Brake disk

A technology for brake discs and motor vehicles, applied in the direction of brake discs, brake types, brake components, etc., can solve the problems of high manufacturing cost, no clearance space for compensation, etc., to ensure additional fixation and avoid end face swing/ Axial runout, the effect of ensuring elastic-plastic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

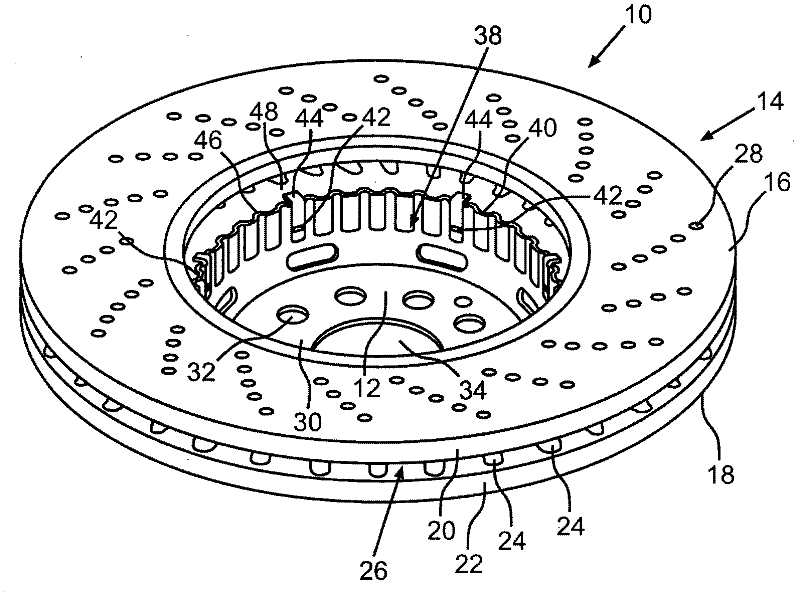

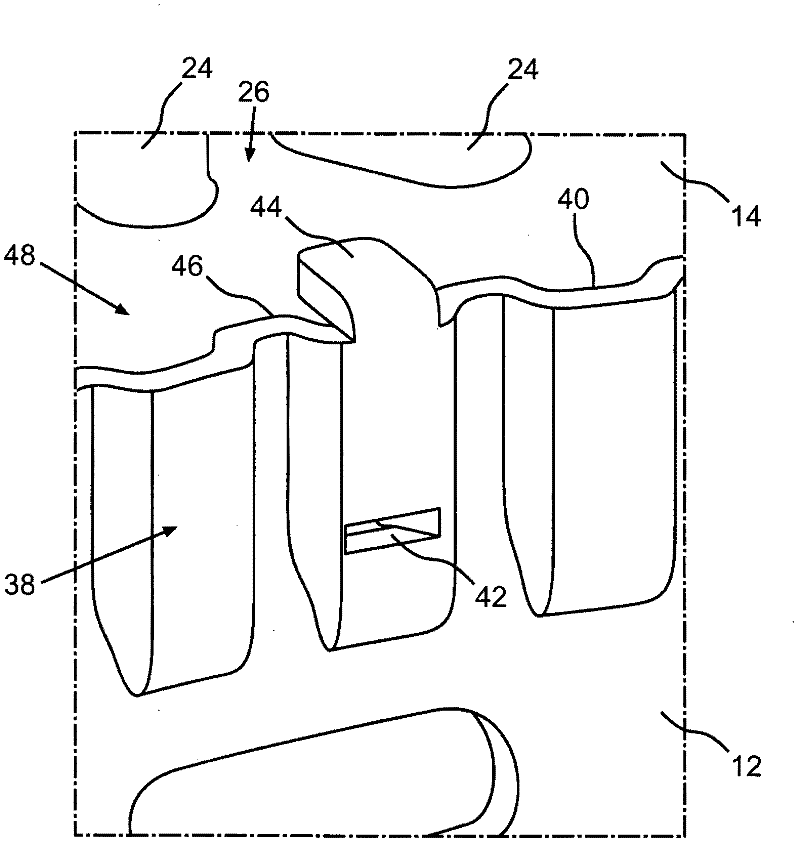

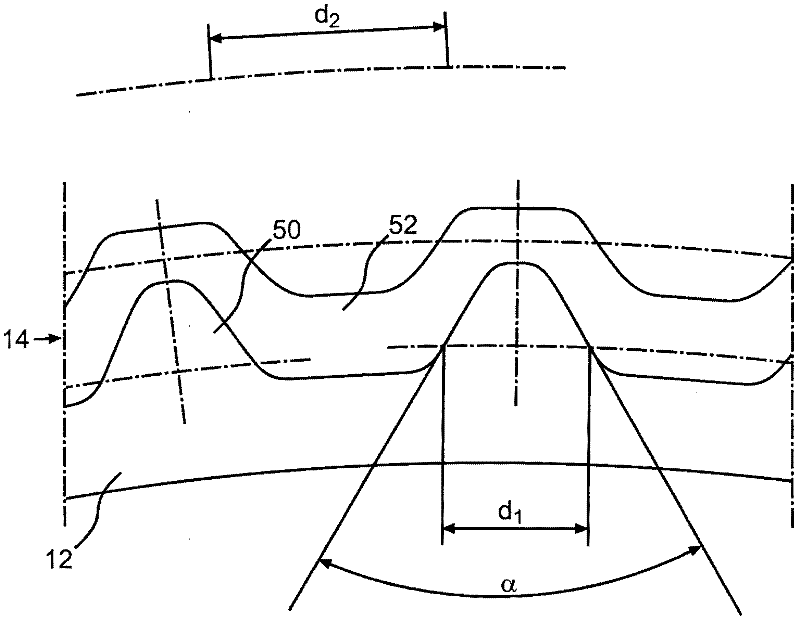

[0024] The brake disc designated by 10 as a whole includes a brake disc hub 12 and a friction ring 14. The friction ring includes two friction surfaces 16, 18 that are in frictional contact with the brake pads when the brake is running. In order to (achieve) particularly good friction properties, such friction rings 14 are usually made of cast iron, especially gray cast iron. In order to dissipate the heat generated during braking operation, the friction ring 14 is made as an internally ventilated friction ring and has two friction ring halves 20, 22, which are connected to each other by connecting protrusions 24, for clarity Not all connecting bumps are shown. Thus, a channel 26 is formed between the friction ring halves 20, 22, through which the ambient air can flow, so that heat can be dissipated. In addition, channels 28 are formed in the friction ring halves 20 and 22 respectively, and the channels 28 open into the channel 26 and pass through the friction surfaces 16 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com