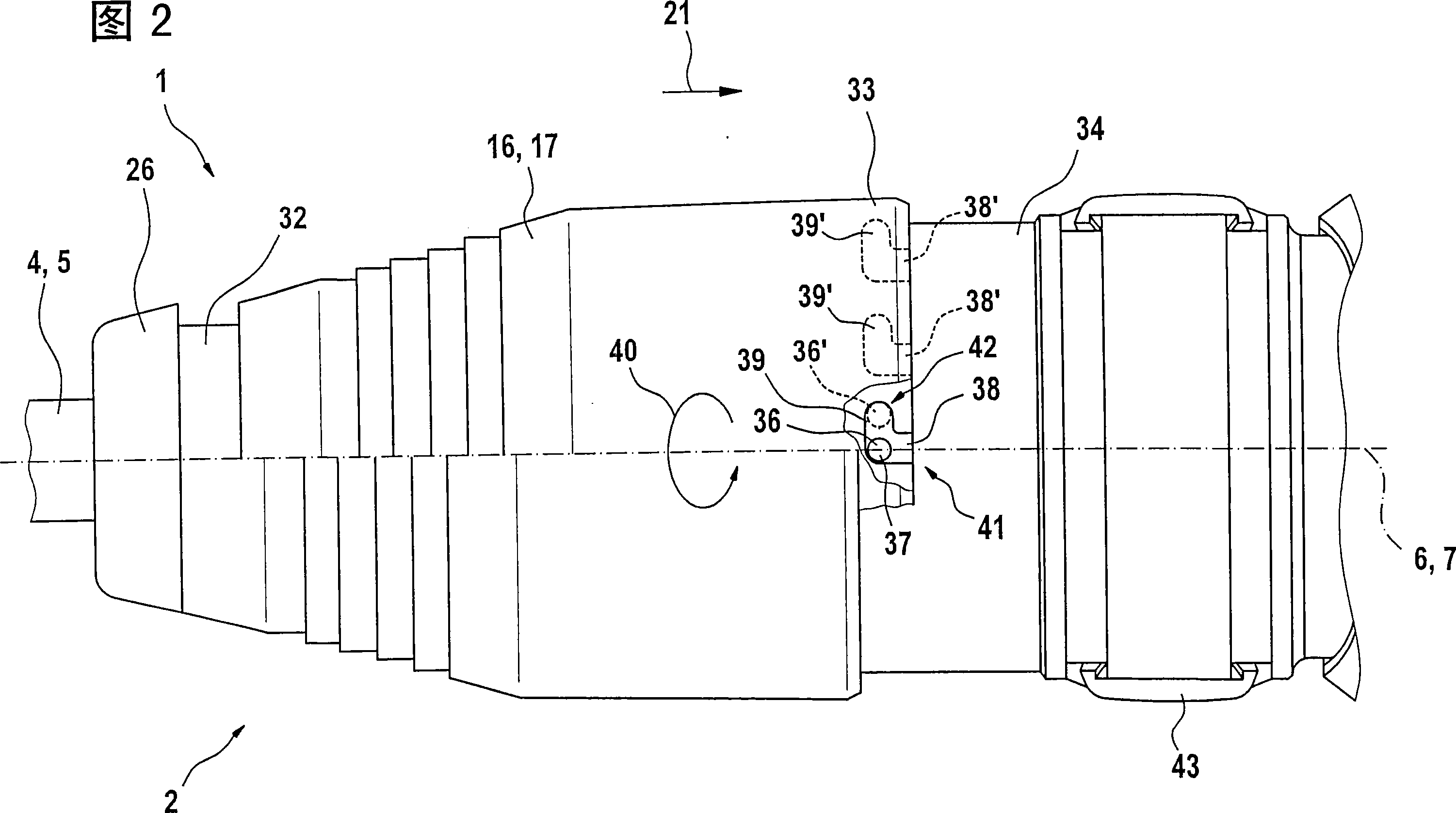

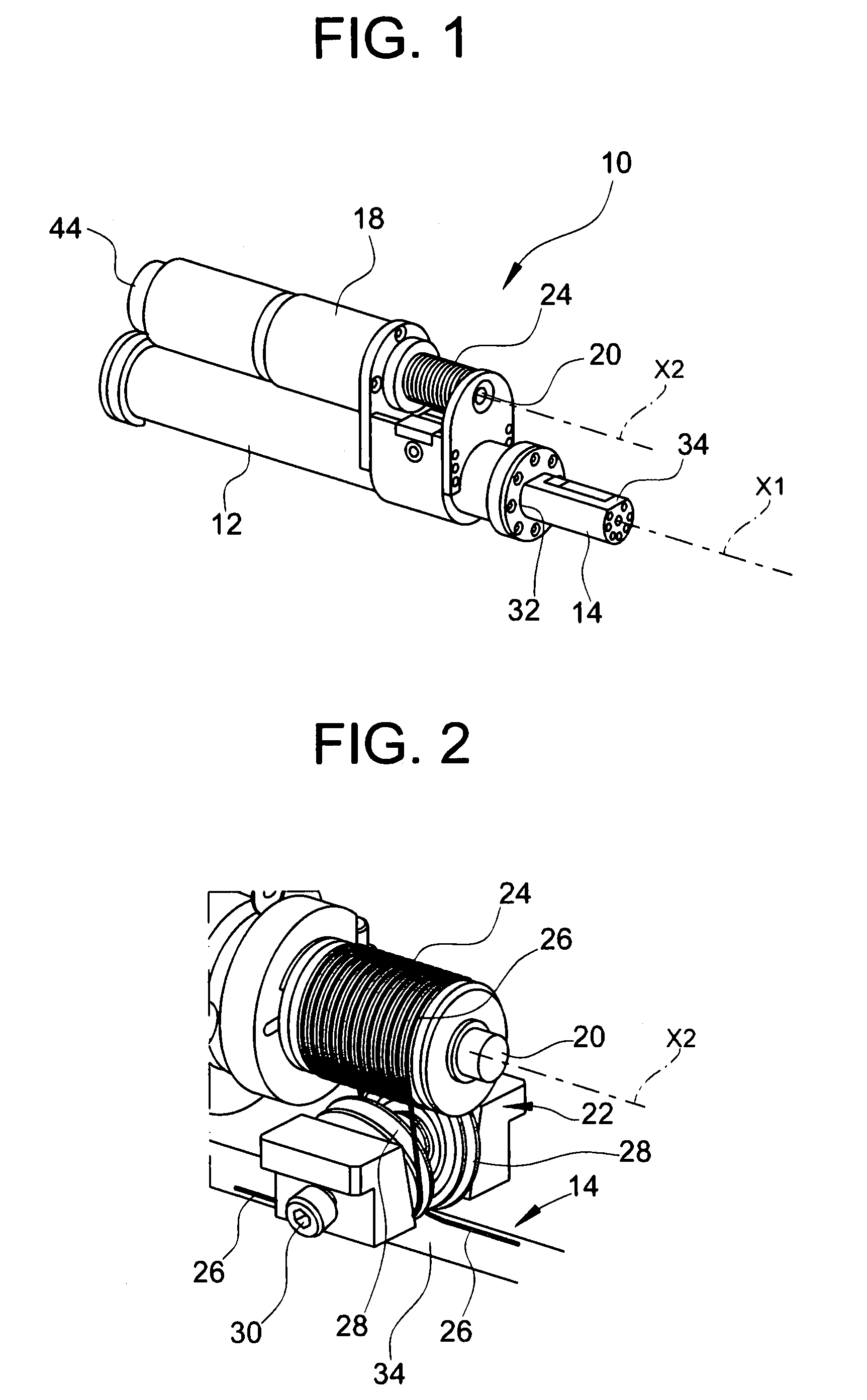

Linear actuator and rehabilitation device incorporating such an actuator

ActiveUS8986232B2Small sizeIncrease in transverse overall size of actuatorGymnastic exercisingChiropractic devicesEngineeringLinear actuator

