Patents

Literature

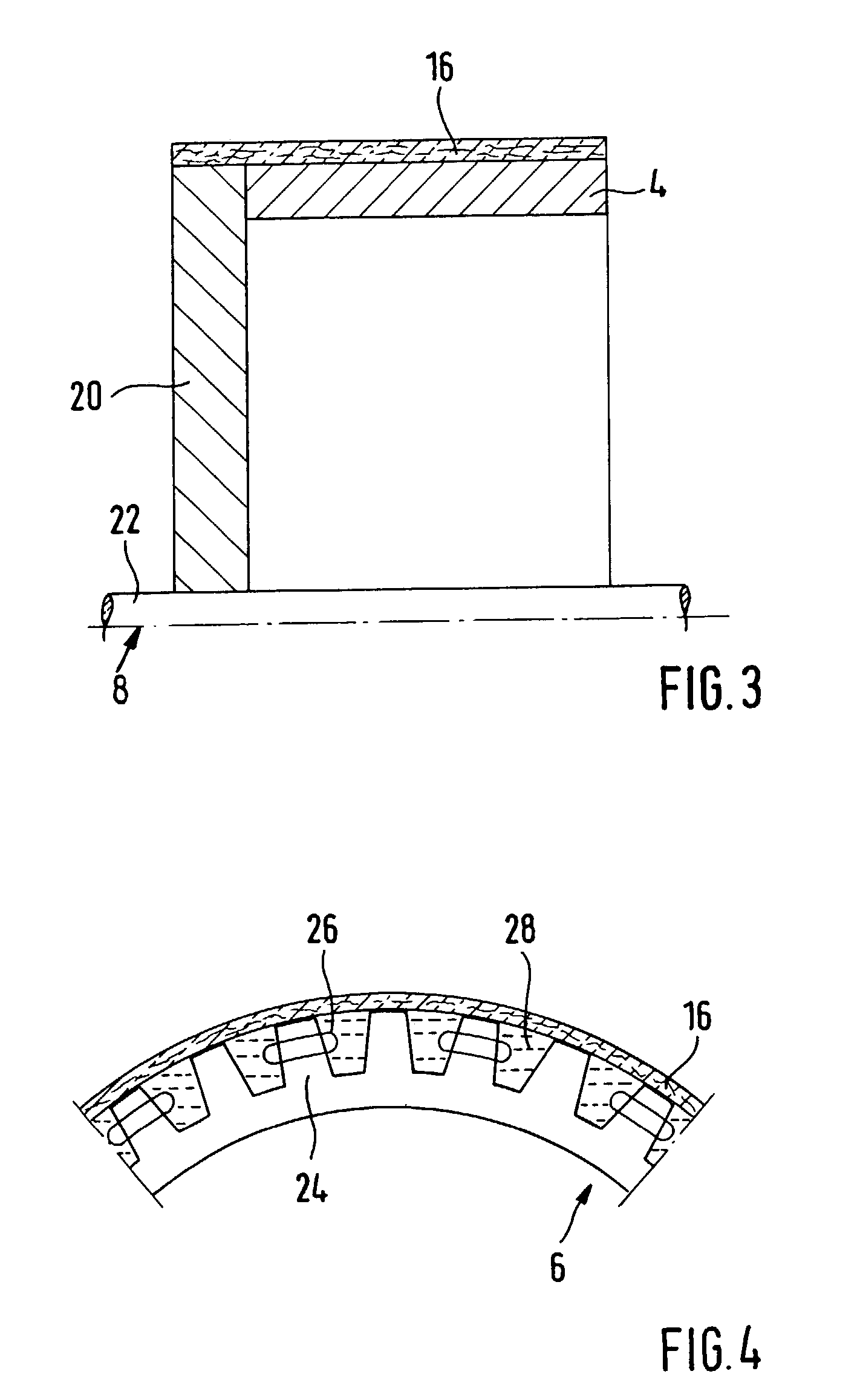

78results about How to "Increase radial force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

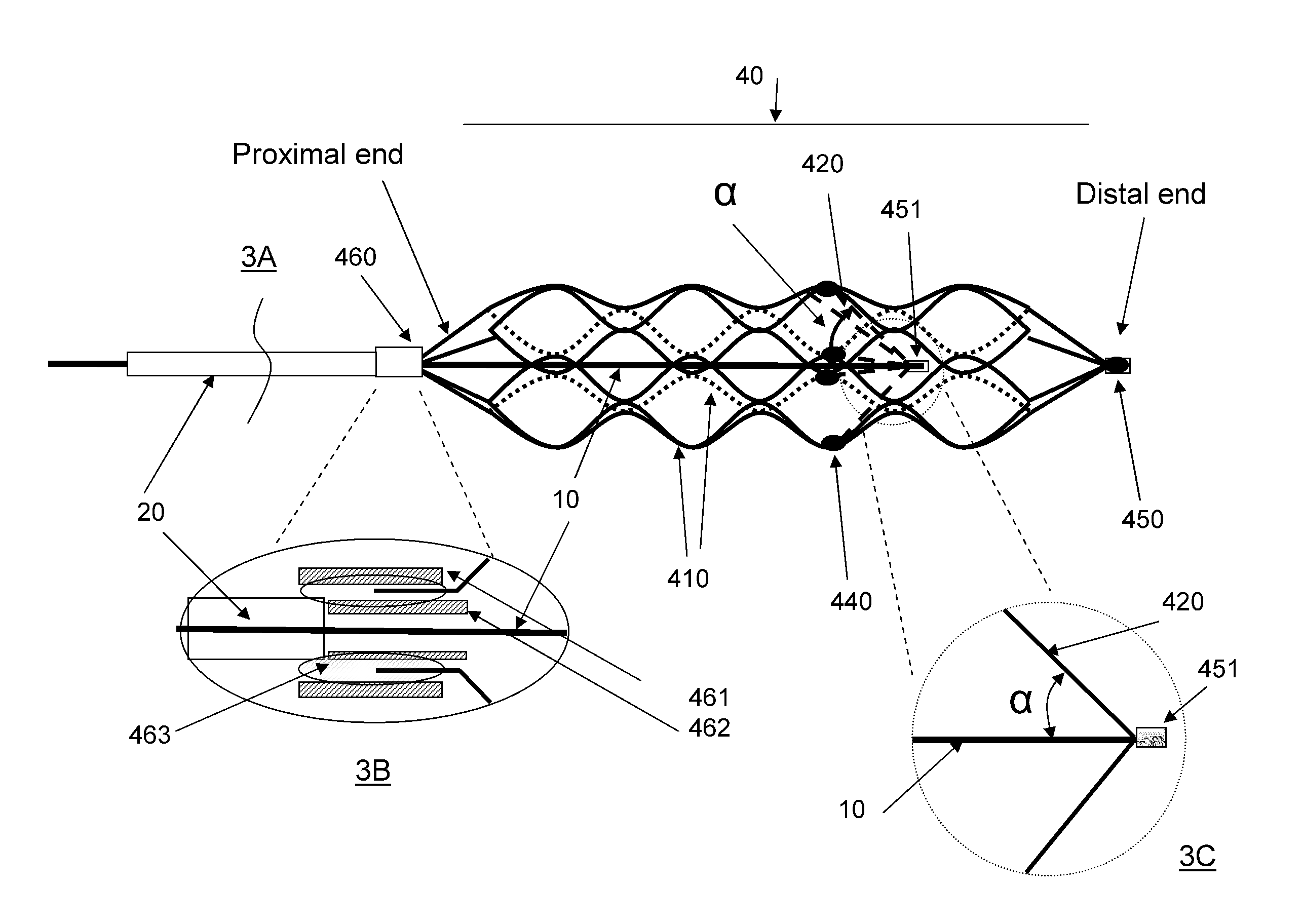

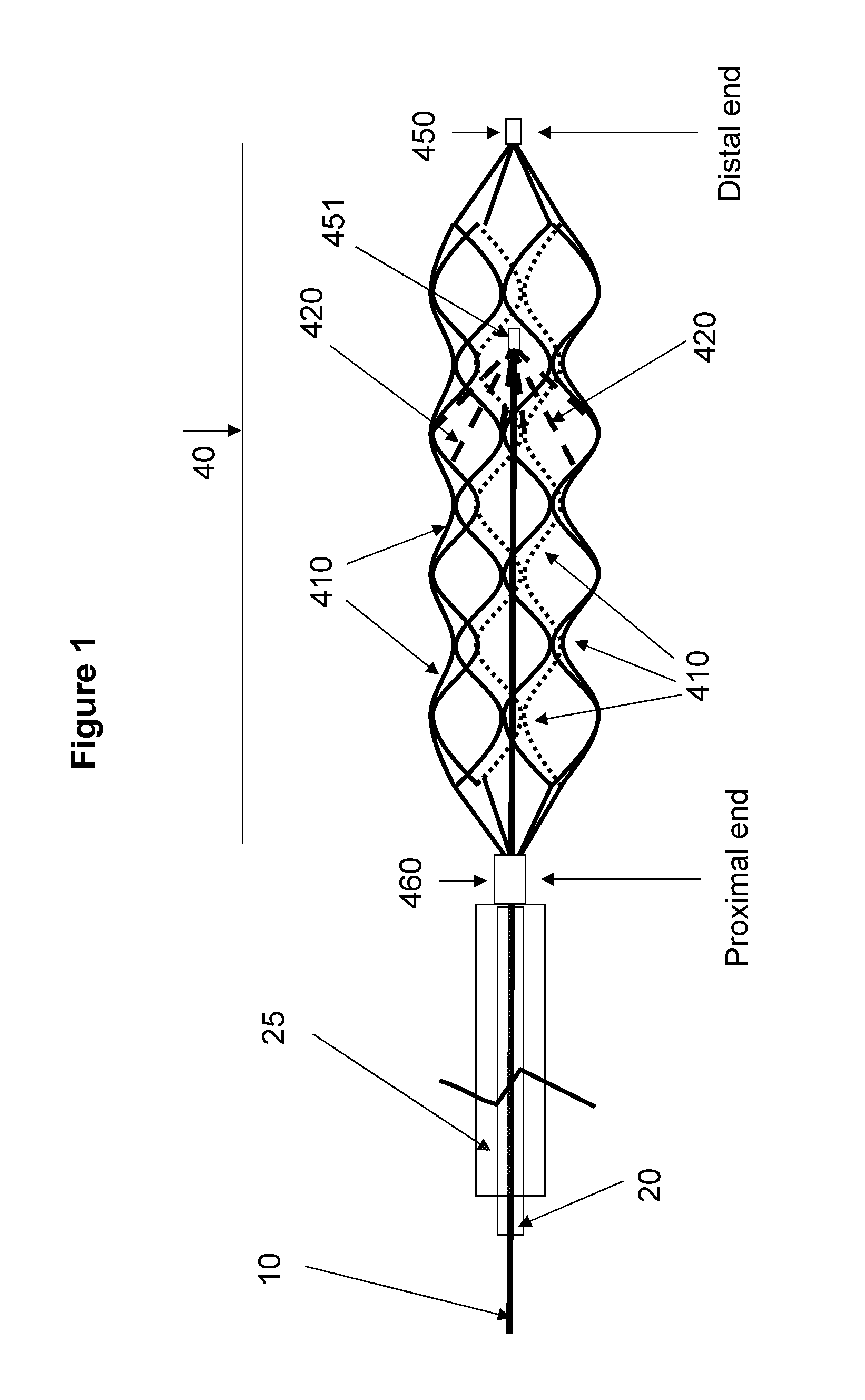

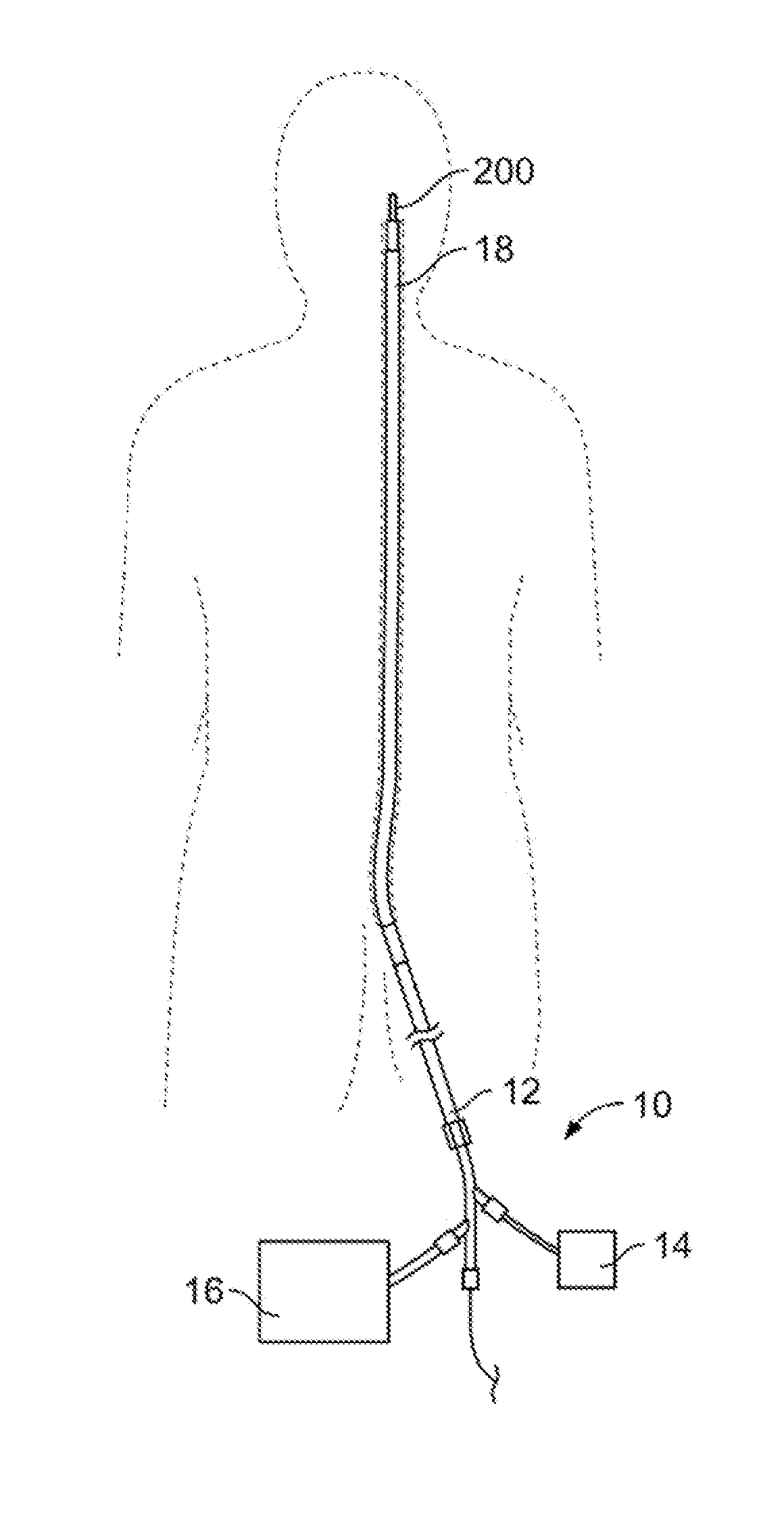

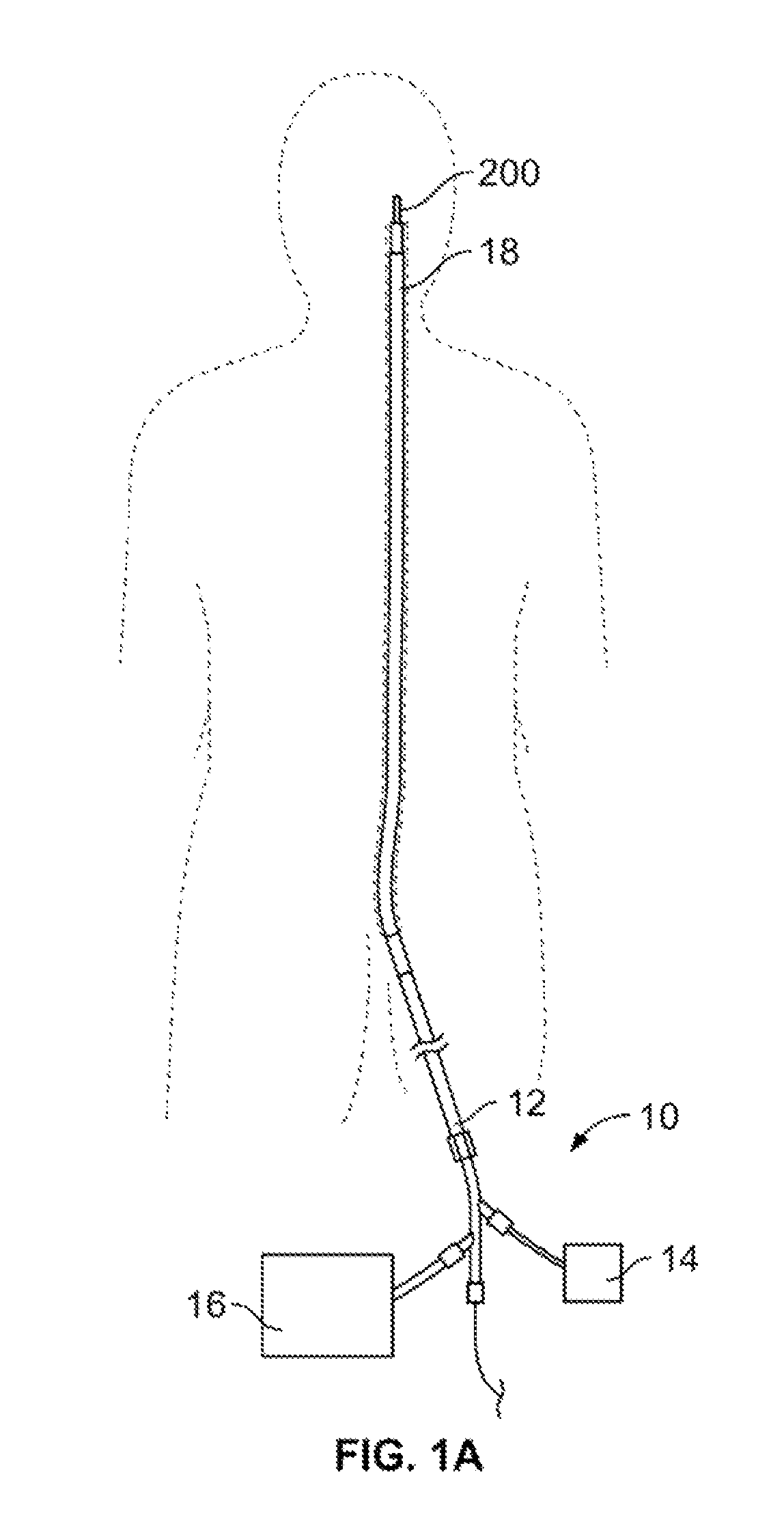

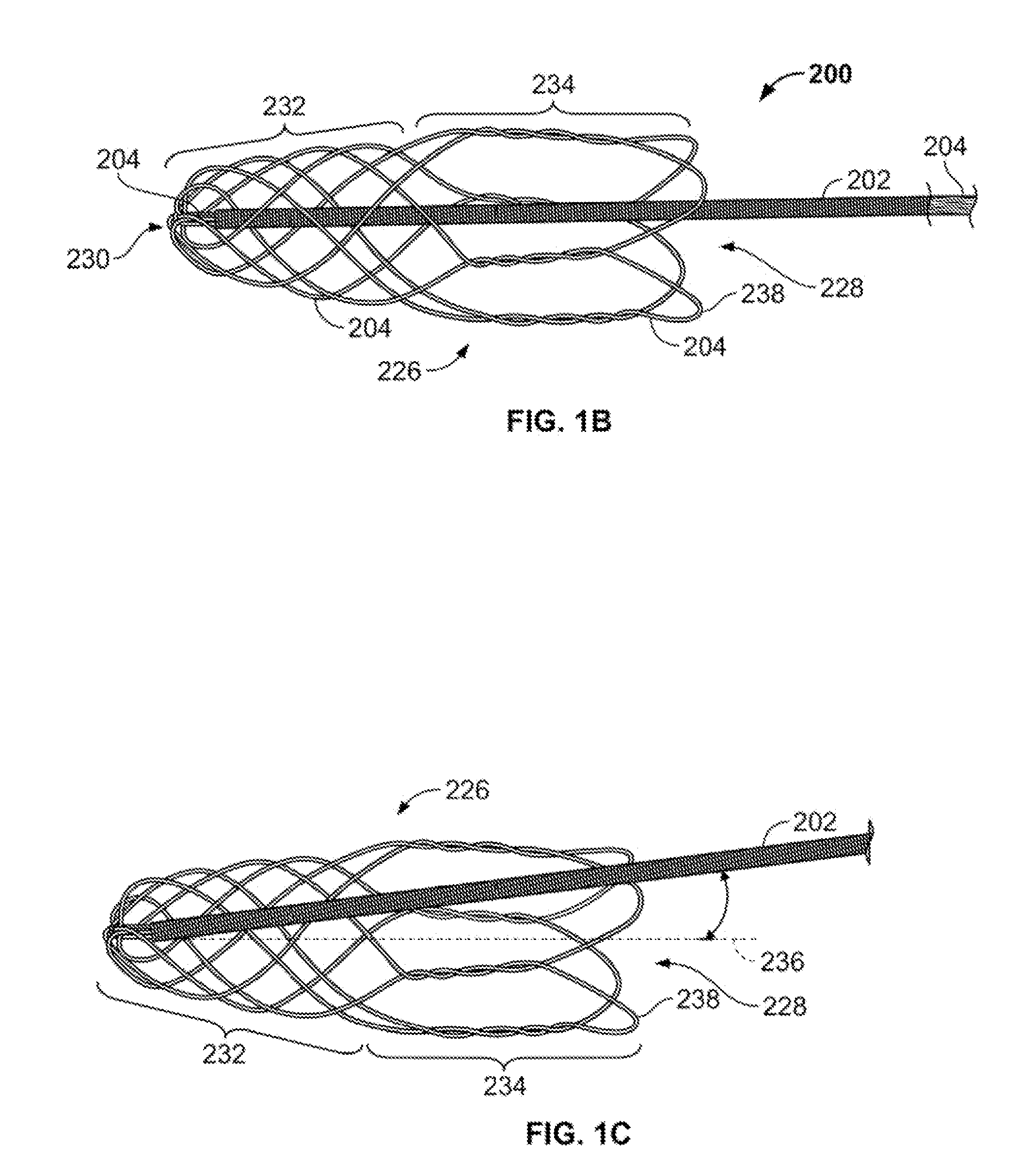

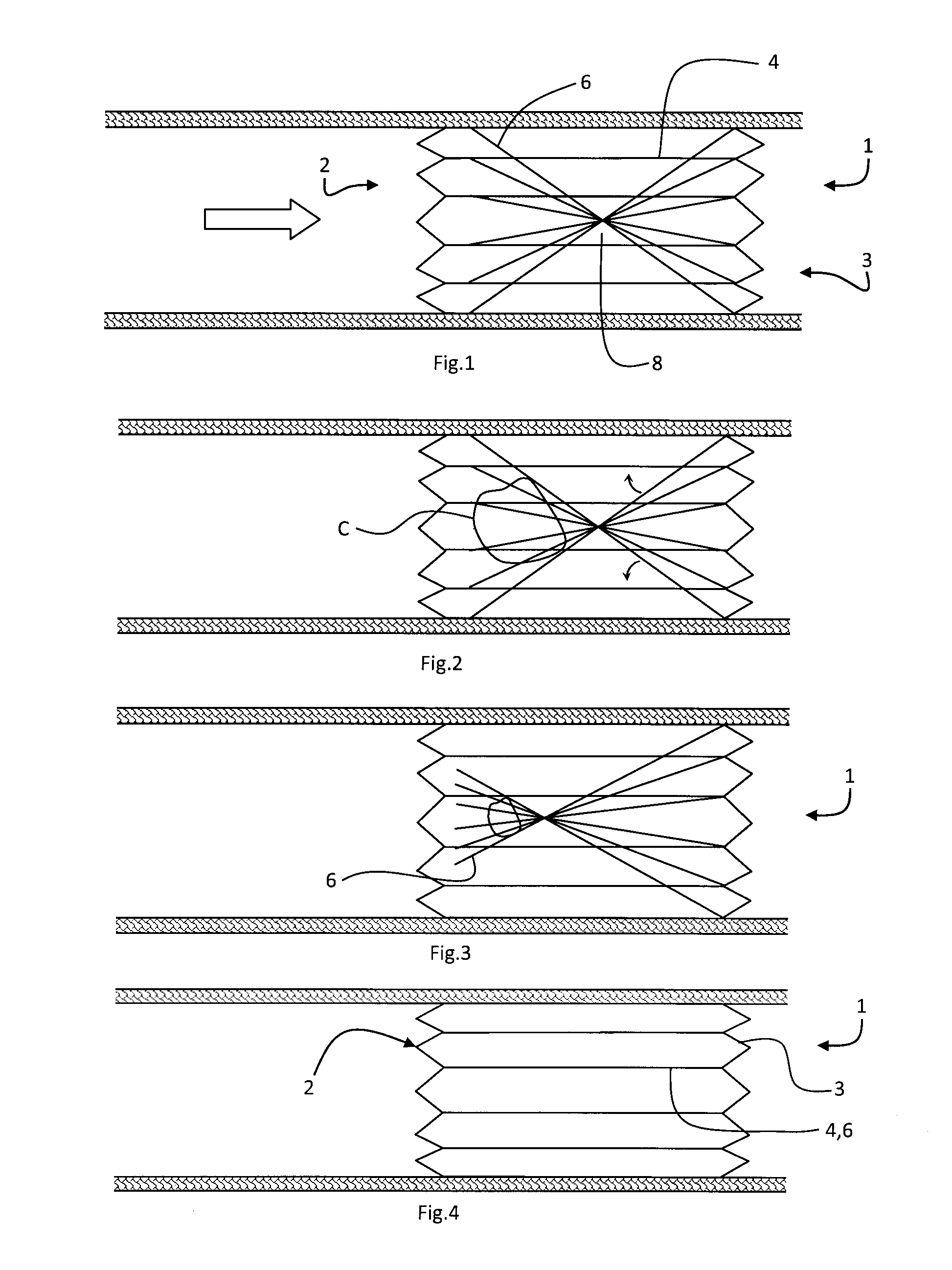

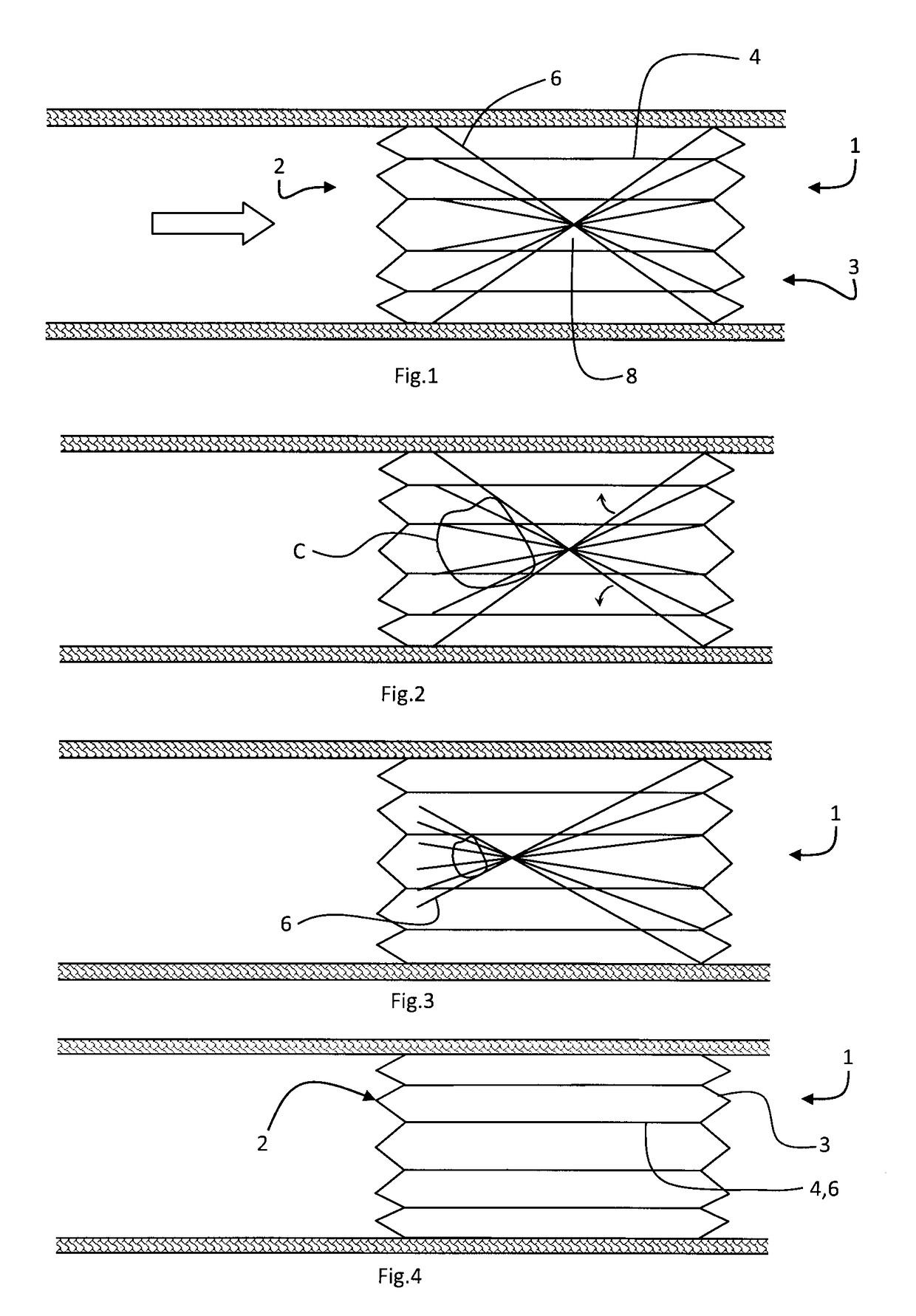

Intravascular thromboembolectomy device and method using the same

A device and a method for increasing or restoring a flow in a body lumen are provided. The device and the method may treat conditions related to a stroke, such as an ischemic stroke, by removing an occlusion from a blood vessel and / or reopen a blood vessel. The device may comprise a pusher tube and an expandable compartment. The expandable compartment may comprise a control element, a reconfigurable element, and supportive element. The supportive element is configured to adjust a radial force and a configuration of the reconfigurable element, thereby allowing highly efficient removal of an occlusion from a blood vessel and / or reopen a blood vessel with least or no damage to the body lumen.

