Patents

Literature

367results about "Key type connections" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

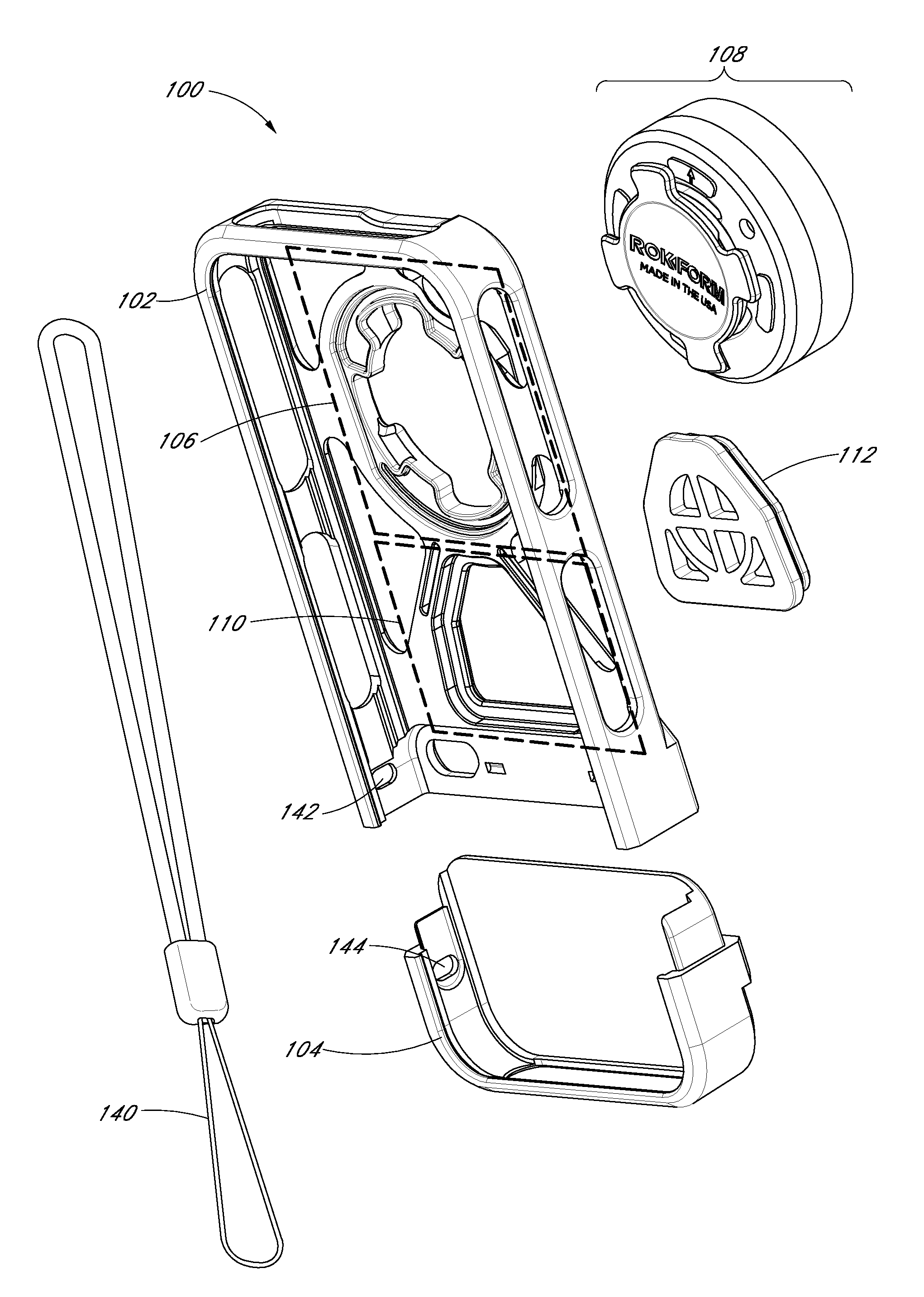

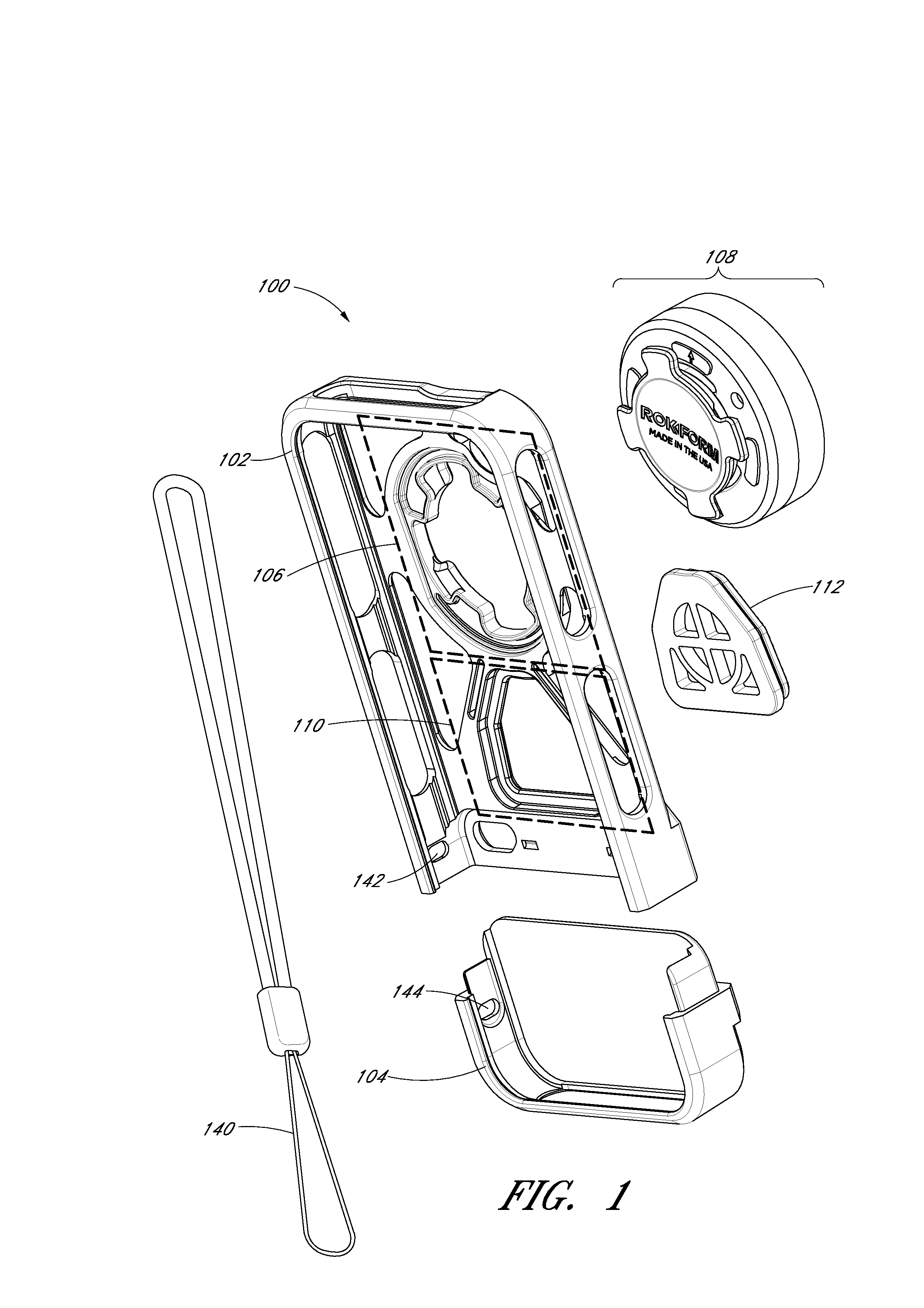

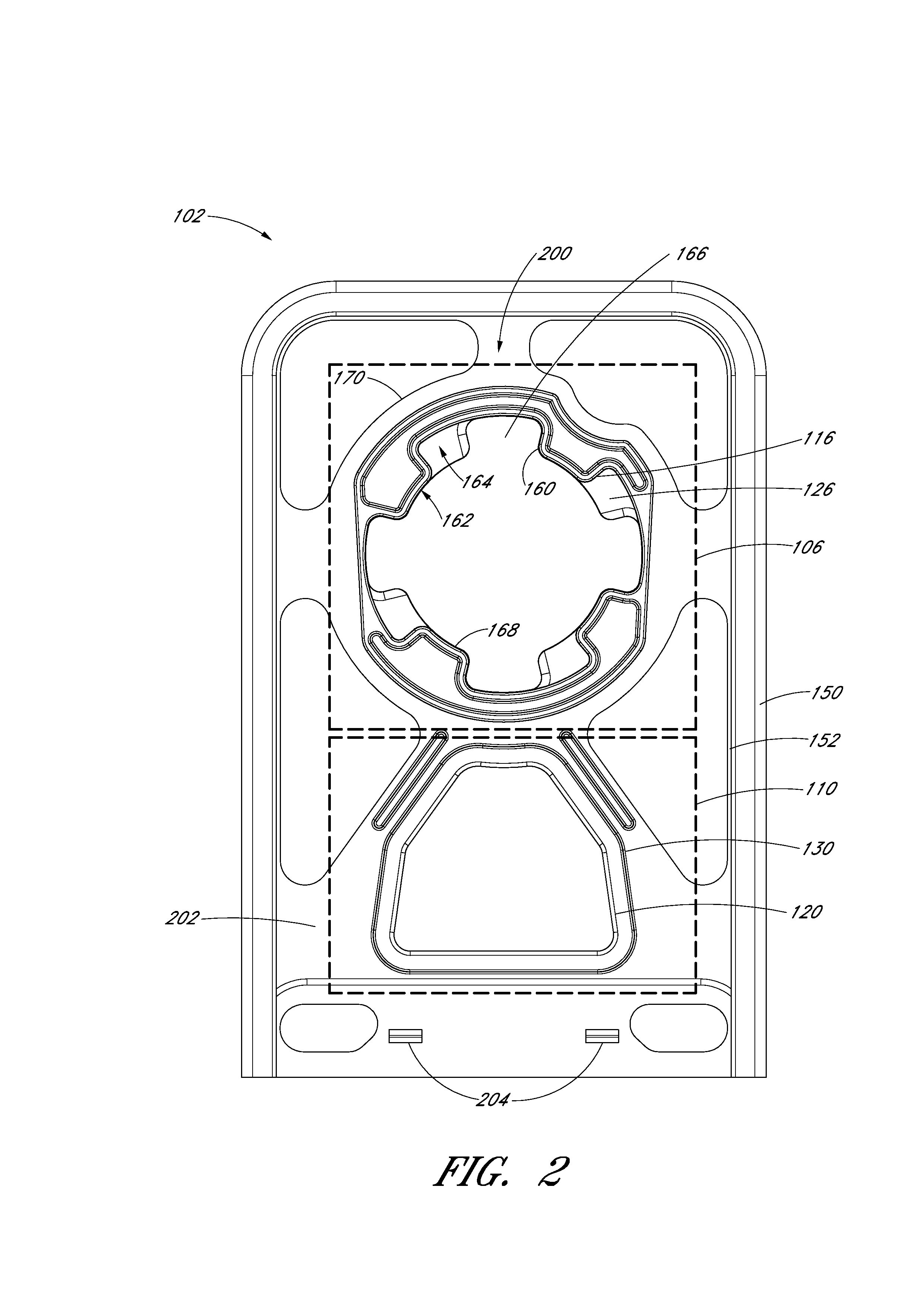

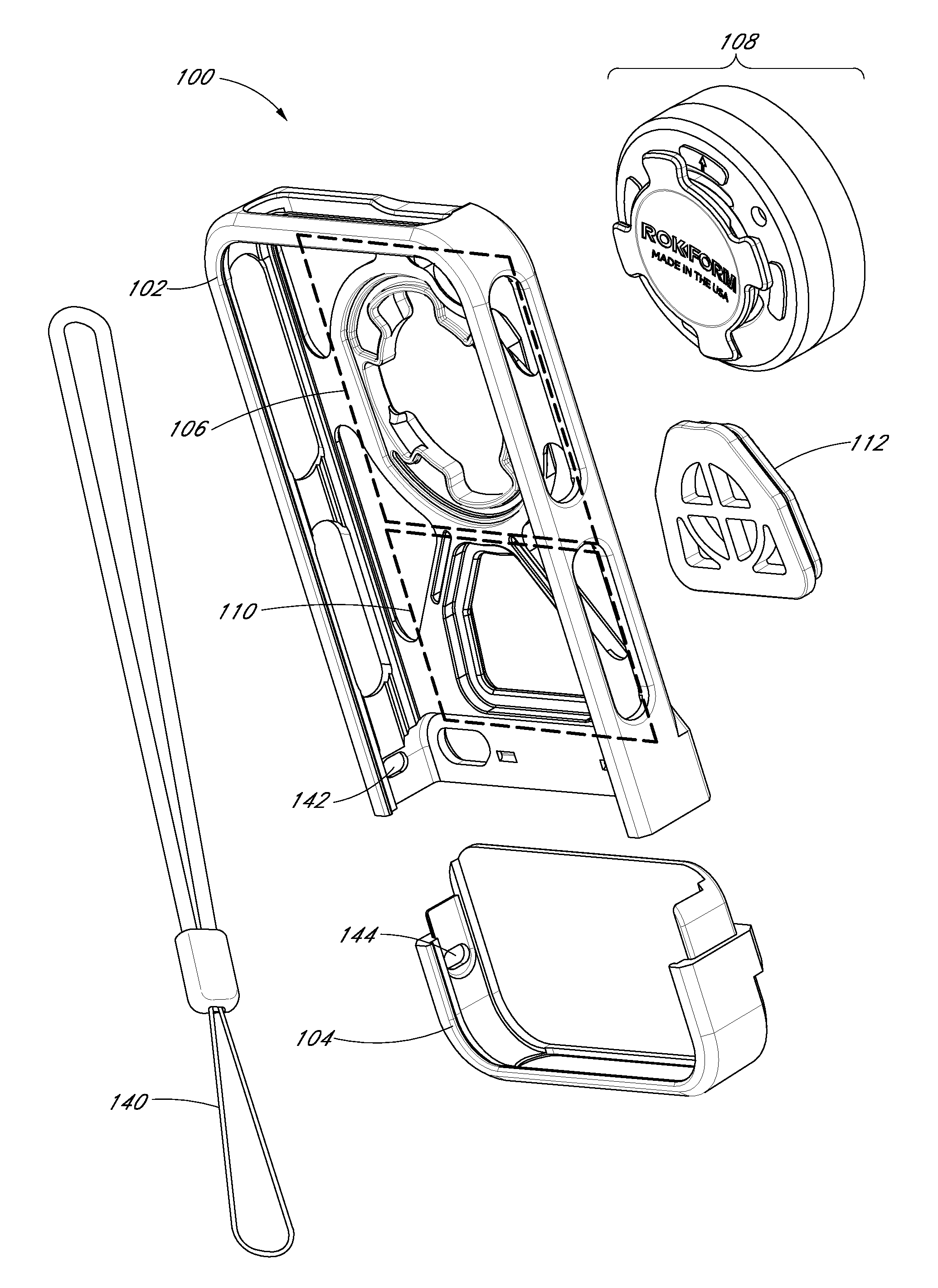

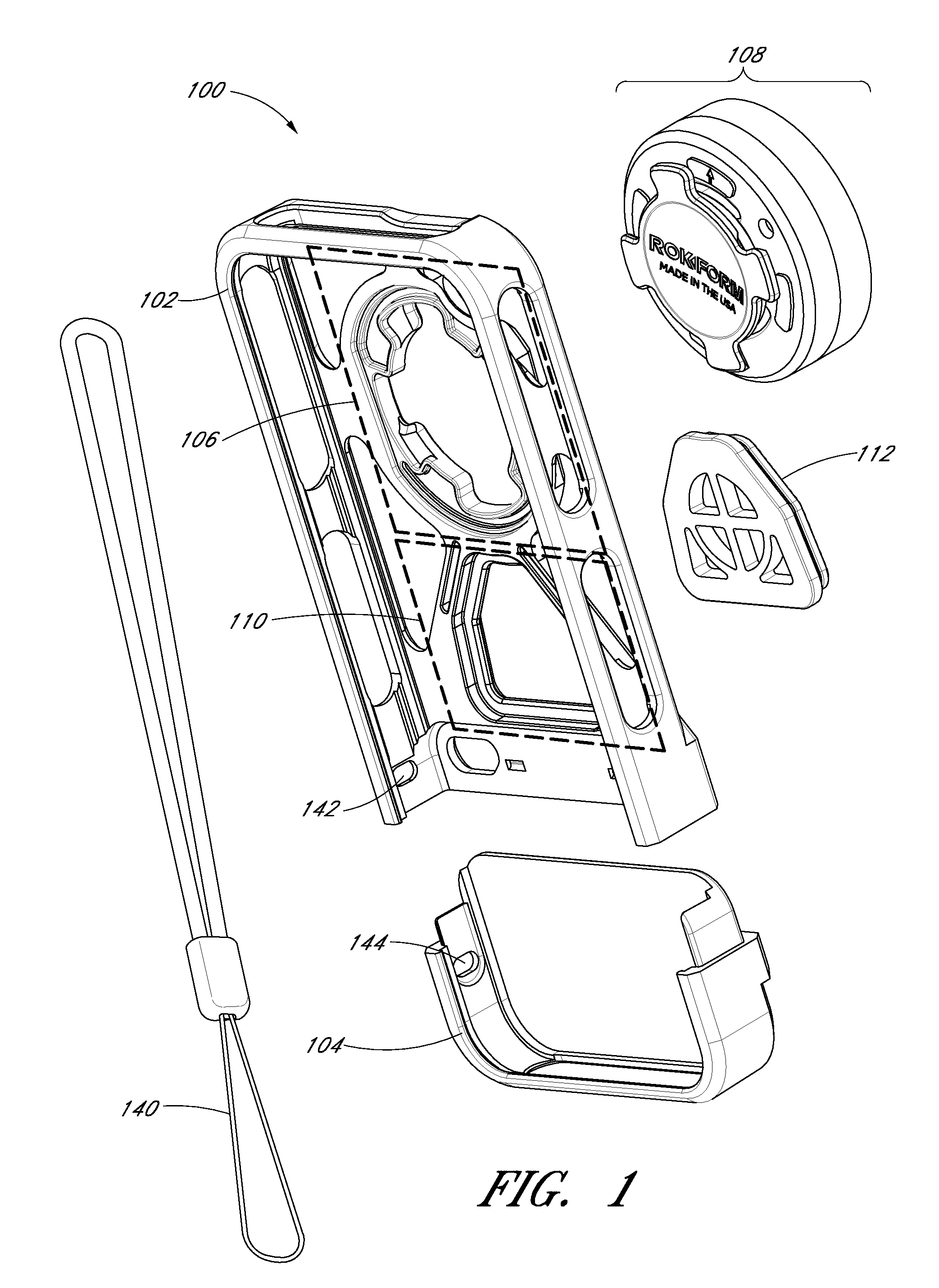

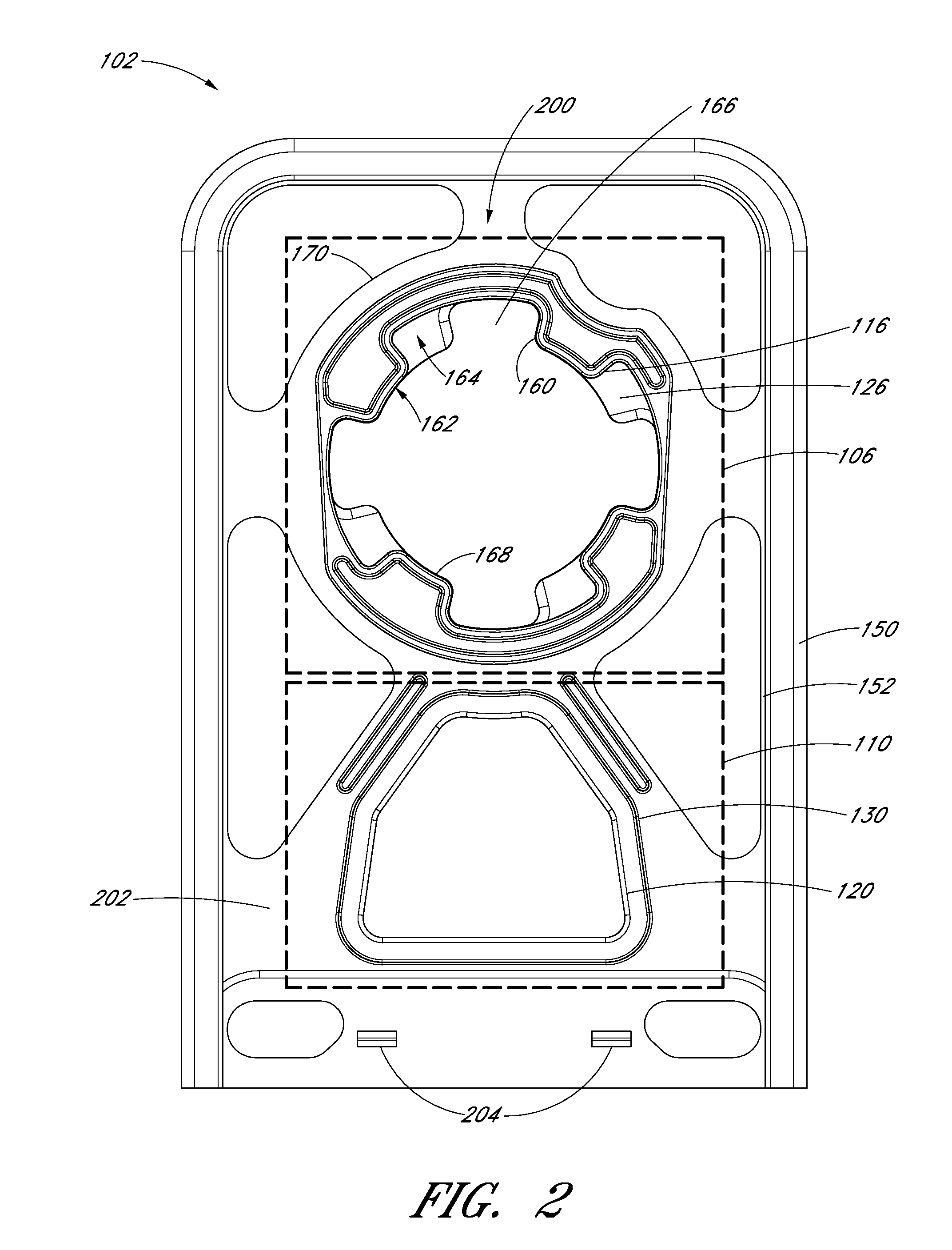

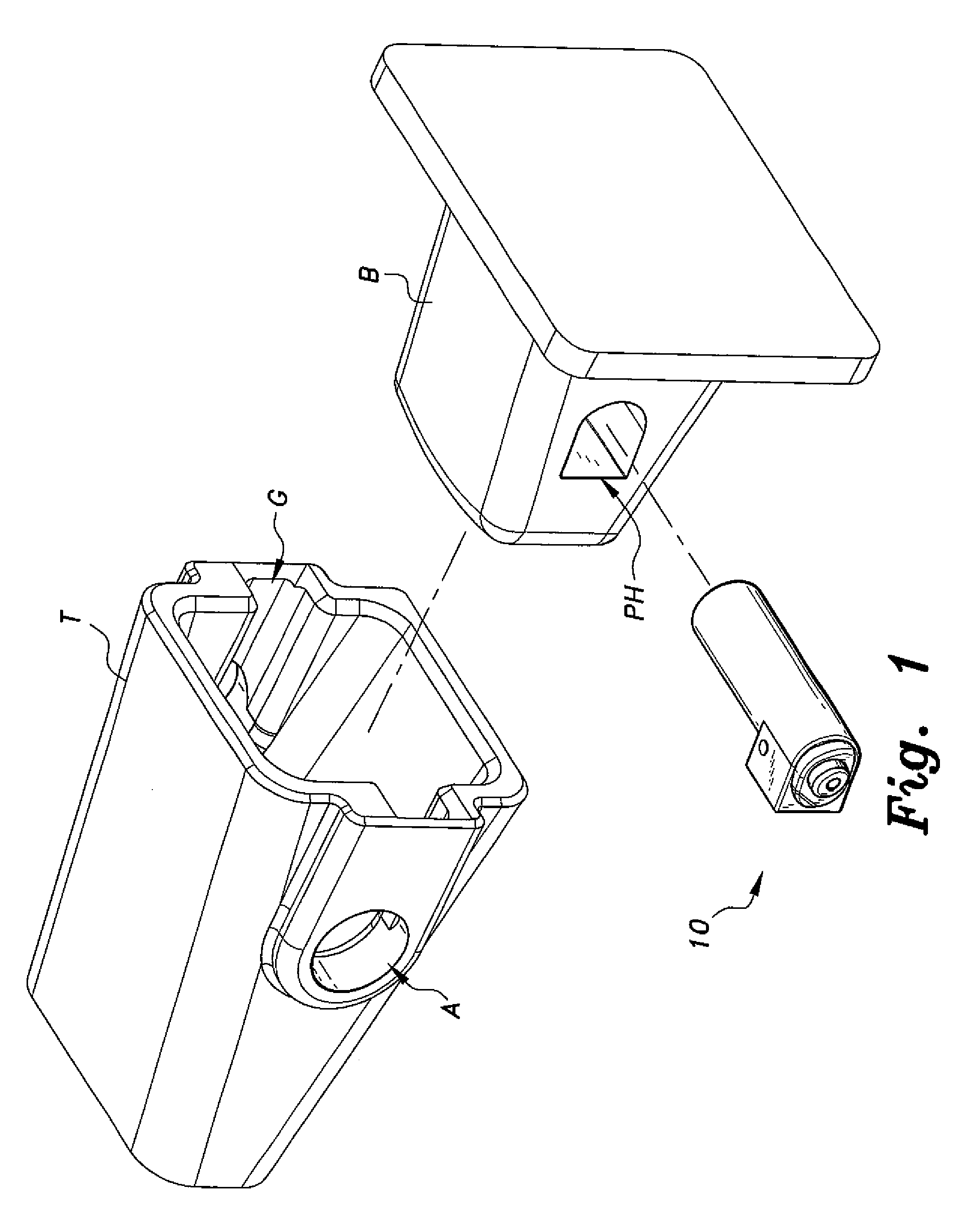

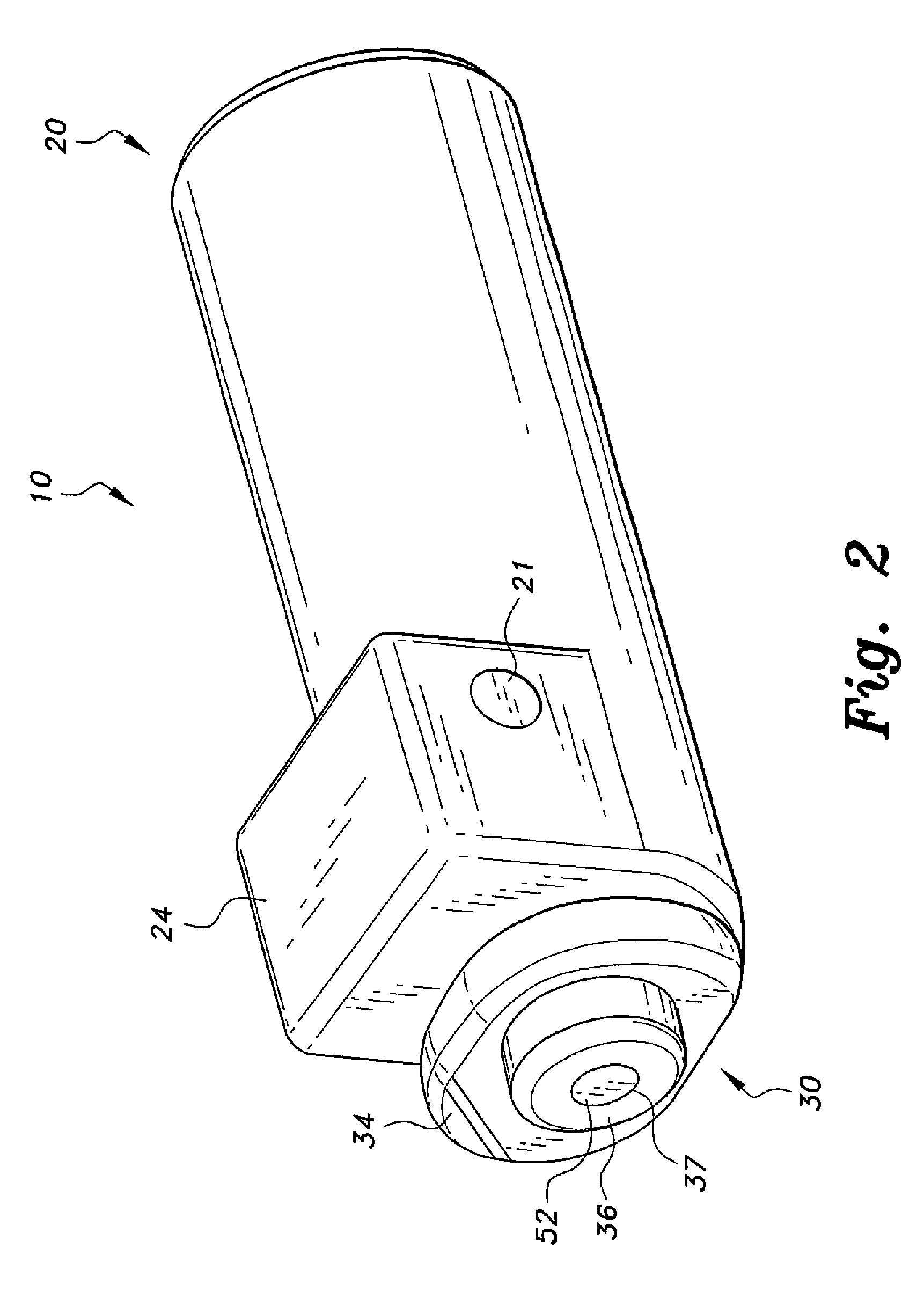

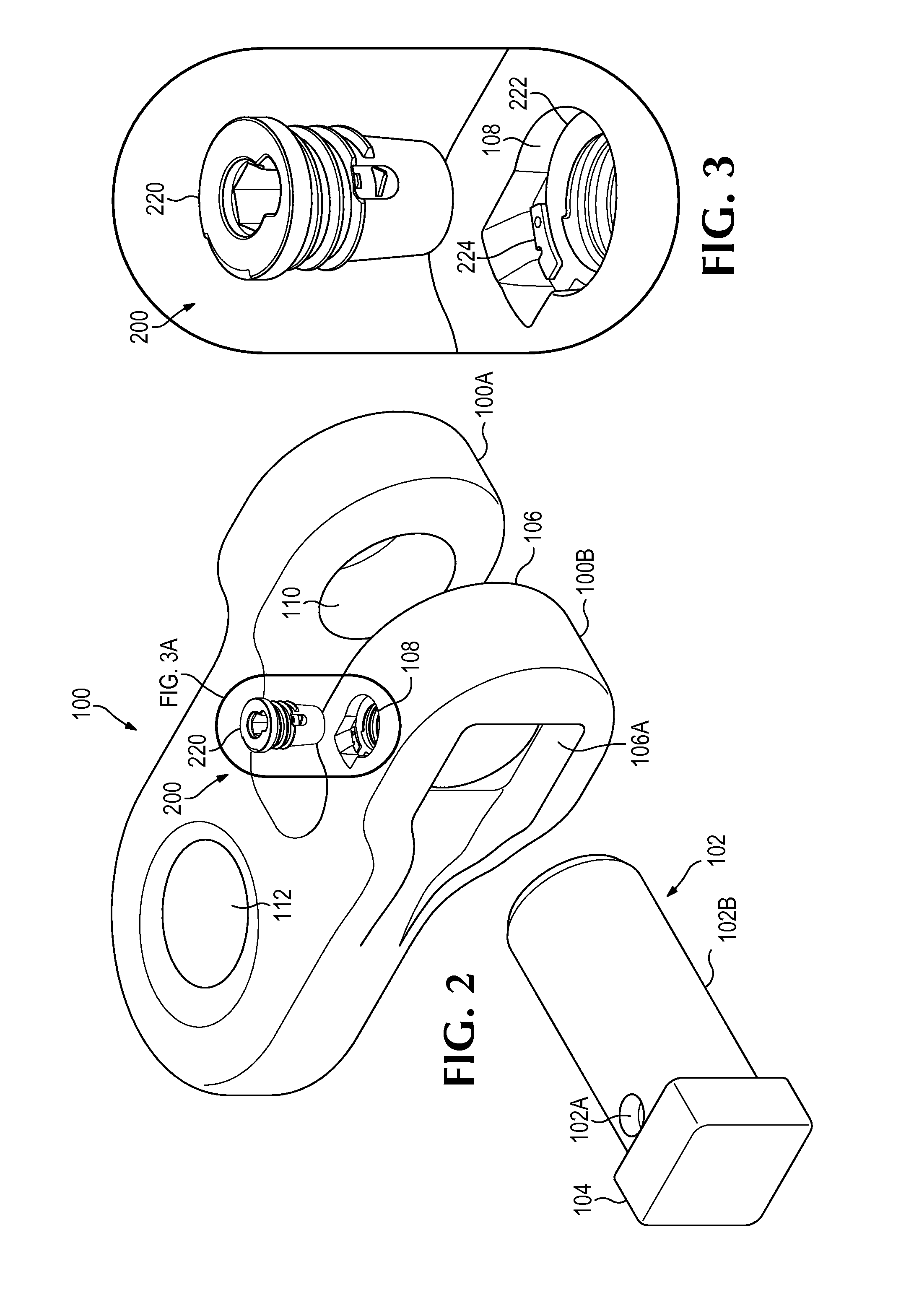

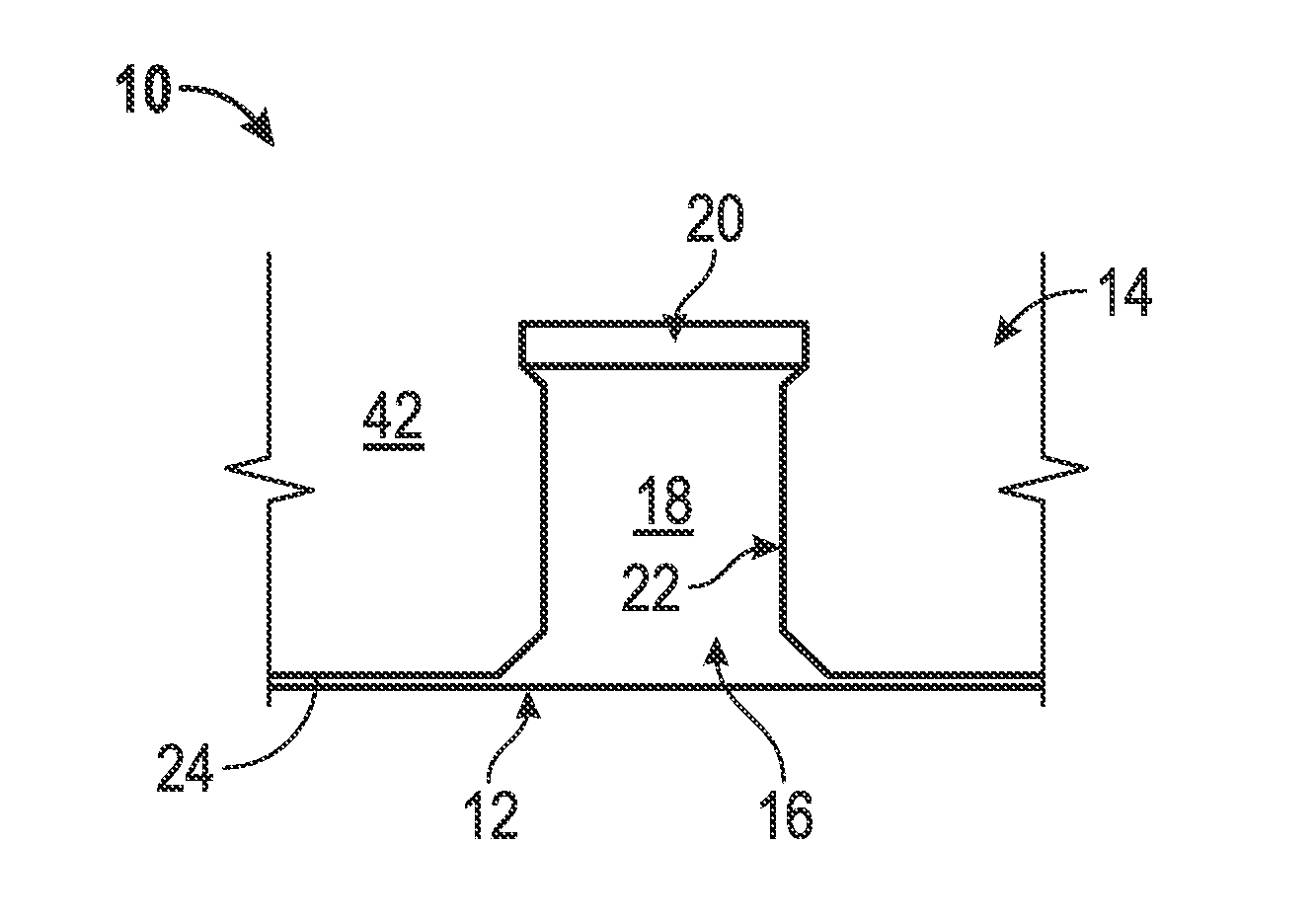

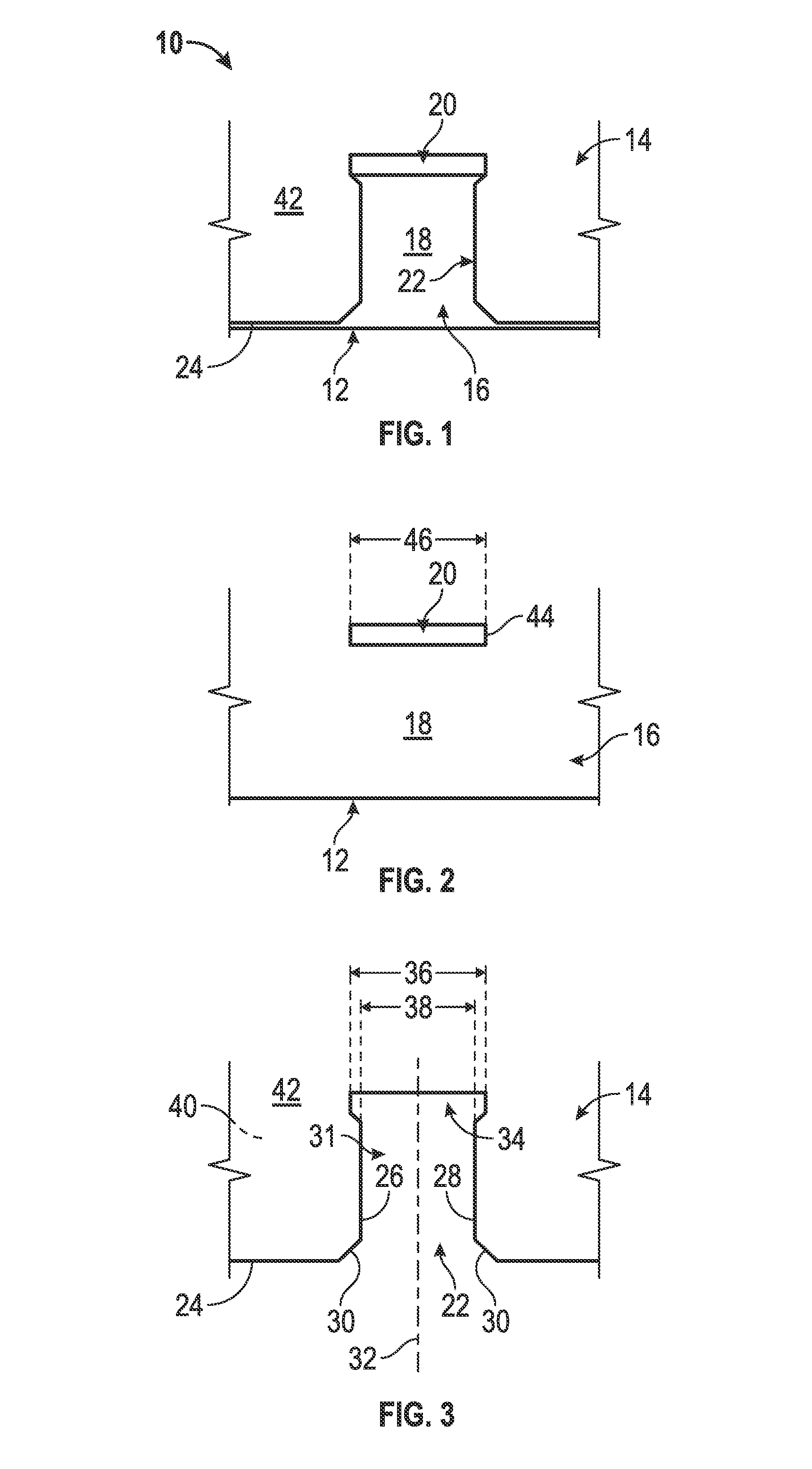

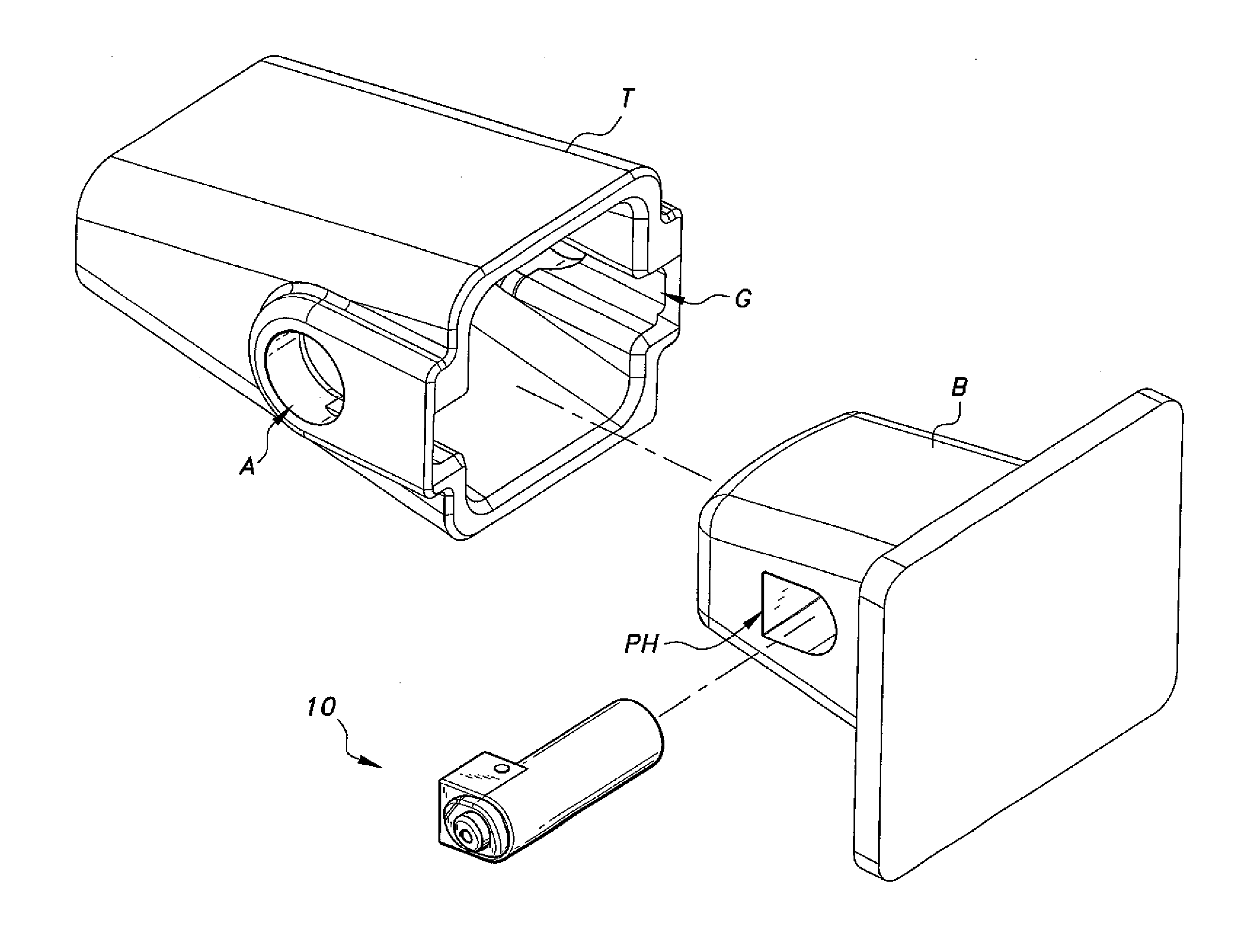

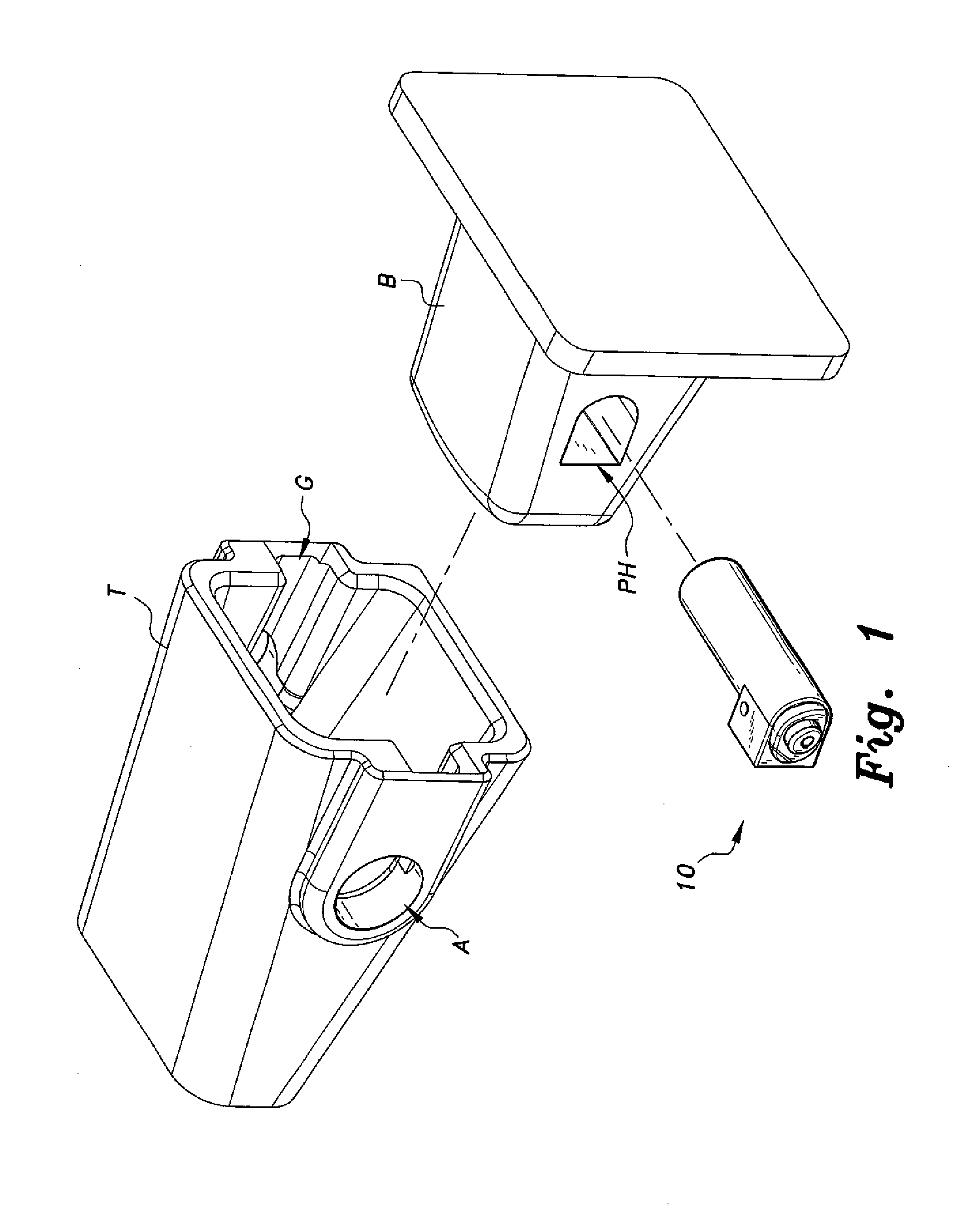

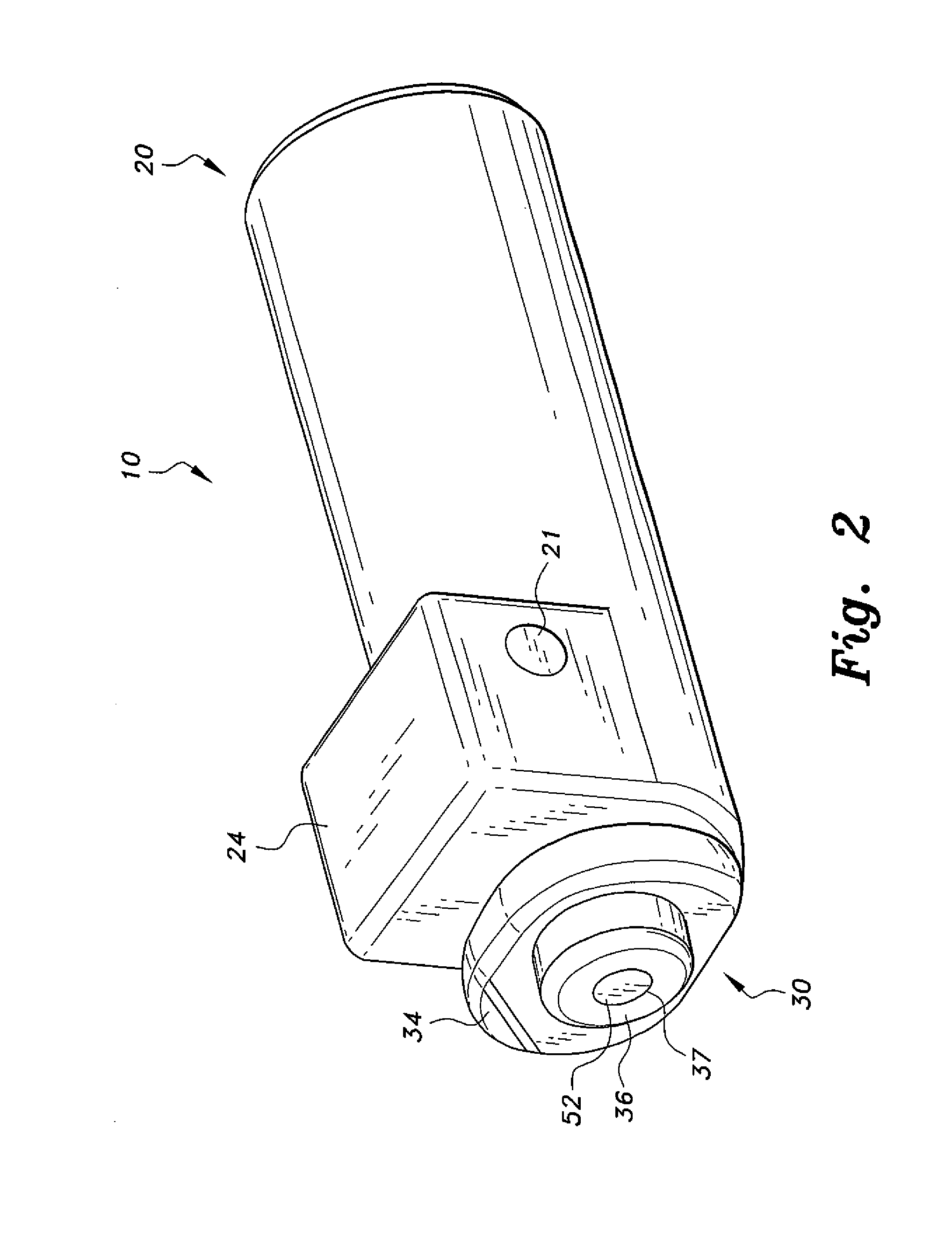

Case and mount system for handheld electronic device

A protective case for a handheld electronic device is provided. The protective case can include a removable mounting system comprised of an interlocking member and a plurality of mounting bases. The protective case may further include a non-slip member to prevent the device from slipping on a surface and a magnet for attaching the device to a magnetic surface.

Owner:ROKFORM IP LLC

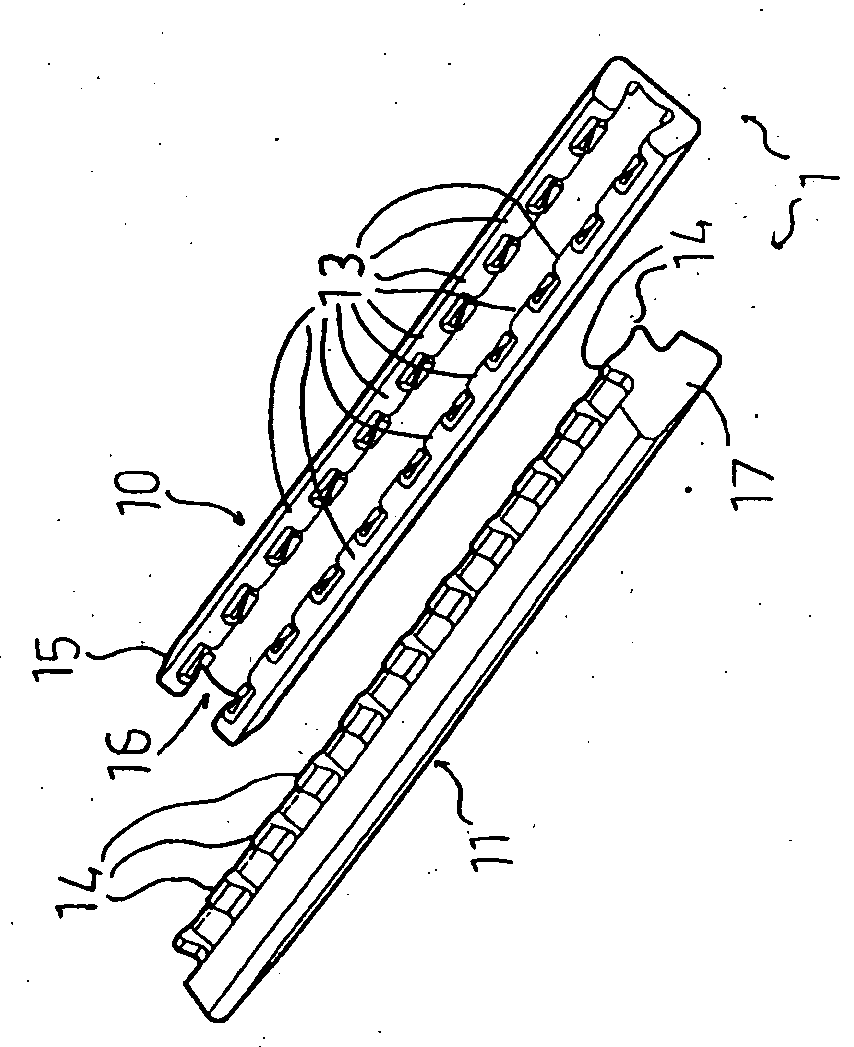

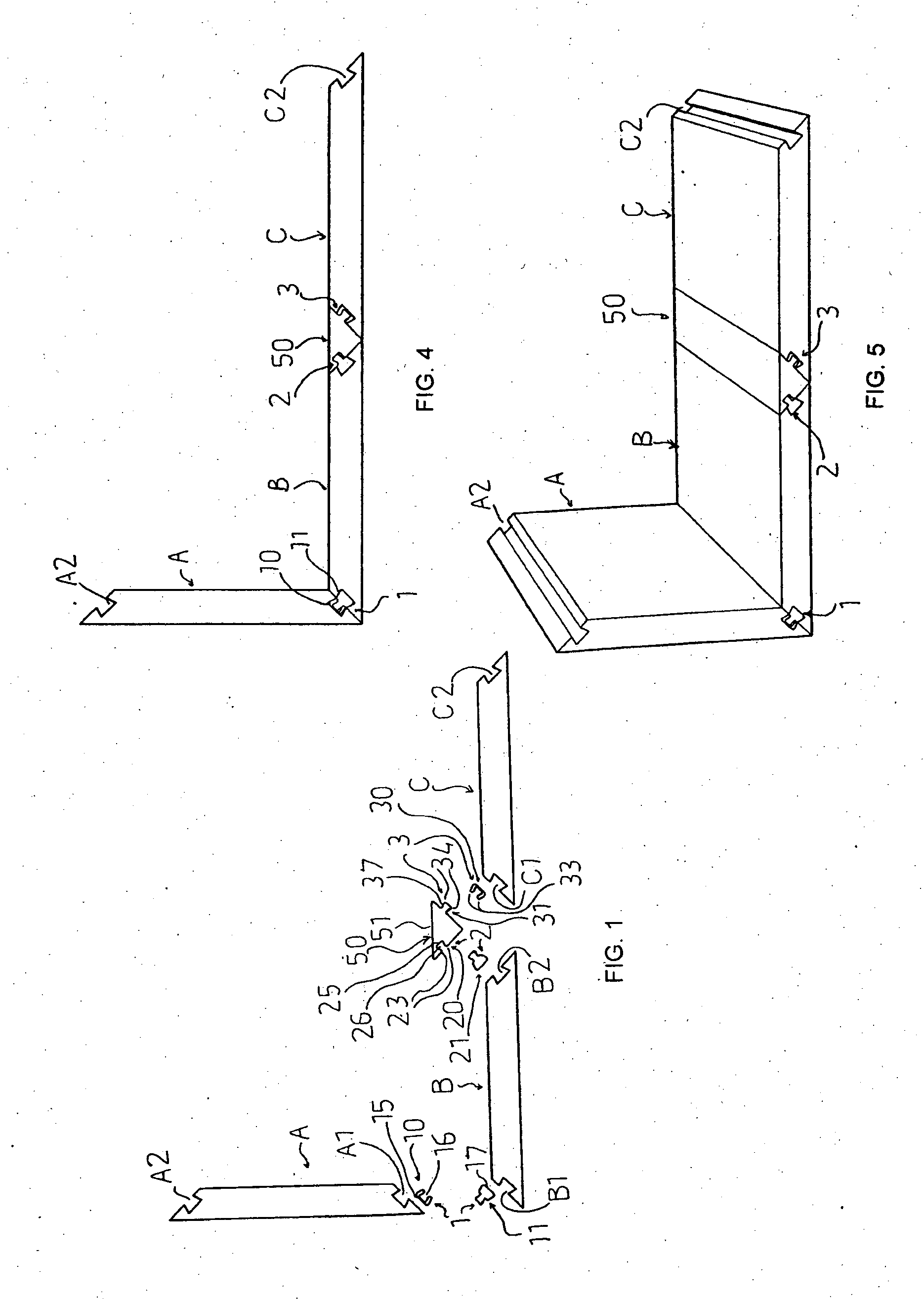

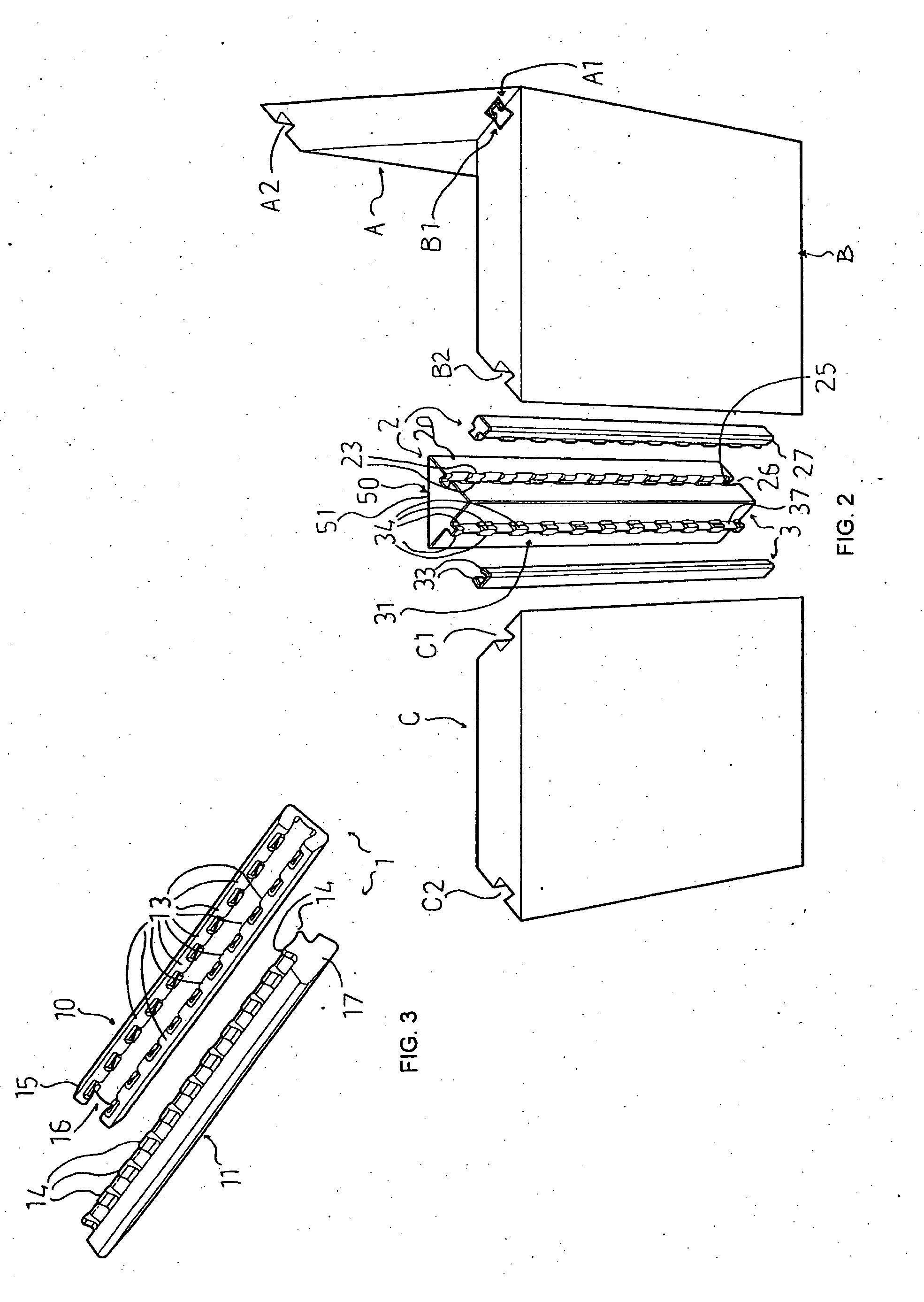

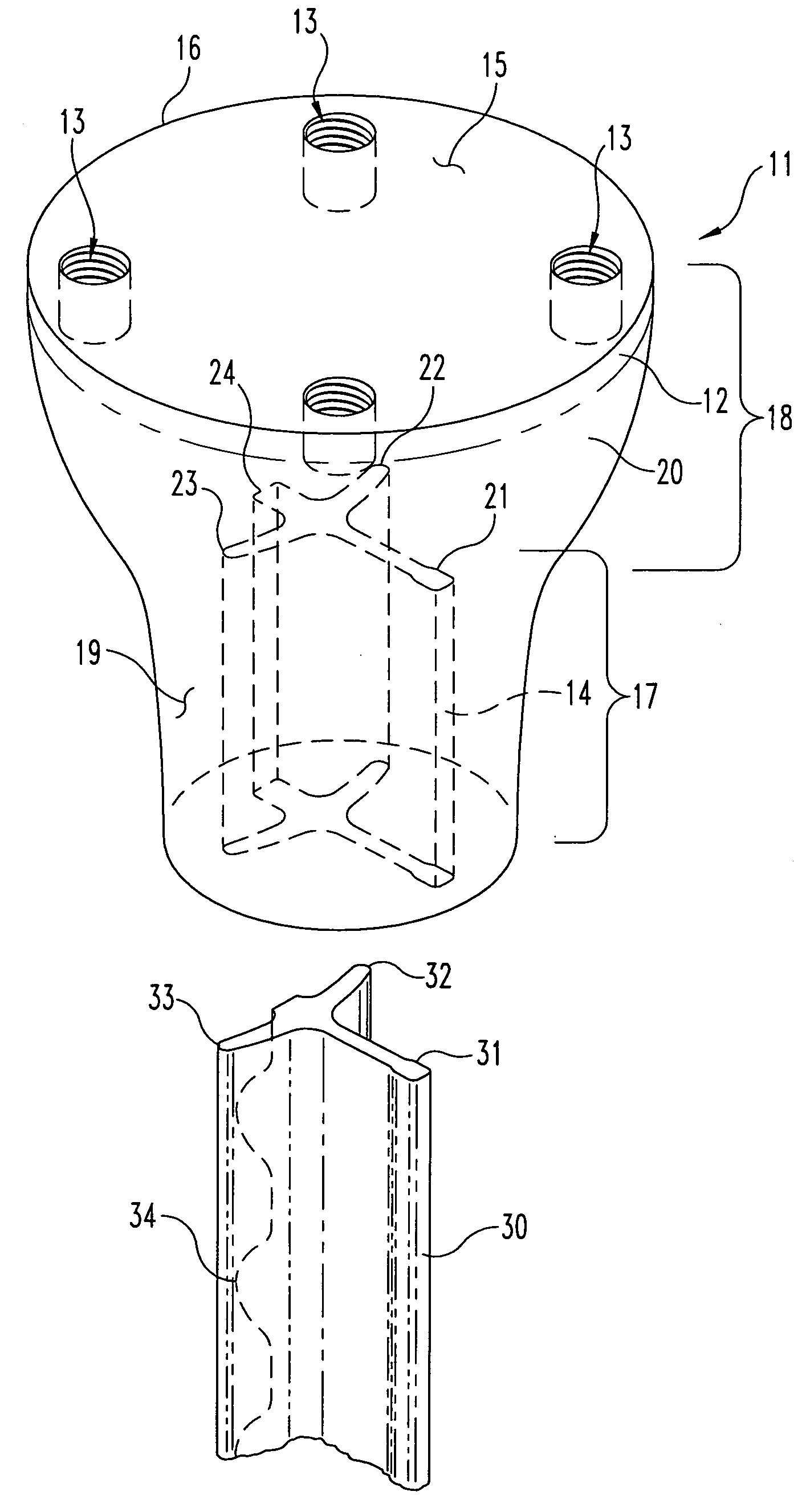