An actuator (10) includes a body (12), an output member (14) slidably received in the body (12) along— a first axis (X1), an electric motor (18) arranged to set into rotation a motor shaft (20) about a, second axis (X2) and a motion conversion mechanism (22) for converting the rotary motion produced by the electric motor (18) about the second axis (X2) into a translational motion of the output member (14) along the first axis (X1). The motion conversion mechanism (22) includes a driving pulley (24) which is drivingly connected for rotation with the motor shaft (20) and an elongated mechanical transmission member which is wound onto the driving pulley (24) and is fastened at its two opposite ends to the output member (14) to draw this latter in either direction along the first axis (X1) as a result of the rotation of the driving pulley (24) in either direction. The output member (14) is shaped as a rod and is received in a cylindrical cavity (16) of the body (12) so as to project partially therefrom. The elongated mechanical transmission member (2S) is fastened to the output member (14) at axially opposite points of this latter with respect to the driving pulley (24).

Owner:FOND INST ITAL DI TECH

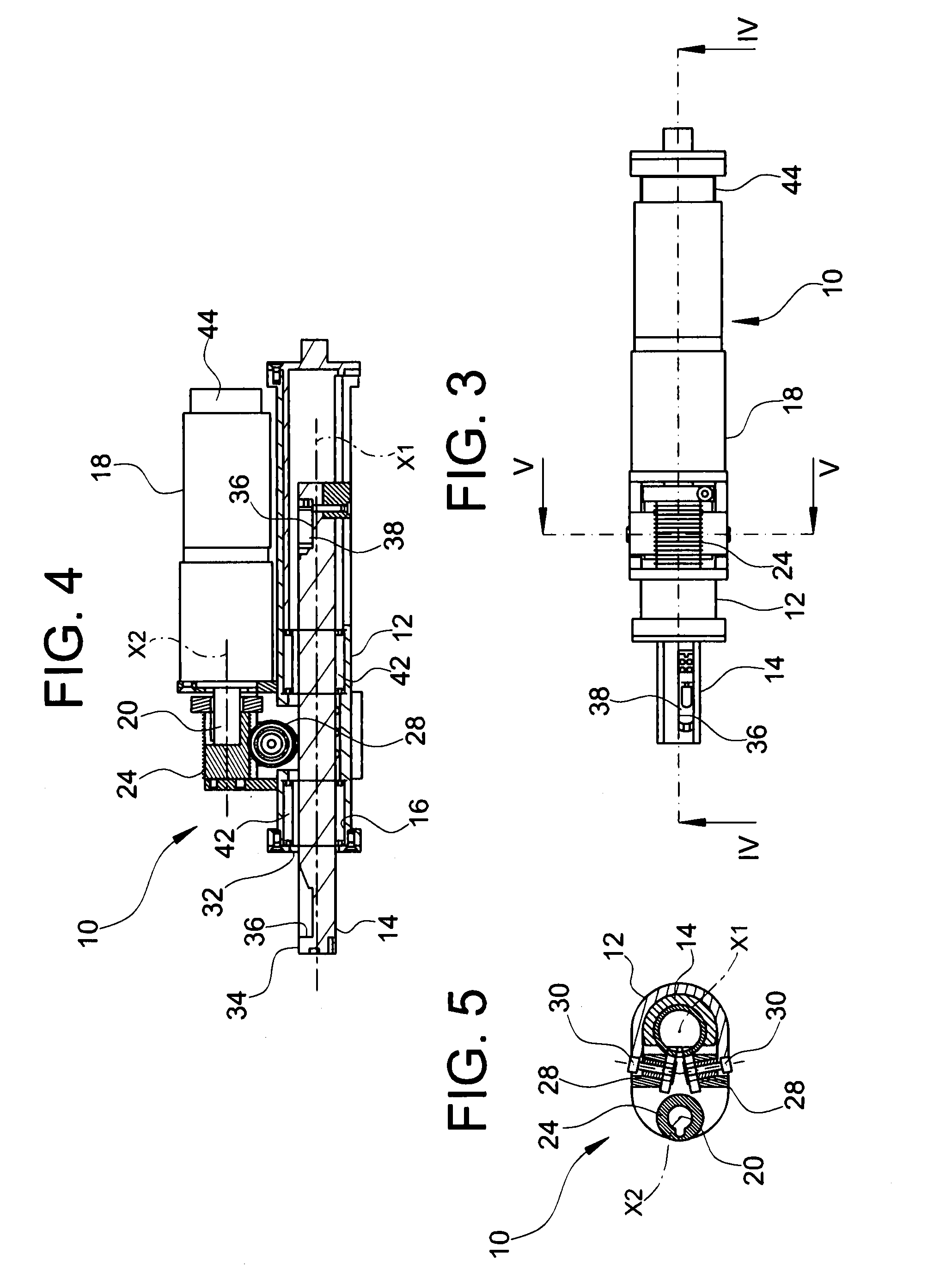

Axial pre-tightening device of ball screw

ActiveCN103433796AHigh precisionHigh adjustment accuracyFeeding apparatusMaintainance and safety accessoriesLinear motionBall screw

The invention provides an axial pre-tightening device of a ball screw. The device comprises a machine tool body, the front end of the machine tool body is provided with a servo motor bearing base, the rear end of the machine tool body is provided with a rear bearing base, a ball screw pair, a pressing nut, a bearing gland and a bearing assembly are arranged in the servo motor bearing base, a protruding guide tenon is arranged on the servo motor bearing base, a guide groove is formed in the position, corresponding to the servo motor bearing base, of the machine tool body, the guide tenon is matched with the guide groove, an adjusting screw rod is arranged in the guide tenon, the adjusting screw rod is connected with a fixing plate on the machine tool body, a boss is arranged on the position, corresponding to the rear bearing base, of the machine tool body, and the boss is in contact with the rear bearing base. After clearance fit of bearings, by means of displacement adjustment of the bearing bases, axial stretching and pre-tightening of the ball screw of a machine tool transmission system are achieved, adjustment precision is improved, axial force is increased, linear motion precision and dynamic response precision of the ball screw are greatly improved, and operation in assembly is facilitated.