Owner:LIKEMARK MEDICAL

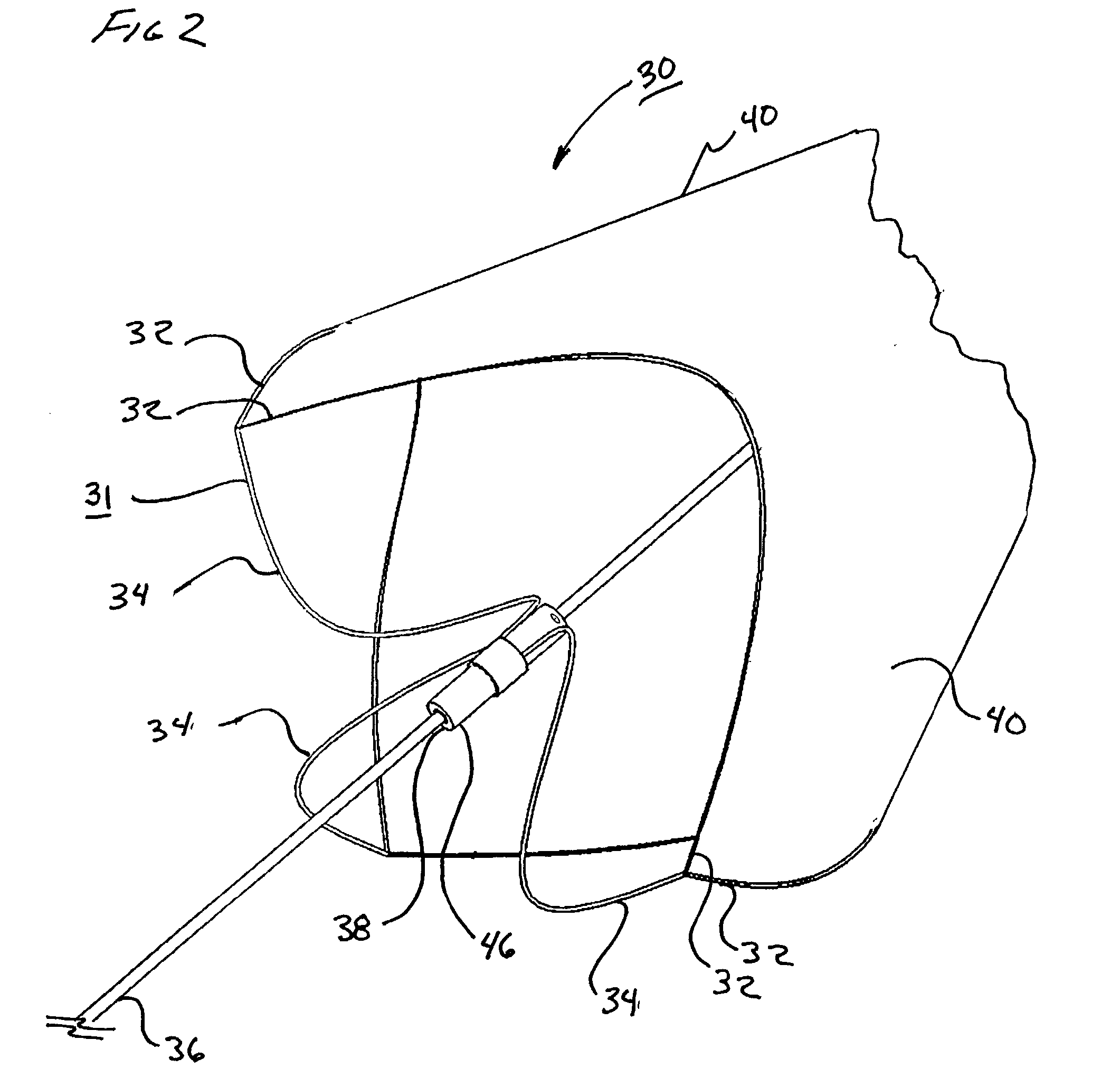

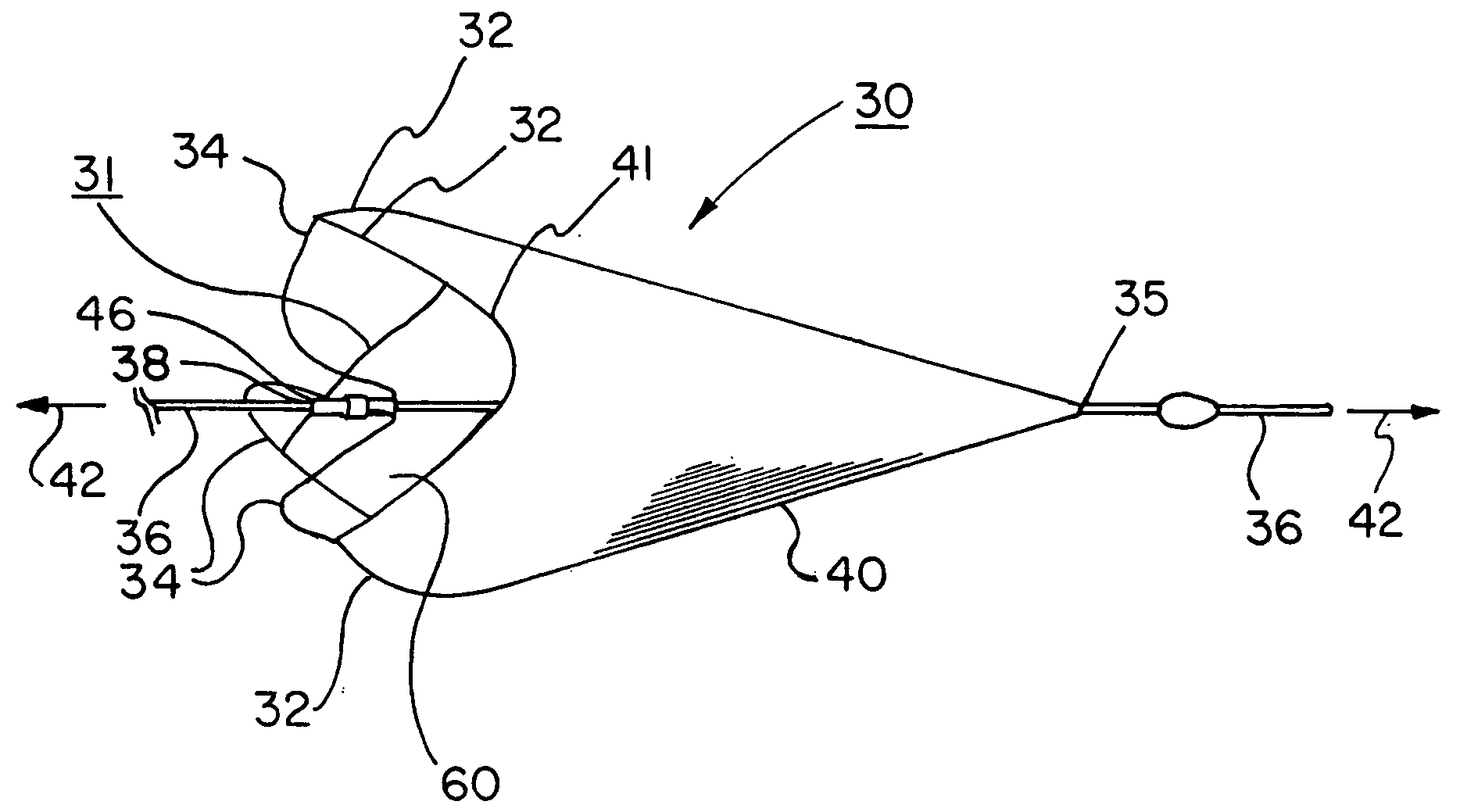

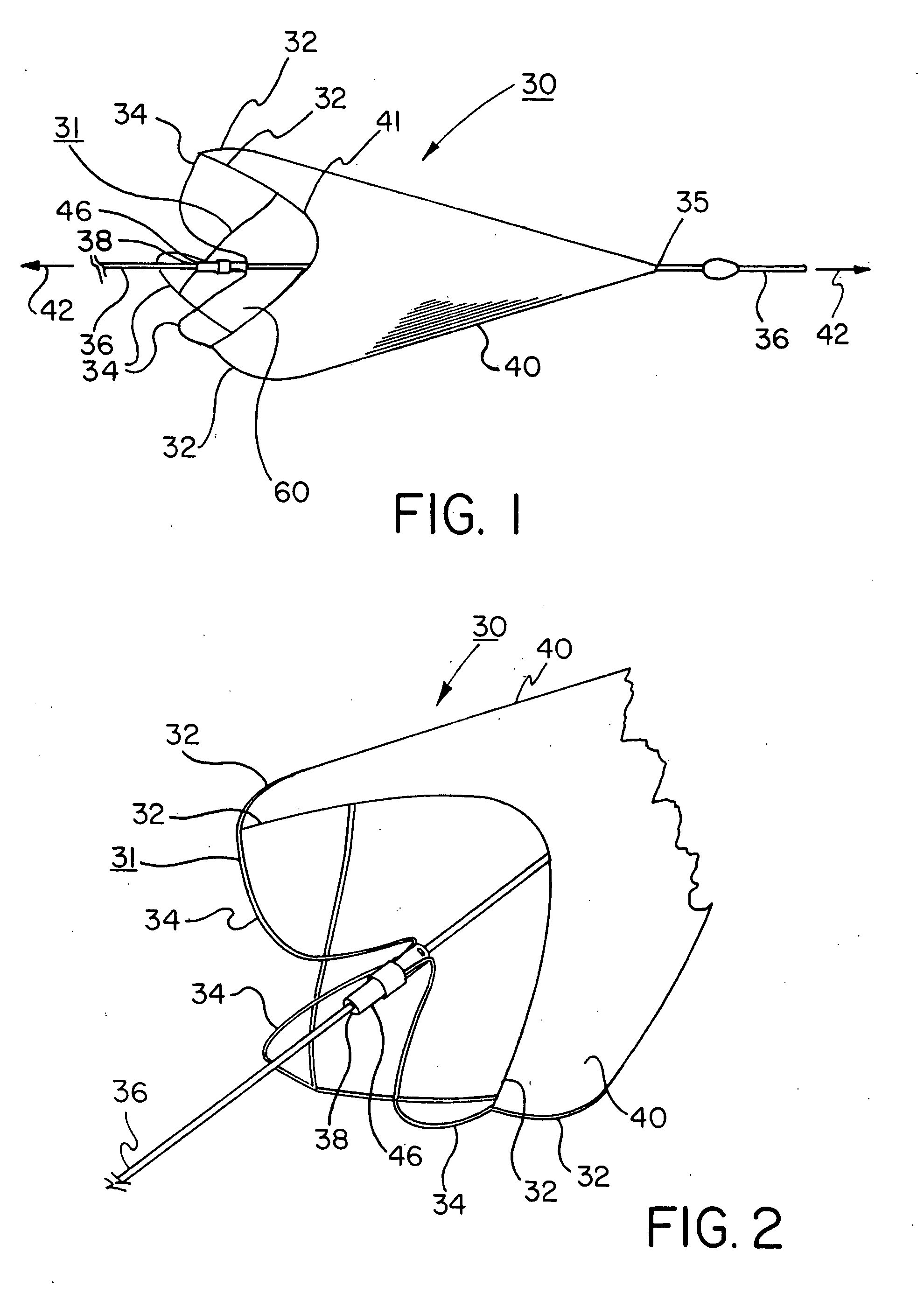

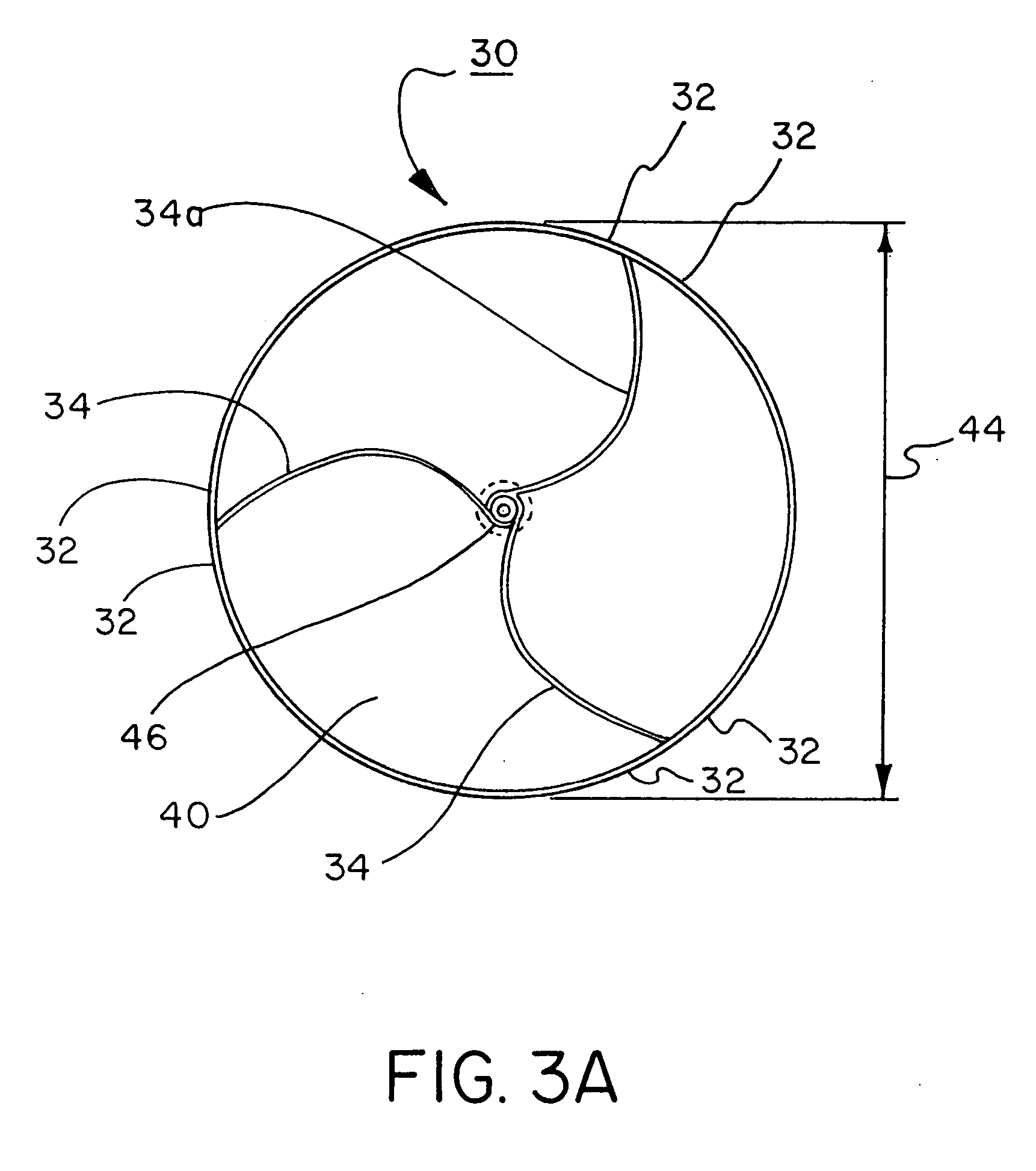

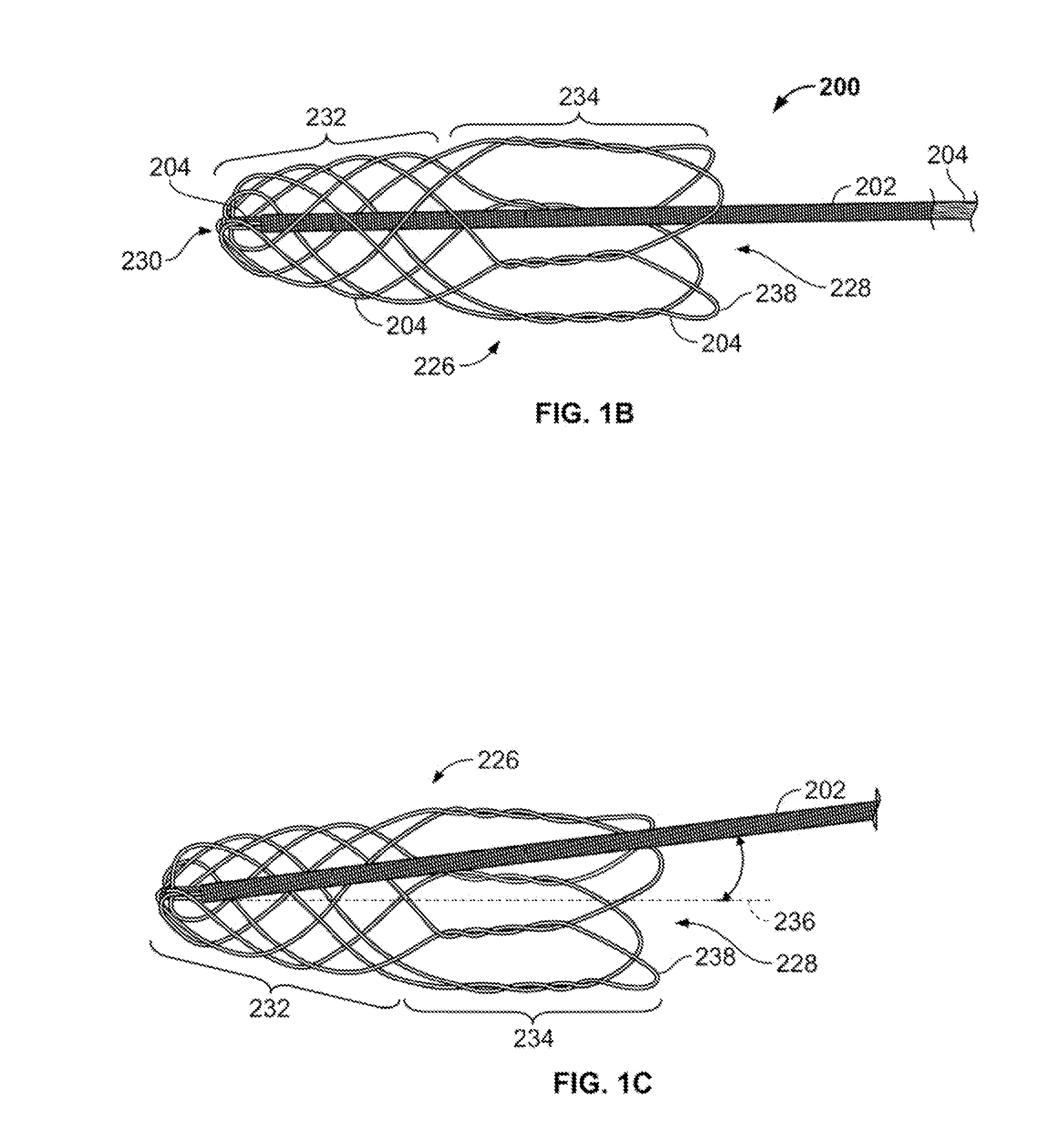

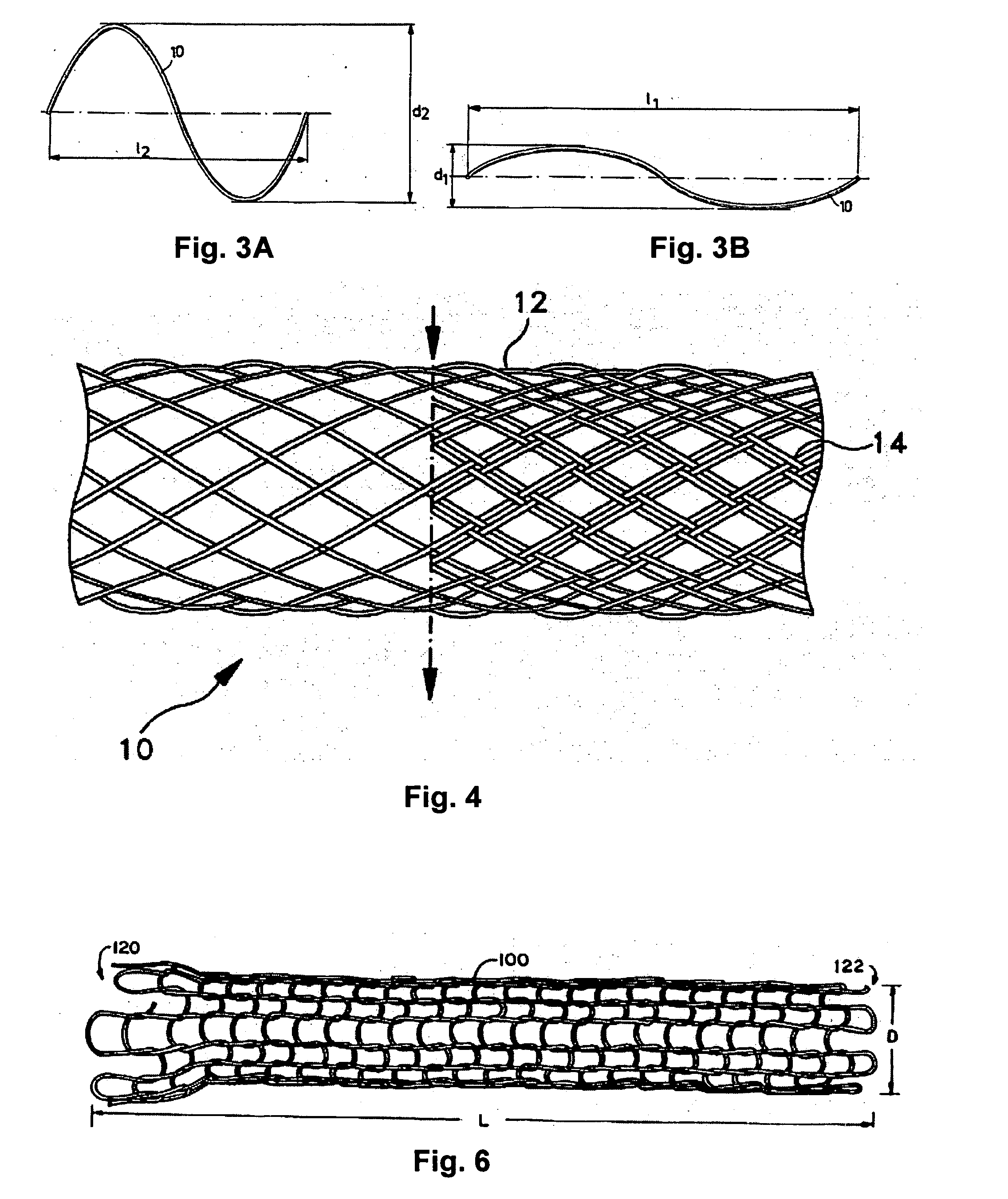

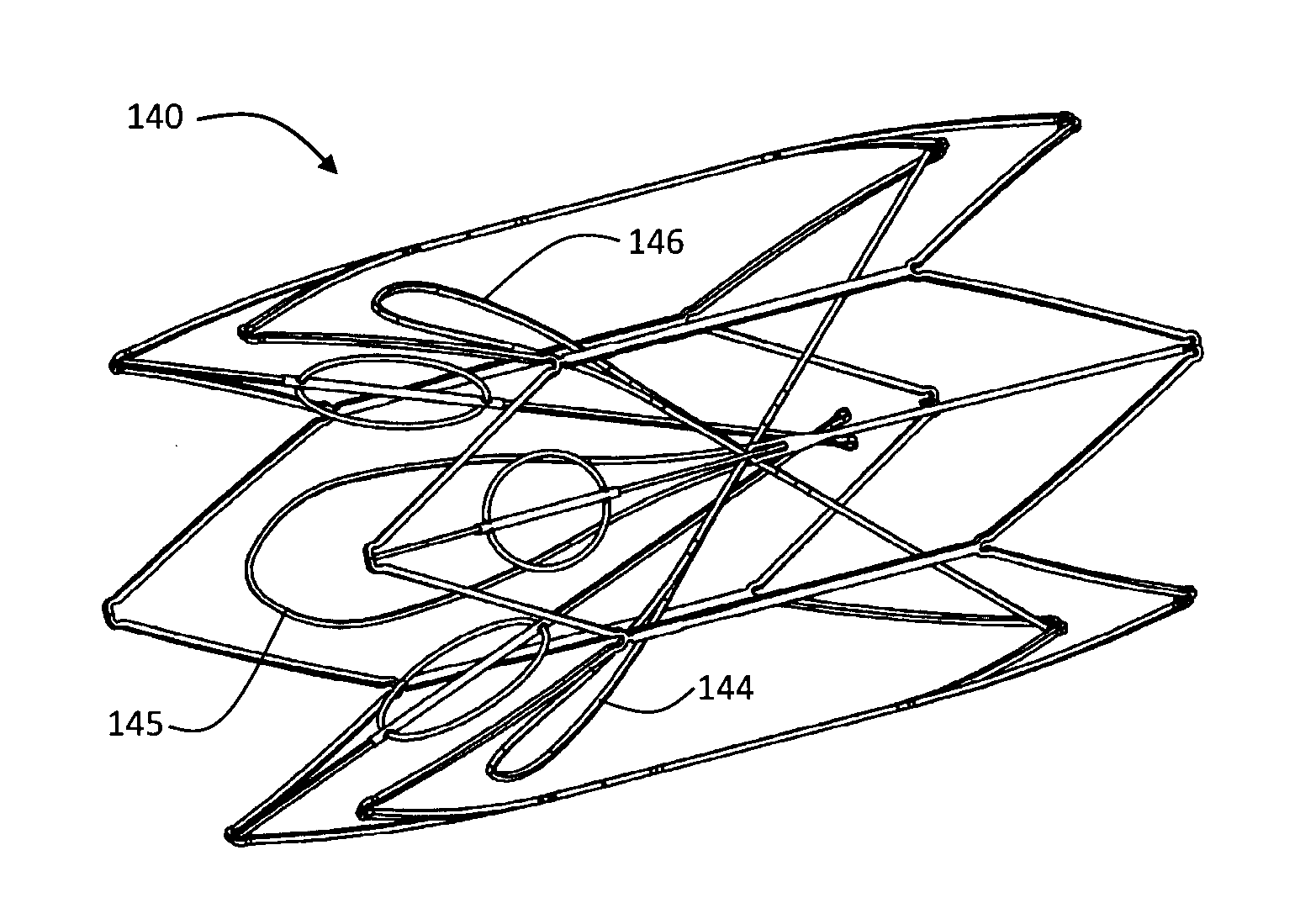

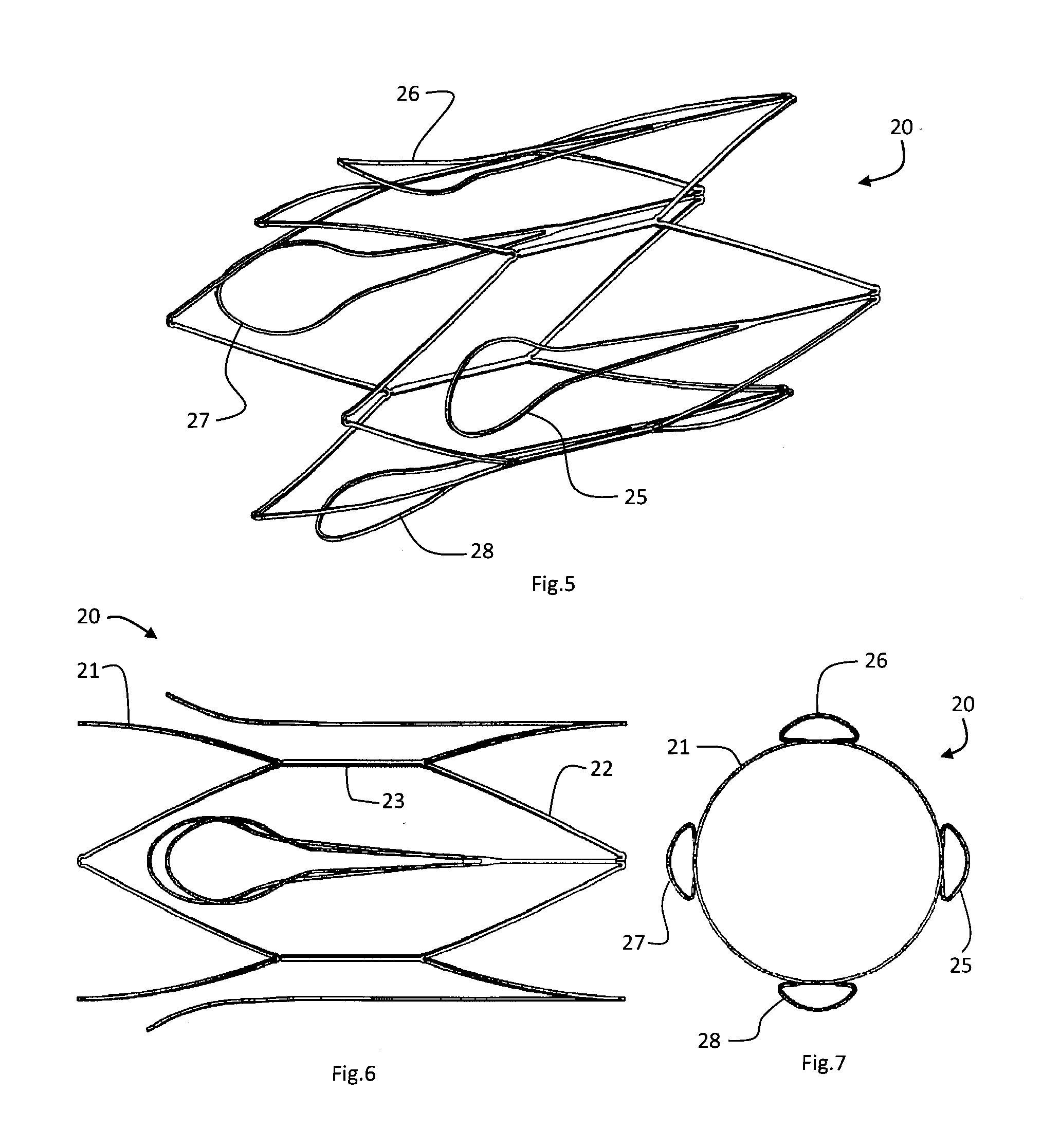

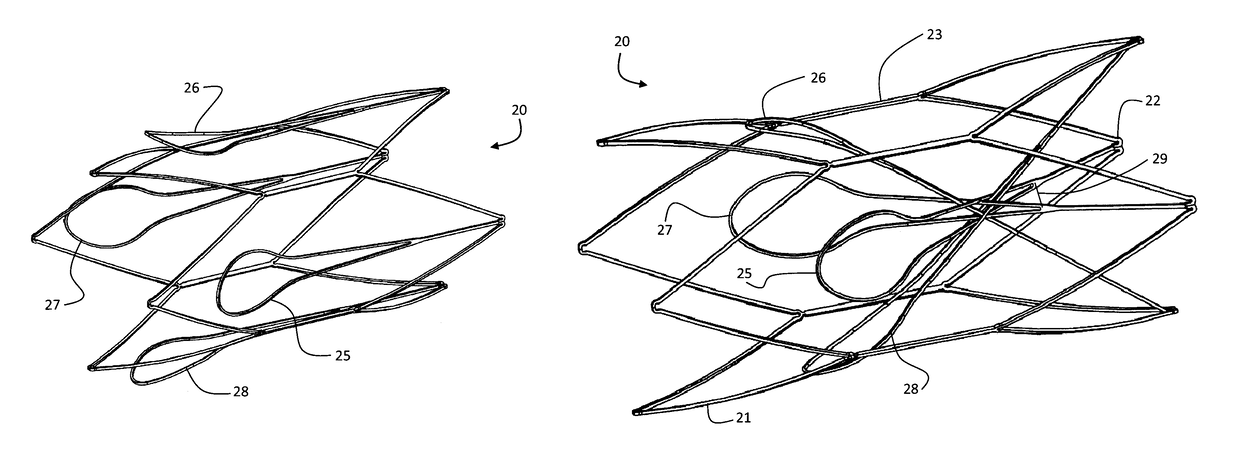

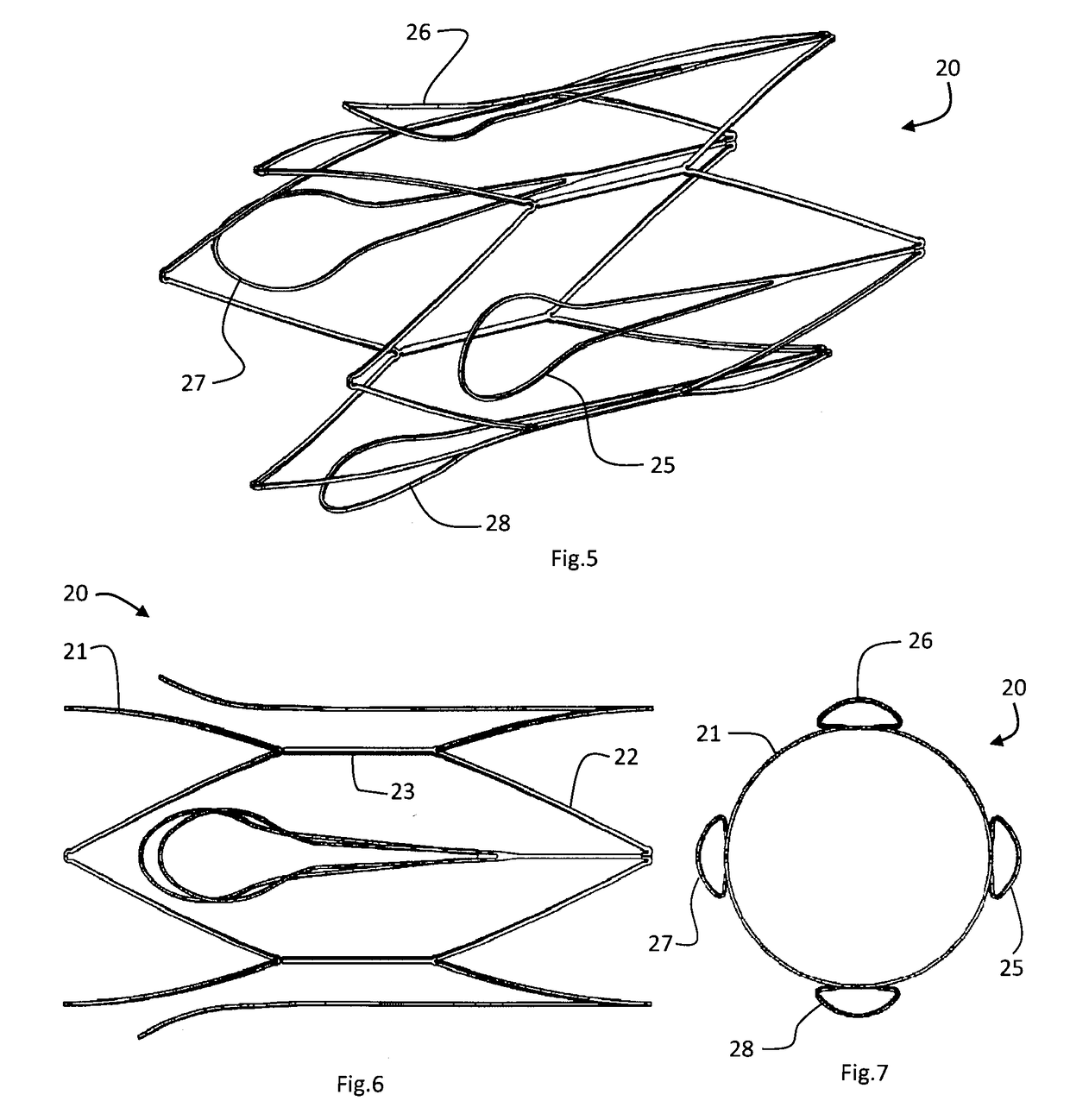

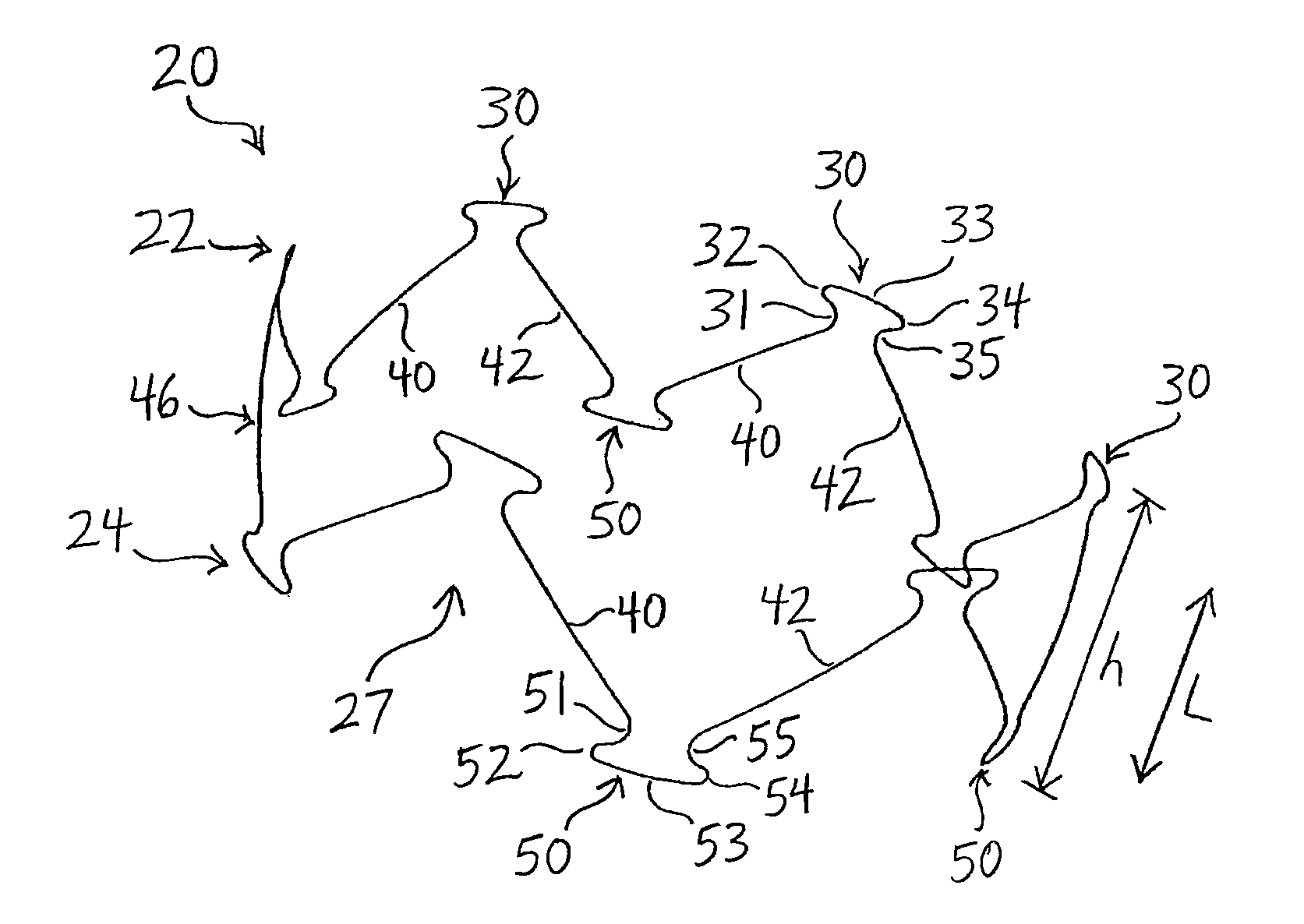

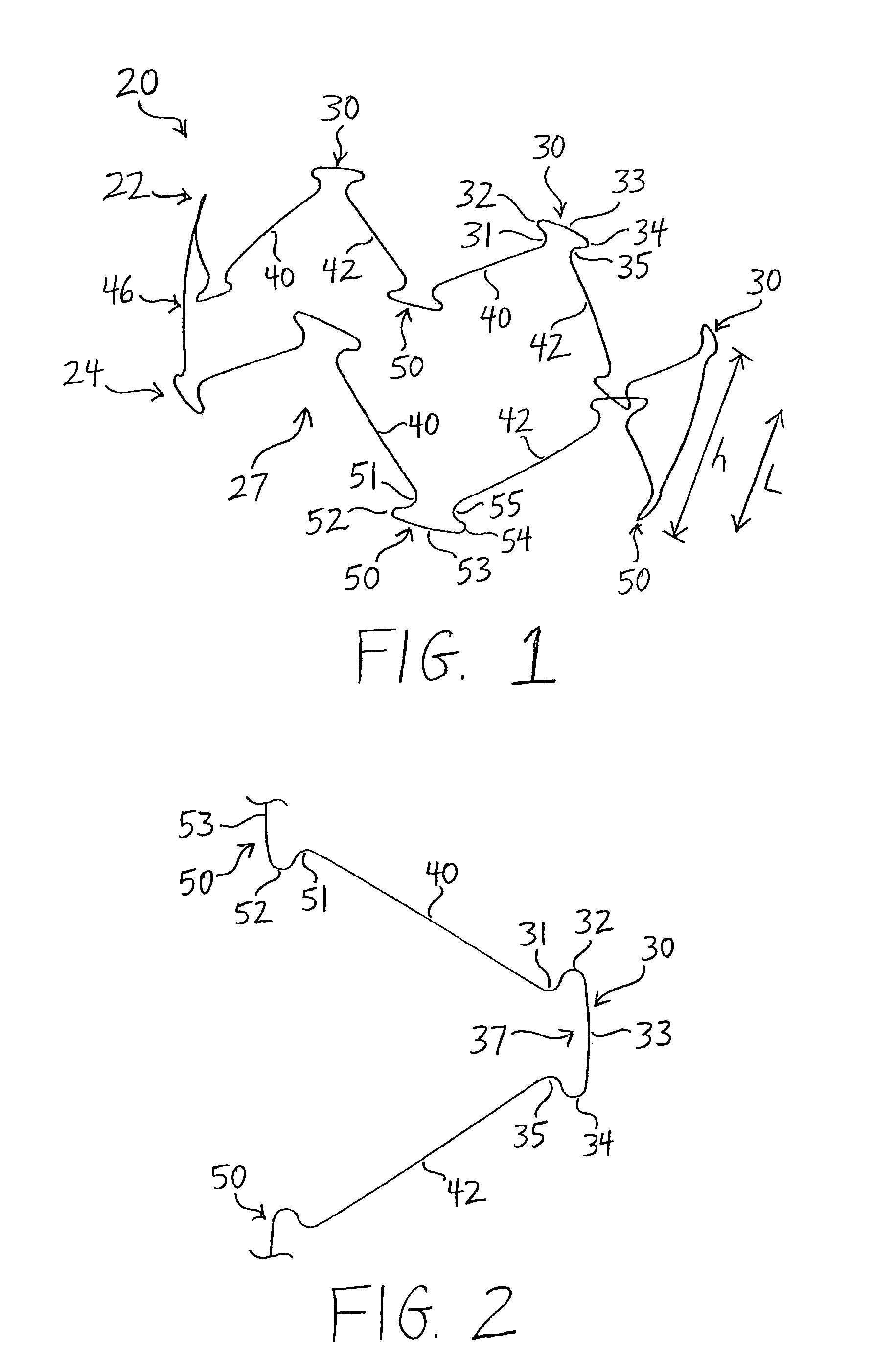

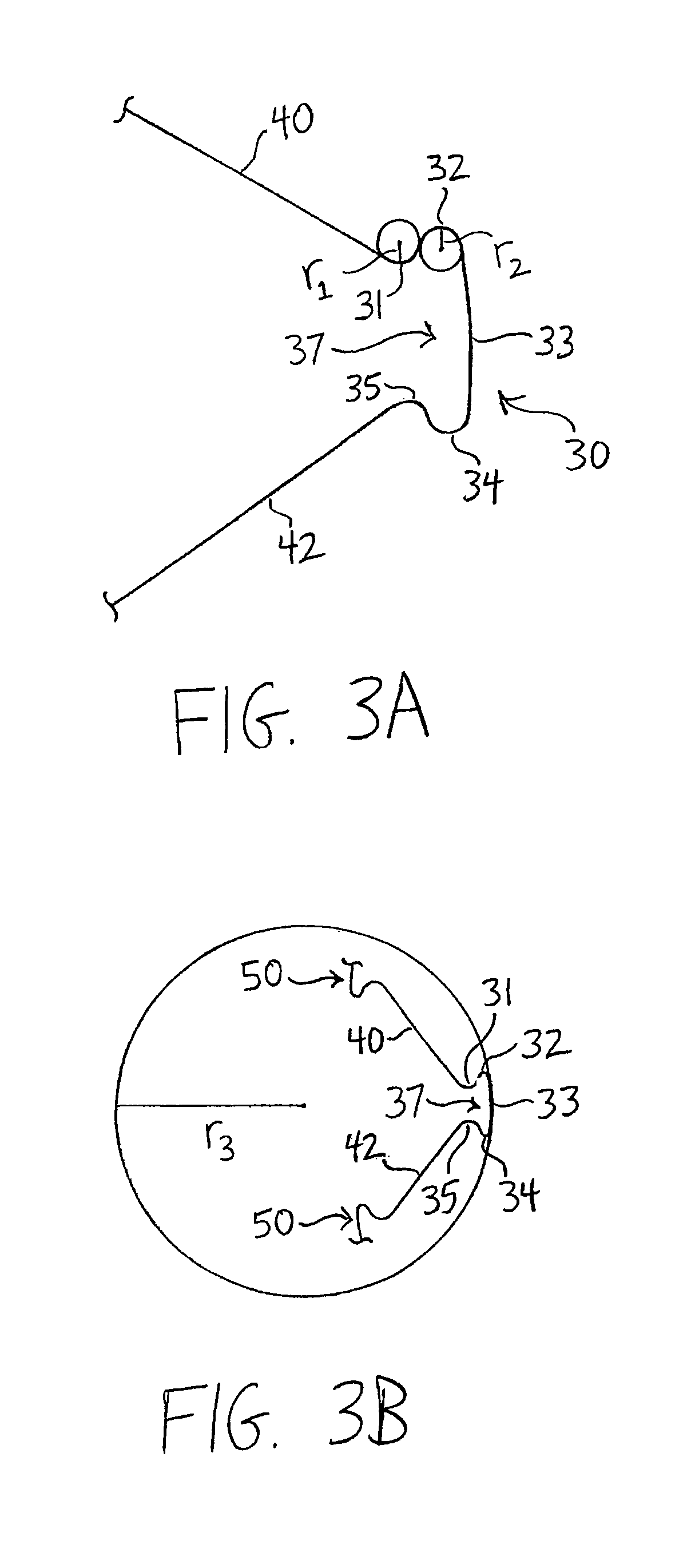

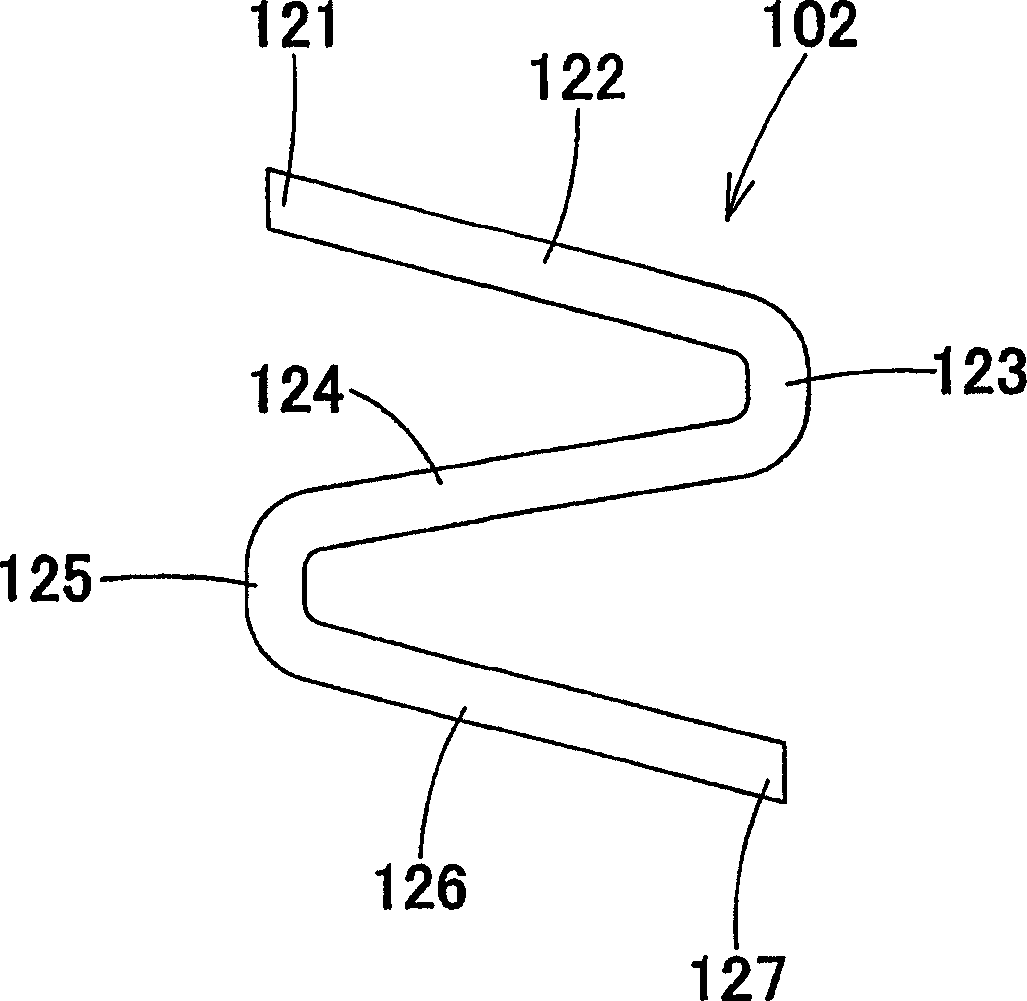

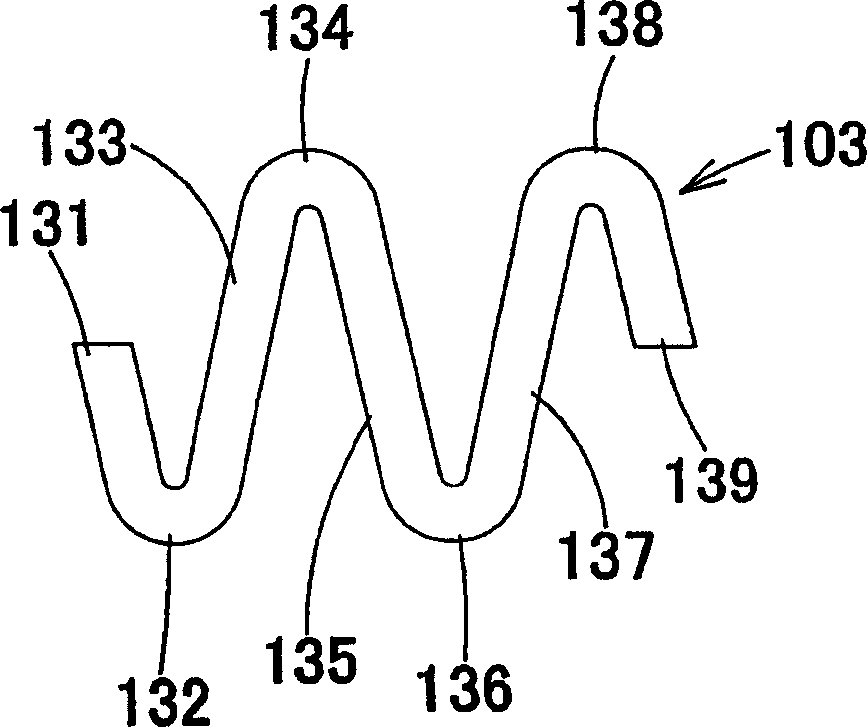

Embolic filter frame having looped support strut elements

InactiveUS20040093012A1Longitudinal compliance be enhanceImprove sealingSurgeryDilatorsEngineeringLower degree

An improved embolic filter frame having looped support struts. The frame configuration provides enhanced longitudinal compliance, improved sealing against a vessel wall, low profile delivery, and a short deployed length. The looped support struts have a high degree of "radial" stiffness with a low degree of "longitudinal" stiffness. In the deployed state, the frame exerts a relatively high stress onto a vessel wall to maintain an effective seal, yet remains compliant in the longitudinal direction. Minor displacements of the support wire or catheter are therefore not translated to the filter. The looped support struts elongate when tensioned and assume a compressed and essentially linear form. While constrained in this linear state by a delivery catheter, the support struts exert minimal stress onto the delivery system. The overall delivery profile and stiffness are therefore reduced. When the delivery catheter constraint is removed during deployment, the struts "snap open" and assume a looped configuration which exert a high degree of force onto the vessel wall, creating an enhanced filter to vessel wall seal. In addition, the looped struts and the central collar connecting the support struts to the support wire, are positioned essentially within the plane of the filter opening. The overall deployed length of the embolic filter is therefore reduced.