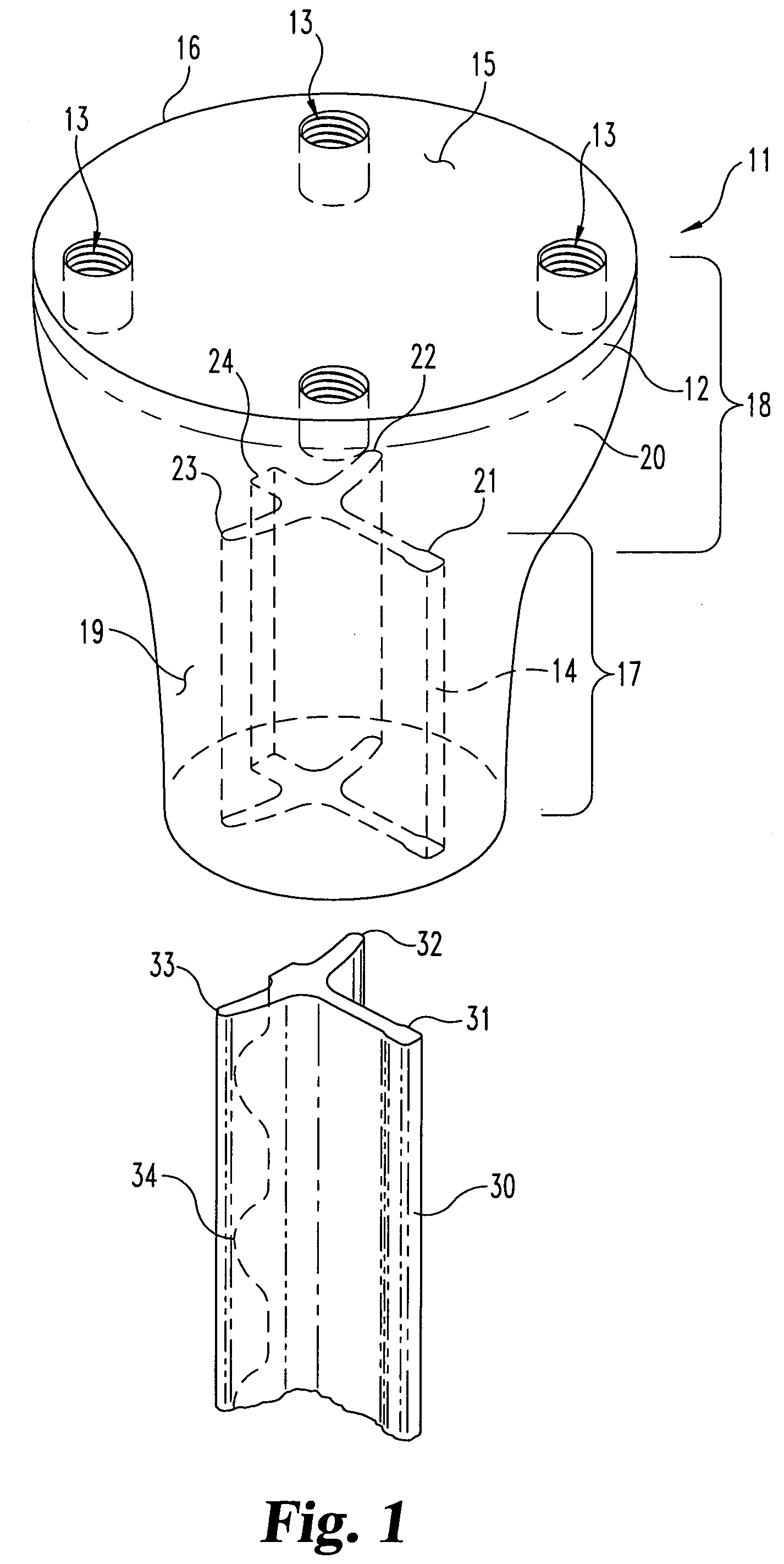

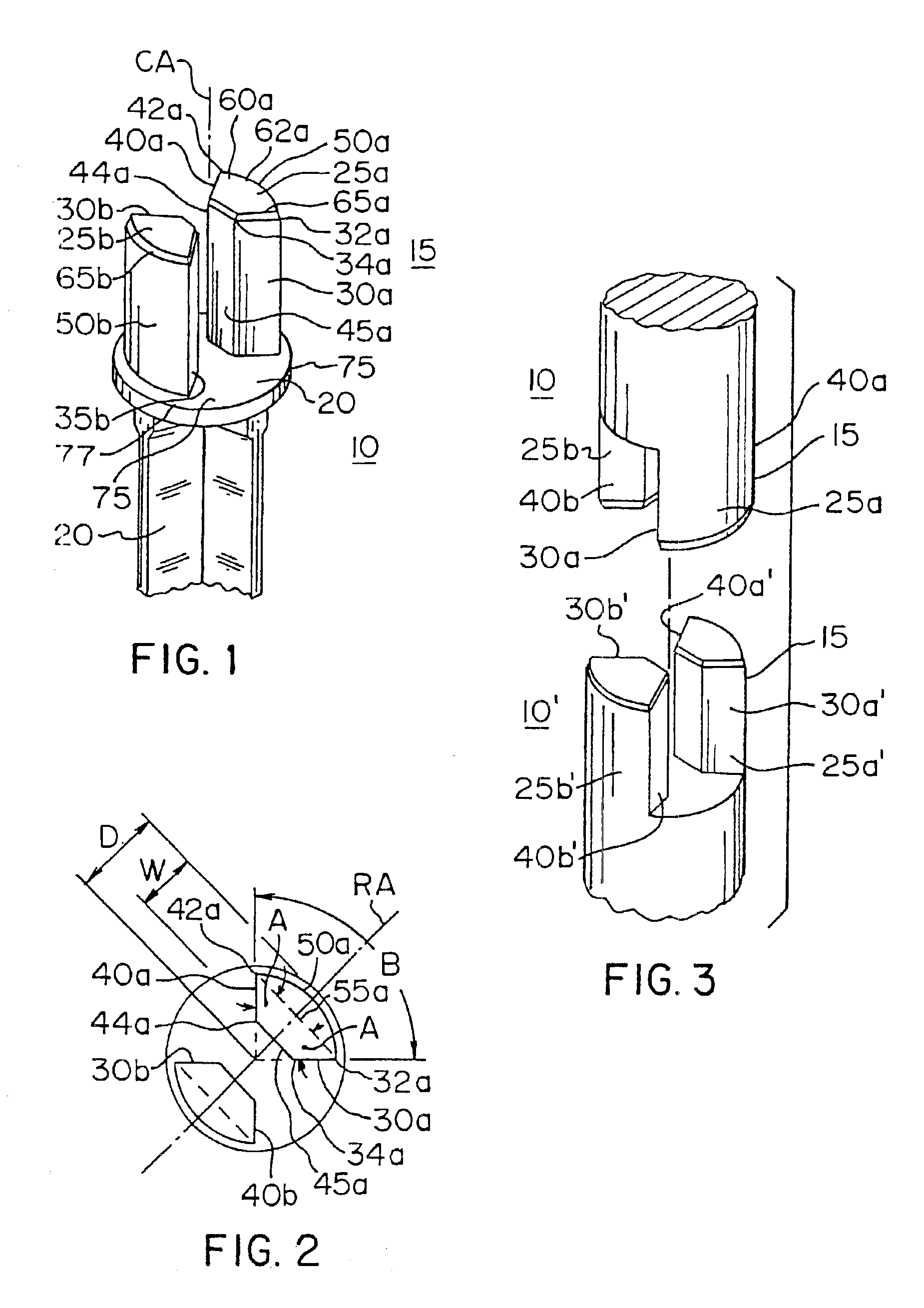

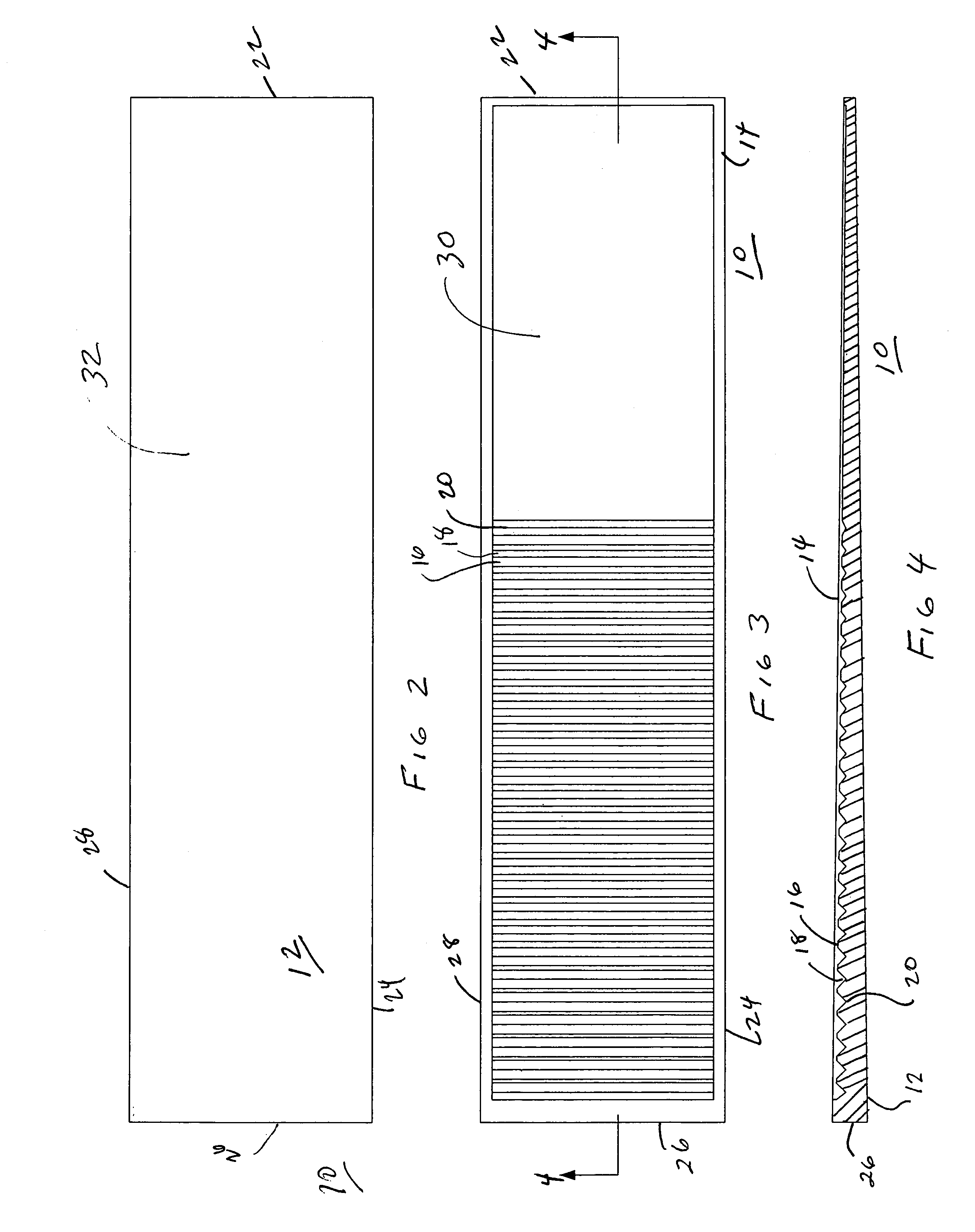

Key and keyway connectors

ActiveUS20130097846A1Furniture joining partsKey type connectionsMechanical engineeringBuilding construction

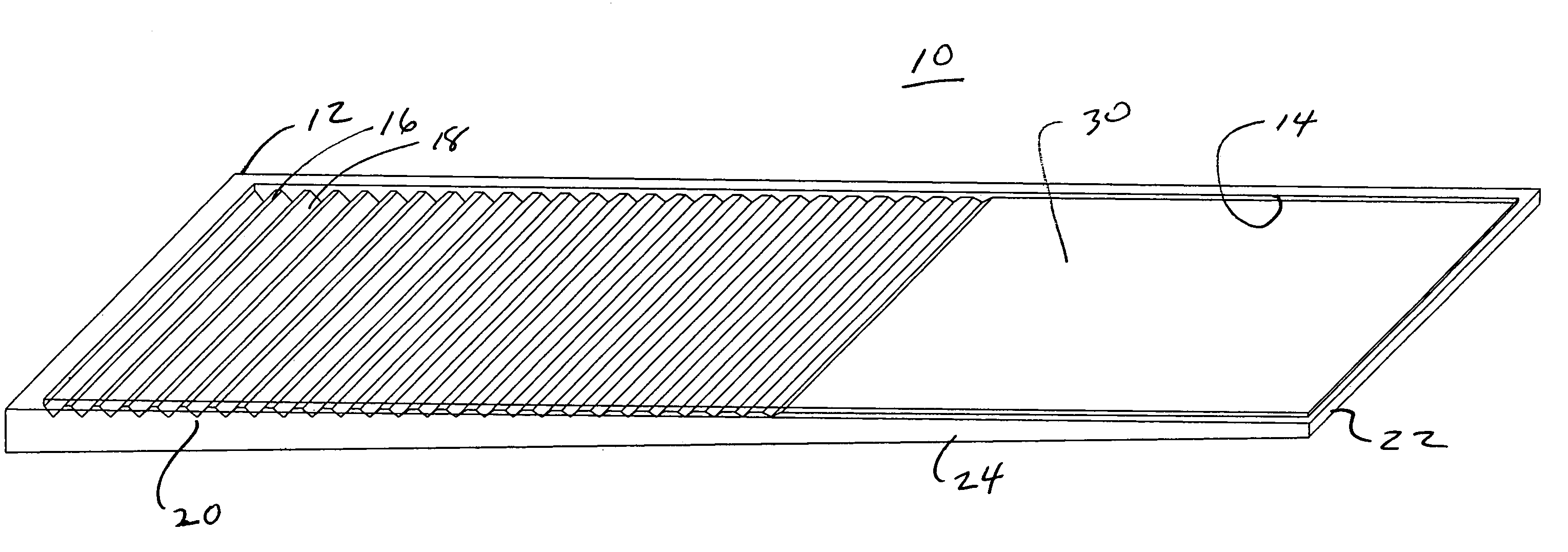

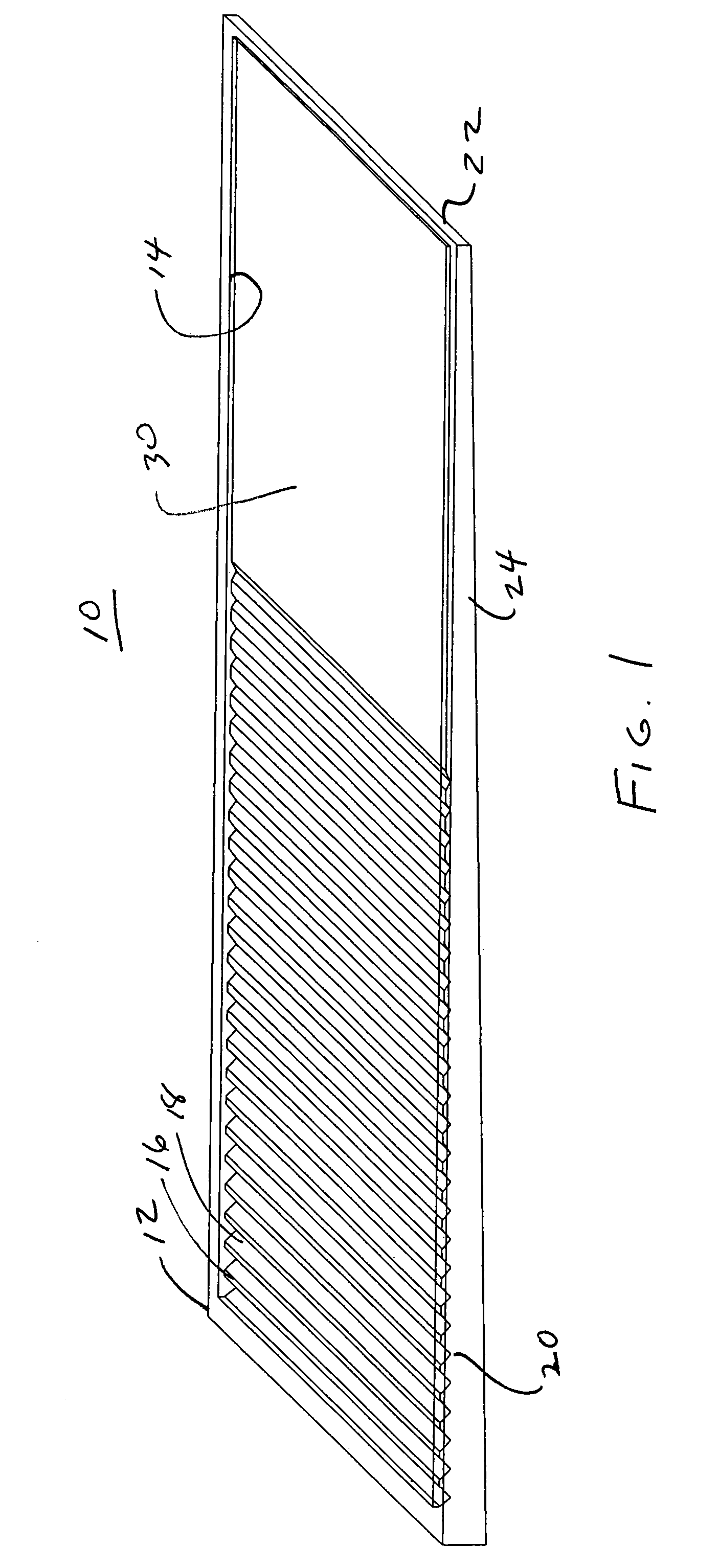

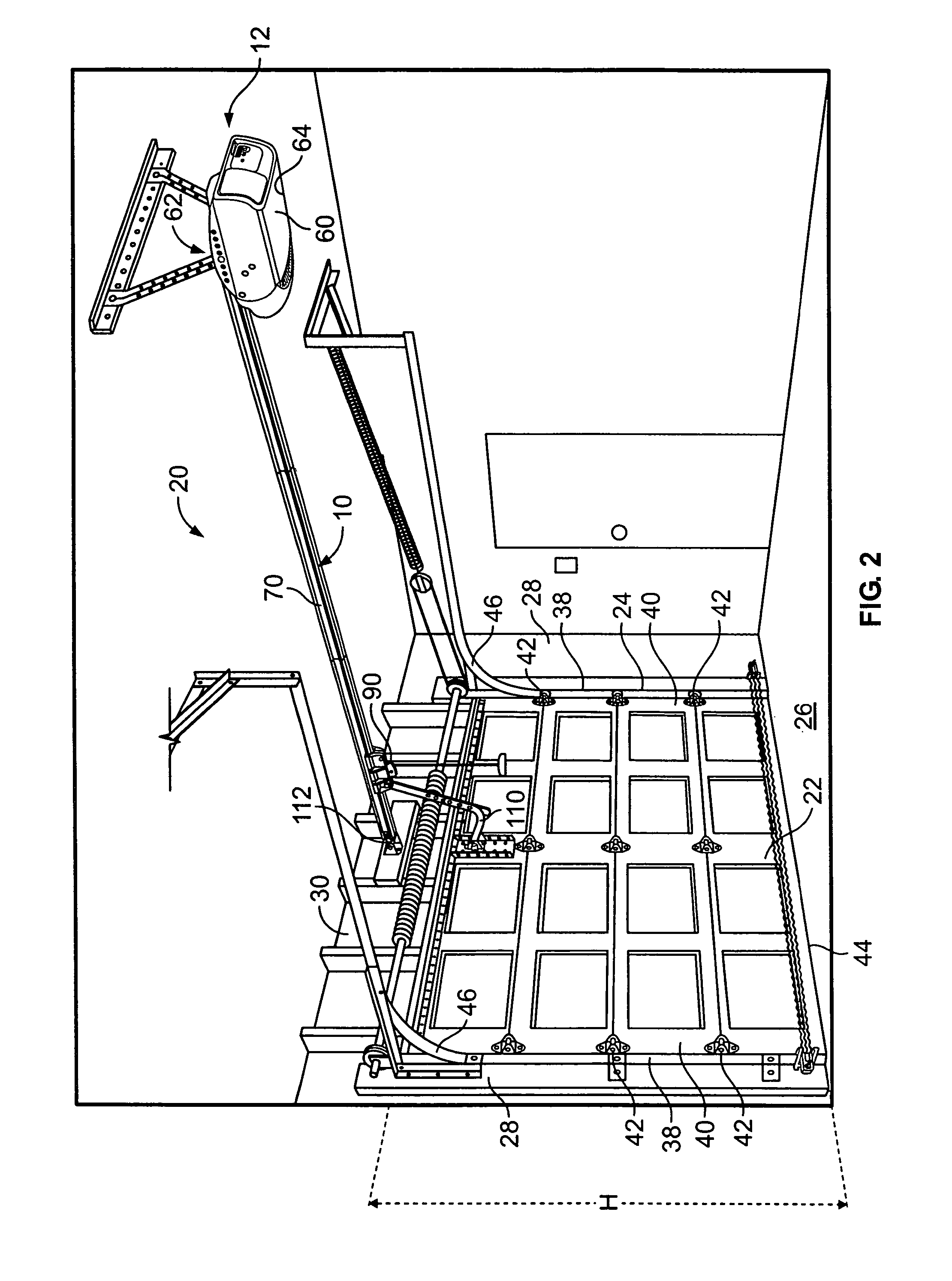

A method of mechanically connecting two or more components together. In one embodiment the method comprises the steps of: i. mounting at least one elongate keyway connector (10) comprising regularly spaced keyways (13) to a first component wherein the keyways (13) provide a longitudinal keyway passage (16); ii. mounting at least one elongate key connector (11) comprising regularly spaced keys (14) to a second component; and iii. extending the keys (14) longitudinally within the keyway passage (16) and engaging the keyways (13) with the keys (14) to connect the first and second components together. The connecting method can be used in the construction of flat-pack and ready-to-assemble designed furniture, in the construction of buildings or other structures, in the construction of storage, packaging, transportation and materials handling products, as well as for the ready replacement of components that tend to wear out during operation or use.