Owner:烟台海德智能装备有限公司

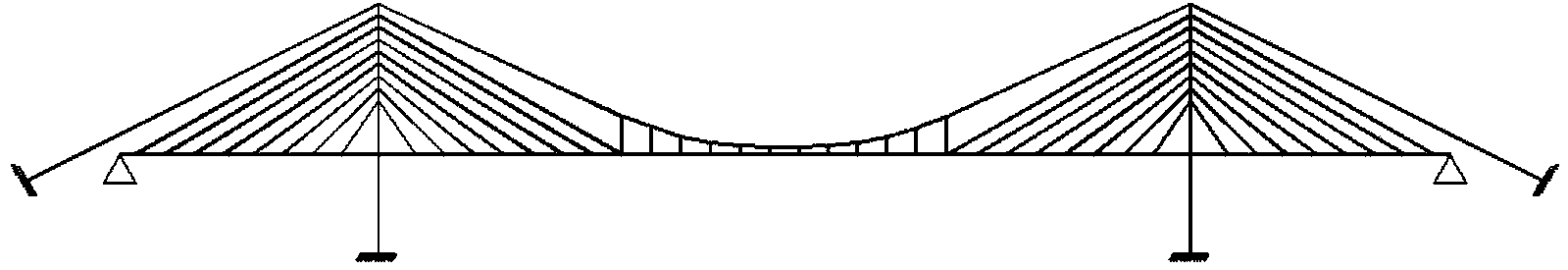

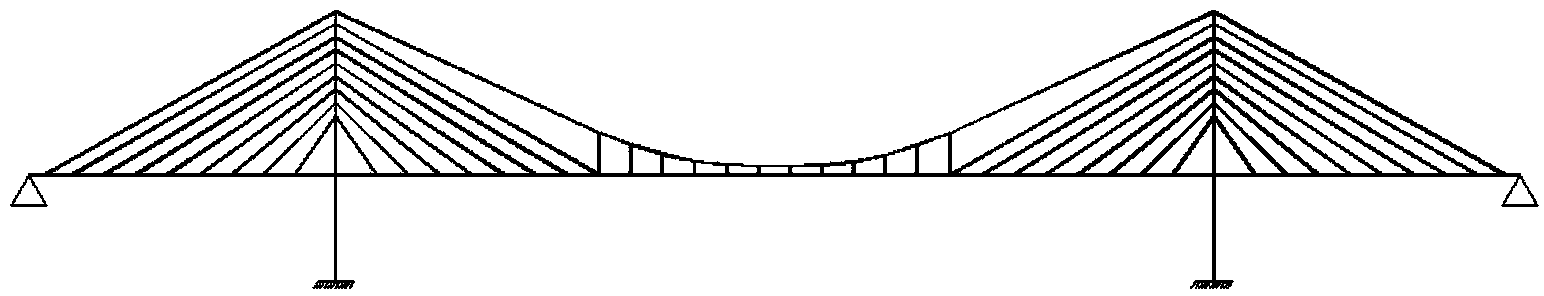

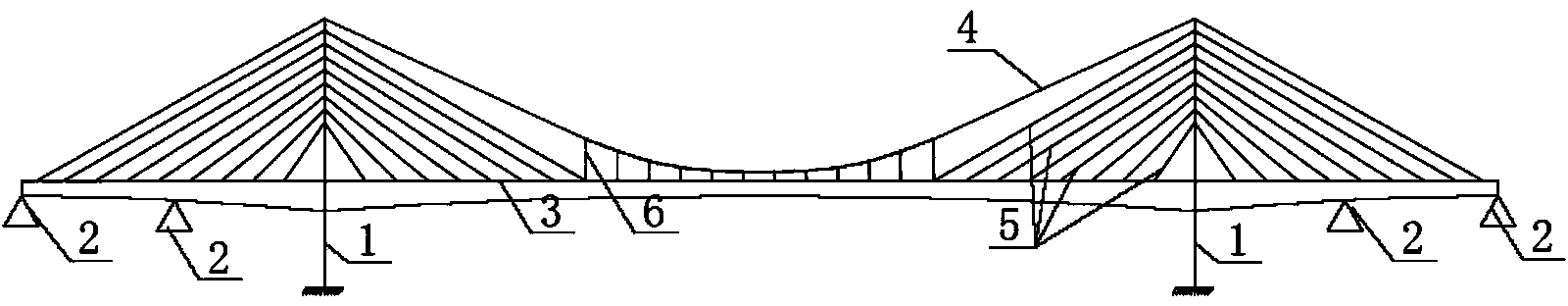

Self-anchoring suspension cable and stay cable cooperative system bridge with girder having variable cross-section

The invention discloses a self-anchoring suspension cable and stay cable cooperative system bridge with a girder having a variable cross-section. The self-anchoring suspension cable and stay cable cooperative system bridge comprises a main tower, a sidespan bridge pier, a girder, a main cable, stay cables and suspenders; the girder is supported by the main tower, the sidespan bridge pier, the main cable and the stay cables; the middle part of the girder is connected to the main cable by the suspenders, and the section height of the girder is gradually varied; the section height of the girder at the root of the main tower is the maximum, and the section heights at the middle point of the girder and the two ends of the girder are the minimum; the section height curve of the girder is symmetrical with respect to the vertical central line of the girder. According to the self-anchoring suspension cable and stay cable cooperative system bridge with the girder having the variable cross-section, through increasing rigidity of the girder, part of girder weight is directly delivered to the root of the main tower by the girder, part of bridge load is delivered to the main tower by the girder, axial force of the girder cable bearing structure delivered to the girder can be reduced, and pressure stress generated by the axial force can be reduced by increasing the section of the girder, thus being capable of avoiding risks of ultralimit of carrying capacity and buckling failure of the girder.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com