Owner:WL GORE & ASSOC INC

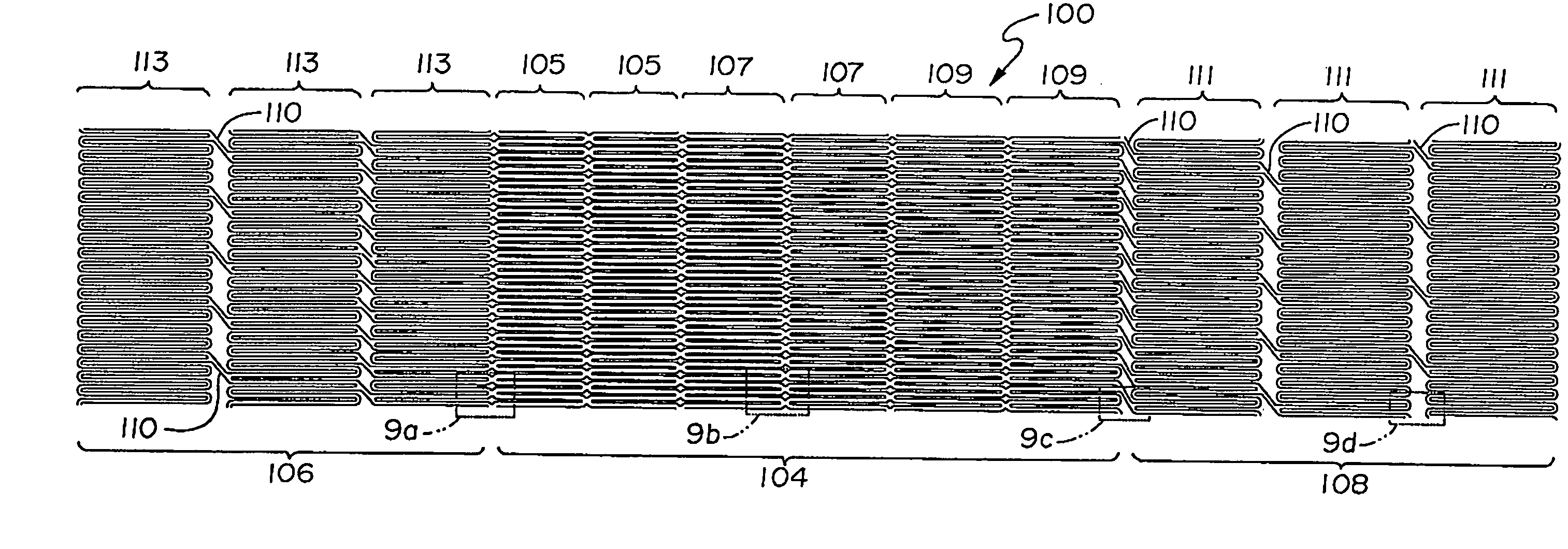

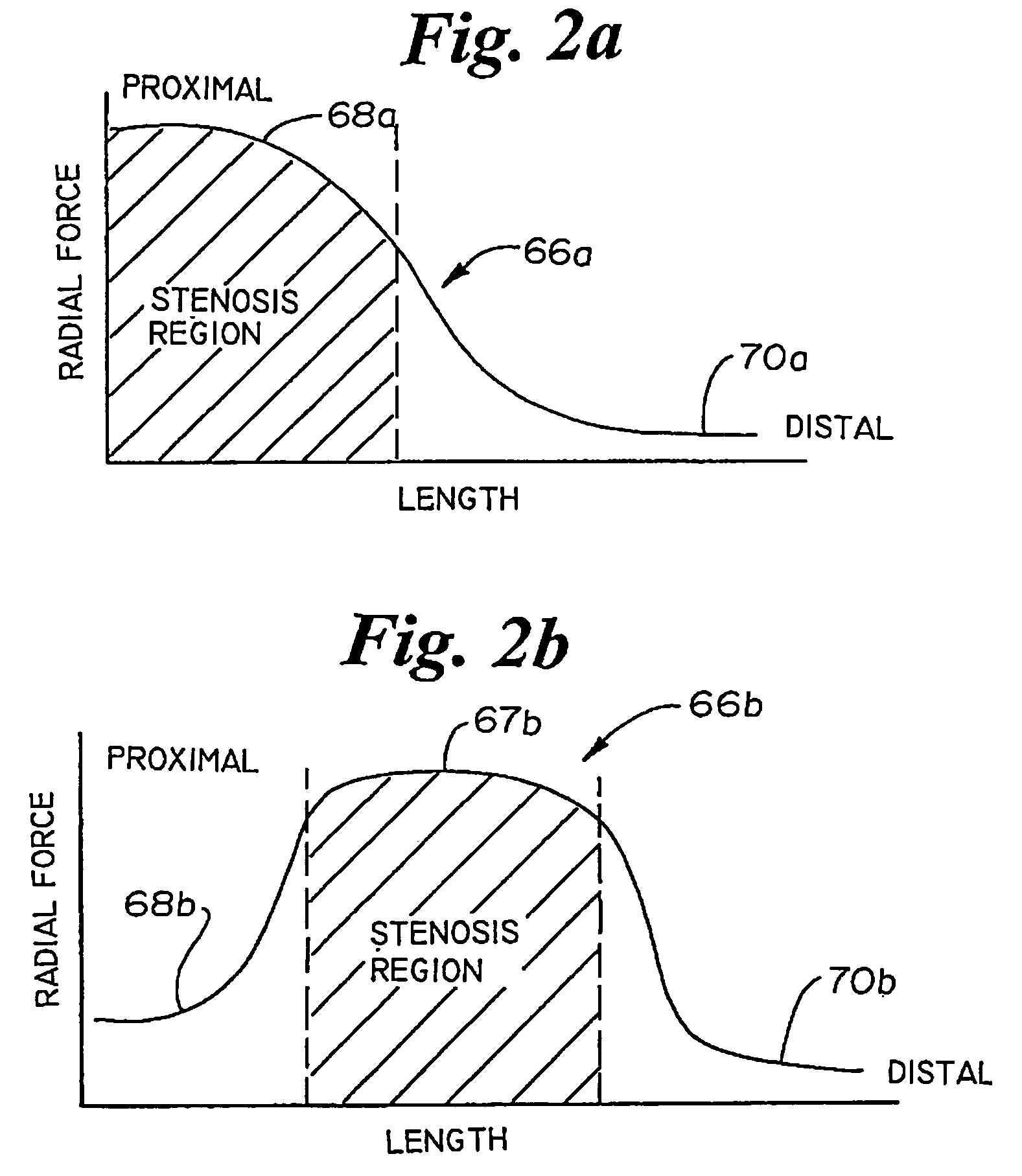

Stent having variable properties and method of its use

InactiveUS7060091B2Increase radial forceFlexible processStentsBlood vesselsVolumetric Mass DensityBlood vessel

Owner:BOSTON SCI SCIMED INC

Embolic filter frame having looped support strut elements

An improved embolic filter frame having looped support struts. The frame configuration provides enhanced longitudinal compliance, improved sealing against a vessel wall, low profile delivery, and a short deployed length. The looped support struts have a high degree of “radial” stiffness with a low degree of “longitudinal” stiffness. In the deployed state, the frame exerts a relatively high stress onto a vessel wall to maintain an effective seal, yet remains compliant in the longitudinal direction. Minor displacements of the support wire or catheter are therefore not translated to the filter. The looped support struts elongate when tensioned and assume a compressed and essentially linear form. While constrained in this linear state by a delivery catheter, the support struts exert minimal stress onto the delivery system. The overall delivery profile and stiffness are therefore reduced. When the delivery catheter constraint is removed during deployment, the struts “snap open” and assume a looped configuration which exert a high degree of force onto the vessel wall, creating an enhanced filter to vessel wall seal. In addition, the looped struts and the central collar connecting the support struts to the support wire, are positioned essentially within the plane of the filter opening. The overall deployed length of the embolic filter is therefore reduced.

Owner:WL GORE & ASSOC INC

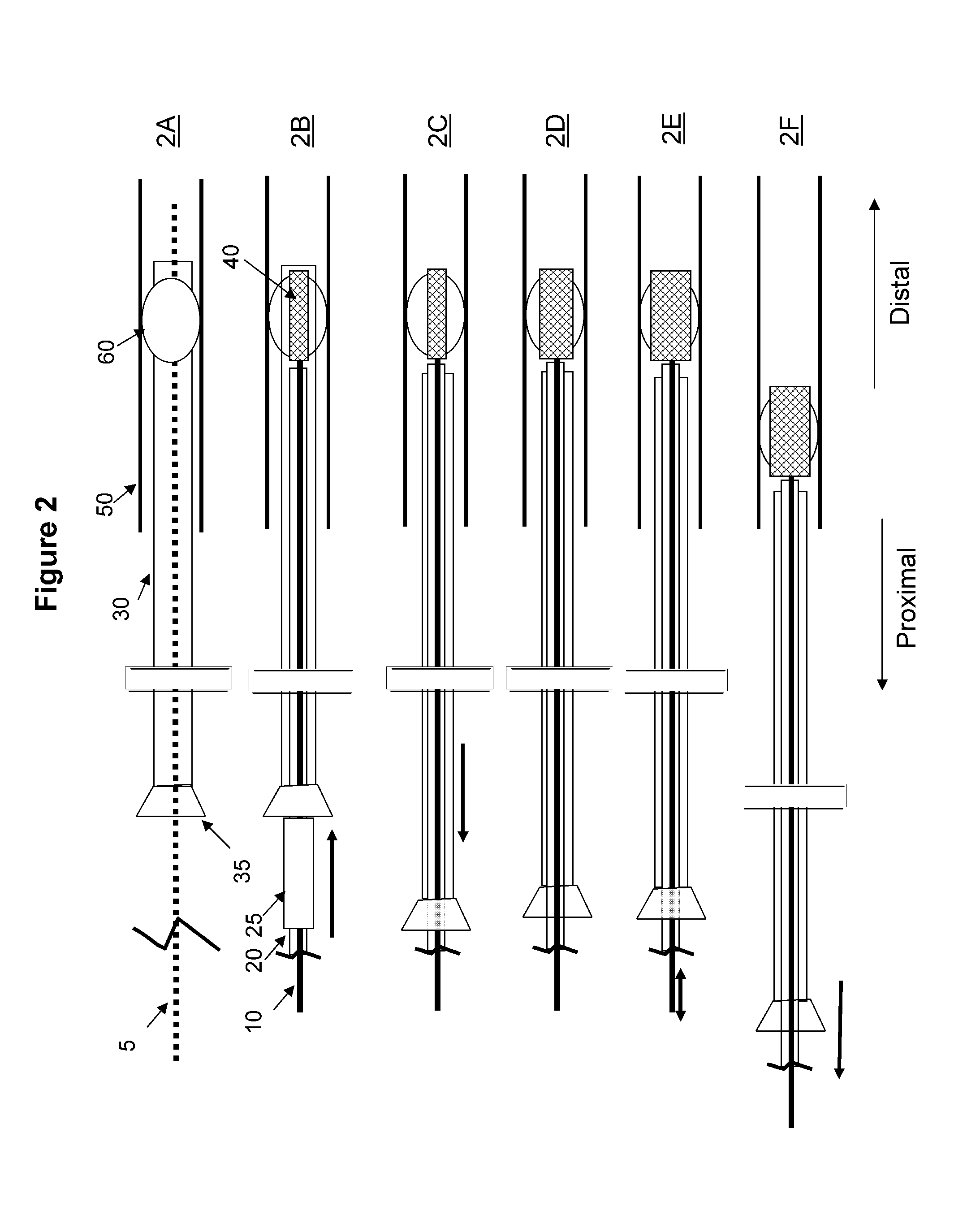

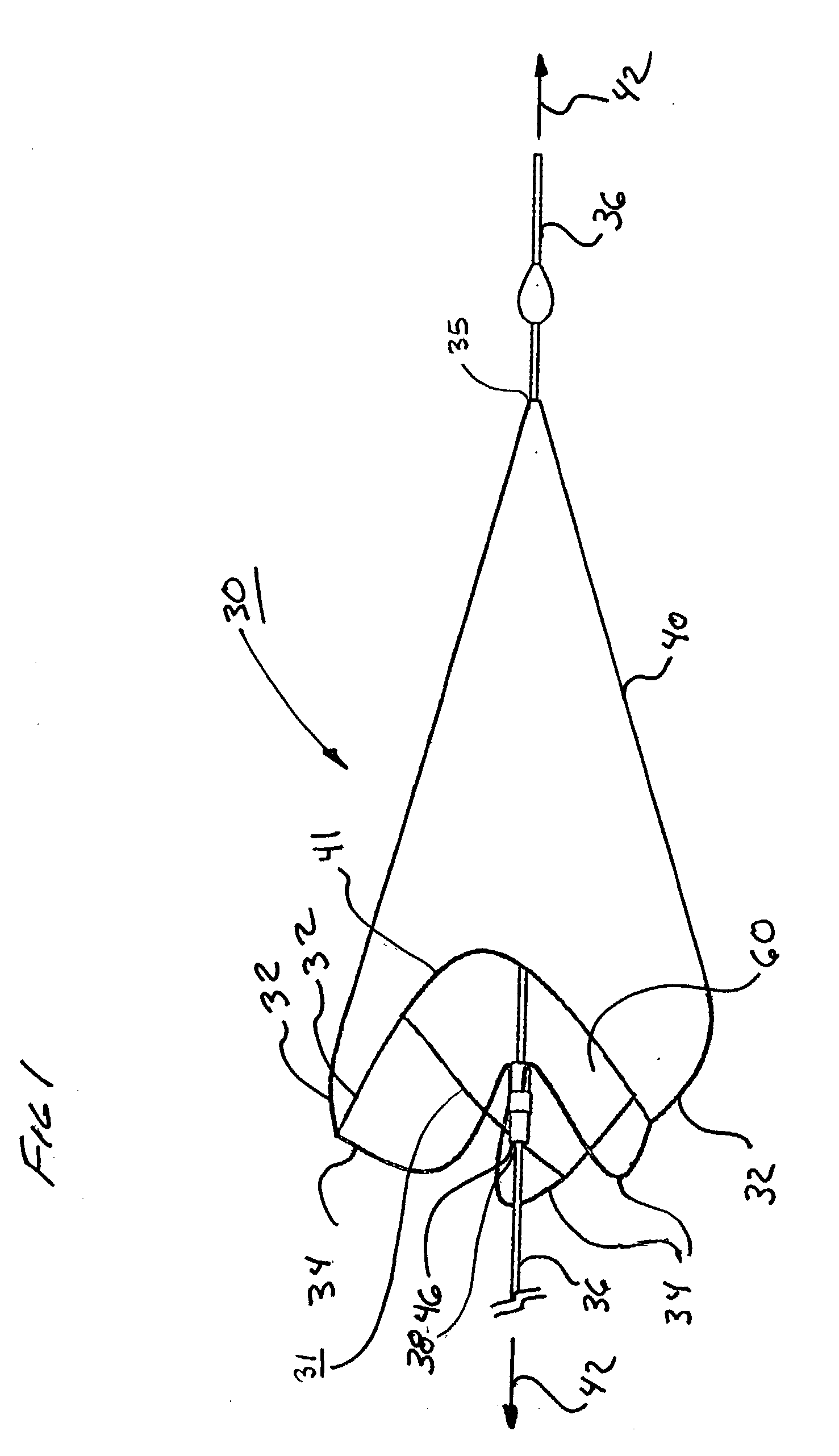

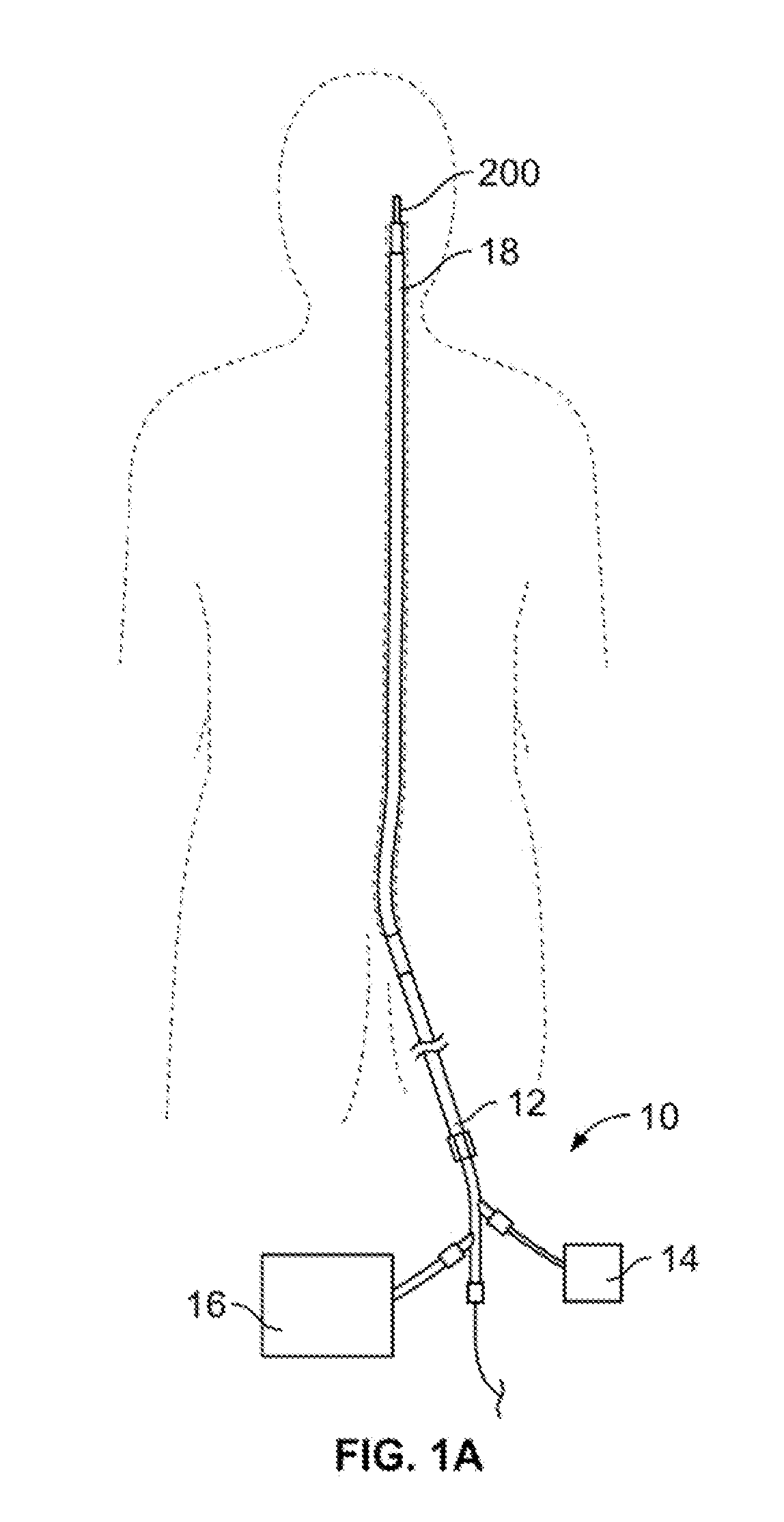

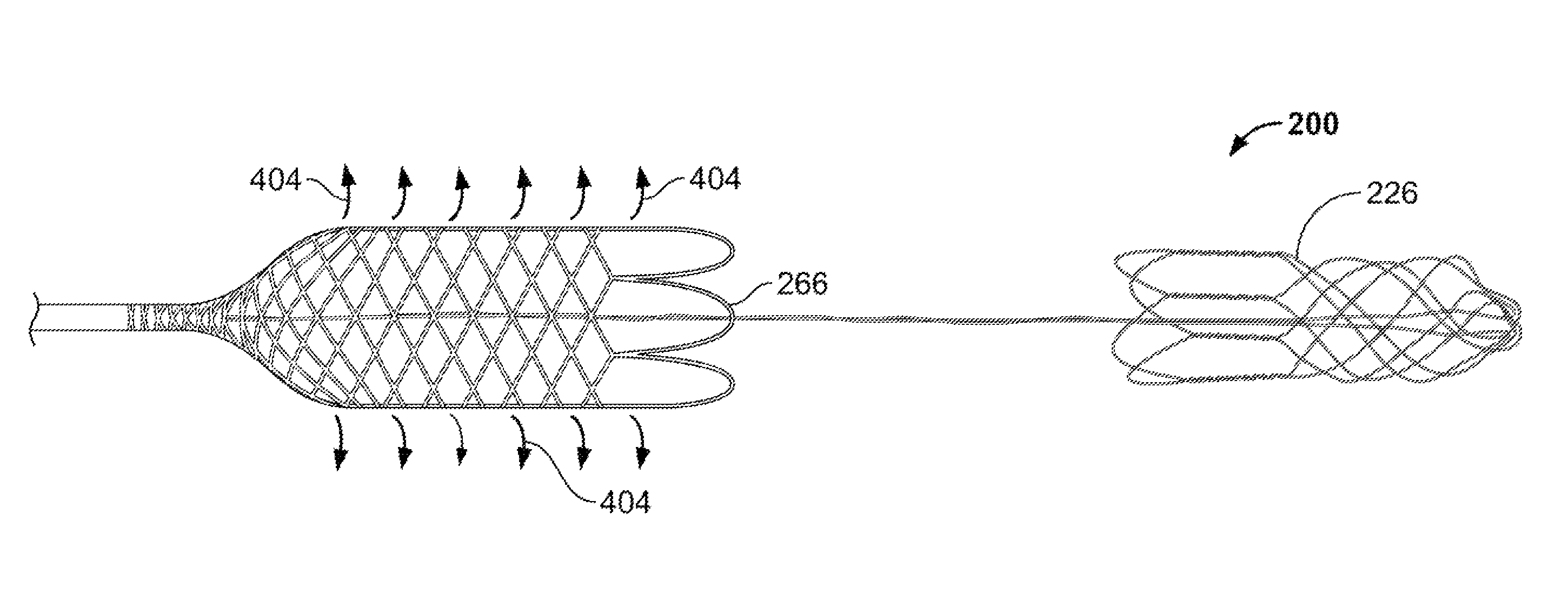

Retrieval systems and methods for use thereof

ActiveUS20120197285A1Improve abilitiesImproves strength and flexibilityGuide needlesBalloon catheterBiomedical engineeringMedicine