Owner:JOINLOCK

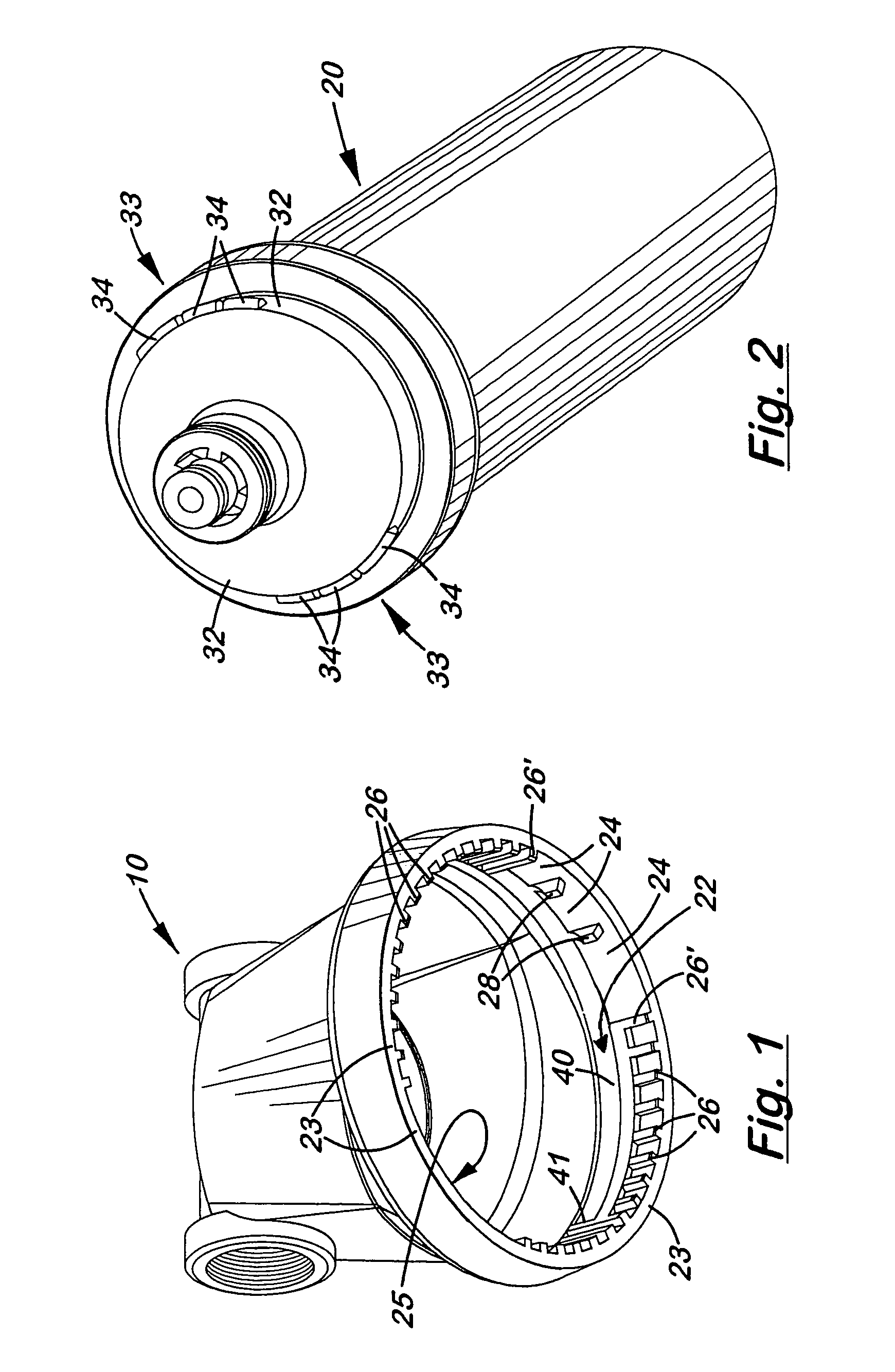

Case and mount system for handheld electronic device

A protective case for a handheld electronic device is provided. The protective case can include a removable mounting system comprised of an interlocking member and a plurality of mounting bases. The protective case may further include a non-slip member to prevent the device from slipping on a surface and a magnet for attaching the device to a magnetic surface.

Owner:ROKFORM IP LLC

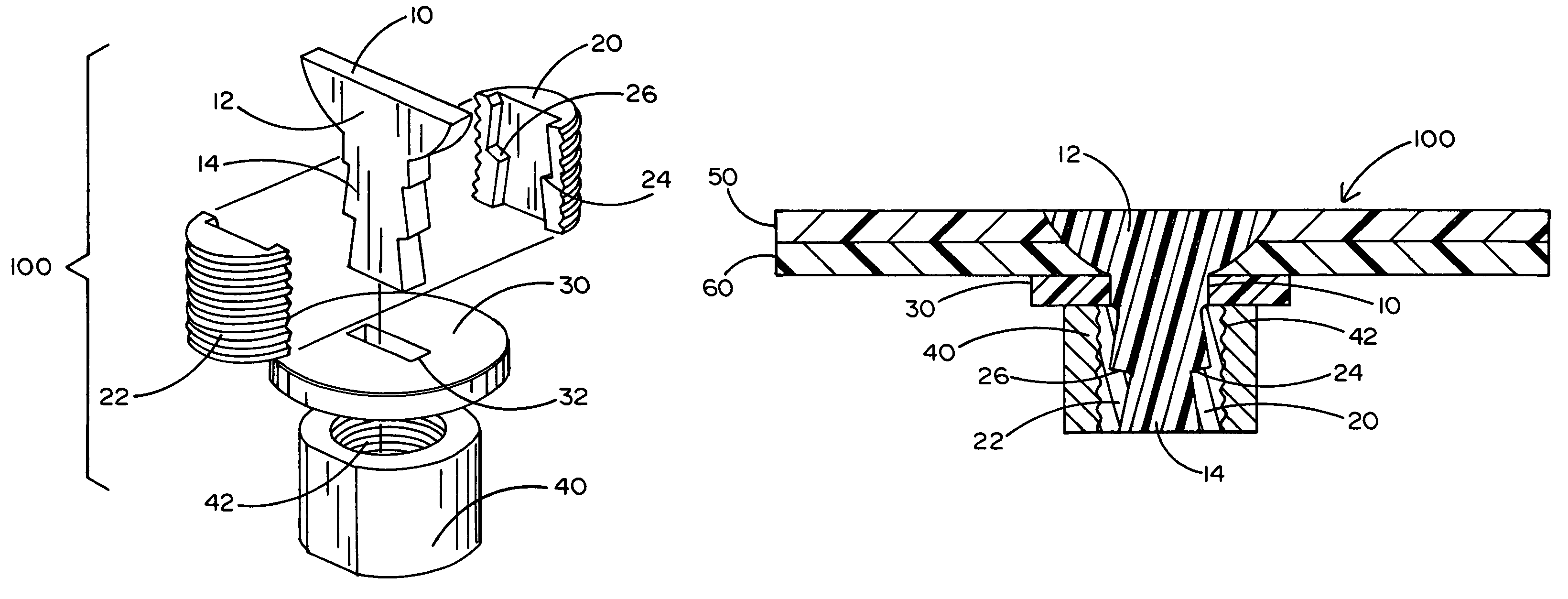

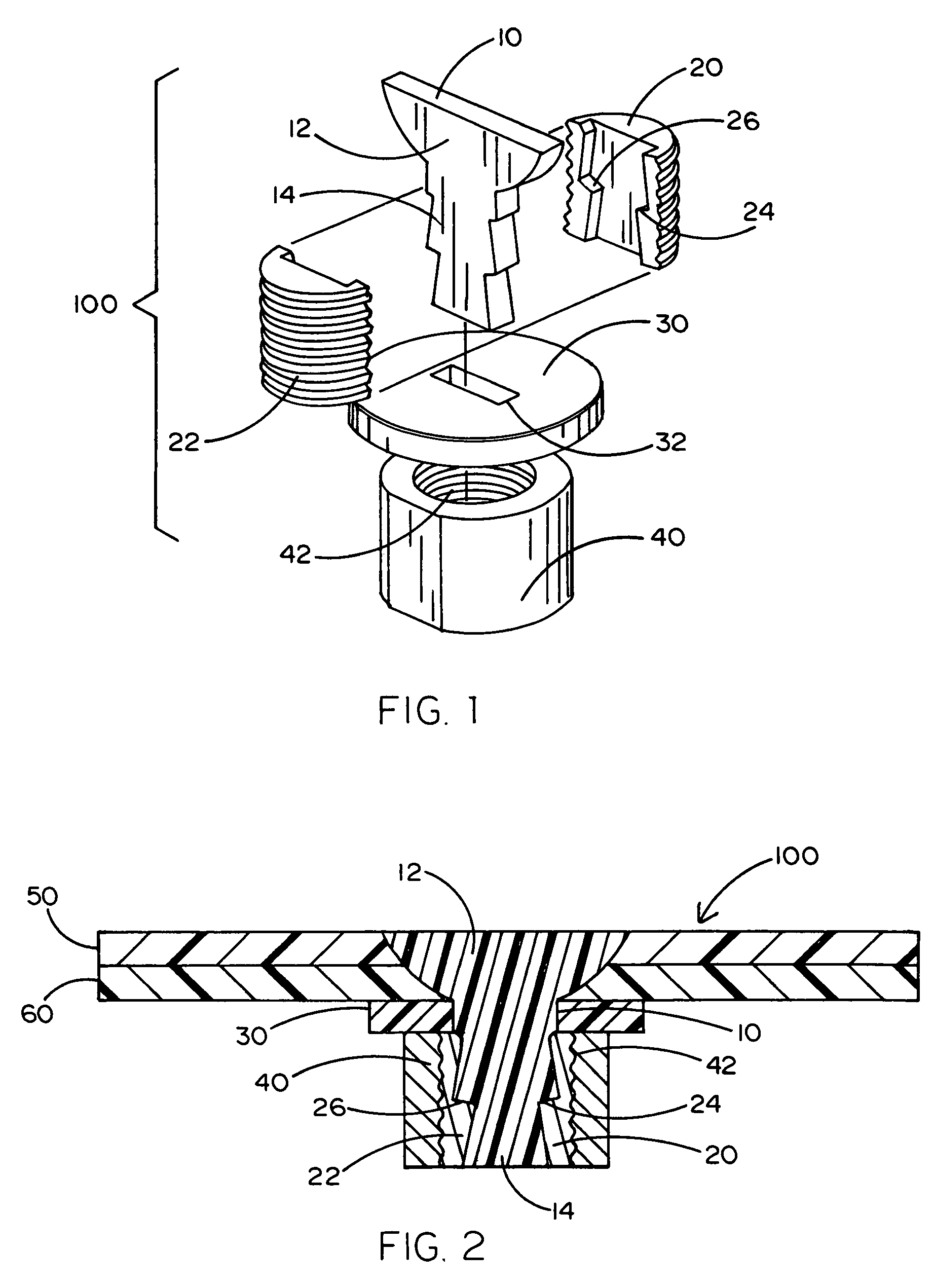

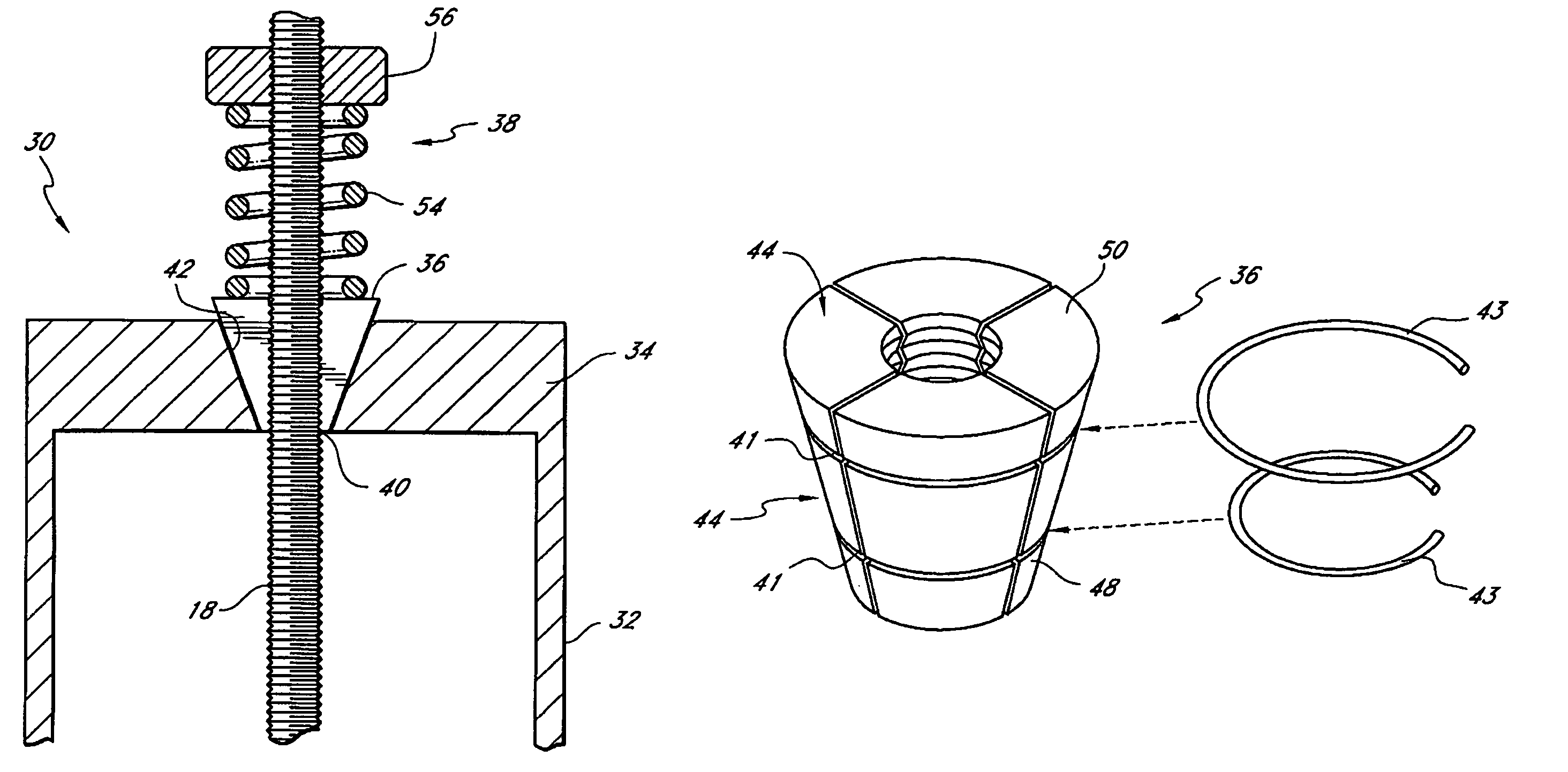

Mechanical fastener system for high-temperature structural assemblies

ActiveUS7988395B2Prevent removalAvoid separationNutsKey type connectionsMatched pairCeramic composite

Owner:ROLLS ROYCE HIGH TEMPERATURE COMPOSITES INC

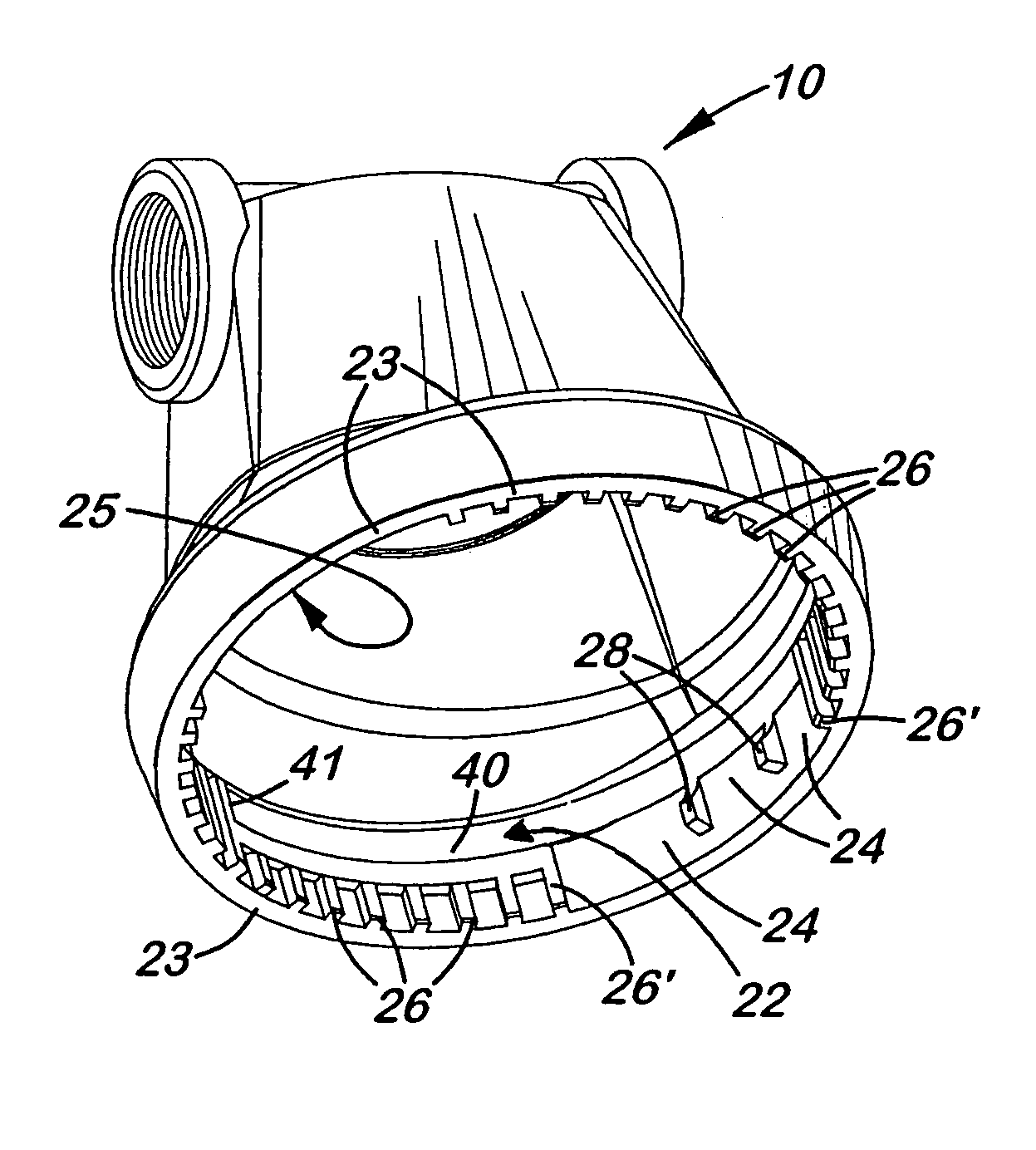

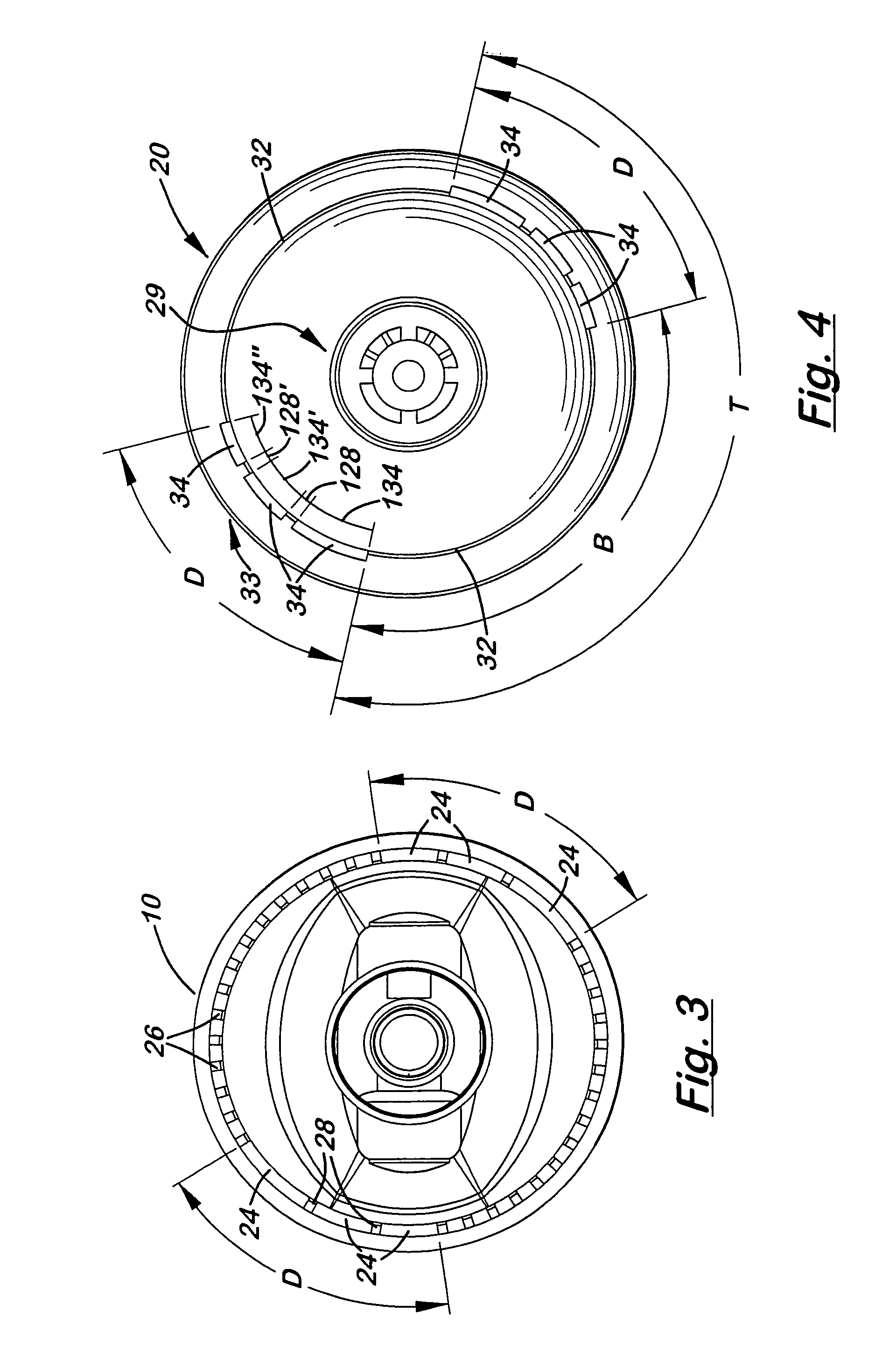

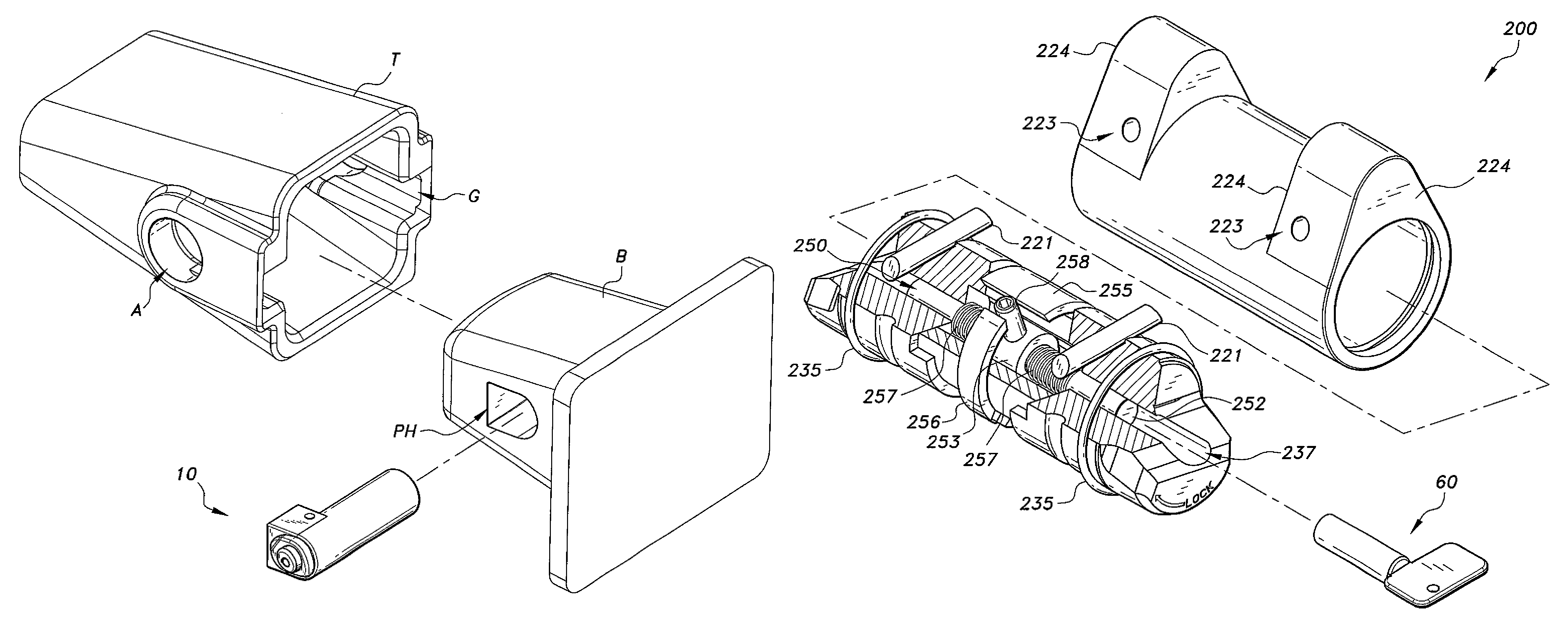

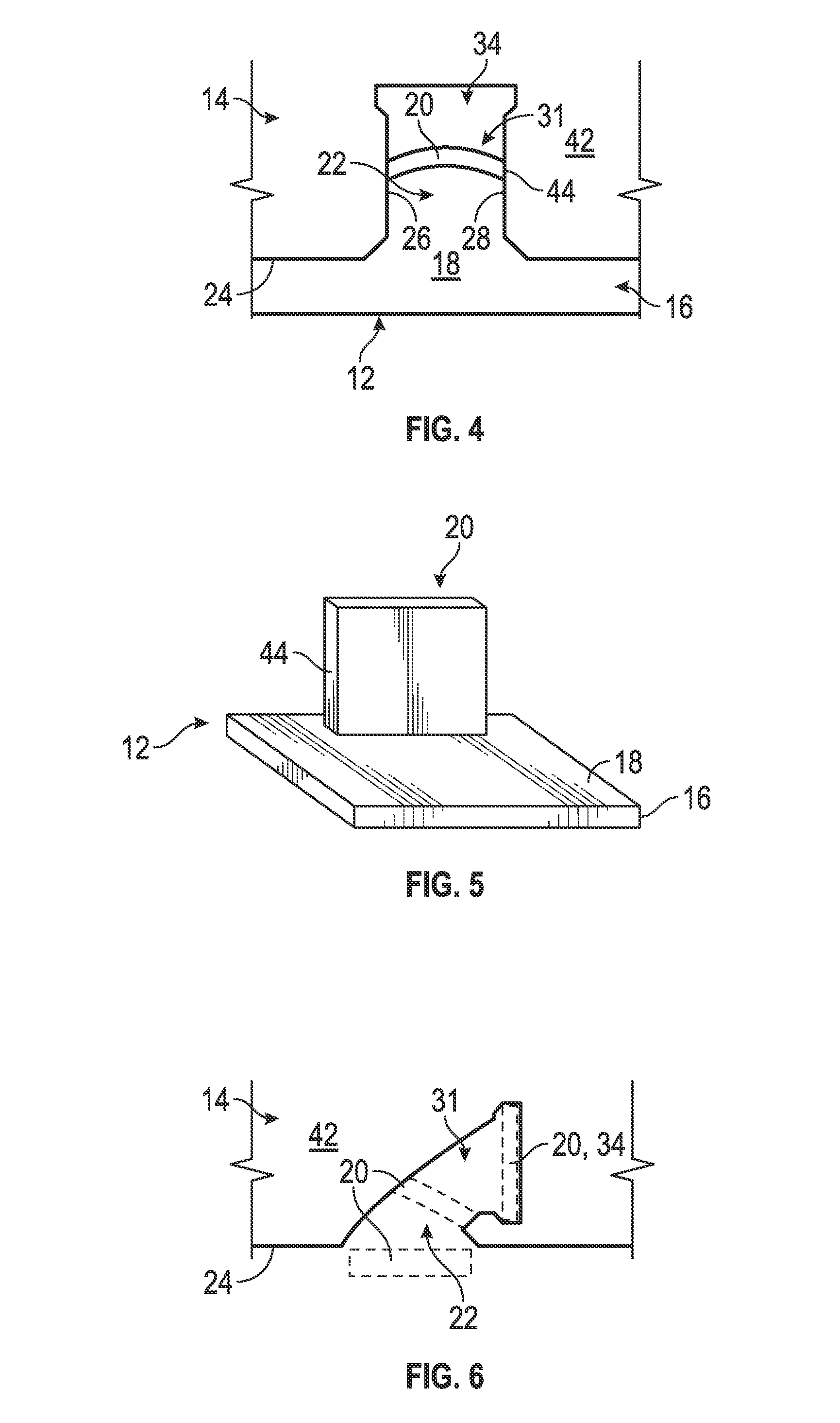

Keyed system for connection of filter cartridge to filter holder

InactiveUS6977006B2Carefully controlledIncentive to provide cheap, low quality copies will be minimizedCombination devicesDispersed particle filtrationFiltrationFilter holder

Embodiments of a key system for filters and their connecting heads / holders are shown. The filter cartridge and its holder each have a keyed surface, one being a protruding “key” and one being a recessed “lock”. Cooperation of these keyed surfaces is required in order for the filter cartridge to be installed in the holder, so that mismatched cartridges cannot be installed into the holder, for example, to prevent a particular type of cartridge from being placed in a filtration or other process where it would be inappropriate, or undesired. The keyed surfaces are selectively locate-able preferably at different circumferential locations on a perimeter of the filter and a corresponding location on a perimeter of the head / holder. The perimeter may be, for example, on an outer shoulder surface of a filter and an inner surface of a valve head, or on outer and inner surfaces of connectors that provide a liquid seal between the filter and the head / holder.

Owner:OMNIPURE FILTER CO INC

Shrinkage-compensating continuity system

Owner:MITEK HLDG INC

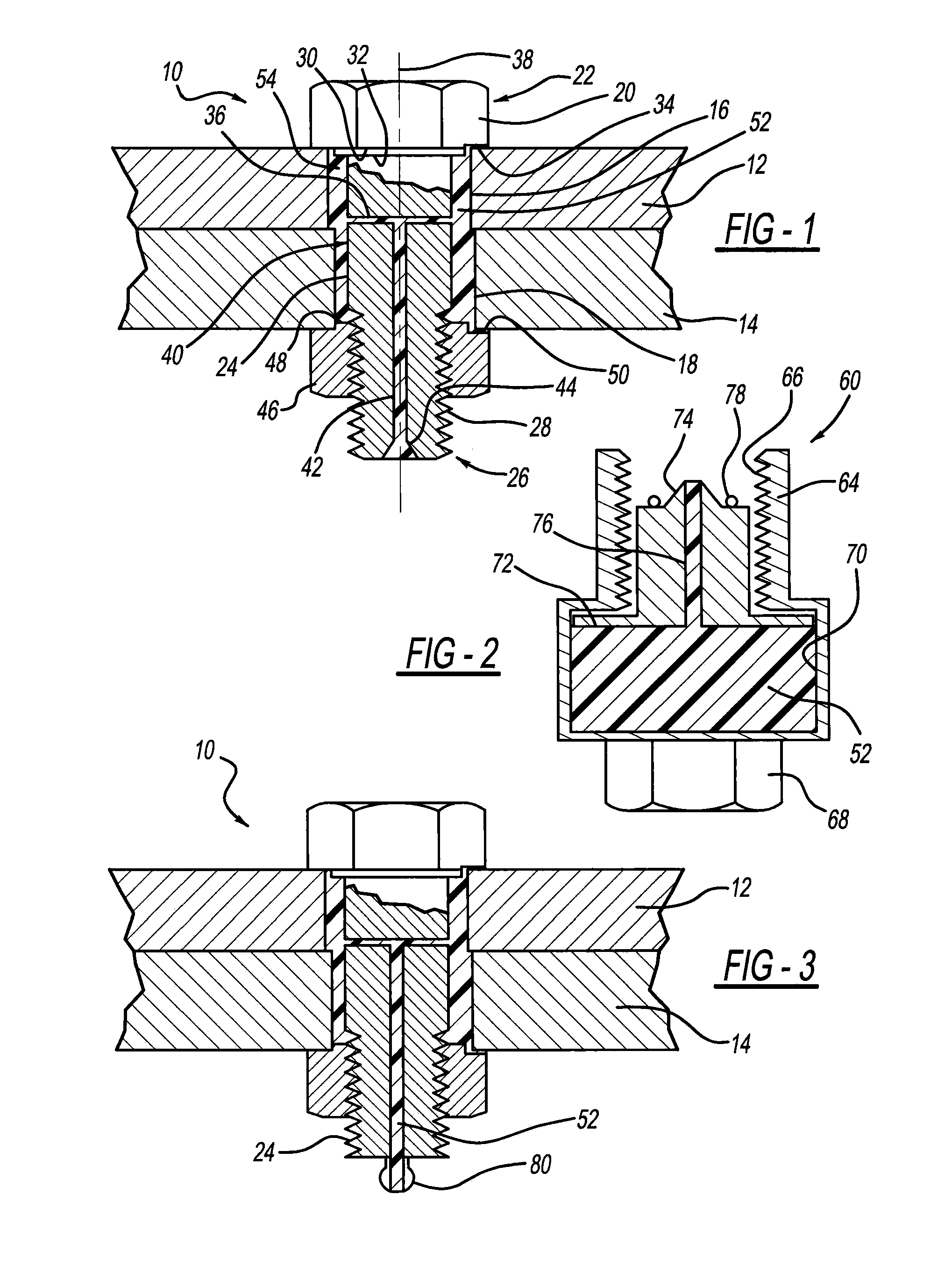

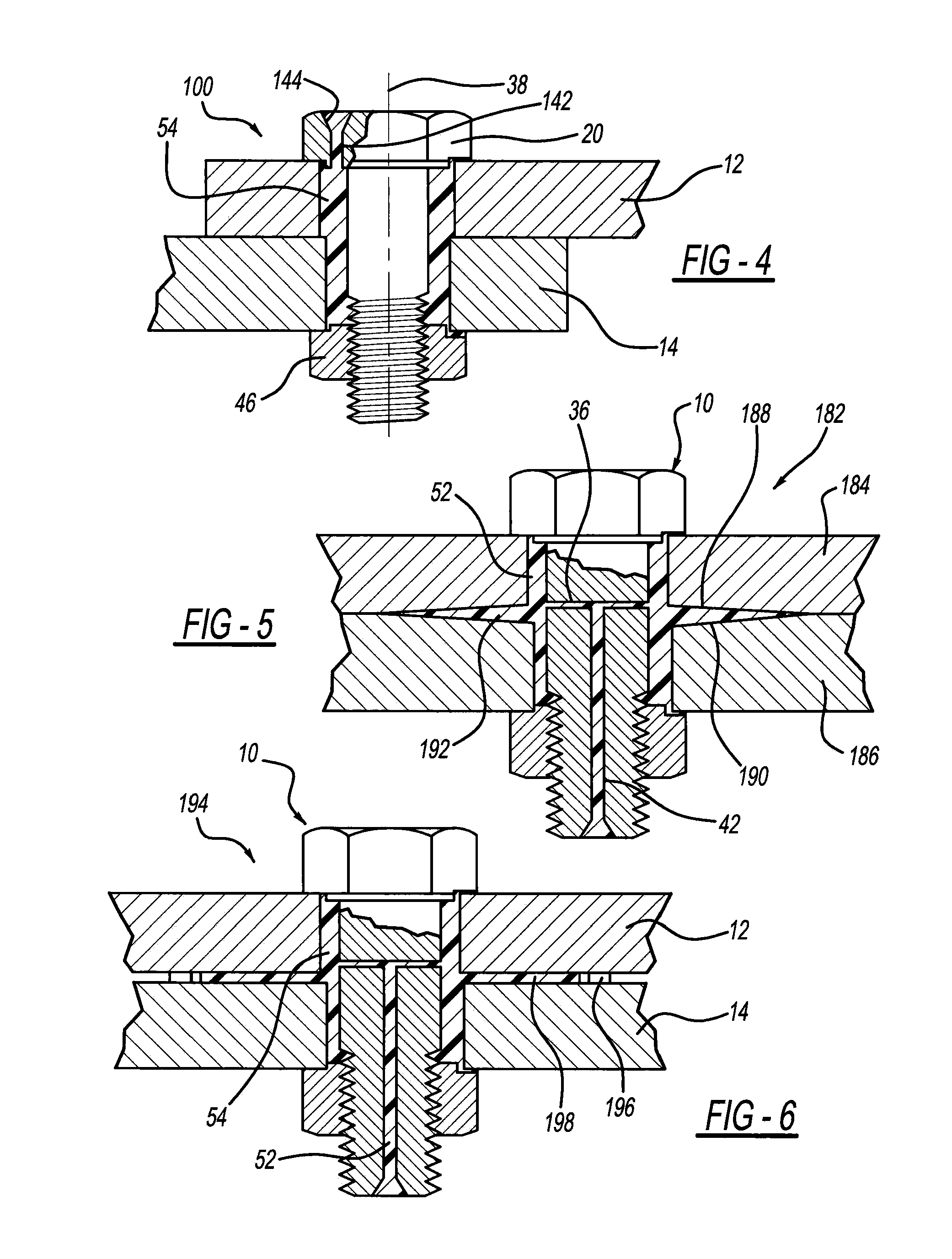

Hybrid fastener

ActiveUS20130330145A1Reduce contact stressReduce stress concentrationPinsMaterial gluingScrew threadBiomedical engineering

A hybrid fastener is provided in combination with a structural insert. The insert is disposed about a shank of the fastener at an unthreaded section. In another aspect, a sleeve surrounds the shank of the fastener and has apertures for receiving the insert therethrough. Methods of using the above-described hybrid fastener for securing workpieces are also disclosed.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Device for supporting systems

ActiveUS20080296443A1Cost efficientLow production costCandle holdersLighting support devicesSupporting systemEngineering

The present invention relates to a device for supporting systems, for example an electric cable or a fluid-carrying pipe, on a structure of an aircraft or space craft, and to an aircraft or space craft with such a device. The device has a basic bracket arrangement which can be fastened to at least one predetermined fastening section of the structure, and also has at least one system bracket for supporting the systems. The at least one system bracket can be fastened to the basic bracket arrangement locationally variable with respect to the fastening section. The advantage of the invention consists in the fact that a route of a system can be flexibly varied even during the equipment assembly, i.e. the structure is no longer modifiable or is only modifiable at considerable expense.

