Halbach permanent magnetic bearing obtained by lap piling of permanent magnetic rings having triangular sections

A permanent magnet bearing and permanent magnet ring technology, applied in the fields of machinery and mechanics, can solve the problems of electromagnetic and superconducting magnetic bearing power consumption, complex structure, friction loss, etc., to save permanent magnet materials, reduce maintenance costs, and adapt to the environment. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

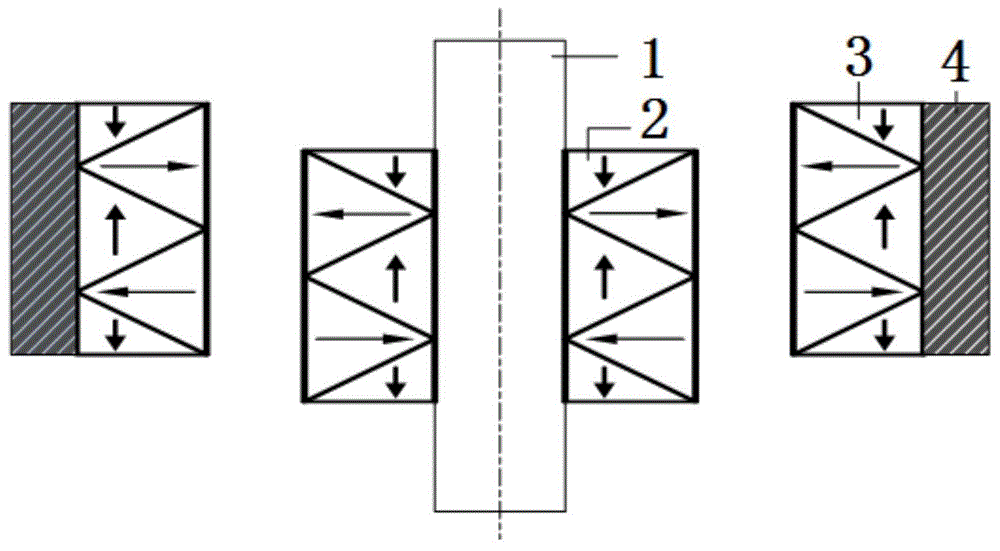

[0023] refer to figure 1 , the present invention adopts the structure of the Halbach permanent magnet bearing stacked with triangular cross-section permanent magnet rings, including the rotor 1 and the stator 4 which are arranged correspondingly, and a plurality of groups of moving magnet rings 2 are stacked on the shaft circumference of the rotor 1, and inside the stator 4 Multiple sets of static magnetic rings 3 are stacked on the circular surface, multiple sets of moving magnetic rings 2 and multiple sets of static magnetic rings 3 are respectively stacked to form a cylindrical shape.

[0024] The rotating shaft 1 and the stator 4 are made of iron and steel, and the moving magnetic ring 2 fixed on the rotating shaft 1 and the static magnetic ring 3 fixed on the stator 4 are made of permanent magnetic materials. Both the moving magnet ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com