Owner:TYCO HEALTHCARE GRP LP

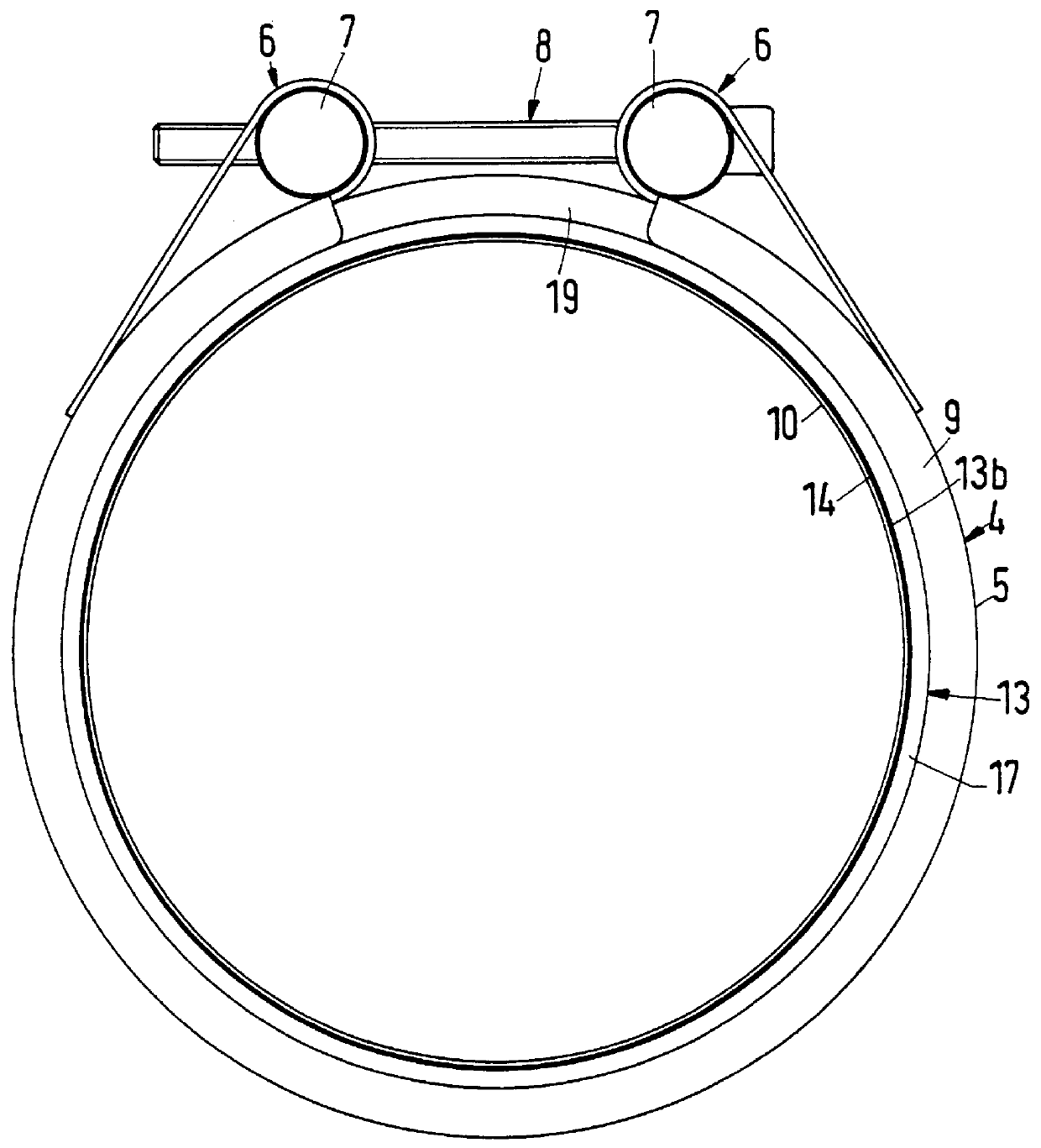

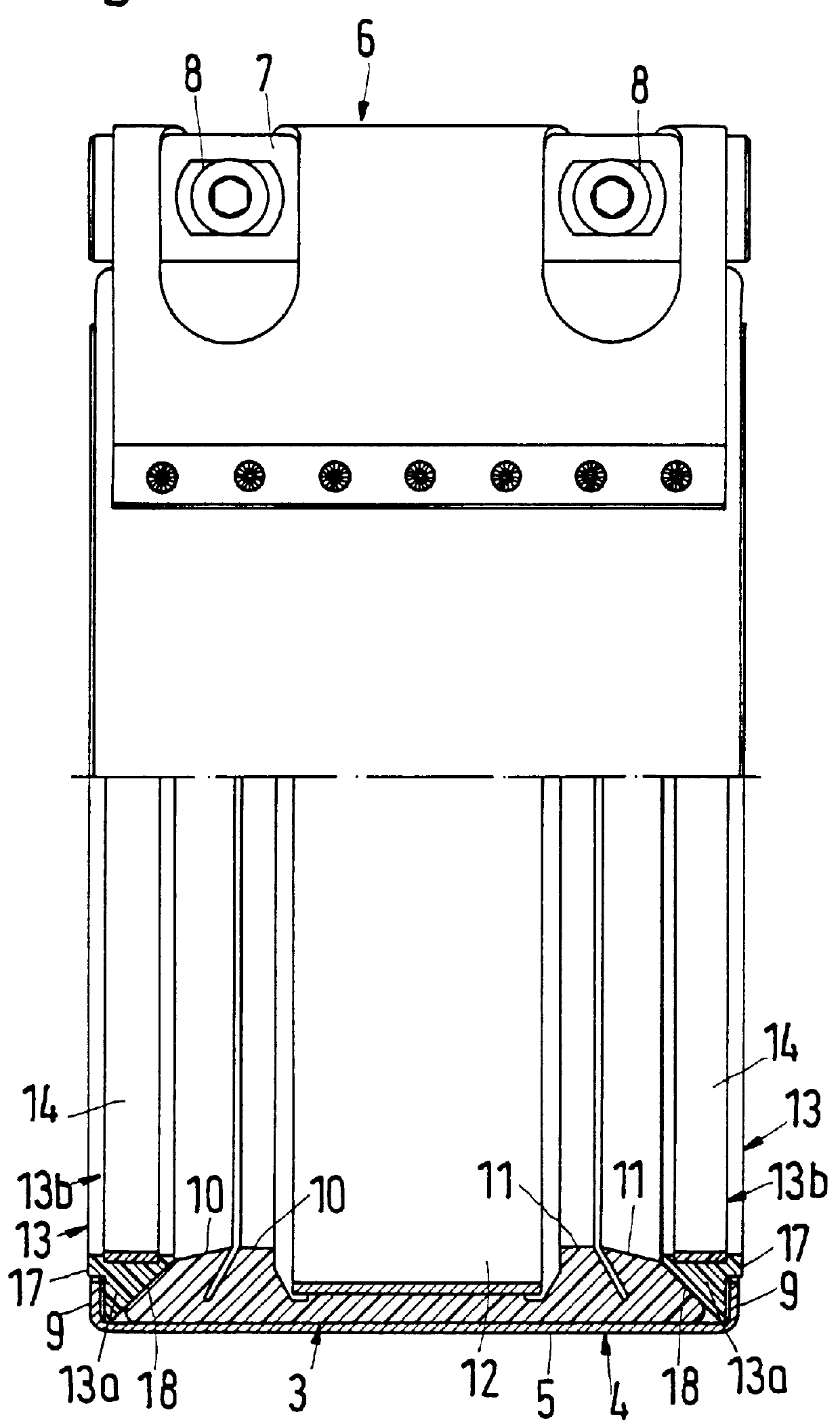

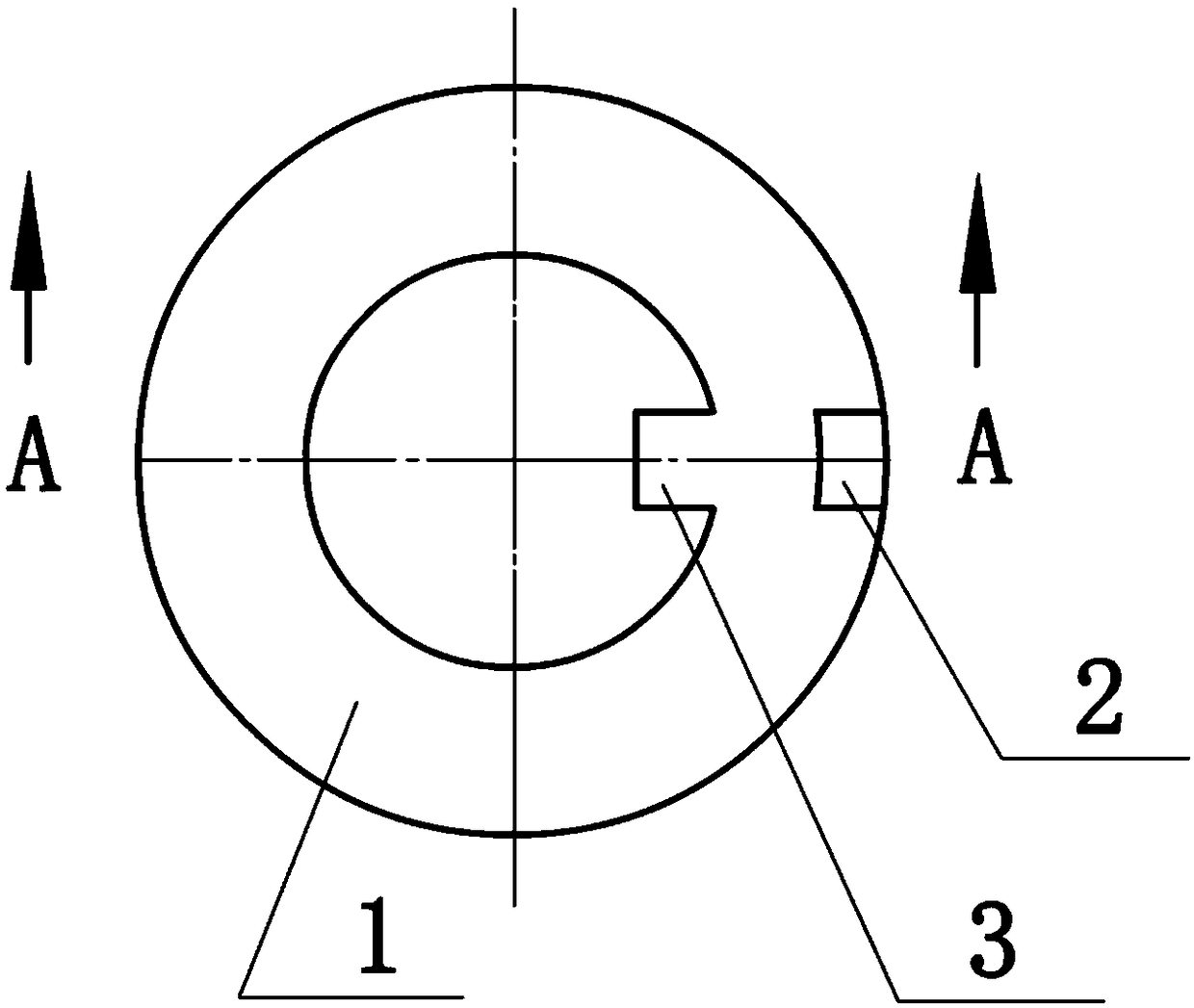

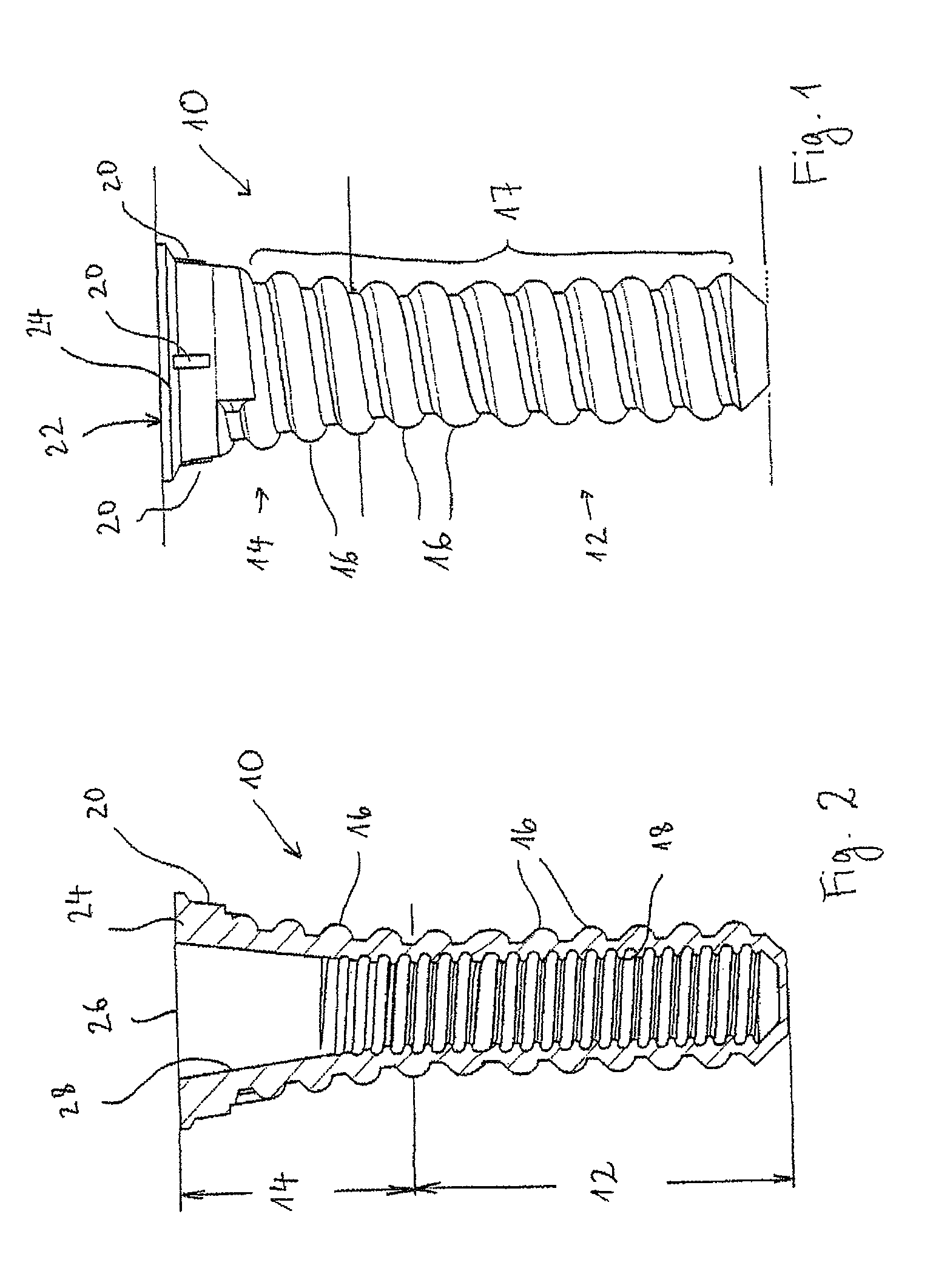

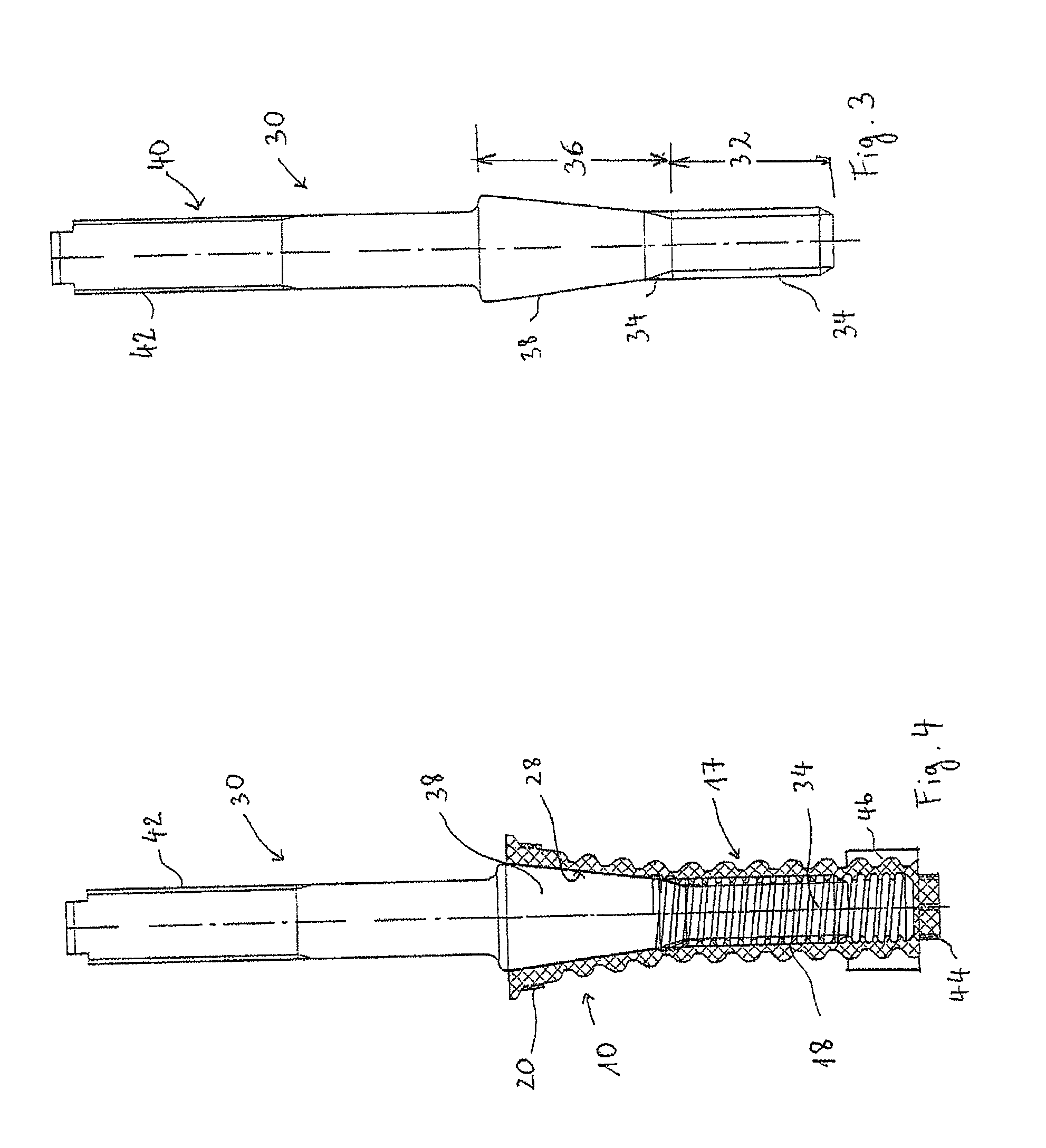

Pipe coupling

InactiveUS6070914AIncrease the cross-sectional areaHigh strengthSleeve/socket jointsFluid pressure sealed jointsCouplingEngineering

A pipe coupling for connecting pipes having unprofiled end sections includes an elastomeric sealing gasket for holding the unprofiled pipe end sections in a sealed manner. A clamping clip surrounds the sealing gasket. The clamping clip includes a clip strap having a first end and a second end. A first clamping jaw is formed at the first end. A second clamping jaw is formed at the second end. The clamping jaws are drawn together by a tensioning device. The clip strap has radially inwardly directed projecting flanges on each of its axial ends. A first C-shaped clamping ring and a second C-shaped clamping ring are each disposed between the sealing gasket and one of the flanges. Each of the C-shaped clamping rings are supported on a radially inner side of the clip strap. Each of the C-shaped clamping rings have projections projecting from its radially inner face and, when said clip strap is tensioned, the projections of the C-shaped rings engage in the pipe material. The clamping rings are substantially made of plastic and approximately fill the space between the sealing gasket and one of the flanges. The clamping rings may be formed as a single part or from two ring parts. If formed of two parts, the radially inner part may be made of a brass alloy. The projections may be formed as encircling ribs.

Owner:NORMA GERMANY GMBH

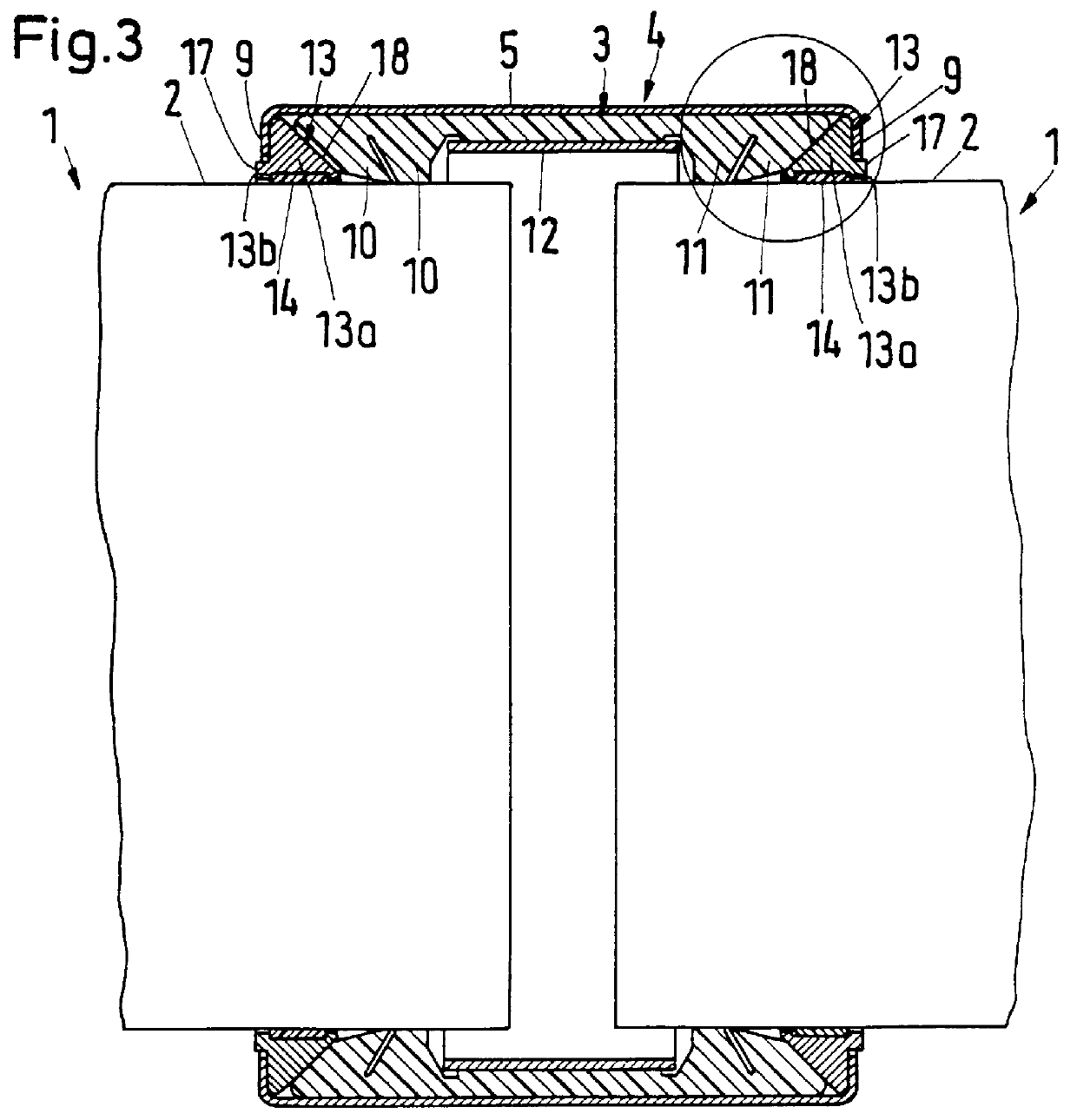

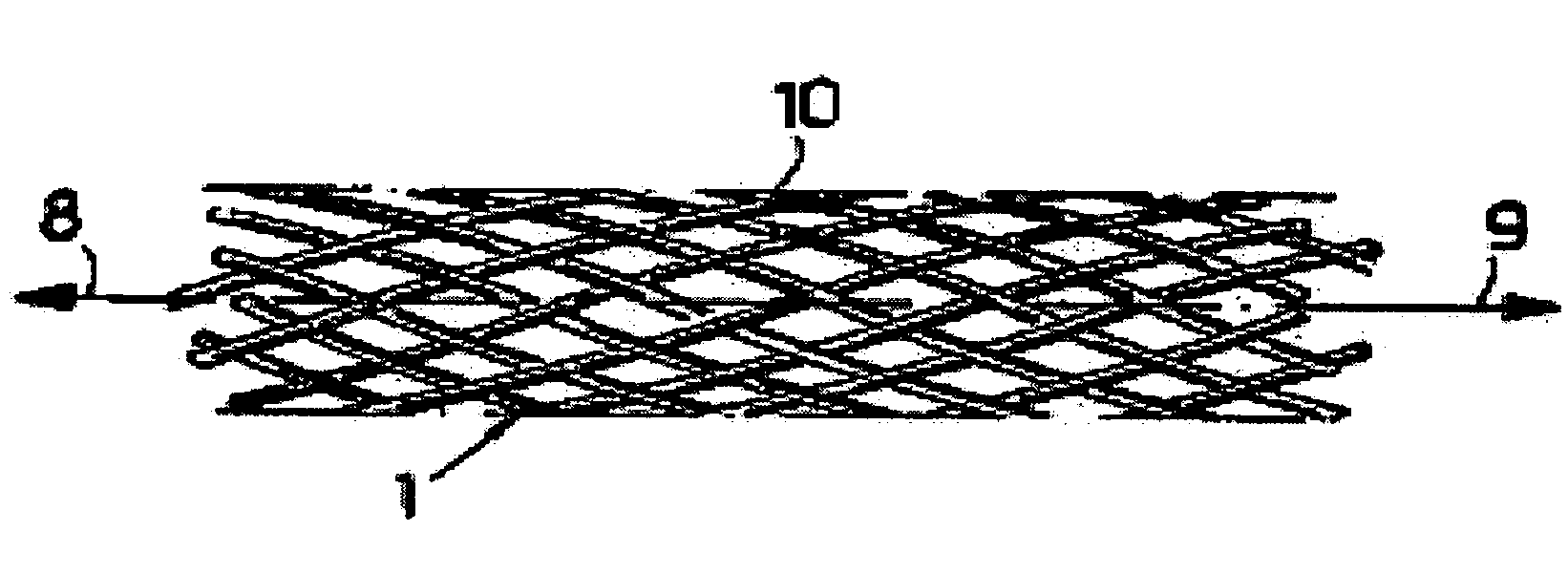

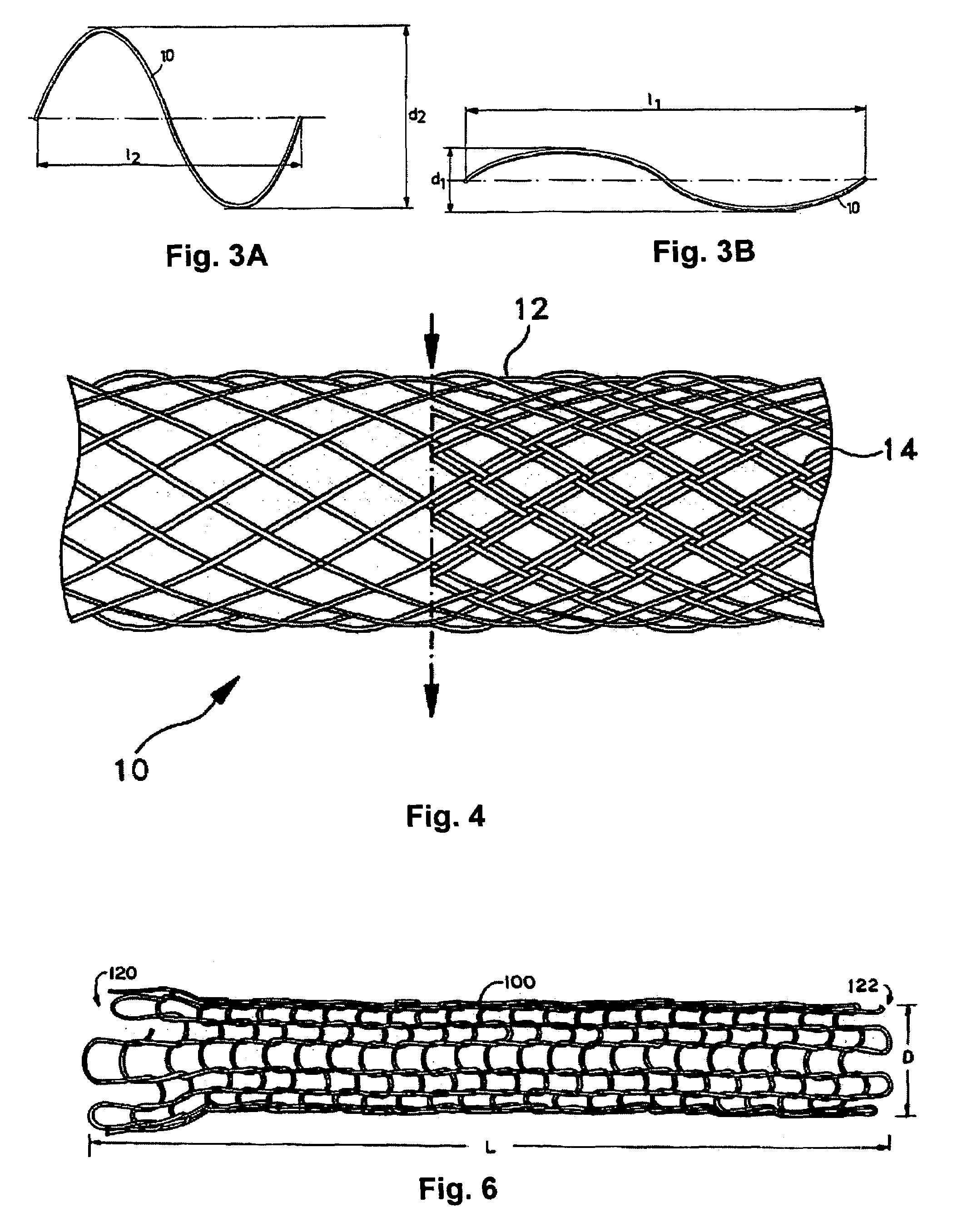

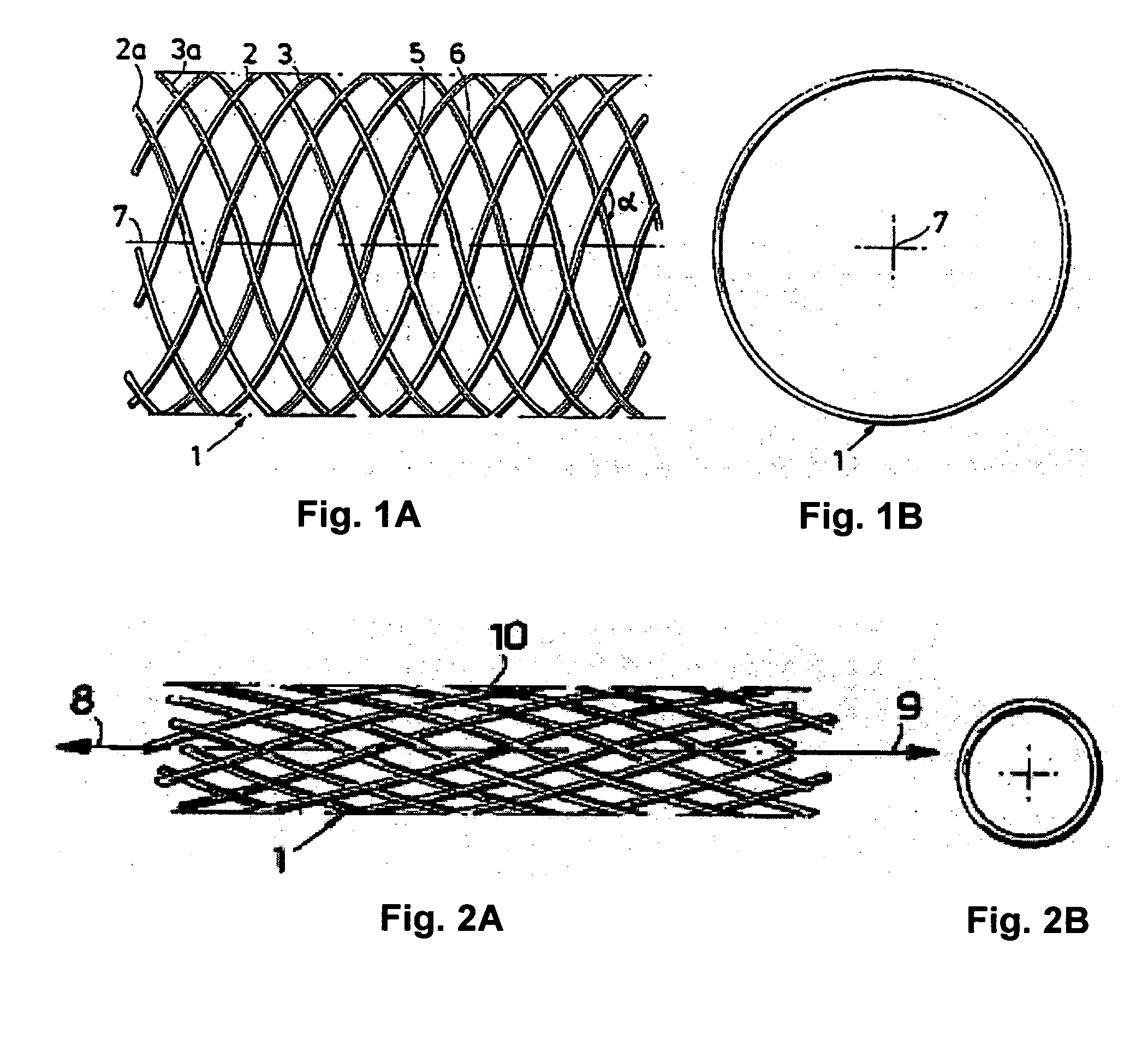

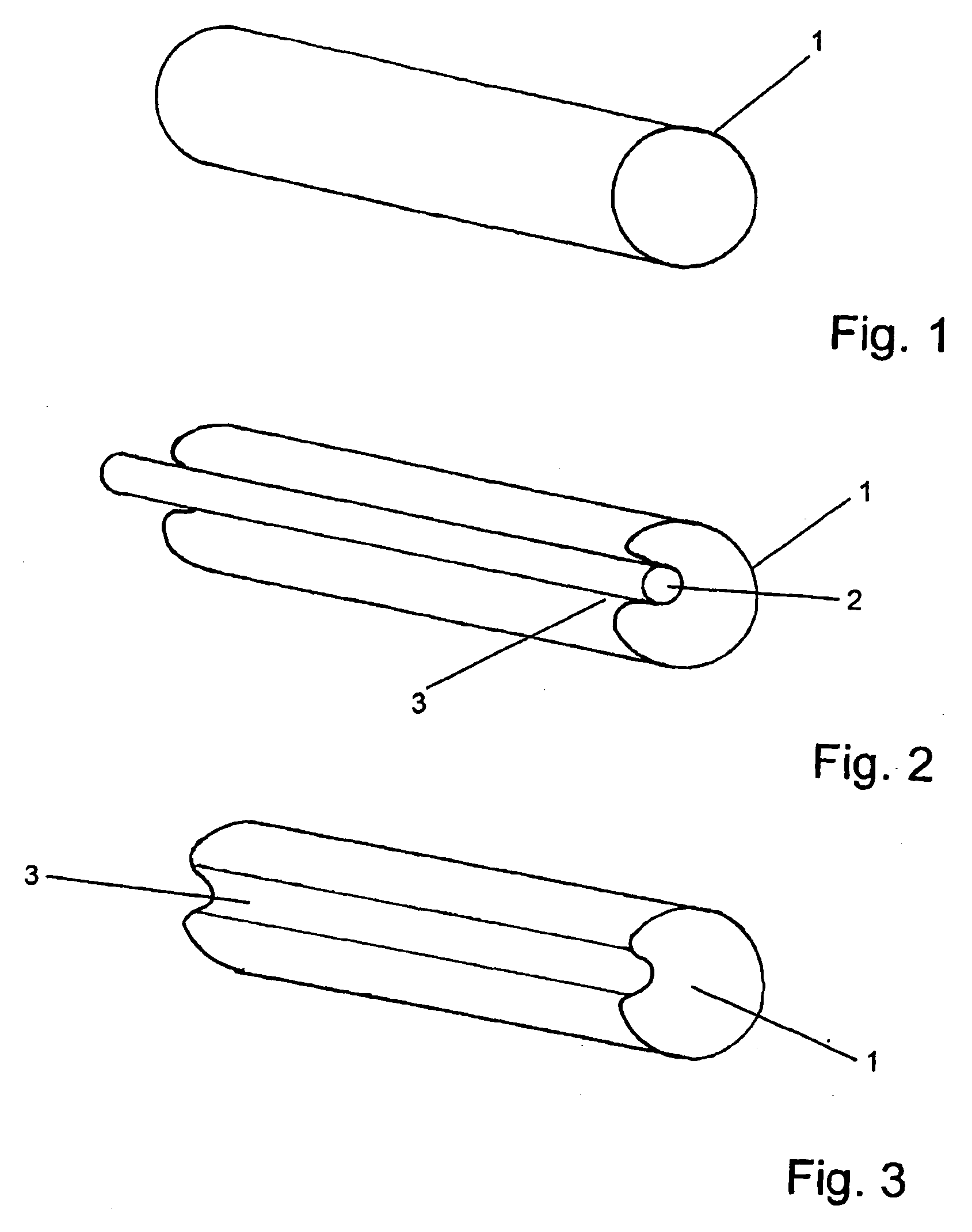

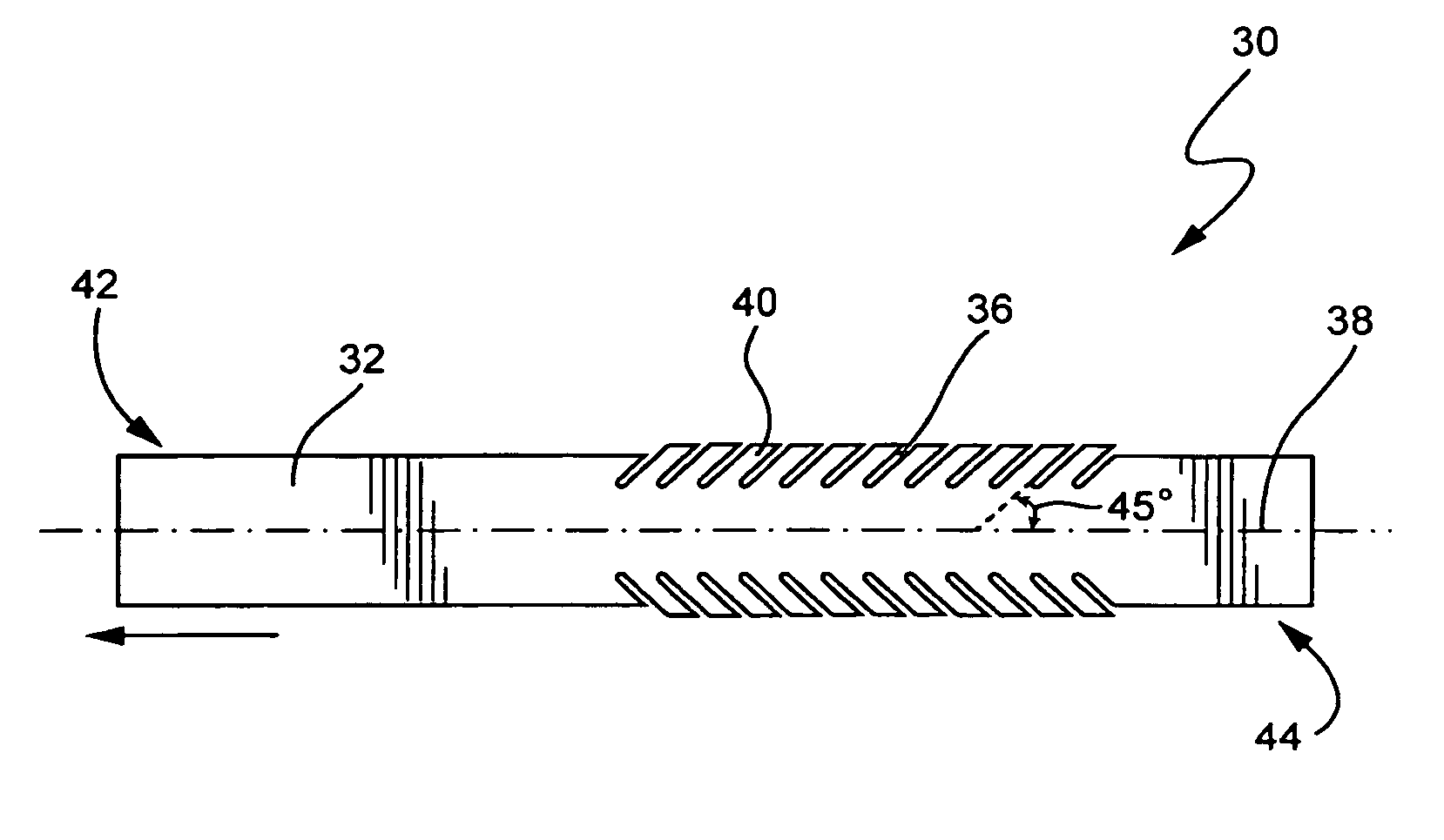

Bioabsorbable stents with reinforced filaments

ActiveUS7594928B2Improve material performanceIncrease radial forceStentsSurgeryBioabsorbable stentPolymer

According to an aspect of the present invention, a stent is provided, which contains at least one filament that has a longitudinal axis and comprises a bioabsorbable polymeric material. Polymer molecules within the bioabsorbable polymeric material are provided with a helical orientation which is aligned with respect to the longitudinal axis of the filament. The stent is at least partially bioabsorbed by a patient upon implantation or insertion of the stent into the patient.

Owner:BOSTON SCI SCIMED INC

Bioabsorbable stents with reinforced filaments

ActiveUS20070270941A1Improve material performanceIncrease radial forceStentsSurgeryBioabsorbable stentBiomedical engineering

According to an aspect of the present invention, a stent is provided, which contains at least one filament that has a longitudinal axis and comprises a bioabsorbable polymeric material. Polymer molecules within the bioabsorbable polymeric material are provided with a helical orientation which is aligned with respect to the longitudinal axis of the filament. The stent is at least partially bioabsorbed by a patient upon implantation or insertion of the stent into the patient.