Owner:AIRBUS OPERATIONS GMBH

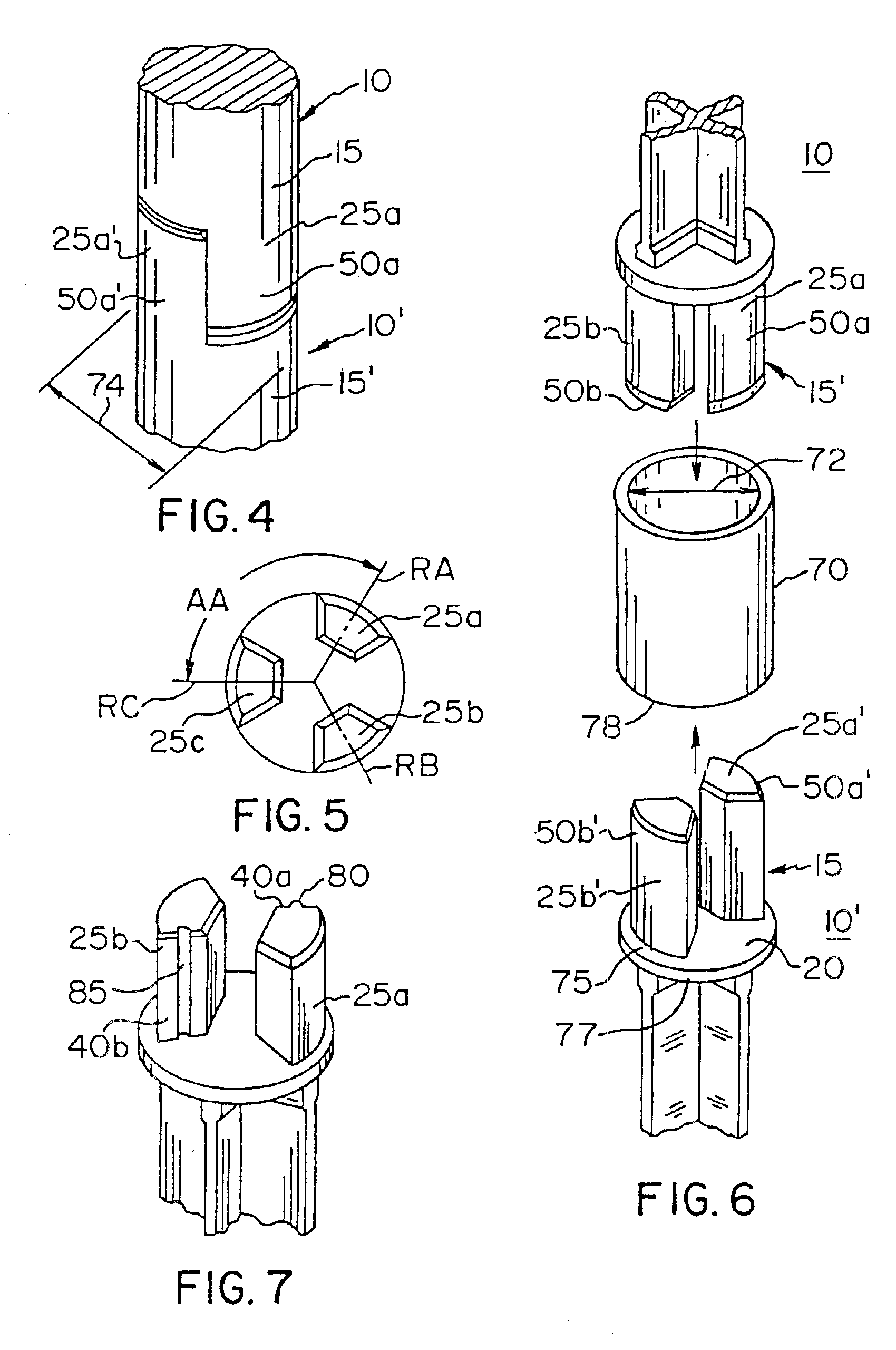

Locking pin assembly

The locking pin assembly includes an elongate pin housing and a pin mechanism insertably mounted into a bore in the pin housing. The pin mechanism includes at least one rotator section integral with a pin shaft. A rotation-locking member is integrally attached to the bottom of the pin shaft, the locking member having a non-circular shape. An elongate post having a rotation-locking collar attached to one end of the post is slidable in a keyhole extending through the pin. A non-circular recess is formed in the rotation-locking collar, which selectively receives the locking member therein. A spring is disposed behind the rotation-locking collar. The spring normally biases the locking collar into engagement with the locking member. A key is provided to axially push the post to selectively disengage the locking member for selective rotation of the rotator section between locked and unlocked positions.

Owner:CUI KAN

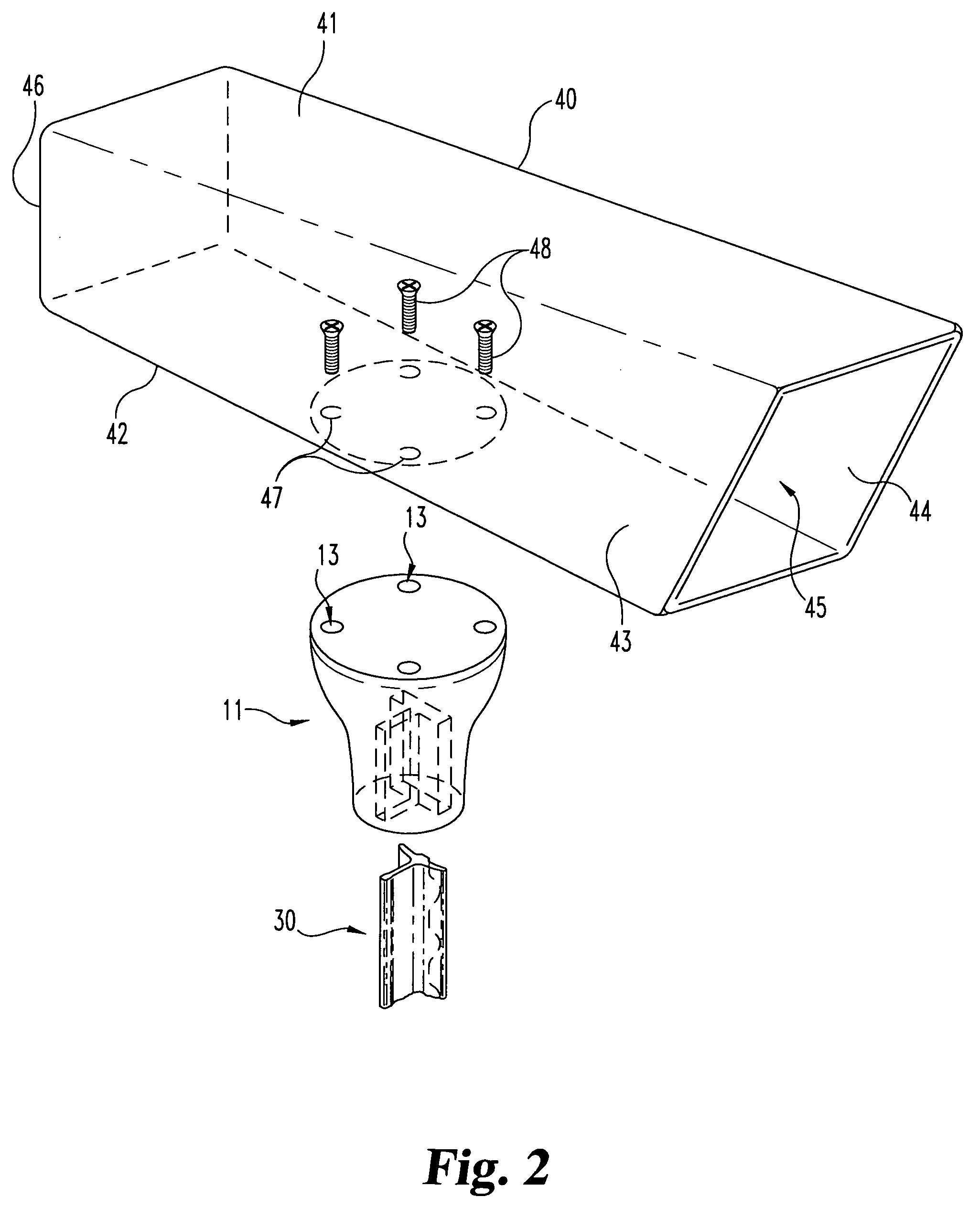

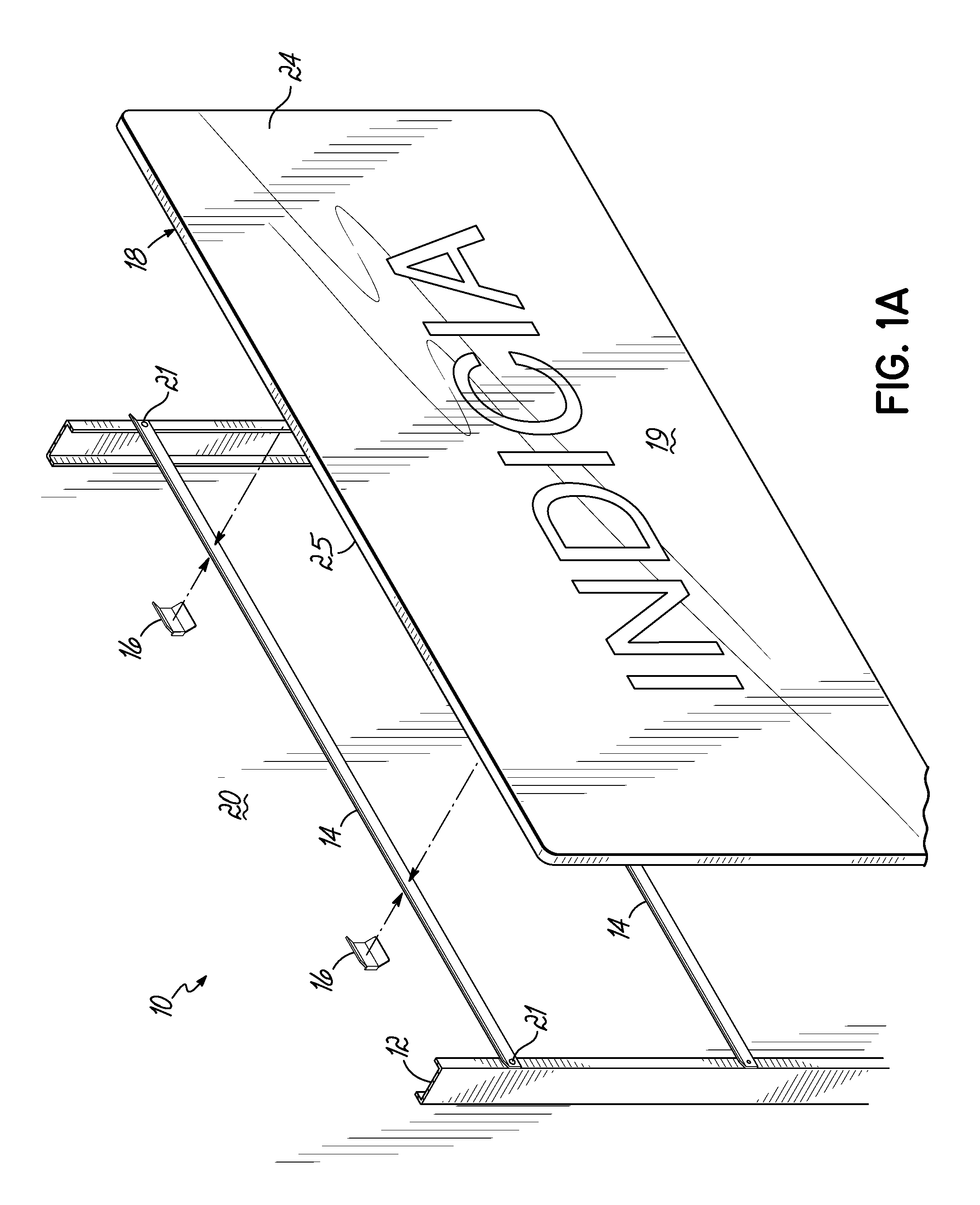

T-post and other mounting systems and accessories

Described in certain embodiments are mounting systems that employ one or more T-posts to support useful implements such as birdhouses, signs, fencing, banners, and the like. Additional disclosed embodiments relate to unique post- or wall-mount systems for such implements.

Owner:BRADLEY SELDON

Axial securing device for two components by means of a locking ring

InactiveUS6561720B2Easy to installImprove retentionPipe elementsSecuring devicesEngineeringMechanical engineering

Owner:ZF FRIEDRICHSHAFEN AG

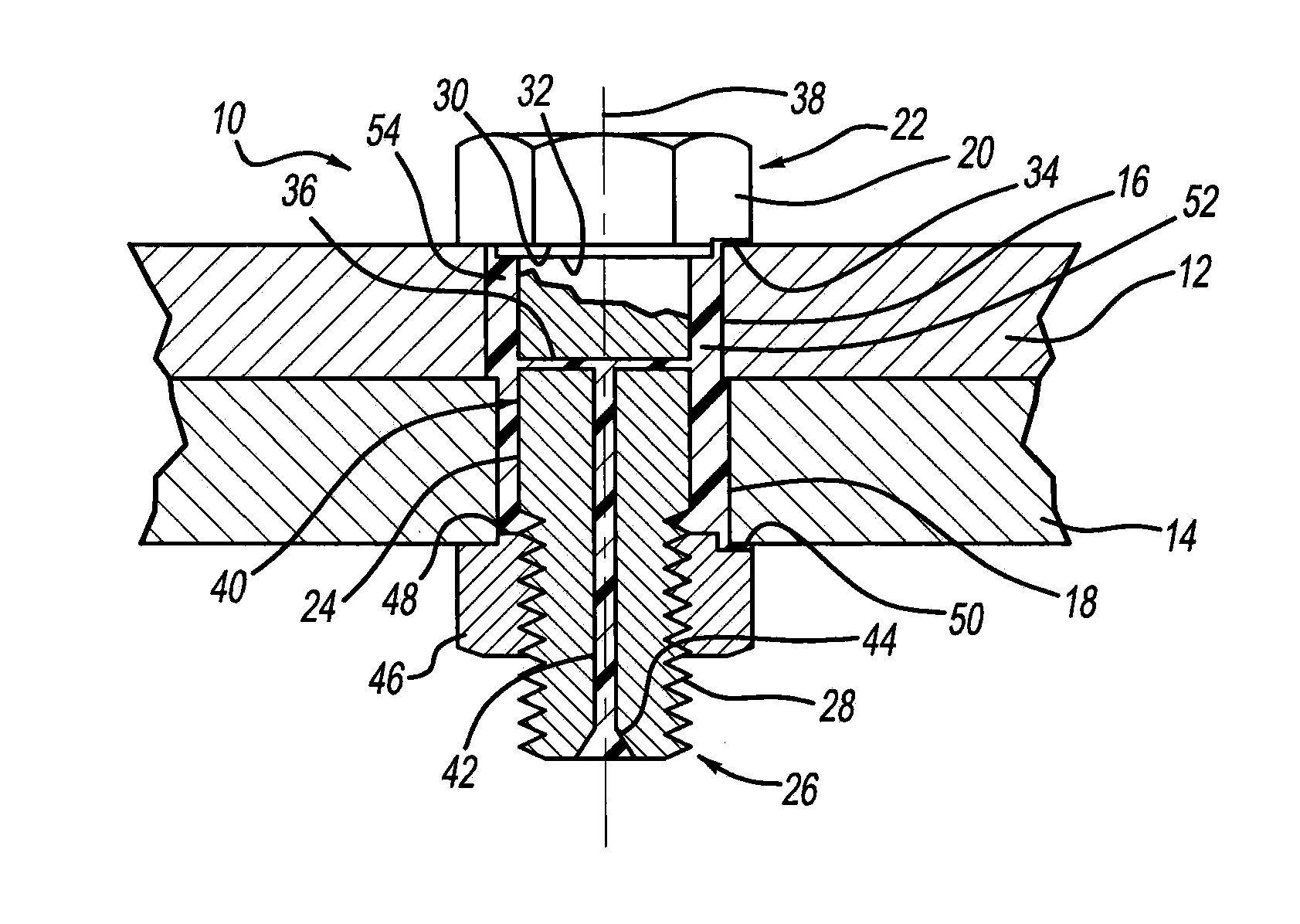

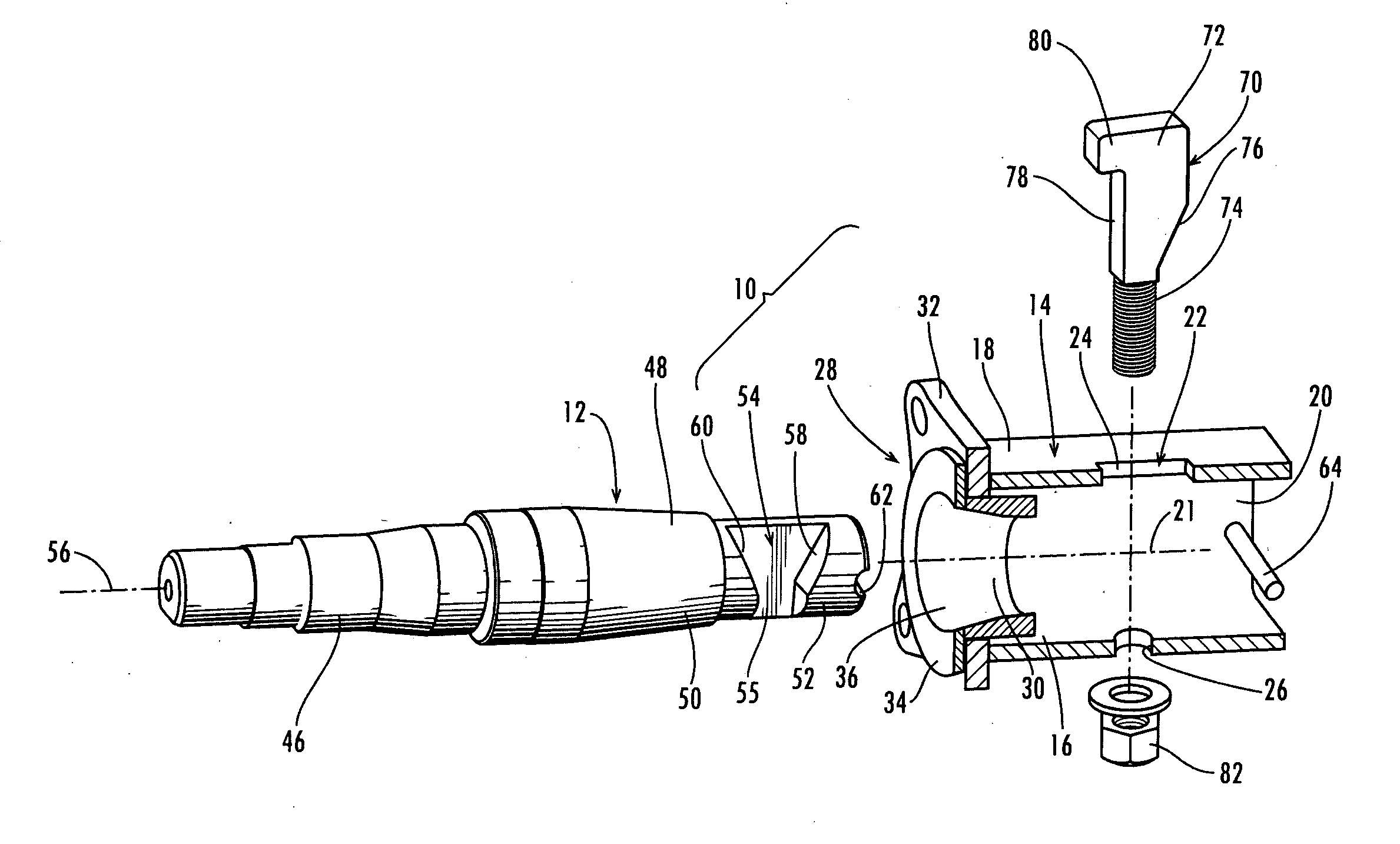

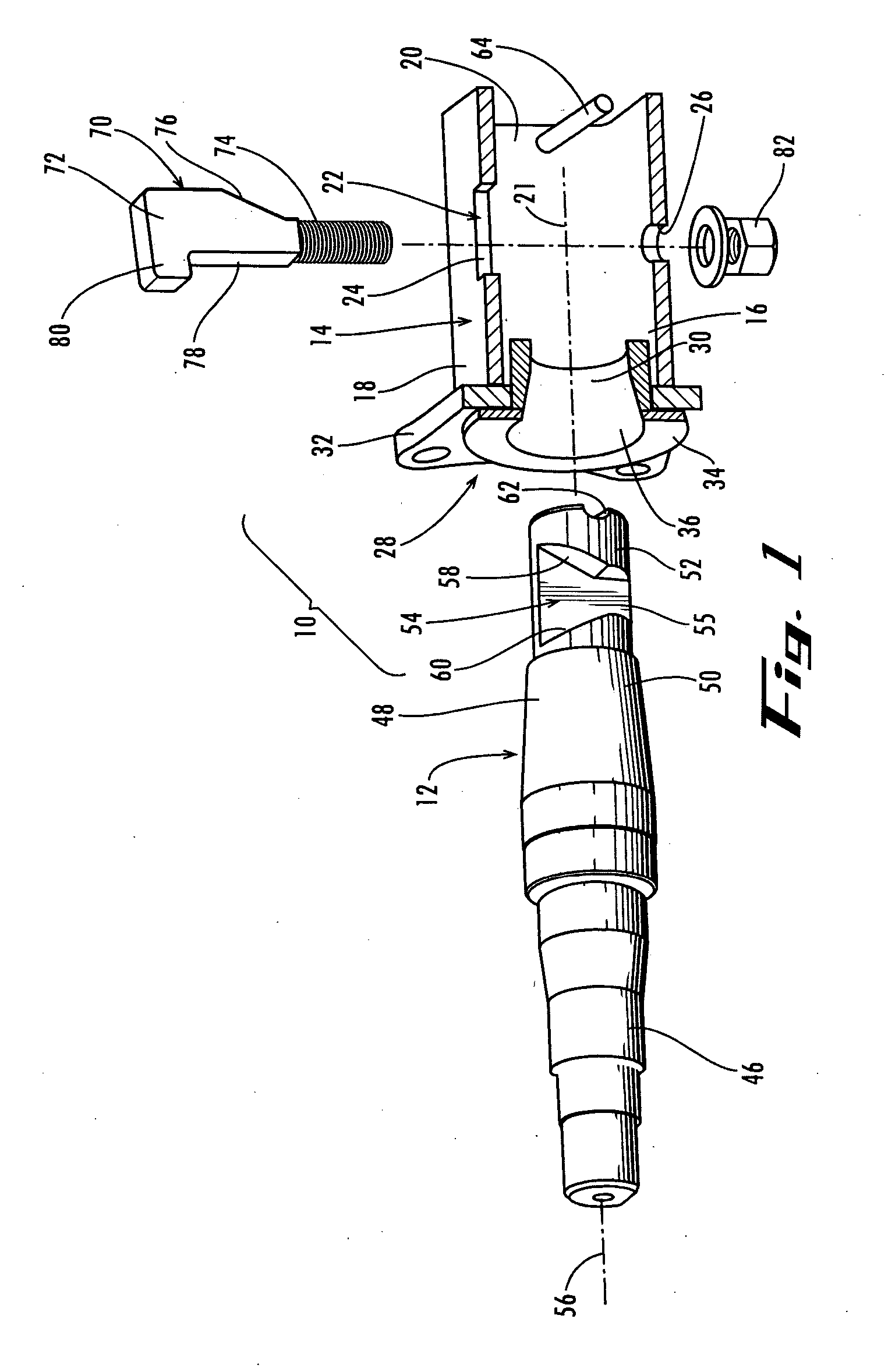

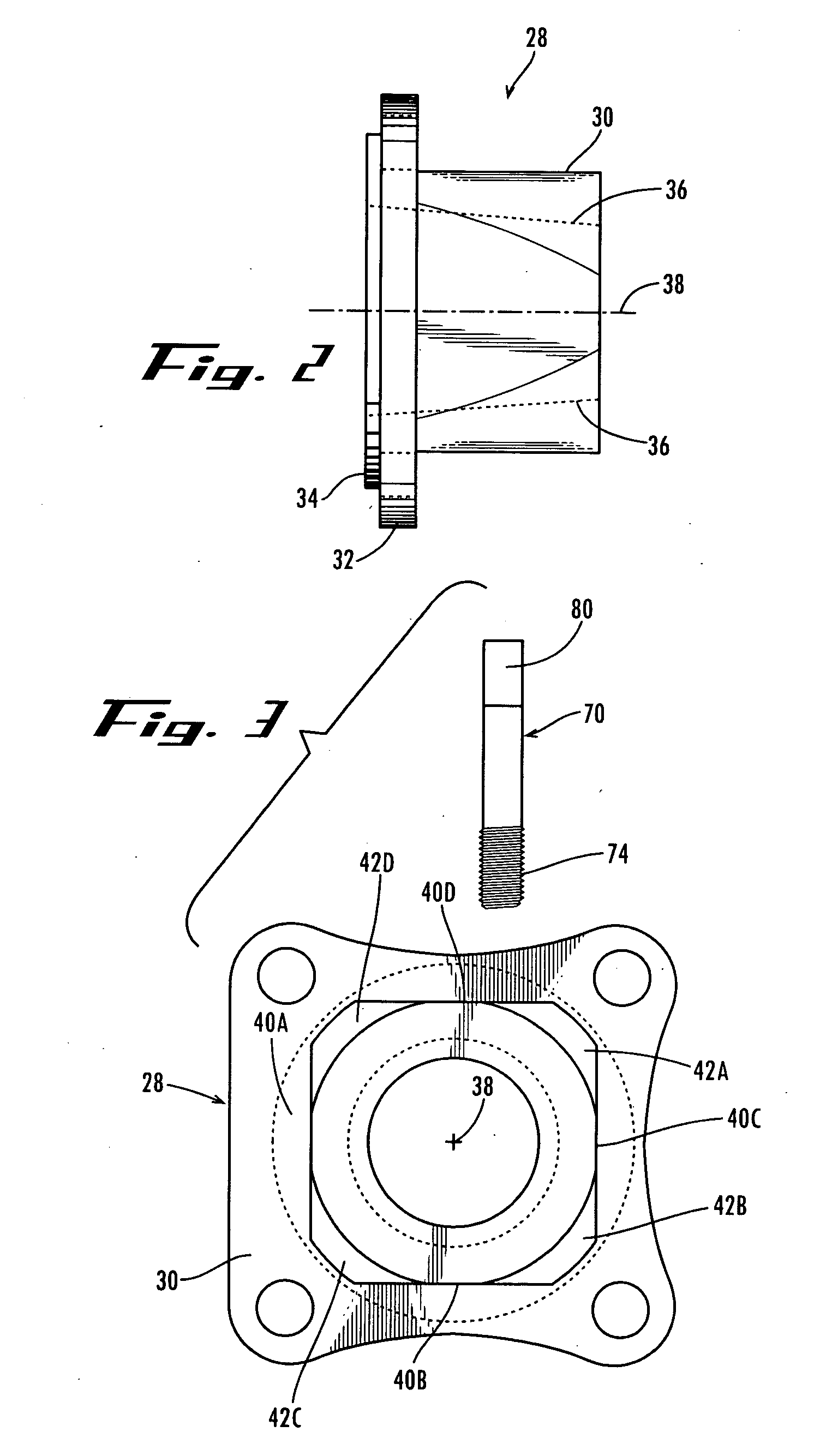

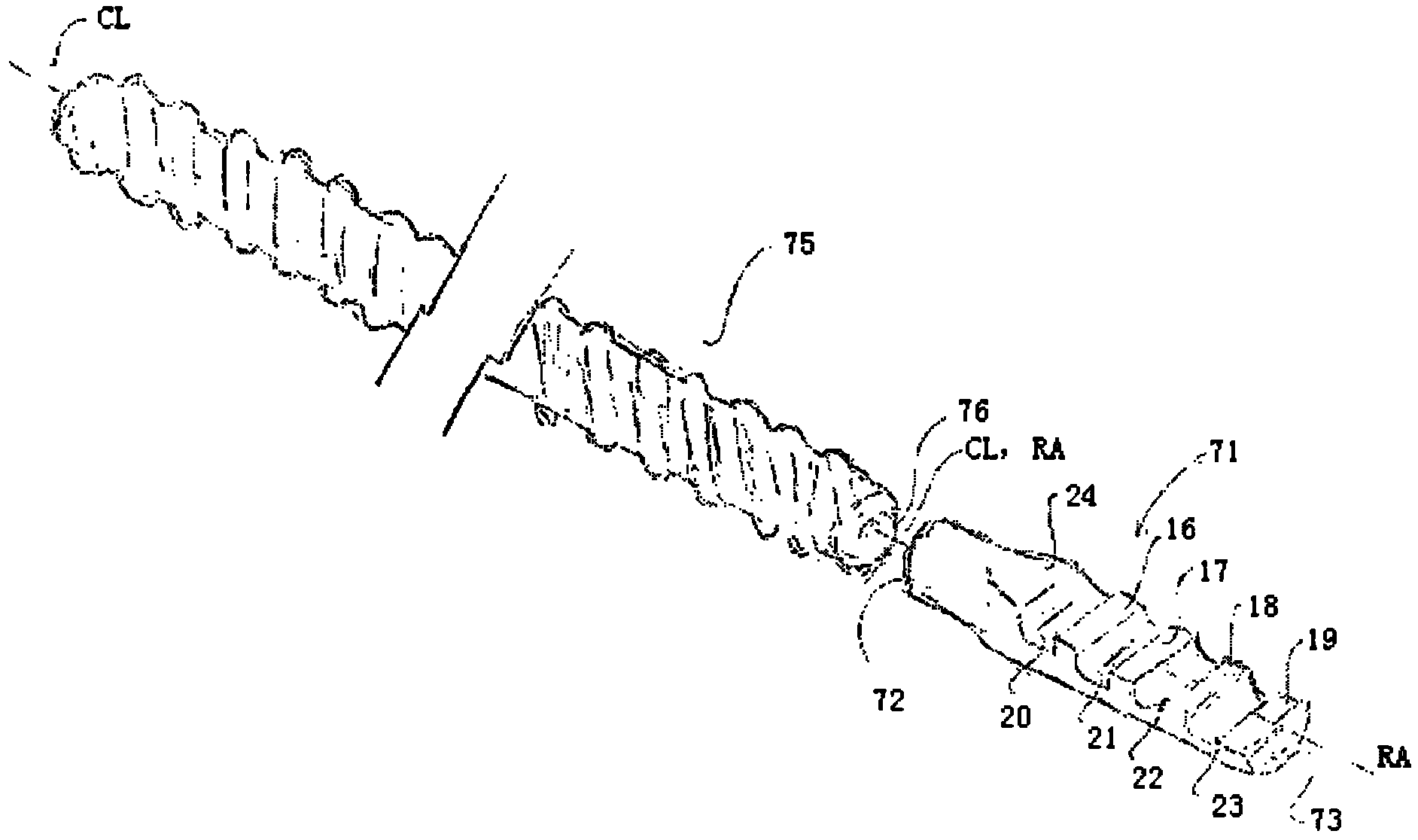

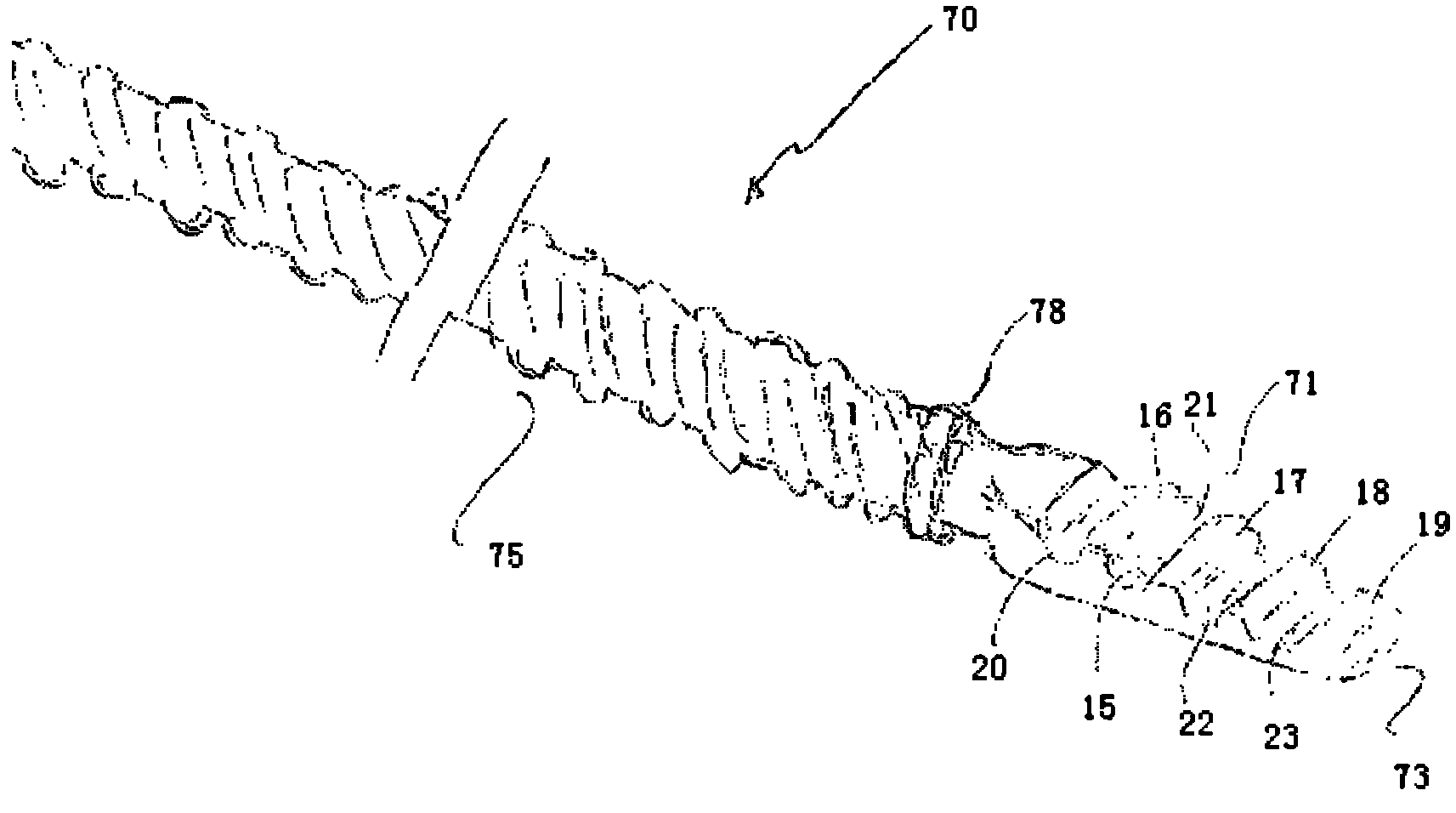

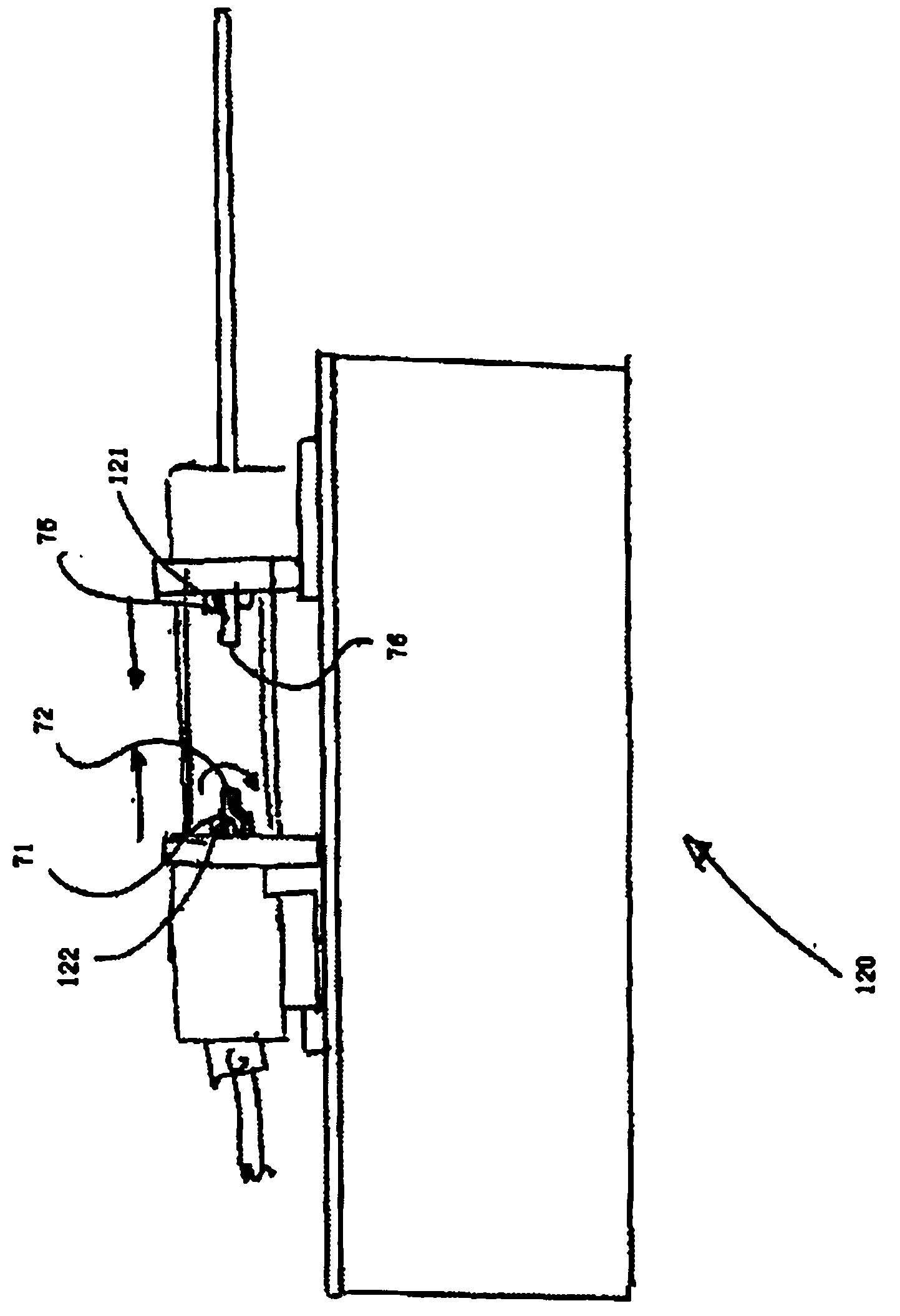

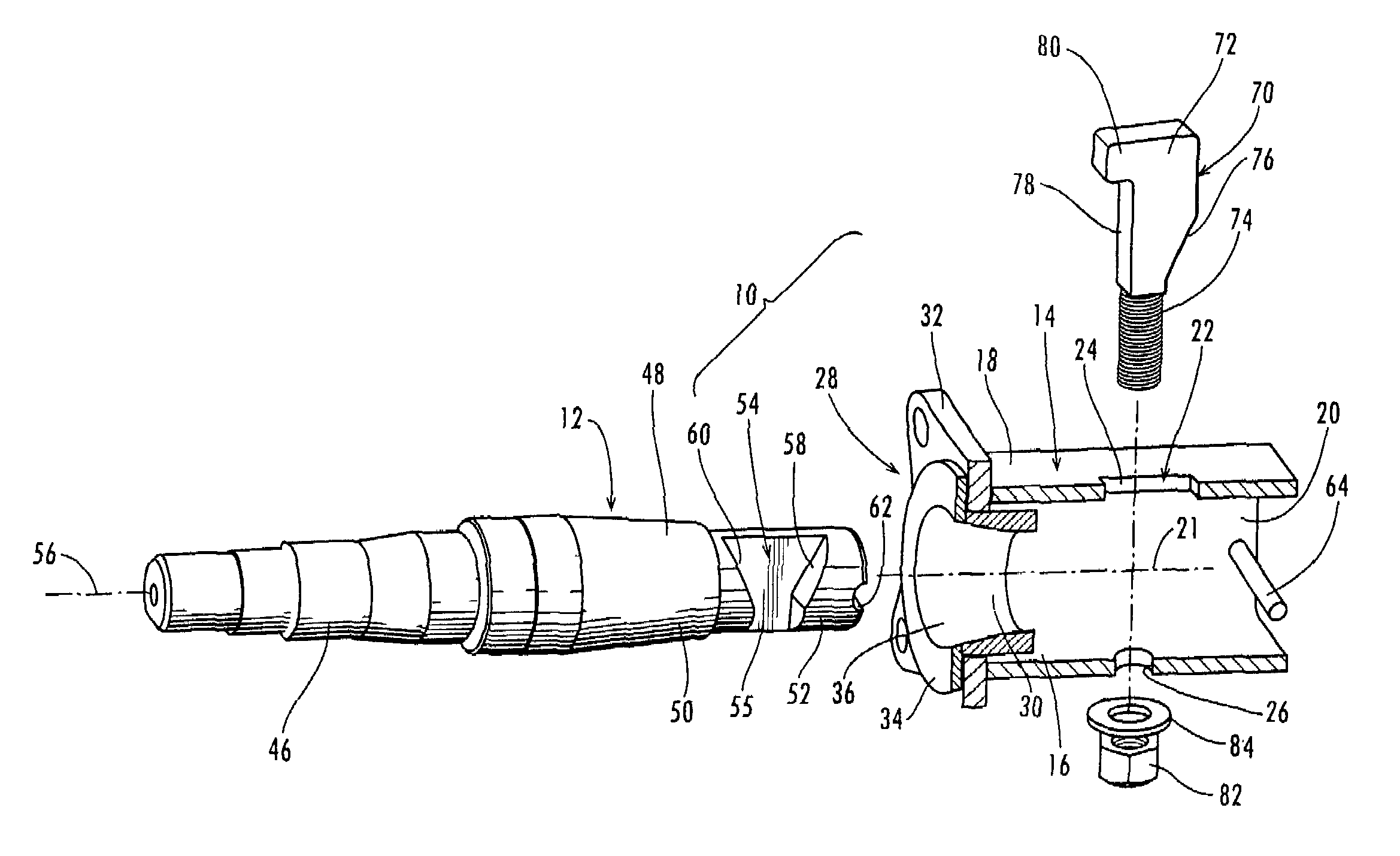

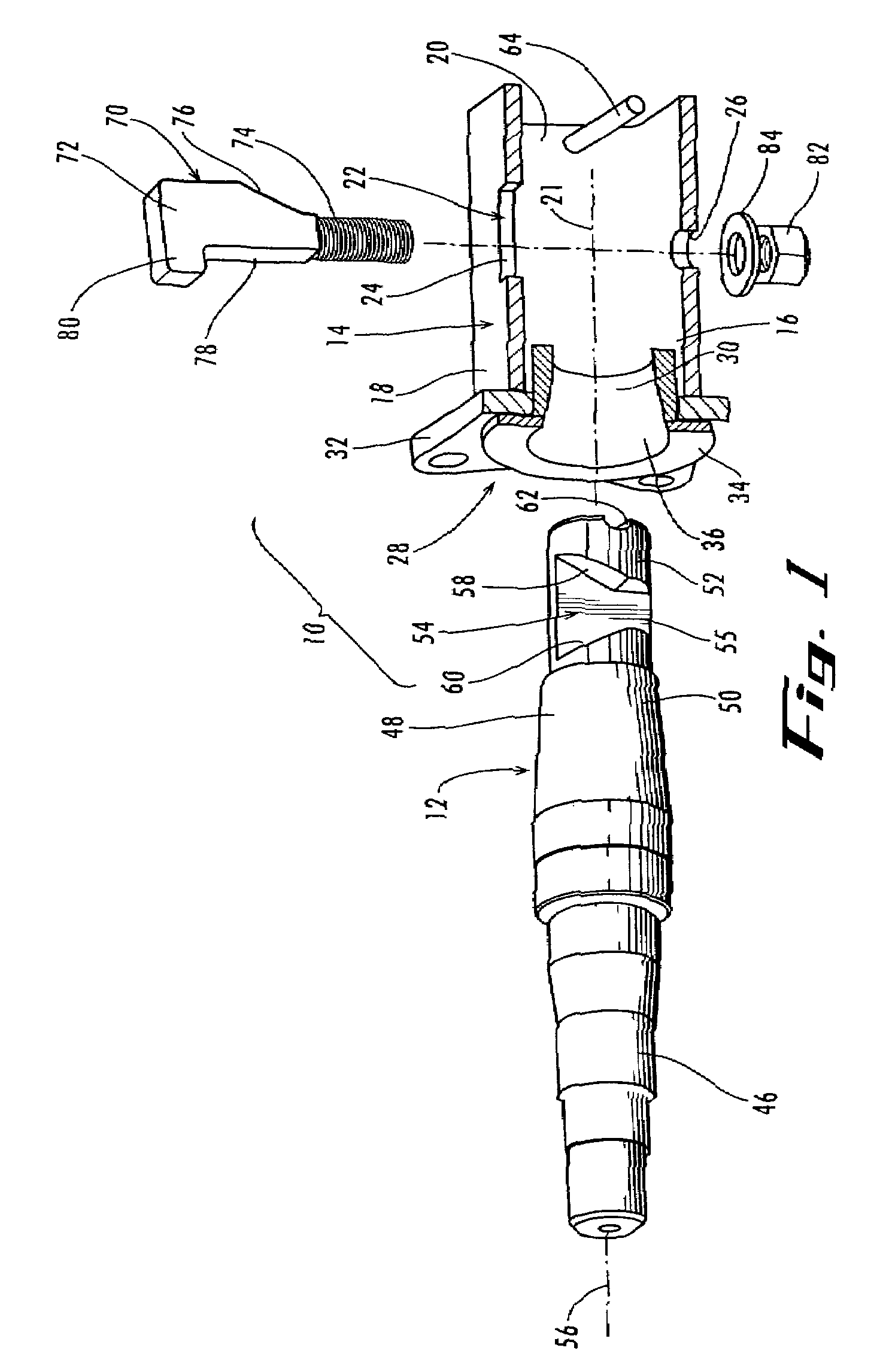

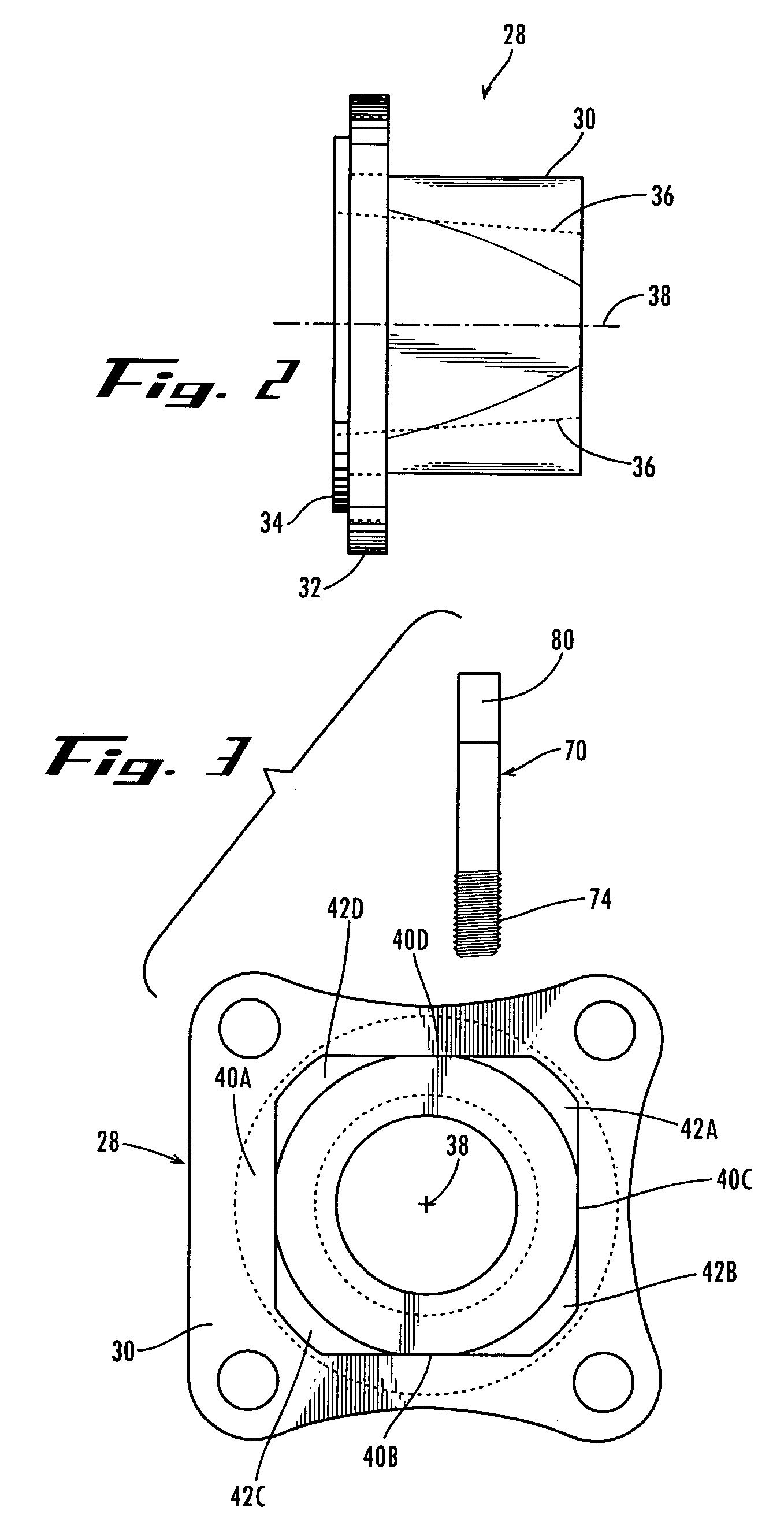

Axle with removable spindle and cam key

An axle assembly includes a spindle (12) that extends through a mounting collar (28) into the open end of the axle. A cam key (70) moves through a key hole (22) in the axle and registers with the cam slot (54) of the spindle. The cam surface (76) of the cam key (70) is reversible with the cam surface (76) engaging either the bearing surface (58) or the bearing surface (60) of the spindle, to urge the spindle into or out of the axle.

Owner:DEXTER MARINE PROD OF GEORGIA LLC

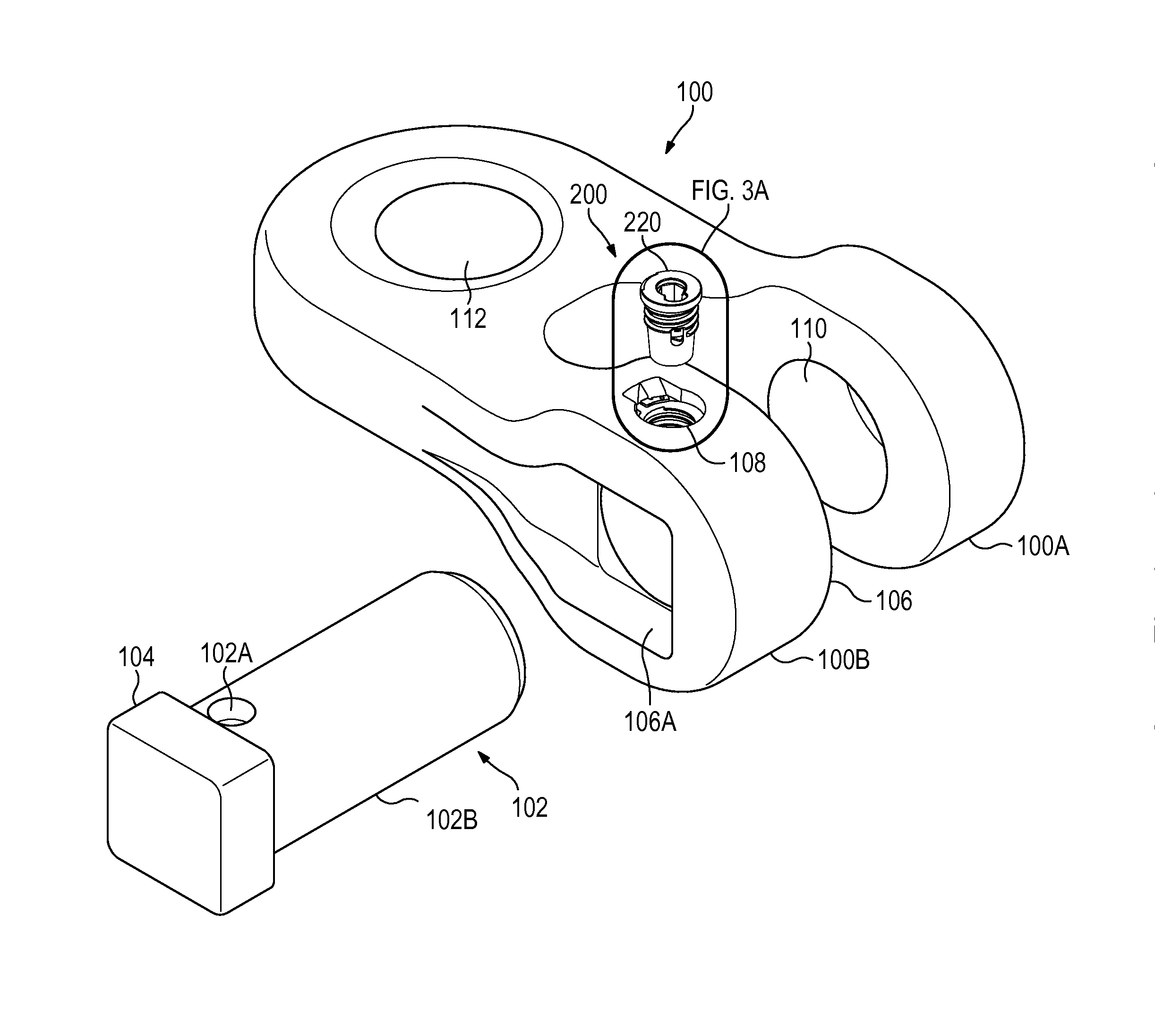

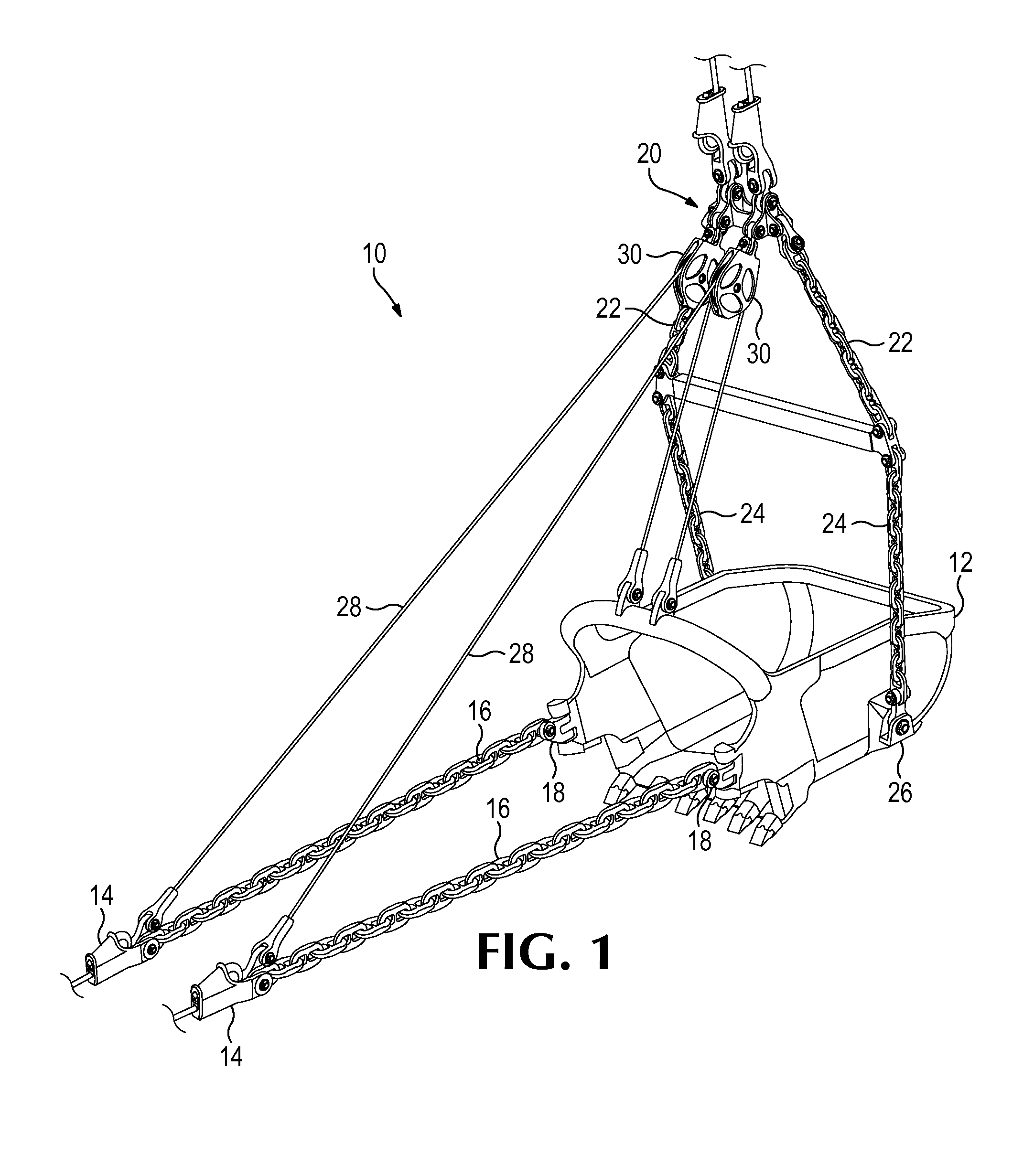

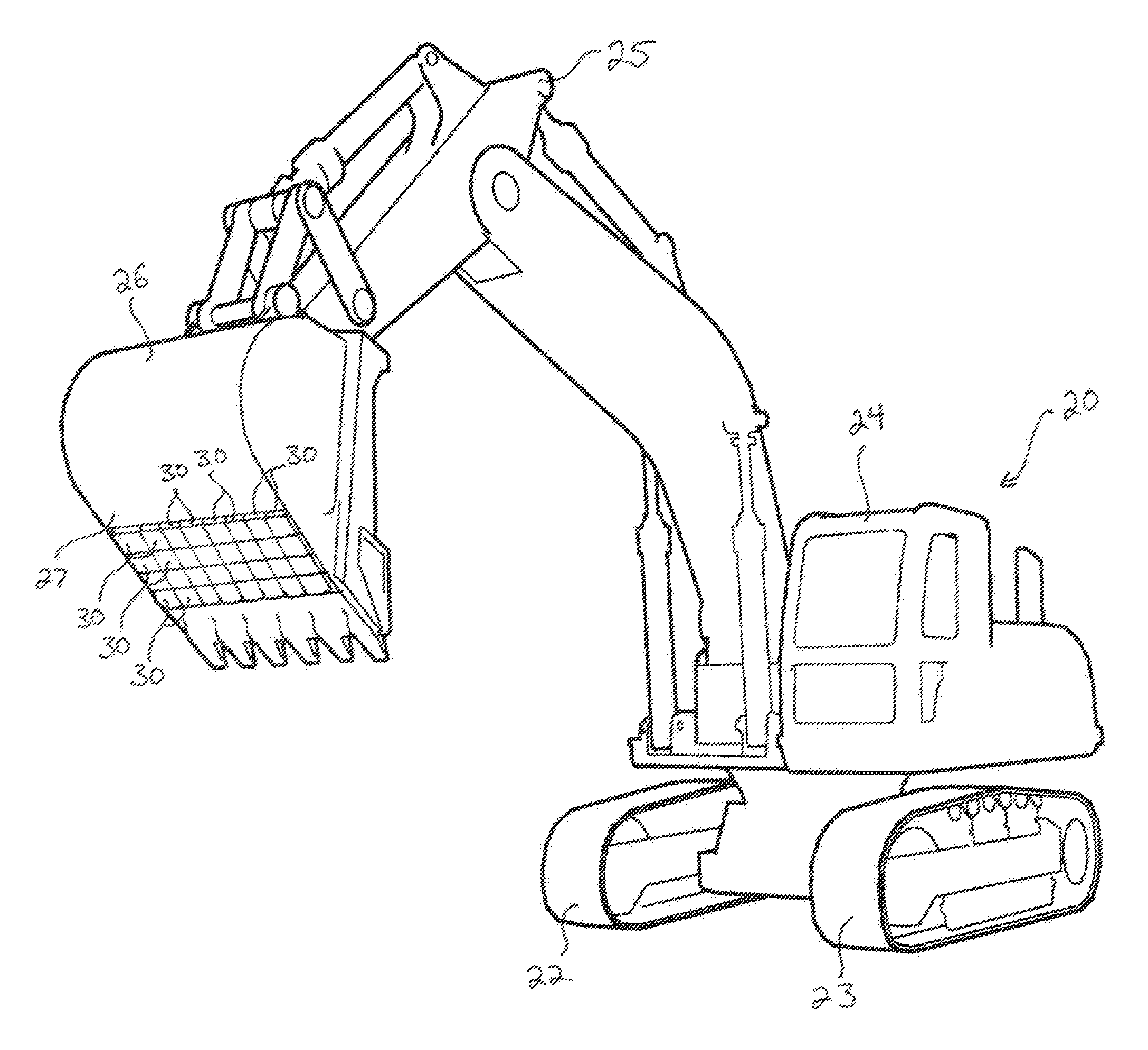

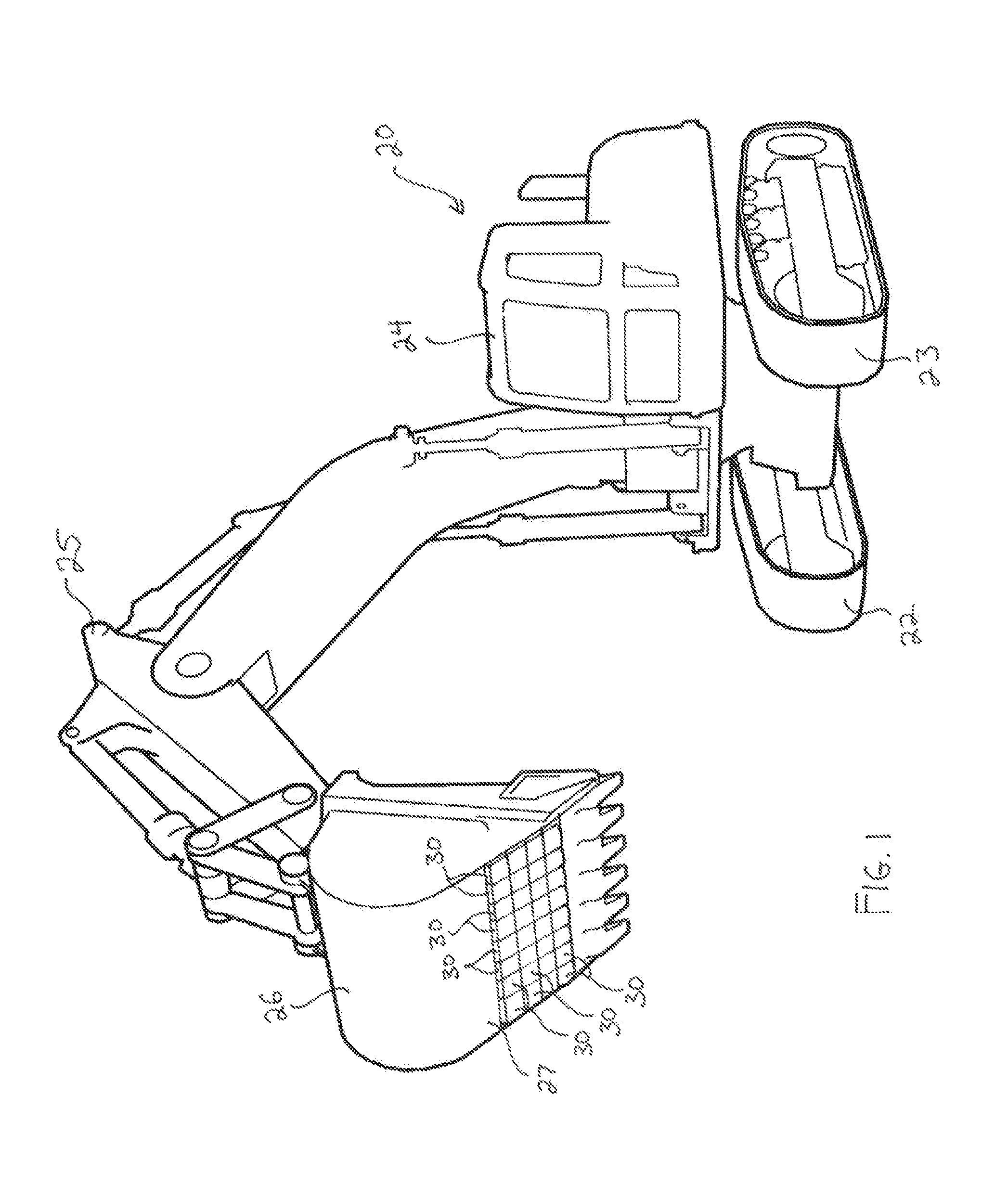

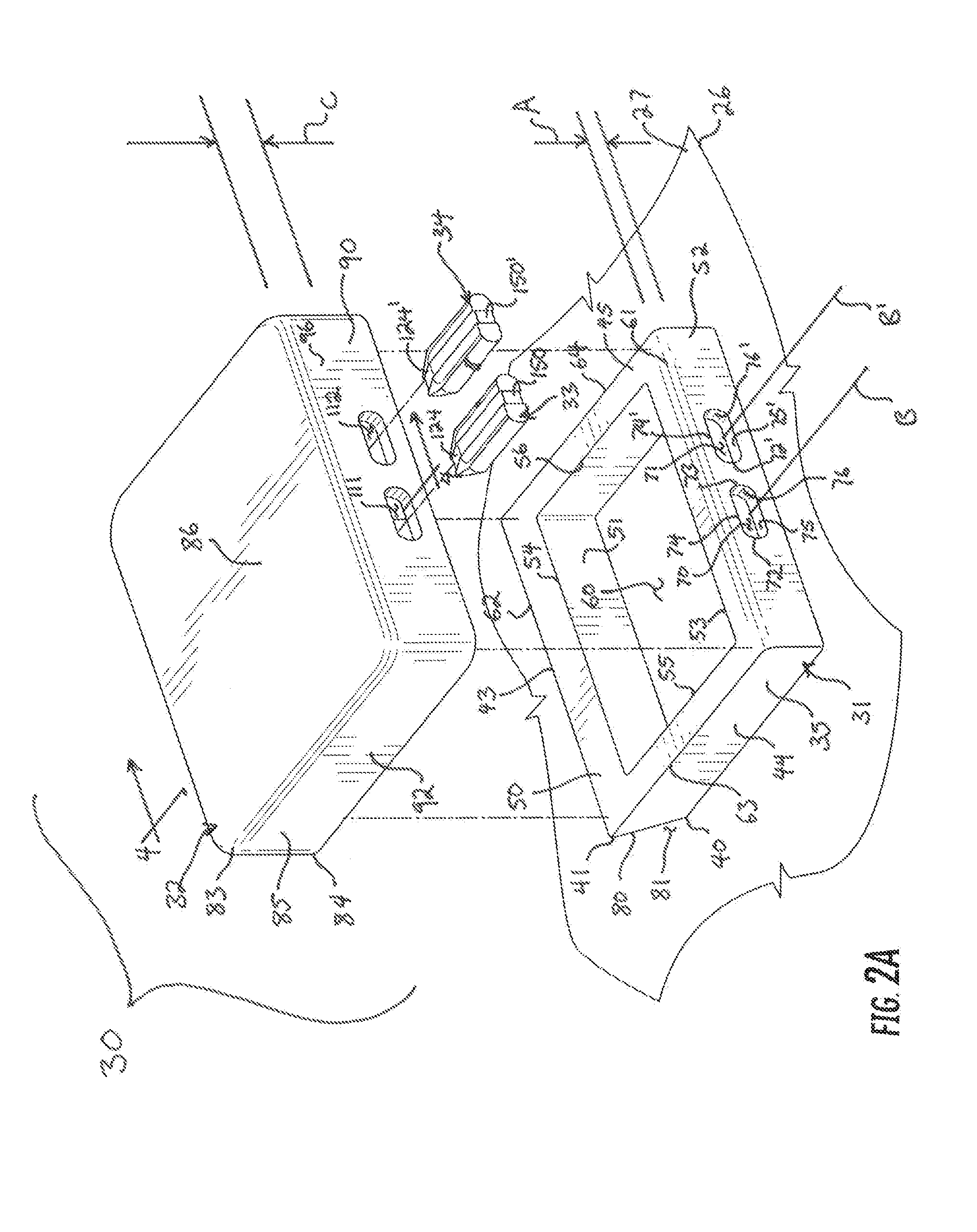

Hammerless Pin Assembly

ActiveUS20160061239A1Reduce handlingShorten the timeMechanical machines/dredgersKey type connectionsEngineeringRelative motion

Owner:ESCO GRP LLC

Construction element and coupling device therefor

A construction element has at least one coupling device and the coupling device has at least two prongs. Each prong is comprised of two radially extending mating surfaces which frictionally engage the radially extending surfaces of a mating coupling device. The construction device may have a straight shaft or an angled shaft to accommodate the needs of the user and, furthermore, the prongs of a coupling device may be inserted within mateable apertures in the shaft of another construction element. Using a plurality of such construction elements, a lattice frame may be constructed.

Owner:ADAMS MFG

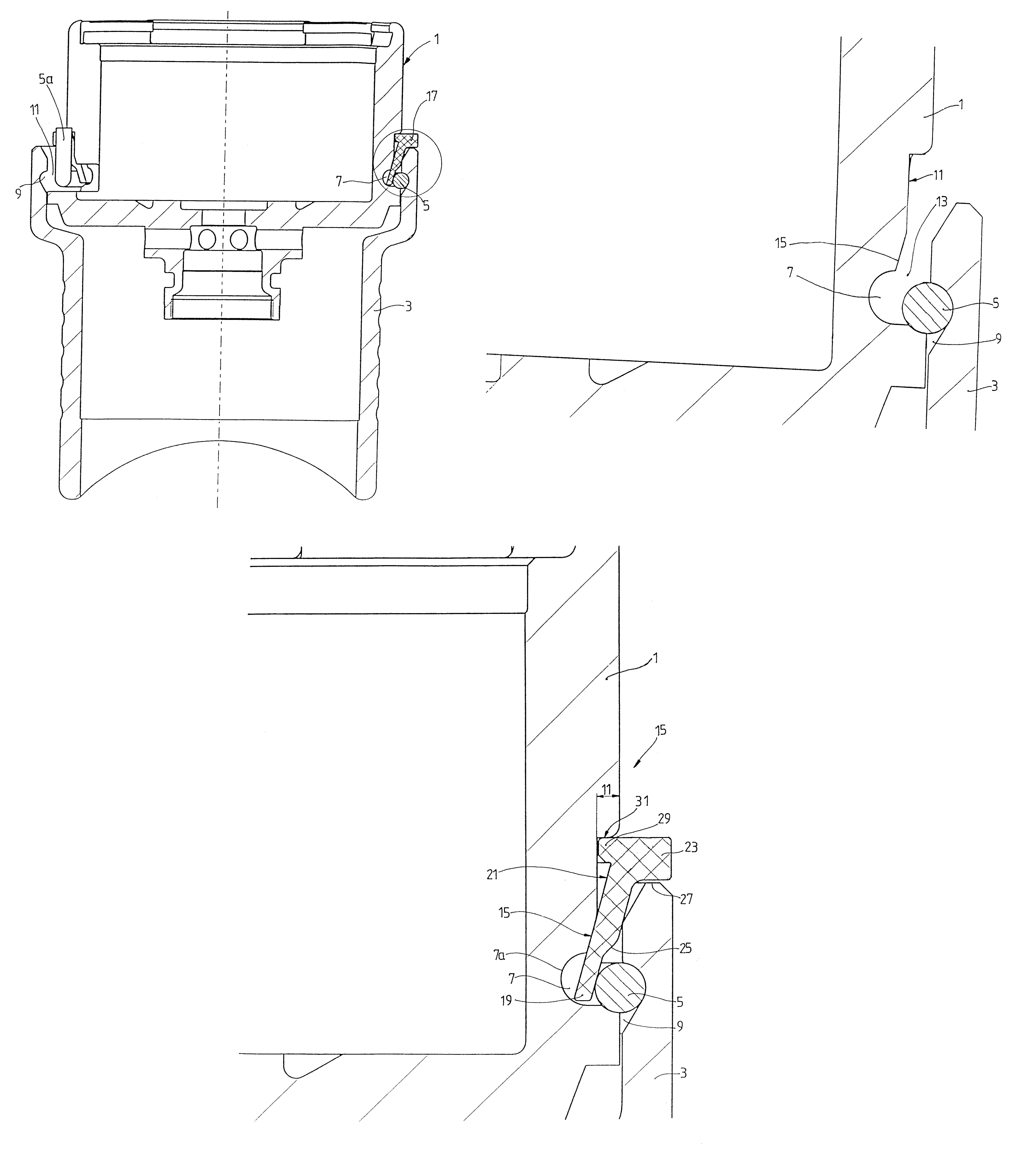

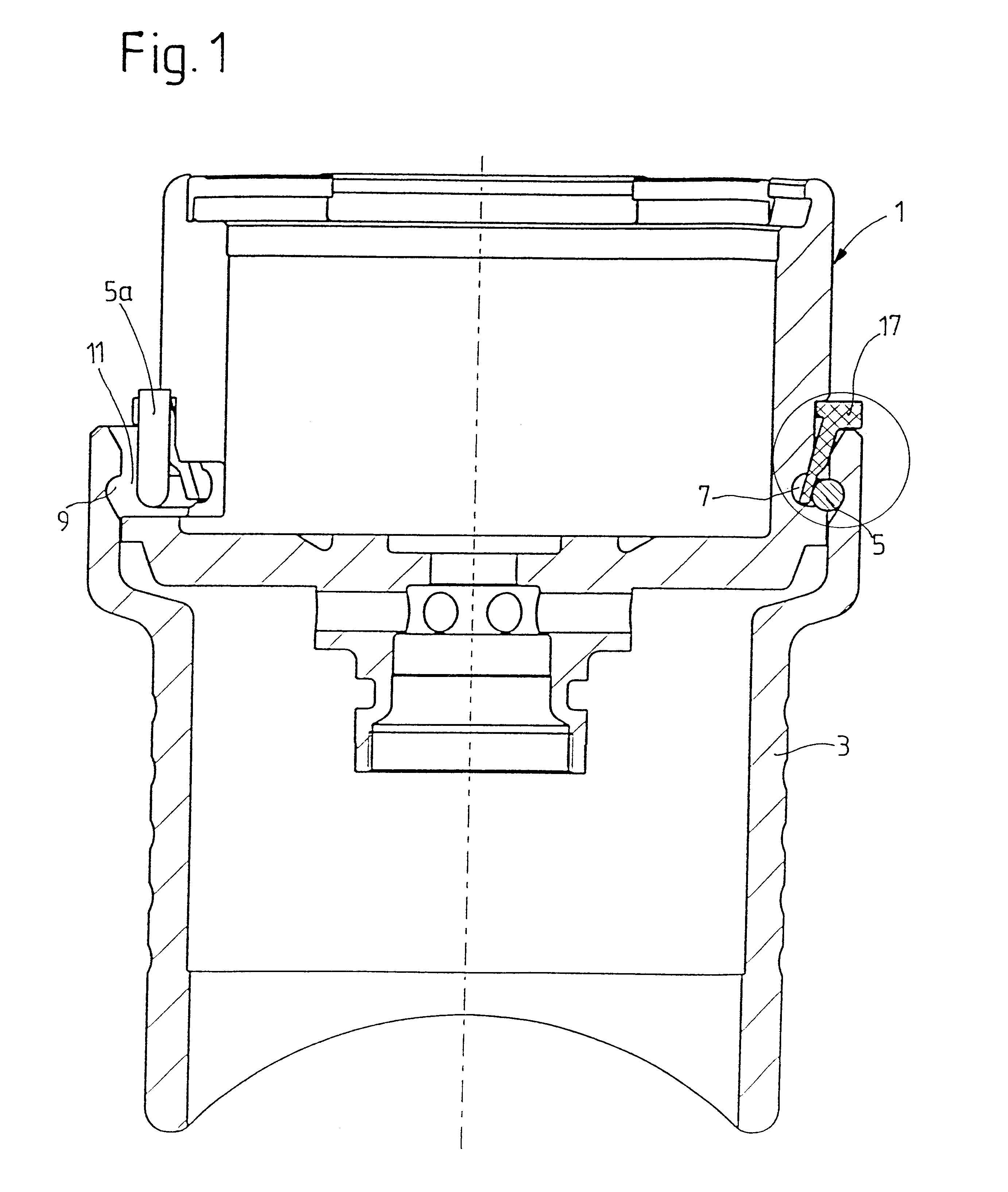

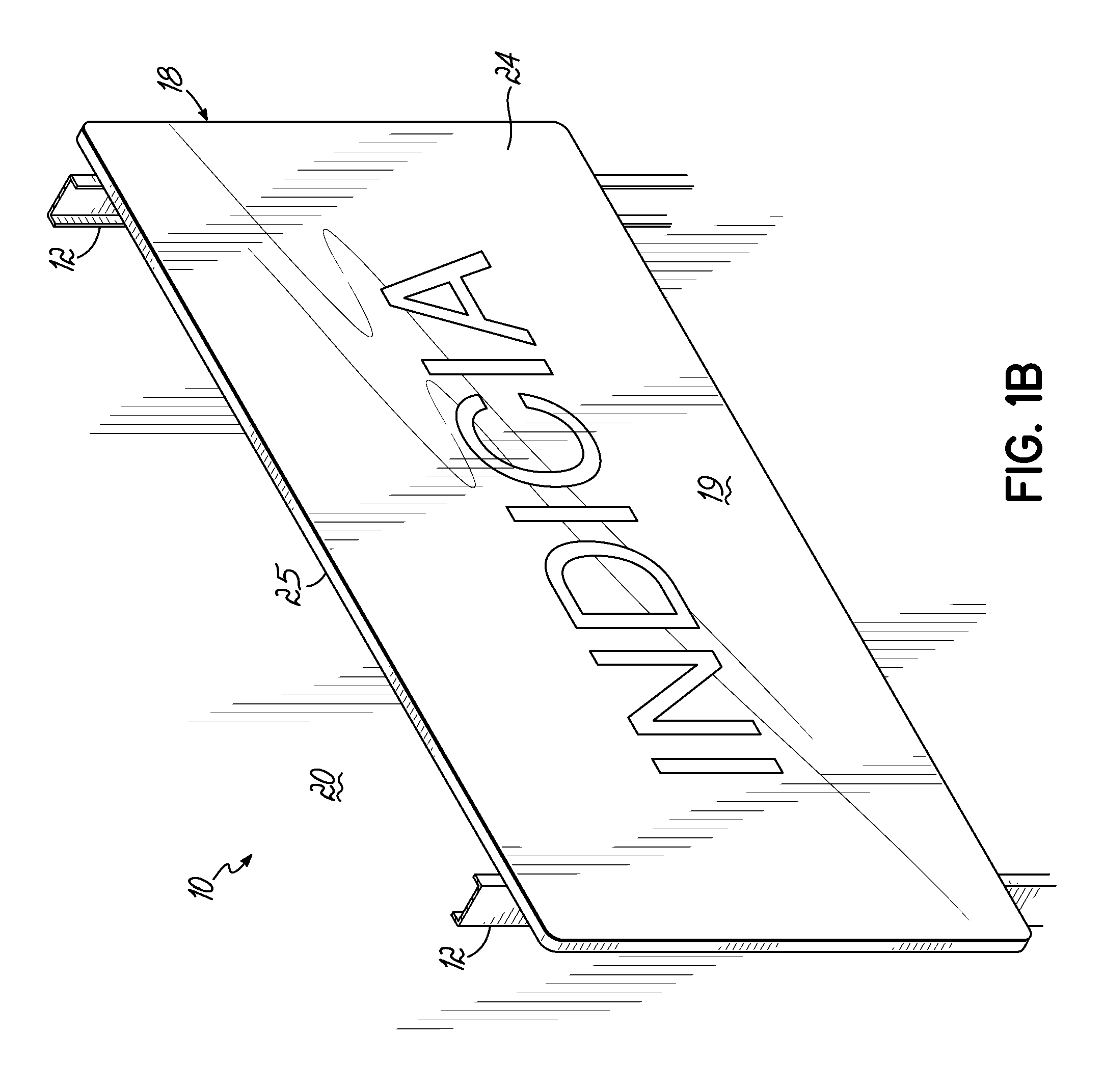

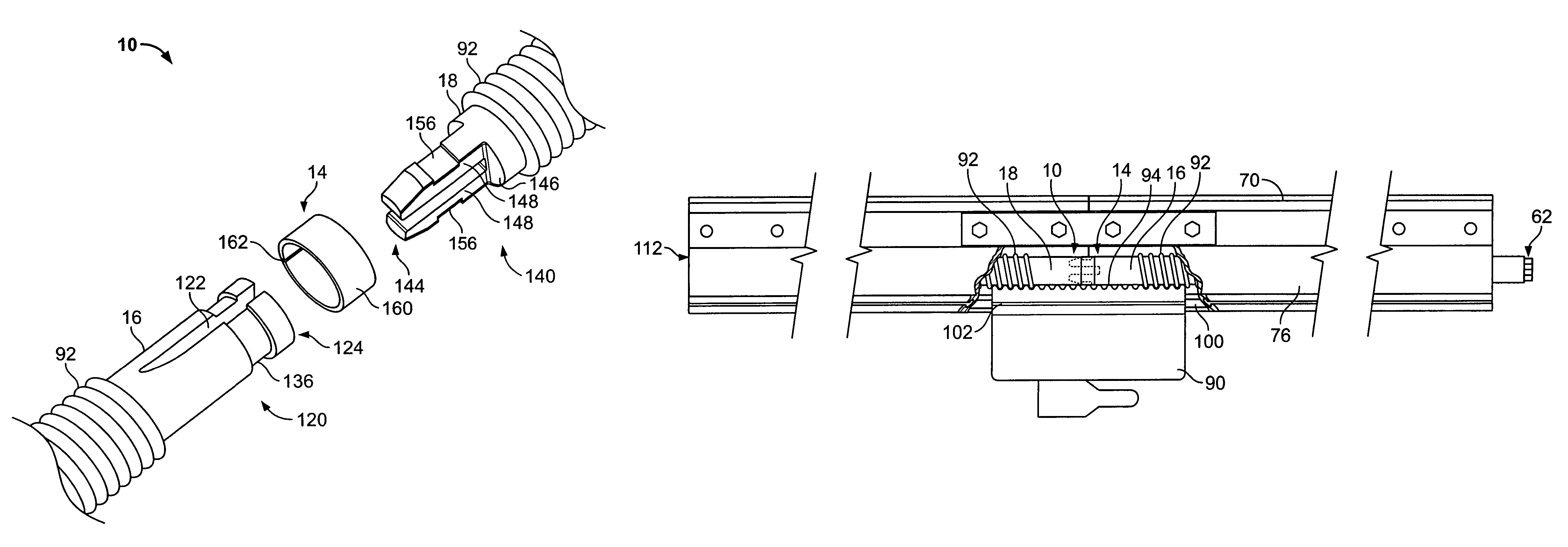

Elastic retaining assembly for matable components and method of assembling

InactiveUS20140369743A1Ropes and cables for vehicles/pulleyKey type connectionsBiomedical engineering

An elastic retaining assembly for matable components includes a first component having a first surface. Also included is a second component configured to be mated with the first component, the second component comprising a second surface. Further included is a receiving feature formed proximate an engagement side of the second component, the receiving feature having a first degree of curvature. Yet further included is an elastically deformable protrusion operatively coupled to, and extending away from, the first component, the elastically deformable protrusion having a second degree of curvature distinct from the first degree of curvature of the receiving feature, wherein the elastically deformable protrusion is formed of an elastically deformable material and configured to elastically deform upon engagement with the receiving feature.