Owner:BOSTON SCI SCIMED INC

Retrieval systems and methods for use thereof

ActiveUS9254371B2Improves strength and flexibilityImprove abilitiesGuide needlesBalloon catheterBiomedical engineering

Owner:COVIDIEN LP

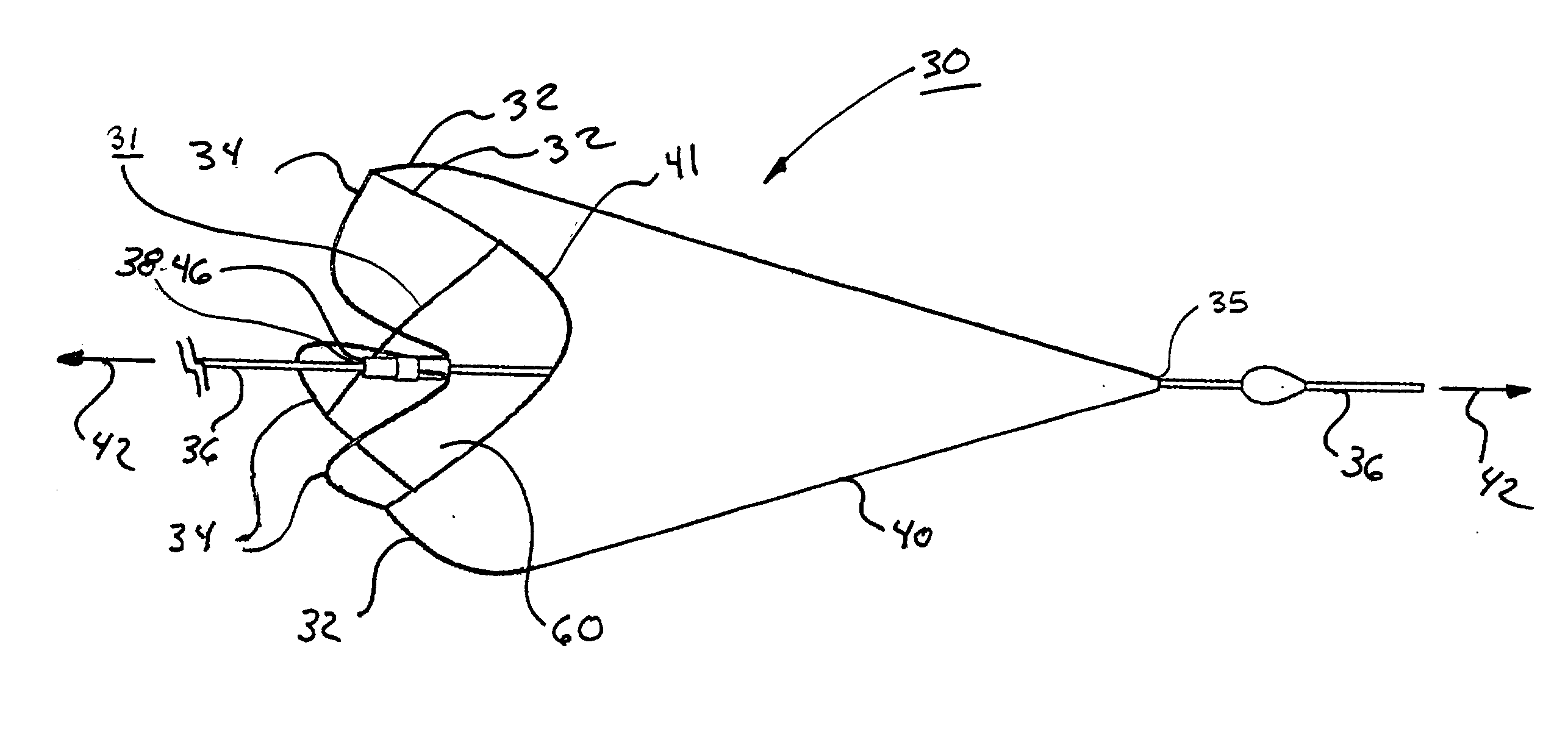

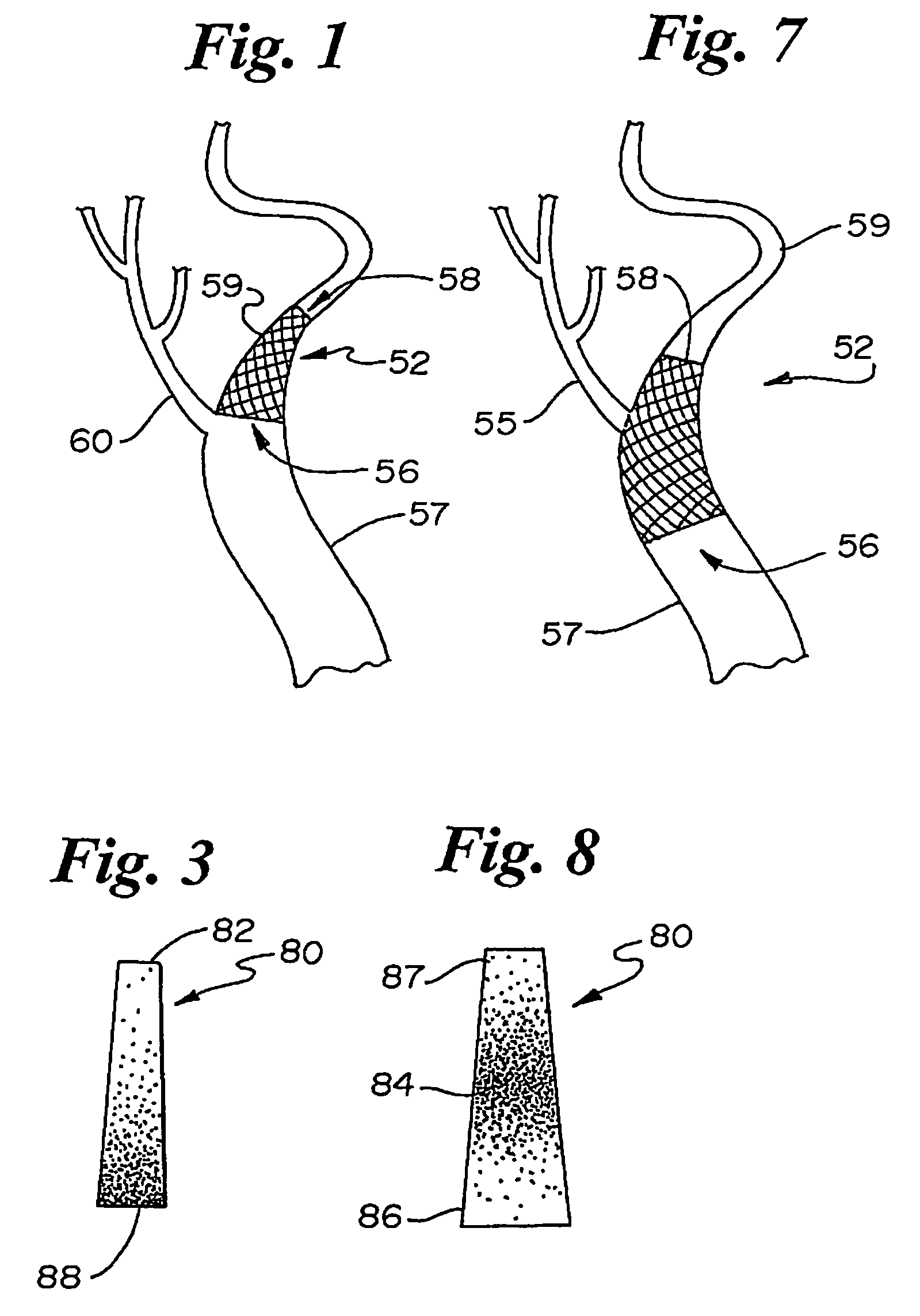

Vascular filter device

A vascular filter device comprises a support; and a filter comprising one or more filter elements configured to capture thrombus passing through a blood vessel. A holder holds the filter in a closed filtering state and releases to convert the filter to an open state after a period of time. The filter is adapted to retain thrombus after said conversion. In one case the filter elements are arranged to remain in a closed state after release by the holder, because they are blocked by a retained clot from opening fully, and the filter elements are biased to the open state with a bias level which is counter balanced by force exerted by a retained clot under action of blood flow.

Owner:COVIDIEN GROUP +1

Vascular filter device

A vascular filter device comprises a support; and a filter comprising one or more filter elements configured to capture thrombus passing through a blood vessel. A holder holds the filter in a closed filtering state and releases to convert the filter to an open state after a period of time. The filter is adapted to retain thrombus after said conversion. In one case the filter elements are arranged to remain in a closed state after release by the holder, because they are blocked by a retained clot from opening fully, and the filter elements are biased to the open state with a bias level which is counter balanced by force exerted by a retained clot under action of blood flow.

Owner:COVIDIEN GROUP +1

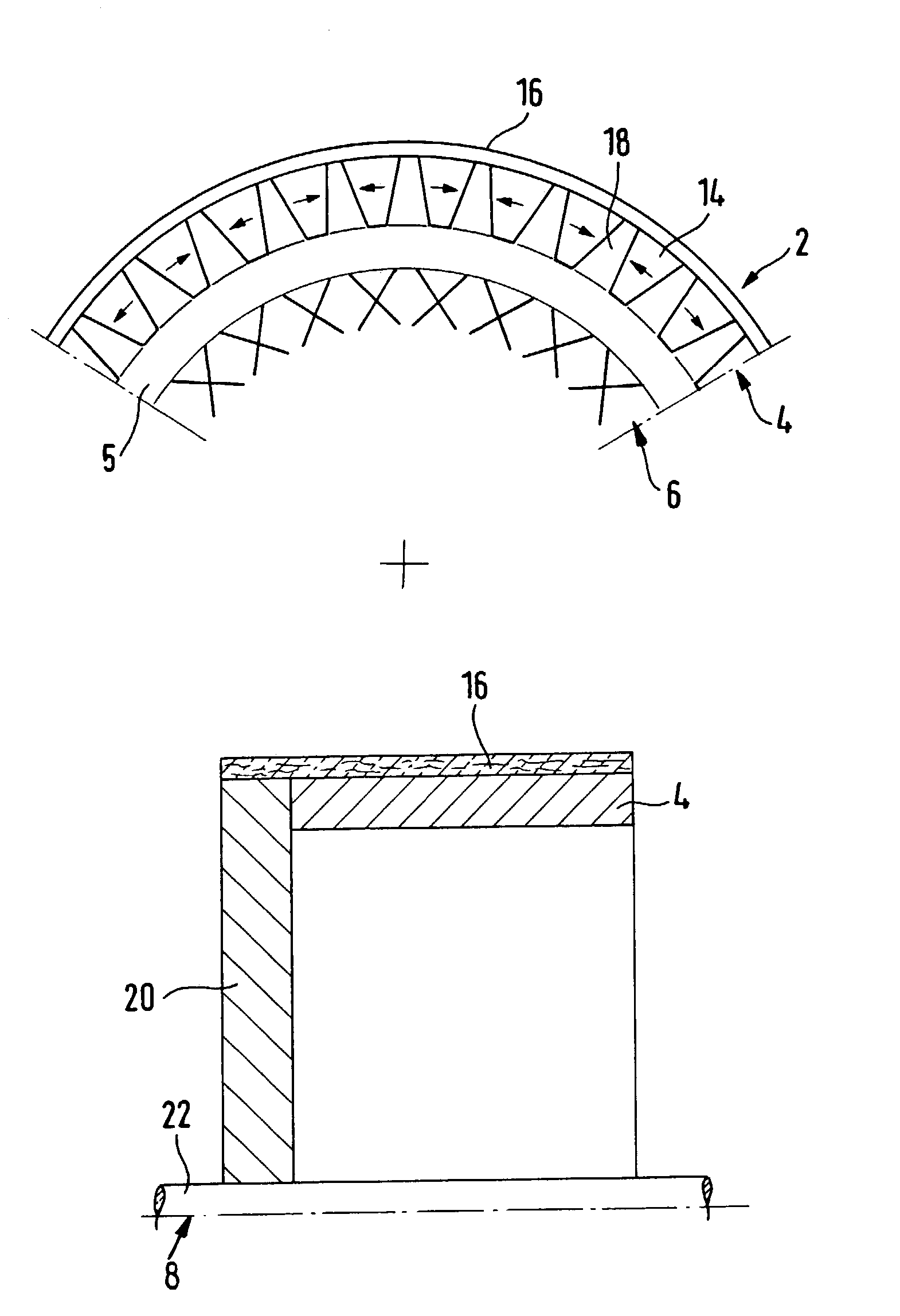

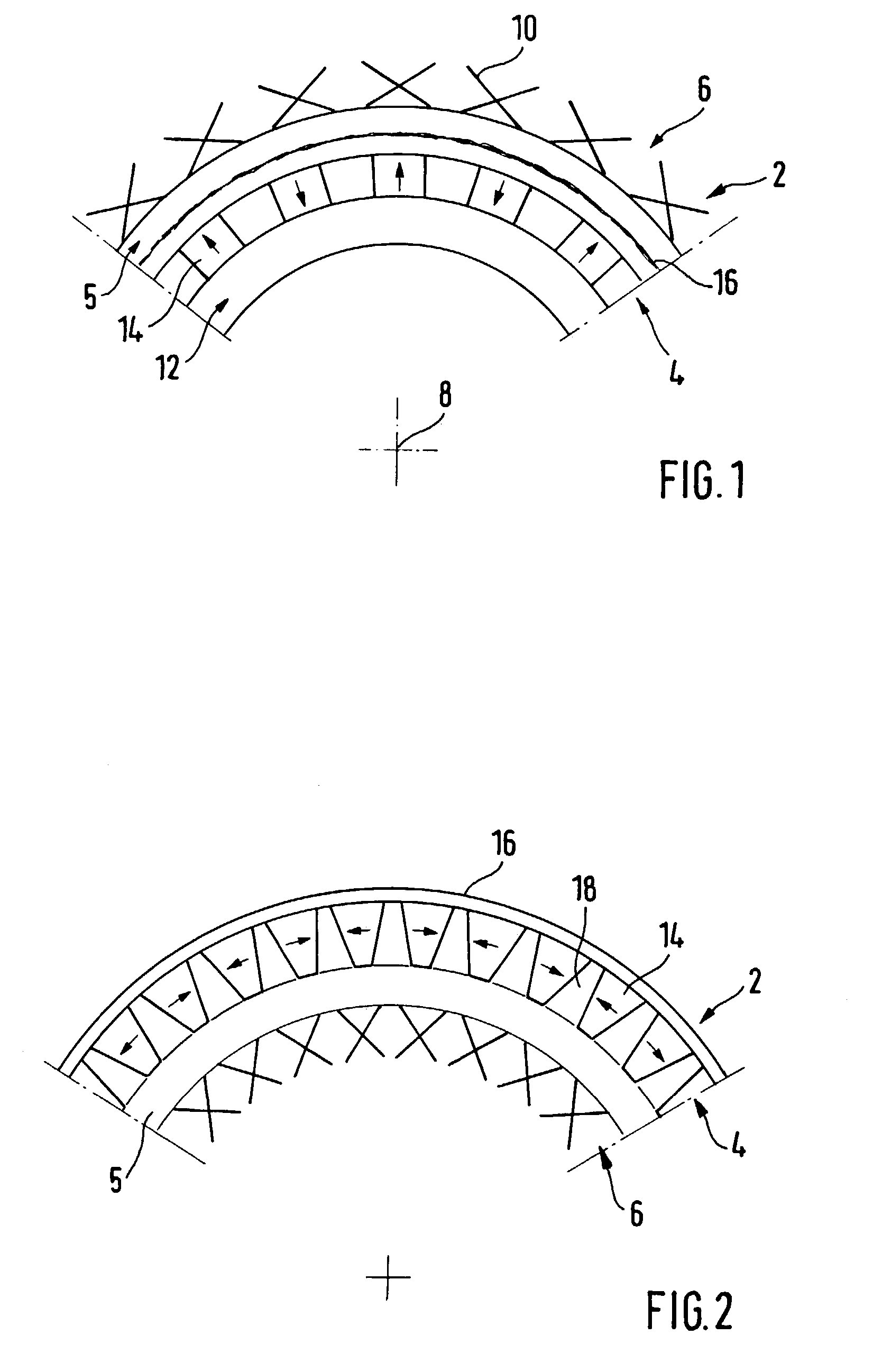

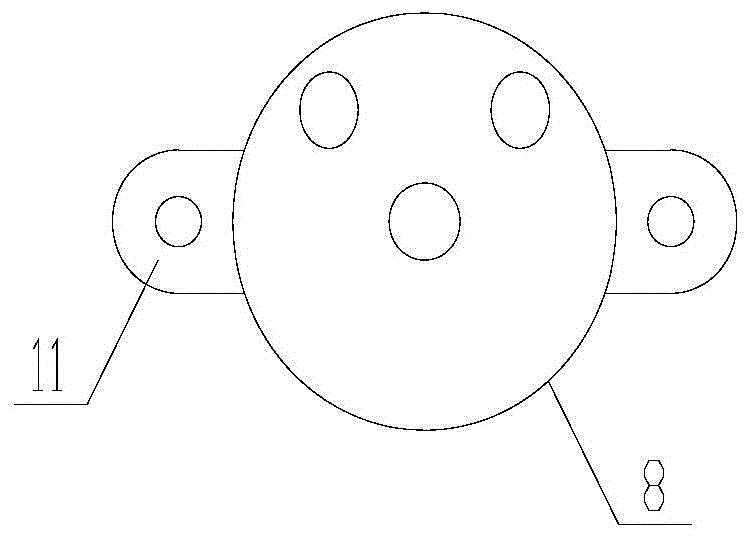

Electric machine

InactiveUS6995489B2Low costIncrease radial forceWindingsMagnetic circuit rotating partsFiberElectric machine

An electric machine (2) comprising a rotor (4) and a stator (6) arranged coaxially therewith, at least one of said rotor (4) and stator (6) being formed of a plurality of parts and there being provided a bandage (16) holding together the plurality of parts of said rotor and / or stator (6), wherein the bandage (16) is formed of an electrically non-conducting fiber material having a coefficient of thermal expansion similar to the coefficient of thermal expansion of the parts of said rotor (4) and / or stator (6).

Owner:L 3 COMM CORP

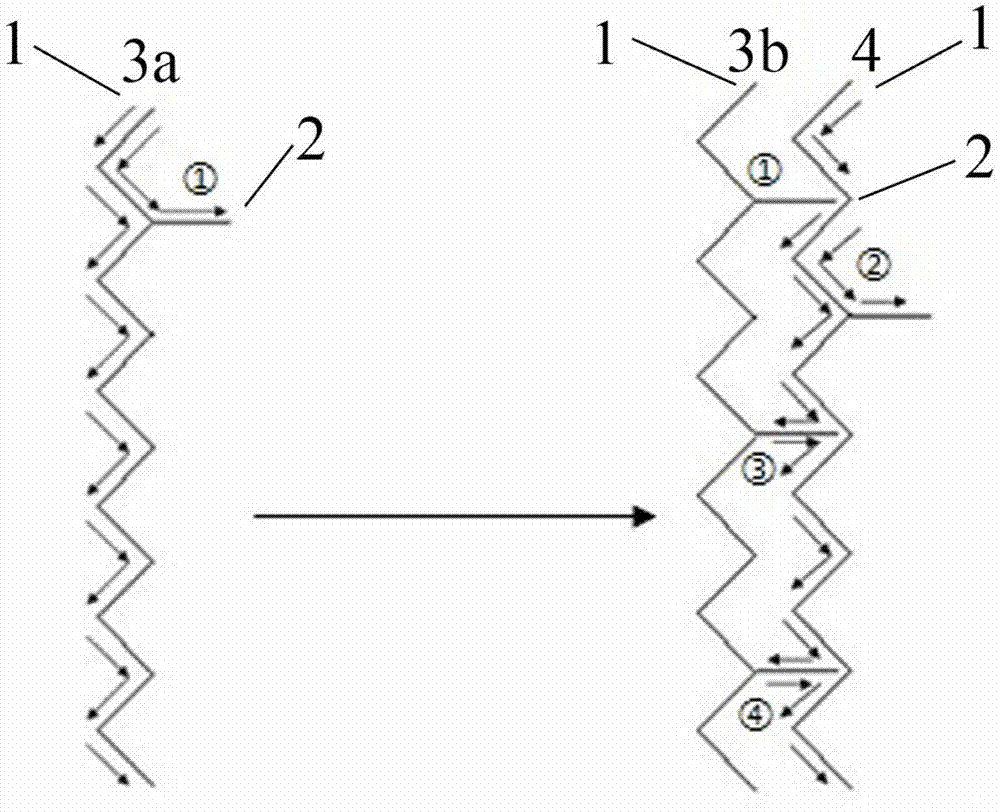

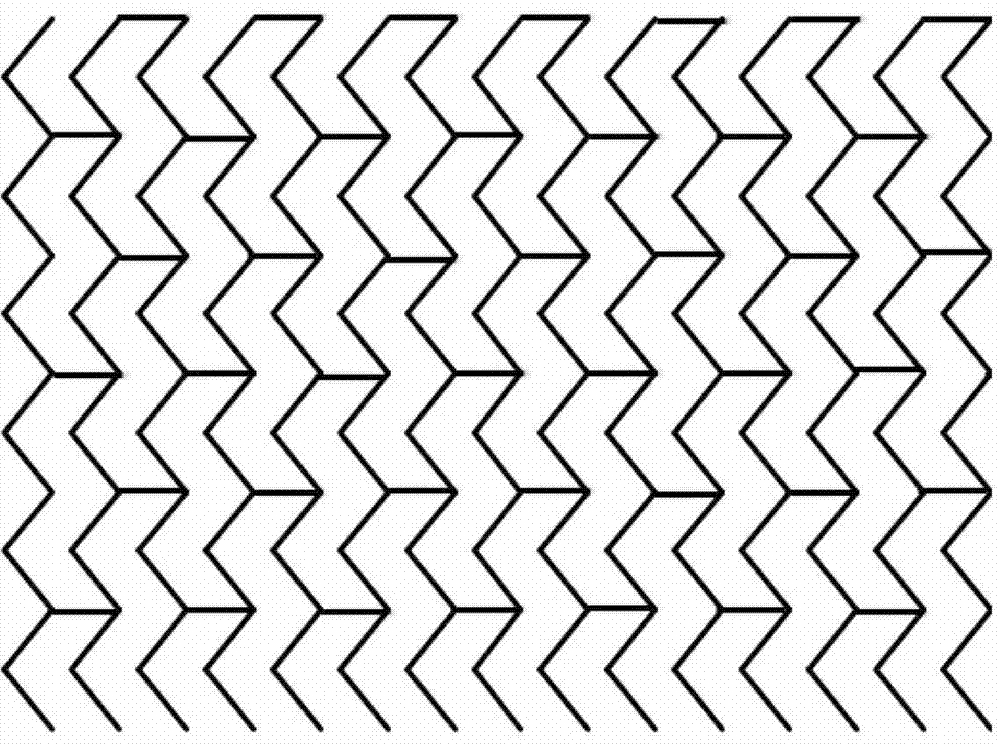

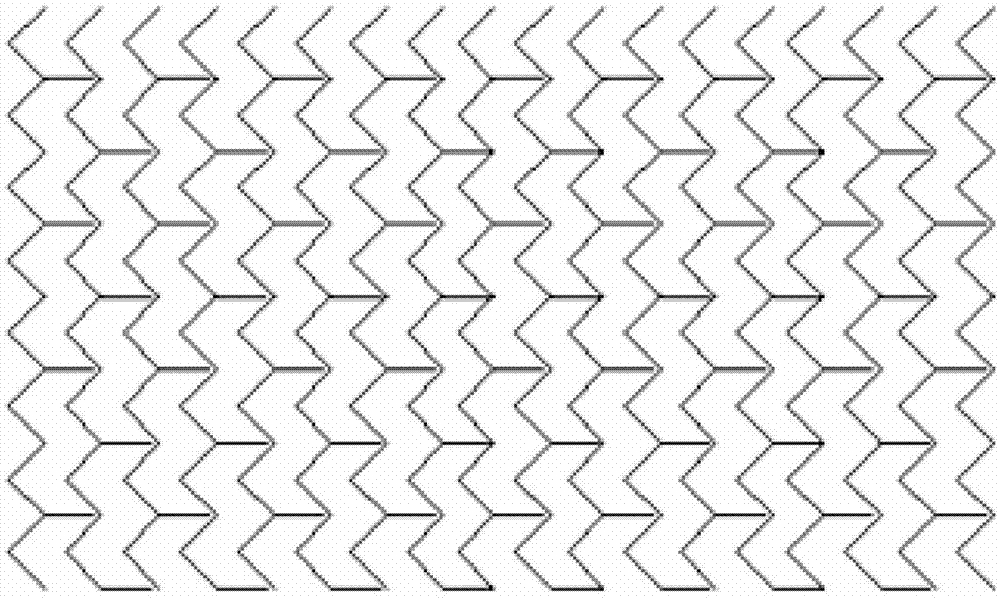

Degradable polymer support as well as forming method and application thereof

ActiveCN104274867AGood biocompatibilityPromote degradationStentsSurgeryPolymer supportedExtrusion moulding

The invention discloses an in vivo degradable support as well as a forming method and an application thereof. The in vivo degradable support is made from a biodegradable material, and an internal structure of the in vivo degradable support is Z-shaped and / or woven structure, a circular structure, a circular double chamfer structure and a woven parallel bridge structure. The forming method needs to utilize a rapid moulding system, wherein the rapid forming system comprises extrusion moulding equipment, a four-axis positioning system and an operating system for controlling production conditions. After a program is edited by utilizing a control system, fiber filaments extruded by extrusion equipment can be wound according to a structure set in the edited program; and the program can be easily changed, an ideal vascular scaffold can be prepared more easily, and better radial support force can be realized.