Owner:GM GLOBAL TECH OPERATIONS LLC

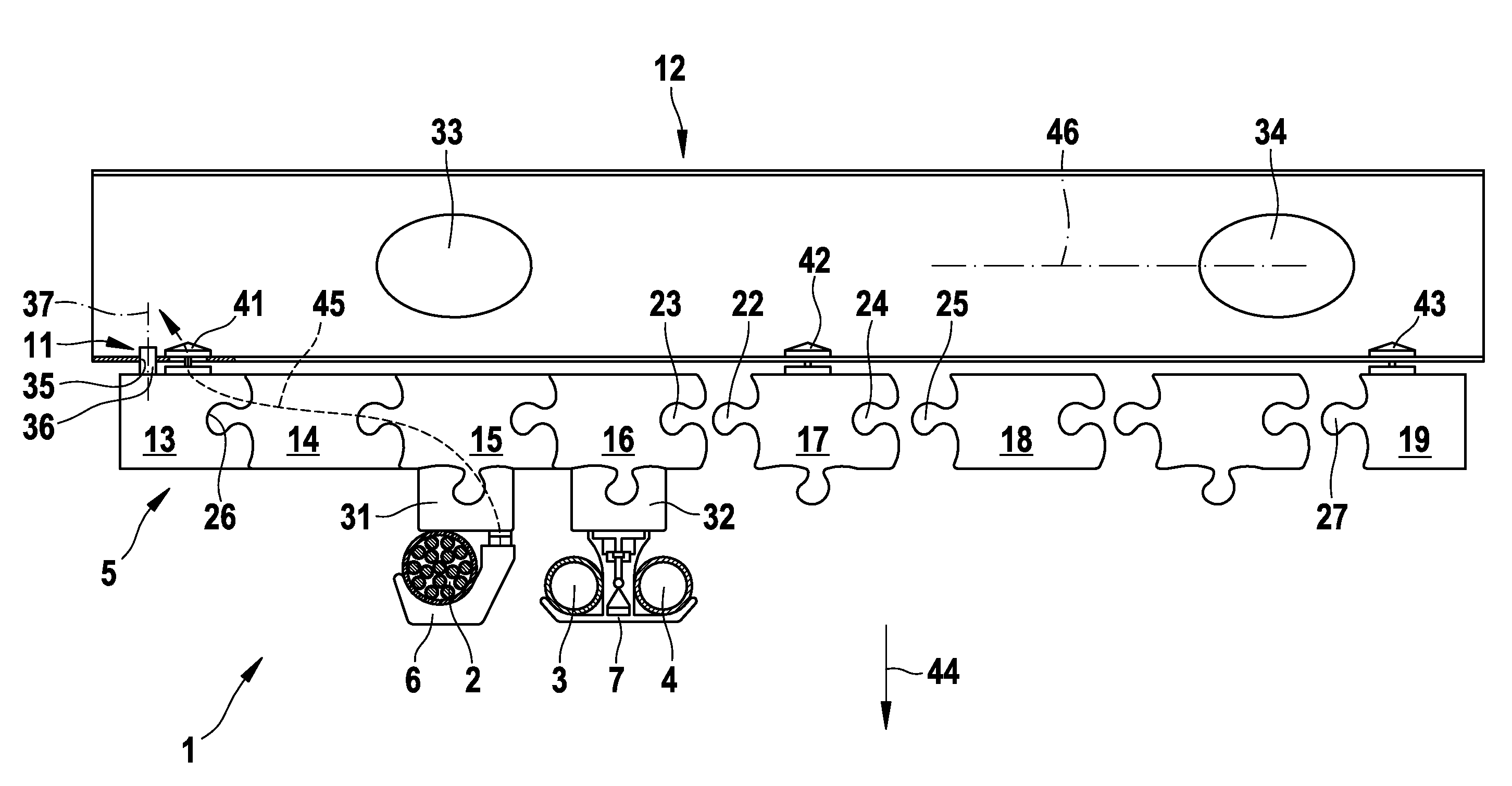

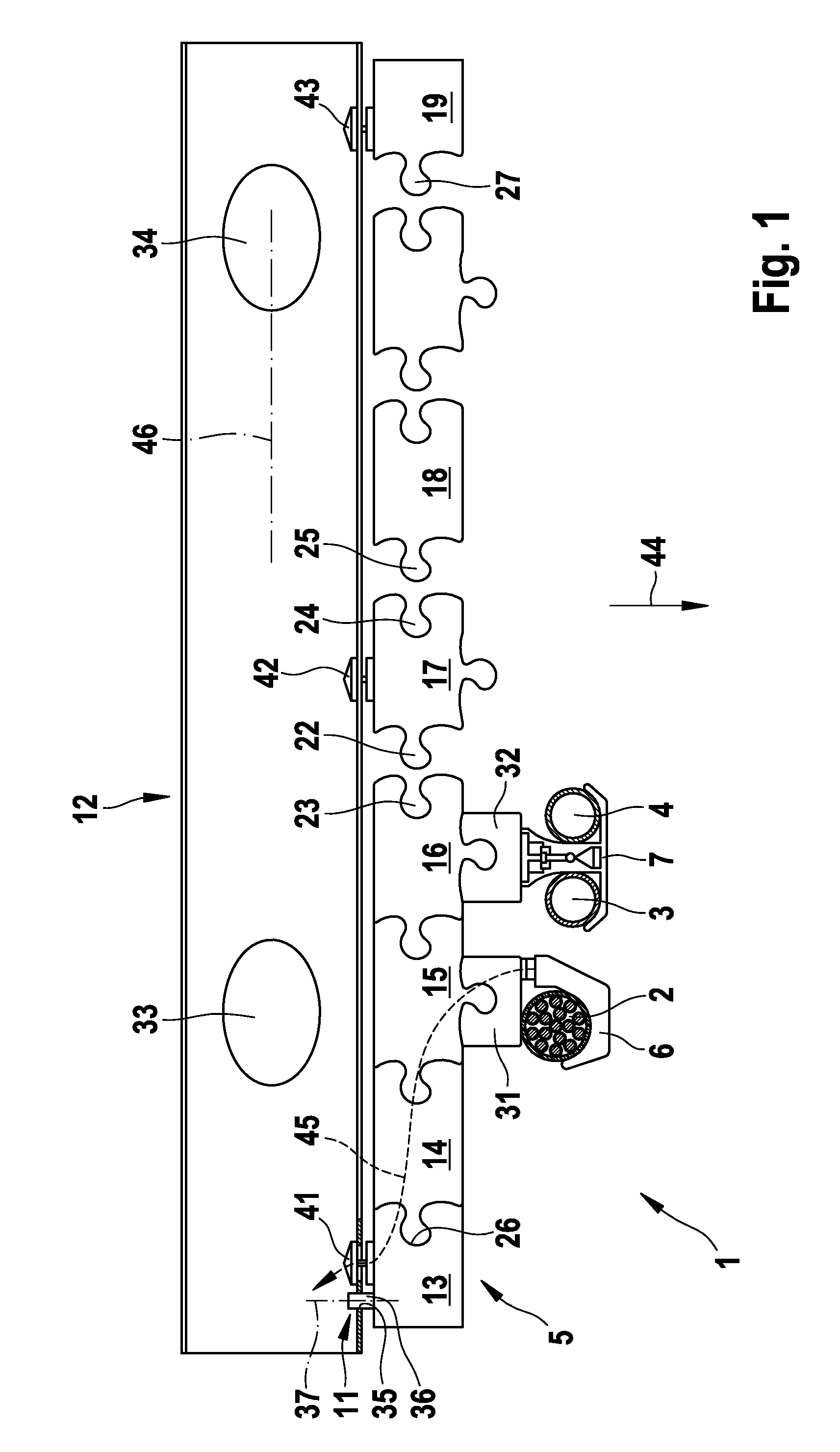

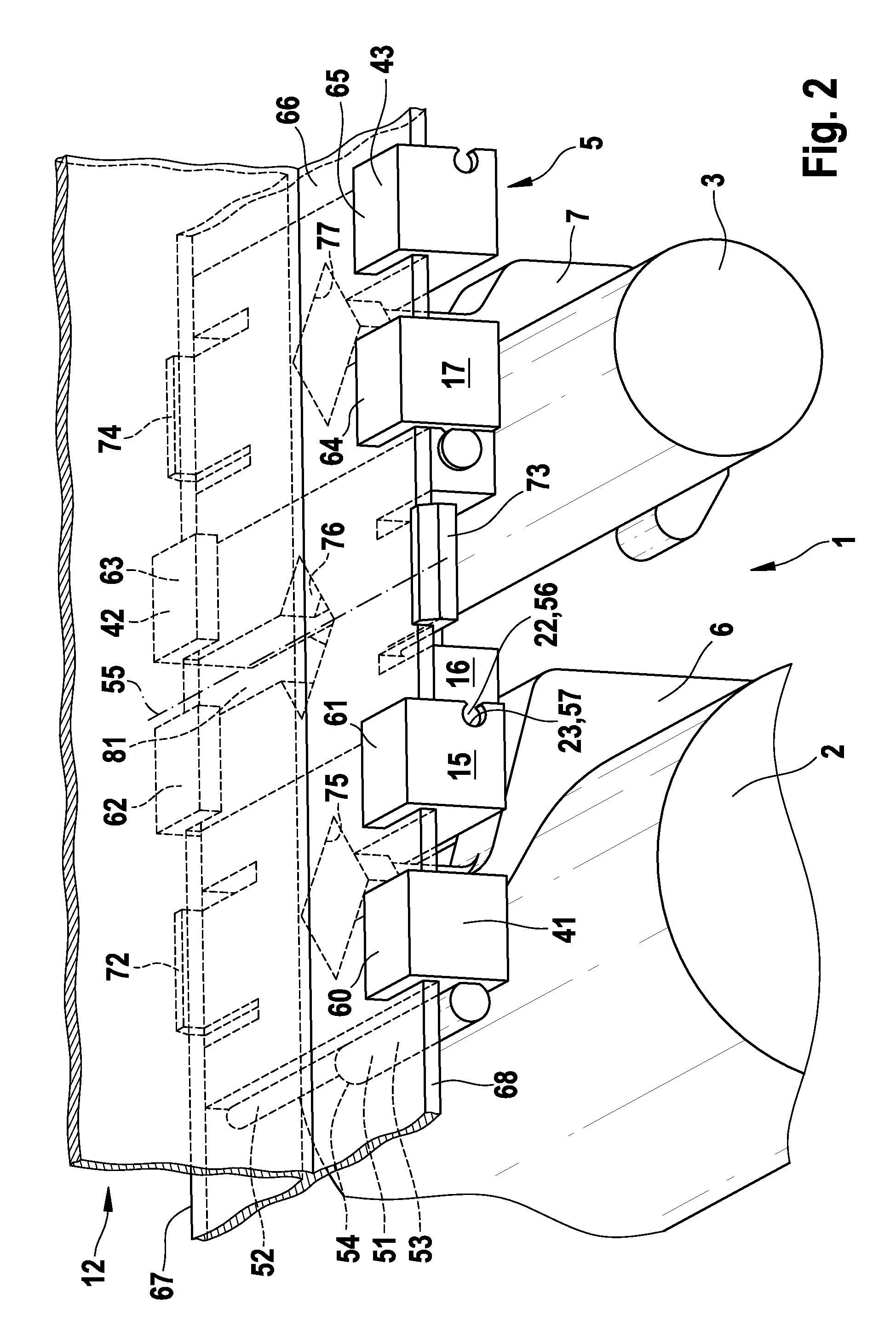

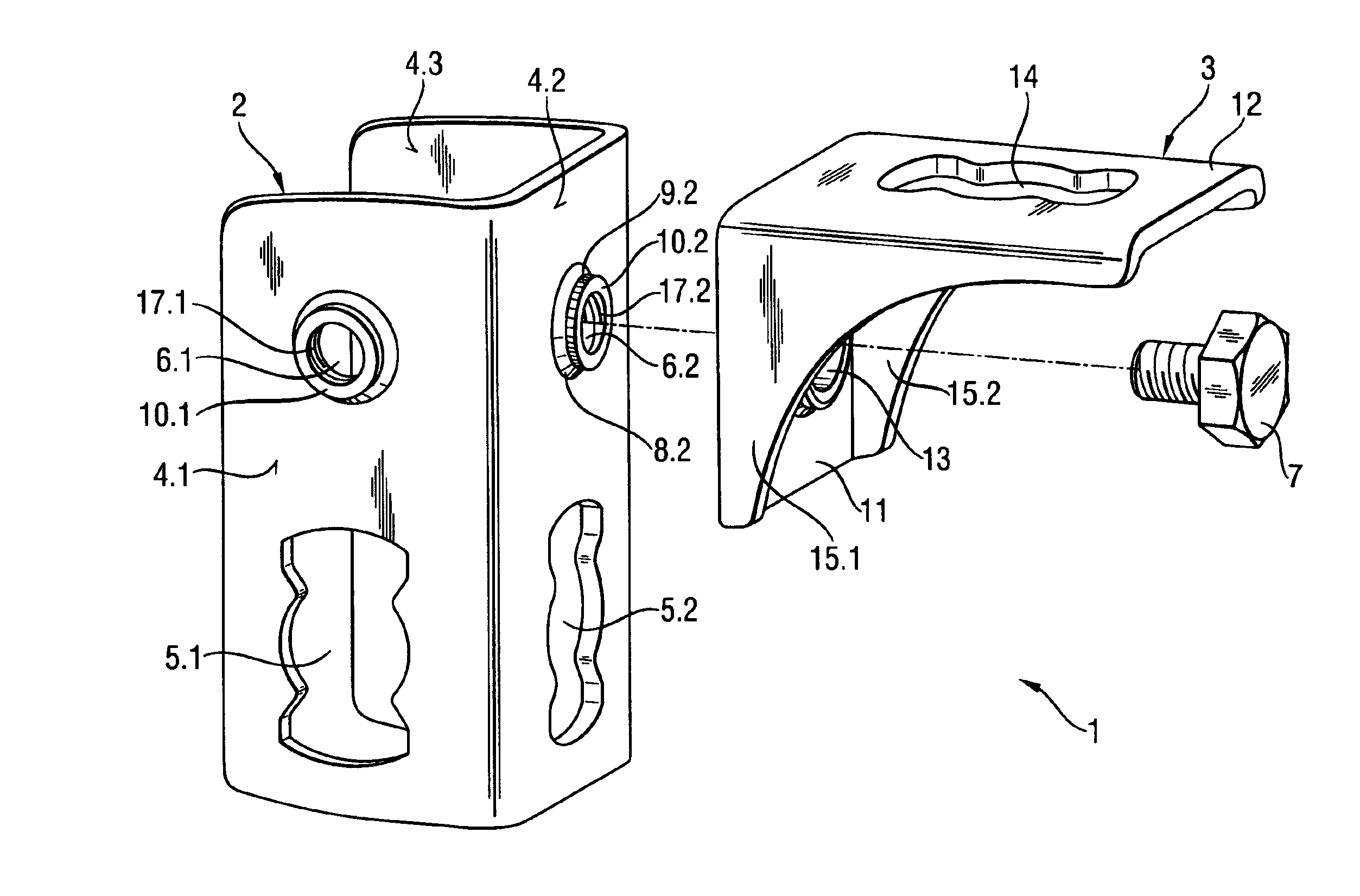

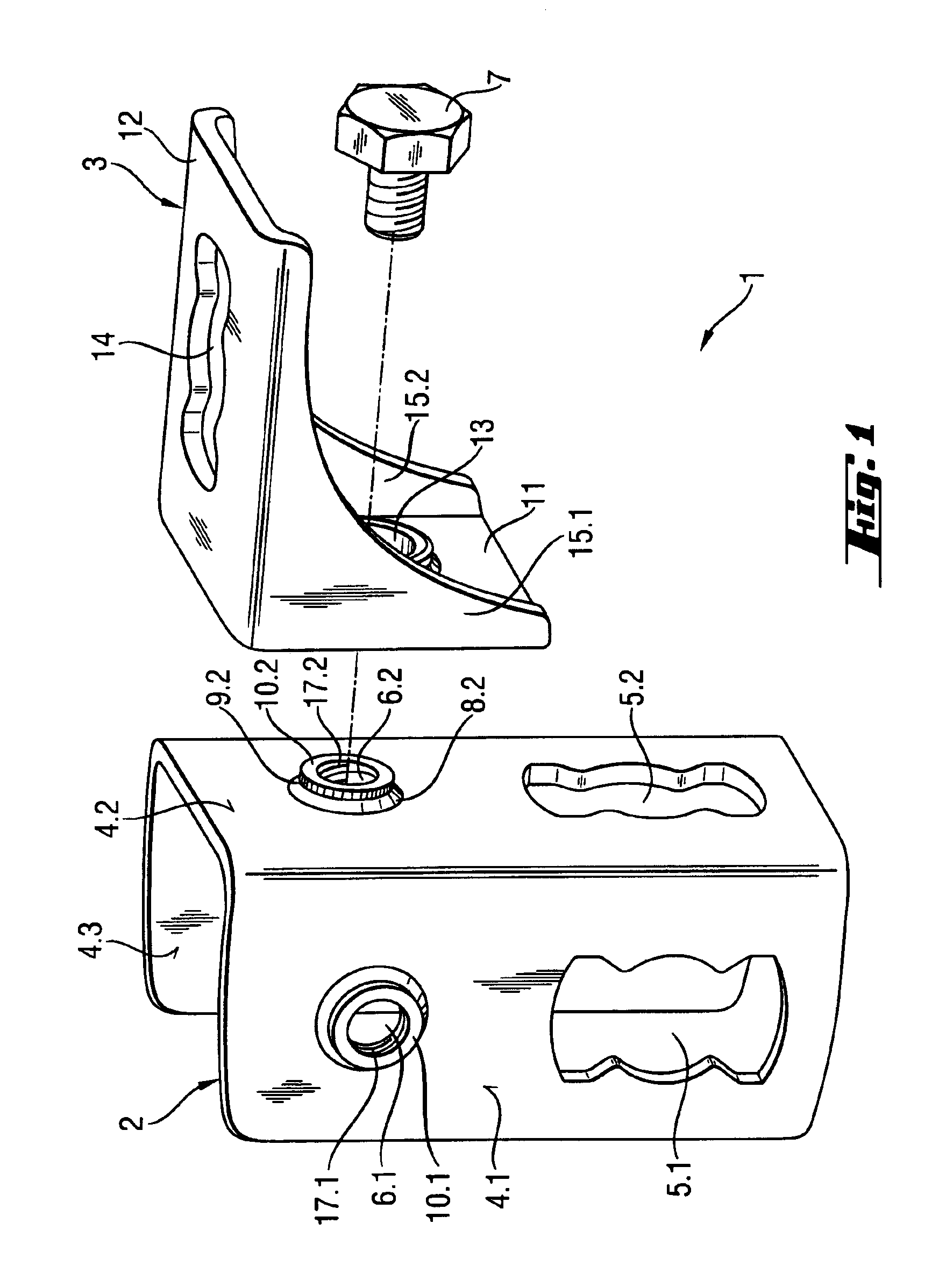

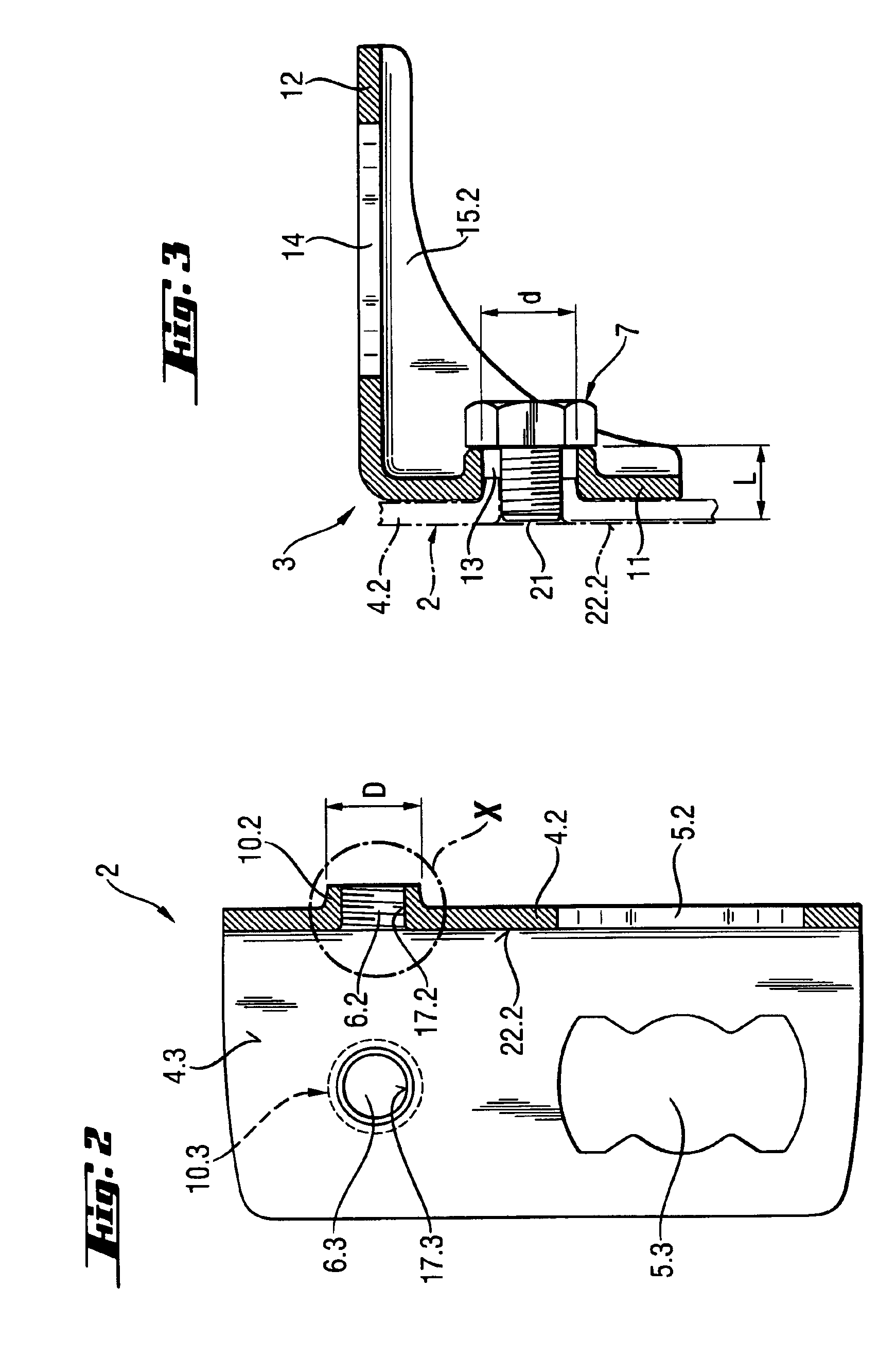

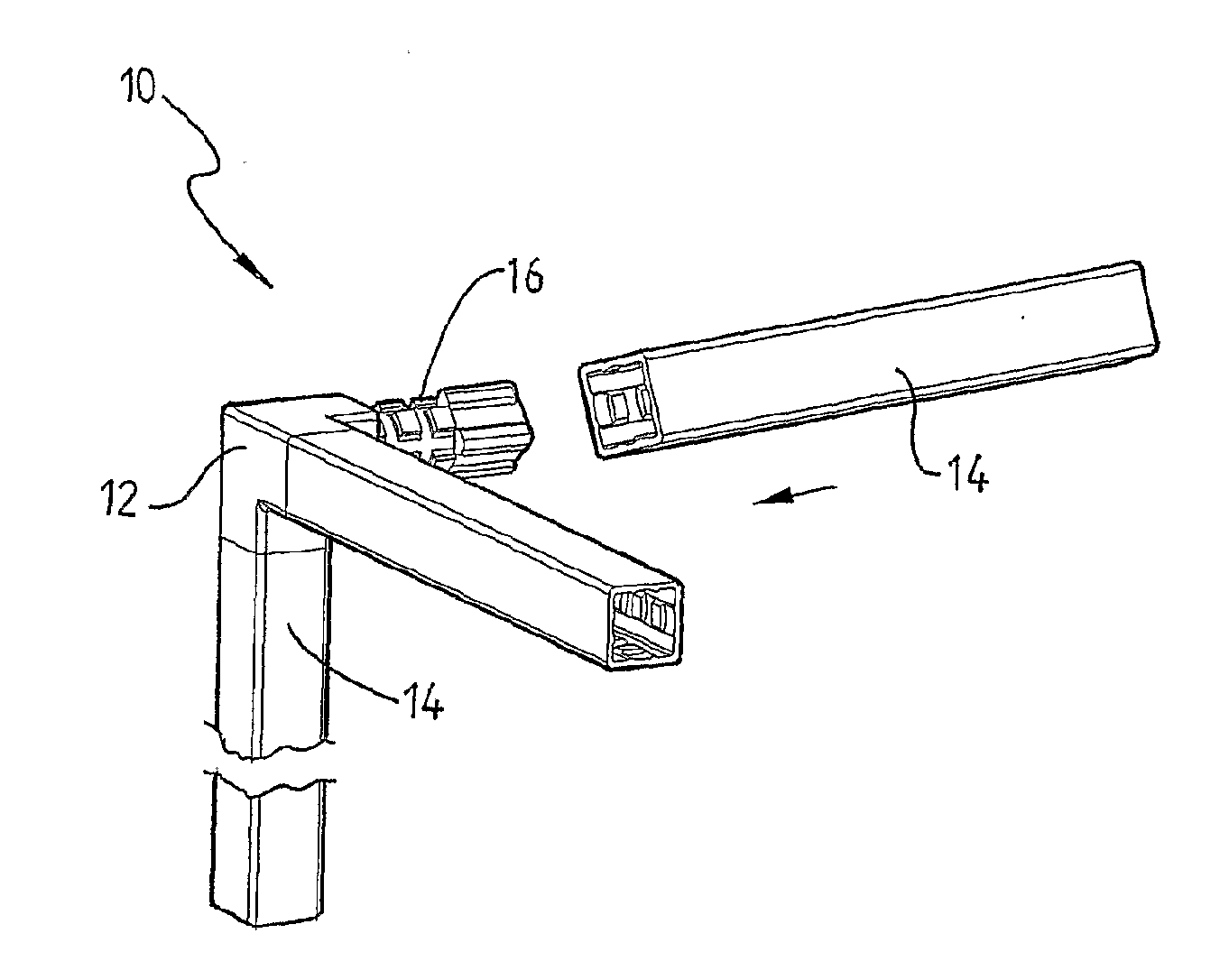

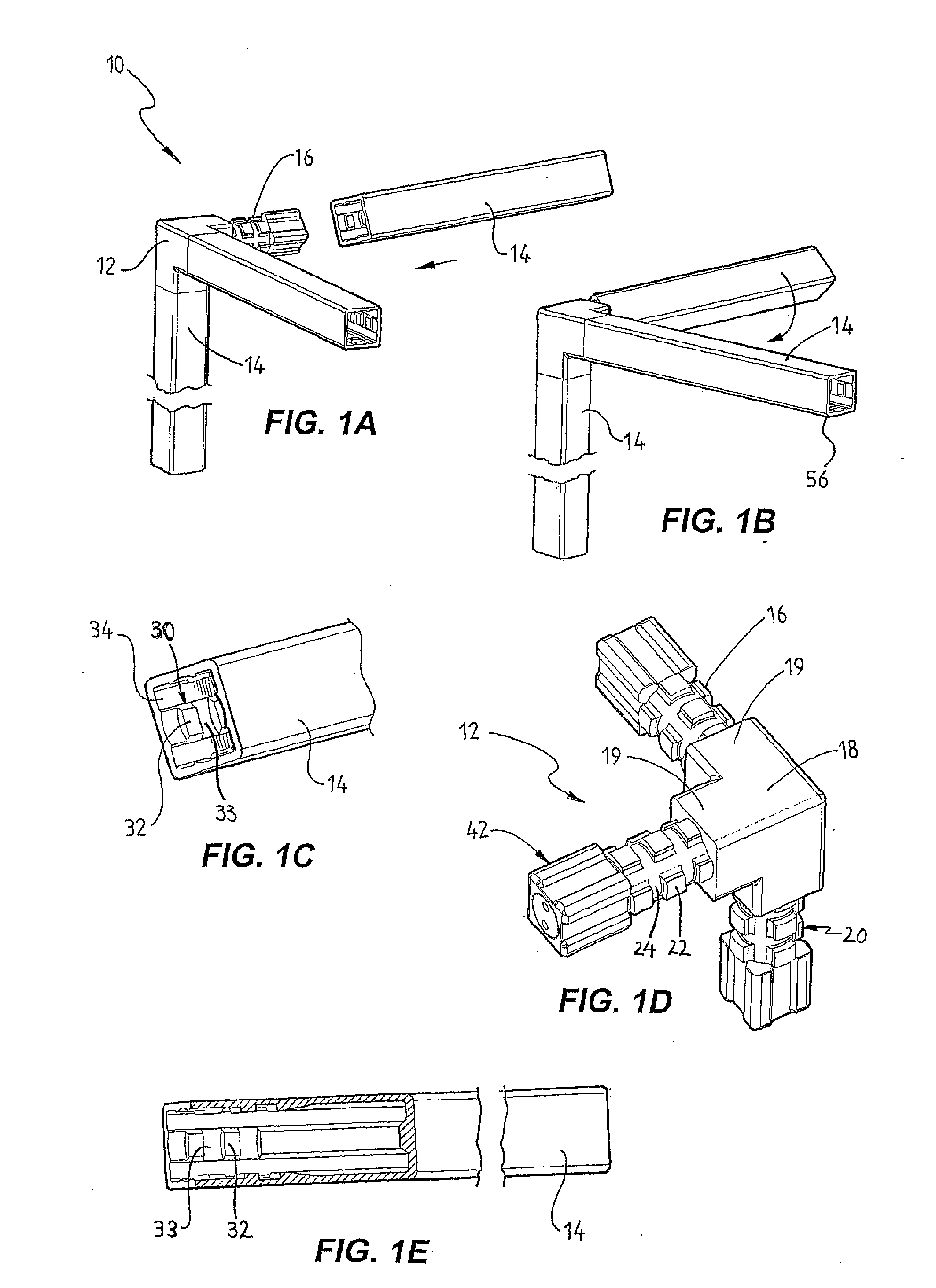

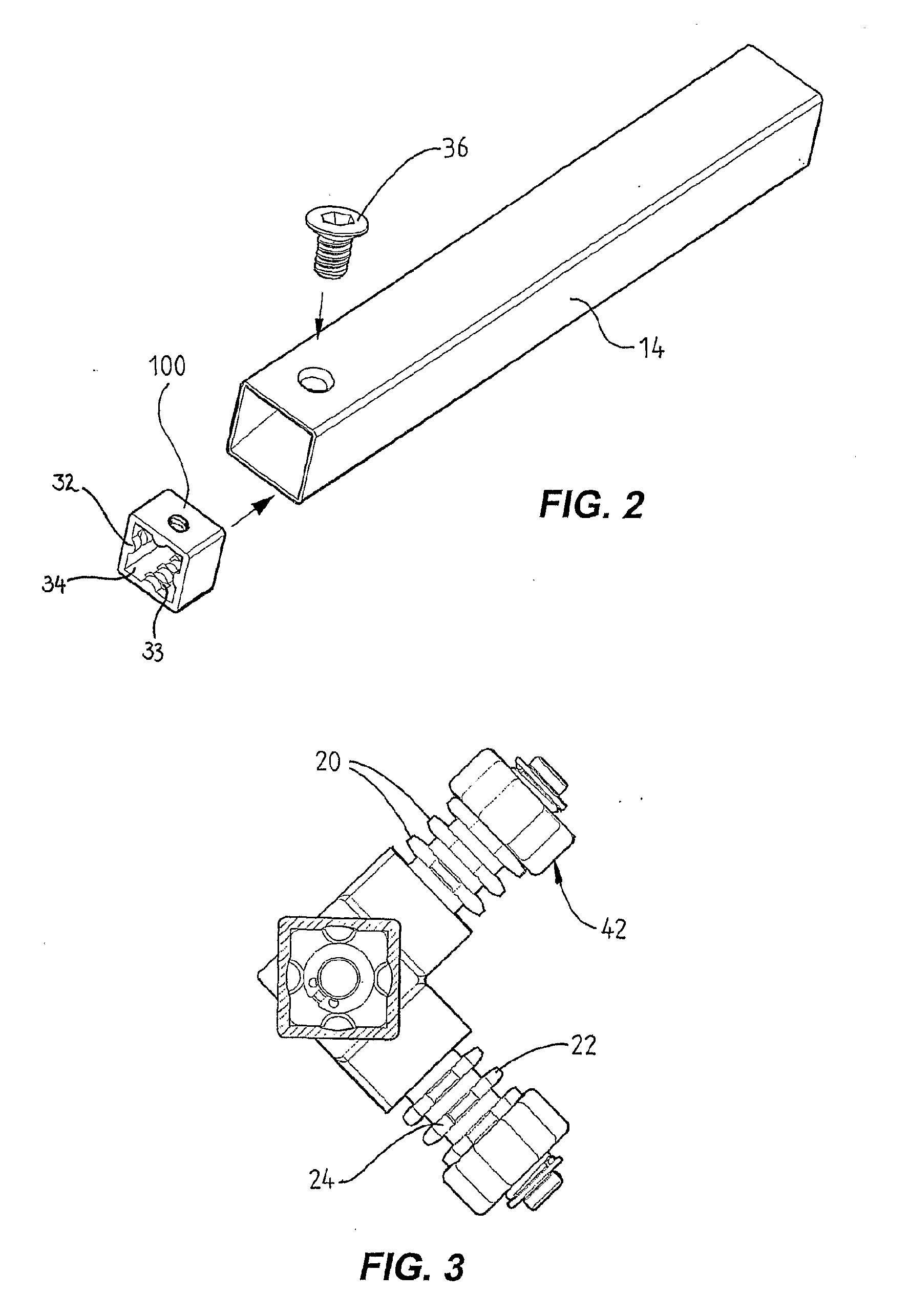

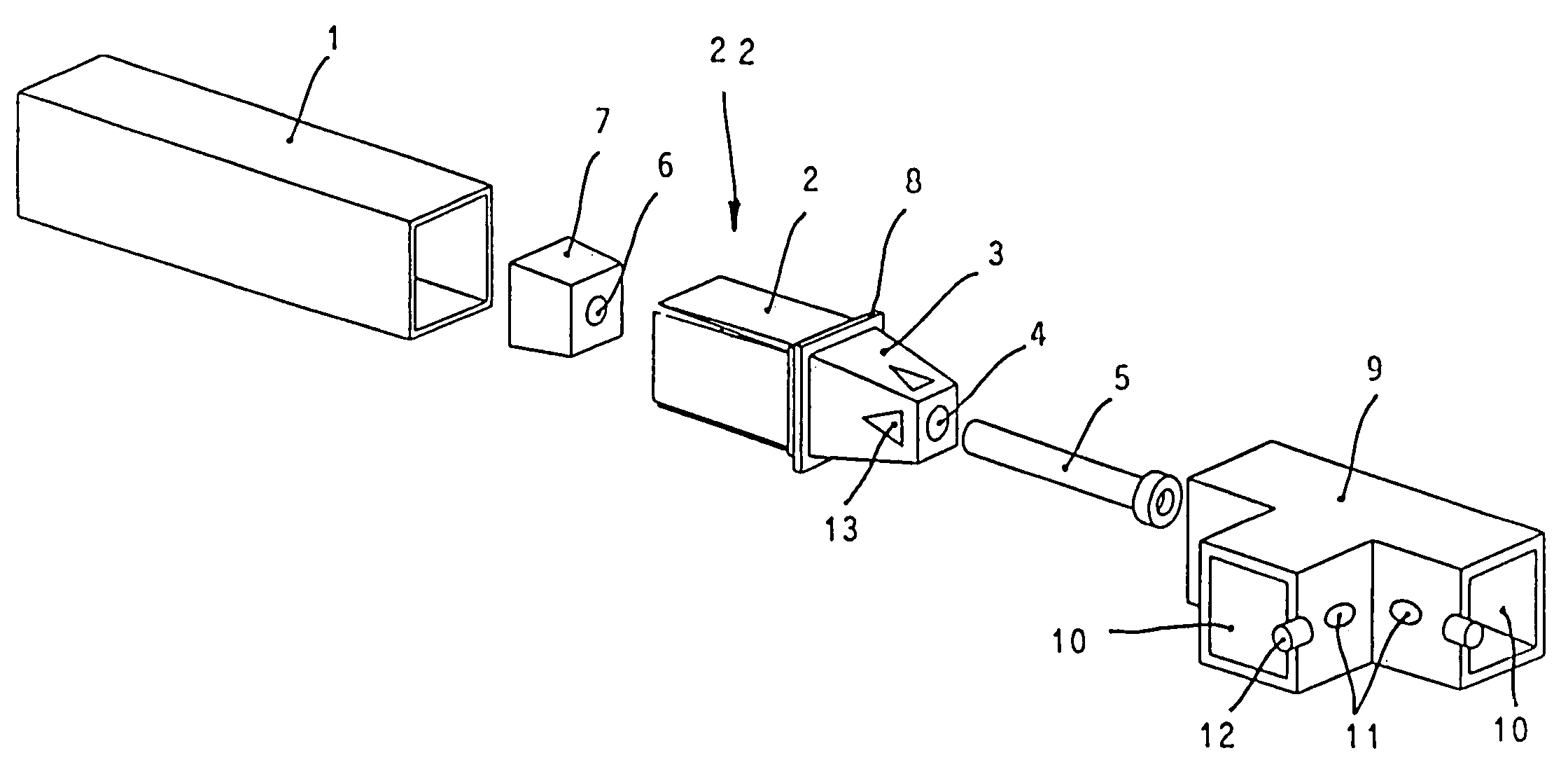

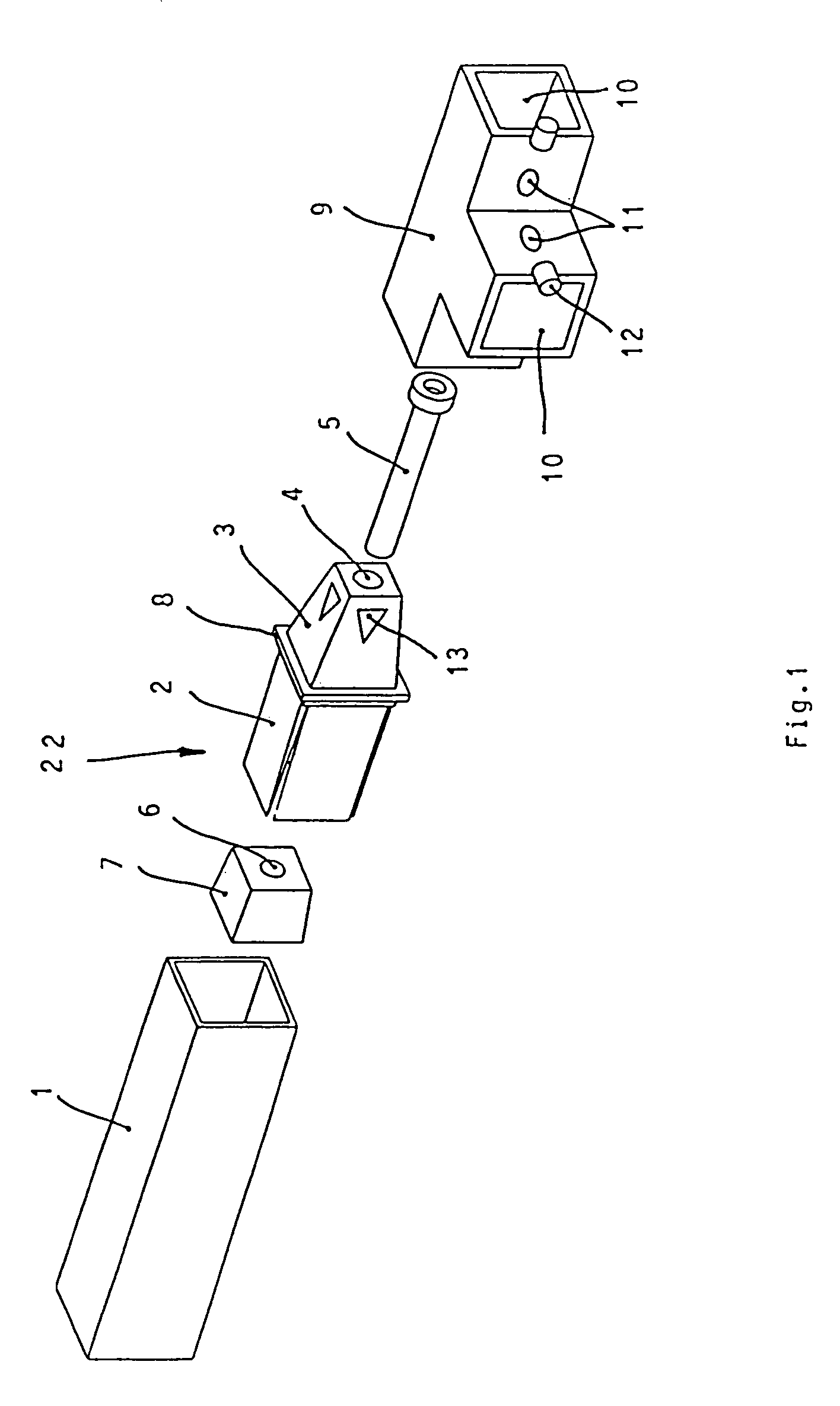

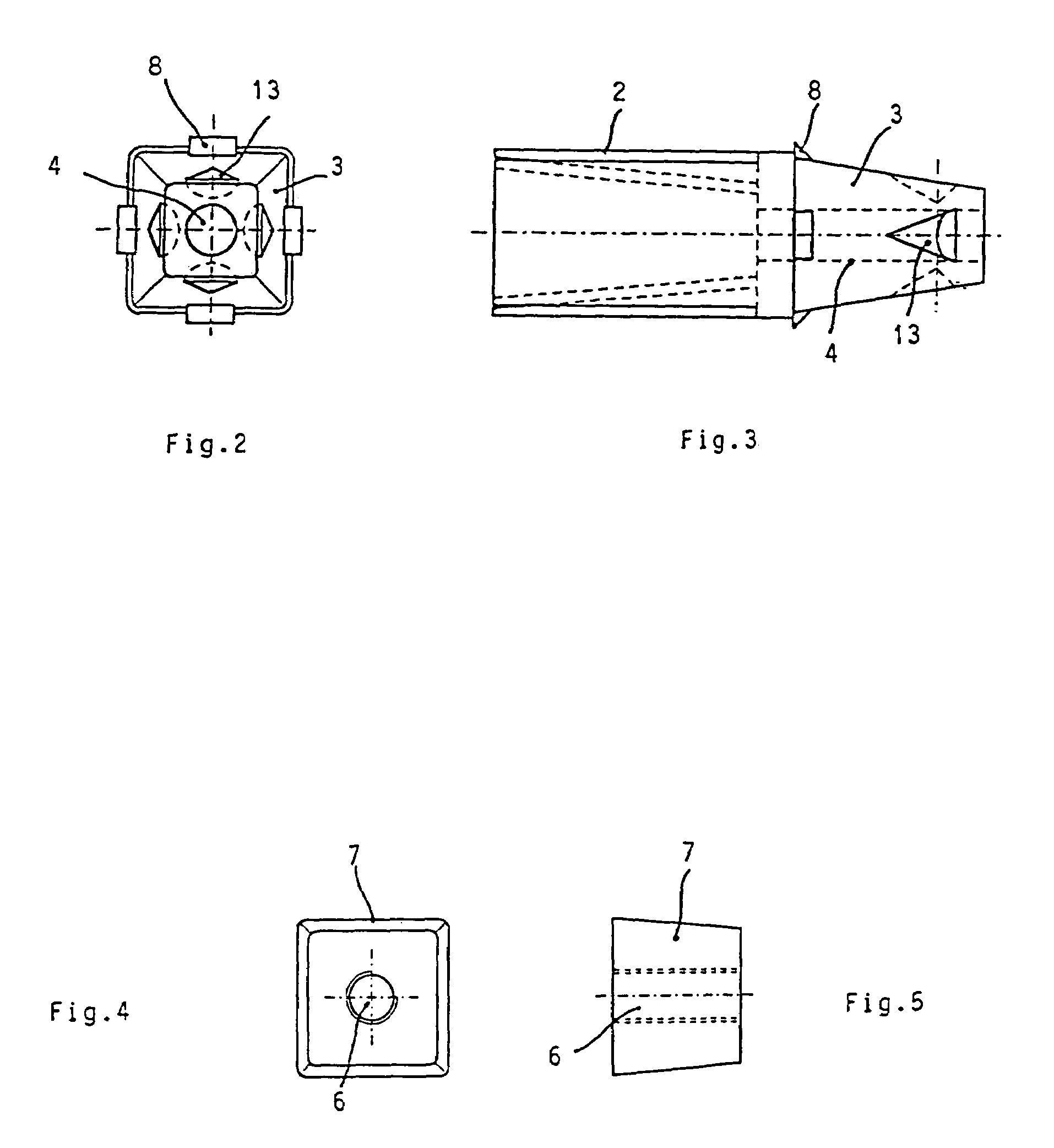

System for connecting mounting rails

ActiveUS6929227B2Consider flexibilityReduce the numberCandle holdersLighting support devicesMechanical engineeringEngineering

A system (1) for connecting mounting rails comprises a base member (2) and an angular attachment member (3). The base member (2) has an opening (6.1, 6.2) in at least one lateral wall (4.1, 4.2 or 4.3) for passage therethrough of a bolt (7). The openings (6.1, 6.2) are each provided with a collar (10.1, 10.2), which can be brought into engagement with the opening (13) in the attachment member (3). The collar (10.1, 10.2) has at least in an axial region a conical section (8.2) shaped as a clamping cone. At the time of tightening the bolt 7, a form- and force-locking connection between the base member (2) and the attachment member (3) is created.

Owner:HILTI AG

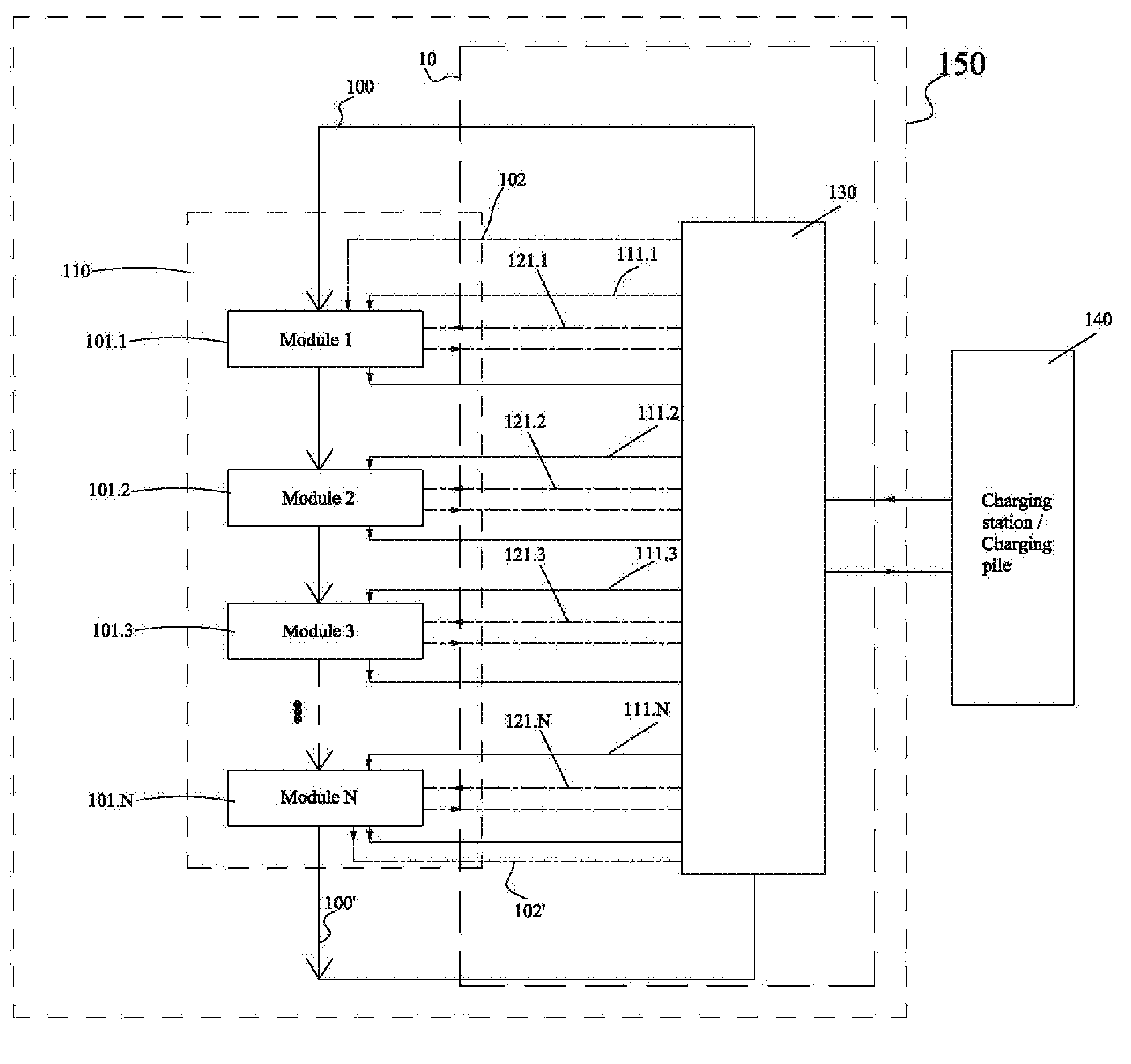

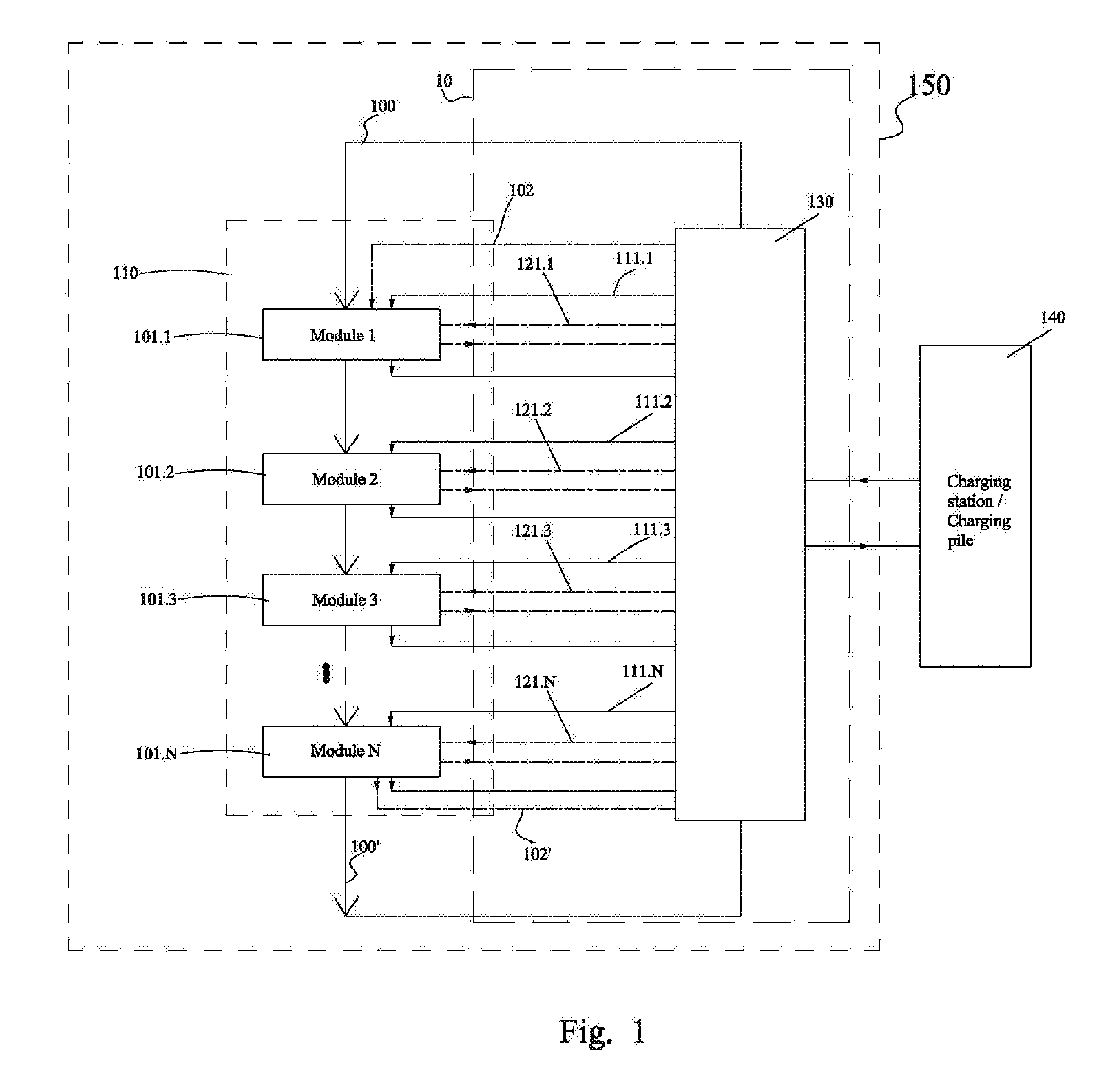

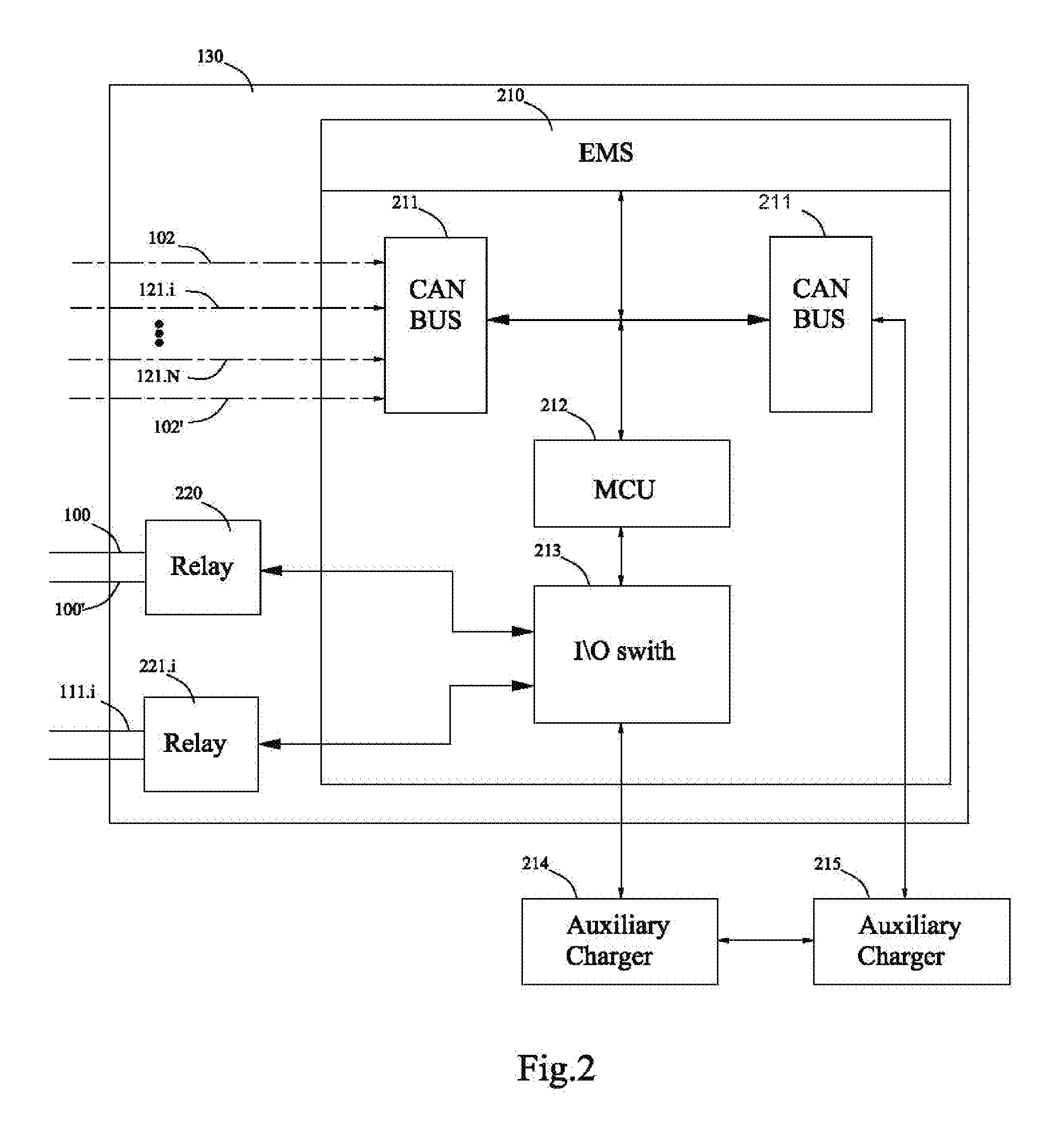

Battery pack, battery charging station, and charging method

Various techniques described herein relate to battery packs of electric vehicles, batteries, and battery charging systems. Batteries may comprise a plurality of battery modules, wherein each battery module may be provided with one or more battery cells, and the plurality of battery modules may be connected in series when providing electric power output. Battery charging systems described herein may comprise a charging circuit that connects a plurality of battery modules in series, and may be used for charging the plurality of battery modules in the battery in series. Additional charging circuits may be connected respectively to the plurality of battery modules, and the additional charging circuits may be used for charging at least one battery module in the plurality of battery modules.

Owner:THUNDER POWER NEW ENERGY VEHICLE DEV CO LTD

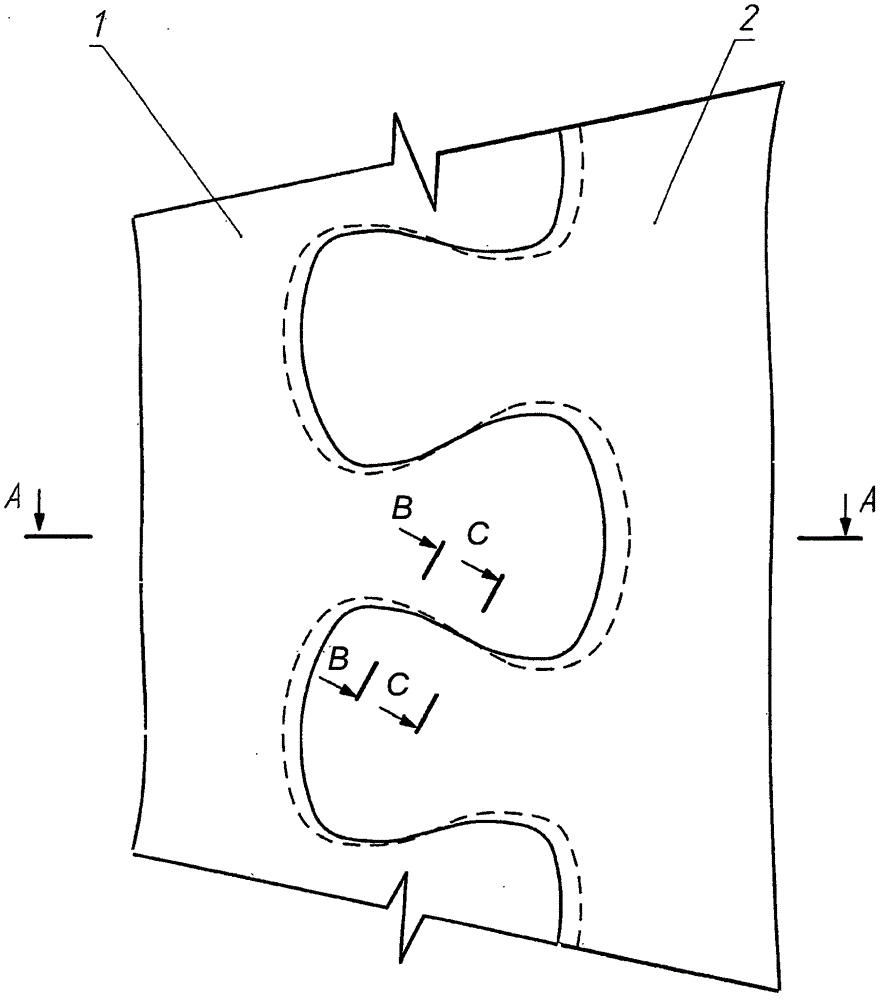

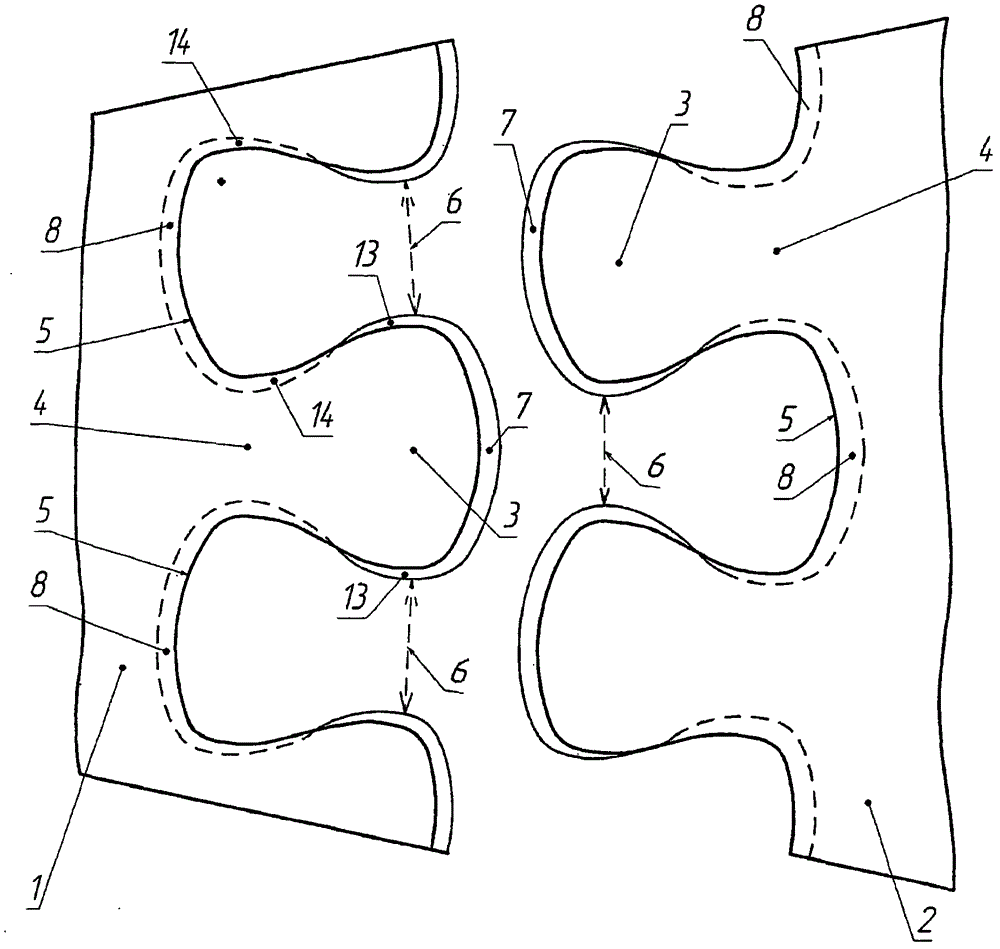

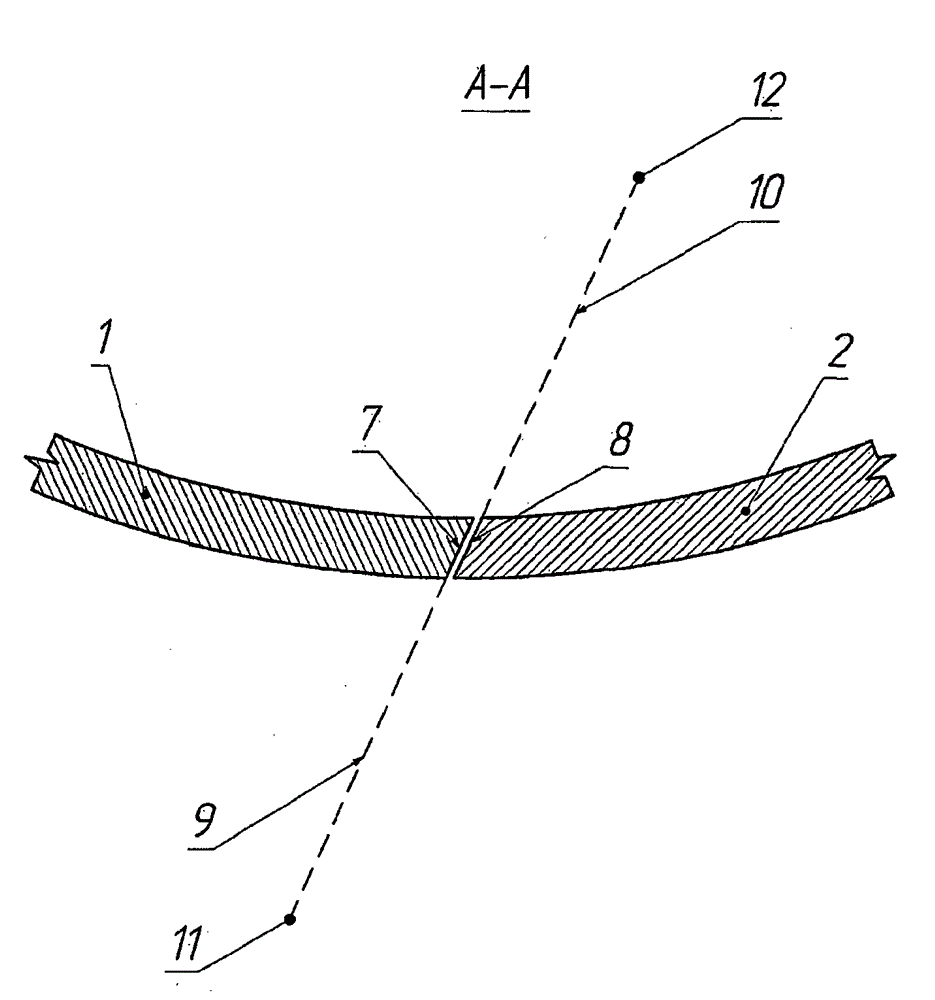

Unit For Connecting Parts

The invention relates to detachable connections of parts, primarily rigid parts, and can be used, in particular, for connecting elements of building structures. The unit for connecting parts with a curvilinear surface comprises protrusions which are formed on those sides of the parts which are to be joined, said protrusions having bulb-like enlargements at the ends and necks at the bases thereof, and grooves which are complementary to the protrusions and constitute bulb-like recesses corresponding to the bulb-like enlargements of the protrusions and merging into cavities corresponding to the necks of the protrusions.; The surfaces of the ends of the protrusions and adjoining surfaces of the bottom of the grooves have a conical shape, and the vertices of the surfaces of the ends of the protrusions and of the bottom of the grooves are arranged along different sides relative to the parts to be connected, the lateral surfaces of the protrusions and adjoining lateral surfaces of the grooves are formed by moving a straight line along a guide, which constitutes an intersecting line of a spherical surface with a cylindrical surface formed by moving the straight line along an S-like guide. The lateral surfaces of the protrusions and the lateral surfaces of the grooves are smoothly joined to the surfaces of the ends of the protrusions and surfaces of the bottom of the grooves, respectively.

Owner:维达里基库祖耶维斯 +1

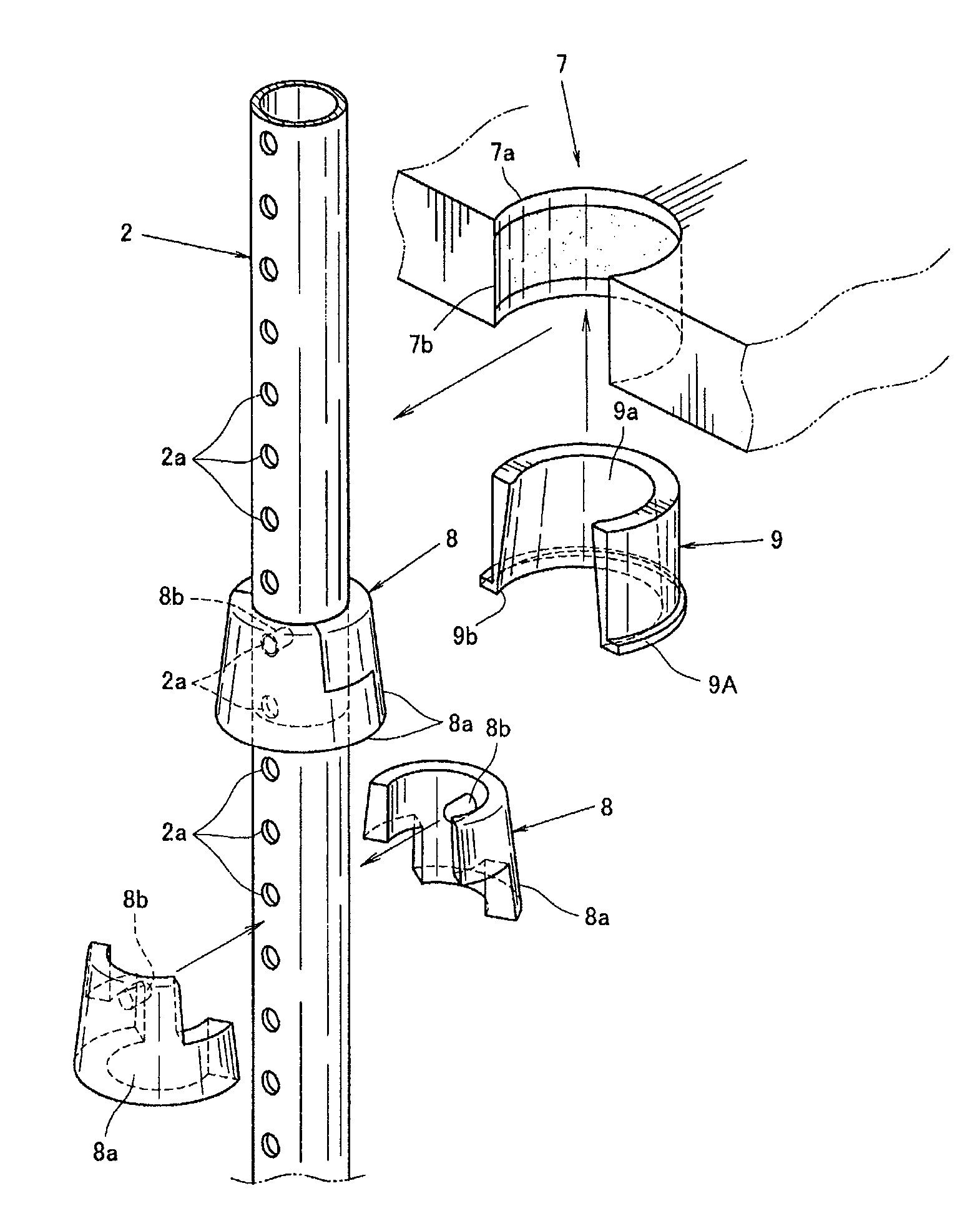

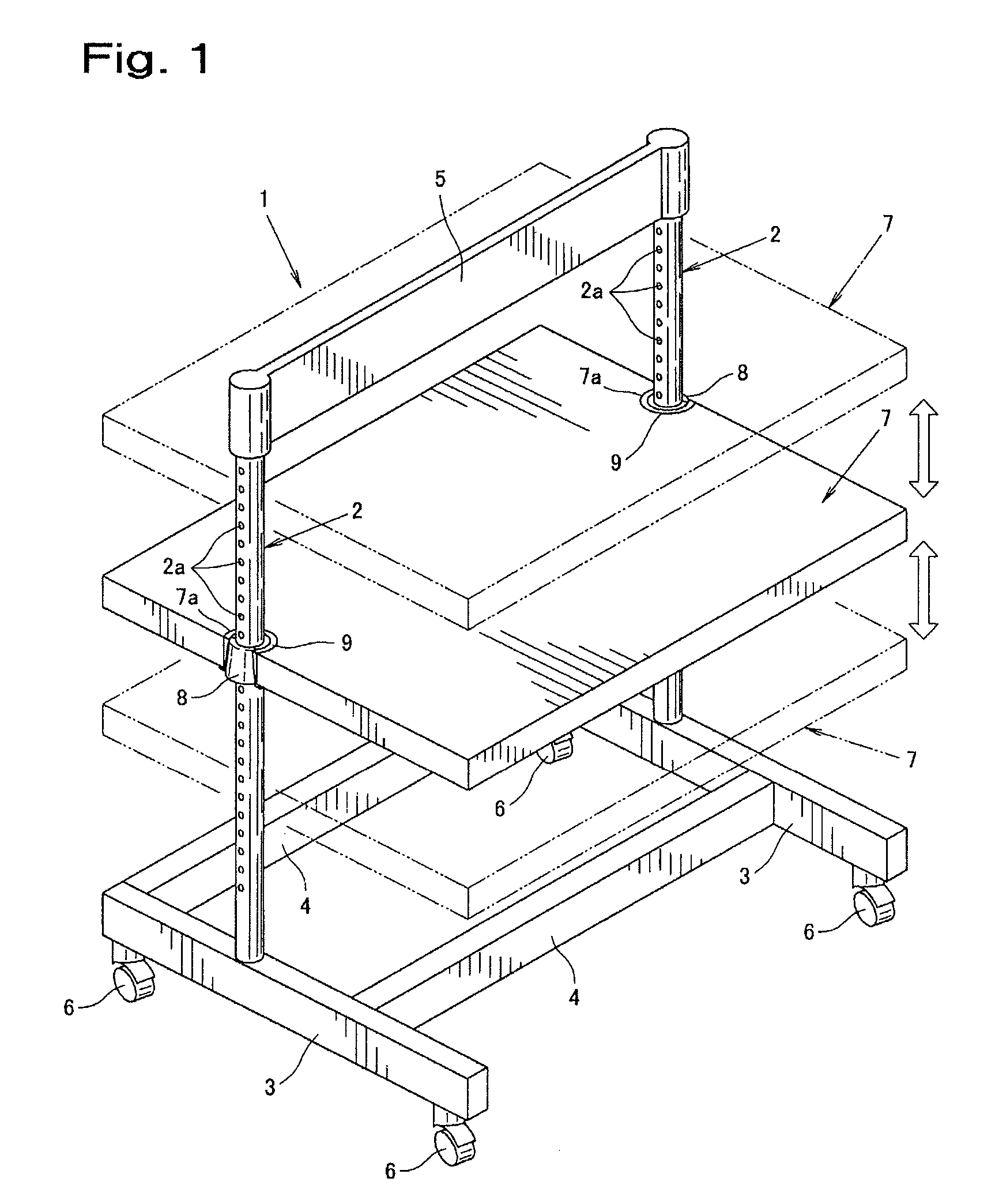

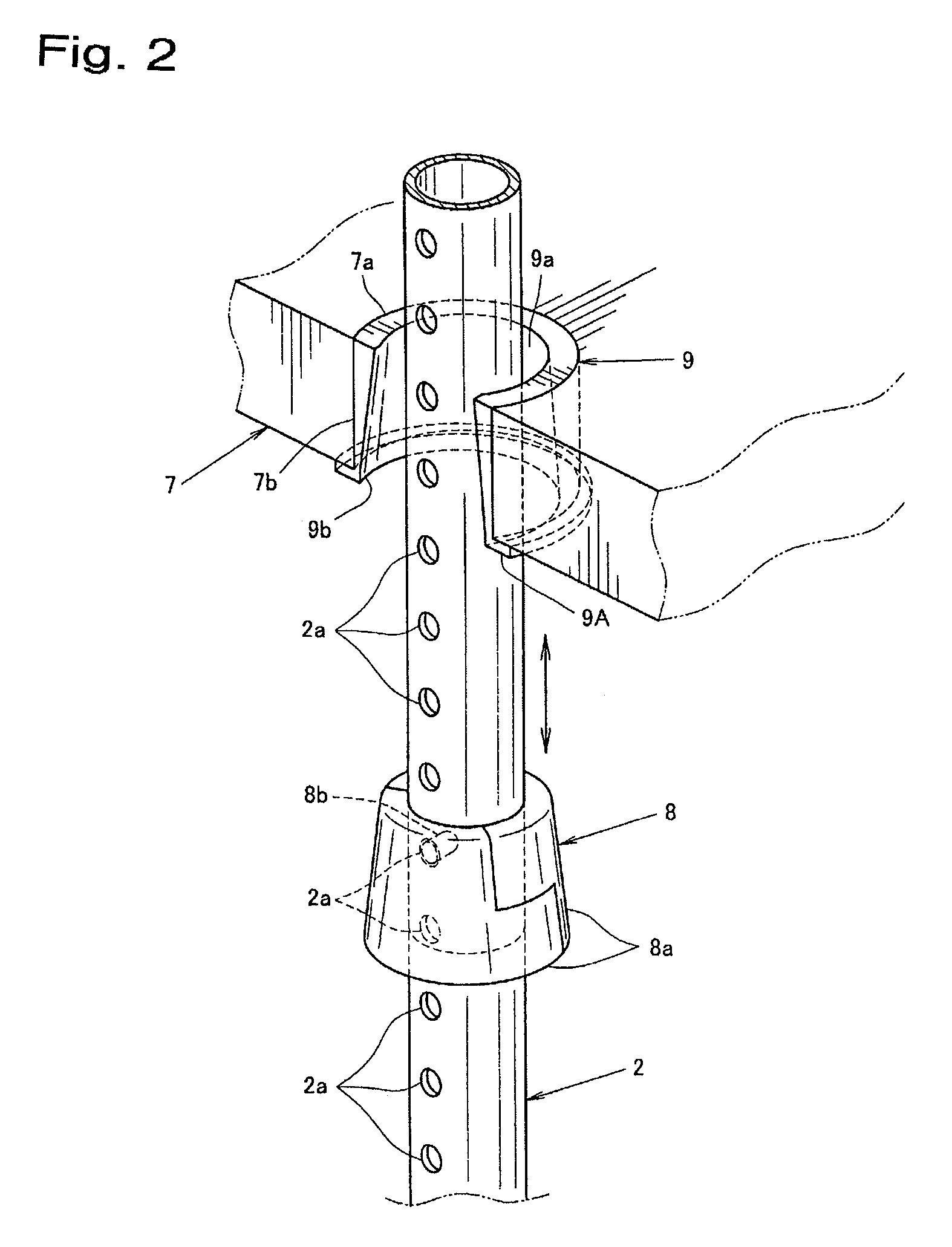

Assembly structure

InactiveUS7543540B2Simple structureLabor savingIncorrect coupling preventionKey type connectionsEngineeringAssembly structure

Owner:FONTAGE

Reinforcing

InactiveCN102209822AWith strengthMalleableKey type connectionsRod connectionsFriction weldingEngineering

Reinforcing is disclosed that comprising a reinforcing bar extending along a portion of the length of the reinforcing and a termination extending along an end portion of the reinforcing. The termination is disclosed as being permanently bonded to the reinforcing bar preferably by a friction welding process so as to form an integral connection. The termination has a body extending in a longitudinal direction between opposite first and second ends, and a lateral engagement face formed on the body. In use the first end is joined to an end the reinforcing bar, and the engagement face incorporates locking formations thereon arranged to interfit with a complementary shaped termination to form an interlock arranged to accommodate loading applied in the longitudinal direction.

Owner:MB连接件有限公司

Locking pin assembly

InactiveUS20140013635A1Readily apparentKey type connectionsSoil-shifting machines/dredgersEngineeringMechanical engineering

The locking pin assembly includes an elongate pin housing and a pin mechanism insertably mounted into a bore in the pin housing. The pin mechanism includes at least one rotator section integral with a pin shaft. A rotation-locking member is integrally attached to the bottom of the pin shaft, the locking member having a non-circular shape. An elongate post having a rotation-locking collar attached to one end of the post is slidable in a keyhole extending through the pin. A non-circular recess is formed in the rotation-locking collar, which selectively receives the locking member therein. A spring is disposed behind the rotation-locking collar. The spring normally biases the locking collar into engagement with the locking member. A key is provided to axially push the post to selectively disengage the locking member for selective rotation of the rotator section between locked and unlocked positions.