Owner:BEIJING ADVANCED MEDICAL TECH

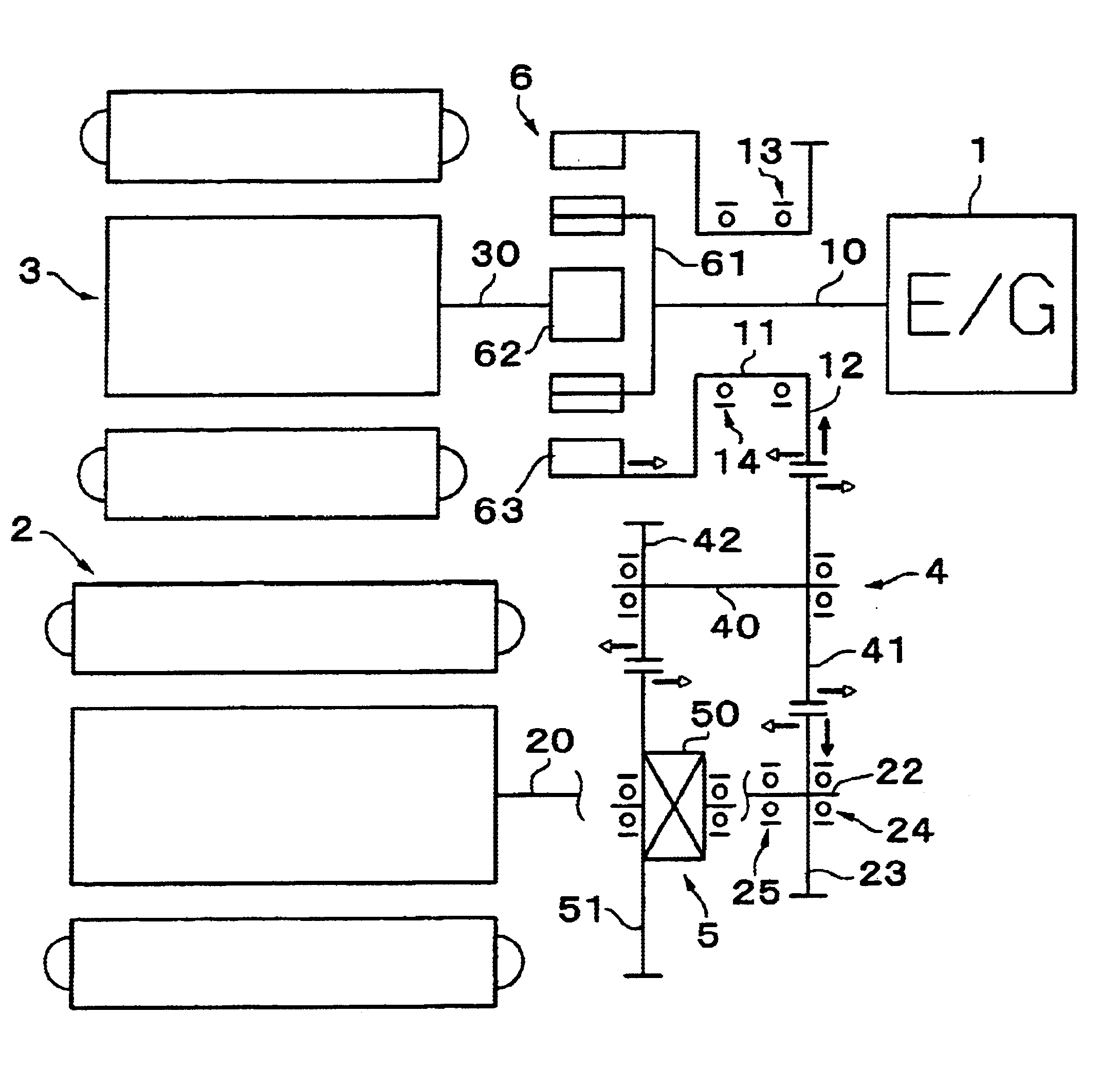

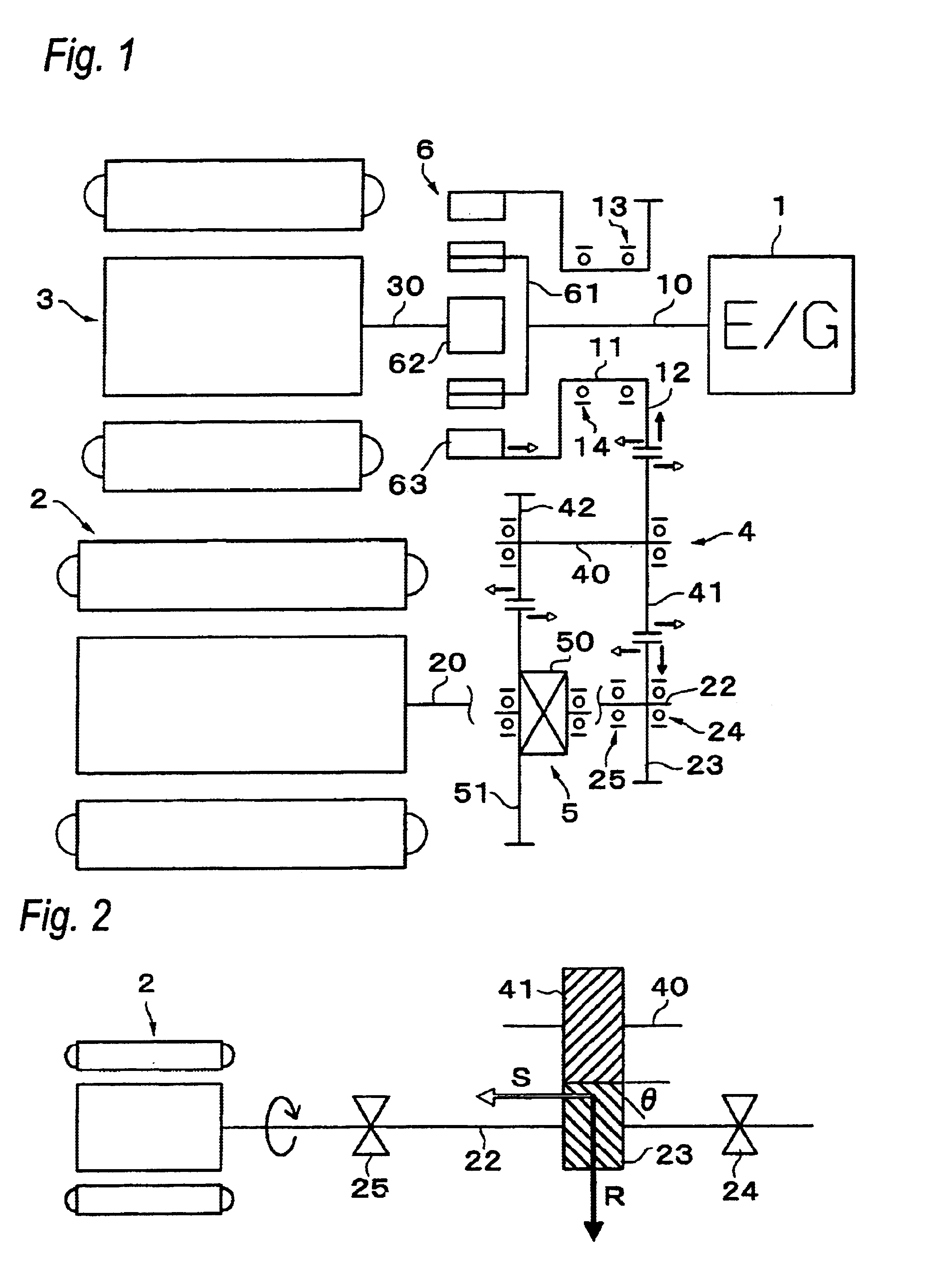

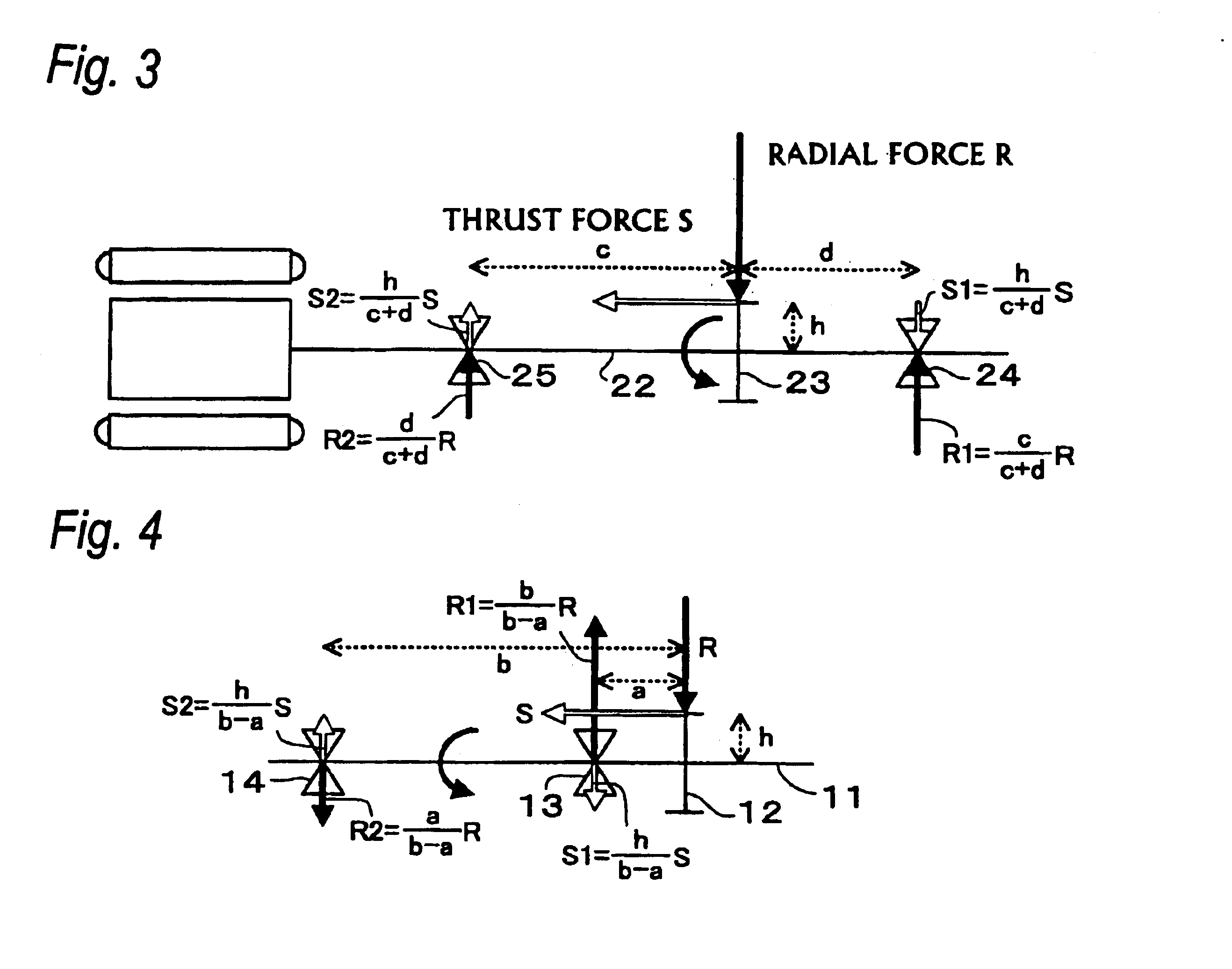

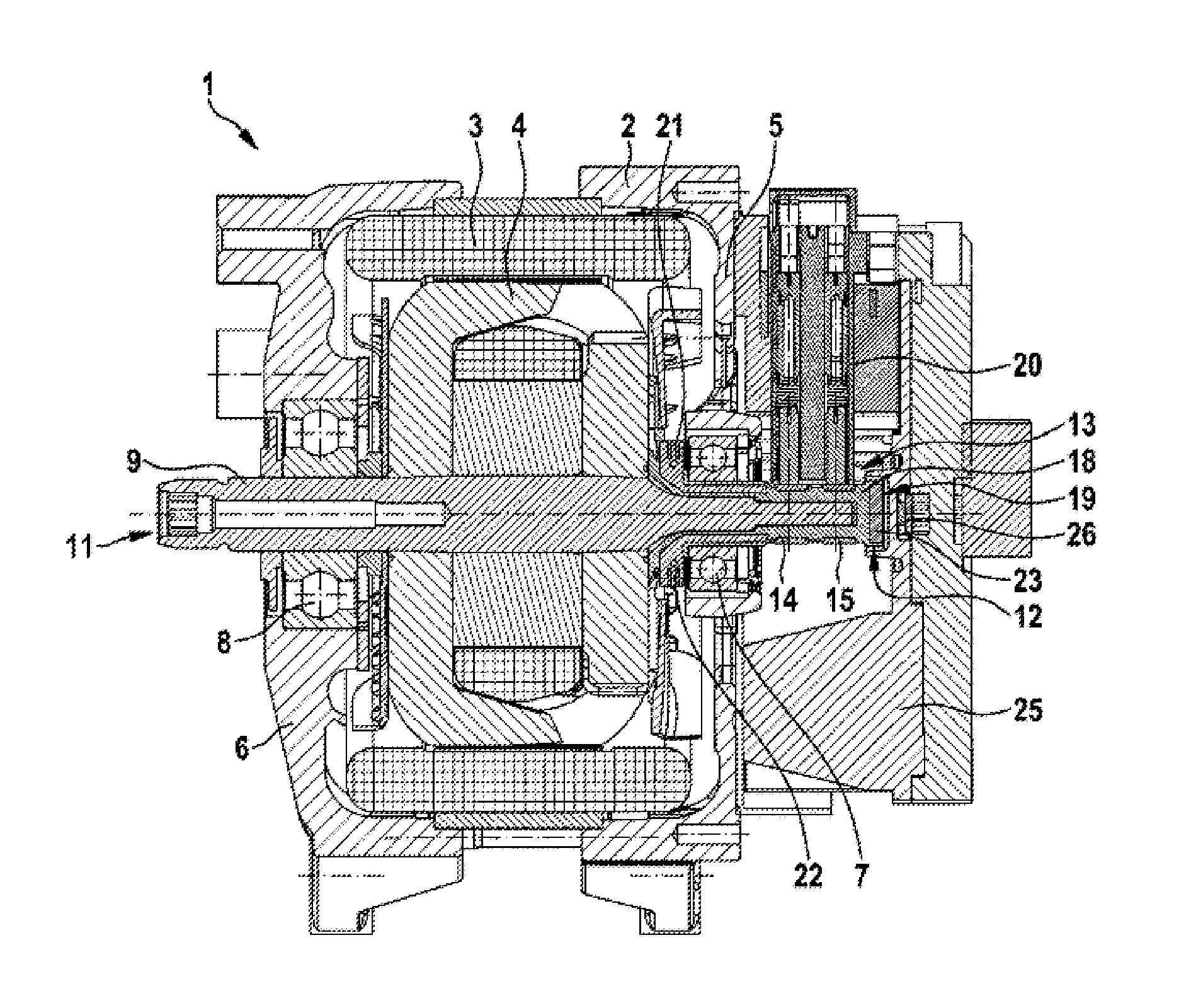

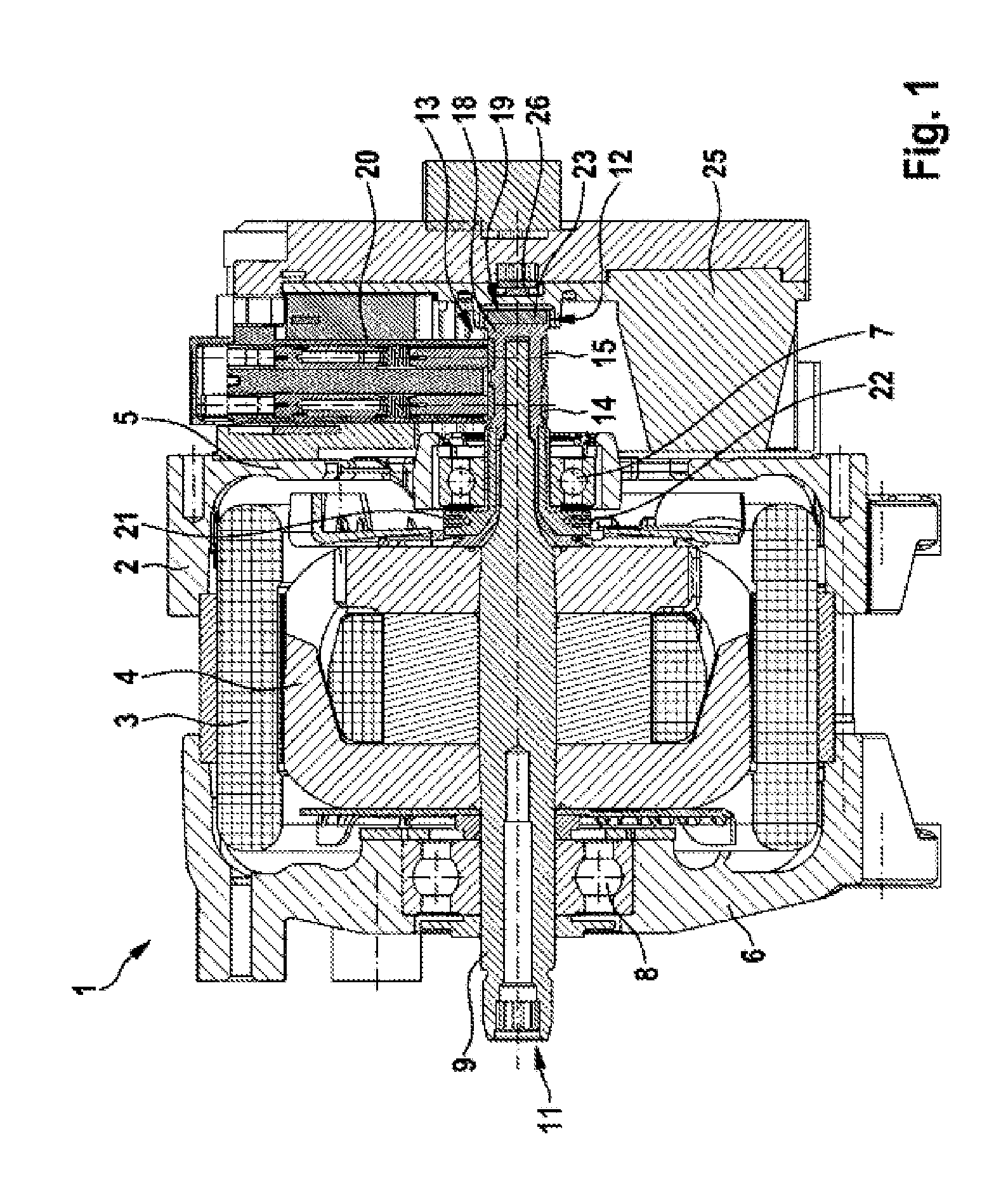

Driving apparatus having a shaft support structure

A driving apparatus having a shaft structure that reduces a load on shaft supports and enhances durability of the motor. The driving apparatus includes an electric motor, an electric motor shaft, first and second shaft supports, a counter drive gear on the electric motor shaft, and a counter driven gear to be meshed with the counter drive gear. Output of the electric motor is transmitted to wheels through both of the gears. The counter drive gear is disposed at a position closer to one of the shaft supports, a helix angle is set in a direction in which a thrust force S acts toward the second shaft support, which is farther from the gear. With this arrangement, a load caused by a radial force applied to the first shaft support, which is closer to the counter drive gear, is reduced.

Owner:AISIN AW CO LTD

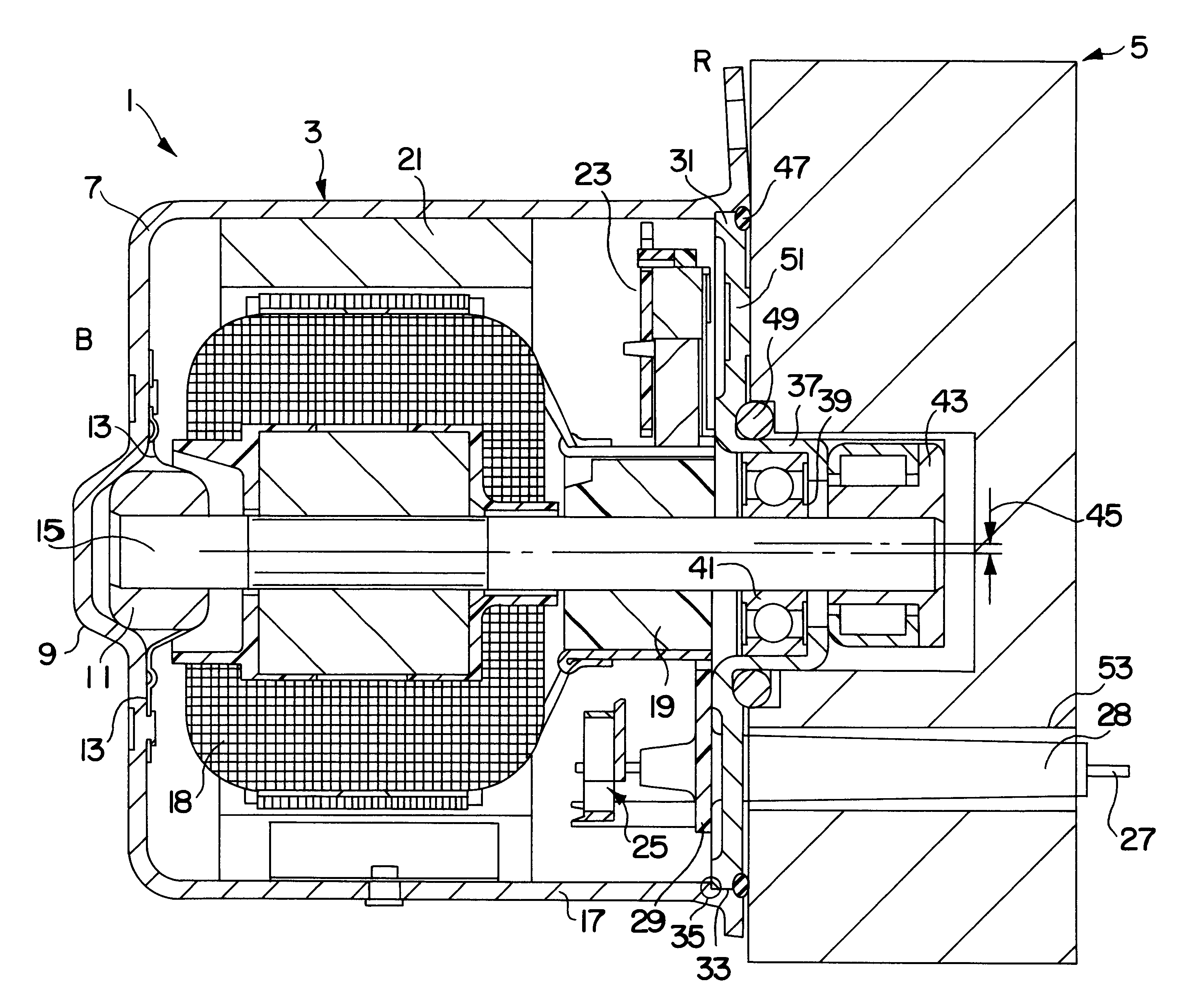

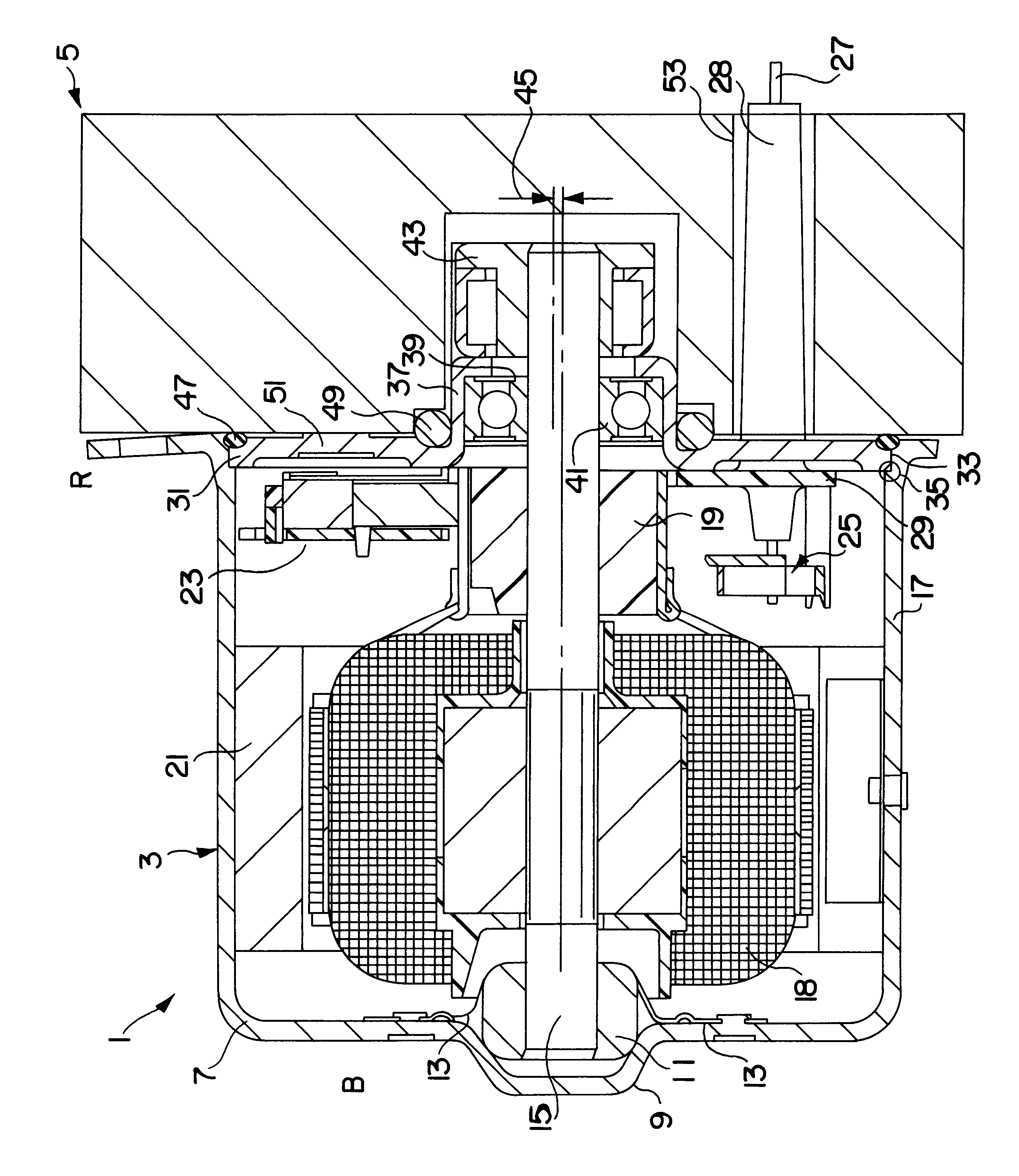

Electric machine

ActiveUS20130200757A1Simple wayConvenient ArrangementWindingsDC commutatorElectric machineEngineering

An electric machine (1), in particular for a drive apparatus for a motor vehicle, comprising a rotor shaft (9), which is mounted rotatably in a housing (2), comprising a slip ring device (13), which has at least two slip rings (14, 15) arranged in rotationally fixed fashion on the rotor shaft (9) and at least two sliding contacts (16, 17), which are arranged in the housing (2) and interact with in each case one of the slip rings (14, 15), and comprising a rotation angle detection device, which has at least one rotation angle encoder (23) arranged on the rotor shaft (9) and at least one rotation angle sensor (26) arranged in the housing for detecting the rotation angle encoder (23).

Owner:ROBERT BOSCH GMBH +1

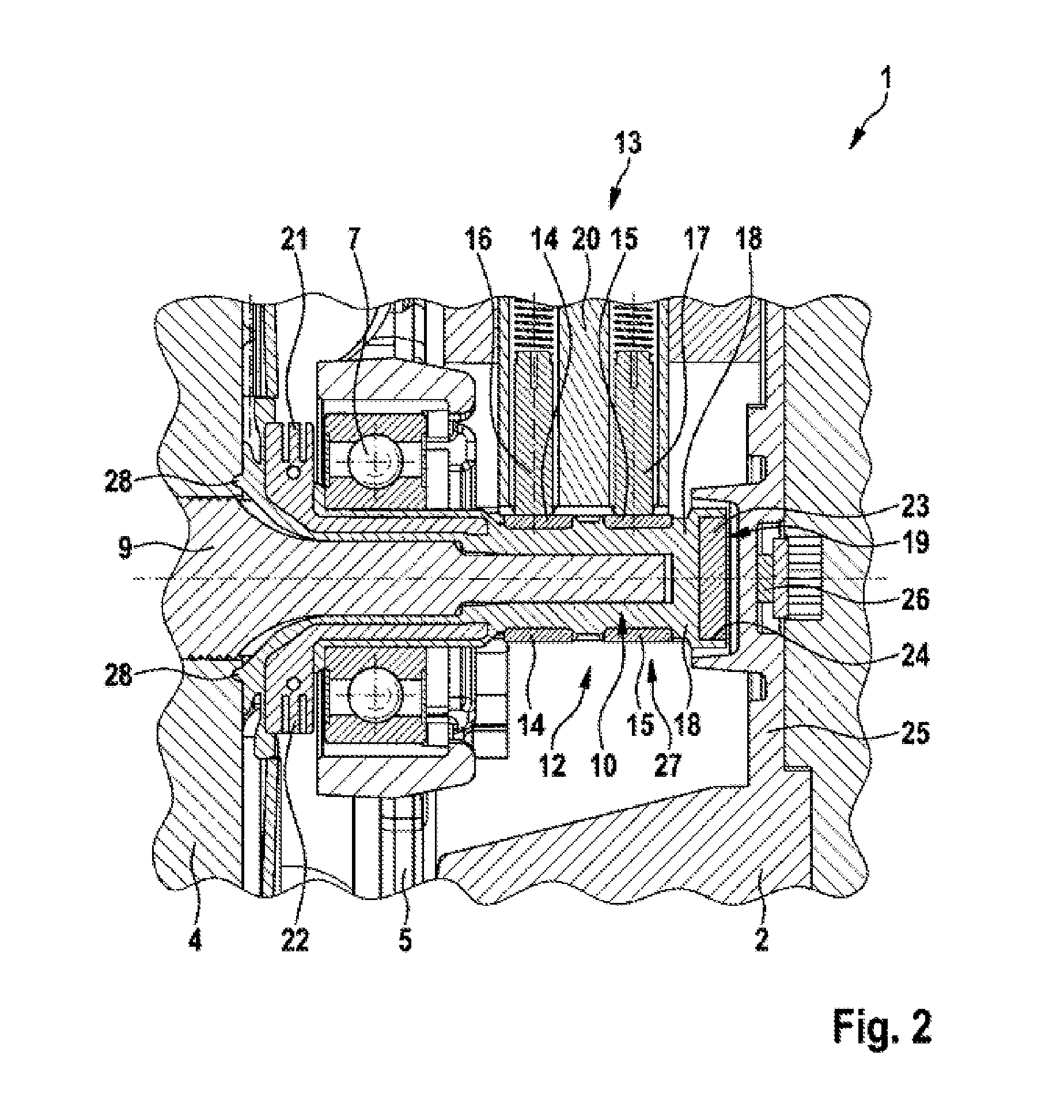

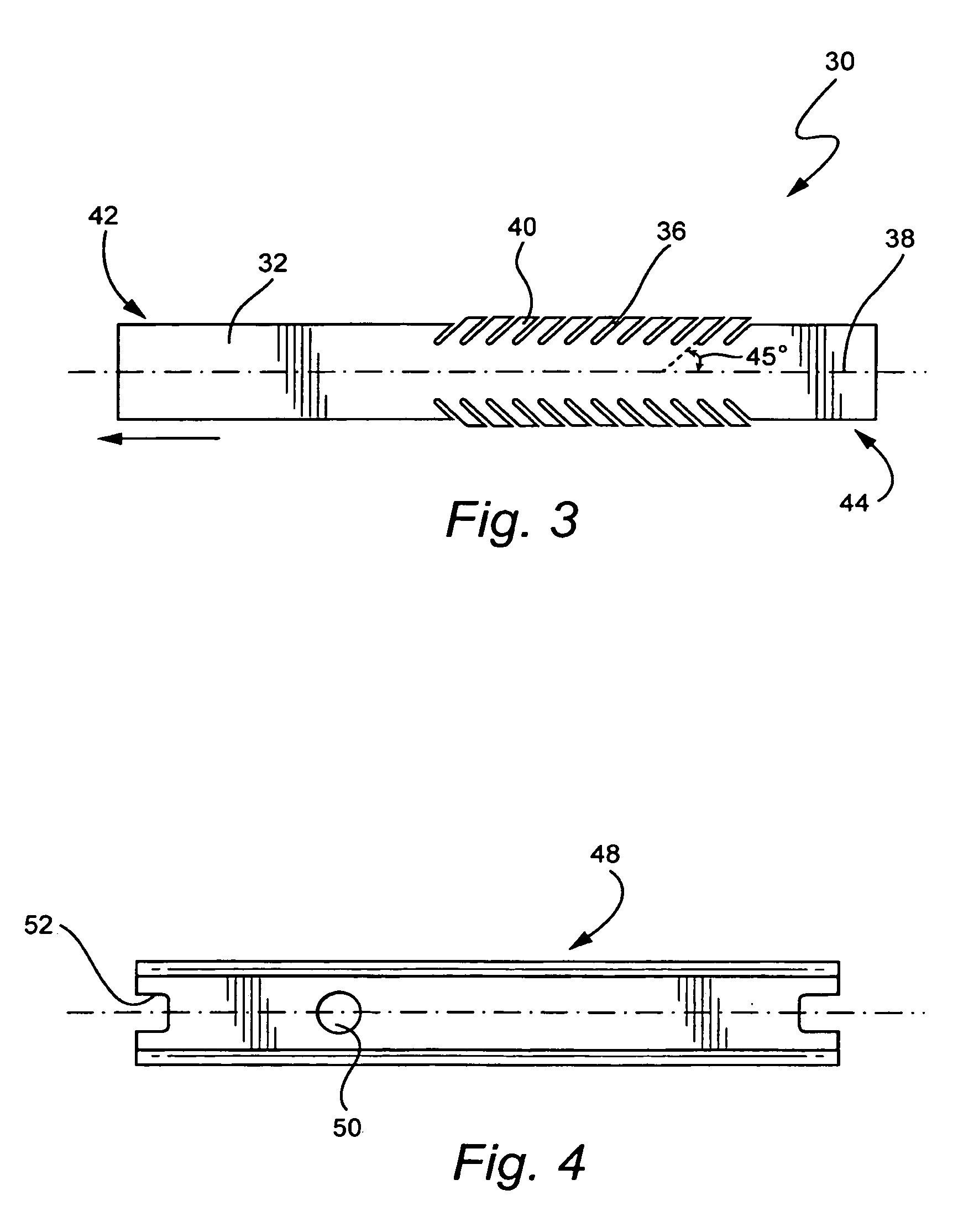

Motor-pump arrangement

InactiveUS6179580B1High strengthIncrease radial forcePiston pumpsMechanical energy handlingDrive shaftEngineering

The invention relates to a motor-pump arrangement, having a cup-shaped motor housing for receiving an electric motor, and a pump housing that can be mounted on the motor housing. The pump housing can be mounted on the face end (R) of the motor housing opposite the cup bottom, and that a cap is provided, which can be pressed into the motor housing on the open face end and seals off this housing, the cap has a central bore for a drive shaft and at least one further opening, near the edge, for a through-plated hole.

Owner:ROBERT BOSCH GMBH

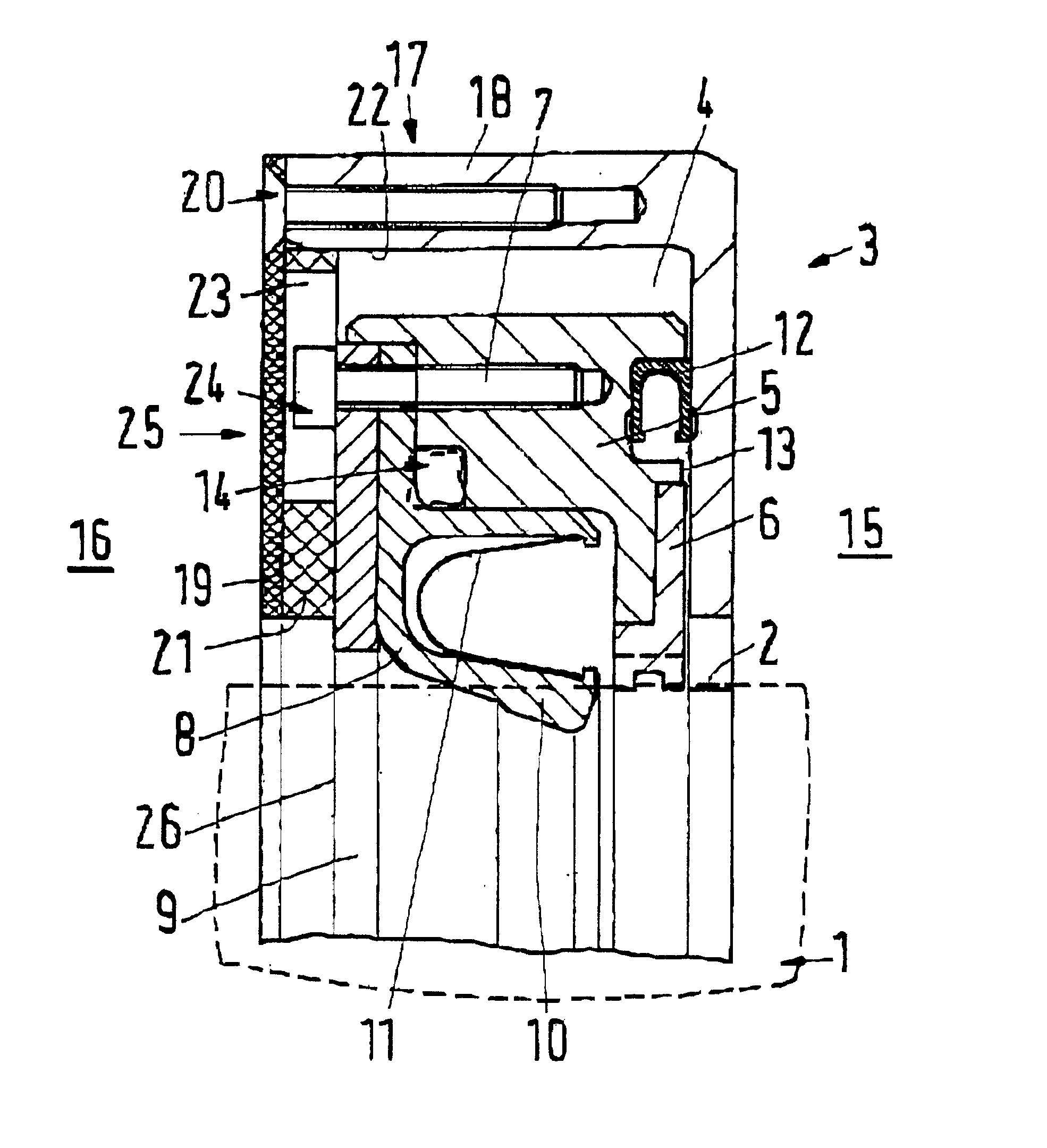

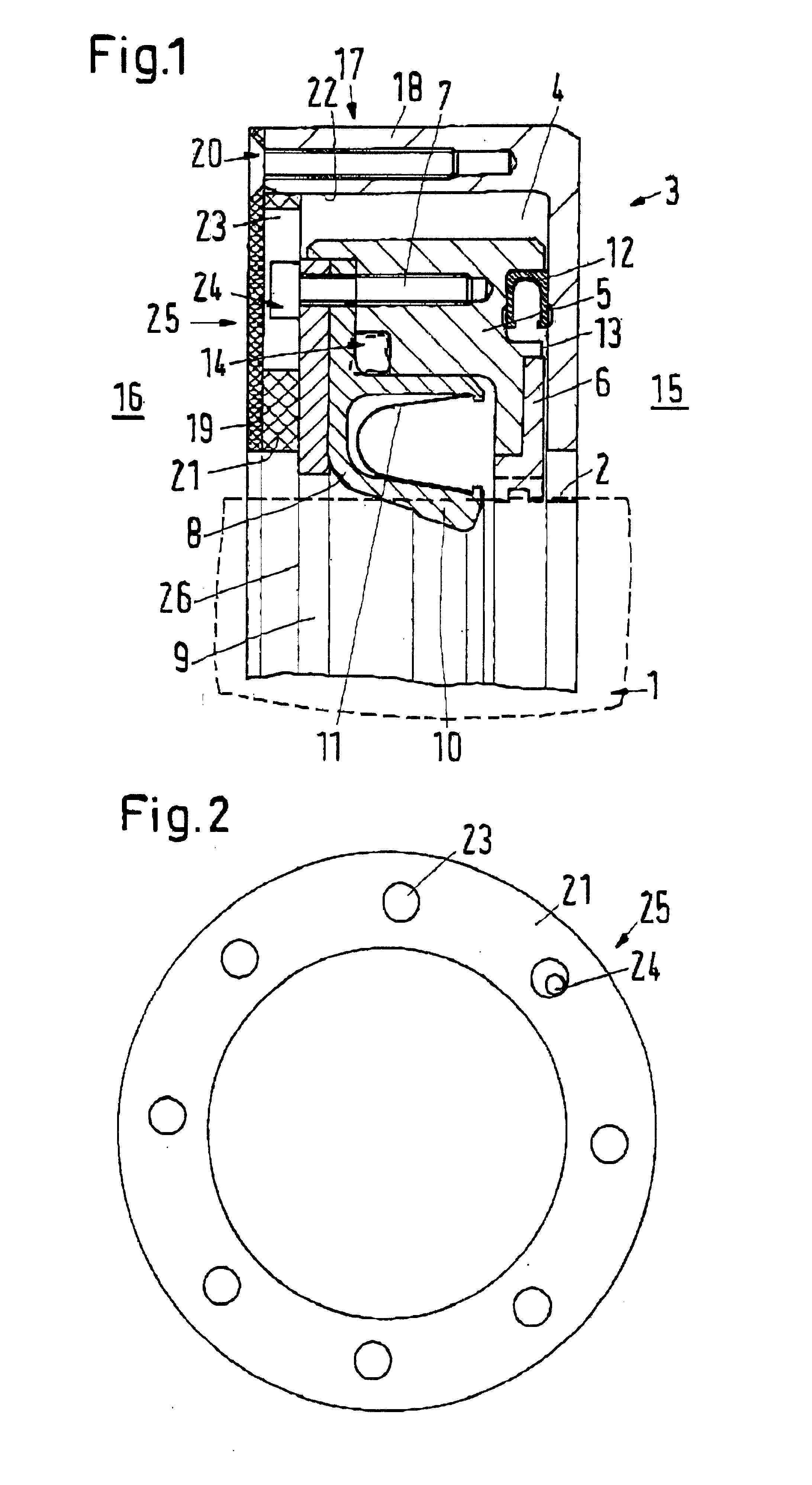

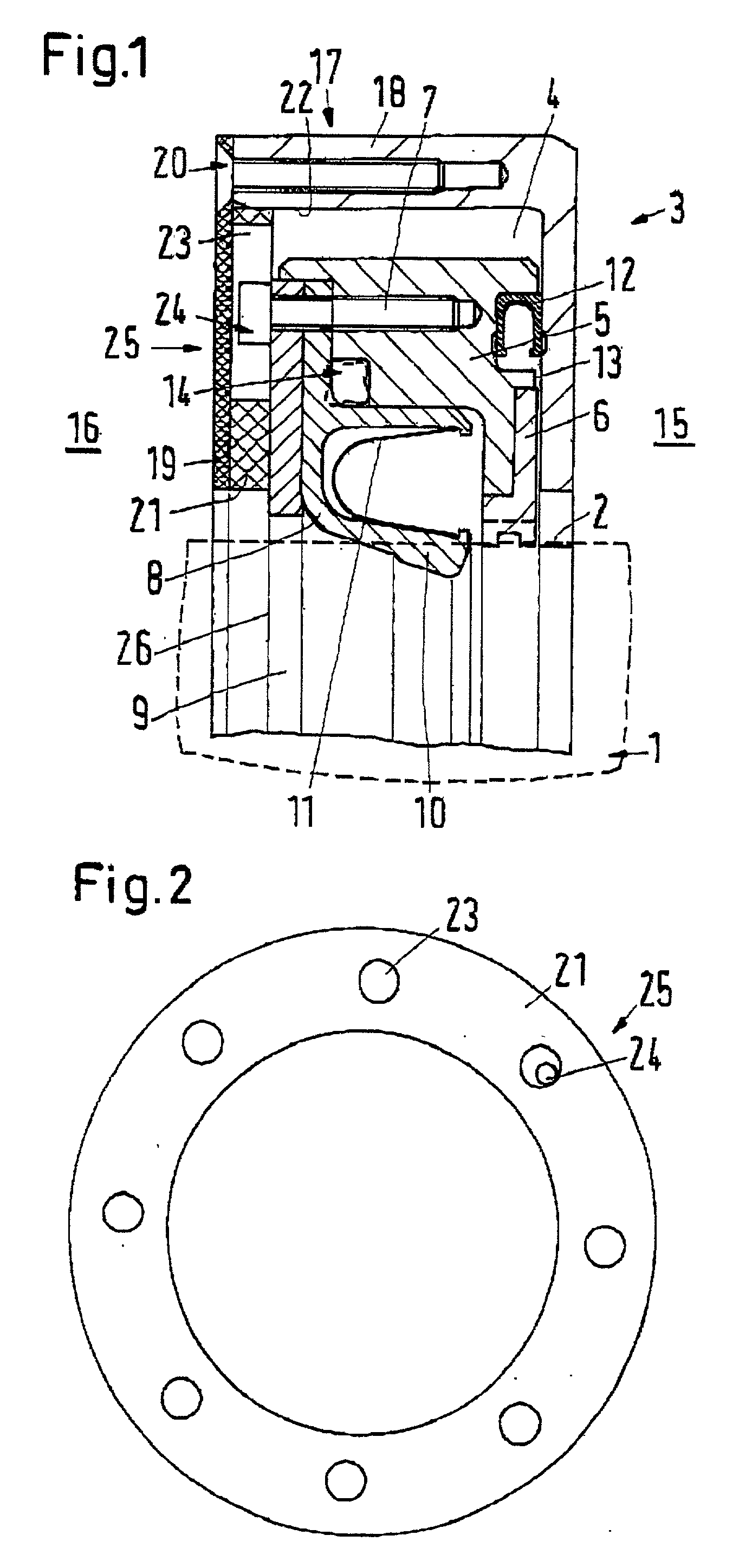

Sealing arrangement between two components rotating relative to one another

Sealing arrangement between relatively rotatable components that includes a first component having a cylindrical circumferential surface on one of an interior and exterior circumference, and a second component having a ring groove open toward the circumferential surface. A ring-shaped carrier is arranged to be displaceable in the ring groove, a centering rod is arranged to guide the ring-shaped carrier on the circumferential surface, and a radial lip seal is arranged to rest against the circumferential surface in an elastic manner. An axial seal is arranged to rest against a side wall of the ring groove, and an anti-twisting device is coupled to the ring-shaped carrier and arranged to enable a limited range of motion in all directions of a radial plane.

Owner:VOITH PATENT GMBH +1

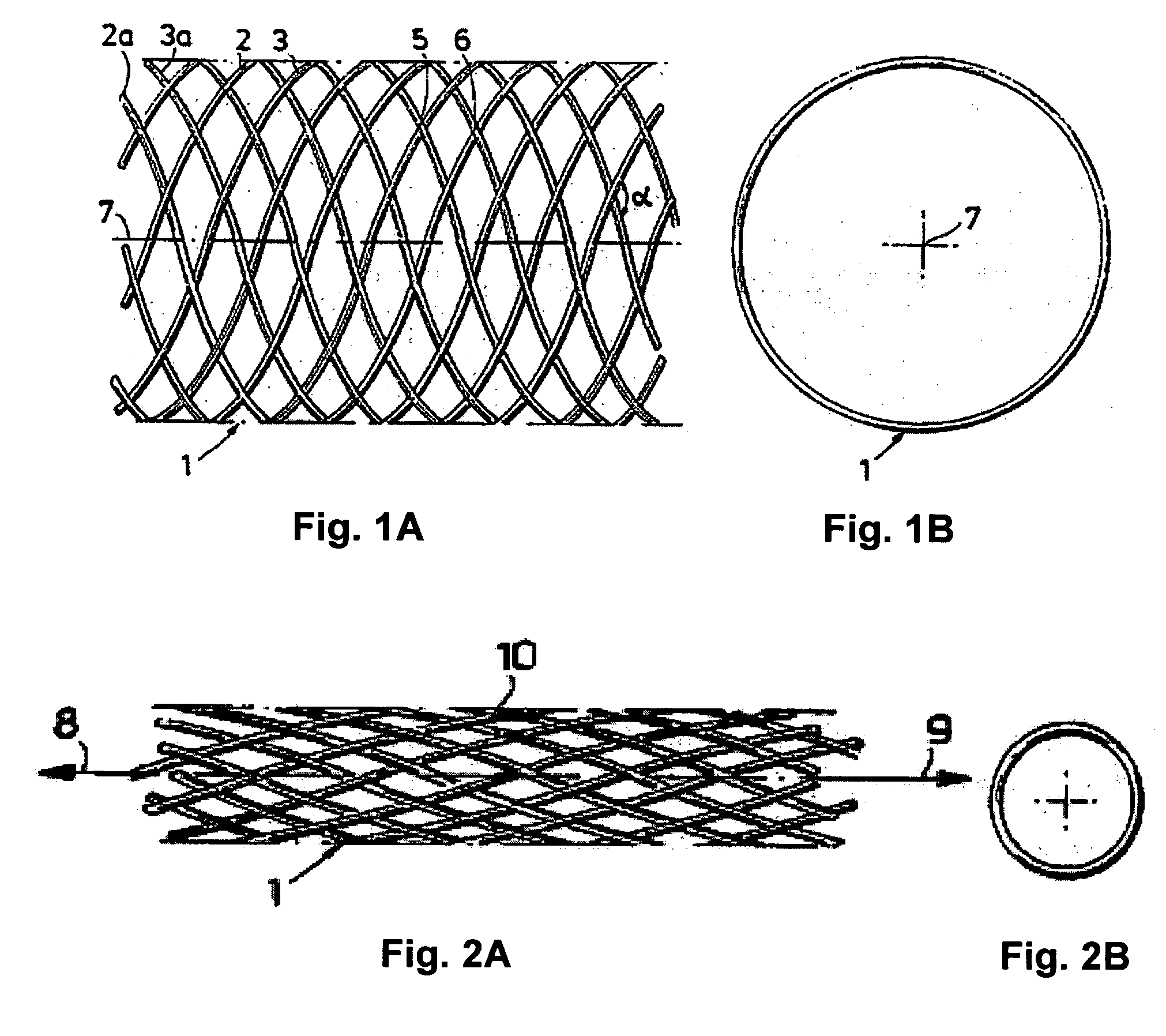

Stent having less invasive ends and improved radial force

The present invention provides a stent having less invasive ends and improved radial force. In one embodiment, the stent comprises a series of proximal apices disposed at a proximal end of the stent, a series of distal apices disposed at a distal end of the stent, and at least one angled strut segment disposed between the proximal and distal apices of the stent. At least one apex of the stent may comprise multiple curved portions. In one example, the radius of curvature of one of the curved portions is significantly greater, for example, at least 10 times greater, than each of the other radii of curvature of the apex. The curved portion having the significantly greater radius of curvature may be configured to engage a vessel wall in a less invasive manner.

Owner:COOK MEDICAL TECH LLC

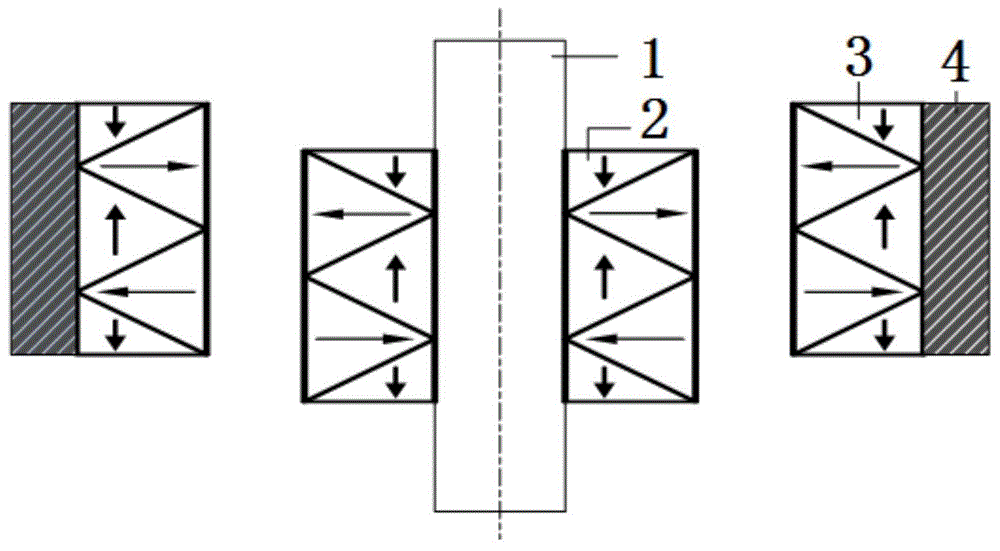

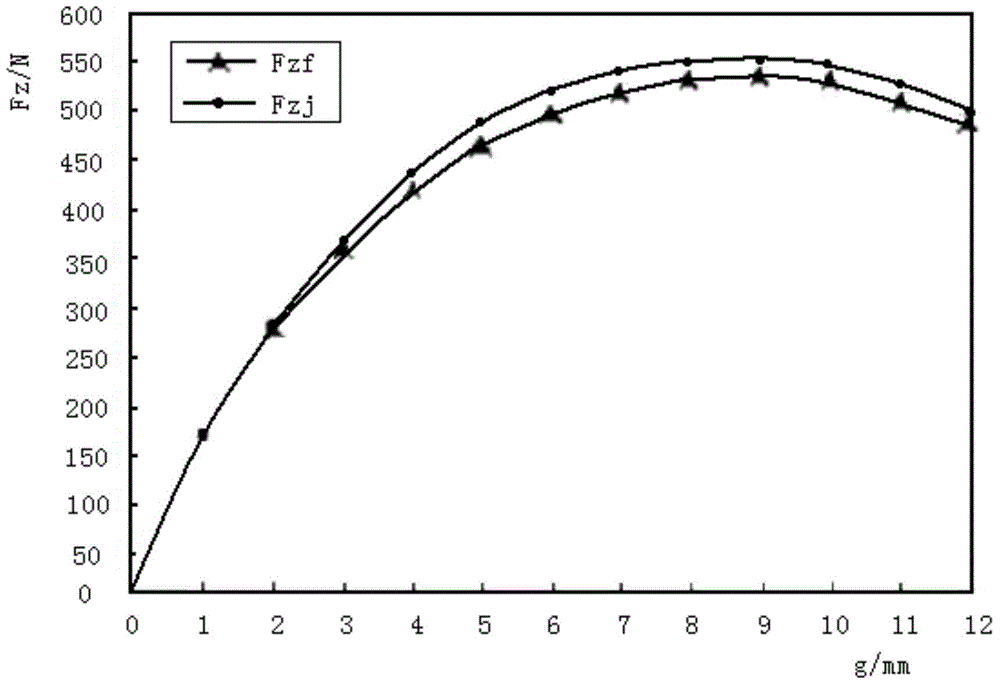

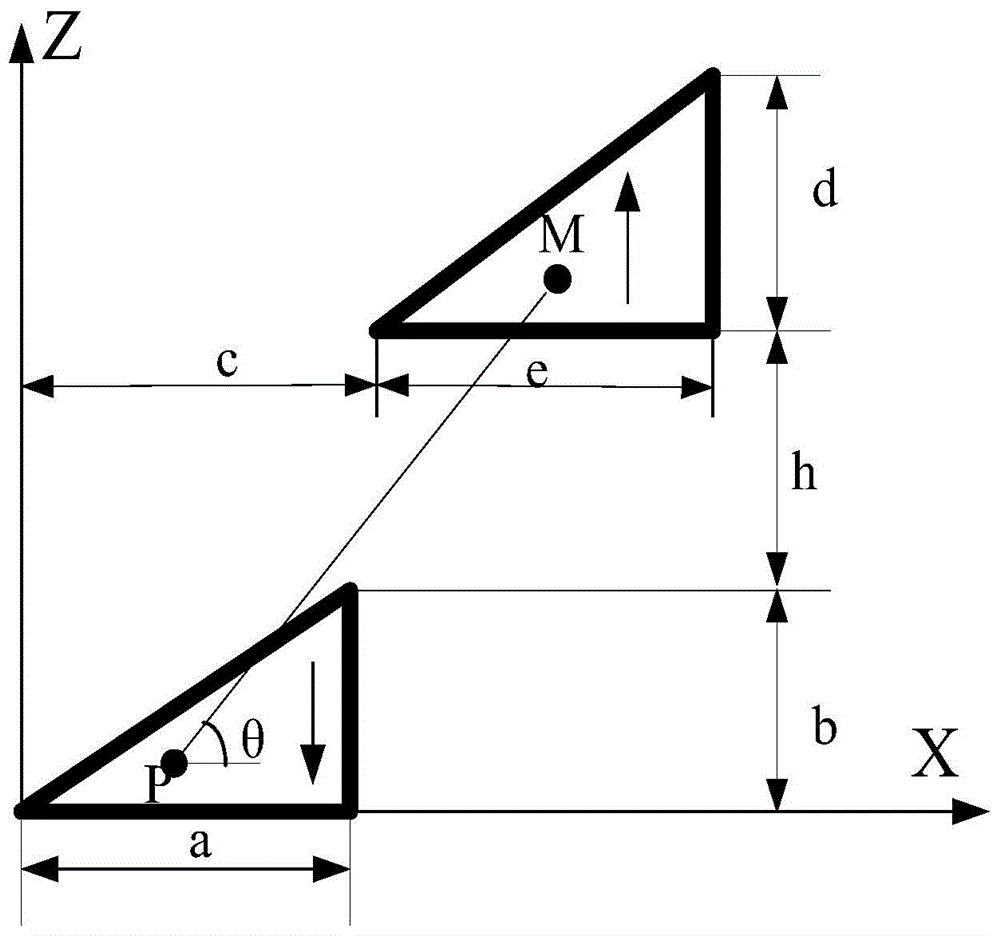

Halbach permanent magnetic bearing obtained by lap piling of permanent magnetic rings having triangular sections

The invention discloses a Halbach permanent magnetic bearing obtained by lap piling of permanent magnetic rings having triangular sections. The Halbach permanent magnetic bearing comprises a rotor and a stator corresponding to the rotor. Multiple movable magnet rings are piled around the shaft of the rotor. Multiple static magnet rings are piled on the inner circle surface of the stator. The multiple static magnet rings and multiple movable magnet rings are respectively piled to form cylindrical structures. The movable magnet rings and the static magnet rings are obtained by lap piling of the permanent magnetic rings having triangle sections according to a Halbach array. The movable magnet rings and the static magnet rings comprise the permanent magnetic rings having triangle sections and different radiuses. The invention also discloses a magnetic force determination method of the Halbach permanent magnetic bearing obtained by lap piling of the permanent magnetic rings having triangle sections. The device and method have the advantages that obvious improvement of a radial force or an axial force is realized, a permanent magnet material is saved, an operation process is simple and accuracy is high.

Owner:XIAN UNIV OF TECH

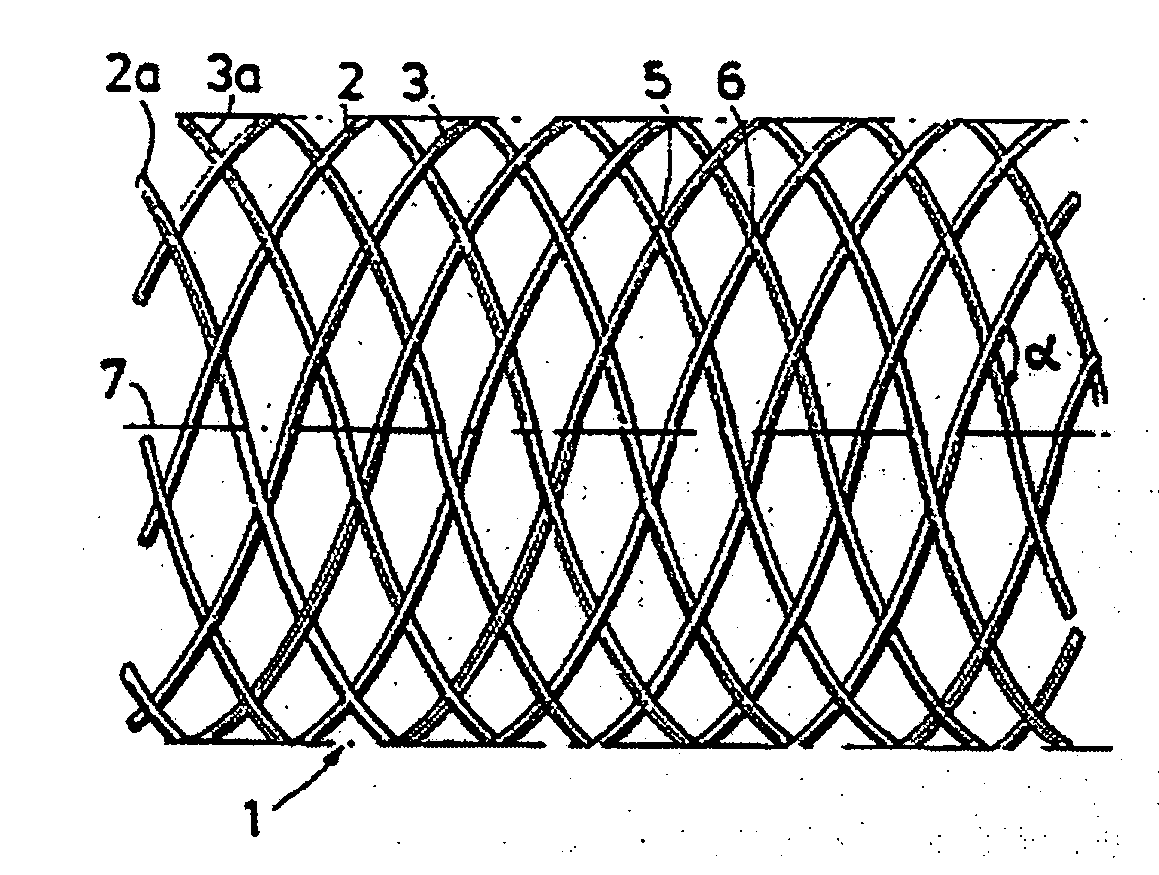

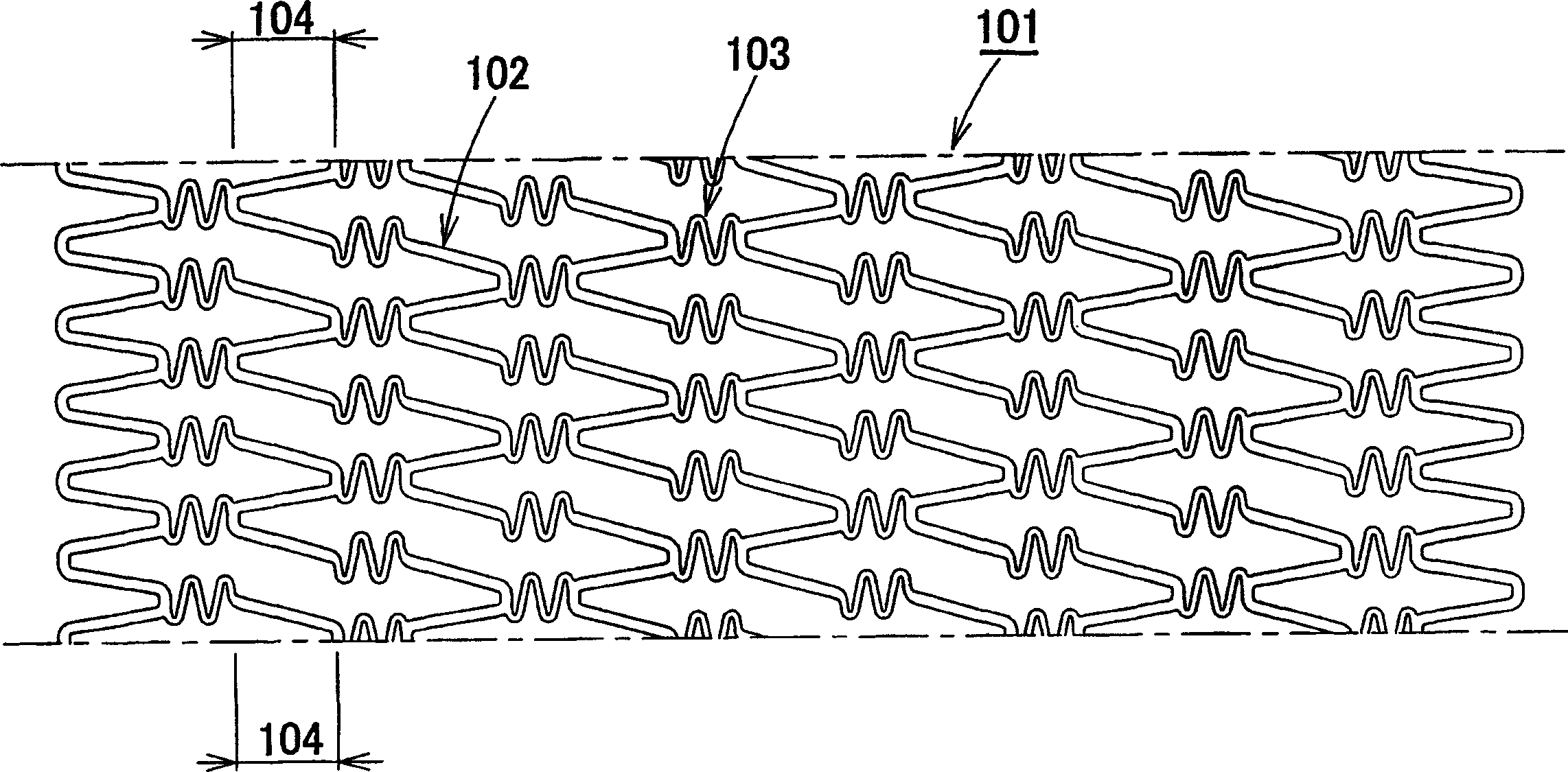

Stent

The present invention provides a stent which is flexible in the axial direction prior to the expansion of the stent, which shows no contraction in the axial length of the stent during expansion of the stent, which has an extremely large resistance to forces exerted by contracting blood vessels after expansion, which can cause uniform expansion of the struts of the stent, and in which there is no problem of the end portions of the stent warping to a greater diameter than the central portion of the stent at the time of expansion, furthermore a stent in which the size of the basic cells that constitute the stent is reduced so that bulging of endothelial cells of vascular tissues into the inside of the stent is suppressed, furthermore a stent which allows Y stenting into branched blood vessels while maintaining a high radial force and superior scaffold properties.

Owner:KANEKA CORP

Sealing arrangement between two components rotating relative to one another

Sealing arrangement between relatively rotatable components that includes a first component having a cylindrical circumferential surface on one of an interior and exterior circumference, and a second component having a ring groove open toward the circumferential surface. A ring-shaped carrier is arranged to be displaceable in the ring groove, a centering rod is arranged to guide the ring-shaped carrier on the circumferential surface, and a radial lip seal is arranged to rest against the circumferential surface in an elastic manner. An axial seal is arranged to rest against a side wall of the ring groove, and an anti-twisting device is coupled to the ring-shaped carrier and arranged to enable a limited range of motion in all directions of a radial plane.

Owner:VOITH PATENT GMBH +1

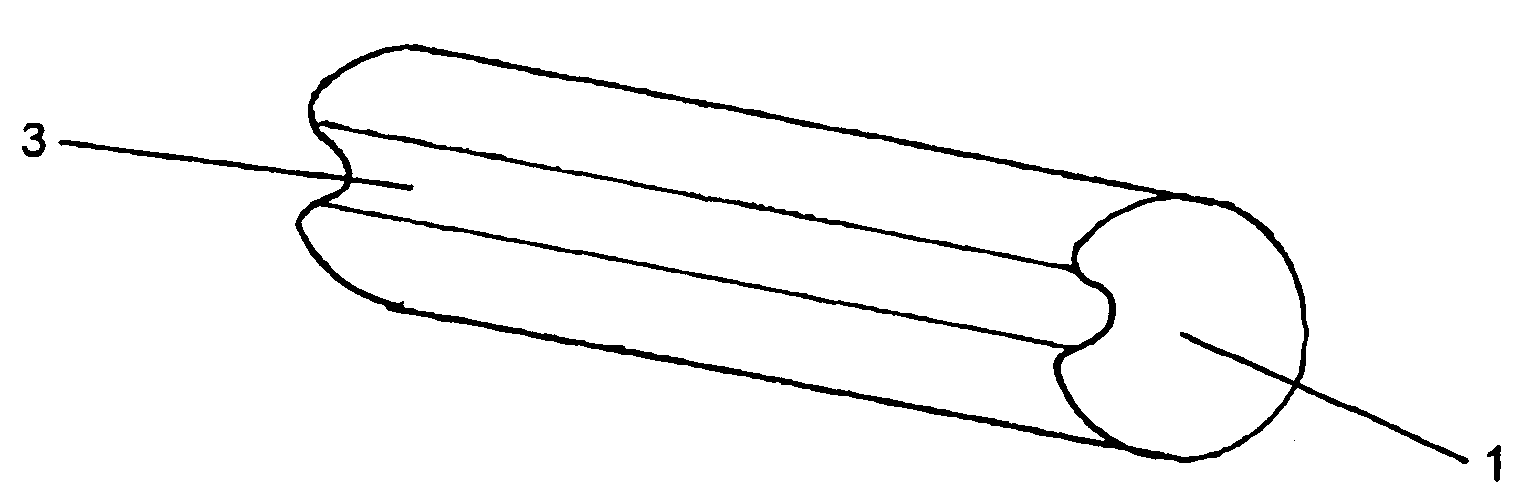

Compressible tubular tissue supports

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH

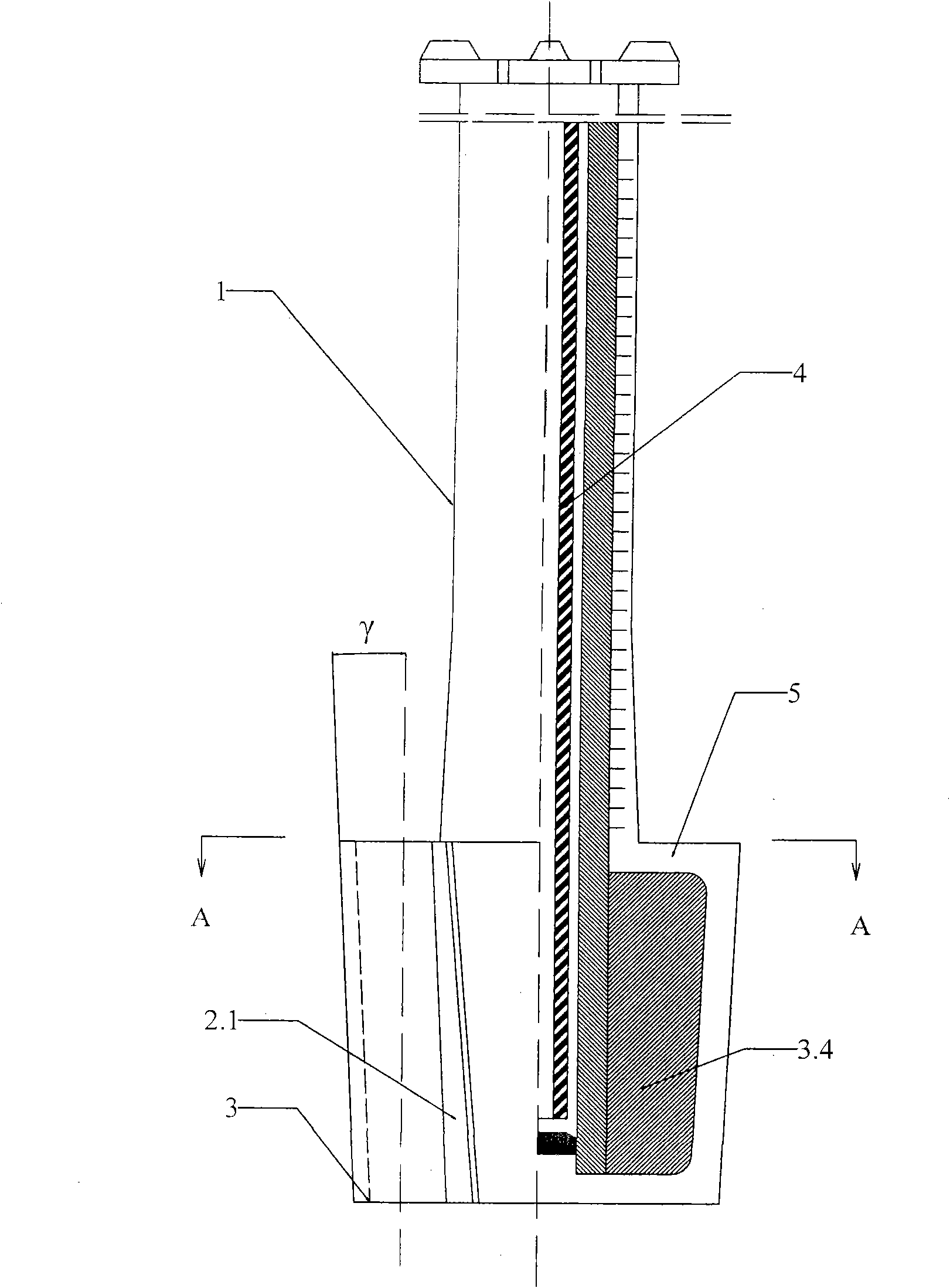

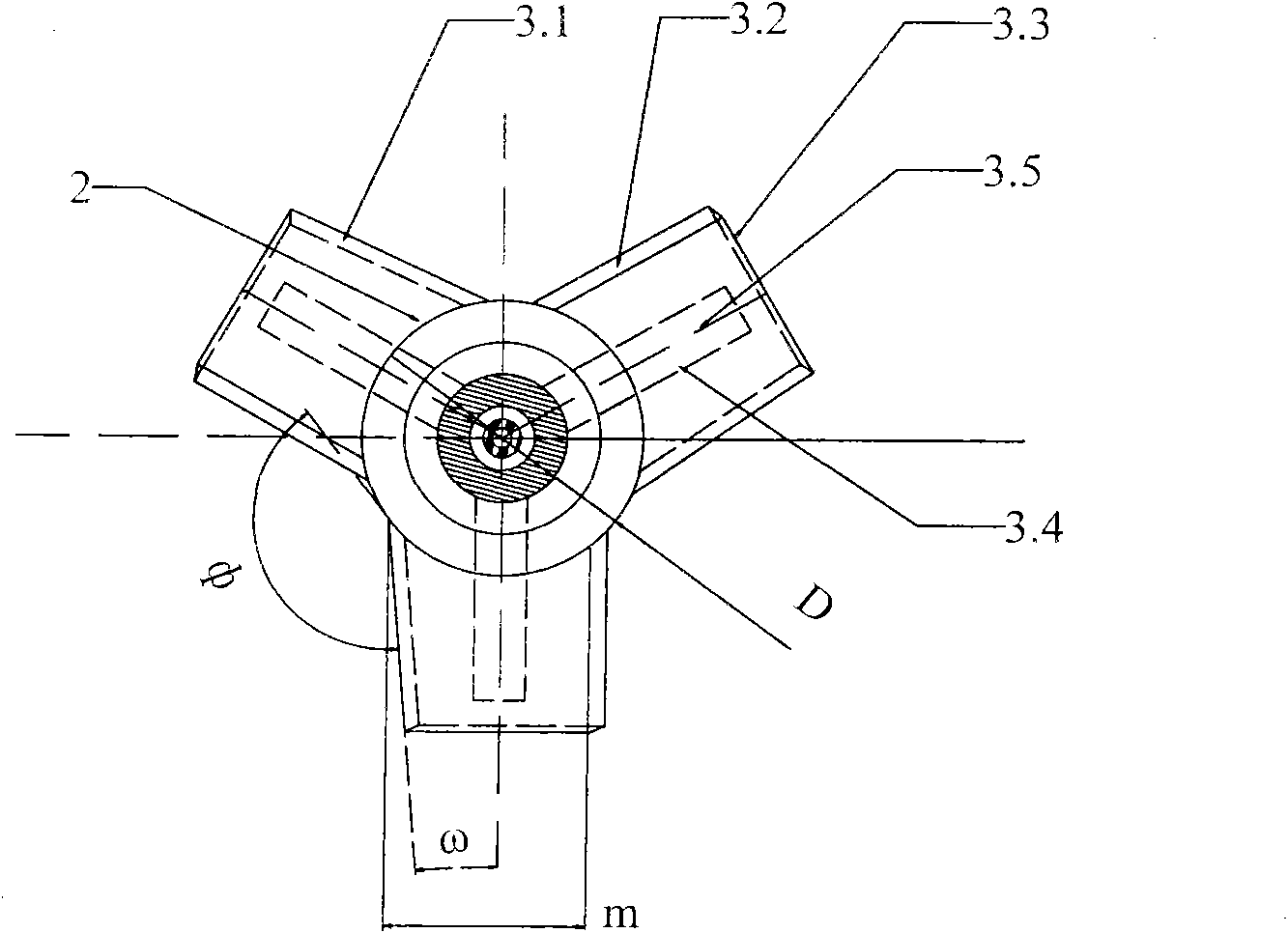

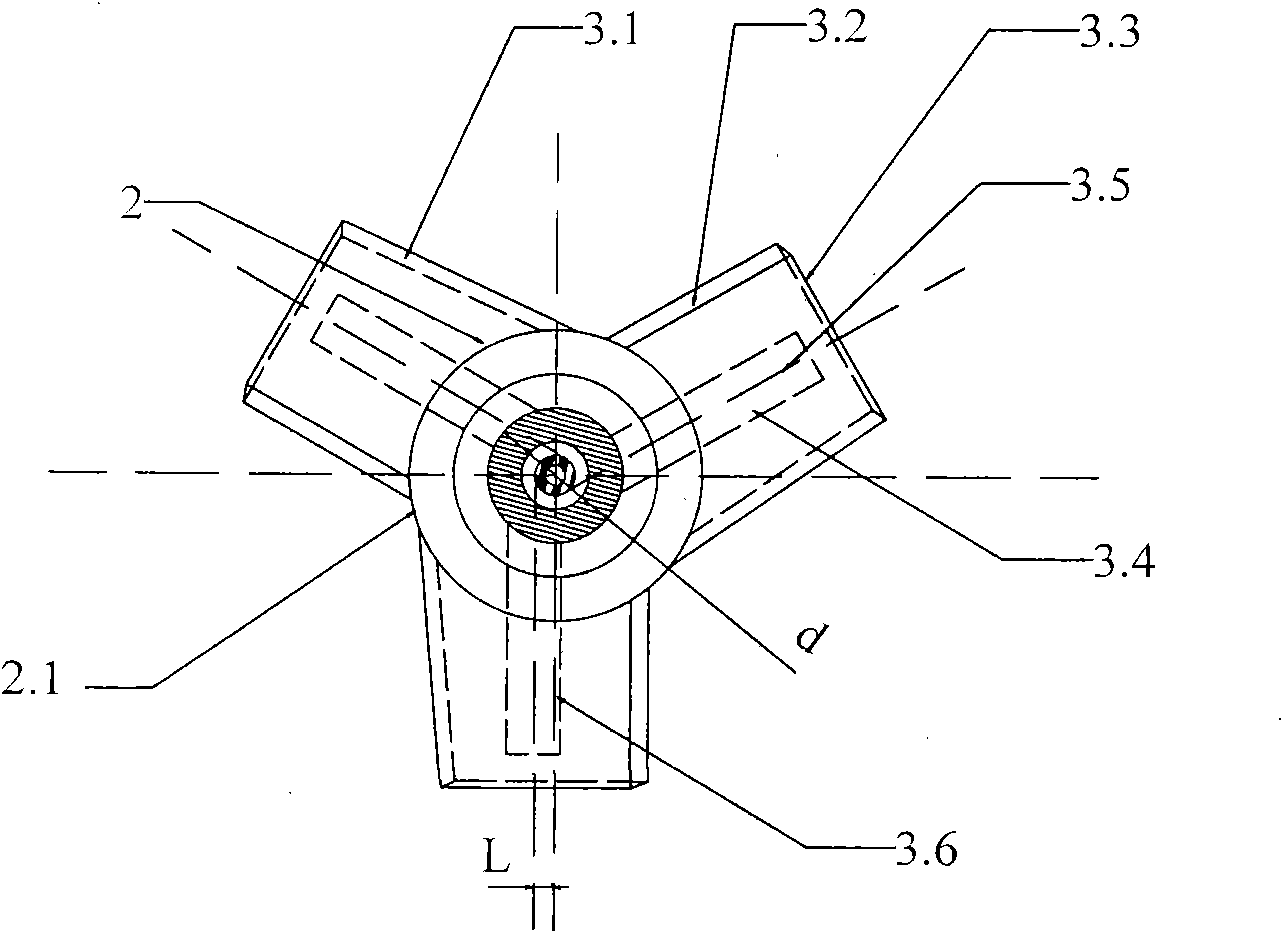

Turbine type stirrer used for molten iron mechanical stirring desulfuration

The invention discloses a turbine type stirrer used for molten iron mechanical stirring desulfuration, comprising a rotating shaft, a wheel hub and three stirring vanes, wherein, each stirring vane comprises a stirring vane metal core and is evenly distributed at the periphery of the wheel hub; the surface facing melt iron, the surface deviating melt iron and the side face of the stirring vane are all inclined planes inclining forwards from bottom to top, and the angles of inclination alpha, beta and gamma respectively satisfy the following conditions: alpha is more than or equal to 1 degree and less than or equal to 10 degrees, beta is more than or equal to alpha and less than or equal to 15 degrees, and gamma is more than or equal to 0 degree and less than or equal to 3 degrees; the stirring vane metal core is in eccentric arrangement; the flat surface on which the thickness symmetry plane of the stirring vane metal core is located is a first vertical plane; the flat surface parallel to the first vertical plane and passing the centre line of the rotating shaft is a second vertical plane; the first vertical plane is overlapped with the second vertical plane horizontally moving a distance of L towards the direction of the surface facing melt iron, wherein, L satisfies the condition that L is more than 0 and less than or equal to (d-a) / 2; d is the diameter of the metal core of the rotating shaft; and a is the thickness of the stirring vane metal core; by applying the invention, the stirring power consumption of the invention is low, the sticky dregs between the stirring vanes are less; and the dynamical condition of stirring desulfuration is good.

Owner:武钢集团有限公司

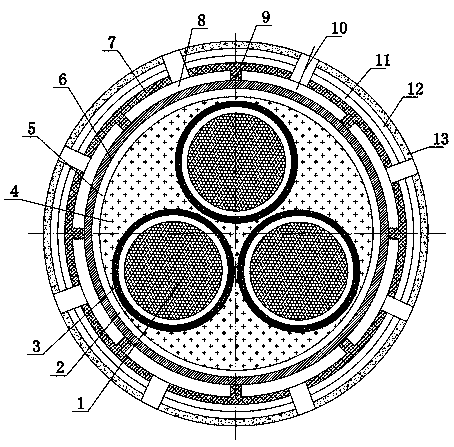

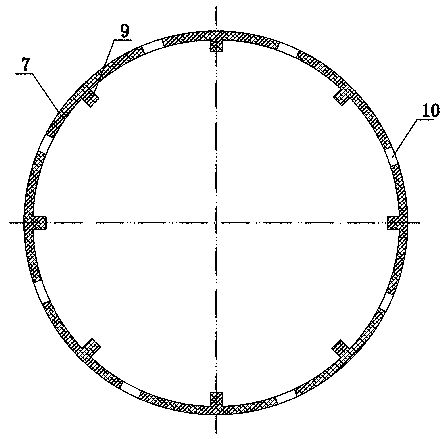

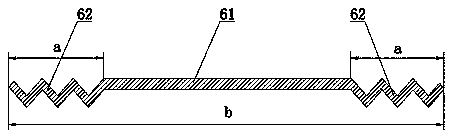

High-efficiency fire-resistant heat-dissipating cable

PendingCN108806856AAccurate lap positioningControl tensionConjugated diene hydrocarbon coatingsPower cables with screens/conductive layersEpoxyWave shape

The invention discloses a high-efficiency fire-resistant heat-dissipating cable. Shielding tapes are coated and connected mutually by wave-shaped overlapped segments at the two sides to form a shielding layer; and heat collecting chambers are arranged between the shielding layer and a heat collecting sheath and are communicated to the outer surface of the cable through cooling holes. Armored steeltapes are coated and connected mutually to form a metal armor layer by steel tape overlap-joint segments at the two sides; embedded holes are formed in the steel tape overlap-joint segment at one side of each armored steel tape; and embedded bosses are arranged at the steel tape overlap-joint segment at the other side of the armored steel tape. When overlapped joint is performed, the embedded bosses are embedded into the embedded holes. Besides, a rare-earth fire-resistant layer is made of a material comprising 8wt% to 12wt% of fluororubber, 5wt% to 8wt% of aluminum hydroxide, 2wt% to 4wt% ofrare earth oxide, 1wt% to 2wt% of glycerol, 2wt% to 4wt% of silicon carbide, 3wt% to 6wt% of lanthanum phosphate, 6wt% to 8wt% of zirconic acid gadolinium, and remainder being epoxy resin. The cablehas the good high-temperature-resistant and flame-retardant performances; heat can be dissipated efficiently; and the cable has the stable structural integrity and the good mechanical performance.