Owner:CUI KAN

Shim

ActiveUS7108901B2Reduced impact strengthEasy and quick breakStampsFlexible coversSource materialCellulose fiber

Shims comprising a mixture of plastic and natural fibers originating from wet processed cellulose fiber based waste source material include an elongate body that tapers down from a thick end to a thin end. A series of ridges and grooves or valleys are formed in at least one face of the body traversing the width of the body from a point adjacent the thick end to a point beyond the longitudinal mid-point of the body. The base of the valleys each form individual break lines preferably spaced apart at predetermined intervals. A raised rim or ridge preferably extends about the outer boundaries of the face in which the ridges and grooves are formed.

Owner:TRUE LINE MOLD & ENG

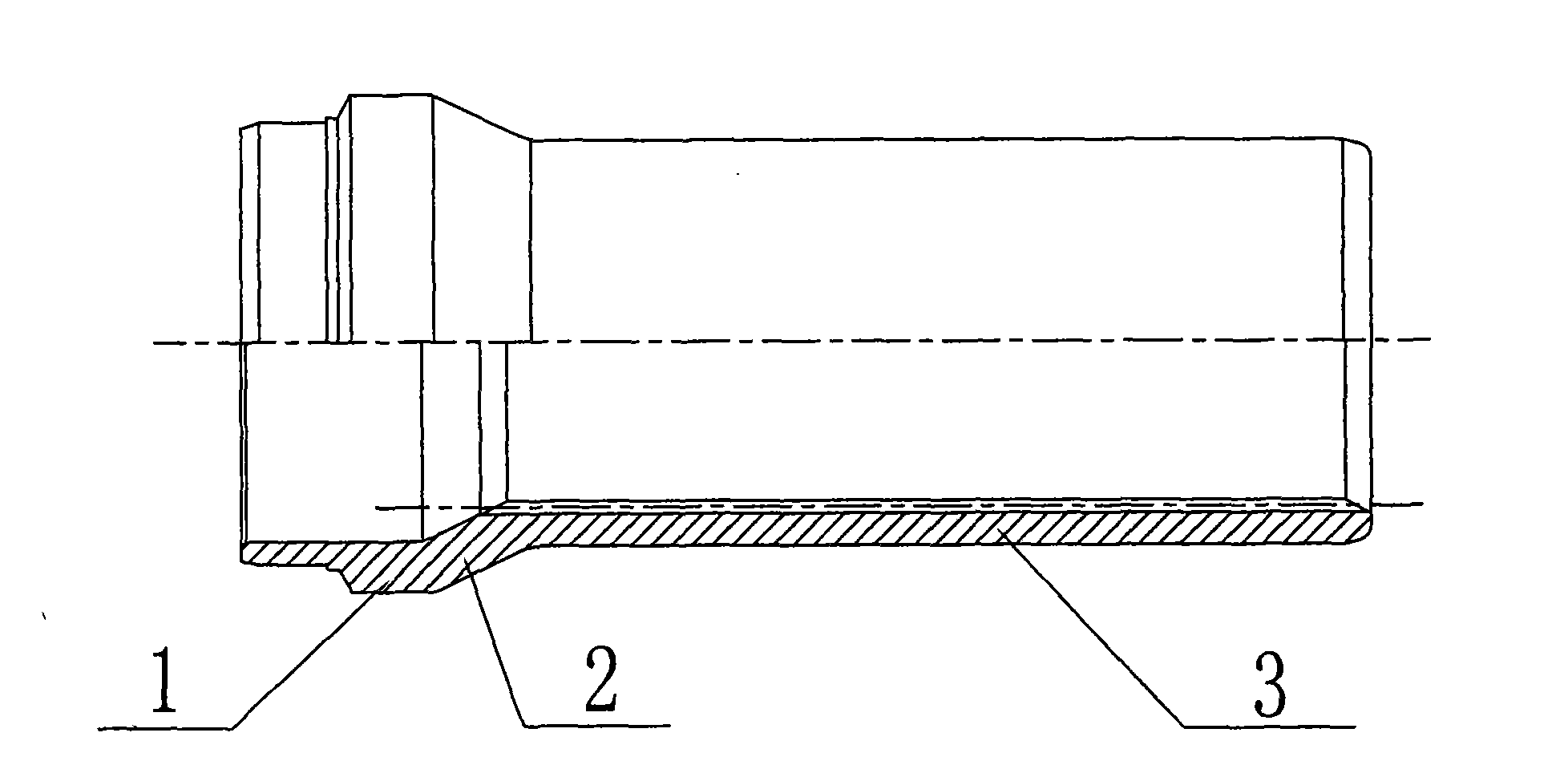

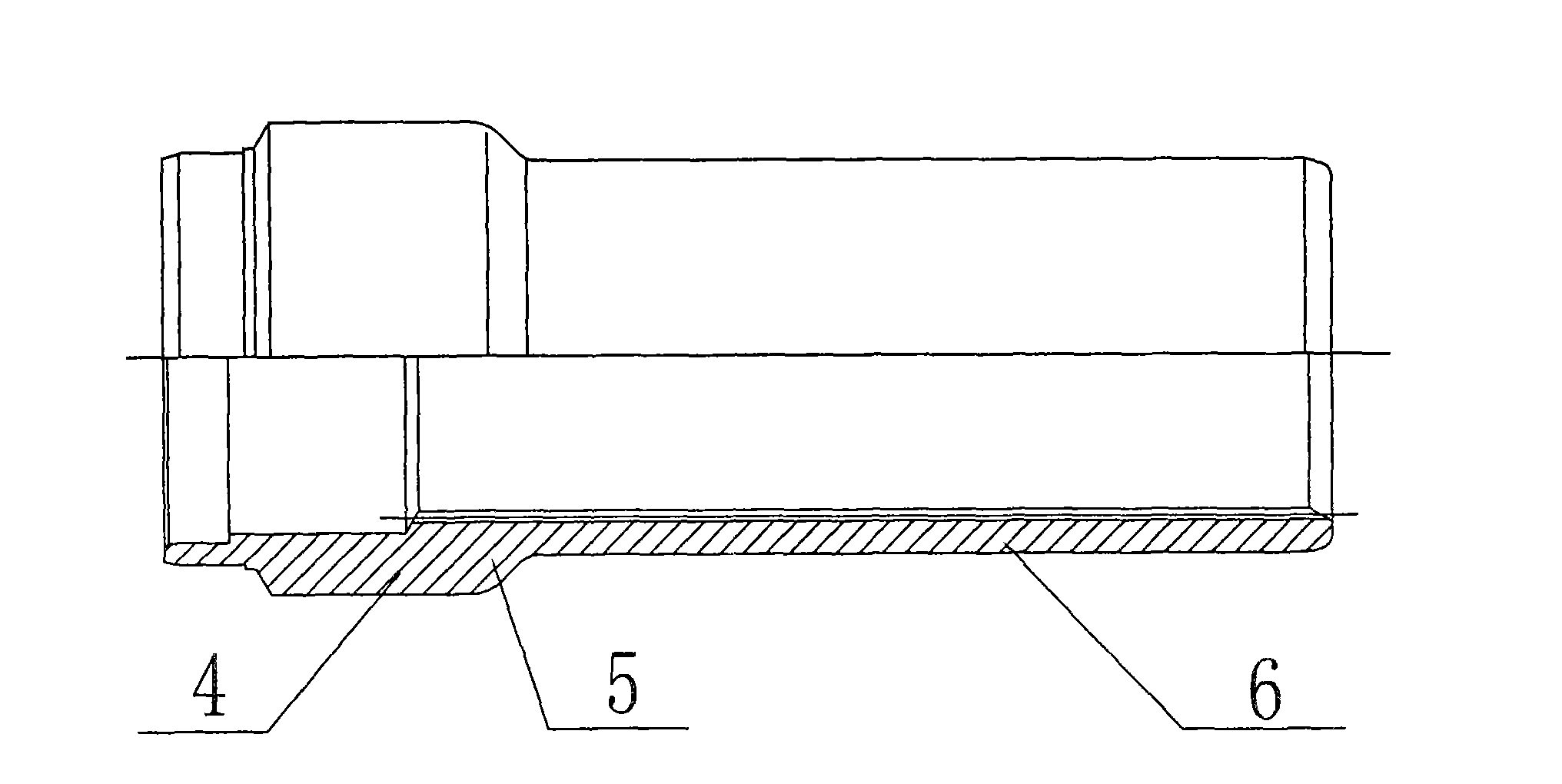

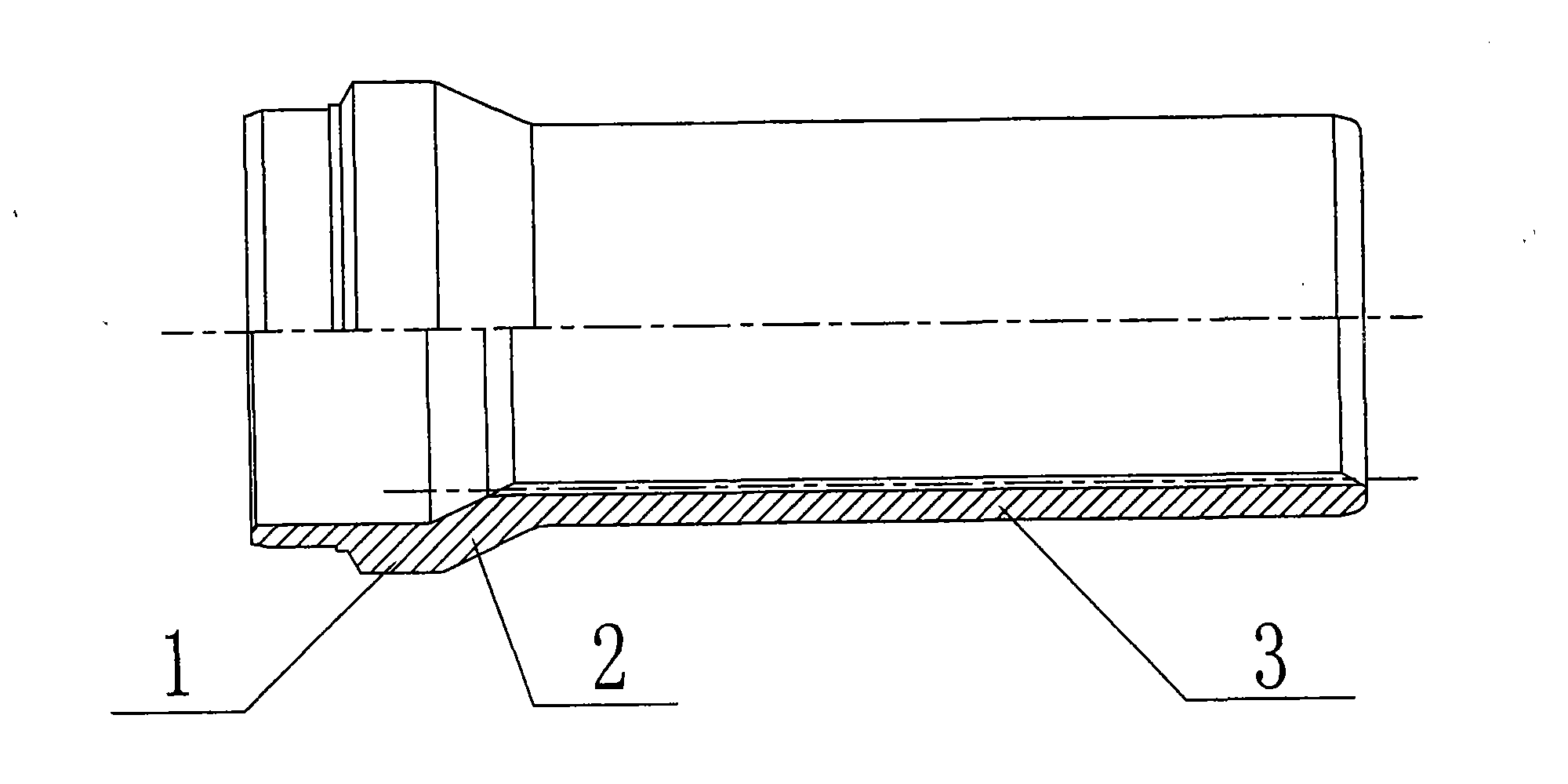

Cold extruding processing method of spline housing and spline housing produced by same

The invention relates to a cold extruding processing method of a spline housing and the spline housing produced by the same. The cold extruding processing method of the spline housing comprises the following steps: blanking of a tubular blank, annealing of the blank, performing turning on an inner bore, saponification of phosphorus, hole shrinkage and extrusion, cold extrusion of the spline and turning and shaping. The wall thicknesses of the larger end, transmission section, and smaller end of the spline manufactured by the method are equal, wherein yield torsion of the spline housing is more than 30,000Nm. The invention has the beneficial effects: firstly, the application of two cold extruding molding processes ensures that the strengthen of the material are improved after the cold-workhardening, the whole part is designed in an equicohesive manner, and greatly improves the material utilization and reduces the process cost; secondly, the processing procedures are reduced, the processing cycle of the part is shorten, and the production efficiency is improved while the cost is lowered; and thirdly, the hot processing procedures such as forging and tempering with high-energy consumption and pollution are cancelled, thus achieving obvious effects of energy saving and emission reduction.

Owner:WANXIANG QIANCHAO TRANSMISSION SHAFT +1

Set of Components Able to Be Coupled Together

Owner:KEYVANLOO AYDIN +2

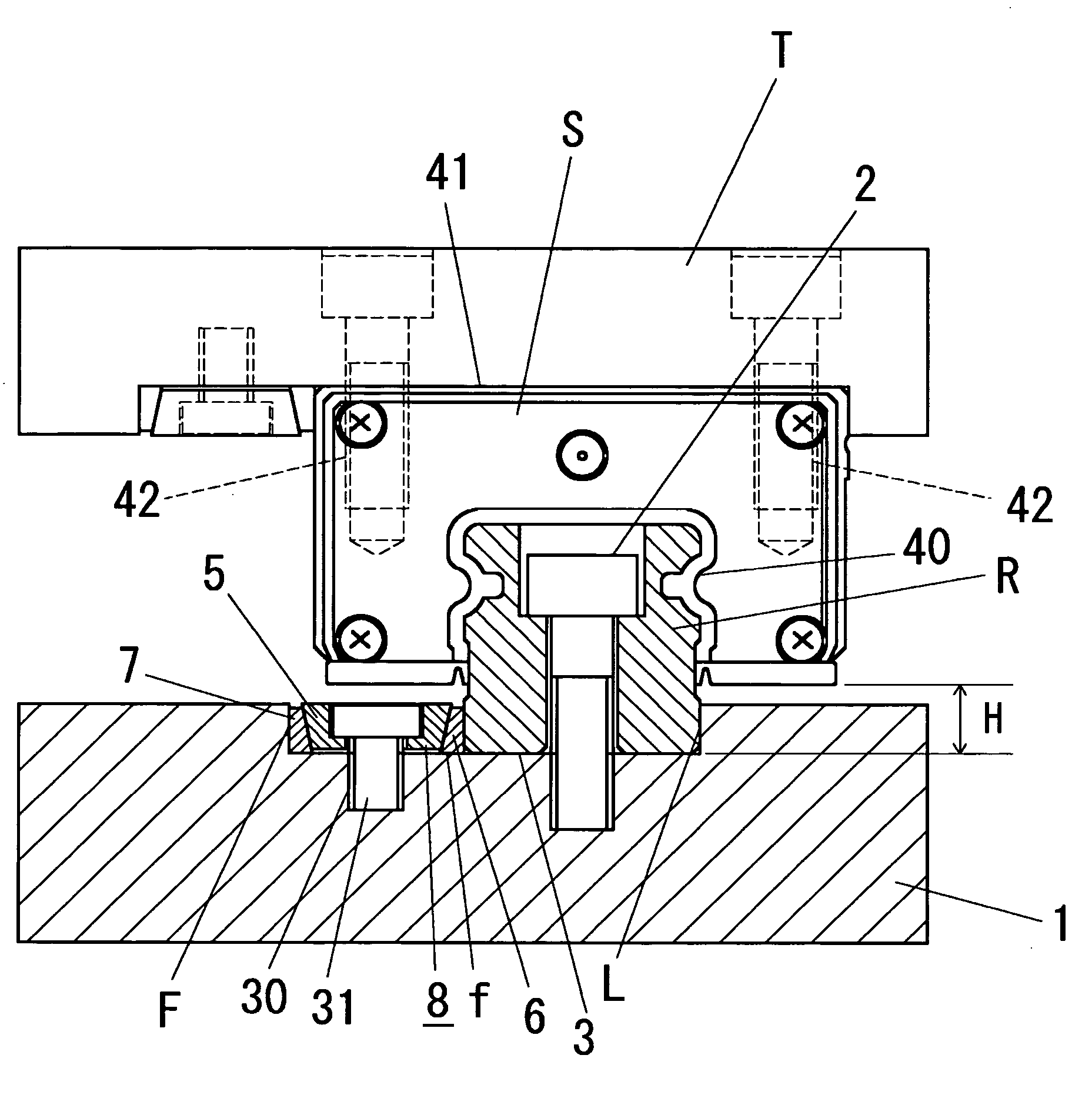

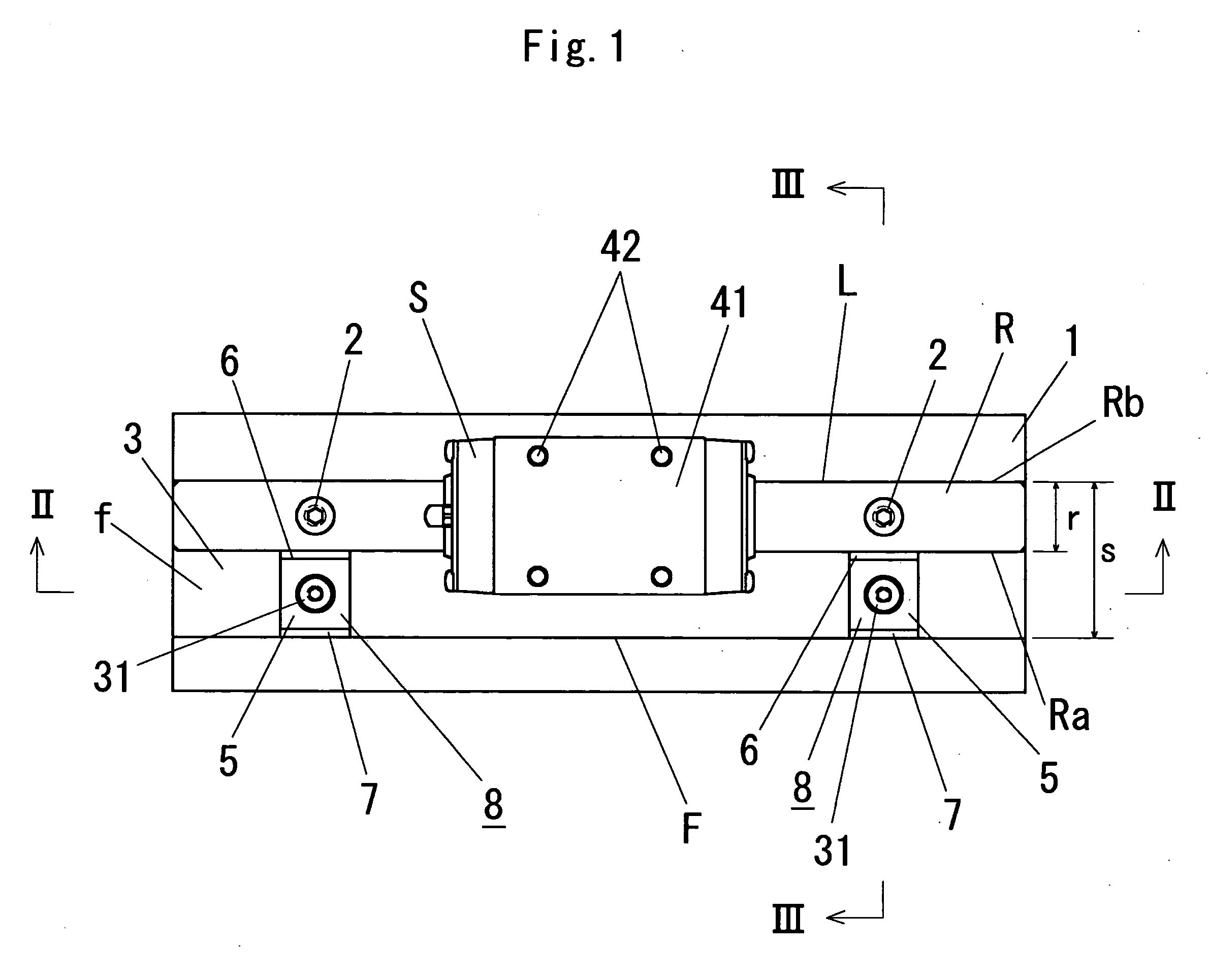

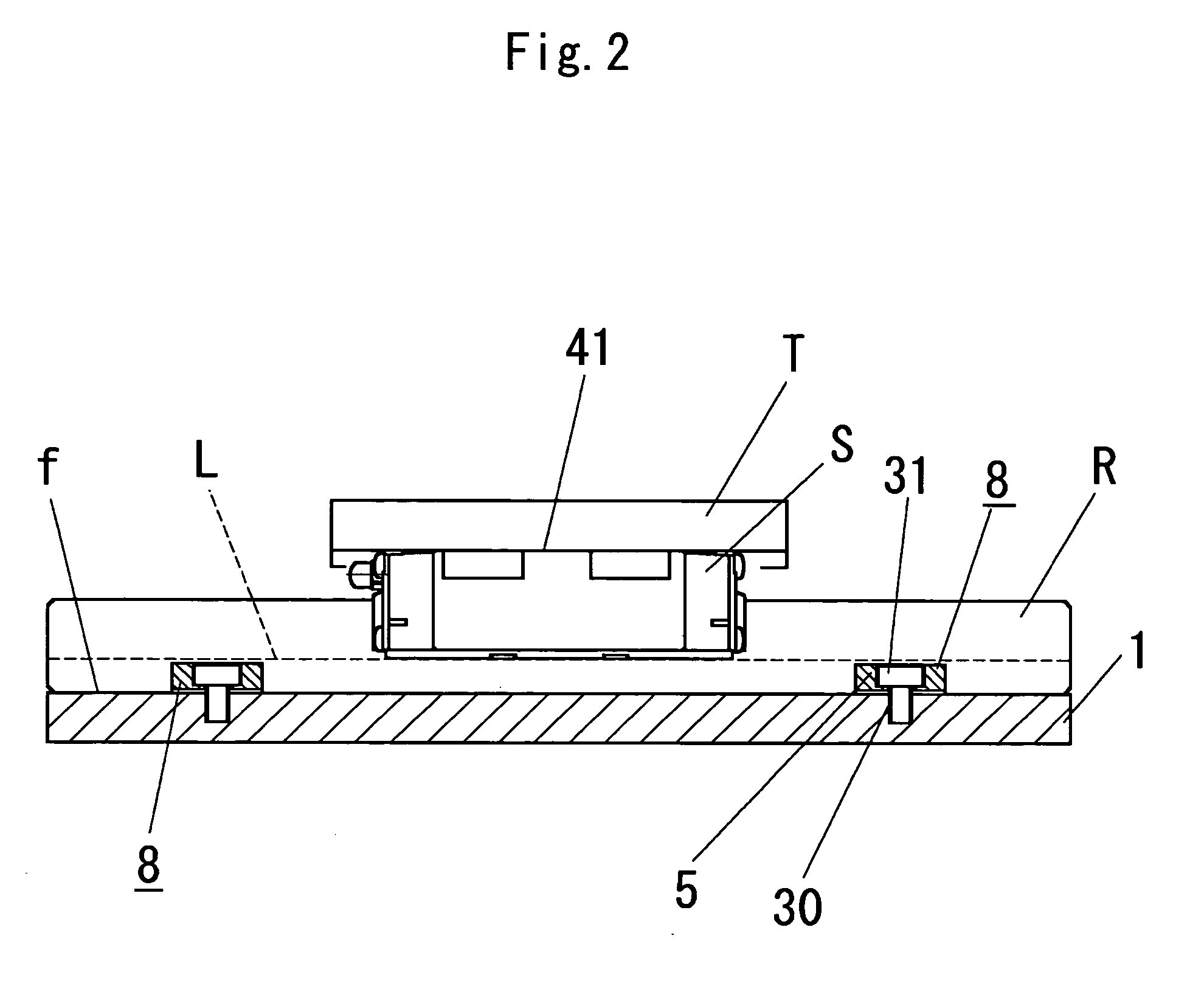

Device for holding linear guide rail

A device for holding a linear guide rail R along a linearly extending vertical reference surface L formed on an installation surface f provided with a vertical counter surface F, including a pressing plate 5, and first and second pressure contacting piece 7 and 6. The pressing plate 5 has a central fitting hole 11 and inwardly downwardly tapered side surfaces 10b, 10a which are face-to-face engageable with tapered side faces 15, 14 of the first and second pieces 7 and 6. When a screw 31 inserted through the fitting hole 11 of the pressing plate is tightened into the female thread hole 30 of the installation surface f, the pressing plate is moved downward so that the first and second pieces 7 and 6 are moved to press the guide rail R positioned on the installation surface f between the reference surface L and the second piece 6 against the reference surface L.

Owner:INFOM

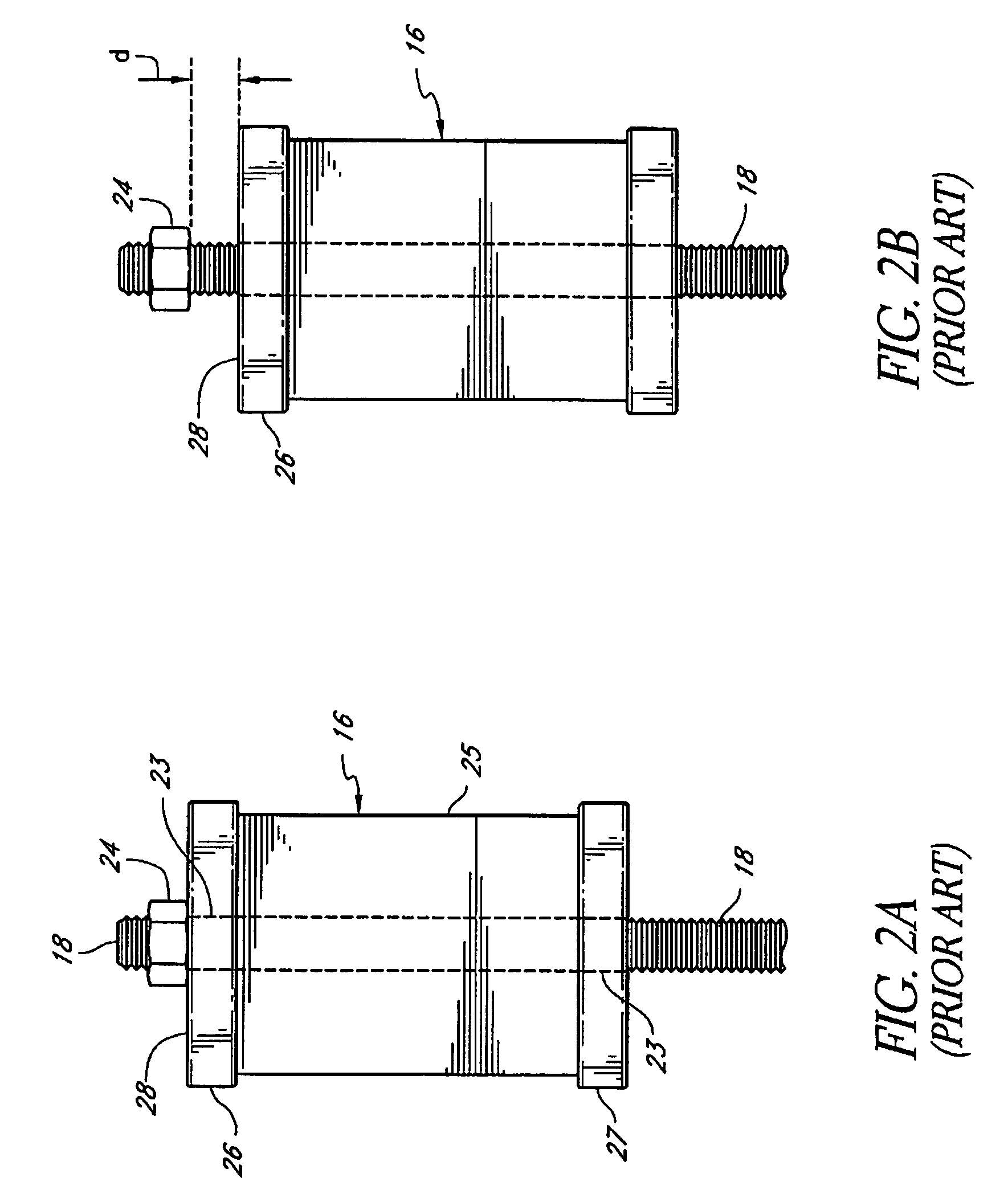

Axle with removable spindle and cam key

InactiveUS7234783B2Easy to disassembleSuspensionsKey type connectionsBearing surfaceMechanical engineering

Owner:DEXTER MARINE PROD OF GEORGIA LLC

Wear plate assembly

A wear plate assembly includes a base, a wear plate, and a key. The wear plate is moveable with respect to the base between free and applied conditions. In the applied condition of the wear plate, the base and the wear plate cooperate to form a keyway for receiving the key. The keyway is located below the top of the base. The key is moveable between a first position corresponding to an unlocked configuration of the wear plate assembly and second position corresponding to a locked configuration of the wear plate assembly.

Owner:LOMBARDO GAETANO +1

Connecting device for tubular elements

InactiveUS7241072B2Quick connectionEasy to adaptFriction grip releasable fasteningsMetal-working hand toolsMechanical engineeringModular structure

Owner:CEAN

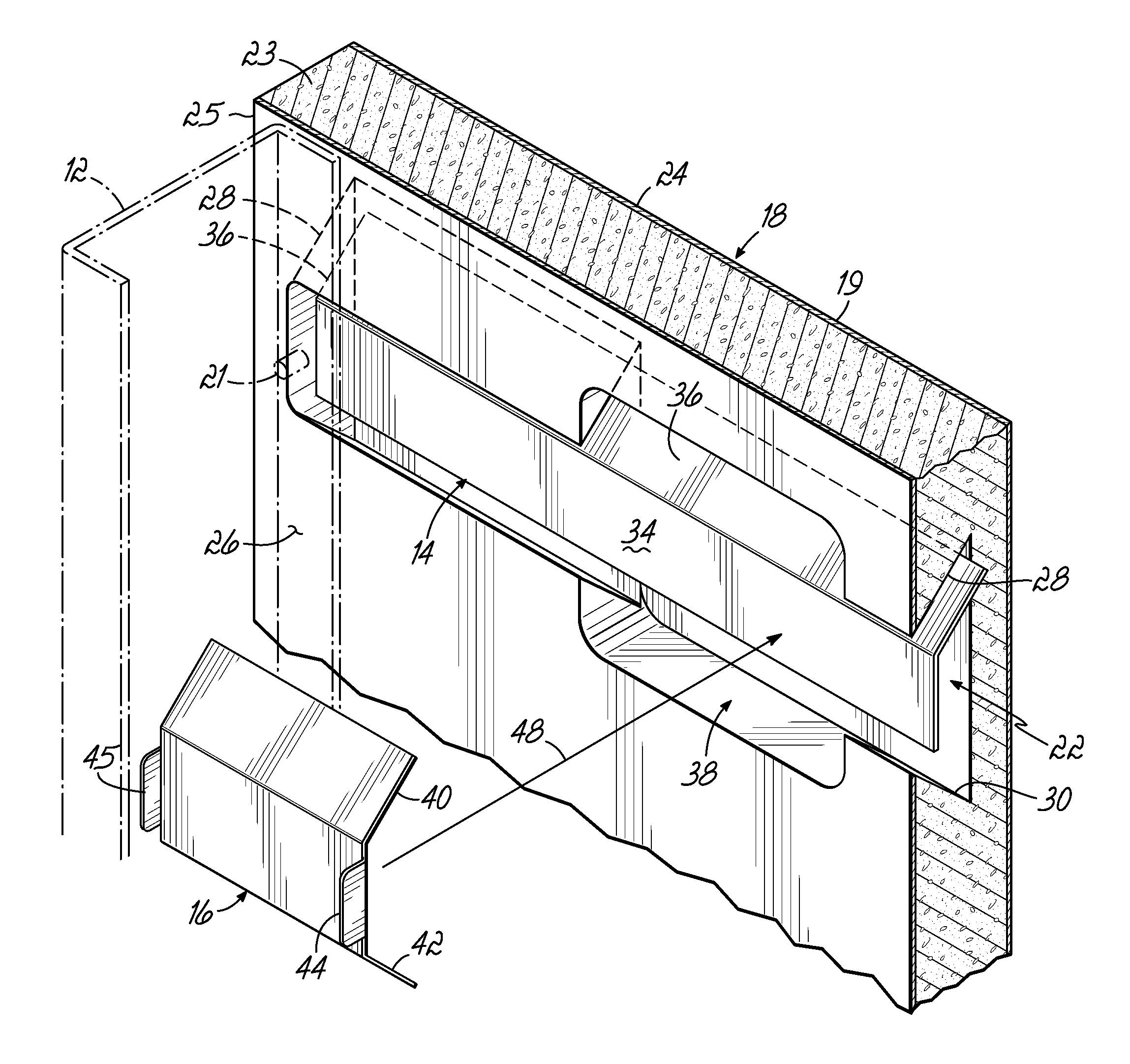

Panel mounting system with removable security cleat

ActiveUS20130183088A1Prevent disengagementCovering/liningsKey type connectionsDisplay deviceEngineering

A panel mounting system and method of securing a panel to a vertical surface. The panel mounting system, which may be used in a point of sale (POS) display, includes a panel having a channel open to a rear surface of the panel. The channel has a top surface configured to engage a portion of a horizontal cleat and a bottom surface. A channel access opening allows a security cleat to be inserted into the channel through the rear surface of the panel. The security cleat is then repositioned laterally along the axis of the channel, thereby engaging the top and bottom surfaces of the channel and securing the horizontal cleat to the panel. The panel may be decoupled from the horizontal cleat by simply repositioning the security cleat to the channel access opening and removing the security cleat.

Owner:EPS SPECIALTIES LTD

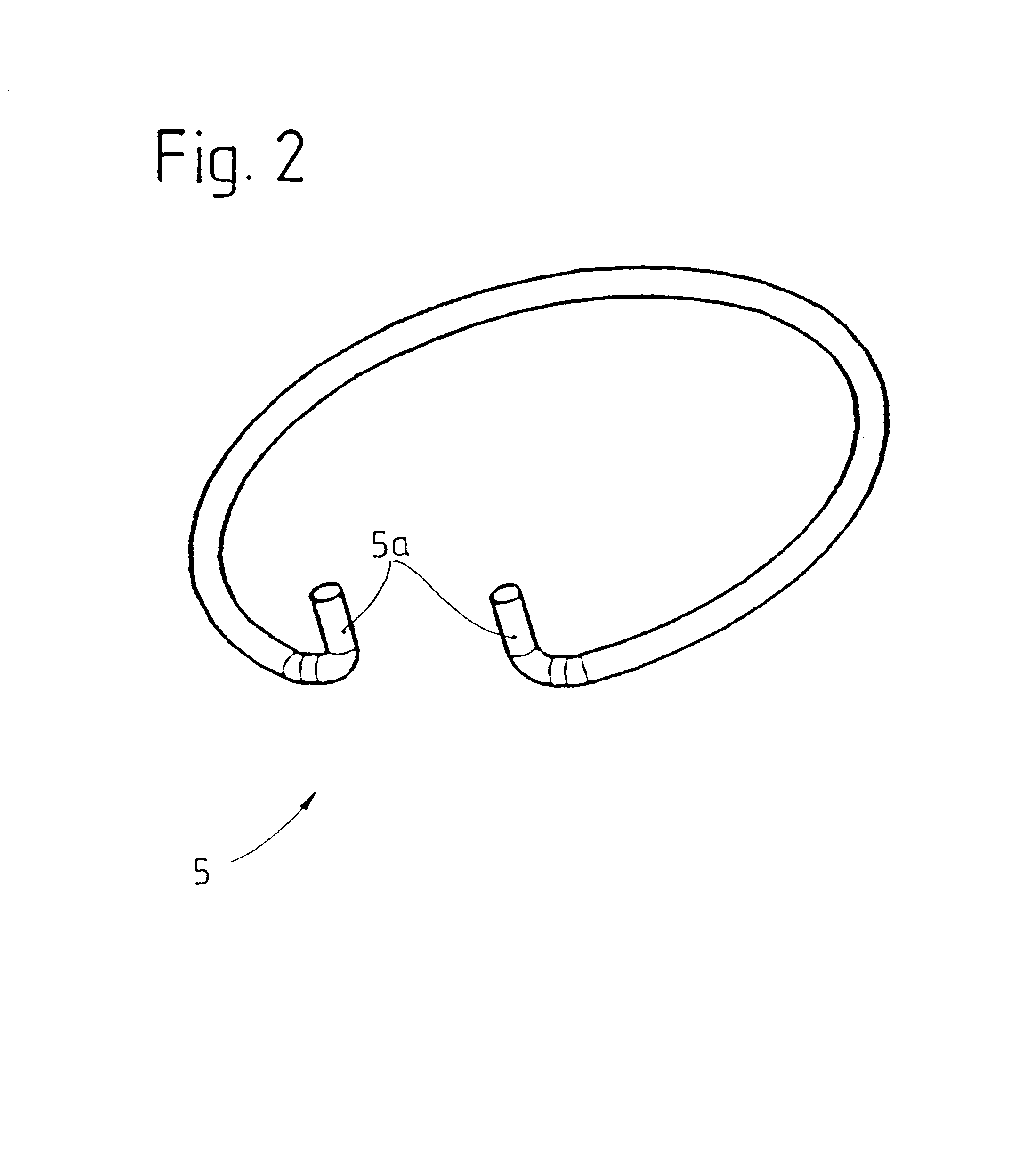

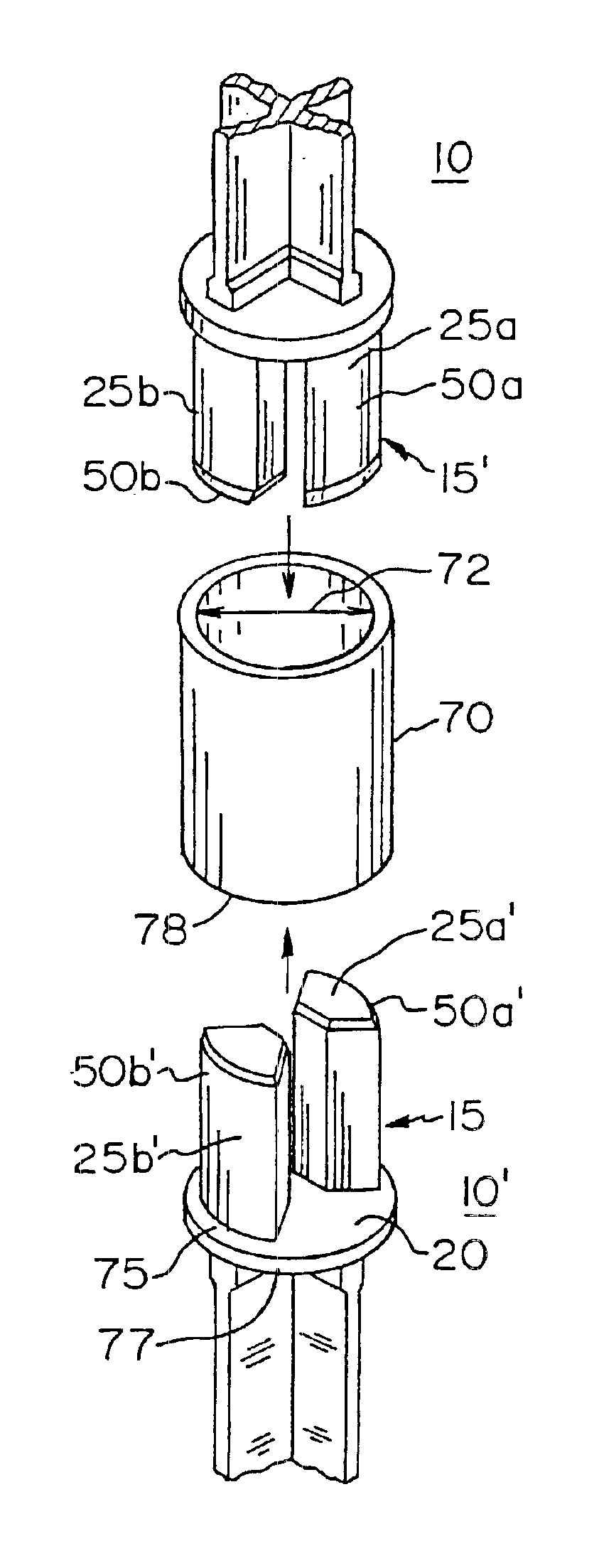

Shaft joint

A shaft such as a worm drive shaft for a movable barrier operator is disclosed. The shaft includes at least two shaft segments having connection ends. The shaft segments include respective connection ends permitting a first connection end to be joined with a second connection end by inserting a portion of at least one of the connection ends within the other connection end along the longitudinal axis of the shaft. The shaft segments may be retained by a resiliently expandable connector such as a snap ring. The connector may expand to permit the joining and then contract to be received within a surface recess on a connection end. The connector may be part of or pre-assembled on a connection end, such as by being positioned within a surface recess thereof. The connector may provide a pre-determined position for joining the first and second connection ends.

Owner:THE CHAMBERLAIN GRP INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com