Owner:JIANGSU DONGQIANG

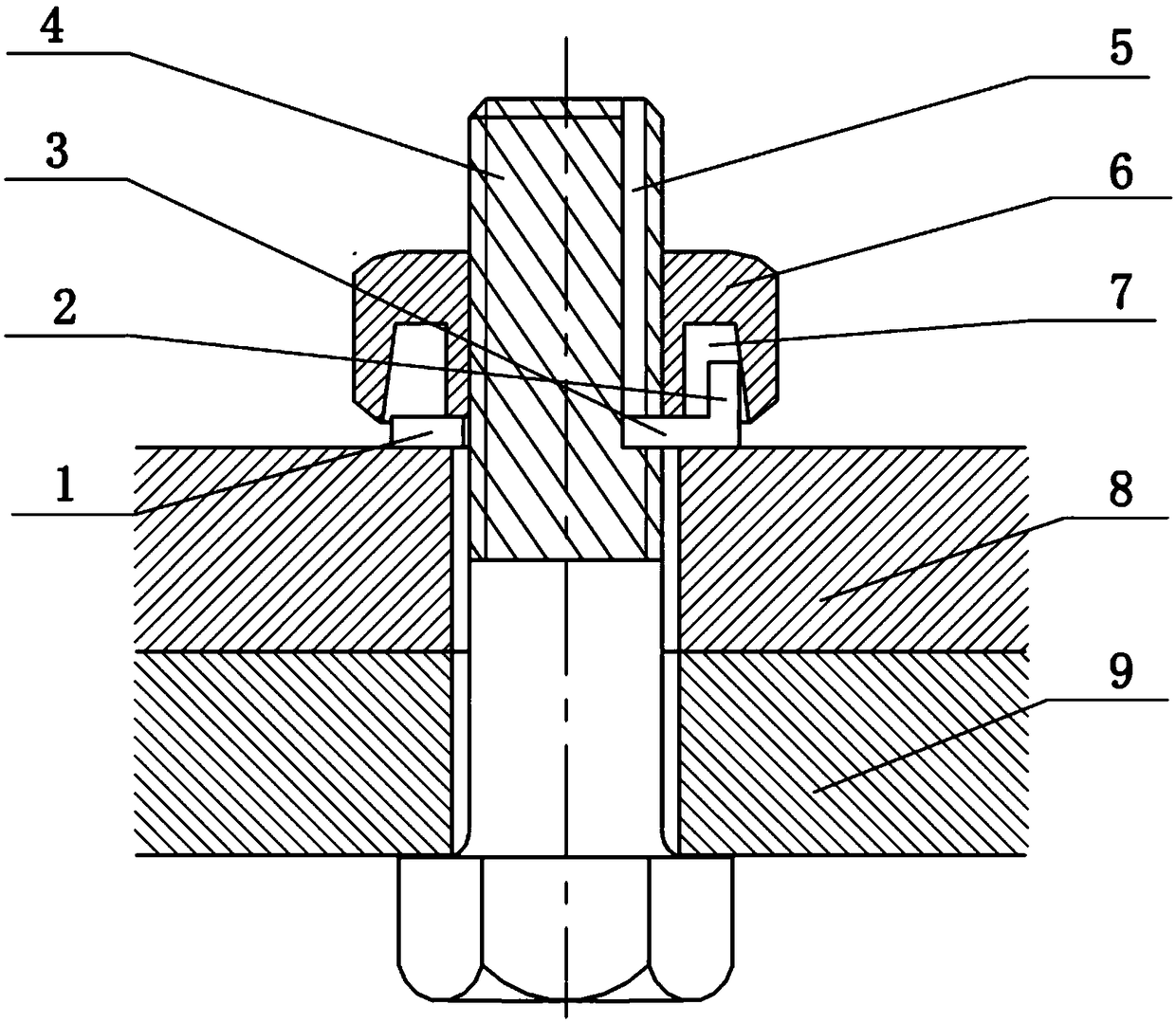

Anti-loose bolt set composed of stop washer and annular groove nut and operation method thereof

The invention discloses an anti-loose bolt set composed of a stop washer and an annular groove nut and an operation method thereof. Through interaction of upright external teeth of the stop washer anda wedge-shaped groove face of the annular groove nut, one radial acting force is added besides axial pretightening force when thread pairs are pretightened, and larger pressure and friction force areformed between the thread pairs. Meanwhile, an additional friction acting point is further added due to the interaction of upright external teeth and the wedge-shaped groove face, thus additional pressure and friction force are increased, the total friction force limit value is increased and is much larger than a friction force limit value generated by a common pretightening bolt, the anti-loosebolt set is better in anti-loose effect, and thus the thread pairs can be prevented from rotating relatively. The anti-loose bolt set is good in reliability and practicability, and can be used for places with severe impact, vibration and alternating load or with large temperature change, maintenance and overhauling of thread connection is reduced effectively, the safety of utilizing of the anti-loose bolt set is improved, and the utilization rate of the anti-loose bolt set is increased.

Owner:韦志锋

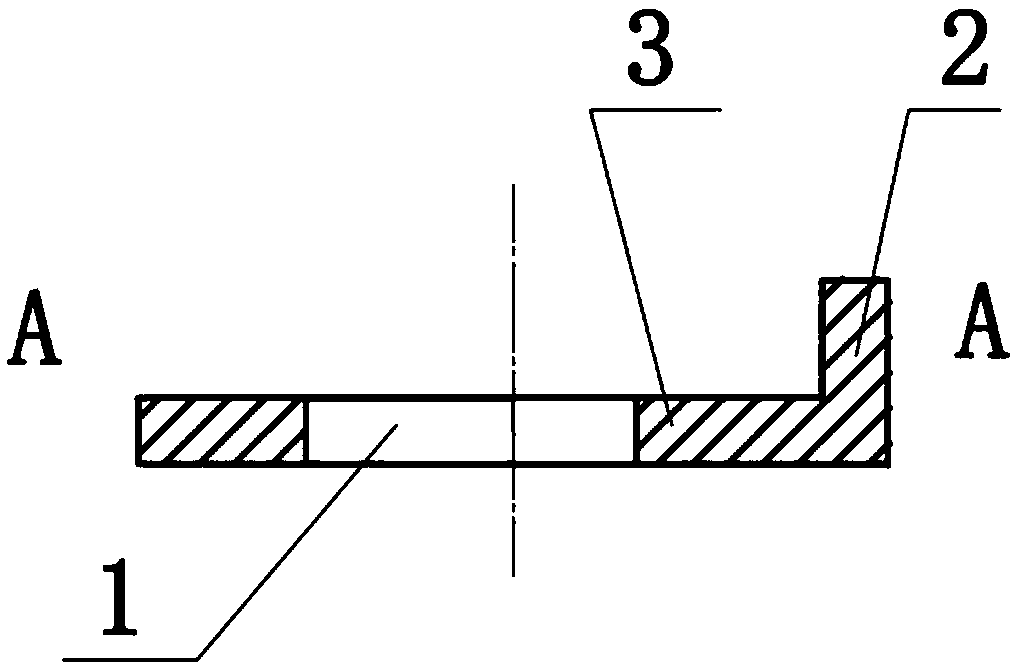

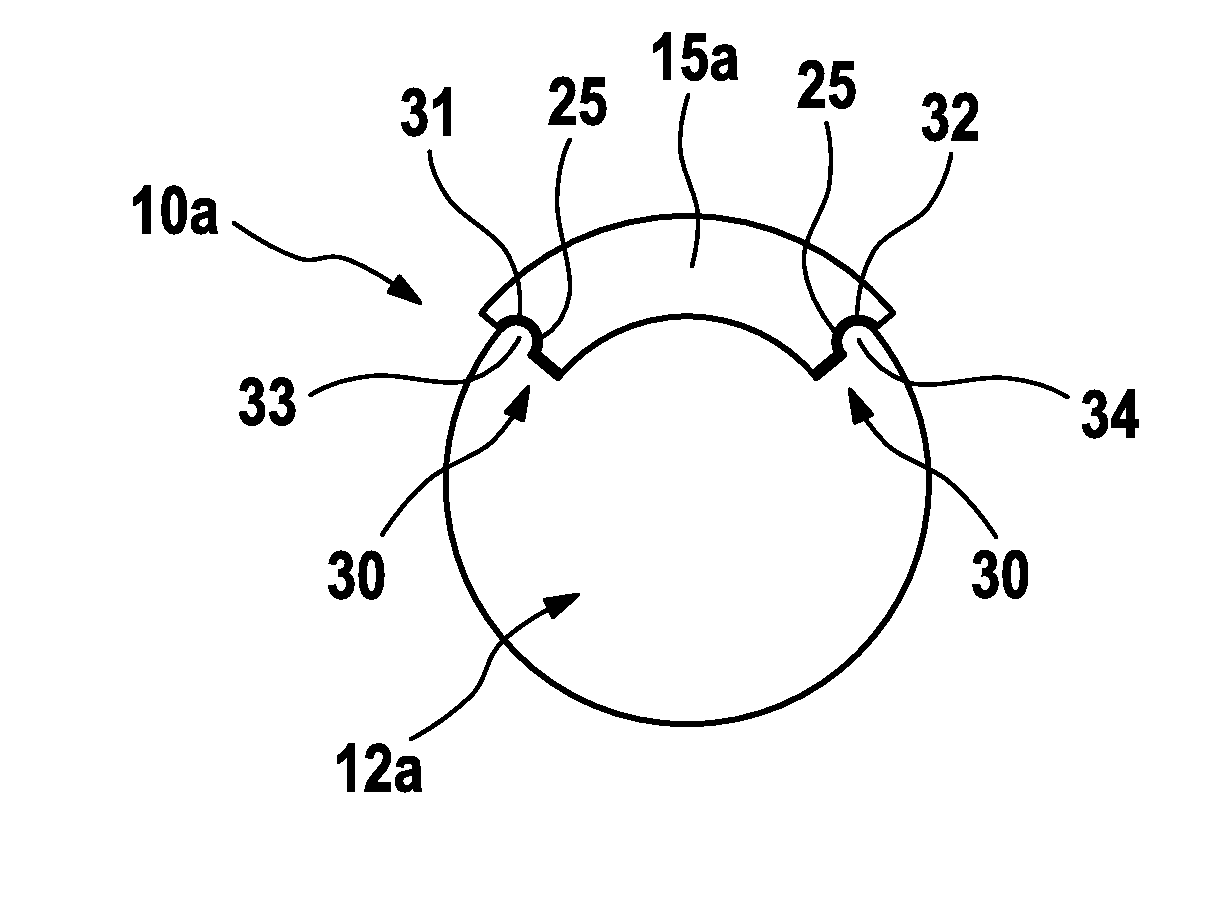

Assembly for an electric machine, method for producing an assembly and electric machine having an assembly

InactiveUS20160241096A1Increase speedImproved thermal connectionMagnetic circuit rotating partsSoldering apparatusElectric machineEngineering

The invention concerns an assembly (10; 10a ; 10b) for an electric machine (1), comprising a rotor (12; 12a; 12b) which is rotatable in a rotational shaft (11) and magnet elements (15; 15a) which are disposed on the periphery of the rotor (12; 12a; 12b) and are connected thereto. According to the invention, the connection between the rotor (12; 12a; 12b) and the magnet elements (15; 15a) takes the form of a solder connection (25).

Owner:ROBERT BOSCH GMBH

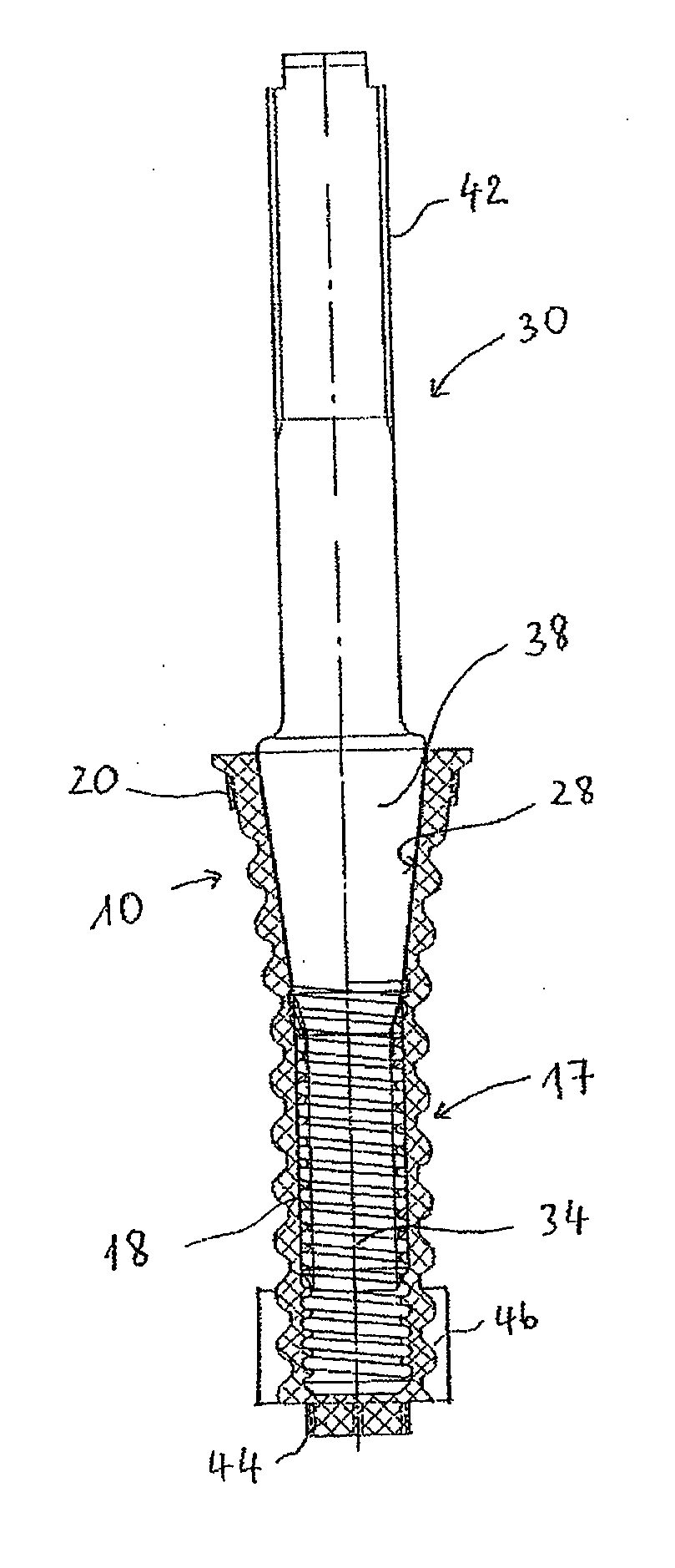

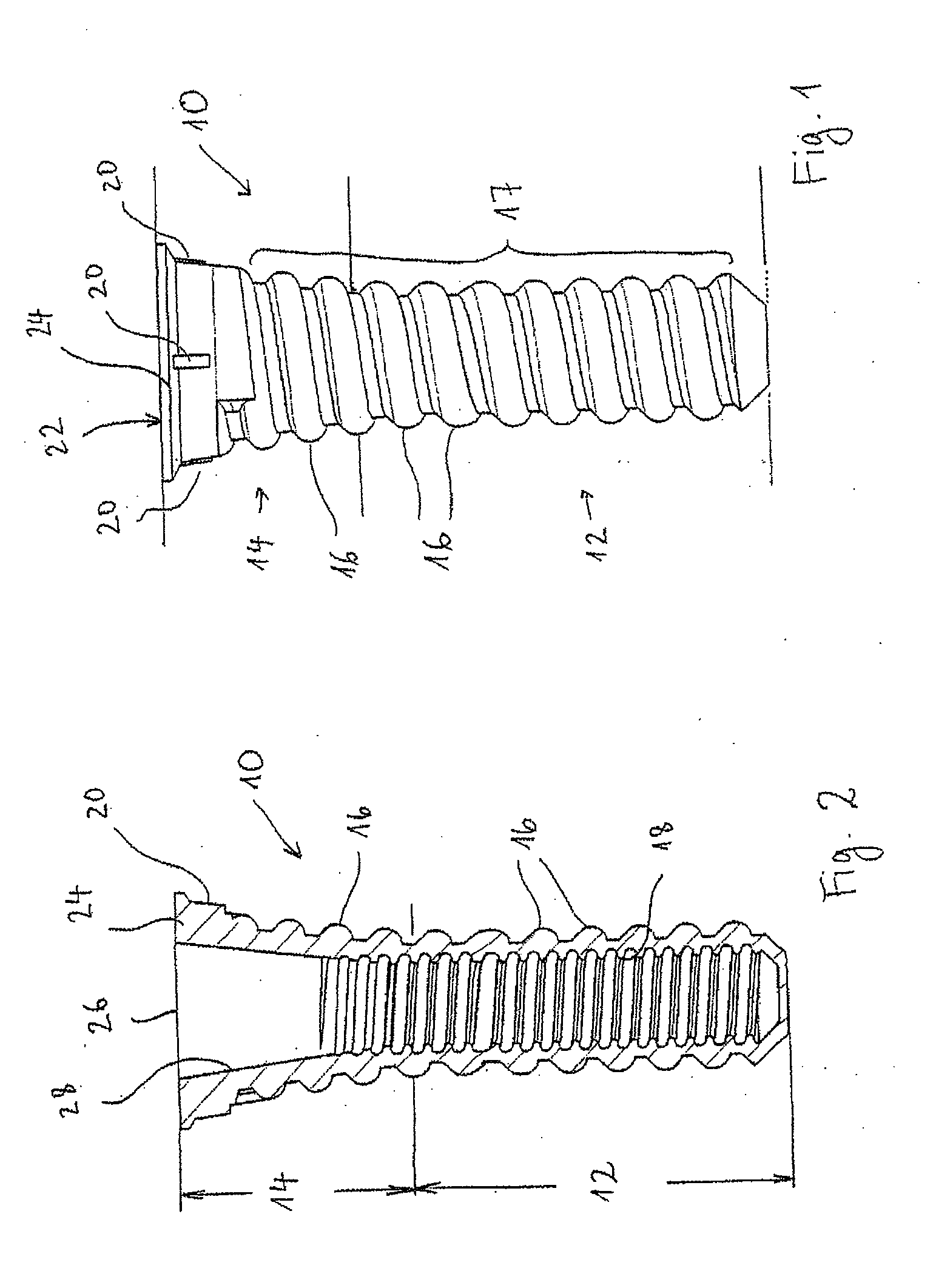

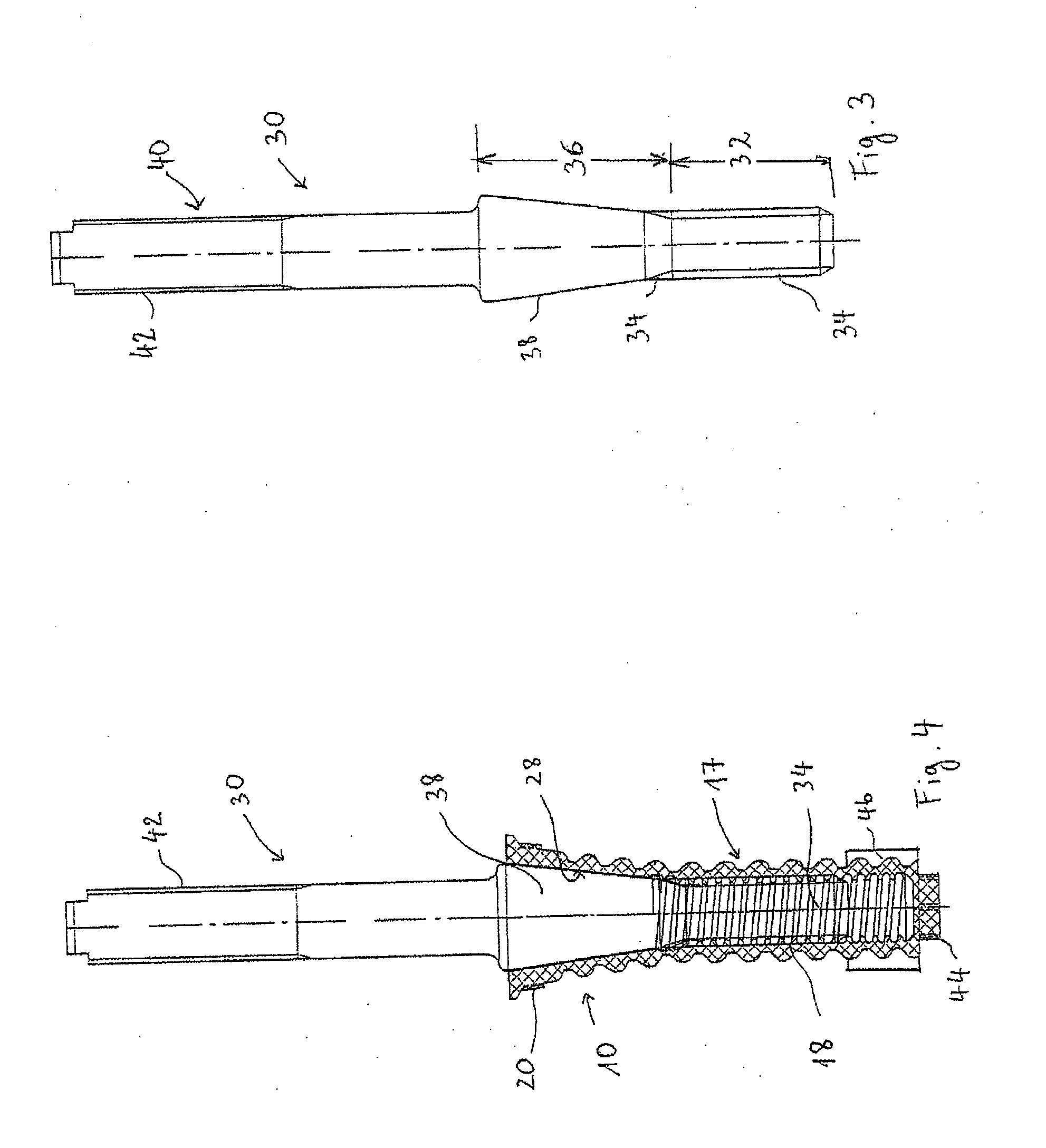

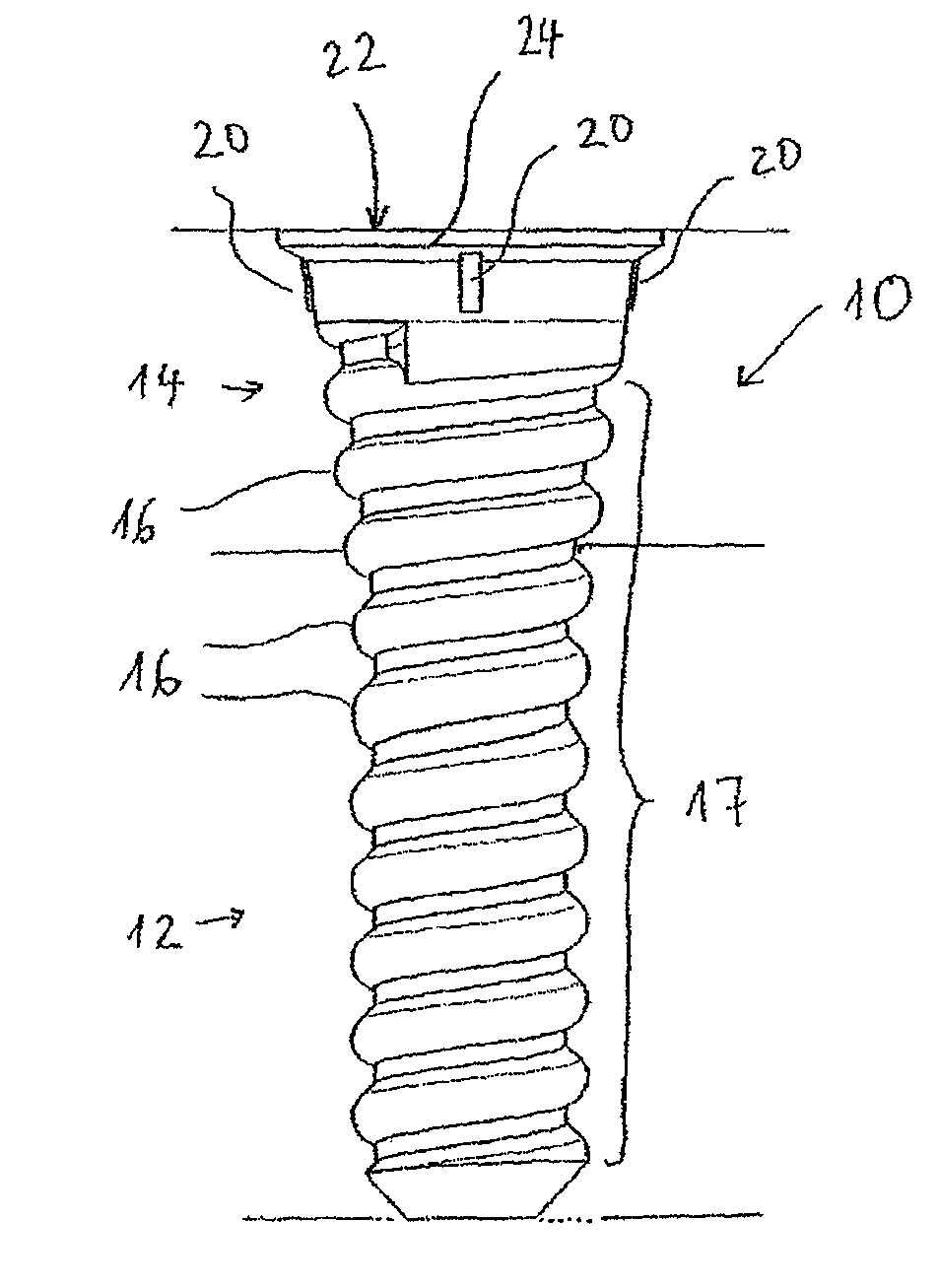

Screw anchor with conical head for rail attachment

InactiveUS20110262241A1Increase the cross-sectional areaSurface pressureNutsKey type connectionsClassical mechanicsEngineering

A screw anchor for concrete attachment to a railroad tie or solid track comprises external threads (16) disposed on the exterior of the screw anchor (10) and internal threads (18) disposed inside the screw anchor (10) for force-fitted connecting to a fastening element (30), wherein the screw anchor (10) comprises two sections (12, 14) adjacent to one another in the longitudinal direction, the first section (12) having a substantially cylindrical external shape and the second section (14) having a substantially conical external shape, and wherein the second section (14) is disposed between the first section (12) and an inlet opening (26) for the fastening element (30).

Owner:VOSSLOH WERKE GMBH

Screw anchor with conical head for rail attachment

InactiveUS8434981B2Increase the cross-sectional areaSurface pressureNutsKey type connectionsEngineeringIliac screw

A screw anchor for concrete attachment to a railroad tie or solid track comprises external threads (16) disposed on the exterior of the screw anchor (10) and internal threads (18) disposed inside the screw anchor (10) for force-fitted connecting to a fastening element (30), wherein the screw anchor (10) comprises two sections (12, 14) adjacent to one another in the longitudinal direction, the first section (12) having a substantially cylindrical external shape and the second section (14) having a substantially conical external shape, and wherein the second section (14) is disposed between the first section (12) and an inlet opening (26) for the fastening element (30).

Owner:VOSSLOH WERKE GMBH

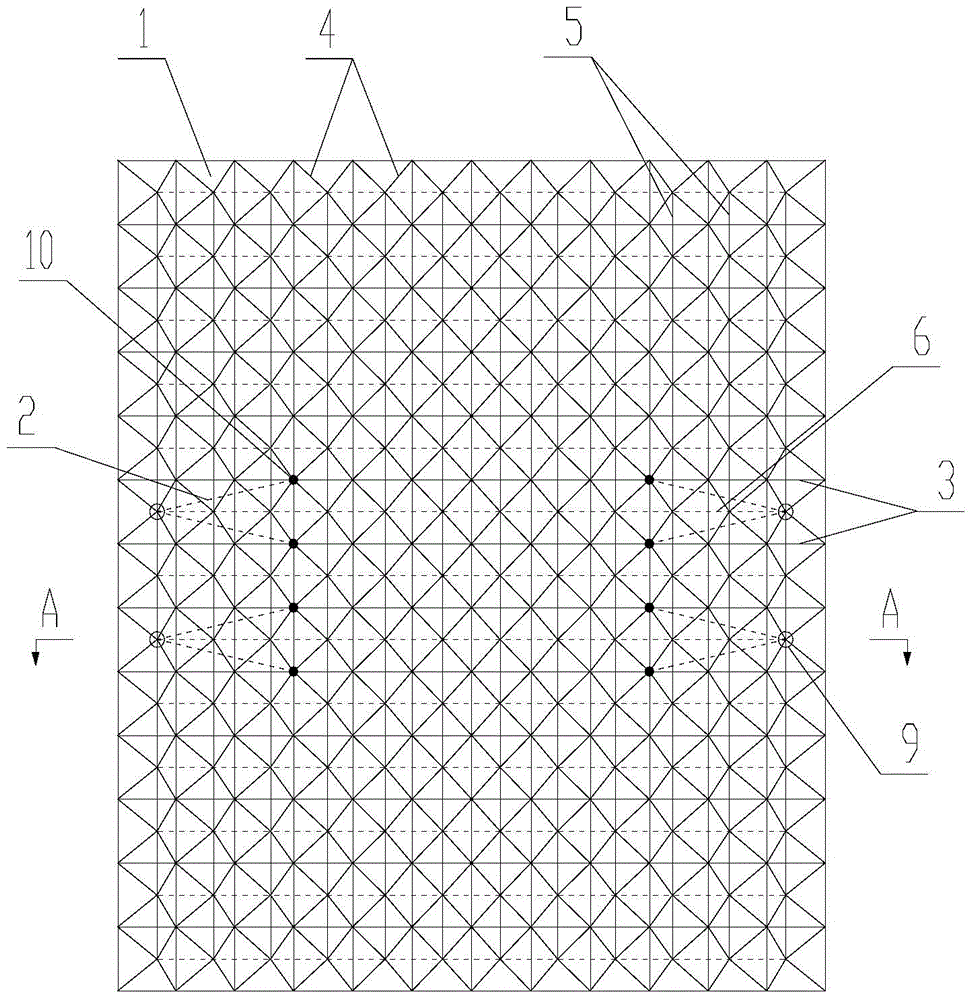

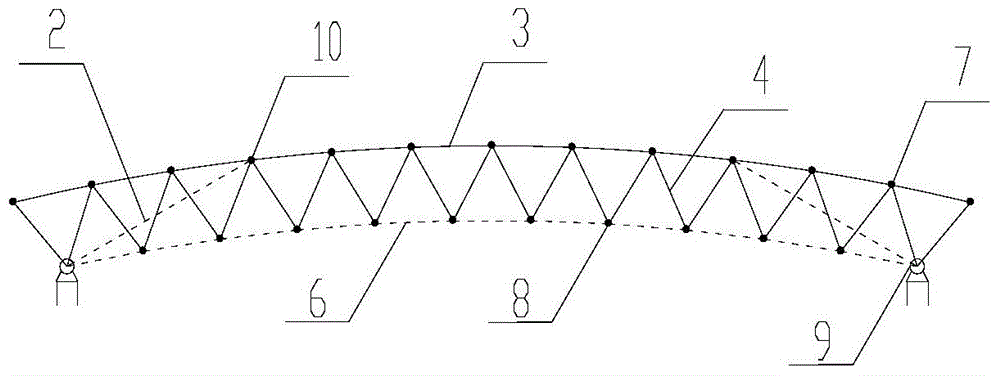

Double-layer column surface net shell with lower chord being prestressed stay rope

InactiveCN104060740ADoes not increase indoor redundant spaceFull strengthBuilding roofsPulp and paper industryLong span

The invention discloses a double-layer column surface net shell with a lower chord being a prestressed stay rope. The double-layer column surface net shell comprises a double-layer column surface net shell body and inclined towing ropes, wherein the double-layer column surface net shell body consists of upper chord rods, web rods, lower chord rods, lower chord ropes, upper-chord bolt ball nodes and lower-chord bolt ball nodes; the upper chord rods and the web rods are connected by the upper-chord bolt ball nodes and the lower-chord bolt ball nodes to form a regular quadrangular pyramid; the lower chord rods are arranged along the long-span direction of the double-layer column surface net shell body; the lower chord ropes are arranged along the short-span direction of the double-layer column surface net shell body; the double-layer column surface net shell body is supported by adopting the peripheries of the lower chords; the inclined towing ropes are symmetrically arranged in the double-layer column surface net shell body; the lower ends of the inclined towing ropes are anchored on downward-bearing type support nodes in the short-span direction of the double-layer column surface net shell body; the upper ends of the inclined towing ropes are connected with upper-chord fixing nodes. The double-layer column surface net shell disclosed by the invention has the characteristics that the prestressed effect is obvious, the indoor redundancy space in a building is not increased, the used steel amount is low, and the adaptability to air-suctioning load can be achieved.

Owner:JIANGSU UNIV OF SCI & TECH +1

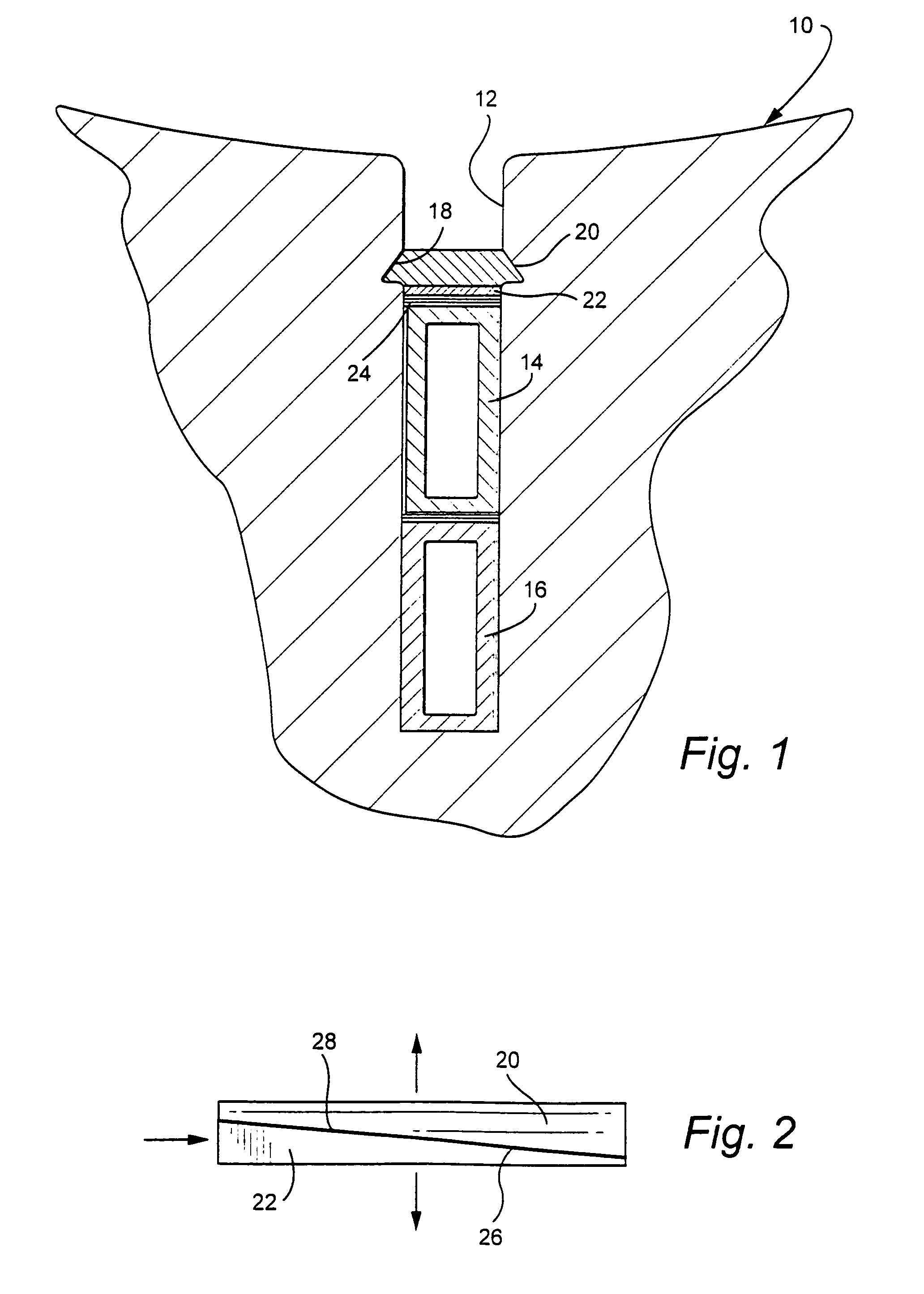

Re-tightenable stator body wedge system

InactiveUS7154205B2Simplify the inspection processShortening outage cyclesWindingsMagnetic circuit stationary partsEngineeringConductor Coil

A generator stator core has a plurality of axially extending radial slots arranged about the periphery thereof with windings in each of the radial slots. At least one adjustable wedge and slide assembly is located in each of the slots, arranged to restrain the windings, the assembly including a wedge component and a slide component which interface along respective sloped surfaces formed on respective sides of each of the wedge component and the slide component. The slide component is formed with a zone of laterally extending, discrete fingers on each side thereof that are angled relative to a longitudinal axis of the slide. The wedge component is slidably received in a pair of dovetail grooves in the radial slot with the slide component located between the wedge component and the windings such that the discrete fingers engage side walls of the radial slot.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com